Page 1

2 7 ” ( 6 9 c m) W i d e

LAUND RY CENT ER

Washer - Dryer

Installation Instr uctions

CENTRO DE LAVANDERÍA

de 27" (69 cm) de ancho

Lavadora - Secadora

Instrucciones para la instalación

Table Of Contents

SUBJECT PAGE

Pre-Installation Requirements...............................2

Electrical Requirements..........................................3

Water Supply Requirements ....................................3

Drain Requirements.................................................3

Exhaust System Requirements .................................4-5

Gas Supply Requirements ...........................................5

Location...................................................................5

Rough-ln Dimensions.............................................6

Mobile Home Installation...........................................7

Unpacking..............................................................7

Electrical Installation.................................................8

Grounding Requirements.........................................8

3 & 4-Wire Connections ............................................9

Installation.......................................................10-11

Replacement Parts.................................................11

P/N 134897500B (0904) www.frigidaire.com

MATERIA PAGINA

Requerimientos de instalación preliminares....................12

Requerimientos eléctricos...........................................13

Requerimientos del suministro de agua..........................13

Requerimientos de desagüe..........................................13

Requerimientos del sistema de escape.....................14-15

Requerimientos del suministro de gas.............................15

Ubicación.......................................................................15

Dimensiones para la instalación.....................................16

Instalación en casas móviles........................................17

Desembalaje........................................................................17

Instalación eléctrica.....................................................18

Requerimientos para la puesta a tierra...........................18

Conexiónes eléctricas - trifilares y tetrafilares..........18-19

Instalación..............................................................19-20

Repuestos...................................................................20

1

Indice

Page 2

IMPORTANT SAFETY INSTRUCTION

This is the safety alert symbol. This symbol alerts you to hazards that can kill or hurt you or others. All safety messages will

be preceded by the safety alert symbol and the word "DANGER" or "WARNING". These words mean:

DANGER

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell you what can happen if the

instructions are not followed.

explosion or to prevent property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors

and liquid in the vicinity of this or any other appliance.

Read all of the following instructions before installing and using this appliance.

• Destroy the carton and plastic bags after the Laundry Center is unpacked. Children might use them for play. Cartons

covered with rugs, bedspreads, or plasic sheets can become airtight chambers causing suffocation. Place all materials in a

garbage container or make materials inaccessible to children.

• Installations must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or license by the state,

province, or region where this appliance is being installed.

• Before beginning installation, carefully read these instructions. This will simplify the installation and ensure the Laundry Center

is installed correctly and safely. Leave these instructions near the Laundry Center after installation for future reference.

• The electrical service to the Laundry Center must conform with local codes and ordinances and the latest edition of the National

Electrical Code, ANSI/NFPA 70, or in Canada, the Canadian electrical code C22.1 part 1.

• The gas service to the Laundry Center must conform with local codes and ordinances and the latest edition of the National Fuel

Gas Code ANSI Z223.1, or in Canada, CAN/ACG B149.1-2000.

• The Laundry Center is designed under ANSI Z 21.5.1 or ANZI/UL 2158 - CAN/CSA C22.2 No. 112 (latest editions) for HOME

USE only. This Laundry Center is not recommended for commercial applications such as restaurants or beauty salons, etc.

• Do not install a Laundry Center with flexible plastic venting materials. Flexible venting materials are known to collapse, be

easily crushed and trap lint. These conditions will obstruct clothes dryer airflow and increase the risk of fire.

• Your safety and the safety of others is very important. We have provided many important safety messages in the

Installation Instructions / Use & Care Guide and on your appliance. Always read and obey all safety messages.

• The instructions in this manual and other literature included with this dryer are not meant to cover every possible condition and

situation that may occur. Good safe practice and caution MUST be applied when installing, operating and maintaing any

appliance.

You can be killed or seriously injured if you don't immediately follow instructions.

can be killed or seriously injured if you don't follow instructions.

You

For your safety the information in this manual must be followed to minimize the risk of fire or

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building or area of all occupants.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for Installation:

• Adjustable pliers.

• Phillips, straight, & square bit screwdrivers.

• Adjustible wrench.

• Pipe wrench for gas supply (gas dryer).

• LP-resistant thread tape (for natural

gas or LP supply, gas dryer)

• Carpenter's level.

• External vent hood.

• Rigid or semi-rigid metal 4 inch

(10.2 cm) exhaust duct work.

• 3-wire or 4-wire 240 volt corg kit

(electric dryer).

2

• 4 in. (10.2 cm) clamp.

• Gas line shutoff valve (gas dryer).

• ½ NPT union flare adapters (x2) and

flexible gas supply line (gas dryer).

• Metal foil tape not (duct tape).

Page 3

ELECTRICAL REQUIREMENTS

ELECTRIC Laundry Center

CIRCUIT - Individual 30 amp. branch circuit fused with 30

amp. time delay fuses or circuit breakers.

Use separately fused circuits for washers and dryers, and DO

NOT operate a washer and a dryer on the same circuit.

NOTE: Do not under

any circumstances

remove grounding

prong from plug.

POWER SUPPLY - 3 wire or 4-wire, 240 volt, single phase, 60

Hz, Alternating Current.

POWER SUPPLY CORD KIT - 3 wire - the dryer MUST employ

a 3-conductor power supply cord NEMA 10-30 type SRDT rated

at 240 volt AC minimum, 30 amp., with 3 open end spade lug

connectors with upturned ends or closed loop connectors and

marked for use with clothes dryers. See ELECTRICAL

CONNECTIONS FOR A 3-WIRE SYSTEM.

4 wire - The dryer MUST employ a 4-conductor power supply

cord NEMA 14-30 type SRDT or ST (as required) rated at 240

volt AC minimum, 30 amp., with 4 open end spade lug

connectors with upturned ends or closed loop connectors and

marked for use with clothes dryers. See ELECTRICAL

CONNECTIONS FOR A 4-WIRE SYSTEM.

(Canada - 4-wire power supply cord is installed on dryer.)

WARNING – Risk of Shock. Appliance grounded to neutral

conductor through a link. Grounding through the neutral link is

prohibited for (1) New branch circuit installations (2) mobile

homes; (3) recreational vehicles; and (4) areas where local codes

do not permit grounding through the neutral, (1) disconnect the

link from the neutral, (2) use grounding terminal or lead to

ground appliance in accordance with local codes and (3) connect

neutral terminal or lead to branch circuit neutral in usual manner

(if the appliance is to be connected by means of a cord kit, use

4-conductor cord for this purpose). USE COPPER CONDUCTOR

ONLY.

Grounding Prong

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within 42 inches

(106.68 cm) of your laundry center’s water inlet. The faucets

MUST be 3/4 inch (1.9 cm) garden hose type so inlet hoses can

be connected. Water pressure MUST be between 10 and 120

pounds per square inch (maximum unbalance pressure, hot vs.

cold, 10 psi). Your water department can advise you of your

water pressure.

DRAIN REQUIREMENTS

1. Drain capable of eliminating 17 gals. per minute.

2. A standpipe diameter of 1¼ inches (3.18 cm) minimum.

3. The standpipe height above the floor should be:

Minimum height: 33 inches (83.82 cm)

Maximum height: 96 inches (244 cm)

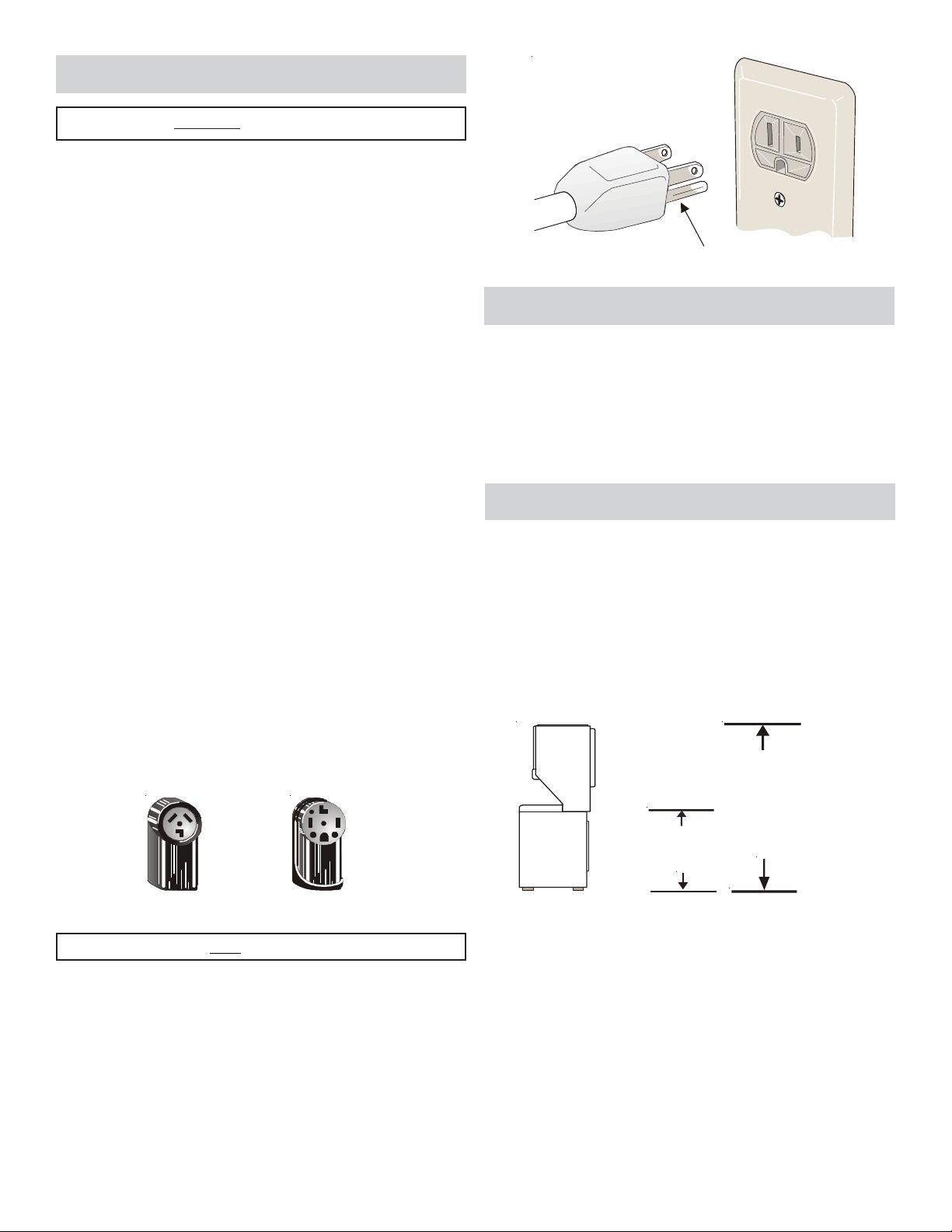

OUTLET RECEPTACLE - NEMA 10-30R receptacle to be located

so the power supply cord is accessible when the dryer is in the

installed position. (Canada - NEMA 14-30R receptacle.)

