Page 1

Installation

Instructions

Gas & Electric Dryer

Instructions

d’installation

Sécheuse à gaz ou électrique

Instrucciones para la

instalación

Secadora a gas y eléctrica

Before beginning installation, carefully read these instructions. This

will simplify the installation and ensure the dryer is installed correctly

and safely. Leave these instructions near the Dryer after installation

for future reference.

NOTE: The electrical service to the Dryer must conform with local

codes and ordinances and the latest edition of the National Electrical

Code, ANSI/NFPA 70 or in Canada, CSA C22.1 Canadian Electrical Code

Part 1.

NOTE: The gas service to the Dryer must conform with local codes and

ordinances and the latest edition of the National Fuel Gas Code ANSI

Z223.1 or in Canada, CAN/CGA B149.12.

NOTE: The Dryer is designed under ANSI Z 21.5.1 or ANSI/UL 2158 CAN/CSA C22.2 No. 112 (latest editions) for HOME USE only. This

Dryer is not recommended for commercial applications such as

restaurants or beauty salons, etc.

Avant de commencer, lire attentivement le présent document. Cela

simplifiera l’installation et assurera la pose correcte et sécuritaire de

la sécheuse. Après l’installation, laisser ce document à proximité de

la sécheuse pour référence future.

REMARQUE : L’alimentation électrique de la sécheuse doit respecter

les codes et ordonnances locaux ainsi que l’édition la plus récente du

Code ANSI/NFPA 70, ou au Canada, le Code canadien d'électricité,

ACNOR C22.1, partie1.

REMARQUE : L’alimentation en gaz de la sécheuse doit respecter les

codes et ordonnances locaux ainsi que l’édition la plus récente du Code

ANSI Z223.1, ou au Canada, le code CAN/ACG B149.12.

REMARQUE : La sécheuse est conçue conformément au code ANSI Z

21.5.1 ou ANSI/UL 2158 - CAN/ACG C22.2 No. 112 (l’édition la plus

récente) pour un USAGE DOMESTIQUE seulement. Cette sécheuse n'est

pas recommandée pour utilisation commerciale, comme par exemple

un restaurant ou un salon de coiffure, etc.

Antes de comenzar la instalación, lea cuidadosamente estas

instrucciones. Esto simplificará la instalación y asegurará que la secadora

se instale correctamente y de manera segura. Después de completar la

instalación, coloque estas instrucciones cerca de la secadora para

referencia futura.

NOTA: La alimentación eléctrica para la secadora deberá cumplir con los

códigos y reglamentos locales y con la última edición del Código Eléctrico

Nacional, ANSI/NFPA 70 o en Canadá CSA C22.1 Código Eléctrico

Canadiense, Parte 1.

NOTA: La alimentación de gas para la secadora deberá cumplir con los

códigos y reglamentos locales y con la última edición del Código Nacional

para Gases Combustibles, ANSI Z223.1 o en Canadá CAN/CGA B149.12.

NOTA: La secadora está clasificada para USO DOMESTICO solamente,

de acuerdo con la norma ANSI Z 21.5.1 o ANSI/UL 2158 - CAN/CSA C22.2

No. 112 (las últimas ediciónes). Esta secadora no se recomienda para

uso commercial tal como en restaurantes, salones de belleza, etc.

Printed in U.S.A.

to minimize the risk of fire or explosion or to prevent property damage,

For your safety the information in this manual must be followed

personal injury or loss of life.

- Do not store or use gasoline or other flammable vapors and liquid in the

vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

· Do not try to light any appliance.

· Do not touch any electrical switch; do not use any phone in your

building.

· Clear the room, building or area of all occupants.

· Immediately call your gas supplier from a neighbor’s phone. Follow

the gas supplier's instructions.

· If you cannot reach your gas supplier, call the fire department.

Installations must be performed by a qualified or licensed contractor,

plumber, or gasfitter qualified or licensed by the state, province, or region

where this appliance is being installed.

le présent guide afin de minimiser les risques d’incendie, d’explosion, de

dommages matériels, de blessures et de mort.

- Ne pas entreposer ni utiliser d’essence ou d’autres vapeurs ou liquides

inflammables à proximité de cette sécheuse ou de tout autre appareil

électroménager.

- QUE FAIRE S’IL Y A UNE ODEUR DE GAZ

· N’allumer aucun appareil électrique.

· Ne toucher aucun commutateur électrique; ne pas utiliser le

téléphone dans l’immeuble.

· Faire sortir tous les occupants de la pièce, de l’immeuble ou de la

zone avoisinante.

· Appeler la compagnie de gaz immédiate-ment en utilisant le

téléphone d’un voisin. Suivre les instructions de la compagnie de

gaz.

· S’il est impossible de joindre la compagnie de gaz, appeler les

pompiers.

L’installation et les réparations doivent être effectuées par un technicien

qualifié, un agent de service ou la compagnie de gaz.

este manual a fin de reducir a un mínimo los riesgos de incendio o explosión

o para evitar daños materiales, lesiones personales o la muerte.

- No almacene ni utilice gasolina u otros vapores y líquidos inflamables en

la proximidad de éste o de cualquier otro artefacto eléctrico.

- QUE DEBE HACER SI PERCIBE OLOR A GAS

· No trate de encender ningún artefacto eléctrico.

· No toque ningún interruptor eléctrico; no use ningún teléfono en su

edificio.

· Haga salir a todos los ocupantes de la habitación, del edificio y del lugar.

· Llame a su proveedor de gas desde el teléfono de un vecino. Siga las

instrucciones del proveedor de gas.

· Si no logra comunicarse con su proveedor de gas, llame al

departamento de bomberos.

La instalación y el servicio de mantenimiento debe de realizarlos un instalador

calificado, la agencia de servicios o el proveedor de gas.

Pour votre sécurité, suivre les directives données dans

Para su seguridad, siga las instrucciones contenidas en

P/N 134296400E (0604)

Page 2

Contents

SUBJECT PAGE

re-Installation Requirements 2

P

Electrical Requirements 2

Exhaust System Requirements 2-3

Gas Supply Requirements 3

Location of Your Dryer 4

Mobile Home Installation 5

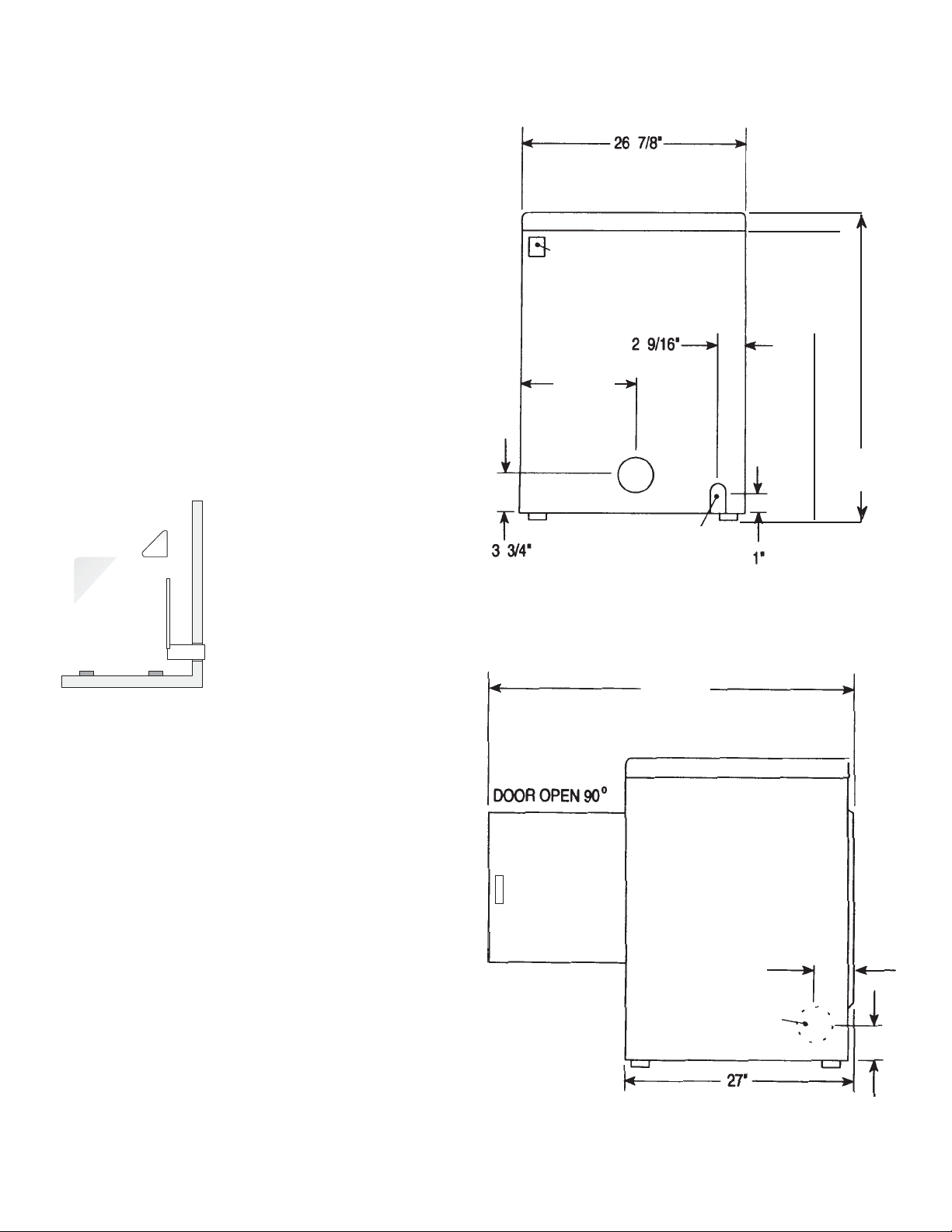

Rough-In Dimensions 5-6

Unpacking 6

Reversing Door Swing 6

Electrical Installation 7

Grounding Requirements 7

Electrical Connections—3-wire 7

Electrical Connections—4-wire 8

Installation 8

Replacement Parts 8

PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for Installation:

1. Phillips head screwdriver.

2. Channel-lock adjustable pliers.

3. Carpenter's level.

4. Flat or straight blade screwdriver.

5. Duct tape.

6. Rigid or flexible metal 4 inch (10.2 cm) duct.

7. Vent hood.

8. Pipe thread sealer (Gas).

9. Plastic knife.

ELECTRICAL REQUIREMENTS

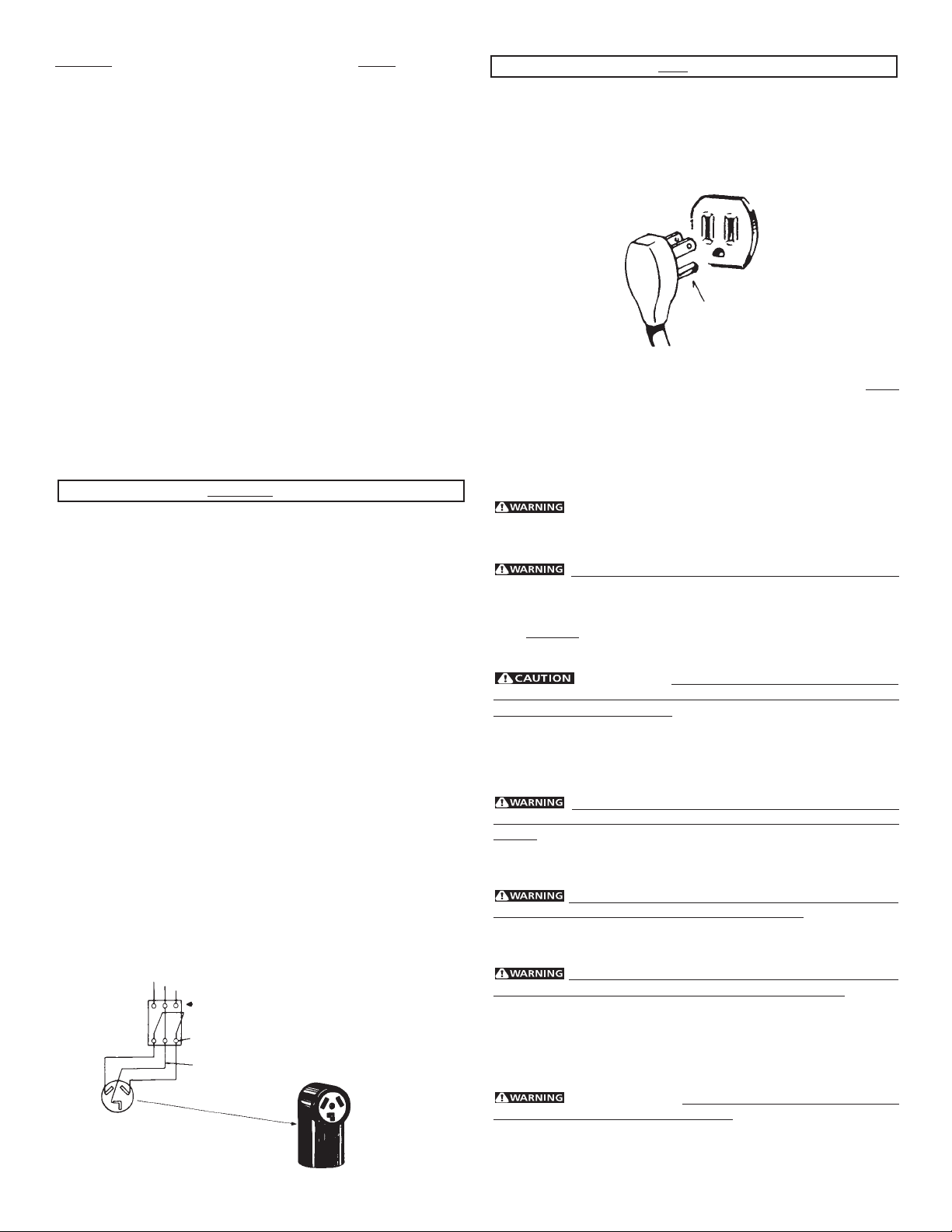

ELECTRIC Dryer

CIRCUIT - Individual 30 amp. branch circuit fused with 30 amp. time

delay fuses or circuit breakers.

