Page 1

27” (69 cm) Wid e

LAUN DR Y CE NTER

Washer - Dryer

Washer - Electric Dryer

Use and Care Guide

Installation Instructions

CENTRO DE LAVANDERÍA

de 27" (69 cm) de anc ho

COMBINE LAVEUSE/SECHUESE

Lavadora - Secadora eléctrica

Largeur de 27pounces (69cm)

Manual de Uso y Cuidado

Instructions d’installation

Models/Modelos

P/N 134897400A (0712) www.frigidaire.com

Page 2

Table Of Contents

SUBJECT PAGE

Pre-Installation Requirements..........................................................................................................................................3

Electrical Requirements.................................................................................................................................................3

Water Supply Requirements ...........................................................................................................................................3

Drain Requirements.......................................................................................................................................................3

Exhaust System Requirements ...................................................................................................................................4

Gas Supply Requirements ............................................................................................................................................5

Location...................................................................................................................................................................5

Rough-ln Dimensions.....................................................................................................................................................6

Mobile Home Installation............................................................................................................................................7

Unpacking...............................................................................................................................................7

Electrical Installation...............................................................................................................................................8

Grounding Requirements.............................................................................................................................................8

3 & 4-Wire Connections ...............................................................................................................................................9

Installation.........................................................................................................................................................10-11

Replacement Parts.....................................................................................................................................................11

Français.............................................................................................................................................................12-20

Laundry Center Safety

Before beginning installation, carefully read these instructions. This will simplify the installation and ensure the laundry center is

installed correctly and safely. Leave these instructions near the laundry center after installation for future reference.

NOTE: The electrical service to the laundry center must conform with local codes and ordinances and the latest edition of the

National Electrical Code, ANSI/NFPA 70, or in Canada, the Canadian Electrical Code, CSA C22.1

NOTE: The gas service to the laundry center must conform with local codes and ordinances and the latest edition of the National

Fuel Gas Code ANSI Z223.1/NFPA 54, or in Canada, the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

NOTE: The laundry center is designed under ANSI Z21.5.1 or ANSI/UL 2158- CAN/CSA C22.2 No. 112 (latest edition) for HOME

USE only. This laundry center is not recommended for commercial applications such as restaurants or beauty salons, etc.

Your safety and the safety of others is very important.

We have provided many important safety messages in the Use & Care Guide, Operating Instructions, Installation Instructions and

on your appliance. Always read and obey all safety messages.

This is the safety alert symbol. This symbol alerts you to hazards that can kill or hurt you or others. All safety messages

will be preceded by the safety alert symbol and the word "DANGER" or "WARNING". These words mean:

You will be killed or seriously injured if you don't follow instructions.

DANGER

You can be killed or seriously injured if you don't follow instructions.

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell you what can happen if the

instructions are not followed.

For your safety the information in this manual must be followed to minimize the risk of fire or explosion or to

prevent property damage, personal injury or loss of life.

- Do not store or use gasoline or other flammable vapors and liquid in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building or area of all occupants. Immediately call your gas supplier from a neighbor’s phone.

• Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be preformed by a qualified installer, service agency or the gas supplier.

2

Page 3

PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for Installation:

1. Phillips head screwdriver.

2. Channel-Iock adjustable pliers.

3. Carpenter’s level.

4. Flat or straight blade screwdriver.

5. Duct tape.

6. Rigid or flexible metal 4 inch (10.16 cm) duct.

7. Vent hood.

8. Pipe thread sealer (Gas).

9. Ratchet with 3/8 inch (0.96 cm) socket.

ELECTRIC Laundry Center

Circuit- Individual 30 amp branch circuit fused with 30 amp

minimum time delay fuses or circuit breakers.

POWER SUPPLY - 3-wire or 4-wire , 240 volt, single phase, 60

Hz, Alternating Current.

POWER SUPPLY CORD KIT- The laundry center MUST employ

a 3-condutor power supply cord NEMA 10-30 type SRDT rated

at 240 volt AC minimum, 30 amp, with 3 open end spade lug

connectors with upturned ends or closed loop connector

4-condutor power supply cord NEMA 14-30 type SRDT or ST (as

required) rated at 240 volt AC minimum, 30 amp, with 4 open

end spade lug connectors with upturned ends or closed loop

connectors and marked for use with clothes dryers. If being

installed in a new branch circuit installation, manufactured

(mobile) home, recreational vehicle or area which prohibits

grounding through the neutral conductor, the laundry center

MUST employ a 4-condutor power supply cord NEMA 14- 30

type SRDT or ST (as required) rated at 240 volt AC minimum,

30 amp, with 4 open end spade lug connectors with upturned

ends or closed loop connectors and marked for use with clothes

dryers. See ELECTRICAL CONNECTIONS. (Canada - 4-wire

power supply cord is installed on laundry center).

OUTLET RECEPTACLE - NEMA 10-30R (3-wire) receptacle or

NEMA 14- 30R (4-wire) receptacle to be located so the power

supply cord is accessible when the laundry center is in an installed

position.

OR a

GAS Laundry Center

CIRCUIT - Individual 15 amp minimum branch circuit fused with

a time delay fuse or circuit breaker.

POWER SUPPLY -3 wire, 120 volt single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD -The gas laundry center is equipped

with a 120 volt 3-wire power cord.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within 42 inches

(106.68 cm) of your laundry center’s water inlet. The faucets

MUST be 3/4 inch (1.9 cm) garden hose type so inlet hoses can

be connected. Water pressure MUST be between 10 and 120

pounds per square inch (maximum unbalance pressure, hot vs.

cold, 10 psi). Your water department can advise you of your

water pressure.

NEMA 10-30R

Page 4

Do not allow combustible materials (for

example: clothing, draperies/curtains, paper) to come in

contact with exhaust system. The dryer MUST NOT be

exhausted into a chimney, a wall, a ceiling, or any concealed

space of a building which can accumulate lint, resulting in a fire

hazard.

Exceeding the length of duct pipe or number

of elbows allowed in the "MAXIMUM LENGTH" charts can

cause an accumulation of lint in the exhaust system. Plugging

the system could create a fire hazard, as well as increase drying

times.

Do not screen the exhaust ends of the vent

system, nor use any screws, rivets or other fastening means

that extend into the duct and catch lint to assemble the

exhaust system. Lint can become caught in the screen, on the

screws or rivets, clogging the duct work and creating a fire hazard

as well as increasing drying times. Use an approved vent hood

to terminate the duct outdoors, and seal all joints with duct

tape. All male duct pipe fittings MUST be installed downstream

with the flow of air.

Explosion hazard. Do not install the dryer

where gasoline or other flammables are kept or stored. If

the dryer is installed in a garage, it must be a minimum of 18

inches (45.7 cm) above the floor. Failure to do so can result in

death, explosion, fire or burns. The exhaust system back pressure

MUST not exceed 0.6 inches (1.52 cm) of water column,

measured with an inclined manometer at the point the exhaust

connects to the dryer. The exhaust system should be inspected

and cleaned a minimum of every 18 months with normal

usage. The more the dryer is used, the more often you should

check the exhaust system and vent hood for proper operation.