NEMA 10-30R NEMA 14-30R

GAS Laundry Center

CIRCUIT - Individual 15 amp minimum branch circuit fused with

a time delay fuse or circuit breaker.

POWER SUPPLY -3 wire, 120 volt single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD -The gas laundry center is equipped

with a 120 volt 3-wire power cord.

96"Max.96"Max.

96"Max.

96"Max.96"Max.

(244 cm)(244 cm)

(244 cm)

(244 cm)(244 cm)

33" Min.33" Min.

33" Min.

33" Min.33" Min.

(83.82cm)(83.82cm)

(83.82cm)

(83.82cm)(83.82cm)

NOTE: For installations requiring a longer drain hose, have a

qualified technician install a longer hose, PIN 134049201,

available from an authorized parts distributor. For drain systems

in the floor, install a siphon break kit, available from your local

hardware store .

3

Page 4

EXHAUST SYSTEM REQUIREMENTS

Use only 4 inch (10.2 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When the

dryer stops, the dampers automatically close to prevent drafts

and the entrance of insects and rodents. To avoid restricting the

outlet, maintain a minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground or any other obstruction.

The following are specific requirements for

proper and safe operation of your dryer. Failure to follow

these instructions can create excessive drying times and

fire hazards.

Do not install a clothes dryer with flexible

plastic venting materials. If your present system is made up

of plastic duct or metal foil duct, replace it with a rigid or flexible

metal duct. Flexible venting materials are known to collapse,

be easily crushed and trap lint. These conditions will obstruct

clothes dryer airflow and increase the risk of fire. Ensure the

present duct is free of any lint prior to installing dryer

duct.

INCORRECT

INCORRECT

Do not allow combustible materials (for

example: clothing, draperies/curtains, paper) to come in

contact with exhaust system. The dryer MUST NOT be

exhausted into a chimney, a wall, a ceiling, or any concealed

space of a building which can accumulate lint, resulting in a fire

hazard.

Exceeding the length of duct pipe or number

of elbows allowed in the "MAXIMUM LENGTH" charts can

cause an accumulation of lint in the exhaust system. Plugging

the system could create a fire hazard, as well as increase drying

times.

Do not screen the exhaust ends of the vent

system, nor use any screws, rivets or other fastening means

that extend into the duct and catch lint to assemble the

exhaust system. Lint can become caught in the screen, on the

screws or rivets, clogging the duct work and creating a fire hazard

as well as increasing drying times. Use an approved vent hood

to terminate the duct outdoors, and seal all joints with duct

tape. All male duct pipe fittings MUST be installed downstream

with the flow of air.

Explosion hazard. Do not install the dryer

where gasoline or other flammables are kept or stored. If

the dryer is installed in a garage, it must be a minimum of 18

inches (45.7 cm) above the floor. Failure to do so can result in

death, explosion, fire or burns. The exhaust system back pressure

MUST not exceed 0.6 inches (1.52 cm) of water column,

measured with an inclined manometer at the point the exhaust

connects to the dryer. The exhaust system should be inspected

and cleaned a minimum of every 18 months with normal

usage. The more the dryer is used, the more often you should

check the exhaust system and vent hood for proper operation.

CORRECT

CORRECT

- Risk of Fire - A clothes dryer must be

exhausted outdoors. Do not exhaust dryer into a chimney, a

wall, a ceiling, an attic, a crawl space or any concealed space

of a building. A clothes dryer produces combustible lint. If the

dryer is not exhausted outdoors, some fine lint will be expelled

into the laundry area. An accumulation of lint in any area of the

home can create a health and fire hazard. The dryer must be

connected to an exhaust outdoors. Regularly inspect the

outdoor exhaust opening and remove any accumulation of lint

around the outdoor exhaust opening and in the surrounding

area.

The maximum length of the exhaust system depends upon the

type of duct used, number of elbows and type of exhaust hood.

The maximum length for both rigid and flexible duct is shown in

the chart below.

EXHAUST DUCT LENGTHS

EXHAUST HOOD TYPE

Number

of 90°

Tur ns

4”

(10.2 CM)

MAXIMUM LENGTH OF 4-INCH (10.2 CM)

DIAMETER RIGID METAL DUCT

0

1

2

3

56 ft. (17.07 m)

46 ft. (14.02 m)

34 ft. (10.36 m)

32 ft. (9.75 m)

Louvered

42 ft. (12.8 m)

36 ft. (10.97 m)

28 ft. (8.53 m)

18 ft. (5.48 m)

2.5”

(6.35 CM)

Do not install flexible plastic or flexible foil venting

material. If installing semi-rigid venting, do not exceed 8 ft.

(2.4m) duct length.

4

Page 5

The laundry center may be exhausted four (4) ways with rear

flush installation:

1. Straight back

2. Down (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid

duct and 1 elbow down)

3. Left (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid

duct, 1 elbow down and 1 elbow left)

4. Right (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid

duct, 1 elbow down and 1 elbow right)

To exhaust up, add an 11 inch (27.94 cm) length of standard 4

inch (10.16 cm) diameter duct and a 90° elbow. The unit will

be positioned about 4½ inches (11.43 cm) away from the wall

(flush to wall exhausting may be done by going below the dryer

then sideways).

An exhaust hood positioned

to line up with the dryer

exhaust can be installed

directly through the outside

wall. To exhaust to the side

or down, add an 8 inch

(20.32 cm) length of standard

4 inch (10.16 cm) diameter

duct and a 90° elbow.

GAS SUPPLY REQUIREMENTS

1.Installation MUST conform with local codes, or in the absence

of local codes, with the National Fuel Gas Code, ANSI Z223.1

(latest edition) or in Canada, the current AN/CGA B149.

2.The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3.If codes allow, flexible metal tubing may be used to connect

your dryer to the gas supply line. The tubing MUST be

constructed of stainless steel or plastic-coated brass.

4.The gas supply line MUST have an individual shutoff valve.

5.A 1/8 inch (0.32 cm) N. P. T. plugged tapping, accessible for

test gage connection, MUST be installed immediately

upstream of the gas supply connection to the dryer.

6.The dryer and its individual shutoff valve MUST be

disconnected from the gas supply piping system during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.45 kPa).

7.The dryer MUST be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2 psig (3.45 kPa).

LOCATION OF YOUR LAUNDRY CENTER

DO NOT INSTALL YOUR LAUNDRY CENTER:

1.In an area exposed to dripping water or outside weather conditions.

2.In an area where it will come in contact with curtains or drapes.

3.On carpet. Floor MUST be solid with a maximum slope of 1 inch (2.54 cm).