Use separately fused circuits for washers and dryers, and DO NOT

operate a washer and a dryer on the same circuit.

POWER SUPPLY - 3 wire, 240 volt, single phase, 60 Hz, Alternating

Current. (Canada - 240 volt, single phase, 60 Hz, Alternating Current.)

POWER SUPPLY CORD KIT - The dryer MUST employ a 3-conductor

power supply cord NEMA 10-30 type SRDT rated at 240 volt AC

minimum, 30 amp., with 3 open end spade lug connectors with

upturned ends or closed loop connectors and marked for use with

clothes dryers.

WARNING – Risk of Shock. Appliance grounded to neutral

conductor through a link. Grounding through the neutral link is

prohibited for (1) New branch circuit installations (2) mobile homes;

(3) recreational vehicles; and (4) areas where local codes do not permit

grounding through the neutral, (1) disconnect the link from the

neutral, (2) use grounding terminal or lead to ground appliance in

accordance with local codes and (3) connect neutral terminal or lead

to branch circuit neutral in usual manner (if the appliance is to be

connected by means of a cord kit, use 4-conductor cord for this

purpose). USE COPPER CONDUCTOR ONLY. The dryer MUST employ

a 4-conductor power supply cord NEMA 14-30 type SRDT or ST (as

required) rated at 240 volt AC minimum, 30 amp., with 4 open end

spade lug connectors with upturned ends or closed loop connectors

and marked for use with clothes dryers. See ELECTRICAL

CONNECTIONS FOR A 4-WIRE SYSTEM.

(Canada - 4-wire power supply cord is installed on dryer.)

OUTLET RECEPTACLE - NEMA 10-30R receptacle to be located so

the power supply cord is accessible when the dryer is in the installed

position. (Canada - NEMA 14-30R receptacle.)

POWER SUPPLY

OUTLET

RECEPTACLE

(COPPER)

3 WIRE GROUNDED NEUTRAL

120-240 VOLT 60 CYCLE

MAIN FUSE BOX

30 AMP DELAYED ACTION

FUSES

OR CIRCUIT BREAKER

NEUTRAL WIRE

SUBJECT TO LOCAL

REGULATIONS

NEMA 10-30R (COPPER)

GAS Dryer

CIRCUIT - Individual 15 amp. branch circuit fused with a 15 amp.

maximum time delay fuse or circuit breaker.

POWER SUPPLY - 3 wire, 120 volt single phase, 60 Hz, Alternating

Current.

POWER SUPPLY CORD - The dryer is equipped with a 120 volt

3-wire power cord.

NOTE: Do not under

any circumstances

remove grounding

prong from plug.

GROUNDING PRONG

EXHAUST SYSTEM REQUIREMENTS

Use only 4 inch (10.2 cm) diameter (minimum) rigid or flexible metal

duct and approved vent hood which has a swing-out damper(s) that

open when the dryer is in operation. When the dryer stops, the

dampers automatically close to prevent drafts and the entrance of

insects and rodents. To avoid restricting the outlet, maintain a

minimum of 12 inches (30.5 cm) clearance between the vent hood

and the ground or any other obstruction.

The following are specific requirements for proper

and safe operation of your dryer. Failure to follow these

instructions can create excessive drying times and fire hazards.

Excessive lint can build up inside exhaust system and create a fire

hazard and restrict air flow. Restricted air flow will increase dryer

times. If your present system is made up of plastic duct or metal foil

duct,

duct is free of any lint prior to installing dryer duct.

lint. If the dryer is not exhausted outdoors, some fine lint will be

expelled into the laundry area. An accumulation of lint in any area of

the home can create a health and fire hazard. The dryer must be

connected to an exhaust outdoors. Regularly inspect the outdoor

exhaust opening and remove any accumulation of lint around the

outdoor exhaust opening and in the surrounding area.

clothing, draperies/curtains, paper) to come in contact with exhaust

system. The dryer MUST NOT be exhausted into a chimney, a wall, a

ceiling, or any concealed space of a building which can accumulate

lint, resulting in a fire hazard.

allowed in the "MAXIMUM LENGTH" charts can cause an

accumulation of lint in the exhaust system. Plugging the system

could create a fire hazard, as well as increase drying times.

use any screws or rivets to assemble the exhaust system. Lint can

become caught in the screen, on the screws or rivets, clogging the

duct work and creating a fire hazard as well as increasing drying

times. Use an approved vent hood to terminate the duct outdoors,

and seal all joints with duct tape. All male duct pipe fittings MUST be

installed downstream with the flow of air.

or other flammables are kept or stored. If the dryer is installed in a

garage, it must be a minimum of 18 inches (45.7 cm) above the floor.

Failure to do so can result in death, explosion, fire or burns.

2

Do not use plastic flexible duct to exhaust the dryer.

replace it with a rigid or flexible metal duct. Ensure the present

- Risk of Fire - A clothes dryer produces combustible

Do not allow combustible materials (for example:

Exceeding the length of duct pipe or number of elbows

Do not screen the exhaust ends of the vent system, nor

Explosion hazard. Do not install the dryer where gasoline

Page 3

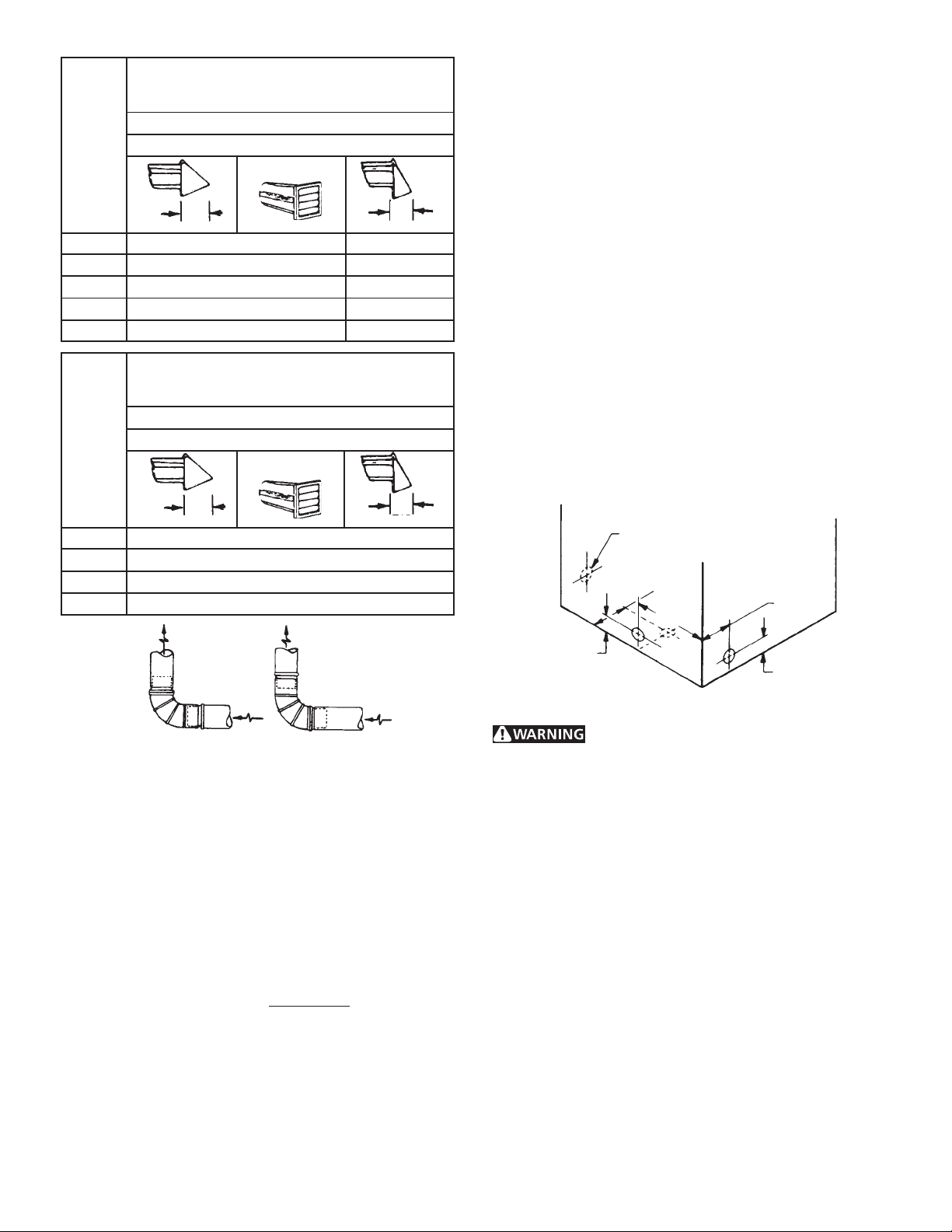

MAXIMUM LENGTH

of 4” (10.2 cm) Dia. Rigid Metal Duct

• Venting vertical through a roof may expose the exhaust

system to down drafts causing an increase in vent

restriction.

VENT HOOD TYPE

(Preferred)

Number

of

90°

Turns

4”

(10.2 cm)

0 60 ft. (18.28 m) 48 ft.(14.63 m)

1 52 ft. (15.84 m) 40 ft.(12.19 m)

2 44 ft. (13.41 m) 32 ft. (9.75 m)

3 32 ft. (9.75 m) 24 ft. (7.31 m)

4 28 ft. (8.53 m) 16 ft. (4.87 m)

Louvered

2½"

(6.35 cm)

MAXIMUM LENGTH

of 4” (10.2 cm) Dia. Flexible Metal Duct

VENT HOOD TYPE

(Preferred)

Number

of

90°

Turns

4”

(10.2 cm)

0 30 ft. (9.14 m) 18 ft. (5.49 m)

1 22 ft. (6.71 m) 14 ft. (4.27 m)

2 14 ft. (4.27 m) 10 ft. (3.05 m)

3 NOT RECOMMENDED

Louvered

2½"

(6.35 cm)

• Running the exhaust system through an uninsulated area

may cause condensation and faster accumulation of lint.

• Compression or crimping of the exhaust system will cause

an increase in vent restriction.

The exhaust system should be inspected and cleaned a

minimum of every 18 months with normal usage. The more the

dryer is used, the more often you should check the

exhaust system and vent hood for proper operation.

EXHAUST DIRECTION

All dryers shipped from the factory are set up for rear exhausting.

However, on electric dryers, exhausting can be to the right or left side

of the cabinet or the bottom of the dryer. On gas dryers, exhausting

can be to the right side of the cabinet or the bottom of the dryer.

Directional exhausting can be accomplished by installing Exhaust Kit,

P/N 131456800, available through your parts distributor. Follow the

instructions supplied with the kit.

EXHAUST DUCT LOCATING DIMENSIONS

SAME AS OTHER SIDESAME AS OTHER SIDE

SAME AS OTHER SIDE

SAME AS OTHER SIDESAME AS OTHER SIDE

5 7/8"5 7/8"

5 7/8"

5 7/8"5 7/8"

(15 cm)(15 cm)

(15 cm)

(15 cm)(15 cm)

13 1/2"13 1/2"

13 1/2"

13 1/2"13 1/2"

(34 cm)(34 cm)

(34 cm)

(34 cm)(34 cm)

4 3/8"4 3/8"

4 3/8"

4 3/8"4 3/8"

(11 cm)(11 cm)

(11 cm)

(11 cm)(11 cm)

CORRECT

INSTALL MALE FITTINGS IN CORRECT DIRECTION

INCORRECT

In installations where the exhaust system is not described in the

charts, the following method must be used to determine if the exhaust system is acceptable:

1. Connect an inclined or digital manometer between the

dryer and the point the exhaust connects to the dryer.

