Page 1

11 "

[]

Preqnstallation Requirements .................................................. 2

Electrical Requirements .............................................................. 2

Exhaust System Requirements ............................................... 2-3

Gas Supply Requirements ................................................ 3

Location of Your Dryer ....................................................... 3

Roughqn Dimensions ......................................................... 4

Mobile Home InstaFFation ..................................................... 5

Unpacking ..................................................................... 5

Reversing Door Swing ........................................................................ 6

Electrical Installation ....................................................................... 7

Grounding Requirements .............................................................. 7

Electrical Connections--3-wire ........................................... 7

Electrical Connections--4-wire .......................................... 8

Gas Connection ............................................................... 8

General installation ............................................................ 8

Replacement Parts ............................................................ 8

Francys ........................................................................... 9-16

Avant I'installation ............................................................. g

Installation _qectrique ...................................................... f_

Evacuation de I'air ............................................................... 9-10

Alimentation en gaz ....................................................... 10

Emplacement de la secheuse .......................................... 11

Dimensions de I'emplacement .......................................... 12

Installation darts une maison mobile ..................................... 13

D_ballage ........................................................... 13

Porte Reversible ................................................................ 14

Installation _,lectrique ..................................................... I 5

Mise _ la terre ........................................................................... 15

Branchement electrique - 3 fils .................................................. 15

Branchement _,lectrique - 4 fils ........................................... 16

Installation .......................................................... 16

Pieces de rechange .............................................................. 16

Before beginning #_stallation, carefully read these instructions, This will simpfify the installation and ensure the dryer is installed correctly

and safely. Leave these instructions near the Dryer after installation for future reference,

NOTE: The electrical service to the Dryer must conform with local codes and ordinances and the latest edition of the National Electrical Code, ANSI/NFPA

70, or in Canada, the Canadian electrical code C221 part 1.

NOTE: The gas service to the Dryer must conform with local codes and ordinances and the latest edition of the National Fuel Gas Code ANSI Z223 I, or in

Canada, CAN/ACG B149.I-2000

NOTE: The Dryer is designed under ANSI Z 21.5.1 or ANSI/UL 2158 - CAN/CSA C222 No. 112 (latest editions) for HOME USE only. This Dryer is not

recommended for commercial applications such as restaurants or beauty salons, etc

Avant de commencer, lire attentivement te present document, Cola simptifiera l'instaltation et assurera la pose

correcte et s_curitaire de ta s_cheuse. Apr_s IqnstaHadon, laisser ce document _ proximit_ de la s_cheuse pour r_f_rence future.

REMAROUE : L'alimentation el_,ctrique de las_cheuse doit respecter los codes et ordonnances Iocaux ainsi que I'_'_ditionla plus re€onto du dode ANSI/NFPA 70,

ou au Canada, le Code canadien d'electricit_, ACNOR C22,1, pattie1,

: L'alimentation en gaz de la J, cheuse dolt respecter los codes et ordonnances Iocaux ainsi que I'edition la plus recente du Code ANSI Z22_/.1, ou

au Canada, le code CAN/ACG B149,I-2000,

: La secheuse est concue conformement au code ANSI Z 21.5.1 ou ANSI/UL 2158 - CAN/ACG C22.2 No. 112 (l'#_dition la plus r_cente) pour un

USAGE DOMESTIQUE seulement. Cette s_,cheuse n'est pas recommandee pour utilisation commerciale, comme par exemple un restaurant ou un salon de

coiffure, etc,

damage, personal injury or loss of life,

- Do not store or use gasoline or other flammable vapors and liquid in the vicinity of this or any other appliance,

o WHAT TO DO IF YOU SMELL GAS

. Do not try to light any appliance,

Do not touch any electrical switch; do not use any phone in your building,

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installel, service agency or the gas supplier.

dommages materiels, de blessures et de mort,

Ne pas entreposer ni utiliser d'essence ou d'autres vapeurs ou liquides inflammables _ proximit_ de cette secheuse ou de tout autre appareil

_ductrorn_mager

QUE FA_RE 5"_L Y A UNE ODEUR DE GAZ

. N'al]umer aucun appareil _'_l_ctrique.

Ne toucher aucun commutateur _lectrique; ne pas utiliser le t#,16phone darts I'immeuble,

Faire sortir tous los occupants de la piece, de I'immeuble ou de la zone avoisinante,

Appeler la compagnie de gaz imrnc:_diate-ment en utilisant le t61_phone d'un voisin. Suivre los instructions de la compagnie de gaz

. S'il est impossible de joindre la compagnie de gaz, appeler los pompiers,

L'installation et los reparations doivent _tre effectuees par un technicien qualifi_,, un agent de service ou la cornpagnie de gaz,

For your safety the information in this manual must be followed to minimize the risk of fire or explosion or to prevent property

Pour votre s_curit#_, suiwe los directives donn#_es darts le present guide afin de minimiser los risques d'incendie, d'explosion, de

Printed in U.S.A. P/N 134722000 (0601)

Page 2

PREqNSTALLATION REQUIREMENTS

EXHA UST 5 Y$TEM REQUIREMENTS

Tools and MateHMs Required for ktstalladon:

1. PhiBps head screwdriver

2. Channe[qock adjustable pliers.

3, Carpenter's [evek

4, Hat or straight blade screwdriver,

5. Duct tape,

6, Rigid or flexible metal 4 inch (10.2 cm) duct,

7. Vent hood.

8, Pipe thread sealer (Gas).

g, Plastic knife.

ELECTRICAL REQUIREMENTS

ELECTRIC Dryer

CIRCUIT - individual 30 amp. branch circuit fused with 30 amp, minimum

time delay fuses or circuit breaker.

POWER SUPPLY - 3 wire or 4-wire, 240 volt, single phase, 60 Hz,

Alternating Current

POWER SUPPLY CORD KiT - The dryer MUST employ a 3<onductor

power supply cord NEMA 10-30 type SRDT rated at 240 volt AC

minimum, 30 amp., with S open end spade lug connedors with upturned

ends or closed loop connectors OR a 4<onductor power supply cord

NEMA 14-30 type SRDT or ST (as required) rated at 240 volt AC

minimum, 30 amp., with 4 open end spade lug connectors with upturned

ends or closed loop connectors and marked for use with clothes dryers.

If being installed in a new branch circuit installation, manufactured

(mobile) home, recreational vehicle or area which prohibits grounding

through the neutral conductor, the dryer MUST employ a 4<onductor

power supply cord NEMA 14-€0 type SRDT or ST {as required) rated at

240 volt AC minimum, 30 amp,, with 4 open end spade lug connectors

with upturned ends or closed loop connectors and marked for use with

clothes dryers, See ELECTRICAL CONNECTIONS for additional

instructions.

CANADA - A 4 wire power cord is installed on dryer,

OUTLET RECEPTACLE - NEMA 10-30R (3-wire) receptacle or NEMA 14-

:_0R (4-wire) receptacle to be located so the power supply cord is

accessible when the dryer is in the installed position

NEMA 10-30R NEMA 14-30R

I GAS Dryer

CiRCUiT - Individual 15 amp. branch circuit fused with a 15 amp.

maximum time delay fuse or circuit breaker.

POWER SUPPLY - 3 wire, 120 volt single phase, 60 Hz, Alternating

Current.

POWER SUPPLY CORD - The dryer is equipped with a 120 volt 3-wire

power cord,

Use separately fused circuits for washers and dryers, and DO NOT

operate a washer and a dryer on the same circuit.

NOTE: Do not under any

circumstances remove

grounding prong from

plug.

Use only 4 inch (10,2 cm) diameter (minimum) rigid or flexible metal duct

and approved vent hood which has a swing-out damper(s) that open

when the dryer is in operation. When the dryer stops, the dampers

automatically close to prevent drafts and the entrance ol insects and

rodents. To avoid restricting the outlet, maintain a minimum of 12 inches

(30.5 cm) clearance between the vent hood and the ground or any other

obstruction,

and safe operation of your dryer. Failure to follow these

instructions can create excessive drying times and fire hazards.

Excessive lint can build up inside exhaust system and create a fire hazard

and restrict air flow. Restricted air flow will increase dryer times. If your

present system is made up of plastic duct or metal foil duct, replace it

with a rigid or flexible metal duct. Ensure the present duct is free of

any tint prior to installing dryer duct.

lint will be expelled into the laundry area. An accumulation of lint in

any area of the home can create a heakh and fire hazard. The dryer

exhaust system MUST be exhausted to the outside of the dwelling!

dothing, draperies/curtains, paper) to come in contact with exhaust

system. The dryer MUST NOT bo exhausted into a chimney, a wall, a

ceiling, or any concealed space of a building which car/ accumulate lint,

resulting in a fire hazard.

elbows allowed in the "MAXIMUM LENGTH" charts car/ cause an

accumulation of lint in the exhaust system. Pluggh'/g the system :ould

create a fire hazard, as well as increase drying times.

nor use any screws or Hvets to assemble the exhaust system. Lint

car/ become caught in the screen, on the screws or rivets, clogging the

duct work and creating a fire hazard as well as increasing drying times.

