Frigidaire 675000800908 User Manual

Dishwasher

Installation

Instructions

Printed in U.S.A.

675000800908

08/09

INSTALLER: Leave

OWNER: Read your dishwasher

important safety information for operating this appliance. It also has

many suggestions for getting the best results from your dishwasher.

Installation Instructions

Use and Care Manual.

with owner.

It contains

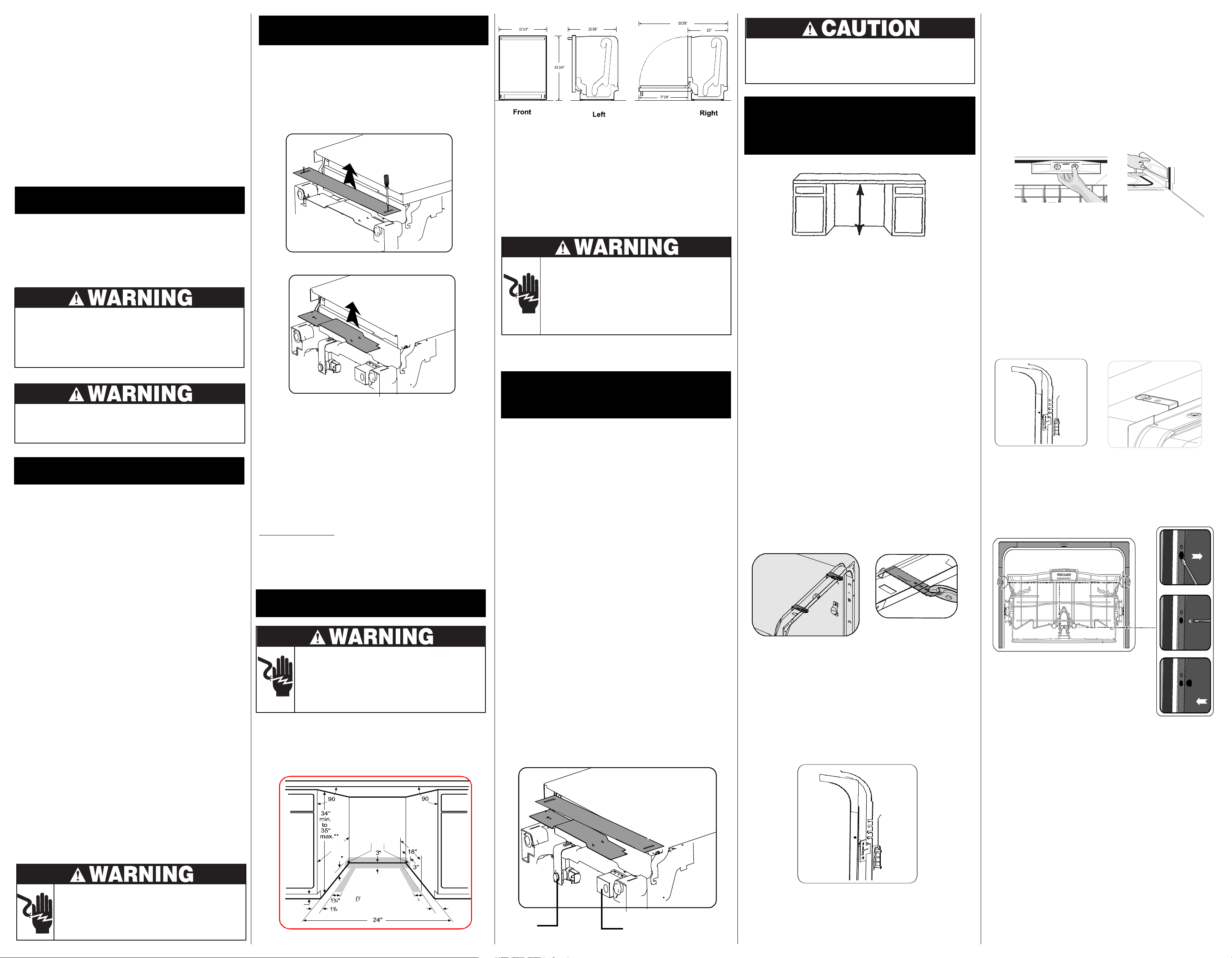

Installation Preparation

NOTE: Put unit on its back being careful not to pinch the Water

Drain Hose.

1. Remove two (2) screws at front of the kickplate using a #2

Phillips screw driver.

2. Tilt and pull forward to remove see figure 1a.

NOTE: It is not necessary to remove the outer door for installation.

2

Figure 3

IMPORTANT: For proper operation and appearance of unit,

cabinet opening should have dimensions as shown in Figure 2.

