Frigidaire CGIF3061NFB, CGIF3061NFC, CGIF3061NFD, CGIF3061NFE, CGIF3061NFF Installation Guide

...

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL iNSPECTOR'S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

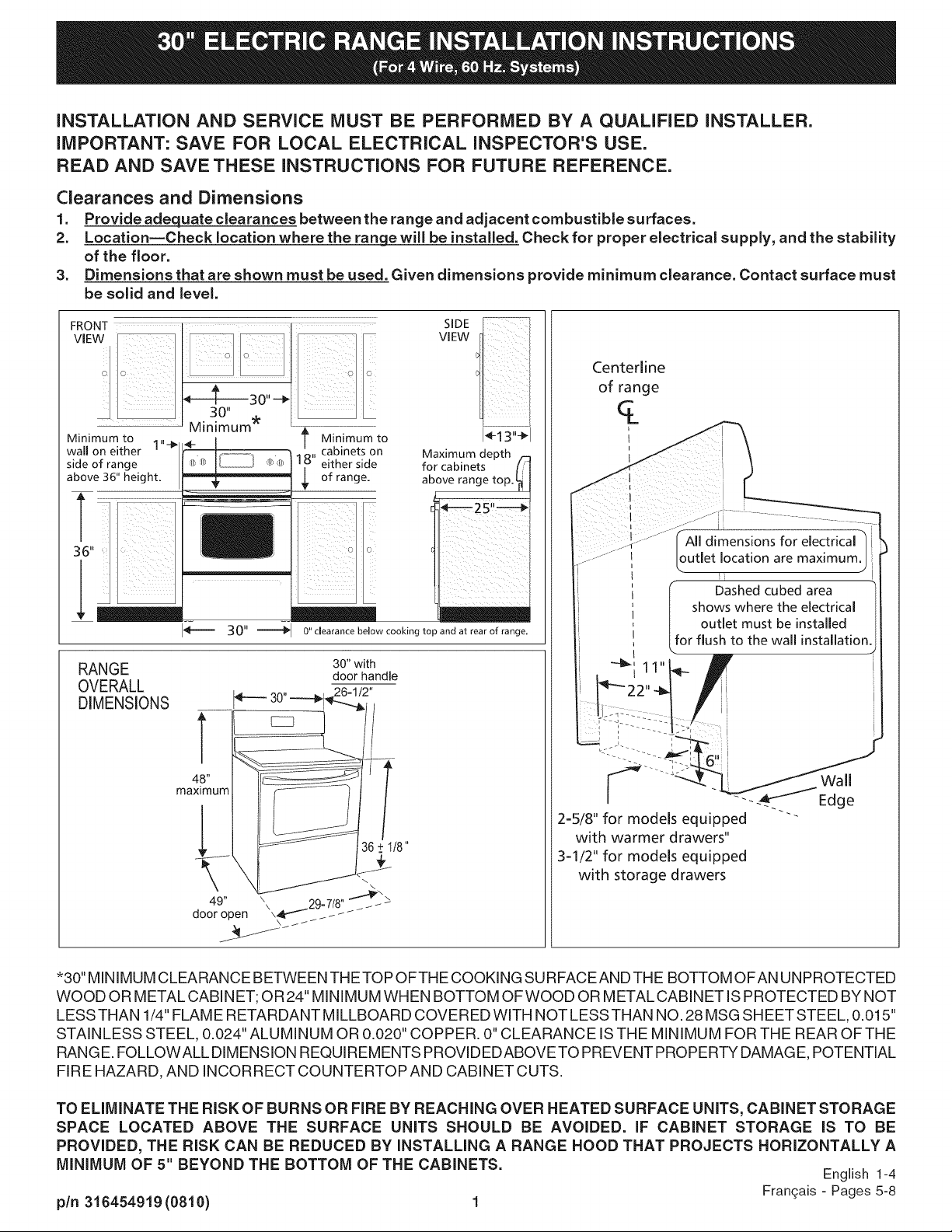

Clearances and Dimensions

1. Provide adequate clearances between the range and adjacent combustible surfaces.

2. Location--Check location where the range will be installed. Check for proper electrical supply, and the stability

of the floor.

3. Dimensions that are shown must be used. Given dimensions provide minimum clearance. Contact surface must

be solid and level.

