Page 1

SERVICE MANUAL

27” Dryers

Gas & Electric

Models with

Electronic Controls

5995393146

November 2003

1

Page 2

SAFE SERVICING PRACTICES - ALL APPLIANCES

To avoid personal injury and/or property damage, it is important that Safe

Servicing Practices be observed. The following are some limited examples of

safe practices:

1. DO NOT attempt a product repair if you have any doubts as to your ability to

complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance:

• Remove the power cord from the electrical outlet, trip the circuit breaker to

the OFF position, or remove the fuse.

• Turn off the gas supply.

• Turn off the water supply.

3. Never interfere with the proper operation of any safety device.

4. USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE.

SUBSTITUTIONS MAY DEFEAT COMPLIANCE WITH SAFETY

STANDARDS SET FOR HOME APPLIANCES.

5. GROUNDING: The standard color coding for safety ground wires is GREEN,

or GREEN with YELLOW STRIPES. Ground leads are not to be used as current

carrying conductors. It is EXTREMELY important that the service technician

reestablish all safety grounds prior to completion of service. Failure to do so

will create a hazard.

6. Prior to returning the product to service, ensure that:

• All electrical connections are correct and secure

• All electrical leads are properly dressed and secured away from sharp

edges, high-temperature components, and moving parts

• All non-insulated electrical terminals, connectors, heaters, etc. are

adequately spaced away from all metal parts and panels

• All safety grounds (both internal and external) are correctly and securely

connected

• All panels are properly and securely reassembled

ATTENTION!!!

This service manual is intended for use by persons having electrical and mechanical

training and a level of knowledge of these subjects generally considered acceptable in

the appliance repair trade. Electrolux Home Products cannot be responsible, nor assume

any liability, for injury or damage of any kind arising from the use of this manual.