If unit is to be placed in a corner, there must be at least a 2-inch

side clearance to open door.

*DIMENSIONS DO NOT INCLUDE INSULATION

Property Damage

Do not use the furnished drain hose or a rubber garden hose

for the water supply line. Either of these hoses can burst.

Flooding may occur and cause property damage.

Leveling and Securing

5

Dishwasher within

Cabinets

6. If levelers need to be removed, make sure that the floor is free of all

obstructions.

7. Carefully place dishwasher inside cabinet area such that is

centered in opening. Use caution when moving dishwasher to

prevent damage to cabinet, dishwasher and floor.

8. Front of door needs to be even with the front of adjoining cabinets.

Front levelers should allow 5/16” below underside of countertop

to top of console.

9. Check that dishwasher is level from side to side by placing a level

against the top front section of the tub. See Figure 5a.

Before You Begin

Read all instructions before installing dishwasher.

For your safety, please read and observe all safety

instructions. This guide will help you anticipate drain, water, and

electrical connections, and help you select the best location for the

dishwasher.

Tip Over Hazard

Do not use dishwasher until completely installed.

Do not push down on open door.

Failure to follow this warning can result in serious

injury.

Cut Hazard

To prevent serious injury from sharp edges, wear work

gloves when handling, unpacking or disassembling unit.

Installation Tips

Tools and Materials Needed for

Installation

• Drill, Electric

• Driver, Socket 5/32”, 1/4” , 5/16”

• Flaring Tool / Tube Cutter (for copper tubing)

• Flashlight

• Level

• Pipe Joint Compound (for iron pipe plumbing) or

Pipe Thread Tape (for sealing threads)

• Pliers

• Safety Glasses

• Saw, Keyhole or 1/2”, 11/2” to 2” Hole Cutters

• Screw Drivers, Slotted and #2 Phillips (magnetic tip

preferred)

• Tape, Electrical or Duct

• Tape, Measuring

• Wire Stripper or Utility Knife

• Wrench, Hex-end

• Wrenches, 2 Adjustable (for copper tubing)

or 2 Pipe wrenches (for iron pipe plumbing)

Parts You Will Need*

• Brass Elbow, 90° with a 3/8” National Pipe Thread

• Conduit Connector (UL Listed)

• Wire Nuts, three (3) for 12-14 gauge wire (UL Listed)

(Not Included)

(Not Included)

1

Figure 1a

Figure 1b

3. Remove two (2) screws at front of the kickplate brace using a

#2 Phillips screw driver. Slide up and pull off.

4. Locate water inlet valve behind kickplate on bottom left

underside of unit.See Figure 4. The valve has a 3/8” NPT female

fitting.

5. Wrap 90° elbow (not included) with pipe thread tape (or apply

joint compound) and thread it into water inlet valve. When

tightened, elbow should point toward the left. To prevent bending

of bracket or breaking of valve, avoid overtightening.

See Figure 4.

Cabinet Preparation:

As a precaution, it is recommended, but not required that the

cabinets enclosing all sides of the dishwasher (including the

underside of the countertop) be sealed with an oil based paint

or moisture-proof polyurethane to prevent possible steam/

moisture damage.

Roughing In

Electric Shock Hazard

Observe all local codes and ordinances for

electrical and plumbing connections. All electrical

and plumbing work should be performed by

qualified persons. Failure to follow this warning

could result in death or serious injury.

1. Make sure your location has the correct drain, water, and

electrical outlets to make the connections.

under a cooktop range. Damage to tub or other components will

occur.

2.

Floor should be flat and free of any obstruction.

Do not install unit

3

IMPORTANT: Drain, water, and electrical lines should be

roughed-in before going any further.

Electric Shock Hazard

Electrical, water, and drain lines must be confined

to shaded areas in Figure 2.

Electric conductors, water, and drain could be

damaged.

Failure to follow these instructions could result in

fire or electric shock.

NOTE: If dishwasher is installed at end of a cabinet, sides and

back must be fully enclosed.

Connections For Electrical,

4

Water, and Drain

Locating the Connections

1. Review dimensions in Figure 2 to locate dishwasher’s drain,

water, and electrical connections.

2. All utilities must be routed in shaded area in the Figure 2.

IMPORTANT: Disconnect power before starting installation.

Note: Locate the electrical supply and dishwasher’s electrical

junction box on right underside of unit behind kickplate

assembly. See Figure 4. Determine where you will connect

to hot water supply. Review Figure 4 and note the location of

water inlet valve. Determine where you will connect the drain

hose.