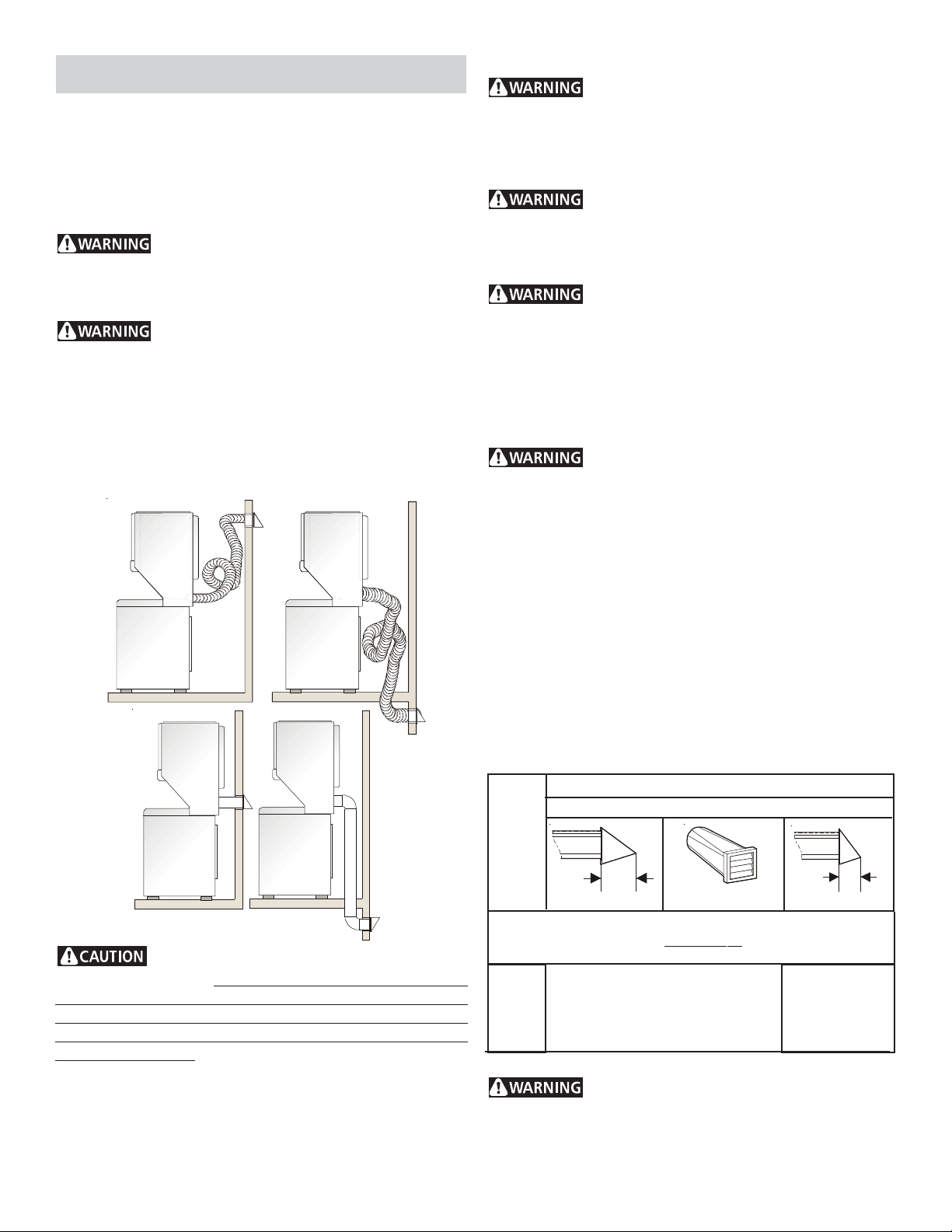

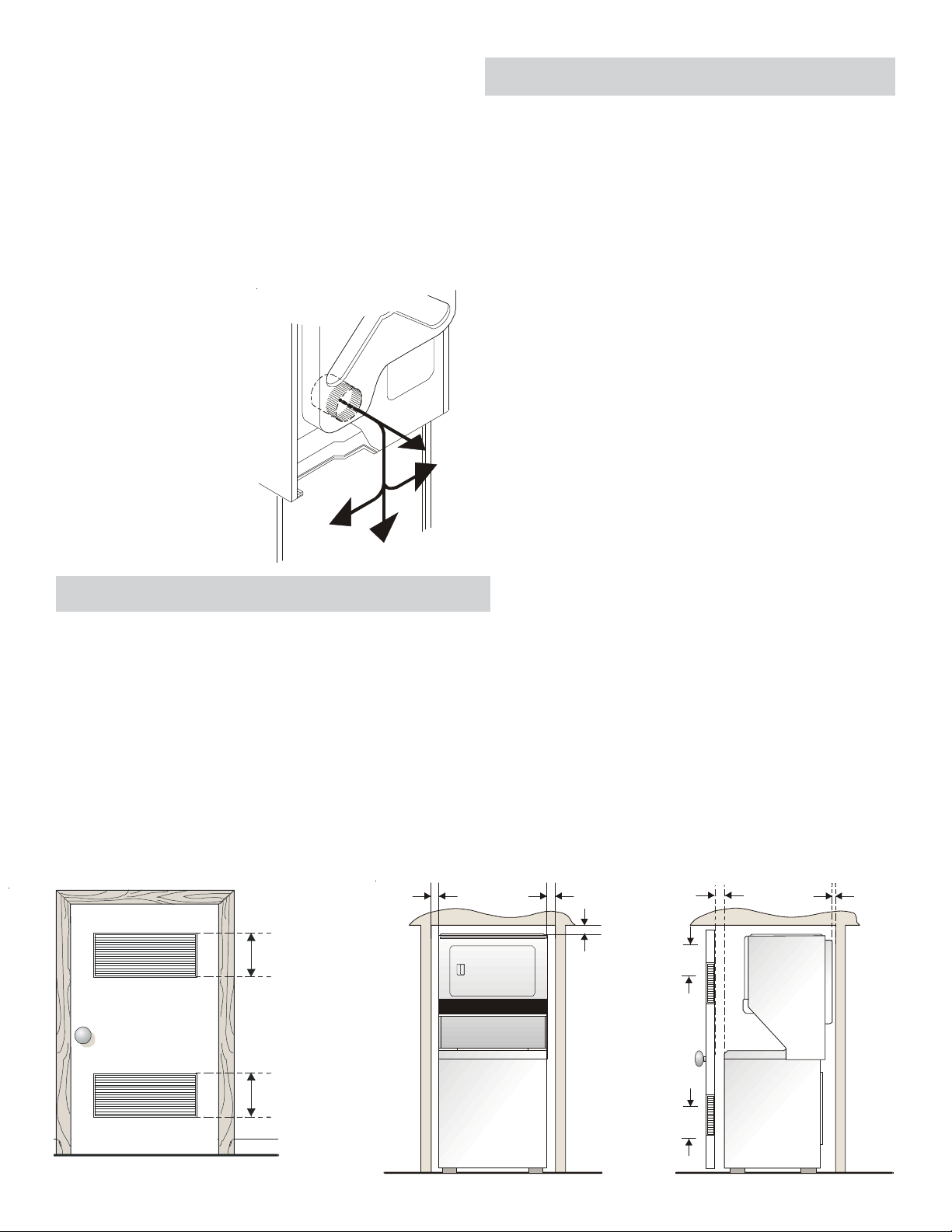

INSTALLATION IN RECESS OR CLOSET

1.A laundry center installed in a bedroom, bathroom, recess or closet, MUST be exhausted outdoors.

2.No other fuel burning appliance shall be installed in the same closet as the Gas laundry center.

3.Your laundry center needs the spacearound it for proper ventilation.

DO NOT INSTALL YOUR LAUNDRY CENTER IN A CLOSET WITH A SOLID DOOR.

4.A minimum of 120 square inches (774.2 square cm) of opening, equally divided at the top and bottom of the door, is required.

Air openings are required to be unobstructed when a door is installed. A louvered door with equivalent air openings for the full

length of the door is acceptable.

5.The following illustrations show minimum clearance dimensions and air openings for proper operation in a recess or closet

installation.

60 SQ. IN.

(387.1 SQ. CM)

0 IN.

(0 C M)

0 IN.

(0 C M)

DRYER

1 IN.

(2.54 C M)

60 SQ. IN.

(387.1 SQ. CM)

0 IN.

(0 C M)

Closet Door

60 SQ. IN.

(387.1 SQ. C M)

WASHER

60 SQ. IN.

(387.1 SQ. CM)

5

Page 6

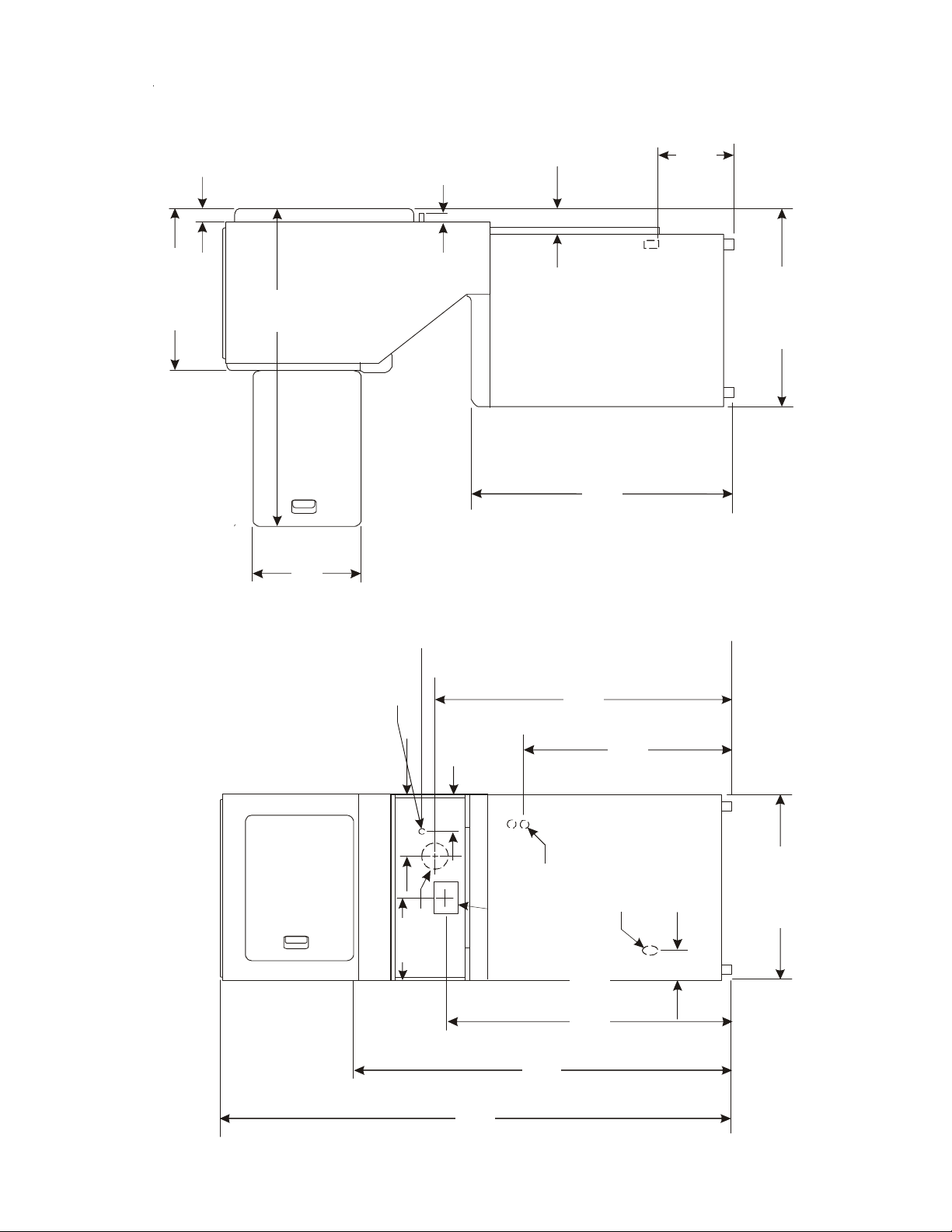

2 ½ IN.

(6.35 CM)

1 7/8 IN.

4 13/16 IN.

(4.76 CM)

(12.22 CM)

11 7/16 IN.

(29.5 CM)

25 ¼ IN.

(64.13 CM)

47“

16 ¼ IN.

(41.27 CM)

ROUGH-IN DIMENSIONS

PIPE (REAR)

GAS SUPPLY

5 ¼ IN.

(13.33 CM)

(78.26 CM)

30 13/16 IN.

36 1/16IN.

(91.60 CM)

43 IN.

(109.22 CM)

41 ¼ IN

(104.77 CM)

29 7/16 IN

(74.77 CM)

9 3/8 IN.

(23.81 CM)

(REAR)

DRAIN OUTLET

VENT

12 ½ IN.

(31.75 CM)

75 ½ IN.

ELECTRICAL

CONNECTION

(191.77 CM)

WATER INLETS

54 5/16 IN.

(137.95 CM)

(REAR)

43 IN.

(109.22 CM)

3 ¾ IN.

(9.52 CM)

27 IN.

(68.58CM)

6

Page 7

MOBILE HOME INSTALLATION

1.Dryer MUST be exhausted outside (outdoors, not beneath the mobile

home) using metal ducting that will not support combustion. Metal

ducting must be 4 inches (10.16 cm) in diameter with no obstructions.

Rigid metal duct is preferred.

2.If dryer is exhausted through the floor and area beneath the mobile

home is enclosed, the exhaust system MUST terminate outside the

enclosure with the termination securely fastened to the mobile home

structure.

