Page 1

All about the

Installation

of your Washer

TABLE OF CONTENTS

Important Safety Instructions ..............................2-3

Installation Requirements ...................................4-5

Installed Dryer Dimensions ....................................6

Unpacking Washer..............................................7-8

www.frigidaire.com USA 1-800-944-9044 www.frigidaire.ca Canada 1-800-265-8352

Installation Instructions ....................................9-10

Accessories .........................................................11

Notes .................................................................12

Français ..............................................................13

137168200A (0901)

Page 2

Important Safety InStructIonS

WarnInG

Please read all instructions before using this washer.

Recognize safety symbols, words and

labels

Safety items throughout this manual are labeled with

a WARNING or CAUTION based on the risk type as

described below:

Denitions

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury

or death.

DanGer

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury.

Installation Checklist

Shipping Hardware

Foam shipping support (under wash tub)

removed and stored

Shipping bolts and spacers removed from rear

of appliance and stored

Hole plugs (shipped in bag in drum) installed

in holes in backsheet

Leveling

Washer is level, side-to-side and front-to-back

Cabinet is setting solid on all corners

Water Supply

Rubber washers (shipped in drum) are

installed in NEW inlet hoses (shipped in drum)

HOT supply is connected to HOT inlet and

COLD supply is connected to COLD inlet

HOT and COLD water supply turned on

No leaks present at water supply connections

or appliance inlet connections -

recheck in 24 hours

WarnInG

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

cautIon

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

Important

IMPORTANT indicates installation, operation or

maintenance information which is important but not

hazard-related.

Drain

Stand pipe or wall drain height minimum 24”

Drain hose snapped in “U” channel (shipped in

drum)

Drain hose secured in place with cable tie

(shipped in drum)

Electrical Power

House power turned on

Washer plugged in

Final Checks

Installation Instructions

Care Guide

Door locks and water enters drum when cycle

starts

Registration card sent in

read thoroughly

and

Use and

2

Page 3

Important Safety InStructIonS

Adjustable

pliers

Adjustable

wrench

3/8” or 10 mm

box wrench

OR OR AND AND

Ratchet and

socket set

Carpenter’s level

note

The electrical service to the washer must conform with

local codes and ordinances and the latest edition of the

National Electrical Code, ANSI/NFPA 70, or in Canada,

the Canadian electrical code C22.1 part 1.

WarnInG

SUFFOCATION HAZARD

Destroy the carton and plastic bags after the washer is

unpacked. Children might use them for play. Cartons

covered with rugs, bedspreads, or plastic sheets can

become airtight chambers causing suffocation. Place

all materials in a garbage container or make materials

inaccessible to children.

cautIon

EXCESSIVE WEIGHT HAZARD

To avoid back or other injury, have more than one

person move or lift the washer.

WarnInG

FIRE HAZARD

For your safety the information in this manual must be

followed to minimize the risk of re or explosion or to

prevent property damage, personal injury or loss of life.

Do not store or use gasoline or other ammable vapors

and liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.•

Do not touch any electrical switch; do not use any •

phone in your building.

Clear the room, building or area of all occupants.•

Immediately call your gas supplier from a neighbor’s •

phone. Follow the gas supplier’s instructions.

If you cannot reach your gas supplier, call the re •

department.

Important

The instructions in this manual and all other literature

included with this washer are not meant to cover

every possible condition and situation that may occur.

Good safe practice and caution MUST be applied when

installing, operating and maintaining any appliance.

Maximum benets and enjoyment are achieved

when all the Safety and Operating Instructions are

understood and practiced as a routine with your

laundering tasks.

Tools and materials needed for installation:

Save these instructions

for future reference.

3

Page 4

InStallatIon requIrementS

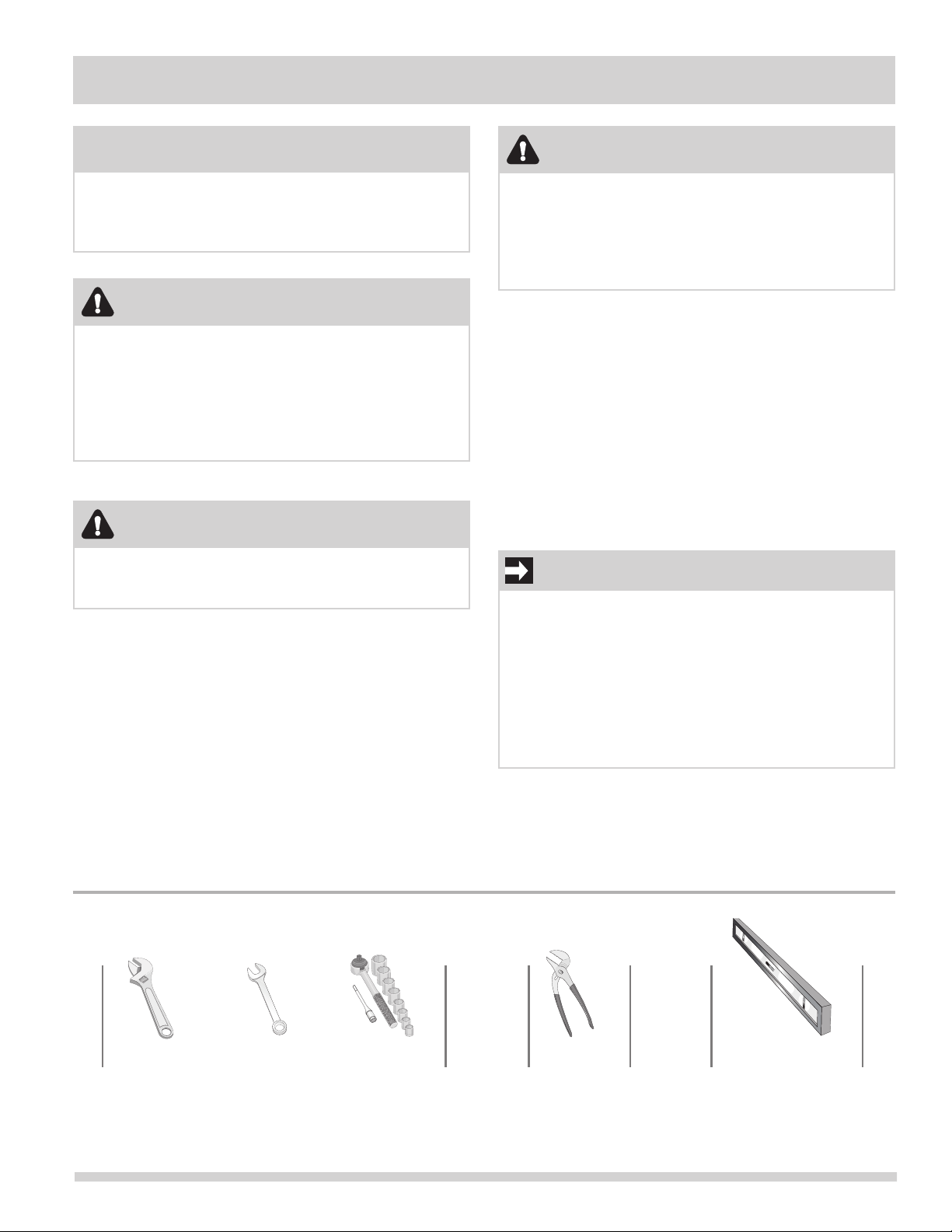

Grounding type

wall receptacle

Power cord with

3-prong grounded plug

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

96”

(244cm)

max.

24”

(61cm)

min.

Electrical system requirements

CIRCUIT - Individual, properly polarized and grounded

15 amp. branch circuit fused with 15 amp. time delay

fuse or circuit breaker.

POWER SUPPLY - 2 wire, with ground, 120 volt single

phase, 60 Hz, Alternating Current.

note

Because of potentially inconsistent voltage capabilities,

the use of this washer with power created by gas

powered generators, solar powered generators, wind

powered generators or any other generator other than

the local utility company is not recommended.