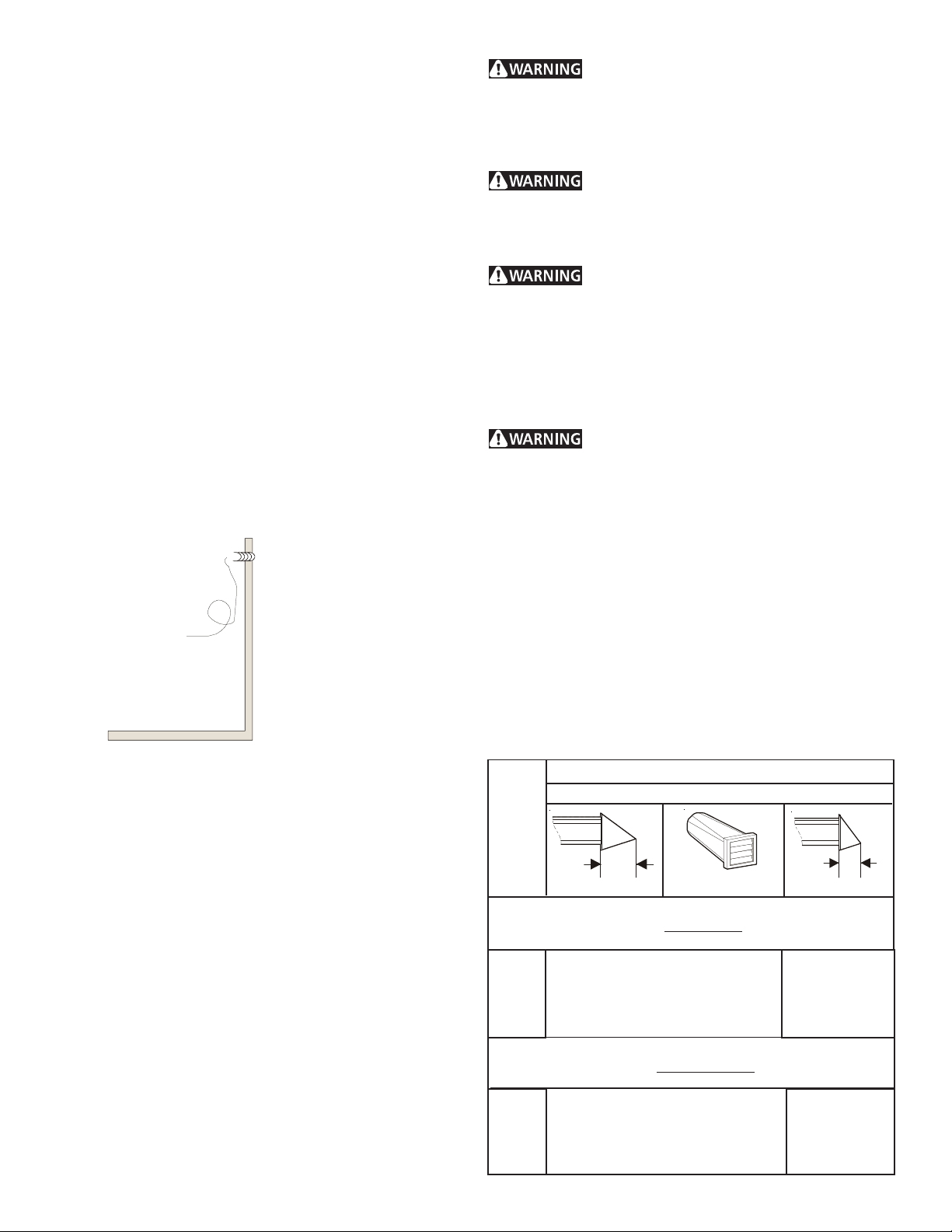

The maximum length of the exhaust system depends upon the

type of duct used, number of elbows and type of exhaust hood.

The maximum length for both rigid and flexible duct is shown in

the chart below.

EXHAUST DUCT LENGTHS

EXHAUST HOOD TYPE

Number

of 90°

Turns

4”

(10.2 CM)

MAXIMUM LENGTH OF 4-INCH (10.2 CM)

DIAMETER RIGID METAL DUCT

0

1

2

3

MAXIMUM LENGTH OF 4-INCH (10.2 CM)

0

1

2

3

56 ft. (17.07 m)

46 ft. (14.02 m)

34 ft. (10.36 m)

32 ft. (9.75 m)

DIAMETER FLEXIBLE METAL DUCT

30 ft. (9.14 m)

22 ft. (6.7 m)

16 ft. (4.88 m)

10 ft. (3.05 m)

Louvered

42 ft. (12.8 m)

36 ft. (10.97 m)

28 ft. (8.53 m)

18 ft. (5.48 m)

22 ft. (6.7 m)

14 ft. (4.27 m)

10 ft. (3.05 m)

5 ft. (1.5 m)

2.5”

(6.35 CM)

4

Page 5

The laundry center may be exhausted four (4) ways with rear

flush installation:

1. Straight back

2. Down (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid

duct and 1 elbow down)

3. Left (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid

duct, 1 elbow down and 1 elbow left)

4. Right (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid

duct, 1 elbow down and 1 elbow right)

To exhaust up, add an 11 inch (27.94 cm) length of standard 4

inch (10.16 cm) diameter duct and a 90° elbow. The unit will

be positioned about 4½ inches (11.43 cm) away from the wall

(flush to wall exhausting may be done by going below the dryer

then sideways).

An exhaust hood positioned

to line up with the dryer

exhaust can be installed

directly through the outside

wall. To exhaust to the side

or down, add an 8 inch

(20.32 cm) length of standard

4 inch (10.16 cm) diameter

duct and a 90° elbow.

GAS SUPPLY REQUIREMENTS

1.Installation MUST conform with local codes, or in the absence

of local codes, with the National Fuel Gas Code, ANSI Z223.1

(latest edition) or in Canada, the current AN/CGA B149.

2.The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3.If codes allow, flexible metal tubing may be used to connect

your dryer to the gas supply line. The tubing MUST be

constructed of stainless steel or plastic-coated brass.

4.The gas supply line MUST have an individual shutoff valve.

5.A 1/8 inch (0.32 cm) N. P. T. plugged tapping, accessible for

test gage connection, MUST be installed immediately

upstream of the gas supply connection to the dryer.

6.The dryer and its individual shutoff valve MUST be

disconnected from the gas supply piping system during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.45 kPa).

7.The dryer MUST be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2 psig (3.45 kPa).

LOCATION OF YOUR LAUNDRY CENTER

DO NOT INSTALL YOUR LAUNDRY CENTER:

1.In an area exposed to dripping water or outside weather conditions.

2.In an area where it will come in contact with curtains or drapes.

3.On carpet. Floor MUST be solid with a maximum slope of 1 inch (2.54 cm).