© 2001 White Consolidated Industries

2

Page 3

SAFE SERVICING PRACTICES 2

QUICK REFERENCE SHEET 7 - 11

Serial nameplate location 7

Serial number breakdown 7

T ech sheet location 7

Failure codes 8

On line test 8

Specification 10

Component resistance chart 1 1

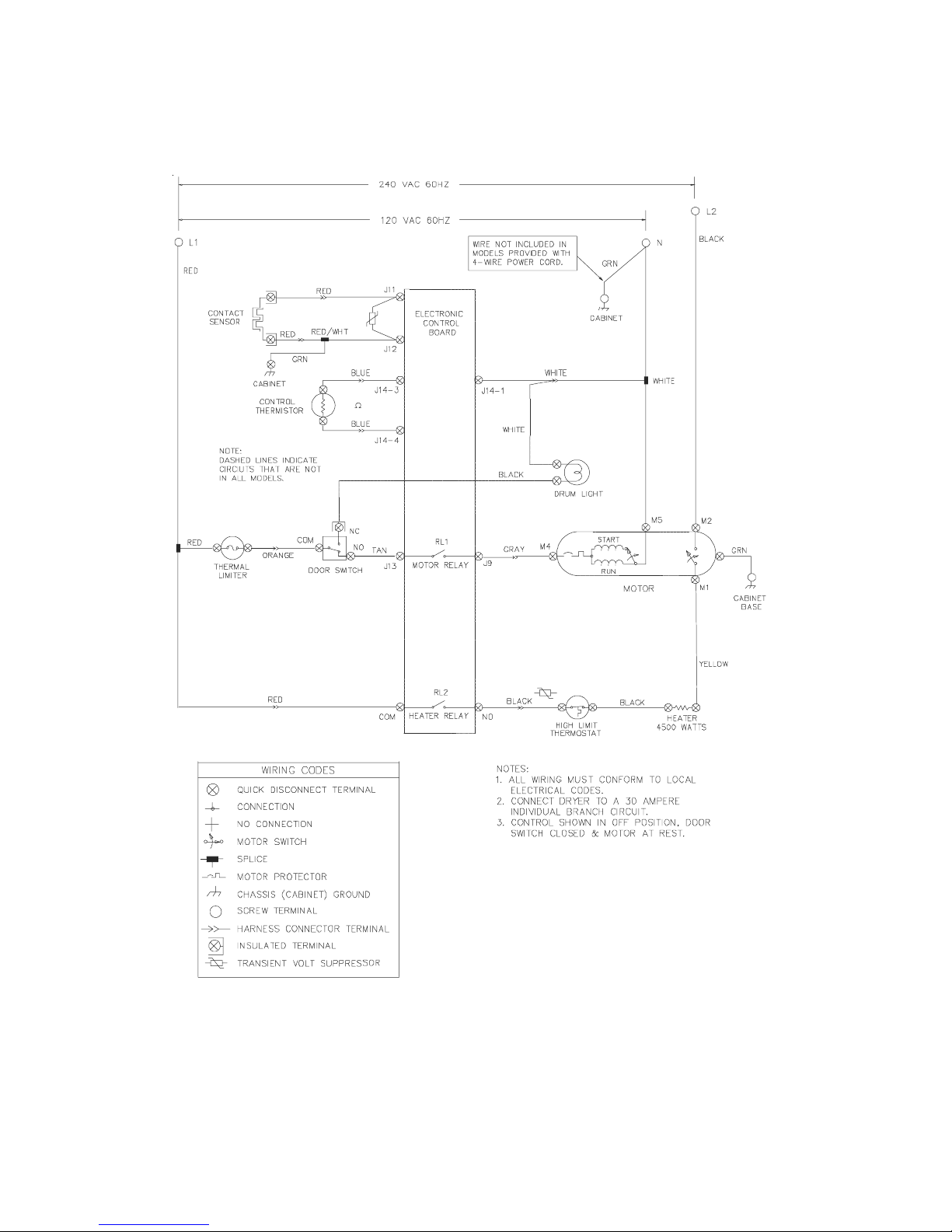

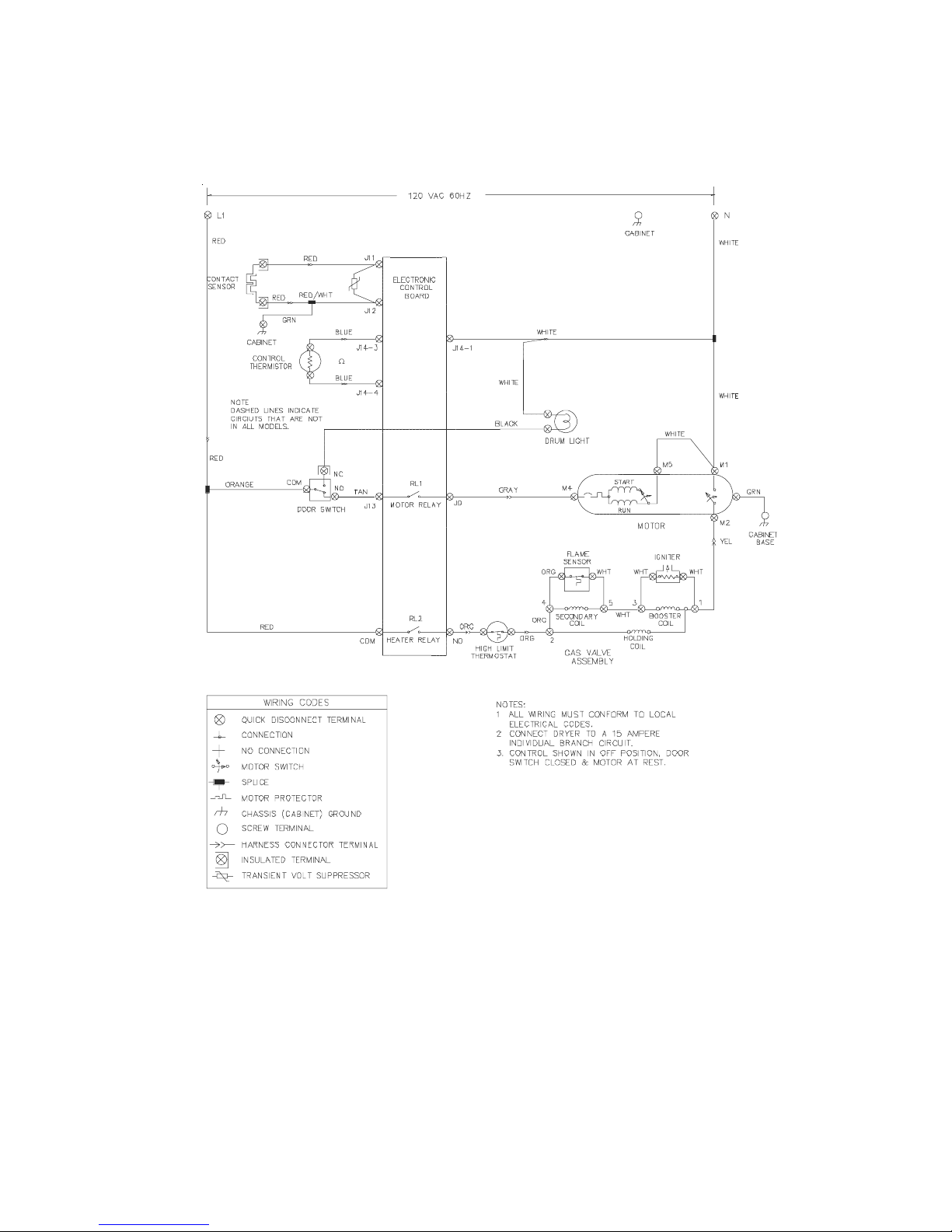

Sample wiring diagrams 12 - 13

Sample wiring diagram for electric models 12

Sample wiring diagram for gas models 13

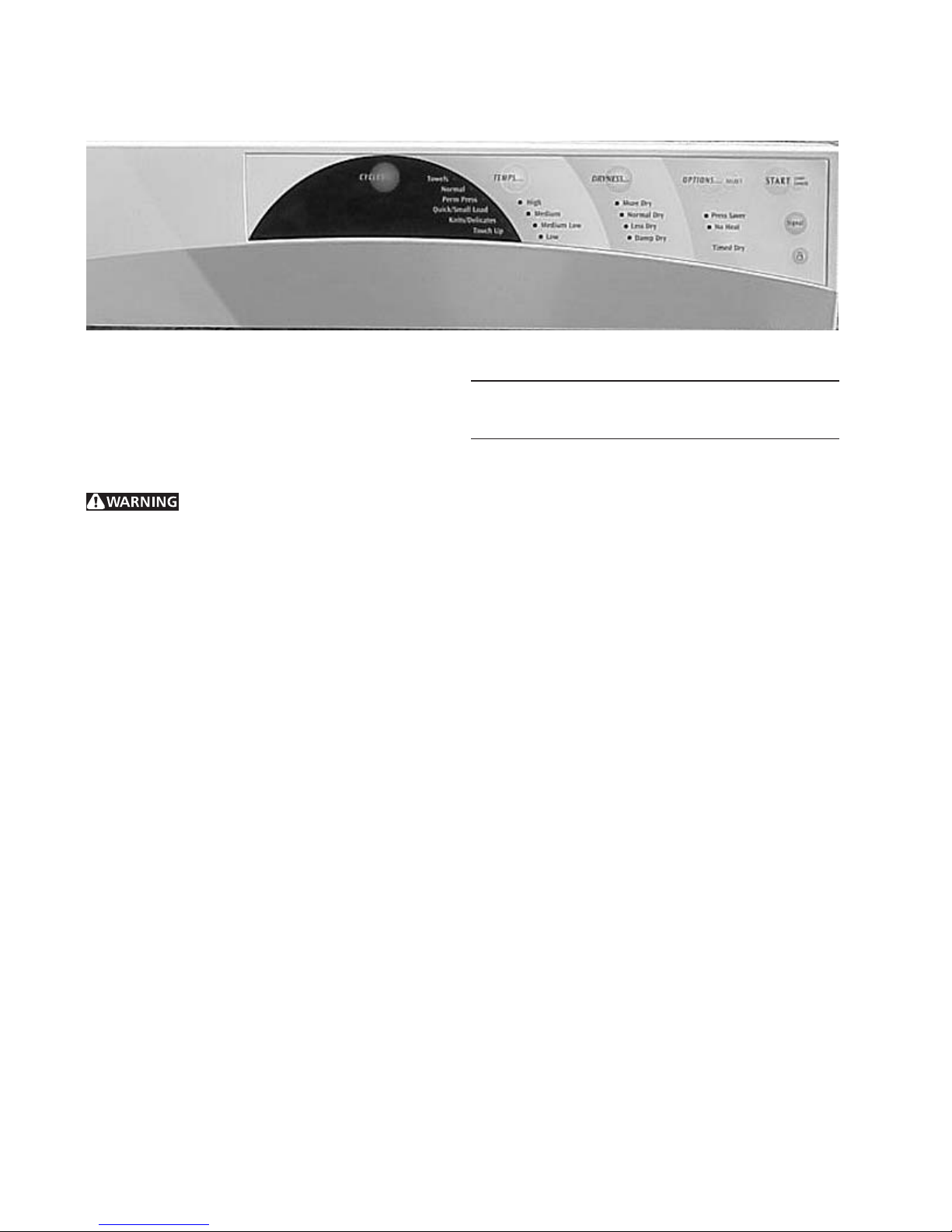

SECTION A - OPERATING INSTRUCTIONS 14 - 17

Before operating your dryer 1 4

Operating steps 14

Cycle Selection 14 - 15

Normal 15

Quick 15

Towels 15

Perm Press 15

Knits / Delicates 15

T ouch Up 15

Cycle Adjustment 15

Temperature Selection 15

Dryness Selection 15

Cycle Options 15

Press Saver 15

Air Fluff/No Heat 1 6

Dryer Features 16

Control Lock 16

Signal 16

Time Dry 16

Error Codes 16

Dryer settings reference chart 1 7

SECTION B - OWNERS GUIDE 18 - 26

Safety information 18 - 19

What to do if you smell gas 1 8

Your Safety and the Safety of other is very Important 1 8

Pedestal 18

Important safety instructions 18

Prevent fire 18

Protect children 19

Prevent injury 19

Drying Procedures 20

Features 21

End of cycle signal 2 1

Drum light 21

Reversible dryer door 2 1

Drying rack 21

Common drying problems 2 2

Care and cleaning 23

Inside 23

Outside 23

Avoid service checklist 24 - 25

Sample Warranty 26

3

Page 4

SECTION C - INSTALLATION INSTRUCTIONS GAS & ELECTRIC DRYER 27 - 36

What to do if you smell Gas 2 7

Pre-installation requirements 2 8

Tools and materials required for installation 28

Electrical requirements 28

Electric dryers 28

Gas dryers 28

Exhaust system requirements 2 8

Exhaust directions 30

Exhaust duct locating dimensions 30

Gas supply requirements 30

Location of your dryer 30

Do not install your dryer 3 0

Installation in a recess or closet 3 0

Minimum installation clearances 30

This dryer must be exhausted outdoors 3 0

Under counter installation 3 1

Mobile home installation 31

Rough-in dimensions 32

Unpacking 33

Reversing door swing 33

Electrical installation 33

Electric dryers 33

Grounding requirements 3 4

For a grounded, cord-connected dryer 3 4

For a permanently connected dryer 34

Gas dryer 34

Electrical connections for 3-wire system 34

Electrical connections for 4-wire system 35

Gas connection 35

General installation 35

Replacement parts 36

SECTION D - ST ACKING INSTRUCTIONS 37 - 3 8

Tool & equipment requirements 37

Kit components 37

Remove washer top panel 37

Install mounting brackets 37

Install dryer support spacer 38

Prepare dryer for stacking 38

Stack the dryer 38

Washer and dryer operation 38

SECTION E - HOW THE COMPONENTS WORK 39 - 47

The basic components 39 - 40

Drum 39

Heat source 39

Electric 39

Gas 39

Drive motor and blower 39

Control thermistor 40

Electronic control board 4 0

Airflow 40

Airflow electric dryers 4 0

Airflow gas dryers 4 1

Airflow problems 42

Restrictions 42

Air leaks 42

4

Page 5

Short unrestricted vents 42

Electrical operation (Electric dryers models) 42- 44

Electronic control board circuits 43

Drive motor circuit 4 3

T emperature sensing circuit 4 3

The heating circuit 44

Drying time 44

Electrical Operation (Gas Dryers Models) 44 - 47

Electronic control board circuits 45

Drive motor circuit 4 5

T emperature sensing circuit 4 5

The heating circuit 45

Drying time 46

SECTION F - TROUBLESHOOTING FLOW CHARTS 48 - 56

Electric dryer completely inoperative 49

Gas dryer completely inoperative 50

Electric and gas dryers; blower motor runs but drum does not turn 5 1

Electric and gas dryers; longer than normal drying times 5 1

Electric dryer not heating properly 52

Gas dryer not heating properly 5 3

Electric and gas dryers; dryer over heating 5 3

Electric dryers; blower motor runs but dryer does not heat 5 4

Gas dryers; blower motor runs but dryer does not heat 5 5

Electric and Gas dryers; clothes not dry in auto cycle 5 6

SECTION G - TEARDOWN 57 - 71

Removing the top panel 57

Removing the console drip rail 57

Removing the front panel 57

Removing the electronic control and display 58

Removing the console 59

Removing the console front panel with touch pad 60

Removing the door 60

Separating the door panel 60

Removing the door seal 60

Removing the door handle 61

Removing the door strike 6 1

Removing the door hinge 61

Removing the door catch 6 1

Removing the door switch 6 1

Removing the sensor bars 6 2

Replacing the drum light bulb 62

Replacing the drum light housing 6 2

Replacing the drum light socket 6 2

Replacing the felt seal 63

Replacing the foam seal 63

Removing the rear vent 63

Releasing the dryer belt 63

Removing the vane from the drum 64

Removing the drum 64

Removing the belt 64

Removing the hitch ball from the drum 65

Removing the teflon glides 65

Removing the drum heat shield (Electric dryers) 6 5

Removing the hitch 65

Removing the high limit thermostat 66

5

Page 6

Removing the thermal limiter (Electric dryers) 6 6

Removing the heating element assembly (Electric dryers) 6 6

Removing the control thermistor 6 6

Removing the blower housing and fan blade 67

Removing the idler pulley 68

Removing the idler pulley assembly 68

Removing the drive motor 6 8

Removing the burner (Gas dryers) 6 8

Removing the ignitor (Gas dryers) 6 8

Removing the gas valve assembly (Gas dryers) 6 9

Removing the gas valve coils (Gas dryers) 6 9

Removing the sensor (Gas dryers) 7 0

Removing the combustion chamber (Gas dryers) 7 0

Removing the duct and heat shield (Gas dryers) 7 0

Removing the manifold pipe (Gas dryers) 7 0

Removing the vent pipe (Gas dryers) 7 1

Removing the gasket between the vent pipe and blower housing 71

6

Page 7

QUICK REFERENCE SHEET

1. Serial nameplate location: on the front

panel at the left side of the dryer door

opening.

2. Serial number breakdown.

3. T ech sheet location

Front console models: on the right-hand

bodyside behind the front panel

and inside rear access panel.

