Page 1

Installation Instructions

Gas & Electric Dryer

Instrucciones de Instalación

Secadora a Gas y Eléctrica

www.frigidaire.com P/N 137111500B (0903)

Page 2

Table of Contents

Important Safety Instructions ................................................2

Pre-installation Requirements ................................................2

Installation Requirements .................................................. 3-7

Installed Dimensions .............................................................8

Installation Instructions ................................................... 9-13

Reversing door .............................................................. 14-15

Accessories/Replacement parts ............................................16

Español ...............................................................................17

Important Safety Instructions

For your safety the information in this manual must be followed to minimize the risk of fi re or explosion or to

prevent property damage, personal injury or loss of life. Do not store or use gasoline or other fl ammable vapors and liquids in

the vicinity of this or any other appliance.

Recognize safety symbols, words and labels

Safety items throughout this manual are labeled with a

WARNING or CAUTION based on the risk type as described:

- RISK OF FIRE - Read all of the following instructions before installing and using this appliance:

Destroy the carton and plastic bags after the dryer is unpacked. Children might use them for play. Cartons covered with •

rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Place all materials in a garbage

container or make materials inaccessible to children.

Clothes dryer installation and service must be performed by a qualifi ed installer, service agency or the gas supplier.•

Install the clothes dryer according to the manufacturer’s instructions and local codes.•

The electrical service to the dryer must conform with local codes and ordinances and the latest edition of the National •

Electrical Code, ANSI/NFPA 70, or in Canada, the Canadian electrical code C22.1 part 1.

The gas service to the dryer must conform with local codes and ordinances and the latest edition of the National Fuel Gas •

Code ANSI Z223.1, or in Canada, CAN/ACG B149.1-2000.

The dryer is designed under ANSI Z 21.5.1 or ANSI/UL 2158 - CAN/CSA C22.2 No. 112 (latest editions) for HOME USE •

only. This dryer is not recommended for commercial applications such as restaurants, beauty salons, etc.

Do not install a clothes dryer with fl exible plastic venting material. Flexible venting materials are known to collapse, be eas-•

ily crushed and trap lint. These conditions will obstruct clothes dryer airfl ow and increase the risk of fi re.

The instructions in this manual and all other literature included with this dryer are not meant to cover every possible •

condition and situation that may occur. Good safe practice and caution MUST be applied when installing, operating and

maintaining any appliance.

may cause serious body harm, death or property damage.

cause bodily injury or property damage.

This symbol alerts you to situations that

This symbol alerts you to situations that may

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.•

Do not touch any electrical switch; do not use any phone in your building.•

Clear the room, building or area of all occupants.•

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.•

If you cannot reach your gas supplier, call the fi re department.•

Save these instructions for future reference.

Pre-Installation Requirements

Tools and materials needed for installation:

Adjustable pliers•

Phillips, straight, & square bit screw-•

drivers

Adjustable wrench•

Pipe wrench for gas supply (gas dryer)•

LP-resistant thread tape (for natural •

gas or LP supply, gas dryer)

Carpenter’s level•

External vent hood•

4-inch (10.2 cm), rigid metal or semi-•

rigid metal exhaust duct work

3-wire or 4-wire 240 volt cord kit •

(electric dryer)

4 in. (10.2 cm) clamp•

2

Gas line shutoff valve (gas dryer)•

½ NPT union fl are adapters (x2) and •

fl exible gas supply line (gas dryer)

Metal foil tape (not duct tape)•

Page 3

Electrical System Requirements

Grounding type

ll receptacle

wer cord with

3-prong grgr

ounded plug

Do not,

under

y cir

cumstances,

cut,

removeve,

or b

ypass the

ounding pr

ong.

Because of potentially inconsistent voltage capabilities, the use of this dryer with power created by gas powered generators, solar powered generators, wind powered generators or any other generator other than the local utility company is not

recommended.

Electrical requirements for electric dryer

CIRCUIT - Individual 30 amp. branch circuit fused with 30 amp. time delay fuses or circuit breakers. Use separately fused

circuits for washer and dryer. DO NOT operate a washer and a dryer on the same circuit.

POWER SUPPLY - 3-wire or 4-wire, 240 volt, single phase, 60 Hz, Alternating Current.

This dryer is internally grounded to neutral unless it was manufactured for sale in Canada. Grounding through

the neutral link is prohibited for: (1) new branch circuit installations, (2) mobile homes, (3) recreational vehicles, and (4) areas

where local codes do not permit grounding through the neutral.

OUTLET RECEPTACLE - NEMA 10-30R or NEMA 14-30R receptacle to be located so the power supply cord is accessible when the

dryer is in the installed position.

GROUNDING CONNECTION - See “Grounding requirements” in Electrical Installation section.

3-WIRE POWER SUPPLY CORD KIT (not supplied)

3-wire receptacle

(NEMA type 10-30R)

The dryer MUST employ a 3-conductor power supply cord

NEMA 10-30 type SRDT rated at 240 volt AC minimum,

30 amp, with 3 open end spade lug connectors with

upturned ends or closed loop connectors and marked

for use with clothes dryers. For 3-wire cord connection

instructions see ELECTRICAL CONNECTIONS FOR A

3-WIRE SYSTEM.

Electrical requirements for gas dryer

CIRCUIT - Individual, properly polarized and grounded 15

amp. branch circuit fused with 15 amp. time delay fuse or

circuit breaker.

POWER SUPPLY - 2-wire, with ground, 120 volt, single phase,

60 Hz, Alternating Current.

POWER SUPPLY CORD - The dryer is equipped with a 120 volt

3-wire power cord.

GROUNDING CONNECTION - See “Grounding requirements”

in Electrical Installation section.

4-WIRE POWER SUPPLY CORD KIT (not supplied)

4-wire receptacle

(NEMA type 14-30R)

The dryer MUST employ a 4-conductor power supply cord

NEMA 14-30 type SRDT or ST (as required) rated at 240

volt AC minimum, 30 amp, with 4 open end spade lug

connectors with upturned ends or closed loop connectors

and marked for use with clothes dryers. For 4-wire cord

connection instructions see ELECTRICAL CONNECTIONS

FOR A 4-WIRE SYSTEM.

Dryers manufactured for sale in Canada have factory-

installed, 4-wire power supply cord (NEMA 14-30R).

Grounding type

wawall receptacl

Do not,

under

anany cir

cumstances,

cut,

remo

or b

ypass th

PoPower cord with

3-prong

ounded plug

grgrounding pr

ong.

3

Page 4

Gas supply requirements

- EXPLOSION HAZARD - Uncoated copper

tubing will corrode when subjected to natural gas, causing

gas leaks. Use ONLY black iron, stainless steel, or plastic-coated brass piping for gas supply.

1. Installation MUST conform with local codes, or in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1 (latest edition).

2. The gas supply line should be 1/2 inch (1.27 cm) pipe.

3. If codes allow, fl exible metal tubing may be used to

connect your dryer to the gas supply line. The tubing

MUST be constructed of stainless steel or plastic-coated

brass.

4. The gas supply line MUST have an individual shutoff valve.

Exhaust system requirements

Use only 4 inch (10.2 cm) diameter (minimum) rigid or fl exible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When

the dryer stops, the dampers automatically close to prevent

drafts and the entrance of insects and rodents. To avoid

restricting the outlet, maintain a minimum of 12 inches (30.5

cm) clearance between the vent hood and the ground or any

other obstruction.

5. A 1/8 inch (0.32 cm) N.P.T. plugged tapping, accessible

for test gauge connection, MUST be installed immediately

upstream of the gas supply connection to the dryer.

6. The dryer MUST be disconnected from the gas supply

piping system during any pressure testing of the gas

supply piping system at test pressures in excess of 1/2 psig

(3.45 kPa).

7. The dryer MUST be isolated from the gas supply piping

system during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psig (3.45 kPa).

8. Connections for the gas supply must comply with the

Standard for Connectors for Gas Appliances, ANSI Z21.24.

- FIRE HAZARD - Failure to follow these in-

structions can create excessive drying times and fi re hazards.

The following are specifi c requirements for

proper and safe operation of your dryer.

- FIRE HAZARD - Do not install a clothes

dryer with fl exible plastic or metal foil venting materials.

Flexible venting materials are known to collapse, be easily

crushed and trap lint. These conditions will obstruct clothes

dryer airfl ow and increase the risk of fi re.

If your present system is made up of plastic duct or metal foil

duct, replace it with a rigid or semi-rigid metal duct. Also,

ensure the present duct is free of any lint prior to installing

dryer duct.