2. Set the dryer timer and temperature to air fluff (cool

down) and start the dryer.

3. Read the measurement on the manometer.

4. The system back pressure MUST NOT be higher than

0.75 inches of water column. If the system back

pressure is less than 0.75 inches of water column, the

system is acceptable. If the manometer reading is

higher than 0.75 inches of water column, the system is

too restrictive and the installation is unacceptable.

Although vertical orientation of the exhaust system is

acceptable, certain extenuating circumstances could affect the performance of the dryer:

• Only the rigid metal duct work should be used.

3 3/4"3 3/4"

3 3/4"

3 3/4"3 3/4"

(9.5 cm)(9.5 cm)

(9.5 cm)

(9.5 cm)(9.5 cm)

3 3/4"3 3/4"

3 3/4"

3 3/4"3 3/4"

(9.5 cm)(9.5 cm)

(9.5 cm)

(9.5 cm)(9.5 cm)

(9.5 cm)(9.5 cm)

(9.5 cm)

(9.5 cm)(9.5 cm)

GAS SUPPLY REQUIREMENTS

Replace copper connecting pipe that is not

plastic-coated. Stainless steel or plastic-coated brass MUST be

used.

1. Installation MUST conform with local codes, or in the absence

of local codes, with the National Fuel Gas Code, ANSI Z223.1

(latest edition) or in Canada, the current CAN/CGA B149.

2. The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3. If codes allow, flexible metal tubing may be used to connect your

dryer to the gas supply line. The tubing MUST be constructed of

stainless steel or plastic-coated brass.

4. The gas supply line MUST have an individual shutoff valve.

5. A 1/8 inch (0.32 cm) N.P.T. plugged tapping, accessible for test

gauge connection, MUST be installed immediately upstream of

the gas supply connection to the dryer.

6. The dryer MUST be disconnected from the gas supply piping

system during any pressure testing of the gas supply piping

system at test pressures in excess of 1/2 psig (3.45 kPa).

7. The dryer MUST be isolated from the gas supply piping system

during any pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2 psig (3.45 kPa).

3

Page 4

CLOSET DOORCLOSET DOOR

CLOSET DOOR

CLOSET DOORCLOSET DOOR

NOTE: Under counter and stack models - 0 inches (0 cm)

for sides, rear, and top.

4

Page 5

UNDER COUNTER & STACK MODELS

ROUGH-IN DIMENSIONS

(68.3 cm)

ELECTRIC CONNECTION

UNDER

COUNTER

34 5/8"

(87.9 cm)

(6.5 cm)

13 1/2"

(34.4 cm)

(91.5 cm)

36"

(9.5 cm)

3/4"3/4"

3/4"

3/4"3/4"

(1.9 cm)(1.9 cm)

(1.9 cm)

(1.9 cm)(1.9 cm)

33

3/8" (0.96 cm) DIA.

33

GAS PIPE

REAR VIEW

47 1/2"

(120.7 cm)

4 3/8"

(11.1 cm)

(2.54 cm)

OPTIONAL

VENT KNOCKOUT

((

(68.6 cm)

((

SIDE VIEWSIDE VIEW

SIDE VIEW

SIDE VIEWSIDE VIEW

3 3/4"

(9.5 cm)

5

Page 6

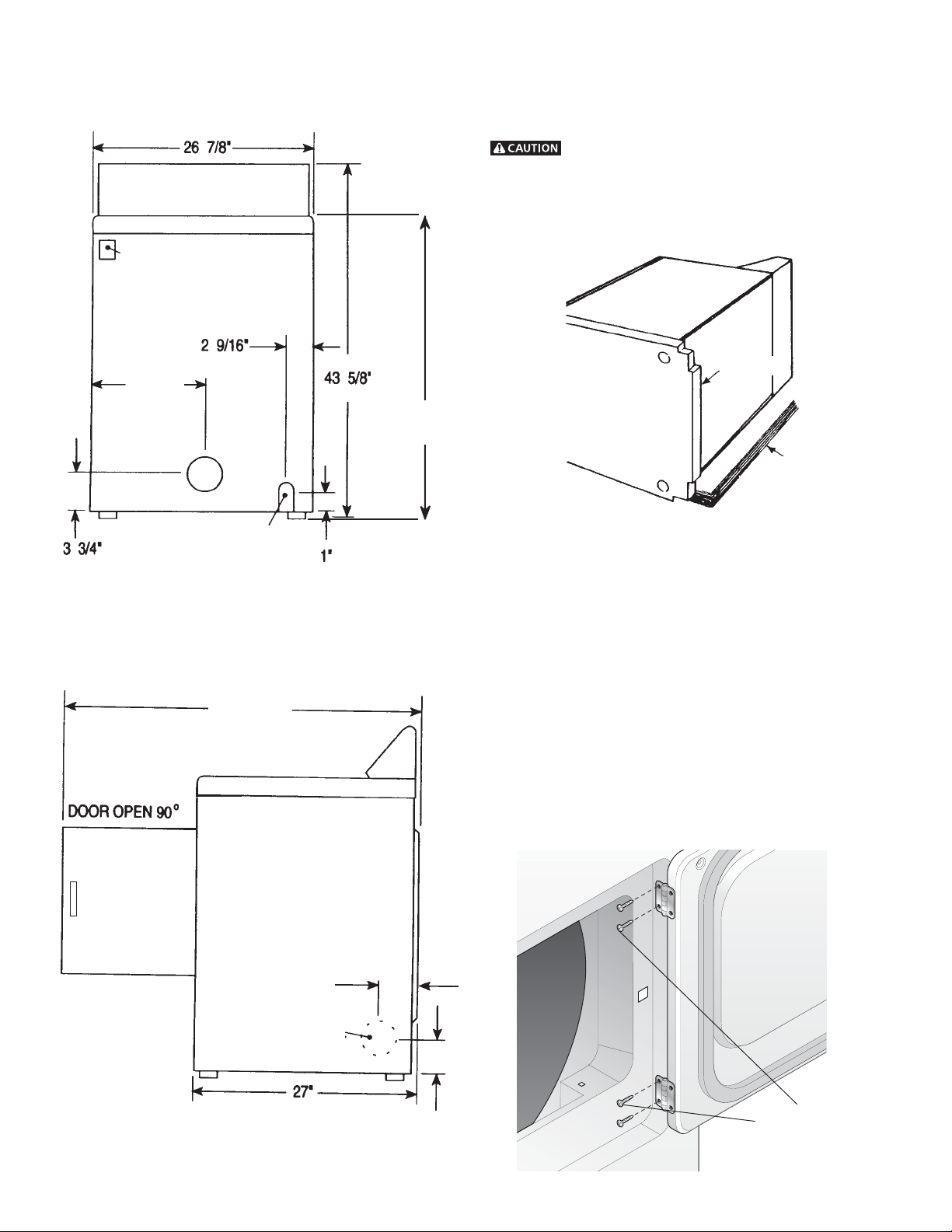

TOP CONSOLE MODELS

ROUGH-IN DIMENSIONSROUGH-IN DIMENSIONS

ROUGH-IN DIMENSIONS

ROUGH-IN DIMENSIONSROUGH-IN DIMENSIONS

UNPACKING

1. Using the four shipping carton corner posts (two on each side),

carefully lay the dryer on its left side and remove foam shipping

base.

(9.5 cm)(9.5 cm)

(9.5 cm)

(9.5 cm)(9.5 cm)

(68.3 cm)(68.3 cm)

(68.3 cm)

(68.3 cm)(68.3 cm)

ELECTRIC CONNECTIONELECTRIC CONNECTION

ELECTRIC CONNECTION

ELECTRIC CONNECTIONELECTRIC CONNECTION

(6.5 cm)(6.5 cm)

(6.5 cm)

(6.5 cm)(6.5 cm)

13 1/2"13 1/2"

13 1/2"

13 1/2"13 1/2"

(34.4 cm)(34.4 cm)

(34.4 cm)

(34.4 cm)(34.4 cm)

3/8" (0.96 cm) DIA.3/8" (0.96 cm) DIA.

3/8" (0.96 cm) DIA.

3/8" (0.96 cm) DIA.3/8" (0.96 cm) DIA.

GAS PIPEGAS PIPE

GAS PIPE

GAS PIPEGAS PIPE

REAR VIEWREAR VIEW

REAR VIEW

REAR VIEWREAR VIEW

(110.7 cm)(110.7 cm)

(110.7 cm)

(110.7 cm)(110.7 cm)

(2.54 cm)(2.54 cm)

(2.54 cm)

(2.54 cm)(2.54 cm)

36"36"

36"

36"36"

(91.5 cm)(91.5 cm)

(91.5 cm)

(91.5 cm)(91.5 cm)

means to pick up or move the dryer.

NOTE: On under counter model clothes dryers, the top panel

may be removed for installation.

2. Return the dryer to an upright position.

To prevent damage, do not use the control panel as a

FOAM

SHIPPING

PACKING

REVERSING DOOR SWING

Your dryer is designed so the door swing may be reversed at any time

without additional parts. Conversion is accomplished by transferring

hinges to the opposite side of the cabinet.

To change the direction of the door opening:

47 1/2"47 1/2"

47 1/2"

47 1/2"47 1/2"

(120.7 cm)(120.7 cm)

(120.7 cm)

(120.7 cm)(120.7 cm)

4 3/8"4 3/8"

4 3/8"

4 3/8"4 3/8"

(11.1 cm)(11.1 cm)

(11.1 cm)

(11.1 cm)(11.1 cm)

OPTIONALOPTIONAL

OPTIONAL

OPTIONALOPTIONAL

VENT KNOCKOUTVENT KNOCKOUT

VENT KNOCKOUT

VENT KNOCKOUTVENT KNOCKOUT

1. Open the dryer door. Remove the four hinge hole plugs from the

left side of the door opening. Place nearby for future installation.

NOTE: You may need a plastic knife to help pull out the plugs. Be

careful not to scratch the paint.

2. Remove the four screws that secure the door hinges to the dryer

front panel (see below). NOTE: Remove one screw from each of

the two hinges first. Hold the door firmly before removing the

last two screws.

3. Rotate the door 180° and reinstall the door hinges to the dryer

front panel with the four screws.

4. Install the four hinge hole plugs in the open screw holes on the

right side of the door opening.

(68.6 cm)(68.6 cm)

(68.6 cm)

(68.6 cm)(68.6 cm)

SIDE VIEWSIDE VIEW

SIDE VIEW

SIDE VIEWSIDE VIEW

3 3/4"3 3/4"

3 3/4"

3 3/4"3 3/4"

(9.5 cm)(9.5 cm)

(9.5 cm)

(9.5 cm)(9.5 cm)

REMOVE 4 SCREWS

(ONE FROM EACH

HINGE FIRST)

6

Page 7

ELECTRICAL INSTALLATION

ALL ELECTRIC Dryers

The following are specific requirements for proper

and safe electrical installation of your dryer. Failure to follow

these instructions can create electrical shock and/or a fire hazard.

This appliance MUST be properly grounded. Electrical shock can

result if the dryer is not properly grounded. Follow the instructions in

this manual for proper grounding.

Do not use an extension cord with this dryer. Some extension

cords are not designed to withstand the amounts of electrical current

this dryer utilizes and can melt, creating electrical shock and/or fire

hazard. Locate the dryer within reach of the receptacle for the length

power cord to be purchased, allowing some slack in the cord. Refer

to the pre-installation requirements in this manual for the proper

power cord to be purchased.

A U.L. approved strain relief must be installed onto power cord. If

the strain relief is not attached, the cord can be pulled out of the

dryer and can be cut by any movement of the cord, resulting in

electrical shock.

Do not use an aluminum wired receptacle with a copper wired

power cord and plug (or vice versa). A chemical reaction occurs

between copper and aluminum and can cause electrical shorts. The

proper wiring and receptacle is a copper wired power cord with

a copper wired receptacle.

NOTE: Dryers operating on 208 volt power supply will have longer

drying times than operating on 240 volt power supply.

GROUNDING REQUIREMENTS

Non-Canadian ELECTRIC Dryer

2. Since your dryer is equipped with a power supply cord having an

equipment-grounding conductor and a grounding plug, the plug

must be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes and

ordinances. If in doubt, call a licensed electrician.

ALL GAS Dryers

1. The laundry center is equipped with a three-prong

(grounding) plug for your protection against shock hazard and

should be plugged directly into a properly grounded

three-prong receptacle. Do not cut or remove the

grounding prong from the plug.

