Page 1

TABLE OF CONTENTS

Important Safety Instructions ........................... 2-3 Accessories ...................................................... 19

Installatton Requirements .............................. 4-10 Notes ............................................................. 20

Installabon Instructions ................................ 11-16 Fran_als .......................................................... 21

Reversmg Door ............................................ 17-18 Espa_ol ........................................................... 41

oo

3>

oo

Page 2

For your safety the information in this manual must be followed to minimize the risk of fire or explosion or to prevent

property damage, personal injury or loss of life. Do not store or usegasoline or other flammable vapors and liquids in

....the vidnity °f th!s °! any °ther app!!ance:......................................................................................................................................................................................................................................................................................................................

AWARNING - RISK OF FIRE

Read all of the following instructions before installing and using this appliance:

* Destroy the carton and plastic bags after the dryer is unpacked. Children might use them for play. Cartons covered

with rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Place all materials in a

garbage container or make materials inaccessible to children.

* Clothes dryer installation and service must be performed by a qualified installer, service agency or the gas supplier.

* Install the clothes dryer according to the manufacturer's instructions and local codes.

* The electrical service to the dryer must conform with local codes and ordinances and the latest edition of the

National Electrical Code, ANS[/NFPA 70, or in Canada, the Canadian electrical code C22.I part 1.

* The gas service to the dryer must conform with local codes and ordinances and the latest edition of the National

Fuel Gas Code ANSI Z223.1, or in Canada, CAN/ACG BI49.1-2000. An individual manual shut-off valve must be

installed within 6 ft (i.83 m) of the dryer in accordance with the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

* The dryer is designed under ANSI Z 21.5.1 or ANS[/UL 2158 - CAN/CSA C22.2 No. i12 (latest editions) for HONE

USE only. This dryer is not recommended for commercial applications such as restaurants, beauty salons, etc.

* Do not install a clothes dryer with flexible plastic or flexible foil venting material. Flexible venting materials are

known to collapse, be easily crushed and trap lint. These conditions will obstruct clothes dryer airflow and increase

the risk of fire.

* The instructions in this manual and all other literature included with this dryer are not meant to cover every

possible condition and situation that may occur. Good safe practice and caution NUST be applied when installing,

operating and maintaining any appliance.

WHAT TO DO IF YOU SMELL GAS:

* Do not try to light any appliance.

* Do not touch any electrical switch; do not use any

phone in your building.

* Clear the room, building or area of all occupants.

* Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

* If you cannot reach your gas supplier, call the fire

department.

personmoveor !!It theapp!iance: ..................

Save these instructions

for future reference.

Tools and materials needed for installation:

Pre-Installation Requirements

* Adjustable pliers * Carpenter's level

* Phillips, straight, & square bit * External vent hood

screwdrivers * 4-inch (!02 mm), rigid metal or

* Adjustable wrench semi-rigid metal exhaust duct work

* Pipewrench for gas supply (gas * 3-wire or 4-wire 240 volt cord kit

dryer) (electric dryer)

* @-resistant thread tape (for natural * 4 in. (!02 mm) clamp

gas or LP supply, gas dryer)

* Gas line shutoff valve (gas dryer)

* _/2NPTunion flare adapters (x2)

and flexible gas supply line (gas

dryer)

Netal foil tape (not duct tape)

Page 3

Pleasereadallinstructionsbeforeusingthisdryer.

Exhaust Venting

Free-flowing, clear of lint buildup

4 inch (102 mm) rigid or semi-rigid ducting of

Recognize safety syrnboisr words

and labels

Safety items throughout this manual are labeled with

a WARNING or CAUTION based on the risk type as

described below:

Definitions

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury

or death.

DANGER indicates an imminently hazardous situation

which if not avoided will result in death or serious

injury, 240v Electric Supply (Electric Dryer)

CAUTION indicates a potentially hazardous situation E3 Test hinge and latch for function

which, if not avoided, may result in minor or moderate

injury. Electrical Power

IMPORTANT indicates installation, operation or

maintenance information which is important but not

hazard-related.

minimal length and turns

E_ NO foil or plastic venting material

E_ Approved vent hood exhausted to outdoors

Leveling

E_ Dryer is level, side-to-side and front-to-back

E3 Cabinet is setting solid on all corners

GasSupplyCGasDryer:

E_ Manual shutoff valve present in supply

E_ AIt connections sealed with approved sealer and

wrench tight

E_ Conversion kit for LPsystem

E_ Gas supply turned on

E3 No leaks present at all connections -

check with soapy water, NEVERcheck with flame

E3 Approved NEMA 10-30R or 14-30R service cord

with all screws tight on terminal block

E3 Approved strain relief installed

E3 Terminal access cover installed before initial

operation

Door Reversal

E3 Follow detailed instructions in this guide

E3 House power turned on

E3 Dryer plugged in

Final Checks

Installation Instructions and Use and Care

Guide read thoroughly

Door latches and drum tumbles when cycle

starts

Registration card sent in

Page 4

Becauseofpotentiallyinconsistentvoltagecapabilities,theuseofthisdryerwithpowercreatedbygaspowered

generators,solarpoweredgenerators,windpoweredgeneratorsoranyothergeneratorotherthanthelocalutility

companyisnotrecommended,

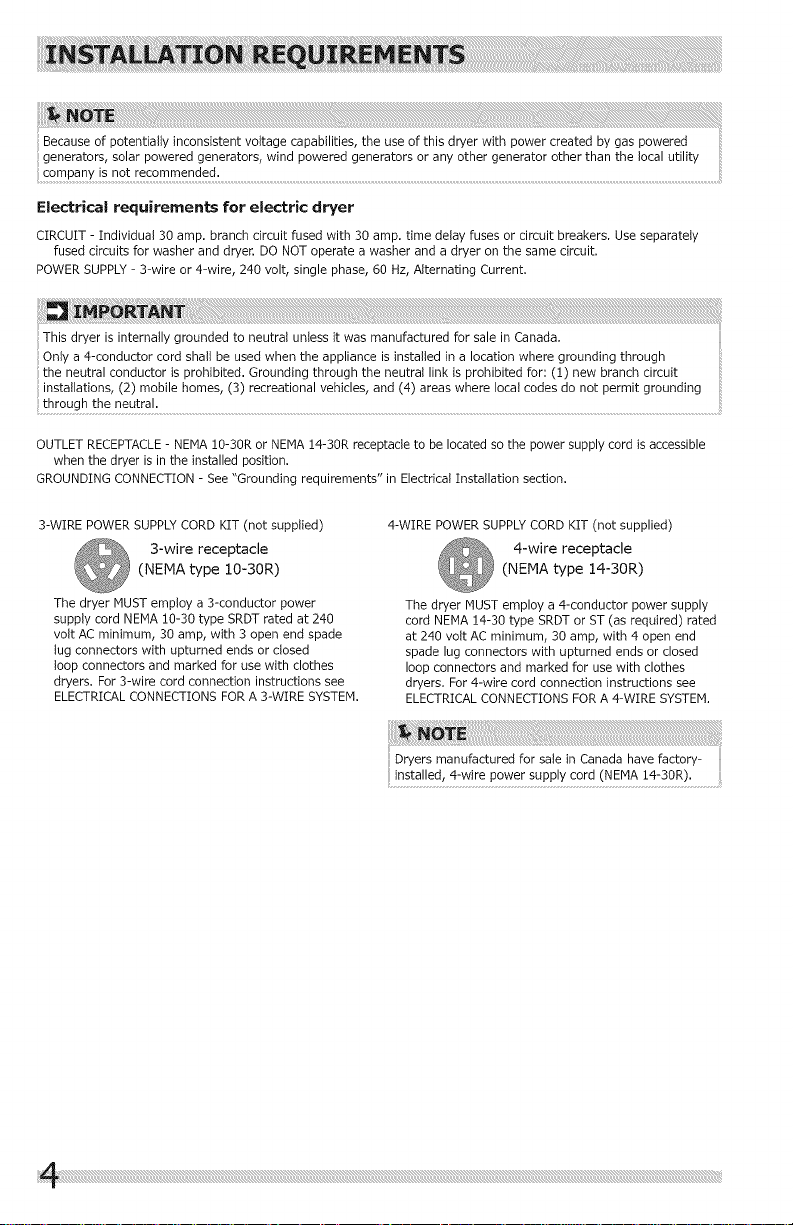

Electrical requirements for electric dryer

CIRCUIT - Individual 30 amp. branch circuit fused with 30 amp. time delay fuses or circuit breakers. Use separately

fused circuits for washer and dryer. DO NOToperate a washer and a dryer on the same circuit.

POWER SUPPLY- 3-wire or 4-wire, 240 volt, single phase, 60 Hz, Alternating Current.

through the neutral.

OUTLET RECEPTACLE- NEMA 10-3ORor NEMA 14-30R rece )tacie to be located so the power supply cord is accessible

when the dryer is in the installed position.

GROUNDING CONNECTION - See "Grounding requirements" in Electrical Installation section.

3-WIRE POWERSUPPLYCORD KIT (not supplied)

3-wire receptacle

(NEMA type 10-30R)

The dryer MUSTemploy a 3-conductor power

supply cord NEMA 10-30 type SRDTrated at 240

volt AC minimum, 30 amp, with 3 open end spade

lug connectors with upturned ends or closed

loop connectors and marked for use with clothes

dryers. For 3-wire cord connection instructions see

ELECTRICALCONNECTIONS FOR A 3-WIRE SYSTEM.

4-WIRE POWER SUPPLYCORD KIT (not supplied)

4-wire receptacle

(NEMA type 14-30R)

The dryer MUST employ a 4-conductor power supply

cord NEMA 14-30 type SRDTor ST (as required) rated

at 240 volt AC minimum, 30 amp, with 4 open end

spade lug connectors with upturned ends or closed

loop connectors and marked for use with clothes

dryers. For 4-wire cord connection instructions see

ELECTRICALCONNECTIONS FORA 4-WIRE SYSTEM.

Page 5

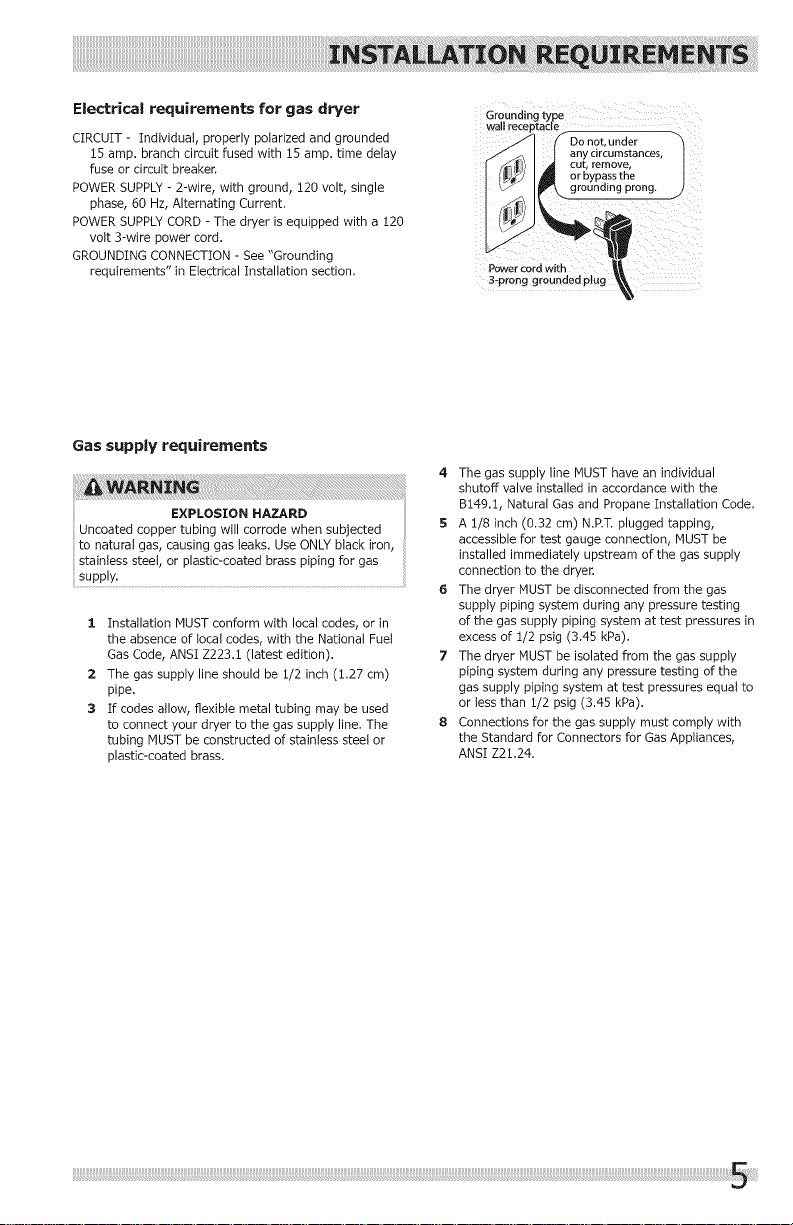

Electrical requirements for gas dryer

CIRCUIT - Individual, properly polarized and grounded

15 amp. branch circuit fused with 15 amp. time delay

fuse or circuit breaker.

POWER SUPPLY- 2-wire, with ground, !20 volt, single

phase, 60 Hz, Alternating Current.

POWER SUPPLYCORD- The dryer is equipped with a 120

volt 3-wire power cord.

GROUNDING CONNECTION - See "Grounding

requirements" in Electrical Installation section.

Gas supply requirements

; EXPLOSION HAZARD

Uncoated copper tubing will corrode when subjected

to natural gas, causing gas leaks. Use ONLYblack iron,

stainless steel, or plastic-coated brass piping for gas

supply.

1 Installation MUST conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.I (latest edition).

2 The gas supply line should be 1/2 inch (1.27 cm)

pipe.

3 If codes allow, flexible metal tubing may be used

to connect your dryer to the gas supply line. The

tubing MUST be constructed of stainless steel or

plastic-coated brass.

Groundingtype

wal receptacle

/ _.\ I |anycircurnstances

_- Do not,under -"

\ I_ grounding prong.

h

B-pronggroundedpl

4. The gas supply line MUST have an individual

shutoff valve installed in accordance with the

B!49.!, Natural Gas and Propane Installation Code.

5 A !/8 inch (0.32 cm) N.P.T.plugged tapping,

accessible for test gauge connection, MUST be

installed immediately upstream of the gas supply

connection to the dryer.

6 The dryer MUSTbe disconnected from the gas

supply piping system during any pressure testing

of the gas supply piping system at test pressures in

excess of !/2 psig (3.45 kPa).

7 The dryer MUSTbe isolated from the gas supply

piping system during any pressure testing of the

gas supply piping system at test pressures equal to

or tessthan Z/2 psig (3.45 kPa).

8 Connections for the gas supply must comply with

the Standard for Connectors for Gas Appliances,

ANSI Z21.24.