Use an approved vent hood to terminate the duct outdoors, and seal all

joints with duct tape All male duct pipe fittings MUST be installed

downstream with the flow of air,

_r__ Explosion hazard. Do not install the dryer where

gasofine or other flammables are kept or stored, If the dryer is

installed in a garage, it must be a minimum of 18 inches (45.7 cm) above

the floor. Failure to do so can result in death, explosion, fire or burns,

Number

of

90°

Turns

0

1

2

3

4

Number

of

90°

Turns

The following are specific requirements for proper

Do not use plastic flexible duct to exhaust the dryer

if the dryer is not exhausted outdoors, some fine

Do not aflow combustible materials (for example:

Exceeding the length of du_ pipe or number of

Do not screen the exhaust ends of the vent system,

MAXiMUM LENGTH

of 4" (10.2 cm) Dia. Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

Louvered

(10.2 cm)

6O ft.

52 ft.

44 ft.

32 ft.

28 ft.

of 4" {10.2 cm) Dia. Flexible Metal Duct

(18.28 m}

(15.s4m}

(13.41 m)

(9.75 m)

(8.53 m)

MAXIMUM LENGTH

VENT HOOD TYPE

{Preferred)

Louvered

(6.35 cm)

48 ft.(14.63 m)

40 ft.(12.19 m)

32 ft. (9,75 m)

24ft, (7:11 m)

16 ft. (487m)

(I0.2 cm)

0

I

2

3

30 ft. (9,I4 m)

22 ft. (6,71 m)

14 ft. (4,27 m)

NOT RECOMMENDED

(6.35 cm)

18 ft. (5.49 m)

14ft. (4.27 m)

10 ft, (3.05 m)

Page 3

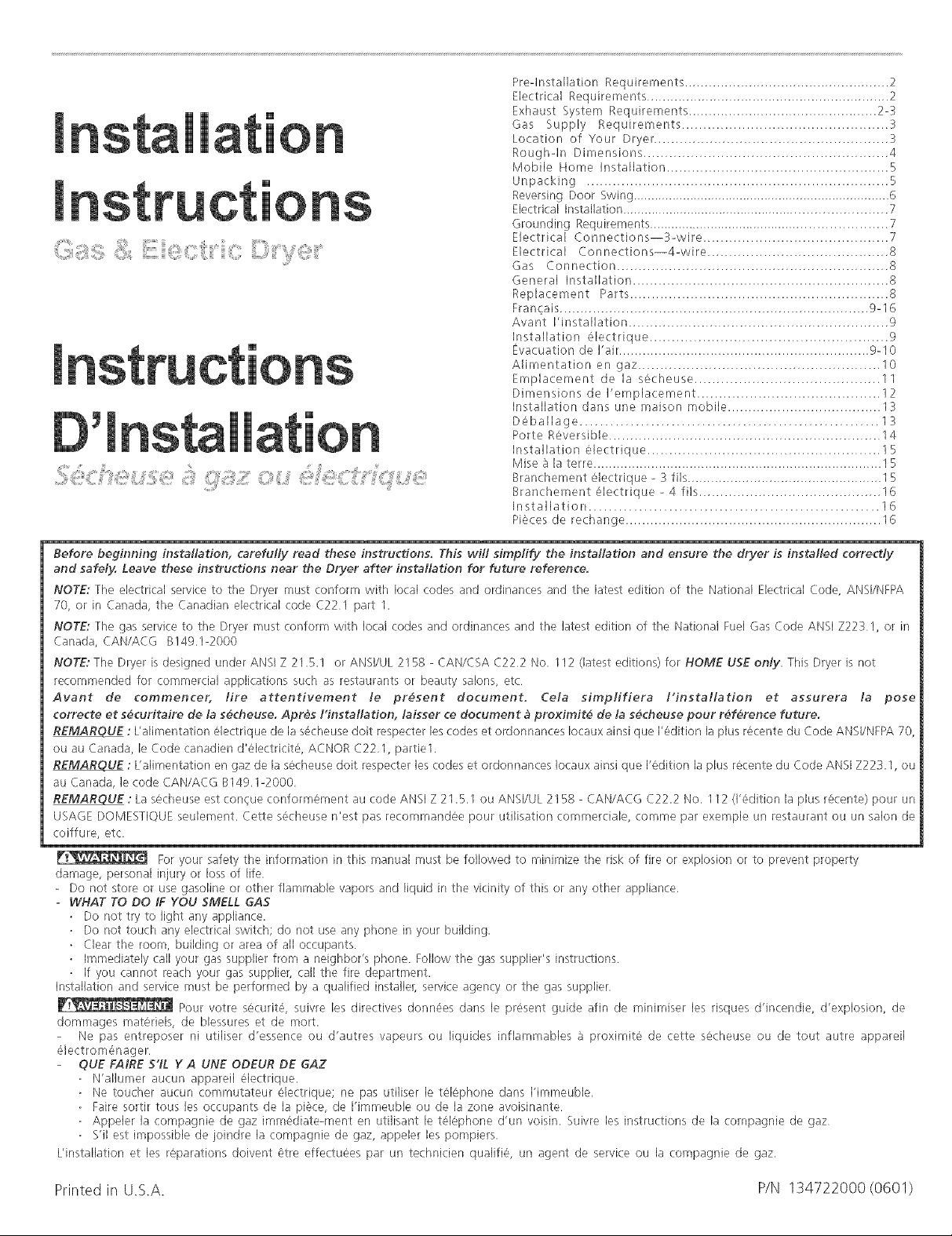

_JNCORRECT

7 The dryer MUST be isolated from the gas supply piping system

during any pressure testing of the gas supply piping system at test

pressures equal to or less than

I/2 psig (345 kPa),

INSTALLMALEFITTINGSINCORRECTDIRECTION

Ininstallationswheretheexhaustsystemisnotdescribedintilecharts,

thefollowingmethodmustbeusedtodetermineiftheexhaustsystemis

acceptable:

I. Connectaninclinedordigitalmanometerbetweenthedryeraridthe

pointtheexhaustconnectstothedryer,

2. Setthedryertimerandtemperaturetoairfluff(cooldown)andstart

thedryer

3. Readthemeasurementonthemanometer

4. ThesystembackpressureMUST NOT be higher than 0.75 inches of

water column, if the system back pressure is less than 0.75 inches

of water column, the system is acceptabb. If the manometer reading

is higher than 0,75 inches of water column, the system is too

restrictive and the installation is unacceptable,

Although vertical orientation of the exhaust system is acceptable, certain

extenuating circumstances could affect the performance of the dryer:

Only the rigid metal duct work should be used.

Venting vertical through a roof may expose the exhaust system

to down drafts causing an increase in vent restriction.

Running the exhaust system through an u/finsulated area may

cause condensation and faster accumulation of lint.

Compression or crimping of the exhaust system will cause an

increase in vent restriction.

The exhaust system should be inspected and cleaned a minimum of

every I8 months with normal usage. The more the dryer is used, the

more often you should check the exhaust system and vent hood for

proper operation,

EXHAUST DIRECTION

All dryers shipped from the factory are set up for rear exhausting.

Howevel, on electric dryers, exhausting can be to the right or left side of

the cabinet or the bottom of the dryer. On gas dryers, exhausting can be

to the right side of the cabinet or the bottom of the dryer. Directional

exhausting can be accomplished by installing Exhaust Kit, P/N

131456800, available through your parts distributor. Follow the

instructions supplied with the kit.

EXHAUST DUCT LOCATtNG DiMENSiONS

LOCATION OF YOUR DRYER

DO NOT INSTALL YOUR DRYER:

1. In an area exposed to dripping water or outside weather conditions.

2, In an area where it will come in contact with curtains, drapes, or

anything that will obstruct the flow of combustion and ventilation air,

3, On carpet, Floor MUST be solid with a maximum slope of 1 inch (2.54

cm).