OUTLET RECEPTACLE - Properly grounded 3-prong

receptacle to be located so the power supply cord is

accessible when the washer is in an installed position.

cord having an equipment-grounding conductor

and a grounding plug, the plug MUST be plugged

into an appropriate, copper wired receptacle that is

properly installed and grounded in accordance with

all local codes and ordinances or in the absence

of local codes, with the National Electrical Codes,

ANSI/NFPA 70 (latest edition). If in doubt, call a

licensed electrician. DO NOT cut off or alter the

grounding prong on the power supply cord. In

situations where a two-slot receptacle is present,

it is the owner’s responsibility to have a licensed

electrician replace it with a properly grounded three

prong grounding type receptacle.

Water supply requirements

Hot and cold water faucets MUST be installed within 42

inches (107 cm) of your washer’s water inlet. The faucets

MUST be 3/4 inch (1.9 cm) with threading for laundry

hose connection. Water pressure MUST be between 30

and 120 psi. Pressure difference between hot and cold

cannot be more than 10 psi. Your water department can

advise you of your water pressure.

Ground requirements

1 The washer MUST be grounded. In the event of

2 Since your washer is equipped with a power supply

note

GFI (Ground Fault Interrupter) receptacle is not

required.

WarnInG

ELECTRICAL SHOCK HAZARD

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check

with a licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

malfunction or breakdown, grounding will reduce

the risk of electrical shock by a path of least

resistance for electrical current.

Drain system requirements

1 Drain capable of eliminating 17 gals (64.3 L) per

minute.

2 A standpipe diameter of 1-1/4 in. (3.18 cm)

minimum.

3 The standpipe height above the oor should be:

Minimum height: 24 in. (61 cm)

Maximum height: 96 in. (244 cm)

note

Drain hose attached to the washer can reach a 74 in.

(188 cm) high standpipe. For higher standpipe, use

hose P/N 137098000, available from an authorized

parts distributor.

4

Page 5

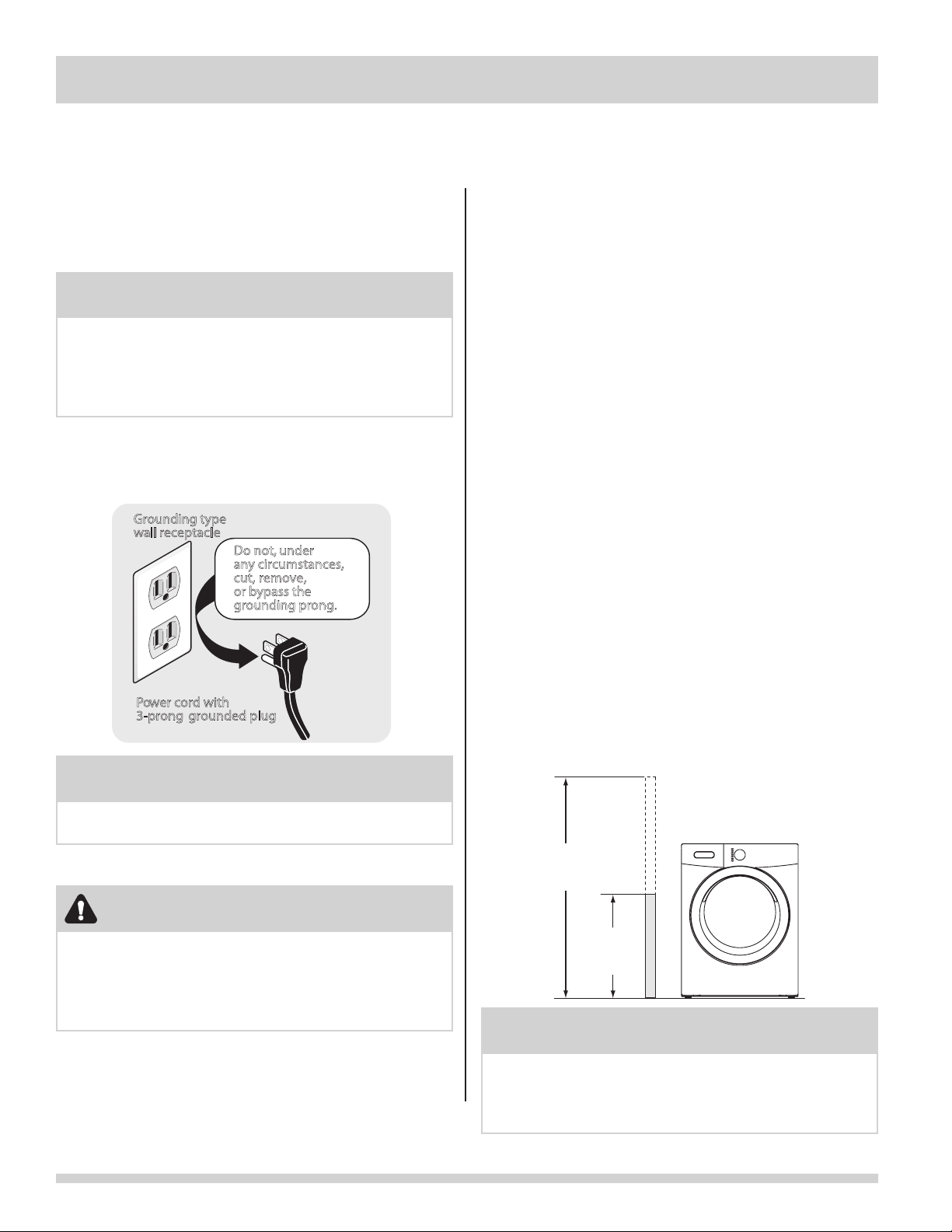

0”

(0cm)

0”

(0cm)

1”

(2.54cm)

0”

(0cm)

60 sq. in.

(387.1cm²)

3”

(7.6cm)

60 sq. in.

(387.1cm²)

3”

(7.6cm)

Clearance requirements

Important

InStallatIon requIrementS

DO NOT INSTALL YOUR WASHER:

1 In an area exposed to dripping water or outside

weather conditions. The ambient temperature

should never be below 60° F (15.6° C) to

maximize detergent effectiveness.

2 In an area (garage or garage-type building)

where gasoline or other ammables (including

automobiles) are kept or stored.

3 On carpet. Floor MUST be solid with a maximum

slope of 1 inch (2.54 cm). To minimize vibration

or movement, reinforcement of the oor may be

necessary.

Installation in a Recess or Closet

If washer and dryer are installed in the same closet,

door ventilation is required: A minimum of 120 square

inches (774.2 cm²) of opening, equally divided at the top

and bottom of the door, is required. Louvered openings

should be located 3 inches (7.6 cm) from bottom and

top of door. Air openings are required to be unobstructed

when a door is installed. A louvered door with equivalent

air openings for the full length of the door is acceptable.

MINIMUM INSTALLATION CLEARANCES - Inches (cm)

SIDES REAR TOP FRONT

Alcove 0” (0 cm) 0” (0 cm)* 0” (0 cm) n/a

Under-

Counter

Closet 0” (0 cm) 0” (0 cm)* 0” (0 cm) 1” (2.54 cm)

