Friedrich Metal Products WE10C33 Installation Manual

INSTALLATION INSTRUCTIONS

FOR "WSD" SLEEVE

MOUNTING HARDWARE PROVIDED

ITEM

NO.

DESCRIPTION

QTY.

1

SCREW, #12A X 2"

5

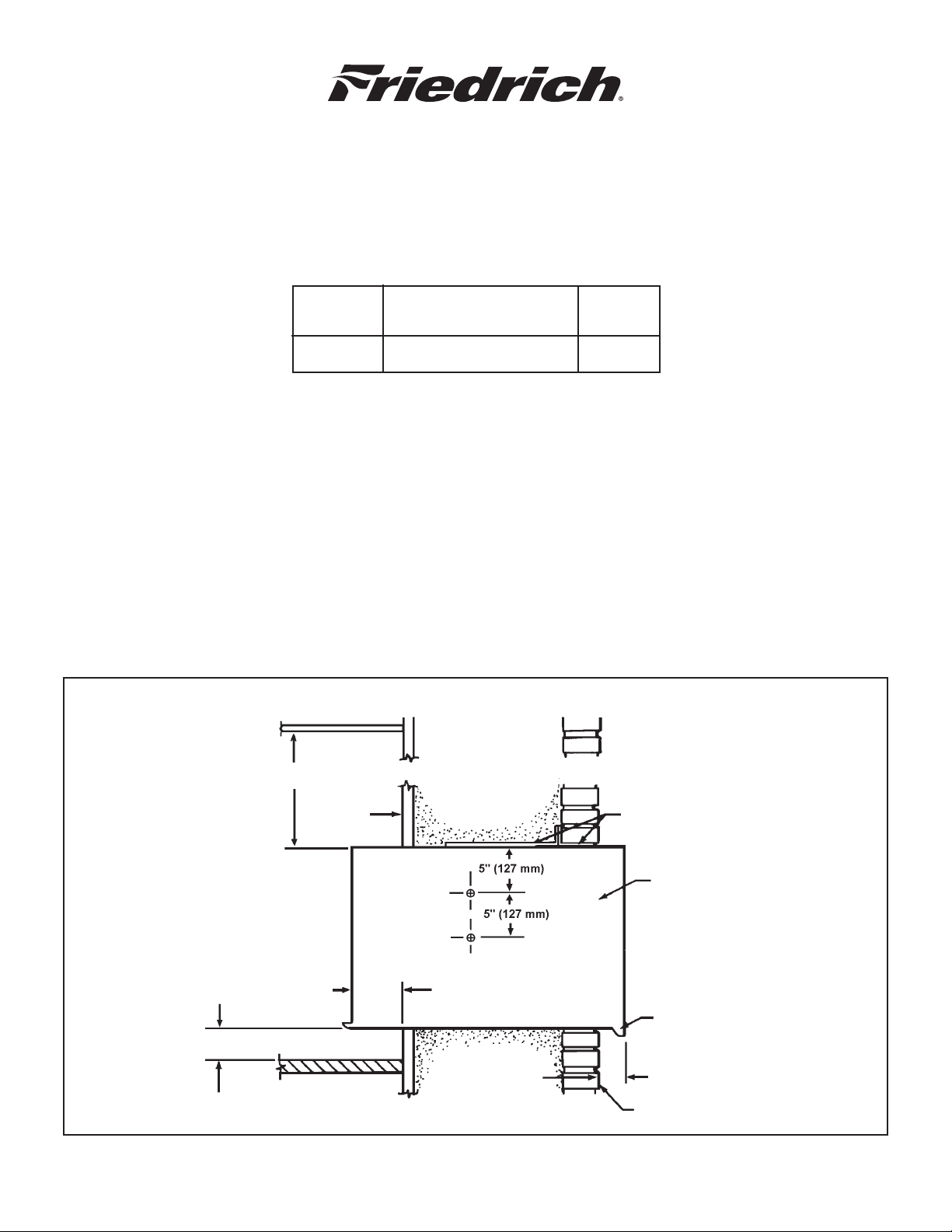

WALL PREPARATION:

STEP 1 The wall opening required for a "WSD" SLEEVE is 17 1/4" high by 27 1/4" wide.

STEP 2 LINTELS must be used in opening of brick veneer and masonry walls to support the material above the "WSD" SLEEVE.