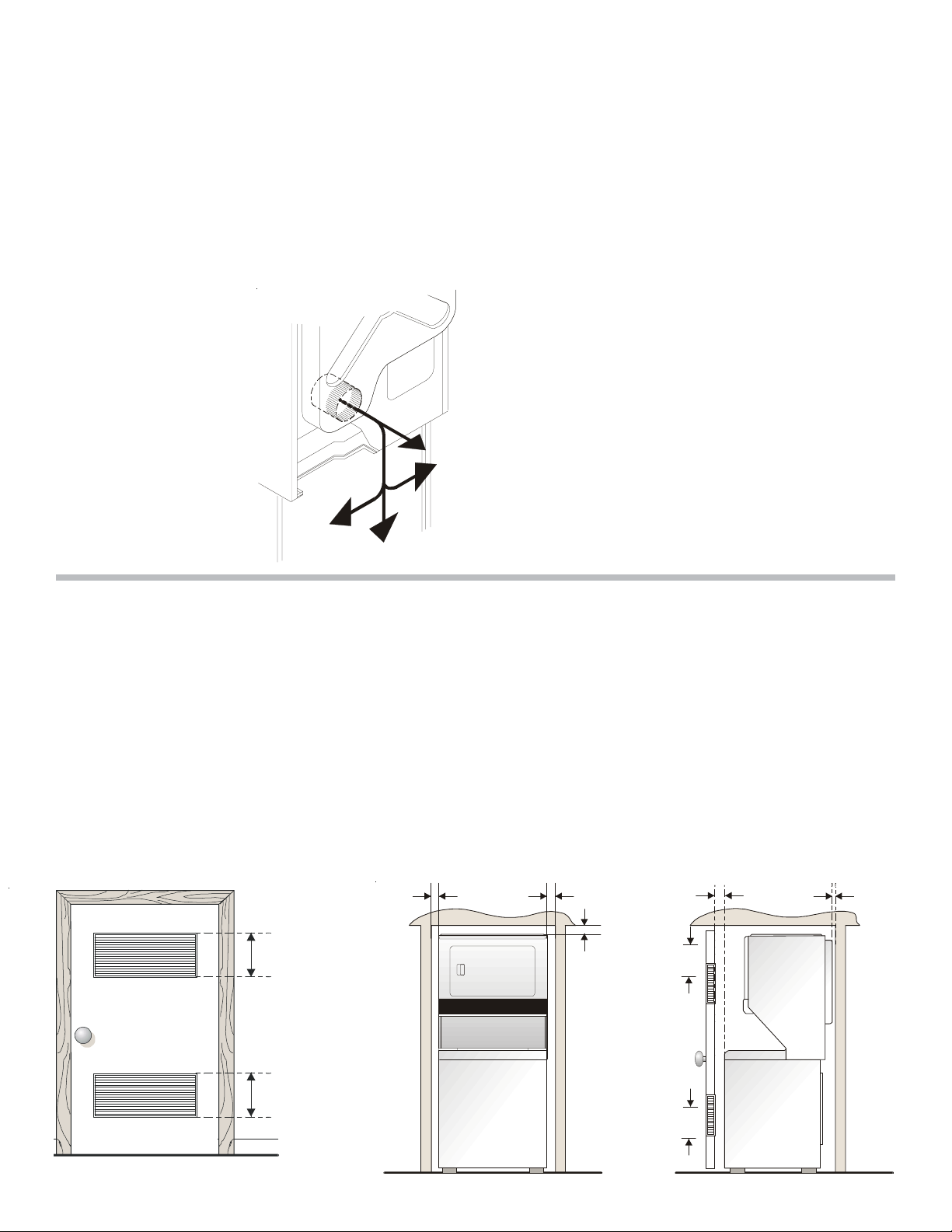

INSTALLATION IN RECESS OR CLOSET

1.A laundry center installed in a bedroom, bathroom, recess or closet, MUST be exhausted outdoors.

2.No other fuel burning appliance shall be installed in the same closet as the Gas laundry center.

3.Your laundry center needs the spacearound it for proper ventilation.

DO NOT INSTALL YOUR LAUNDRY CENTER IN A CLOSET WITH A SOLID DOOR.

4.A minimum of 120 square inches (774.2 square cm) of opening, equally divided at the top and bottom of the door, is required.

Air openings are required to be unobstructed when a door is installed. A louvered door with equivalent air openings for the full

length of the door is acceptable.

5.The following illustrations show minimum clearance dimensions and air openings for proper operation in a recess or closet

installation.

60 SQ. IN.

(387.1 SQ. CM)

0 IN.

(0 C M)

0 IN.

(0 C M)

DRYER

1 IN.

(2.54 CM)

60 SQ. IN.

(387.1 SQ. CM)

0 IN.

(0 C M)

Closet Door

60 SQ. IN.

(387.1 SQ. CM)

WASHER

60 SQ. IN.

(387.1 SQ. CM)