Page 6

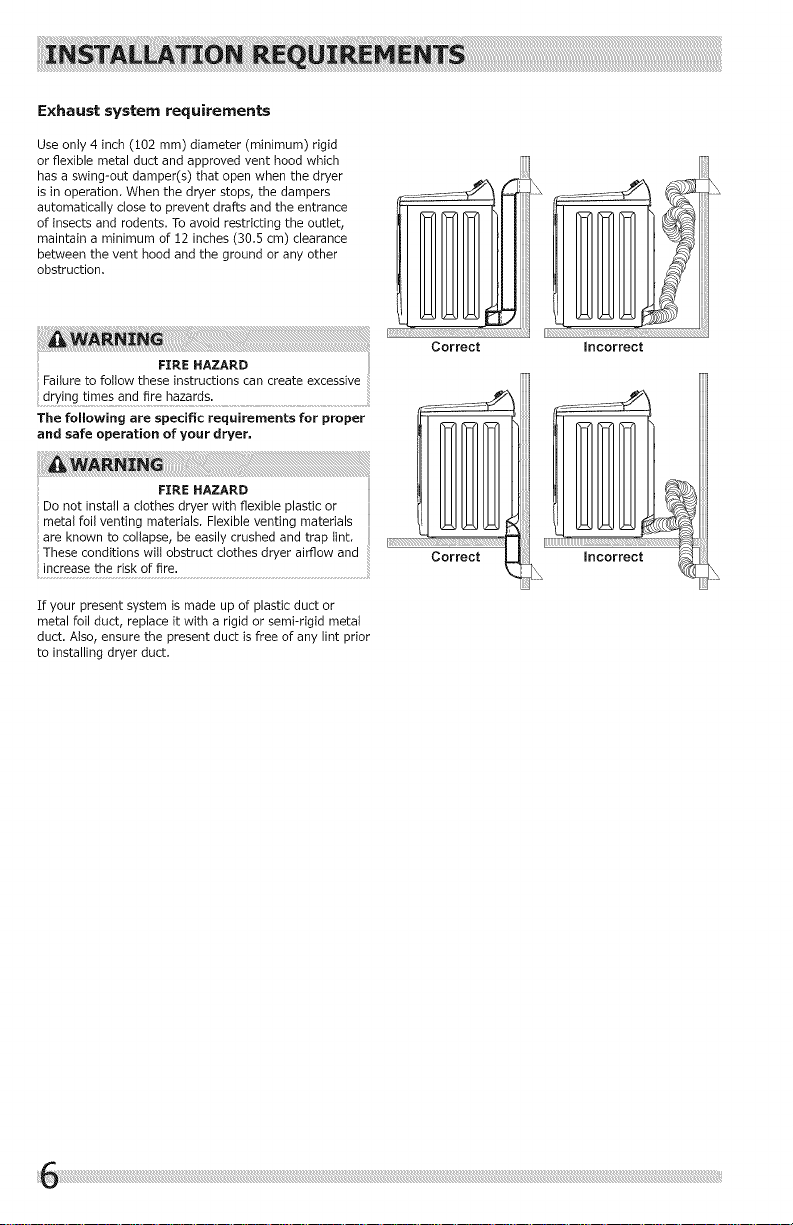

Exhaust system requirements

Use only 4 inch (i02 mm) diameter (minimum) rigid

or flexible metal duct and approved vent hood which

has a swing-out damper(s) that open when the dryer

is in operation. When the dryer stops, the dampers

automatically close to prevent drafts and the entrance

of insects and rodents. To avoid restricting the outlet,

maintain a minimum of !2 inches (30.5 cm) clearance

between the vent hood and the ground or any other

obstruction.

Failure to follow these instructions can create excessive

FIRE HAZARD

drying times and fire hazards.

The following are specific requirements for proper

and safe operation of your dryer,

li;;:_:_;:;_!! :_iiiii; ;_i¸__;i;_¸i¸!_;;_i_ii ;_11 iiii

Correct

Do not install a clothes dryer with flexible plastic or

FIRE HAZARD

metal foil venting materials. Flexible venting materials

are known to collapse, be easily crushed and trap tint.

These conditions witt obstruct clothes dryer airflow and

increase the risk of fire.

If your present system is made up of plastic duct or

metal foil duct, replace it with a rigid or semi-rigid metal

duct. Also, ensure the present duct is free of any lint prior

to installing dryer duct.

[_; ¸i¸i¸i¸i¸i¸i¸i¸i¸i¸i¸i¸i¸i¸i¸i¸i

L

Incorrect

Page 7

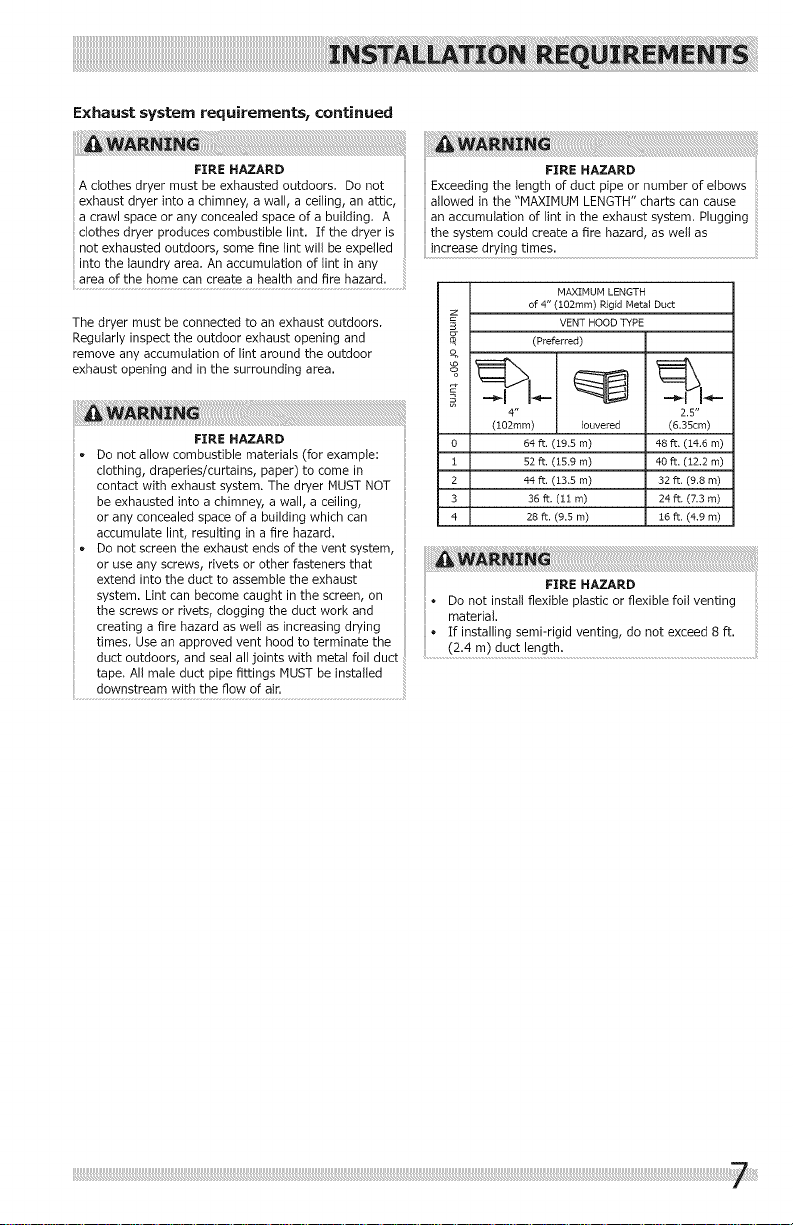

Exhaust system requirements, continued

FIRE HAZARD FIRE HAZARD

A clothes dryer must be exhausted outdoors• Do not Exceeding the length of duct pipe or number of elbows

exhaust dryer into a chimney, a wall, a ceiling, an attic, allowed in the "MAXIMUM LENGTH" charts can cause

a crawl space or any concealed space of a building• A an accumulation of lint in the exhaust system• Plugging

clothes dryer produces combustible lint. If the dryer is

not exhausted outdoors, some fine lint will be expelled

into the laundry area• An accumulation of tint in any

area of the home can create a health and fire hazard.

The dryer must be connected to an exhaust outdoors.

Regularly inspect the outdoor exhaust opening and

remove any accumulation of lint around the outdoor

exhaust opening and in the surrounding area.

FIRE HAZARD

Do not allow combustible materials (for example:

clothing, draperies/curtains, paper) to come in

contact with exhaust system. The dryer MUST NOT

be exhausted into a chimney, a wall, a ceiling,

or any concealed space of a building which can

accumulate lint, resulting in a fire hazard.

Do not screen the exhaust ends of the vent system,

or use any screws, rivets or other fasteners that

extend into the duct to assemble the exhaust

system. Lint can become caught in the screen, on

the screws or rivets, clogging the duct work and material.

creating a fire hazard as welt as increasing drying

..... * If nsta ngsem-rgdventng do not exceed8ft

t mes Use an approved vent hood to term nate the "2 4 m" duct len th

• _. ) g •

duct outdoors, and seal all ]omts wtth metal fotl duct .....

tape, All male duct pipe fittings MUST be instalied

downstream with the flow of air.

the system could create a fire hazard, as welt as

increase drying times.

MAXIMUM LENGTH

of 4" (102mm) Rigid Metal Duct

9 VENT HOOD TYPE

0 64 ft. (19.5 m) 48 ft. (14.6 m)

1 52 ft. (15,9 m) 40 ft, (12.2 m)

2 44 ft. (13,5 m) 32 ft, (9.8 m)

3 36 ft. (11 m) 24 ft. (7.3 m)

4 28 ft. (9,5 m) 16 ft, (4.9 m)

(Preferred)

4" 2.5"

(102ram) Iouvered (6.35cm)

o Do not install flexible plastic or flexible foil venting

Page 8

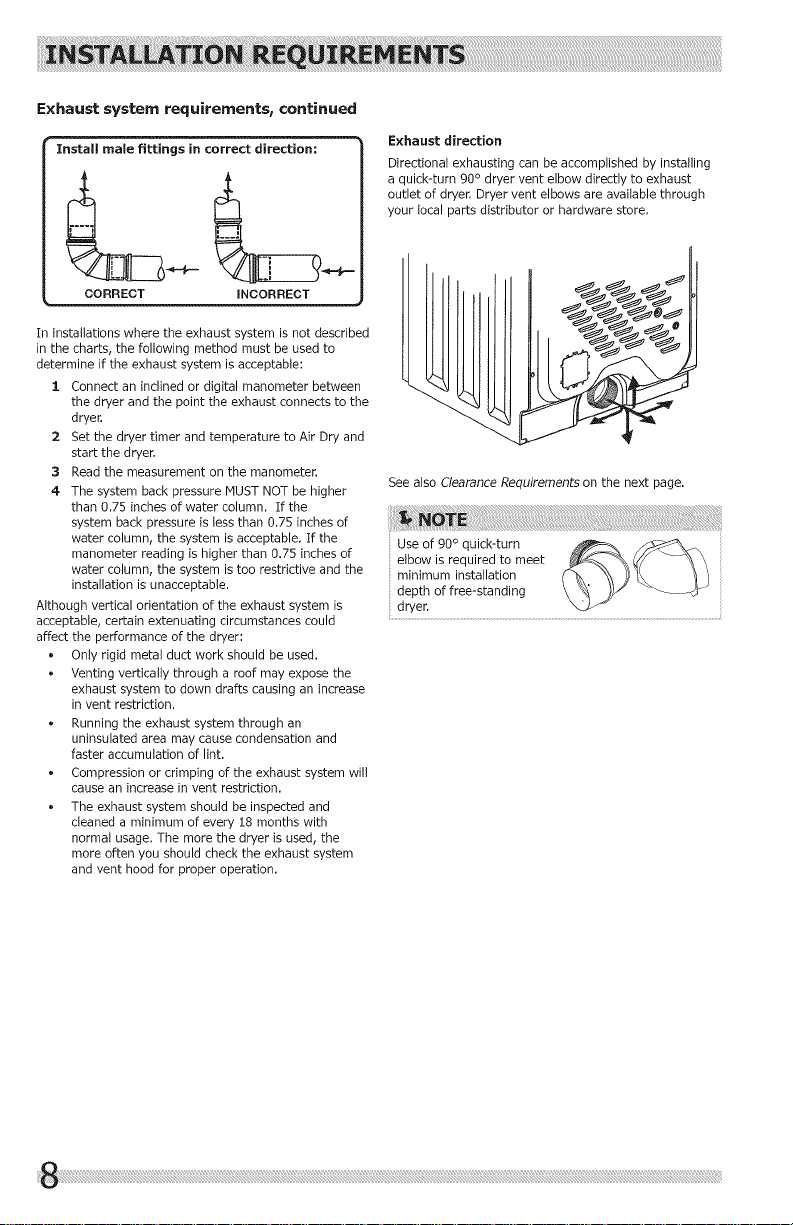

Exhaust system requirements, continued

Install male fittings in correct direction:

CORRECT INCORRECT

In installations where the exhaust system is not described

in the charts, the following method must be used to

determine if the exhaust system is acceptable:

:1. Connect an inclined or digital manometer between

the dryer and the point the exhaust connects to the

dryer.

2 Set the dryer timer and temperature to Air Dry and

start the dryer.

3 Read the measurement on the manometer.

4 The system back pressure MUST NOT be higher

than 0.75 inches of water column. If the

system back pressure is tess than 0.75 inches of

water column, the system is acceptable. If the

manometer reading is higher than 0.75 inches of

water column, the system is too restrictive and the

installation is unacceptable.

Although vertical orientation of the exhaust system is

acceptable, certain extenuating circumstances could

affect the performance of the dryer:

• Only rigid metal duct work should be used.

• Venting vertically through a roof may expose the

exhaust system to down drafts causing an increase

in vent restriction.

• Running the exhaust system through an

uninsulated area may cause condensation and

faster accumulation of lint.

• Compression or crimping of the exhaust system will

cause an increase in vent restriction.

• The exhaust system should be inspected and

cleaned a minimum of every 18 months with

normal usage. The more the dryer is used, the

more often you should check the exhaust system

and vent hood for proper operation.

Exhaust direction

Directional exhausting can be accomplished by installing

a quick-turn 90 ° dryer vent elbow directly to exhaust

outlet of dryer. Dryer vent elbows are available through

your local parts distributor or hardware store.

See also Clearance Requirements on the next page.

Use of 90 ° quick-turn

elbow is required to meet

minimum installation

depth of free-standing

dryer.

Page 9

Manufactured or mobile home installation

1 Installation MUST conform to current Manufactured

Home Construction & Safety Standard, Title 24

CFR, Part 32-80 (formerly the Federal Standard

for Mobile Home Construction and Safety, Title 24,

HUD Part 280) or Standard CAN/CSAZ240 MH.

2 Dryer MUST be exhausted outside (outdoors, not

beneath the mobile home) using metal ducting

that wilt not support combustion. Metal ducting

must be 4 inches (i0.i6 cm) in diameter with no

obstructions. Rigid metal duct is preferred.

