Page 1

iMPORTANT: SAVE FOR LOCAL ELECTRICAL iNSPECTOR'S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

OBSERVE ALL GOVERNING CODES AND ORDINANCES.

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS:

* Do not try to light any appliance.

* Do not touch any electrical switch; do not use any phone in your building.

®

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

®

If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

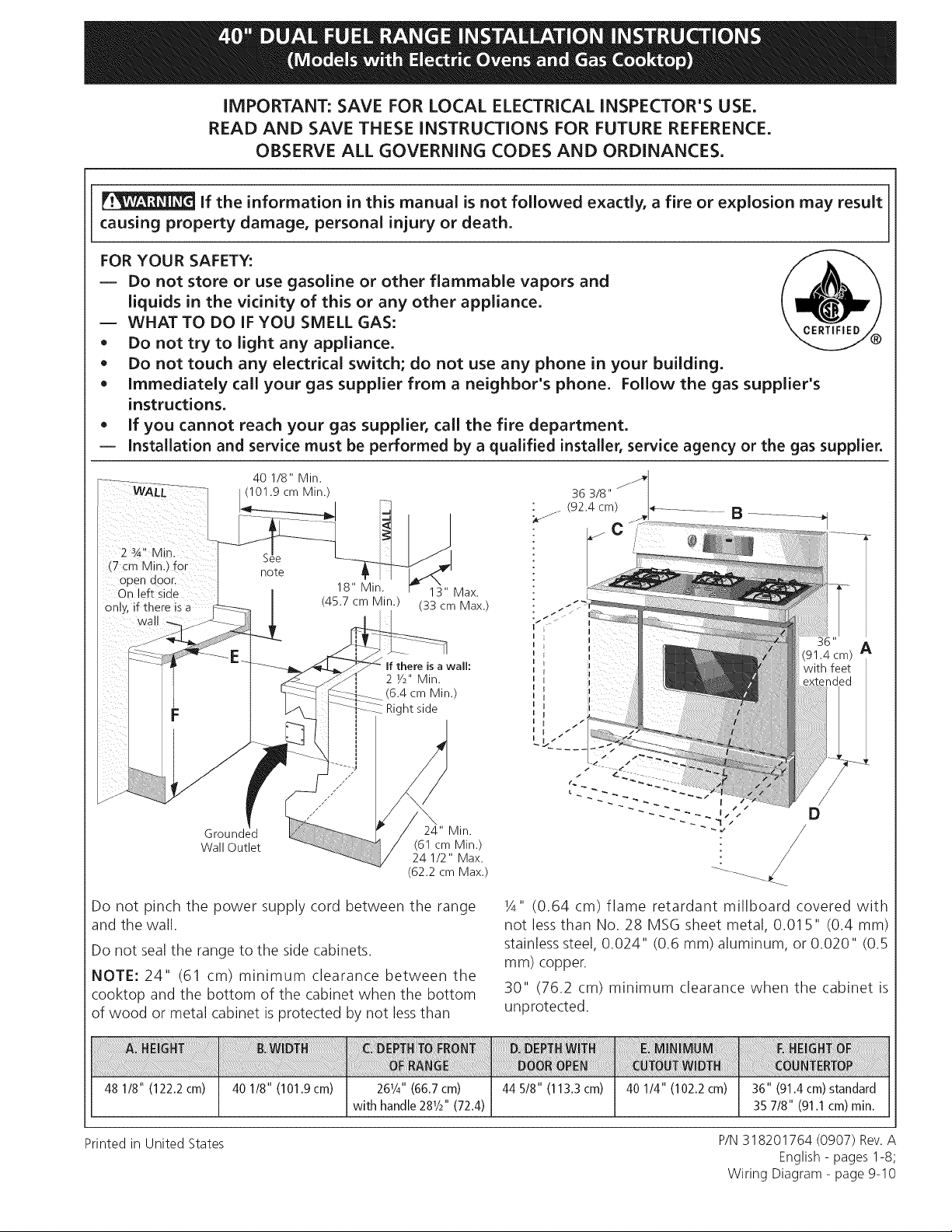

40 1/8" Min.

(101.9 cm Min.)

/

36 3/8"

/

(92.4 cm) _ .......... B .......... -_1

On left side (45.7 cm Min.) (33 cm Max.)

all:

___!_i 21/2"Min.

k[__ __ (6.4 crn Min.)

I: _ ----_-i_ Right side

(62.2 cm Max.)

Do not pinch the power supply cord between the range

and the wall.

Do not sealthe range to the side cabinets.

NOTE: 24" (61 cm) minimum clearance between the

cooktop and the bottom of the cabinet when the bottom

of wood or metal cabinet is protected by not less than

:(91.4cm) A

with feet

extended

D

/

1/4" (0.64 cm) flame retardant millboard covered with

not less than No. 28 MSG sheet metal, 0.015" (0.4 mm)

stainless steel, 0.024" (0.6 mm) aluminum, or 0.020" (0.5

ram) copper.

30" (76.2 cm) minimum clearance when the cabinet is

unprotected.

48 1/8" (122.2 cm) 40 1/8" (10119cm) 261/4"(66.7cm) 44 5/8" (113.3 cm) 40 1/4" (102.2cm) 36" (91.4cm) standard

with handle 281/2'`(72.4) 35 7/8" (91.1cm) min.

Printed in United States

P/N318201764 (0907) Rev.A

English - pages 1-8;

Wiring Diagram - page 9-10

Page 2

Important Notes to the Installer

1.Readall instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the electrical supply to

the range (see "Preparation ", page 5).

3.Two anti-tip brackets, located inside the oven cavity MUST

be installed (see "Anti-Tip Bracket Installation", page 8).

4.Observe all governing codes and ordinances.

5.Be sure to leave these instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your owner's guide for future

reference.

IMPORTANT SAFETY

Make sure the wall coverings around the range

can withstand the heat generated by the range.

Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at least 90°F (32.2 °C ) above

room temperature without shrinking, warping or

discoloring, Do not install the range over carpeting

unless you place an insulating pad or sheet of 1/4"

(0.6 cm) thick plywood between the range and

carpeting.

Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may become

hot while the oven is in operation. This range requires

fresh air for proper burner combustion.

INSTRUCTION

Installation of this range must conform with local codes

or, in the absence of local codes, with CAN/CGA-B149.1

and CAN/CGA-B149.2 standards.

This range has been design certified by the American

Gas Association. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Use and Care

Guide., read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

o All ranges can

tip.

Injury to

persons could

result.

Install anti-tip

device packed

with range.

This range must be electrically grounded in

accordance with local codes or, in their absence,

with CSA standard C22.1, Canadian Electrical

Code, Part 1.

The installation of appliances designed for

manufactured (mobile) home installation must conform

with Manufactured Home Construction and Safety

Standard, title 24CFR, part 3280 [Formerly the Federal

Standard for Mobile Home Construction and Safety,

title 24, HUD (part 280)] or when such standard

is not applicable, the Standard for Manufactured

Home Installation 1982 (Manufactured Home Sites,

Communities and Setups), ANSI Z225.1/NFPA 501A-

latest edition, or with CAN/CSA-Z240 MH.

To reduce the risk of tipping

of the range, the range

must be secured by properly

installed anti-tip bracket(s)

provided with the range.

To check if the bracket(s) is

installed properly, remove

the lower panel or stor-

age drawer and verify that

the anti-tip bracket(s)is

engaged.

Never leave children alone or

unattended in the area where an appliance is in

use, As children grow, teach them the proper, safe use

of all appliances. Never leave the oven door open when

the range is unattended.

Stepping, leaning or sitting on the

door(s) or drawer of this range can result in serious

injuries and can also cause damage to the range.

• Do not store items of interest to children in

the cabinets above the range. Children could be

seriously burned climbing on the range to reach items.

To eliminate the need to reach over the surface

units, cabinet storage space above the units

should be avoided,

Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil,

Excessiveflame is hazardous.

Do not use the oven as a storage space. This

creates a potentially hazardous situation.

Never use your range for warming or heating the

room, Prolonged use of the range without adequate

ventilation can be dangerous.

Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance, Explosions or fires could result.

In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn

the Surface Control knob to Lite. Use caution when

lighting surface burners manually.

• Reset all controls to the "off" position after using

a programmable timing operation,

This appliance is equipped with a

4-prong grounding plug for your protection against

shock hazard, and should be plugged directly into a

properly grounded receptacle. Do not cut or remove

the ground prong from this plug,

Page 3

FORMODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils

before self-cleaning the oven. Wipe up excess

spillage. Follow the pre-cleaning instructions in the Use

and Care Guide.

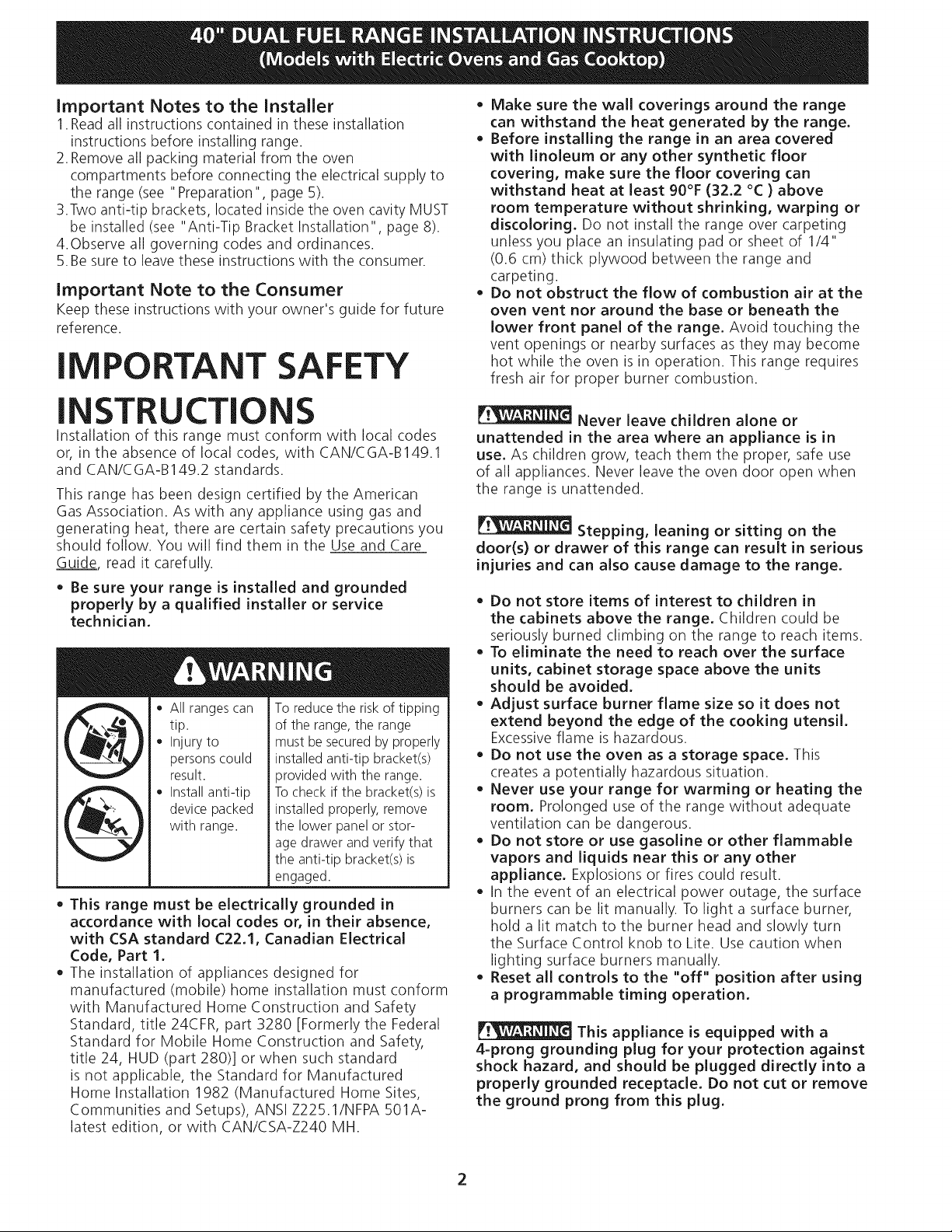

Model and Serial Number Location

The serial plate is located on the oven front frame behind

the large oven door.

When ordering

parts for or making

inquiries about your

range, always be sure

to include the model

and serial numbers

and a lot number or

letter from the serial

plate on your range.