0” (0 cm) 0” (0 cm)* 0” (0 cm) n/a

closet door

5

Page 6

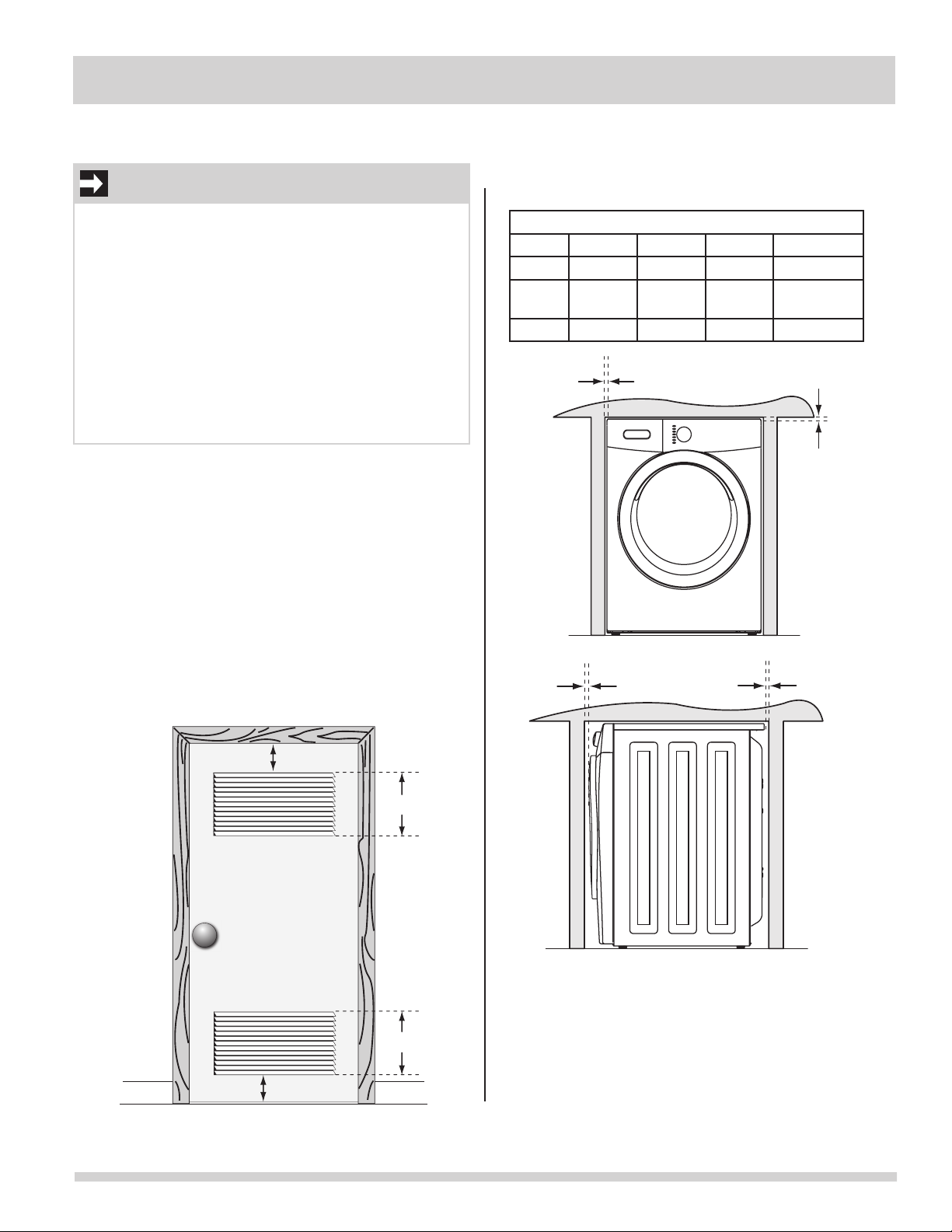

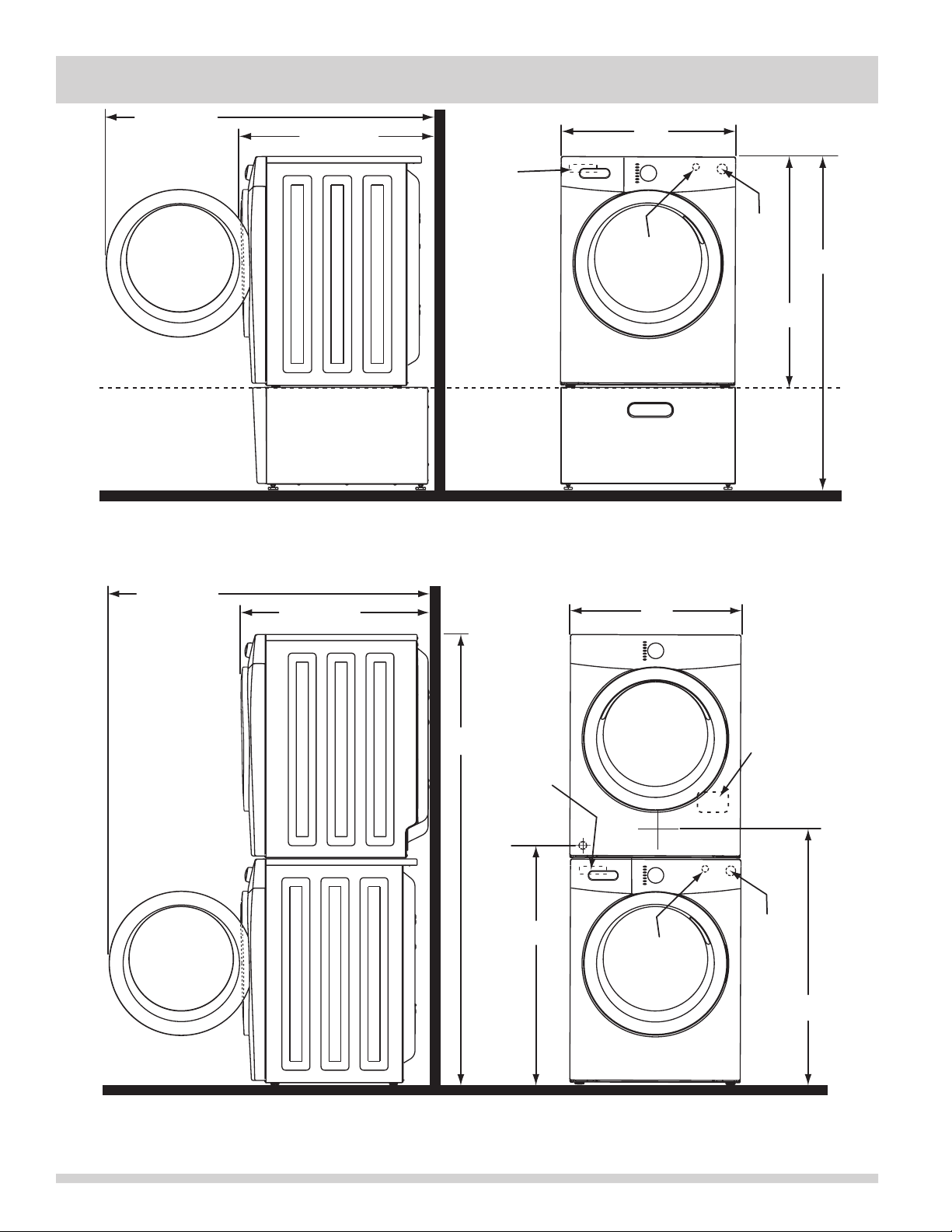

INSTALLED WASHER DIMENSIONS

50.8” (129cm)

to clear open door

freestand washer

on oor

oor line

washer mounted on

optional pedestal

oor line

* To obtain these minimal depth dimensions, dryer must be vented straight back. Using a quick-turn 90° elbow (right or down on freestanding dryer) adds approximately 0.75 in. (2.0 cm)

to installation depth. Upward venting of exhaust on pedestal-mounted or freestanding dryer adds approximately 4 in. (10.2 cm) to installation depth. Leftward venting on

pedestal-mounted or freestanding dryer adds approximately 3.75 in. (9.5 cm) to installation depth. Downward venting of exhaust on pedestal-mounted dryer adds approximately

2.25 in. (5.7 cm) to installation depth.

1Hot and cold inlet hose length approximately 43 inches (109cm)

2Power supply cord length approximately 60 inches (152.5cm).

3Drain hose length approximately 52 inches (132cm).

50.8” (129cm)

to clear open door

29.75” (75.5cm)*

to front of closed door

29.75” (75.5cm)*

to front of closed door

water supply

connection

on rear of unit

1

27.0”

(68.5cm)

power cord

on rear of unit

27.0”

(68.5cm)

2

drain hose

on rear

3

of unit

36.0”

(91.5cm)

51.25”

(130cm)

electrical

71.5”

(182cm)

* To obtain these minimal depth dimensions, dryer must be vented straight back. Using a quick-turn 90° elbow (right) adds approximately 0.75 in. (2 cm) to installation depth.

Upward venting of exhaust on stacked dryer adds approximately 4 in. (10.2 cm) to installation depth. Downward venting of exhaust on stacked dryer adds approximately

2.25 in. (6.5 cm) to installation depth. Leftward venting of exhaust on stacked dryer adds approximately 3.75 in. (9.5 cm) to installation depth.

