Page 1

TABLE OF

Important Safety Instructions .............................. 2-3

Installation Requirements ................................. 4_10

Installed Dryer Dimensions .................................. !1

Installation Instructions .................................. 12-17

CONTENTS

_versing Door ............... 18-2:1.

Fran_ais ............................... 23

................;!?!!!Y;iii!ii!!iiiiiiiiii)!il..........

L,,J

F_

o

3>

Page 2

For your safety the information in this manual must be followed to minimize the risk of fire or explosion or to prevent

property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

A WARNING - RISK OF FIRE

Read all of the following instructions before installing and using this appliance:

o Destroy the carton and plastic bags after the dryer is unpacked. Children might use them for play. Cartons covered

with rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Place all materials in a

garbage container or make materials inaccessible to children.

Clothes dryer installation and service must be performed by a qualified installer, service agency or the gas supplier.

Install the clothes dryer according to the manufacturer's instructions and local codes.

The electrical service to the dryer must conform with local codes and ordinances and the latest edition of the Na-

tional Electrical Code, ANSI/NFPA 70, or in Canada, the Canadian electrical code C22.1 part 1.

The gas service to the dryer must conform with local codes and ordinances and the latest edition of the National

Fuel Gas Code ANSI Z223.1, or in Canada, CAN/ACG B149.1-2000.

The dryer is designed under ANSI Z 21.5.1 or ANSI/UL 2158 - CAN/CSA C22.2 No. 112 (latest editions) for HONE

USE only. This dryer is not recommended for commercial applications such as restaurants, beauty salons, etc.

Do not install a clothes dryer with flexible plastic venting material. Flexible venting materials are known to collapse,

be easily crushed and trap lint. These conditions will obstruct clothes dryer airflow and increase the risk of fire.

Do not stack a dryer on top of washer already installed on pedestal. Do not stack washer on top of dryer. Do not

stack washer on top of another washer.

The instructions in this manual and all other literature included with this dryer are not meant to cover every pos-

sible condition and situation that may occur. Good safe practice and caution MUST be applied when installing,

operating and maintaining any appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Save these instructions for future reference.

Pre-Installation Requirements

Tools and materials needed for installation:

Adjustable pliers

Phillips, straight, & square bit

screwd rivers

Adjustable wrench

Pipe wrench for gas supply (gas

dryer)

LP-resistant thread tape (for natu-

ral gas or LP supply, gas dryer)

Carpenter's level

External vent hood

4-inch (102 mm), rigid metal or

semi-rigid metal exhaust duct work

3-wire or 4-wire 240 volt cord kit

(electric dryer)

4 in. (10.2 cm) clamp

Gas line shutoff valve (gas dryer)

1/2NPT union flare adapters (x2)

and flexible gas supply line (gas

dryer)

Metal foil tape (not duct tape)

Page 3

Pleasereadallinstructionsbeforeusingthisdryer.

Recognize safety symbols, words and

labels

Safety items throughout this manual are labeled with

a WARNING or CAUTION based on the risk type as

described below:

Definitions

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury

or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury,

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

Exhaust Venting

[] Free-flowing, clear of lint buildup

[] 4 inch (102 mm) rigid or semi-rigid ducting of

minimal length and turns

[] NO foil or plastic venting material

[] Approved vent hood exhausted to outdoors

Leveling

[] Dryer is level, side=to-side and front-to-back

[] Cabinet is setting solid on all corners

Gas Supply (Gas Dryer)

[] Manual shutoff valve present in supply

[] All connections sealed with approved sealer

and wrench tight

[] Conversion kit for LP system

[] Gas supply turned on

[] No leaks present at all connections -

check with soapy water, NEVERcheck with

flame

240v Electric Supply (Electric Dryer)

[] Approved NEMA 10-30R or 14-30R service

cord with all screws tight on terminal block

[] Approved strain relief installed

[] Terminal access cover installed before initial

operation

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

IMPORTANT indicates installation, operation or

maintenance information which is important but not

hazard-related,

Door Reversal

[] Follow detailed instructions in this guide

[] Test hinge and latch for function

Electrical Power

[] House power turned on

[] Dryer plugged in

Final Checks

[] Installation Instructions and Use and

Care Guide read thoroughly

[] Door latches and drum tumbles when cycle

starts

[] Registration card sent in

Page 4

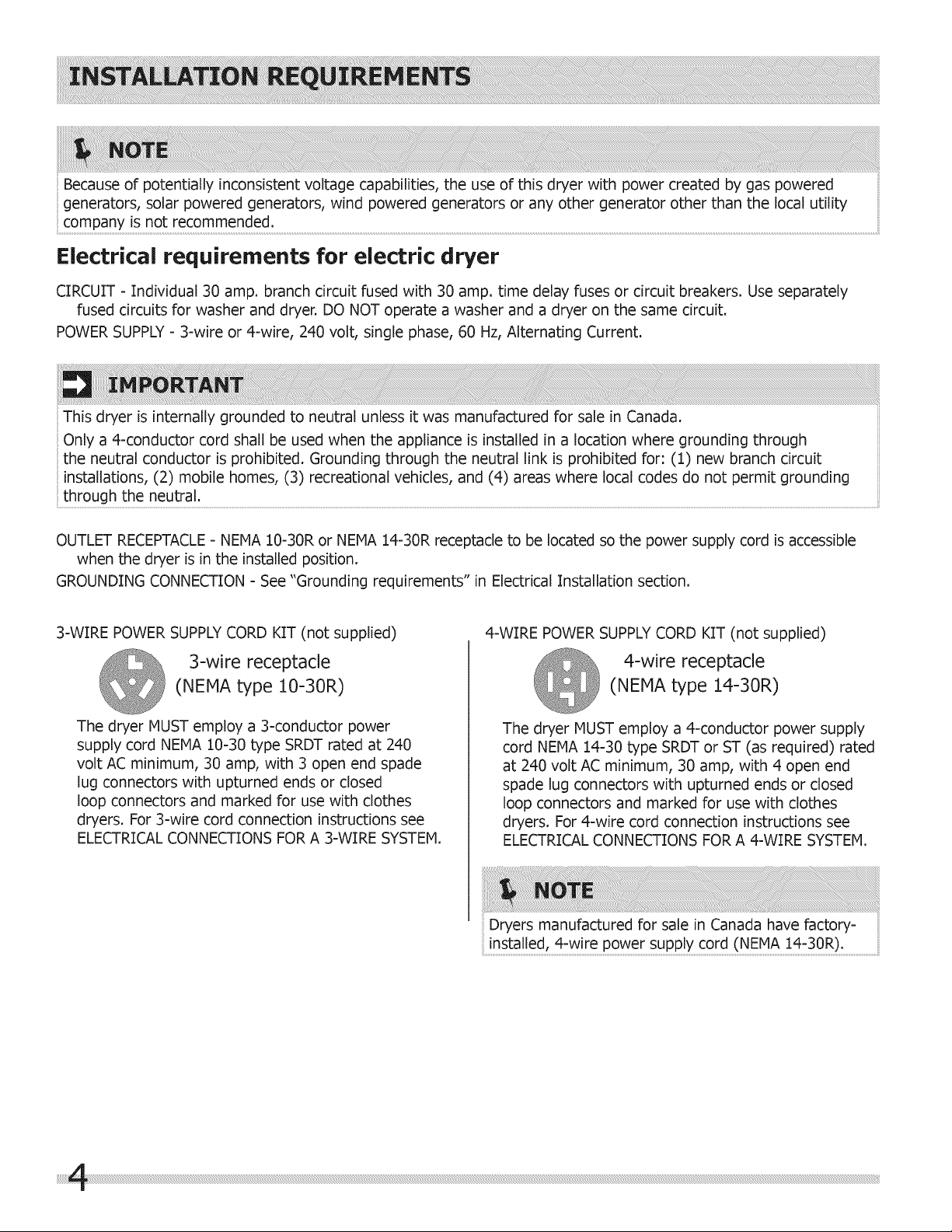

Electrical requirements for electric dryer

CIRCUIT - Individual 30 amp. branch circuit fused with 30 amp. time delay fuses or circuit breakers. Use separately

fused circuits for washer and dryer. DO NOT operate a washer and a dryer on the same circuit.

POWER SUPPLY- 3-wire or 4-wire, 240 volt, single phase, 60 Hz, Alternating Current.

This dryer is internally grounded to neutral unless it was manufactured for sale in Canada.

Only a 4-conductor cord shall be used when the appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the neutral link is prohibited for: (1) new branch circuit

installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local codes do not permit grounding

OUTLET RECEPTACLE- NEMA 10-30R or NEMA 14-30R receptacle to be located so the power supply cord is accessible

when the dryer is in the installed position.

GROUNDING CONNECTION - See "Grounding requirements" in Electrical Installation section.

3-WIRE POWER SUPPLYCORD KIT (not supplied)

3-wire receptacle

(NEMA type 10=30R)

The dryer MUST employ a 3-conductor power

supply cord NENA 10-30 type SRDT rated at 240

volt AC minimum, 30 amp, with 3 open end spade

lug connectors with upturned ends or closed

loop connectors and marked for use with clothes

dryers. For 3-wire cord connection instructions see

ELECTRICALCONNECTIONS FOR A 3-WIRE SYSTEM.

4-WIRE POWER SUPPLYCORD KIT (not supplied)

4-wire receptacle

(NEMA type 14=30R)

The dryer MUST employ a 4-conductor power supply

cord NEMA 14-30 type SRDT or ST (as required) rated

at 240 volt AC minimum, 30 amp, with 4 open end

spade lug connectors with upturned ends or closed

loop connectors and marked for use with clothes

dryers. For4-wire cord connection instructions see

ELECTRICAL CONNECTIONS FOR A 4-WIRE SYSTEM.

Dryers manufactured for sale in Canada have factory-

installed, 4:w! re power Supply €ord (NEMA 14:30R): ..................................

Page 5

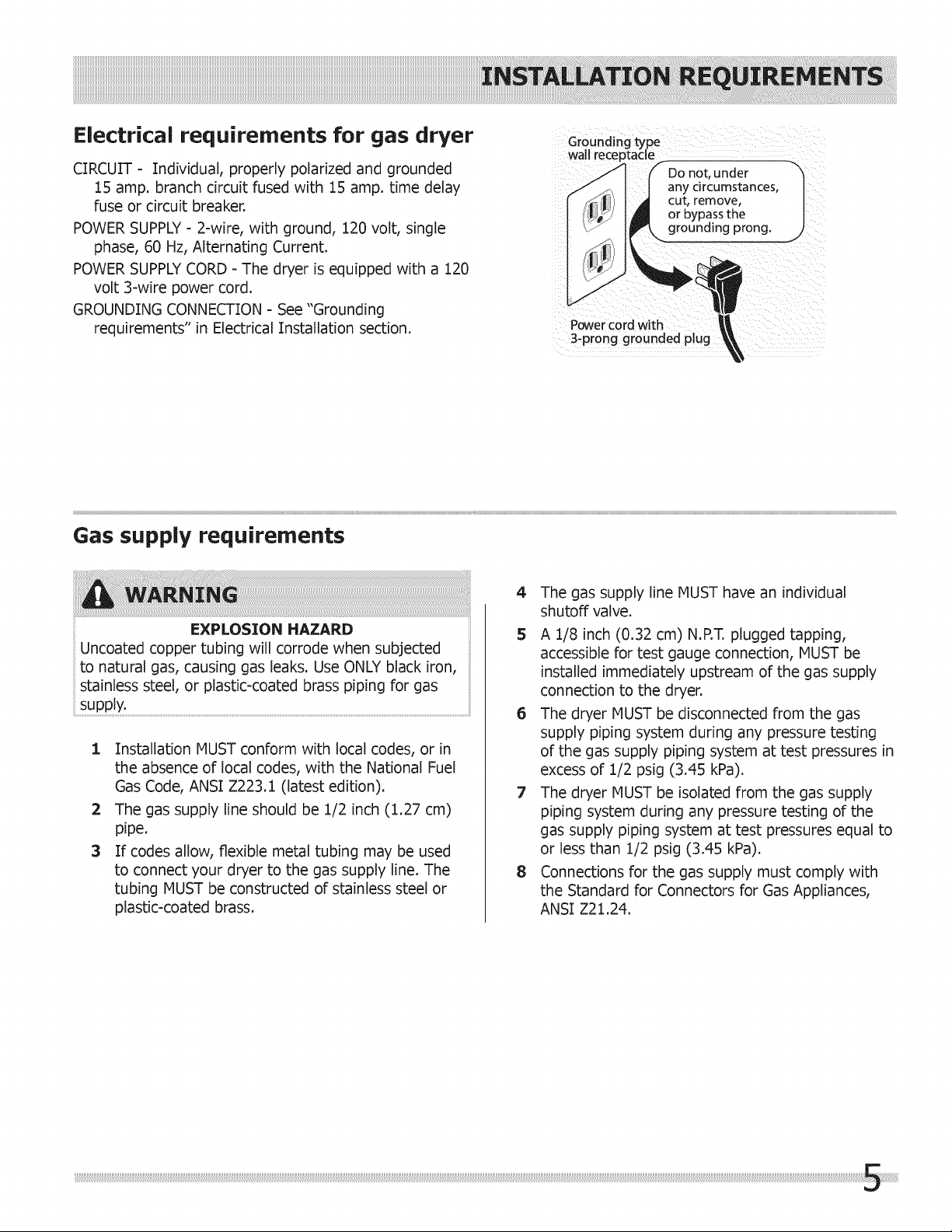

Electrical requirements for gas dryer

CIRCUIT - Individual, properly polarized and grounded

15 amp. branch circuit fused with 15 amp. time delay

fuse or circuit breaker.