X D 3 2 3 0 4 2 4 7

Incremented unit number

Production week

Last digit of production year

Product identification

Manufacturing Facility

7

Page 8

QUICK REFERENCE SHEET

Failure codes:

Display shows: F 04

Display shows: F 01

Indicates: An internal fault in the control.

Correction: Touch the Stop/Clear pad. If the dis-

play continues to display F 01 or if the

code returns when the dryer is re-

started, replace the control.

Display shows: F 02

Indicates: Control temperature sensor open or

shorted.

Correction: Removed the wires from the control

temperature sensor and measure the

resistance of the sensor. If the meter

does not read 50,000 Ohms +/- 10%

replace the sensor. If the meter reading

is within 10% of 50,000 Ohms, check

the wiring between the electronic con-

trol board and the sensor. If the wiring

is good, replace the electronic control

board.

Indicates: The drying time has exceeded the pro-

gram time for that cycle.

Correction: Touch the Stop/Clear pad. Program the

dry for a NORMAL CYCLE with HIGH

HEA T and touch ST ART . Check for anything that would extend the dry time

such as:

1. Dryer not heating.

2. Restricted vent.

3. Blower fan blade broken or loose.

4. Dryer installed in a closet with a

solid door.

5. Bad connect in sensor bar circuit or

dirty sensor bars.

If the dryer operates normally but the

F 04 code returns, replace the control.

Display shows: F 03

Indicates: No heat

Correction: Touch the Stop/Clear pad to clear the

F 03. Program the dry for a NORMAL

CYCLE with HIGH HEAT and touch

START. Measure the voltage drop

across the terminals of relay RL 2 on

the electronic control board. If the meter

reads 240 VAC on electric models or

120 VAC on gas models, replace the

electronic control board. If the meter

reads zero, remove power from the dryer

and disconnect the black wire electric

models and orange wire gas models

from the relay. Reconnect power and

measure the voltage drop between red

wire on the relay RL 2 to neutral. If the

meter reads zero, the wire between the

incoming line and relay RL 2 is open. If

the meter reads 120 VAC, check the

rest of the heating circuit as described

in the trouble shooting section.

Display shows: F 05

Indicates: A problem with the key pad.

Correction: Disconnect the keypad ribbon from the

control and reconnect the ribbon. Try

all keypad switches to see they all function correctly . If they do not, try cleaning the end of the ribbon with a soft cotton cloth. Reinstall the ribbon and program the dryer to operate. If the code,

reoccurs replace the touch pad.

Note: See control removal instruction on

how to disconnect ribbon.

On line test:

T o start the test programs, remove power from the dryer .

Reconnect power to the dryer and within 10 seconds

press and hold the temp and the stop pads for at least 2

seconds, then release. The control is now in the test

function.

1. After activation, the WRINGLE RID icon should be

on.

8

Page 9

QUICK REFERENCE SHEET

2. Touch the start pad and the test will advance to

the HEA T test. (H) will appear in the display, the

drive motor will run and the electric heating element

or gas burner will operate depending on the model.

3. Retouch the start pad and the test will advance to

the AIR FLUFF test. (AF) will appear in the

display and the drive motor will run.

4. Retouch the start pad and the test will advance to

the AUT O DRY MOISTURE COUNTS test. The

AUTO DRY icon will illuminate and a number will

appear in the display . Open the door , place your

hand against the sensor bars and the amount of

the number in the display should go down.

5. Retouch the start pad and the test will advance to

the MEMBRANE test. The display will be blank.

Press each cycle pad and the LEDs should light.

6. Retouch the start pad and the test will advance to

the COOL DOWN test. The COOL DOWN icon will

illuminate and a number will appear in the display

and the drive motor will run.

7. Retouch the start pad and the test will advance to

the TIME DRY test. The TIME DRY icon will

illuminate and a number will appear in the display .

The drive motor will run and the electric heating

element or gas burner will operate depending on the

model.

Press Start to repeat the test. T o remove the dryer from

the test mode, disconnect power to the dryer or press

and hold the stop and cycle pads for at least 2 seconds

then release.

9

Page 10

QUICK REFERENCE SHEET

SPECIFICATION

Electrical

Volts 120/208 or 120/240

Amps (circuit)

Motor wattage

Heat input (Watts @ 240 VAC)

Heat input (BTU/Hr.)

Auto. Elec. Ignition

Drum

Size (Cu. Ft.)

Finish

R.P.M.

Airflow CFM

DRUM TEMPERATURES (Max.

opening on 1st cycle)

High

Medium

Low

Dimension (Inches)

Height (Stack Models)

Width

Depth

ELECTRIC MODELS

120/208 or 120/240

30

160-350 Watts

3200/4500

---

---

5.7

Power Paint Epoxy

48 - 54

200

145° - 190°

140° - 180°

135° - 175°

35 1/4”

26 7/8”

27”

GAS MODELS

120

15

160-350 Watts

---

20,000

Yes

5.7

Power Paint Epoxy

48 - 54

200

145° - 190°

140° - 180°

135° - 170°

35 1/4”

26 7/8”

27”

Vent Capability**

T op Finish

Port Opening (Sq. In.)

** Electric dryers can be vented four ways: through back, bottom, right or left side.

** Gas dryers can be vented three ways: through back, bottom, or right side.

4-Way

Power Paint Enamel

235

±

±

±

±

±

3-Way

Power Paint Enamel

235

10

Page 11

QUICK REFERENCE SHEET

Component Resistances*

Drive motor (120 volt, 60 Hz, 1/4 h.p. 1725 rpm)

Motor Start Winding

Motor Run Winding

Heating Element

Control Thermistor

Burner Assembly

Ignitor

Secondary Coil

Booster Coil

* +/- 10% @ 77° F

Electric Models

4.5 Ohms

3.8 Ohms

12.8 Ohms

50,000 Ohms

---

---

---

Gas Models

4.5 Ohms

3.8 Ohms

50,000 Ohms

50 - 400 Ohms

1200 Ohms

1320 Ohms

11

Page 12

SAMPLE WIRING DIAGRAM FOR ELECTRIC MODELS

CAUTION: DISCONNECT ELECTRIC CURRENT BEFORE SERVICING. LABEL ALL WIRES PRIOR TO

DISCONNECTION WHEN SERVICING CONTROLS. WIRING ERRORS CAN CAUSE IMPROPER AND

DANGEROUS OPERA TION. VERIFY PROPER OPERA TION AFTER SERVICING .

50K

12

Page 13

SAMPLE WIRING DIAGRAM FOR GAS MODELS

CAUTION: DISCONNECT ELECTRIC CURRENT BEFORE SERVICING. LABEL ALL WIRES PRIOR TO

DISCONNECTION WHEN SERVICING CONTROLS. WIRING ERRORS CAN CAUSE IMPROPER AND

50K

13

Page 14

SECTION A - OPERATING INSTRUCTIONS

Before Operating Your Dryer

Read your dryer Use and Care Guide. It has impor-

tant safety and warranty information. It also has many

suggestions for best drying results.

To reduce the risk of fire, electric shock

or injury to persons, read the IMPORT ANT SAFETY INSTRUCTIONS in your dryer Use and Care Guide before

operating this appliance.

Operating Steps

Read “Drying Procedures” in your Use and Care Guide.

It explains these operating steps in detail.

1. Prepare items for drying.

2. Check that lint screen is clean and in place.

3. Load the dryer. If desired, add a dryer fabric sof tener

sheet. Close the door.

4. Press CYCLES until desired cycle is selected. Suit-

able drying temperature, dryness level and options

will automatically be displayed. To change these

settings, press TEMPS, DRYNESS and OPTIONS

until the desired selections are made. Those adjustments to the cycle will automatically be remembered

each time that cycle is selected.

Note: To provide the best care for your laundry

items, not all temperatures, dryness levels

and options are available with all cycles.

7. Add desired features by pressing symbols for

· Control Lock

· End-of-Cycle Signal

· Time Dry

8. Press START to begin cycle.

· To pause the cycle, press STOP/CLEAR

once. “P AU” will flash alternately with the

time remaining display . To resume the cycle,

press ST ART again.

· To stop or clear the cycle, press STOP/

CLEAR twice.

9. A signal will sound near the end of the cycle and

periodically during Press Saver when the signal option is selected. When the cycle ends, remove items

immediately and hang or fold.

10. Clean lint screen after every load.

Cycle Selection

5. T o select or delete Press Saver and Air Fluff/No Heat,

press OPTIONS until the flashing light indicates a

desired option. Then press SELECT to add or delete

the option.

6. If you wish to return to the factory settings, press and

hold “CYCLES” and “OPTIONS” at the same time for

5 seconds and release. The display will show two

dashes for a few seconds indicating that the factory

settings have been selected.

For best results, follow the fabric care label instructions

on items to be dried.

Auto Dry cycles take the guesswork out of drying time.

The load will automatically be dried at the selected temperature to the desired dryness level. The dryer senses

the moisture level of the load as it tumbles through heated

air. Auto Dry cycles save time and energy and protect

fabrics.

14

Page 15

When the load has reached the selected dryness level,

it will continue to tumble, unheated, during a Cool Down

period. This helps reduce wrinkling and makes items

easier to handle during unloading.

Drying time varies depending on size and dampness of

load and fabric type. Room temperature and humidity ,

type of installation and electrical voltage or gas pressure

can also affect drying time.

The following will be displayed during an Auto Dry cycle:

· The Estimated Drying time for the cycle selected

will be displayed for approximately 5 minutes.