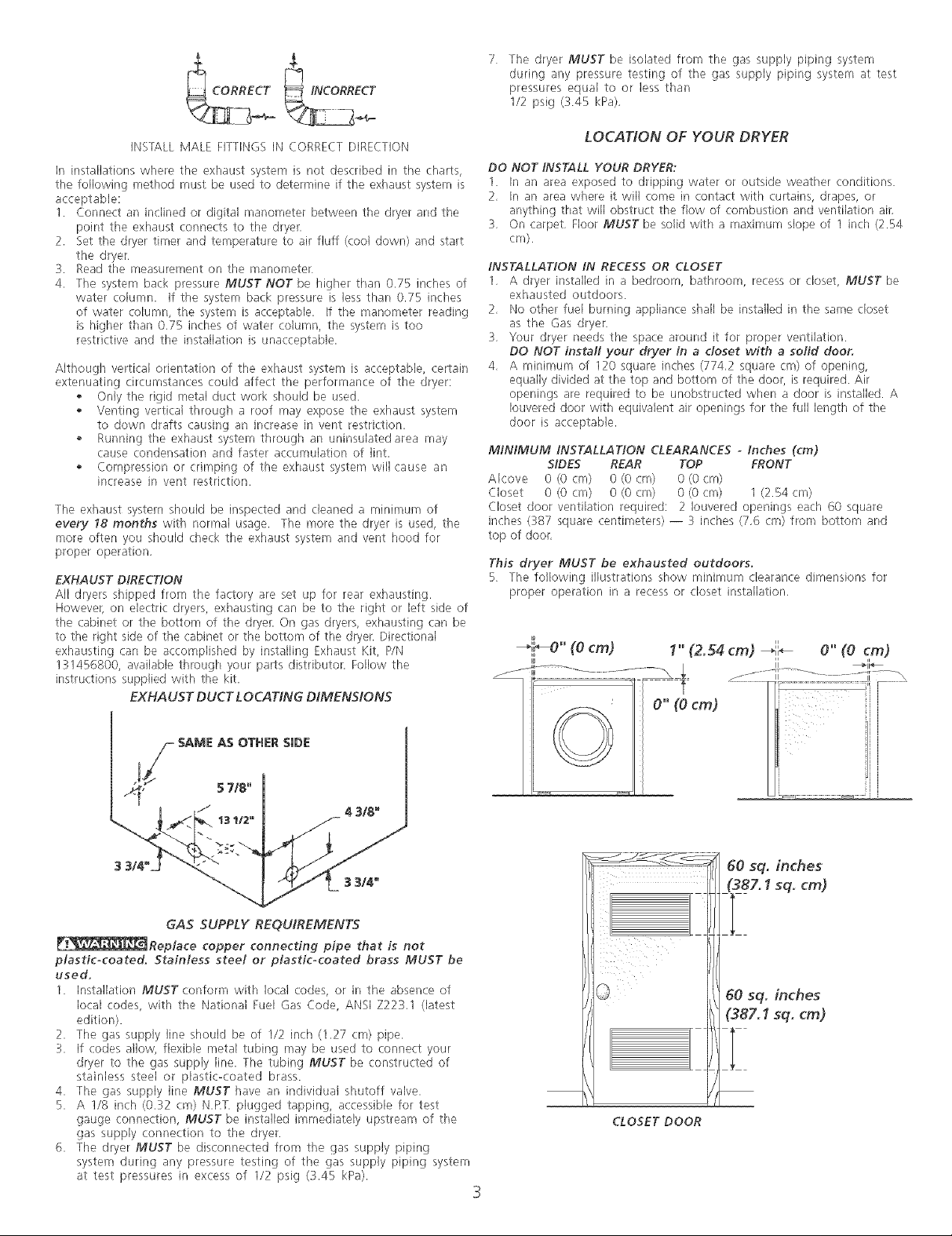

iNSTALLATION IN RECESS OR CLOSET

1, A dryer instalk_d in a bedroom, bathroom, recess or closet, MUST be

exhausted outdoors.

2, No other fuel burning appliance shall be installed in the same closet

as the Gas dryer.

:L Your dryer needs the space around it for proper ventilation.

DO NOT instafl your dryer in a closet with a sofid door.

4, A minimum of 120 square inches (774,2 square cm) of opening,

equally divided at the top and bottom of the door, is required. Air

openings are required to be unobstructed when a door is installed. A

Iouvered door with equivalent air openings for the full length of the

door is acceptable.

MINIMUM INSTALLATION CLEARANCES - Inches (cm)

SIDES REAR TOP FRONT

Alcov:_ 0(0:m) 0(0:m) 0(0:m)

Closet 0 (0 cm) 0 (0 cm) 0 (0 cm) I (2.54 cm)

Closet door ventilation required: 2 Iouvered openings each 60 square,

inches (38-7 square centimeters) -- 3 inches (7,6 cm) from bottom and

top of door,

This dryer MUST be exhausted outdoors,

5 The following illustrations show minimum clearance dimensions for

proper operation in a recess or closet installation,

5 7/8"

/_ SAME AS OTHER SIDI:

/ 4 318"

13I/2"

GAS SUPPLY REQUIREMENTS

_Replace copper connecting pipe that is not

plastic-coated, Stainless steel or plastic-coated brass MUST be

used,

1. Installation MUST corfform with local codes, or in the absence of

local codes, with the National Fuel Gas Code, ANSI Z223,I (latest

edition).

2. The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3. if codes allow, flexible metal tubing may be used to connect your

dryer to the gas supply line. The tubing MUST be constructed of

stainless steel or plastic-coated brass.

4. The gas supply line MUST }lave an individual shutoff valve,

5. A I/8 inch (0.32 cm) N,RT, plugged tapping, accessible for test

gauge connection, MUST be installed immediately upstream of the

gas supply connection to the dryer.

6. The dryer MUST be disconnected from the gas supply piping

system during any pressure testing of the gas supply piping system

at test pressures in excess of I/2 psig (3.45 kPa).

CLOSET DOOR

3

Page 4

23%"

(60°33)

Dryer tnstM/ation Dimensions

Free-Standing & Under Counter

24"

(60.96) Electrical euppty

__(13.97) [_

5.875"(¢4.93)

To base

exhaust

4.375"{11._2)

To side

exhausts

5.g"(12.7) 5 !I

CenterJibe (12.70)

r height for rear, __

29%"

175,57)

on rear of unit

13%"

(34,29) 23/8"

35 _

'_8&90)

34 _

(86.:6)

4---

2

To front of cabinet

88.25"{71.78)

To c_ear kobs

28.75"(73.03)

To clear door

29.8"(74.93)

To clear open door

53"(134.82)

85/8"

(8.67)

pipe on rear

, right, left refit _'4 Gas s_y

_!t 5/8" of unit

(4.t3) 27"

(s&sa)

Stacked Dryer tnstM/adon Dimensions

72.00"

(172.88)

Gas

supply

pipe on

rear of

unit "--.,

2.375",

(8.03)

(34.29) _" ,,

27 _

(88.58)

/

\

I"

(&72)

I 2,25"

E_ectrica_

supply on

rear of

unit

inches (cm)

38.25"

(87.fS)

