Page 1

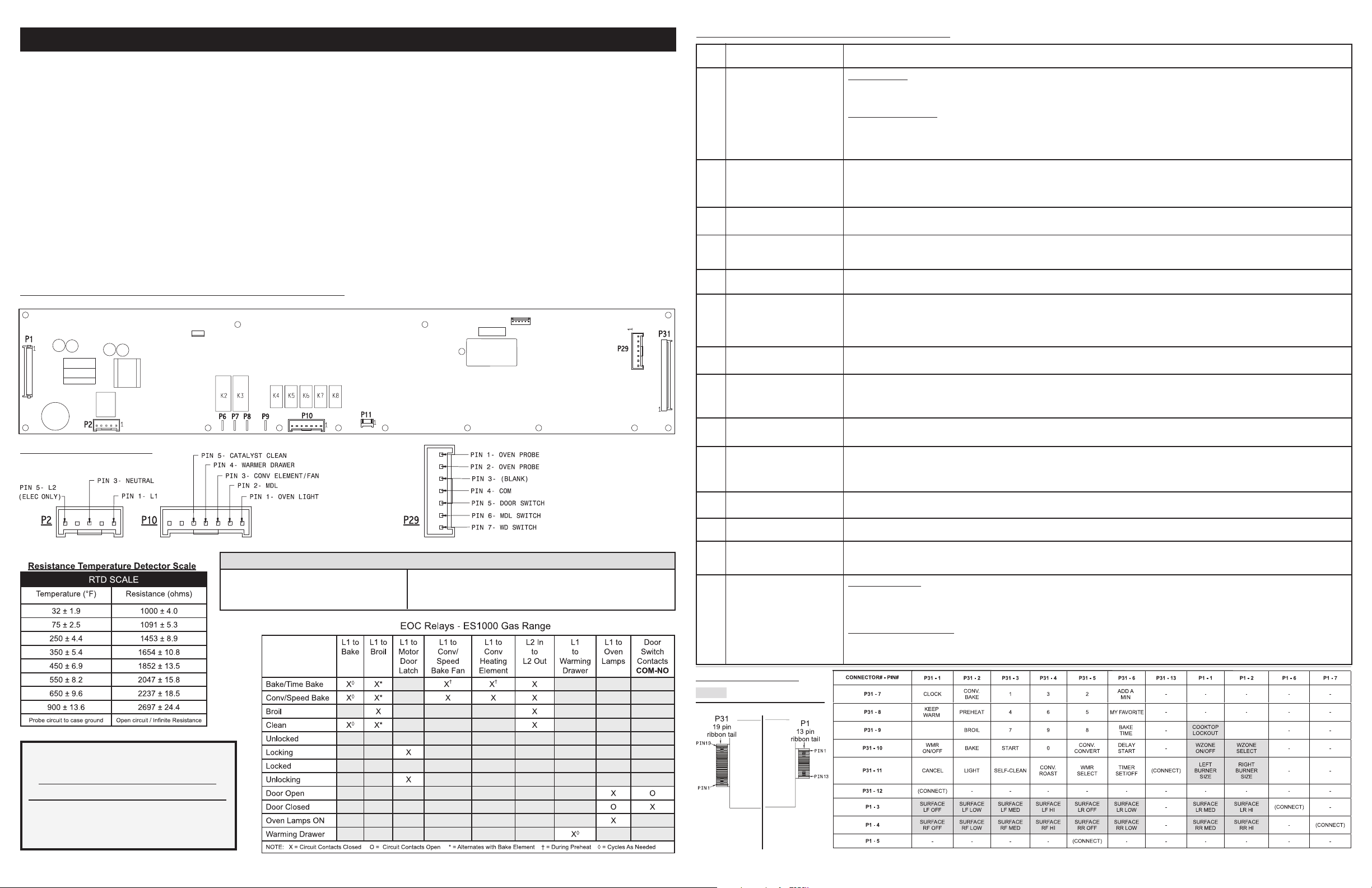

SERVICE DATA SHEET - Gas Range with ES 1000 Electronic Oven Control

NOTICE - This service data sheet is intended for use by persons having electrical

and mechanical training and a level of knowledge of these subjects generally

considered acceptable in the appliance repair trade. The manufacturer cannot be

responsible, nor assume any liability for injury or damage of any kind arising from

the use of this data sheet.