Cycle Adjustments

A suitable drying temperature and dryness level will automatically be displayed for the cycle selected. To

change settings, press TEMPS and DRYNESS until the

desired selections are made. These adjustments to the

cycle will automatically be remembered each time that

cycle is selected.

Temperature Selection

For best results, follow the fabric care label instructions

on items to be dried. Select the temperature setting most

suitable for each load.

· The “Ad” is displayed until the Estimated Drying Time

for your specific load has been determined.

· The cycle status will change from “Auto Dry” to “Cool

Down” while the load is being tumbled without heat.

· “dn” is displayed when the cycle is done.

· If the Press Saver option has been selected, the

load will continue to tumble without heat. The cycle

status will change to “Press Saver” and “dn” will be

displayed.

Normal

Select this Auto Dry cycle for cotton items.

Quick

Select this Timed Dry cycle to quickly dry a small load

made up of just a few items. (Auto Dry is not available with

this cycle.)

Towels

Select this Auto Dry cycle for towel loads.

To avoid fire hazard, do not use heat to dry

items containing feathers or down, foam rubber, plastics,

or similarly textured, rubber-like materials. Use the Air

Fluff-No Heat cycle only.

High is recommended for sturdy fabrics.

Medium is recommended for wrinkle free, permanent

press and lightweight fabrics.

Medium-Low is recommended for most knits.

Low is recommended for delicate fabrics.

Note : To prevent shrinkage, every temperature is

not available with every cycle.

Dryness Selection

Select Normal Dry for most loads.

Occasionally a load may seem too damp or over-dried at

the end of the cycle. To increase drying time for similar

loads in the future, select More Dry. For loads requiring

less drying time, select Less Dry.

Perm Press

Select this Auto Dry cycle for permanent press items.

Knits / Delicates

Select this Auto Dry cycle for knit and delicate items.

Touch Up

Select Touch Up to help remove wrinkles from clean and

dry items that were not taken from the dryer at the end of

the cycle, have been stored in crowded closets or

drawers, or unpacked from luggage following a trip. It

provides approximately 10 minutes of low heat tumbling

followed by a 5-minute cool down period.

Select Damp Dry for items you wish to partially dry

before hanging or ironing. Select the temperature most

suitable for the load.

Note : To prevent over-drying, every dryness level

is not available with every cycle.

Cycle Options

Press Saver

If the dried load cannot be removed promptly at the end

of the cycle, unheated tumbling continues for approximately 30 minutes to help reduce wrinkling. When the

signal is selected, it will beep briefly approximately every

15

Page 16

4 minutes as a reminder to remove the load. The dried

load can be removed at any time during Press Saver.

No Heat

sensor.

· F 03 - There may be a problem with the heater

system.

This option provides up to 30 minutes of tumbling without

heat and can only be selected in the Timed Dry cycle.

Use it to dry items containing feathers or down, foam

rubber, plastics or similarly textured, rubber-like materials, to freshen clothing, pillows or blankets, or to dust

draperies.

Dryer Features

Control Lock

To prevent accidental operation of the dryer or alteration

of the cycle settings, press and hold the lock symbol until

you hear 3 beeps and “LOC” is displayed. To cancel,

press and hold the lock symbol until “LOC” is no longer

displayed.

Signal

A signal will sound at the end of the cycle and periodically

during Press Saver. Press the signal symbol to select

one of three volume levels or turn off the signal. This

selection will be programmed until you change it.

Timed Dry

· F 04 - The dryer may have run too long. Clean the

lint filter and be sure the vent is not blocked before

calling for service.

· F 05 - There may be a problem with the keypad.

Use this feature to manually select the drying time for any

load. Select the temperature desired. You will not be

able to select a cycle or dryness level.

NOTE: Timed Dry is required when using the No

Heat option.

Press TIMED DRY to select 45 minutes of drying time.

The time will increase 5 minutes each time TIMED DRY

is pressed. The maximum drying time is approximately

110 minutes. If you desire less than 45 minutes, you

must advance beyond the 110 minute mark to start again

at 15 minutes.

Error Codes

If the dryer stops and the F 01, F 02, F 03, F 04 or F 05

error code is flashing in the display, press STOP/CLEAR,

select a cycle and press START. If the error code

appears again, call for service to correct the problem.

· F 01 - There may be an internal problem with the

control.

· F 02 - There may be a problem with the temperature

16

Page 17

Dryer settings reference chart

A V AILABLE CYCLE SETTING - These temperatures, dryness levels and opions available with the following

cycles.

Normal Quick** Towels Perm Press Knits/Delicates Touch Up** Timed Dry

Temperatures

High * X * X * X X

Medium X X X * X X * X

Medium Low X X X X X X

Low X * X * X X

Dryness Level

More Dry X * X X

Normel Dry * X X * X X

Less Dry X X X * X

Damp Dry X X X

Options

Press Saver * X X X * X * X * X X

Air Fluff- X

No Heat

* Factory setting

** Timed Dry cycle only

17

Page 18

SECTION B - OWNERS GUIDE

For your safety, the information in this manual must be followed to minimize the risk of fire or

explosion or to prevent property damage, personal injury or loss of life.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building or area of all occupants.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

Your safety and the safety of others is very

important.

We have provided many important safety messages in

the Use and Care Guide, Operating Instructions,

Installation Instructions and on your appliance. Always

read and obey all safety messages.

This is the safety alert symbol. This symbol alerts

you to hazards that can kill or hurt you or others. All

safety messages will be preceded by the safety alert

symbol and the word "DANGER" or "WARNING". These

words mean:

DANGER

you don't follow instructions.

you don't follow instructions.

All safety messages will identify the hazard, tell

you how to reduce the chance of injury, and tell

you what can happen if the instructions are not

followed.

Pedestal

A pedestal accessory specifically designed for this dryer

may be used when elevating the dryer for ease of use.

Failure to use accessories certified by the manufacturer

could result in personal injury, property damage or

damage to the dryer.

You will be killed or seriously injured if

You can be killed or seriously injured if

Important Safety Instructions

Read all instructions before using this dryer.

To reduce the risk of fire, electrical shock,

or injury to persons when using this dryer, comply with

the basic warnings listed below.

Failure to comply with these warnings could result in

serious personal injuries.

Prevent Fire

Do not dry items that have been previously

cleaned in, soaked in, or spotted with gasoline, cleaning

solvents, kerosene, waxes, etc. Do not store these items

on or near the dryer. These substances give off vapors

that could ignite or explode.

To prevent fire, do not use heat to dry

items containing plastic, foam rubber or similarly textured

rubber-like materials, or items containing feathers or

down. Use Air Fluff (No Heat) only.

Clean the lint screen before or after

each load. The interior of the dryer, lint screen housing

and exhaust duct should be cleaned approximately

every 18 months by qualified service personnel. An

excessive amount of lint build-up in these areas could

result in inefficient drying and possible fire. See Care

and Cleaning.

Do not operate the dryer if the lint screen

is blocked, damaged or missing. Fire hazard,

overheating and damage to fabrics can occur. If your

18

Page 19

dryer has a drying rack, always replace the lint screen

Grounding type

w

grounding plug

when finished using the drying rack.

GAS DRYERS:

Keep area around the exhaust opening

and surrounding areas free from the accumulation of lint,

dust and dirt.

Do not obstruct the flow of ventilating air.

Do not stack or place laundry or throw rugs against the

front or back of the dryer.

Do not spray any type of aerosol into, on

or near dryer at any time.

Do not use fabric softeners or products to

eliminate static unless recommended by the manufacturer

of the fabric softener or product.

Failure to comply with these warnings could result in

fire, explosion, serious bodily injury and/or damage to the

rubber or plastic parts of the dryer.

This Use and Care Guide provides general operating

instructions for your dryer. It also contains information

about features for several other models. Your dryer may

not have every feature included.

Use the dryer only as instructed in this Use & Care Guide

and the Operating Instructions card included with your

dryer.

all receptacle

Do not under

any circumstances

cut, remove,

or bypass

the grounding prong

from this plug.

Power supply

cord with 3-prong

CORRECT

Use this way ONLY

Note: The instructions appearing in this Owner's Guide

are not meant to cover every possible condition and

situation that may occur. Common sense and caution

must be practiced when installing, operating and

maintaining any appliance.

Protect Children

Do not allow children to play on or in the

dryer. Close supervision of children is necessary when

the dryer is used near children. As children grow, teach

them the proper, safe use of all appliances.

Avoid fire hazard or electrical shock. Do

not use an adaptor plug or extension cord or remove

grounding prong from electrical power cord. Failure to

follow this warning can cause serious injury, fire or death.

ELECTRIC DRYERS:

14-30R

DRYER

FUSED 30 AMP

120/240 V OR

120/208 V

WALL

RECEPTACLE

Use this way ONLY

DRYER

SERVICE

CORD

CORRECT

Destroy the carton, plastic bag and other

packing materials after the dryer is unpacked. Children

might use them for play. Cartons covered with rugs,

bedspreads or plastic sheets can become airtight

chambers.

Keep laundry products out of children's

reach. To prevent personal injury, observe all warnings

on product labels.

Before the dryer is removed from service

or discarded, remove the dryer door to prevent accidental

entrapment.

Failure to comply with these warnings could result

in serious personal injuries.

Prevent Injury

To prevent shock hazard and assure

stability during operation, the dryer must be installed and

electrically grounded by a qualified service person in

accordance with local codes. Installation instructions are

packed in the dryer for the installer's reference. Refer to

19

Page 20

INSTALLATION INSTRUCTIONS for detailed grounding

procedures. If the dryer is moved to a new location, have

it checked and reinstalled by a qualified service person.