3.Refer to page 4 for other important venting requirements.

4.When installing a gas dryer into a mobile home, a provision must be

made for outside make up air. This provision is to be not less than twice

the area of the dryer exhaust outlet.

5.Installation MUST conform to current Manufactured Home Construction

& Safety Standard (which is a Federal Regulation Title 24 CFR-Part 32-

80) or when such standard is not applicable, with American National

Standard for Mobile Homes. In Canada, the CSA Z240 is applicable.

WARN ING

The laundry center is designed under ANSI Z 21.5.1for HOME USE only.

UNPACKING

1. Using the four shipping carton corner posts (two on each

side), carefully lay the laundry center on its left side and

remove foam shipping base.

AUTION

C

people to move Laundry Center.

2. Using a ratchet with 3/8 inch (0.96 cm) socket, remove the

mechanism shipping bolt and plastic spacer block from the

center of the base.

NOTE: If the laundry center is to be transported at a later

date, the tub blocking pad, shipping bolt, and plastic

spacer block should be retained.

PLASTIC SPAC ER

BLOC K

Excessive weight. Use two or more

3. Return laundry center to an upright position.

4. Remove:

(a) foam tub blocking pad.

(b) tape from dryer door.

(c) foam dryer support pads.

(d) inlet hoses.

(e ) enclosure package.

5. From the back of the washer, remove the wire shipping clips

securing the drain hose and power cord (if equipped).

Plastic clamps secure the drain hose to the right side of the

washer backsheet. These clamps form a standpipe to prevent

water syphoning. DO NOT REMOVE THESE CLAMPS.

6. Carefully move the laundry center to within 4 feet (1.22 m)

of the final location to begin the installation.

MECHANISM

SHIPPING

BOLT

FOAM

SHIPPING

PA D

SHIPPING CARTON CORNER POSTS

POWER CORD

(IF EQUIPPED)

DRAIN HOSE

7

Page 8

ELECTRICAL INSTALLATION

GROUNDING REQUIREMENTS

ALL ELECTRIC Laundry Centers

WARNING

The following are specific requirements for

proper and safe electrical installation of your laundry center.

Failure to follow these instructions can create electrical shock

and/or a fire hazard.

WARNING

Electrical shock can result if the laundry center is not properly

grounded. Follow the instructions in this manual for proper

grounding.

WARNING

laundry center. Some extension cords are not designed to

withstand the amounts of electrical current this laundry center

utilizes and can melt, creating electrical shock and/or fire hazard.

Locate the laundry center within reach of the receptacle for the

length power cord to be purchased, allowing some slack in the

cord. Refer to the pre-installation requirements in this manual

for the proper power cord to be purchased.

WARNING

installed onto power cord. If the strain relief is not attached, the

cord can be pulled out of the laundry center and can be cut by

any movement of the cord, resulting in electrical shock.

This appliance MUST be properly grounded.

Do not use an extension cord with this

A U.L. approved strain relief must be

Non-Canadian ELECTRIC Laundry Center

DANGER

grounding conductor can result in a risk of electrical shock.

Check with a licensed electrician if you are in doubt as to whether

the appliance is properly grounded.

For a grounded, cord-connected laundry center:

1. The laundry center MUST be grounded. In the event of

malfunction or breakdown, grounding will reduce the risk of

electrical shock by a path of least resistance for electrical

current.

2. If your laundry center is equipped with a power supply cord

having an equipment-grounding conductor and a grounding

plug, the plug MUST be plugged into an appropriate, copper

wired receptacle that is properly installed and grounded in

accordance with all local codes and ordinances. If in doubt,

call a licensed electrician. Do not modify plug provided

with the appliance.

For a permanently connected laundry center:

The laundry center MUST be connected to a grounded metal,

permanent wiring system; or an equipment grounding conductor

MUST be run with the circuit conductors and connected to the

equipment-grounding terminal or lead on the appliance.

Improper connection of the equipment

Canadian ELECTRIC Laundry Center

WARNING

Do not use an aluminum wired receptacle

with a copper Wired power cord and plug (or vice versa). A

chemical reaction occurs between copper and aluminum and

can cause electrical shorts.

The proper wiring and receptacle is a copper wired power

cord with a copper wired receptacle OR aluminum wired

power cord with an aluminum wired receptacle.

NOTE: Laundry centers operating on a 208 volt power supply

will have longer drying times than laundry centers operating on

a 240 volt power supply.

DANGER

grounding conductor can result in a risk of electrical shock.

Check with a licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

For a grounded cord connected laundry center:

1. The laundry center MUST be grounded. In the event of

malfunction or breakdown, grounding will reduce the risk of

electrical shock by providing a path of least resistance for

the electrical current.

2. Since your laundry center is equipped with a power supply

cord having an equipment-grounding conductor and a

grounding plug, the plug MUST be plugged into an

appropriate outlet that is properly installed and grounded in

accordance with all codes and ordinances. If in doubt, call a

licensed electrician.

Improper connection of the equipment

ALL GAS Laundry Centers

1. The laundry center is equipped with a three-prong (grounding)

plug for your protection against shock hazard and should

be plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong from

the plug.

8

Page 9

ELECTRICAL CONNECTIONS

FOR A 3-WIRE SYSTEM

ELECTRICAL CONNECTIONS

FOR A 4-WIRE SYSTEM

NON-CANADIAN ELECTRIC Laundry Center

1. Remove the screw securing the

terminal block access cover to

the rear panel and remove cover.

2. Install a U.L. approved strain

relief connector in the entry

hole on the back panel.

3. Insert a NEMA 10-30 Type SRDT,

U.L. approved power cord through the strain relief.

4. Attach the power cord neutral (central wire) conductor to

the silver colored center terminal on the terminal block.

Tighten the screw securely.

GREEN GROUND SCREW

NEUTRAL

GROUND

WIRE

SILVER TERMINAL

NON-CANADIAN ELECTRIC Laundry Center

1. Remove the screw securing the

terminal block access cover to the

rear panel and remove cover.

2. Install a U.L. approved strain relief

connector in the entry hole on the

back panel.

3. Remove the neutral ground wire from the green ground

screw located above the termial block.

NEUTRAL

GROUND

WIRE

5. Attach the remaining two power cord outer conductors to

the outer brass colored terminals on the terminal block.

Tighten both screws securely.

6. Tighten the screws securing the cord restraint against the

power cord.

7. Reinstall the terminal access cover.

4. Insert a NEMA 14-30 Type ST or SRDT, U.L. approved power

cord through the strain relief.

5. Attach the green power cord ground wire to the cabinet

with the green ground screw.

6. Attach the white (neutral) wire from the power cord and the

neutral ground wire from the appliance harness to the silver

colored center terminal on the terminal block. Tighten the

screw securely.

7. Attach the red and black wires from the power cord to the

outer brass-colored terminals on the terminal block. Tighten

both screws securely.

8. Tighten the screws securing the cord restraint firmly against

the power cord.

9. Reinstall the terminal block access cover.

9

Page 10

INSTALLATION

1. Run some water from the hot and cold faucets to flush the

water lines and remove particles that might clog up the

water valve screens.

c. Open the shutoff valve in the gas supply line.

d. Test all connections by brushing on a soapy water solution.

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

2. Check inlet hoses to ensure the rubber washers are installed

in each end.

3. Carefully connect the inlet hoses to the water valve (on the

left side of the washer cabinet), tighten by hand, then tighten

another 2/3 turn with pliers.

AUT IO N

C

4. Determine which water faucet is the HOT water faucet

and carefully connect the bottom inlet hose to the HOT

water faucet, tighten by hand, then tighten another 2/3

turn with pliers. Carefully connect the top inlet hose to the

COLD water faucet, tighten by hand, then tighten another

2/3 turn with pliers.

CAUTION

Turn the water on and check for leaks at both connections.

5. Carefully move the laundry center to its final location.

6. To ensure the laundry center is level and solid on all four

legs, tilt the laundry center forward so the rear legs are off

the ground. Gently set the laundry center back down to

allow the rear legs to self adjust. Place a level on top of the

washer. Check it side to side, then front to back. Screw

the front leveling legs up or down to ensure the laundry

center is resting solid on all four legs (no rocking of the

laundry center should exist).

NOTE: Keep the leg extension at a minimum to prevent

excessive vibration.

DO NOT CROSS THREAD OR

OVERTIGHTEN THESE CONNECTIONS.

DO NOT CROSS THREAD OR

OVERTIGHTEN THESE CONNECTIONS.

8. Form a “ U “ shape on the end of the drain hose with the

hose pointed toward the drain. Place the formed end in a

laundry tub or a standpipe and secure with a cable tie

provided in the enclosure package.

WATER WILL SYPHON FROM THE WASHER IF THE ABOVE

INSTRUCTIONS ARE NOT FOLLOWED.

Cable

Tie

9. Remove the two (2) screws securing the dryer front access

panel to the dryer cabinet. Lift the panel until the tabs can

be disengaged from the cabinet. Remove the panel and set

aside.

7. GAS CONNECTION (Gas laundry centers only)

a. Remove the shipping cap from gas pipe at the rear of the

dryer.

NOTE: DO NOT connect the laundry center to L.P. gas service

without converting the gas valve. An L.P. conversion kit must

be installed by a qualified gas technician.

b. Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or approved

pipe from the gas supply line to the 3/8 inch (0.96 cm) pipe

located on the back of the dryer. Use a 1/2 inch (1.27 cm)

to 3/8 inch (0.96 cm) reducer for the connection. Apply an

approved thread sealer that is resistant to the corrosive

action of liquefied gases on all pipe connections.

Access

Panel

Screws

10

Page 11

10. Connect the exhaust duct to outside duct work. Use duct

tape to seal all joints.

REPLACEMENT PARTS

If replacement parts are needed for your laundry center, contact

the source where you purchased your laundry center.

11. Plug the power cord into a grounded outlet.

12. Reinstall the dryer front access panel.

NOTE: Check to ensure the power is off at a circuit breaker/

fuse box before plugging the power cord into an

outlet.

13. Turn on the power at a circuit breaker/fuse box.

Before operating the dryer, make

sure the dryer area is clear and free from

combustible materials, gasoline, and other

flammable vapors. Also see that nothing (such as

boxes, clothing, etc.) obstructs the flow of

combustion and ventilation air.

14. Run the washer and dryer though a cycle. Check for proper

operation.