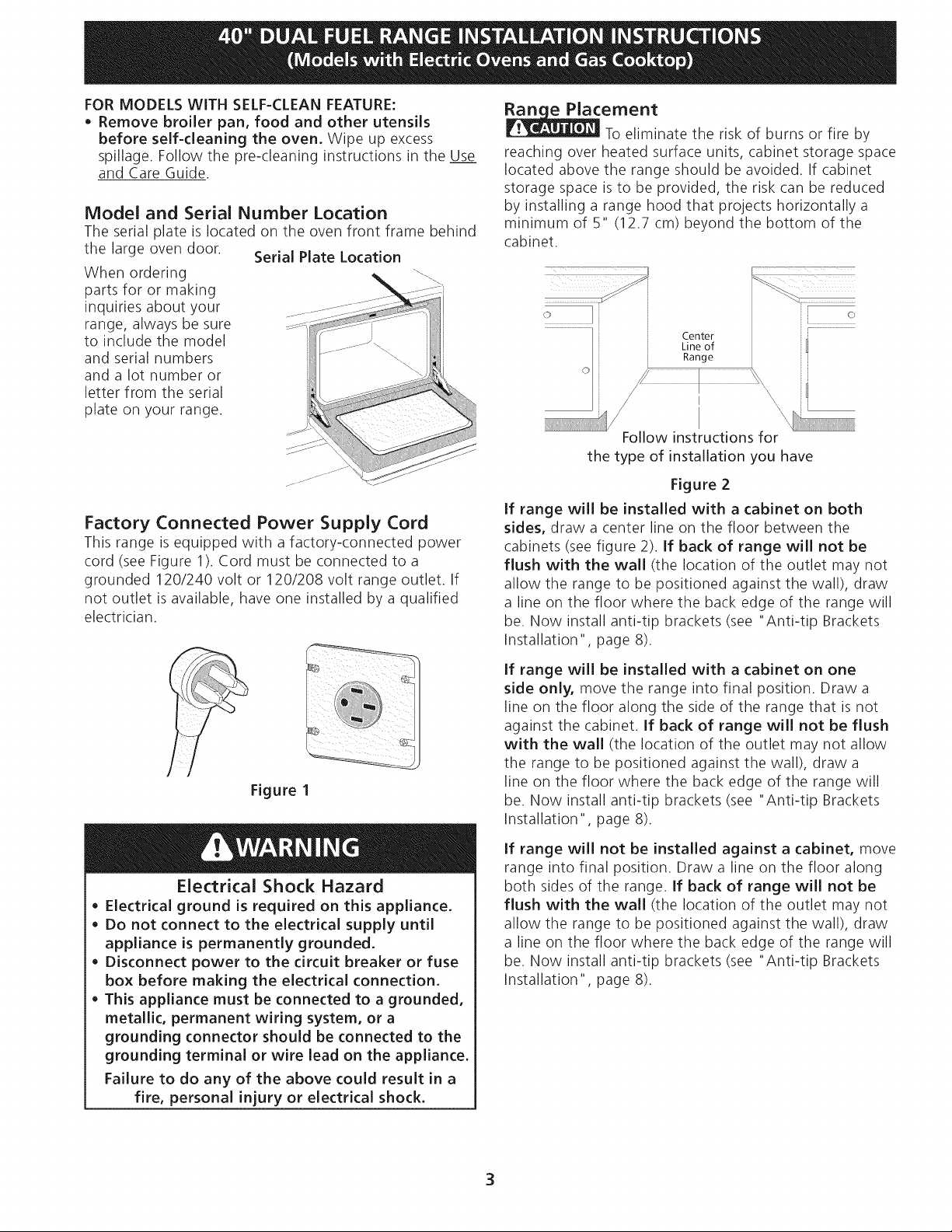

Factory Connected Power Supply Cord

This range is equipped with a factory-connected power

cord (see Figure 1). Cord must be connected to a

grounded 120/240 volt or 120/208 volt range outlet. If

not outlet is available, have one installed by a qualified

electrician.

Serial Plate Location

- - - - - - -

ement

To eliminate the risk of burns or fire by

reaching over heated surface units, cabinet storage space

located above the range should be avoided. If cabinet

storage space is to be provided, the risk can be reduced

by installing a range hood that projects horizontally a

minimum of 5" (12.7 cm) beyond the bottom of the

cabinet.

[ o

}

Center

Line of

Range

I \\,

\

'\

Follow instructions for

the type of installation you have

Figure 2

If range will be installed with a cabinet on both

sides, draw a center line on the floor between the

cabinets (see figure 2). If back of range will not be

flush with the wall (the location of the outlet may not

allow the range to be positioned against the wall), draw

a line on the floor where the back edge of the range will

be. Now install anti-tip brackets (see "Anti-tip Brackets

Installation", page 8).

Figure 1

Electrical Shock Hazard

Electrical ground is required on this appliance.

Do not connect to the electrical supply until

appliance is permanently grounded.

Disconnect power to the circuit breaker or fuse

box before making the electrical connection.

This appliance must be connected to a grounded,

metallic, permanent wiring system, or a

grounding connector should be connected to the

grounding terminal or wire lead on the appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock.

If range will be installed with a cabinet on one

side only, move the range into final position. Draw a

line on the floor along the side of the range that is not

against the cabinet. If back of range will not be flush

with the wall (the location of the outlet may not allow

the range to be positioned against the wall), draw a

line on the floor where the back edge of the range will

be. Now install anti-tip brackets (see "Anti-tip Brackets

Installation", page 8).

If range will not be installed against a cabinet, move

range into final position. Draw a line on the floor along

both sides of the range. If back of range will not be

flush with the wall (the location of the outlet may not

allow the range to be positioned against the wall), draw

a line on the floor where the back edge of the range will

be. Now install anti-tip brackets (see "Anti-tip Brackets

Installation", page 8).

3

Page 4

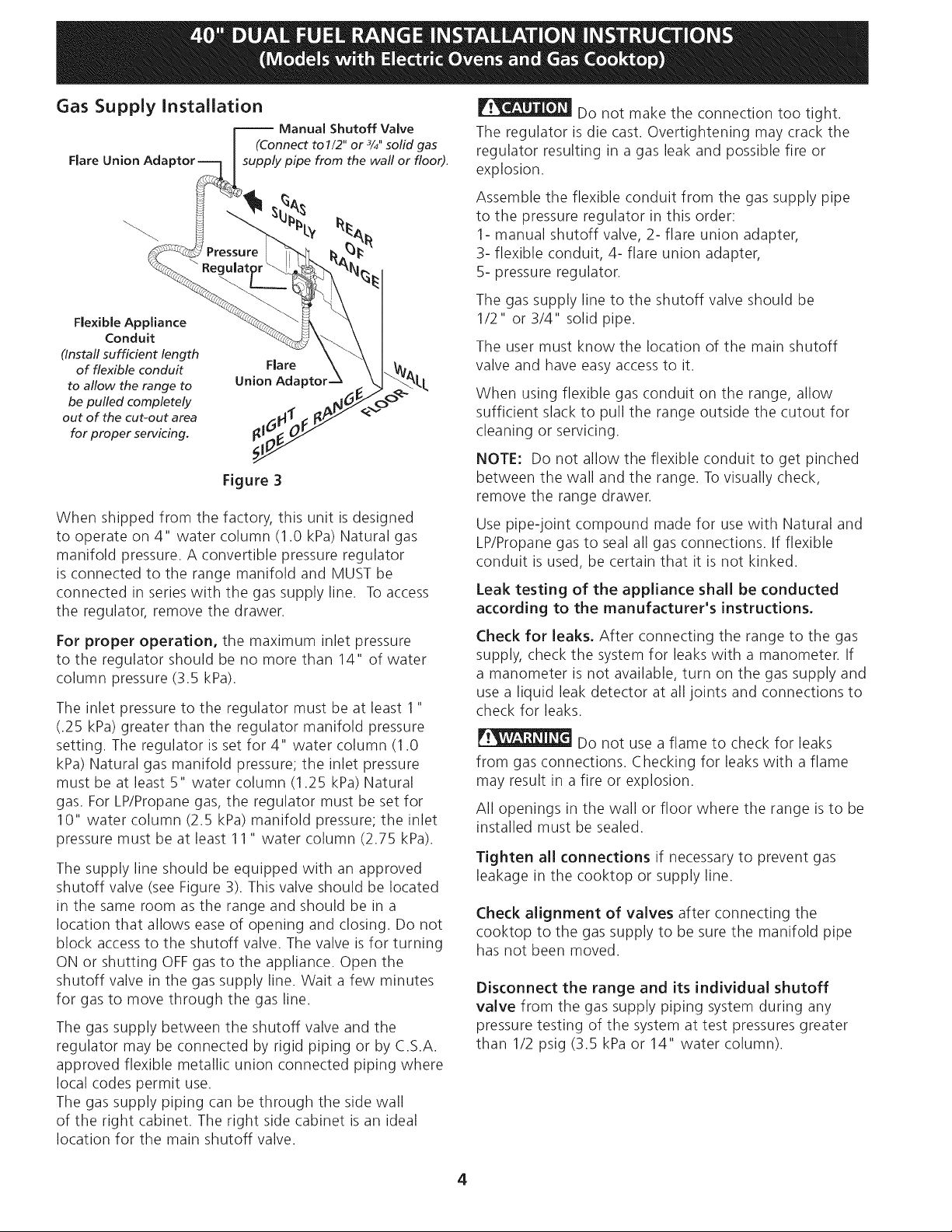

Gas Supply installation

r Manual Shutoff Valve

I (Connect to 1/2" or 3/4"solid gas

Flare Union Adaptor---_ I supply pipe from the wall or floor).

(Install sufficient length . - \ _\ ]

of flexible conduit -. Flare \ \ I_._.

to allow the range to Union Adaptor--_ _ k_k L

Figure 3

When shipped from the factory, this unit is designed

to operate on 4" water column (1.0 kPa) Natural gas

manifold pressure. A convertible pressure regulator

is connected to the range manifold and MUST be

connected in series with the gas supply line. To access

the regulator, remove the drawer.

For proper operation, the maximum inlet pressure

to the regulator should be no more than 14" of water

column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least 1"

(.25 kPa) greater than the regulator manifold pressure

setting. The regulator is set for 4" water column (1.0

kPa) Natural gas manifold pressure; the inlet pressure

must be at least 5" water column (1.25 kPa) Natural

gas. For LP/Propane gas, the regulator must be set for

10" water column (2.5 kPa) manifold pressure; the inlet

pressure must be at least 11 " water column (2.75 kPa).

The supply line should be equipped with an approved

shutoff valve (see Figure 3). This valve should be located

in the same room as the range and should be in a

location that allows ease of opening and closing. Do not

block access to the shutoff valve. The valve is for turning

ON or shutting OFF gas to the appliance. Open the

shutoff valve in the gas supply line. Wait a few minutes

for gas to move through the gas line.

The gas supply between the shutoff valve and the

regulator may be connected by rigid piping or by C.S.A.

approved flexible metallic union connected piping where

local codes permit use.

The gas supply piping can be through the side wall

of the right cabinet. The right side cabinet is an ideal

location for the main shutoff valve.

Do not make the connection too tight.

The regulator is die cast. Overtightening may crack the

regulator resulting in a gas leak and possible fire or

explosion.

Assemble the flexible conduit from the gas supply pipe

to the pressure regulator in this order:

1- manual shutoff valve, 2- flare union adapter,

3- flexible conduit, 4- flare union adapter,

5- pressure regulator.

The gas supply line to the shutoff valve should be

1/2" or 3/4" solid pipe.

The user must know the location of the main shutoff

valve and have easy access to it.

When using flexible gas conduit on the range, allow

sufficient slack to pull the range outside the cutout for

cleaning or servicing.

NOTE: Do not allow the flexible conduit to get pinched

between the wall and the range. To visually check,

remove the range drawer.

Use pipe-joint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If flexible

conduit is used, be certain that it is not kinked.

Leak testing of the appliance shall be conducted

according to the manufacturer's instructions.

Check for leaks. After connecting the range to the gas

supply, check the system for leaks with a manometer. If

a manometer is not available, turn on the gas supply and

use a liquid leak detector at all joints and connections to

check for leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

All openings in the wall or floor where the range is to be

installed must be sealed.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

Check alignment of valves after connecting the

cooktop to the gas supply to be sure the manifold pipe

has not been moved.

Disconnect the range and its individual shutoff

valve from the gas supply piping system during any

pressure testing of the system at test pressures greater

than 1/2 psig (3.5 kPa or 14" water column).

4

Page 5

LP/Propane Gas Conversion

This appliance can be used with Natural Gas or Propane

Gas. It is shipped from the factory for use with natural gas.

If you wish to convert your range for use with LP/Propane

gas, use the supplied fixed orifices; they are contained in

a special bag along with instructions marked "FOR LP/

PROPANEGAS CONVERSION", located on the back of

the range, close to the appliance regulator valve,

The conversion must be performed by a qualified installer,

LPsupplier or service technician in accordance with

the installation instructions furnished with this range

and all codes and requirements of all local codes and

requirements. Failure to follow instructions could result in

serious injury or property damage. The qualified agency

performing this work assumesresponsibility for the

conversion.

Failure to make the appropriate conversion

can result in personal injury and property damage.

Any additions, changes or conversions

required in order for this appliance to satisfactorily meet

the application needs must be made by an authorized

SearsService Center, Distributor or Qualified Agency.