3 If dryer is exhausted through the floor and area

beneath the mobile home is enclosed, the exhaust

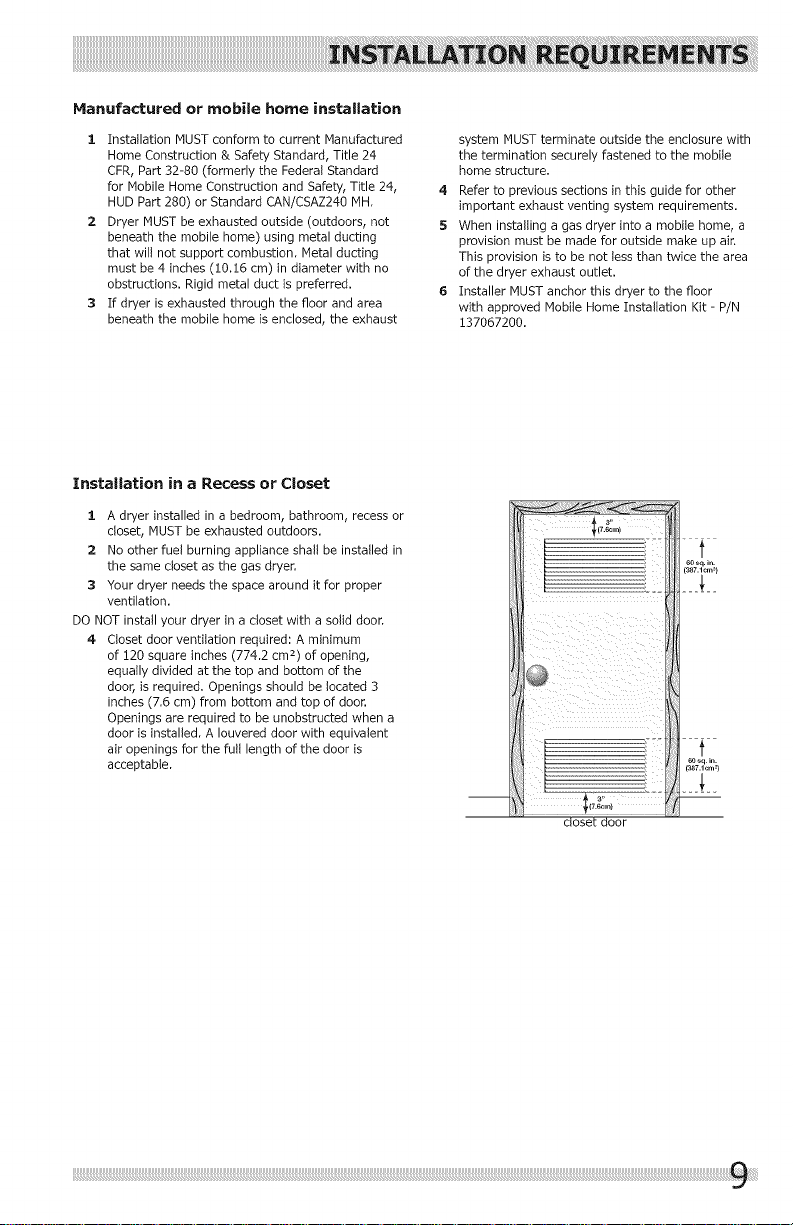

Installation in a Recess or Closet

1 A dryer installed in a bedroom, bathroom, recess or

closet, MUST be exhausted outdoors.

2 No other fuel burning appliance shall be installed in

the same closet as the gas dryer.

3 Your dryer needs the space around it for proper

ventilation.

DO NOT install your dryer in a closet with a solid door.

4 Closet door ventilation required: A minimum

of !20 square inches (774.2 cm 2) of opening,

equally divided at the top and bottom of the

door, is required. Openings should be located 3

inches (7.6 cm) from bottom and top of door.

Openings are required to be unobstructed when a

door is installed. A Iouvered door with equivalent

air openings for the full length of the door is

acceptable,

system MUST terminate outside the enclosure with

the termination securely fastened to the mobile

home structure.

4 Refer to previous sections in this guide for other

important exhaust venting system requirements.

5 When installing a gas dryer into a mobile home, a

provision must be made for outside make up air.

This provision is to be not less than twice the area

of the dryer exhaust outlet.

6 Installer MUST anchor this dryer to the floor

with approved Mobile Home Installation Kit - P/N

137087200.

closet door

Page 10

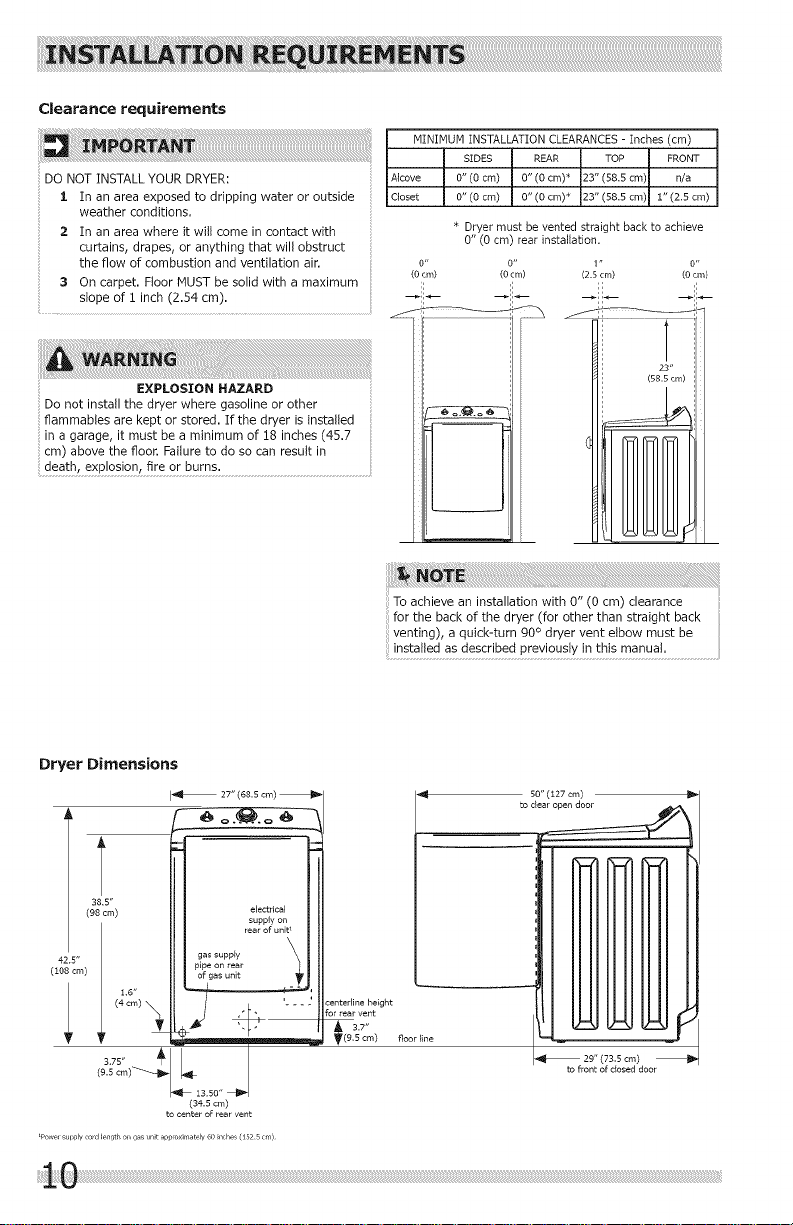

Clearance requirements

INSTALLYOUR DRYER:

I In an areaexposedtodrippingwateroroutside

weatherconditions.

2 In an areawhere itwillcome incontactwith

curtains,drapes,or anythingthatwillobstruct

theflowofcombustionand ventilationair.

3 On carpet.FloorMUST be solidwitha maximum

slope of i inch (2.54 cm).

MINIMUM INSTALLATION CLEARANCES - Inches (cm)

SIDES REAR TOP FRONT

Alcove 0" (0 cm) 0" (O cm)* 23" (58.5 cm) n/a

Closet 0"(0 crn) 0" (0 cm) _ 23" (58.5 crn) 1" (2.5 crn)

* Dryer must be vented straight back to achieve

0" (0 cm) rear installation.

(oO#i_) o"

(0cm)

1" "

(2.5 cm) (00cm)

_ii_ -iL

Do not install the dryer where gasoline or other

EXPLOSION HAZARD

flammables are kept or stored. If the dryer is installed

in a garage, it must be a minimum of !8 inches (45.7

cm) above the floor. Failure to do so can result in

death, explosion, fire or burns.

Dryer Dimensions

I_ 27' (68,5 cm)

42,5"

(108 cm)

38,5"

(98 cm)

electrical

supply on

rear of unitI

pipe on rear

gas supply _

of gas unit

:enterline height

3.7"

(9,5 cm) floorline

To achieve an installation with 0" (0 cm) clearance

for the back of the dryer (for other than straight back

venting), a quick-turn 90 ° dryer vent elbow must be

installed as described previously in this manual,

S0" (127cm) _lJ

to

I_ 29" (73,5 cm)

to front of dosed door

(34,5 cm)

to center of rear vent

iPowe, sul)ply cmd length on gas unit ap]3mxima_ely 6O in( he£ (1525 cm)

i!!i!i!l!_!0 ill

Page 11

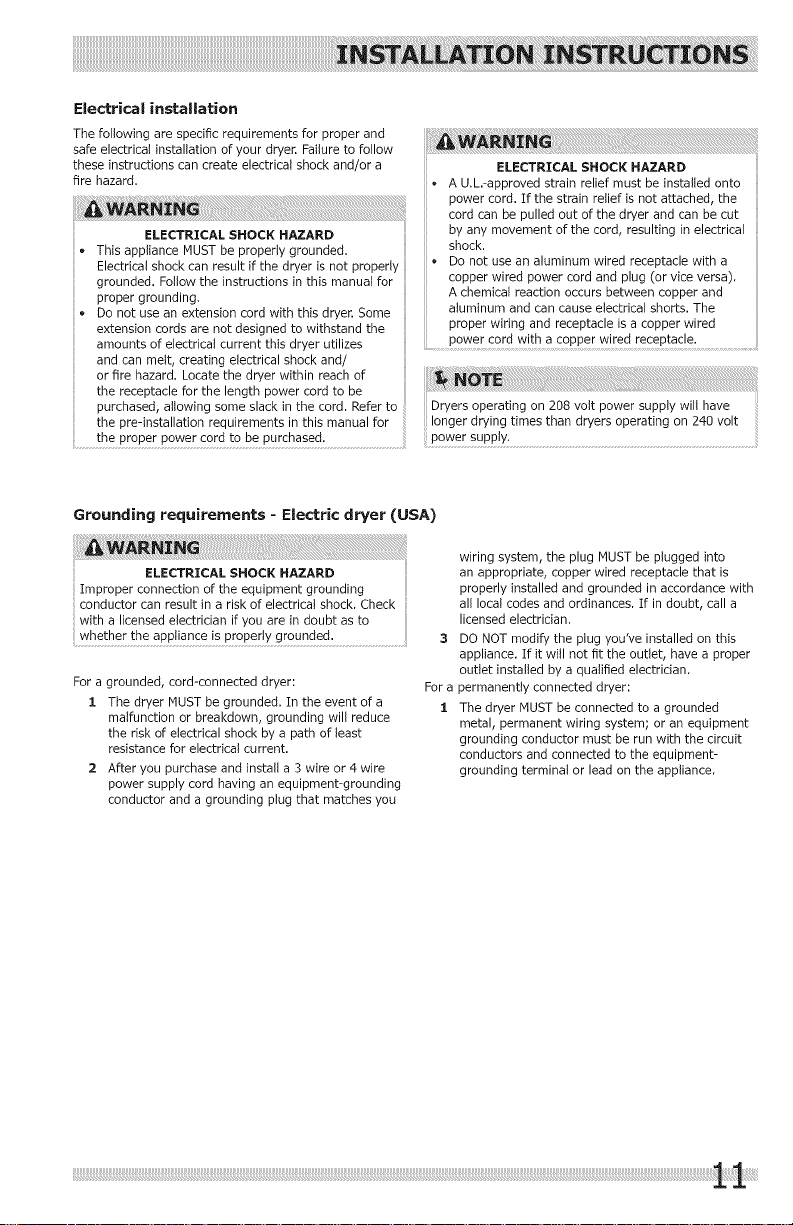

Electrical installation

The following are specific requirements for proper and

safe electrical installation of your dryer. Failure to follow

these instructions can create electrical shock and/or a

fire hazard.

ELECTRICAL SHOCK HAZARD

This appliance MUST be properly grounded.

Electrical shock can result if the dryer is not properly

grounded. Follow the instructions in this manual for

o

proper grounding.

extension cords are not designed to withstand the

amounts of electrical current this dryer utilizes

and can melt, creating electrical shock and/

or fire hazard. Locate the dryer within reach of

the receptacle for the length power cord to be

• Do not use an extension cord with this dryer. Some

purchased, allowing some slack in the cord. Refer to

the pre-installation requirements in this manual for

the proper power cord to be purchased power supply.

• A U.L.-approved strain relief must be installed onto

Grounding requirements - Electric dryer (USA)

conductor can result in a risk of electrical shock. Check

with a licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

For a grounded, cord-connected dryer:

1 The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce

the risk of electrical shock by a path of least

resistance for electrical current.

2 After you purchase and install a 3 wire or 4 wire

power supply cord having an equipment-grounding

conductor and a grounding plug that matches you

3 DO NOT modify the plug you've installed on this

For a permanently connected dryer:

1 The dryer MUST be connected to a grounded

ELECTRICAL SHOCK HAZARD

power cord. If the strain relief is not attached, the

cord can be pulled out of the dryer and can be cut

by any movement of the cord, resulting in electrical

shock.

Do not use an aluminum wired receptacle with a

copper wired power cord and plug (or vice versa).

A chemical reaction occurs between copper and

aluminum and can cause electrical shorts. The

proper wiring and receptacle is a copper wired

power cord with a copper wired receptacle.

wiring system, the plug MUSTbe plugged into

an appropriate, copper wired receptacle that is

properly installed and grounded in accordance with

all local codes and ordinances. If in doubt, call a

licensed electrician.

appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

metal, permanent wiring system; or an equipment

grounding conductor must be run with the circuit

conductors and connected to the equipment-

grounding terminal or lead on the appliance.

Page 12

Grounding requirements - Electric dryer (Canada)

2 Since your dryer is equipped with a power supply

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check

with a licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

For a grounded, cord-connected dryer:

ELECTRICAL SHOCK HAZARD

cord having an equipment-grounding conductor and

a grounding plug, the plug must be plugged into

an appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances. If in doubt, call a licensed electrician.

3 DO NOT modify the plug provided with this

appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

1 The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance

for electrical current.