1Hot and cold inlet hose length approximately 43 inches (109cm)

2Power supply cord length approximately 60 inches (152.5cm).

3Drain hose length approximately 52 inches (132cm).

water supply

connection

on rear of unit

gas supply

pipe on rear

of gas unit

37”

(94cm)

1

power cord

on rear of unit

2

supply on

rear of unit

drain hose

on rear

of unit

centerline

height for

rear vent

3

39”

(99cm)

6

Page 7

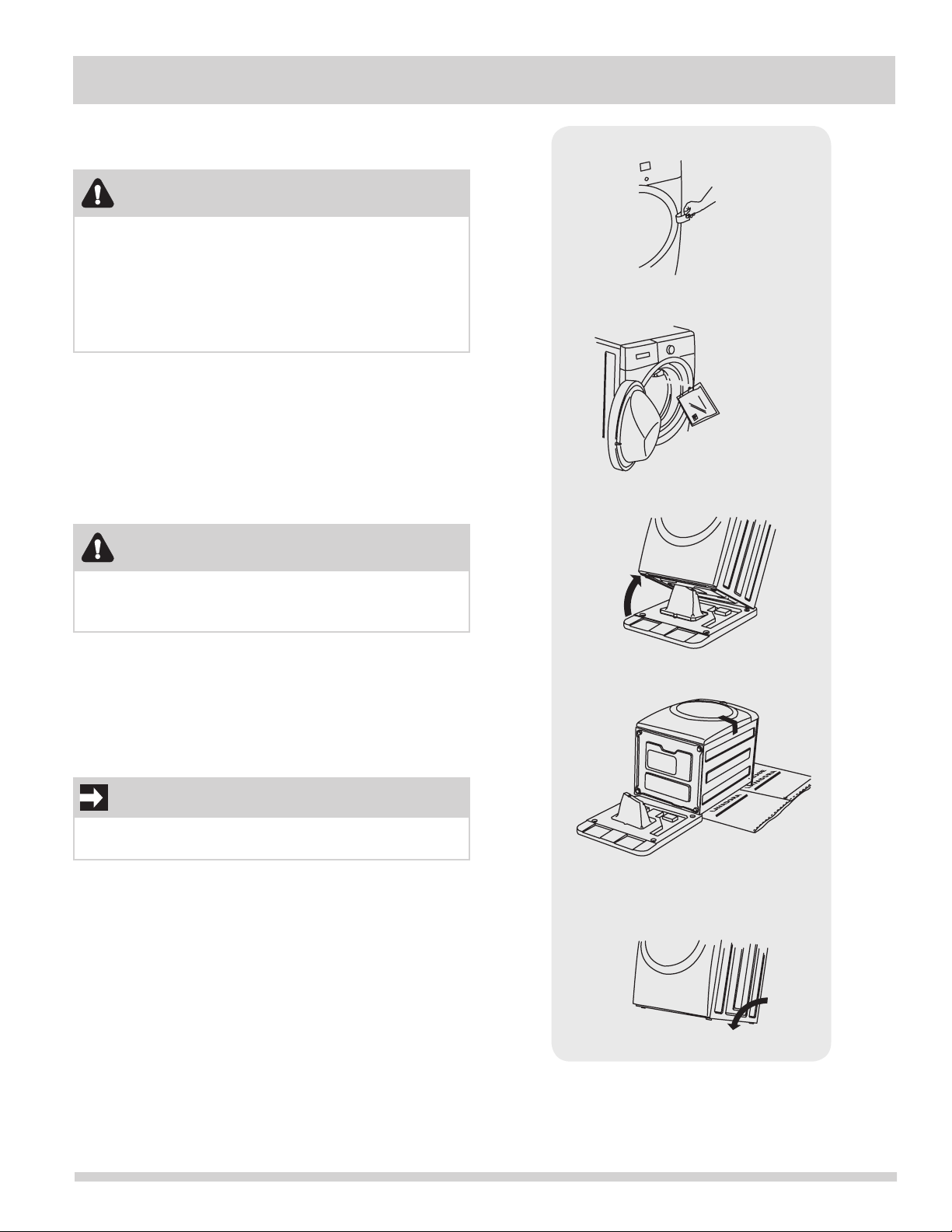

Removing foam packaging

WarnInG

SUFFOCATION HAZARD

Destroy the carton and plastic bags after the washer is

unpacked. Children might use them for play. Cartons

covered with rugs, bedspreads, or plastic sheets can

become airtight chambers causing suffocation. Place

all materials in a garbage container or make materials

inaccessible to children.

1 Temporarily remove door tape.

2 Open washer door and remove everything from the

drum.

3 Close door and reapply door tape.

4 Using a rug, blanket or piece of cardboard to

protect the oor, carefully lay the washer on it’s

back.

UNPACKING WASHER

cautIon

EXCESSIVE WEIGHT HAZARD

To avoid back or other injury, have more than one

person move or lift the washer.

5 Remove styrofoam base and shipping plug and set

them aside.

6 Carefully return the washer to an upright position.

7 Carefully move the washer to within 4 feet (1 m) of

its nal location.

Important

Save styrofoam base and shipping plug for use to help

prevent washer damage during any future moves.

7

Page 8

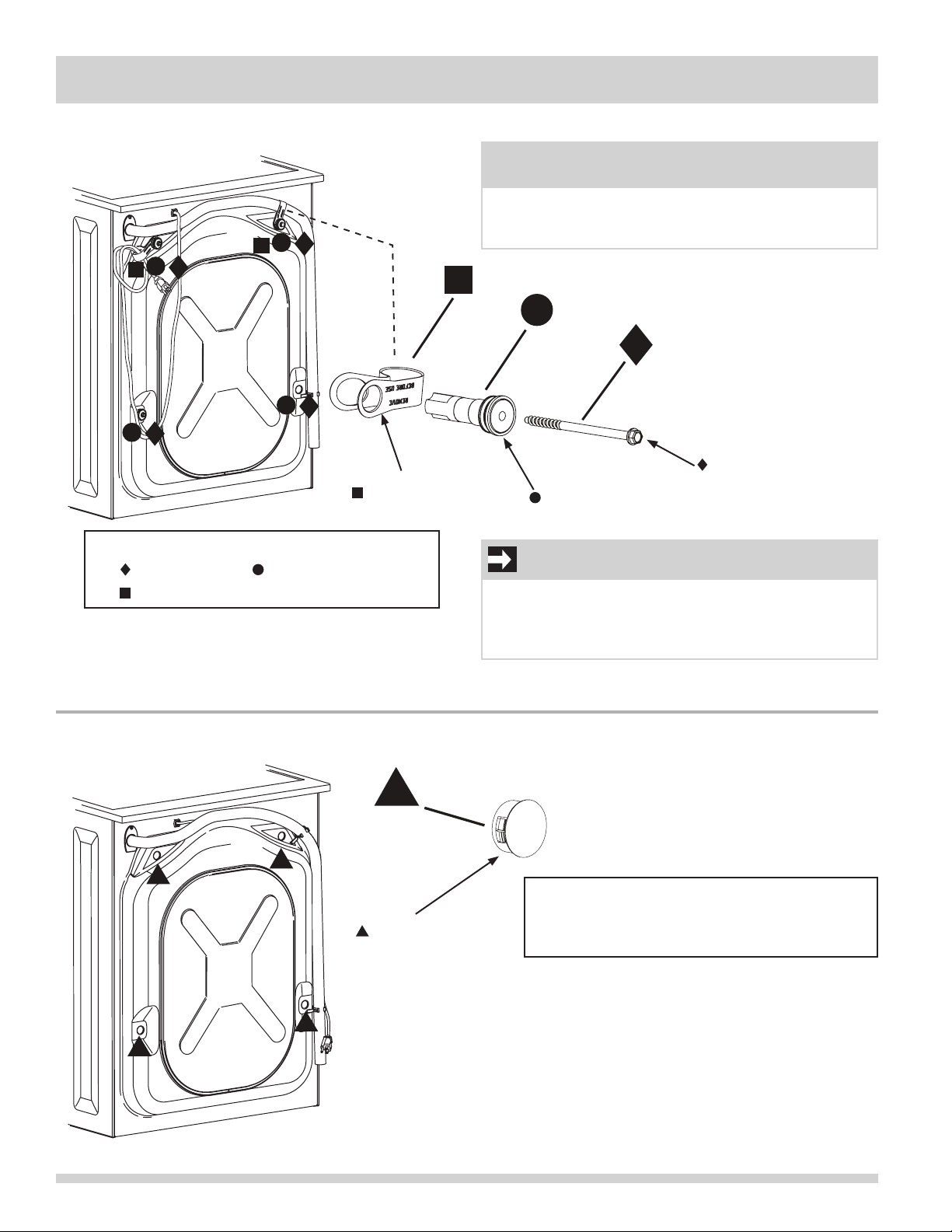

UNPACKING WASHER

x 4

x 4

x 2

x 4

Removing shipping hardware

note

Rubber expansion material on spacers may need

time to relax before they can be easily pulled through

shipping hole.