WARNING

band after the laundry center is unpacked. Children might use

them for play. Cartons covered with rugs, bedspreads, or plastic

sheets can become airtight chambers causing suffocation. Place

all materials in a garbage container or make materials inaccessible

to children.

servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

WARNING

literature included with this laundry center are not meant to

cover every possible condition and situation that may occur. Good

safe practice and caution MUST be applied when installing,

operating and maintaining any appliance.

Maximum benefits and enjoyment are achieved when

all the Safety and Operating instructions are understood

and practiced as a routine with your laundry tasks.

Destroy the carton, plastic bags, and metal

Label all wires prior to disconnection when

The instructions in this manual and all other

NOTE: On gas dryers, before the burner will light, it is

necessary for the gas line to be bled of air. If the burner

does not light within 45 seconds the first time the

dryer is turned on, the safety switch will shut the

burner off. If this happens, turn the timer to “OFF”

and wait 5 minutes before making another attempt to

light.

15. If your laundry center does not operate, please review the

“Avoid Service Checklist” located in your Owner’s Guide

before calling for service.

16. Place these instructions in a location near the laundry

center for future reference.

NOTE: A wiring diagram is located behind the dryer front

access panel.

11

Page 12

SEGURIDAD de CENTRO DE LAVANDARIA

Este símbolo significa alerta. Este símbolo lo alerta acerca de peligros que pueden matar o lesionar, tanto a usted como a

otras personas. Todos los mensajes de seguridad serán precedidos por el símbolo de alerta para su seguridad y la palabra "PELIGRO

o ADVERTENCIA" (DANGER” o WARNING). Estas palabras significan:

PELIGRO (DANGER) Usted morirá o resultará seriamente lesionado si no sigue las instrucciones siguientes.

ADVERTENCIA (WARNING) Usted puede morir o resultar seriamente lesionado si no sigue las

instrucciones siguientes.

Todos los mensajes de seguridad identificarán el peligro, le dirán a usted cómo reducir la posibilidad de lesión y

también qué puede suceder si no se siguen las instrucciones.

RIESGO DE INCENDIO. Para su seguridad, siga las instrucciones contenidas en este manual a fin de reducir

a un mínimo los riesgos de incendio o explosión o para evitar daños materiales, lesiones personales o la muerte. GUARDE ESTAS

INSTRUCCIONES.

• Hemos proporcionado muchos mensajes importantes para la seguridad en las Instrucciones de Operación del Manual de Uso y

Mantenimiento, las Instrucciones de Instalación y en el mismo aparato. Siempre lea y obedezca todos los mensajes para

seguridad.La instalación y el servicio de la centro de lavadaría de ropa se deben realizar por un instalador calificado, la agencia

de servicio o el surtidor de gas.

• Instale la centro de lavadaría de ropa según las instrucciones del fabricante y los códigos locales. Antes de comenzar la

instalación, lea cuidadosamente estas instrucciones. Esto simplificará la instalación y asegurará que la secadora se instale

correctamente y de manera segura. Después de completar la instalación, coloque estas instrucciones cerca de la secadora para

referencia futura.

• La alimentación eléctrica para la centro de lavadaría deberá cumplir con los códigos y reglamentos locales y con la última edición del

Código Eléctrico Nacional, ANSI/NFPA 70 o en Canadá CSA C22.1 Código Eléctrico Canadiense, Parte 1.

• La alimentación de gas para la centro de lavadaría deberá cumplir con los códigos y reglamentos locales y con la última edición del

Código Nacional para Gases Combustibles, ANSI Z223.1 o en Canadá CAN/CGA B149.12.

• La secadora está clasificada para USO DOMESTICO solamente, de acuerdo con la norma ANSI Z 21.5.1 o ANSI/UL 2158 - CAN/CSA

C22.2 No. 112 (las últimas ediciónes). Esta secadora no se recomienda para uso commercial tal como en restaurantes, salones de

belleza, etc.

• Los materiales de ventilación flexibles se pueden colapsar o apachurrar fácilmente y atrapar pelusa. Estas condiciones obstruirán la

circulación de aire de la centro de lavadaría de ropa y aumentarán el riesgo de incendio.

• No almacene ni utilice gasolina u otros vapores y líquidos inflamables en la proximidad de éste o de cualquier otro artefacto eléctrico.

• La instalación y el servicio de mantenimiento debe de realizarlos un instalador calificado, la agencia de servicios o el proveedor de

gas.

QUE DEBE HACER SI PERCIBE OLOR A GAS

• No trate de encender ningún artefacto eléctrico.

• No toque ningún interruptor eléctrico; no use ningún teléfono en su edificio.

• Haga salir a todos los ocupantes de la habitación, del edificio y del lugar.

• Llame a su proveedor de gas desde el teléfono de un vecino. Siga las instrucciones del proveedor de gas.

• Si no logra comunicarse con su proveedor de gas, llame al departamento de bomberos.

Requisitos de preinstalación

Herramientas y materiales necesarios para la instalación:

• Pinzas ajustables

• Destornilladores Philips con punta

derecha y cuadrada

• Llave ajustable

• Llave para tubos de suministro de gas

• Cinta aislante resistente al gas LP

(para suministro de gas natural o LP)

• Nivel de carpintero

• Capucha de ventilación externa

• Conducto de escape de metal rígido

o semirígido de 4 pulgadas (10 cm)

• Kit de cables de alimentación trifilar

o tetrafilar de 240 voltios (secadora

eléctrica)

• Abrazadera de 4” (10,2 cm)

12

• Válvula de cierre de línea de gas

(secadora a gas)

• Adaptadores NPI de unión acampanada

(x2) y línea flexible de suministro de

gas (secadora a gas) de ½’ (15,2 cm)

• Cinta de papel aluminio (no cinta

adhesiva aislante)

Page 13

REQUERIMIENTOS ELÉCTRICOS

Centro de lavanderia ELÉCTRICAS

Centro de lavandería a GAS

CIRCUITO - Circuito individual derivado de 15 amp mínimo, con

fusibles de retardo máximo o disyuntor.

CIRCUITO: circuito independiente individual de 30 A con fusibles

de acción retardada o disyuntores.

Use circuitos con fusibles separados para las lavadoras y

secadoras y NO haga funcionar una lavadora y una secadora

en el mismo circuito.

SUMINISTRO ELÉCTRICO: trifilar o tetrafilar, 240 V, 1 fase, 60

Hz, corriente alterna.

CABLE DE ALIMENTACIÓN ELÉCTRICA: Trifilar: la lavadoras

y secadora DEBE emplear un cable de alimentación eléctrica

de 3 conductores tipo NEMA 10-30, SRDT calificado para CA

mínima de 240 voltios, 30 A., con 3 conectores de terminal

horquilla con extremos doblados hacia arriba o de bucle cerrado

y calificados para uso en secadoras de ropa. Vea CONEXIONES

ELÉCTRICAS PARA UN SISTEMA TRIFILAR.

Tetrafilar: la secadora DEBE emplear un cable de alimentación

eléctrica de 4 conductores tipo NEMA 14-30, SRDT o ST (según

se especifique) calificado para CA mínima de 240 voltios, 30

amp., con 4 conectores de terminal horquilla con extremos

doblados hacia arriba o de bucle cerrado y calificados para uso

en secadoras de ropa. Vea CONEXIONES ELÉCTRICAS PARA

UN SISTEMA TETRAFILAR.

(Canadá - cable de alimentación eléctrica de 4 cables instalado

en la lavadoras y secadora.)

ADVERTENCIA: riesgo de choque eléctrico Electrodoméstico

puesto a tierra a través de un enlace al conductor neutro. La

puesta a tierra a través del neutro está prohibida para (1)

instalaciones de circuitos de bifurcación nuevos (2) casas

rodantes; (3) vehículos recreativos; y (4) áreas cuyas leyes locales

no permiten la puesta a tierra a través del neutro; (1) desconecte

el enlace al neutro; (2) use un terminal o cable de puesta a

tierra para realizar la conexión según las leyes locales; y (3)

conecte el terminal o cable del neutro al neutro del circuito de

bifurcación como se hace normalmente (si el electrodoméstico

se va a conectar a través de un kit de cordón eléctrico, use un

cable tetrafilar). SÓLO USE CABLES DE COBRE.

RECEPTÁCULO DEL TOMACORRIENTE: Receptáculo NEMA

10-30R (trifilar) o receptáculo NEMA 14-30R (tetrafilar) que debe

estar ubicado en un lugar al que el cable de alimentación

eléctrica pueda acceder cuando la secadora esté instalada.

ALIMENTACIÓN ELÉCTRICA - Corriente alterna, monofásica,

60 Hz, 120 voltios, trifilar.

CORDÓN ELÉCTRICO - La secadora está equipada con un cordón

eléctrico trifilar para 120 voltios.

NOTE: Do not under

NOTA: No saque por

any circumstances

ningún motivo la espiga

remove grounding

de puesta a tierra del

prong from plug.

enchufe.

Espiga de puesta a tierra

Grounding Prong

REQUERIMENTOS DE SUMINISTRO DE AGUA

Las llaves del agua caliente y fría DEBERÁN ser instaladas a no

más de 42 pulgadas (106,68 cm) de la entrada de agua de su

centro de lavandería. La boca DEBE ser de 3/4 pulgada (1,9

cm) de diámetro para que las mangueras de jardin puedan ser

conectadas. La presión de agua DEBE SER entre 10 y 120lbs./

pulg.² (la màxima diferencia entre la presión no equilibrada

del agua caliente y fría es 10lbs./pulg.²) La compañià de agua

potable puede informarle sobre le presión del agua.

REQUERIMINTOS DE DESAGÜE

1. Capacidad para desaguar 17 galones por minuto.

2. Diàmetro de la toma de agua: 1-1/4 pulgadas (3,16) como

mínimo.

3. Altura de la toma de agua sobre el piso:

Altura mínima: Altura màxima:

33 pulgadas (83,82 cm) 96 pulgadas (244 cm)

96"Max.96"Max.

96"Max.

96"Max.96"Max.

(244 cm)(244 cm)

(244 cm)

(244 cm)(244 cm)

33" Min. 33" Min.

33" Min.

33" Min. 33" Min.