SIDE

VIEW

wall on either 1"-_

side of range

above 36" height.

RANGE

OVERALL

DIMENSIONS

T

48"

maximum

49"

door open

1_-13"_1

Maximum depth rr

for cabinets [/'

above range top. _

_25"_

_ O" clearance below cooking top and at rear of range.

30" with

door handle

36±1/8"

\ ///

Wall

Edge

2=5/8" for models equipped "'""

with warmer drawers"

3=1/2" for models equipped

with storage drawers

*30" MINIMUM CLEARANCE BETWEEN THE TOP OFTHE COOKING SURFACE AND THE BOTTOM OFAN UNPROTECTED

WOOD OR METAL CABINET; OR 24" MINIMUM WHEN BOTTOM OFWOOD OR METAL CABINET IS PROTECTED BY NOT

LESS THAN 1/4" FLAME RETARDANT MILLBOARD COVERED WITH NOT LESS THAN NO. 28 MSG SHEET STEEL, 0.015"

STAINLESS STEEL, 0.024" ALUMINUM OR 0.020" COPPER. 0" CLEARANCE IS THE MINIMUM FOR THE REAR OF THE

RANGE. FOLLOWALL DIMENSION REQUIREMENTS PROVIDEDABOVETO PREVENT PROPERTY DAMAGE, POTENTIAL

FIRE HAZARD, AND INCORRECT COUNTERTOP AND CABINET CUTS.

TO ELIMINATE THE RISK OF BURNS OR FIRE BY REACHING OVER HEATED SURFACE UNITS, CABINET STORAGE

SPACE LOCATED ABOVE THE SURFACE UNITS SHOULD BE AVOIDED. IF CABINET STORAGE IS TO BE

PROVIDED, THE RISK CAN BE REDUCED BY INSTALLING A RANGE HOOD THAT PROJECTS HORIZONTALLY A

MINIMUM OF 5" BEYOND THE BOTTOM OF THE CABINETS. English 1-4

pin 316454919 (0810) 1 Fran_ais - Pages 5-8

iMPORTANT SAFETY

iNSTRUCTiONS

If the information inthis manual is not followed

exactly, afire or electrical shock may result causing property

damage, personal injury or death.