The following considerations should also be given:

A. Adjustable SUB-BASE SB–89 or other unit support must be provided for panel wall type construction and for

walls less than 8" thick

B. A minimum distance of 1" must be allowed on all sides of the unit to adjacent wall and floor. Where the sub–base

is required, the minimum distance from the floor to the sleeve must be 3 1/2". To minimize chances of short

cycling of the compressor, the minimum clearance between the ceiling and the top of the unit should be 24".

(See Figure 1).

.

FIGURE 1

MINIMUM OF 24" REQUIRED

FROM TOP OF UNIT TO CEILING.

INSIDE

WALL

LINTELS

1" MINIMUM

3 1/2" FOR

SUBBASE

920-037-02 (6-09)

MINIMUM OF 1"

SPACING REQUIRED

ON ALL SIDES OF

THE UNIT.

WSD SLEEVE

MUMINIM "8/7

DRAIN

EXTENSION

9/16" MINIMUM

OUTSIDE WALL

920-037-02 (6-09)

INSTALLATION REQUIREMENTS:

STEP 1 The "WSD" SLEEVE should be positioned so that the DRAIN EXTENSION extends a minimum of 9/16" beyond the

OUTSIDE WALL (See Figure 1).

STEP 2 The "WSD" SLEEVE must extend a minimum of 7/8" beyond the INSIDE WALL.