4

Page 5

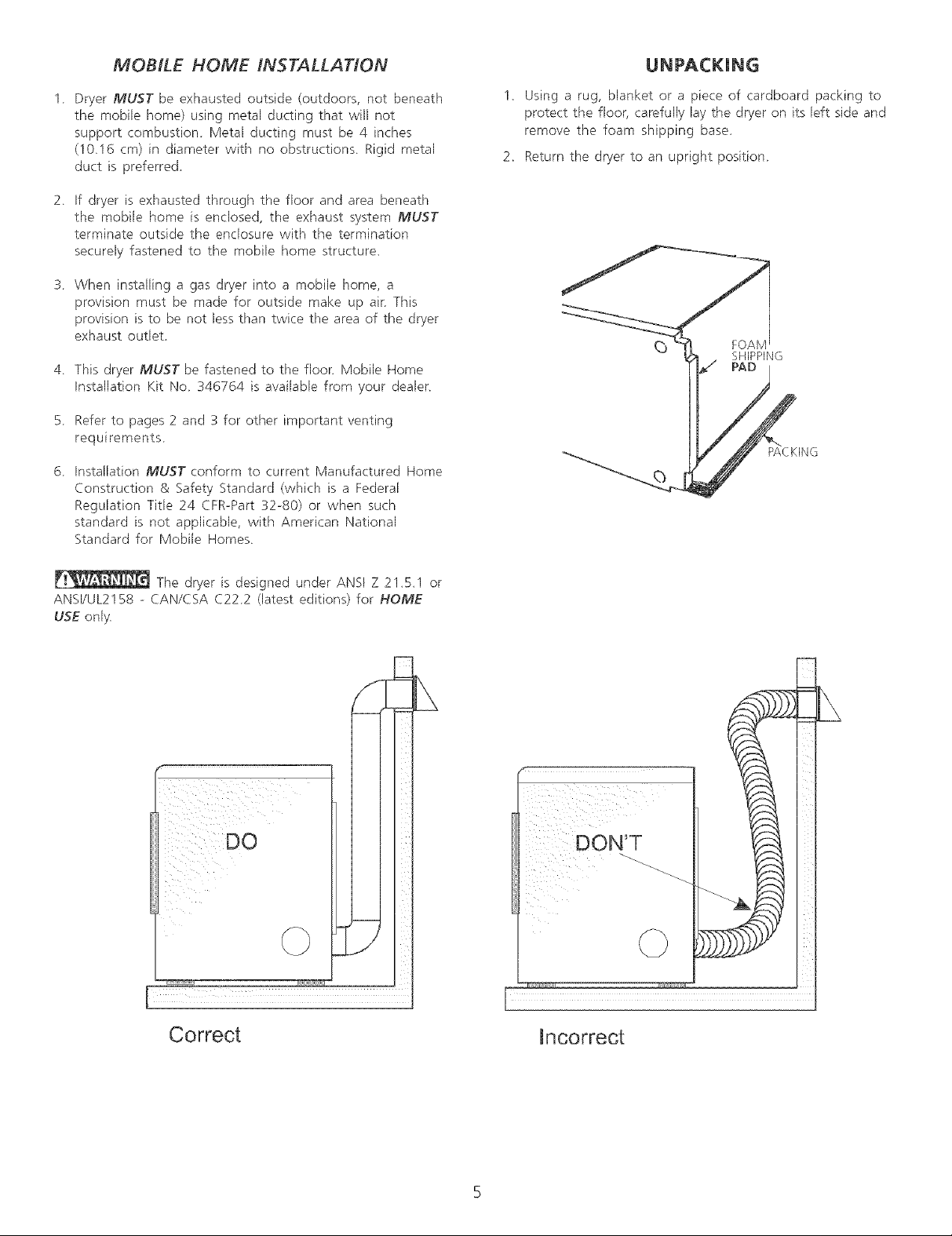

MOBILE HOME INSTALLATION

UNPACKMNG

1 Dryer MU5T be exhausted outside (outdoors, not beneath

the mobile home) using metal ducting that will not

support combustion Metal ducting must be 4 inches

(10,16 cm) in diameter with no obstructions Rigid metal

duct is preferred

2 If dryer is exhausted through the floor and area beneath

the mobile home is enclosed, the exhaust system MUST

terminate outside the enclosure with the termination

securely fastened to the mobile home structure,

3 When installing a gas dryer into a mobile home, a

provision must be made for outside make up air This

provision is to be not less than twice the area of the dryer

exhaust outlet

4 This dryer MUST be fastened to the floor, Mobile Home

Installation Kit No 346764 is available from your dealer,

5 Refer to pages 2 and 3 for other important venting

requirements

6 Installation MUST conform to current Manufactured Home

Construction & Safety Standard (which is a Federal

Regulation Title 24 CFR-Part 32-80) or when such

standard is not applicable, with American National

Standard for Mobile Homes

1, Using a rug, blanket or a piece of cardboard packing to

protect the floor, carefully lay the dryer on its left side and

remove the foam shipping base

2. Return the dryer to an upright position

FOAM

SHIPPING

The dryer is designed under ANSI Z 21.5.1 or

ANSI/UL2158 - CAN/CSA C222 (latest editions) for HOME

USE only.

DO

Correct

Incorrect

Page 6

DRYER DOOR REVERSAL mNSTRUCTIONS

Be sure to wear gloves while reversing the door assembly.

5. Remove the hinge cutout plug.

1. Open the dryer door. opposite side of the outer door.

2. Remove the five screws, 1 thru 5 and the two screws, 6 and

7, that attach the inner door assembly to the outer door

assembly. Lift the outer door assembly out of the inner

door assembly and place on a soft flat surface.

6. Removethetwo screwsthatsecurethe hingetothefront

pane!.

3. Remove the two (2) hinge attachment screws and place the

inner door assembly on a soft fiat surface.

Rotate it and install it in the

4. Remove the screws that attach the strike plate. Rotate the

strike plate and reattach it to the opposite side of the inner

door.

7. Remove the catch plate from the front pane!.

8. Rotate and reinstall the hinge and the catch plate in the sides

opposite of where they were removed.

9. Reattach the door assemblies in reverse order.

10. Close the door.

Page 7

ELECTRICAL INSTALLATION

I ELECTRICDryer m[

F:_ The following are specific requirements for proper and

safe electrical installation of your dryer, Failure to follow these

instructions can create electrical shock andlor a fire hazard.

This appfiance MUST be properly grounded. Uectrkal

shock can result if tile dry_,r is not properly grounded Follow the

instructions in this manual for proper grounding.

Do not use an extension cord with this dryer. Some

extension cords are not designed to withstand the arnounts of electrical

current this dryer utilizes and can melt, creating electrical shock and/or

fire hazard. Locate the dryer within reach of the receptacle for the

length power cord to be purchased, allowing some slack in the cord,

Refer to the pre-installation requirements in this manual for the proper

power cord to be purchased.

A U.L approved strain refief must be installed onto

power cord. If the strain relief is not attached, the cord can be pulled out

of the dryer and can be cut by any movement of the cord, resulting in

electrical shock,

Do not use an aluminum wired receptacle with a

copper wired power cord and plug (or vice versa). A chemical

reaction occurs between copper and ahminum and carl cause electrical

shorts. The proper wiring and receptacle is a copper wired power

cord with a copper wired receptacle.

NOTE: Dryers operating on 208 volt pow_,r supply will have longer

drying times than operating on 240 volt power supply

GROUNDING REQUIREMENT5

Improper connection of the equipment grounding conductor

can result in a risk of electrical shock. Check with a licensed electrician if

you are in doubt as to whether the appliance is properly grounded,

For a grounded, cord-connected dryer:

1, The dryer MUST be grounded, in the event of a malfunction or

breakdown, grounding will reduce the risk of electrical shock by a

path of least resistance for electrical current,

ALL GASDryers

This dryer isequipped with athree-prong (grounding) plug for your protection

against shock hazard and should be plugged directly into a properly grounded

three-prong receptacle. Do not cut or remove the grounding prong from this

plug,

ELECTRICAL CONNECTtONSFOR 3-WIRE SYSTEM

NONoCANAD/AN ELECTR/C Dryer

Remove th_ screws securing the terminal block access cover and the,

strain relief mounting bracket located on the back of the dryer upper

corner

2,

Install a U.L. approved strain relief into the power cord entry hole of

the mounting bracket. Finger tighten the nut only at this time

3,

Thread a U,L. approved 30 amp. power cord, NEMA 10-30 type

SRDT, through the strain relief.

4,

Attach the power cord neutral (center wire) conductor to the silver

colored center terminal on the terminal block, Tighten the screw

securely.

Attach the remaining two power cord outer conductors to the outer

brass colored terminals on the terminal block. Tighten both screws

securely.

l_:_J_ Do not make a sharp bend or crimp wiring/conductor

at connections

Reattach the strain relief mounting bracket to the back of the dryer

with two screws Tighten screws securely.

GREEN

1

2, If your dryer is equipped with a power supply cord having an

equipment-grounding conductor and a grounding plug, the plug

MUST be plugged into an appropriate, copper wired receptacle that

is properly installed and grounded in accordance with all local codes

and ordinances. If in doubt, call a licensed electrician. Do not

modify plug provided with the appliance.

For a permanently connected dryer."

1, The dryer MUST be connected to a grounded metal, permanent

wiring system; or an equipment grounding conductor must be run

with the circuit conductors and connected to the equipment-

grounding terminal or lead on the appliance.

Canadian ELECTR/C Dryer

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check with a licensed

electrician if you are in doubt as to whether the appliance is properly

grounded.

For a qrounded, cord-connected drw, r:

1, The dryer must be grounded, In the event of a malfunction or

breakdown, grounding will reduce the risk of electrical shock by a

path el least resistance for electrical current,

2, Since your dryer is equipped with a power supply cord having an

equipment-grounding conductor and a grounding plug, the plug must

be plugged into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances, if in

doubt, call a licensed electrician Do not modify plug provided

with the appliance,

BRACKET POWER CORD

7.

Tighten the screws securing the cord restraint firmly against the

power cord.

8.

Tighten the strain relief nut securely so the strain relief does not

turn.

9.

Reinstall the terminal block cover.

Page 8

ELECTRICAL CONNECTIONS FOR 4-W/RE SYSTEM

NONoCANAD/AN ELECTR/C Dryer

1. Rer'now_th_ screws securing th_ terminal block access cover and

the strain relief mounting bracket located on the back of the dryer

upper corner,

2. Install a U.L, approved strain relief in the entry hole of the mounting

bracket, Finger tighten the nut only at this time.

VALVE OPEN / GAS FLOW POSITION

4. lest all connections by brushing on a soapy water solution. NEVER

test for gas leaks with an open flame.

3. Remove the ground wire from the green ground screw located

above the terminal block.

GREEN GROUND WIRE

SCREW TERMINAL

GROUND WHITE TO THESE

WIRE HREADS

4. Thread a U.L. approved 30 amp power cord, NEMA 14-30 type ST or

SRDTthrough the strain relief.

TYPICAL 4 BLACK

CONDUCTOR TYPICAL 4

30 AMP NEMA 14o30 TYPE SRDT OR BT "_GREEN

Attach tile green power cord ground wire to the cabinet with the

green ground screw,

Attach the white (neutral) power cord conductor from the power

cord and the neutral ground wire from the dryer harness to the

silver-colored center terminal on the terminal block. Tighten the

screw securely.

Attach the red and black power cord conductors to the outer

brass<olored terminals on the terminal block,

at the connections,

8. Tighten the screws securing the cord restraint firmly against the

power cord.

9, Tighten the strain relief nut securely so the strain relief does not

turn,

10, Reinstall the terminal block access cover.

GREEN POWER CORD

SILVERTERMINAL

BLOCK

BLACK TIGHTEN

NUT

STRAIN\

RELIEF "

BRACKET.