POWER SUPPLY- 2-wire, with ground, 120 volt, single

phase, 60 Hz, Alternating Current.

POWER SUPPLYCORD - The dryer is equipped with a 120

volt 3-wire power cord.

GROUNDING CONNECTION - See "Grounding

requirements" in Electrical Installation section.

Gas supply requirements

1 Installation MUST conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1 (latest edition).

2 The gas supply line should be 1/2 inch (1.27 cm)

pipe.

3 If codes allow, flexible metal tubing may be used

to connect your dryer to the gas supply line. The

tubing MUST be constructed of stainless steel or

plastic-coated brass.

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Powercord with

3-prong grounded plug

4 The gas supply line MUST have an individual

shutoff valve.

5 A 1/8 inch (0.32 cm) N.RT. plugged tapping,

accessible for test gauge connection, MUST be

installed immediately upstream of the gas supply

connection to the dryer.

6 The dryer MUST be disconnected from the gas

supply piping system during any pressure testing

of the gas supply piping system at test pressures in

excess of 1/2 psig (3.45 kPa).

7 The dryer MUST be isolated from the gas supply

piping system during any pressure testing of the

gas supply piping system at test pressures equal to

or less than 1/2 psig (3.45 kPa).

8 Connections for the gas supply must comply with

the Standard for Connectors for Gas Appliances,

ANSI Z21.24.

Page 6

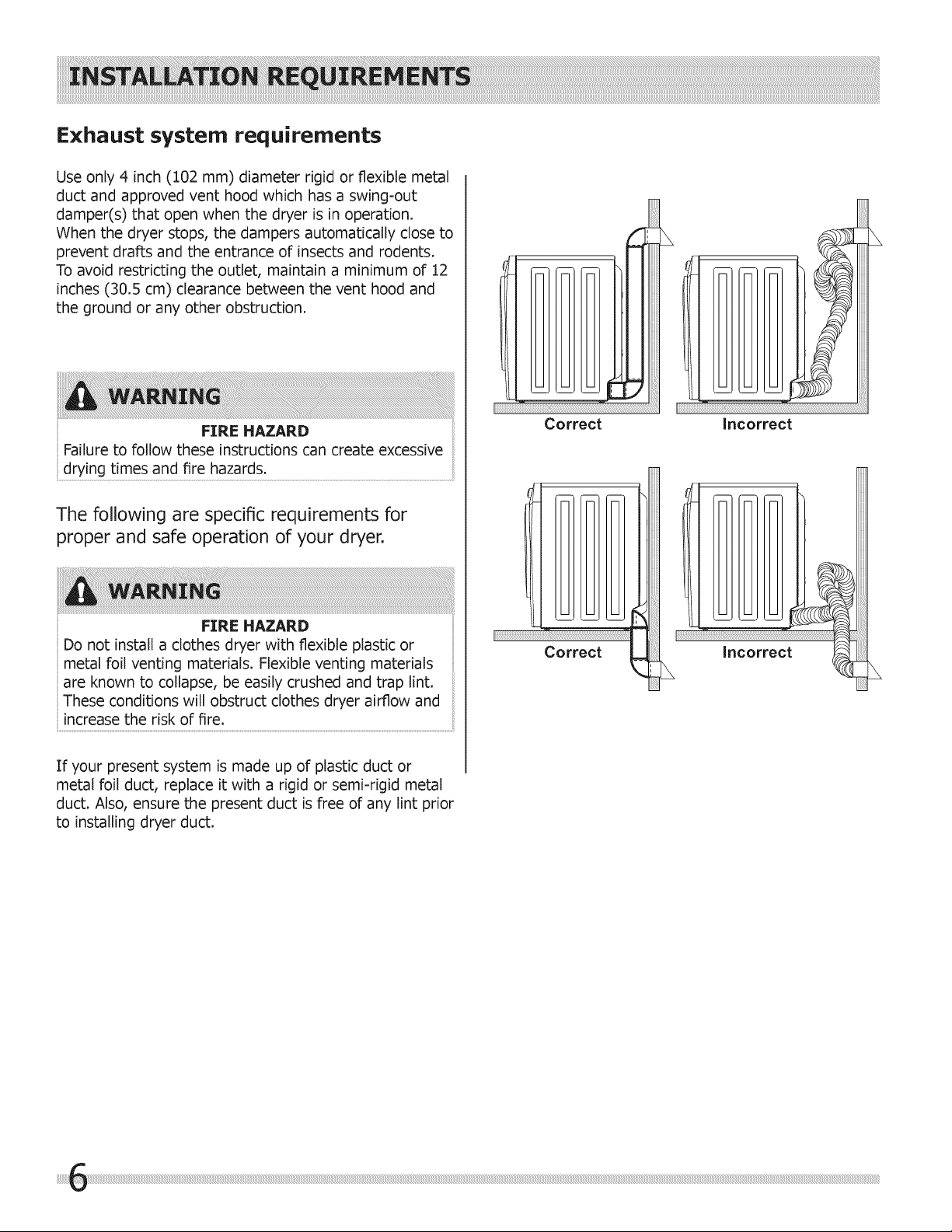

Exhaust system requirements

Use only 4 inch (102 mm) diameter rigid or flexible metal

duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation.

When the dryer stops, the dampers automatically close to

prevent drafts and the entrance of insects and rodents.

To avoid restricting the outlet, maintain a minimum of 12

inches (30.5 cm) clearance between the vent hood and

the ground or any other obstruction.

f

1i

FIRE HAZARD

Failure to follow these instructions can create excessive

drying times and fire hazards.

The following are specific requirements for

proper and safe operation of your dryer.

FIRE HAZARD

Do not install a clothes dryer with flexible plastic or

metal foil venting materials. Flexible venting materials

are known to collapse, be easily crushed and trap lint.

These conditions will obstruct clothes dryer airflow and

increase the risk of fire:...........................................................................................................................................................................................................

:If your present system is made up of plastic duct or

metal foil duct, replace it with a rigid or semi-rigid metal

duct. Also, ensure the present duct is free of any lint prior

to installing dryer duct.

Correct

Correct

Incorrect

Page 7

Exhaust system requirements, continued

FIRE HAZARD

A clothes dryer must be exhausted outdoors. Do not

exhaust dryer into a chimney, a wall, a ceiling, an attic,

a crawl space or any concealed space of a building. A

clothes dryer produces combustible lint. If the dryer is

not exhausted outdoors, some fine lint will be expelled

into the laundry area. An accumulation of lint in any

area of the home can create a health and fire hazard.

The dryer must be connected to an exhaust outdoors.

Regularly inspect the outdoor exhaust opening and

remove any accumulation of lint around the outdoor

exhaust opening and in the surrounding area.

FIRE HAZARD

- Do not allow combustible materials (for example:

clothing, draperies/curtains, paper) to come in

contact with exhaust system. The dryer MUST NOT

be exhausted into a chimney, a wall, a ceiling,

or any concealed space of a building which can

ii

accumulate lint, resulting in a fire hazard.

- Do not screen the exhaust ends of the vent system,

or use any screws, rivets or other fasteners that

extend into the duct to assemble the exhaust

system. Lint can become caught in the screen, on

the screws or rivets, clogging the duct work and

ii

creating a fire hazard as well as increasing drying

ii

times. Use an approved vent hood to terminate the

duct outdoors, and seal all joints with metal foil duct

tape. All male duct pipe fittings MUST be installed

downstream with the flow of air.

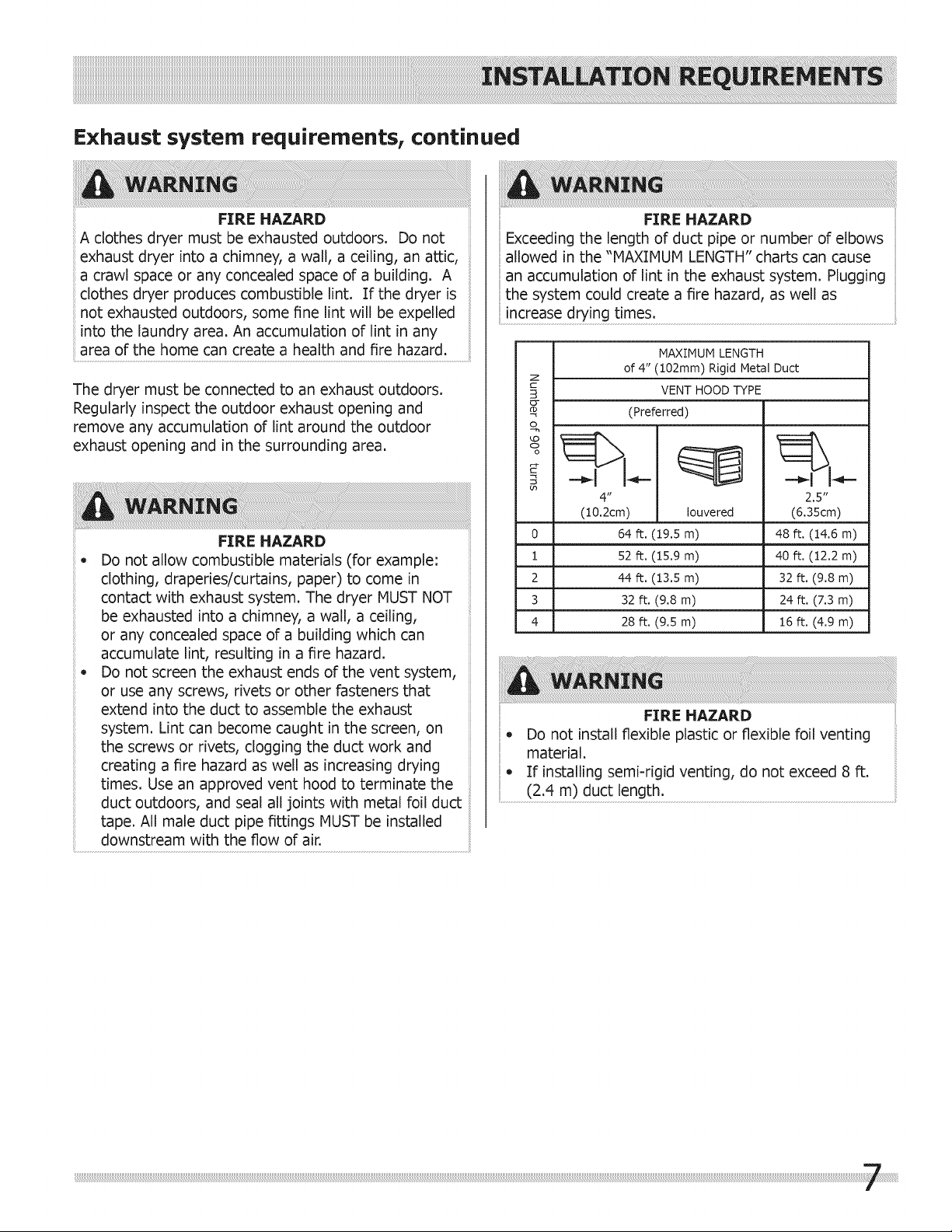

FIRE HAZARD

Exceeding the length of duct pipe or number of elbows

allowed in the "MAXIMUM LENGTH" charts can cause

an accumulation of lint in the exhaust system. Plugging

the system could create a fire hazard, as well as

MAXIMUM LENGTH

z

€-

3

of 4" (102mm) Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

o

E

S

go

(10.2cm) Iouvered

0

1 52 ft. (15.9 m) 40 ft. (12.2 m)

2 44 ft. (13.5 m) 32 ft. (9.8 m)

3 32 ft. (9.8 m) 24 ft. (7.3 m)

4 28 ft. (9.5 m) 16 ft. (4.9 m)

64 ft. (19.5 m)

2.5"

(6.35cm)

48 ft. (14.6 m)

FIRE HAZARD

- Do not install flexible plastic or flexible foil venting

material.

- If installing semi-rigid venting, do not exceed 8 ft.