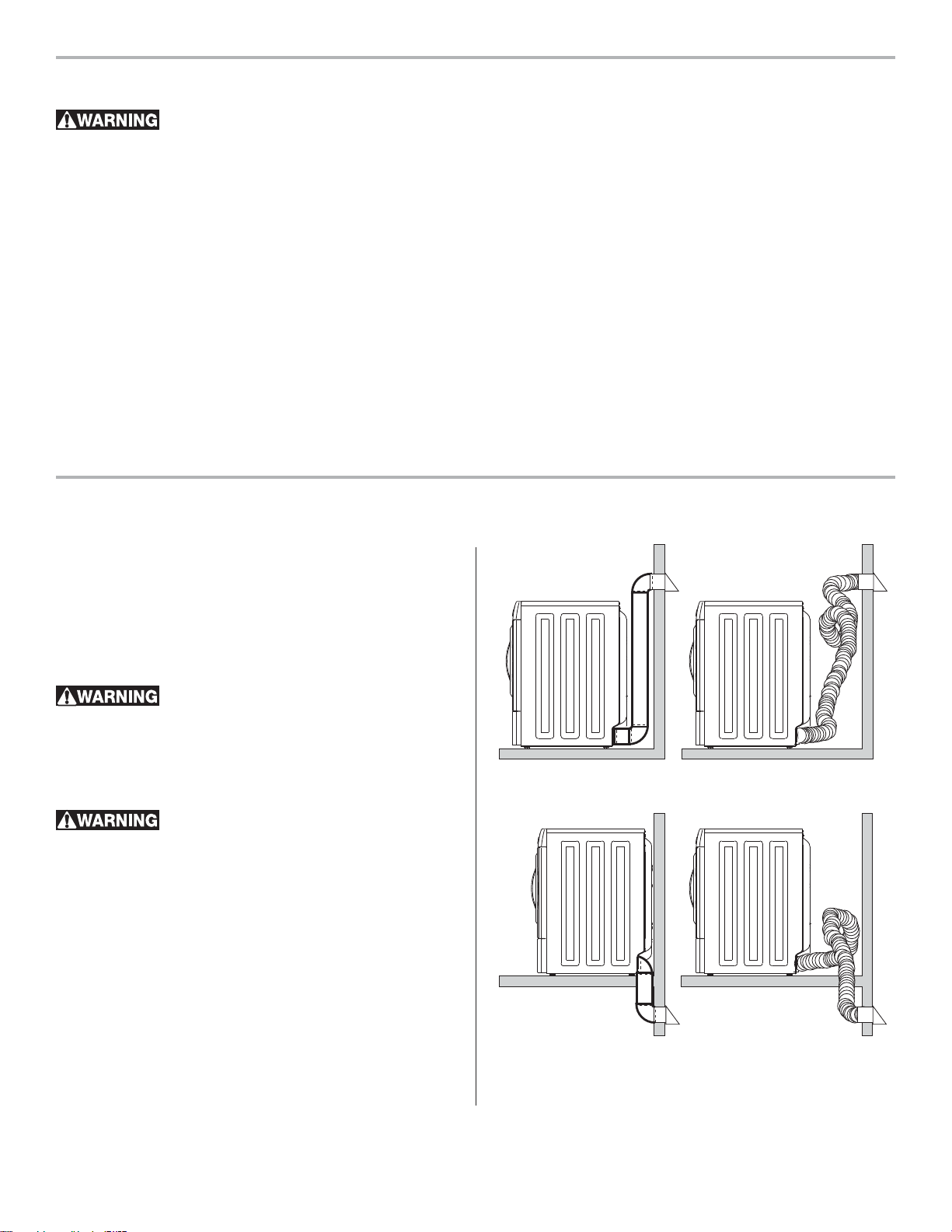

Correct Incorrect

Correct Incorrect

4

Page 5

Exhaust system requirements, continued

- FIRE HAZARD - A clothes dryer must be

exhausted outdoors. Do not exhaust dryer into a chimney, a

wall, a ceiling, an attic, a crawl space or any concealed space

of a building. A clothes dryer produces combustible lint. If

the dryer is not exhausted outdoors, some fi ne lint will be

expelled into the laundry area. An accumulation of lint in any

area of the home can create a health and fi re hazard.

The dryer must be connected to an exhaust outdoors.

Regularly inspect the outdoor exhaust opening and remove

any accumulation of lint around the outdoor exhaust opening

and in the surrounding area.

- FIRE HAZARD -

Do not allow combustible materials (for example: clothing, •

draperies/curtains, paper) to come in contact with exhaust

system. The dryer MUST NOT be exhausted into a chimney, a wall, a ceiling, or any concealed space of a building

which can accumulate lint, resulting in a fi re hazard.

Do not screen the exhaust ends of the vent system, or use •

any screws, rivets or other fasteners that extend into the

duct to assemble the exhaust system. Lint can become

caught in the screen, on the screws or rivets, clogging the

duct work and creating a fi re hazard as well as increasing

drying times. Use an approved vent hood to terminate the

duct outdoors, and seal all joints with duct tape. All male

duct pipe fi ttings MUST be installed downstream with the

fl ow of air.

- FIRE HAZARD - Exceeding the length of

duct pipe or number of elbows allowed in the “MAXIMUM

LENGTH” charts can cause an accumulation of lint in the exhaust system. Plugging the system could create a fi re hazard,

as well as increase drying times.

MAXIMUM LENGTH

Number of 90° turns

0 64 ft. (19.5 m) 48 ft. (14.6 m)

1 52 ft. (15.9 m) 40 ft. (12.2 m)

2 44 ft. (13.5 m) 32 ft. (9.8 m)

3 32 ft. (9.8 m) 24 ft. (7.3 m)

4 28 ft. (9.5 m) 16 ft. (4.9 m)

of 4” (10.2cm) Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

4”

(10.2cm) louvered

2.5”

(6.35cm)

- FIRE HAZARD -

Do not install fl exible plastic or fl exible foil venting mate-•

rial.

If installing semi-rigid venting, do not exceed 8 ft. (2.4 m) •

duct length.

Install male fi ttings in correct direction:

CORRECT

INCORRECT

5

Page 6

Exhaust system requirements, continued

In installations where the exhaust system is not described in

the charts, the following method must be used to determine

if the exhaust system is acceptable:

1. Connect an inclined or digital manometer between the

dryer and the point the exhaust connects to the dryer.

2. Set the dryer timer and temperature to air fl uff (cool

down) and start the dryer.

3. Read the measurement on the manometer.

4. The system back pressure MUST NOT be higher than

0.75 inches of water column. If the system back pressure

is less than 0.75 inches of water column, the system is

acceptable. If the manometer reading is higher than .075

inches of water column, the system is too restrictive and

the installation is unacceptable.

Although vertical orientation of the exhaust system is

acceptable, certain extenuating circumstances could affect

the performance of the dryer:

Only the rigid metal duct work should be used.•

Venting vertically through a roof may expose the exhaust •

system to down drafts causing an increase in vent

restriction.

Running the exhaust system through an uninsulated area •

may cause condensation and faster accumulation of lint.

Compression or crimping of the exhaust system will cause •

an increase in vent restriction.

The exhaust system should be inspected and cleaned a •

minimum of every 18 months with normal usage. The

more the dryer is used, the more often you should check

the exhaust system and vent hood for proper operation.

Exhaust direction

Directional exhausting can be accomplished by installing a

quick-turn 90° dryer vent elbow directly to exhaust outlet of

dryer. Dryer vent elbows are available through your local parts

distributor or hardware store.

See also CLEARANCE REQUIREMENTS on the next page.

Use of 90° quick-turn elbow required to meet mini-

mum installation depth of free-standing dryer:

Straight back venting allows for 0” (0 cm) installation.•

Venting right with 90° elbow allows for 0.75” (2 cm) •

installation.

Venting downward with 90° elbow allows for 0.75” (2 cm) •

installation.

Venting left with short, straight adapter and 90° elbow •

allows for 3.75” (9.5 cm) installation.

Venting upward with short, straight adapter and 90° •

elbow allows for 4” (10.5 cm) installation.

Manufactured or mobile home installation

Installation MUST conform to current Manufactured 1.

Home Construction & Safety Standard, Title 24 CFR, Part

32-80 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD Part 280) or

Standard CAN/CSAZ240 MH.

Dryer MUST be exhausted outside (outdoors, not beneath 2.

the mobile home) using metal ducting that will not support

combustion. Metal ducting must be 4 inches (10.16 cm) in

diameter with no obstructions. Rigid metal duct is preferred.

If dryer is exhausted through the fl oor and area beneath 3.

the mobile home is enclosed, the exhaust system MUST

6

terminate outside the enclosure with the termination

securely fastened to the mobile home structure.

Refer to previous sections in this guide for other important 4.

exhaust venting system requirements.

When installing a gas dryer into a mobile home, a 5.

provision must be made for outside make up air. This

provision is to be not less than twice the area of the dryer

exhaust outlet.

Installer MUST anchor this (1) dryer or (2) dryer mounted 6.

on pedestal to the fl oor with approved Mobile Home

Installation Kit - P/N 137067200.

Page 7

Clearance requirements

- EXPLOSION HAZARD - Do not install the

dryer where gasoline or other fl ammables are kept or stored.

If the dryer is installed in a garage, it must be a minimum

of 18 inches (45.7 cm) above the fl oor. Failure to do so can

result in death, explosion, fi re or burns.

DO NOT INSTALL YOUR DRYER:

In an area exposed to dripping water or outside weather 1.

conditions.

In an area where it will come in contact with curtains, 2.

drapes, or anything that will obstruct the fl ow of combustion and ventilation air.

On carpet. Floor MUST be solid with a maximum slope of 3.

1 inch (2.54 cm).

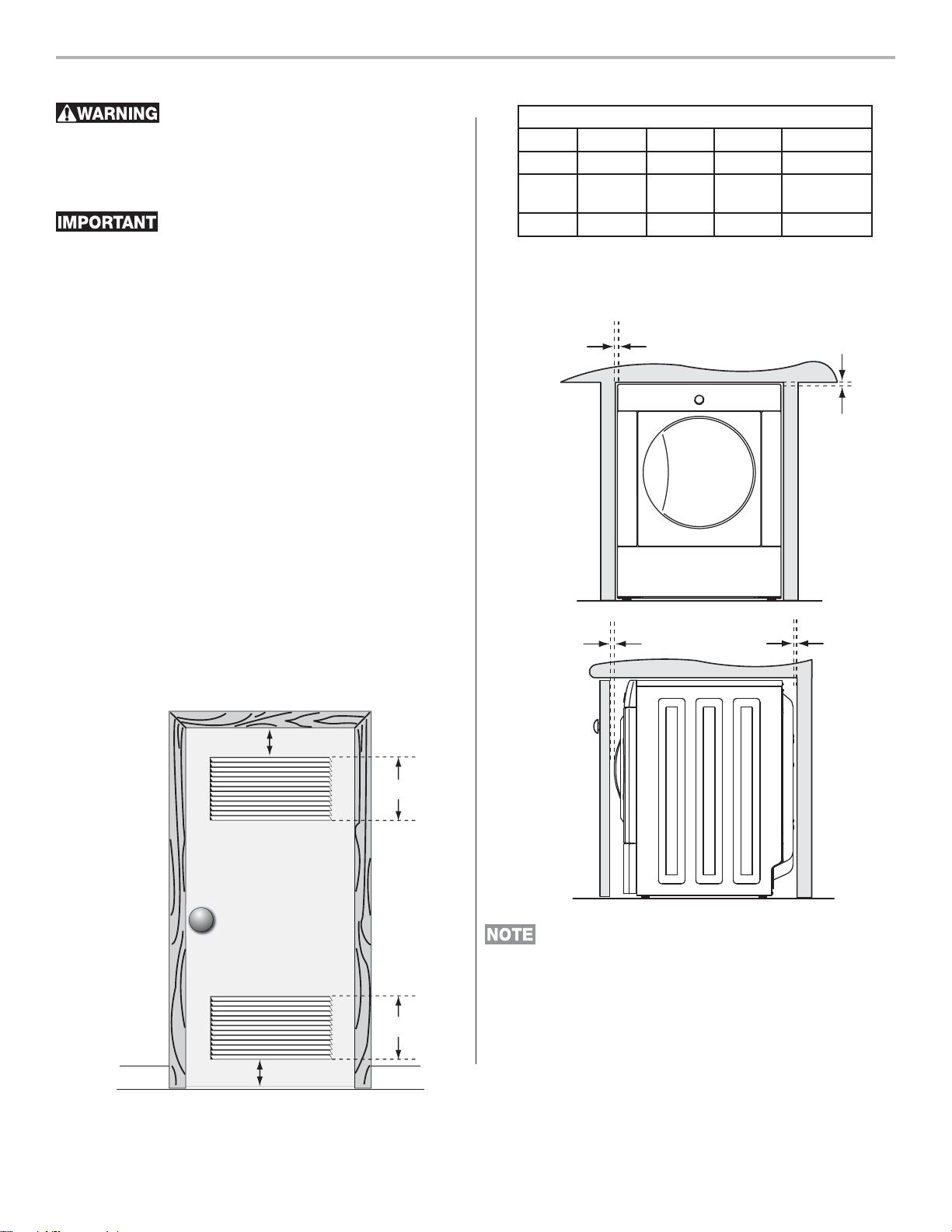

INSTALLATION IN A RECESS OR CLOSET

1. A dryer installed in a bedroom, bathroom, recess or closet,

MUST be exhausted outdoors.