To prevent personal injury or damage to

the dryer, the electrical power cord of a gas dryer must

be plugged into a properly grounded and polarized 3prong outlet. The third grounding prong must never

be removed. Never ground the dryer to a gas pipe.

Do not use an extension cord or an adaptor plug.

ALWAYS disconnect the dryer from

the electrical supply before attempting any service or

cleaning. Failure to do so can result in electrical shock

or injury.

• Always read and follow fabric care labels and

laundry product labels.

To reduce the risk of fire, electrical

shock, or injury to persons, read Important Safety

Instructions before operating this dryer.

Do not use any type spray cleanser when

cleaning dryer interior. Hazardous fumes or electrical

shock could occur.

To prevent injury, do not reach into the

dryer if the drum is moving. Wait until the dryer has

stopped completely before reaching into the drum.

To prevent injury and damage to the

dryer:

• All repairs and servicing must be performed by

an authorized servicer unless specifically

recommended in this Owner's Guide. Use only

authorized factory parts.

• Do not tamper with controls.

• Do not install or store the dryer where it will be

exposed to the weather.

A thermal limiter switch automatically turns off the

motor in the unlikely event of an overheated situation

(electric dryers only). A service technician must replace

the thermal limiter switch after correcting the fault.

1. Prepare items for drying.

• Dry items of similar fabric, weight and

construction in the same load.

• Separate dark items from light-colored items.

Separate items that shed lint from those that

attract lint. If an item sheds lint, turn it inside

out.

• Be sure buckles, buttons and trim are heatproof

and won't damage the drum finish. Close

zippers, fasten hooks and Velcro®-like

fasteners. Tie strings and sashes to prevent

snagging and tangling.

• If possible, turn pockets inside out for even

drying.

• Check for stains which may not have been

removed in washing. Dryer heat may

permanently set some stains. Repeat stain

removal process before drying.

• Place small items in a mesh bag to prevent

tangling and for easy removal.

Failure to comply with these warnings could result

in serious personal injuries.

SAVE THESE INSTRUCTIONS

Drying Procedures

• Follow the guidelines below for preparing the load for

drying.

• Read the Operating Instructions card for operating

your specific model.

2. Check that lint screen is clean and in place.

20

Page 21

3. Load the dryer.

• The average load will fill the drum 1/3 to 1/2 full.

Items need room to tumble freely for even

drying and less wrinkling. Do not overload

dryer.

• To resume the cycle, press START again

.

• To stop the dryer, press STOP/CLEAR twice.

Two dashes will be displayed for

approximately thirty seconds.

6. When the cycle ends, remove items immediately

and hang or fold. If load is removed before the cycle

ends, press STOP/CLEAR twice to cancel the cycle.

Features

End of Cycle Signal

A signal will sound at the end of the cycle and periodically

during Press Saver at the volume level selected. (some

models)

Drum Light (some models)

• When drying large items, dry only 2 or 3 at a

time. Fill out the load with small and medium

sized items.

• For delicate or very small loads, add 2 lint-free

towels for better drying, less wrinkling, and to

prevent grease stains caused by fabric softener

sheets.

• Do not overdry items. Overdrying can cause

wrinkling, shrinkage, harshness, and a build-up

of static electricity, which can produce more

lint.

• If desired, add a dryer fabric softener sheet.

4. Close the dryer door and set dryer controls

(some models).

See Operating Instructions card for your specific

model imformation.

5. Start the dryer.

A drum light will come on whenever the door is opened

to illuminate the dryer drum during loading and

unloading. Closing the door turns off the light.

Reversible Dryer Door

Your dryer is equipped with a reversible door. The door

can be hinged on the right or left side. Refer to the

INSTALLATION INSTRUCTIONS for directions on

changing the door.

Drying Rack (some models)

Use the drying rack to dry items which should not be

tumble dried.

1. Open the dryer door and remove the lint screen.

2. Insert drying rack into the dryer drum. Place the

front bar under the lip of the lint screen opening.

• Press START.

• To change selections after the cycle has

started, press STOP/CLEAR twice. Make

changes and restart dryer.

• To add or remove items when the dryer is

running, press STOP/CLEAR once to pause

the dryer. "PAU" will be displayed. The dryer

will always stop when the door is opened.

Allow the drum to come to a complete stop

before reaching inside.

3. Place items to be dried on top of the rack. Weight

should not exceed 10 lbs. Leave space between

items, but do not let items hang over the sides or

21

Page 22

through the grids. Do not tumble other items when

using the drying rack.

5. When items are dry, remove the rack and replace the

lint screen. If lint screen is not in place, tumbling

items could enter the exhaust system and cause

4. Select a timed dry. Use only the Air Fluff (no heat)

damage to the dryer.

temperature setting for items containing plastic,

foam rubber, rubber-like materials, feathers or down.

Common Drying Problems

Many drying problems involve poor cleaning results, poor soil and stain removal, residues of lint and scum, and

fabric damage. For satisfactory drying results, follow these suggestions provided by The Soap and Detergent

Association.

PROBLEM

Greasy, oily

stains

Lint

Pilling

(Fibers break

off, ball up

and cling to

fabric.)

POSSIBLE CAUSES

• Fabric softener sheet.

• Overloading.

• Overdrying causes

static electricity.

• Lint screen not clean

when cycle began.

• Lint is attached to

"pills."

• Pilling is normal with

synthetic and

permanent press

fabrics. This is due to

abrasion from normal

wear.

SOLUTIONS

• Rub fabric softener stains

with bar soap. Rinse and

rewash.

• Reduce load size and

rewash using liquid fabric

softener in the final rinse.

• Or, add a fabric softener

sheet and tumble without

heat.

• Use lint brush or roller to

remove lint.

• Use a lint brush or shaver

to remove pills.

PREVENTIVE MEASURES

• Add a few bath towels to small

loads for proper tumbling.

• Some "silk-like" fabrics should

be air dried.

• Use proper drying temperature.

• Place fabric softener sheet on

top of load before starting the

dryer.

• Do not overload dryer.

• Use fabric softener in washer or

dryer to reduce static electricity.

• Remove items when they are

slightly damp to avoid

overdrying.

• Check that lint screen is clean

and in place.

• Use fabric softener to lubricate

fibers.

• When ironing, use spray starch

or fabric finish on collars and

cuffs.

• Turn items inside out to reduce

abrasion.

Shrinking

Wrinkling

• Overdrying.

• Overloading.

• Leaving items in dryer

after cycle ends.

• Irreversible condition.

• Reduce load size and

tumble at medium or low

heat for 5-10 minutes.

• Remove items

immediately. Hang or fold.

22

• Follow fabric care label

directions.

• If shrinking is a concern, check

load often.

• Remove items while slightly

damp and hang or lay flat to

complete drying.

• Block knits into shape.

• Do not overload dryer.

• Remove items as soon as cycle

ends.

Page 23

Care and Cleaning

Outside

To reduce risk of fire or serious injury to

persons or property, comply with the basic warnings

listed in Important Safety Instructions and those listed

below.

• Before cleaning the dryer interior, unplug the

electrical power cord to avoid electrical shock

hazards.

• Do not use any type spray cleanser when cleaning

dryer interior. Hazardous fumes or electrical shock

could occur.

Inside

• Clean the lint screen after every load. Lint build-up

in the screen restricts air flow, which causes longer

drying times. The screen is located at the bottom of

the door opening. Remove by pulling straight up.

Remove the lint and replace the screen.

• Clean the cabinet with mild soap and water. Never

use harsh, gritty or abrasive cleansers.

• If the cabinet becomes stained, clean with diluted

chlorine bleach [1/2 cup(120 ml) in 1 quart (.95 liter)

water]. Rinse several times with clear water.

• Remove glue residue from tape or labels with a

mixture of warm water and mild detergent. Or,

touch residue with the sticky side of the tape or

label.

• Before moving the dryer, place a strip of cardboard

or thin fiberboard under the front leveling legs to

prevent damage to floor.

• Occasionally a waxy build-up may form on the lint

screen from using dryer-added fabric softener

sheets. To remove this build-up, wash the lint

screen in warm, soapy water. Dry thoroughly and

replace. Do not operate the dryer without the lint

screen in place.

• If the dryer drum becomes stained from noncolorfast

fabrics, clean the drum with a damp cloth and a mild

liquid household cleanser. Remove cleanser residue

before drying the next load.

• Every 18 months an authorized servicer should

clean the dryer cabinet interior and exhaust duct.

These areas can collect lint and dust over time. An

excessive amount of lint build-up could result in

inefficient drying and possible fire hazard.

Do not store or place laundry products on top of dryer at

any time. They can damage the finish or controls.

23

Page 24

Avoid Service

Checklist

OCCURRENCE

Dryer does not start.

Before calling for service, review this list. It may save both time and expense. The list

includes common occurrences that are not the result of defective workmanship or materials

in this dryer.

POSSIBLE CAUSE

Electrical power cord is not securely

plugged in or plug may be loose.

SOLUTION

Make sure the plug fits tightly in wall outlet.

Dryer runs but won't heat.

Drying cycle takes too long,

outside of the dryer feels too

hot or smells hot.

House fuse blown or circuit breaker

tripped.

Thermal limiter tripped.

There are 2 house fuses in the dryer

circuit. If 1 of the 2 fuses is blown, the

drum may turn but the heater will not

operate.

Gas supply valve is not open (gas

models).

Dryer does not have enough air supply

to support the burner flame (gas

models).

LP gas supply tank is empty or there

has been a utility interruption of natural

gas (gas models).

Lint screen is clogged with lint.

Exhaust duct requirements have not

been met.