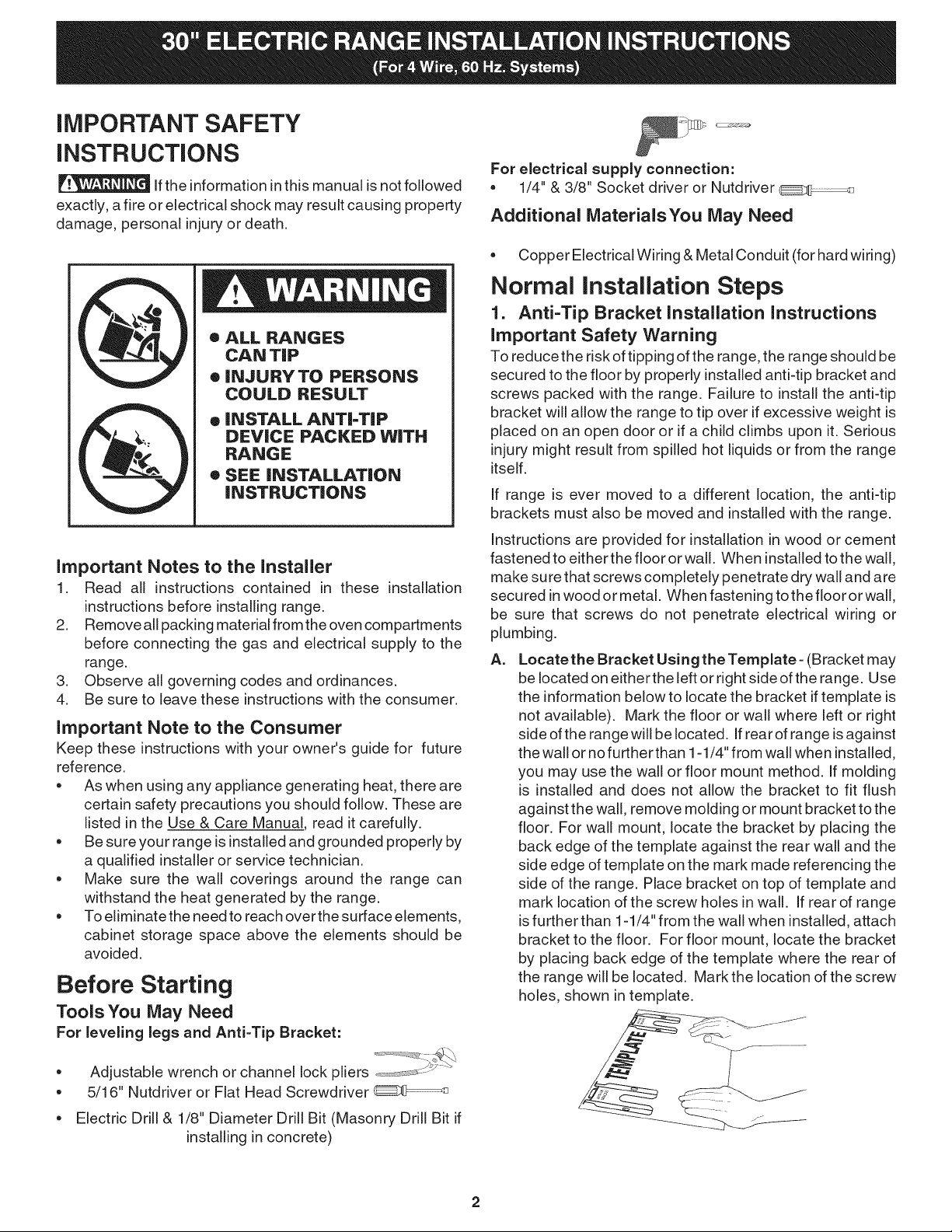

• ALL RANGES

CAN TiP

• INJURYTO PERSONS

COULD RESULT

e iNSTALL ANTI-TIP

DEVICE PACKED WiTH

RANGE

• SEE INSTALLATION

iNSTRUCTiONS

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven compartments

before connecting the gas and electrical supply to the

range.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your owner's guide for future

reference.

As when using any appliance generating heat, there are

certain safety precautions you should follow. These are

listed in the Use & Care Manual, read it carefully.

Be sure your range is installed and grounded properly by

a qualified installer or service technician.

Make sure the wall coverings around the range can

withstand the heat generated by the range.

To eliminate the need to reach over the surface elements,

cabinet storage space above the elements should be

avoided.

Before Starting

Tools You May Need

For leveling legs and Anti-Tip Bracket:

For electrical supply connection:

1/4" & 3/8" Socket driver or Nutdriver

Additional MaterialsYou May Need

Copper Electrical Wiring &Metal Conduit (for hard wiring)

Normal installation Steps

1. Anti-Tip Bracket Installation Instructions

Important Safety Warning

To reduce the risk of tipping ofthe range, the range should be

secured to the floor by properly installed anti-tip bracket and

screws packed with the range. Failure to install the anti-tip

bracket will allow the range to tip over if excessive weight is

placed on an open door or if a child climbs upon it. Serious

injury might result from spilled hot liquids or from the range

itself.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the range.

Instructions are provided for installation in wood or cement

fastened to either the floor or wall. When installed to the wall,

make sure that screws completely penetrate dry wall and are

secured in wood or metal. When fastening to the floor or wall,

be sure that screws do not penetrate electrical wiring or

plumbing.

A.

Locate the Bracket Using the Template- (Bracket may

be located on either the left or right side of the range. Use

the information below to locate the bracket if template is

not available). Mark the floor or wall where left or right

side of the range will be located. If rear of range isagainst

the wall or no further than 1-1/4" from wall when installed,

you may use the wall or floor mount method. If molding

is installed and does not allow the bracket to fit flush

against the wall, remove molding or mount bracket to the

floor. For wall mount, locate the bracket by placing the

back edge of the template against the rear wall and the

side edge of template on the mark made referencing the

side of the range. Place bracket on top of template and

mark location of the screw holes inwall. If rear of range

is further than 1-1/4" from the wall when installed, attach

bracket to the floor. For floor mount, locate the bracket

by placing back edge of the template where the rear of

the range will be located. Mark the location of the screw

holes, shown in template.

• Adjustable wrench or channel lock pliers _,_-_: .....