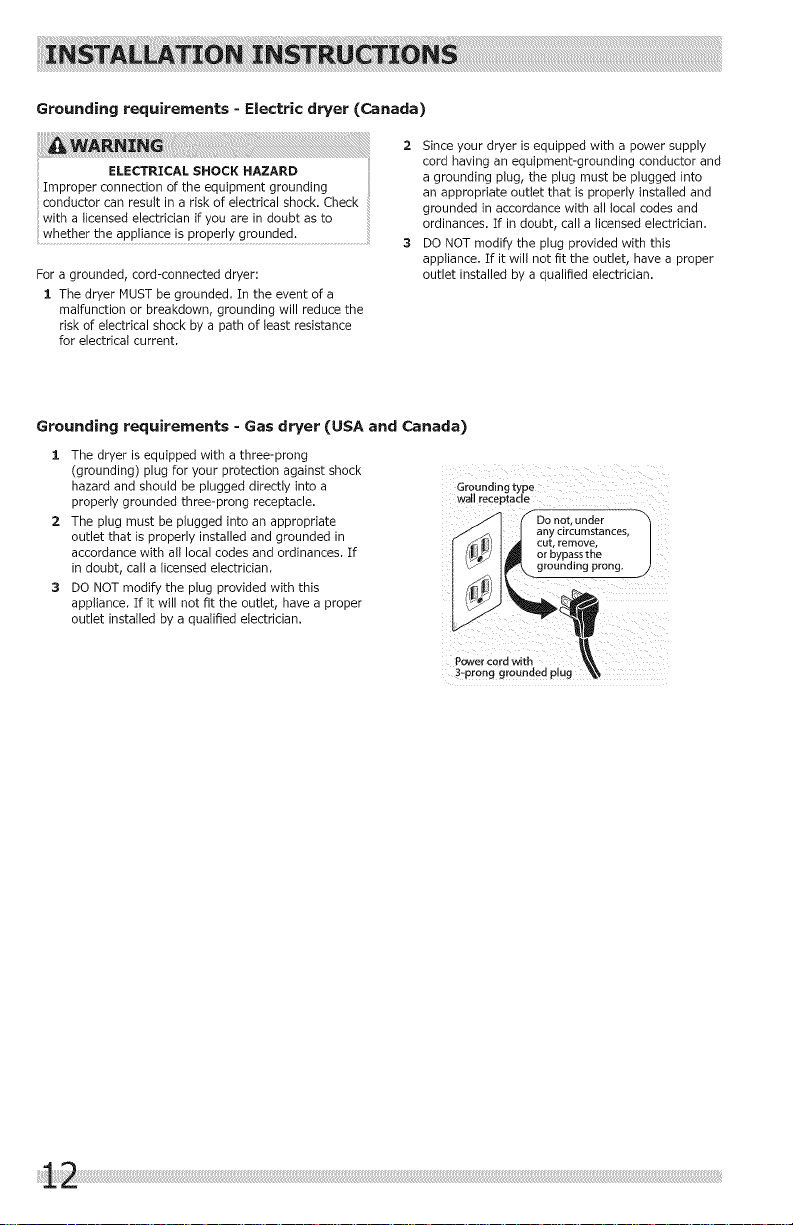

Grounding requirements = Gas dryer (USA and Canada)

1 The dryer is equipped with a three-prong

(grounding) plug for your protection against shock

hazard and should be plugged directly into a

properly grounded three-prong receptacle.

2 The plug must be plugged into an appropriate

outlet that is properly installed and grounded in

accordance with all local codes and ordinances. If

in doubt, call a licensed electrician.

3 DO NOT modify the plug provided with this

appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

Grounding type

wail receptacle

Pc_er cord with

3-prong grounded plug

f Do not. under

any circumstances

or bypass the

__ grounding prong.

Page 13

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_i_i_i_i!!!_i_iiii_!i! _ii _i!_i!i_!i!_iii_i_ii_i_illi_i_ii!i_ii_i_iii!_ii

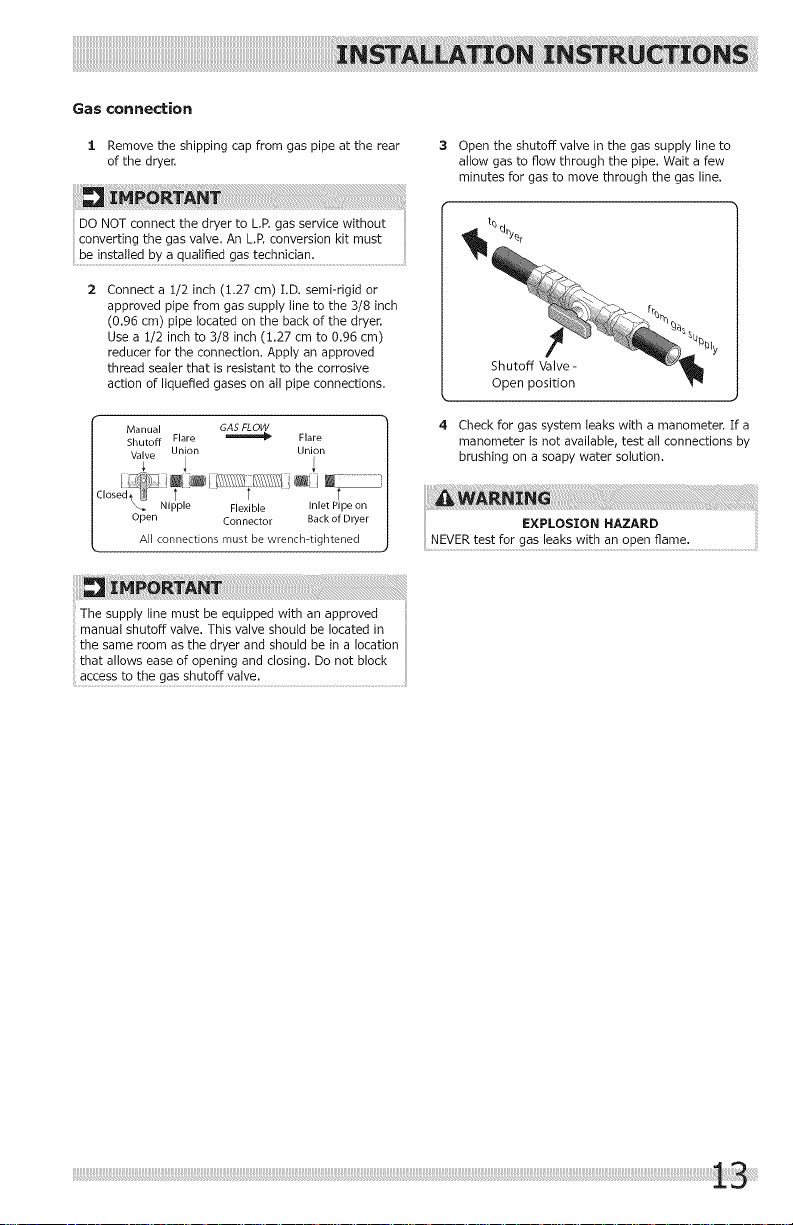

Gas connection

:1. Remove the shipping cap from gas pipe at the rear

of the dryer.

DO NOT connect the dryer to L.P,gas service without

converting the gas valve. An L.P.conversion kit must

be installed by a qualified gas technician.

Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or

approved pipe from gas supply line to the 3/8 inch

(0.96 cm) pipe located on the back of the dryer.

Use a 1/2 inch to 3/8 inch (1.27 cm to 0.96 cm)

reducer for the connection. Apply an approved

thread sealer that is resistant to the corrosive

action of liquefied gases on all pipe connections.

Manua GAS FLOW

Shutoff Flare _ Flare |

Valve Union Union |

,o_/:_ed71_Fi_'_i l_'_:::l_:_\_/_'i I I

: ,_tl t ' t t [

\. Nipple Flexible Inlet Pipe on |

Open Connector Back of Dryer |

All connections mustbe wrench-tightened J

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in

the same room as the dryer and should be in a location

that allows ease of opening and closing. Do not block

access to the gas shutoff valve.

3 Open the shutoff valve in the gas supply line to

allow gasto flow through the pipe. Wait a few

minutes for gas to move through the gas line.

Open position

4 Check for gas system leaks with a manometer. If a

manometer is not available, test all connections by

l

brushing on a soapy water solution,

Page 14

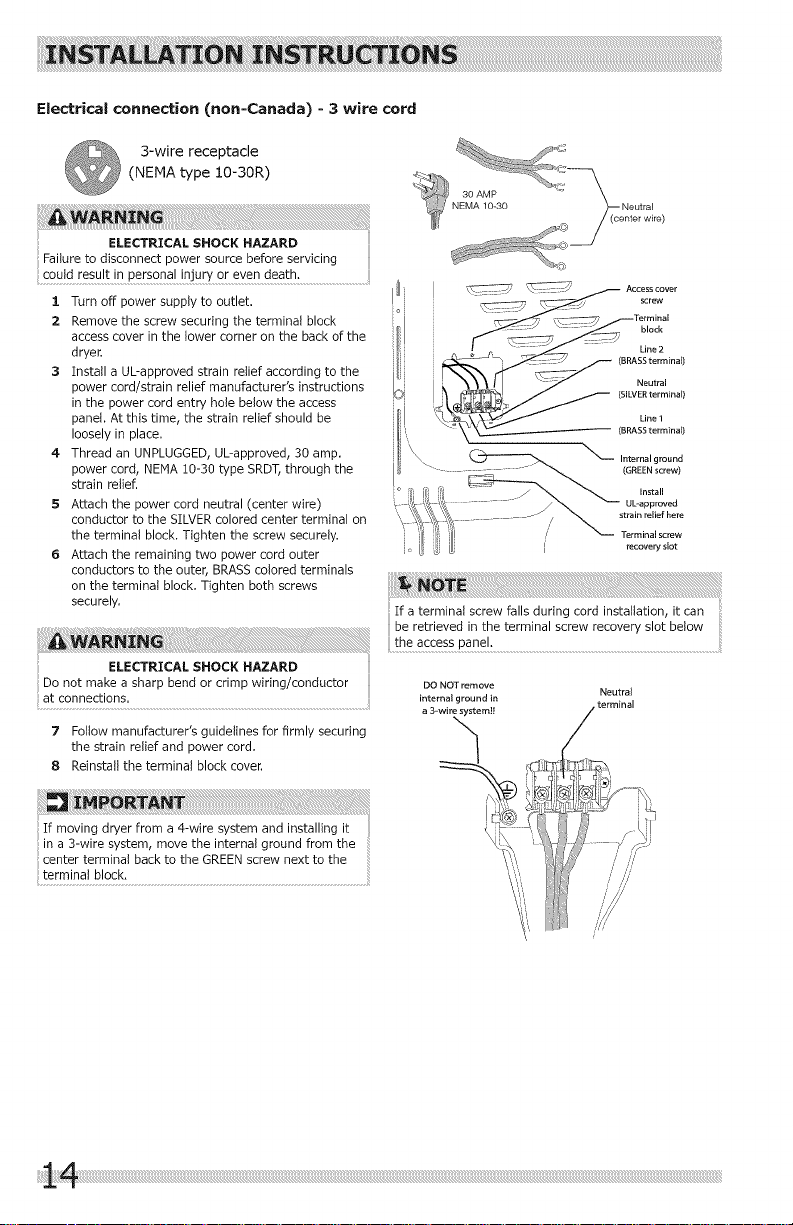

Electrical connection (non=Canada) - 3 wire cord

3-wire receptacle

(NEMA type 10-30R)

Failure to disconnect power source before servicing

ELECTR:CALS.OCK.AzARD

could result in personal injury or even death.

:1. Turn off power supply to outlet.

2 Remove the screw securing the terminal block

access cover in the lower corner on the back of the

dryer.

3 Install a UL-approved strain relief according to the

power cord/strain relief manufacturer's instructions

in the power cord entry hole below the access

panel. At this time, the strain relief should be

loosely in place.

4 Thread an UNPLUGGED,UL-approved, 30 amp.

power cord, NEHA 10-30 type SRDT,through the

strain relief.

5 Attach the power cord neutral (center wire)

conductor to the SILVERcolored center terminal on

the terminal block, Tighten the screw securely.

6 Attach the remaining two power cord outer

conductors to the outer, BRASS colored terminals

on the terminal block, Tighten both screws

securely,

Do not make a sharp bend or crimp wiring/conductor

at connections.

7 Follow manufacturer's guidelines for firmly securing

the strain relief and power cord.

8 Reinstall the terminal block cover.

(SILVER terminal)

Line 1

(BRASS terminal)

_ Internal ground

(GREEN screw)

recoveryslot

If a terminal screw falls during cord installation, it can

DO NOT remove

internal ground in terminal

a 3-wire system]!

Neutral

:If moving dryer from a 4-wire system and installing it

in a 3-wire system, move the internal ground from the

center terminal back to the GREENscrew next to the

terminal block.

Page 15

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_i_i_i_i!!!_i_iiii_!i! _ii _i!_i!i_!i!_iii_i_ii_i_illi_i_ii!i_ii_i_iii!_ii

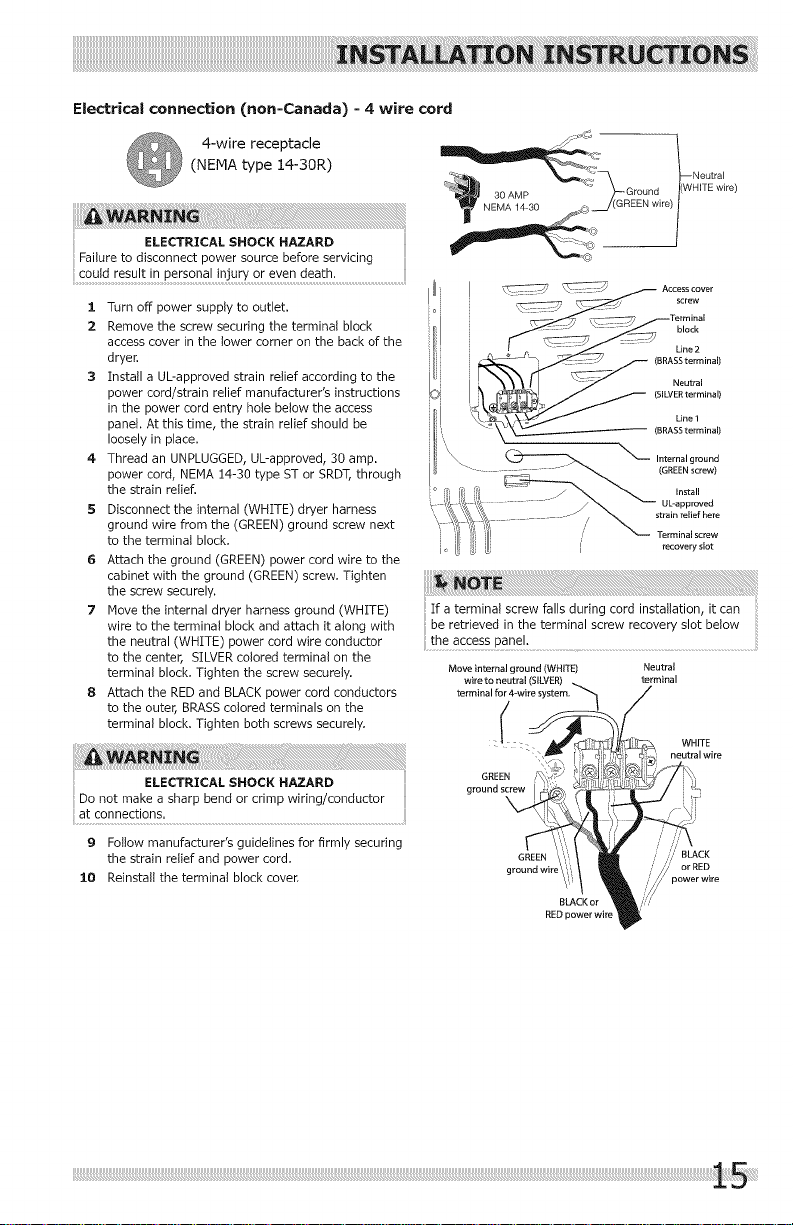

Electrical connection (non=Canada) = 4 wire cord

4-wire receptacle

(NEMA type 14-30R)

3. Turn off power supply to outlet.

2 Remove the screw securing the terminal block

access cover in the lower corner on the back of the

dryer.