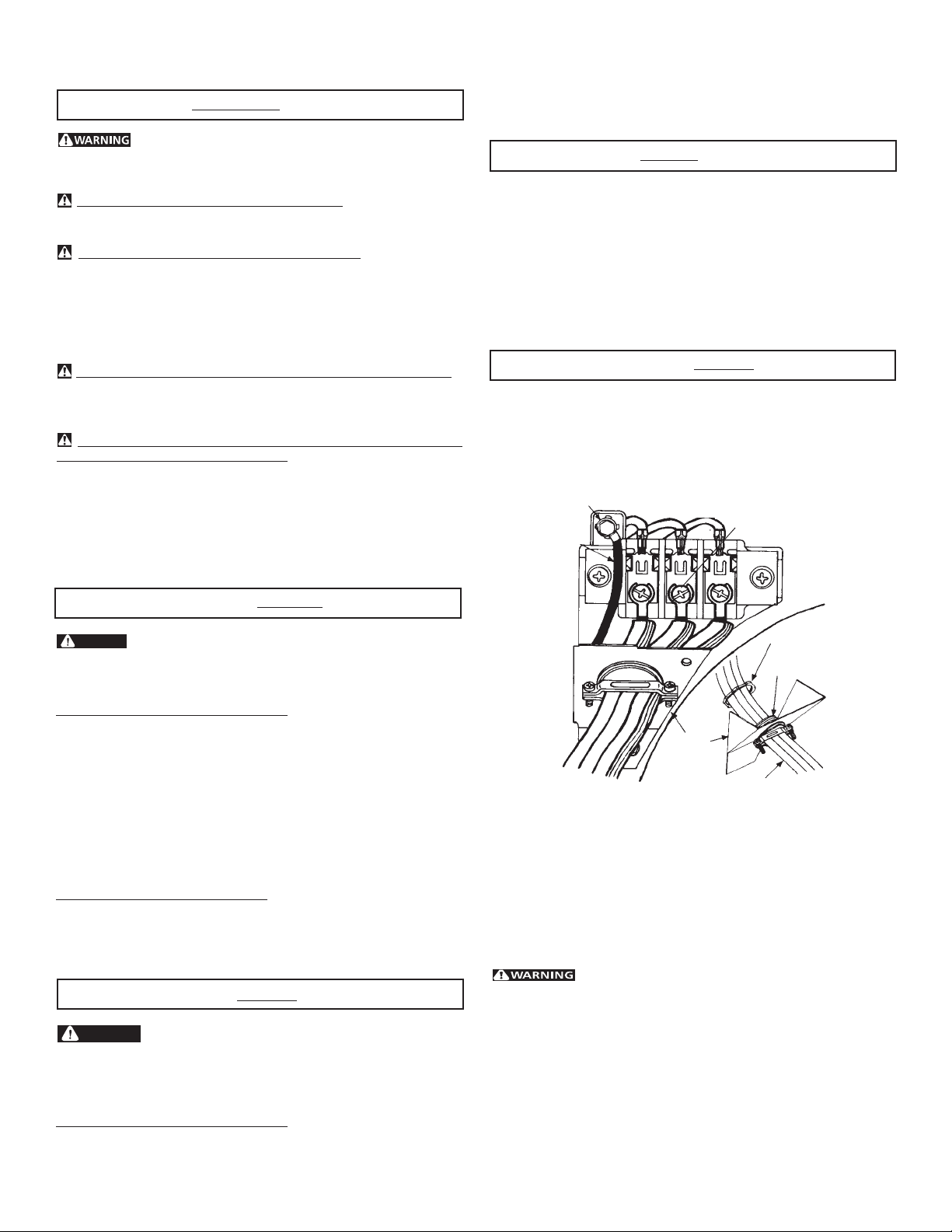

ELECTRICAL CONNECTIONS

FOR 3-WIRE SYSTEM

Non-Canadian ELECTRIC Dryer

1. Remove the screws securing the terminal block access cover and

the strain relief mounting bracket located on the back of the

dryer upper corner.

2. Install a U.L. approved strain relief into the power cord entry hole

of the mounting bracket. Finger tighten the nut only at this time.

GREEN GROUND SCREW

NEUTRAL

GROUND

WIRE

SILVER TERMINAL

DANGER

conductor can result in a risk of electrical shock. Check with a licensed

electrician if you are in doubt as to whether the appliance is properly

grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event of a malfunction or

breakdown, grounding will reduce the risk of electrical shock by

a path of least resistance for electrical current.

2. If your dryer is equipped with a power supply cord having an

equipment-grounding conductor and a grounding plug, the plug

MUST be plugged into an appropriate, copper wired receptacle

that is properly installed and grounded in accordance with all

local codes and ordinances. If in doubt, call a licensed electrician.

Do not modify plug provided with the appliance.

For a permanently connected dryer:

1. The dryer MUST be connected to a grounded metal, permanent

wiring system; or an equipment grounding conductor must be

run with the circuit conductors and connected to the equipmentgrounding terminal or lead on the appliance.

Improper connection of the equipment grounding

Canadian ELECTRIC Dryer

DANGER

conductor can result in a risk of electrical shock. Check with a licensed

electrician if you are in doubt as to whether the appliance is properly

grounded.

For a grounded, cord-connected dryer:

1. The dryer must be grounded. In the event of a malfunction or

breakdown, grounding will reduce the risk of electrical shock by

a path of least resistance for electrical current.

Improper connection of the equipment grounding

NUT

TIGHTEN NUT TO

THESE THREADS

STRAIN

RELIEF

MOUNTING

BRACKET

3. Thread a U.L. approved 30 amp. power cord, NEMA 10-30 Type

SRDT, through the strain relief.

4. Attach the power cord neutral (center wire) conductor to the

silver colored center terminal on the terminal block. Tighten the

screw securely.

5. Attach the remaining two power cord outer conductors to the

outer brass colored terminals on the terminal block. Tighten both

screws securely.

Do not make a sharp bend or crimp wiring/ conductor

at connections.

6. Reattach the strain relief mounting bracket to the back of the

dryer with two screws. Tighten screws securely.

7. Tighten the screws securing the cord restraint firmly against the

power cord.

8. Tighten the strain relief nut securely so that the strain relief does

not turn.

9. Reinstall the terminal block cover.

POWER CORD

7

Page 8

ELECTRICAL CONNECTIONS

FOR 4-WIRE SYSTEM

Non-Canadian ELECTRIC Dryer

1. Remove the screws securing the terminal block access cover and

the strain relief mounting bracket located on the back of the dryer

upper corner.

2. Install a U.L. approved strain relief in the entry hole of the mounting

bracket. Finger tighten the nut only at this time.

GREEN

GROUND

SCREW

NEUTRAL

GROUND

WIRE

3. Remove the ground wire from the green ground screw located

above the terminal block.

4. Thread a U.L. approved 30 amp power cord, NEMA 14-30 type ST

or SRDT through the strain relief.

5. Attach the green power cord ground wire to the cabinet with the

green ground screw.

6. Attach the white (neutral) power cord conductor from the power

cord and the neutral ground wire from the dryer harness to the

silver-colored center terminal on the terminal block. Tighten the

screw securely.

GREEN POWERCORD

GROUND WIRE

RED

MOUNTING

POWER

CORD

TYPICAL 4

CONDUCTOR

TYPICAL 4

CONDUCTOR

30 AMP NEMA 14-30 TYPE SRDT OR30 AMP NEMA 14-30 TYPE SRDT OR

30 AMP NEMA 14-30 TYPE SRDT OR

30 AMP NEMA 14-30 TYPE SRDT OR30 AMP NEMA 14-30 TYPE SRDT OR

SILVER TERMINAL

WHITE

STRAIN

RELIEF

BRACKET

TERMINAL

BLOCK

BLACK

NUT

BLACK

WHITE

RED 240V

GREEN

TIGHTEN NUT

TO THESE

THREADS

INSTALLATION

1. GAS CONNECTION (Gas dryers only)

a. Remove the shipping cap from gas pipe at the rear of the

dryer.

NOTE: DO NOT connect the dryer to L.P. gas service without

converting the gas valve. An L.P. conversion kit must be

installed by a qualified gas technician.

b. Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or approved pipe

from gas supply line to the 3/8 inch (0.96 cm) pipe located

on the back of the dryer. Use a 1/2 inch to 3/8 inch (1.27 cm

to 0.96 cm) reducer for a connection. Apply an approved

thread sealer that is resistant to the corrosive action of

liquefied gases on all pipe connections.

c. Open the shutoff valve in the gas supply line.

d. Test all connections by brushing on a soapy water solution.

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

2. Connect the exhaust duct to outside exhaust system. Use duct

tape to seal all joints.

3. With the dryer in its final position, adjust one or more of the legs

until the dryer is resting solid on all four legs. Place a level on top

of the dryer. THE DRYER MUST BE LEVEL AND RESTING SOLID

ON ALL FOUR LEGS.

4. Plug the power cord into a grounded outlet. NOTE: Check to

ensure the power is off at circuit breaker/fuse box before

plugging the power cord into the outlet.

5. Turn on the power at the circuit breaker/fuse box.

Before operating the dryer, make sure the dryer area

is clear and free from combustible materials, gasoline, and other

flammable vapors. Also see that nothing (such as boxes, clothing,

etc.) obstructs the flow of combustion and ventilation air.

6. Run the dryer through a cycle check for proper operation.

NOTE: On gas dryers, before the burner will light, it is necessary

for the gas line to be bled of air. If the burner does not light

within 45 seconds the first time the dryer is turned on, the safety

switch will shut the burner off. If this happens, turn the timer to

"OFF" and wait 5 minutes before making another attempt to

light.

7. If your dryer does not operate, please review the "Avoid Service

Checklist" located in your Owner's Guide before calling for

service.

8. Place these instructions in a location near the dryer for future

reference.

NOTE: A wiring diagram is located inside the dryer console or

under the top panel.

REPLACEMENT PARTS

7. Attach the red and black power cord conductors to the outer

brass-colored terminals on the terminal block.

Do not make a sharp bend or crimp wiring/ conductor

at the connections.

8. Tighten the screws securing the cord restraint firmly against the

power cord.

9. Tighten the strain relief nut securely so the strain relief does not

turn.

10. Reinstall the terminal block access cover.

If replacement parts are needed for your dryer, contact the source

where you purchased your dryer.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

Destroy the carton and plastic bags after the dryer is

unpacked. Children might use them for play. Cartons covered with

rugs, bedspreads, or plastic sheets can become airtight chambers

causing suffocation. Place all materials in a garbage container or

make materials inaccessible to children.

The instructions in this manual and all other literature

included with this dryer are not meant to cover every possible

condition and situation that may occur. Good safe practice and

caution MUST be applied when installing, operating and

maintaining any appliance.

8

Page 9

SUJET PAGE

Avant l’installation 9

Installation électrique 9

Évacuation de l’air 9-10

Alimentation en gaz 10

Emplacement de la sécheuse 11

Installation dans une maison mobile 12

Dimensions de l’emplacement 12-13

Déballage 13

Porte Réversible 13

Installation électrique 14

Mise à la terre 14

Branchement électrique - 3 fils 14

Branchement électrique - 4 fils 15

Installation 15

Pièces de rechange 15

Outils et matériel requis pour l’installation :

1. Tournevis à pointe cruciforme

2. Pinces multiprise

3. Niveau de menuisier

4. Tournevis à pointe plate ou à lame droite

5. Ruban adhésif pour conduites

6. Conduite en métal rigide ou flexible de 10,2 cm (4 po)

7. Grille de sortie

8. Pâte à joint pour conduites (modèle à gaz)

9. Couteau à mastic en plastique

AVANT L’INSTALLATION

INSTALLATION ÉLECTRIQUE

Sécheuses ÉLECTRIQUES

CIRCUIT - Dérivation distincte de 30 A avec fusibles à retardement ou

disjoncteurs d’au 30 A.

Utilisez des circuits avec un disjoncteur ou fusible séparé pour les

machines à laver et sécheuses, et NE PAS faire fonctionner une machine

à laver et une sécheuse sur un même circuit.

ALIMENTATION ÉLECTRIQUE - 3 fils, 240 volts, une phase, 60 Hz,

courant alternatif. (Canada - 240 volts, une phase, 60 Hz, courant

alternatif.)

CORDON D’ALIMENTATION ÉLECTRIQUE - La sécheuse DOIT être

reliée à un cordon d’alimentation électrique à 3 conducteurs NEMA

10-30 de type SRDT d’une capacité minimale de 240 volts, courant

alternatif, 30 A, avec fiche en L à 3 broches pleines ou repliées conçue

pour le branchement d’une sécheuse.