5

Page 6

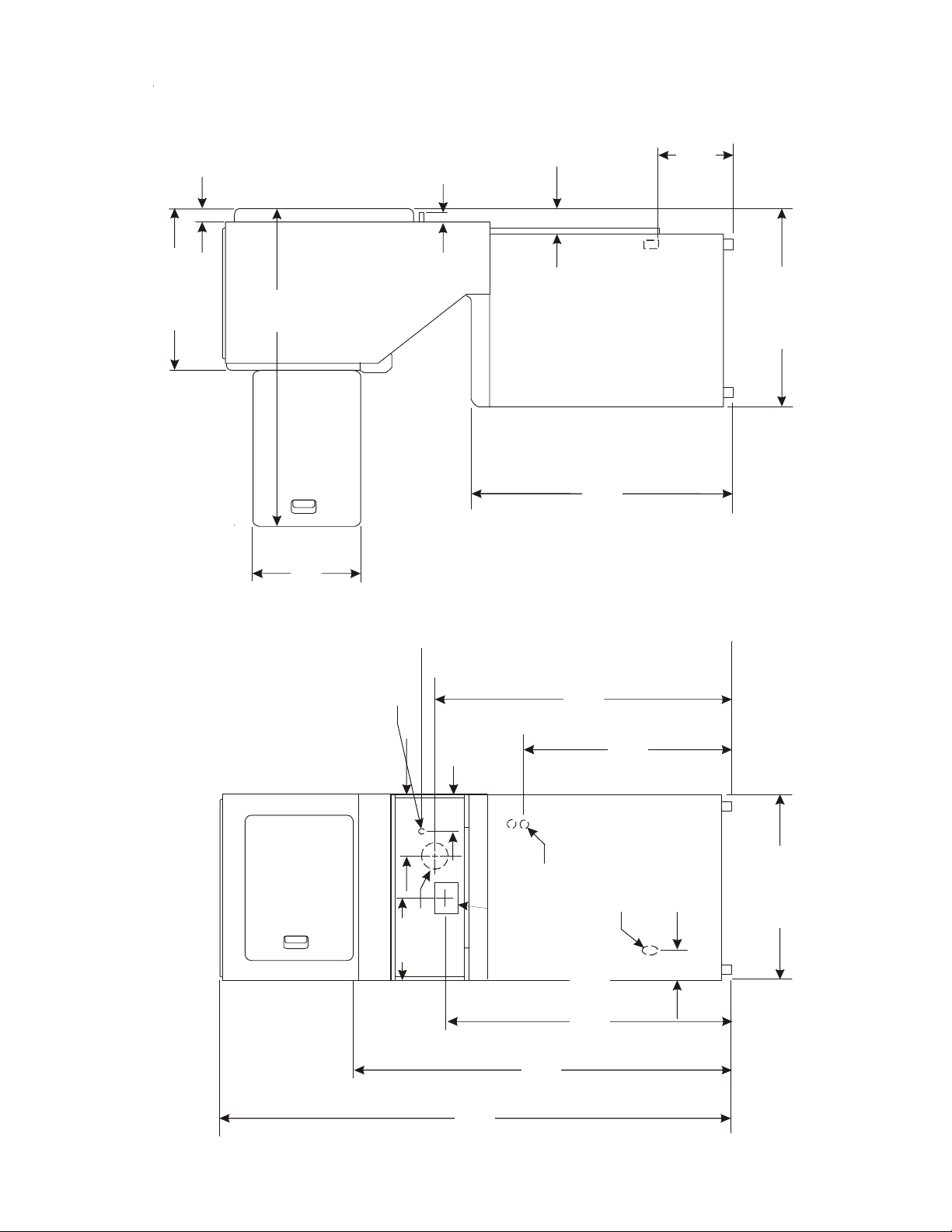

2 ½ IN.

(6.35 CM)

1 7/8 IN.

(4.76 CM)

4 13/16 IN.

(12.22 CM)

11 7/16 IN.

(29.5 CM)

25 ¼ IN.

(64.13 CM)

47“

16 ¼ IN.

(41.27 CM)

ROUGH-IN DIMENSIONS

(78.26 CM)

30 13/16 IN.

36 1/16IN.

(91.60 CM)

43 IN.

PIPE (REAR)

GAS SUPPLY

5 ¼ IN.

(13.33 CM)

(109.22 CM)

41 ¼ IN

(104.77 CM)

29 7/16 IN

(74.77 CM)

9 3/8 IN.

(23.81 CM)

(REAR)

DRAIN OUTLET

VENT

12 ½ IN.

(31.7 5 CM)

ELECTRICAL

CONNECTION

75 ½ IN.

(191.77 CM)

54 5/16 IN.

(REAR)

WATER INLETS

43 IN.

(109.22 CM)

(137.95 CM)

3 ¾ IN.

(9.52 CM)

27 IN.

(68.58CM)

Page 7

PLASTIC SPACER

BLOC K

MECHANISM

SHIPPING

BOLT

FOAM

SHIPPING

PA D

POWER CORD

(IF EQUIPPED)

DRAIN HOSE

Page 8

ELECTRICAL INSTALLATION

GROUNDING REQUIREMENTS

ALL ELECTRIC Laundry Centers

WARNING

The following are specific requirements for

proper and safe electrical installation of your laundry center.

Failure to follow these instructions can create electrical shock

and/or a fire hazard.

WARNING

Electrical shock can result if the laundry center is not properly

grounded. Follow the instructions in this manual for proper

grounding.

WARNING

laundry center. Some extension cords are not designed to

withstand the amounts of electrical current this laundry center

utilizes and can melt, creating electrical shock and/or fire hazard.

Locate the laundry center within reach of the receptacle for the

length power cord to be purchased, allowing some slack in the

cord. Refer to the pre-installation requirements in this manual

for the proper power cord to be purchased.

WARNING

installed onto power cord. If the strain relief is not attached, the

cord can be pulled out of the laundry center and can be cut by

any movement of the cord, resulting in electrical shock.

This appliance MUST be properly grounded.

Do not use an extension cord with this

A U.L. approved strain relief must be

Non-Canadian ELECTRIC Laundry Center

DANGER

grounding conductor can result in a risk of electrical shock.

Check with a licensed electrician if you are in doubt as to whether

the appliance is properly grounded.

For a grounded, cord-connected laundry center:

1. The laundry center MUST be grounded. In the event of

malfunction or breakdown, grounding will reduce the risk of

electrical shock by a path of least resistance for electrical

current.

2. If your laundry center is equipped with a power supply cord

having an equipment-grounding conductor and a grounding

plug, the plug MUST be plugged into an appropriate, copper

wired receptacle that is properly installed and grounded in

accordance with all local codes and ordinances. If in doubt,

call a licensed electrician. Do not modify plug provided

with the appliance.

For a permanently connected laundry center:

The laundry center MUST be connected to a grounded metal,

permanent wiring system; or an equipment grounding conductor

MUST be run with the circuit conductors and connected to the

equipment-grounding terminal or lead on the appliance.

Improper connection of the equipment

Canadian ELECTRIC Laundry Center

WARNING

Do not use an aluminum wired receptacle

with a copper Wired power cord and plug (or vice versa). A

chemical reaction occurs between copper and aluminum and

can cause electrical shorts.

The proper wiring and receptacle is a copper wired power

cord with a copper wired receptacle OR aluminum wired

power cord with an aluminum wired receptacle.

NOTE: Laundry centers operating on a 208 volt power supply

will have longer drying times than laundry centers operating on

a 240 volt power supply.

DANGER

grounding conductor can result in a risk of electrical shock.

Check with a licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

For a grounded cord connected laundry center:

1. The laundry center MUST be grounded. In the event of

malfunction or breakdown, grounding will reduce the risk of

electrical shock by providing a path of least resistance for

the electrical current.

2. Since your laundry center is equipped with a power supply

cord having an equipment-grounding conductor and a

grounding plug, the plug MUST be plugged into an

appropriate outlet that is properly installed and grounded in

accordance with all codes and ordinances. If in doubt, call a

licensed electrician.

Improper connection of the equipment

ALL GAS Laundry Centers

1. The laundry center is equipped with a three-prong (grounding)

plug for your protection against shock hazard and should

be plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong from

the plug.

8

Page 9

ELECTRICAL CONNECTIONS

FOR A 3-WIRE SYSTEM

ELECTRICAL CONNECTIONS

FOR A 4-WIRE SYSTEM

NON-CANADIAN ELECTRIC Laundry Center

1. Remove the screw securing the

terminal block access cover to

the rear panel and remove cover.

2. Install a U.L. approved strain

relief connector in the entry

hole on the back panel.

3. Insert a NEMA 10-30 Type SRDT,

U.L. approved power cord through the strain relief.

4. Attach the power cord neutral (central wire) conductor to

the silver colored center terminal on the terminal block.

Tighten the screw securely.

GREEN GROUND SCREW

NEUTRAL

GROUND

WIRE

SILVER TERMINAL

NON-CANADIAN ELECTRIC Laundry Center

1. Remove the screw securing the

terminal block access cover to the

rear panel and remove cover.

2. Install a U.L. approved strain relief

connector in the entry hole on the

back panel.