Moving the Appliance for

Servicing and Cleaning

Turn OFFthe range line fuse or circuit breakers at the

main power source, and turn off the manual gas shut-off

valve. Make sure the range is cold. Remove the service

drawer and open the oven door. Lift the range at the

front and slide it out of the cut-out opening without

creating undue strain on the flexible gas conduit.

Isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.SkPa or 14"

water column).

Range Installation

NOTE:

1. The back of the range may be installed directly

against the wall.

2. To reduce possible scorching of vertical walls and

to minimize potential fire hazards under abnormal

surface unit use conditions such as high heat or

no pans and to conform to C.S.A. requirements,

a minimum of 2 1/2" (6.4 cm) spacing should be

provided on both sides of the cooktop.

3. If a wall is present on the left side of range, allow

a minimum of 2 3/4" (7 cm) to open the auxiliary

door.

Excessive Weight Hazard

o Use 2 or more people to move and install range.

Failure to follow this instruction can result in

back or other injury.

Preparation

1. Put on safety glasses and gloves. Remove oven racks

and parts package from inside the oven. Remove

shipping materials, tape and protective film from the

range.

2. Take 4 cardboard corners from the carton. Stack

one on top of another. Repeat with other 2 corners.

Place corners lengthwise on the floor in back of the

range to support range.

3. Firmly grasp the range and gently lay it on its back

on the cardboard corners.

4. Remove the 4 shipping bolts from the skid. Discard

skid.

5. Lay a large piece of cardboard in front of the range.

Carefully stand the range upright on cardboard.

6. Adjust the leveling legs to a point where the range

base does not touch the floor.

Make sure not to pinch the flexible gas conduit at the

back of the range when replacing the unit into the cut-

out opening. Replace the drawer, close the door and

switch on the electrical power and gas to the range.

If the pressure regulator is connected to rigid piping,

the regulator must be disconnected before moving the

appliance.

Reassemble in reverse order (seefigure 3).

Page 6

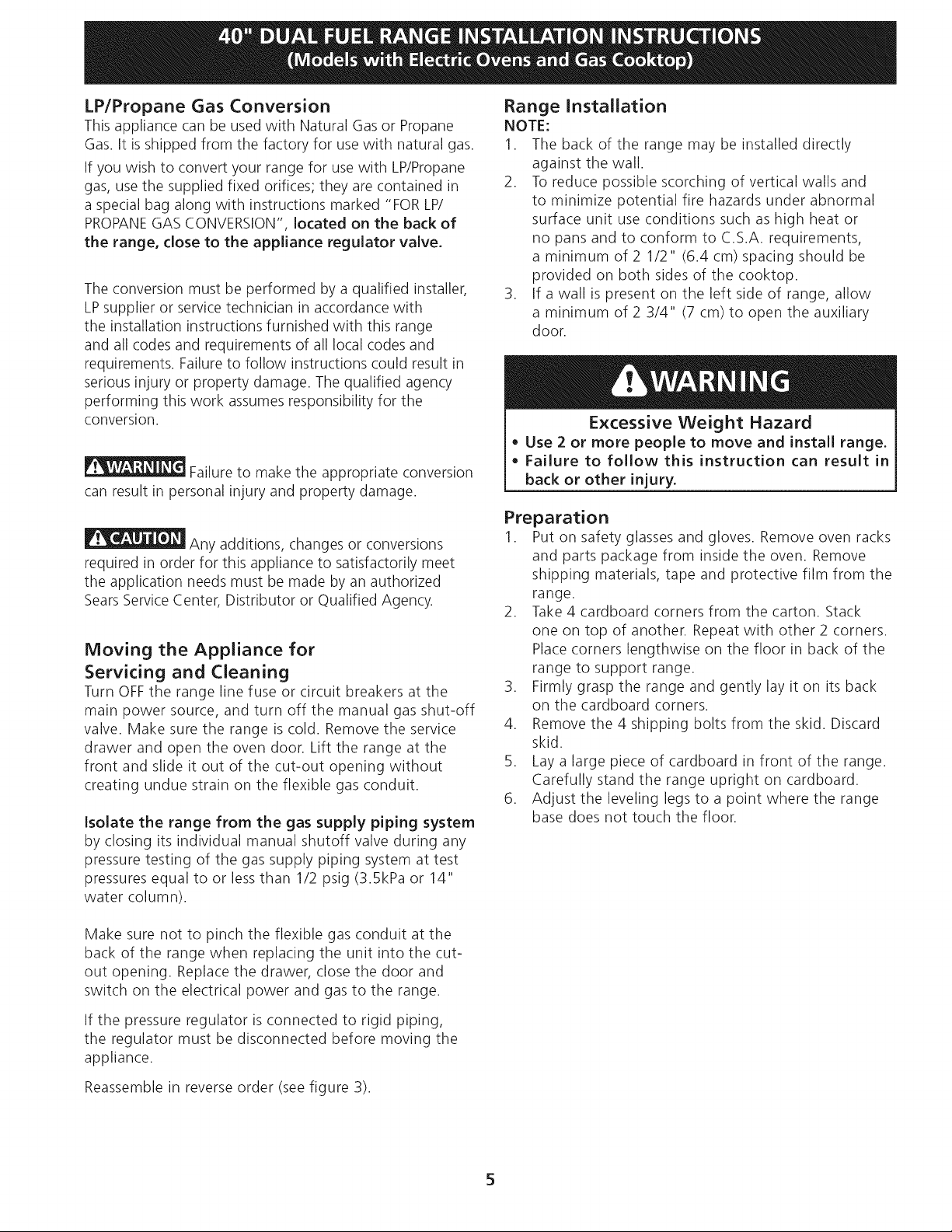

Leveling the Range

Level the range and set cooktop height before

installation in the cut=out opening (if applicable).

1. Install an oven rack in the center of the oven.

2. Place a level on the rack (see figure 4). Take 2

readings with the level placed diagonally in one

direction and then the other. Level the range, if

necessary, by adjusting the 4 leveling legs with a

wrench (see Figure 8).

3. Slide range into cut-out opening and double check

for levelness. If the range is not level, pull unit out

and readjust leveling legs, or make sure floor is level.

Check Operation

Refer to the Use and Care Guide and the Electronic Oven

Control Guide packaged with the range for operating

instructions and for care and cleaning of your range.

Remove all packaging from the oven before testing.

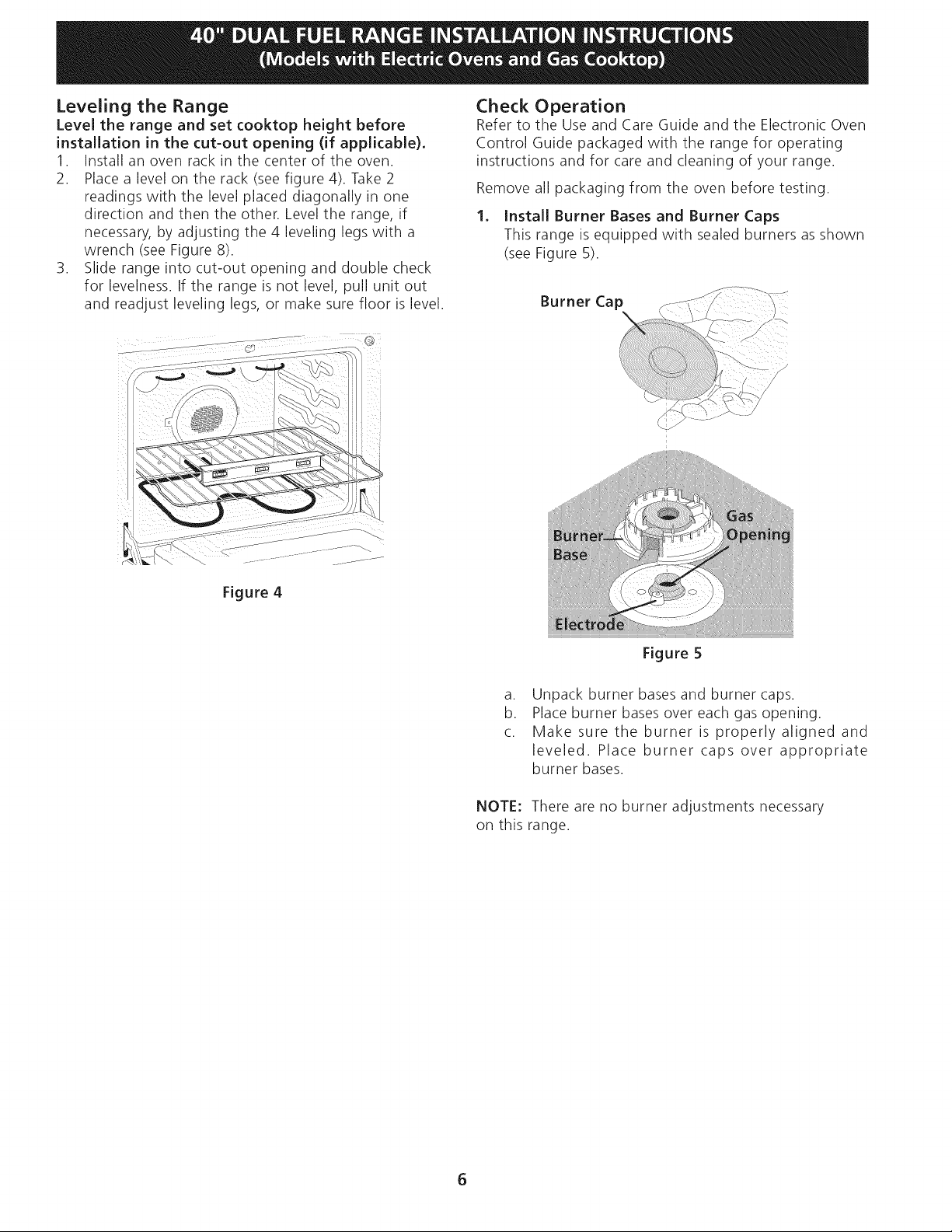

1, Install Burner Bases and Burner Caps

This range is equipped with sealed burners as shown

(see Figure 5).

Figure 4

Figure 5

a. Unpack burner bases and burner caps.

b. Place burner bases over each gas opening.

c. Make sure the burner is properly aligned and

leveled. Place burner caps over appropriate

burner bases.

NOTE: There are no burner adjustments necessary

on this range.

Page 7

2_

Turn ON Electrical Power and Open Main

Shutoff Gas Valve

3_

Check the Igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power. Tocheck for proper lighting:

a. Push in and turn a surface burner knob to the

LITEposition. You will hear the igniter sparking.

b. The surface burner should light when gas is

available to the top burner. Each burner should

light within four (4) seconds in normal operation

after air has been purged from supply lines.

Visually check that burner has lit.

c. Once the burner lights, the control knob should

be rotated out of the LITEposition.

There are separate ignition devices for each burner.

Try each knob separately until all burner valves have

been checked.

4_

Adjust the ""LOW"" Setting of Surface Burner

Valves (see Figure 6)

a. Push in and turn each control to LITEuntil

burner ignites.

b. Quickly turn knob to LOWEST POSITION.

c. If burner goes out, readjust valve as follows:

Reset control to OFE Remove the surface burner

control knob, insert a thin-bladed screwdriver

into the hollow valve stem and engage the

slotted screw inside. Flame size can be increased

or decreased with the turn of the screw. Adjust

flame until you can quickly turn knob from LITE

to LOWEST POSITIONwithout extinguishing

the flame. Flame should be as small as possible

without going out.

5. Operation of Oven Elements

The oven is equipped with an electronic oven control. Each

of the functions has been factory checked before shipping.

However, it is suggested that you verify the operation of

the electronic oven controls once more. Referto the Use

and Care Guide for operation. Follow the instructions for

the Clock, Timer, Bake, Broil, Convection (some models)

and Clean (some models) functions.

_When checking oven element operation,

do not touch the elements. They will be hot enough to

cause serious burns.

Bake-After setting the oven to 350°F (177°C) for

baking, the lower element in the oven should become

red.

Broil-When the oven is set to BROIL,the upper element

in the oven should become red.

Clean-When the oven is set for a self-cleaning cycle, the

upper element should become red during the preheat

portion of the cycle. After reaching the self-cleaning

temperature, the lower element will become red.

Convection-When the oven is set to CONV. BAKE/

ROAST at 350°F (177°C), both elements cycle on and

off alternately and the convection fan will turn. The

convection fan will stop turning when the oven door is

opened during convection baking or roasting.

When All Hookups are Complete

Make sure all controls are left in the OFFposition.

Before You Call for Service

Read the Avoid Service Checklist and operating

instructions in your Use and Care Guide. It may save you

time and expense. The list includes common occurrences

that are not the result of defective workmanship or

materials in this appliance.

Figure 6

Refer to the warranty and service information in your

Use and Care Guide for our phone number and address.

Please call or write if you have inquiries about your range

product and/or need to order parts.