>OWER

CORD

CONDUCTOR WHITE

_ ,_P_ED

Do not make a sharp bend or crimp wiring/conductor

GAS CONNECTION

Remove the shipping cap from gas pipe at the r_,ar of th_ dryer.

NOTE: DO NOT connect the dryer to L.R gas service without

converting the gas valve. An L,R conversion kit must be installed

by a qualified gas technician,

GENERAL INSTALLATION

1. Connect the exhaust duct to outside exhaust syst_,m (see pages 3

and 4). Use duct tape to seal all joints,

With the dryer in its final position, adjust one or more of the legs

until the dryer is resting solid on all four legs Place a level on top

of the dryer, The dryer MUST be level and resdng sofid on aft

four legs.

3. Plug the power cord into a grounded outlet. NOTE: Check to

ensure the power is off at circuit breaker/fuse box before plugging

the power cord into the outlet.

Turn on the power at the circuit breaker/fuse box.

Before operating the dryer, make sure the

dryer area is clear and free from combustible materials,

gasoline, and other flammable vapors. Also see that

nothing (such as boxes, clothing, etc.) obstructs the flow

of combustion and ventilation air.

Run the dryer through a cycle check for proper operation.

NOTE: On gas dryers, before the burner will light, it is necessary

for the gas line to be bled of air. If the burner does not light within

45 seconds the first time the dryer is turned on, the safety switch

will shut the burner off. if this happens, turn the timer to "OFF" and

wait B minutes before making another attempt to light,

6. If your dryer does not operate, please review the "Avoid Service

Checklist" located in your Use and Care Guide before calling for

service,

Place these instructions in a location near the dryer for future

reference.

NOTE: A wiring diagram/tech sheet is in an envelope attached to

the inside side panel of the dryer by the blower housing,

Pedestal

A pedestal accessory, Model No. APWD15W, specifically designed

for this dryer may be used when elevating the dryer for ease of use,

Failure to use accessories certified by the manufacturer could result

in personal injury, property damage or damage to the dryer,

REPLA CEMENT PARTS

If replacements parts are needed for your dryer, contact the source

where you purchased your dryer, call 1-800-944-9044, or visit our

website, www.frigidaire.com, for the Frigidaire Company Authorized

Parts Distributor nearest you.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing

Destroy the carton and plastic bags after the dryer is

unpacked, Children might use them for play, Cartons covered with

rugs, bedspreads, or plastic sheets can become airtight chambers

causing suffocation, Place all materials in a garbage container or make

materials inaccessible to children.

Connect a 1/2 inch (1,27 cm) I.D. semi-rigid or approved pipe from

gas supply line to the 3/8 inch (0.96 cm) pipe located on the back

of the dryer (see pages 6 and 7). Use a I/2 inch to :V8 inch (1,27

cm to 0.96 cm) reducer for a connection. Apply an approved

thread sealer that is resistant to the corrosive action of liquefied

gases on all pipe connections,

3. Open the shutoff valve in the gassupply line to allow gas to flow

through the pipe.

The instructions in this manual and all other literature

included with this dryer are not meant to cover every possible

condition arid situation that may occur. Good safe practice and caution

MUST be applied when installing, operating arid maintaining any

appliance,

8

Page 9

AVANT L'INSTALLATION

Oud/s et materiel requis pour I'insta/lation :

1. Tournevis apointe cruciforme

2. Pinces multiprise

3. Niveau de menuisier

4. Tournevis a pointe plate ou a lame droite

5. Ruban adh6sif pourconduites

6. Conduite en metal rigide ou flexible de 10,2 cm (4 po)

7. Grille de sortie

8. P_te a joint pour conduites (modele a gaz)

9. Couteau 8 mastic en plastique

INSTALLATION ELECTRIQUE

CORDON D'ALIMENTATION ELECTRIQUE - La secheuse est

pourvue d'un cordon d'alimentation electrique _ 3 fils de

volts,

120

REMARQUE: I1ne faut _[ _1_

terre de la fiche, k /} Y_

. _ A LA TERRE

EVACUATION DE L'A_R

Utiliser uniquement une conduite en metal rigide ou flexible de

10,2 cm (4 po) de diametre (minimum) ainsi qu'une grille de

sortie approuvee pourvue de clapets qui s'ouvrent Iorsque la

secheuse fonctionne. Quand la secheuse s'arr6te, los clapets se

ferment automatiq uement pour eviter loscou rants d'air et I'entr6e

d'insectes ou de rongeurs. Afin de ne pas obstruer I'evacuation

S_cheu.ce.¢ ELECTRIOUE5

CIRCUIT- D_rivation distincte de 30 A avec fusibles

retardement ou disjoncteurs d'au moins 30 A.

AMMENTATtON ELECTRIQUE - 3 fils, 240 volts, une phase,

60 Hz, courant alternatif. (Canada - 240 volts, une phase, 60 Hz,

courant alternatif.)

CORDON D'ALIMENTATtON ELECTRIQUE - La secheuse DOIT

Ctre reliee _ un cordon d'alimentation electrique _ 3 conducteurs

NEMA 10-30 de type SRDTd' une capacite minimale de 240 volts,

courant alternatif, 30 A, avec fiche en L a 3 broches pleines ou

repliees con_ue pour le branchement d'une secheuse. Si 6tant

insta!le darts une nouvelle installation de circuit de branche,

manufacturee (mobile) a la maison, v_hicule la recreationnel

ou secteur qui interdisent fondre par le conducteur neutre, elle

DOtT Ctre reliee a un cordon d'alimentation electrique

4 conducteurs NEMA 14-30 de type SRDTou ST(au besoin) d'une

capacite minimale de 240 volts, courant alternatif, 30 A, avec

fiche en L _ 4 broches pleines ou repliees con_ue pour le

branchement d'une secheuse. Se reporter ;_ la section

BRANCHEMENT ELECTRIQUE D'UNE INSTALLATION/_ 4 FILS.

(Canada - Cordon d'alimentation _ 4 fils branche a la secheuse.)

PRISE - Prise NEMA 10-30R situee de faqon _]ce que le cordon

d'alimentation electrique soit accessible une fois la secheuse en

place. (Canada - prise NEMA de 14-30R.)

AUMENrA_ON

PRISEMURALE(CUIVRE}

SOUSR£SERVEDESEXIGENCES

LOCALES

5#cheuses # G,4Z

CIRCUIT- Derivation distincte de 15 A avec fusible a retardement

ou disjoncteur d'au plus 15 A,

ALIMENTATION ELECTRIQUE- 3 fils, 120 volts, une phase, 60

Hz, courant alternatif.

NEMA 10-30R (CUIVRE)

de Fair, laisser une distance minimum de 30,5 cm (12 po) entrela grille de sortie et le sol ou tout autre obstacle.

Le_ mises en garde qui suivent _e

rapportent directement au fonctionnement correct et

secufitaire de la secheuse. Toute derogation _ ce_ mises

en garde pourrait ralentir le sechage et entra_ner des

risques d'incendie.

_Ne pas utiliser de conduites en plastique flexible pour evacuer

Fair de la secheuse. Une quantite excessive de charpie pourrait

s'accumuler dans la conduite d'evacuation, ce qui r_duirait la

circulation de I'air et presenterait un risque d'incendie. Toute

obstruction de la circulation de Fair ralentit le sechage. Si la

conduite existante est en plastique ou en papier m_tallique, la

par une conduite en metal rigide ou flexible. S'assurer

qu'i/ n'y a pas de charpie clans la conduite exi_tante avant

d'in_taHer la conduite de/a secheuse.

PI_Si I'air n'etait pas repousse ,_!'exterieur de la maison de

petites particules de charpie se retrouveraient darts la piece oO

est installee la secheuse. Toute accumulation de charpie dans la

maison peut presenter des risques pour la santo et des risques

d'incendie. La conduite d'evacuation de la secheuse

DOIVENT se terminer a I'exterieur de/a maison!

Ne laisser aucun materiau inflammable (comme des

v_tements destentures, desrideauxou du papier) entreren

contact avec los conduits d'evacuation. L'air de la s_cheuse NE

DOITPA5 _tre evacue darts une cheminee, un mur_ un plafond

ni tout espace ferm_ d'un batiment oO la charpie pourrait

s'accumuler et presenter un risque d'incendie.

_l_menter la Iongueur du conduit rigide ou le hombre de

coudes permis au tableau _LONGUEUR MAXIMUMs> risque de

reduire la capacite d'evacuation du circuit. Obturer le circuit pout

creer un risque d'incendie et augmenter le temps de sechage.

_Ne pas poser de grillage sur !'ouverture exterieure des

conduites d'evacuation d'air ni utiliser des vis ou des rivets pour

assembler la conduite d'evacuation. De la charpie pourrait

s'emprisonner darts le grillage ou sur los vis ou les rivets et ainsi

engorger la conduite d'evacuation en plus de presenter un risque

d'incendie et de ralentir le sechage. Utiliser une grille de sortie

approuvee pour fermer I'ouverture ext_rieure et sceller tous los

joints _ !'aide d'un ruban adh_sif pour conduites. L'extremite mgle

de chaque composante de la conduite DO/TCtre installee en aval

par rapport _ la circulation de Fair.