3. Remove the neutral ground wire from the green ground

screw located above the termial block.

NEUTRAL

GROUND

WIRE

5. Attach the remaining two power cord outer conductors to

the outer brass colored terminals on the terminal block.

Tighten both screws securely.

6. Tighten the screws securing the cord restraint against the

power cord.

7. Reinstall the terminal access cover.

4. Insert a NEMA 14-30 Type ST or SRDT, U.L. approved power

cord through the strain relief.

5. Attach the green power cord ground wire to the cabinet

with the green ground screw.

6. Attach the white (neutral) wire from the power cord and the

neutral ground wire from the appliance harness to the silver

colored center terminal on the terminal block. Tighten the

screw securely.

7. Attach the red and black wires from the power cord to the

outer brass-colored terminals on the terminal block. Tighten

both screws securely.

8. Tighten the screws securing the cord restraint firmly against

the power cord.

9. Reinstall the terminal block access cover.

Page 10

9. Remove the two (2) screws securing the dryer front access

panel to the dryer cabinet. Lift the panel until the tabs can

be disengaged from the cabinet. Remove the panel and set

aside.

Access

Panel

Screws

Page 11

REPLACEMENT PARTS

10. Connect the exhaust duct to outside duct work. Use duct

tape to seal all joints.

11. Plug the power cord into a grounded outlet.

NOTE: Check to ensure the power is off at a circuit breaker/

fuse box before plugging the power cord into an

outlet.

12. Turn on the power at a circuit breaker/fuse box.

Before operating the dryer, make

sure the dryer area is clear and free from

combustible materials, gasoline, and other

flammable vapors. Also see that nothing (such as

boxes, clothing, etc.) obstructs the flow of

combustion and ventilation air.

13. Reinstall the dryer front access panel.

14. Run the washer and dryer though a cycle. Check for proper

operation.

NOTE: On gas dryers, before the burner will light, it is

necessary for the gas line to be bled of air. If the burner

does not light within 45 seconds the first time the

dryer is turned on, the safety switch will shut the

burner off. If this happens, turn the timer to “OFF”

and wait 5 minutes before making another attempt to

light.

If replacement parts are needed for your laundry center, contact

the source where you purchased your laundry center.

WARNING

band after the laundry center is unpacked. Children might use

them for play. Cartons covered with rugs, bedspreads, or plastic

sheets can become airtight chambers causing suffocation. Place

all materials in a garbage container or make materials inaccessible

to children.

servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

WARNING

literature included with this laundry center are not meant to

cover every possible condition and situation that may occur. Good

safe practice and caution MUST be applied when installing,

operating and maintaining any appliance.

Maximum benefits and enjoyment are achieved when

all the Safety and Operating instructions are understood

and practiced as a routine with your laundry tasks.

Destroy the carton, plastic bags, and metal

Label all wires prior to disconnection when

The instructions in this manual and all other

15. If your laundry center does not operate, please review the

“Avoid Service Checklist” located in your Owner’s Guide

before calling for service.

16. Place these instructions in a location near the laundry

center for future reference.

NOTE: A wiring diagram is located behind the dryer front

access panel.

10

Page 12

Table des matières

SUJET PAGE

Avantl’installation................................................................................................................................................13

Exigences électriques.............................................................................................................................................13

Exigences d'alimentation.......................................................................................................................................13

Exigenses de vidange.............................................................................................................................................13

Exigenses du circuit d'evacuation......................................................................................................................14-15

Exigenses d'alimentation en gas..........................................................................................................................15

Emplacement du combiné laveuse/sécheus........................................................................................................15

Dimensions de l’emplacement...............................................................................................................................16

Installation dans une maison mobile....................................................................................................................17

Déballage.................................................................................................................................................................17

Installation électrique...........................................................................................................................................18

Exigences de mise à la terre...................................................................................................................................18

Connexions électrique s - 3 fils et 4 fils.............................................................................................................18-19

Installation..........................................................................................................................................................19-20

Pièces de rechange................................................................................................................................................20

Sécuritaire de la Laveuse / Sécheuse

Avant de commencer, lire attentivement le présent document. Cela simplifiera l’installation et assurera la pose

correcte et sécuritaire de la sécheuse. Après l’installation, laisser ce document à proximité de la sécheuse pour

référence future.

REMARQUE : L’alimentation électrique de la sécheuse doit respecter les codes et ordonnances locaux ainsi

que l’édition la plus récente du Code ANSI/NFPA 70, ou au Canada, le Code canadien d'électricité, ACNOR

C22.1, partie1.

REMARQUE : L’alimentation en gaz de la sécheuse doit respecter les codes et ordonnances locaux ainsi que

l’édition la plus récente du Code ANSI Z223.1, ou au Canada, le code CAN/ACG B149.12.

REMARQUE : La sécheuse est conçue conformément au code ANSI Z 21.5.1 ou ANSI/UL 2158 - CAN/ACG

C22.2 No. 112 (l’édition la plus récente) pour un USAGE DOMESTIQUE seulement. Cette sécheuse n'est pas

recommandée pour utilisation commerciale, comme par exemple un restaurant ou un salon de coiffure, etc.

Pour votre sécurité, suivre les directives données dans le présent guide afin de minimiser

les risques d’incendie, d’explosion, de dommages matériels, de blessures et de mort.

- Ne pas entreposer ni utiliser d’essence ou d’autres vapeurs ou liquides inflammables à proximité de

cette sécheuse ou de tout autre appareil électroménager.

- QUE FAIRE S’IL Y A UNE ODEUR DE GAZ

· N’allumer aucun appareil électrique.

· Ne toucher aucun commutateur électrique; ne pas utiliser le téléphone dans l’immeuble.

· Faire sortir tous les occupants de la pièce, de l’immeuble ou de la zone avoisinante.

· Appeler la compagnie de gaz immédiate-ment en utilisant le téléphone d’un voisin. Suivre les

instructions de la compagnie de gaz.

· S’il est impossible de joindre la compagnie de gaz, appeler les pompiers.

L’installation et les réparations doivent être effectuées par un technicien qualifié, un agent de service ou

la compagnie de gaz.

12

Page 13

AVANT L’INSTALLATION

Outils et matériel requis pour l’installation :

1. Tournevis à pointe cruciforme

2. Pinces multiprise

3. Niveau de menuisier

4. Tournevis à pointe plate ou à lame droite

5. Ruban adhésif pour conduites

6. Conduite en métal rigide ou flexible de 10,2 cm (4 po)

7. Grille de sortie

8. Pâte à joint pour conduites (modèle à gaz)

9. Couteau à mastic en plastique

CORDON D’ALIMENTATION - Le combiné laveuse/ sécheuse á

gaz est d’un cordon d’alimentation électrique à 3 fils de 120 volts.

NOTE: Do not under

REMARQUE : Il ne faut

any circumstances

en aucun cas retirer la

broche de mise à la

remove grounding

terre de la fiche.

prong from plug.