(83.82cm)(83.82cm)

(83.82cm)

(83.82cm)(83.82cm)

NEMA 10-30RNEMA 10-30R

NEMA 10-30R

NEMA 10-30RNEMA 10-30R

NEMA 14-30RNEMA 14-30R

NEMA 14-30R

NEMA 14-30RNEMA 14-30R

NOTA : Para las instalaciones que requieran un tubo de màs

largo, pida a un técnico capacitado que instale un tubo màs

largo, P/N 131461201, disponsible en los disribuidores

autorizados de piezas de repuesto. Para los sistemas de drenaje

en el piso, instale un uego para detener la acción de sifón,

disponsible de una ferretería local.

13

Page 14

REQUERIMIENTOS DEL

SISTEMA DE ESCAPE

Utilice solamente ductos metálicos, rígidos o flexibles de 4"

(10,2 cm) de diámetro (mínimo) y una caperuza de salida de uso

aprobado, con registros que giren hacia afuera que se abren cuando

la secadora se encuentra en funcionamiento. Cuando la secadora

se detiene, los registros se cierran automáticamente para evitar

las corrientes de aire y la entrada de insectos y roedores. Para evitar

obstruir la salida, mantenga una altura libre mínima de 12"(30,5

cm) entre la caperuza de salida y el piso o entre cualquier otra

obstrucción.

Los siguientes requerimientos son

específicos para el funcionamiento correcto y seguro de su

secadora. El incumplimiento de estas instrucciones puede

causar prolongación excesiva del tiempo de secado y riesgos

de incendio.

No instale la centro de lavadaría con materiales de ventilación

plásticos flexibles. Los materiales de ventilación flexibles se pueden

colapsar o apachurrar fácilmente y atrapar pelusa. Estas condiciones

obstruirán la circulación de aire de la Secadora de ropa y aumentarán

el riesgo de incendio.

Si su sistema de escape actual tiene ductos de plástico o de láminas

metálicas delgadas, reemplácelo con un ducto metálico rígido o

flexible. Asegúrese de que los ductos existentes no tengan

pelusas antes de instalar el ducto de la secadora.

INCORRECT

INCORRECT

No permita que los materiales combustibles (por ejemplo: la

ropa, cortinas/cortinajes, papel) tengan contacto con los ductos.

El escape de la secadora NO DEBE dirigirse hacia el interior de

una chimenea, hacia una pared, hacia el cielo raso o hacia cualquier

otro espacio reducido del edificio, donde puede ocurrir

acumulación de pelusas y constituir un peligro de incendio.

Exceder la longitud del conducto rigido o los números de codos

permitidos en los diagramas "LARGO MÁXIMO" puede disminuir

la capacidad de exhaustación del sistema. Obstruir el conducto

puede provocar peligro de incendio, así como aumentar el tiempo

de secado.

No obstruya los extremos del tubo de ventilacion, ni utilice

tornillos, remaches u otros medios de fijación que puedan obstruir

el conducto y atrapar pelusa. Las pelusas podrían quedar atrapadas

en los filtros, en los tornillos o en los remaches, lo cual obstruiría el

sistema de escape y crearía un riesgo de incendio, así como

también prolongaría el tiempo de secado. Use una caperuza de

salida adecuada para el extremo del ducto que salga al exterior

de la vivienda y selle todas las juntas con cinta adhesiva para ductos.

Todos los accesorios de tubería machos, DEBEN ser instalados aguas

abajo del flujo de aire.

Riesgo de explosión. No instale la centro

de lavadaría donde se guarda gasolina u otros materiales

inflamables. Si la centro de lavadaríase instala en un garage, ella

debe estar por lo menos 18 pulgadas (45,7 cm) por encima del

suelo. El incumplimiento puede resultar en la muerte, explosión,

incendio, o quemaduras.

1. La constrapresión del sistema de escape NO DEBE exceder

0,6 pulgadas (1,52 cm) de columna de agua, medida con

un manómetro inclinado en la conexión del ducto de escape

a la secadora.

2. El sistema de escape debe ser inspeccionado y limpiado

cada 2 años como mínimo, bajo condiciones de uso

normal. Mientras màs se use la secadora, con mayor

frecuencia deben inspeccionarse el sistema de escape y la

caperuza de salida para verificar su buen funcionamiento.

El largo màximo sistema de escape depende del tipo de ducto

que se usa, del número de codos y del tipo de caperuza de

salida. En la tabla se muestra el largo màximo tanto para

ductos flexibles como rigidos.

CORRECT CORRECT

Riesgo de incendio - La secadora debe ser ventilada al exterior

de la vivienda. No ventile la secadora a una chimenea, pared, techo,

ático, pasajes entre pisos o cualquier espacio oculto de la vivienda.

Las secadoras de ropa producen pelusa combustible. Si no se ventila

la secadora al exterior, algunas pelusas finas se acumularán en el

área de lavandería. La acumulación de pelusa en cualquier área

de la vivienda puede constituir un peligro sanitario y un riesgo de

incendio. La secadora debe estar conectada a un sistema de

escape que termine en el exterior de la vivienda. Inspeccione

la abertura de escape al exterior con frecuencia y elimine cualquier

acumulación de pelusa en tal abertura y en el área que la rodea.

LARGO MÁXIMO del Conducto Metálico

Rigido de 4” (10,2 cm) de Diámetro

TIPO DE CAPERUZA DE SALIDA

(Preferido)

Número

de Codos

a 90°

0 56 pies (17,07 m) 42 pies (12,8 m)

1 46 pies (14,02 m) 36 pies (10,97 m)

2 34 pies (10,36 m) 28 pies (8,53 m)

3 32 pies (9,75 m) 18 pies (5,48 m)

4”

(10,2 cm)

Apersianada

Si va a instalar conductos de ventilación

semirrígidos, no exceda una longitud de 8 pies (2,4 m).

14

2½"

(6.35 cm)

Page 15

Se puede colocar el ducto de escape de cuatro (4) maneras

distíntas cuando el artefacto està instalado con el fondo paralelo

con la pared.

1. Derecho hacia atràs.

2. Hacia abajo - ducto rigido, 8 pulgadas (20.32 cm) de longitud

y 4 pulgadas (10,16 cm) de diàmetro & 1 ducto acodado

hacia abajo.

3. Hacia la izquierda - ducto rigido, 8 pilgadas (20,32 cm) de

longitud y 4 pulgadas (10,16 cm) de diàmetro, 1 ducto

acodado hacia abajo y un ducto acodado hacia la derecha.

4. Hacia la derecha - ducto rigido, 8 pulgadas (20,32 cm) de

longitud y 4 pulgadas (10,16 cm) de diàmetro, 1 ducto

acodado hacia abajo y un ducto acodado hacia la derecha.

Aungue un sistema vertical sea aceptable, algunas circunstancias

atenuantes pueden afectar el funcionamiento de la secadora:

• Se debe utilizar solamente conductos

metalicos rigidos.

• Una salida del sistema vertical en el

techo, puede exponerle a un corriente

de aire descendente y disminuir así su

capacidad de exhaustación.

• El aislante que debe atravesar el sistema

puede causar condensación y disminuir

así la capacidad de exhaustación del

sistema.

• La capacidad de exhaustación de un sistema de exhaustación

comprimido o ondulado puede disminuirse.

Para colocar el ducto de escape hacia arriba, añada un ducto

de 11 pulgadas (27,94 cm) de longitud y de 4 pulgadas (10,16

cm) de diàmetro y un ducto acodado de 90°. El artefacto

debe estar a aproximadamente 4 1/2 pulgadas (11,43 cm) de

la pared (Se puede colocar el ducto de escape paralelo con la

pared por colocarlo debajo de la secadora y dirigirlo hacia un

lado). Una caperuza de escape colocada en forma tal que se

alinie con el escape de la secadora,

puede ser instalada directamente a través de la pared exterior.

Para colocar el ducto de escape hacia arriba, añada un ducto 11

pulgadas (27,94 cm) de longitud y 4 pulgadas (10,16 cm) de

diàmetro y un ducto acodado de 90°. El artefacto debe estar a

aproximadamente 4 1/2 pulgadas (11,43 cm) de la pared (se puede

colocar el ducto de escape paralelo con la pared colocàndolo debajo

de la secadora y dirigido hacia un lado). Para permitir el escape

lateral o inferior, agregue un ducto de 8 pulgadas (20,32 cm) de

largo y 4 pulgadas (10,16 cm) de diàmetro estàndar y un codo de

90°.

REQUERIMIENTOS DEL SUMINISTRO DE GAS

1. La instalación DEBE hacerse cumplir con los códigos locales o en

ausencia de los mismos, de acuerdo con los estandares del National

Fuel Gas Code (Código Nacional para Gases Combustibles), ANSI

Z223.1 (la última editión). Para Canadá, el Estandar CAN/CGA

B149 que esté en vigor.

2. La tubería de alimentación de gas debe ser de 1/2 pulgada

(1,27 cm) de diámetro.

3. Si está permitido por los códigos locales, se puede usar tubería de

metal para conectar su secadora a la línea de suministro de gas.

La tubería DEBE ser fabricada de acero inoxidable o cobre

recubierto de plástico.

4. La tubería de alimentación de gas DEBE tener una llave de cierre

individual.

5. Una toma de 1/8 de pulgada (0,32 cm) N.P.T. accesible para

conexión del manómetro de prueba, DEBE ser instalada

inmediatamente aguas arriba de la conexión de la tubería de

alimentación de gas a la secadora.

6. La secadora DEBE ser desconectada del sistema de tuberías de

alimentación de gas durante cualquier ensayo de presión del

sistema de tuberías de alimentación de gas realizado a presiones

de prueba de más de 1/2 lbs/pulg.2 (3,45 kPa).

7. La secadora DEBE aislarse del sistema de tuberías de alimentación

de gas durante cualquier ensayo de presión del sistema de tuberías

de alimentación de gas realizado en ensayos de presión iguales o

inferiores a 1/2 lbs/pulg.2 (3,45 kPa).

UBICACIÓN DE SU LAVANDERÍA

NO INSTALE SU LAVANDERÍ:

1. En un lugar donde puede haber goteos de agua o quede expuesta a las inclemencias del tiempo.

2. En un área donde pueda entrar en contacto con cortinas, cortinajes o cualquier otra cosa que obstruya el flujo de combustión y

ventilación de aire.

3. Sobre alfombras. El piso DEBE ser firme con un desnivel máximo de 1 pulgada (2,54 cm).

INSTALACIÓN DENTRO DE UN NICHO O ARMARIO

1. Si la secadora es instalada en un dormitorio, cuarto de baño, nicho o armario, el tubo del escape DEBE ser instalado hacia el exterior.

2. No se debe instalar ningún otro artefacto que queme combustible en el mismo armario en que está instalada la secadora a Gas.