Risques d'exptosion. Ne pas installer la

secheuse _ un endroit oO I'on garde de la gazoline ou tout autre

produit inflammable. Si la secheuse est installee dans un garage,

e!le dolt Ctre a un minimum de 45,7 cm (18 po) au-dessus du

plancher. Toute derogation pourrait provoquer lamort, I'explosion,

I'encendie ou los brOlures.

9

Page 10

Nombre de

coudes ,_

90°

0

1

2

3

4

Nombre de

coudes

90 °

o

1

2

3

LONGUEUR MAXIMUM

d'une conduite en metM rigide de

10,I6 cm (4 po) de diam.

TYPE DE GRILLE DE $ORTtE

(Recommand_)

voiet

(4po)

18,28 rn

15,84 rn

13,41 rn

9,75 m

8,53 m

(60 po)

(52 po)

(44 po)

!32 po)

(28po)

14,63 m (48 po)

12,19 m (40 po)

9,75 rn (32 po)

7,31 m (24 po)

4,87 m (16 po)

LONGUEUR MAXIMUM

d'une conduite en metM flexible de

I0,16 cm (4 po) de diam.

TYPE DE GRILLE DE 50RTIE

(Recommande)

voiet

_4p_

9,14 rn (30 po}

6,71 rn (22 po}

4,27 rn (14 po}

NON RECOMMAND_

5,49 rn (18 po)

4,27 m (14 po}

3,05 m (10 p@

Une sortie sur un toit d'un circuit vertical peut exposer celui-

ci _]un contre-tirage et ainsi reduire sa capacit6 d'_vacuation,

L'isolant que dolt traverser un tel circuit peut causer de la

condensation et ainsi reduire la capacite d'evacuation du

circuit,

Un circuit d'6vacuation comprim6 ou ondulant peut voir sa

capacit_ d'_vacuation r6duite.

IIfaut inspecter le circuit d'evacuation et le nettoyer au moins

tousles t8 mois d'utilisation normale. Plus la secheuse est

utilis6e, plus il faut proceder souvent a une v6rification du bon

fonctionnement du circuit d'6vacuation et du couvercle du

registre ou de 1'6vent.

DIRECTION DE L'EVA CUATtON D'AIR

Toutes les s6cheuses empaquet6es par I'usine sont concues de fa_on

ace que I'evacuation d'air se fasse a I'arriere, Toutefois, dans Jecas des

secheuses 61ectriques, 1'6vacuation d'air peut se faire sur la droite ou

sur Ja gauche du bottier ou encore, sous la s6cheuse, Dans le cas des

s6cheuses a gaz, J'6vacuation d'air peut se faire sur la droite du bottier

ou sous la secheuse, On peut donc modifier I'orientation de

J'6vacuation d'air en instalJant un ensemble d'6vacuation d'air n ° de

piece 131456800 disponible chez d'un fournisseur de pi6ces agr6e,

Suivre les directives qui accornpagnent cet ensemble,

EMPLA CEMENT DES BOUCHE5 D'EVA CUATION

COTE

15cm

(s 7/8 pe)

34 cm

11 cm

POSERLESRACCORDS MALES DANS LA BONNE DIRECTION

Pour les installations dont le circuit d'evacuation n'est pas decrit

darts les tableaux, il faut utiliser la m6thode suivante si le circuit

d'evacuation n'est pas acceptable:

1. Brancher un manometre digital ou a tube incline entre la

secheuse et le raccord d'evacuation de la secheuse.

2. Regler la minuterie de la secheuse et la temperature a air froid

(refroidissement) et demarrez la secheuse.

3. Lire la mesure indiquee au manometre.

4. La basse pression ne dolt pas 6tre superieure a 0,75 pouce de

colonne d'eau. Si la basse pression est inferieure a0,75 pouce

decolonned'eau, lecircuitestacceptable. Si la lecture

indique une pression superieure a 0,75 pouce de co!onne

d'eau, la capacit6 du circuit est insuffisante et I'installation

inacceptable.

Bien qu'un circuit vertical soit acceptable, certaines circonstances

att6nuantes peuvent influencer la performance de la secheuse.

IIfaut utiliser uniquement des conduits rigides en metal.

9,5 cm

(3 3/4 po)

9,5 cm

(3 3/4 po)

AMMENTATiON EN GAZ

Remplacer le tuyau de raccordement en

cuivre non recouvert de plastique. II FAUT utiliser du laiton

inoxydaMe ou recouvert de plastique.

1 L'installation DOITrespecter [es codes Iocaux, ou s'il n'existe pas

de codes Iocaux, le code ANS! Z223 1 (l'_dition la plus r_cente) ou

au Canada, le Code actuel CAN/CGA B149

2 La conduite d'aJirnentation en gaz doit mesurer 1,27 cm (1/2 po)

3, Siles codes le perrnettent, un tuyau en rn_tal flexible peut Ctre utilis_

pour connecter la s_cheuse a J'alirnentation en gaz. Le tuyau DOlT

Ctre fabrique en acier inoxydable ou en cuivre avec un revCtement

de plastique

4 La conduite d'alimentation en gaz DOtTcornporter un robinet

d'arr_t distinct

5 Une prise de 0,32 crn (1/8 po) NPT accessible pour le branchement

d'un manometre DOITCtre installee tout juste en arnont du

branchernent de la conduite d'alirnentation en gaz sur la s_cheuse,

6 La secheuse DOIT_tre d_branch_e de [a canalisation de gaz

pendant toute v6rification de pression de I'alirnentation en gaz

des pressions qui d6passent 3,45 kPa (1/2 Ib/po%

7 La s6cheuse DOtTCtre isolee de Ja canaJisation de gaz pendant

toute v6rification de pression de J'alirnentation en gaz a des

pressions egales ou inf6rieures a 3,45 kPa (1/2 Ib/po _)

10

Page 11

EMPLACEMENT DE LA S_CHEUSE

NE PA5 INSTALLER LA SeLCHEUSE:

1, Dans un endroit expos_ a un 6coulement d'eau ou aux conditions

atmosph6riques

2, Dansun endroit o_ elleserait en contact avecdes rideaux, draperies

ou tout ce qui obstruera le flux d'air de combustion et de

ventilation,

3, Surun tapis Leplancher DOIT_tre fermeet presenter une pente

de 2,54 cm (I po) au maximum.

fNSTALLATtON DANS UNE ALC6VE OU UN PLACARD

1, Toute s_cheuse install_e dans une chambre a coucher, une

saJlede bain, une aJc6ve ou un placard DOIT_tre reli_e a une

conduite d'evacuation d'air se terminant _ I'ext_rieur de Ja

maison

2, Aucun autre appareil brOlant du combustible ne dolt _tre

instaJl_ dans le re@meplacard que Jas_cheuse au Gaz,

3, La s6cheuse a besoin d'un d_gagement suffisant pour

permettre la circulation de I'air

NE PA 5 tN5 TALLER LA 5ECHEUSE DA N5 UN PLA CA RD POUR VU

D'UNEPORTE PLEINE,

4. Une ouverture minimum de 774,2 cm 2(120 po 2) r_partie

egaJement entre le haut et le bas de Ja porte est requise, Cette

ouverture ne dolt pas _tre obstru@e Iorsque la porte est en place

Une porte _ volets dont les ouvertures totalisent la norme d_crite

ci-dessus est acceptable,

DL:GAGEMENT5 MtNtMAUX POUR LVNSTALLATtON

en po (cm)

D'AVANT COTES ARRIERE DESSUS

Alc6ve ou sous un

comptoir 0 (0) 0 (0) 0 (0) 0 (0)

Armoire 1 (2,54) 0 (0) 0 (0) 0 (0)

A6ration n@cessaire dans la porte de J'armoire: 2 ouvertures

persiennes de 60 pouces carr6s (387 cm carr_s) chacun - ,_3 pouces

(7,6 cm) du bas et du haut de Japorte.