Safe servicing practices

To avoid the possibility of personal injury and/or property damage, it is important that safe

servicing practices be observed. The following are examples, but without limitation, of

such practices.

1. Before servicing or moving an appliance remove power cord from electrical outlet,

trip circuit breaker to OFF, or remove fuse.

2. Never interfere with the proper installation of any safety device.

3. GROUNDING: The standard color coding for safety ground wires is GREEN or

GREEN WITH YELLOW STRIPES. Ground leads are not to be used as current

carrying conductors. It is extremely important that the service technician

reestablish all safety grounds prior to completion of service. Failure to do so

will create a potential safety hazard.

4. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp edges, hightemperature components, and moving parts.

Electronic oven control (EOC) & jumper connection locations

EOC jumper connections

Tech Sheet Abbreviations and Terminology

EOC = Electronic Oven Control

VSC = Variable Speed Control

PS = Power Supply board (PS1 , PS2, etc.)

• All uninsulated electrical terminals, connectors, heaters, etc. are adequately

spaced away from all metal parts and panels.

• All safety grounds (both internal and external) are correctly and securely

reassembled.

Oven Calibration

Set the electronic oven control for normal baking at 350°F. Obtain an average oven

temperature after a minimum of 5 cycles. Press cancel keypad to end bake mode.

Temperature Adjustment

1. While in a non-cooking mode, press and hold the bake key pad for 6 seconds.

2. The current calibration offset (temperature adjustment) should appear in the

temperature display.

3. Use the number key pads (0-9) to enter the desired amount of adjustment (up to

35°F).

4. Press the self-clean key pad to change the sign of the adjustment to a (-) if

necessary. A positive adjustment will not display a sign.

5. Once the desired adjustment (-35° to 35° F) has been entered, press the start

key pad to accept the change or the cancel key pad to reject the change.

NOTE: Changing calibration affects all Baking modes. The adjustments made will not

change the self-cleaning temperature.

RTD = Resistance Temperature Device. (Temp Probe or

Temp Sensor)

TCO = Thermal Cut Out also “Thermo Disc” or “Thermal Limiter”

Electonic Oven Control Fault Code Descriptions

Fault

Likely failure

Code

condition/cause

Runaway temperature.

F10

Oven heats when no cook

cycle is programmed.

Shorted keypad or selector

F11

switch.

EOC Internal software error

F12

or failure.

F13

Keyboard tail failure.

F14

EOC Internal hardware error

F15

of failure.

F19

Open oven sensor probe

F30

circuit.

F31

Shorted oven sensor probe

circuit.

EOC internal software

F42

configuration error.

EOC oven temperature.

F60

Higher than normal

temperature detected on the

EOC board.

Internal signal voltage error. Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up, replace EOC.

F62

Display communication error.

F63

Time Base failure - The EOC

F64

cannot determine if

connected to 50 or 60Hz

power supply.

Keyboard short circuit or

F65

internal EOC failure.

F66

failure.

High voltage condition. L1 or

F68

L2 may be crossed with

F69

Neutral on incoming PS.

Door lock motor or latch

F90

circuit failure.

F91

F92

F93

F94

F95

If Oven is cold:

1. If fault code is present with cold oven test oven temperature sensor probe circuit resistance. Use RTD scale found in the tech sheet.

2. Replace probe or repair wiring connections if defective.

3. If temperature sensor probe circuit is good but fault code remains when oven is cold replace the EOC.

If Oven is overheating:

1. If oven is severely overheating/heating when no cook cycle is programmed test oven temperature sensor probe circuit resistance using

the RED scale found in the service tech sheet. Also verify that the temperature sensor probe in properly installed in the oven cavity.

2. Disconnect power from the range, wait 30 seconds and reapply power. If oven continues to heat when the power is reapplied, replace

the EOC. NOTE: Severe overheating may require the entire oven to be replaced should damage be extensive.

1. Reset power supply to range - Disconnect power, wait 30 seconds and reapply power.

2. Check/reseat ribbon harness connections between touch panel and EOC.

3. Test keyboard circuits using test matrix. Replace touch panel if defective.

4. If keyboard ciruits check good replace the EOC.

Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up, replace EOC.

1. Check/reseat ribbon harness connections between keyboard touch panel and EOC..

2. Test keyboard circuits using test matrix (below). Replace touch panel if defective.

3. If keyboard circits check good replace EOC.

Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up, replace EOC.