AVERTISSEMENT – Risque de choc électrique. Un appareil mis à la

terre à l’aide d’un lien ou câble conducteur neutre. La mise à la terre à

l’aide d’un conducteur ou câble neutre est interdite dans les cas suivants

: (1) les installations de nouveau circuit déviré (2) les maisons mobiles

(3) les véhicules récréatifs ou caravanes et (4) les régions où les codes

locaux interdisent la mise à la terre à l’aide d’un câble ou conducteur

neutre. (1) Débranchez le conducteur ou câble du neutre, (2) utilisez la

borne de mise à la terre ou le câble de mise à la terre de l’appareil

conformément aux codes locaux et (3) connectez ou branchez la borne

neutre ou le câble au neutre du circuit déviré de la manière habituelle

(si l’appareil doit être connecté à l’aide d’un cordon, utilisez un cordon

à 4 câbles ou fils pour ce faire). N’UTILISEZ QUE DES CÂBLES OU FILS EN

CUIVRE.

Elle DOIT être reliée à un cordon d’alimentation électrique à

4 conducteurs NEMA 14-30 de type SRDT ou ST (au besoin) d’une

capacité minimale de 240 volts, courant alternatif, 30 A, avec fiche en

L à 4 broches pleines ou repliées conçue pour le branchement d’une

sécheuse. Se reporter à la section BRANCHEMENT ÉLECTRIQUE D’UNE

INSTALLATION À 4 FILS.

(Canada - Cordon d'alimentation à 4 fils branché à la sécheuse.

PRISE - Prise NEMA 10-30R située de façon à ce que le cordon

d’alimentation électrique soit accessible une fois la sécheuse en place.

(Canada - prise NEMA de 14-30R.)

Table des matières

ALIMENTATION

ÉLECTRIQUE

PRISE MURALE (CUIVRE)

SOUS RÉSERVE DES EXIGENCES

LOCALES

BOÎTE À FUSIBLES PRINCIPALE

NEUTRE À 3 FILS 120-240 VOLTS 60 CYCLES

FUSIBLES À RETARDEMENT OU

DISJONCTEUR DE 30 A

FIL NEUTRE

NEMA 10-30R (CUIVRE)

Sécheuses à GAZ

CIRCUIT - Dérivation distincte de 15 A avec fusible à retardement ou

disjoncteur d’au plus 15 A.

ALIMENTATION ÉLECTRIQUE - 3 fils, 120 volts, une phase, 60 Hz,

courant alternatif.

CORDON D’ALIMENTATION ÉLECTRIQUE - La sécheuse est

pourvue d’un cordon d’alimentation électrique à 3 fils de

120 volts.

REMARQUE : Il ne faut

en aucun cas retirer la

broche de mise à la

terre de la fiche.

BROCHE DE MISE

À LA TERRE

ÉVACUATION DE L’AIR

Utiliser uniquement une conduite en métal rigide ou flexible de

10,2 cm (4 po) de diamètre (minimum) ainsi qu’une grille de sortie

approuvée pourvue de clapets qui s’ouvrent lorsque la sécheuse

fonctionne. Quand la sécheuse s’arrête, les clapets se ferment

automatiquement pour éviter les courants d’air et l’entrée d’insectes

ou de rongeurs. Afin de ne pas obstruer l’évacuation de l’air, laisser

une distance minimum de 30,5 cm (12 po) entre la grille de sortie et le

sol ou tout autre obstacle.

directement au fonctionnement correct et sécuritaire de la

sécheuse. Toute dérogation à ces mises en garde pourrait ralentir

le séchage et entraîner des risques d’incendie.

Ne pas utiliser de conduites en plastique flexible pour évacuer l’air

de la sécheuse. Une quantité excessive de charpie pourrait s’accumuler

dans la conduite d’évacuation, ce qui réduirait la circulation de l’air et

présenterait un risque d’incendie. Toute obstruction de la circulation

de l’air ralentit le séchage. Si la conduite existante est en plastique ou

en papier métallique, la

ou flexible. S’assurer qu’il n’y a pas de charpie dans la conduite

existante avant d’installer la conduite de la sécheuse.

– Risque d’incendie – Une sécheuse à linge produit de la charpie

combustible. Si l’air n’était pas repoussé à l’extérieur de la maison, de

petites particules de charpie se retrouveraient dans la pièce où est

installée la sécheuse. Toute accumulation de charpie dans la maison

peut présenter des risques pour la santé et des risques d’incendie. La

sécheuse doit être connectée à une bouche d’évacuation vers

l’extérieur du bâtiment ou de l’immeuble. Vous devez inspecter

régulièrement l’évent extérieur et enlever toute accumulation de

charpie autour de l’évent et dans la cavité du conduit d’évacuation.

Ne laisser aucun matériau inflammable (comme des vêtements,

des tentures, des rideaux ou du papier) entrer en contact avec les

conduits d’évacuation. L’air de la sécheuse NE DOIT PAS être évacué

dans une cheminée, un mur, un plafond ni tout espace fermé d’un

bâtiment où la charpie pourrait s’accumuler et présenter un risque

d’incendie.

Augmenter la longueur du conduit rigide ou le nombre de coudes

permis au tableau «LONGUEUR MAXIMUM» risque de réduire la

capacité d'évacuation du circuit. Obturer le circuit peut créer un risque

d'incendie et augmenter le temps de séchage.

Ne pas poser de grillage sur l’ouverture extérieure des conduites

d’évacuation d’air ni utiliser des vis ou des rivets pour assembler la

conduite d’évacuation. De la charpie pourrait s’emprisonner dans le

grillage ou sur les vis ou les rivets et ainsi engorger la conduite

d’évacuation en plus de présenter un risque d’incendie et de ralentir le

séchage. Utiliser une grille de sortie approuvée pour fermer l’ouverture

extérieure et sceller tous les joints à l’aide d’un ruban adhésif pour

conduites. L’extrémité mâle de chaque composante de la conduite DOIT

être installée en aval par rapport à la circulation de l’air.

endroit où l'on garde de la gazoline ou tout autre produit inflammable.

Si la sécheuse est installée dans un garage, elle doit être à un minimum

de 45,7 cm (18 po) au-dessus du plancher. Toute dérogation pourrait

provoquer la mort, l'explosion, l'encendie ou les brûlures.

9

Les mises en garde qui suivent se rapportent

remplacer par une conduite en métal rigide

Risques d'explosion. Ne pas installer la sécheuse à un

Page 10

LONGUEUR MAXIMUM

d’une conduite en métal rigide de

10,16 cm (4 po) de diam.

TYPE DE GRILLE DE SORTIE

(Recommandé)

Nombre de

coudes à

90°

10,210,2

10,2

10,210,2

cmcm

cm

cmcm

(4 po)(4 po)

(4 po)

(4 po)(4 po)

0 18,28 m (60 po) 14,63 m (48 po)

1 15,84 m (52 po) 12,19 m (40 po)

2 13,41 m (44 po) 9,75 m (32 po)

3 9,75 m (32 po) 7,31 m (24 po)

4 8,53 m (28 po) 4,87 m (16 po)

à volet

6,35 6,35

6,35

6,35 6,35

cmcm

cm

cmcm

(2 1/2 po)(2 1/2 po)

(2 1/2 po)

(2 1/2 po)(2 1/2 po)

LONGUEUR MAXIMUM

d’une conduite en métal flexible de

10,16 cm (4 po) de diam.

TYPE DE GRILLE DE SORTIE

(Recommandé)

Nombre de

coudes à

90

°

10,210,2

10,2

10,210,2

cmcm

cm

cmcm

(4 po)(4 po)

(4 po)

(4 po)(4 po)

0 9,14 m (30 po) 5,49 m (18 po)

1 6,71 m (22 po) 4,27 m (14 po)

2 4,27 m (14 po) 3,05 m (10 po)

3 NON RECOMMANDÉ

CORRECTCORRECT

CORRECT

CORRECTCORRECT

POSER LES RACCORDS MÂLES DANS LA BONNE DIRECTION

Pour les installations dont le circuit d'évacuation n'est pas décrit

dans les tableaux, il faut utiliser la méthode suivante si le circuit

d'évacuation n'est pas acceptable:

1. Brancher un manomètre digital ou à tube incliné entre la

sécheuse et le raccord d'évacuation de la sécheuse.

2. Régler la minuterie de la sécheuse et la température à air froid

(refroidissement) et démarrez la sécheuse.

3. Lire la mesure indiquée au manomètre.

4. La basse pression ne doit pas être supérieure à 0,75 pouce de

colonne d'eau. Si la basse pression est inférieure à 0,75 pouce

de colonne d'eau, le circuit est acceptable. Si la lecture

indique une pression supérieure à 0,75 pouce de colonne

d'eau, la capacité du circuit est insuffisante et l'installation

inacceptable.

Bien qu'un circuit vertical soit acceptable, certaines circonstances

atténuantes peuvent influencer la performance de la sécheuse.

• Il faut utiliser uniquement des conduits rigides en métal.

• Une sortie sur un toit d'un circuit vertical peut exposer celui-

à volet

INCORRECTINCORRECT

INCORRECT

INCORRECTINCORRECT

6,35 6,35

6,35

6,35 6,35

cmcm

cm

cmcm

(2 1/2 po)(2 1/2 po)

(2 1/2 po)

(2 1/2 po)(2 1/2 po)

ci à un contre-tirage et ainsi réduire sa capacité d'évacuation.

• L'isolant que doit traverser un tel circuit peut causer de la

condensation et ainsi réduire la capacité d'évacuation du

circuit.

• Un circuit d'évacuation comprimé ou ondulant peut voir sa

capacité d'évacuation réduite.

Il faut inspecter le circuit d'évacuation et le nettoyer au moins à

tous les 18 mois d'utilisation normale. Plus la sécheuse est

utilisée, plus il faut procéder souvent à une vérification du bon

fonctionnement du circuit d'évacuation et du couvercle du

registre ou de l'évent.

DIRECTION DE L’ÉVACUATION D’AIR

Toutes les sécheuses empaquetées par l’usine sont conçues de façon

à ce que l’évacuation d’air se fasse à l’arrière. Toutefois, dans le cas des

sécheuses électriques, l’évacuation d’air peut se faire sur la droite ou

sur la gauche du boîtier ou encore, sous la sécheuse. Dans le cas des

sécheuses à gaz, l’évacuation d’air peut se faire sur la droite du boîtier

ou sous la sécheuse. On peut donc modifier l’orientation de

l’évacuation d’air en installant un ensemble d'évacuation d'air n° de

pièce 131456800 disponible chez d’un fournisseur de pièces agréé.

Suivre les directives qui accompagnent cet ensemble.

EMPLACEMENT DES BOUCHES D’ÉVACUATION

COMME SUR L’AUTRE CÔTÉ

15 cm

9,7cm9,7cm

9,7cm

9,7cm9,7cm

(5 7/8 po)

11 cm

(4 3/8 po)

(6,0 cm)(6,0 cm)

(6,0 cm)

(6,0 cm)(6,0 cm)

9,5 cm

(3 3/4 po)

(9,5 cm)(9,5 cm)

(9,5 cm)

(9,5 cm)(9,5 cm)

9,5 cm

(3 3/4 po)

(9,5 cm)(9,5 cm)

(9,5 cm)

(9,5 cm)(9,5 cm)

34 cm

(33,3 cm)(33,3 cm)

(33,3 cm)

(33,3 cm)(33,3 cm)

(13 1/2 po)

ALIMENTATION EN GAZ

cuivre non recouvert de plastique. Il FAUT utiliser du laiton

inoxydable ou recouvert de plastique.

1. L’installation DOIT respecter les codes locaux, ou s’il n’existe pas

de codes locaux, le code ANSI Z223.1 (l’édition la plus récente) ou

au Canada, le Code actuel CAN/CGA B149.

2. La conduite d’alimentation en gaz doit mesurer 1,27 cm (1/2 po).

3. Si les codes le permettent, un tuyau en métal flexible peut être utilisé

pour connecter la sécheuse à l’alimentation en gaz. Le tuyau DOIT

être fabriqué en acier inoxydable ou en cuivre avec un revêtement

de plastique.

4. La conduite d’alimentation en gaz DOIT comporter un robinet

d’arrêt distinct.

5. Une prise de 0,32 cm (1/8 po) NPT accessible pour le branchement

d’un manomètre DOIT être installée tout juste en amont du

branchement de la conduite d’alimentation en gaz sur la sécheuse.

6. La sécheuse DOIT être débranchée de la canalisation de gaz

pendant toute vérification de pression de l’alimentation en gaz à

des pressions qui dépassent 3,45 kPa (1/2 lb/po²).

7. La sécheuse DOIT être isolée de la canalisation de gaz pendant

toute vérification de pression de l’alimentation en gaz à des

pressions égales ou inférieures à 3,45 kPa (1/2 lb/po²).