2. No other fuel burning appliance shall be installed in the

same closet as the gas dryer.

3. Your dryer needs the space around it for proper

ventilation.

DO NOT install your dryer in a closet with a solid door.

4. Closet door ventilation required: A minimum of 120

square inches (774.2 cm²) of opening, equally divided at

the top and bottom of the door, is required. Openings

should be located 3 inches (7.6 cm) from bottom and top

of door. Openings are required to be unobstructed when

a door is installed. A louvered door with equivalent air

openings for the full length of the door is acceptable.

MINIMUM INSTALLATION CLEARANCES - Inches (cm)

SIDES REAR TOP FRONT

Alcove 0” (0 cm) 0” (0 cm)* 0” (0 cm) n/a

Under-

Counter

0” (0 cm) 0” (0 cm)* 0” (0 cm) n/a

Closet 0” (0 cm) 0” (0 cm)* 0” (0 cm) 1” (2.54 cm)

F*

or other than straight back venting, a quick-turn 90°

dryer vent elbow (vented right or down in free-standing

dryer or right on pedestal-mounted dryer) must be

installed to achieve 0” (0 cm) installation.

0”

(0cm)

0”

(0cm)

1”

(2.54cm)

0”

(0cm)

3”

(7.6cm)

3”

(7.6cm)

closet door

60 sq. in.

(387.1cm²)

60 sq. in.

(387.1cm²)

To achieve an installation with 0” (0 cm) clearance

for the back of the dryer (for other than straight back venting), a quick-turn 90° dryer vent elbow must be installed as

described previously in this manual.

7

Page 8

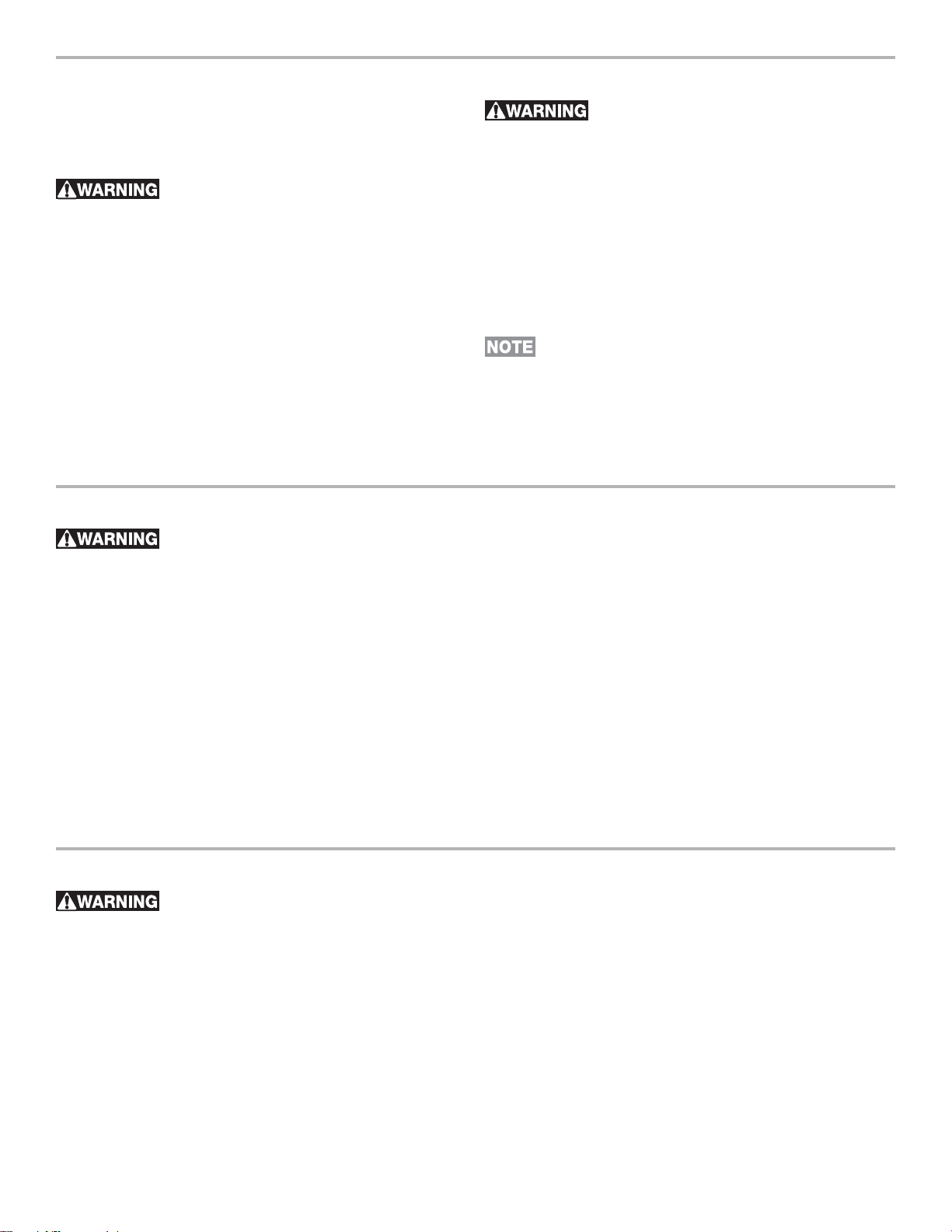

Installed dryer dimensions

48.25” (122.5cm)*

to clear open door

freestand dryer

on floor

floor line

30.5” (77.5cm)*

to front of closed door

51.25”

(130cm)

36.0”

(91.5cm)

gas supply

pipe on rear

of gas unit

1.6”

(4cm)

27.0”

(68.5cm)

electrical

supply on

rear of unit

centerline

height for

rear vent

3.7”

(9.5cm)

dryer mounted on

optional pedestal

floor line

* To obtain these minimal depth dimensions, dryer must be vented straight back.

Using a quick-turn 90° elbow (right or down on freestanding dryer) adds approximately

0.75 in. (2.0 cm) to installation depth. Upward venting of exhaust on pedestal-mounted

or freestanding dryer adds approximately 4 in. (10.2 cm) to installation depth. Leftward

venting on pedestal-mounted or freestanding dryer adds approximately 3.75 in. (9.5 cm)

to installation depth. Downward venting of exhaust on pedestal-mounted dryer adds

approximately 2.25 in. (5.7 cm) to installation depth.

48.25” (122.5cm)*

to clear open door

30.5” (77.5cm)*

to front of closed door

(182cm)

71.5”

16.9”

(43cm)

3.75”

(9.5cm)

gas supply

pipe on rear

of gas unit

13.50”

(34.5cm)

to center of rear vent

27.0”

(68.5cm)

19.0”

(48cm)

electrical

supply on

rear of unit

centerline

height for

rear vent

37”

(94cm)

* To obtain these minimal depth dimensions, dryer must be vented straight back. Using a quick-turn 90° elbow (right) adds approximately 0.75 in. (2 cm) to

installation depth. Upward venting of exhaust on stacked dryer adds approximately 4 in. (10.2 cm) to installation depth. Downward venting of exhaust on

stacked dryer adds approximately 2.25 in. (6.5 cm) to installation depth. Leftward venting of exhaust on stacked dryer adds approximately 3.75 in. (9.5 cm) to

installation depth.

39”

(99cm)

8

Page 9

Electrical installation

The following are specifi c requirements for proper and safe

electrical installation of your dryer. Failure to follow these

instructions can create electrical shock and/or a fi re hazard.

- ELECTRICAL SHOCK HAZARD -

This appliance MUST be properly grounded. Electrical •

shock can result if the dryer is not properly grounded.

Follow the instructions in this manual for proper grounding.

Do not use an extension cord with this dryer. Some ex-•

tension cords are not designed to withstand the amounts

of electrical current this dryer utilizes and can melt, creating electrical shock and/or fi re hazard. Locate the dryer

within reach of the receptacle for the length power cord

to be purchased, allowing some slack in the cord. Refer

to the pre-installation requirements in this manual for the

proper power cord to be purchased.

A U.L.-approved strain relief must be installed onto pow-•

er cord. If the strain relief is not attached, the cord can be

pulled out of the dryer and can be cut by any movement

of the cord, resulting in electrical shock.

Do not use an aluminum wired receptacle with a copper •

wired power cord and plug (or vice versa). A chemical

reaction occurs between copper and aluminum and can

cause electrical shorts. The proper wiring and receptacle

is a copper wired power cord with a copper wired receptacle.

longer drying times than dryers operating on 240 volt power

supply.

Grounding requirements - Electric dryer (USA)

- ELECTRICAL SHOCK HAZARD -

Dryers operating on 208 volt power supply will have

- ELECTRICAL SHOCK HAZARD - Improper

connection of the equipment grounding conductor can result

in a risk of electrical shock. Check with a licensed electrician

if you are in doubt as to whether the appliance is properly

grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance for

electrical current.

2. After you purchase and install a 3 wire or 4 wire power

supply cord having an equipment-grounding conductor

and a grounding plug that matches you wiring system,

the plug MUST be plugged into an appropriate, copper

wired receptacle that is properly installed and grounded

in accordance with all local codes and ordinances. If in

doubt, call a licensed electrician.

DO NOT modify the plug you’ve installed on this appliance.

For a permanently connected dryer:

1. The dryer MUST be connected to a grounded metal,

permanent wiring system; or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead

on the appliance.

Grounding requirements - Electric dryer (Canada)

- ELECTRICAL SHOCK HAZARD - Improper

connection of the equipment grounding conductor can result

in a risk of electrical shock. Check with a licensed electrician

if you are in doubt as to whether the appliance is properly

grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance for

electrical current.