1. (F30) Check resistance at room temperature & compare to RTD Sensor resistance chart. If resistance is correct replace the EOC. If

resistance does not match the RTD chart replace RTD Sensor Probe. Check Sensor wiring harness between EOC & Sensor Probe

connector.

2. (F31) Check resistance at room temperature, if less than 500 ohms, replace RTD Sensor Probe. Check for shorted Sensor Probe

harness between EOC & Probe connector. If resistance is correct replace the EOC.

Usually this failure code would only appear if the EOC has been replaced with an incorrect version. Verify that the correct replacement

part number is being used.

1. Verify proper assembly of backguard panel. Check for damaged or loose panels, brackets, endcaps, etc.

2. Check for blocked ventilation slots in control panel rear cover.

3. Inspect oven vent for proper assembly and air flow.

4. Verify operation of cooling fan (if present).

Confirm that range is connected to proper power source (50Hz or 60Hz). Generators or other portable power supplies and solar grids, etc.

may not provide proper power supply. If power source is correct replace the EOC.

1. Test keyboard circuits using test matrix. Replace touch panel if defective.

2. If keyboard circuits check good replace the EOC

Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up, replace EOC.EOC internal power supply

1. Verify proper incoming line voltage and polarity of L1, L2 and Neutral power supply connections at range terminal block.

2. If power supply voltage and polarity are correct replace EOC.

If lock motor runs:

1. Test continuity of wiring between EOC and lock switch on lock motor assy. Repair if needed.

2. Advance motor until cam depresses the plunger on lock motor switch. Test continuity of switch contacts. If switch is open replace

lock motor assemblyy.

3. If motor runs and switch contacts and wiring harness test good, replace the EOC.

If lock motor does not run:

1. Test continuity of lock motor windings. Replace lock motor assembly if windings are open.

2. Test lock motor operation by using a test cord to apply voltage. If motor does not operate replace lock motor assy.

3. If motor runs with test cord check continuity of wire harness to lock motor terminals. If harness is good replace the EOC.

Suggested Corrective Action

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE

INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

p/n 316905023 EN (0906)

Keypad Test Matrix

for Electric models only

Left side

View: control overlay from front

Right side

To test keypad function check for continuity between indicated pin locations while pressing keypad. Example: To test the Bake keypad use

pin #2 & pin #10 on connector P31. To test cooktop keypad use pin 1 on connector P1 & pin 9 on connector P31.