7

Page 8

Important Safety Warning

To reduce the risk of tipping of the range, the range

must be secured to the floor by properly installed anti-tip

brackets and screws packed with the range. Those parts

are located in a plastic bag in the oven. Failure to install

the anti-tip brackets will allow the range to tip over if

excessive weight is placed on an open door or if a child

climbs upon it. Serious injury might result from spilled

hot liquids or from the range itself.

Follow the instructions below to install the anti-tip

brackets.

If range is ever moved to a different location, the anti-

tip brackets must also be moved and installed with the

range. To check for proper installation, see step 5.

Tools Required:

5/16" (8 mm) Nutdriver

Adjustable Wrench

Electric Drill

3/16" (4.8 mm) Diameter Drill Bit

3/16" (4.8 mm) Diameter Masonry Drill Bit (if installing in

concrete

Anti-tip Bracket Installation

Brackets attach to the floor at the back of the range to

hold both rear leg levelers. When fastening to the floor,

be sure that screws do not penetrate electrical wiring or

plumbing. The screws provided will work in either wood

or concrete.

1. Unfold paper template and place it flat on the floor

with the back and side edges positioned exactly

where the back and sides of range will be located

when installed. (Use the diagram in figure 7 to locate

brackets if template is not available.)

2. Mark on the floor the location of the 4 mounting

holes (2 holes per bracket) shown on the template.

For easier installation, 3/1 6" (4.8 mm) diameter pilot

holes 1/2" (1.3 cm) deep can be drilled into the

floor.

3. Remove template and place brackets on floor with

turned up flanges to the outside (see figure 7). Line

up holes in brackets with marks on floor and attach

with 4 screws provided (2 screws per bracket).

Brackets must be secured to solid floor. If attaching

to concrete floor, first drill 3/16" (4.8 mm) dia. pilot

holes using a masonry drill bit.

4. Level range if necessary, by adjusting the 4 leveling

legs with a wrench. (See Figure 8 below.) A minimum

clearance of 1/8" (3.2 mm)is required between the

bottom of the range and the rear leveling legs to

allow room for the anti-tip brackets.

5. Slide range into place making sure rear legs are

trapped by ends of brackets. Range may need to be

shifted slightly to one side as it is being pushed back

to allow rear legs to align with brackets.

6. After installation, verify that the anti-tip bracket is

engaged. Open and remove drawer and check to

make sure the anti-tip bracket is engaged.

I

Anti-tip Bracket

!.... 3_,, (1.9 cm) Typ.

_\ _"

Anti-tip Bracket _q4 ..... <c3c_j,_ . -.

-,-_%, (1.3 cm) Sides of

...." _" ,_z _ range

3A,,(1.gcm) Typz_ ]-_'d

Figure 7 Figure 8

Slide Back

8

Page 9

OVEN CIRCUIT//CIRCUITO DE HORNO//CIRCUIT FOUR

L2 BK-7 CONTROL DE HORNO ELECTRONICO/

R-7

N lillllllllllllllll iiiiiiiiiiiii IIIIIIIIIIIIIIIIII Illl

W-5 =

J3

=

W-5

CONVECTION FAN/

VENTELADOR OE CON%EOCION/

VEN]ELATEUR CONVECTION

BR-14

\ f

W-14

W-5

i

: VENTILATEUR BE REFROIDISBEMENT

• y •

OVEN LA_!P /

LUZ DE HORNO/

LUMI ERE POUR

OVEN LAMP/

LUZ DE HORNO/

LUMIERE FOUR

COOLING FAN/VENTILADOR DE ENFRIA_IIENTO/ I

HIGH/ALTA/HAUTE

T SOME MODELS/ALGUNOS MOOELOS/

",CERTAENS MODELES

LATCH MOTOR/ i

MOTOR CERROJO/ =

MOTEUR VERROU

4 GY:I_! ....

85-14 E

8R-14 BR-14E

/

BR 14=

R-5."

[]

[]

BK-5

[]

[]

[]

[]

[]

[]

=

L1 ELECTRONIC OVEN CONTROL/

CONTROLE ELECTRONIQUE FOUR

ES 5XX

Pll

[]

[]

[]

[]

BK-20

BK_20

8

BK_14

= BK 20 " BK-2O

[]

[]

i BK-14 ._--...o BK-_4

[]

CONY []

BA[]

BR

L2 OUT

"o-e _ ................o-6

=

= BAKE ELEMENT/

: ELEMENT OUISSON

" Y_6

=M:e...................._ ................

" R_RMRNTOB_,.,GE

;BL*8 I_ _/ _] BL-7

TEMPERATURE PROBE /

SONDA DE TEMPERATURA/

SONDE THERMIQUE

) _\t)>_ _.............

DOOR SWATCH/

INIERRUPTOR DE PUERIA/

]NTERRUPTEUR PORTE

MOTOR SWITCH LATCH/

INTERRUPTO5 MOTOR DE LOQUETA DE PUERT#

INTERRUPTEUR MOTEUR VERROU

NO C

CONVECTION ELEMENT/

ELE_/ENTO DE CONVECCION/

ELEMENT CONVECTION

ELEtAENTOOE HORNO/

BROIL ELEMENT/

ELEMENTO BE ASADO/

i

i THERNAL CIRCUIT BREAKER/

I INTERRUPTOR DE CIRCUITO

I TERMICO/DISJONOTEUR THERMIQUE:

L ]

=

|IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIP

AUXILIAIRY OVEN // HORNO LATERAL // FOUR AUXILIAIRE

LEFT OVEN DOOR SWITCH/ LUZ ME IIORNO IZQUIERMO/

INTERRUPTOR DE PUERTA DE HORNO [ZQUIERDO/ LA_PE DE POUR GAUCHE

]N[ERRUP[EUR DE PORTE ME POUR GAUCHE

BK-IO _/" BR 10 W-1

lEFT OVEN THER_STAT SW, / LEFT OVEN BROIl ELEMENT/

INTENNUPTOR DE TER_OSTATO ELE_ENTO DE ASAO0 DE HORNO _ZQUIERDO/

OR HORNS IZOUIEROO/ ELEI_ENT DE BRIItAGE FOUR GAUDNE

INTENRUPTEUR THERMOSTAT

DR FOUR OAUDNE BL-5 A BL 5 BL 5

BM_5 _ ELEMENTO DE HORNEO

CAUTiON:DISCONNECT POWER BEFORE SERVICING UNIT*

ATENCION:CORTAR LA CORRIENTE ANTES BE REALIZAR EL MANTENEMEENTO DEL ELECTRODOMESTICO.

ATTENTION;COUPEZ L'ALINENTATION AVANT B'EFFECTUER LA REPARATION.

A LEFT OVEN INDICATOR// _'_?_ ......

/ZQUIERDO/IND]OAIEUR

FUR AU HE ELEMENT DE CUISSDN TERMOSTATO DE SEGURIDAD/

0 O ¢

P '_ c FOUR __ THERMOSTAT DE SURETE

B LEFT OVEN THERMOSTAT/

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS,

WIRINGS ERRORS CAN CAUSE _MPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

ETIQUETE TODOS LOS CABLES ANTES DE OEBCONECTAR CUANDO NAGA EL BERVIC[O A LOS OONTROLES,

ERRORES AL VOLVER A ENSABBLAR LOS CABLES PUEDE CAUSAR FALLAS U OPERACEONES PELIGROSAS.

VERIF[QUE LA CORREOTA OPERAOION DESPUES DEL BERVICIO.

IDENTIFIEZ TOUS LED FILS AVANT DE LEG DEBRANCHER GGAND L'APPAREIL EST HORS SERVICE.

LES ERREURS DE CONNECTION DE FILS PEUVENT CAUSER UN MAL FONCTIONNEMENT ET UM DANGER

D'USAGB DE L'APPAREtL, VEBIFIEZ LE BON FONOTtONNEMENT DE L'APPAREtL APBES LE SERVICE,

HORNO IZQUIERDO/ SAFETY THERMOSTAT/

Y ,

LEFT OVEN LAI_P/

TERMOSTATO DE IIORNO IZQUIERDO/

THERMOSTAT ME FOUR GAUCHE

[] °

L2 IN _ IN[ERRUP]OR CERROJO

L2

CONNECTOR/

CONECTOR/

CONNECTEUR

DOOR LATCH sw/rcH

DE PUER]A/INIERRUP]EUR

DE PORTE VERROU

COLOR CODE/CODIGOS DE COLOR

CODE DE COULEUR

MY, GREY/GRIS/GRIS

G, GREEN/VERDE/VENT

W, WHITE!BLANCO/BLANC

R. RED/ROJO/ROUGE

O. ORANGE/NARANJA/ORANGE

Y, YELLOVMA_ARILLO/dAUNE

DR, 5ROVINICAFE/BRUN

BL,-BLUE/AZUL/BLEU

BM, OLACK/NEGRO/NOIR

CODE GAUGE TEMP/C CSA U

CODIGO MEDIDA

CODE CALIBRE

1 18 125 0L1251 3123

2 IE 125 CL1251 3173

3 14 125 CL1251 3173

4 12 25 CL1251 3173

5 18 50 EXL- 150 3321

6 18 150 EXL- 150 3321

7 14 150 EXL 150 3321

8 12 150 EXL 150 3321

9 13 150 EXL 150 3321

t0 18 200 SEW 1 3122

tl 15 200 SEW 1 3122

12 12 250 3252

13 15 250 3252

14 20 150 EXL- 150 3321

15 8 150 EXL* 150 3321

16 8 60

t7 10 60

18 10 200 SEW-I 3122

19 20 125 OI 1251 3173

20 20 200 SEW- 1 3122

2t 22 125 3266

22 22 150 10109

23 18 200 3573

34 18 2OO 3512

35 18 2OO 3512

37 14 200 3512

41 23 200 3512

318045341 REV:A

PAGE" 1 /2

9

Page 10

......................................................................................COOKTOP CIRCUIT / CIRCUITO DE PLANCHA DE COCINAR /CIRCUIT TABLE CUISSON

WITH WARMER ZONE / AREA DE CALENTADOR / AVEC ZONE RECHAUD

** ELE_NTIELEMENTO/L_ITEUR

E{:O fARO

_b 2b I

_-_---_

_,].' ..............

COOKTO_ £!#CUIT / OIRCUITO D E _L_£_ DE

CIRCUIT TABLE CUISSON

CENTER REAR IGNITER GWZTCH/

INTERRGPlO£ ENCENDIDO

CEN1RO IGAS_O/

INTERRUPTEUB O ALLUMAGE

ARR_ER_ CENTRE

RIGHT REAR IGNITER SWITCH/

[NTERRUPTOR ENCE_OIO0

TRASERODERECHO/

INTERRUPTEURO'ALLUMAGE

A_RIERE O_OITE

RIGHT FRONT IGNITER SWITOH/

INTERRUPTOR ENCENOIOO

FRENTE DERECHO/

INTERRUPTEURO'ALLU_AGE

AVAN10ROII_

LEFT FRONT IGNITER SWITCH/

INTERRbRTOR ENUR_OIO0

FREN1_ IZGU[_OO/

INTERRUPTEURD'ALLUB#,GE

AVANT GAUCHE

[¸EFT REAR IONITE_ SWatCH/

IN_E_RGPIO_ ENC_NOIGO

TRASERO IZOUIERO0/

INTERRGPTEUBD_UMAGE

ARRIERE GAUCHE

_W-5

L2 R-_4 _4

R-14 4

R-14 _14

R 14

IGNITER MODULE BOARD/

CUARDODE NODULO DE ENCENDIDO/

B[OO CONNECTIOND'A[[UMEUR

LJ

<2

u

/ /

CAUTION: DISCONNECT POWER BEFORE SERVICING UNIT,

ATENCION:OORTAR LA CORIENTE ANTES DE REALIZAR ELNANTENIMIENTO GEL ELECTRODONESTtCO, 318045341 REV:A

TOP BURNER IGNITER/

GUE#ADOR _E ENCEN_EDO SUPERIOR/

BOUGIE D'AL[UMAGE DE BRU[EUR

W 10

TOP BURNER IGNITER/

QUE_ZAROR OE ENCENGZDO SUPERIOR/

W lO _,_

ULEUR

ATTENTION:COUPEZ L'ALIMENTATION AVANT D'EFFECTUER LA REPARATION, PAGE "2/2

i_ _m,_o_ _ETRASERO Llr, ZTEa/

RL 1o

i IrDZ_aT_U_s_ SU_Ace I

BK÷7 i C-'_Te_ _rT _ae_w

itBK_TBK'7...... cL_.-: • R-1111 _ 11

i[F,l_R# Fe 1 P2 4 i 6E_]_ _F eL aEn i

051 @ I

i_ E_NTO o_ OENT_OIZOU_ _O0/I

i ii - _ / BK.11 Ekm_E_tc_rraE GAUO-_

I =_ EM_NTO D= O_NTRO I_Q/E_R_/

BL_IO I I

CE_T_S_'ITC_' O-5

!_OICAT_ OE_UR_AC_

0_5 Z_IOIOAT_U_SUaFA6_CI_UO_

i

I I I

05

CEN7#_ P2 _ _ R-II I I

R2 4a CEnteR EL_M_ r _

BK 5 BL=IO El[_IENTCEF_TR_

_IGHT _A£ SWITCN

[nTeRRUmO_ _S_aO U_eCaO/

_VEnRUPtEO_ AnR_E_e _ROIT_

BK*11 i D, i

L _ _ J

ELE_E_TO DE O_N_RO/

BL1O i i BL lO_ BL*2O

i_icA_o,o_ s_,_c_e HOT sur_,',ce _N_ICATOR/

_o_¢ATr_ _E S_,_ACe N*_ICADORn_ Sm_R_ C_ Cal I_nVE'

o 5 _ 0-5 _DICATEUR SURFACECHAUO_

B- 11 ** LI_iTADO_ sw tc_/

BK11 F qBR 1"-_ R-6

_GHI aONf SWITCh/ L;:TE EXTERlr ECTER[E,F_R i i 2 p1

INTERRUPOR OE FRNTE OERECHO/

INT RRUPTE_R_VANr OROIrE EL _,_E_IODE aENI_ hER CHO/

BL

I 0

[LB_NT AVAST o_oit i IGY-IO _ BL:t2p

_OT_:

SeRWCE:_ _EPLACE_IEnlO_ _Em_INA_SBEC0_ESNECESSA_Y,C_PA_BL_WIn_ _YP_An0

_ ANOCO_PA_ABL_TE_LS _ST BE USEO,

_OTA:

E_ CASOQUES_A NECESA_I00E REE_PLAZ_ LOSBORN£S,ES_ECESARI0_EUTILIZAB

EL _1_0 T_O 0E A_A_m_ V 0_ _EO_DO_Y _1 _IIS_O_IFO OE _0_eS

SERWCE:S_ _ESFILS 0U0EBCOSSESDOIW_T _T_ER_mLAC_S,UTI[IS_Z O_SpIECES 0_

CA_I_ _T O_ _YP_ E_[VAI_NrSL_S FI_S DO,Writ _R_ _4 CUIVR_.

-L_B_t ALL _I£_S _RIO£ TO D_SCO_NEOTIONWN_N $ERV_OINGCO_TBOtSW_RIN_ER_O£CAN

CAUSE I_PR0_R A_0 0AN_0US 0P_RATION,VE_I_YP_0PE_0PE_ATI0_AFTERSERWC_N_

AVt_0:

-ET_QUE_ TOPOS LOS aLA_S_S AnT_S _E O_SCOn_CTA_PA_ _EALITAR_L I_ANVE_nTO DE LOS

CONTROL_SE_O_ OE ALA_SRAJEPUEO_CAUSARUN FUNCIONAM_EnTOI_O0_RECTOY _ELI_ROSO

V_IF_QUE Sl _LFUNC_ONA_IE_¢'0eST_ 00_CT0 DES_ES _L _U_VE_U_E_TO

-ET_QUET_RC_A0UE _IL AVAHT _ B_CH_I_nT 0_ C_UX-Cl.UN_ _RR_UR _ BF_NC_m_ENTP_U_

CAU_[RU_E O_AT_O_ OA_Ur_U_EVER_ZER _ _ON_ONCT_ONN_T nE _'AP_ARE:LAFROS

TOUT_ r_PA_T_On

WAqI{ING:

#$SCONNSOT PO?;E£ BEFOR_ 5_BVICING UNIT,

AWSO:

_UPE_ LE _U_A_V AWN_ D'_FFECTU_ L_ R_Pa_ArZO_,

SWITCH/

LI_{ZP-_R

I I

i i w-lo _ BL 20

_OT SUR_AC _o_ca o_

F ] BR-1 _- R÷6

, _4t'_

i i 2 P1

i i BR-IO /T_ BL_20

LtO[ BUR ACE INO_GA-O[_

INDICADOR DE 8UPERFZOIE GALI_NTE

_N_IOA_U_SU_Ce C_U_

I

i I YIO _;_ BL-2O

L __

HOTSURFACEINDICATOR/

INOICA00ROES_PE_F_CI_CALI_IE'

_OICA_Lm SUa_ACEC_AUO_

_ NT_RUPTO,4 /

, _ 4_-_

_0T SU_AC_ l_m,IC_TO_,'

INOIOAO0__ SUP[_FtCI[ CALI_t_T[/

IIDICA ES_SU_FAC_C_AUO_

L1 N L2

o

&.....

Page 11

UN INSTALLATEUR QUALIFli_ DOlT EFFECTUER L'INSTALLATION ET LE SERVICE

iMPORTANT: CONSERVEZ CES iNSTRUCTiONS POUR LES INSPECTEURS LOCAUX.

USEZ CES iNSTRUCTiONS ET CONSERVEZ-LES POUR RI_Fi_RENCES ULTi_RIEURES.

i_ Si les instructions de ce manuel ne sont pas suivies a la lettre, il pourrait en r_sulter un

incendie ou une explosion susceptible de causer des dommages materiels, des blessures ou m_me la mort.

POUR VOTRE SECURITE:

-- N'entreposez et n'utilisez pas d'essence ou d'autres produits

inflammables a proxirnit_ de cet appareil ou de tout autre appareil.

-- QUE FAIRE SI VOUS DECELEZ UNE ODEUR DE GAZ:

• Ne tentez d'allumer aucun appareil.

N'actionnez aucun interrupteur _lectrique; n'utilisez aucun appareil t_l_phonique de I'_difice.

• Communiquez imrn_diatement avec votre fournisseur de gaz en vous servant du t_l_phone

d'un voisin. Suivez les instructions que le fournisseur vous donnera.

• S'il vous est impossible de rejoindre votre distributeur de gaz, communiquez avec le service

d'incendie.

-- Uinstallation et I'entretien doivent _tre effectu_s par un installateur qualifi_, un service d'en=

tretien ou de r_paration accr_dit_ ou le distributeur de gaz.

40 1/8" Min.

(101.9 cm Min.)

2 3A" Min.

(7 cm Min.) pour

I'ouverture de la

auche seule[ (45.7 cm Min.) (33 cm Max.)

Prise mu (61 cm Min.)

mise _ la terre 24 1/2" Max.

note

18" Min.

13" Max.

2 1/2" Min.

(6.4 cm Min.)

du c6t_ droit

24" Min.

(62.2 cm Max.)

Ne coincez pas le cordon d'alimentation ou le conduit de

gaz entre le mur et I'appareil.

Ne scellez pas I'appareil aux armoires lat_rales.

**NOTE: D_gagement minimum de 24" (76.2 cm) entre

la plaque de cuisson et la has de I'armoire du haut Iorsque

le dessousde I'armoire en bois ou en m_tal est prot_g_ par

un celloderme retardateur de flammes d'un minimum de

D

F4" (0.64 cm) recouvert d'une feuille de m_tal MSG No.

28, d'acier inoxydable d'un minimum de 0.015" (0.4 mm),

d'aluminium de 0.024" (0.6 mm) ou de cuivre de 0.020"

(0.5 ram).

D_gagement minimum de 30" (91.4 cm) Iorsque

I'armoire n'est pas protegee.

48 1/8" 40 1/8" 26Y4"(66.7 cm)

(122.2cm) (101.9 cm) avecla poign_e28Y2"(72.4)

Imprime aux Etats-Unis

44 5/8" (113.3cm) 40 1/4" (102.2 cm) 36" (91.4 cm)standard

35 7/8" (91.1 cm) min.

P/N318201764 (0907) Rev.A

Francais - pages 1-8

Schemas de c_blage - page 9-10

Page 12

Notes irnportantes a I'Instailateur

1. Liseztoutes lesinstructions contenues dans lesInstructions

d'installation avant d'installer la cuisini_re.

2. Enlevez tout le materiel d'emballage des compartiments

du four avant de connecter I'alimentation _ gaz et _lec-

trique _ la cuisini_re. (volt "Preparation ", page 5).

3. Les deux supports anti-bascule qui se trouvent dans le

four DOIVENT_tre insta%s (Volt "Installation dessupports

anti-bascule" _ la page 8).

5. Respecteztousles codes et r_glements applicables.

6. N'oubliez pasde laisserces instructions au consommateur.

Note irnportante au consornrnateur

Conservez cesinstructions avec le guide de I'utilisateur pour

r_f_rence ult_rieure.

INSTRUCTIONS DE Si'CURITi"

IMPORTANTES

Cette cuisini_re dolt _tre install_e conform_ment aux

r_glements Iocaux, ou en leur absence, aux normes CAN/

ACG-B149.1 et CAN/ACG-B149.2.

La conception de cette cuisini_re a _t_ approuv_e par

International Approval Services. II faut prendre certaines

precautions d'usage Iors de I'utilisation de tout appareil

fonctionnant au gaz naturel ou produisant de la chaleur.

Vous trouverez celles-ci dans votre Guide d'utilisateur

lisez-les avec attention.

oToutesles

cuisinieres

peuvent basculer.

Desblessures

pourraient

survenin

•Installer les

supports qui

accompagnent

lacuisiniere.

Assurez-vous que votre cuisiniere est correctement

installee et raise a la terre par un installateur ou

un technicien d'entretien qualifi&

• Le circuit electrique de cette cuisiniere doit Ctre

misa la terre conformement aux r_glements Iocaux,

ou en leur absence, _ la norme canadienne d'_lectricit_,

ACNOR C22.1, pattie 1.

• L'installation d'appareils conc us pour les maisons

(mobiles) dolt se conformer aux normes de la

Manufactured Home Construction and Safety Standard,

titre 24CFR, pattie 3280 (ant_rieurement Federal

Standard for Mobile Home Construction and Safety,

titre 24, HUD (pattie 280)) ou en leur absence, aux

normes de la Manufactured Home Installation 1982

(Manufactured Home Sites, Communities and Setups),

ANSI Z225.1/NFPA 501A-derni_re _dition, ou aux codes

Iocaux. Lorsque I'installation se fait au Canada, elle dolt

se conformer _ la norme CAN/ACNOR-Z240 MH.

• Assurez-vous que la tapisserie a proximite du four

peut resister a la chaleur g_neree par la cuisiniere,

Pour prevenir que la cuisiniere

bascule, elle dolt _tre fixe

correctement au plancher

I'aide des supports qui

I'accompagnent. Pourverifier

si les supports sont installes

correctement, retirez le tiroir

de rangement et assurez-

vous que lessupports sont

enclenches.

• Avant d'installer la cuisiniere a un endroit recouvert

de linoleum ou de tout autre couvre-plancher

synth_tique, assurez-vous que celui-ci peut

resister a un minimum de 90°F (32,2°C) de chaleur

au-dessus de la temperature de la piece sans se

rapetisser, se deformer ou se decolorer. N'installez

pas la cuisini_re sur un tapis, _ moins de placer un

tampon isolant ou une feuille de contreplaqu_ d'une

@aisseur de 1/4"(0.6 cm) entre la cuisini_re et le tapis.

• Ne bloquez pas la circulation d'air a I'orifice de

ventilation du four ni autour de la base ou sous

le panneau inf_rieur avant de la cuisiniere. Evitez

de toucher les ouvertures de I'orifice de ventilation ou

les surfaces avoisinantes car elles risquent de devenir

chaudes Iorsque le four fonctionne. Les brQleurs ont

besoin d'air frais pour assurer une bonne combustion.

Ne laissez jamais les enfants

seuls ou sans surveillance pres d'un appareil en

fonctionnement. Apprenez-leur _ utiliser les appareils

_lectrom_nagers de facon s_curitaire et appropri_e. Ne

laissez jamais la porte du four ouverte Iorsque la cuisini_re

est sans surveillance.

Le fait de monter sur les portes

ou les tiroirs de cette cuisiniere, de s'y appuyer ou

de s'y asseoir peut occasionner des blessures graves,

et endommager I'appareil.

• N'entreposez pas d'objets susceptibles d'interesser

les enfants dans les armoires situees au-dessus de

la cuisiniere. IIs risquent de se brQler s_rieusement s'ils

tentent de grimper sur I'appareil.

• ltvite z de placer des armoires de rangement

au-dessus des brQleurs afin d'_liminer les gestes

inutiles au-dessus de ceux-ci.

Reglez la flamme du brQleur pour qu'elle ne

depasse pas le bord de I'ustensile utilise pour la

cuisson. Une flamme excessive est dangereuse.

• N'utilisez pas le four a des fins de rangement. Ceci

g_n_re une situation _ventuellement dangereuse.

• N'utilisez jamais votre cuisiniere pour r_chauffer ou

chauffer la piece. L'utilisation prolong_e de la cuisini_re

sans une ventilation adequate peut s'av_rer dangereuse.

• Ne gardez pas de produits combustibles, d'essence

et d'autres produits inflammables & proximit_ de

cet appareil ou de tout autre appareil. II pourrait en

r_sulter des explosions ou un incendie.