2. Since your dryer is equipped with a power supply

cord having an equipment-grounding conductor and

a grounding plug, the plug must be plugged into an

appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances. If in

doubt, call a licensed electrician.

DO NOT modify the plug provided with the appliance.

9

Page 10

Grounding type

ll receptacle

wer cord with

3-prong grgr

ounded plug

Do not,

under

y cir

cumstances,

cut,

removeve,

or b

ypass the

ounding pr

ong.

Grounding requirements - Gas dryer (USA and Canada)

The dryer is equipped with a three-prong (grounding) plug 1.

for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong

receptacle.

The plug must be plugged into an appropriate outlet that 2.

is properly installed and grounded in accordance with all

local codes and ordinances. If in doubt, call a licensed

electrician.

DO NOT cut or remove ground prong from the plug.

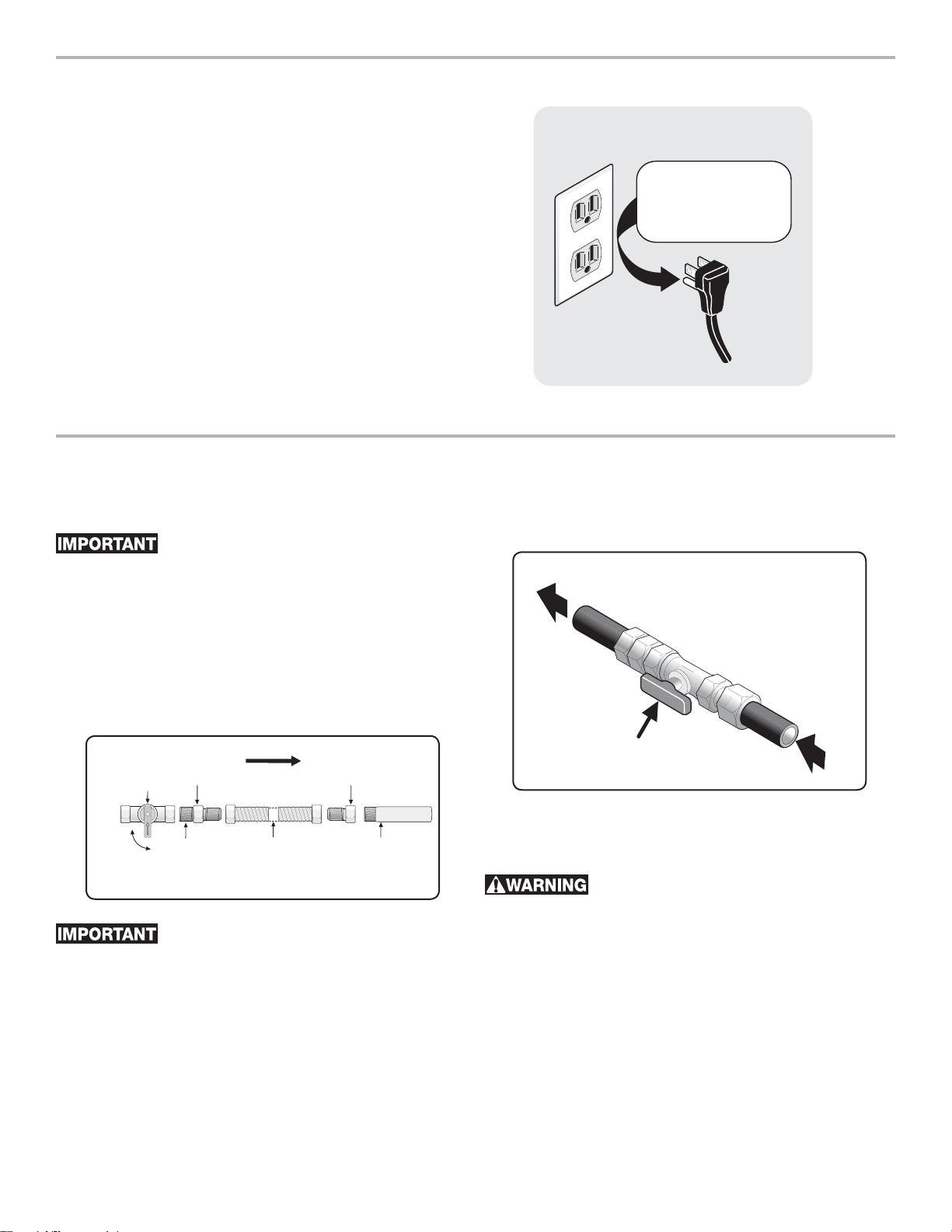

Gas connection

Remove the shipping cap from gas pipe at the rear of the 1.

dryer.

DO NOT connect the dryer to L.P. gas service

without converting the gas valve. An L.P. conversion kit must

be installed by a qualifi ed gas technician.

Grounding type

wawall receptacl

Do not,

under

anany cir

cumstances,

cut,

remo

or b

ypass th

PoPower cord with

3-prong

ounded plug

grgrounding pr

ong.

Open the shutoff valve in the gas supply line to allow gas 3.

to fl ow through the pipe. Wait a few minutes for gas to

move through the gas line.

to dryer

Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or approved 2.

pipe from gas supply line to the 3/8 inch (0.96 cm) pipe

located on the back of the dryer. Use a 1/2 inch to 3/8

inch (1.27 cm to 0.96 cm) reducer for the connection.

Apply an approved thread sealer that is resistant to the

corrosive action of liquefi ed gases on all pipe connections.

Closed

Manual

Shuto

Valve

Open

Flare

Union

All connections must be wrench-tightened

The supply line must be equipped with an ap-

elppiN

GAS FLOW

Flexible

Connector

Flare

Union

Inlet Pipe on

Back of Dryer

proved manual shutoff valve. This valve should be located in

the same room as the dryer and should be in a location that

allows ease of opening and closing. Do not block access to

the gas shutoff valve.

from gas supply

Shuto Valve Open position

Check for gas system leaks with a manometer. If a 4.

manometer is not available, test all connections by

brushing on a soapy water solution.

- EXPLOSION HAZARD - NEVER test for gas

leaks with an open fl ame.

10

Page 11

Electrical connection (non-Canada) - 3 wire cord

Internal ground

(GREEN screw)

Install

UL-approved

strain relief here

Terminal screw

recovery slot

Line 1

(BRASS terminal)

Neutral

(SILVER terminal)

Line 2

(BRASS terminal)

Access cover

screw

Terminal

block

Neutral

(center wire)

30 AMP

NEMA 10-30

DO NOT remove

internal ground in

a 3-wire system!!

Neutral

terminal

3-wire receptacle

(NEMA type 10-30R)

- ELECTRICAL SHOCK HAZARD - Failure

to disconnect power source before servicing could result in

personal injury or even death.

Turn off power supply to outlet. 1.

Remove the screw securing the terminal block access 2.

cover in the lower corner on the back of the dryer.

Install a UL-approved strain relief according to the power 3.

cord/strain relief manufacturer’s instructions in the power

cord entry hole below the access panel. At this time, the

strain relief should be loosely in place.

Thread an UNPLUGGED, UL-approved, 30 amp. power 4.

cord, NEMA 10-30 type SRDT, through the strain relief.

30 AMP

NEMA 10-30

Neutral

(center wire)

Access cover

screw

Terminal

block

Line 2

(BRASS terminal)

Neutral

(SILVER terminal)

Line 1

(BRASS terminal)

Attach the power cord neutral (center wire) conductor to 5.

the SILVER colored center terminal on the terminal block.

Tighten the screw securely.

Attach the remaining two power cord outer conductors 6.

to the outer, BRASS colored terminals on the terminal

block. Tighten both screws securely.

make a sharp bend or crimp wiring/conductor at connections.

Follow manufacturer’s guidelines for fi rmly securing the 7.

strain relief and power cord.

Reinstall the terminal block cover.8.

installing it in a 3-wire system, move the internal ground from

the center terminal back to the GREEN screw next to the

terminal block.

- ELECTRICAL SHOCK HAZARD - Do not

If moving dryer from a 4-wire system and

Internal ground

(GREEN screw)

Install

UL-approved

strain relief here

Terminal screw

recovery slot

If a terminal screw falls during cord installation, it

can be retrieved in the terminal screw recovery slot below the

access panel.

DO NOT remove

internal ground in

a 3-wire system!!

Neutral

terminal

11

Page 12

Electrical connection (non-Canada) - 4 wire cord

Internal ground

(GREEN screw)

Install

UL-approved

strain relief here

Terminal screw

recovery slot

Line 1

(BRASS terminal)

Neutral

(SILVER terminal)

Line 2

(BRASS terminal)

Access cover

screw

Terminal

block

Neutral

(WHITE wire)

30 AMP

NEMA 14-30

Ground

(GREEN wire)

Move internal ground (BLACK)

wire to neutral (SILVER)

terminal for 4-wire system.

Neutral

terminal

GREEN

ground screw

BLACK or

RED power wire

BLACK

or RED

power wire

GREEN

ground wire

WHITE

neutral wire

4-wire receptacle

(NEMA type 14-30R)

- ELECTRICAL SHOCK HAZARD - Failure

to disconnect power source before servicing could result in

personal injury or even death.

30 AMP

NEMA 14-30

Ground

(GREEN wire)

Neutral

(WHITE wire)

Turn off power supply to outlet. 1.

Remove the screw securing the terminal block access 2.

cover in the lower corner on the back of the dryer.

Install a UL-approved strain relief according to the power 3.

cord/strain relief manufacturer’s instructions in the power

cord entry hole below the access panel. At this time, the

strain relief should be loosely in place.

Thread an UNPLUGGED, UL-approved, 30 amp. power 4.

cord, NEMA 14-30 type ST or SRDT, through the strain

relief.

Disconnect the internal (BLACK) dryer harness ground 5.

wire from the (GREEN) ground screw next to the terminal

block.

Attach the ground (GREEN) power cord wire to the 6.

cabinet with the ground (GREEN) screw. Tighten the

screw securely.

Move the internal dryer harness ground (BLACK) wire to 7.

the terminal block and attach it along with the neutral

(WHITE) power cord wire conductor to the center, SILVER

colored terminal on the terminal block. Tighten the screw

securely.

Attach the RED and BLACK power cord conductors to 8.

the outer, BRASS colored terminals on the terminal block.

Tighten both screws securely.

- ELECTRICAL SHOCK HAZARD - Do not

make a sharp bend or crimp wiring/conductor at connections.

Access cover

screw

Terminal

block

Line 2

(BRASS terminal)

Neutral

(SILVER terminal)

Line 1

(BRASS terminal)

Internal ground

(GREEN screw)

Install

UL-approved

strain relief here

Terminal screw

recovery slot

If a terminal screw falls during cord installation, it

can be retrieved in the terminal screw recovery slot below the

access panel.