4 BOLTS

Remove all of the following:

4 BOLTS

2 P CLAMPS

Installing hole plugs

4 SPACERS

2 P CLAMPS

4 HOLE PLUGS

(IN BAG)

4 SPACERS

Important

Save all shipping bolts and spacers for future use. If

the washer is to be transported at a later date, the

shipping hardware must be reinstalled to help prevent

shipping damage.

Locate 4 hole plugs in the small bag supplied

with washer instruction guides. Insert them in

the holes in washer back panel.

8

Page 9

a

b

c

d

a

e

f

g

b

c

d

Leveling your washer

Excessive noise and vibration can be prevented by

properly leveling the washer.

1 For free standing installation and with the washer

within 4 feet (1 m) of its nal location, place a level

on top of the washer.

2 Use adjustable pliers to adjust the leveling legs so

the washer is level front-to-rear and side-to-side,

and stable corner-to-corner.

3 Press down on alternate corners and sides and feel

for the slightest movement. Adjust the appropriate

leg(s) so the washer sits solidly on the oor on

ALL four legs. Keep the leveling leg extension at a

minimum for best performance of the washer.

note

For pedestal installations, see additional installation

instructions included with the pedestal.

Connecting inlet water

1

Run some water from the hot and cold faucets to

ush the water lines and remove particles that might

clog the water valve screens and to determine which

faucet is hot and which is cold supply.

2

Remove the inlet hoses and rubber washers from the

plastic bag located in the drum of the washer and install

the rubber washers in each end of the inlet hoses.

InStallatIon InStructIonS

raise

lower

RUBBER WASHERS

MUST BE PRESENT

3

Connect the HOT inlet hose to the HOT inlet

connection on the washer and the COLD inlet hose to

the COLD inlet connection on the washer. Tighten by

hand until snug. Then tighten each supply connection

another 2/3 turn with pliers. Do not cross thread

or over-tighten these connections.

4 Connect the HOT inlet hose to the HOT water

supply and the COLD inlet hose to the COLD water

supply. Tighten by hand until snug.

each supply connection another 2/3 turn with pliers.

5 Turn on the water and check for leaks.

uSe only

NEW HOSES

COLD

HOT

Then tighten

9

Page 10

InStallatIon InStructIonS

Grounding type

wall receptacle

Power cord with

3-prong grounded plug

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Connecting drain and electrical

1 Snap one end of the drain hose hanger (shipped

in washer drum) onto the drain hose. Continue

wrapping it around the hanger and snap it in place.

2 Place the hook end of the drain hose in the drain

opening. Secure the drain hose with the cable

tie (provided in the enclosure package) to the

standpipe, inlet hose, laundry tub, etc. so the hose

does not pull out from the force of the water.

Important

Check to ensure the power is off at a circuit breaker/

fuse box before plugging the power cord into an outlet.

3 Plug the power cord into a grounded outlet.

caBle tIe

4 Turn on the power at a circuit breaker/fuse box.

5 Carefully slide the washer to its nal position.

Recheck for level and rock corners for stability.

Remove and discard door tape.

6 Read the Use & Care Guide provided with the

washer. It contains valuable and helpful information

that will save you time and money.

7 If you have any questions during initial operation,

please review the “Service Prevention Checklist” in

your Use & Care Guide before calling for service.

8 Place these instructions in a location near the

washer for future reference.

note

A wiring diagram and technical data sheet are located

under the washer top panel, on top of the detergent

dispenser housing.

10

Page 11

26.44”

(67.16cm)

15.00”

(38.10cm)

27.00”

(68.58cm)

MATCHING STORAGE PEDESTAL

White Pedestal - P/N APWD15

Black Pedestal - P/N APWD15E

Classic Red Pedestal - P/N APWD15R

A storage pedestal accessory, specically designed for

this washer may be used to elevate the washer for ease

of use. This pedestal will add about 15” (38 cm) to the

height of your unit for a total height of 51.25” (130 cm).

DRYER STACKING KIT

P/N 134700600

Depending on the model you purchased, a kit for stacking

a matching dryer on top of this washer may have been

included in the initial purchase of your dryer. If your

model did not include a stacking kit or you desire another

stacking kit, you may order one.

DRAIN HOSE EXTENSION KIT

P/N 137098000

In order to reach standpipe heights or distances beyond

the reach of the drain hose supplied, order the DRAIN

HOSE EXTENSION KIT.

acceSSorIeS

cautIon

Failure to use accessories manufactured by (or

approved by) the manufacturer could result in personal

injury, property damage or damage to the washer.

MOBILE HOME INSTALLATION KIT

P/N 137067200

Installation in a mobile home requires the use of a

MOBILE HOME INSTALLATION KIT.

UNIVERSAL APPLIANCE WRENCH

P/N 137019200

A UNIVERSAL APPLIANCE WRENCH is available to aid in

dryer/washer/pedestal feet adjustment.

TOUCH UP PAINT PENS

White Touch Up Pen - P/N 5304468812

Black Touch Up Pen - P/N 5304458932

Classic Red Touch Up Pen - P/N 5304471227

Replacement parts: 1-800-944-9044 (in Canada 1-800-265-8352)

If replacements parts are needed for your washer,

contact the source where you purchased your washer, call

1-800-944-9044 (in Canada 1-800-265-8352), or visit our

website, www.frigidaire.com, for the Frigidaire Authorized

Parts Distributor nearest you.

WarnInG

ELECTRICAL SHOCK HAZARD

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

11

Page 12

noteS

12

Page 13

Tout à propos de

Installation

de votre Laveuse

TABLE DES MATIÈRES

Mesures de sécurité importantes ..................... 14-15

Exigences d’installation ................................... 16-17

Dimensions, appareil installé ................................ 18

www.frigidaire.com États-Unis 1-800-944-9044 www.frigidaire.ca Canada 1-800-265-8352

Déballage de la laveuse .................................. 19-20

Instructions d’installation ................................ 21-22

Accessoires .........................................................23

Page 14

meSureS De SécurIté ImportanteS

aVertISSement

Veuillez lire ces instructions au complet avant d’utiliser

le laveuse.

Sachez reconnaître les symboles, les

avertissements et les étiquettes de sécurité.

Les mesures de sécurité présentées dans ce guide sont

identiées par le mot AVERTISSEMENT ou ATTENTION

selon le type de risque présenté ci-dessous.

Dénitions

Voici le symbole d’avertissement concernant la sécurité.

Il est utilisé pour vous avertir des risques de blessures

potentiels. Respectez tous les messages qui suivent ce

symbole an de prévenir les blessures ou la mort.

DanGer

La mention DANGER indique un risque imminent qui

causera la mort ou de graves blessures, s’il n’est pas

évité.

aVertISSement

La mention AVERTISSEMENT indique une situation

potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait entraîner des blessures graves ou même la mort.

attentIon

La mention ATTENTION signale la présence d’une

situation potentiellement dangereuse susceptible de

causer des blessures mineures ou moyennement graves

si elle n’est pas évitée.

Important

IMPORTANT - Cette mention précède des renseignements

importants relatifs à l’installation, au fonctionnement ou à

l’entretien. Toutefois, ceux-ci n’impliquent aucune notion

de danger.