INSTALLATION ÉLECTRIQUE

Sécheuses ÉLECTRIQUES

CIRCUIT - Dérivation distincte de 30 A avec fusibles à retardement

ou disjoncteurs d’au moins 30 A.

ALIMENTATION ÉLECTRIQUE - 3 fils, 240 volts, une phase,

60 Hz, courant alternatif. (Canada - 240 volts, une phase, 60 Hz,

courant alternatif.)

CORDON D’ALIMENTATION ÉLECTRIQUE - La sécheuse DOIT

être reliée à un cordon d’alimentation électrique à 3 conducteurs

NEMA 10-30 de type SRDT d’une capacité minimale de 240 volts,

courant alternatif, 30 A, avec fiche en L à 3 broches pleines ou

repliées conçue pour le branchement d’une sécheuse. Si étant

installé dans une nouvelle installation de circuit de branche,

manufacturée (mobile) à la maison, véhicule la récréationnel

ou secteur qui interdisent fondre par le conducteur neutre, elle

DOIT être reliée à un cordon d’alimentation électrique à

4 conducteurs NEMA 14-30 de type SRDT ou ST (au besoin) d’une

capacité minimale de 240 volts, courant alternatif, 30 A, avec

fiche en L à 4 broches pleines ou repliées conçue pour le

branchement d’une sécheuse. Se reporter à la section

BRANCHEMENT ÉLECTRIQUE D’UNE INSTALLATION À 4 FILS.

(Canada - Cordon d'alimentation à 4 fils branché à la sécheuse.)

BROCHE DE MISE

Grounding Prong

À LA TERRE

EXIGENCES D'ALIMENTATION EN EAU

Les robinets d'eau chaude et d'eau chaude et d'eau froide

DOIVENT êntre installés à moins de 42 pounces ( 106,68 cm )

de

l'arrivée d'eau du combiné. Les robinets DOIVENT tre du type

pour boyau de jardin de 3/4 pounce (1,9 cm), de manière à

pouvoir raccader les boyaux d'arrivée d'eau. La pression d'eau

DOIT se siteur entre 10 et 120 livres par pounce carré ( déséquilibre de pression maximale, eau chaude vs eau froide, 10

psi ). Le service d'aqueduc peut vous informer sur la pression

d'eau.

EXIGENCES DE VIDANGE

1. Le circit de vidange doit permettre d'évacuer 17 gallons à la

minute.

2. Le diamétre du tuyau de vidange doit être d'un minimum

de 1 - 1/4 po (3,18 cm).

3. La hauteur hors sol du tuyau de vidange doit être :

Minimale: 33 po (83,82 cm)

Maximale: 96 po (244 cm)

PRISE - Prise NEMA 10-30R située de façon à ce que le cordon

d’alimentation électrique soit accessible une fois la sécheuse en

place. (Canada - prise NEMA de 14-30R.)

NEMA 10-30R

Combiné laveuse /sécheuse à GAZ

NEMA 14-30R

CIRCUIT - Dérivation distincte de 15 A minimum avec fusible à

retardement ou disjoncteur.

ALIMENTATION ÉLECTRIQUE - 3 fils, 120 volts, une phase, 60

Hz, courant alternatif.

96 po Max.

(244 cm)

33 po Min.

(83.82cm)

NOTA: Si l'installation nécessite un tuyau de vidange plus

long, demandez à un technicien qualifié d'installer un

boyau de vindage plus long, P/N 131461201,

disponsible chez un distributeur autorisé de pièces.

Pour les circuits de vidange au sol, installez un ensemble

de siphon, se procurer auprès d'une quincaillerie locale.

13

Page 14

ÉVACUATION DE L’AIR

Utiliser uniquement une conduite en métal rigide ou flexible de

10,2 cm (4 po) de diamètre (minimum) ainsi qu’une grille de sortie

approuvée pourvue de clapets qui s’ouvrent lorsque la sécheuse

fonctionne. Quand la sécheuse s’arrête, les clapets se ferment

automatiquement pour éviter les courants d’air et l’entrée

d’insectes ou de rongeurs. Afin de ne pas obstruer l’évacuation de

l’air, laisser une distance minimum de 30,5 cm (12 po) entre la

grille de sortie et le sol ou tout autre obstacle.

Les mises en garde qui suivent se

rapportent directement au fonctionnement correct et

sécuritaire de la sécheuse. Toute dérogation à ces mises en

garde pourrait ralentir le séchage et entraîner des risques

d’incendie.

N’installez pas la Sécheuse avec des matériels de

ventilation en matières plastiques flexibles.

Si la conduite existante est en plastique ou en papier métallique,

la remplacer par une conduite en métal rigide ou flexible. Au

Canada et aux Etats-Unis si le conduit est de métal (type feuille

d’aluminium), celui-ci doit être d’un type spécifique identifié par

le fabricant, recommandé pour l’utilisation avec des Sécheuses ;

et aux Etats-Unis il doit en outre remplir la norme UL 215Å. Les

matériaux de ventilation flexibles peuvent s’abimer facilement et

recueillir du duvet. Ces conditions obstrueront la circulation d’air

de la Sécheuse de vêtements et augmenteront le risque

d’incendie. S’assurer qu’il n’y a pas de charpie dans la

conduite existante avant d’installer la conduite de la

sécheuse.

La sécheuse doit être connectée à une bouche d’évacuation

vers l’extérieur du bâtiment ou de l’immeuble. Vous devez

inspecter régulièrement l’évent extérieur et enlever toute

accumulation de charpie autour de l’évent et dans la cavité du

conduit d’évacuation.

Ne laisser aucun matériau inflammable (comme des

vêtements, des tentures, des rideaux ou du papier) entrer en

contact avec les conduits d’évacuation.

Augmenter la longueur du conduit rigide ou le nombre de

coudes permis au tableau «LONGUEUR MAXIMUM» risque de

réduire la capacité d'évacuation du circuit. Obturer le circuit peut

créer un risque d'incendie et augmenter le temps de séchage.

N’obstruez pas les extrémités du tube de ventilation, ni utilisez

des vis, rivets ou autres moyens de fixation qui peuvent obstruer

le conduit et recueillir du duvet. L’engorgement subséquent

risquerait de ralentir le temps de séchage, voire de causer un

incendie. Installer une bouche d’évacuation approuvée à l’extérieur

et sceller tous les joints à l’aide d’un ruban adhésif à conduits.

Tous les raccords de conduit mâles

le sens de la circulation d’air.

Risques d'explosion. Ne pas installer la

sécheuse à un endroit où l'on garde de la gazoline ou tout autre

produit inflammable. Si la sécheuse est installée dans un garage,

elle doit être à un minimum de 45,7 cm (18 po) au-dessus du

plancher. Toute dérogation pourrait provoquer la mort, l'explosion,

l'encendie ou les brûlures.

1. La contre-pression du circuit d'evacuation ne DOIT pas

excéder 0.6 ponces (1,52 cm) de colonne d'eau, mesuréeavec

un manométre à tube incliné au point ou le conduit

d'évacuation est connecté sécheuse.

2. Il faut vérifier et nettoyer le circuit d'évacuation au moins

tous les deux ans dans des conditions d'utilisation normale.