3. Cut access holes for the Electrical, Water and Drain hoses in the

shaded areas as shown in Figure 2.

4. The dishwasher operates on a 120 volt, 60 Hz electrical supply.

Provide a separate circuit with a fuse or circuit breaker rated for

at least 15 amps (20 amps if connected with disposer) but not

more than 20 amps.

5. Pull electrical cable through hole into installation area.

6. Be sure water inlet valve is protected from freezing. If valve

freezes and ruptures, flooding may occur.

7. Determine amount of tubing needed to connect hot water supply

to the unit’s water inlet valve. Extra hose length is necessary.

High-pressure and high-temperature Stainless Flexible hose with

a minimum inner diameter of 1/4” may be used. A shut-off valve

installed outside dishwasher cabinet is best.

8. Route water supply line into installation area.

9. Stand dishwasher back upright for further installation.

IMPORTANT: Incoming hot water temperature should be at

least 120°F (49°C). Water pressure should be between

20–90 psi.

1. Measure height of cabinet opening from underside of countertop

to floor.

2. Move dishwasher to front of installation area.

3. Loosen the rear leveling legs by turning counterclockwise.

Dishwasher Anchoring

5. Choose one of the methods of attachment below to secure unit,

holes need to be pre-drilled using a #5 drill bit regardless of

the option chosen:

a. Top Mount Cabinet Clips (Preferred Method of attachment)

b. Side Mount Cabinet Clips (to be used when Side Mount

is not an available option)

CAUTION: Use extreme care in mounting the dishwasher as

to not scratch, bump or otherwise damage the console or tub.

To install using Top Mount Cabinet Clips:

Depending on the depth of cabinet, the Top Mount

Clip have a break off point that can be removed if

necessary.

NOTE: Install Top Mount Clips before unit is installed into the

cabinet. Insert the installation brackets to the front

top slots of the dishwasher. (See image below)

To install the Side Mounting Clips.

Depending on space allowed in cabinet the Side Mounting

Clips can be installed with the holes for the screw up (preferred

method) or down as shown in the illustrations below.

NOTE: Install Side Mount Brackets before unit is installed into

the cabinet. Insert the installation brackets to the side slots

of the dishwasher. (See image below)

Figure 5bFigure 5a

10. Check that the dishwasher is level from front to back by taking

out the lower rack, place level on the lower rack wheel support at

the bottom of the tub. See Figure 5b.

11. Adjust levelers up or down until dishwasher is level.

Holes need to be pre-drilled using a #5 drill to secure

unit.

12. Screw mounting brackets firmly to cabinet using screws

provided in literature packet. See Image Below.

Figure 5c Figure 5d

13. Open the door remove the tub cap on both sides of the tub.

Install screw through the dishwasher side hole to the wall of

cabinet. Reinstall tub cap.

14. Open and close dishwasher door slowly. Ensure that there is

clearance to the console. Adjust accordingly until door opens

and closes freely.

*

If required:

• “Y” Branch Tailpiece and

Connector Kit (See Step 4)

• Air Gap Kit (See Step 4)

All the parts can be found at local hardware, electrical and

plumbing supply stores.

Electric Shock Hazard

Disconnect electrical power at the fuse box or

circuit breaker box before beginning installation.

Failure to follow this warning could result in death

or serious injury.

Figure 2

WATER L INE

(NOT I NCLUDED)