• 5/16" Nutdriver or Fiat Head Screwdriver _

Electric Drill & 1/8" Diameter Drill Bit (Masonry Drill Bit if

installing in concrete)

,

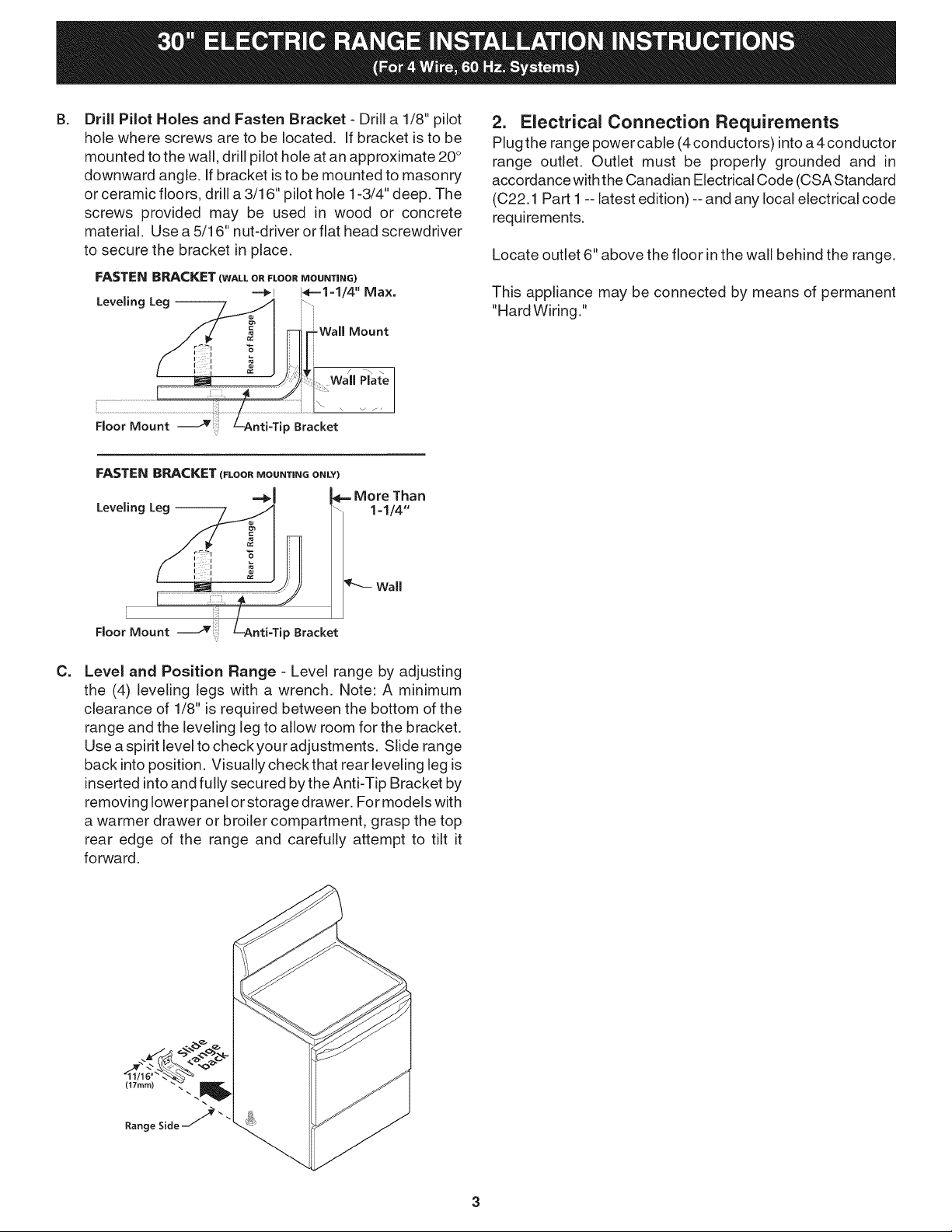

Drill Pilot Holes and Fasten Bracket - Drill a 1/8" pilot

hole where screws are to be located. If bracket is to be

mounted to the wall, drill pilot hole at an approximate 20°

downward angle. Ifbracket is to be mounted to masonry

or ceramic floors, drill a 3/16" pilot hole 1-3/4" deep. The

screws provided may be used in wood or concrete

material. Use a 5/16" nut-driver or flat head screwdriver

to secure the bracket in place.