Reset circuit breaker or replace fuse.

Make sure electrical line is not overloaded and the

dryer is on a separate circuit.

Call authorized service person for replacement.

Replace fuse.

Check to make sure supply valve is open. See

INSTALLATION INSTRUCTIONS for procedure.

See INSTALLATION INSTRUCTIONS.

Refill or replace tank.

Dryer should heat when utility service is restored.

Make sure all lint has been removed from the dryer

lint screen before starting each cycle.

Exhaust duct must be at least 4 inches in diameter

and made of rigid or flexible metal.

Excessive wrinkling.

Electric dryer is connected to a 208 volt

circuit.

Drying procedures have not been

followed.

Outside exhaust hood or exhaust duct

may be clogged or restricted.

High humidity.

Dryer is overloaded.

Items left in dryer too long.

Insufficient sorting of items.

Drying temperature too high.

When in place, the duct must have no more than two

90° bends and must not exceed length listed in

INSTALLATION INSTRUCTIONS.

Drying time will be 20% longer than drying on a 240

volt circuit.

See Drying Procedures.

Clean out any obstruction.

Use a dehumidifier near the dryer.

Do not overload. See Drying Procedures.

Remove items as soon as cycle ends.

See Drying Procedures.

Follow fabric care label instructions.

24

Page 25

Avoid Service

Checklist

Before calling for service, review this list. It may save both time and expense. The list includes

common occurrences that are not the result of defective workmanship or materials in this dryer.

OCCURRENCE

Scratching or

chipping of the

drum finish.

POSSIBLE CAUSE

Foreign objects such as coins, pins, clips

or buttons are inside the dryer.

Permanently attached items such as belt

buckles, zippers and fasteners may be

hitting the inside of the drum.

SOLUTION

Always remove foreign objects from pockets

before laundering. Remove objects from drum

and restart dryer.

It may be necessary to baste a scrap of

material securely around ornaments before

drying to prevent scratching and damage to

the dryer.

Drum damage caused by foreign objects or

permanently attached items is not covered

by the warranty.

25

Page 26

FRIGIDAIRE DRYER WARRANTY

Your Frigidaire product is protected by this warranty

Sample warranty - always check

warranty with product

WARRANTY

PERIOD

FULL ONE-YEAR

WARRANTY

LIMITED WARRANTY

(Applicable to the

State of Alaska)

Your appliance is warranted by Frigidaire Home Products, a division of White Consolidated Industries, Inc. We authorize no person to change

or add to any of our obligations under this warranty. Our obligations for service and parts under this warranty must be performed by Frigidaire

or an authorized Frigidaire servicer.

One year from original

purchase date.

Time period listed above.

FRIGIDAIRE, THROUGH ITS AUTHORIZED

SERVICERS, WILL:

Pay all costs for repairing or replacing any parts

of this appliance which prove to be defective

in materials or workmanship.

All of the provisions of the full warranty above

and the exclusions listed below apply.

Costs of service calls that are listed under IMPORTANT

RESPONSIBILITIES OF THE CONSUMER.*

Costs of the technician's travel to the home and any

costs for pick up and delivery of the appliance required

because of service.

THE CONSUMER WILL BE

RESPONSIBLE FOR:

This warranty applies only to products in ordinary household use, and the consumer is responsible

for the items listed below:

1. Proper use of the appliance in accordance with instructions provided with the product.

2. Proper installation by an authorized servicer in accordance with instructions provided with the

appliance and in accordance with all local plumbing, electrical and/or gas codes.

3. Proper connection to a grounded power supply of sufficient voltage, replacement of blown fuses,

repair of loose connections or defects in house wiring.

4. Expenses for making the appliance accessible for servicing, such as removal of trim, cupboards,

shelves, etc., which are not a part of the appliance when it was shipped from the factory.

5. Damages to finish after installation.

6. Replacement of light bulbs and/or fluorescent tubes (on models with these features).

This warranty does not cover the following:

1. CONSEQUENTIAL OR INCIDENTAL DAMAGES SUCH AS PROPERTY DAMAGE AND

INCIDENTAL EXPENSES RESULTING FROM ANY BREACH OF THIS WRITTEN OR ANY

IMPLIED WARRANTY.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages,

so this limitation or exclusion may not apply to you.

2. Service calls which do not involve malfunction or defects in workmanship or material, or for

appliances not in ordinary household use. The consumer shall pay for such service calls.

3. Damages caused by services performed by servicers other than Frigidaire or its authorized

servicers; use of parts other than genuine Frigidaire Home Products parts; obtained from

persons other than such servicers; or external causes such as abuse, misuse, inadequate

power supply or acts of God.

4. Products with original serial numbers that have been removed or altered and cannot be readily

determined.

Keep your bill of sale, delivery slip, or some other appropriate payment record. The date on the bill

establishes the warranty period should service be required. If service is performed, it is in your best

interest to obtain and keep all receipts. This written warranty gives you specific legal rights. You may

also have other rights that vary from state to state. Service under this warranty must be obtained by

contacting Frigidaire Home Products:

800 • 944 • 9044

Frigidaire Home Products

P.O. Box 212378

Augusta, GA 30917

Product features or specifications as described or illustrated are subject to change without notice.

All warranties are made by White Consolidated Industries, Inc. This warranty applies only in the 50

states of the U.S.A. and Puerto Rico.

26

Page 27

SECTION C - INSTALLATION INSTRUCTIONS GAS & ELECTRIC DRYER

Before beginning installation, carefully read these instructions. This will simplify the installation and ensure the

dryer is installed correctly and safely . Leave these instructions near the Dryer after installation for future reference.

NOTE: The electrical service to the Dryer must conform with local codes and ordinances and the latest edition

of the National Electrical Code, ANSI/NFPA 70.

NOTE: The gas service to the Dryer must conform with local codes and ordinances and the latest edition of the

National Fuel Gas Code ANSI Z223.1.

NOTE: The Dryer is designed under ANSI Z 21.5.1 or ANSI/UL 2158 - CAN/CSA C22.2 (latest editions) for

HOME USE only. This Dryer is not recommended for commercial applications such as restaurants or beauty

salons, etc.

For your safety the information in this manual must be followed to minimize

the risk of fire or explosion or to prevent property damage, personal injury or loss of life.

- Do not store or use gasoline or other flammable vapors and liquid in the vicinity of this

or any other appliance.

- WHA T T O DO IF YOU SMELL GAS

· Do not try to light any appliance.

· Do not touch any electrical switch; do not use any phone in your building.

· Clear the room, building or area of all occupants.

· Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier's

instructions.

· If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

27

Page 28

PRE-INST ALLATION REQUIREMENTS

Tools and Materials Required for Installation:

1. Phillips head screwdriver.

2. Channel-lock adjustable pliers.

3. Carpenter's level.

4. Flat or straight blade screwdriver.

5. Duct tape.

NEMA 10-30R NEMA 14-30R

6. Rigid or flexible metal 4 inch (10.2 cm) duct.

7. Vent hood.

8. Pipe thread sealer (Gas).

9. Plastic knife

ELECTRICAL REQUIREMENTS

ELECTRIC Dryer

CIRCUIT - Individual 30 amp. branch circuit fused with

30 amp. minimum time delay fuses or circuit breakers.

POWER SUPPL Y - 3 or 4 wire, 240 volt, single phase,

60 Hz, Alternating Current.

POWER SUPPLY CORD KIT - The dryer MUST

employ a 3-conductor power supply cord NEMA 10-30

type SRDT rated at 240 volt AC minimum, 30 amp.,

with 3 open end spade lug connectors with upturned

ends or closed loop connectors or a 4-conductor power

supply cord NEMA 14-30 type SRDT or ST (as required)

rated at 240 volt AC minimum, 30 amp., with 4 open end

spade lug connectors with upturned ends or closed loop

connectors and marked for use with clothes dryers. If

being installed in a manufactured (mobile) home,

thedryer must employ a 4-conductor power supplycord

NEMA 14-30 type SRDT or ST (as required) rated at

240 volt AC minimum, 30 amp., with 4 open end spade

lug connectors with upturned ends or closed loop

connectors and marked for use with clothes dryers See

ELECTRICAL CONNECTIONS FOR for additional

instructions

OUTLET RECEPTACLE - NEMA 10-30R (3wire)

receptacle or NEMA 14-30R (4wire) receptacle to be

located so the power supply cord is accessible when

the dryer is in the installed position.

GAS Dryer

CIRCUIT - Individual 15 amp. branch circuit fused with a

15 amp. maximum time delay fuse or circuit breaker.

POWER SUPPL Y - 3 wire, 120 volt single phase, 60 Hz,

Alternating Current.

POWER SUPPL Y CORD - The dryer is equipped with a

120 volt 3-wire power cord.

NOTE: Do not under

any circumstances

remove grounding

prong from plug.

GROUNDING PRONG

EXHAUST SYSTEM REQUIREMENTS

Use only 4 inch (10.2 cm) diameter (minimum) rigid or

flexible metal duct and approved vent hood which has

a swing-out damper(s) that open when the dryer is in

operation. When the dryer stops, the dampers

automatically close to prevent drafts and the entrance

of insects and rodents. To avoid restricting the outlet,

maintain a minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground or any other

obstruction.

The following are specific

requirements for proper and safe operation of your

dryer. Failure to follow these instructions can

create excessive drying times and fire hazards.

Do not use plastic flexible duct to exhaust the

dryer. Excessive lint can build up inside exhaust system

and create a fire hazard and restrict air flow. Restricted

air flow will increase dryer times. If your present system

is made up of plastic duct or metal foil duct, replace it

with a rigid or flexible metal duct. Ensure the present

duct is free of any lint prior to installing dryer duct.