Remplacer le tuyau de raccordement en

10

Page 11

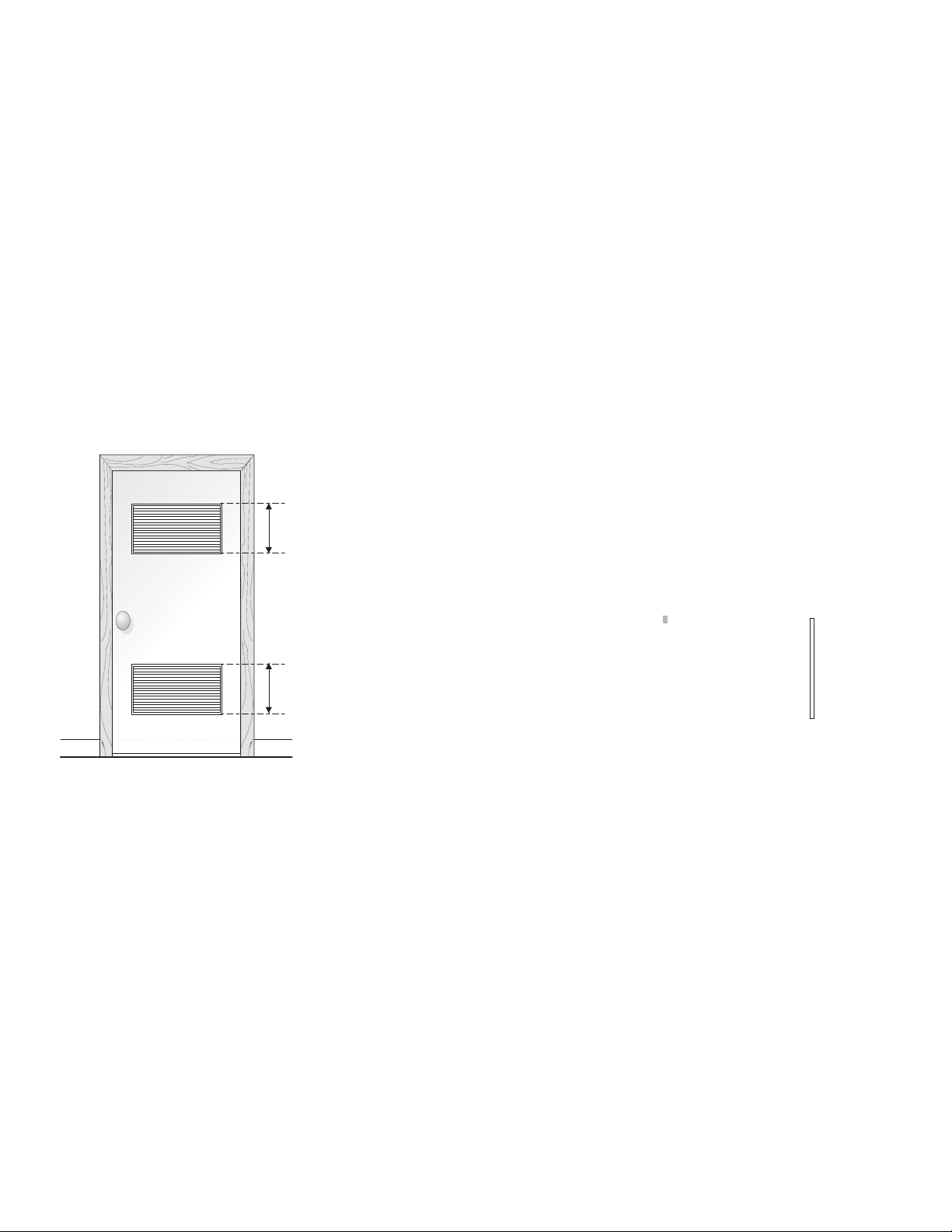

EMPLACEMENT DE LA SÉCHEUSE

NE PAS INSTALLER LA SÉCHEUSE :

1. Dans un endroit exposé à un écoulement d’eau ou aux conditions

atmosphériques.

2. Dans un endroit où elle serait en contact avec des rideaux, draperies

ou tout ce qui obstruera le flux d'air de combustion et de

ventilation.

3. Sur un tapis. Le plancher DOIT être ferme et présenter une pente

de 2,54 cm (1 po) au maximum.

INSTALLATION DANS UNE ALCÔVE OU UN PLACARD

1. Toute sécheuse installée dans une chambre à coucher, une

salle de bain, une alcôve ou un placard DOIT être reliée à une

conduite d’évacuation d’air se terminant à l’extérieur de la

maison.

2. Aucun autre appareil brûlant du combustible ne doit être

installé dans le même placard que la sécheuse au Gaz.

3. La sécheuse a besoin d’un dégagement suffisant pour

permettre la circulation de l’air.

NE PAS INSTALLER LA SÉCHEUSE DANS UN PLACARD POURVU

D’UNEPORTE PLEINE.

0 cm (0 po)0 cm (0 po)

0 cm (0 po)

0 cm (0 po)0 cm (0 po)

387,1 cm387,1 cm

²²

387,1 cm

²

387,1 cm387,1 cm

²²

(60 po(60 po

²²

))

(60 po

²

)

(60 po(60 po

²²

))

4. Une ouverture minimum de 774,2 cm² (120 po²) répartie

également entre le haut et le bas de la porte est requise. Cette

ouverture ne doit pas être obstruée lorsque la porte est en place.

Une porte à volets dont les ouvertures totalisent la norme décrite

ci-dessus est acceptable.

DÉGAGEMENTS MINIMAUX POUR L'INSTALLATION

en po (cm)

D'AVANT CÔTÉS ARRIÈRE DESSUS

Alcôve ou sous un

comptoir 0 (0) 0 (0) 0 (0) 15 (38,1)

Armoire 1 (2,54) 0 (0) 0 (0) 15 (38,1)

Aération nécessaire dans la porte de l'armoire: 2 ouvertures à

persiennes de 60 pouces carrés (387 cm carrés) chacun - à 3 pouces

(7,6 cm) du bas et du haut de la porte.

L'AÉRATION DE CETTE SÉCHEUSE SE FAIT VERS L'EXTERIEUR.

5. Les illustrations qui suivent donnent le dégagement minimum pour

une installation dans une alcôve ou un placard.

2,54 cm2,54 cm

2,54 cm

38,1 cm (15 po)38,1 cm (15 po)

38,1 cm (15 po)

38,1 cm (15 po)38,1 cm (15 po)

2,54 cm2,54 cm

(1 po)(1 po)

(1 po)

(1 po)(1 po)

0 cm (0 po)0 cm (0 po)

0 cm (0 po)

0 cm (0 po)0 cm (0 po)

387,1 cm387,1 cm

²²

387,1 cm

²

387,1 cm387,1 cm

²²

(60 po(60 po

²²

))

(60 po

²

)

(60 po(60 po

²²

))

PORTE DU PLACARDPORTE DU PLACARD

PORTE DU PLACARD

PORTE DU PLACARDPORTE DU PLACARD

NOTA: Pour les modèles qui s'installent sous un comptoir et les

modèles superposables — 0 cm (0 po) sur les côtés, l'arrière

et le dessus.

2,54 cm2,54 cm

2,54 cm

0 cm (0 po)0 cm (0 po)

0 cm (0 po)

0 cm (0 po)0 cm (0 po)

0 cm (0 po)0 cm (0 po)

0 cm (0 po)

0 cm (0 po)0 cm (0 po)

2,54 cm2,54 cm

(1 po)(1 po)

(1 po)

(1 po)(1 po)

0 cm (0 po)0 cm (0 po)

0 cm (0 po)

0 cm (0 po)0 cm (0 po)

INSTALLATION SOUS UN COMPTOIR

Si vous désirez effectuer une installation sous un comptoir*, il FAUT installer un ensemble P/N 131629100, une tôle

supérieure de carrosserie. Cet ensemble est disponible chez un distributeur de pièces autorisé.

* Un dessus de comptoir sur mesure est nécessaire.

11

Page 12

INSTALLATION DANS UNE MAISON MOBILE

1. L’évacuation d’air de la sécheuse DOIT se faire à l’extérieur de la

maison (à l'éxterieur et non pas au-dessous de la maison mobile)

à l'aide de conduit en métal non inflammable, à l'épreuve du feu.

Les conduits en métal doivent avoir 10,16 cm (4 pouces) de diamètre

sans obstructions. Les conduits en métal rigide sont préférables.

2. Si la conduite d’évacuation d’air traverse le plancher et un espace

fermé situé sous la maison mobile, l’évacuation d’air DOIT se

terminer à l’extérieur de cet espace fermé, et la sortie bien fixée à la

structure de la maison mobile.

3. Lors de l'installation d'une sécheuse à gaz dans une maison mobile,

il faut prévoir un apport d'air extérieur. L'espace à prévoir doit être

supérieur de deux fois celui du conduit d'évacuation de la sécheuse.

4. Cette sécheuse DOIT être fixée au plancher. L'ensemble

d'installation no. 169840 pour maison mobile est disponible chez

votre distributeur.

5. Se référer aux pages 2 et 3 pour de plus amples informations ur les

exigences de ventilation.

6. L’installation DOIT respecter la norme fédérale sur la construction

et la sécurité des maisons mobiles en vigueur (Manufactured Home

Construction & Safety Standard) (partie intégrante du règlement

fédéral 24 CFR Partie 32-80) ou, lorsque cette norme ne s’applique

pas, elle doit respecter la norme nationale américaine pour les

maisons mobiles (American National Standard for Mobile Homes).

Lorsque l'installation se fait au Canada, elle doit se conformer aux

normes ACNOR Z240.

La sécheuse est conçue conformément à la

norme ANSI Z 21.5.1 pour un USAGE DOMESTIQUE seulement.

MODELES DE DESSOUS DE COMPTOIR ET

SUPERPOSÉS

DIMENSIONS DE L’EMPLACEMENT

68,3 cm68,3 cm

68,3 cm

68,3 cm68,3 cm

(26 7/8 po)(26 7/8 po)

(26 7/8 po)

(26 7/8 po)(26 7/8 po)

BRANCHEMENT

ÉLECTRIQUE

(2 9/16 po)(2 9/16 po)

(2 9/16 po)

(2 9/16 po)(2 9/16 po)

34,4 cm34,4 cm

34,4 cm

34,4 cm34,4 cm

(13 1/2 po)

6,5 cm

SOUS UN

COMPTOIR

87,9 cm

(34 5/8 po)

91,5 cm91,5 cm

91,5 cm

91,5 cm91,5 cm

(91,5 cm)(91,5 cm)

(91,5 cm)

(91,5 cm)(91,5 cm)

(36 po)

9,5 cm9,5 cm

9,5 cm

9,5 cm9,5 cm

(3 3/4 po)

OUVERTURE

DE LA PORTE

BRANCHEMENT DU

TUYAU DE GAZ

0,96 cm (3/8 po)

DE DIAMÈTRE

VUE ARRIÈRE

90°

2,54 cm (1 po)

120,7 cm

(47 1/2 po)

11,1 cm

(4 3/8 po)

TROU DE

VENTILATION

À PERFORER

FACULTATIF

68,6 cm

(27 po)

9,5 cm

(3 3/4 po)

12

VUE LATÉRALE

Page 13

MODELES AUTONOMES AVEC CONSOLE

SUPÉRIEURE

DIMENSIONS DE L'EMPLACEMENT

DÉBALLAGE

1. À l’aide des quatre coins de protection de l’emballage (deux sur

chaque côté), déposer délicatement la sécheuse sur son côté gauche

et retirer le morceau de mousse placé sous la sécheuse pour

l’expédition.

OUVERTURE

DE LA PORTE

90°

VUE ARRIÈRE

120,7 cm

(47 1/2 po)

(122,2 cm)(122,2 cm)

(122,2 cm)

(122,2 cm)(122,2 cm)

prendre prise sur le panneau de commande pour soulever ou déplacer

la sécheuse.

REMARQUE : Si la sécheuse doit être installée sous un comptoir, le

panneau du dessus peut être démonté pour l’installation.

2. Remettre la sécheuse à la verticale.

Pour ne pas endommager la sécheuse, ne pas

MORCEAU

DE MOUSSE

EMBALLAGE

PORTE RÉVERSIBLE

La sécheuse est conçue de façon à ce que l’ouverture de la porte

puisse être inversée en tout temps sans que des pièces

additionnelles ne soient requises. L’inversion de la porte requiert le

transfert des charnières au côté opposé du boîtier.

Pour inverser l’ouverture de la porte:

1. Ouvrir la porte de la sécheuse. Retirer les quatre bouchons

de trous de vis du côté gauche de la porte. Les laisser à

proximité pour installation future. NOTA : Un couteau à mastic en plastique peut s’avérer nécessaire pour retirer les

bouchons de trous de vis. Veiller à ne pas égratigner la

peinture.

2. Retirer les quatre vis fixant les charnières de la porte au

panneau avant de la sécheuse (voir ci-dessous). NOTA :

Retirer d’abord une vis dans chacune des deux charnières.