FASTEN BRACKET (WALL OR FLOOR MOUNTING)

Leveling Leg --

==_l I,e-1=1/4'' Max,

2. Electrical Connection Requirements

Plug the range power cable (4 conductors) into a 4 conductor

range outlet. Outlet must be properly grounded and in

accordance withthe Canadian Electrical Code (CSA Standard

(C22.1 Part 1-- latest edition) --and any local electrical code

requirements.

Locate outlet 6" above the floor in the wall behind the range.

This appliance may be connected by means of permanent

"Hard Wiring."

Floor Mount

ip Bracket

FASTENBRACKET(FLOORMOUNTINGoNw)

Leveling Leg --

Floor Mount

C=

Level and Position Range - Level range by adjusting

-q

1=1/4"

Wall

ip Bracket

the (4) leveling legs with a wrench. Note: A minimum

clearance of 1/8" is required between the bottom of the

range and the leveling leg to allow room for the bracket.

Use a spirit level to check your adjustments. Slide range

back into position. Visually checkthat rear leveling leg is

inserted into and fully secured by the Anti-Tip Bracket by

removing lower panel or storage drawer. For models with

a warmer drawer or broiler compartment, grasp the top

rear edge of the range and carefully attempt to tilt it

forward.

(17ram)

Range Side -_'"

Model and Serial Number Location

The serial plate is located on the right-hand surface of the

oven front frame at the storage or warmer drawer; or the

lower panel area.

When ordering parts for or making inquires about your range,

always be sure to include the model and serial numbers and

a lot number or letter from the serial plate on your range.

Your serial plate also tells you the Kilowatt rating (power

requirements) and Voltage ratings

Care, Cleaning and Maintenance

Refer to the Use & Care Manual for cleaning instructions.

If removing the range is necessary for cleaning or

maintenance, disconnect the electrical power supply. If the

electrical supply is inaccessible, liftthe unit slightly atthe front

and pull out away from the wall. Pull only as far as necessary

to disconnect the electrical supply. Finish removing the unit

for servicing and cleaning. Reinstall in reverse order making

sure to level the range and check electrical connections. See

pages 2 and 3 for proper anchoring instructions.

i_i!i!,

Before You Call for Service

Read the "Before You Call" and operating instruction sections

in your Use & Care Manual. It may save you time and

expense. The list includes common occurrences that are not

the result of defective workmanship or materials in this

appliance.

Refer to the warranty in your Use & Care Manual for our toll-

free service number and address. Please call or write if you

have inquiries about your range product and/or need to order

parts.

Serial plate location

Open storage or warmer drawer,

or remove lower panel

(on some models)

L'INSTALLATION ET L'ENTRETIEN DOIVENT ETRE EFFECTUES PAR UN INSTALLATEUR QUALIFIE

iMPORTANT: A CONSERVER POUR CONSULTATION PAR L'INSPECTEUR EN ELECTRICITE.

LISEZ ET CONSERVEZ CES iNSTRUCTiONS POUR CONSULTATION FUTURE.

Dimensions et espaces libres

1. Laissez des espaces libres ad4quats entre la cuisini4re et les surfaces combustibles adjacentes.

2. Localisation=V4rifiez I'endroito_ la cuisini_resera install4e. Assurezvousque les ali mentations d'41ectricit4sont

ad4quates et que le plancher est solide.

3. Les distances indiqu4es doivent _tre appliqu4es. Les distances donn4es sont minimales. La surface de support

doit _tre solide et au niveau.

Ligne de Centre

de la cuisini_re

q_

i

Espace minimum 1 "-I_

aux c6t_s de ia

cuisini&re, au dessus

de 914mm (36")

, _

_..........._, g. des armoires de

__ l- chaque c6t6 de

_ _'_ 11 ==......._ ....... p ..... qui ..... la surface de cui ...... &

t Distance rain,

_ _ la cuisini_re

I'arriere de la cuisini_re.