28

Page 29

If the dryer is not exhausted outdoors, some

fine lint will be expelled into the laundry area. An

accumulation of lint in any area of the home can create

a health and fire hazard. The dryer exhaust system

MUST be exhausted to the outside of the dwelling!

Do not allow combustible materials (for

example: clothing, draperies/curtains, paper) to

come in contact with exhaust system. The dryer

MUST NOT be exhausted into a chimney , a wall, a ceiling,

or any concealed space of a building which can

accumulate lint, resulting in a fire hazard.

Exceeding the length of duct pipe or number of

elbows allowed in the "MAXIMUM LENGTH" charts

can cause an accumulation of lint in the exhaust system.

Plugging the system could create a fire hazard, as well

as increase drying times.

MAXIMUM LENGTH

of 4” (10.2 cm) Dia. Flexible Metal Duct

VENT HOOD TYPE

(Preferred)

Number

of

90°

Turns

(10.2 cm)

0 30 ft. (9.14 m) 18 ft. (5.49 m)

1 22 ft. (6.71 m) 14 ft. (4.27 m)

2 14 ft. (4.27 m) 10 ft. (3.05 m)

3 NOT RECOMMENDED

In installations where the exhaust system is not described in the charts, the following method must be

used to determine if the exhaust system is acceptable:

Louvered

2½"

(6.35 cm)

Do not screen the exhaust ends of the vent

system, nor use any screws or rivets to assemble

the exhaust system. Lint can become caught in the

screen, on the screws or rivets, clogging the duct work

and creating a fire hazard as well as increasing drying

times. Use an approved vent hood to terminate the duct

outdoors, and seal all joints with duct tape. All male

duct pipe fittings MUST be installed downstream with

the flow of air.

Explosion hazard. Do not install the

dryer where gasoline or other flammables are kept

or stored. If the dryer is installed in a garage, it must be

a minimum of 18 inches (45.7 cm) above the floor. Failure

to do so can result in death, explosion, fire or burns.

MAXIMUM LENGTH

of 4” (10.2 cm) Dia. Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

Number

of

90°

Turns

0 60 ft. (18.28 m) 48 ft.(14.63 m)

1 52 ft. (15.84 m) 40 ft.(12.19 m)

2 44 ft. (13.41 m) 32 ft. (9.75 m)

3 32 ft. (9.75 m) 24 ft. (7.31 m)

4 28 ft. (8.53 m) 16 ft. (4.87 m)

4”

(10.2 cm)

Louvered

2½"

(6.35 cm)

1. Connect an inclined or digital manometer between

the dryer and the point the exhaust connects to

the dryer.

2. Set the dryer timer and temperature to air fluff (cool

down) and start the dryer.

3. Read the measurement on the manometer.

4. The system back pressure MUST NOT be higher

than 0.75 inches of water column. If the system

back pressure is less than 0.75 inches of water

column, the system is acceptable. If the

manometer reading is higher than 0.75 inches of

water column, the system is too restrictive and the

installation is unacceptable.

Although vertical orientation of the exhaust system is

acceptable, certain extenuating circumstances could

affect the performance of the dryer:

• Only the rigid metal duct work should be used.

• Venting vertical through a roof may expose the

exhaust system to down drafts causing an increase

in vent restriction.

• Running the exhaust system through an

uninsulated area may cause condensation and

faster accumulation of lint.

CORRECT

CORRECTCORRECT

CORRECT

CORRECTCORRECT

CORRECT

INSTALL MALE FITTINGS IN CORRECT DIRECTION

INCORRECT

INCORRECTINCORRECT

INCORRECT

INCORRECTINCORRECT

INCORRECT

• Compression or crimping of the exhaust system

will cause an increase in vent restriction.

The exhaust system should be inspected and cleaned

a minimum of every 18 months with normal usage. The

more the dryer is used, the more often you should check

the exhaust system and vent hood for proper operation.

29

Page 30

EXHAUST DIRECTION

All dryers shipped from the factory are set up for rear

exhausting. However, on electric dryers, exhausting can

be to the right or left side of the cabinet or the bottom

of the dryer. On gas dryers, exhausting can be to the

right side of the cabinet or the bottom of the dryer.

Directional exhausting can be accomplished by

installing Exhaust Kit, P/N 131456800, available

through your parts distributor. Follow the instructions

supplied with the kit.

7. The dryer MUST be isolated from the gas supply

piping system during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 1/2 psig (3.45 kPa).

LOCATION OF YOUR DRYER

DO NOT INSTALL YOUR DRYER:

1. In an area exposed to dripping water or outside

weather conditions.

EXHAUST DUCT LOCATING DIMENSIONS

SAME AS OTHER SIDESAME AS OTHER SIDE

SAME AS OTHER SIDE

SAME AS OTHER SIDESAME AS OTHER SIDE

5 7/8"5 7/8"

5 7/8"

5 7/8"5 7/8"

(15 cm)(15 cm)

(15 cm)

3 3/4"3 3/4"

3 3/4"

3 3/4"3 3/4"

(9.5 cm)(9.5 cm)

(9.5 cm)

(9.5 cm)(9.5 cm)

(15 cm)(15 cm)

13 1/2"13 1/2"

13 1/2"

13 1/2"13 1/2"

(34 cm)(34 cm)

(34 cm)

(34 cm)(34 cm)

4 3/8"4 3/8"

4 3/8"

4 3/8"4 3/8"

(11 cm)(11 cm)

(11 cm)

(11 cm)(11 cm)

3 3/4"3 3/4"

3 3/4"

3 3/4"3 3/4"

(9.5 cm)(9.5 cm)

(9.5 cm)

(9.5 cm)(9.5 cm)

(9.5 cm)(9.5 cm)

(9.5 cm)

(9.5 cm)(9.5 cm)

GAS SUPPLY REQUIREMENTS

Replace copper connecting pipe that

is not plastic-coated. Stainless steel or plasticcoated brass MUST be used.

1. Installation MUST conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1 (latest edition)

2. The gas supply line should be of 1/2 inch (1.27 cm)

pipe.

3. If codes allow, flexible metal tubing may be used

to connect your dryer to the gas supply line. The

tubing MUST be constructed of stainless steel or

plastic-coated brass.

4. The gas supply line MUST have an individual

shutoff valve.

5. A 1/8 inch (0.32 cm) N.P.T. plugged tapping,

accessible for test gauge connection, MUST be

installed immediately upstream of the gas supply

connection to the dryer.

6. The dryer MUST be disconnected from the gas

supply piping system during any pressure testing

of the gas supply piping system at test pressures in

excess of 1/2 psig (3.45 kPa).

2. In an area where it will come in contact with curtains,

drapes, or anything that will obstruct the flow of

combustion and ventilation air.

3. On carpet. Floor MUST be solid with a maximum

slope of 1 inch (2.54 cm).

INSTALLATION IN RECESS OR CLOSET

1. A dryer installed in a bedroom, bathroom, recess or

closet, MUST be exhausted outdoors.

2. No other fuel burning appliance shall be installed in

the same closet as the Gas dryer.

3. Your dryer needs the space around it for proper

ventilation.

DO NOT INSTALL YOUR DRYER IN A CLOSET

WITH A SOLID DOOR.

4. A minimum of 120 square inches (774.2 square cm)

of opening, equally divided at the top and bottom of

the door, is required. Air openings are required to

be unobstructed when a door is installed. A louvered

door with equivalent air openings for the full length

of the door is acceptable.

MINIMUM INSTALLATION CLEARANCES (Inches)

SIDES REAR TOP FRONT

Alcove 0 (0 cm) 0 (0 cm) 15 (38.1 cm)

Closet 0 (0 cm) 0 (0 cm) 15 (38.1 cm) 1 (2.54 cm)

Closet door ventilation required: 2 louvered openings

each 60 square inches (387 square centimeters) — 3

inches (7.6 cm) from bottom and top of door.

NOTE: Under counter and stack models - 0 inches

(0 cm) for sides, rear, and top.

THIS DRYER MUST BE EXHAUSTED OUTDOORS.

5. The following illustrations show minimum clearance

dimensions for proper operation in a recess or closet

installation.

30

Page 31

CLOSET DOOR

0" (0 cm)0" (0 cm)

0" (0 cm)

0" (0 cm)0" (0 cm)

60 SQ. IN.

(387.1 SQ.

60 SQ. IN.

(387.1 SQ. CM)

NOTE: Under counter and stack models - 0 inches (0 cm)

0" (0 cm)0" (0 cm)

0" (0 cm)

0" (0 cm)0" (0 cm)

0" (0 cm)

for sides, rear, and top.

15"

(38.1 cm)

1" (2.54 cm)

0" (0 cm)

1" (2.54 cm)1" (2.54 cm)

1" (2.54 cm)

1" (2.54 cm)1" (2.54 cm)

0" (0 cm)0" (0 cm)

0" (0 cm)

0" (0 cm)0" (0 cm)

MOBILE HOME INST ALLA TION

1. Dryer MUST be exhausted outside (outdoors, not

beneath the mobile home) using metal ducting that

will not support combustion. Metal ducting must be 4

inches (10.16 cm) in diameter with no obstructions.

Rigid metal duct is preferred.

2. If dryer is exhausted through the floor and area beneath

the mobile home is enclosed, the exhaust system

MUST terminate outside the enclosure with the

termination securely fastened to the mobile home

structure.

3. When installing a gas dryer into a mobile home, a

provision must be made for outside make up air. This

provision is to be not less than twice the area of the

dryer exhaust outlet.