Liste de vérication

d’installation

Matériel d’expédition

Le support d’expédition en mousse (sous la

cuve de lavage) a été enlevé et remisé

Les boulons d’expédition situés à l’arrière de

l’appareil ont été enlevés et remisés

Les bouchons (inclus dans le sac situé dans

la cuve) ont été insérés dans les trous situés

dans la paroi arrière de la laveuse

Mise à niveau

La laveuse est au niveau latéralement et de

l’avant vers l’arrière

Les quatre coins de la caisse reposent

fermement sur le plancher

Alimentation en eau

Les rondelles en caoutchouc (inclus dans

la cuve) sont installées dans les tuyaux

d’alimentation NEUFS (inclus dans la cuve)

Le tuyau d’entrée d’eau CHAUDE est raccordé

au robinet d’eau CHAUDE et le tuyau d’entrée

d’eau FROIDE est raccordé au robinet d’eau

FROIDE

Les robinets d’eau CHAUDE et d’eau FROIDE

sont ouverts

Les raccords d’alimentation en eau ou les

raccords d’arrivée d’eau de l’appareil ne

présentent aucune fuite -

refaites une vérication 24 heures plus tard

Tuyau de vidange

La colonne montante ou le drain de mur est à

une hauteur d’au moins 61 cm (24 po)

Le tuyau de vidange est xé dans le canal en «

U » (inclus dans la cuve)

Le tuyau de vidange est xé avec l’attache

(incluse dans la cuve)

Alimentation en électricité

Le système électrique de la maison est sous

tension

La laveuse est branchée

Vérications nales

Vous avez lu entièrement les

d’installation

d’entretien

La porte se verrouille et l’eau entre dans la

cuve lorsqu’un cycle démarre

La carte d’enregistrement est envoyée

et le

Guide d’utilisation et

instructions

14

Page 15

meSureS De SécurIté ImportanteS

OU OU ET ET

Pince

réglable

Clé à

molette

Clé polygonale

de 3/8 po

ou de 10 mm

Cliquet et

ensemble

de douilles

Niveau de charpentier

remarque

L’installation électrique de la laveuse doit être conforme

aux codes et aux règlements locaux ainsi qu’à la

toute dernière édition du National Electrical Code

(ANSI/NFPA 70), ou au Canada, au Code canadien de

l’électricité (C22.1, article 1).

aVertISSement

RISQUE D’ÉTOUFFEMENT

Détruisez le carton d’emballage et les sacs en plastique

après avoir déballé l’appareil. Les enfants pourraient

les utiliser pour jouer. Le carton recouvert de tapis, les

couvertures et les feuilles de plastique peuvent être

étanches à l’air et provoquer la suffocation. Déposez

tous les matériaux d’emballage dans un conteneur à

déchets ou faites en sorte que les enfants ne puissent y

avoir accès.

attentIon

DanGer De poIDS eXceSSIf

Pour éviter les blessures au dos ou d’autres types de

blessure, demandez l’aide d’autres personnes pour

déplacer ou soulever la laveuse.

aVertISSement

RISQUE D’INCENDIE

Pour votre sécurité, l’information contenue dans

ces instructions doit être suivie an de réduire les

risques d’incendie ou d’explosion ou pour prévenir les

dommages matériels, les blessures ou la mort. Vous ne

devez ni entreposer, ni utiliser d’essence ou d’autres

vapeurs ou liquides inammables à proximité de cet

appareil ou de tout autre appareil électroménager.

QUE FAIRE SI VOUS DÉTECTEZ UNE ODEUR DE GAZ :

Ne mettez pas d’appareil en marche.•

Ne touchez à aucun commutateur électrique; n’utilisez •

aucun téléphone de votre domicile.

Évacuez la pièce, le bâtiment ou la zone touchée.•

En utilisant le téléphone d’un voisin, appelez immédia-•

tement le fournisseur de gaz. Suivez ses instructions.

Si vous ne pouvez joindre votre fournisseur de gaz, •

appelez les pompiers.

Important

Les instructions comprises dans ce guide et toute

autre documentation fournie avec cet appareil ne sont

pas conçues pour couvrir toutes les éventualités ou

situations qui pourraient survenir. Vous DEVEZ faire

preuve de bon sens et de prudence durant l’installation,

l’utilisation et l’entretien de tout appareil ménager.

Vous tirerez le maximum de votre appareil lorsque

toutes les instructions relatives à la sécurité et à son

fonctionnement auront été bien assimilées et mises en

pratique de façon routinière.

Conservez ces instructions pour vous y

Outils et matériel nécessaires à l’installation :

reporter ultérieurement.

15

Page 16

EXIGENCES D’INSTALLATION

96”

(244cm)

max.

24”

(61cm)

min.

Prise murale avec

mise à la terre

à la terre de cette che.

Ne coupez pas, n'enlevez

pas et ne mettez pas hors

circuit la broche de mise

Cordon électrique muni

avec mise à la terre

d’une che à trois broches

Exigences des systèmes électriques

CIRCUIT - Circuit indépendant de 15 ampères, polarisé

et mis à la terre, avec fusible temporisé ou disjoncteur

de 15 A.

ALIMENTATION ÉLECTRIQUE - Câble monophasé à deux

ls mis à la terre, 120 volts, 60 Hz; courant alternatif.

remarque

Étant donné les variations de tension possibles, l’utilisation

de cette laveuse avec une source d’alimentation produite

par une génératrice à essence, solaire ou éolienne ou

par toute autre source d’alimentation différente de celle

fournie par les services publics n’est pas recommandée.

PRISE - Prise à trois alvéoles et mise à la terre située à

un endroit où il est possible de raccorder le cordon

d’alimentation de la laveuse une fois que cette

dernière est installée.

cordon d’alimentation pourvu d’un conducteur de

mise à la terre et d’une che de mise à la terre, la

che DOIT être raccordée à une prise appropriée

(avec conducteurs en cuivre) correctement installée

et mise à la terre conformément aux codes et

règlements locaux ou, si aucun code local ne régit

ce type d’installation, à la plus récente édition du

National Electrical Code (ANSI/NFPA 70). En cas

de doute, faites appel à un électricien qualié. NE

COUPEZ PAS et NE MODIFIEZ PAS la broche de mise

à la terre du cordon d’alimentation. Si votre prise

murale n’est pourvue que de deux fentes, il incombe

au propriétaire de faire appel à un électricien qualié

pour la remplacer par une prise à trois alvéoles et

mise à la terre de façon adéquate.

Exigences relatives à l’alimentation en eau

Les robinets d’eau chaude et d’eau froide DOIVENT être

installés à une distance de 107 cm (42 po) ou moins de

l’arrivée d’eau de votre laveuse. Les robinets DOIVENT

être de 1,9 cm (3/4 po) et letés en fonction d’un

raccordement de tuyau de laveuse. La pression de l’eau

DOIT se situer entre 206,8 et 827,4 kPa (30 et 120 lb/

po²). La différence de pression entre l’eau chaude et

l’eau froide ne doit pas dépasser 68,9 kPa (10 lb/po²). Le

service des eaux de votre localité peut vous informer sur

la pression de votre alimentation en eau.

Une prise GFI (disjoncteur de fuite de terre) n’est pas

nécessaire.

Exigences relatives à la mise à la terre

Un raccordement inadéquat du conducteur de terre

de l’équipement peut accroître les risques de choc

électrique. En cas de doute quant à la mise à la terre

de l’appareil, consultez un électricien qualié.

1 Cet appareil DOIT être mis à la terre. En cas de

2

remarque

aVertISSement

RISQUE DE CHOC ÉLECTRIQUE

mauvais fonctionnement ou de panne, la mise à

la terre diminue les risques de choc électrique en

fournissant au courant électrique une trajectoire de

moindre résistance.

Étant donné que votre laveuse est équipée d’un

Exigences relatives au système d’évacuation

1 Le drain doit pouvoir évacuer 64,3 L (17 gal) d’eau

à la minute.

2 Tuyau d’évacuation d’au moins 3,18 cm (1-1/4 po)

de diamètre.