Page 8

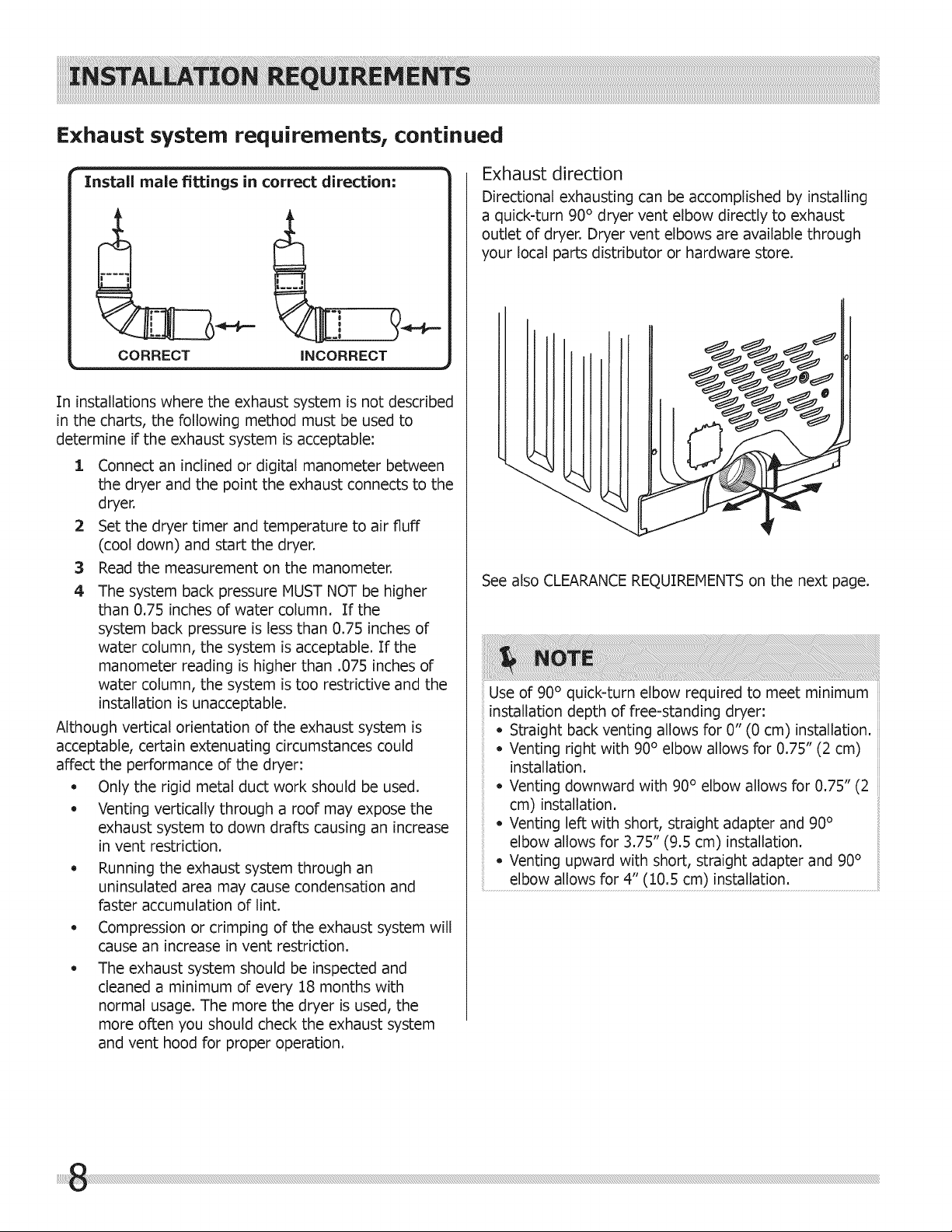

Exhaust system requirementsr continued

Install male fittings in correct direction"

CORRECT iNCORRECT

In installations where the exhaust system is not described

in the charts, the following method must be used to

determine if the exhaust system is acceptable:

:[ Connect an inclined or digital manometer between

the dryer and the point the exhaust connects to the

dryer.

2 Set the dryer timer and temperature to air fluff

(cool down) and start the dryer.

3 Read the measurement on the manometer.

4 The system back pressure MUST NOT be higher

than 0.75 inches of water column. If the

system back pressure is less than 0.75 inches of

water column, the system is acceptable. If the

manometer reading is higher than .075 inches of

water column, the system is too restrictive and the

installation is unacceptable.

Although vertical orientation of the exhaust system is

acceptable, certain extenuating circumstances could

affect the performance of the dryer:

o Only the rigid metal duct work should be used.

Venting vertically through a roof may expose the

exhaust system to down drafts causing an increase

in vent restriction.

Running the exhaust system through an

uninsulated area may cause condensation and

faster accumulation of lint.

Compression or crimping of the exhaust system will

cause an increase in vent restriction.

The exhaust system should be inspected and

cleaned a minimum of every 18 months with

normal usage. The more the dryer is used, the

more often you should check the exhaust system

and vent hood for proper operation.

Exhaust direction

Directional exhausting can be accomplished by installing

a quick-turn 90° dryer vent elbow directly to exhaust

outlet of dryer. Dryer vent elbows are available through

your local parts distributor or hardware store.

See also CLEARANCE REQUIREMENTS on the next page.

Use of 90° quick-turn elbow required to meet minimum

installation depth of free-standing dryer:

• Straight back venting allows for 0" (0 cm) installation.

Venting right with 90° elbow allows for 0.75" (2 cm)

installation.

Venting downward with 90° elbow allows for 0.75" (2

cm) installation.

Venting left with short, straight adapter and 90°

elbow allows for 3.75" (9.5 cm) installation.

Venting upward with short, straight adapter and 90°

.......................e/bow a!!ows for 4" (10-5 cm) !nsta/lat!on- ..............................................................................

Page 9

Manufactured or mobile home installation

1 Installation MUST conform to current Manufactured

Home Construction & Safety Standard, Title 24

CFR, Part 32-80 (formerly the Federal Standard

for Mobile Home Construction and Safety, Title 24,

HUD Part 280) or Standard CAN/CSAZ240 MH.

2 Dryer MUST be exhausted outside (outdoors, not

beneath the mobile home) using metal ducting

that will not support combustion. Metal ducting

must be 4 inches (10.16 cm) in diameter with no

obstructions. Rigid metal duct is preferred.

3 If dryer is exhausted through the floor and area

beneath the mobile home is enclosed, the exhaust

Clearance requirements

EXPLOSION HAZARD

Do not install the dryer where gasoline or other

flammables are kept or stored. If the dryer is installed

in a garage, it must be a minimum of 18 inches (45.7

cm) above the floor. Failure to do so can result in

death, explosion, fire or burns.

system MUST terminate outside the enclosure with

the termination securely fastened to the mobile

home structure.

4 Refer to previous sections in this guide for other

important exhaust venting system requirements.

5 When installing a gas dryer into a mobile home, a

provision must be made for outside make up air.

This provision is to be not less than twice the area

of the dryer exhaust outlet.

6 Installer MUST anchor this (1) dryer or (2) dryer

mounted on pedestal to the floor with approved

Mobile Home Installation Kit - P/N 137067200.

NOT INSTALL YOUR DRYER:

1 In an area exposed to dripping water or outside

weather conditions.

2 In an area where it will come in contact with

curtains, drapes, or anything that will obstruct

the flow of combustion and ventilation air.

3 On carpet. Floor MUST be solid with a maximum

slope of 1 inch (2.54 cm).

Page 10

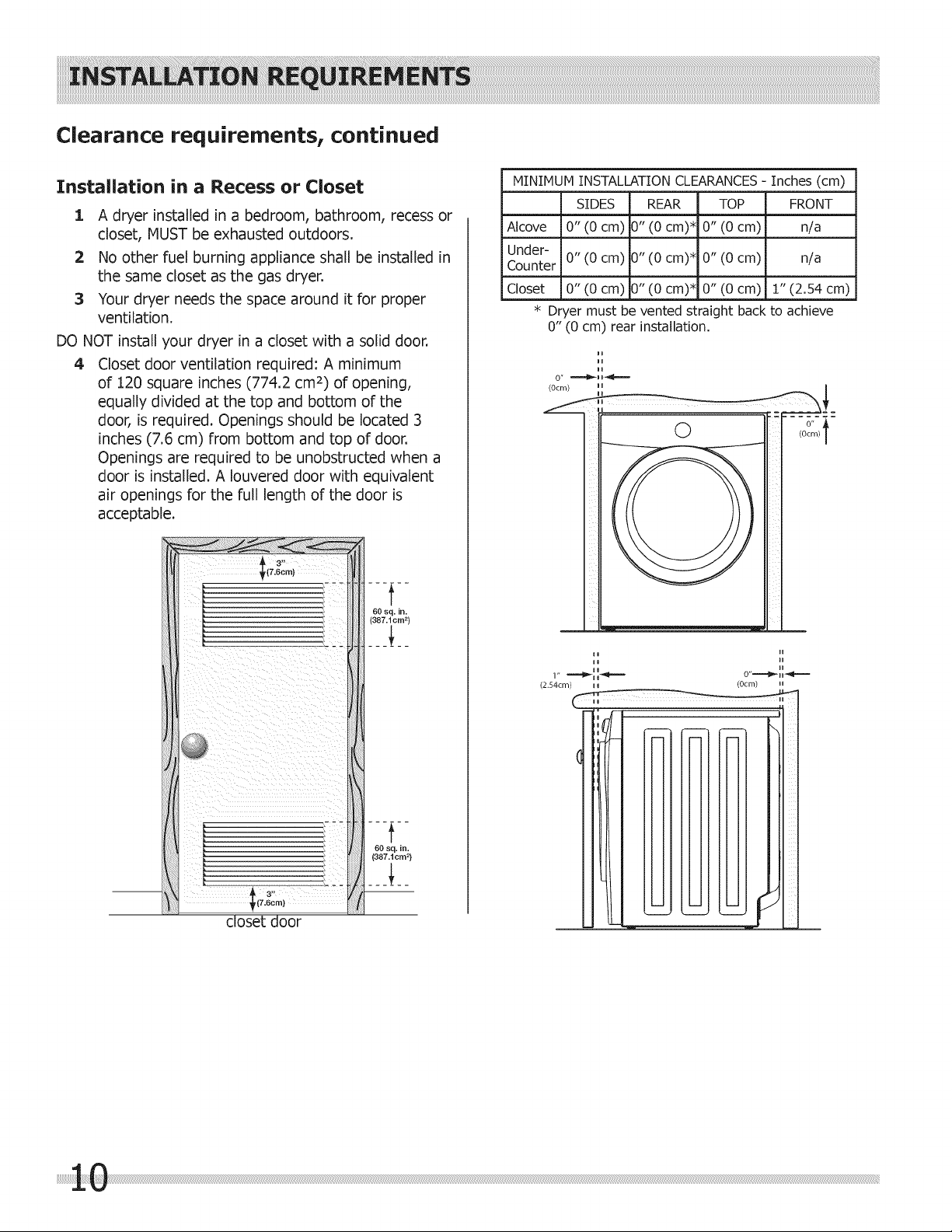

Clearance requirements, continued

Installation in a Recess or Closet

:[ A dryer installed in a bedroom, bathroom, recess or

closet, MUST be exhausted outdoors.

2 No other fuel burning appliance shall be installed in

the same closet as the gas dryer.

3 Your dryer needs the space around it for proper

ventilation.

DO NOT install your dryer in a closet with a solid door.

4 Closet door ventilation required: A minimum

of 120 square inches (774.2 cm 2) of opening,

equally divided at the top and bottom of the

door, is required. Openings should be located 3

inches (7.6 cm) from bottom and top of door.

Openings are required to be unobstructed when a

door is installed. A Iouvered door with equivalent

air openings for the full length of the door is

acceptable.

-1--

60 sq. in.

(387.1cm =)

MINIMUM INSTALLATION CLEARANCES- Inches (cm)

SIDES REAR TOP FRONT

Alcove _ " )" 0"

Under- 0" (0 cm) :)" (0 cm) * 0" (0 cm) n/a

Counter

Closet _ " :)" 0" 1"

_0 (0 cm) (0 cm)* (0 cm) n/a

!0 (0 cm) (0 cm)* (0 cm) (2.54 cm)

Dryer must be vented straight back to achieve

0" (0 cm) rear installation.

©

O" t

(Ocm)

3"

(7.6c m]

closet door

f

60 sq. in.