Page 2

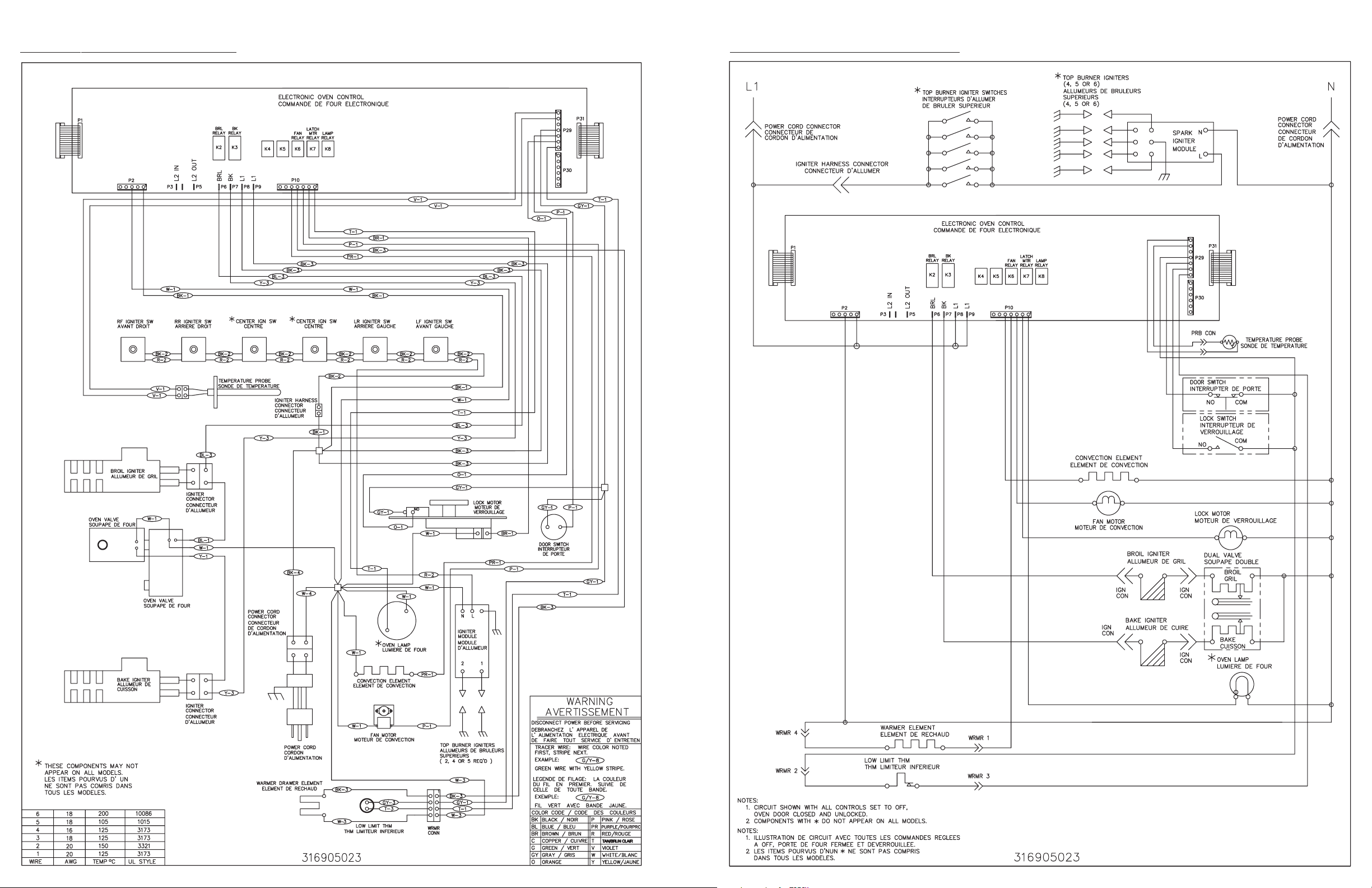

General Troubleshooting Diagram General Troubleshooting Schematic

Page 3

FICHE DE RÉPARATION - Cuisinière à gaz avec régulateur électronique de four ES 1000

AVIS : Cette fiche de réparation a été conçue pour être utilisée par des personnes qui

possèdent une formation en mécanique et en électricité ainsi qu’un niveau de

connaissance de ces sujets jugé généralement acceptable dans le domaine de la

réparation. Le fabricant ne peut être tenu responsable des blessures ou des

dommages que l’utilisation de cette fiche pourrait entraîner.

Procédures d’entretien sécuritaires

L’observation de procédures d’entretien sécuritaires est importante pour éviter les blessures

ou les dommages matériels. La section suivante présente des exemples de procédures

d’entretien sécuritaires, mais sans s’y limiter.

1. Avant de réparer ou de déplacer l’appareil, débranchez-le, mettez le disjoncteur du circuit à

la position ARRÊT ou enlevez le fusible.

2. Ne modifiez jamais l’installation d’un dispositif de sécurité.

3. MISE À LA TERRE : Le code de couleur standard pour les fils de mise à la terre est VERT

ou VERT RAYÉ JAUNE. Les conducteurs de mise à la terre ne doivent pas être utilisés

comme des conducteurs normaux. Il est extrêmement important que le technicien en

entretien rétablisse tous les dispositifs de mise à la terre avant de terminer la

réparation. Le non-respect de cette recommandation entraînera un risque

d’accident.

4. Avant de remettre l’appareil en service, assurez-vous que :

• Toutes les connexions électriques sont correctes et sécuritaires.

• Tous les conducteurs sont couverts et à l’abri de rebords coupants, de composants qui

atteignent de hautes températures et de pièces mobiles.

• Tous les éléments chauffants, connecteurs, bornes non isolées, etc. sont à une distance

adéquate de tout panneau ou de pièce métallique.

Emplacement du régulateur électronique de four et des connexions

Connexions du régulateur

électronique de four

BROCHE 5 –

L2 (ÉLEC. SEUL.)