Move internal ground (BLACK)

wire to neutral (SILVER)

terminal for 4-wire system.

Neutral

terminal

Follow manufacturer’s guidelines for fi rmly securing the 9.

strain relief and power cord.

Reinstall the terminal block cover.10.

12

GREEN

ground screw

GREEN

ground wire

WHITE

neutral wire

BLACK

or RED

power wire

BLACK or

RED power wire

Page 13

General installation

Grounding type

ll receptacle

wer cord with

3-prong grgr

ounded plug

Do not,

under

y cir

cumstances,

cut,

removeve,

or b

ypass the

ounding pr

ong.

Connect the exhaust duct to the outside exhaust system 1.

(see pages 4 through 6). Use of a 4” (10.2 cm) clamp (item

A) is recommended to connect the dryer to the exhaust

vent system. Use metal foil tape to seal all other joints.

Carefully slide the dryer to its fi nal position. Adjust one or 2.

more of the legs until the dryer is resting solidly on all four

legs. Place a level on top of the dryer. The dryer MUST be

level and resting solidly on all four legs. Rock alternating

corners to check for stability. Remove and discard door

tape.

Be sure the power is off at a circuit breaker/

fuse box before plugging the power cord into an outlet.

Plug the power cord into a grounded outlet.3.

Turn on the power at the circuit breaker/fuse box.4.

Read the5. Use & Care Guide provided with the dryer. It

contains valuable and helpful information that will save

you time and money.

If you have any questions during initial operation, please 6.

review the “Avoid Service Checklist” in your Use & Care

Guide before calling for service.

Place these instructions in a location near the dryer for 7.

future reference.

A

A wiring diagram and technical data sheet are

located inside the dryer console.

Grounding type

wawall receptacl

PoPower cord with

3-prong

Do not,

anany cir

cut,

remo

or b

ypass th

grgrounding pr

ounded plug

under

cumstances,

ong.

13

Page 14

Window Door Reversal Instructions

Figure 1

1.Open door and remove four (4) plugs in the door opening

opposite the hinges. Retain all parts for uses later, unless

otherwise noted. (Figure 1) Note: Use care in removing plugs

in not scratching paint on the front panel.

Figure 2

2. Begin removing the four (4) screws that attach the hinge to

the front panel. (Figure 2) For best results, start by only

removing one screw per hinge. Then only loosen the two

remaining screws while firmly holding door to prevent damage

to hinge, front panel or door. After the remaining screws are

loosened, continue to remove all.

Figure 4

5. Remove two (2) door handle screws and two (2) hole plugs

from door. Again taking care not to scratch paint on door.

(Figure 4)

Figure 5

6. Pull handle away from door assembley. (Figure 5)

Figure 3

3. Place door on a towel or pad handle side down to prevent

any possible scratches to door. Remove all remaining four (4)

screws between hinge and door. (Figure 3)

4. Remove four (4) screws from side of door opposite of where

hinge was mounted.

Figure 6

7. Separate the outer door from the inner door assembly with

a putty knife or flat screw driver. (Figure 6)

14

Page 15

Figure 7

8. Remove lens locating screw. (Figure 7)

9. Disengaging several of the retention tabs and pull lens away

from the transition ring. (Figure 8)

Figure 8

11. Reassemble lens to transition ring with holes to install

handle on right-hand side of door assembly. For proper fit

insure the retention tabs on transition ring are on top of lens

Figure 11

12. Reassembly outer door to inner door assembly. (Figure 11)

13. Install four (4) screws securing hinge to door assembly in

the new location, take note to place hinge in correct

orientation.

14. Install four (4) screws into holes that had secured the

hinge.

15. Remove striker and discard.

16. Remove square plug and reinstall in hole striker was just

removed.

17. Install striker (included in literature bag) into hole square

plug was previously installed.

Figure 9

Figure 10

10. Remove two (2) transition ring plugs and reinstall on

previous handle side. (Figures 9 and 10)

Figure 12

18. Reinstall door handle by placing the handle mounting

bosses through holes in lens and transition ring and installing

screws through inner door and tighten into handle bosses.

(Figure 12).

19. Grasping firmly the top of the door, position the door near

the door opening and align the top hinge hole to the top hole

in the front panel door opening. Once the first screw is started,

attach the second screw to the lower hinge. Once both screws

are tightened, install the remaining two screws.

20. Install four (4) plugs into the front panel door opening

where hinges were originally installed.

15

Page 16

26.44”

(67.16cm)

15.00”

(38.10cm)

27.00”

(68.58cm)

Accessories

MATCHING STORAGE PEDESTAL

White Pedestal - P/N NLPWD15

Black Pedestal - P/N NLPWD15E

A storage pedestal accessory, specifi cally designed for this

dryer may be used to elevate the dryer for ease of use. This

pedestal will add about 15” (38 cm) to the height of your

unit for a total height of 51.25” (130 cm).

DRYER STACKING KIT

P/N 134700600

Depending on the model you purchased, a kit for stacking

this dryer on top of matching washer may have been

included in the initial purchase of your dryer. If your model

did not include a stacking kit or you desire another stacking

kit, you may order one.

LP CONVERSION KIT

P/N PCK4200

Gas dryers intended for use in a location supplied with LP

must use a conversion kit prior to installation.

MOBILE HOME INSTALLATION KIT

P/N 137067200

Installations in mobile homes require use of MOBILE HOME

INSTALLATION KIT.

Failure to use accessories manufactured by (or

approved by) the manufacturer could result in personal injury,

property damage or damage to the dryer.

27.00”

(68.58cm)

15.00”

(38.10cm)

26.44”

(67.16cm)

DRYING RACK

P/N 137067300

Depending on the model you purchased, a drying rack may

have been included in the initial purchase of your dryer.

If your model did not include a drying rack or you desire

another drying rack, you may order one.

UNIVERSAL APPLIANCE WRENCH

P/N 137019200

A UNIVERSAL APPLIANCE WRENCH is available to aid in

dryer/washer/pedestal feet adjustment.

TOUCH UP PAINT PENS

White Touch Up Pen - P/N 5303321319

Black Touch Up Pen - P/N 5304458932

Replacement parts: 1-800-944-9044 (in Canada 1-800-265-8352)

If replacements parts are needed for your dryer, contact

the source where you purchased your dryer, call 1-800944-9044 (in Canada 1-800-265-8352), or visit our

website, www.frigidaire.com, for the Frigidaire Authorized

Parts Distributor nearest you.

- ELECTRICAL SHOCK HAZARD - Label all

wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous operation. Verify

proper operation after servicing.

16

Page 17

Índice

Instrucciones importantes de seguridad ...............................17

Requisitos de preinstalación ................................................17

Requisitos de instalación ............................................... 18-22

Dimensiones de la lavadora instalada ..................................23

Instrucciones de instalación ........................................... 24-28

Inversión de la puerta .................................................... 29-30

Accesorios/Piezas de repuesto .............................................31

Instrucciones importantes de seguridad

Para su seguridad, debe seguir la información de esta guía para minimizar el riesgo de incendio o

explosión o para evitar daños a la propiedad, lesiones personales o incluso la muerte. No almacene ni utilice gasolina ni otros

líquidos o vapores infl amables cerca de este o de cualquier otro electrodoméstico.

Identifi cación de los símbolos, palabras y avisos de

seguridad

Las indicaciones de seguridad incluidas en este manual

aparecen precedidas de un aviso titulado “ADVERTENCIA” o

“PRECAUCIÓN”, de acuerdo con el nivel de riesgo.

- PELIGRO DE INCENDIO - Lea las siguientes instrucciones antes de instalar y utilizar este electrodoméstico:

Después de desembalar la secadora, destruya los cartones y las bolsas de plástico. Los niños podrían utilizarlos para jugar. Los •

cartones cubiertos con alfombras, cubrecamas, o láminas de plástico pueden convertirse en cámaras de aire herméticamente

cerradas y provocar asfi xia. Coloque todos los materiales en un basurero o manténgalos fuera del alcance de los niños.

La instalación y el servicio de la secadora de ropa deben ser llevados a cabo por un instalador califi cado, agencia de servi-•

cios o proveedor de gas.

Instale la secadora de ropa de acuerdo con las instrucciones del fabricante y los códigos locales.•

La reparación eléctrica de la secadora debe cumplir con los códigos y las ordenanzas locales y la última edición del Código •

Eléctrico Nacional (National Electrical Code), el ANSI/NFPA 70, o bien en Canadá, el CSA C22.1 del Código Eléctrico de

Canadá (Canadian Electrical Code) Parte 1.

El servicio de gas de la secadora debe cumplir con los códigos y las ordenanzas locales, y la última edición del Código de •

Gas Nacional (National Fuel Gas Code), el ANSI Z223.1, o bien en Canadá, el CAN/CGA B149,1-2000.

La secadora se diseñó conforme a los códigos ANSI Z 21.5.1 o ANSI/UL 2158 - CAN/CSA C22.2 N.º 112 (últimas edicio-•

nes) solo para USO DOMÉSTICO. No se recomienda esta secadora para uso comercial, como por ejemplo, en restaurantes,

salones de belleza, etc.

No utilice materiales de ventilación de plástico ni de papel de aluminio fl exibles para instalar la secadora de ropa. Por lo •

general, dichos materiales se desarman, se deterioran con facilidad y acumulan pelusa. Estas condiciones obstruyen el

fl ujo de aire de la secadora y aumentan el riesgo de incendio.

Las instrucciones de esta guía y todo el material que se incluye con esta secadora no tienen como propósito cubrir todas •

las condiciones y situaciones que puedan presentarse. Cuando instale, opere o repare cualquier artefacto DEBE tener cuidado y hacer uso de buenas prácticas de seguridad.

situaciones que pueden causar lesiones personales graves, la

muerte o daños materiales.

nes que pueden causar lesiones personales o daños materiales.

Este símbolo le advierte sobre

Este símbolo le advierte sobre situacio-

QUÉ HACER SI SIENTE OLOR A GAS:

No intente encender ningún electrodoméstico.•

No toque ningún interruptor eléctrico; no utilice ningún teléfono en la vivienda.•

Despeje la habitación, el edifi cio o el área de todos los ocupantes.•

Llame inmediatamente a su proveedor de gas desde el teléfono de un vecino. Siga las instrucciones del proveedor de gas.•

Si no puede ponerse en contacto con el proveedor de gas, llame a los bomberos.•

Conserve estas instrucciones para referencia futura.