(387.1cm _)

Page 11

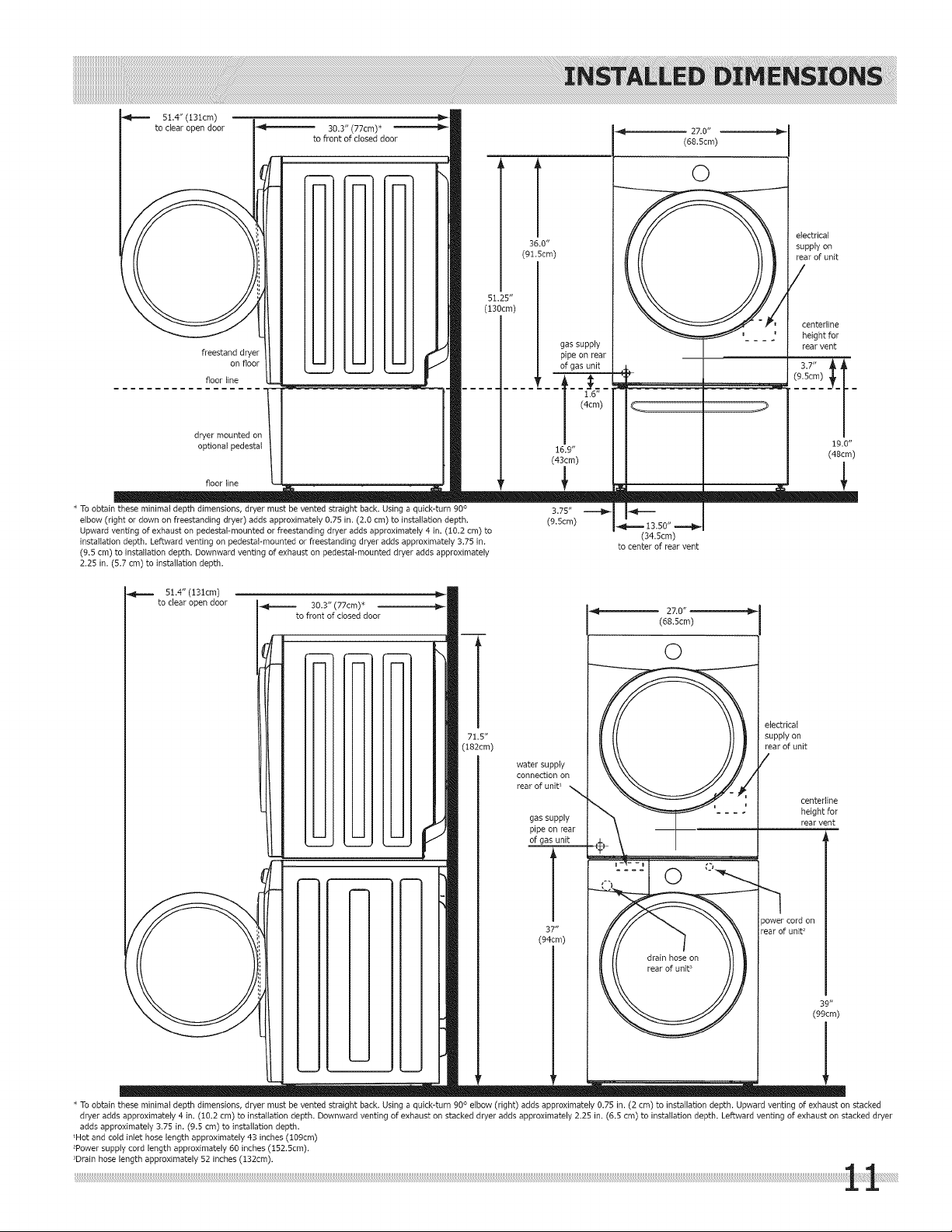

51.4" (131cm)

freestanddryer

on floor

floorline

30.3"(77cm)*

to front of closed door

51.25"

(130cm)

[

36.0"

(91.5cm)

gas supply

pipe on rear

of gas unit

27.0"

(68.5cm)

©

electrical

supply on

rear of unit

centerline

height for

rear vent

dryer mounted on

op_onalpedes_l

floorline

* To obtain these minimal depth dimensions, dryer must be vented straight back. Using a quick-turn 90°

elbow (right or down on freestanding dryer) adds approximately 0.75 in. (2.0 cm) to installation depth.

Upward venting of exhaust on pedestal-mounted or freestanding dryer adds approximately 4 in. (10.2 cm) to

installation depth. Leftward venting on pedestaFmounted or freestanding dryer adds approximately 3.75 in.

(9.5 cm) to installation depth. Downward venting of exhaust on pedestal-mounted dryer adds approximately

2.25 in. (5.7 cm) to installation depth.

51,4" (131cm)

to clear open door

30.3" (77cm)*

to front of closed door

(182cm)

71.5"

16.9"

(43cm)

3.75"

(9.5cm)

water supply

connection on

rear of unit 1

gas supply

pipe on rear

of gas unit

(34.5cm)

to center of rear vent

27.0"

(68.5cm)

0

0

electrical

supply on

rear of unit

centerline

height for

rear vent

19.0"

(48cm)

37"

(94cm)

drain hose on

rear of unit 3

* To obtain these minimal depth dimensions, dryer must be vented straight back. Using a quick-turn 90° elbow (right) adds approximately 0.75 in. (2 cm) to installation depth. Upward venting of exhaust on stacked

dryer adds approximately 4 in. (t0.2 cm) to installation depth. Downward venting of exhaust on stacked dryer adds approximately 2.25 in. (6.5 cm) to installation depth. Leftward venting of exhaust on stacked dryer

adds approximately 3.75 in. (9.5 cm) to installation depth.

1Hot and cold inlet hose length approximately 43 inches (t09cm)

2Powersupply cord length approximately 60 inches (t52.5cm).

3Drain hose length approximately 52 inches (t32cm).

power cord on

rear of unit 2

(99cm)

39"

Page 12

Electrical installation

The following are specific requirements for proper and

safe electrical installation of your dryer. Failure to follow

these instructions can create electrical shock and/or a fire

hazard.

ELECTRICAL SHOCK HAZARD

* This appliance MUST be properly grounded.

Electrical shock can result if the dryer is not properly

grounded. Follow the instructions in this manual for

proper grounding.

* Do not use an extension cord with this dryer. Some

extension cords are not designed to withstand the

amounts of electrical current this dryer utilizes

and can melt, creating electrical shock and/

or fire hazard. Locate the dryer within reach of

the receptacle for the length power cord to be

purchased, allowing some slack in the cord. Refer to

the pre-installation requirements in this manual for

the proper power cord to be purchased.

ELECTRICAL SHOCK HAZARD

* A U.L.-approved strain relief must be installed onto

power cord. If the strain relief is not attached, the

cord can be pulled out of the dryer and can be cut

by any movement of the cord, resulting in electrical

shock.

Do not use an aluminum wired receptacle with a

copper wired power cord and plug (or vice versa).

A chemical reaction occurs between copper and

aluminum and can cause electrical shorts. The

proper wiring and receptacle is a copper wired

power cord with a copper wired receptacle.

Dryers operating on 208 volt power supply will have

longer drying times than dryers operating on 240 volt

Grounding requirements =Electric dryer (USA)

wiring system, the plug MUST be plugged into

ELECTRICAL SHOCK HAZARD

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check

with a licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

ii

For a grounded, cord-connected dryer:

1 The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce

the risk of electrical shock by a path of least

resistance for electrical current.

2 After you purchase and install a 3 wire or 4 wire

power supply cord having an equipment-grounding

conductor and a grounding plug that matches you

an appropriate, copper wired receptacle that is

properly installed and grounded in accordance with

all local codes and ordinances. If in doubt, call a

licensed electrician.

3

DO NOT modify the plug you've installed on this

appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

For a

permanently connected dryer:

1

The dryer MUST be connected to a grounded

metal, permanent wiring system; or an equipment

grounding conductor must be run with the circuit

conductors and connected to the equipment-

grounding terminal or lead on the appliance.

Page 13

Grounding requirements = Electric dryer (Canada)

the risk of electrical shock by a path of least

resistance for electrical current.

ELECTRICAL SHOCK HAZARD

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check

with a licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

2 Since your dryer is equipped with a power supply

cord having an equipment-grounding conductor

and a grounding plug, the plug must be plugged

into an appropriate outlet that is properly installed

and grounded in accordance with all local codes

and ordinances. If in doubt, call a licensed

For a grounded, cord-connected dryer:

1 The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce

electrician.

3 DO NOT modify the plug provided with this

appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

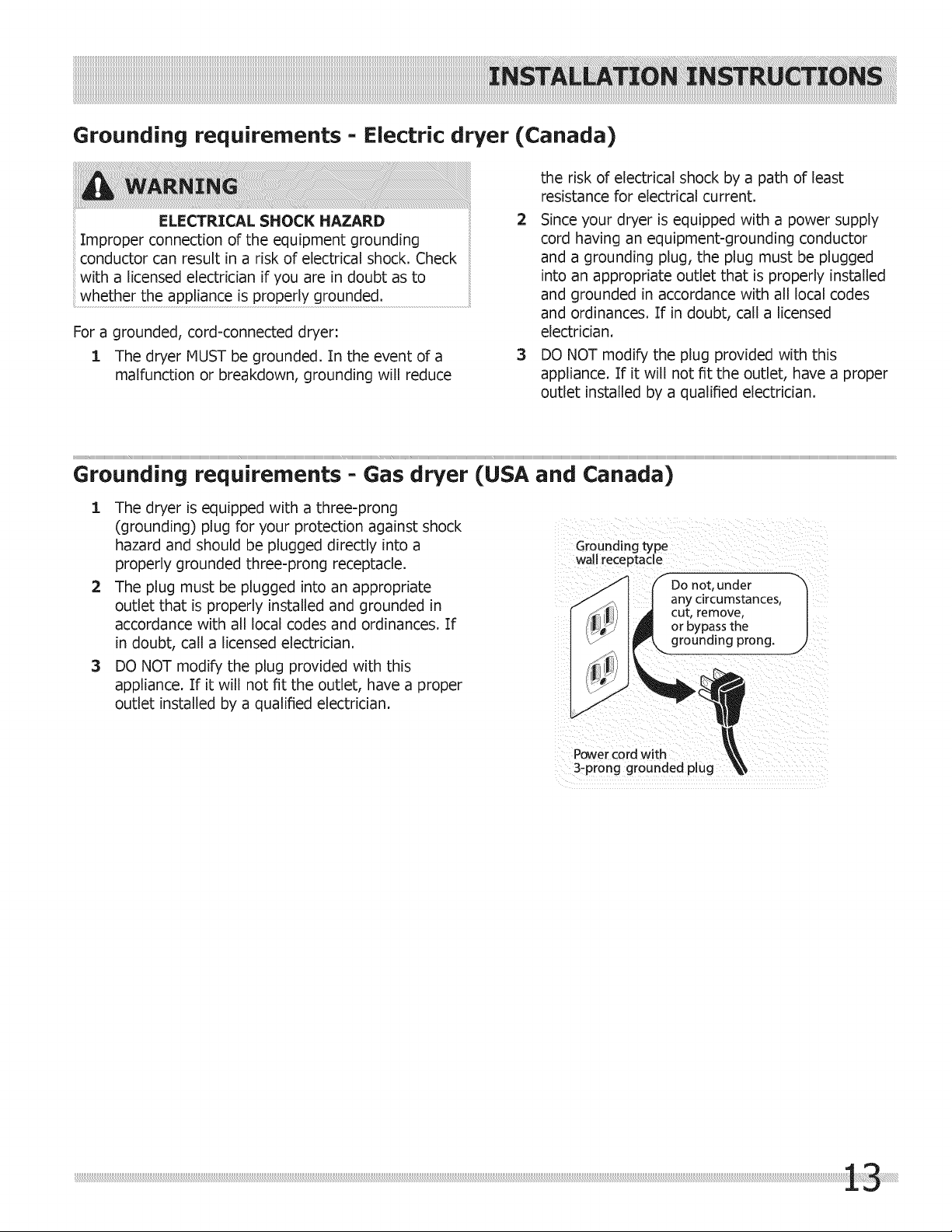

Grounding requirements - Gas dryer (USA and Canada)

1 The dryer is equipped with a three-prong

(grounding) plug for your protection against shock

hazard and should be plugged directly into a

properly grounded three-prong receptacle.

2 The plug must be plugged into an appropriate

outlet that is properly installed and grounded in

accordance with all local codes and ordinances. If

in doubt, call a licensed electrician.

3 DO NOT modify the plug provided with this

appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

Grounding type

wall receptacle

/ any circumstances,

f

Do not, under

cut, remove,

or bypass the

grounding prong.