3. La secadora necesita espacio a su alrededor para una ventilación adecuada.

NO INSTALE LA SECADORA EN UN ARMARIO CON PUERTA MACIZA.

4. Se requiere como mínimo una abertura de 120 pulgadas cuadradas

(774,2 cm2), dividida

equitativamente para la

parte superior e inferior de

la puerta. Cuando se instala

una puerta, es necesario

proveer aberturas para el

aire. Una puerta

apersianada con aberturas

para el aire en todo el largo

de la puerta es aceptable.

5. Las siguientes

ilustraciónes muestran las

dimensiónes mínimas de

espacio libre que debe

existir para el buen

funcionamiento de la

secadora cuando se instala

en un nicho o en un armario.

0 IN.

(0 C M)

0 IN.

(0 C M)

DRYER

SECADORA

LAVADORA

WASHER

1 IN.

(2.54 CM)

60 SQ. IN.

Pulg.²

(387.1 SQ. CM)

60 SQ. IN.

Pulg.²

(387.1 SQ. CM)

15

0 IN.

(0 C M)

PUERPUER

TT

A DELA DEL

PUER

T

A DEL

PUERPUER

TT

A DELA DEL

ARMARIOARMARIO

ARMARIO

ARMARIOARMARIO

Closet Door

Pulg.²Pulg.²

60 SQ. IN.

Pulg.²

Pulg.²Pulg.²

(387.1 SQ. CM)

60 SQ. IN.

Pulg.²Pulg.²

Pulg.²

Pulg.²Pulg.²

(387.1 SQ. CM)

Page 16

2 ½ IN.

(6.35 CM)

1 7/8 IN.

(4.76 CM)

4 13/16 IN.

(12.22 CM)

11 7/16 IN.

(29.5 CM)

25 ¼ IN.

(64.13 CM)

47“

(78.26 CM)

30 13/16 IN.

36 1/16IN.

(91.60 CM)

16 ¼ IN.

(41.27 CM)

43 IN.

LINA DE ALIMENTATION

DE GAS (ATRAS)

GAS SUPPLY

PIPE (REAR)

(109.22 CM)

41 ¼ IN

(104.77 CM)

5 ¼ IN.

(13.33 CM)

29 7/16 IN

(74.77 CM)

DIMENSIONES PARA LA INSTALACION

9 3/8 IN.

(23.81 CM)

(REAR)

DRENAJE

ENTRADAS DE

VENT

12 ½ IN.

(31.75 CM)

CONEXIÓNES

ELECTRICAL

AGUA (ATRAS)

ELÉCTRICAS

CONNECTION

(REAR)

WATER INLETS

SALIDA AL

(9.52 CM)

3 ¾ IN.

(ATRAS)

DRAIN OUTLET

27 IN.

(68.58CM)

43 IN.

(109.22 CM)

54 5/16 IN.

(137.95 CM)

75 ½ IN.

(191.77 CM)

16

Page 17

INSTALACIÓN EN CASAS MÓVILES

1. El tubo de escape de la secadora DEBE ser instalado hacia el

exterior (El escape debe colocarse en la parte exterior y no

debajo de la casa móvil.) Debe usarse ducto de metal que no

sea combustible. El ducto de metal debe tener cuatro pulgadas

(10,16 cm) de diámetro y no tener obstrucciones. Es preferible

usar ducto de metal que sea rígido.

2. Si el tubo de escape de la secadora corre a través del piso y el

área debajo de la casa móvil es cerrada, el ducto de escape

DEBE terminar fuera del recinto, con el extremo final asegurado

en contra de la estructura de la casa móvil.

3. Al instalar una secadora de gas en una casa móvil, hay que

instalar una provisión de aire fresco suplementario. La provisión

tiene que ser más grande que dos veces el espacio del escape

de la secadora.

4. Vea las páginas 2 y 3 para otros requísitos importantes de

ventilación.

5. La instalación DEBE cumplir con las estándares aplicables de

la Manufactured Home Construction & Safety Standard Estándares de Seguridad y Construcción de Casas Prefabricadas

(Título 24 CFR - Parte 32-80 del Reglamento Federal) o cuando

dichos estándares no sean aplicables, se deben complir con

los estándares de la American National Standard for Mobile

Homes (Estándares Nacionales Americanas para Viviendas

Móviles). En Canadá se aplica el Estándar CSA Z240.

Esta secadora ha sido diseñada PARA

USO DOMESTICO solamente, de acuerdo con la norma ANSI Z

21.5.1.

DESEMBALAJE

1. Utilizando las cuatro esquineras de embarque de la caja de

cartón (dos a cada lado), coloque cuidadosamente la secadora

sobre el costado izquierdo y saque la base de espuma de

embarque.

Peso excesivo. Se necesitan dos o más

personas para mover la Lavadora.

2. Utilizando la llave de tubo de 3/8 de pulgada (0,96 cm) saque

el perno de embarque y el bloque espaciador de plàtico del

centro de la base.

NOTA: Si el centro de lavandería via ser transportada a otro

lugar a otra lugar posteriormente, conserve la espuma

de bloqueo de la tina, el perno de embarque y el

espaciador de plàstico.

3. Vuelva a colocar el centro de lavanderia en la posición vertical

Bloque

espaciador de

PLASTIC SPACER

plàstico

BLOC K

MECHANISM

Perno de

SHIPPING

embarque

BOLT

4. Saque:

(a) la pieza de espuma que bloquea la cavidad;

(b) la cinta de la puerta de la secadora;

(c) las piezas de espuma para apoyar la seadora;

(d) los tubos de entrada de agua;

(e) el paquete.

5. Saque las pinzas metàlicas del embalaje de la parte posterior

de la lavadora, que sujetan el tubo de drenaje y el cable

eléctrico. Hay abrazaderas de plàstico que sujetan el tubo

de drenaje en labo derecho del resaldo de la lavadora.

Estas abrazaderas forman una tuberîa vertical para prevenir

el sifonaje de agua. NO SAQUE ESTAS ABRAZADERAS.

6. Con cuidado, mueva el centro de lavanderia a cuatro pies

(1,22 m) de su ubicación definitiva para la instalación final.

SHIPPING C ARTON CORNER POSTS

FOAM

Espuma

SHIPPING

protectora

PA D

de embareque

17

POWER CORD

Cordon eléctrico

(IF EQUIPPED)

(si viene el equipo)

Manguera de

DRAIN HOSE

desagüe

Page 18

INSTALACIÓN ELÉCTRICA

TODAS los centro lavandoria ELÉCTRICAS

Los siguientes requerimientos son

específicos para el funcionamiento correcto y seguro de su

secadora. El incumplimiento de estas instrucciones puede

causar prolongación excesiva del tiempo de secado y riesgos

de incendio.

Este artefacto DEBE ser puesto a tierra de

manera correcta. Si la lavanderia no está debidamente puesta a

tierra se puede producir un choque eléctrico. Siga las instrucciones

indicadas en este manual para la puesta a tierra en forma correcta.

No use un cordón de extensión con esta

lavanderia. Algunos cordones de extensión no pueden soportar la

cantidad de corriente eléctrica que utiliza esta secadora y pueden

fundirse, creando un peligro de choque eléctrico y/o incendio.

Ubique la lavanderia de manera que el cordón eléctrico llegue

hasta el tomacorriente que se va a usar, dejando un poco de holgura

para el cordón. Consulte los requerimientos de instalación

preliminares indicados en este manual para el cordón eléctrico que

debe ser adquirido.

Se debe instalar un anclaje aprobado por el

U.L. para el cordón eléctrico. Si no se utiliza un anclaje para sujetar

el cordón eléctrico, éste puede salirse de la lavanderia y cortarse

con cualquier movimiento, resultando en un choque eléctrico.

No utilice un tomacorriente con cables de

aluminio con un cordón y un enchufe de cobre (o viceversa). Se

produce una reacción química entre el cobre y el aluminio que

puede causar cortacircuitos. El cableado y tomacorriente

apropiado es un cordón eléctrico equipado con conductores

de cobre con un tomacorriente con conductores de cobre.

NOTA: Las lavanderia que operan con un suministro de energía

de 208 voltios usarán más tiempo de secado que aquellas que

operan con un suministro de energía de 240 voltios.

REQUERIMIENTOS PARA LA PUESTA A TIERRA

Para una lavanderia conectada permanentemente:

1. La lavanderia DEBE ser conectada a un sistema de cableado

metálico permanente, puesto a tierra; o se debe instalar un

conductor de puesta a tierra de equipo junto con los

conductores del circuito y conectarse al borne de puesta a tierra

del equipo o al cable del artefacto.

Centro de lavanderia ELÉCTRICAS canadienses

La conexión indebida del conductor de puesta

a tierra del equipo puede ocasionar un riesgo de choque eléctrico.

Consulte con un electricista profesional si tiene alguna duda

respecto a la puesta a tierra correcta del artefacto.

Para una lavanderia puesta a tierra, con cordón eléctrico:

1. La lavanderia DEBE ser puesta a tierra.En caso de

malfuncionamiento o falla, la puesta a tierra reducirá el riesgo

de choque eléctrico proporcionando un trayecto de menor

resistencia a la corriente eléctrica.

2. Si su lavanderia está equipada con un cordón eléctrico que

posee un conductor de puesta a tierra del equipo y un enchufe

de puesta a tierra, dicho enchufe DEBE ser conectado a un

tomacorriente adecuado, debidamente instalado y puesto a

tierra de acuerdo con todos los códigos y reglamentos locales.

Si tiene alguna duda consulte a un electricista profesional. N o

modifique el enchufe proporcionado la aplicación.

TODOS los centros lavanderia a GAS

Esta lavenderia está equipada con un enchufe de tres espigas (de

puesta a tierra) para protección en contra de choques eléctricos

y debe ser conectada directamenta en un receptáculo para tres

espigas el cual debe estar puesto a tierra. No corte ni elimine la

espiga de puesta a tierra de este enchufe.

CONEXIÓNES ELÉCTRICAS PARA

UN SISTEMA TRIFILAR

Centro de lavanderia ELÉCTRICAS No canadienses

La conexión indebida del conductor de puesta

a tierra del equipo puede ocasionar un riesgo de choque eléctrico.

Consulte con un electricista profesional si tiene alguna duda respecto

a la puesta a tierra correcta del artefacto.