3 Le tuyau d’évacuation doit être situé entre une

hauteur minimale de 61 cm (24 po) et une

hauteur maximale de 244 cm (96 po)

remarque

Le tuyau de vidange raccordé à la laveuse peut convenir

à un tuyau d’évacuation de 188 cm (74 po) de hauteur.

Pour des tuyaux d’évacuation plus hauts, utilisez le tuyau

portant le numéro de pièce 137098000 que vous pouvez

obtenir auprès d’un distributeur de pièces autorisé.

16

Page 17

0”

(0cm)

0”

(0cm)

1”

(2.54cm)

0”

(0cm)

60 sq. in.

(387.1cm²)

3”

(7.6cm)

60 sq. in.

(387.1cm²)

3”

(7.6cm)

Exigences de dégagement

EXIGENCES D’INSTALLATION

Important

N’INSTALLEZ PAS VOTRE LAVEUSE :

1 À un endroit exposé aux écoulements d’eau

ou aux aléas des conditions météorologiques

extérieures. La température ambiante ne

devrait jamais tomber sous 15,6 °C (60 °F) an

d’optimiser l’efcacité du détergent.

2 À un endroit (garage ou bâtiment similaire) où

de l’essence ou d’autres substances inammables

sont entreposées (incluant des automobiles).

3 Sur un tapis. Le plancher DOIT être solide et

présenter une pente inférieure à 2,54 cm (1 po).

An d’éviter les vibrations et le déplacement de

l’appareil, il peut être nécessaire de renforcer le

plancher.

Installation dans un Endroit en Retrait ou

une Armoire

Si la laveuse et la sécheuse sont installées dans le

même placard, une ventilation est requise dans la

porte : Une ouverture d’au moins 774,2 cm2 (120 po2),

divisée également au-dessus et au-dessous de la porte,

est requise. Les ouvertures à persiennes doivent être

situées à 7,6 cm (3 po) du haut et du bas de la porte.

Les ouvertures d’aération ne doivent pas être obstruées

lorsqu’une porte est installée. Une porte à persiennes

dont les ouvertures sur l’ensemble de la porte sont

équivalentes aux recommandations peut être utilisée.

DÉGAGEMENTS MINIMAUX - Centimètres (pouces)

CÔTÉS ARRIÈRE DESSUS AVANT

Alcôve 0 cm (0 po) 0 cm (0 po)* 0 cm (0 po) s. o.

Sous

le comptoir

Placard 0 cm (0 po) 0 cm (0 po)* 0 cm (0 po)

0 cm (0 po) 0 cm (0 po)* 0 cm (0 po) s. o.

2,54 cm

(1 po)

Porte de placard

17

Page 18

DIMENSIONS, APPAREIL INSTALLÉ

50.8” (129cm)

Avec la porte

grande ouverte

Laveuse autonome

sur le plancher

Plancher

Laveuse montée sur

le socle optionnel

Plancher

*

Pour obtenir ces dimensions de profondeur minimales, la sécheuse doit être ventilée tout droit par l’arrière. L’utilisation d’un coude à 90° à courbe immédiate (vers la droite ou vers le bas sur une sécheuse

autonome) nécessite environ 2 cm (0.75 po) de profondeur de plus pour l’installation. Les sécheuses montées sur un socle ou autonomes munies d’un système d’évacuation de l’air vers le haut requièrent

environ 10.2 cm (4 po) de profondeur de plus pour l’installation. Les sécheuses montées sur un socle ou autonomes munies d’un système d’évacuation vers la gauche nécessitent environ 3.75 cm (9.5 po) de

profondeur de plus pour l’installation. Les sécheuses montées sur un socle munies d’un système d’évacuation de l’air vers le bas requièrent environ 5.7 cm (2.25 po) de profondeur de plus pour l’installation.

1Longueur des tuyaux d’entrée d’eau chaude et froide, environ 109 cm (43 po).

2Longueur du cordon d’alimentation, environ 152,5 cm (60 po).

3Longueur de tuyau de vidange, environ 132 cm (52 po).

50.8” (129cm)

Avec la porte

grande ouverte

29.75” (75.5cm)*

À partir de l’avant de la porte

lorsqu’elle est fermée

29.75” (75.5cm)*

À partir de l’avant de la porte

lorsqu’elle est fermée

Raccord de

l’alimentation en eau

à l’arrière de la laveuse

27.0”

(68.5cm)

1

Tuyau de

vidange

Cordon d’alimentation

à l’arrière de la laveuse

27.0”

(68.5cm)

à l’arrière

de la

2

laveuse

3

36.0”

(91.5cm)

51.25”

(130cm)

Alimentation

électrique

71.5”

(182cm)

Raccord de

l’alimentation

en eau à l’arrière

de la laveuse

*

Pour obtenir ces dimensions de profondeur minimales, la sécheuse doit être ventilée tout droit par l’arrière. L’utilisation d’un coude à 90° à courbe immédiate (vers la droite ou vers le bas sur une sécheuse

autonome) nécessite environ 2 cm (0.75 po) de profondeur de plus pour l’installation. Les sécheuses montées sur un socle ou autonomes munies d’un système d’évacuation de l’air vers le haut requièrent

environ 10.2 cm (4 po) de profondeur de plus pour l’installation. Les sécheuses montées sur un socle ou autonomes munies d’un système d’évacuation vers la gauche nécessitent environ 3.75 cm (9.5 po) de

profondeur de plus pour l’installation. Les sécheuses montées sur un socle munies d’un système d’évacuation de l’air vers le bas requièrent environ 5.7 cm (2.25 po) de profondeur de plus pour l’installation.

1Longueur des tuyaux d’entrée d’eau chaude et froide, environ 109 cm (43 po).

2Longueur du cordon d’alimentation, environ 152,5 cm (60 po).

3Longueur de tuyau de vidange, environ 132 cm (52 po).

1

gas supply

pipe on rear

of gas unit

37”

(94cm)

Cordon d’alimentation

à l’arrière de la laveuse

2

à l’arrière de

la sécheuse

Hauteur de la

ligne centrale

de l’évent arrière

Tuyau de

vidange

à l’arrière

de la laveuse

3

39”

(99cm)

18

Page 19

Retrait de l’emballage en mousse

aVertISSement

RISQUE D’ÉTOUFFEMENT

Détruisez le carton d’emballage et les sacs en plastique

après avoir déballé l’appareil. Les enfants pourraient

les utiliser pour jouer. Le carton recouvert de tapis, les

couvertures et les feuilles de plastique peuvent être

étanches à l’air et provoquer la suffocation. Déposez

tous les matériaux d’emballage dans un conteneur à

déchets ou faites en sorte que les enfants ne puissent y

avoir accès.

1 Retirez temporairement le ruban de la porte.

2 Ouvrez la porte de la laveuse et retirez tout ce qui

se trouve dans le tambour.

3 Fermez la porte et posez le ruban de porte à

nouveau.

4 Pour protéger le plancher, utilisez un tapis, une

couverture ou une pièce de carton et couchez la

laveuse sur le côté arrière.

DéBallaGe De la laVeuSe

attentIon

DanGer De poIDS eXceSSIf

Pour éviter les blessures au dos ou d’autres types de

blessure, demandez l’aide d’autres personnes pour

déplacer ou soulever la laveuse.

5 Retirez la base en styromousse et le bouchon

d’expédition; mettez-les de côté.

6 Remettez soigneusement la laveuse en position

verticale.

7 Déplacez soigneusement la laveuse à moins de

1,2 m (4 pi) de son emplacement dénitif.

Important

Conservez la base en styromousse et le bouchon

d’expédition an d’éviter d’endommager l’appareil dans

le cas d’un déplacement éventuel.

19

Page 20

DéBallaGe De la laVeuSe

x 4

x 4

x 2

x 4

Retrait de la quincaillerie d’expédition

remarque

Il se peut que le matériel de caoutchouc utilisé pour les

espaceurs nécessite quelque temps pour se relâcher

an de pouvoir être retiré des trous d’expédition.

Retirez les composants suivants :

4 BOULONS

2 SERRES EN P

Pose des bouchons

4 CALES D’ESPACEMENT

2 SERRES EN P

4 BOUCHONS

(DANS UN SAC)

4 BOULONS

4 CALES D’ESPACEMENT

Important

Conservez les boulons et cales d’espacement

d’expédition pour un usage ultérieur. Si la laveuse doit

être transportée plus tard, ces pièces d’expédition

doivent être installées pour éviter de l’endommager.