3 Install a UL-approved strain retief according to the

power cord/strain relief manufacturer's instructions

in the power cord entry hole below the access

paneh At this time, the strain relief should be

loosely in place.

4 Thread an UNPLUGGED,UL-approved, 30 amp.

power cord, NEHA 14-30 type ST or SRDT,through

the strain relief.

5 Disconnect the internal (WHITE) dryer harness

ground wire from the (GREEN) ground screw next

to the terminal block.

6 Attach the ground (GREEN) power cord wire to the

cabinet with the ground (GREEN) screw. Tighten

the screw securely.

7 Nave the internal dryer harness ground (WHITE)

wire to the terminal block and attach it along with

the neutral (WHITE) power cord wire conductor

to the center, SILVERcolored terminal on the

terminal block. Tighten the screw securely.

8 Attach the RED and BLACKpower cord conductors

to the outer, BRASScolored terminals on the

terminal block. Tighten both screws securely.

ELEC'r.'CALS,oCK"AZAP,D

Donotmakeasbarpbendorcrimpwirhg/conductor

at connections.

9 Follow manufacturer's guidelines for firmly securing

the strain relief and power cord.

3.0 Reinstall the terminal block cover.

__ Acc_ cover

f_ black

Ifa terminal screw falls during cord installation, it can

be retrieved in the terminal screw recovery slot below

Line 2

(BRASS terminal)

Neutral

(SILVER terminal)

Line 1

(BRASS terminal)

-_ Internal ground

(GREEN screw)

Install

UL-approved

strain relief here

Terminal screw

recovery slot

the access panel. ...............

Move internal ground (WHITE)

wire to neutral (SILVER)

terminal for 4-wRe s

Neutral

terminal

{

neutral wire

GREEN

ground screw

\

GREEN

ground wit

BLACK

power wire

RED power wir

Page 16

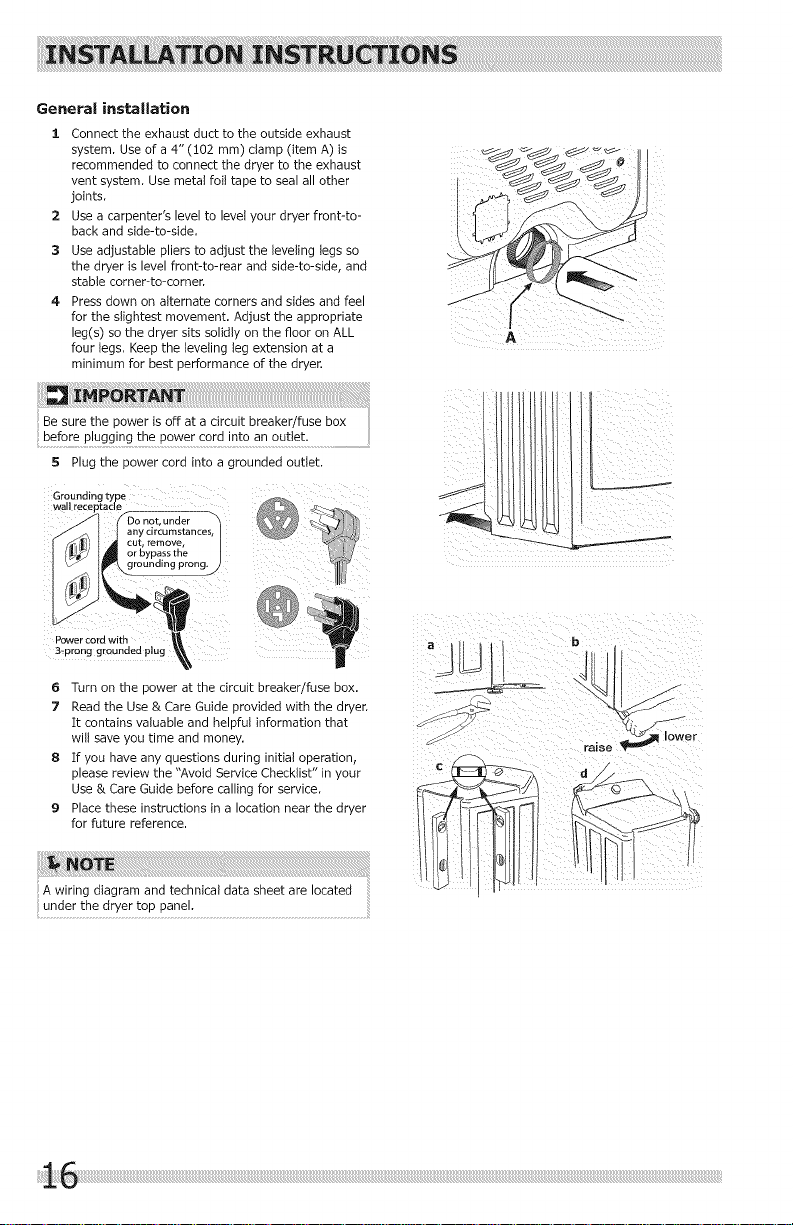

General installation

1 Connect the exhaust duct to the outside exhaust

system, Use of a 4" (102 mm) clamp (item A) is

recommended to connect the dryer to the exhaust

vent system, Use metal foit tape to seal all other

joints,

2 Use a carpenter's level to level your dryer front-to-

back and side-to-side,

3 Use adjustable pliers to adjust the leveling legs so

the dryer is level front-to-rear and side-to-side, and

stable comer-to-corner,

4 Press down on alternate corners and sides and feel

for the slightest movement. Adjust the appropriate

leg(s) so the dryer sits solidly on the floor on ALL

four tegs, Keep the leveling leg extension at a

minimum for best performance of the dryer.

5 Plugthe power cord into a grounded outlet.

..... I1receptacle

Power cord with

3:prong grounded plug

any circumstances,

_._ti,tea nce s' Icut ........

grounding prong.j_

6 Turn on the power at the circuit breaker/fuse box.

7 Read the Use & Care Guide provided with the dryer.

It contains valuable and helpful information that

wilt saveyou time and money.

8 If you have any questions during initial operation,

please review the "Avoid Service Checklist" in your

Use & Care Guide before calling for service.

9 Placethese instructions in a location near the dryer

for future reference.

Page 17

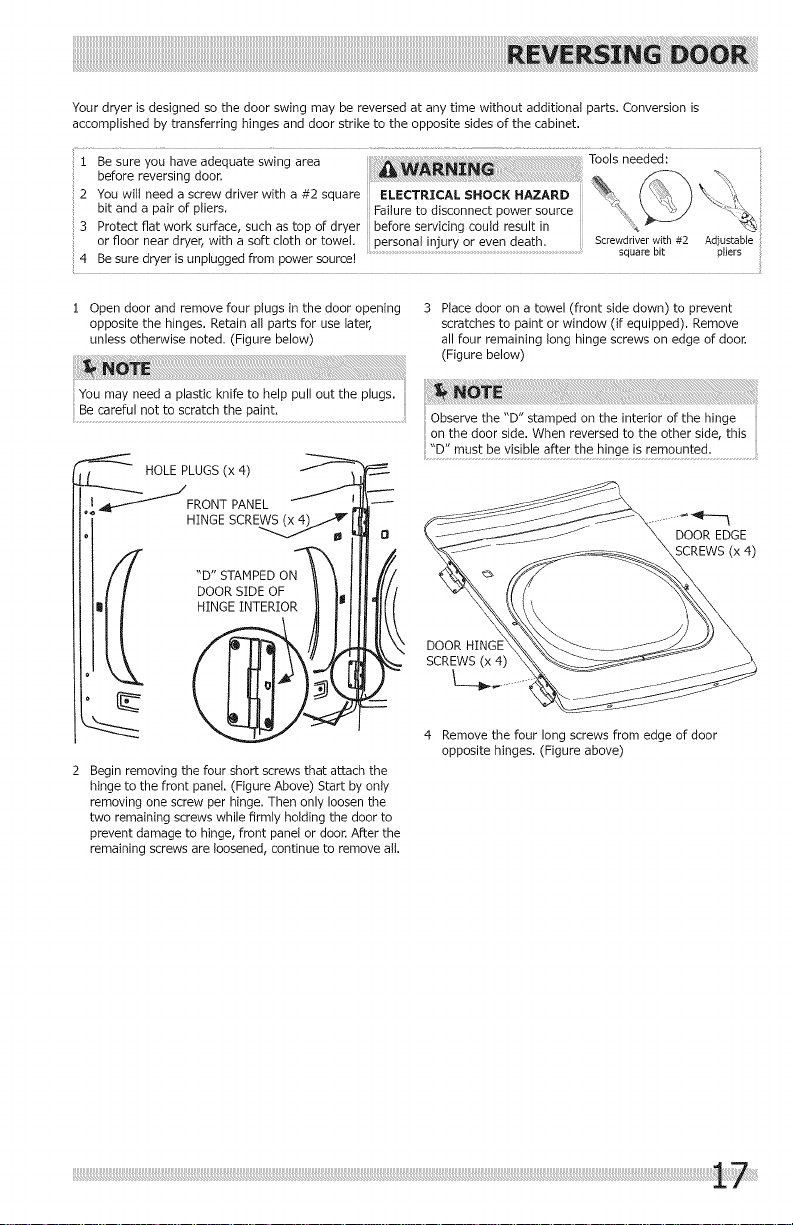

Yourdryerisdesignedsothedoorswingmaybereversedatanytimewithoutadditionalparts.Conversionis

accomplishedbytransferringhingesanddoorstriketotheoppositesidesofthecabinet.

I Be sure you have adequate swing area Tools needed:

before reversing door. _ _ %_,

2 You will need a screw driver with a #2 square ELECTRICAL SHOCK HAZARD _, ( \,_ } "*_, :i_

: bit and a pair of pliers. Failure to disconnect power source _,t,, _' ">- X_!_

3 Protect flat work surface such as top of dryer before servicing could result in

or floor near dryer, with a soft cloth or towel, personal injury or even death. Screwdriverwith #2 Adjustable

4 Be sure dryer is unplugged from power source! ......................................................................................................................................................squarebit pliers

! Open door and remove four plugs in the door opening 3 Place door on a towel (front side down) to prevent

opposite the hinges. Retain all parts for use later, scratches to paint or window (if equipped). Remove

unless otherwise noted. (Figure below) all four remaining long hinge screws on edge of door.

Be careful not to scratch the paint.

f--_2: HOLE PLUGS(x4) "D" must be visible after the hinge is remounted.

HINGE SCREW_

"D" STAMPEDON

DOOR SIDE OF

HINGE INTERIOR

2 Begin removing the four short screws that attach the

hinge to the front panel. (Figure Above) Start by only

removing one screw per hinge. Then only loosen the

two remaining screws while firmly holding the door to

prevent damage to hinge, front panel or door. After the

remaining screws are loosened, continue to remove all.

Observe the "D" stamped on the interior of the hinge

on the door side. When reversed to the other side, this

DOOR EDGE

SCREWS(x 4)

DOOR

SCREWS (x 4)

4 Remove the four long screws from edge of door

opposite hinges. (Figure above)

Page 18

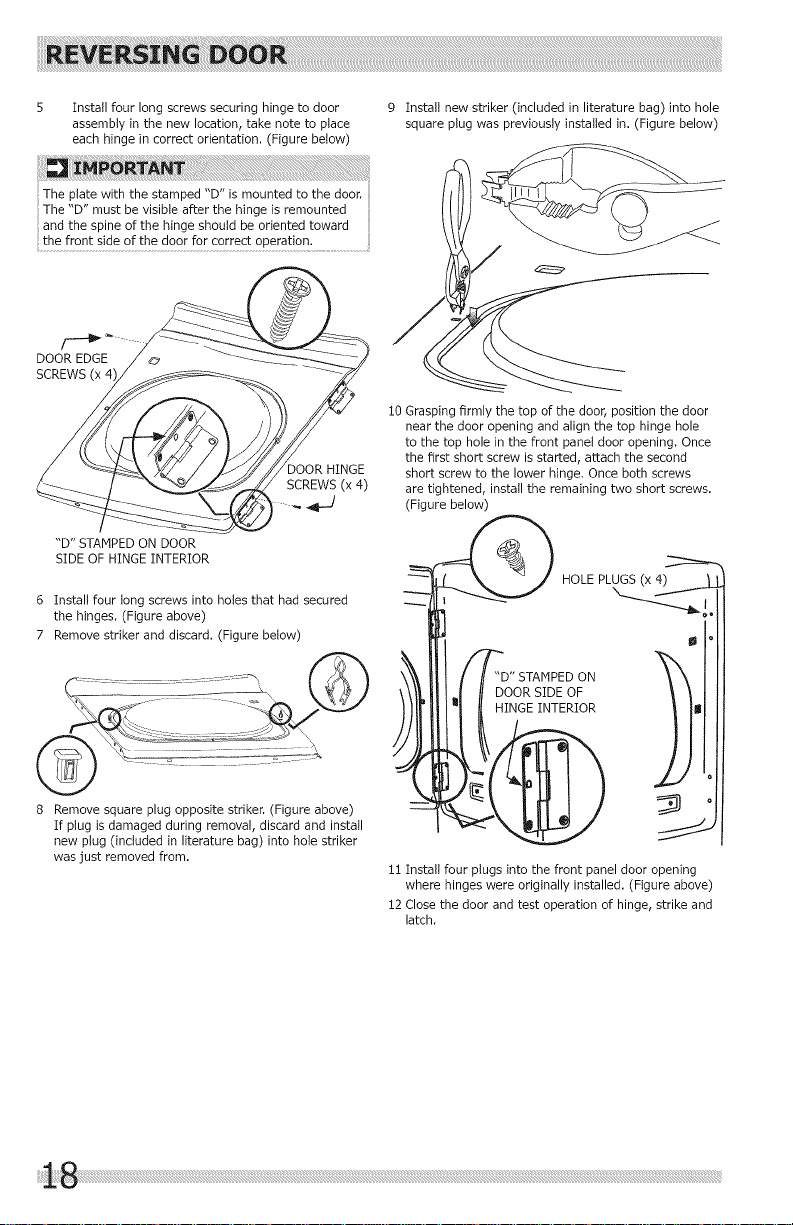

5 Installfourlongscrewssecuringhingetodoor

assemblyinthenewlocation,takenotetoplace

eachhingeincorrectorientation.(Figurebelow)

Theplatewiththestamped"D"ismountedtothedoor.