Tenir la porte fermement avant de dévisser les deux dernières

vis.

3. Tourner la porte à un angle de 180° et reposer les charnières

de porte au panneau avant de la sécheuse avec les quatre

vis.

4. Poser les quatre bouchons de trous de vis du côté droit de la

porte.

11,1 cm

(4 3/8 po)

TROU DE

VENTILATION À

PERFORER

FACULTATIF

68,6 cm

(27 po)

VUE LATÉRALE

9,5 cm

(3 3/4 po)

13

Page 14

INSTALLATION ÉLECTRIQUE

TOUTES les sécheuses ÉLECTRIQUES

directement au branchement électrique correct et sécuritaire

de la sécheuse. Toute dérogation à ces mises en garde pourrait

entraîner des risques choc électrique et d’incendie.

Les mises en garde qui suivent se rapportent

14

Page 15

BRANCHEMENT ÉLECTRIQUE

D’UNE INSTALLATION À 4 FILS

Sécheuses ÉLECTRIQUES non-canadiennes

1. Retirer les vis qui retiennent le couvercle du panneau de

branchement ainsi que le support de montage du détendeur

situés dans le coin supérieur à l’arrière de la sécheuse.

2. Poser un détendeur approuvé par U.L. dans le trou du support.

Serrer simplement l’écrou à la main pour le moment.

VIS DE MISE À LA

TERRE VERTE

FILDE

TERRE

NEUTRE

ROUGE

CONDUCTEUR VERT

FIL DE TERRE

CORDON

D’ALIMENTATION

3. Retirer le fil de terre de la vis de mise à la terre verte neutre située

au-dessus du panneau de branchement.

4. Enfiler un cordon d’alimentation NEMA 10-30 approuvé par U.L.

de 30 A de type SRDT dans le détendeur.

PRISE TYPIQUE À 4

OUVERTURES

CORDON

D’ALIMENTATION

TYPIQUE À 4 FILS

NEMA 14-30 DE 30 A DE TYPE SRDT OU STNEMA 14-30 DE 30 A DE TYPE SRDT OU ST

NEMA 14-30 DE 30 A DE TYPE SRDT OU ST

NEMA 14-30 DE 30 A DE TYPE SRDT OU STNEMA 14-30 DE 30 A DE TYPE SRDT OU ST

5. Fixer le fil de terre vert du cordon d’alimentation au boîtier de la

sécheuse à l’aide de la vis de mise à la terre verte.

6. Fixer le conducteur blanc (neutre) du cordon d’alimentation ainsi

que le fil de terre neutre du boîtier de la sécheuse à la borne centrale

argentée du bloc de branchement.

7. Fixer les conducteurs rouge et noir du cordon d’alimentation aux

bornes cuivrées extérieures du panneau de branchement.

Ne pas tordre excessivement ni sertir les

conducteurs sur les bornes.

8. Serrer à fond les vis qui retiennent le dispositif de retenue du

cordon autour du cordon d’alimentation.

9. Serrer l’écrou du détendeur de façon à ce que cette pièce ne tourne

pas.

10. Réattacher le couvercle du panneau de branchement.

BORNE

ARGENTÉE

BLANC

SUPPORT DE

MONTAGE DU

DÉTENDEUR

PANNEAU DE BRANCHEMENT

NOIR

SERRER L’ÉCROU SUR

CES FILETS

ÉCROU

NOIR - 240 V

BLANC - NEUTRE

ROUGE - 240 V

VERT - FIL DE TERRE

INSTALLATION

1. BRANCHEMENT DU GAZ (Sécheuses à gaz seulement)

a. Retirer le couvercle qui recouvre le tuyau de gaz à l’arrière de la

sécheuse.

REMARQUE: NE PAS brancher la sécheuse sur une alimentation

au propane sans avoir posé un nécessaire de

conversion. Ce nécessaire doit être installé par un

technicien agréé.

b. Brancher un tuyau semi-rigide ou approuvé de 1,27 cm

(1/2 po) de diamètre intérieur entre la conduite d’alimentation

en gaz et le tuyau de 0,96 cm (3/8 po) situé sur l’arrière de la

sécheuse. Utiliser un réducteur de 1,27 cm-0,96 cm (1/2 po3/8 po) pour le branchement. Appliquer un mastic de fermeture

pour filets approuvé qui résiste à la corrosion qu’exercent les

gaz liquéfiés sur tous les raccords de tuyaux.

c. Ouvrir le robinet d’arrêt de la conduite d’alimentation en gaz.

d. Vérifier tous les branchements en versant de l’eau savonneuse

sur les joints. NE JAMAIS VÉRIFIER S’IL Y A DES FUITES À

L’AIDE D’UNE FLAMME VIVE.

2. Relier les conduits d’évacuation d’air à la conduite d'évacuation

extérieure. Utiliser un ruban adhésif pour conduites pour sceller

les joints.

3. Une fois la sécheuse dans son emplacement définitif, ajuster les

pieds de nivellement jusqu’à ce que la sécheuse repose fermement

sur ses quatre pieds. Placer un niveau sur le dessus de la sécheuse.

LA SÉCHEUSE DOIT ÊTRE À NIVEAU ET REPOSER

FERMEMENT SUR SES QUATRE PIEDS.

4. Brancher le cordon d’alimentation électrique dans une prise mise

à la terre. REMARQUE : S’assurer que le courant est coupé à la boîte

de fusibles ou de disjoncteurs avant de brancher le cordon

d’alimentation dans une prise.

5. Remettre le courant à la boîte de fusibles ou de disjoncteurs.

Avant d’utiliser la sécheuse, s’assurer que les environs

de la sécheuse sont exempts de tout matériau inflammable, d’essence

et de toute autre vapeur inflammable. S’assurer également qu’aucun

objet (boîtes, vêtements, etc.) n’obstrue la circulation de l’air servant

à la combustion et à la ventilation.

6. Faire fonctionner la sécheuse sur un cycle complet pour en vérifier

le fonctionnement.

REMARQUE: Dans le cas des sécheuses à gaz, la conduite doit être

vidée de son air avant que le brûleur ne puisse s’allumer. Si le brûleur

ne s’allume pas dans les 45 secondes qui suivent le premier

démarrage, l’interrupteur de sûreté éteint automatiquement le

brûleur. Si cela se produit, remettre la minuterie à «OFF» et attendre

5 minutes avant de tenter une nouvelle fois d’allumer le brûleur.

7. Si la sécheuse ne fonctionne pas, passer en revue la section de

dépannage inclus dans le Guide de l’utilisateur avant d’appeler

un centre de service.

8. Placer cette notice près de la sécheuse pour référence future.

REMARQUE: Un schéma de câblage se trouve dans le panneau de

commande ou sous le couvercle de la sécheuse.

PIÈCES DE RECHANGE

Pour obtenir des pièces de rechange pour la sécheuse, contacter le

magasin d’où vient la sécheuse .

commandes, étiqueter tous les câbles avant de les débrancher. Les

erreurs de connexion de câble peuvent entraîner un fonctionnement

incorrect et dangereux. Une fois la réparation ou l’entretien terminé,

assurez-vous que l’appareil fonctionne correctement.

déballé la sécheuse. Des enfants risqueraient de s’en servir comme

jouet. Les cartons recouverts d’un tapis, d’un couvre-lit ou d’une feuille

de plastique peuvent former une chambre étanche et faire suffoquer

un enfant. Placer le matériel d’emballage dans une poubelle ou les

mettre hors de portée des enfants.

les autres documents qui accompagnent la sécheuse ne sauraient

couvrir toutes les circonstances et les situations possibles. IL FAUT

donc faire preuve de jugement et de prudence pendant l’installation,

l’utilisation et l’entretien de tout appareil électroménager.

15

Lors de tout travail d’entretien ou de réparation des

Détruire le carton et les sacs en plastique après avoir

Les directives qui figurent dans cette notice et dans

Page 16

Indice

MATERIA PAGINA

Requerimientos de instalación preliminares 16

Requerimientos eléctricos 16

Requerimientos del sistema de escape 16-17

Requerimientos del suministro de gas 17

Ubicación de su secadora 18

Instalación en casas móviles 19

Dimensiones para la instalación 19-20

Desembalaje 20

Puerta reversible 20

Instalación eléctrica 21

Requerimientos para la puesta a tierra 21

Conexiónes eléctricas - trifilares 21

Conexiónes eléctricas - tetrafilares 22

Instalación 22

Piezas de recambio 22

REQUERIMIENTOS DE INSTALACIÓN PRELIMINARES

Herramientas y materiales necesarios para la instalación:

1. Destornillador Phillips

2. Alicates universales

3. Nivel de carpintero

4. Destornillador para tornillo de cabeza plana o recta

5. Cinta para ductos

6. Ducto metálico rígido o flexible de 4"(10,2 cm)

7. Caperuza de salida

8. Sellador de tuberías (gas)

9. Un cuchillo de plástico

REQUERIMIENTOS ELÉCTRICOS

Secadoras ELÉCTRICAS

CIRCUITO - Circuito derivado individual de 30 amperes, con fusibles de

30 amp. del tipo de retardo o disyuntores.

Use unos circuitos con un interruptor o fusible separadamente para las

lavadoras y las secadoras y no hace funcionar una lavadora y una secadora

sobre el mismo circuito.

ALIMENTACIÓN ELÉCTRICA - Corriente alterna, monofásica, 60 Hz,

240 voltios; trifilar. (Canadá - 240 voltios, monofásico, 60 Hz, corrienta

alterna.)

CORDÓN ELÉCTRICO - En la secadora se DEBE usar un cordón eléctrico

trifilar NEMA 10-30 tipo SRDT para un voltaje nominal mínimo de 240

voltios CA, 30 amp, con 3 conectores de horquillas con terminales

abiertos y extremos dirigidos hacia arriba o conectores de anillo cerrado

y marcados para uso en secadoras de ropa. AVERTISSEMENT – Risque

de choc électrique. Un appareil mis à la terre à l’aide d’un lien ou câble

conducteur neutre. La mise à la terre à l’aide d’un conducteur ou câble

neutre est interdite dans les cas suivants : (1) les installations de nouveau

circuit déviré (2) les maisons mobiles (3) les véhicules récréatifs ou

caravanes et (4) les régions où les codes locaux interdisent la mise à la

terre à l’aide d’un câble ou conducteur neutre. (1) Débranchez le

conducteur ou câble du neutre, (2) utilisez la borne de mise à la terre ou

le câble de mise à la terre de l’appareil conformément aux codes locaux

et (3) connectez ou branchez la borne neutre ou le câble au neutre du

circuit déviré de la manière habituelle (si l’appareil doit être connecté à

l’aide d’un cordon, utilisez un cordon à 4 câbles ou fils pour ce faire).

N’UTILISEZ QUE DES CÂBLES OU FILS EN CUIVRE. Se DEBE utilizar un

cordón eléctrico tetrafilar NEMA 14-30 tipo SRDT o ST (como sea

necesario) para un voltaje nominal mínimo de 240 voltios CA, 30 amp

con 4 conectores de horquillas con terminales abiertos y extremos

dirigidos hacia arriba o conectores de anillo cerrado y marcados para

uso en secadoras de ropa. Ver CONEXIÓNES ELÉCTRICAS PARA

SISTEMAS TETRAFILARES.

(Canadá - un cordón de suministro de energía de 4 alambres es instalado

en la secadora.)

TOMACORRIENTE - El tomacorriente NEMA 10-30R debe estar ubicado

de manera que el cordón eléctrico llegue hasta él cuando la secadora

esté instalada. (Canadá - receptáculo NEMA 14-30R.)

ALIMENTACIÓN

ELÉCTRICA

TOMACORRIENTE

(COBRE)

INSTALACIÓN SUJETA A LOS

REGLAMENTOS LOCALES

CAJA PRINCIPAL DE FUSIBLES CON CONDUCTOR NEUTRO

PUESTO A TIERRA, TRIFILAR, 120-240 VOLTIOS 60

CICLOS

FUSIBLES DE ACCIÓN RETARDADA

DE 30 AMP O DISYUNTOR

CONDUCTOR NEUTRO

NEMA 10-30R (COBRE)

Secadoras a GAS

CIRCUITO - Circuito individual derivado de 15 amp, con fusibles de 15

amp. de retardo máximo o disyuntor.

ALIMENTACIÓN ELÉCTRICA - Corriente alterna, monofásica, 60 Hz,

120 voltios, trifilar.

CORDÓN ELÉCTRICO - La secadora está equipada con un cordón

eléctrico trifilar para 120 voltios.

NOTA: No saque por

ningún motivo la

espiga de puesta a

tierra del enchufe.