Profondeur max. des

armoires au dessus F

de la cuisini_re I!

i i

i

t i

1

]

.........._ Toutes les dimensions de "]

:---"_ | remplacement de la sortie |

; _ 61ectrique sont maximales

La r6gion de la bo_te pointill6e

rnontre la localisation de la sorti_

_lectrique pour une installation

contre le tour

DIMENSIONS HORS

TOUT DE LA

I

CUlSINI_RE

T

48"

maximum

67ram (2-5/8")pourlesmodules ""'-

6quip4savectiroJrs¢hauffants

89ram (3=1/2") pour les modules

6quip6s avec des tiroirs de

stockage

\

49" \ 29, 7/8" ""_ \"

pour ouverte '\4r__ _.............

"762mm (30") MINIMUM D'ESPACE LIBRE DOIVENT ItTRE LAISSI_S ENTRE LA PARTIE SUPt_RIEURE DE LA SURFACE DE

CUISSON ET LE DESSOUS D'UNE ARMOIRE DE BOIS OU DE Mt_TAL NON PROTI_GI_; OU UN MINIMUM DE 610mm (24")

LORSQUE LE DESSOUS DE L'ARMOIRE DE BOIS OU DE Mt_TAL EST PROTI_GI_ PAR AU MOINS 1/4" DE CELLODERME

IGNIFUGE RECOUVERT PAR UNE FEUILLE D'ACIER D'AU MOINS 28 DE JAUGE, D'ACIER INOXYDABLE DE 0.015",

D'ALUMINIUM DE 0.024" OU DE CUIVRE DE 0.020". L'ESPACE LIBRE EST LE MINIMUM POUR L'ARRIt_RE DE LA CUISINII_RE.

SUIVEZ TOUTES LES EXIGENCES DE DIMENSIONS FOURNIES CI-DESSUS AFIN D't_VITER LES DOMMAGES A LA

PROPRIFtTFt, LES RISQUES D'INCENDIE AINSI QUE DES COUPES ERRONFtES D'ARMOIRES ET DE DESSUS DE COMPTOIR.

DES ARMOIRES D'ESPACE DE RANGEMENT SITUEES AU-DESSUS DES UNITES DE SURFACE DEVRAIENT #TRE EVITEES AFIN

D'IeLIMINER LES RISQUES DE BRULURES OU D'INCENDIE EN TENDANT LA MAIN PAR=DESSUS LES UNITIES DE SURFACE

CHAUDES. LE RISQUE PEUT #TRE RIEDUIT EN INSTALLANT UNE HOTTE DE CUISINII_RE QUI DIEPASSE HORIZONTALEMENT D'AU

MOINS 127mm (5") LE DESSOUS DES ARMOIRES Sl DES ARMOIRES D'ESPACE DE RANGEMENT SONT INSTALLIEES.

Mur

English - Pages 1-4

Frangais - Pages 5-8

DiRECTiVES IMPORTANTES DE

SECURITE

Un feu ou une 61ectrocution peut survenir et

6tre la cause de dommages & la propri6t6, de blessures ou

entrafner la mort si les instructions de ce manuel ne sont

pas suivies & la lettre.

®

TOUTES LESCUISINIERES

PEUVENT ETRERENVERSEES

®

DES BLESSURESPEUVENT

EN RESULTER

®

INSTALLEZ LE DiSPOSiTIF

DE CONTRE=RENVERSEMENT

EMBALLE AVEC LA CUISINll=RE

®

VOIR LES iNSTRUCTIONS

D'INSTALLATION

Notes importantes a I'installateur

1. Lisez toutes les instructions contenues dans cette notice

d'installation avant d'installer la cuisini_re.

2. Retirez tout mat6riau d'empaquetage des cavit6s du

fourneau avant d'alimenter la cuisini_re en 61ectricit6.

3. Respectez tousles codes et ordonnances applicables.

4. Assurez-vous de laisser ces instructions au

consommateur.

Note importante au consommateur

Conservez ces instructions avec votre guide du consommateur

pour consultation future.

• II y a certaines pr6cautions de s6curit6 que vous devez

respecter Iorsque vous utilisez des appareils produisant de

la chaleur. Celles-ci sont inscrites dans le manuel d'utilisation

et d'entretien, lisez-le soigneusement.

• Soyez certain que votre cuisini_re est correctement install6e

et mise & la terre par un installateur ou un technicien de

service qualifi6.

• Assurez-vous que les rev6tements muraux autours de la

cuisini_re peuvent endurer la chaleur produite par lacuisini_re.