Page 14

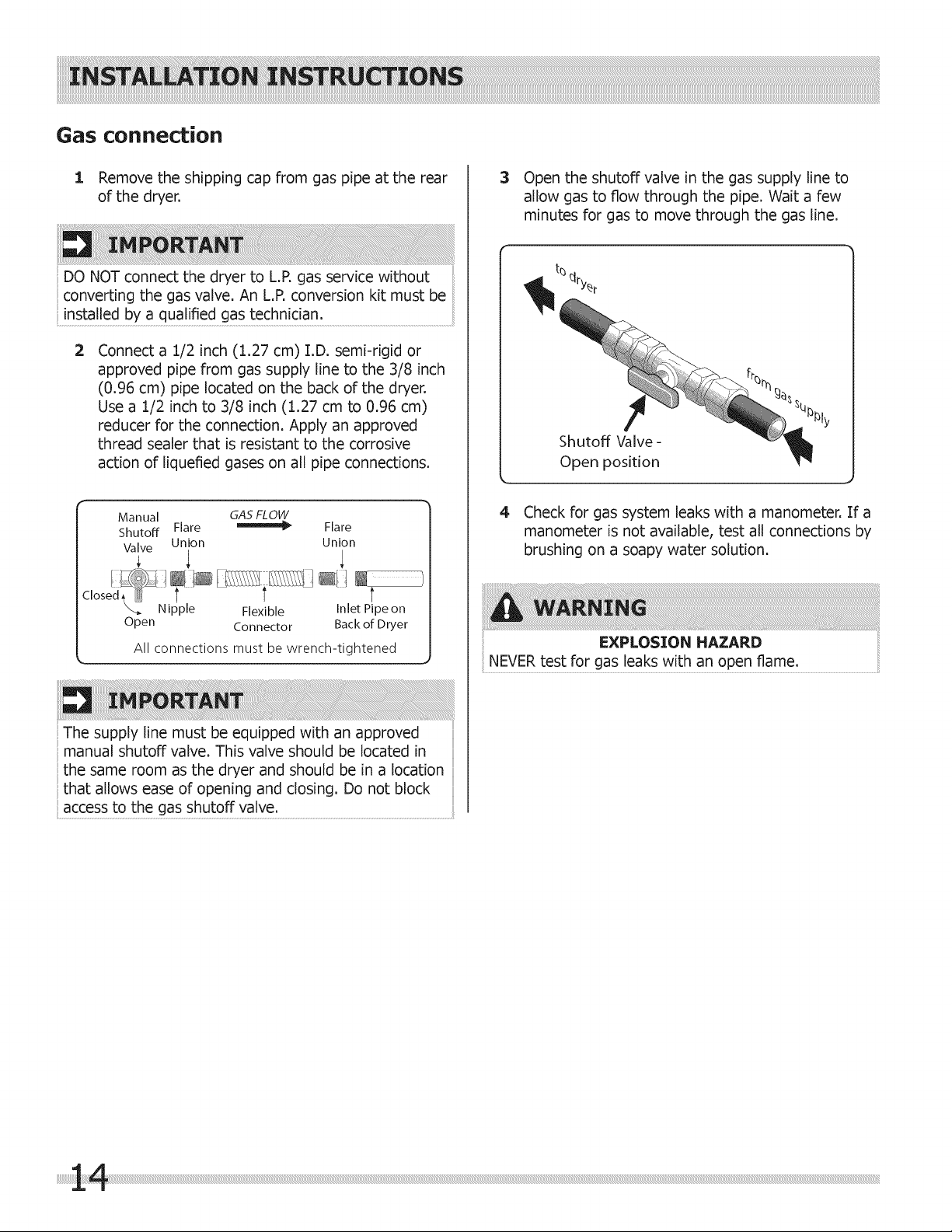

Gas connection

1 Remove the shipping cap from gas pipe at the rear

of the dryer,

DO NOT connect the dryer to LP. gas service without

converting the gas valve. An L.P. conversion kit must be

installed by a qualified gas technician.

Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or

approved pipe from gas supply line to the 3/8 inch

(0.96 cm) pipe located on the back of the dryer.

Use a 1/2 inch to 3/8 inch (1.27 cm to 0.96 cm)

reducer for the connection. Apply an approved

thread sealer that is resistant to the corrosive

action of liquefied gases on all pipe connections.

Manual GASFLOW

Shutoff Flare _ Flare

Valve Union Union

:losea__ t ...... t t

Nipple Flexible Inlet Pipe on

Open Connector Back of Dryer

All connections must be wrench-tightened

3

Open the shutoff valve in the gas supply line to

allow gas to flow through the pipe. Wait a few

minutes for gas to move through the gas line.

Shutoff Valve-

Open position

4

Check for gas system leaks with a manometer. If a

manometer is not available, test all connections by

brushing on a soapy water solution.

EXPLOSION HAZARD

NEVER test for gas leaks with an open flame.

ii

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in

the same room as the dryer and should be in a location

that allows ease of opening and closing, Do not block

access to the gas shutoff valve- ..........................................................................................................................................................

Page 15

Electrical connection (non=Canada) - 3 wire cord

3=wire receptacle

(NEMA type 10-30R)

ELECTRICAL SHOCK HAZARD

Failure to disconnect power source before servicing

could result in personal injury or even death.

1 Turn off power supply to outlet.

2 Remove the screw securing the terminal block

access cover in the lower corner on the back of the

dryer.

3 Install a UL-approved strain relief according to the

power cord/strain relief manufacturer's instructions

in the power cord entry hole below the access

panel. At this time, the strain relief should be

loosely in place.

4 Thread an UNPLUGGED, UL-approved, 30 amp.

power cord, NEMA 10-30 type SRDT, through the

strain relief.

5 Attach the power cord neutral (center wire)

conductor to the SILVER colored center terminal on

the terminal block. Tighten the screw securely.

6 Attach the remaining two power cord outer

conductors to the outer, BRASScolored terminals

on the terminal block. Tighten both screws

securely.

_ _ Access cover

_jj screw

__z'-L_- _ (BRASSterminal)

..... (BRASSterminal)

_ internal ground

Line 2

Line 1

(GREEN screw)

Terminal screw

recovery slot

ELECTRICAL SHOCK HAZARD

Do not make a sharp bend or crimp wiring/conductor at

connections,

7 Follow manufacturer's guidelines for firmly securing

the strain relief and power cord.

8 Reinstall the terminal block cover.

If moving dryer from a 4-wire system and installing it

in a 3-wire system, move the internal ground from the

center terminal back to the GREEN screw next to the

terminal block.

the access panel.

DO NOT remove

internal ground in

a 3-wire system!!

iii

Neutral

terminal

Page 16

Electrical connection (non=Canada) - 4 wire cord

4-wire receptacle

(NEMA type 14-30R)

ELECTRICAL SHOCK HAZARD

Failureto disconnect power source before servicing

could result in personal injury or even death.

1 Turn off power supply to outlet.

2 Remove the screw securing the terminal block

access cover in the lower corner on the back of the

dryer.

3 Install a UL-approved strain relief according to the

power cord/strain relief manufacturer's instructions

in the power cord entry hole below the access

panel. At this time, the strain relief should be

loosely in place.

4 Thread an UNPLUGGED, UL-approved, 30 amp.

power cord, NEMA 14-30 type ST or SRDT, through

the strain relief.

5 Disconnect the internal (WHITE) dryer harness

ground wire from the (GREEN) ground screw next

to the terminal block.

6 Attach the ground (GREEN) power cord wire to the

cabinet with the ground (GREEN) screw. Tighten

the screw securely.

7 Move the internal dryer harness ground (WHITE)

wire to the terminal block and attach it along with

the neutral (WHITE) power cord wire conductor

to the center, SILVER colored terminal on the

terminal block. Tighten the screw securely.

8 Attach the RED and BLACK power cord conductors

to the outer, BRASS colored terminals on the

terminal block. Tighten both screws securely.

ELECTRICAL SHOCK HAZARD

Do not make a sharp bend or crimp wiring/conductor at

connections,

9 Follow manufacturer's guidelines for firmly securing

the strain relief and power cord.

IO Reinstall the terminal block cover.

If a terminal screw falls during cord installation, it can

be retrieved in the terminal screw recovery slot below

........... _ Install

Move internal ground (WHITE)

wire to neutral (SILVER)

terminal for 4-wire system.

GREEN

ground screw

GREEN

ground wir_

REDpower wire

Neutral

WHITE wire)

UL-approved

strain relief here

Terminal screw

recovery slot

Neutral

terminal

WHITE

neutral wire

BLACK

or RED

power wire

BLACKor

Page 17

General installation

1 Connect the exhaust duct to the outside exhaust

system (see pages 6 through 8). Use of a 4" (102

mm) clamp (item A) is recommended to connect

the dryer to the exhaust vent system. Use metal

foil tape to seal all other joints.

2 Carefully slide the dryer to its final position. Adjust

one or more of the legs until the dryer is resting

solidly on all four legs. Place a level on top of the

dryer. The dryer MUST be level and resting solidly

on all four legs. Rock alternating corners to check

for stability, Remove and discard door tape,

Be sure the power is off at a circuit breaker/fuse box

before plugging the power cord into an outlet,

3 Plug the power cord into a grounded outlet,

4 Turn on the power at the circuit breaker/fuse box.

5 Read the Use & Care Guide provided with the dryer.

It contains valuable and helpful information that

will save you time and money.

6 If you have any questions during initial operation,

please review the "Avoid Service Checklist" in your

Use & Care Guide before calling for service.

7 Place these instructions in a location near the dryer

for future reference.

A wiring diagram and technical data sheet are located

inside the dryer console.

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Page 18

Removing the door

1 Protect fiat work surface, such as top of dryer or

floor near dryer, with a soft cloth or towel.

2 Open dryer door and remove the two hinge screws.

Remove lower screw first, then upper screw.

Supporting door with both hands, squarely lift door

and hinge upward approximately 3/8" (10 mm) so

"T" post on back of hinge can slide out through "T"

slot on front panel.

"T" SLOT IN

FRONT PANEL

"T" POST ON

DOOR HINGE

4

Gently place dryer door face down on fiat, covered

work surface.

5

Locate the 5 indented head screws (no. 1-5) in

the small, circular recesses (at 11, 1, 4, 6, and 8

o'clock positions) of the inner door. Remove and

save these 5 screws.

2

5 4

7

Do not attempt to remove the 2 "tamper-resistant"

screws that hold the inner glass !n place:....................................................................

6 Locate the 2 pan head screws (no. 6=7) on the

inner door nearest the metal strike and center of

hinge (9 and 3 o'clock positions). Remove and save

these 2 screws.

7 Separate inner door assembly from outer door

assembly.

Page 19

Reversing the hinge

1

Carefully pull out the 2 small round hole plugs from

the front panel and save, Remove and save the

square "T" slot cover by sliding it up and pulling

it out. Move all 3 plugs to the opposite side of the

front panel and insert.

\

ROUND PLUG

1

ROUND PLUG_

2 Turn tuner door assembly over to expose retaining

tabs of metal strike. Grip tabs fully with pliers to

remove. Discard old metal strike.

4

From the back side of the inner door, pinch the

retaining tabs of the plastic square plug to release

it. Save square plug for reinstallation.

Carefully remove the 2 round plugs from the inner

door and move them to the opposite holes and

reinstall.

OUT

3

Turn the inner door assembly back over and locate

the 2 pan head hinge screws. Remove and save the

2 screws and separate the hinge from inner door

assembly.

HINGE SCREWS

IN

Rotate the hinge and move it to the opposite side

of the inner door. Attach it with the 2 pan head

screws removed previously. Reinstall plastic plug in

the square hole next to the hinge.

Page 20

Reassembling the door

:[ Locate and remove the hinge cutout gate from the

outer door assembly. Rotate and move it to the

opposite hole in the outer door.

2 Rest the opening of the inner door at a 90 degree

angle on the "shoulders" of the hinge cutout gate.

Pivot the inner door down onto the outer door.

3 Replace indented head screws (no. 1-5)removed

earlier. Take care not to strip out the plastic holes.

4 Replace pan head screws (no. 6-7) removed earlier.

Take care not to strip out the plastic holes.

2

5

Locate new metal strike supplied with dryer

manuals. Grip new strike with pliers as shown

below. Firmly insert the strike so it is oriented

vertically.

Page 21

Reattaching the door

1

Holding the door in both hands, squarely insert

the "T" post on the back of the hinge into the "T"

slot on the front panel and lower it to align the

mounting holes.

"T" SLOT IN

"T" POST ON

DOOR HINGE

FRONT PANEL

Close the door and test operation of hinge, strike

and latch.

2

While supporting the door, install the upper pan

head screw first and then the lower one.

Correctly installed hinge screws will press hinge flush

to front panel. Any gap between hinge and front panel

will cause misalignment of strike to latch.

Page 22

MATCHINGSTORAGE PEDESTAL*

ClassicWhite Pedestal- P/N CFPWD15W

ClassicBluePedestal- P/N CFPWD15N

ClassicRedPedestal- P/N CFPWD15R

ClassicSilver Pedestal- P/NCFPWD15A

ClassicBlack Pedestal- P/N CFPWD15B

A storage pedestal accessory, specifically designed for this dryer

may be used to elevate the dryer for ease of use. This pedestal will

add about 15" (38 cm) to the height of your unit for a total height

of51.25"(130cm).

*Other colors may be available. Contact the source where you purchased your

dryer.

DRYER STACKING KIT

P/N134700400

Dependingon the model you purchased,a kitforstackingthisdryer

on top of matching washer may have been included in the initial

purchase of your dryer. If your model did not include a stacking kit or

you desire another stacking kit, you may order one.

LP CONVERSION KIT

P/NPCK4200

Gas dryersintendedforuse ina locationsuppliedwithLP must use a

conversionkitpriorto installation.

MOBILE HOME INSTALLATION KIT

P/N 137067200

Installationina mobilehome requiresthe use ofa MOBILE HOME

INSTALLATION KIT.

Failure to use accessories manufactured by

(orapproved by)the manufacturercould

resultinpersonalinjury,propertydamage or

damage to the dryer.

DRYING RACK

P/N 137067300

Depending on the model you purchased, a drying rack may have been

included in the initial purchase of your dryer. If your model did not

include a drying rack or you desire another drying rack, you may order

one.

UNIVERSAL APPLIANCE WRENCH

P/N137019200

A UNIVERSAL APPLIANCE WRENCH isavailabletoaidindryer/

washer/pedestalfeetadjustment.