ESPIGA DE PUESTA

A TIERRA

REQUERIMIENTOS DEL SISTEMA DE ESCAPE

Utilice solamente ductos metálicos, rígidos o flexibles de 4"

(10,2 cm) de diámetro (mínimo) y una caperuza de salida de uso

aprobado, con registros que giren hacia afuera que se abren cuando la

secadora se encuentra en funcionamiento. Cuando la secadora se

detiene, los registros se cierran automáticamente para evitar las

corrientes de aire y la entrada de insectos y roedores. Para evitar obstruir

la salida, mantenga una altura libre mínima de 12"(30,5 cm) entre la

caperuza de salida y el piso o entre cualquier otra obstrucción.

Los siguientes requerimientos son específicos

para el funcionamiento correcto y seguro de su secadora. El

incumplimiento de estas instrucciones puede causar prolongación

excesiva del tiempo de secado y riesgos de incendio.

No use ductos flexibles de plástico para el escape de la secadora.

Se puede acumular un exceso de pelusas en el sistema de escape, crear

un riesgo y obstruir el flujo de aire. La restricción del flujo del aire

prolongará el tiempo de secado. Si su sistema de escape actual tiene

ductos de plástico o de láminas metálicas delgadas,

reemplácelo con

un ducto metálico rígido o flexible. Asegúrese de que los ductos

existentes no tengan pelusas antes de instalar el ducto de la

secadora.

Risque d’incendie – Une sécheuse à linge produit de la charpie

combustible. Si el escape de la secadora no se dirige al exterior, algunas

pelusas finas serán sopladas hacia el recinto donde se efectúa el lavado.

La acumulación de pelusas en cualquier lugar de la casa, puede crear un

peligro para la salud y un riesgo de incendio. La sécheuse doit être

connectée à une bouche d’évacuation vers l’extérieur du bâtiment

ou de l’immeuble. Vous devez inspecter régulièrement l’évent extérieur

et enlever toute accumulation de charpie autour de l’évent et dans la

cavité du conduit d’évacuation.

No permita que los materiales combustibles (por ejemplo: la ropa,

cortinas/cortinajes, papel) tengan contacto con los ductos. El escape de

la secadora NO DEBE dirigirse hacia el interior de una chimenea, hacia

una pared, hacia el cielo raso o hacia cualquier otro espacio reducido

del edificio, donde puede ocurrir acumulación de pelusas y constituir

un peligro de incendio.

Exceder la longitud del conducto rigido o los números de codos

permitidos en los diagramas "LARGO MÁXIMO" puede disminuir la

capacidad de exhaustación del sistema. Obstruir el conducto puede

provocar peligro de incendio, así como aumentar el tiempo de secado.

No coloque un filtro en el extremo del escape del sistema ni emplee

tornillos o remaches para ensamblar el sistema de escape. Las pelusas

podrían quedar atrapadas en los filtros, en los tornillos o en los remaches,

lo cual obstruiría el sistema de escape y crearía un riesgo de incendio, así

como también prolongaría el tiempo de secado. Use una caperuza de

salida adecuada para el extremo del ducto que salga al exterior de la

vivienda y selle todas las juntas con cinta adhesiva para ductos. Todos

los accesorios de tubería machos, DEBEN ser instalados aguas abajo

del flujo de aire.

Riesgo de explosión. No instale la secadora donde

se guarda gasolina u otros materiales inflamables. Si la secadora se instala

en un garage, ella debe estar por lo menos 18 pulgadas (45,7 cm) por

encima del suelo. El incumplimiento puede resultar en la muerte,

explosión, incendio, o quemaduras.

16

Page 17

LARGO MÁXIMO

del Conducto Metálico Rigido

de 4” (10,2 cm) de Diámetro

TIPO DE CAPERUZA DE SALIDA

(Preferido)

Número

de Codos

a 90°

4”

(10,2 cm)

0 60 pies (18,28 m) 48 pies(14,63 m)

1 52 pies (15,84 m) 40 pies(12,19 m)

2 44 pies (13,41 m) 32 pies (9,75 m)

3 32 pies (9,75 m) 24 pies (7,31 m)

4 28 pies (8,53 m) 16 pies (4,87 m)

Apersianada

(6.35 cm)

LARGO MÁXIMO

del Conducto Metálico Flexible

de 4” (10,2 cm) de Diámetro

TIPO DE CAPERUZA DE SALIDA

(Preferido)

Número

de Codos

a 90°

4”

(10,2 cm)

0 30 pies (9,14 m) 18 pies (5,49 m)

1 22 pies (6,71 m) 14 pies (4,27 m)

2 14 pies (4,27 m) 10 pies (3,05 m)

3 NO RECOMENDADO

Apersianada

(6.35 cm)

2½"

2½"

corriente de aire descendente y disminuir así su capacidad de

exhaustación.

• El aislante que debe atravesar el sistema puede causar condensación

y disminuir así la capacidad de exhaustación del sistema.

• La capacidad de exhaustación de un sistema de exhaustación

comprimido o ondulado puede disminuirse.

El sistema de exhaustación debe de ser inspeccionado y limpiado por lo

menos cada 18 meses de uso normal. Cuanto más la secadora está

utilizada, más debe verificar el buen funcionamiento del sistema de

exhaustación y de la tapa del orificio de ventilación.

UBICACIÓN DEL ESCAPE

Todas las secadoras vienen de fábrica equipadas con escape trasero.

Sin embargo, en las secadoras eléctricas, el escape puede hacerse al

lado derecho o izquierdo del gabinete o en la parte inferior de la secadora.

En las secadoras a gas, el escape del aire puede estar en el lado derecho

del gabinete o en la parte inferior de la secadora. El escape direccional

puede efectuarse instalando un Juego de Escape, P/N 131456800,

disponible a través de su distribuidor de repuestos. Siga las instrucciones

que se suministran con el juego.

DIMENSIONES PARA LA UBICACIÓN DEL DUCTO DE ESCAPE

IGUAL QUE EL OTRO LADOIGUAL QUE EL OTRO LADO

IGUAL QUE EL OTRO LADO

IGUAL QUE EL OTRO LADOIGUAL QUE EL OTRO LADO

5 7/8"5 7/8"

5 7/8"

5 7/8"5 7/8"

(15 cm)(15 cm)

(15 cm)

3 3/4"3 3/4"

3 3/4"

3 3/4"3 3/4"

(9,5 cm)(9,5 cm)

(9,5 cm)

(9,5 cm)(9,5 cm)

(15 cm)(15 cm)

13 1/2"13 1/2"

13 1/2"

13 1/2"13 1/2"

(34 cm)(34 cm)

(34 cm)

(34 cm)(34 cm)

4 3/8"4 3/8"

4 3/8"

4 3/8"4 3/8"

(11 cm)(11 cm)

(11 cm)

(11 cm)(11 cm)

3 3/4"3 3/4"

3 3/4"

3 3/4"3 3/4"

(9,5 cm)(9,5 cm)

(9,5 cm)

(9,5 cm)(9,5 cm)

CORRECTOCORRECTO

CORRECTO

CORRECTOCORRECTO

INSTALE LOS ACCESORIOS MACHOS EN LA DIRECCIÓN CORRECTA

INCORRECTOINCORRECTO

INCORRECTO

INCORRECTOINCORRECTO

Para las instalaciónes cuyas sistema de exhaustación no se encuentre

en el diagrama, se puede utilizar el metodo a continuación para

determinar si el sistema de exhaustación es apropiado.

1. Conecte un manómetro a tubo inclinado o digital entre la

secadora y el unión de exhaustación de la secadora.

2. Ponga el contador de tiempo de la secadora y la temperatura

a aire frío (enfiriamiento), y la secadora en la posición de

marcha.

3. Lea la medida indicada en el manómetro.

4. La baja presión NO DEBE exceder 0.75 pulgada de la columna

de agua. Si la baja presión es inferior a 0.75" de la columna

de agua, el sistema es aceptable. Si la lectura indica una

presión superior a 0.75" de la columna de agua, la capacidad

del circuito es insuficiente y la instalación es inaceptable.

Aungue un sistema vertical sea aceptable, algunas circunstancias

atenuantes pueden afectar el funcionamiento de la secadora:

• Se debe utilizar solamente conductos metalicos rigidos.

• Una salida del sistema vertical en el techo, puede exponerle a un

REQUERIMIENTOS DEL SUMINISTRO DE GAS

Reemplace la tubería de conexión de cobre

que no está recubrida con plástico. El latón inoxidable o recubrido

con plástico DEBE SER utilizado.

1. La instalación DEBE hacerse cumplir con los códigos locales o en

ausencia de los mismos, de acuerdo con los estandares del National

Fuel Gas Code (Código Nacional para Gases Combustibles), ANSI

Z223.1 (la última editión). Para Canadá, el Estandar CAN/CGA B149

que esté en vigor.

2. La tubería de alimentación de gas debe ser de 1/2 pulgada (1,27 cm)

de diámetro.

Si está permitido por los códigos locales, se puede usar tubería

3.

de metal para conectar su secadora a la línea de suministro

de gas. La tubería DEBE ser fabricada de acero inoxidable o

cobre recubierto de plástico.

4. La tubería de alimentación de gas DEBE tener una llave de cierre

individual.

5. Una toma de 1/8 de pulgada (0,32 cm) N.P.T. accesible para conexión

del manómetro de prueba, DEBE ser instalada inmediatamente

aguas arriba de la conexión de la tubería de alimentación de gas a la

secadora.

6. La secadora DEBE ser desconectada del sistema de tuberías de

alimentación de gas durante cualquier ensayo de presión del sistema

de tuberías de alimentación de gas realizado a presiones de prueba

de más de 1/2 lbs/pulg.

7. La secadora DEBE aislarse del sistema de tuberías de alimentación

de gas durante cualquier ensayo de presión del sistema de tuberías

de alimentación de gas realizado en ensayos de presión iguales o

inferiores a 1/2 lbs/pulg.

2

(3,45 kPa).

2

(3,45 kPa).

17

Page 18

UBICACIÓN DE SU SECADORA

NO INSTALE SU SECADORA:

1. En un lugar donde puede haber goteos de agua o quede expuesta

a las inclemencias del tiempo.

2. En un área donde pueda entrar en contacto con cortinas, cortinajes

o cualquier otra cosa que obstruya el flujo de combustión y

ventilación de aire.

3. Sobre alfombras. El piso DEBE ser firme con un desnivel máximo de

1 pulgada (2,54 cm).

INSTALACIÓN DENTRO DE UN NICHO O ARMARIO

1. Si la secadora es instalada en un dormitorio, cuarto de baño, nicho

o armario, el tubo del escape DEBE ser instalado hacia el exterior.

2. No se debe instalar ningún otro artefacto que queme combustible

en el mismo armario en que está instalada la secadora a Gas.

3. La secadora necesita espacio a su alrededor para una ventilación

adecuada.

NO INSTALE LA SECADORA EN UN ARMARIO CON PUERTA

MACIZA.

4. Se requiere como mínimo una abertura de 120 pulgadas cuadradas (774,2 cm

2

), dividida equitativamente para la parte superior e

inferior de la puerta. Cuando se instala una puerta, es necesario

proveer aberturas para el aire. Una puerta apersianada con aberturas para el aire en todo el largo de la puerta es aceptable.

DESPEJES MÍNIMOS DE INSTALACIÓN (Pulgadas)

PART E PART E PART E

Alcoba o

encastradas 0 (0 cm) 0 (0 cm) 0 (0 cm) 15 (38,1 cm)

Armario 1 (2,54 cm) 0 (0 cm) 0 (0 cm) 15 (38,1 cm)

Ventilación requirida en la puerta del armario: dos aberturas rejilladas

cada 60 pulg.

superior de la puetra.

EL TUBO DEL ESCAPE DE LA SECADORA DEBE SER INSTALADO

HACIA EL EXTERIOR.

5. Las siguientes ilustraciónes muestran las dimensiónes mínimas de

espacio libre que debe existir para el buen funcionamiento de la

secadora cuando se instala en un nicho o en un armario.

DELANTERA LADOS TRASERA SUPERIOR

2

(387 cm2) — 3" (7,6 cm) desde la parte inferior y

PUERPUER

TT

A DEL ARMARIOA DEL ARMARIO

PUER

T

A DEL ARMARIO

PUERPUER

TT

A DEL ARMARIOA DEL ARMARIO

60 Pulg.²60 Pulg.²

60 Pulg.²

60 Pulg.²60 Pulg.²

(387,1 cm(387,1 cm

(387,1 cm

(387,1 cm(387,1 cm

60 Pulg.²60 Pulg.²

60 Pulg.²

60 Pulg.²60 Pulg.²

(387,1 cm(387,1 cm

(387,1 cm

(387,1 cm(387,1 cm

0" (0 cm)0" (0 cm)

22

2

22

))

)

))

22

2

22

))

)

))

15" (38,1 cm)15" (38,1 cm)

15" (38,1 cm)

15" (38,1 cm)15" (38,1 cm)