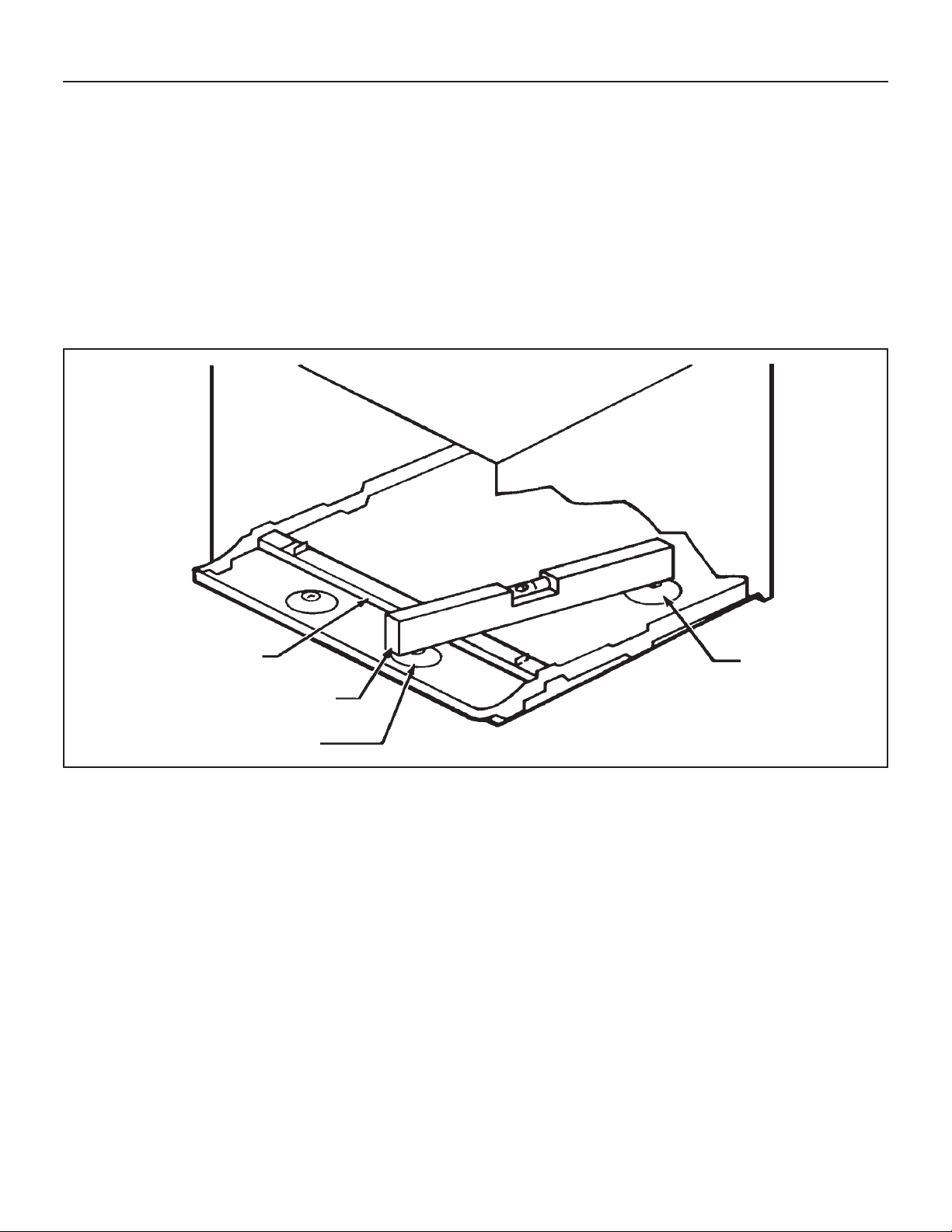

STEP 3 The "WSD" SLEEVE must be installed level side to side.

STEP 4 The "WSD" SLEEVE must also be installed with a downward tilt toward the outside of the building. If a le

that it res

ts on the FRONT and BACK UNIT REST as shown in Figure 2, a properly installed unit provides a 1/2 bubble

vel is placed so

slope to the outside of the building.

CAUTION: SLEEVE projections and leveling precautions must be observed to prevent the entry of water into the room.

FIGURE 2

RAISED LEDGE

LEVEL

BACK UNIT REST

FRONT UNIT REST

SLEEVE INSTALLATION:

STEP 1 After unpacking the "WSD" SLEEVE from the carton, remove the FRONT PANEL.

For immediate installation o

Remove the rear WEATHER PANEL. Reverse grille and place lower edge into sleeve tab (Friedrich logo facing out). Align

slots with screw holes. Secure grille with screws.

Place "WSD" SLEEVE in the wall opening following the instructions given in the INSTALLATION REQUIREMENTS section.

Attach the SLEEVE to the INSIDE WALL b

Shim at the top of the SLEEVE, midway between the sides. Drive one #12A x 2" screw in the top of the sleeve, close to

the shim. Install screws from inside the SLEEVE. If the wall opening is not framed with wood, use expansion anchor bolts

or molly (toggle) bolts (not provided).

STEP 2 Once the SLEEVE has been installed, ch

Apply shims, if required, to maintain the proper slope.

STEP 3 Caulk the perimeter of the entire opening on the inside and the outside between the SLEEVE and the WALL.

STEP 4 The front panel removed in Step 1 above must be remounted back in place if masonry work is to be done

and/or if the "WSD" CHASSIS is to be installed

2

f sleeve and chassis (skip if installing chassis into sleeve at a later date):

y driving two #12A x 2" screws in each side of the SLEEVE (see Figure 1.).

eck the LEVEL again to be sure the 1/2 bubble downward tilt is maintained.

at a later date.

INSTRUCCIONES DE INSTALACION

PARA LA BASE DE EMPOTRAJE CUBIERTA "WSD"