The"D"mustbevisibleafterthehingeisremounted

andthespineofthehingeshouldbeorientedtoward

thefrontsideofthedoorforcorrectoperation............

DOOREDGE

SCREWS(x4',

DOOR HINGE

SCREWS (x 4)

"D"STAMPEDONDOOR

SIDEOFHINGEINTERIOR

6 Install four long screws into holes that had secured

the hinges. (Figure above)

7 Remove striker and discard. (Figure below)

9 Install new striker (included in literature bag) into hole

square plug was previously installed in. (Figure below)

i0 Grasping firmly the top of the door, position the door

near the door opening and align the top hinge hole

to the top hole in the front panel door opening. Once

the first short screw is started, attach the second

short screw to the lower hinge. Once both screws

are tightened, install the remaining two short screws.

(Figure below)

HOLE PLUGS(x

8 Remove square plug opposite striker. (Figure above)

If plug is damaged during removal, discard and install

new plug (included in literature bag) into hole striker

was just removed from.

DOOR SIDE OF

HINGE INTERIOR

i! Install four plugs into the front panel door opening

where hinges were originally installed. (Figure above)

i2 Close the door and test operation of hinge, strike and

latch.

ON

Page 19

LP CONVERSION KIT

P/N PCK4200

Gas dryers intended for use in a location supplied with LP

must use a conversion kit prior to installation.

MOBILE HOME INSTALLATION KIT

P/N137067200

Installation in a mobile home requires the use of a

MOBILE HOME INSTALLATION KIT.

DRYING RACK (FOR USE WITH HODELS EQUIPPED

WITH MOISTURE SENSING BARS)

P/N137067300

Depending on the model you purchased, a drying rack

may have been included in the initial purchase of your

dryer. If your model did not include a drying rack or you

desire another drying rack, you may order one,

UNIVERSAL APPLIANCE WRENCH

P/N137019200

A UNIVERSAL APPLIANCE WRENCHis available to aid in

dryer/washer/pedestal feet adjustment,

TOUCH UP PAINT PENS*

Classic White Touch Up Pen - P/N 5304468812

_Other colors may be available. Contact the source where you

purchased your dryer.

Technical Sheet/Wiring Diagram:

A wiring diagram and technical data sheet are located

inside the dryer console.

To remove the console faceplate follow the directions

below:

1. Disconnect dryer from electrical source.

2. Remove the two screws toward the top on the back of

the console housing.

3. Insert a small screw driver through each hole on the

back of the console housing and gently press inward

to disengage each upper faceplate retaining tab.

4. Gently lay the console faceplate forward to access

technical/wiring diagram.

5. When finished with repair, return sheet inside console,

ensure lower retaining tabs are in place and snap

faceplate to upper retaining tabs. Reinsert the two

screws removed earlier.

approved by) the manufacturer could result in personal

TECH DATA SHEET/

Replacement parts:

Ifreplacementspartsareneeded foryourdryer,contact

the source where you purchased your dryer or refer to

your Useand Care Guide for more information. ELECTRICAL SHOCK HAZARD

Label all wires prior to disconnection when servicing

controls. Wiring errors cancause improper and dangerous

operation. Verify proper operation after servicing.

Page 20

Page 21

TABLE DES

Mesures de s_curit6 _mportantes .................. 22-23

Extgences d'lnstallatlon ................................. 24-30

Instrucbons d'mstallabon .............................. 31-36

MATIERES

Inversion de la porte .................................... 37-38

Accessolres ..................................................... 39

Remarques ...................................................... 40

Page 22

Pourvotres_curit6,l'informationcontenueclanscesinstructionsdoit_tresuivieafinder_duirelesrisquesd'incendieou

d'explosionoupourpr_venirtesdommagesmateriels,tesblessuresoulamort.Vousnedeveznientreposer,niutiliser

d%ssenceoud'autreSvapeursou!!quides!nfiammab!es_Rrgx!m!t_dece!appare!!oudetoutautreappare!!_lectrom_nager.

A AVERTISSEMENT

RISq D'I E

Lisez toutes les instructions de s_curit_ suivantes avant d'instalter et d'utiliser votre appareil :

• D_truisez le carton d'emballage et les sacs enplastique apr6s avoir dSball_ I'appareil. Les enfants pourraient les utile

ser pourjouer. Le carton recouvert de tapis, lescouvertures et lesfeuilles de plastique peuvent _tre 6tanches 5 Fair et

provoquer la suffocation. DSposeztousles matSriauxd'emballage dans un conteneur 5 dSchetsou faites en sorte que les

enfants ne puissent y avoir acc6s.

L'installation et I'entretien de cette s_cheuse doivent _tre r6alis_s par un instaltateur qualifi_, un technicien de

service ou le fournisseur de gaz.

Instaltez t'appareil conform_ment aux instructions du fabricant et aux codes Iocaux.

[_'installation _tectrique de la s_cheuse doit _tre conforme aux codes et aux rSglements Iocaux ainsi qu% ta toute

derni6re _dition du National Electrical Code (ANSI/NFPA 70), ou au Canada, au Code canadien de 1'61ectricit_

(C22.!, article i).

• [_'installation de gaz de ta s_cheuse dolt _tre conforme aux codes et aux r@glements tocaux ainsi qu% la route

derni@re_dition du Fuel Gas Code (ANSI Z223.:!), ou au Canada, au CAN/ACG B149.:!-2000. Un robinet d'arr%t

manuel distinct dolt @treinstalt_ 5 moins de !,83 m (6 pi) de la s@cheuseconform_ment au National Fuel Gas

Code, ANSI Z223.1/NFPA 54.

• La s@cheuseest ctass@e,envertu des r_glements ANSI Z 21.5.1 ou ANSI/UL 2158 - CAN/CSA C22.2 N° 112

(derni%resversions), pour un USAGEDOMESTIQUE uniquement. II n'est pas recommand_ d'utiliser cette s_cheuse

pour des usages commerciaux, comme des restaurants, des salons de coiffure, etc.

• N'installez pas une s_cheuse avec du mat@riel d'_vacuation en plastique ou en feuille m_taltique flexible. Le mat@-

riel de ventilation flexible peut s'_craser facilement et emprisonner la charpie. Ces conditions nuiraient 5 l'_coule-

merit d'air de votre s@cheuseet pourraient accro_tre le risque d'incendie.

• Les instructions comprises dans ce guide et route autre documentation fournie avec cet appareil ne sont pas

congues pour couvrir toutes les @ventualit@sou situations qui pourraient survenir. Vous DEVEZ faire preuve de bon

sens et de prudence durant I'installation, l'utilisation et l'entretien de tout appareil m@nager.

QUE FAIRE SI VOUS Dt_TECTEZ UNE ODEUR DE GAZ :

Ne mettez pas d'appareil en marche.

Ne touchez 5 aucun commutateur _lectrique; n'utilisez

aucun t_t_phone de votre domicile.

Evacuez ta piece, le bStiment ou ta zone touch_e.

En utilisant te t_l_phone d'un voisin, appetez immediate-

merit te fournisseur de gaz. Suivez ses instructions.

Sivous ne pouvez joindre votre fournisseur de gaz,

appelez les pompiers.

Pour #viter les blessures au dos ou d'autres types

de blessure, demandez l'aide d'autres personnes

pour d6placer ou soulever Ia s6cheuse.

Conservez ces instructions pour vous

y reporter uit rieurement,

Exigences avant I'installation

Outils et materiel n_cessaires &I'installation :

• Pince r#glable

• Tournevis Phillips _ pointe plate et

pointe carrie

• Cl_ _ molette

, Cl#_ tuyau pour I'atimentation en gaz

• Ruban _ filetage r_sistant au GPL

(pour I'alimentation en gaz naturet

ou en GPL)

Niveau de charpentier • Robinet d'arr_t pour conduite de

Event ext6rieur gaz (s6cheuse 5 gaz)

Conduit d'_vacuation de i02 mm (4 _ Deux raccords-unions 5 6vasement

po) en m_tal rigide ou semi-rigide de U2 po (i,3 cm) NPT et une

Ensemble pour cordon d'alimenta- gaz (s6cheuse 5 gaz)

tion de 240 V _ 3 ou 4 ills (s_cheu-

se _lectrique) • Ruban m_tallique (et non du ruban

Collier de 10,2 cm (4 po)

conduite flexible d'alimentation en

conduits)

Page 23

Veuitteztirecesinstructionsaucompletavantd'utiliser

les4cheuse.

Sachez reconnaitre lee symboles, les

avertissemen_s et les _tiquettes de

s_curit_.

Les mesures de s4curit4 pr_sent_es dans ce guide sont

identifi_es par te mot AVERTISSEHENT ou A_q-ENTION

selon le type de risque pr4sent_ ci-dessous.

D4finitions

Voici le symbole d'avertissement concemant la

s_curit_. II est utilis_ pour vous avertir des risques de

blessures potentiels. Respectez tous tes messages qui

suivent ce symbole afin de pr4venir les blessures ou la

mort.

La mention DANGER indique un risque imminent qui

causera la mort ou de graves blessures, s'il n'est pas

La mention AVERTISSEMENTindique une situation

potentietlement dangereuse qui, si elle n'est pas _vit_e,

situation potentiellement dangereuse susceptible de

causer des blessures mineures ou moyennement graves

sie!len%stpas_V!t_e..........................................................................................................

Conduit d'dvacuation

Lair circule librement, il n'y a aucune

accumulation de cbarpie

Le conduit rigide ou semi-rigide de 102 mm (4

po) est le plus court et te plus direct possible

[I n'y a AUCUN mat4riel de ventilation en papier

d'aluminium ou en plastique

Le syst4me d'_chappement dolt 4vacuer l'air a

I'ext4rieur a I'aide d'un 4vent approuve

Hise _ niveau

La s4cheuse est au niveau lat_ralement et de

I'avant vers l'arri_re

IZi Leequatre coins de la caisse reposent

fermement sur le plancber

Alimentationau gaz(sdcheuseaugaz)

lZi Le conduit d'alimentation comporte un robinet

d'arr&t manuel

lZi Tous lee raccords sont 4tancb4ifi4s 5 I'aide de

joints certifi4s serr4s avec une cl4

lZi N4cessaire de conversion pour syst_me au GPL

I_ L'alimentation en gaz est ouverte

r] Aucun raccord ne pr4sente de fuite -

v4rifiez 5 t'aide d'eau savonneuse, ne faites

]AHA_S cette v4rification avec une flamme

Alirnentation 41ectrique de 240 V (sdch, _lect)

lZi Le cordon d'alimentation est certifi4 NEHA i0-

30R ou i4-30R et it fix4 solidement avec routes

les vie clans le bornier

IZi Un r4ducteur de tension certifi4 est install4

IZi Le couvre-borne est install4 avant la premiere

mise en marche

:Inversion de la porte

iS1 Suivez tee instructions d4taiil_es contenues dane

ce guide

V4rifiez que la charni&re et le loquet

fonctionnent correctement

Alimentation en 41ectricit4

Le syst&me 41ectrique de la maison est sous

tension

IZi La s4cheuse est brancb4e

Vdrifications finales

Vous avez tu enti_rement tes instructions

d'instaiiation et le Guide d'utiiisation et

d'entretien

La porte se verrouilte et te tambour tourne

Iorsqu'un cycle d4marre

151 La carte d'enregistrement est envoy_e

Page 24

Exigences _lectriques de ia s_cheuse _lectrique:

CIRCUIT - Circuit ind_pendant de 30 amperes avec fusible temporis_ ou disjoncteur de 30 A, Utilisez des circuits

ind_pendants pour la laveuse et ta s_cheuse. NE BRANCHEZ PAS la laveuse et ta s_cheuse sur le m_me circuit.

ALIMENTATION teLECTRIQUE - C_ble monophas_ _ trois ou quatre ills, 240 volts, 60 Hz; courant altematifl

terre par le fit d'alimentation neutre.

PRISE - Prise NEMA I0-30R ou NEMA 14-30R situ_e de mani&re _ permettre I'acc&s au cordon d'alimentation Iorsque

ta s_cheuse est _ sa position de fonctionnement.

CONNEXION DE HISE A LA TERRE - Consuttez la rubrique <<Exigences de raise _ la terre >>dans la section

d'installation _lectrique,

TROUSSEDECORDON D'ALIMENTATION,_TROIS FILS

(non fournie)

Prise _ 3 alv&oles

(NEMA type 10-30R)

La s#cheuse DOIT utiliser un cordon d'alimentation

trois ills NEMA !0-30 de type SRDT d'une capacit# de

240 volts (c.a.) et d'au moins 30 amperes, avec trois

connecteurs ouverts embrochables avec extr#mit_s

renvers#es, ou connecteurs _ boucle ferm#e,

sp_cialement indiqu_s pour une utitisation avec une

s_cheuse. Pour les instructions de raccordement du

cordon _ 3 ills, consultez ia section CONNEXIONS

12LECTRIQUES POUR UN SYSTEME _, TROIS FILS.

TROUSSEDE CORDON D'ALIMENTATION ,_ QUATRE FILS

(non fournie)

Prise _ 4 alv&oles

(NEMA type 14-30R)

La s#cheuse DOIT utiliser un cordon d'alimentation

quatre ills NEMA i4-30 de type SRDT d'une capacit#

de 240 volts (c.a.) et d'au moins 30 amperes,

avec quatre connecteurs ouverts embrochables

avec extr#mit#s renvers#es, ou connecteurs

boucle ferm#e, sp_cialement indiqu#s pour une

utilisation avec une s#cheuse. Pour tes instructions

de raccordement du cordon _ quatre ills, consultez

la section CONNEXIONS teLECTRIQUES POUR UN

SYSTEME A QUATRE FILS.

Les s_cheuses destinies _ la vente au Canada sont

munies d'un cordon d'alimentation _ 4 fits (NEMA 14-

30R).

Page 25

E×igences _lectriques de la s_cheuse gaz

CIRCUIT - Circuit ind#pendant de i5 amp6res, polaris_

et mis _ la terre, avec fusible temporis# ou disjoncteur

de i5 A.

ALINENTATION I_LECTRIQUE- C_ble monophas_ _ deux

flls mis _ la terre, i20 volts, 60 Hz; courant alternatif,

CORDON D'ALINENTATION - La s_cheuse est dot#e d'un

cordon d'alimentation de i20 volts _ trois fils,

CONNEXION DE MISE A LATERRE - Consuttez la rubrique

<<Exigences de raise _ la terre >>dans la section

d'instaltation _lectrique,

Exigences relatives & I'alimentatiom en gaz

Un tuyau en cuivre sans rev&tement se corrode Iorsqu'il

entre en contact avec le gaz naturel, entra_nant des

fuites, Utilisez SEULEMENT des tuyaux en fer noir, en

acier inoxydable ou encore en cuivre avec rev&tement

i L'instaltation DOlT @tre conforme aux codes

2 Le tuyau d'alimentation en gaz dolt &tre d'un

3 Si les codes le permettent, un tuyau m@tallique

RISQUE D'EXPLOSION

Iocaux ou au code national sur te combustible,

ANSI Z223.! (derni@re version), s'il n'existe pas de

codes Iocaux.

diam&tre int_rieur de !,27 cm (!/2 po).

flexible peut @tre utilis_ pour raccorder votre

s@cheuse au tuyau d'alimentation en gaz. Le tuyau

DOIT @tre fabriqu_ en acier inoxydable ou en laiton

avec rev@tement en plastique.