Para una secadora puesta a tierra, con cordón eléctrico:

1. La lavanderia DEBE ser puesta a tierra. En caso de

malfuncionamiento o falla, la puesta a tierra reducirá el riesgo

de choque eléctrico proporcionando un trayecto de menor

resistencia a la corriente eléctrica.

2. Si su lavanderia está equipada con un cordón eléctrico que posee

un conductor de puesta a tierra del equipo y un enchufe de

puesta a tierra, dicho enchufe DEBE ser conectado a un

tomacorriente adecuado, debidamente instalado y puesto a

tierra de acuerdo con todos los códigos y reglamentos locales.

Si tiene alguna duda consulte a un electricista profesional. No

modifique el enchufe proporcionado la aplicación.

Centro de lavanderia ELÉCTRICAS No canadienses

1. Saque los tornillos que sujetan la cubierta

de acceso del tablero de bornes y el soporte

de montaje del anclaje del cordón, situado

en la esquinasuperior de la parte trasera de

la secadora.

2. Instale un anclaje de cable aprobado por el

U.L., en el orificio deentrada del cordón

eléctrico en el soporte de montaje. Luego

apriete la tuerca con los dedos solamente.

3. Inserte un cordón eléctrico de 30 amp, NEMA

10-30 Tipo SRDT, aprobado por el U.L., a

través del anclaje de cable.

18

Page 19

4. Conecte el conductor neutro del cordón eléctrico (cable central)

al borne central plateado del tablero de bornes. Apriete

firmemente el tornillo.

TORNILLO VERDE DE

PUESTA A

TIERRA

CABLE DE

PUESTA A

TIERRA

NEUTR0

BORNE PLATEADO

5. Conecte los dos conductores externos restantes del cordón

eléctrico a los bornes bronceados externos del tablero de

bornes. Apriete firmemente los tornillos.

6. Apriete firmemente los tornillos del anclaje de cable contra el

cordón eléctrico.

7. Coloque nuevamente la cubierta del tablero de bornes.

CONEXIÓNES ELÉCTRICAS PARA

UN SISTEMA TETRAFILAR

Centro de lavanderia ELÉCTRICAS No canadienses

3. Desconecte el cable de puesta a tierra neutral del tornillo

verde de puesta a tierra situado en la parte superior del tablero

de bornes.

4. Inserte un cordón eléctrico te trafilar de 30 amp, NEMA 10-30

Tipo ST o SRDT, aprobado por el U.L., a través del anclaje de

cable.

5. Conecte el cable verde de puesta a tierra del cordón eléctrico

al gabinete mediante el tornillo verde de puesta a tierra.

6. Conecte el conductor blanco (neutro) del cordón eléctrico y

el cable depuesta a tierra neutro del mazo de cables de

la secadora al borne plateado central del tablero de bornes.

7. Conecte los conductores rojo y negro del cordón eléctrico a

los bornes bronceados externos del tablero de bornes.

8. Apriete firmemente los tornillos del anclaje de cable contra

el cordón eléctrico.

9. Coloque nuevamente la cubierta del tablero de bornes.

INSTALACION

1. Deje correr un poco de agua de las llaves de agua caliente

y fría para pilgar las lîneas y eliminar las particulas que pued

en obstriur las rejillas de las vàlvulas de agua.

2. Examine los tubos de entrada de agua para asegurarse de

que las arandelas de caucho estén instaladas en cada extremo.

3. Conecte con cuidado los tubos de entrada a la vàlvula de

agua (en el lado izquierdo de la lavadora), apriete a mano y

luego apriete 2/3 d vuelta con unos alicates.

1. Saque los tornillos que sujetan la cubierta de acceso del tablero

de bornes y el soporte de montaje del anclaje de cable situado

en la esquina superior en la parte trasera de la secadora.

2. Instale un anclaje de cable aprobado por el U.L., en el orificio

de entrada del cordón eléctrico en el soporte de montaje.

Luego apriete la tuerca con los dedos solamente.

TORNILLO VERDE

DE PUESTA

A TIERRA

CABLE DE

PUESTA A

TIERRA

NEUTR0

ROJO

CONDUCTOR VERDE DE CORDÓN

ELÉCTRICO

DE MONTAJE

DEL ANCLAJE DE

CORDÓN

ELÉCTRICO

BORNE PLATEADO

BLANCO

SOPORTE

CABLE

TABLERO DE

BORNES

NEGRO

NO ESTROPEE LAS ROSCAS NI APRIETE

ESTAS CONEXIONES EXCESIVAMENTE.

4. Determine cuàl de las llaves de agua es la de agua CALIENTE

y conecte con cuidado el tubo inferior de entrada a la llave

de agua CALIENTE, apriete a mano y luego apriete 2/3 de

vuelta con unos alicates. Conecte con cuidado el tubo

superior de entrada a la llave de agua FRIA, apriete a mano

y luege apriete 2/3 vuelta con unos alicates

NO ESTROPEE LAS ROSCAS NI APRIETE

ESTAS CONEXIONES EXCESIVAMENTE.

Abra la llave del agua y compuebe que no haya fugas en

ninguna de lasdos conexiones.

5. Con cuidado, mueve el centro de lavanderia hasta su

ubicación definitiva para instalación final.

6. Para verificar si el centro de lavanderia está nivelado y

firmemente asentado sobre las cuatro patas, inclínelo hacia

adelante de modo que las patas posteriors queden en

el aire. Luego vuelva a depositar cuidadosamente la

màquina para permitir que las patas posteriores se ajusten.

Coloque un nivel de carpintero encima de la lavadora.

Atornille o destornille los tornillos nivel de posteriores de la

lavadora

según sea necesario para que el centro de lavanderia quede

firmemente asentado sobre sus cuatro patas (no debe haber

movimiento de vaivén.

NOTA: Mantenga las patas de nivelación al mínimo para

prevenir excesiva vibración.

19

Page 20

.

7 . CONEXIÓN DEL GAS (Secadoras a gas solamente)

a. Saque la tapa de embarque de la tubería de gas de la

secadora situada en la parte trasera.

NOTA: NO conecte la lavandería al suministro de propano, sin

primero instalar el juego de conversión a propano. El juego de

conversión a propano debe ser instalado por un técnico de gas

calificado.

b.Conecte una tubería semirígida de 1/2" (1,27 cm) D.I. o

una tubería aprobada, desde la línea de suministro de

gas a la tubería de 3/8" (0,96 cm) ubicada en la parte

trasera de la secadora. Utilice un reductor de 1/2" (1,27

cm) a 3/8" (0,96 cm) para la conexión. Aplique un sellador

de roscas de uso aprobado, resistente a la corrosión de

los gases licuados, en todas las uniones de la tubería.

c. Abra la válvula de cierre en la tubería de suministro de

gas.

d. Pruebe todas las conexiones aplicando con una

escobilla una solución jabonosa.

NUNCA UTILICE UNA LLAMA ABIERTA PARA DETECTAR

FUGAS DE GAS.

8. Forme una "U" en el extremo del tubo de drenage co el

tubo señalando hacia el drenaje. Coloque el extremo

formado del tubo de drenaje en lavadero or una tubería

vertical y fíjelo con su sujetacables incluido en el paquete.

10. Conecte el ducto de escapeal sistema de escape exterior. Utilice

cinta para obturar todas as uniones.

11.Conecte el cordón eléctrico a un tomacorriente puesto a tierra.

12. Vuelva a instalar el panel de acceso delantero de la seadora.

NOTA: Asegúrese de que la corriente esté desconectada en el

disyuntor/caja de fusibles, antes de conectar el cordón eléctrico

en el tomacorriente.

13.Conecte la corriente en el disyuntor/caja de fusibles.

Antes de poner en funcionamiento la

secadora, asegúrese de que no haya materiales combustibles,

gasolina y otros vapores inflamables cerca de la secadora.

Además asegúrese de que no haya nada (tal como cajas, ropas,

etc.) que obstruya el flujo del aire de combustión y ventilación.

14. Haga funcionar la secadora durante un ciclo completo para

comprobar su buen funcionamiento.

NOTA: En las secadoras a gas, antes de encender el quemador

es necesario purgar el aire de la tubería del gas. Si el quemador

no enciende dentro de 45 segundos, cuando la secadora se

enciende por primera vez, el interruptor de seguridad apagará

el quemador. Si ésto sucede, gire el contador de tiempo a la

posición "OFF" (apagado) y espere 5 minutos antes de intentar

encender la secadora nuevamente.

15.Si su lavandería no funciona, consulte la sección "Lista de

Control de Averías" que se encuentra en su Manual del

Usuario, antes de llamar para obtener servicio.

16.Conserve estas instrucciones cerca de la secadora para

referencia futura.

NOTA: Dentro de la consola de la secadora o debajo del panel

superior se encuentra un diagrama del cableado.

Atadura

de

alambre

SI NO SE SIGUEN LAS INSTRUCCIONES ANTERIORE, EL

SIFON SACARA EL AGUA DE LA LAVADORA.

9. Saque los dos (2) tornillos que sujen el panel de acceso de

lantero de la secadora al gabinete de la secadora. Levante

el panel hasta que las lengüetas se desenganchen del

gabinet saque el panel y colóque lo a un lado.

Tornillos del

panle de

acceso

PIEZAS DE RECAMBIO

Si necesita obtener piezas de recambio para su secadora, póngase

en contacto con el distribuidor donde compró su secadora.

Cuando se reparan los controles, marque todos

los cables con etiquetas antes de desconectarlos. Cualquier error

de cableado puede causar una operación inadecuada y peligrosa.

Asegúrese de que la secadora funcione adecuadamente después

de repararla.

Destruya la caja de cartón, las bolsas de

plástico y la banda metálica después de haber desempacado el

centro de lavandería. Los niños pueden ponerse a jugar con ellos.

Las cajas de cartón cubiertas con alfombras, colchas o pedazos

de plástico pueden convertirse en cámaras sin aire y causar asfixia.

Elimine todos los materiales poniéndolos en la basura o fuera

del alcance de los niños.

Las instrucciones incluidas en este manual

y en el resto de la documentación que se entrega con la lavandería

no pueden cubrir todas las situaciones o condiciones posibles que

puedan presentarse. Por lo tanto, se DEBEN seguir prácticas

seguras y tener cuidado cuando se instala cualquier artefacto

doméstico.

Se obtiene el máximo de beneficios y resultadoscuando todas

las instrucciones de seguridad y defuncionamiento son

comprendidas y puestas en prácticade forma rutinaria cada

vez que se lava la ropa

20

Loading...

Loading...