ÉCHELLE DU DÉTECTEUR DE TEMPÉRATURE

Température (°F)

32 ± 1,9

75 ± 2,5

250 ± 4,4 1 453 ± 8,9

350 ± 5,4

450 ± 6,9

550 ± 8,2

650 ± 9,6

900 ± 13,6

Circuit de la sonde mise

à la terre à la caisse

BROCHE 3 - NEUTRE

BROCHE 1 - L1

À RÉSISTANCE

Résistance (ohms)

1 000 ± 4,0

1 091 ± 5,3

1 654 ± 10,8

1 852 ± 13,5

2 047 ± 15,8

2 237 ± 18,5

2 697 ± 24,4

Circuit ouvert/

résistance infinie

IMPORTANT

N’ENLEVEZ PAS CE SAC OU NE

DÉTRUISEZ PAS SON CONTENU.

IL CONTIENT LES SCHÉMAS DE CÂBLAGE ET

L’INFORMATION DE RÉPARATION.

REMETTEZ LE CONTENU

DANS LE SAC.

p/n 316905023 FR (0906)

BROCHE 5 - CATALYSEUR (NETTOYAGE)

BROCHE 4 - TIROIR RÉCHAUD

BROCHE 3 - ÉLÉMENT/VENTILATEUR DE CONVECTION

BROCHE 2 - LOQUET MOTORISÉ DE LA PORTE

BROCHE 1 - LAMPE DU FOUR

Abréviations et terminologie utilisées dans la fiche technique

EOC = Régulateur électronique de four

VSC = Commande de vitesse variable

PS = Carte d’alimentation électrique (PS1, PS2, etc.)

Relais du régulateur électronique de four - Cuisinière à gaz ES1000

Cuisson/Cuisson min.

Conv./Cuisson rapide

Gril

Nettoyage

Déverrouillé

Verrouillage

Verrouillé

Déverrouillage

Porte ouverte

Porte fermée

Lampes de four allumées (ON)

Tiroir réchaud

REMARQUE :

X = Contacts du circuit fermés

L1 à

Cuisson

• Toutes les connexions à la terre (à l’intérieur de l’appareil et à l’extérieur) ont été

Calibration du four

Réglez le régulateur électronique de four pour une cuisson normale à 350 °F (177 °C).

Vous devez obtenir une température moyenne de four après 5 cycles. Appuyez sur la

touche CANCEL (Annuler) pour mettre fin au mode de cuisson.

Réglage de la température

1. Assurez-vous de ne sélectionner aucun mode de cuisson, puis appuyez sur la touche

BAKE (Cuisson au four) et maintenez-la enfoncée pendant 6 secondes.

2. L’afficheur de température indique l’écart actuel de calibration (ajustement de

température).

3. Utilisez les touches numériques (0 à 9) pour entrer l’ajustement désiré

(jusqu’à 35 °F/18 °C).

4. Appuyez sur la touche SELF-CLEAN (Autonettoyage) pour ajouter le signe (-) à

l’ajustement, si nécessaire. Aucun signe n’apparaît pas si l’ajustement est positif.

5. Lorsque vous avez fait le réglage désiré (-35 à 35 °F / -18 °C à 18 °C), appuyez sur

la touche START (Mise en marche) pour confirmer le choix ou CANCEL (Annuler) pour

l’annuler.

REMARQUE : La modification de la calibration influe sur tous les modes de cuisson. Les

ajustements n’affectent pas la température du cycle d’autonettoyage.

L1 à

Gril

O = Contacts du circuit ouverts

correctement remises en place.

BROCHE 1 - SONDE DU FOUR

BROCHE 2 - SONDE DU FOUR

BROCHE 3 - (VIDE)

BROCHE 4 - COM

BROCHE 5 - INTERR. DE PORTE

BROCHE 6 - INTERR. DU LOQUET MOTORISÉ DE LA PORTE

BROCHE 7 - INTERR. DU TIROIR RÉCHAUD

RTD = Capteur de température à résistance (sonde ou capteur de

température)

TCO = Coupe-circuit thermique (aussi « disque thermique » ou

« limiteur thermique »)

L1 au

loquet du

moteur de

la porte

L1 au

vent. à conv./

cuisson rapide

Speed Bake

élément

chauffant à

convection

* = Alterne avec l’élément de cuisson au four

L1 à

L2 entrée

à

L2 sortie

L1 aux

L1

lampes

à

tiroir

réchaud

† = Pendant le préchauffage

du four

Contacts

d’interr. de

porte

COM-NO

= Cycles, au besoin

Description des codes d’erreurs du régulateur électronique de four

Code

d’erreur

F10

F11

F12

F13

F14

F15

F19

F30

F31

F42

F60

F62

F63

F64

F65

F66

F68

F69

F90

F91

F92

F93

F94

F95

Tableau de tests pour les touches

Pièce de raccordement

du câble-ruban à

BROCHE 19

BROCHE 1

Côté gauche

Vue : Plaque de recouvrement des commandes

Cause probable

du problème

Emballement de la température.