• Lots d'une panne de courant _lectrique, les brQleurs de

surface peuvent _tre allum_s manuellement; placez une

allumette allum_e pros de la t_te du brQleur et tournez

lentement le bouton de commande de surface _ la

position LITE. Redoublez de prudence si vous allumez

un brQleur de surface manuellement.

• Replacez toutes les commandes _ la position arr_t

"off" apr_s I'utilisation d'une fonction programmable

chronom_tr_e.

Cet appareil comprend une

fiche de courant a quatre broches incluant celle

de la raise a la terre pour vous proteger contre les

chocs electriques. Branchez cette fiche directement

dans une prise de courant correctement raise & la

terre. Ne coupez pas ou n'enlevez pas la broche de

mise a la terre de la fiche.

Page 13

POURLESMODELES MUNIS DE L'AUTO- NETTOYAGE:

• Enlevez la I_chefrite, les aliments et les autres

ustensiles avant I'auto-nettoyage du four. Essuyez

tousles renversements excessifs. Suivez les instructions

pour le pr_-nettoyage dans le Guide de I'utilisateur.

Emplacement de ia plaque de serie

La plaque de s_rie est situ_ sur I'encadrement du four

principal. Emplacement de la

Lots d'un commande plaque de; _rie

de pi_ces ou pour

toute demande de .............

renseignements au sujet de

votre cuisini_re, assurez-

vous de toujours inclure

les num_ros de module, de

s_rie et le num_ro de lot ou

la lettre qui se trouve sur

la plaque de s_rie de votre

appareil.

Modeles avec cordon d'alimentation

branche en usine

cette cuisini_re est munie d'un cordon d'alimentation

branch_ en usine (volt Figure 1). II dolt _tre connect_

une prise d'alimentation de 120/240 volt, mise _ la terre,

ou _ une prise de courant pour cuisini_res de 120/208

volt. Si aucune prise d'alimentation n'est disponible,

demandez _ un _lectricien competent d'en installer une.

Figure I

Risque de choc electrique

o La mise a la terre de cet appareil est obligatoire.

• Ne branchez pas I'appareil au circuit electrique

avant qu'il soit mis a la terre correctement, en

permanence.

• Interrompez le courant dans la boite de jonction

avant d'effectuer la connexion electrique.

• Cet appareil doit _tre branche a un systeme de

c_blage metaHique, mis a la terre en permanence,

ou un connecteur mis a la terre doit _tre branche

la borne de mise a la terre ou directement sur

I'appareiL

• N'utilisez pas la ligne d'alimentation en gaz pour la

mise a la terre de I'appareiL

Emplacement de ia cuisiniere

Pour _liminer les risques de br01ures

ou de feu, en _tendant le bras au-dessus des surfaces de

cuisson chaudes, _vitez d'installer des armoires au-dessus

de ces derni_res. Si vous devez en installer, il est possible

de r_duire le risque en placant une hotte pour cuisini_re

qui exc_de horizontalement d'un minimum de 5" (12.7

cm) la base de I'armoire.

©

Ligne du milieu

de la cuisiniere

\\\

',\

Suivezles instructionspour letype

d'installation quevous avez.

Figure 2

Si la cuisini_re est installee entre deux armoires,

dessinez une ligne au centre des armoires (voir figure 2).

Si le dos de I'appareil n'est pas appuy_ au mur (la

position de la prise d'alimentation ne permet peut-_tre

pas _ I'appareil de se reculer compl_tement au tour),

dessinez une ligne _ I'endroit ou I'arri_re de I'appareil

sera positionn_. Installez maintenant les supports anti-

bascule (volt "Installation des supports anti-bascule" _ la

page 8).

Si la cuisini_re est installee avec une armoire d'un

c6t_ seulement, placez I'appareil _ la position finale

voulue. Dessinez une ligne sur le plancher le long de

I'appareil du c6t_ ou il n'y a pas d'armoire. Si le dos de

I'appareil n'est pas appuy_ au tour (la position de la

prise d'alimentation ne permet peut-_tre pas _ I'appareil

de se reculer compl_tement au mur), dessinez une ligne

I'endroit ou I'arri_re de I'appareil sera positionn_.

Installez maintenant les supports anti-bascule (volt

"Installation des supports anti-bascule" _ la page 8).

Si la cuisini_re est installee sans armoire, placez

I'appareil a sa position finale. Dessinez une ligne

sur le plancher le long de I'appareil de chaque c6t_.

Si le dos de I'appareil n'est pas appuy_ au tour

(la position de la prise d'alimentation ne permet peut-

_tre pas _ I'appareil de se reculer compl_tement au

tour), dessinez une ligne ou I'arri_re de I'appareil sera

positionn_. Installez maintenant les supports anti-bascule

(volt "Installation des supports anti-bascule" _ la page

8).

Si vous ne suivez pas les instructions precitees a la

lettre, il peut en resulter un incendie, des blessures ou

un choc electrique.

3

Page 14

Aiirnentation en gaz - Installation

Robinet d'alimentation manuel

Adaptateur de

raccord evase

de I'appareil (Instaltez unE

Iongueur suffisante de

conduit flexible pour

permettre _ I'appareil d'etre

tir_ compl_tement hors

de son emplacement

pour I'entretien.

Figure 3

3ression

Adaptateur d_

raccord _vas_

(Branchez bun tuyau

d'alimentation en gaz 1/2"

ou 3/4"b partir du

mur ou du plancher).

La tuyauterie d'alimentation en gaz peut _tre install_e

travers lemur lateral de I'armoire droite. L'armoire

lat_rale droite est I'endroit ideal pour I'installation du

robinet d'alimentation principal.

Ne serrez pas trop les raccords. Le

r_gulateur est moul_ sous pression. Un serrage excessif

pourrait le fissurer et provoquer une fuite de gaz

susceptible de causer un incendie ou une explosion.

Assemblez le connecteur flexible du conduit

d'alimentation en gaz au r_gulateur de pression dans

I'ordre qui suit:l- robinet d'arr_t manuel, 2- adaptateur

de raccord _vas_, 3- connecteur flexible, 4- adaptateur

de raccord _vas_, 5- r_gulateur de pression.

Le conduit d'alimentation en gaz branch_ au robinet

d'alimentation dolt _tre un tuyau solide de 1/2"(1,27 cm)

3/4(1,9 cm)".

L'utilisateur dolt connattre I'emplacement du robinet

d'alimentation principal et _tre en mesure d'y acceder

facilement.

Cet appareil a _t_ conc u en usine pour fonctionner au

gaz naturel avec une pression d'admission de 4"(10,16

cm). de colonne d'eau (1.0 kpa). Un r_gulateur de

pression convertible est branch_ avec la rampe _ gaz

de la cuisini_re, et dolt rester connect_ en s_rie avec le

tuyau d'alimentation. Pour acceder au r_gulateur enlevez

le tiroir.

Pour un fonctionnement normal, la pression int_rieure

maximum au r_gulateur ne dolt pas _tre sup_rieure

14"(35,56 cm) (3.5 kpa) de pression de colonne d'eau.

La pression d'admission au r_gulateur dolt _tre

sup_rieure d'au moins un pouce (ou de .25 kpa) au

r_gulateur ajust_ _ la rampe _ gaz. Pour le gaz naturel,

le r_gulateur _tant ajust_ _ 4" (10,16 cm) de pression

(1.0 kpa), la pression d'admission dolt _tre d'au moins

5 "(12,7 cm) de colonne d'eau (1.25 kpa). Pour le gaz

propane, le r_gulateur _tant ajust_ _ 10"(25,4 cm) de

pression (2.5 kpa), la pression d'admission dolt _tre d'au

moins 11 " (27,9 cm) (2.75 Kpa).

La ligne d'alimentation dolt _tre munie d'un robinet

d'arr_t approuv_ (volt Figure 3). Ce robinet dolt se

trouver dans la m_me piece que la cuisini_re et

un endroit qui permette de I'ouvrir et de le fermer

facilement. Ne bloquez pas I'acc_s au robinet d'arr_t. II

est destin_ _ OUVRIR et _ FERMERI'alimentation en gaz

de I'appareil.

Ouvrez le robinet de la ligne d'alimentation en gaz.

Attendez quelques minutes pour que le gaz commence

circuler _ travers la canalisation pour le gaz.

L'alimentation en gaz entre le robinet d'alimentation

manuel peut-_tre raccord_e par un tuyau m_tallique

flexible homologu_ CSA ou un tuyau rigide sujet

I'application des normes locales.

Lorsqu'un conduit de gaz flexible est utilis_, laissez

suffisamment de mou pour _tre en mesure de d_gager la

cuisini_re de I'ouverture pour le nettoyage et I'entretien.

NOTE : Veillez _ ce que le conduit flexible ne soit pas

coinc_ entre lemur et la cuisini_re. Pour v_rifier si tel est

le cas, enlevez le tiroir.

Utilisez des p_tes _ joints de tuyauterie fabriqu_es pour

utilisation avec gaz naturel et propane, pour sceller les

connexions de gaz. Si des connecteurs flexibles sont

utilis_s, assurez-vous qu'ils ne sont pas tordus.

Les v_rifications contre les fuites doivent Ctre

effectu_es conform_ment aux instructions du

manufacturier.

Veillez a ce qu'il n'y ait pas de fuites. Apr6s avoir

raccord6 I'alimentation en gaz a la cuisini6re, a I'aide

d'un manom6tre v6rifiez si le syst6me ne fuit pas. Si vous

ne disposez pas d'un manom6tre, ouvrez I'alimentation

en gaz et utilisez un liquide d6tecteur de fuites sur tous

les joints et les raccords.

N'utilisez pas de flamme nue pour

v6rifier les fuites de gaz. La d6tection des fuites a I'aide

d'une flamme pourrait provoquer un incendie ou une

explosion.

Toutes les ouvertures a travers le plancher ou lemur ou

la cuisini_re sera install_e doivent _tre scell_es.

Resserrez tousles raccords si n_cessaire, afin de

pr_venir les fuites de gaz dans la plaque de cuisson ou le

tuyau d'alimentation.

4

Page 15

V_rifiez I'alignement des robinets, apr_s avoir reli_

la plaque de cuisson a I'alimentation en gaz, afin de

vous assurer que la rampe du conduit de gaz n'a pas _t_

d_plac_e.

D_branchez la cuisini_re et fermez son robinet

d'alimentation en gaz lots de toute v_rification de

pression du circuit d'alimentation de gaz _ une pression

sup_rieure a 1/2 Ib/po2 (3.5 kpa ou 14"(35,56 cm).

colonne d'eau).

Conversion au gaz propane

Cet appareil fonctionne au gaz naturel ou au gaz

propane. II est r_gl_ en usine pour fonctionner au gaz

naturel.

Si vous d_sirez convertir votre cuisini_re au gaz propane,

servez-vous des orifices fixes fournis dans I'enveloppe

portant I'inscription <<POURCONVERSIONAU GAZ

PROPANE>>situee _ I'arri_re de I'appareil pros de la

valve du regulateur de I'appareil,

Un installateur quail% dolt effectuer la conversion

conform_ment aux instructions du fabricant et a tous

les codes et r_glements applicables. Sices instructions

ne sont pas suivies a la lettre, il pourrait en r_sulter

de s_rieuses blessures corporelles ou des dommages

materiels. L'entreprise d'installation quali%e qui effectue

ce travail assume la responsabilit_ de la conversion.

Si on n'effectue pas la conversion

correctement, il pourrait en r_sulter des blessures

corporelles et des dommages materiels.

Si le r_gulateur de pression est branch_ a une tuyauterie

rigide, le r_gulateur dolt _tre d_branch_ avant de

d_placer I'appareil.

R@assemblezdans I'ordre inverse (volt la figure 3).

Installation de ia cuisiniere

NOTE:

1. L'arri_re de la cuisini_re dolt _tre appuy_ directement

contre lemur.

2. Pour r@duire le risque que le mur devienne br01ant ou

pour minimiser les possibilit@s qu'un feu surviennent

lots de situations anormales, tel que : haute

temp@rature ou utilisation des br01eurs sans ustensile,

et pour @treconforme aux normes de I'agence CSA,

vous devez laisser un espace minimum de 2 1/2(6.4cm)

de chaque c6t@de la surface de cuisson.

3. Si un mur est pr@sent_ gauche de I'appareil, un

minimum de 2 3/4" (7 cm) entre I'appareil et lemur

est requis afin de permettre I'ouverture de la porte

du four auxiliaire.

Risque de charge excessive

• 2 personnes ou plus sont necessaires pour

installer ou d_placer la cuisini_re.

Si vous ne tenez pas compte de cet avertissement

des blessures graves au dos ou ailleurs peuvent

survenir.

Pour que toutes les additions,

modifications ou conversions apport_s _ cet appareil soit

conformes, elles doivent _tre effectu_es par un centre

de service agree, un distributeur autoris_ ou une agence

autoris_e.