TOUCH UP PAINT PENS*

ClassicWhite TouchUp Pen- P/N5304468812

ClassicRedTouch Up Pen - P/N 5304471227

ClassicBlue Touch UpPen- P/N 5304471229

ClassicSilverTouch Up Pen - P/N 5304471228

ClassicBlackTouch Up Pen- P/N5304458932

*Other colors may be available. Contact the source where you purchased your

dryer.

Replacement parts:

If replacements parts are needed for your washer,

contact the source where you purchased your washer or

refer to your Use and Care Guide for more information.

Label all wires prior todisconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

ELECTRICAL SHOCK HAZARD

//

/i/

Page 23

TABLEDESMA_I_RES

Mesures de ,s6cur,t6 importantes ..................... 24-25 [n_rSion de I_ po_e ..... . .ii i!i.! !i.ii!! !!i!!!.!ii i 40_43

Exigences d installation ................................... 26:32 _essoires ........................ 44

Dimensions, appareil install6 ................................ 33 Rema_ques ........................]]]]] ii]]]]!]]]!!]!]!]]]]]]i]]!] 67

Instructions d'insta!tation ................................ 34-39

Page 24

Pourvotres_curit_,I'informationcontenuedanscesinstructionsdolt_tresuivieafinder_duirelesrisquesd'incendieou

d'explosionoupourpr_venirlesdommagesmateriels,lesblessuresoulamort.Vousnedeveznientreposer,niutiliser

d'essenceoud'autresvapeursouliquidesinflammables_proximit_decetappareiloudetoutautreappareil_lectrom_nager.

A AVERTISSEMENT - RISQUE D'INCENDIE

Lisez toutes les instructions de s_curit_ suivantes avant d'installer et d'utiliser votre appareil :

• D_truisez lecarton d'emballage et les sacs en plastique apr_s avoir d_ball_ I'appareil, Les enfants pourraient les utiliser

pour jouer, Le carton recouvert de tapis, les couvertures et les feuilles de plastique peuvent _tre _tanches _ I'air et pro-

voquer la suffocation, D_posez tousles mat_riaux d'emballage dans un conteneur _ d_chets ou faites en sorte que les

enfants ne puissent y avoir acc&s.

- L'installation et I'entretien de cette s_cheuse doivent _tre r_alis_s par un installateur qualifi_, un technicien de ser-

vice ou le fournisseur de gaz.

- Installez I'appareil conform_ment aux instructions du fabricant et aux codes Iocaux.

- L'installation _lectrique de la s_cheuse dolt _tre conforme aux codes et aux r_glements Iocaux ainsi qu'_ la toute

derni_re _dition du National Electrical Code (ANSI/NFPA 70), ou au Canada, au Code canadien de I'_lectricit_

(C22.1, article 1).

- L'installation de gaz de la s_cheuse doit _tre conforme aux codes et aux r_glements Iocaux ainsi qu'_ la toute der-

nitre _dition du Fuel Gas Code (ANSI Z223.1), ou au Canada, au CAN/ACG B149.1-2000.

- La s_cheuse est class_e, en vertu des r_glements ANSI Z 21.5.1 ou ANSI/UL 2158 - CAN/CSA C22.2 N° 112 (der-

nitres versions), pour un USAGE DOMESTIQUE uniquement. II n'est pas recommand_ d'utiliser cette s_cheuse pour

des usages commerciaux, comme des restaurants, des salons de coiffure, etc.

- N'installez pas une s_cheuse avec du materiel d'_vacuation en plastique ou en feuille m_tallique flexible. Le mate-

riel de ventilation flexible peut s'_craser facilement et emprisonner la charpie. Ces conditions nuiraient _ I'_coule-

ment d'air de votre s_cheuse et pourraient accroTtre le risque d'incendie.

- Ne superposez pas une s_cheuse sur une laveuse d_j_ install_e sur un socle. Ne superposez pas une laveuse sur

une s_cheuse. Ne superposez pas une laveuse sur une autre laveuse.

- Les instructions comprises dans ce guide et route autre documentation fournie avec cet appareil ne sont pas

con(;ues pour couvrir routes les _ventualit_s ou situations qui pourraient survenir. Vous DEVEZ faire preuve de bon

sens et de prudence durant I'installation, I'utilisation et I'entretien de tout appareil m_nager.

QUE FAIRE SI VOUS DETECTEZ UNE ODEUR DE GAZ :

- Ne mettez pas d'appareil en marche.

- Ne touchez _ aucun commutateur _lectrique; n'utilisez aucun t_l_phone de votre domicile.

- Evacuez la piece, le b_timent ou la zone touch_e.

- En utilisant le t_l_phone d'un voisin, appelez imm_diatement le fournisseur de gaz. Suivez ses instructions.

- Si vous ne pouvez joindre votre fournisseur de gaz, appelez les pompiers.

Conservez ces instructions pour vous y reporter ult rieurement,

Exigences avant l'installation

Outils et mat6riel n6cessaires _ I'installation :

- Pince r_glable

- Tournevis Phillips _ pointe plate et

pointe carrie

- CI_ _ molette

• CI_ _ tuyau pour I'alimentation en gaz

- Ruban _ filetage r_sistant au GPL

(pour I'alimentation en gaz naturel

ou en GPL)

o

Niveau de charpentier

o

Event ext_rieur

o

Conduit d'_vacuation de 102 mm (4

po) en m_tal rigide ou semi-rigide

- Ensemble pour cordon d'alimenta-

tion de 240 V _ 3 ou 4 ills (s_cheuse

_lectrique)

- Collier de 10,2 cm (4 po)

- Robinet d'arr_t pour conduite de gaz

(s_cheuse _ gaz)

- Deux raccords-unions _ _vasement

de 1/2 po (1,3 cm) NPT et une

conduite flexible d'alimentation en

gaz (s_cheuse _ gaz)

- Ruban m_tallique (et non du ruban

conduits)

Page 25

Veuillezlirecesinstructionsaucompletavant

d'utiliserles_cheuse.

ii

Sachez reconnaitre los symboMs, les

avertissements et los _tiquettes de s_curit_,

Les mesures de s_curit_ pr_sent_es dans ce guide

sont identifi_es par le mot AVERTISSEMENT ou

ATTENTION selon le type de risque pr_sent_ ci-

dessous.

D_finitions

Voici le symbole d'avertissement concernant la

s_curit_. II est utilis_ pour vous avertir des risques de

blessures potentiels. Respectez tous los messages qui

suivent ce symbole afin de pr_venir los blessures ou

la mort.

La mention DANGER indique un risque imminent

qui causera la mort ou de graves blessures, s'il

Conduit d'_vacuation

Lair circule librement, il n'y a aucune accumulation

de charpie

Le conduit rigide ou semi-rigide de 102 mm (4 po)

est le plus court et le plus direct possible

II n'y a AUCUN materiel de ventilation en papier

d'aluminium ou en plastique

1:::1Le syst_me d'_chappement dolt _vacuer I'air a

I'ext_rieur a I'aide d'un _vent approuve

Mise _ niveau

1:::1La s_cheuse est au niveau lat_ralement et de

I'avant vers I'arri_re

Les quatre coins de la caisse reposent fermement

sur le plancher

Alimentation au gaz (s_cheuse au gaz)

l:::l Le conduit d'alimentation comporte un robinet

d'arr_t manuel

Tous los raccords sont _tanch_ifi_s _ I'aide de

joints certifies serf,s avec une cl_

N_cessaire de conversion pour syst_me au GPL

L'alimentation en gaz est ouverte

Aucun raccord ne pr_sente de fuite -

v_rifiez _ I'aide d'eau savonneuse, ne faites JAMAIS

cette v_rification avec une flamme

La mention AVERTISSEMENT indique une situation

potentiellement dangereuse qui, si elle n'est pas

6vit6e, pourrait entraTner des blessures graves ou

m6me la mo_: ..................................................................................................................................................................................................................

La mention ATTENTION signale la presence d'une

situation potentiellement dangereuse susceptible

de causer des blessures mineures ou moyennement

Alimentation _lectrique de 240 V

(s_cheuse _iectrique)

Le cordon d'alimentation est certifi_ NEMA 10-30R

ou 14-30R et il fix_ solidement avec toutes los vis

dans le bornier

Un r_ducteur de tension certifi_ est install_

Le couvre-borne est install_ avant la premiere mise

en marche

Inversion de la porte

Suivez los instructions d6taill6es contenues dans ce

guide

V_rifiez que la charni_re et le Ioquet fonctionnent

correctement

Alimentation en _lectricit_

IMPORTANT - Cette mention precede des

renseignements importants relatifs _ I'installation,

au fonctionnement ou _ I'entretien. Toutefois, ceux-

ci n impliquent aucune notion de danger.

I::::1Le syst_me _lectrique de la maison est sous tension

[:::1 La s_cheuse est branch_e

V_rifications finales

Vous avez lu enti_rement les instructions

d'installatien et le Guide d'utilisatien et

d'entretien

La porte se verrouille et le tambour tourne

Iorsqu'un cycle d_marre

I:::l La carte d'enregistrement est envoy_e

i!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!2 ¸!¸¸!¸¸!¸¸51¸i!i_iiiiilililililili!i:i!i;il

Page 26

Etant donn_ les variations de tension possibles, I'utilisation de cette s_cheuse avec une source d'alimentation produite

par une g_n_ratrice _ essence, solaire ou _olienne ou par toute autre source d'alimentation diff_rente de celle fournie

par les services publics n'est pas recommand_e.

Exigences lectriques de ia s cheuse lectrique=

CIRCUIT - Circuit ind_pendant de 30 amperes avec fusible temporis_ ou disjoncteur de 30 A. Utilisez des circuits

ind_pendants pour la laveuse et la s_cheuse. NE BRANCHEZ PAS la laveuse et la s_cheuse sur le m_me circuit.

ALIMENTATION ELECTRIQUE - Cable monophas_ _ trois ou quatre ills, 240 volts, 60 Hz; courant alternatif.

Cette s_cheuse est mise _ la terre par le fil d'alimentation neutre, sauf si elle est destin_e _ la vente au Canada. La

mise _ la terre par le fil d'alimentation neutre est interdit pour • (1) un nouveau circuit de d_rivation, (2) les maisons

mobiles, (3) les v_hicules r_cr_atifs, et (4) les r_gions o_ les codes Iocaux ne permettent pas la mise _ la terre par le

fil d'alimentation neutre.

PRISE - Prise NEMA 10-30R ou NEMA 14-30R situ_e de mani_re _ permettre I'acc_s au cordon d'alimentation Iorsque la

s_cheuse est _ sa position de fonctionnement.

CONNEXION DE MISE _, LA TERRE - Consultez la rubrique <<Exigences de mise _ la terre >>dans la section d'installation

_lectrique.

TROUSSE DE CORDON D'ALIMENTATION A TROIS FILS

(non fournie)

Prise _ 3 alv#oles

(NEMA type 10-30R)

La s_cheuse DOIT utiliser un cordon d'alimentation

trois ills NEMA 10-30 de type SRDT d'une capacit_ de

240 volts (c.a.) et d'au moins 30 amperes, avec trois

connecteurs ouverts embrochables avec extr_mit_s

renvers_es, ou connecteurs _ boucle ferm_e,

sp_cialement indiqu_s pour une utilisation avec une

s_cheuse. Pour les instructions de raccordement du

gordon _ 3 ills, consultez la sec,tion ,CONNEXIONS

ELECTRIQUES POUR UN SYSTEME A TROIS FILS.

TROUSSE DE CORDON D'ALIMENTATION _, QUATRE FILS

(non fournie)

Prise _ 4 alv_oles

(NEMA type 14-30R)

La s_cheuse DOIT utiliser un cordon d'alimentation

quatre ills NEMA 14-30 de type SRDT d'une capacit_

de 240 volts (c.a.) et d'au moins 30 amperes, avec

quatre connecteurs ouverts embrochables avec

extr_mit_s renvers_es, ou connecteurs _ boucle ferm_e

sp_cialement indiqu_s pour une utilisation avec une

s_cheuse. Pour les instructions de raccordement du

cordon _ quatre ills, consultez !a section CONNEXIONS

ELECTRIQUESPOUR UN SYSTEMEA QUATREFILS.

Les s6cheuses destin6es _ la vente au Canada sont

munies d'un cordon d'alimentation _ 4 ills (NEMA 14-

30R).

Page 27

Exigences iectriques de la s cheuse

gaz:

CIRCUIT - Circuit ind_pendant de 15 amperes, polaris_

et mis _ la terre, avec fusible temporis_ ou disjoncteur

de 15A.

ALIMENTATION ELECTRIQUE - Cable monophas_ _ deux

ills mis _ la terre, 120 volts, 60 Hz; courant alternatifi

CORDON D'ALIMENTATION - La s_cheuse est dot_e d'un

cordon d'alimentation de 120 volts _ trois ills.

CONNEXION DE MISE _, LA TERRE - Consultez la rubrique

<<Exigences de mise _ la terre >>dans la section

d'installation _lectrique.