Trouvez les 4 bouchons du petit sac fourni avec

les guides de votre laveuse. Insérez-les dans

les trous du panneau arrière de la laveuse.

20

Page 21

a

b

c

d

a

e

f

g

b

c

d

INSTRUCTIONS D’INSTALLATION

Mise à niveau de votre appareil

Les bruits excessifs et les vibrations peuvent être

évités en mettant correctement la laveuse à niveau.

1 Pour une installation autonome où la laveuse est à

moins de 1,2 m (4 pi) de son emplacement dénitif,

placez un niveau sur le dessus de l’appareil.

2 Utilisez la clé universelle pour ajuster les pieds de mise

à niveau de façon à ce que la laveuse soit de niveau

d’avant en arrière et latéralement, et qu’elle soit stable

aux quatre coins.

3

Appuyez sur chaque coin et chaque côté pour déterminer

les endroits qui nécessitent un réglage. Ajustez les pieds

de mise à niveau appropriés de manière à ce que la laveuse

repose solidement sur ses QUATRE pieds. Gardez les pieds

de mise à niveau le plus près possible de la laveuse an

d’optimiser le rendement de la laveuse.

remarque

Pour une installation sur socle, reportez-vous aux instructions

d’installation complémentaires incluses avec le socle.

Branchement de l’entrée d’eau

1 Faites couler de l’eau chaude et froide des robinets

pour purger les tuyaux d’eau, pour éliminer toute

particule qui pourrait obstruer les grillages des robinets,

et pour déterminer quels robinets fournissent l’eau

chaude et l’eau froide.

2

Enlevez du sac en plastique les tuyaux d’arrivée et les

rondelles caoutchoucet installez les rondelles àchaque

extrémité.

soulever

abaisser

UTILISEZ

Seulement

LES RONDELLES

EN CAOUTCHOUC

DOIVENT ÊTRE

PRÉSENTES

3

Raccordez le tuyau d’entrée d’eau CHAUDE au raccord

pour l’eau CHAUDE de la laveuse et le tuyau d’entrée

d’eau FROIDE au raccord pour l’eau FROIDE de la

laveuse. Serrez fermement à la main. Avec des pinces,

serrez chaque raccord de 2/3 de tour. Ne faussez pas le

letage et ne serrez pas trop.

4

Branchez le tuyau d’entrée d’eau CHAUDE au robinet

d’eau CHAUDE, et le tuyau d’eau d’entrée d’eau FROIDE

au robinet d’eau FROIDE. Serrez fermement à la main.

Avec des pinces, serrez chaque raccord de 2/3 de tour.

5 Ouvrir les robinets et s’assurer qu’il n’y a pas de fuite.

leS nouVeauX

TUYAU D’EN-

TRÉE D’EAU

HOT

(CHAUDE)

COLD

(FROIDE)

21

Page 22

INSTRUCTIONS D’INSTALLATION

Prise murale avec

mise à la terre

à la terre de cette che.

Ne coupez pas, n'enlevez

pas et ne mettez pas hors

circuit la broche de mise

Cordon électrique muni

avec mise à la terre

d’une che à trois broches

Branchement électrique et branchement

du tuyau de vidange

1

Fixez l’une des extrémités du crochet du tuyau de vidange

(inclus dans la cuve) au tuyau de vidange. Continuez de

l’enrouler autour du crochet et pincez-le en position.

2

Placez le côté du tuyau de vidange en forme de crochet

dans l’ouverture du tuyau d’évacuation. Fixez le tuyau de

vidange au moyen d’une attache (incluse dans la trousse

d’installation fournie) au tuyau d’évacuation, au tuyau

d’entrée, à la cuve à lessive, etc. de façon à ce que le

tuyau ne puisse être arraché sous la force de l’eau.

Important

Assurez-vous que l’alimentation électrique est coupée au

disjoncteur ou au boîtier de fusibles avant de brancher le

cordon d’alimentation dans une prise électrique.

3 Branchez le cordon d’alimentation à la prise électrique

mise à la terre.

4 Ouvrez l’alimentation électrique au disjoncteur ou au

boîtier de fusibles.

5 Faites glisser soigneusement la laveuse à son

emplacement dénitif. Vériez à nouveau la stabilité de

l’appareil. Retirez et jetez le ruban de la porte.

6 Reportez-vous au Guide d’utilisation et d’entretien

fourni avec la laveuse. Il contient des renseignements

très utiles qui vous permettent d’économiser temps et

argent.

7 Pour toute question relative à l’utilisation initiale,

veuillez revoir la section intitulée « Liste de vérication

avant service » de votre Guide d’utilisation et

d’entretien avant d’effectuer une demande de service.

8 Laissez ces instructions à proximité de la laveuse pour

vous y reporter ultérieurement.

remarque

Un schéma électrique et une che technique sont situés

sous le panneau supérieur de la laveuse, au-dessus du

logement de distributeur de détergent.

ATTACHE

22

Page 23

26.44”

(67.16cm)

15.00”

(38.10cm)

27.00”

(68.58cm)

Socle De ranGement aSSortI

Socle Blanc -PIÈCE N° APWD15

Socle Noir - PIÈCE N° APWD15E

Socle Rouge - PIÈCE N° APWD15R

Un socle de rangement, conçu expressément pour cette

laveuse, peut être utilisé an de soulever votre appareil,

facilitant ainsi son utilisation. Le socle ajoute environ 38 cm

(15 po) à votre laveuse, pour une hauteur totale de 130 cm

(51.25 po).

NÉCESSAIRE DE SUPERPOSITION DE SÉCHEUSE

PIÈCE N° 134700600

Selon le modèle que vous avez acheté, il se peut qu’un

nécessaire pour superposer cette sécheuse sur une laveuse

assortie ait été inclus dans l’achat initial de votre sécheuse.

Si votre modèle ne comprenait pas de nécessaire de

superposition ou que vous en désirez un autre, il vous est

possible d’en commander un.

néceSSaIre De rallonGe De tuyau De VIDanGe

PIÈCE N° 137098000

Pour atteindre un tuyau d’évacuation qui est trop haut ou

trop loin pour la longueur de tuyau fournie, commandez le

NÉCESSAIRE DE RALLONGE DE TUYAU DE VIDANGE.

acceSSoIreS

attentIon

Tout défaut d’utiliser les accessoires fabriqués ou

certiés par le fabricant pourrait entraîner des

blessures, des dommages aux biens ou à la laveuse.

TROUSSE D’INSTALLATION DE MAISON MOBILE

PIÈCE N° 137067200

Toute installation dans une maison mobile nécessite

l’utilisation d’une TROUSSE D’INSTALLATION DE MAISON

MOBILE.

CLÉ D’APPAREIL UNIVERSELLE

PIÈCE N° 137019200

UNE CLÉ D’APPAREIL UNIVERSELLE est offerte pour faciliter

le réglage des pieds de sécheuse/laveuse/socle.

CRAYONS DE PEINTURE DE RETOUCHE

Crayon de retouche Blanc - PIÈCE N° 5304468812

Crayon de retouche Noir - PIÈCE N° 5304458932

Crayon de retouche Rouge - PIÈCE N° P/N 5304471227

Pièces de rechange : 1-800-944-9044 (au Canada 1-800-265-8352)

Si vous devez commander des pièces de rechange pour

votre laveuse, communiquez avec le marchand qui

vous a vendu votre appareil, composez le 1-800-9449044 (au Canada 1-800-265-8352), ou visitez notre site

Web à l’adresse www.frigidaire.com, pour connaître le

distributeur de pièces autorisé Frigidaire le plus près de

chez vous.

aVertISSement

rISque électrIque

Étiquetez tous les ls avant de les débrancher pendant

l’entretien des commandes. Des erreurs de câblage

pourraient nuire au bon fonctionnement de l’appareil, et

même être dangereuses. Vériez le bon fonctionnement

de l’appareil après tout entretien.

23

Page 24

Loading...

Loading...