L'AERATtON DE CETTE 5_'CHEUSE 5E FAIT VER5 L'EXTER]EUR,

5, Lesillustrations qui suivent donnent led@gagement minimum pour

une installation dans une alc6ve ou un placard

--_ii_-O'' (0 cm) 1" (2.54 cm) _;_ O" (0 cm)

0" (O cm)

PORTE DU P_CARD

11

Page 12

Dimensions DqnstMladon De 5echeuse

Independant Et Sous Le Compteur

24"

(60.96)

-- 5%"

_ (13o97)

__S

AHmentation

e_ectrique sur

I'arri_re de I'unite

inches (cm)

25/8"

(&sT)

Aux @chappements

d'arri_re et de base

13%"

293/4"

(34,29) 23/8"

75,57)

5_

(12.70)

- t

gaz sur ['arri_re

de _'unit_

2?'_

(6&$8)

Dimensions Empil#es DqnstMladon De Secheuse

(6o03)÷,

27 _

(68.88)

2,25"

(5.72)

Alimentation

e[ectrique

-- sur I'arri_re

: . @

35 _

:8&e0)

de _'u_it_

Pour affronter [e coffret

28.28"(71.78)

Au× boutons c_airs

28.78"{73.03)

,& la poign_e claire

de porte

28.5"(74.93)

A ['espace libre ouvrez

la porte

83"{134.82)

T

72.00"

(172.88)

_,.378"

[1t.12)

Echappemeats

Lat_raux

[

41 .OO"

(97.18)

Ligne taiHe

centrale

_our arri_re,

i droit, part[,

passage

Pipe

d'offre de

gaz sur

['arri_re

de ['unit_

2.375"J

(8.03)

38.25"

(97.18)

\

(34.29)/ ,

\

: = : ?@@)

I /

[

inches (cm)

12

Page 13

iNSTALLATiON DAN$ UNE MAISON MOBILE

1 L'6vacuation d'air de la s_cheuse DOITse faire a I'ext_rieur de la

maison (a J'6xterieur et non pas au-dessous de la maison mobile)

I'aide de conduit en m_tal non inflammable, a I'epreuve du feu

Lesconduits en m_tal doiventavoir 10,16 cm (4 pouces) de diametre

sans obstructions_ Les conduits en m_tal rigide sont pr6f_rables

2 Si Jaconduite d'_vacuation d'air traverse le pJancher et un espace

ferm6 situ6 sous Ja maison mobile, I'evacuation d'air DOlT se

term iner _ J'ext6rieur de cet espace fermi, et la sortie bien fixee & Ja

structure de la maison mobile

3 Lots de I'installation d' une secheuse a gaz clans une maison mobile,

iJfaut prevoir u n apport d'air ext6rieur L'espace a pr6voir doit _tre

superieur de deux fois celui du conduit d'evacuation de la s_cheuse

4 Cette s6cheuse DOlT _tre fix_e au plancher_ L'ensemble

d'instaJJation no 169840 pour maison mobile est disponible chez

votre distributeun

5 Ser6f6rerauxpages2 et3 pour depJusampJesinformationsurles

exigences de ventilation

6 L'installation DOITrespecter Janorme f_d6rale sur Jaconstruction

et Jasecurit_ des maisons mobiles en vigueur (Manufactured Home

Construction & Safety Standard) (pattie integrante du reglement

f_dera124 CFR Pattie 32-80) ou, Jorsque cette norme ne s'applique

pas, eJle doit respecter Ja norme nationale am6ricaine pour Jes

maisons mobiles (American National Standard for Mobile Homes)

Lorsque J'instaJJation se fait au Canada, die doit se conformer aux

normes ACNOR Z240.

__ La s_cheuse est concue conform6ment a la

normeANSI Z 21_5 loANSI/UL2158- CAN/CSA C22 2 pour un USAGE

DOMESTIQUE seulement

1. A I'aide des quatre coins de protection de I'emballage (deux sur

chaque c6t@, d@oser d_licatement la s_cheuse sur son c6t_ gauche

et retirer le morceau de mousse plac_ sous la secheuse pour

Fexpedition

Pour ne pas endommager la s_cheuse, ne pas

prendre prise sur le panneau de commande pour soulever ou d6placer

la s6cheuse

REMARQUE : Si la s6cheuse dolt 6tre install_e sous un comptoir, le

panneau du dessus peut _tre d_mont_ pour I'installation.

2, Remettre la s_cheuse a laverticale

MORCEAU

DE MOUSSE

/

ALLAGE

Correct

OUI

©

Incorrect

13

Page 14

INSTRUCTIONSPOURINVERSERLA PORTED'UNESE_CHEUSE

Assurez-vous de porter des gants [ors de ['inversion de [a porte.

1, Ouvrez la pate,

2_

Demontez les cinq vis, 1 & 5 et les deux vis 6 et 7, qui fixent la

contre-porte a la partie exterieure de la porte, Soulevez la

partie exterieure hors de la contreoporte et couchez-la sur

une surface plate et douce aa toachen

3,

Demontez les deux (2) vis de fixation de la 3enture et couchez

la contre-porte sar une surface plate et douce au toucher,

5, Retirez le bouchon de decoupe de penture. Tournez-le de

180 degres et reposez-le du c6te oppose.

Demontez les deux vis de fixation qui joignent la penture au

panneau avant.

4,

Demontez les vis de fixation de la gSche, Tournez la g_che

de 180 degres et remontez-la sur le c6te oppose.

Demontez la g_che du panneaux avant.

8. Tournez la gSche de 180 degre et reposez la penture et la

g#_che du cSte oppose a celui ou elles etaient posees,

9, Reposez la porte en executant les operations ci-dessus en

ordre inversee,

10, Fermez la porte,

14

Page 15

INSTALLATIONELECTRIQUE

TOUTESles s6cheuses ELECTRIOUES I

Les raises en garde qui suivent se rapportent

directement au branchement 6Mctrique correct et s_curitaire de ta

s_cheuse. Toute d#rogation a cos mises en garde pourrait entrMner

des risques choc 61ectrique et d'incendie.

convenablement mise _la terra. Respecter les directives de raise a la terra J

contenues dans cette notice pour une raise a la terra correcte. l

courant qu'utilise cette s_cheuse; iB peuvent fondre et presenter un risque

choc d,lectrique ou d'incendie. Placer la s@cheuse_ portee de la prise murale

afin de d6terminer la Iongueur du cordon a acheter et pr6voir un certain jeu

dans la Iongueur du cordon. Se reporter _la section <<AvantFinstallation>_ de

cette notice pour savoir quel type de cordon acheter.

_.__ Un detendeur approuvd, par U.L. dolt #tre fix#, au cordon

d'alimentation. Sile d6tendeur n'@lait pas presenh le cordon pourrait 6tre

arrache de la socheuse ou coup@ par tout type de mouvement, ce qui

prd_senterait un risque choc @lectrique.

chimique seproduit entre lecuivre et I'aluminium qui pourrait causer un court-

circuit. It faut utitiser un cordon d'alimentation a conducteurs en cuivre

avec une prise a conducteurs en cuivre.

REMARQUE : Les s_cheuses qui fonctionnent avec une Mimentation

de 208 volts auront un temps de s6chage plus long que cellos qui

utilisent une aflmentadon de 240 volts,

MISE ,_ LA TERRE

S6cheuses fLECTR/QUESnon-Canad/ennes

__ Le branchement inadd,quat du conducteur de mise b la

terre pourrait pr_senter un risque choc @lectrique. En cas de doute quant _a

la raise _ la terre adequate de I'appareil, contacter un electriden agr@o.

Pour brancher et mettre _ la terre la secheuse _ I'aide d'un cordon

d'alimentation :

1. La s6cheuse DOIT_tre mise _ la terre En cas de mauvais fonctionnement

ou de panne, la raise _ laterre r@duitles dsques choc #,lectrique en offrant

un parcours de moindre r@sistance au courant.

2. Si la s#cheuse est pourvue d'un cordon d'alimentation electrique

comportant un conducteur et une fiche de terre, la fiche DOtT_tre

branch#e dans urle prise murale _ conducteur en cuivre convenabbment

raccord@e au rd_seauet raise _ laterre conformd_ment _ tous los codes et

ordonnances Iocaux. En cas de doute, con_acter un electrician agre#,.

Ne modifiez pas _aprise equip_e d'appareiL

Pour brancher la secheuse on perman_,nce :

1. La secheuse DOlT 6tre branch6e _ une installation m_ta[lique raise _ [a

terre en permanence; sinon, un conducteur de raise a la terre de ['apparel[

dolt suivre les conducteurs du circuit et #tre branch?_a la borne ou _ la

connexion de raise _ la terre de I'appareiL

S6cheuses ELECTR/OUES Canadiennes ]

[!'__ Le branch_m_mt inad#quat du conduct_,ur de mise _ ]a

terra pourrait presenter un risque choc _lectrique, En cas de doute quant

]a raise a la terre adequate de I'apparei], contacter un electrician agr#,e,

Pour brancher et mettre a la terra la secheuse a I'aide d'un cordon

d'alimentation :

1, La s?_cheusedoit 6tre raise a ]a terra, En cas de mauvais fonctionnement

ou de panne, la mise a la terra r6duit les risques choc electrique en offrant

un parcours de moindre r#,sistance au courant.

2, Puisque la secheuse est pourvue d'un cordon d'alimentation electrique

comportant un conducteur et une fiche deterre, la fiche doit #tre branchee

dans une prise murale a conducteur en cuivre convenablement raccord#e

au reseau et raise a la torte conformement a tous lescodes et ordonnances

Iocaux. En cas de doute, contacter un #,lectricien agr#,A Ne modifiez

pas la prise equipee d"appareiL

m

TOUTES los s6cheuses _ GAZ

Pour votre protectior_ contre los chocs (qectriques, la secheuse est _qu[p#,e

d'une fiche _ trois bornes (raise _ [a terra) et dolt 6tre branchia directement

dans une prise _3 bornes correctement raise _ la terra. Ne pas couper ni enlever

la fiche de mise _ la terra de cette prise.