Le four chauffe lorsqu’aucun cycle

de cuisson n’est programmé.

Court-circuit du clavier ou du

sélecteur.

Erreur logicielle interne ou

défectuosité du régulateur

électronique de four.

Défectuosité de la pièce de

raccordement du clavier.

Erreur matérielle interne ou

défectuosité du régulateur

électronique de four.

Circuit de la sonde du four ouvert.

Court-circuit du circuit de la sonde

du four.

Erreur de configuration logicielle

interne dans le régulateur

électronique de four.

Température du four anormale selon

le régulateur électronique de four.

Température plus élevée que la

normale détectée sur la carte du

régulateur électronique de four.

Erreur de tension du signal interne. Coupez l’alimentation électrique, attendez 30 secondes, et rebranchez l’appareil. Si le problème n’est pas réglé, remplacez le régulateur électronique de four.

Défaillance de communication de

l’affichage.

Anomalie liée aux bases de temps –

Le régulateur électronique de four

est incapable de déterminer s’il est

branché à une source d’alimentation

de 50 ou 60 Hz.

Court-circuit du clavier ou anomalie

interne du régulateur électronique

de four.

régulateur électronique de four.

Tension élevée. Il se peut que le fil

d’arrivée L1 ou L2 soit croisé avec le

fil neutre au niveau de la carte

d’alimentation électrique.

Défaillance du circuit du moteur de

verrouillage ou du loquet.

modèles électriques seulement

19 broches

vue de l’avant

Pièce de raccordement

du câble-ruban à

13 broches

Côté droit

Si le four est froid :

1. Si un code d’erreur apparaît lorsque le four est froid, vérifiez la résistance du circuit de la sonde du détecteur de température du four. Servez-vous de l’échelle du détecteur

de température à résistance se trouvant sur la fiche technique.

2. Remplacez la sonde ou réparez les raccordements de fils, s’ils sont défectueux.

3. Si le circuit de la sonde du détecteur de température semble correct, mais que le code d’erreur réapparaît pendant que le four est froid, remplacez le régulateur

électronique de four.

Si le four surchauffe :

1. Si le four chauffe/surchauffe de façon excessive sans qu’il y ait de programme de cuisson sélectionné, vérifiez la résistance du circuit de la sonde du détecteur de

température du four au moyen de l’échelle ROUGE se trouvant sur la fiche technique d’entretien. Vérifiez également si la sonde du détecteur de température est bien

installée dans la cavité du four.

2. Coupez l’alimentation électrique de la cuisinière, attendez 30 secondes, puis rebranchez l’appareil. Si le four chauffe toujours lorsque l’alimentation est rebranchée,

remplacez le régulateur électronique du four. REMARQUE : Le four doit être remplacé au complet si une surchauffe excessive a causé des dommages importants.

1. Réinitialisation de l’alimentation à la cuisinière - Coupez l’alimentation, attendez 30 secondes, puis rebranchez l’appareil.

2. Vérifiez et replacez les connexions du câble-ruban entre le panneau tactile et le régulateur électronique de four.

3. Vérifiez les circuits du clavier au moyen du tableau de tests. Remplacez le panneau tactile, s’il est défectueux.

4. Si les circuits du clavier semblent corrects, remplacez le régulateur électronique de four.

Coupez l’alimentation électrique, attendez 30 secondes, et rebranchez l’appareil. Si le problème n’est pas réglé, remplacez le régulateur électronique de four.

1. Vérifiez et replacez les connexions du câble-ruban entre le panneau tactile du clavier et le régulateur électronique de four.

2. Vérifiez les circuits du clavier au moyen du tableau de tests (voir ci-dessous). Remplacez le panneau tactile, s’il est défectueux.

3. Si les circuits du clavier semblent corrects, remplacez le régulateur électronique de four.

Coupez l’alimentation électrique, attendez 30 secondes, et rebranchez l’appareil. Si le problème n’est pas réglé, remplacez le régulateur électronique de four.