Plus la sécheuse est utilisée fréquemment, plus le circuit

et le registre d'évacuation doivent être vérifies pour assurer

un bon.

La longueur maximum du systém d'évacuation dépend du type

de conduit utilisé, du nombre de coudes et du type de registre

d'évacuation. La longueur maximum de conduits rigides et

flexibles est indiquée dans le tableau suivant:

DOIVENT

être installés dans

– Risque d’incendie – une Sécheuse de vêtement doit être

aéré à l’air libre. N’aérez pas la Sécheuse dans une cheminée,

une paroi, un plafond, un espace fermé ou aucun espace caché

du bâtiment. Une sécheuse à linge produit de la charpie

combustible. Si l’air n’était pas repoussé à l’extérieur de la maison,

de petites particules de charpie se retrouveraient dans la pièce où

est installée la sécheuse. Toute accumulation de charpie dans la

maison peut présenter des risques pour la santé et des risques

d’incendie.

14

Page 15

EMPLACEMENT DU COMBINÉE LAVEUSE/SÉCHEUSE

NE PAS INSTALLER COMBINÉ LAVEUSE/ SÉCHEUSE :

1. Dans un endroit exposé à un écoulement d’eau ou aux

conditions atmosphériques.

2. Dans un endroit où elle serait en contact avec des rideaux,

draperies ou tout ce qui obstruera le flux d'air de combustion

et de ventilation.

3. Sur un tapis. Le plancher DOIT être ferme et présenter une

pente de 2,54 cm (1 po) au maximum.

INSTALLATION DANS UNE ALCÔVE OU UN PLACARD

1. Toute sécheuse installée dans une chambre à coucher, une

salle de bain, une alcôve ou un placard DOIT être reliée à une

conduite d’évacuation d’air se terminant à l’extérieur de la

maison.

2. Aucun autre appareil brûlant du combustible ne doit être

installé dans le même placard que la sécheuse au Gaz.

3. La sécheuse a besoin d’un dégagement suffisant pour

permettre la circulation de l’air.

NE PAS INSTALLER LA SÉCHEUSE DANS UN PLACARD

POURVU D’UNEPORTE PLEINE.

4. Une ouverture minimum de 774,2 cm² (120 po²) répartie

également entre le haut et le bas de la porte est requise. Cette

ouverture ne doit pas être obstruée lorsque la porte est en place.

Une porte à volets dont les ouvertures totalisent la norme décrite

ci-dessus est acceptable.

5. Les illustrations qui suivent indiquent la dimension minimum

de dégagement pour un fonctionnement adéquat dans une

niche ou une armoire.

ALIMENTATION EN GAZ

Remplacer le tuyau de raccordement en

cuivre non recouvert de plastique. Il FAUT utiliser du laiton

inoxydable ou recouvert de plastique.

1. L’installation DOIT respecter les codes locaux, ou s’il n’existe

pas de codes locaux, le code ANSI Z223.1 (l’édition la plus

récente) ou au Canada, le Code actuel CAN/CGA B149.

2. La conduite d’alimentation en gaz doit mesurer 1,27 cm (1/

2 po).

3. Si les codes le permettent, un tuyau en métal flexible peut être

utilisé pour connecter la sécheuse à l’alimentation en gaz. Le

tuyau DOIT être fabriqué en acier inoxydable ou en cuivre avec

un revêtement de plastique.

4. La conduite d’alimentation en gaz DOIT comporter un robinet

d’arrêt distinct.

5. Une prise de 0,32 cm (1/8 po) NPT accessible pour le

branchement d’un manomètre DOIT être installée tout juste

en amont du branchement de la conduite d’alimentation en

gaz sur la sécheuse.

6. La sécheuse DOIT être débranchée de la canalisation de gaz

pendant toute vérification de pression de l’alimentation en gaz

à des pressions qui dépassent 3,45 kPa (1/2 lb/po²).

7. La sécheuse DOIT être isolée de la canalisation de gaz pendant

toute vérification de pression de l’alimentation en gaz à des

pressions égales ou inférieures à 3,45 kPa (1/2 lb/po²).

15

Page 16

2 ½ IN.

(6.35 CM)

1 7/8 IN.

(4.76 CM)

4 13/16 IN.

(12.22 CM)

11 7/16 IN.

(29.5 CM)

25 ¼ IN.

(64.13 CM)

47“

(78.26 CM)

30 13/16 IN.

36 1/16IN.

(91.60 CM)

16 ¼ IN.

(41.27 CM)

(ARRIÉRE)

43 IN.

TUYAU D'ALIMENTATION EN GAZ

PIPE (REAR)

GAS SUPPLY

(109.22 CM)

41 ¼ IN

(104.77 CM)

5 ¼ IN.

(13.33 CM)

29 7/16 IN

(74.77 CM)

Dimensions de l’emplacement

9 3/8 IN.

(23.81 CM)

12 ½ IN.

(31.75 CM)

VENT

CONNEXCIONS ÉLECTRIQUES

ELECTRICAL

75 ½ IN.

(191.77 CM)

WATER INLETS

CONNECTION

ARRIVÉES D'EAU (ARRIÉRE)

54 5/16 IN.

(137.95 CM)

16

(REAR)

DRAIN OUTLET

VIDANGE (ARRIÉRE)

3 ¾ IN.

(9.52 CM)

27 IN.

(68.58CM)

(REAR)

43 IN.

(109.22 CM)

Page 17

17

Page 18

INSTALLATION ÉLECTRIQUE

TOUS combinées laveude/sécheuses ÉLECTRIQUES

Les mises en garde qui suivent se

rapportent directement au branchement électrique correct

et sécuritaire de la sécheuse. Toute dérogation à ces mises

en garde pourrait entraîner des risques choc électrique et

d’incendie.

Pour brancher la sécheuse en permanence :

La combiné DOIT être branchée à une installation métallique

mise à la terre en permanence; sinon, un conducteur de mise

à la terre de l’appareil doit suivre les conducteurs du circuit et

être branché à la borne ou à la connexion de mise à la terre

de l’appareil.

Combiné laveuse/sécheuses ÉLECTRIQUES Canadiennes

Cet appareil DOIT être convenablement mis à la terre. Si le

combiné présenterait des risques choc électrique si elle n’était

pas convenablement mise à la terre. Respecter les directives de

mise à la terre contenues dans cette notice pour une mise à la

terre correcte.

Ne pas utiliser de cordon de rallonge avec ce combiné.

Certains cordons de rallonge ne sont pas conçus pour supporter

l’intensité du courant qu’utilise cette combiné; ils peuvent fondre

et présenter un risque choc électrique ou d’incendie. Placer la

sécheuse à portée de la prise murale afin de déterminer la

longueur du cordon à acheter et prévoir un certain jeu dans la

longueur du cordon. Se reporter à la section «Avant l’installation»

de cette notice pour savoir quel type de cordon acheter.