Requisitos de preinstalación

Herramientas y materiales necesarios para la instalación:

Pinzas ajustables•

Destornilladores Philips con punta •

derecha y cuadrada

Llave ajustable•

Llave para tubos de suministro de gas •

Cinta aislante resistente al gas LP •

(para suministro de gas natural o LP)

Nivel de carpintero•

Capucha de ventilación externa•

Conducto de escape de metal rígido •

o semirígido de 4 pulgadas (10 cm)

Kit de cables de alimentación trifi lar o te-•

trafi lar de 240 voltios (secadora eléctrica)

Abrazadera de 4” (10,2 cm)•

Válvula de cierre de línea de gas (se-•

cadora a gas)

Adaptadores NPI de unión acampana-•

da (x2) y línea fl exible de suministro de

gas (secadora a gas) de ½’ (15,2 cm)

Cinta de papel aluminio (no cinta •

adhesiva aislante)

17

Page 18

Requisitos del sistema eléctrico

Tom

acorriente con

puesta a tierra

ninguna circunstancia.

No corte, retire ni

deshabilite la clavija de

conexión a tierra bajo

Cordón eléctrico de 3 clavijas

con puesta a tierra

Debido a posibles variaciones en el voltaje, no se recomienda utilizar esta secadora con electricidad generada a

partir de generadores a gas, solares, eólicos ni de ninguna otra clase que no sean los empleados por su empresa de electricidad local.

Requisitos eléctricos de la secadora eléctrica:

CIRCUITO: circuito independiente individual de 30 amp. con fusibles de acción retardada o disyuntores. Use circuitos con

fusibles separados para la lavadora y la secadora. NO haga funcionar una lavadora y una secadora en el mismo circuito.

SUMINISTRO ELÉCTRICO: trifi lar o tetrafi lar, 240 V, 1 fase, 60 Hz, corriente alterna.

A menos que haya sido fabricada para la venta en Canadá, esta secadora está conectada a tierra internamente a

través de un enlace a un conductor neutro. La conexión a tierra a través del neutro está prohibida para: (1) instalaciones de circuitos de

bifurcación nuevos; (2) casas rodantes; (3) vehículos recreativos; y (4) áreas cuyas leyes locales no permiten la puesta a tierra a través del

neutro.

RECEPTÁCULO DEL TOMACORRIENTE - receptáculo NEMA 10-30 R o NEMA 14-30 R que debe estar ubicado en un lugar al

que pueda acceder el cable de alimentación eléctrica cuando la secadora esté instalada.

CONEXIÓN A TIERRA: consulte “Requisitos de conexión a tierra” en la sección Instalación eléctrica.

CABLE DE ALIMENTACIÓN ELÉCTRICA TRIFILAR (no

incluido)

Receptáculo trifi lar

(tipo NEMA 10-30R)

La secadora DEBE emplear un cable de alimentación

eléctrica de 3 conductores tipo NEMA 10-30, SRDT

califi cado para CA mínima de 240 voltios, 30 amp., con 3

conectores de terminal horquilla con extremos doblados

hacia arriba o de bucle cerrado y califi cados para uso en

secadoras de ropa. Para obtener instrucciones sobre la

conexión trifi lar, consulte CONEXIONES ELÉCTRICAS PARA

UN SISTEMA TRIFILAR.

Requisitos eléctricos de la secadora a gas:

CIRCUITO - Circuito individual de bifurcación de 15 amp.,

correctamente polarizado y con conexión a tierra con fusible

de retardo de 15 amp. o con interruptor automático.

SUMINISTRO ELÉCTRICO: corriente alterna de 2 cables, con

conexión a tierra, 120 voltios, monofásica, 60 Hz.

CABLE DE ALIMENTACIÓN ELÉCTRICA: la secadora está

CONEXIÓN A TIERRA: consulte “Requisitos de conexión a tierra”

equipada con un cable de alimentación trifi lar de 120 voltios.

en la sección Instalación eléctrica.

CABLE DE ALIMENTACIÓN ELÉCTRICA TETRAFILAR (no

incluido)

Receptáculo tetrafi lar

(tipo NEMA 14-30R)

La secadora DEBE emplear un cable de alimentación

eléctrica de 4 conductores tipo NEMA 14-30, SRDT o

ST (según se especifi que) califi cado para CA mínima

de 240 voltios, 30 amp., con 4 conectores de terminal

horquilla con extremos doblados hacia arriba o de bucle

cerrado y califi cados para uso en secadoras de ropa.

Para obtener instrucciones sobre la conexión tetrafi lar,

consulte CONEXIONES ELÉCTRICAS PARA UN SISTEMA

TETRAFILAR.

Las secadoras fabricadas para la venta en Canadá vienen con un cable de alimentación eléctrica tetrafi lar (NEMA

14-30R) de fábrica.

Tom

acorriente con

puesta a tierr

No corte, retire ni

deshabilite la clavija de

conexión a tierra bajo

ninguna circunstancia.

Cordón eléctrico de 3 clavijas

con puesta a tierra

1818

Page 19

Requerimientos del suministro de gas

- PELIGRO DE EXPLOSIÓN - Las tube-

rías de cobre sin recubrimiento se corroen al exponerse al gas

natural, lo que provoca pérdidas de gas. Utilice SOLAMENTE

tuberías de hierro negro, acero inoxidable o latón plastifi cado

para el suministro de gas.

1.

La instalación DEBE realizarse de acuerdo con los códigos

locales o, en ausencia de ellos, con el Código de Gas

Nacional (National Fuel Gas Code), ANSI Z223.1 (última

edición).

2. La línea de suministro de gas debe ser un tubo de 1,27 cm

(1/2 pulgada).

3. Si los códigos lo permiten, se puede utilizar un tubo de

metal fl exible para conectar la secadora a la línea de

suministro de gas. La tubería DEBE ser de acero inoxidable

o de latón plastifi cado.

Requisitos del sistema de escape

Utilice solo un conducto de metal fl exible o rígido de 10,2

cm (4 pulgadas) de diámetro (mínimo) y una capucha de

ventilación aprobada que tenga uno o más reguladores de

tiro que se abran cuando la secadora esté en funcionamiento.

Cuando la secadora se detiene, el regulador de tiro se

cierra automáticamente para evitar la corriente de aire y el

ingreso de insectos y roedores. Para evitar restringir la salida

del conducto, mantenga un espacio mínimo de 30,5 cm

(12 pulgadas) entre la capucha de ventilación y el suelo, o

cualquier otra obstrucción.

4. La línea de suministro de gas DEBE tener una válvula de

cierre individual.

5. Se DEBE instalar una derivación N.P.T de 0,32 cm (1/8

pulgadas) con tapón roscado, que permita conectar

un medidor de prueba, inmediatamente después de

la conexión de suministro de gas a la secadora, en

contracorriente al fl ujo de gas.

6. La secadora DEBE estar desconectada de la tubería de gas

durante cualquier prueba en la que la presión exceda los

3,45 kPa (1/2 psig).

7. La secadora DEBE estar aislada de la tubería de gas

durante cualquier prueba en la que la presión sea igual o

inferior a 3,45 kPa (1/2 psig).

8. Las conexiones del suministro de gas deben cumplir con

la norma de conexiones de electrodomésticos a gas, ANSI

Z21.24.

- PELIGRO DE INCENDIO - El no

seguir estas instrucciones puede producir tiempos de secado

excesivos y peligro de incendio.

Los siguientes son requisitos necesarios para el

funcionamiento seguro y correcto de su secadora.

- PELIGRO DE INCENDIO - No utilice

materiales de ventilación de plástico ni de papel de aluminio

fl exibles para instalar la secadora de ropa. Por lo general,

dichos materiales se desarman, se deterioran con facilidad y

acumulan pelusa. Estas condiciones obstruyen el fl ujo de aire

de la secadora y aumentan el riesgo de incendio.

Si su sistema actual está compuesto de un conducto de

plástico o papel de aluminio, reemplácelo por un conducto

de metal rígido o semirígido. Asegúrese de que el conducto

existente no tenga pelusas antes de instalar el conducto de la

secadora.

Correcto Incorrecto

Correcto Incorrecto

19

Page 20

Requisitos del sistema de escape (continuación)

- PELIGRO DE INCENDIO - Una seca-

dora de ropa debe tener ventilación al exterior. No ventile la

secadora a una chimenea, pared, techo, ático, pasajes entre

pisos ni ningún espacio oculto de la vivienda. Las secadoras

de ropa producen pelusa combustible. Si la secadora no tiene

ventilación al exterior, algunas pelusas fi nas se expulsarán en

el área de lavandería. La acumulación de pelusa en cualquier

área de la vivienda puede constituir un peligro sanitario y un

riesgo de incendio.

La secadora debe estar conectada a un sistema de escape que

termine en el exterior de la vivienda. Inspeccione la abertura

de escape al exterior con frecuencia y elimine cualquier

acumulación de pelusa en la abertura y en el área que la

rodea.

- PELIGRO DE INCENDIO -

No permita que materiales combustibles (por ejemplo: •

ropa, tapicería/cortinas, papel) entren en contacto con

el sistema de escape. La secadora NO DEBE tener escape

a una chimenea, una pared, un techo ni ningún espacio

cerrado de un edifi cio que pueda acumular pelusa y constituir un peligro de incendio.

No bloquee los extremos de escape del sistema de ven-•

tilación, ni utilice tornillos, remaches ni otros sujetadores

que se extiendan hacia la parte interna del conducto para

ensamblarlo. Es posible que la pelusa quede atrapada en

el fi ltro, los tornillos o los remaches, lo que puede obstruir

la red de conductos y constituir un peligro de incendio,

así como también aumentar los tiempos de secado. En la

salida del conducto al exterior, utilice una capucha de ventilación aprobada y selle todas las uniones con cinta para

conductos. Todos los accesorios macho para tubos DEBEN

instalarse teniendo en cuenta el fl ujo de aire.

- PELIGRO DE INCENDIO - Si se exce-

de la longitud del tubo del conducto o el número de codos

permitidos en las tablas de “LONGITUD MÁXIMA”, se pueden acumular pelusas en el sistema de escape. La obstrucción

del sistema podría constituir un peligro de incendio, así como

aumentar los tiempos de secado.

Cantidad de codos de 90°

Conducto de metal rígido de 10,2 cm (4 pulgadas)

(recomendada)

4”

(10,2 cm)

0 19.5 m (64 pies) 14.6 m (48 pies)

1 15.9 m (52 pies) 12.2 m (40 pies)

2 13.5 m (44 pies) 9.8 m (32 pies)

3 9.8 m (32 pies) 7.3 m (24 pies)

4 9.5 m (28 pies) 4.9 m (16 pies)

LONGITUD MÁXIMA

TIPO DE CAPUCHA DE VENTILACIÓN

aberturas de

ventilación

- PELIGRO DE INCENDIO -

2.5”

(6,35 cm)

No utilice material de ventilación fl exible de plástico o •

aluminio.