Figure 4

ELECTRICAL B OX

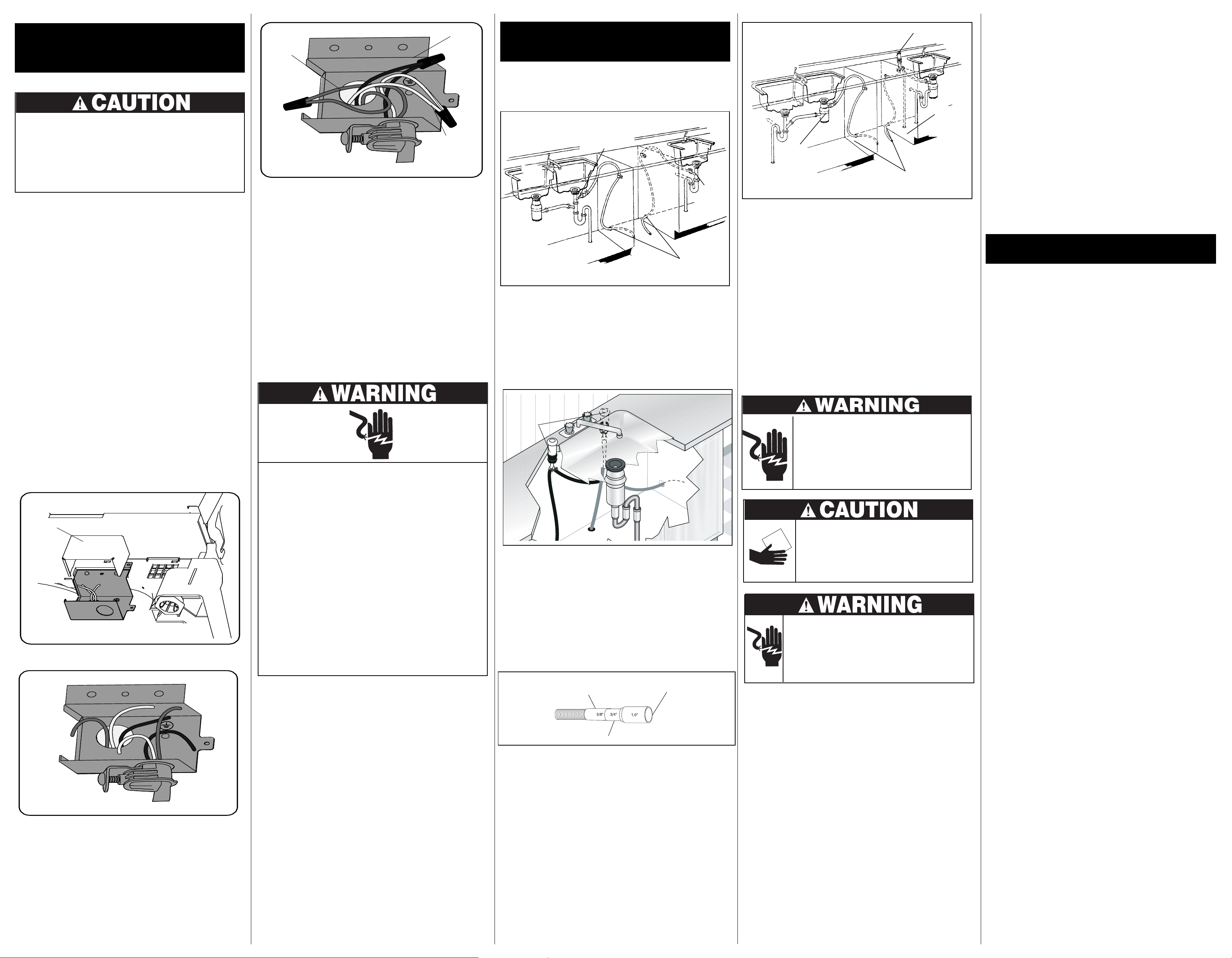

Finishing the Water and

6

Electrical Connection

Property Damage

Do not solder within 6” of the water inlet valve. Damage to

the plastic parts in the valve may occur.

Use care that no sealer, dirt, or other objects enter the valve.

Damage to the filter screen may occur.

Be sure the dishwasher is placed where the water inlet

valve will be kept from freezing. If the valve freezes, it may

rupture and flooding may occur.

Water Line

GREEN

WIRE TO

GREEN

WIRE

(GROUND)

Figures 6a

4. Replace junction box cover.

BLACK

WIRE TO

BLACK

WIRE

(HOT)

WHITE

WIRE TO

WHITE

WIRE

(NEUTRAL)

Finishing the Drain

7

Connection

1. Review Figures 7, 8 and 9 to see the different ways to connect

dishwasher to drain system. Choose method that best suits

your need.

Entry Must be

Above Trap

“Y”

Branch

Tailpiece

Drain Air Gap

Sink at Left

Alternate

Drain

Through

Floor into

Separate

Trap

Remove

Knockout

Plug in

Disposer

Figure 9(b)

Sink at Right

2” Drain Hose Hole

The drain hose loop must be at least 32” high from the floor

to insure proper drainage.

check these items:

Water and drain lines have no kinks and move freely

behind the dishwasher.

Water supply is turned on.

Joints are free of leaks.

Wiring connections to junction box are tight all access

panels are secured back in place.

Replace kickplate and kickplate brace. (See Figure 1)

Drain hose is assembled to Drain Hose Connector.

All packing materials and consumer literature have

been removed from inside unit.

Dishwasher is level and securely fastened.

Open and close door to make sure it does not hit

surrounding cabinet or countertop.

Make sure that all tape is removed from the Silverware

Baskets.

1. Flush water line before connecting it to water inlet valve to

prevent early clogging of filter screen. Place a bunched towel

over end of line to prevent splashing. Open water supply valve for

a few seconds and let water drain into a pan.

supply at shut-off valve.