Un détendeur approuvé par U.L. doit être fixé au cordon

d’alimentation. Si le détendeur n’était pas présent, le cordon

pourrait être arraché de la combiné ou coupé par tout type de

mouvement, ce qui présenterait un risque choc électrique.

Ne pas utiliser une prise à conducteurs en aluminium avec

un cordon ou une prise à conducteurs en cuivre (ni l’inverse). Une

réaction chimique se produit entre le cuivre et l’aluminium qui

pourrait causer un court-circuit. Il faut utiliser un cordon

d’alimentation à conducteurs en cuivre avec une prise à

conducteurs en cuivre.

REMARQUE : Le délai séchage d'un combiné laveuse/

sécheuse qui fonctionnent avec une alimentation de 208

volts auront un temps de séchage plus long que celles qui

utilisent une alimentation de 240 volts.

MISE À LA TERRE

DANGER

mise à la terre pourrait présenter un risque choc électrique. En

cas de doute quant à la mise à la terre adéquate de l’appareil,

contacter un électricien agréé.

Pour brancher et mettre à la terre la sécheuse à l’aide d’un cordon

d’alimentation :

1. La sécheuse doit être mise à la terre. En cas de mauvais

fonctionnement ou de panne, la mise à la terre réduit les

risques choc électrique en offrant un parcours de moindre

résistance au courant.

2. Puisque la sécheuse est pourvue d’un cordon d’alimentation

électrique comportant un conducteur et une fiche de terre, la

fiche doit être branchée dans une prise murale à conducteur

en cuivre convenablement raccordée au réseau et mise à la

terre conformément à tous les codes et ordonnances locaux.

En cas de doute, contacter un électricien agréé.

Le branchement inadéquat du conducteur de

TOUS combinés laveuse/ sécheuses à GAZ

Pour votre protection contre les chocs électriques, la sécheuse

est équipée d'une fiche à trois bornes (mise à la terre) et doit être

branchée directement dans une prise à 3 bornes correctement

mise à la terre. Ne pas couper ni enlever la fiche de mise à la

terre de cette prise.

BRANCHEMENT ÉLECTRIQUE D’UNE INSTALLATION À 3 FILS

Non-Canadien

Combiné laveuse/sécheuses ÉLECTRIQUES

Sécheuses ÉLECTRIQUES non-Canadiennes

DANGER

mise à la terre pourrait présenter un risque choc électrique. En

cas de doute quant à la mise à la terre adéquate de l’appareil,

contacter un électricien agréé.

Pour brancher et mettre à la terre la sécheuse à l’aide d’un cordon

d’alimentation :

1. Las combiné DOIT être mise à la terre. En cas de mauvais

fonctionnement ou de panne, la mise à la terre réduit les

risques choc électrique en offrant un parcours de moindre

résistance au courant.

2. Si la combiné est pourvue d’un cordon d’alimentation

électrique comportant un conducteur et une fiche de terre, la

fiche DOIT être branchée dans une prise murale à conducteur

en cuivre convenablement raccordée au réseau et mise à la

terre conformément à tous les codes et ordonnances locaux.

En cas de doute, contacter un électricien agréé. Ne modifiez

pas la prise équipée d’appareil.

Le branchement inadéquat du conducteur de

1. Retirer les vis qui retiennent le couvercle

du panneau de branchement ainsi que le

support de montage du détendeur situés

dans le coin supérieur à l’arrière de la

sécheuse.

2. Poser un détendeur approuvé par U.L. dans le trou du support

où s’insère le cordon d’alimentation. Serrer simplement

l’écrou à la main pour le moment.

3. Enfiler un cordon d’alimentation NEMA 10-30 approuvé par

U.L. de 30 A de type SRDT dans le détendeur.

18

Page 19

4. Fixer le conducteur neutre (conducteur central) du cordon

d’alimentation à la borne centrale argentée du panneau de

branchement. Serrer la vis à fond.

5. Fixer les deux conducteurs restants du cordon d’alimentation

aux bornes cuivrées extérieures du panneau de branchement.

Serrer les deux vis à fond.

6. Serrer à fond les vis qui retiennent le dispositif de retenue du

cordon autour du cordon d’alimentation.

7. Réattacher le couvercle du panneau de branchement.

19

Page 20

10. Reliez les conduits d'évacuation d'air conduit d'évacuation

extétieur. Utilisez un ruban adhésif pour conduits pour

sceller les joints.

11. Brancher le cordon d’alimentation électrique dans une

prise mise à la terre. REMARQUE : S’assurer que le

courant est coupé à la boîte de fusibles ou de disjoncteurs

avant de brancher le cordon d’alimentation dans une

prise.

12. Remettre le courant à la boîte de fusibles ou de disjoncteurs.

Avant d’utiliser la combiné, s’assurer que les

environs de la sécheuse sont exempts de tout matériau

inflammable, d’essence et de toute autre vapeur inflammable.

S’assurer également qu’aucun objet (boîtes, vêtements, etc.)

n’obstrue la circulation de l’air servant à la combustion et à la

ventilation.

13. Faire fonctionner la laveuse/sécheuse sur un cycle complete

pour en vérifier le fonctionnement.

REMARQUE: Dans le cas des laveuse/sécheuses à gaz, la

conduite doit être vidée de son air avant que le brûleur ne

puisse s’allumer. Si le brûleur ne s’allume pas dans les

45 secondes qui suivent le premier démarrage, l’interrupteur

de sûreté éteint automatiquement le brûleur. Si cela se

produit, remettre la minuterie à «OFF» et attendre 5 minutes

avant de tenter une nouvelle fois d’allumer le brûleur.

14 Si la combiné ne fonctionne pas, passer en revue la section

de dépannage inclus dans le Guide de l’utilisateur avant

d’appeler un centre de service.

15. Placer cette notice près de la combiné pour référence future.

REMARQUE: Un schéma de câblage se trouve dans le panneau

de commande ou sous le couvercle de la sécheuse.

PIÈCES DE RECHANGE

Pour obtenir des pièces de rechange pour la laveuse/sécheuse,

contacter le magasin d’où vient la sécheuse .

Lors de tout travail d’entretien ou de

réparation des commandes, étiqueter tous les câbles avant de

les débrancher. Les erreurs de connexion de câble peuvent

entraîner un fonctionnement incorrect et dangereux. Une fois la

réparation ou l’entretien terminé, assurez-vous que l’appareil

fonctionne correctement.

Détruire le carton et les sacs en plastique

après avoir déballé la combiné. Des enfants risqueraient de s’en

servir comme jouet. Les cartons recouverts d’un tapis, d’un

couvre-lit ou d’une feuille de plastique peuvent former une

chambre étanche et faire suffoquer un enfant. Placer le matériel

d’emballage dans une poubelle ou les mettre hors de portée des

enfants.

Les directives qui figurent dans cette notice

et dans les autres documents qui accompagnent la sécheuse ne

sauraient couvrir toutes les circonstances et les situations

possibles. IL FAUT donc faire preuve de jugement et de prudence

pendant l’installation, l’utilisation et l’entretien de tout appareil

électroménager.

20

Loading...

Loading...