Prisemurale avec

raise & la terre

iN/_ecoupez pas, n,enleve,_

,_ pas et ne mettez pas hors I

8circuit labroche de raise /

pm_ la terre de cette fiche. )

Cordon 61ectrk_uemuni _

d'unefiche _troisbroches_

ave=raise_la terre _,%

4 Le tuyau d'alimentation en gaz DOlT @tre muni d'un

robinet d'arr&t distinct conform_ment & la norme

B!49.!, Code d'installation du gaz naturel et du

propane.

5 Un orifice taraud@ de 0,32 cm (i/8 po) bouch_,

accessible pour le branchement de la jauge d'essai,

DOlT @tre install@ directement en amont du

branchement du tuyau d'alimentation en gaz avec

la s_cheuse.

6 Cette s_cheuse DOlT @tre d@branch_e de ta

canalisation de gaz pendant toute v@rification de

pression de la canalisation de gaz _ des pressions

sup_rieures & 3,45 kPa (!/2 tb/po2).

7 Cette s_cheuse DOlT @tre isol_e de la canalisation

de gaz pendant toute v@rification de pression de

la canalisation de gaz _ des pressions @gales ou

inf@rieures _ 3,45 kPa (i/2 Ib/po2).

8 Les branchements d'alimentation en gaz doivent

&tre conformes _ ta norme Connectors for Gas

Appliances (Raccords pour appareils au gaz) ANSI

Z21,24.

Page 26

E×igences du syst_rne d'_vacuation

Utilisez seutement des conduites m_taltiques rigides ou

flexibles d'au moins 10,2 cm (4 po) de diam&tre, et une

bouche d'_vacuation qui poss&de un ou des volets qui

s'ouvrent lorsque I'appareit est en fonction. Lorsque la

s_cheuse s'arr@te, les volets se ferment automatiquement

pour emp@cher les infiltrations d'air, d'insectes et de

rongeurs. Pour _viter de bloquer la sortie, gardez un

espace minimal de 30,5 cm (i2 po) entre le bas de la

bouche d'_vacuation et le sol ou toute autre obstruction.

Le non-respect de ces instructions pourrait augmenter

d_mesur_ment tes temps de s_chage et entra_ner des

risques d'incendie.

Vous trouverez ci-dessous les exigences pour l'uti =

lisation adequate et s_curitaire de votre appareiL

Iii__________________________!___;___Ji;;;;_?i iii¸

Correct

N'installez pas une s6cheuse avec du mat_riet

d'_vacuation en plastique ou en feuille m6tallique

flexible. Le materiel de ventilation flexible peut

s'_craser facilement et emprisonner la charpie. Ces

conditions nuiraient _ I'_coutement d'air de votre

s_cheuse et pourraient accro_tre te risque d'incendie.

Si votre syst&me actuel utilise une conduite en plastique

ou en feuille m_taltique, remplacez-la par une conduite

m_taltique rigide ou semi-rigide. De plus, assurez-vous

que la conduite en place est tibre de charpie avant

d'installer la conduite de s_cheuse.

RISQUE D'INCENDIE

incorrect

Page 27

E×igences de systb_e d°_vacuation (suite)

Une s6cheuse doit _tre _vacu6e vers Fext_rieur.

N'_vacuez pas une s_cheuse dans une chemin6e, un

mur, un plafond, un grenier, un vide sanitaire ou dans

tout espace dos d'un b_timent. La s_cheuse produit

de la charpie inflammable1 Si la s6cheuse n'est pas

6vacu6e vers I'ext_rieur, de la charpie pourrait _tre

6vacu6e dans I'aire de buanderie. L'accumulation de

charpie dans toute piece de ta maison peut entra_ner

des risques pour la sant_ et des risques d'incendie.

La s_cheuse dolt &tre branch_e _ une _vacuation

ext_rieure. Inspectez r6guti6rement Fouverture de

I'_vacuation ext_rieure et retirez toute accumulation de

charpie pr6s de Fouverture et de la r_gion avoisinante.

RISQUE D'INCENDIE

• Ne laissez pas de mati_re combustible (par

exemple : des v_tements, des rideaux, du papier)

entrer en contact avec le syst_me d'_vacuation.

La s_cheuse NE DOIT PAS_tre _vacu_e clans une

chemin_e, un mur, un plafond, ou dans tout espace

confin_ d'un b_timent qui pourrait accumuter la

charpie, entrainant un risque d'incendie.

• Ne placez pas degrillage _ I'extr_mit_ du syst_me

d'_vacuation, ni de vis, de rivet ou autre fixation

de mani&re _ ce qu'its se prolongent dans la

conduite du syst&me d'_vacuation. De la charpie

pourrait s'accumuter sur te grillage, les vis ou

les rivets, et obstruer 1'6coulement d'air dans

le syst&me, entrainant un risque d'incendie et

I'augmentation des temps de s6chage. Utilisez

une bouche d'_vacuation approuv_e pour terminer

la conduite _ t'ext_rieur, et scellez tousles joints

avec du ruban m_tallique. Toutes les extr_mit_s

m_les des conduites doivent &tre instalt_es en aval

ii

relativement au sensde I'_coulement d'air.

Le fait de d6passer la Iongueur de conduites ou te

:: ::nombre de coudes indiqu6s dans les tableaux de

<<LONGUEURMAXIMALE >>peut entrainer l'accumutation

de charpie clans le syst6me. Toute obstruction au

:: ::syst6me d'6vacuation peut entra_nerun risque

::d'incendie, en plus d'accro_tre le temps de s6chage.

LONGUEUR MAXIMALE

o_ pour le conduit en m_tal rigide de 10,2 cm (4 po)

9 TYPE DE BOUCHE D'EVACUATION

o-

0 19,5 m (64 pi) 14,6 m (48 pi)

1 15.9 m (52 pi) 12,2 m (40 pi)

2 13.5 m (44 pi) 9.8 m (32 pi)

3 11 m (36 pi) 7.3 m (24 pi)

4 9.5 m (28 pi) 4,9 m (16 pi)

(De pr_f6rence)

10 cm 6.5 cm

(4 po) _, volets (2.5 po)

* N'installez pas de materiel de ventilation en

plastique ou en aluminium flexible.

. Si vous installez du materiel de ventilation semi-

rigide, il est n_cessaire que la tongueur du conduit

soit _gale ou inf_rieure _ 2,4 m (8 pi),

Page 28

E×igences de syst_rne d'_vacuation (suite)

InstaHez les raccords m_les clans le bon sens :

CORRECT iNCORRECT

Pour une installation o3 le syst#me d'#vacuation n'est pas

d_crit dans tes tableaux, ta m_thode suivante doit _tre

utilis_e pour v#rifier la conformit# du syst_me :

1 Branchez un manom_tre 5 tube inclin_ ou un

manom_tre num#rique entre la s_cheuse et te point

o3 I'#vacuation est raccord_e 5 la s#cheuse.

2 R_glez la minuterie de la s_cheuse, ta temperature

duvetage (refroidissement), et mettez l'appareil

en fonction,

3 Relevez te r_suttat du manom_tre,

4 La contre-pression du syst#me NE DOIT PAS _tre

sup#rieure 5 19 mm (0.75 po) de colonne d'eau,

Si la contre-pression du syst_me est inf_rieure

19 mm (0,75 po) de colonne d'eau, te syst&me

est conforme. Si la lecture du manom_tre indique

une colonne d'eau sup_rieure 5 19 mm (0.75 po),

le syst_me est trop restreignant et n'est pas

conforme.

Bien que t'orientation verticale du syst_me d'#vacuation

soit acceptable, certaines circonstances pourraient influer

sur le rendement de t'appareil,

Seule une conduite m#tallique rigide doit _tre

utilis_e,

L'#vacuation verticale par le toit peut entra_ner

le ph_nom_ne de contre-tirage, ce qui accro_t la

restriction du syst_me d'_vacuation.

L'acheminement de la conduite d'_vacuation

dans un endroit non isol_ peut entra_ner de la

condensation et I'accumulation plus rapide de

charpie.

Le fait de comprimer ou de pincer le syst&me

d'_vacuation entra_nera t'augmentation de la

restriction dans te syst_me.

Le syst&me d'#vacuation doit _tre inspect# et

v#rifi# au moins tous les 18 mois avec un usage

normal. Plus I'appareil est utilis_, plus ta p_riode

de v#rification du syst_me et de la bouche

d'_vacuation doit _tre raccourcie,

Direction d'_vacuation

II est possible de diriger t'_vacuation en posant un coude

de 90° _ courbe immediate directement _ la sortie

d'6vacuation de la s_cheuse. Les coudes pour 6vacuation

de s6cheuse sont disponibles aupr&s du distributeur de

pi&ces de votre r6gion ou _ la quincaillerie.

Consultez #galement ta section EXIGENCES DE

DEGAGEHENT _ la page suivante,

L'utilisation d'un coude

90° _ courbe immediate

est n_cessaire pour

r_pondre aux exigences

de profondeur minimale

de la s_cheuse autonome.

Page 29

Installation darts une maison usin_e ou mobile

1 [_'installation DOIT _tre conforme _ ta norme

Manufactured Home Construction and Safety

Standard, titre 24 CFR, article 32-80 (anciennement

d_sign_e comme la Federal Standard for Mobile

Home Construction and Safety, titre 24, HUD,

article 280) ou _ la norme CAN/CSAZ240 MH.

2 La s_cheuse DOIT _tre _vacu_e vers I'ext_rieur

(_ I'air tibre et non sous la maison mobile) avec

une gaine m_tallique ininflammable. La conduite

m_taltique dolt poss_der un diam&tre de 10,!6 cm

(4 po) et ne contenir aucune obstruction. De

preference, utitisez une conduite m_taltique rigide.

3 Si la s_cheuse est _vacu_e par le plancher et que

I'espace sous la maison mobile est cloisonne, le

syst&me d'_vacuation DOIT se terminer _ I'ext_rieur

de la cloison et _tre fix6 solidement _ la structure

de la maison.

4 Reportez-vous aux sections pr6c_dentes de

ce guide retativement aux autres exigences

d'6vacuation importantes.

5 Lors de I'installation d'une s_cheuse _ gaz dans

une maison mobile, des dispositions doivent _tre

prises pour permettre t'entr_e d'air d'appoint de

l'ext_rieur. Cette installation ne dolt pas mesurer

moins de deux lois la surface de la bouche

d'6vacuation.

6 L'installateur DOIT ancrer cette s_cheuse au sol

avec une trousse d'installation de maison mobile,

n° de piece 137067200.

Installation darts un Endroit en Retrait ou une Armoire

1 Une s#cheuse instalt#e dans une chambre

coucher, une salte de bains, un renfoncement ou un

placard DOIT _tre #vacu#e vers I'ext_rieur.

2 Aucun autre appareil _ combustion ne doit &tre

install# dans le m_me placard que la s_cheuse.

3 Votre s_cheuse a besoin d'espace pour assurer une

ventilation ad#quate.

N'INSTALLEZ PAS votre s#cheuse dans un placard muni

d'une porte pleine

a, Porte de placard assurant une ventilation requise :

Une ouverture d'au moins 774,2 cm2 (120 po2),

divis#e #galement au-dessus et au-dessous de

la porte, est requise. Les ouvertures doivent _tre

situ_es _ 7,6 cm (3 po) du haut et du bas de la

porte. Les ouvertures ne doivent pas _tre obstru_es

Iorsqu'une porte est instalt_e. Une porte

persiennes dont les ouvertures sur I'ensemble de la

porte sont _quivalentes aux recommandations peut

&tre utilis_e.

Page 30

Exigences de d_gagement

N'INSTALLEZ PAS VOTRE SECHEUSE :

:t A un endroit expos_ aux &oulements d'eau

ou aux alias des conditions m@_oro!ogiques

ext_rieures.

2 A un endroit o0 elle entrera en contact avec

des rideaux ou tout autre objet qui nuirait

I'_coutement de I'air de combustion ou de

ventilation.

3 Sur un tapis, Le plancher DOIT &tre solide et

presenter une pente inf_rieure _ 2,5 cm (i po).

DEGAGEMENTS MINIMAUX - Pouces (Centim&tres)

C6TES ARRIERE DESSUS AVANT

AIc6ve O" (0 cm) O" (O cm)* 23" (58.5 cm) n/a

Placard 0" (0 cm) 0" (0 cm)* 23" (58,5 cm) 1" (2.5 cm)

Pour toute installation autre qu'une _vacuation

directe, un coude de 90° _ courbe immediate dolt

@tre utilis_ pour respecter I'exigence de 0 cm (0 po),

o....

(0 cm) (00cm)

1" 0"

(2.5 cm) (0 cm)

N'installezpas la s&heuse i_o_ de l'essenceou autres

RISQUED;EXPLosioN

mati_res inflammables sont entrepos_es. Si la s_cheuse

est instalt_e dans un garage, elle dolt 6tre plac6e au

moins _ 45,7 cm (!8 po) du sol, Le non-respect de cette

recommandation peut entra_ner un choc _tectrique, une

explosion,unincendieoum_melatoo..

Dimensions de S_cheuse

I_ 2T' (68,5 era)

38.5"

(98 cm)

42.5"

(108 cm)

(9.s0_)"'-_1_

Duc6t@jusqu'au

centrede I'@ventarri@re

LonguecN du co_do_ d'alimentation de la s&heuse & ciaz, environ _52,S cm (6O po)

gaz _ rarriere de

Alimentation en

I'appareil & gaz

(34,5 cm)

AEimentation

@tectrique

rarn&re de la

_@cheuse _

....

Hauteur de la

ligne centra_e

de r@vent ard&re

Pour obtenir une installation avec un d_gagement

de 0 cm (0 po) _ t'arri&re de ta s_cheuse (pour une

installation autre qu'avec une sortie directe), un coude

de 90° _ courbe immediate dolt &tre install6, comme il

est d6crit pr_c6demment dans ce guide.

_(9 !5?c'm) P{ancher

50" (127 cm)

29"(73,5 cm)

Jorsqu'eHe estferm@e

po_e

ii!i!i!3 i!0 ........................................................................................................................................................................................................................................................................................................................................................................................................................................................iill

Page 31

Installation _lectrique

Vous trouverez ci-dessous les exigences pour t'installation

#lectl,ique ad#quate et s#cul,itaire de votre appareit. Le

non-l,espect de ces instructions poul,rait entra_ner le

risque de choc ou d'incendie.