BRANCHEMENT ELECTRIQUED'UNE INSTALLATION

3 IlLS

S#cheusesEZECFR/@UE5non-Canad/ennes

1.

ReSrer los vis qu[ retiennen_ le couverde du panneau de branchemen_

ainsi qua lesupport de montage du de[endeur situ?_sdarts lecoin sup#,rieur

Farriere de la s#,cheuse.

2. Poser un d?_[endeur approuv6 par UZ. darts [etrou du support oO s'ins6re

le cordon d'alimentation. Serrer simplement Fecrou a la main pour le

mornent.

3. Enfiler un cordon d'a[imentation NEMA 10-30 approuv#, par U.L. de 30 A

de type SRDTclans le de[endeur.

4. Fixer [econducteur neutre (conducteur central) du cordon d'alimentation

la borne centrale argent#_e du panneau de branchement. Serrer la vis

fond.

5. Fixer [es deux conducteurs res_ants du cordon d'alimentation aux bornes

cuivr¢,es ext_,rieures du panneau de branchemenL Serrer los deux vis

fond.

_'__ Ne pas tordre excessivement ni sertir los conducteurs sur

les bornes.

6. R_attacher le support de montage du d6tendeur sur I'arri_re de la s_cheuse

I'aide de deux vis. Serrer los vis a fond.

VI5 DE MISE,A

VERTE BORNE

FIL DE

TERRE

NEL,rFRE

ECROU

5DR CE5 FILETS

SUPPORT DE

MONTAGE

DU CORDON

DF.TENDEUR D'ALIMENTATION

7. Sorriera fond lesvisqui re_iennent b dispositif de re_enu_ du cordon autour

du cordon d'alimentation.

8. Serrer l'6crou du dOtendaur de fat on ace qua cette piercene tourne pas.

9. R_attacher le couvercle du panneau de branchement.

15

Page 16

BRANCHEMENT ELECTRIQUE D'UNE

INSTALLATION A 4 FIL5

I S_cheuses EL ECI'R/QUES non-Canadiennes

I. R_,tirer k-,svis qui retiennent le ceuvercle du panr/eau d_, branchement

ainsi que lesupport de montage du detendeur situ_s dans le coin superieur

a I'arri¢,re de la s_,cheuse.

2. Poser un d_tendeur approuve par UL. dans le trou dtJ support. Serrer

simplement I'ecrou a la main pour le moment.

3. Retirer le fil de terre de la vis de mise a la terre verte neutre situee au-

dessus du panneau de branchement.

VI5 DE MISE A LA CONDUCTEUR VERT BORNE

TERREVERTE

FIL DE

TERRE

NEL,rFRE f

ROUGE"

4. Enfiler un cordon d'alimentation NEMA I0-30 approuv#, par UL. de 30 A

de type SRDT darts le detendeur.

5. Fixer le fil de terre vert du cordon d'alimentation au bottier de la s_,cheuse

a I'aide de la vis de mise a la terre verte.

6. Fixer le conducteur blanc (neutre) du cordon d'alimentation ainsi que le fil

de terre neutre du bottler de la s6cheuse a la borne centrale argentee du

bloc de branchement.

7 Fixer les conductetJrs rouge et noir du cordon d'alimentation aux bornes

cuivrees ext_rieures du panneau de branchement.

V_ Ne pas tordre excessivement ni sertir les conducteurs

sur les bornes.

8. Serrer a fond les vis qtJi retiennent le dispositif de reten_Jedu cordon

autour du cordon d'alimentation.

9. Serrer I'ecrou du d_,tendeur de faqon a ce que cette pi_:,cene tourne pas.

10. R6attacher le couvercle du panneau de branchement.

D'ALIMENTATION

TYPIQUE,,4 4 FILS

NEMA 14-30 DE 30A DE TYPE SRDT OU ST

INSTALLATION

I. BRANCHEMENT DU GAZ (5_-_cheuses_ gaz seu/ement)

secheuse.

a. Retirer le couvercle qui recouvre le tuyau de gaz a I'arri_re de la

REMARQUE: NE PA5 brancher la s_cheuse sur une alimentation au

propane sans avoir poso un necessaire de conversion. Ce

n#,cessaire (n° de pi_:,ce1:_4285300) dolt #,tre installe par

b. Brancher un tuyau semi-rigide ou approuve de 1,27 cm

(1/2 po) de diam_,tre int_rieur entre laconduite d'alimentation en gaz

et le tuyau de o,g6 cm (3/8 po)situe sur I'arriere de la s6cheuse. Utiliser

un reducteur de 1,27 cm-O,g6 cm (1/2 po-3/8 po) pour le

branchement. Appliquer un mastic de fermeture pour filets approuve

qui r_siste a la corrosion qu'exercent les gaz liqu#,fi_,s sur tousles

raccords de tuyaux.

c Ouvrir le robinet d'arr6t de la conduite d'alimentation en gaz.

d. V_rifier tousles branchements en versant de I'eau savonneuse sur les

joints. NE JAMAIS VERIFER S'IL Y A DES FU_TES,,_L'AIDE D'UNE

FLAMME WVE

2. Relier les _onduits d'_,vacuation d'air a la conduite d'evacuation _,xterieuro.

Utiliser un ruban adhesif pour conduites pour sceller lesjoints.

3. Une fois la secheuse dans son emplacement d¢,finitif, ajuster les pieds de

nivellement jusqu'a ce que la s_,cheuse repose fermement sur ses quatre

pieds Placer un niveau sur le dessus de la s_cheuse. LA 5E-CHEUSE DOlT

ETRE_, NIVEA U ET REPOSER FERMEMENT SUR SES QUATRE PEDS.

4. Brancher le c:ordon d'alim_,r_tatior_d,lectriqu_, dans une [)rise raisea la terre.

REMAR©UE : S'assurer que le courant est coup_ a la boi_tede fusibles ou

de disjoncteurs avant de brancher le cordon d'alimentation darts une prise.

5. Remettre le courant a la botte de fusibles ou de disjoncteurs.

autre vapeur inflammable. S"assurer d}ga/ement qu'aucun objet (boites,

v_tement:s, etc) n'obstrue /a drculadon de/'air servant a la combust/on et

la venti/atMn.

6. Fake fonctionner la sd,cheuse sur un cycle complet pour en vd,rifier le

fonctionnement.

REMARQUE: Dans le cas des secheuses a gaz, la conduite doit 6tre vidd_e

de son air avant que le brOleur ne puisse s'allumer. Sile brOleur ne s'allume

pas darts les 45 secondes qui suivent le premier d_:,marrage, I'interrupteur

de sOrete Oteint automatiquement le brOleur. Si cela se produit, remettre

la minuterie a <<OFF>>et a_tendre 5 minutes avant de tenter une nouvelle

fois d'allumer le brOleur.

7. Sila s_,cheusene fonctionne pas, passer en revue la section de depannage

inclus dans le Guide de I'utilisateur avant d'appeler un centre de service.

8. Placer cette notice pros de la s_-,cheusepour rd,ference future.

REMARQUE: Un sch_ma de cBblage setrouve dans le panneau de

Pi_destal

Un accessoire de pi6des_al, N ° de Mod_te APWD15W, a sp6cifiquement

conqu pour cette s#,cheuse peut #,tre utilis_ en #,levant la secheuse pour

la facilite d'utilisation. Le manque d'utiliser des accessoires certifies par le

fabricant a pu avoir comme consequence des blessures, des dommages

mat6riels ou des dommages a la secheuse.

5i vous desirez des pieces de remplacement pour votre machine a laver,

communiquez avec le num6ro sans frais de Service et pieces de Frigidaire

Company Authorized Parts Distributor, 1-800-944-9044, ou visitez notre website

, www.frigidaire .corn.

__ Lors de tout travail d'entretien ou de r6paration des

commandes, ¢,tiqueter tousles cables avant de les d_,brancher. Les erreurs de

connexion de cable peuvent entratner un fonctionnement incorrect et

dangereux Une fois la reparation ou I'entretien termin#,, assurez-vous que

I'appareil fonctionne correctement.

_.__ D¢,truire le carton et les sacs en plastique apres avoir

deballe la s_cheuse Des enfants risqueraient de s'en servir comme jouet. Les

cartons recouverts d'un tapis, d'un couvreqit ou d'une feuille de plastique

peuvent former une chambre etanche et faire suffoquer un enfant. Placer le

mat¢,riel d'emballage dans une poubelle ou les mettre hors de portee des

enfants.

¥_I_ Les directives qui figurent clans cette notice et darts les

autres documents qui accompagnent la secheuse ne sauraient couvrir toutes

les circonstances et les situations possibles. IL FAUT donc faire preuve de

jugement et de prudence pendant I'installation, I'utilisation et I'entretien de

tout appareil _'qectrom_'mager.

16

un technicien agro(_.

commande ou sous le couvercle de la sd,cheuse.

PtECES DE RECHANGE

Loading...

Loading...