• Les armoires de rangement au-dessus de la cuisini_re

devraient 6tre 6vit6es afin d'61iminer le besoin de tendre la

main au-dessus des 616ments chauffants.

Avant de commencer

Outils dont vous aurez besoin

Pour les pattes de raise _niveau et lesupport de contrerenversement

Pour le raccordement de I'alimentation _lectrique :

• Des tourne-6crous ou douilles de 1/4" et 3/8" (_

IVlat6riel suppl6mentaire dont vous aurez besoin

• Un cordon d'alimentation de puissance ou

• Filage 61ectrique de cuivre et conduit m6tallique (pour

connexion sans prise).

i tapes normales d'installation

1. instructions de montage du support de contre=

renversement

La cuisini_re dolt 6tre fix6e au plancher par rinstallation ad6quate de

vis et de support de contre-renversement empaquet6s avec la

cuisini_re afin de r6duire le risque de renversement de celle-ci. La

cuisini_re peut s'incliner si un poids excessif est plac6 sur une porte

ouverte ou si un enfant monte sur la porte, si vous n6gligez d'installer

le support de contre-renversement. Des blessures s6rieuses peuvent

r6sulter de liquides brOlants renvers6s ou par la cuisini_re elle-m6me.

Le support de contre-renversement dolt aussi 6tre d6plac6 et

install6 avec la cuisini_re si celle-ci est relocalis6e.

Des instructions sont fournies pour une installation sur du bois ou

du ciment, fix6e soit au plancher ou au mur. Assurez-vous que les

vis p6n_trent compDtement la cloison du mur et qu'elles sont bien

ancr6es dans le bois ou le m6tal, Iorsque rinstallation est faite au

mur. Assurez-vous que les vis ne traversent pas la plomberie ou des

ills 61ectriquesdurant la fixation au plancher ou au mur.

A. Situez le support en utilisant le gabarit- (Le support peut

6tre Iocalis6 & gauche ou & droite de la cuisini&re. Utilisez

I'information donn6e ci-apr&s pour situer le support si le

gabarit n'est pas disponible.) Marquez le plancher ou le

mur & I'endroit o(_ le c6t6 gauche ou droit de la cuisini&re

sera situ6. Vous pouvez utiliser la m6thode de montage

au mur ou au plancher si I'arri&re de la cuisini&re est appuy6

au mur ou pas plus 61oign6 du mur que 3 cm (1 1/4") apr&s

installation. Enlevez la moulure ou fixez le support au

plancher si une moulure est install6e et ne permet pas au

support de s'appuyer fermement sur le mur. Pour un

montage contre le mur, situez le support en pla£ant la

partie arri&re du gabarit contre lemur arri&re et le bord du

gabarit sur la marque faite qui identifie le c6t6 de la

cuisini&re. Placez le support par-dessus le gabarit et

identifiez I'emplacement des trous des vis dans le mur.

Fixez le support au plancher si I'arri&re de la cuisini&re est

plus 61oign6 que 3 cm (1 1/4") du mur apr&s I'installation.

Situez le support en plaqant la partie arri&re du gabarit &

I'endroit oQ I'arri&re de la cuisini&re sera Iocalis6 pour un

montage sur le plancher. Marquez I'emplacement des

trous des vis indiqu6s sur le gabarit.

• CI6 r6glable ou pince multiprise ordinaire _=_==--_-

• Tourne-6crou de 5/16" ou tournevis plat

Perceuse 61ectrique et m_che de perceuse de 1/8" de

diam_tre. (m_che pour la ma£onnerie de 5/32" si vous

installez dans le b6ton).

>/_k. I

B,

Percez les trous d'alignement et fixez le support -

Percez un trou de 3 mm (1/8") aux endroits o3 les vis

seront Iocalisees. Percez un trou d'alignement _. un

angle descendant d'approximativement 20° si le

support doit _tre installe sur lemur. Percez un trou

d'alignement de 4.76 mm (3/16") par 44 mm (1-3/4") de

profondeur si le support doit _tre installe dans la

magonnerie ou des planchers de ceramique. Les vis

fournies peuvent _tre utilisees dans le bois ou des

materiaux en beton. Utilisez un serre ecrou ou un

tournevis plat afin de fixer le support en place.