Exigences relatives & i'alimentation en gaz

Prisemurale avec

mise_ la terre

/NNecoupezpas, n'enlev_

pas et ne mettez pashors I

circuit la broche de raise I

_a terre de cette fiche,j,}

Cordon_lectriquemuni

avecmise_ laterre

RISQUE D'EXPLOSION

Un tuyau en cuivre sans rev_tement se corrode lorsqu'il

entre en contact avec le gaz naturel, entratnant desfuites.

Utilisez SEULEMENTdes tuyaux en fer noir, en acier

inoxydable ou encore en cuivre avec rev_tement en plastique

pour l'alimentation en gaz.

1 L'installation DOIT 6tre conforme aux codes

Iocaux ou au code national sur le combustible,

ANSI Z223.1 (derni_re version), s'il n'existe pas de

codes Iocaux.

2 Le tuyau d'alimentation en gaz dolt _tre d'un

diam_tre int6rieur de 1,27 cm (1/2 po).

3 Si les codes le permettent, un tuyau m6tallique

flexible peut 6tre utilis6 pour raccorder votre

s6cheuse au tuyau d'alimentation en gaz. Le tuyau

DOIT 6tre fabriqu_ en acier inoxydable ou en laiton

avec rev_tement en plastique.

4 Le tuyau d'alimentation en gaz DOIT _tre muni

d'un robinet d'arr_t distinct.

5 Un orifice taraud_ de 0,32 cm (1/8 po) bouch_,

accessible pour le branchement de la jauge d'essai,

DOIT _tre install_ directement en amont du

branchement du tuyau d'alimentation en gaz avec

la s_cheuse.

6 Cette s_cheuse DOIT _tre d_branch_e de la

canalisation de gaz pendant route v_rification de

pression de la canalisation de gaz _ des pressions

sup_rieures _ 3,45 kPa (1/2 Ib/po2).

7 Cette s_cheuse DOIT _tre isol_e de la canalisation

de gaz pendant toute v_rification de pression de

la canalisation de gaz _ des pressions _gales ou

inf_rieures _ 3,45 kPa (1/2 Ib/po2).

8 Les branchements d'alimentation en gaz doivent

6tre conformes _ la norme Connectors for Gas

AppLiances (Raccords pour appareils au gaz) ANSI

Z21.24.

Page 28

Exigences du syst_me d'_vacuation

Utilisez seulement des conduites m_talliques rigides ou

flexibles d'au moins 102 mm (4 po) de diam_tre, et une

bouche d'_vacuation qui poss_de un ou des volets qui

s'ouvrent Iorsque I'appareil est en fonction. Lorsque la

s_cheuse s'arr_te, les volets se ferment automatiquement

pour emp_cher les infiltrations d'air, d'insectes et de

rongeurs. Pour _viter de bloquer la sortie, gardez un

espace minimal de 30,5 cm (12 po) entre le bas de la

bouche d'_vacuation et le sol ou toute autre obstruction.

f

1i

RISQUE D'INCENDIE

Le non-respect de ces instructions pourrait augmenter

d_mesur_ment les temps de s_chage et entra;ner des

Vous trouverez ci-dessous les exigences pour

I'utilisation ad6quate et s6curitaire de votre

appareil,

RISQUE D'INCENDIE

N'installez pas une s_cheuse avec du materiel

d'_vacuation en plastique ou en feuille m_tallique

flexible. Le materiel de ventilation flexible peut

s'_craser facilement et emprisonner la charpie. Ces

conditions nuiraient _ I'_coulement d'air de votre

s_cheuse et pourraient accro_tre !e r!sque d'!ncend!e: ........................

Si votre syst_me actuel utilise une conduite en plastique

ou en feuille m_tallique, remplacez-la par une conduite

m_tallique rigide ou semi-rigide. De plus, assurez-vous

que la conduite en peaceest libre de charpie avant

d'installer la conduite de s_cheuse.

Correct

Correct

Incorrect

Page 29

Exigences de syst me d' vacuation {suite)

RISQUE D'INCENDIE

Une s_cheuse doit 6tre _vacu_e vers I'ext_rieur.

N'_vacuez pas une s_cheuse dans une chemin_e, un

mur, un plafond, un grenier, un vide sanitaire ou dans

tout espace clos d'un b_timent. La s_cheuse produit

de la charpie inflammable. Si la s_cheuse n'est pas

_vacu_e vers I'ext_rieur, de la charpie pourrait 6tre

_vacu_e dans I'aire de buanderie. L'accumulation de

charpie dans toute piece de la maison peut entraTner

uespo urla sant_ et des e ......................................

La s_cheuse doit _tre branch_e _ une _vacuation

ext_rieure. Inspectez r_guli_rement I'ouverture de

I'_vacuation ext_rieure et retirez route accumulation de

charpie pros de I'ouverture et de la r_gion avoisinante.

RISQUE D'INCENDIE

- Ne laissez pas de mati_re combustible (par

exemple • des v_tements, des rideaux, du papier)

entrer en contact avec le syst_me d'_vacuation.

La s_cheuse NE DOIT PAS_tre _vacu_e dans une

chemin_e, un mur, un plafond, ou dans tout espace

ii

confin_ d'un b_timent qui pourrait accumuler la

charpie, entraTnant un risque d'incendie.

- Ne placez pas de grillage _ I'extr_mit_ du syst_me

d'_vacuation, ni de vis, de rivet ou autre fixation

ii

de mani_re _ ce qu'ils se prolongent dans la

ii

conduite du syst_me d'_vacuation. De la charpie

pourrait s'accumuler sur le grillage, les vis ou

les rivets, et obstruer I'_coulement d'air dans

le syst_me, entraTnant un risque d'incendie et

ii

I'augmentation des temps de s_chage. Utilisez

une bouche d'_vacuation approuv_e pour terminer

la conduite _ I'ext_rieur, et scellez tousles joints

avec du ruban m_tallique. Toutes les extr_mit_s

ii

m_les des conduites doivent _tre install_es en aval

relativement au sens de I'_coulement d'air.

ii

RISQUE D'INCENDIE

Le fait de d_passer la Iongueur de conduites ou le

nombre de coudes indiqu_s dans les tableaux de

<<LONGUEURNAXINALE >>peut entrgner I'accumulation

de charpie dans le syst_me. Toute obstruction au

syst_me d'_vacuation peut entra;ner un risque

d'incendie, en p/us d'accro_tre !e temps de sechage-.....................................

LONGUEUR MAXIMALE

pour le conduit en m@tal rigide de 102 mm (4 po)

o_

• _PF DEBOUCHE D'_VACUATION

_b

C_

d)

(De preference)

s_

4"

(10.2cm)

0

1

2

3

4

64 ft. (19.5 m)

52 ft. (1£9 m)

44 ft. (13.5 m)

32 ft. (9.8 m)

28 ft. (9.5 m)

A volets

2.5"

(6.35cm)

48 ft. (14.6 m)

40 ft. (12.2 m)

32 ft. (9.8 m)

24 ft. (7.3 m)

16 ft. (4.9 m)

RISQUE D'INCENDIE

* N'instaIlezpas de materielde ventilationen

plastiqueou en aluminiumflexible.

. Sivous installezdu materielde ventilationsemi-

rigide,ilestn_cessaireque lalongueurdu conduit

.......................so!t ega!e ou !nferieure a 2,4 m (8 Pi)-.................................................................................................

Page 30

E×igences de syst me d' vacuation (suite)

Installez les raccords m_les dans le bon sens :

)_

CORRECT INCORRECT

Pour une installation o_ le syst_me d'_vacuation n'est pas

d_crit dans les tableaux, la m_thode suivante dolt 6tre

utilis_e pour v_rifier la conformit_ du syst_me :

1 Branchez un manom_tre _ tube inclin6 ou un

manom_tre num_rique entre la s_cheuse et le point

oO I'_vacuation est raccord_e _ la s_cheuse.

2 R_glez la minuterie de la s_cheuse, la temperature

duvetage (refroidissement), et mettez I'appareil

en fonction.

3 Relevez le r_sultat du manom_tre.

4 La contre-pression du syst_me NE DOIT PAS_tre

sup_rieure _ 25 mm (1 po) de colonne d'eau. Si la

contre-pression du syst_me est inf_rieure _ 25 mm

(1 po) de colonne d'eau, le syst_me est conforme.

Si la lecture du manom_tre indique une colonne

d'eau sup_rieure _ 25 mm (1 po), le syst_me est

trop restreignant et n'est pas conforme.

Bien que I'orientation verticale du syst_me d'_vacuation

soit acceptable, certaines circonstances pourraient influer

sur le rendement de I'appareil.

o Seule une conduite m_tallique rigide dolt 6tre

utilis_e.

o L'_vacuation verticale par le toit peut entra_ner

le ph_nom_ne de contre-tirage, ce qui accroTt la

restriction du syst_me d'_vacuation.

- L'acheminement de la conduite d'_vacuation

dans un endroit non isol_ peut entra_ner de la

condensation et I'accumulation plus rapide de

charpie.

- Le fair de comprimer ou de pincer le syst_me

d'_vacuation entraTnera I'augmentation de la

restriction dans le syst_me.

- Le syst_me d'_vacuation dolt 6tre inspect_ et

v_rifi_ au moins tousles 18 mois avec un usage

normal. Plus I'appareil est utilis_, plus la p_riode

de v_rification du syst_me et de la bouche

d'_vacuation dolt _tre raccourcie.

Direction d'_vacuation

II est possible de diriger I'_vacuation en posant un coude

de 90° _ courbe immediate directement _ la sortie

d'_vacuation de la s_cheuse. Les coudes pour _vacuation

de s_cheuse sont disponibles aupr_s du distributeur de

pi_ces de votre r_gion ou _ la quincaillerie.

Consultez _galement la section EXIGENCESDE

DEGAGEMENT _ la page suivante.

L'utilisation d'un coude _ 90 ° _ courbe imm6diate est

n_cessaire pour r_pondre aux exigences de profondeur

minimale de la s_cheuse autonome :

Une installation _ sortie directe permet d'avoir un

d_gagement de 0 cm (0 po).

Une _vacuation de Fair vers la droite au moyen d'un

coude _ 90 ° permet d'avoir un d_gagement de 2 cm

(0.75 po).

• Une _vacuation de Fair vers le bas au moyen d'un

coude _ 90 ° permet d'avoir un d_gagement de 2 cm

(0.75 po).

• Une _vacuation de I'air vers la gauche au moyen d'un

adaptateur droit et court et d'un coude _ 90° permet

d'avoir une installation comportant un d_gagement

de 9.5 cm (3.75 po).

Une _vacuation vers le haut au moyen d'un adaptateur

droit et court et d'un coude _ 90° permet une installa-

tion comportant un d_gagement de 10.5 cm (4 po).

Page 31

Installation dans une rnaison usin4e ou mobile

1 L'installation DOIT 6tre conforme _ la norme

Manufactured Home Construction and Safety

Standard, titre 24 CFR, article 32-80 (anciennement

d6sign6e comme la Federal Standard for Mobile

Home Construction and Safety, titre 24, HUD,

article 280) ou _ la norme CAN/CSAZ240 MH.

2 La s6cheuse DOIT _tre 6vacu4e vers I'ext6rieur

(_ I'air libre et non sous la maison mobile) avec

une gaine m4tallique ininflammable. La conduite

m4tallique dolt poss6der un diam_tre de 10,16 cm

(4 po) et ne contenir aucune obstruction. De

pr4f4rence, utilisez une conduite m4tallique rigide.

3 Si la s6cheuse est 6vacu4e par le plancher et que

I'espace sous la maison mobile est cloisonn4,

le syst_me d'6vacuation DOIT se terminer

Exigences de d4gagernent

RISQUE D'EXPLOSION

N'installez pas la s4cheuse I_ oO de I'essence ou autres

mati_res inflammables sont entrepos6es. Si la s4cheuse

est install6e dans un garage, elle doit 6tre plac4e au

moins _ 45,7 cm (18 po) du sol. Le non-respect de cette

recommandation peut entrainer un choc 41ectrique, une

explosion, un incendie ou m6me la mort.

I'ext6rieur de la cloison et 6tre fix6 solidement _ la

structure de la maison.

4 Reportez-vous aux sections pr6c4dentes de

ce guide relativement aux autres exigences

d'4vacuation importantes.

5 Lors de I'installation d'une s4cheuse _ gaz dans

une maison mobile, des dispositions doivent 6tre

prises pour permettre I'entr4e d'air d'appoint de

I'ext4rieur. Cette installation ne doit pas mesurer

moins de deux fois la surface de la bouche

d'6vacuation.

6 L'installateur DOIT ancrer (1) cette s4cheuse ou

(2) la monter sur un socle au sol avec une trousse

d'installation de maison mobile, n° de piece

137067200.

N'!NSTALLEZ PAS VOTRE SI_CHEUSE:

1 _, un endroit expos4 aux 4coulements d'eau

ou aux al4as des conditions m4t4orologiques

ext4rieures.

2 _, un endroit o_ elle entrera en contact avec

des rideaux ou tout autre objet qui nuirait

1'6coulement de I'air de combustion ou de

ventilation.