4. This dryer MUST be fastened to the floor. Mobile Home

Installation Kit No. 346764 is available from your

dealer.

5. Refer to pages 27 and 28 for other important venting

requirements.

6. Installation MUST conform to current Manufactured Home

Construction & Safety Standard (which is a Federal

Regulation Title 24 CFR-Part 32-80) or when such

standard is not applicable, with American National

Standard for Mobile Homes.

The dryer is designed under ANSI Z

21.5.1or ANSI?UL2158 - CAN/CSA C22.2 (latest editions)

for HOME USE only.

31

Page 32

UNDER COUNTER & STACK MODELS

ROUGH-IN DIMENSIONS

32

Page 33

UNP ACKING

1. Using the four shipping carton corner posts (two

on each side), carefully lay the dryer on its left

side and remove foam shipping base.

To prevent damage, do not use the

control panel as a means to pick up or move the dryer .

2. Return the dryer to an upright position.

FOAM

SHIPPING

PAD

ELECTRICAL INST ALLA TION

ELECTRIC Dryers

REMOVE 4 SCREWS

(ONE FROM EACH

HINGE FIRST)

PACKING

REVERSING DOOR SWING

Your dryer is designed so the door swing may be

reversed at any time without additional parts.

Conversion is accomplished by transferring hinges to

the opposite side of the cabinet.

To change the direction of the door opening:

1. Open the dryer door. Remove the four hinge hole

plugs from the left side of the door opening. Place

nearby for future installation. NOTE: Y ou may need

a plastic knife to help pull out the plugs. Be careful

not to scratch the paint.

2. Remove the four screws that secure the door hinges

to the dryer front panel. NOTE: Remove one screw

from each of the two hinges first. Hold the door

firmly before removing the last two screws.

3. Rotate the door 180° and reinstall the door hinges

to the dryer front panel with the four screws.

4. Install the four hinge hole plugs in the open screw

holes on the right side of the door opening.

The following are specific

requirements for proper and safe electrical

installation of your dryer. Failure to follow these

instructions can create electrical shock and/or a

fire hazard.

This appliance MUST be properly grounded.

Electrical shock can result if the dryer is not properly

grounded. Follow the instructions in this manual for

proper grounding.

Do not use an extension cord with this dryer.

Some extension cords are not designed to withstand

the amounts of electrical current this dryer utilizes and

can melt, creating electrical shock and/or fire hazard.

Locate the dryer within reach of the receptacle for the

length power cord to be purchased, allowing some slack

in the cord. Refer to the pre-installation requirements in

this manual for the proper power cord to be purchased.

A U.L. approved strain relief must be installed

onto power cord. If the strain relief is not attached, the

cord can be pulled out of the dryer and can be cut by

any movement of the cord, resulting in electrical shock.

Do not use an aluminum wired receptacle with

a copper wired power cord and plug (or vice versa).

A chemical reaction occurs between copper and

aluminum and can cause electrical shorts. The proper

wiring and receptacle is a copper wired power cord

with a copper wired receptacle.

NOTE: Dryers operating on 208 volt power supply will

have longer drying times than operating on 240 volt

power supply .

33

Page 34

GROUNDING REQUIREMENTS

ELECTRIC Dryer

DANGER

Improper connection of the equipment

grounding conductor can result in a risk of electrical

shock. Check with a licensed electrician if you are in

doubt as to whether the appliance is properly grounded.

GREEN

GROUND

SCREW

GREEN

NEUTRAL

GROUND

WIRE

SILVER TERMINAL

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance

for electrical current.

2. If your dryer is equipped with a power supply cord

having an equipment-grounding conductor and a

grounding plug, the plug MUST be plugged into an

appropriate, copper wired receptacle that is properly

installed and grounded in accordance with all local

codes and ordinances. If in doubt, call a licensed

electrician.

For a permanently connected dryer:

1. The dryer MUST be connected to a grounded metal,

permanent wiring system; or an equipment

grounding conductor must be run with the circuit

conductors and connected to the equipmentgrounding terminal or lead on the appliance.

GAS Dryers

This dryer is equipped with a three-prong (grounding)

plug for your protection against shock hazard and

should be plugged directly into a properly grounded threeprong receptacle. Do not cut or remove the grounding

prong from this plug.

NUT

TIGHTEN NUT

TO THESE

THREADS

STRAIN

RELIEF

MOUNTING

BRACKET

POWER CORD

ELECTRICAL CONNECTIONS

FOR 3-WIRE SYSTEM

ELECTRIC Dryer

1. Remove the screws securing the terminal block

access cover and the strain relief mounting bracket

located on the back of the dryer upper corner.

2. Install a U.L. approved strain relief into the power

cord entry hole of the mounting bracket. Finger

tighten the nut only at this time.

3. Thread a U.L. approved 30 amp. power cord, NEMA

10-30 Type SRDT, through the strain relief.

4. Attach the power cord neutral (center wire) conductor

to the silver colored center terminal on the terminal

block. Tighten the screw securely.

5. Attach the remaining two power cord outer

conductors to the outer brass colored terminals on

the terminal block. Tighten both screws securely.

Do not make a sharp bend or crimp

wiring/ conductor at connections.

6. Reattach the strain relief mounting bracket to the

back of the dryer with two screws. Tighten screws

securely.

7. T ighten the screws securing the cord restraint firmly

against the power cord.

8. Tighten the strain relief nut securely so that the strain

relief does not turn.

9. Reinstall the terminal block cover .

34

Page 35

GREEN

GROUND

SCREW

GREEN

NEUTRAL

GROUND

WIRE

RED

GREEN POWER CORD

GROUND WIRE

WHITE

STRAIN

RELIEF

MOUNTING

BRACKET

POWER

CORD

SILVER TERMINAL

TERMINAL BLOCK

NUT

TIGHTEN

NUT

TO THESE

THREADS

BLACK

ELECTRICAL CONNECTIONS

FOR 4-WIRE SYSTEM

ELECTRIC Dryer

1. Remove the screws securing the terminal block

access cover and the strain relief mounting bracket

located on the back of the dryer upper corner.

2. Install a U.L. approved strain relief in the entry hole

of the mounting bracket. Finger tighten the nut only

at this time.

3. Remove the green neutral ground wire from the

green ground screw located above the terminal

block.

Do not make a sharp bend or crimp

wiring/ conductor at the connections.

8. Tighten the screws securing the cord restraint firmly

against the power cord.

9. Tighten the strain relief nut securely so the strain

relief does not turn.

10.Reinstall the terminal block access cover .

GAS CONNECTION

1. Remove the shipping cap from gas pipe at the rear

of the dryer.

NO T E : DO NOT connect the dryer to L.P . gas service

without converting the gas valve. An L.P.

conversion kit must be installed by a qualified

gas technician.

2. Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or

approved pipe from gas supply line to the 3/8 inch

(0.96 cm) pipe located on the back of the dryer. Use

a 1/2 inch to 3/8 inch (1.27 cm to 0.96 cm) reducer

for a connection. Apply an approved thread sealer

that is resistant to the corrosive action of liquefied

gases on all pipe connections.

3. Open the shutoff valve in the gas supply line to allow

gas to flow through pipe.

4. T est all connections by brushing on a soapy water

solution. NEVER TEST FOR GAS LEAKS WITH AN

OPEN FLAME.

TYPICAL 4

CONDUCTOR

RECEPTACLE

TYPICAL 4

CONDUCTOR

CORD

30 AMP NEMA 14-30 TYPE SRDT OR ST

BLACK 240V

WHITE

NEUTRAL

RED 240V

GREEN GROUND

4. Thread a U.L. approved 30 amp power cord, NEMA

14-30 type ST or SRDT through the strain relief.

5. Attach the green power cord ground wire to the

cabinet with the green ground screw.

6. Attach the white (neutral) power cord conductor from

the power cord and the green ground wire from the

dryer harness to the silver-colored center terminal

on the terminal block. Tighten the screw securely.

7. Attach the red and black power cord conductors to

the outer brass-colored terminals on the terminal

block.

GENERAL INST ALLA TION

1. Connect the exhaust duct to outside exhaust

system. Use duct tape to seal all joints.

2. With the dryer in its final position, adjust one or more

of the legs until the dryer is resting solid on all four

legs. Place a level on top of the dryer. THE DR YER

MUST BE LEVEL AND RESTING SOLID ON ALL

FOUR LEGS.

3. Plug the power cord into a grounded outlet.

NOTE: Check to ensure the power is off at circuit

breaker/fuse box before plugging the power cord

into the outlet.

5. Turn on the power at the circuit breaker/fuse box.

Before operating the dryer, make

sure the dryer area is clear and free from

combustible materials, gasoline, and other

35

Page 36

flammable vapors. Also see that nothing (such as

boxes, clothing, etc.) obstructs the flow of

combustion and ventilation air.

6. Run the dryer through a cycle check for proper

operation.

NOTE: On gas dryers, before the burner will light, it is

necessary for the gas line to be bled of air. If

the burner does not light within 45 seconds the

first time the dryer is turned on, the safety switch

will shut the burner off. If this happens, turn the

timer to "OFF" and wait 5 minutes before making

another attempt to light.

7. If your dryer does not operate, please review the

"Avoid Service Checklist" located in your Use and

Care Guide before calling for service.

8. Place these instructions in a location near the dryer

for future reference.

REPLACEMENT P ARTS

If replacement parts are needed for your dryer , contact

the source where you purchased your dryer.

Label all wires prior to disconnection

when servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

Destroy the carton and plastic bags after

the dryer is unpacked. Children might use them for

play . Cartons covered with rugs, bedspreads, or plastic

sheets can become airtight chambers causing