2. Route water line to water inlet valve as shown in Figure 4.

3. While firmly pulling water supply line into 90° elbow, tightly

connect water supply to water inlet valve. Supply line must be

free of kinks, scales, chips, and lubricants.

4. Turn on water supply and check for leaks.

Turn off water

Electrical Supply

1. Remove junction box cover and pull house wiring into junction

box. See Figures Below.

2. Use a UL listed conduit connector (not included) at box to

stabilize wiring.

3. Connect incoming black lead to dishwasher’s black lead,

incoming white lead to dishwasher’s white lead and incoming

green lead to dishwasher’s green lead with wire nuts. (See

Grounding Instruction Warning). Wire nuts must be tight.

JUNCTION B OX

COVER

check these items:

Water and electrical lines are hooked up to dishwasher.

All four leg levelers are positioned properly.

Cabinet Seals are positioned on the sides and top of the

dishwasher.

Cabinet Attachment Clips are attached to the cabinet or

countertop and kickplate brace.

Replace Toe and Kickplate. Note: When replacing

Kickplate and kickplate brace hand tighten screws.

Electric Shock Hazard

Grounding Instructions:

The dishwasher must be connected to a grounded metal,

permanent wiring system or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the appliance’s equipment grounding terminal

or lead. It is the consumer’s responsibility to contact a

qualified installer to make sure the electrical installation

conforms with the National Electrical Code and local codes

and ordinances.

Do not connect the dishwasher to the power supply until the

appliance is permanently grounded.

All wiring connections must be enclosed in the junction box.

This unit has copper lead wires.

Joining aluminum building wire to stranded copper wire

should be done by a qualified electrician using materials

recognized by UL and local codes.

Do not use an extension cord. Such use can result in fire,

electrical shock, or other personal injury.

Failure to follow these instructions could result in death or

serious injury.

Sink at Left

2” Drain Hose Hole

Figure 7

Sink at Right

The drain hose loop must be at least 32” high from the floor

to insure proper drainage.

2. If you connect to a sink drain, entry will need to be above trap.

A “Y” branch tailpiece and connector kit, not included, will make

this method easier and includes all needed fittings and

instructions. See Figure 7.

Air Gap

Right Side

Installation

7

Figure 8

3. If you connect to a sink trap, local codes may require you to

install an air gap kit, (not included). The drain hose will be routed

from dishwasher to air gap inlet as shown in Figure 8. An air

gap kit is available from a plumbing supply store. (If the drain

hose is installed through the floor, an air gap is necessary).

4. If you connect to a disposer, the large end of drain hose will fit.

Figure 9(a).

inside disposer inlet before making the final fit to drain

hose.

The knock out plug must be removed from

See Figure 9(b).

Cut for 5/8” connection.

Larger end

of hose

fits disposer

inlet fitting.

5. If the cabinet wall is wood, sand edges of hole until smooth and

rounded. If cabinet wall is metal, cover all sharp edges with

electrical or duct tape to avoid cutting drain hose.

6. Move unit back in place while routing drain hose through access

hole. Use caution to prevent damage to the dishwasher, floor and

cabinets. IMPORTANT: Make sure there are no sharp bends

or kinks that might restrict drain flow.

7. Secure drain hose to sink drain, disposer, or separate trap with a

clamp. IMPORTANT: Be careful not to overtighten clamp or

you may damage end of hose. Do not connect hose to

horizontal pipe between sink drain and disposer.

8. Be sure unit does not rest on drain hose. It should be free of

electrical components and door springs. Do not cut corrugated

drain hose. Pull excess through cabinet and place under sink.

Make sure hose does not come in contact with any sharp edges.

Electric Shock Hazard

Disconnect electrical power at the fuse box

or circuit breaker box before beginning

installation.

Failure to follow this warning could result in

death or serious injury.

Cut Hazard

Metal color panels are sharp and should be

handled with care. Wear gloves to protect

hands.

Failure to follow this warning may result in

injury.

Electric Shock Hazard

If all connections are correct, there are no leaks,

and unit runs properly, replace the kickplate

assembly before placing unit into operation.

Failure to follow this warning could result in

electric shock.

Checking the Installation

Operate the machine through at

least one fill and pump-out,

checking the following items:

At first fill, approximately 1 minute make sure water

completely covers filter surface.

At pump-out: (pump-out is either when the cycle is

completed or canceled. refer to the Use and Care Manual

for Start/Cancel), make sure all water is pumped out.

Check water connections again for leaks.

8

Figure 9(a)

Drain Hose

Cut for 3/4” connection.

Loading...

Loading...