Si va a instalar conductos de ventilación semirrígidos, no •

exceda una longitud de 8 pies (2,4 m).

Instale los accesorios macho en la dirección

correcta:

- PELIGRO DE INCENDIO -

No permita que materiales combustibles (por ejemplo: •

ropa, tapicería/cortinas, papel) entren en contacto con

el sistema de escape. La secadora NO DEBE tener escape

a una chimenea, una pared, un techo ni ningún espacio

cerrado de un edifi cio que pueda acumular pelusa y constituir un peligro de incendio.

No bloquee los extremos de escape del sistema de ven-•

tilación, ni utilice tornillos, remaches ni otros sujetadores

que se extiendan hacia la parte interna del conducto para

ensamblarlo. Es posible que la pelusa quede atrapada en

el fi ltro, los tornillos o los remaches, lo que puede obstruir

la red de conductos y constituir un peligro de incendio,

así como también aumentar los tiempos de secado. En la

salida del conducto al exterior, utilice una capucha de ventilación aprobada y selle todas las uniones con cinta para

conductos. Todos los accesorios macho para tubos DEBEN

instalarse teniendo en cuenta el fl ujo de aire.

20

CORRECTO

INCORRECTO

Page 21

Requisitos del sistema de escape (continuación)

En instalaciones en las que el sistema de escape no se

describa en las tablas, se debe utilizar el siguiente método

para determinar si dicho sistema es aceptable:

1. Conecte un manómetro inclinado o digital entre la

secadora y el punto donde el tubo de escape se conecta

con la secadora.

2. Coloque el temporizador y la temperatura de la secadora

en la opción Air fl uff - cool down (Esponjado con aire,

enfriamiento) y ponga en marcha la secadora.

3. Lea la medición del manómetro.

4. La contrapresión del sistema NO DEBE ser mayor que 2,5

cm (1 pulgada) de columna de agua. Si la contrapresión

del sistema es menor que 2,5 cm (1 pulgada) de

columna de agua, el sistema es aceptable. Si la lectura

del manómetro es mayor que 2,5 cm (1 pulgada) de

columna de agua, el sistema es demasiado restrictivo y la

instalación es inaceptable.

Si bien la orientación vertical del sistema de escape es

aceptable, ciertas circunstancias atenuantes podrían afectar el

funcionamiento de la secadora:

Sólo se debe utilizar una red de conductos de metal rígido.•

Si la ventilación se efectúa en forma vertical a través del •

techo, es posible que el sistema de escape se vea expuesto

a ráfagas descendentes que restringirán la ventilación.

Si el sistema de escape se extiende a través de un área •

que no está aislada, puede producirse condensación y una

acumulación más rápida de pelusa.

La compresión o los pliegues del sistema de escape •

aumentarán la restricción de la ventilación.

Se debe inspeccionar y limpiar el sistema de escape cada •

18 meses como mínimo cuando se le da un uso normal.

Cuanto más utilice la secadora, más a menudo deberá

comprobar que el sistema de escape y la capucha de

ventilación funcionan correctamente.

Dirección del escape

El escape direccional se puede lograr mediante la instalación

de un codo de ventilación de giro rápido de 90° directamente

en la salida de la secadora. Los codos de ventilación de la

secadora se encuentran disponibles a través de su distribuidor

de repuestos o ferretería local.

Consulte también los REQUISITOS DE DESPEJE en la siguiente

página.

Utilice un codo de giro rápido de 90° para cumplir

con la profundidad mínima de instalación de la secadora

independiente.

La ventilación derecho hacia atrás permite la instalación de •

la secadora a 0" (0 cm) de la pared.

La ventilación hacia la derecha con un codo de 90° permite •

la instalación de la secadora a

La ventilación hacia abajo con un codo de 90° permite la •

instalación de la secadora a

La ventilación hacia la izquierda con un adaptador recto corto •

y un codo de 90° permite la instalación a 3.75" (9.5 cm) de

la pared.

La ventilación hacia arriba con un adaptador recto corto y •

un codo de 90° permite la instalación a 4" (10.2 cm) de la

pared.

0.75" (2 cm)

0.75" (2 cm)

de la pared.

de la pared.

Instalación en una casa rodante

La instalación DEBE cumplir con la actual Norma de 1.

Seguridad y Construcción de Casas Rodantes, título 24

CFR, Parte 32-80 (que anteriormente se conocía como

la Norma Federal de Seguridad y Construcción de Casas

Rodantes [Federal Standard for Mobile Home Construction

and Safety], título 24, HUD parte 280) o la Norma CAN/

CSAZ240 MH.

La secadora DEBE tener evacuación al exterior (no a la 2.

parte de abajo de la casa rodante) mediante conductos

metálicos que no admitan combustión. Los conductos

metálicos deben tener un diámetro de 10,16 cm (4

pulgadas) y no deben presentar obstrucciones. Se

recomiendan los conductos de metal rígido.

Si la secadora tiene evacuación a través del piso, y el 3.

área debajo de la casa rodante es cerrada, el sistema de

evacuación DEBE terminar fuera del espacio cerrado y el

extremo debe quedar sujetado fi rmemente a la estructura

de la casa rodante.

Para obtener información sobre otros requisitos 4.

importantes del sistema de escape, consulte las secciones

anteriores de esta guía.

Cuando se instale una secadora a gas en una casa 5.

rodante, se debe dejar espacio en el exterior para la salida

de aire. Este espacio debe ser por lo menos el doble del

área de la salida de escape de la secadora.

El técnico de instalación DEBE anclar esta secadora (1) 6.

o secadora sobre pedestal (2) al piso usando un kit de

instalación para casas rodantes, pieza número 137067200.

21

Page 22

Requisitos de despeje

- PELIGRO DE EXPLOSIÓN - No insta-

le la secadora en el mismo lugar en el que haya o se almacene gasolina u otros productos infl amables. Si la secadora

se instala en un garaje, debe estar a una altura mínima de

45,7 cm (18 pulgadas) por encima del suelo. De lo contrario,

podría producirse una explosión, un incendio, quemaduras o

incluso la muerte.

NO INSTALE LA SECADORA:

En una zona expuesta a la humedad o a las condiciones 1.

climáticas externas.

En un área en la que esté en contacto con cortinas, telas 2.

colgantes o cualquier otra cosa que pueda obstruir el

fl ujo de aire de ventilación y combustión.

Sobre una alfombra. El piso DEBE ser fi rme con una pen-3.

diente máxima de 2,54 cm (1 pulgada).

INSTALACIÓN EN UN NICHO O ARMARIO

1. Una secadora instalada en un dormitorio, baño, nicho o

armario, DEBE tener ventilación al exterior.

2. No se debe instalar ningún otro artefacto de combustión

en el mismo armario que la secadora a gas.

3. La secadora necesita espacio a su alrededor para que la

ventilación sea adecuada.

NO instale la secadora en un armario con puerta maciza.

4. Ventilación requerida en la puerta del armario: Se necesita

un mínimo de 774,2 cm² (120 pulgadas²) de abertura,

dividido en partes iguales en la parte superior e inferior

de la puerta. Las aberturas de ventilación deben estar

ubicadas a 7,6 cm (3 pulgadas) de la parte superior e

inferior de la puerta. Es necesario que las aberturas de

aire no estén obstruidas al instalar una puerta. Se acepta

una puerta que tenga aberturas de ventilación distribuidas

uniformemente en toda la superfi cie.

ESPACIOS MÍNIMOS PARA LA INSTALACIÓN: cm (pulgadas)

LATERALES

PARTE

TRASERA

PARTE

SUPERIOR

PARTE

DELANTERA

Alcôve 0 cm (0”) 0 cm (0”) 0 cm (0”) n/d

Sous

le comptoir

0 cm (0”) 0 cm (0”) 0 cm (0”) n/d

Placard 0 cm (0”) 0 cm (0”) 0 cm (0”) 2,54 cm (1”)

Para otra que no sea la ventilación recta hacia atrás, se debe *

instalar un codo de ventilación de giro rápido de 90° para

lograr una instalación de 0 cm (0”).

0”

(0cm)

0”

(0cm)

1”

(2.54cm)

0”

(0cm)

3”

(7.6cm)

3”

(7.6cm)

puerta del armario

60 sq. in.

(387.1cm²)

60 sq. in.

(387.1cm²)

Para lograr una instalación con 0 cm (0”) de despeje

en la parte trasera de la secadora (para otra que no sea la

ventilación hacia atrás), se debe instalar un codo de ventilación de giro rápido de 90° según se describe anteriormente

en esta guía.

22

Page 23

Dimensiones de la secadora instalada

48.25” (122.5cm)*

para destapar

abra la puerta

secadora independiente

sobre el piso

línea del piso

30.5” (77.5cm)*

al frente de la puerta cerrada

51.25”

(130cm)

36.0”

(91.5cm)

tubería de

suministro

de gas en

la parte

trasera de la

unidad de gas

1.6”

(4cm)

27.0”

(68.5cm)

suministro

eléctrico

en la parte

trasera de

la unidad

altura de la

línea central

para

ventilación

trasera

3.7”

(9.5cm)

secadora colocada sobre

pedestal opcional

línea del piso

* Para obtener estas dimensiones mínimas de profundidad, la secadora debe ser ventilada

derecho hacia atrás. Si se usa un codo de giro rápido de 90° (hacia la derecha o hacia abajo

en la secadora independiente), se agregan aproximadamente 0.75" (2.0 cm) a la profundidad

de instalación. Si se orienta el escape de la secadora independiente o sobre un pedestal hacia

arriba, la profundidad de instalación aumentará aproximadamente en 4" (10.2 cm). Si se orienta el

escape de la secadora independiente o sobre un pedestal hacia la izquierda, la profundidad de

instalación aumentará aproximadamente en 3.75" (9.5 cm). Si se orienta el escape de la secadora sobre

un pedestal hacia abajo, la profundidad de instalación aumentará aproximadamente en 2.25" (5.7 cm).