3 Sur un tapis. Le plancher DOIT 6tre solide et

pr4senter une pente inf6rieure _ 2,54 cm (1 po).

Page 32

Exigences de d_gagernent (suite)

Installation dans un Endroit en Retrait ou

une Armoire

1 Une s6cheuse install6e dans une chambre

coucher, une salle de bains, un renfoncement ou un

placard DOlT 6tre 6vacu6e vers I'ext6rieur.

2 Aucun autre appareil _ combustion ne dolt 6tre

install6 dans le m6me placard que la s6cheuse.

3 Votre s6cheuse a besoin d'espace pour assurer une

ventilation ad6quate.

N'INSTALLEZ PAS votre s6cheuse dans un placard muni

d'une porte pleine

4 Porte de placard assurant une ventilation requise :

Une ouverture d'au moins 774,2 cm2 (120 po2),

divis6e 6galement au-dessus et au-dessous de

la porte, est requise. Les ouvertures doivent 6tre

situ_es _ 7,6 cm (3 po) du haut et du bas de la

porte. Les ouvertures ne doivent pas 6tre obstru6es

Iorsqu'une porte est install6e. Une porte

persiennes dont les ouvertures sur I'ensemble de la

porte sont 6quivalentes aux recommandations peut

6tre utilis6e,

DI_GAGEMENTSMINIMAUX - Centim&tres (pouces)

COTI_S ARRII_RE DESSUS AVANT

AIc6ve 0" (0 cm) 0" (0 cm)* 0" (0 cm) n/a

Sous le

comptoir

Placard O" (0 cm) O" (0 cm)* O" (0 cm) 1" (2.54 cm)

* Une installation _ sortie directe permet d'avoir un

d_gagement de 0 cm (0 po).

0" (0 cm) 0" (0 cm)* 0" (0 cm) n/a

3':

(7,6cm)

Porte de placard

t

60 sq. in.

(387.1 cm 2}

______

f

60 sq. in.

(387.1cm 2}

__!__

Page 33

51.4" (131cm)

Avec la porte

grande ouverte

30.3" (77cm)*

/_ partir de I'avant de la porte

Iorsqu'elle est ferm_e

27.0"

(68.5cm)

©

51.25"

(130cm)

S_cheuse autonome

sur le planchel

Plancher

S_cheuse mont_e sur

le sode optionnei

Piancher

* Pour obtenir cesdimensions de profondeur mJnJmates,la s_cheuse dolt _tre ventil6e tout droit par ['arrJ&re. L'utilisation

d'un coude _ 90 ° & courbe imm@diate (vers la droite ou vers le bas sur une s6cheuse autonome) n_cessite environ 2

cm (0.75 po) de profondeur de plus pour I'installation. Les s_cheuses mont_es sur un socle ou autonomes munies d'un

syst_me d'_vacuation de Fairvers le haut requi&rent environ 10.2 cm (4 po) de profondeur de plus pour t'installation. Les

s6cheuses mont6es sur un sode ou autonomes munies d'un syst6me d'6vacuation vers la gauche n@cessitent environ

3.75 cm (9.5 po) de profondeur de plus pour Finstallation. Les s6cheuses mont_es sur un sode munies d'un sys%me

d'_vacuation de Fair vers le bas requi_rent environ 5.7 cm (2.25 po) de profondeur de plus pour I'instatlation.

51,4" (131cm)

Avec la porte

grande ouverte

30.3" (77cm)*

#,partir de I'avant de la porte

Iorsqu'elle est ferm6e

F

[

36.0"

(91.5cm)

Alimentation en

gaz _ Farri_re de

(9.5cm)

16,9"

(43cm)

3.75"

gaz

Du c6t@jusqu'au

centre de I'_vent arri_re

(34.5cm)

(68.5cm)

27.0"

O

Alimentation

_lectrique

I'arri&re de

la s_cheuse

Hauteur de la

[igne centraie

de 1'6vent arri&re

19.0"

(48cm)

Alimentation

71.5"

(182cm) Raccord de

J

* Pour obtenir cesdimensions de profondeur minimaIes, la s6cheuse dolt _tre ventil_e tout droit par I'arri_re. L'utilisation d'un coude _ 90° _ courbe imm6diate (orient6 vers la droite) n6cessite environ 0.75 po (2 cm)

de profondeur de plus pour FinstaIlation. Les s6cheuses superpos_es munies d'un syst_me d'6vacuation de Fair vers le haut requi_rent environ 4 po (10.2 cm) de profondeur de plus pour I'installation. Les s_cheuses

superpos6es munies d'un syst&me d'6vacuation de Fair vers le bas requi&rent environ 2.25 po (6.5 cm) de profondeur de plus pour {'installation. Les s_cheuses superpos_es munies d'un syst_me d'6vacuation de Fair

vers la gauche requi&rent environ 3.75 po (9.5 cm) de profondeur de plus pour t'installation.

1La{ongitud de las mangueras de admisi6n de agua caliente y fr{a es de aproximadamente 43" (109 cm).

2La{ongitud del cable de alimentaci6n es de aproximadamente 60" (152,5 cm).

3LaIongitud de la manguera de desagOe es de aproximadamente 52" (132 cm).

m

I'alimentation

en eau _ t'arri&re

de la laveuse _

Alimentation en

gaz _ l'arri&re de

Fappareil _ gaz

37"

(94cm)

O

Tuyau de vidal

I'arri&re de la laveuse 3

_lectrique

I'arri_re de

la s6cheuse

Hauteur de la

ligne centraie

de I'_vent arri_re

Cordon

d'alimentation

t'arri&re de la

laveuse2

39"

(99cm)

Page 34

Installation 61ectrique

Vous trouverez ci-dessous les exigences pour I'installation

_lectrique adequate et s_curitaire de votre appareil. Le

non-respect de ces instructions pourrait entra_ner le

risque de choc ou d'incendie.

RISQUE DE CHOC ELECTRIQUE

* Cet appareil DOIT _tre ad_quatement mis _ la

terre. La mise _ la terre inadequate de la s_cheuse

pourrait entrafner des risques de choc _lectrique.

Suivez les instructions de ce guide pour une mise

la terre adequate.

- N'utilisez pas de rallonge avec cet appareil. Certains

cordons prolongateurs ne sont pas con€us pour

la quantit_ de courant _lectrique utilis_ par cette

s_cheuse et pourraient fondre, ,entraTnant des

risques de choc _lectrique ou d incendie. Placez la

s_cheuse _ une distance de la prise convenant

la Iongueur de la rallonge, permettant d installer la

rallonge I_chement. Reportez-vous aux exigences de

pr_installation de ce guide pour savoir quel cordon

d alimentation acheter.

RISQUE DE CHOC ELECTRIQUE

- Un r6ducteur de tension certifi6 UL doit 6tre install6

sur le cordon d'alimentation. Si le r6ducteur de

tension n'est pas install6, le cordon peut 6tre

attach6 de I'appareil ou coup6 par tout mouvement,

ce qui entraTnerait un risque de choc 61ectrique.

N'utilisez pas une prise avec c_blage en aluminium

avec un cordon d'alimentation et une fiche avec ills

en cuivre (ou I'inverse). Une r6action chimique se

produit entre I'aluminium et le cuivre, ce qui pourrait

entra_ner un court-circuit. II faut utiliser un cordon,

une fiche et une prise avec des ills en cuivre.

Les s6cheuses aliment6es par une tension de 208 V

poss6deront des temps de s6chage plus longs qu'une

s6cheuse aliment6e par une tension de 240 V.

Exigences de rnise & ia terre =S6cheuse 61ectrique (E.-U.)

RISQUE DE CHOC ELECTRIQUE

Un raccordementinad_quatdu conducteurde mise _ la

terrede i'_quipementpeut accroTtrelesrisquesde choc

_lectrique.En casde doutequant _ lamise_ iaterre

de I'appareil,consultezun _lectridenqualifi&

Pour une s_cheuse avec cordon, mise _ la terre :

:[ Cet appareil DOIT _tre mis _ la terre. En cas de

mauvais fonctionnement ou de panne, la mise

la terre diminue les risques de choc _lectrique en

fournissant au courant _lectrique une trajectoire de

moindre r_sistance.

2 Apr_s I'achat et I'installation d'un cordon

d'alimentation _ 3 ou 4 ills dot_ d'un fil de mise

la terre et d'une fiche de mise _ la terre qui

correspond _ votre syst_me de c_blage, la fiche

DOIT _tre branch_e dans un r_ceptacle cuivr_

install_ et mis _ la terre conform_ment aux codes

et r_glements Iocaux. En cas de doute, faites appel

un _lectricien qualifi&

3 NE MODIFIEZ PAS la fiche fournie avec cet

appareil. Si elle ne s'ins_re pas dans la prise,

demandez _ un _lectricien qualifi_ d'installer la

prise adapt_e.

Pour une s_cheuse avec branchement permanent :

1 La s_cheuse DOIT 6tre branch_e _ un syst_me de

cables m_talliques permanents mis _ la terre; ou

un conducteur de mise _ la terre dolt _tre install_

avec les conducteurs de circuit et branch_ _ la

borne ou au fil de mise _ la terre de I'appareil.

Page 35

Exigences de raise _ ia terre = $_cheuse _lectrique (Canada)

RISQUE DE CHOC #|.ECTRIQUE

Un raccordement inad_quat du conducteur de mise & la terre

de I'_quipement peut accroTtreles risques de choc_lectrique.

Encasde doute quant _ la mise _ la terre de I'appareil,

consultezun _lectricien qualifi&

Pour une s6cheuse avec cordon, mise _ la terre :

1 Cet appareil DOIT 6tre mis _ la terre. En cas de

mauvais fonctionnement ou de panne, la mise

la terre diminue les risques de choc 61ectrique en

fournissant au courant 61ectrique une trajectoire de

2 Puisque votre appareil est muni d'un cordon

d'alimentation avec filet fiche de mise _ la terre,

la fiche dolt 6tre branch_e dans un r_ceptacle

install_ et mis _ la terre conform_ment aux codes

et r_glements Iocaux. En cas de doute, faites appel

un _lectricien qualifi&

3 NE HODIFIEZ PAS la fiche fournie avec cet

appareil. Si elle ne s'ins_re pas dans la prise,

demandez _ un _lectricien qualifi_ d'installer la

prise adapt_e.

Exigences de raise & ia terre - S_cheuse & gaz (E,-U, et Canada)

1 Cet appareil est muni d'une fiche _ trois broches

moindre r_sistance.

(mise _ la terre) pour assurer votre protection

contre les chocs _lectriques. Cette fiche dolt _tre

branch_e directement dans une prise _ trois

alv_oles correctement mise _ la terre.

2 La fiche dolt 6tre branch_e dans un r_ceptacle

install_ et mis _ la terre conform_ment aux codes

et r_glements Iocaux. En cas de doute, faites appel

un _lectricien qualifi&

3 NE HODIFIEZ PAS la fiche fournie avec cet

appareil. Si elle ne s'ins_re pas dans la prise,

demandez _ un _lectricien qualifi_ d'installer la

prise adapt_e.

Prise murale avec

mise _ la terre

coupez pas, n'enleve_zz

pas et ne mettez pas hors

circuit la broche de mise

la terre de cette fiche.

Cordon_lectrique

munidune fiche_trois

brochesavecraise&laterre

Page 36

Connexion de gaz

1 Retirez le capuchon d'exp_dition de la conduite de

gaz _ I'arri_re de I'appareil.

NE RACCORDEZPASla s_cheuse _ une alimentation

en propane liquide sans avoir pr_alablement converti la

soupape de gaz, Le n_cessaire de conversion au propane

liquide dolt _tre install_ par un technicien qualifi_.

Branchez un tuyau semi-rigide ou approuv_

d'un diam_tre int_rieur de 1,27 cm (1/2 po) de

la conduite d'alimentation de gaz au tuyau de

0,96 cm (3/8 po) situ_ _ I'arri_re de I'appareil.

Utilisez un r_ducteur de 1,27 cm _ 0,96 cm (1/2 po

3/8 po) pour effectuer le raccordement. Utilisez

du ruban d'_tanch_it_ r_sistant _ Faction corrosive

des gaz _ I'_tat liquide _ chaque raccord.

ECOULEMENT

Robinet Raccord- _ Raccord-

d'arr_t union _ union

manuel _vasement _vasement

_._ Duse Raccord Tuyau d'entr_e

Ouvert flexible raccord6 _ I'arri6re

Tousles raccords doivent &tre serr_s au moyen d'une cl6

DU GAZ

de la s6cheuse

3 Ouvrez le robinet d'arr_t dans la conduite

d'alimentation de gaz pour permettre au gaz de

s'_couler dans le tuyau. Attendez quelques minutes

pour que le gaz s'_coule dans la conduite.

I

Robinet d'arr6t

en position ouverte

4

V_rifiez le syst_me avec un manom_tre pour

d6celer toute fuite. Si vous n'avez pas de

manom_tre, v_rifiez les raccords en appliquant de

I'eau savonneuse sur les connexions.

RISQUE D'EXPLOSION

Nev_rifiez ]AMAIS la presencede fuites _ I'aide d'une