RISQUE DE CHOC ELECTRIQUE al,rach# de t'appareil ou coup# pal, tout mouvement,

Cet appal,eil DOIT &tl,e ad#quatement mis _ la ce qui entra_nerait un risque de choc #lectrique.

ii i.

tel're. La mise _ la tel're inad#quate de la s_cheuse _ N'utilisez pas une prise avec c_blage en aluminium

• Un r#ducteul, de tension certifi# UL doit &tre install#

sul, te cordon d'alimentation. Site r#ducteur de

tension n'est pas installS, le cordon peut &tre

pourl,aitentl,a_nel,desl,:squesdechoc_lectl,ique. aveconcordond'alimentationetuneficheavecfils

Suivez les instructions de ce guide pour une mise _ en cuivl,e (ou I'invel,se). Une l,_action chimique se

ta tel're ad#quate, pl,oduit entre I'aluminium et le cuivre, ce qui pourrait

N'utilisez pas de rallonge avec cet appal,eil. Certains entra_ner un court-circuit. It faut utiliser un cordon,

ii_i"

cordons pl,o!ongateul,s ne sont pas con_us pour ....................................................................................................................................................................................

la quantit_ de coul,ant #lectrique utitis# pal, cette

s_cheuse et pourl,aient fondre, entl,a_nant des

risques de choc _lectl,ique ou d'incendie. Placez la

s_cheuse _ une distance de la prise convenant _ .... Les s_cheuses aliment_es pal, une tension de 208 V

la tongueul, de la l,allonge, pel,mettant d'installel, la poss#deront des temps de s#chage plus longs qu'une

rallongeI_chement.Reportez-vousauxexigencesde s_cheuseatimentaeparunetensionde240V.

pr_instaltation de ce guide pour savoir quel cordon

: d'atimentation acheter.

E×igences de raise & la terre - S_cheuse _lectrique (E,-U,)

une fiche et une prise avec des ills en cuivre.

:Un raccordement inad_quat du conducteur de mise _ la

terl,e de I'_quipement peut accro_tl,e les risques de choc

_lectrique. En cas de doute quant _ la mise _ la terre

de I'appareit, consultez un _lectricien quatifi_.

Pour une s_cheuse avec cordon, mise _ la tel,re :

:1. Cet appareit DOIT _tre mis _ la terl,el En cas de

mauvais fonctionnement ou de panne, la mise

la terl,e diminue les risques de choc _tectrique en

fournissant au courant _lectl,ique une trajectoire de

moindl,e r_sistance.

2 Apr_s I'achat et I'instaltation d'un cordon

d'alimentation _ 3 ou 4 ills dot_ d'un fil de mise

la tel're et d'une fiche de mise _ la terre qui

correspond & votre syst@me de c_blage, la fiche

DOIT @tre branch@e dans un r@ceptacle cuivr@

install@ et mis _ la terre conform@ment aux codes

et r@glements locaux. En cas de doute, faites appel

un @lectricien qualifi@.

NE MODIFIEZ PAS ta fiche fournie avec cet

appareil. Si elle ne s'ins@re pas dans la prise,

demandez _ un @lectricien qualifi@ d'installer la

prise adapt_e.

Pour

une s_cheuse avec branchement permanent :

1

La s_cheuse DOIT _tre branch_e _ un syst&me de

c_bles m_taltiques permanents mis _ la terre; ou un

conducteur de mise _ la terre dolt &tre install_ avec

les conducteurs de circuit et branch_ _ la borne ou

au fil de mise _ la terre de l'appareil.

Page 32

E×igences de raise & la terre =S_cheuse _lectrique (Canada)

2 Puisque votre appareit est muni d'un cordon

d'alimentation avec filet fiche de raise _ la terre,

Un raccordement inad6quat du conducteur de raise _ la terre

de J'6quipement peut accroTtre Jes risques de choc _Jectrique.

En cas de doute quant _ la raise _ la terre de I'appareiJ,

consuJtez un 61ectricien quaJifi6.

Pour une s_cheuse avec cordon, mise _ la terre :

1 Cet appareil DOIT _tre mis _ ta terre. En cas de

mauvais fonctionnement ou de panne, ta raise

la terre diminue les risques de choc _lectrique en

fournissant au courant _lectrique une trajectoire de

moindre r_sistance.

la fiche dolt _tre branch_e dans un r_ceptacle

install_ et mis _ la terre conform_ment aux codes

et r&glements locaux. En cas de doute, faites appel

un _lectricien qualifi_.

3 NE IqODIFIEZ PASta fiche fournie avec cet

appareil. Si elle ne s'ins_re pas dans la prise,

demandez _ un _lectricien qualifi_ d'installer la

prise adapt_e.

Exigences de raise _ la terre =S_cheuse _ gaz (E,=U. et Canada)

1 Cet appareit est muni d'une fiche _ trois broches

(raise _ la terre) pour assurer votre protection

contre les chocs _tectriques, Cette fiche doit &tre

branch_e directement dans une prise _ trois

alv_oles correctement raise _ ta terre.

2 La fiche dolt _tre branch_e dans un r_ceptacle

install6 et mis _ la terre conform_ment aux codes

et r&glements Iocaux, En cas de doute, faites appel

un _lectricien qualifi_.

3 NE IqODIFIEZ PASta fiche fournie avec cet

appareit. Si etle ne s'ins&re pas dans la prise,

demandez _ un 61ectricien quaiifi6 d'installer la

prise adapt_e.

Prise murale avec

raise _ la terre

jpas et ne mettez pas hors

._ circuit la broche de mise

(N.... pez pas, n'enleve_

rre de cette fiche.,

Page 33

Connexion de gaz

1 Retirez te capuchon d'exp_dition de la conduite de

gaz _ i'arri&re de !'appareil.

NE RACCORDEZPAS la s_cheuse _ une alimentation

en propane liquide sans avoir pr_alablement converti la

soupape de gaz. Le n_cessaire de conversion au propane

!!qu!de doit _tre !nsta!!_ par un techn!den qua!!fi_ ................................

2 Branchez un tuyau semi-rigide ou approuv_ d'un

diam&tre int_rieur de 1,27 cm (1/2 po) de la

conduite d'alimentation de gaz au tuyau de 0,96 cm

(3/8 po) situ_ _ t'arri&re de I'appareil. Utilisez un

r6ducteur de 1,27 cm _ 0,96 cm (1/2 po _ 3/8 po)

pour effectuer te raccordement. Utilisez du ruban

d'_tanch_it_ r6sistant _ I'action corrosive des gaz

I'_tat liquide _ chaque raccord.

ECOULEMENT

Robinet Raccord- _ Raccord-

d'arr_t union _ union

manuel _vasement _vasement

DU GAZ

30uvrez le robinet d'arr_t dans la conduite

d'alimentation de gaz pour permettre au gaz de

s'_couler dana te tuyau. Attendez quetques minutes

pour que le gaz s'_coule dana la conduite.

Robinet d'arr_t

en position ouverte

4 V_rifiez le syst_me avec un manom&tre pour

d_celer toute fuite. Si vous n'avez pas de

manom&tre, v_rifiez tes raccords en appliquant de

I'eau savonneuse sur les connexions.

flexible raccord_ _ I'arri_re

Tous les raccords doivent _tre serr_s au moyen d'une el&

de la s_cheuse

La conduite d'atimentation dolt &tre munie d'un robinet

d'arr_t approuv_. Ce robinet dolt &tre situ_ dana la

m&me piece que la s_cheuse et plac_ de mani_re

&tre facilement accessible. Ne bloquez pas I'acc_s au

robinet d'arr&t de t'atimentation de gaz.

Nev_rifiez ]AMAIS la presencede fuites _ I'aided'une

flamme nue.

Page 34

Connexion_lectrique(saufau Canada) = cordon & 3 ills

Prise _ 3 alv_oles

(NEMA type 10-30R)

Le fair de ne pas d#brancher t'appareil de sa source

d'alimentation en #lectricit# avant son entretien peut

causer des blessures, voire la mort.

1 Coupez I'alimentation _ la prise.

2 Retirez ta vis qui fixe le couvercle d'acc&s du bornier

darts le coin inf_rieur du dos de la s_cheuse.

3 [nstallez un r_ducteur de tension certifi6 UL

conform_ment aux instructions du fabricant de

cordon d'alimentation ou de r6ducteur de tension

darts I'orifice de cordon d'alimentation sous te

panneau d'acc_s./_ ce moment, te r6ducteur de

tension devrait &tre instatt_ l_chement,

4 Passezun cordon de 30 A certifi_ UL NENA 10-30

de type SRDT,NON BRANCHIa,dans le r6ducteur de

tension.

5 Fixez tefil neutre du cordon d'alimentation (ill du

centre) _ ta borne centrale ARGENT du bornier.

Serrez bien tavis.

6 Fixez tesdeux autres ills aux bornes externes en

LAITON du bornier. Serrez bien les deux vis.

Si une vis de borne tombe pendant l'installation du

F[] 1

LAITON)

LAITON)

N'effectuez pas de courbe soudaine, et ne pincez pas le

c_blage ou les conducteurs aux connexions.

7 Suivez tesconsignes du fabricant pour fixer

solidement le r_ducteur de tension et le cordon

d'alimentation.

8 R_installez le couvercle du panneau d'acc6s au

bornier.

Si vous passez d'un syst&me 5 quatre ills 5 un syst&me

trois ills, d_placez le fil de mise 5 ta terre interne de

la borne centrate du bornier 5 la vis VERTE5 c6t_ du

bornier.

N'ENLEVEZ PAS la raise

la terre interne dans neutre

un syst6me &trois ills]

Borne

Page 35

Connexion _ledcrique (sauf au Canada) - cordon & 4 fils

Prise _ 4 alv&oles

(NEMA type 14-30R)

_9--/ (Fils VERTS)

Le fait de ne pas d#brancher t'appareil de sa source

d'alimentation en #lectricit# avant son entretien peut

causer des blessures, voire la mort.

1 Coupez I'alimentation _ la prise.

2 Retirez ta vis qui fixe le couverde d'acc&s du bornier

dans le coin inf_rieur du dos de la s_cheuse.

3 [nstallez un r_ducteur de tension certifi_ UL

conform_ment aux instructions du fabricant de

cordon d'alimentation ou de r_ducteur de tension

dans I'orifice de cordon d'alimentation sous te

panneau d'acc_s. Ace moment, te r_ducteur de

tension devrait &tre instatt_ l_chement.

4 Passezun cordon de 30 A certifi_ UL NENA 14-30

de type SRDT,NON BRANCHt--',clans le r6ducteur de

tension.

5 D_branchez te fil de mise _ laterre du faisceau

_lectrique interne de la s_cheuse (BLANC)de la vis

de raise _ la terre (VERTE) pros du bornier.

6 Fixez tefil de raise _ ta terre (VERT) du cordon

d'alimentation _ la caisse avec la vis de mise _ la

terre (VERTE). Serrez bien la vis.

7 D_placezle fil de raise_ laterre du faisceau

_lectrique interne (BLANC) au bornier et fixez-te avec

le fil neutre du cordon d'aiimentation (BLANC) _ la

borne centrale ARGENTdu bornier. Serrez bien la vis.

8 Fixez tesfils ROUGEet NOIR du cordon

d'alimentation aux bornes externes en LAITON du

bornier. Serrez bien les deux vis.

Si une vis de borne tombe pendant l'installation du

cordon, elle peut &tre r_cup_r_e dans la fente de

r_cup_ration sous te panneau d'acc&s.

Darts un syst_me _ 4 ills, bi'anchez

le fil de raise & laterre interne (BLANC) ._

zsur la borne neutre (ARGENT). /

Fils neutres

(Fiis BLANCS)

Borne

neutre

N'effectuez pas de courbe soudaine, et ne pincez pas le

c_blage ou les conducteurs aux connexions.

9 Suivez lesconsignes du fabricant pour fixer

solidement le r_ducteur de tension et le cordon

d'alimentation.

10 R_installez le couvercle du panneau d'acc&s au

bornier.

Visdemise /_ i' i

BLANC

_la terreV_ _:

la re,re VERT

Page 36

Installation (g_n_rale)

1 Branchez la conduite d'6vacuation au syst_me

d'#vacuation ext_rieur L'utitisation d'un collier

(pi&ce A) de !02 mm (4 po) est recommand_e pour

raccorder ta s_cheuse au syst&me d'#vacuation.

Utilisez du ruban m_tallique pour sceller les autres

joints.

2 Utilisez un niveau _ butte pour mettre I'appareil

niveau de l'avant vers I'arri&re et lat#ralement.

3 Utilisez tacl# universelle pour ajuster tes pieds de

mise _ niveau de faqon _ ce que la laveuse soit de

niveau d'avant en arri&re et tat#ralement, et qu'elle

soit stable aux quatre coins.

4 Appuyez sur chaque coin et chaque c6t# pour

d#terminer les endroits qui n_cessitent un r#glage.

Ajustez les pieds de mise _ niveau appropri#s de

mani&re _ ce que la taveuse repose solidement

sur ses QUATRE pieds. Gardez les pieds de mise

niveau te ptus pr&s possible de ta laveuse afin

d'optimiser le rendement de la s_cheuse.

5 Branchez le cordon d'alimentation _ la prise

_lectrique mise _ la terre.

i_ i_ i i i i i i

b

60uvrez t'alimentation _lectrique au disjoncteur ou

au bottler de fusibles.

7 Reportez-vous au Guide d'utilisation et d'entretien

fourni avec la s_cheuse. II contient des

renseignements trSs utiles qui vous permettent

d'_conomiser temps et argent.

8 Pourroute question relative 5 l'utilisation initiale,

veuillez vous reporter 5 la section <<Liste de

v_rification >7de votre Guide d'utitisation et d'entretien

avant d'effectuer une demande de service.

9 Laissez ces instructions 5 proximit_ de la s_cheuse

pour vous y reporter utt_rieurement.

Un schema _tectrique et une fche technique sont

situ_s _ I'int_rieur de ta console de I'appareit.

soui!_ er

Page 37

La s_cheuse est concue de fa_on que t'ouverture de la porte puisse _tre invers6e entout temps sans pi_ces

additionnelles. L'inversion de [a porte requiert [e transfert des charni_res au c6t_ oppos_ du chassis,

i Assurezvous0u'i,yosu, sommeoi;e :: n

: avant d'inverser la porte. _ _ _

2 Vous aurez besom d'un tournews a po_nte RXSQUE BE ¢HO¢ ELECTRXQUE _, I: _\_',, _ x_ti_

carr6e n° 2, Le fait de ne pas d6brancher :":," _: _'_

3 Prot6gez la surface de travail comme ledessus 'appare de sa source "_ "_

de ta s6cheuse ou te plancher prosde ta d'alimentation en _tectricit_ avant Tournevis avec Pince

s&:heuse, avec un chiffon doux ou une serviette, son entretien peut causer des embout..... 6 no2 r6glable

4 Assurez-vous que la s6cheuse n'est pas btessures, voire ta mort.

branch6e _ une source d'atimentation!

10uvrez la porte et retirez tes quatre bouchons situ6s

darts t'ouverture de la porte oppos6e aux charni6res,

A moins d'indication contraire, conservez toutes tes

pi&ces pour tes r6utiliser plus tard, (Voir l'illustration

ci-dessous,)

Un couteau _ mastic en plastique peut s'av_rer

n6cessaire pour retirer tes bouchons. Prendre soin de La tettre<< D >>est grav_e _ t'int6rieur des charni&res