D_placernent de i'appareii en vue d'en faire

ie service ou pour faire du nettoyage

COUPEZ I'alimentation _lectrique de I'appareil _ la botte

de fusibles ou des disjoncteurs et fermez le robinet

d'alimentation _ gaz manuel. Assurez-vous que I'appareil

est froid. Retirez le tiroir de rangement, puis ouvrez la

porte du four. Soulevez la cuisini_re _ I'avant et faites-la

glisser hors de son gtte, tout en _vitant de soumettre le

conduit _ gaz flexible _ des contraintes excessives.

Isolez la cuisini_re du reseau d'alimentation en gaz

en fermant son robinet d'arr_t manuel, lots de toute

v_rification de pression du circuit d'alimentation en gaz

une pression inf_rieure ou _gale _ 1/2 Ib/po2 (3.5kPa ou

14" colonne d'eau).

Lorsque la cuisini_re est replac_e dans son gtte, veillez

ne pas coincer le conduit _ gaz flexible et le cable

d'alimentation _lectrique derriere I'appareil.

Preparation

1. Portez des lunettes et des gants de s_curit_. Retirez

les grilles et la botte d'accessoires du four. Enlevez le

materiel d'emballage, les rubans adh_sifs et les films

protecteur de I'appareil.

2. Retirez les 4 coins de carton de la botte. Placez-les

deux par deux un sur I'autre _ I'arri_re de I'appareil

sur le sol dans le sens de la Iongueur afin de

supporter I'appareil.

3. Basculez doucement I'appareil sur le dos dessus les

coins de carton.

4. Enlevez les 4 vis fixant la base d'emballage

I'appareil. Jetez la base.

6. Etendez un grand morceau de carton sur le devant

de I'appareil. Doucement relevez I'appareil afin qu'il

se retrouve debout sur le carton.

7. Ajustez les pieds niveleurs pour que I'appareil

repose sur ces derniers et non sur la base de I'appareil.

Page 16

Mise a niveau de ia cuisiniere

Mettez la cuJsJni_rede niveau et ajustez la hauteur

de la table de cuJsson avant de I'instaJler dans le

decoupage du comptoir (sJ applicable).

1. Installez une grille au centre du four.

2. D@osez un niveau a bulle sur la grille (figure 4).

Prenez 2 lectures en placant le niveau en diagonale

dans une direction, puis dans I'autre direction. Si

n_cessaire, ajustez les 4 vis de nivellement a I'aide

d'une cl_ pour niveler I'appareil (reportez-vous a la

figure 9).

3. Glissez d_licatement la cuisini_re dans le d_coupage

du comptoir et v_rifiez si elle est encore de niveau.

Si la cuisini_re n'est plus de niveau, tirez-la hors du

d_coupage et r_ajustez les vis de nivellement ou

assurez-vous que le plancher est bien au niveau.

j

Verification du fonctionnement

R_f_rez-vous au Guide de I'utilisateur indus avec la

cuisini_re pour les directives de fonctionnement et pour

I'entretien et le nettoyage de votre cuisini_re.

Enlevez tout le materiel d'emballage du four avant de

commencer les essais.

1. Mise en place des bases et des couverdes de

breleurs

Cette cuisini_re est munie de br01eurs scell_s comme

indiqu_ ci-contre (figure 5).

Couvercle de

brO[eur

Figure 4

Figure 5

a. D_ballez les bases de br01eur et les couvercles.

b. Placez les bases de br01eurs au-dessus de chaque

orifice d'alimentation.

c. V_rifiez que le br01eur est correctement align_

et _ niveau. Placez le couvercle sur la base de

br01eur appropri_e.

NOTE : Aucun r_glage de br01eur n'est n_cessaire dans

ce genre de cuisini_re.

Page 17

2_

Branchez I'alimentation en electricite et OUVREZ

le robinet principal d'alimentation en gaz,

3_

V_rifiez les allumeurs

II faut v_rifier le fonctionnement des allumeurs

_lectriques apr_s que la cuisini_re et les raccords du

tuyau d'alimentation aient _t_ eux-m_mes v_rifi_s

relativement aux fuites et que la cuisini_re ait _t_

branch_e b la prise de courant. Pour v_rifier si

I'allumage est ad_quat :

A. Appuyez sur le bouton de commande d'un

br01eur de surface et tournez-le b la position

<<LITE>>.Vous entendrez les _tincelles de

I'allumeur _lectrique qui allume le br01eur.

B. Le br01eur de surface dolt s'allumer Iorsque

le gaz est disponible au br01eur sup_rieur. En

fonctionnement normal, chaque br01eur dolt

s'allumer dans un d_lai de quatre (4) secondes

apr_s que I'air ait _t_ purg_ des canalisations

d'alimentation. Regardez si le br01eur est allum_.

C. Une fois le br01eur allum_, le bouton de

commande dolt _tre tourn_ b une autre position

que LITE.

II existe des dispositifs d'allumage s@ar_s pour

chaque br01eur. Essayezchaque bouton s@ar_ment

jusqu'b ce que tousles robinets de br01eur aient _t_

v_rifi_s.

4_

Reglez la position LOW des robinets des

brOleurs de surface (voir Figure 6)

A. Appuyez sur chaque commande et tournez-les

LITEjusqu'_ ce que le br01eur s'allume.

B. Tournez rapidement le bouton _ la position la

plus basse (LOW).

C. Si le br01eur s'_teint, r_-ajustez le robinet comme

suit : Remettez le bouton de commande

arr_t (OFF). Enlevez le bouton de commande

du br01eur de surface, ins_rez un tournevis

pointe droite fine dans la tige creuse du robinet

et ins_rez dans la t_te de la vis. La hauteur de

la flamme peut _tre augment_e ou diminu_e en

tournant la vis. Ajustez la flamme jusqu'_ ce que

vous puissiez tourner rapidement le bouton de

LITE_ la plus base position (LOW) sans _teindre

la flamme. Celle-ci devrait _tre aussi minuscule

que possible sans s'_teindre.

5. Fonctionnement des elements du four

Ce four est _quip_ d'un contr61eur _lectronique. Chacune

des fonctions a_t_ v_rifi_e b I'usine avant I'exp_dition.

Nous vous sugg_rons cependant de v_rifier une fois de

plus le fonctionnement des commandes du contr61eur

_lectronique. Rd_rez-vous au Guide de I'utilisateur pour

le mode de fonctionnement. Suivezles instructions sur

les fonctions de I'Horloge (Clock), de la Minuterie (Timer),

de la cuisson au four (Bake), au gril (Broil), par convection

(Convection) (certains modules) et de nettoyage (Clean).

Ne touchez pas aux _l_ments du four

Iorsque vous v_rifiez les operations. Ces derniers peuvent

_tre assezchauds pour causer des brOlures.

Cuisson au four (Bake)- Apr_s avoir r_gl_ le four

350°F (177°C) pour la cuisson au four, I'_l_ment inf_rieur

du four dolt devenir rouge.

Cuisson au gril (Broil)- Lorsque le four est r_gl_

Cuisson au GRIL (BROIL), I'_l_ment sup_rieur du four dolt

devenir rouge.

Nettoyage (Clean)- Lorsque le four est r_gl_ pour un

cycle auto-nettoyant, I'_l_ment sup_rieur devrait devenir

rouge durant le pr_chauffage du cycle. Une fois la

temperature auto-nettoyante atteinte, I'_l_ment inf_rieur

deviendra rouge.

Convection- Lorsque le four est r_gl_ _ CONV. BAKE/

ROAST _ 350°F (177°C), les deux _l_ments ex_cutent

tour de r61e le cycle d'allumage et d'extinction et le

ventilateur de convection se met _ tourner. Le ventilateur

de convection arr_te de tourner Iorsque la porte du four

est ouverte durant la cuisson par convection.

Lorsque tous les raccords sont terminus

V_rifiez que toutes les commandes sont en position d'arr_t

(OFF).

Avant d'appeler ie service d'entretien

R@isez la liste de v_rifications pr@entives et les

instructions d'op_ration dans votre Guide de I'utilisateur.

Vous sauverez probablement du temps et de I'argent. La

liste contient les _v_nements ordinaires qui ne r_sultent

pas de d_fectuosit_s dans le materiel ou la fabrication de

cet appareil.

Pour obtenir I'adresse et le num_ro de t_l@hone, r_f_-

rez-vous _ la garantie et aux renseignements sur lesservi-

ces d'entretien dans votre Guide de I'utilisateur.

Figure 6

7

Page 18

instructions de securite importantes

Pour r_duire le risque de basculement de la cuisini_re,

prot_gez-la en installant les vis et les supports anti-bascule

fournis avec la cuisini_re. IIs sont situ_s dans un sac de

plastique dans le four. Si vous n'installez pas ces supports

de anti-bascule, la cuisini_re risque de basculer si un poids

excessif est plac_ sur une porte ouverte ou si un enfant

y grimpe. Les renversements de liquides chauds ou la

cuisini_re peuvent provoquer de s_rieuses blessures.

Suivez les instructions ci-dessous pour installer les

supports de anti-bascule.

Si vous d_placez la cuisini_re pour I'installer _ un autre

endroit, vous devez _galement d@lacer les supports anti-

bascule pour les installer avec la cuisini_re. Voyez I'_tape 5

pour v_rifier comment proc_der _ une installation correcte.

Outils Requis:

Tourne-_crou de 5/1 6"(0,79 cm), CI_ _ molette,

Perceuse 61ectrique, Foret de 3/16" (0,48 cm) de

diam_tre, Foret de maconnerie de 3/1 6"(0,48 cm)

diam6tre (si I'installation se fait dans du b6ton).

Instructions d'instailation des supports

anti-bascule

Les supports anti-bascule se fixent au plancher, _ I'arri_re

de la cuisini_re, pour retenir les deux pieds niveleurs.

En les fixant au plancher, assurez-vous que les vis ne

p_netrent pas dans la plomberie ou le c_blage _lectrique.

Les vis fournies fonctionneront aussi bien dans du bois

que dans du b_ton.

1. D@liez le gabarit de papier et placez-le _ plat sur

le plan-chef, I'endos et les extr_mit_s des c6t_s

exactement _ I'endroit o0 I'arri_re et les c6t_s de la

cuisini_re seront places lots de I'installation (utilisez le

diagramme ci-dessous pour Iocaliser les supports anti-

bascule si le gabarit de papier n'est pas disponible).

2. Tracez sur le plancher I'emplacement des 4 trous

de mon-tage indiqu_s sur le gabarit. Pour faciliter

I'installation, des trous pilotes d'un 1/2"(1.3 cm) de

profondeur et 3/1 6" (4.8 mm) de diam_tre peuvent

_tre perc_s dans le plancher.

3. Enlevez le gabarit et placez les supports de anti-

bascule sur le plancher, le rebord renvers_ vers I'avant.

(voir figure 7). Alignez les trous dans les supports

antibascule avec les trous trac_s sur le plancher et

fixez avec les 4 vis fournies. Les supports anti-bascule

doivent _tre fixes sur un plancher solide.Si vous les

fixez _ un plancher en b_ton, percez d'abord des

trous pilotes de 3/16" (0.5 cm) de diam_tre _ I'aide

d'un foret _ maconnerie de 3/16" (0.5 cm) diam_tre.

4. Mettez la cuisini_re _ niveau au besoin, en I'ajustant

avec les 4 pieds niveleurs _ I'aide d'une cl_ _ molette

(voir Figure 9). Un d_gagement minimum de 1/8"

(0.3 cm) est requis entre le has de la cuisini_re et les

pieds niveleurs artistes pour disposer de suffisamment

d'espace pour installer les supports anti-bascule.

5. Replacez la cuisini_re en la faisant glisser, en vous

assurant que les pieds artistes ont _t_ bien agripp_s

par les extr_mit_s des supports anti-bascule. II est

possible que vous ayez _ la d@lacer I_g_rement d'un

c6t_ en la repoussant vers I'arriere pour que les pieds

artistes s'alignent avec les supports anti-bascule.

6.Apr_s I'installation v_rifiez si les supports anti-bascule

sont bien engag_ en ouvrant et retirant le tiroir.

Support anti-bascule

\

Support de anti- , ......_,_,_-, .._

bascule .<(d'e ....." ,_._¢ _ .......-

\.j- .-_-\ 1/2"

::"_!_-> (1.3 cm)

C6t_s _e

I'appareil

3_" (1.9 cm) Typ.

Glissez

I'appareil

(1.9cm)Typ.