48.25” (122.5cm)*

para destapar

abra la puerta

30.5” (77.5cm)*

al frente de la puerta cerrada

71.5”

(182cm)

16.9”

(43cm)

3.75”

(9.5cm)

tubería de

suministro

de gas en

la parte

trasera de la

unidad de gas

13.50”

(34.5cm)

hacia el centro de

la ventilación trasera

27.0”

(68.5cm)

19.0”

(48cm)

suministro

eléctrico

en la parte

trasera de

la unidad

altura de la

línea central

para

ventilación

trasera

37”

(94cm)

* Para obtener estas dimensiones mínimas de profundidad, la secadora debe ser ventilada derecho hacia atrás. Si se usa un codo de 90° (hacia la derecha),

se agregan aproximadamente 0.75" (2 cm) a la profundidad de instalación. Si se orienta el escape de la secadora instalada sobre la lavadora hacia arriba, la

profundidad de instalación aumentará aproximadamente en 4" (10,2 cm). Si se orienta el escape de la secadora instalada sobre la lavadora hacia abajo, la

profundidad de instalación aumentará aproximadamente en 2.25" (6.5 cm). Si se orienta el escape de la secadora instalada sobre la lavadora hacia la

izquierda, la profundidad de instalación aumentará aproximadamente en 3.75" (9.5 cm).

39”

(99cm)

23

Page 24

Instalación eléctrica

Los siguientes son requisitos necesarios para la instalación

eléctrica segura y correcta de su secadora. El no seguir estas

instrucciones puede producir una descarga eléctrica y/o incendio.

- PELIGRO DE DESCARGA ELÉCTRICA -

Este electrodoméstico DEBE estar debidamente conec-•

tado a tierra. Si la secadora no está conectada a tierra

correctamente, se pueden producir descargas eléctricas.

Siga las instrucciones de esta guía para ver cómo se realiza una correcta conexión a tierra.

No utilice un cable de extensión con esta secadora. Algu-•

nos cables de extensión no están diseñados para soportar

la cantidad de corriente eléctrica que utiliza esta secadora y pueden derretirse, lo que constituye un peligro de

descarga eléctrica y/o incendio. Ubique la secadora en un

lugar donde el cable de alimentación que compre esté al

alcance del receptáculo, permitiendo que el cable quede

holgado. Consulte los requisitos de preinstalación de esta

guía para ver cuál es el cable de alimentación correcto

que se debe comprar.

Debe instalarse, en el cable de alimentación, un disposi-•

tivo de liberación de tensión aprobado por U.L. Si no se

coloca un dispositivo de liberación de tensión, el cable

podría desenchufarse de la secadora y cortarse por cualquier movimiento, y provocar así una descarga eléctrica.

No utilice un receptáculo con cableado de aluminio para •

un enchufe y cable de alimentación con cables de cobre

(o viceversa). La reacción química que tiene lugar entre el

cobre y el aluminio puede causar cortocircuitos eléctricos.

El receptáculo y el cableado correcto consiste en un cable

de alimentación con alambres de cobre con un receptáculo de cables de cobre.

Las secadoras que funcionan con 208 voltios de corriente eléctrica tendrán tiempos de secado más prolongados

que las que funcionan con 240 voltios de corriente eléctrica.

- PELIGRO DE DESCARGA ELÉCTRICA -

Requisitos de conexión a tierra: secadora eléctrica (Estados Unidos)

- PELIGRO DE DESCARGA ELÉCTRICA -

Una conexión incorrecta del conductor de conexión a tierra del

equipo puede provocar un peligro de descarga eléctrica. Si no

está seguro de haber realizado correctamente la conexión a

tierra del artefacto, consulte a un electricista autorizado.

Para una secadora conectada a tierra:

1. La secadora DEBE tener conexión a tierra. En el caso

de que la secadora no funcione correctamente o se

descomponga, la conexión a tierra reduce el riesgo de

descarga eléctrica porque ofrece una trayectoria de menor

resistencia para la corriente eléctrica.

2. Después de comprar e instalar un cable de alimentación

trifi lar o tetrafi lar con un conductor de conexión a tierra,

el enchufe DEBE estar conectado a un receptáculo

adecuado con cable de cobre correctamente instalado y

con conexión a tierra, de acuerdo con todos los códigos y

las ordenanzas locales. Ante cualquier duda, comuníquese

con un electricista autorizado.

NO realice modifi caciones al enchufe que haya instalado en

este artefacto.

Para una secadora conectada de forma permanente:

1. La secadora DEBE estar conectada a un sistema de

cableado permanente de metal conectado a tierra, o bien

se debe colocar un conductor de conexión a tierra con

los conductores del circuito y debe estar conectado al

terminal de conexión a tierra del equipo o al cable a tierra

del artefacto.

Requisitos de conexión a tierra: secadora eléctrica (Canadá)

- PELIGRO DE DESCARGA ELÉCTRICA -

Una conexión incorrecta del conductor de conexión a tierra del

equipo puede provocar un peligro de descarga eléctrica. Si no

está seguro de haber realizado correctamente la conexión a

tierra del artefacto, consulte a un electricista autorizado.

Para una secadora conectada a tierra:

1. La secadora DEBE tener conexión a tierra. En el caso

de que la secadora no funcione correctamente o se

descomponga, la conexión a tierra reduce el riesgo de

descarga eléctrica porque ofrece una trayectoria de menor

resistencia para la corriente eléctrica.

2. Debido a que la secadora está equipada con un cable de

alimentación eléctrica que cuenta con un conductor de

conexión a tierra, el enchufe debe estar conectado a un

tomacorriente correctamente instalado y con conexión a

tierra, de acuerdo con todos los códigos y las ordenanzas

locales. Ante cualquier duda, comuníquese con un

electricista autorizado.

NO realice modifi caciones al enchufe que se proporciona con

este artefacto.

24

Page 25

Requisitos de conexión a tierra: secadora a gas (Estados Unidos y Canadá)

Tom

acorriente con

puesta a tierra

ninguna circunstancia.

No corte, retire ni

deshabilite la clavija de

conexión a tierra bajo

Cordón eléctrico de 3 clavijas

con puesta a tierra

La secadora está equipada con un enchufe de tres patas 1.

(conexión a tierra) para evitar el peligro de electrocución

y debe estar conectada directamente a un receptáculo

de enchufe de tres patas que cuente con una conexión a

tierra adecuada.

El enchufe debe estar conectado a un tomacorriente 2.

correctamente instalado y con conexión a tierra, de

acuerdo con todos los códigos y las ordenanzas locales.

Tom

acorriente con

puesta a tierr

No corte, retire ni

deshabilite la clavija de

conexión a tierra bajo

ninguna circunstancia.

Ante cualquier duda, comuníquese con un electricista

autorizado.

NO corte ni retire la espiga de conexión a tierra del enchufe.

Cordón eléctrico de 3 clavijas

con puesta a tierra

Conexión de gas

Quite el tapón del tubo de gas en la parte trasera de la 1.

secadora.

NO conecte la secadora al servicio de gas

LP sin convertir la válvula de gas. El kit de conversión a gas LP

debe ser instalado por un técnico califi cado.

Conecte un tubo aprobado o uno semi-rígido de 1,27 2.

cm (1/2 pulgada) de diámetro interior desde la línea

de suministro de gas al tubo de 0,96 cm (3/8 pulgada)

ubicado en la parte trasera de la secadora. Utilice un

reductor de 1,27 cm a 0,96 cm (1/2 pulgada a 3/8

pulgada) para realizar la conexión. Aplique un sellador

para roscas que sea resistente a la acción corrosiva de los

gases licuados en todas las conexiones de los tubos.

doble

FLUJO DE GAS

Conector

exible

Conector

doble

Tubo de admisión

en la parte posterior

de la secadora

Válvula

de cierre

manual

Cerrado

Abierto

Todas las conexiones deben estar ajustadas con llave

equipada con una válvula de cierre manual aprobada. Esta

válvula debe estar ubicada en la misma habitación que la secadora, en una ubicación que permita la facilidad de apertura

y cierre. No bloquee el acceso a la válvula de cierre de gas.

Conector

Conector

La línea de suministro de gas debe estar

Abra la válvula de cierre de la línea de suministro de 3.

gas para que el gas fl uya a través de la tubería. Espere

unos minutos a que el gas fl uya a través de la línea de

suministro de gas.

hacia la secadora

desde el suministro de gas

Válvula de cierre:

posición abierta

Utilice un manómetro para verifi car que no haya fugas 4.

en el suministro de gas. Si no cuenta con un manómetro,

pruebe todas las conexiones aplicando agua jabonosa en

estas.

- PELIGRO DE EXPLOSIÓN - NUNCA

compruebe si hay fugas de gas con una llama abierta.

25

Page 26

Conexión eléctrica (fuera de Canadá): trifi lar

Connexión

tierra interna

(tornillo VERDE)

Instale aquí un

dispositivo de

liberación de tensión

aprobado por U.L.

Ranura de

recuperación de

tornillos del terminal

Línea 1

(terminal de

LATÓN)

Neutro

(terminal

PLATEADA)

Línea 2

(terminal de

LATÓN)

Tornillo de

cubierto

de acceso

Tablero de

terminales

Neutro

(cable central)

30 AMP

NEMA 10-30

¡NO retire la conexión

interna a tierra

en los sistemas trifilares!

Terminal

neutro

Receptáculo trifi lar

(tipo NEMA 10-30R)

- PELIGRO DE DESCARGA ELÉCTRICA -

El no desconectar el suministro eléctrico antes de realizar

cualquier reparación puede ocasionar lesiones personales o

incluso la muerte.

30 AMP

NEMA 10-30

Neutro

(cable central)

Desconecte el suministro eléctrico del tomacorriente. 1.

Extraiga el tornillo que sujeta la cubierta de acceso del 2.

bloque terminal que se encuentra en la esquina inferior

de la parte trasera de la secadora.

Instale un dispositivo de liberación de tensión aprobado 3.

por U.L., de acuerdo con las instrucciones relativas

al cable de alimentación/dispositivo de liberación de

tensión del fabricante, en el orifi cio de entrada del cable

de alimentación debajo del panel de acceso. En este

momento, el dispositivo de liberación de tensión debe

estar holgadamente en su lugar.

Pase un cable de alimentación aprobado por U.L. 4.

DESENCHUFADO, de 30 amp. tipo NEMA 10-30, SRDT a

través del dispositivo de liberación de tensión.

Conecte el conductor neutro (cable del centro) del cable 5.

de alimentación al terminal PLATEADO del centro del

bloque terminal. Ajuste el tornillo con fi rmeza.

Conecte los dos conductores externos restantes del cable 6.

de alimentación a los terminales externos de color LATÓN

del bloque terminal. Ajuste los dos tornillos con fi rmeza.

Tornillo de

cubierto

de acceso

Tablero de

terminale

Línea 2

(terminal de