1. (F30) Vérifiez la résistance à la température de la pièce et comparez-la au tableau de résistance de la sonde du détecteur de température à résistance. Si la résistance

est correcte, remplacez le régulateur électronique de four. Si la résistance ne correspond pas au tableau de résistance de la sonde du détecteur de température à

résistance, remplacez la sonde. Vérifiez le faisceau électrique entre le régulateur électronique de four et le connecteur de la sonde.

2. (F31) Vérifiez la résistance à la température de la pièce. Si elle est plus faible que 500 ohms, remplacez la sonde du détecteur de température à résistance. Vérifiez s’il

y a un court-circuit au niveau du faisceau de la sonde, entre le régulateur électronique du four et le connecteur de la sonde. Si la résistance est correcte, remplacez le

régulateur électronique de four.

Habituellement, ce code d’erreur n’apparaît que lorsque le régulateur électronique de four a été remplacé et que sa version est incompatible avec le système. Assurez-vous

que les pièces de rechange utilisées sont compatibles au système en vérifiant leur numéro de modèle.

1. Vérifiez l’installation du panneau du dosseret. Vérifiez l’état des panneaux, des supports, des capuchons, etc.

2. Vérifiez si les fentes de ventilation du couvercle arrière du panneau de commande sont obstruées.

3. Vérifiez le montage et l’écoulement d’air de l’évent de four.

4. Vérifiez le fonctionnement du ventilateur de refroidissement (le cas échéant).

Assurez-vous que la cuisinière est branchée à une source d’alimentation appropriée (de 50 ou 60 Hz). Il est possible que les génératrices ou d’autres sources d’alimentation

électrique portatives, ainsi que les systèmes à énergie solaire, etc. ne fournissent pas une quantité d’énergie suffisante. Si la source d’alimentation est correcte, remplacez

le régulateur électronique de four.

1. Vérifiez les circuits du clavier au moyen du tableau de tests. Remplacez le panneau tactile, s’il est défectueux.

2. Si les circuits du clavier semblent corrects, remplacez le régulateur électronique de four.

Coupez l’alimentation électrique, attendez 30 secondes, et rebranchez l’appareil. Si le problème n’est pas réglé, remplacez le régulateur électronique de four.Anomalie d’alimentation interne du

1. Vérifiez si la tension et la polarité des connexions d’alimentation des fils d’arrivée L1, L2 et neutre sont correctes au niveau du bornier de la cuisinière.

2. Si la tension et la polarité de l’alimentation sont adéquates, remplacez le régulateur électronique de four.

Si le moteur du loquet fonctionne :

1. Vérifiez la continuité du câblage entre le régulateur électronique de four et l’interrupteur du loquet du moteur de verrouillage. Réparez au besoin.

2. Faites avancer le moteur jusqu’à ce que la came appuie sur le poussoir du moteur de verrouillage. Vérifiez la continuité des contacts des contacteurs. Si le contacteur

est ouvert, remplacez le moteur de verrouillage.

3. Si le moteur de verrouillage fonctionne, et que les essais des contacts et du faisceau ne révèlent aucune anomalie, remplacez le régulateur électronique de four.

Si le moteur de verrouillage ne fonctionne pas :

1. Vérifiez la continuité des bobines du moteur de verrouillage. Si les bobines sont ouvertes, remplacez le moteur de verrouillage.

2. Vérifiez le fonctionnement du moteur de verrouillage en utilisant un câble volant pour appliquer la tension. Si le moteur de verrouillage ne fonctionne pas, remplacez-le.

3. Si le moteur fonctionne avec le câble volant, vérifiez la continuité entre le faisceau et les bornes du moteur. Si le faisceau fonctionne correctement, remplacez le

régulateur électronique de four.

BROCHE 1

BROCHE 13

Pour tester le fonctionnement des touches, vérifiez la continuité des contacts entre les broches indiquées et les touches lorsqu’elles sont enfoncées. Exemple : Pour tester la

touche BAKE (Cuisson au four), utilisez les broches 2 et 10 sur le connecteur P31. Pour tester le clavier de la table de cuisson, utilisez la broche 1 du connecteur P1 et la

broche 9 du connecteur P31.

Mesure corrective suggérée

Page 4

Schéma de dépannage général Schéma de dépannage général

Loading...

Loading...