Figure 7

/

i ii!

niveleurs

Figure 8

8

Page 19

OVEN CIRCUIT//CIRCUITO DE HORNO//CIRCUIT FOUR

L2 BK-7 CONTROL DE HORNO ELECTRONICO/

R-7

N lillllllllllllllll iiiiiiiiiiiii IIIIIIIIIIIIIIIIII Illl

W-5 =

J3

=

W-5

CONVECTION FAN/

VENTELADOR OE CON%EOCION/

VEN]ELATEUR CONVECTION

BR-14

\ f

W-14

W-5

i

: VENTILATEUR BE REFROIDISBEMENT

• y •

OVEN LA_!P /

LUZ DE HORNO/

LUMI ERE POUR

OVEN LAMP/

LUZ DE HORNO/

LUMIERE FOUR

COOLING FAN/VENTILADOR DE ENFRIA_IIENTO/ I

HIGH/ALTA/HAUTE

T SOME MODELS/ALGUNOS MOOELOS/

",CERTAENS MODELES

LATCH MOTOR/ i

MOTOR CERROJO/ =

MOTEUR VERROU

4 GY:I_! ....

85-14 E

8R-14 BR-14E

/

BR 14=

R-5."

[]

[]

BK-5

[]

[]

[]

[]

[]

[]

=

L1 ELECTRONIC OVEN CONTROL/

CONTROLE ELECTRONIQUE FOUR

ES 5XX

Pll

[]

[]

[]

[]

BK-20

BK_20

8

BK_14

= BK 20 " BK-2O

[]

[]

i BK-14 ._--...o BK-_4

[]

CONY []

BA[]

BR

L2 OUT

"o-e _ ................o-6

=

= BAKE ELEMENT/

: ELEMENT OUISSON

" Y_6

=M:e...................._ ................

" R_RMRNTOB_,.,GE

;BL*8 I_ _/ _] BL-7

TEMPERATURE PROBE /

SONDA DE TEMPERATURA/

SONDE THERMIQUE

) _\t)>_ _.............

DOOR SWATCH/

INIERRUPTOR DE PUERIA/

]NTERRUPTEUR PORTE

MOTOR SWITCH LATCH/

INTERRUPTO5 MOTOR DE LOQUETA DE PUERT#

INTERRUPTEUR MOTEUR VERROU

NO C

CONVECTION ELEMENT/

ELE_/ENTO DE CONVECCION/

ELEMENT CONVECTION

ELEtAENTOOE HORNO/

BROIL ELEMENT/

ELEMENTO BE ASADO/

i

i THERNAL CIRCUIT BREAKER/

I INTERRUPTOR DE CIRCUITO

I TERMICO/DISJONOTEUR THERMIQUE:

L ]

=

|IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIP

AUXILIAIRY OVEN // HORNO LATERAL // FOUR AUXILIAIRE

LEFT OVEN DOOR SWITCH/ LUZ ME IIORNO IZQUIERMO/

INTERRUPTOR DE PUERTA DE HORNO [ZQUIERDO/ LA_PE DE POUR GAUCHE

]N[ERRUP[EUR DE PORTE ME POUR GAUCHE

BK-IO _/" BR 10 W-1

lEFT OVEN THER_STAT SW, / LEFT OVEN BROIl ELEMENT/

INTENNUPTOR DE TER_OSTATO ELE_ENTO DE ASAO0 DE HORNO _ZQUIERDO/

OR HORNS IZOUIEROO/ ELEI_ENT DE BRIItAGE FOUR GAUDNE

INTENRUPTEUR THERMOSTAT

DR FOUR OAUDNE BL-5 A BL 5 BL 5

BM_5 _ ELEMENTO DE HORNEO

CAUTiON:DISCONNECT POWER BEFORE SERVICING UNIT*

ATENCION:CORTAR LA CORRIENTE ANTES BE REALIZAR EL MANTENEMEENTO DEL ELECTRODOMESTICO.

ATTENTION;COUPEZ L'ALINENTATION AVANT B'EFFECTUER LA REPARATION.

A LEFT OVEN INDICATOR// _'_?_ ......

/ZQUIERDO/IND]OAIEUR

FUR AU HE ELEMENT DE CUISSDN TERMOSTATO DE SEGURIDAD/

0 O ¢

P '_ c FOUR __ THERMOSTAT DE SURETE

B LEFT OVEN THERMOSTAT/

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS,

WIRINGS ERRORS CAN CAUSE _MPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

ETIQUETE TODOS LOS CABLES ANTES DE OEBCONECTAR CUANDO NAGA EL BERVIC[O A LOS OONTROLES,

ERRORES AL VOLVER A ENSABBLAR LOS CABLES PUEDE CAUSAR FALLAS U OPERACEONES PELIGROSAS.

VERIF[QUE LA CORREOTA OPERAOION DESPUES DEL BERVICIO.

IDENTIFIEZ TOUS LED FILS AVANT DE LEG DEBRANCHER GGAND L'APPAREIL EST HORS SERVICE.

LES ERREURS DE CONNECTION DE FILS PEUVENT CAUSER UN MAL FONCTIONNEMENT ET UM DANGER

D'USAGB DE L'APPAREtL, VEBIFIEZ LE BON FONOTtONNEMENT DE L'APPAREtL APBES LE SERVICE,

HORNO IZQUIERDO/ SAFETY THERMOSTAT/

Y ,

LEFT OVEN LAI_P/

TERMOSTATO DE IIORNO IZQUIERDO/

THERMOSTAT ME FOUR GAUCHE

[] °

L2 IN _ IN[ERRUP]OR CERROJO

L2

CONNECTOR/

CONECTOR/

CONNECTEUR

DOOR LATCH sw/rcH

DE PUER]A/INIERRUP]EUR

DE PORTE VERROU

COLOR CODE/CODIGOS DE COLOR

CODE DE COULEUR

MY, GREY/GRIS/GRIS

G, GREEN/VERDE/VENT

W, WHITE!BLANCO/BLANC

R. RED/ROJO/ROUGE

O. ORANGE/NARANJA/ORANGE

Y, YELLOVMA_ARILLO/dAUNE

DR, 5ROVINICAFE/BRUN

BL,-BLUE/AZUL/BLEU

BM, OLACK/NEGRO/NOIR

CODE GAUGE TEMP/C CSA U

CODIGO MEDIDA

CODE CALIBRE

1 18 125 0L1251 3123

2 IE 125 CL1251 3173

3 14 125 CL1251 3173

4 12 25 CL1251 3173

5 18 50 EXL- 150 3321

6 18 150 EXL- 150 3321

7 14 150 EXL 150 3321

8 12 150 EXL 150 3321

9 13 150 EXL 150 3321

t0 18 200 SEW 1 3122

tl 15 200 SEW 1 3122

12 12 250 3252

13 15 250 3252

14 20 150 EXL- 150 3321

15 8 150 EXL* 150 3321

16 8 60

t7 10 60

18 10 200 SEW-I 3122

19 20 125 OI 1251 3173

20 20 200 SEW- 1 3122

2t 22 125 3266

22 22 150 10109

23 18 200 3573

34 18 2OO 3512

35 18 2OO 3512

37 14 200 3512

41 23 200 3512

318045341 REV:A

PAGE" 1 /2

9

Page 20

......................................................................................COOKTOP CIRCUIT / CIRCUITO DE PLANCHA DE COCINAR /CIRCUIT TABLE CUISSON

WITH WARMER ZONE / AREA DE CALENTADOR / AVEC ZONE RECHAUD

** ELE_NTIELEMENTO/L_ITEUR

E{:O fARO

_b 2b I

_-_---_

_,].' ..............

COOKTO_ £!#CUIT / OIRCUITO D E _L_£_ DE

CIRCUIT TABLE CUISSON

CENTER REAR IGNITER GWZTCH/

INTERRGPlO£ ENCENDIDO

CEN1RO IGAS_O/

INTERRUPTEUB O ALLUMAGE

ARR_ER_ CENTRE

RIGHT REAR IGNITER SWITCH/

[NTERRUPTOR ENCE_OIO0

TRASERODERECHO/

INTERRUPTEURO'ALLUMAGE

A_RIERE O_OITE

RIGHT FRONT IGNITER SWITOH/

INTERRUPTOR ENCENOIOO

FRENTE DERECHO/

INTERRUPTEURO'ALLU_AGE

AVAN10ROII_

LEFT FRONT IGNITER SWITCH/

INTERRbRTOR ENUR_OIO0

FREN1_ IZGU[_OO/

INTERRUPTEURD'ALLUB#,GE

AVANT GAUCHE

[¸EFT REAR IONITE_ SWatCH/

IN_E_RGPIO_ ENC_NOIGO

TRASERO IZOUIERO0/

INTERRGPTEUBD_UMAGE

ARRIERE GAUCHE

_W-5

L2 R-_4 _4

R-14 4

R-14 _14

R 14

IGNITER MODULE BOARD/

CUARDODE NODULO DE ENCENDIDO/

B[OO CONNECTIOND'A[[UMEUR

LJ

<2

u

/ /

CAUTION: DISCONNECT POWER BEFORE SERVICING UNIT,

ATENCION:OORTAR LA CORIENTE ANTES DE REALIZAR ELNANTENIMIENTO GEL ELECTRODONESTtCO, 318045341 REV:A

TOP BURNER IGNITER/

GUE#ADOR _E ENCEN_EDO SUPERIOR/

BOUGIE D'AL[UMAGE DE BRU[EUR

W 10

TOP BURNER IGNITER/

QUE_ZAROR OE ENCENGZDO SUPERIOR/

W lO _,_

ULEUR

ATTENTION:COUPEZ L'ALIMENTATION AVANT D'EFFECTUER LA REPARATION, PAGE "2/2

i_ _m,_o_ _ETRASERO Llr, ZTEa/

RL 1o

i IrDZ_aT_U_s_ SU_Ace I

BK÷7 i C-'_Te_ _rT _ae_w

itBK_TBK'7...... cL_.-: • R-1111 _ 11

i[F,l_R# Fe 1 P2 4 i 6E_]_ _F eL aEn i

051 @ I

i_ E_NTO o_ OENT_OIZOU_ _O0/I

i ii - _ / BK.11 Ekm_E_tc_rraE GAUO-_

I =_ EM_NTO D= O_NTRO I_Q/E_R_/

BL_IO I I

CE_T_S_'ITC_' O-5

!_OICAT_ OE_UR_AC_

0_5 Z_IOIOAT_U_SUaFA6_CI_UO_

i

I I I

05

CEN7#_ P2 _ _ R-II I I

R2 4a CEnteR EL_M_ r _

BK 5 BL=IO El[_IENTCEF_TR_

_IGHT _A£ SWITCN

[nTeRRUmO_ _S_aO U_eCaO/

_VEnRUPtEO_ AnR_E_e _ROIT_

BK*11 i D, i

L _ _ J

ELE_E_TO DE O_N_RO/

BL1O i i BL lO_ BL*2O

i_icA_o,o_ s_,_c_e HOT sur_,',ce _N_ICATOR/

_o_¢ATr_ _E S_,_ACe N*_ICADORn_ Sm_R_ C_ Cal I_nVE'

o 5 _ 0-5 _DICATEUR SURFACECHAUO_

B- 11 ** LI_iTADO_ sw tc_/

BK11 F qBR 1"-_ R-6

_GHI aONf SWITCh/ L;:TE EXTERlr ECTER[E,F_R i i 2 p1

INTERRUPOR OE FRNTE OERECHO/

INT RRUPTE_R_VANr OROIrE EL _,_E_IODE aENI_ hER CHO/

BL

I 0

[LB_NT AVAST o_oit i IGY-IO _ BL:t2p

_OT_:

SeRWCE:_ _EPLACE_IEnlO_ _Em_INA_SBEC0_ESNECESSA_Y,C_PA_BL_WIn_ _YP_An0

_ ANOCO_PA_ABL_TE_LS _ST BE USEO,

_OTA:

E_ CASOQUES_A NECESA_I00E REE_PLAZ_ LOSBORN£S,ES_ECESARI0_EUTILIZAB

EL _1_0 T_O 0E A_A_m_ V 0_ _EO_DO_Y _1 _IIS_O_IFO OE _0_eS

SERWCE:S_ _ESFILS 0U0EBCOSSESDOIW_T _T_ER_mLAC_S,UTI[IS_Z O_SpIECES 0_

CA_I_ _T O_ _YP_ E_[VAI_NrSL_S FI_S DO,Writ _R_ _4 CUIVR_.

-L_B_t ALL _I£_S _RIO£ TO D_SCO_NEOTIONWN_N $ERV_OINGCO_TBOtSW_RIN_ER_O£CAN

CAUSE I_PR0_R A_0 0AN_0US 0P_RATION,VE_I_YP_0PE_0PE_ATI0_AFTERSERWC_N_

AVt_0:

-ET_QUE_ TOPOS LOS aLA_S_S AnT_S _E O_SCOn_CTA_PA_ _EALITAR_L I_ANVE_nTO DE LOS

CONTROL_SE_O_ OE ALA_SRAJEPUEO_CAUSARUN FUNCIONAM_EnTOI_O0_RECTOY _ELI_ROSO

V_IF_QUE Sl _LFUNC_ONA_IE_¢'0eST_ 00_CT0 DES_ES _L _U_VE_U_E_TO

-ET_QUET_RC_A0UE _IL AVAHT _ B_CH_I_nT 0_ C_UX-Cl.UN_ _RR_UR _ BF_NC_m_ENTP_U_