HERRAMIENTA DE MONTAJE SUMINISTRADA

ELEMENTO # DESCRIPCION CANTIDAD

1 TORNILLO #12A x 2" 5

PULGADAS

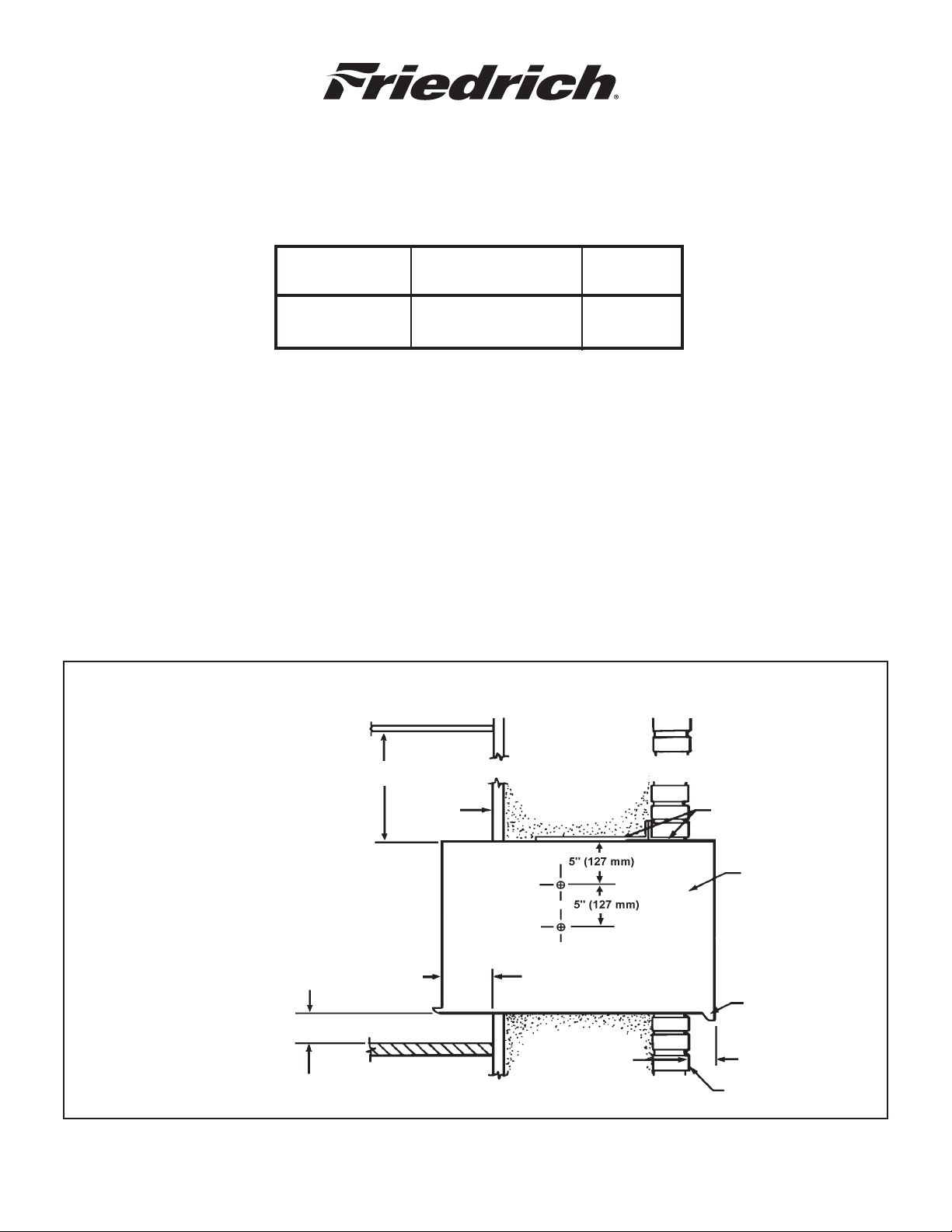

PREPARACION DE LA PARED:

PASO 1 La abertura necesaria para la BASE DE EMPOTRAJE "WSD" es de una altura de 17–1/4" pulgada por 27–1/4" pulgada

de ancho (438 mm x 692 mm).

PASO 2 Deben emplearse zapatas (lintels) para sostener el material encima de la base de empotraje en aberturas de paredes

enchapadas de ladrillo o de albañilería. También debe tenerse en cuenta lo siguiente:

FIGURA 1

ESPACIO MINIMO REQUERIDO DE

24" PULGADAS (610 mm), DE LA

PARTE SUPERIOR DE LA BASE DE

EMPOTRAJE AL CIELO RASO (TECHO).

A. Debe emplearse la

base inferior SB-89 u

otro tipo de apoyo o sostenimiento para la unidad en

construcción de paredes tipo pánel y otras paredes de menos de 8" pulgadas (200 mm) de grueso.

B. Deje una distancia mínima de 1" pulgada (25 mm) en cada lado de la unidad, la pared y el piso dyacente. Donde

se necesita una base inferior, la distancia mínima del piso a la base de empotraje será de 3 y 1/2" pulgada (90

mm)

. Para minimizar la posibilidad de corto circuito en el condensador, el espacio libre mínimo entre el cielo

raso (techo) y la parte superior de la unidad debe ser de 24" pulgadas (610 mm). (Ver Figura 1).

ESPACIO MINIMO REQUERIDO

DE 1" PULGADA (25 mm) A LOS

LADOS DE LA UNIDAD

PARED

INTERIOR

)mm 22( ADAGLUP

"8/7 OMINIM

ZAPATAS

BASE DE

EMPOTRAJE

(CUBIERTA) WSD

920-037-02 (6-09)

MINIMO 1" PULGADA (25 mm) 3 1/2" (90 mm) PARA LA

BASE INFERIOR

EXTENSION DE

DRENAJE

MINIMO DE 9/16"

PULGADA (14 mm)

PARED EXTERIOR

3

Loading...

Loading...