FiXEZ LE SUPPORT (MONTAGEAUMURouAUPLANCHER)

--_1 I_-- 1=1/4 '' Max.

niveau i i

= =

-Montage

au Mur

Plaque

Murale

- Support de

contre-renversernent

FiXEZ LE SUPPORT (MONTAGE AU PLANCHER SEULEMENT)

Patte de

,_niveau

=_1 I_==Plus que

1=1/4"

h

Montage au _ - Support de

plancher contre=renversement

C=

Mise en place et _ niveau de la cuisini_re - Mettez la

cuisiniere _. niveau en ajustant les (4) pattes de mise

_. niveau _. I'aide d'une cle _. molette. Note : Un

espacement minimum de 3 mm (1/8") est NOTICE

D'INSTALLATION POUR CUISINIERE E_LECTRIQUE

DE 762mm (30") (pour les systemes 60 Hz _. 3 ou 4

fils)requis entre le bas de la cuisiniere et la patte

d'ajustement afin de permettre un espace pour le

support. Utilisez un niveau _. bulle pour verifier vos

ajustements. Glissez la cuisiniere vers sa position.

Verifiez visuellement que la patte de mise _. niveau

arriere est completement inseree et fixee dans le

support de contre-renversement en retirant le panneau

inferieur ou le tiroir de rangement. Saisissez la partie

superieure arriere de la cuisiniere et essayez

prudemment de la faire basculer vers I'avant, pour les

modeles possedant un tiroir-rechaud ou une rGtisserie.

2. Exigences du raccordement _lectrique

Branchez le cable electrique de cuisiniere & une sortie de

fourneau de 4 conducteurs. La sortie doit &tre correctement

fondue et selon canadien electrique le code (Piece C22.1 1,

la derniere edition standard de CSA) - et toutes conditions

electriques locales de code.

Localisez la sortie 6 "au-dessus du plancher dans lemur

derriere le fourneau.

Cet appareil peut _tre relie _.I'aide "du c&blage dur

permanent. "

Emplacement du no. de rnodele /

no. de s_rie

La plaque signaletique est Iocalisee sur la surface & droite

du devant du cadre du fourneau, a la partie inferieure du

panneau derriere le devant du tiroir rechaud ou de

rangement.

Assurez vous de toujours fournir le no. de modele et de

serie ainsi que le no. de lot ou lettre sur la plaque

d'identification de votre cuisiniere Iorsque vous commandez

des pieces ou demandez de I'information concernant votre

cuisiniere

Votre plaque signaletique vous indique aussi la capacite

en Kilowatts (exigence de puissance) et la tension

nom[nale.

Soins, nettoyage et entretien

Pour les instruction de nettoyage, referez vous & votre

Guide d'utilisation et d'entretien.

Debranchez I'alimentation de puissance electrique s'il est

necessaire de deplacez la cuisiniere pour le nettoyage ou

I'entretien. Soulevez legerement I'appareil & I'avant et

firez afin de I'eloigner du mur si I'acces & I'alimentation

electrique est inaccessible. N'eloignez du mur que de la

distance necessaire pour debrancher I'alimentation

electrique. Finissez de deplacer I'appareil pour I'entretien

et le nettoyage. Reinstallez en ordre inverse en vous

assurant de mettre la cuisiniere & niveau et verifiez les

raccordements electriques. Voyez les pages 2 et 3 pour

les instructions correctes d'ancrage.

Avant que vous ne fassiez un

i_i!i!,

................. JII:I:;):::!;T

)

Emplacement de la plaque signaletique

Ouvrez le tiroir-rechaud ou de rangement

ou enlevez le panneau inferieur

(sur certains modeles)

appel de service

Lisez "Avant d'appeler" et les sections de notices

d'operation de votre Guide d'utilisation et d'entretien, ils

peuvent vous sauver temps et argent. IIs comprennent

des occurrences qui ne parviennent pas de defaut de

materiau ou de main-d'oeuvre dans cet appareil.

Pour connaftre notre no. de telephone sans frais et notre

adresse, referez vous & la garantie dans votre Guide

d'utilisation et d'entretien. S[ vous avez des questions

concernant votre cuisiniere et/ou devez commander des

pieces de rechange n'hesitez pas & nous tel6phoner ou &

nous ecrire

Loading...

Loading...