Friedrich Metal Products VERT-I-PAK A Installation Manual

®

VERT-I-PAK A-Series

Single Package Vertical Air Conditioning System

9,000 - 18,000 BTU/h

Installation and Operation Manual

NOTE: This manual only applies to 9,000-18,000BTu models.

For 24,000BTu models refer to manual 920-159-06.

920-075-12 (5-10)

Table of Contents

General Information

General Instructions ....................................................................................................................

Warnings .....................................................................................................................................

Your Safety and the Safety of Others............................................................................................

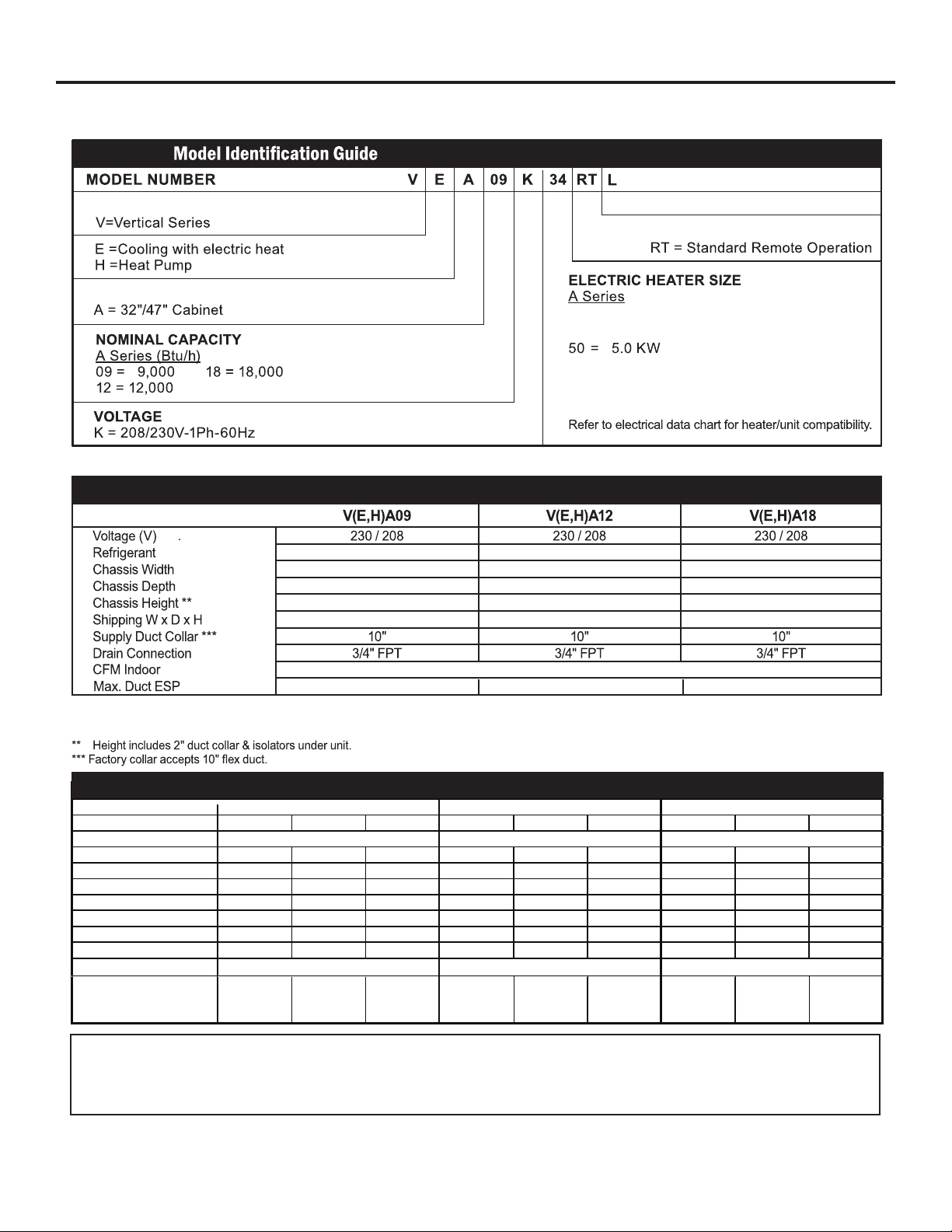

General Specifications

Model Number Identification Guide ...............................................................................................

Chassis Specifications....................................................................................................................

Electrical Data .................................................................................................................

Electrical Requirements..................................................................................................................

Electrical Rating Table.....................................................................................................

.................................................2

.................................................3

.................................... 1

.................................... 1

.................................. 1

................................... 2

.................................. 2

.................................. 3

Installation Recommendations ..................................................................................................

Installation

Utility Closet Dimensions ......................................................................................................

Wall Plenum & Architectural Louver Installation .................................................................................

Condensate Disposal System .....................................................................................................

Indoor Return Air Grille Installation..........................................................................................

Ductwork ............................................................................................................................

Indoor Air Flow Data ..........................................................................................................

Chassis Installation ............................................................................................................

Remote Thermostat Operation

Remote Thermostat........................................................................................................................................................ 12

Desk Control Terminals ............................................................................................................

Auxiliary Fan Control ..............................................................................................................

Control Board......................................................................................................................

Thermostat Connections ....................................................................................................................

Electrical and Thermostat Wiring Diagrams .......................................................................................

Chassis Final Connection

Final Installation checklist

.................................................................................................................................

............................................ 10

............................................ 11

............................................ 11

.................................. 4

........................................... 5

.............................. 6

................................... 9

.......................................10

...................................... 12

........................................ 12

........................................... 12

............................ 12

............................ 13

.............. 14

Chassis Operation

Fresh Air Door..................................................................................................................

Low Ambient Compressor Lock Out.......................................................................................

Room Freeze Protection ..........................................................................................................

Emergency Heat Operation.......................................................................................................

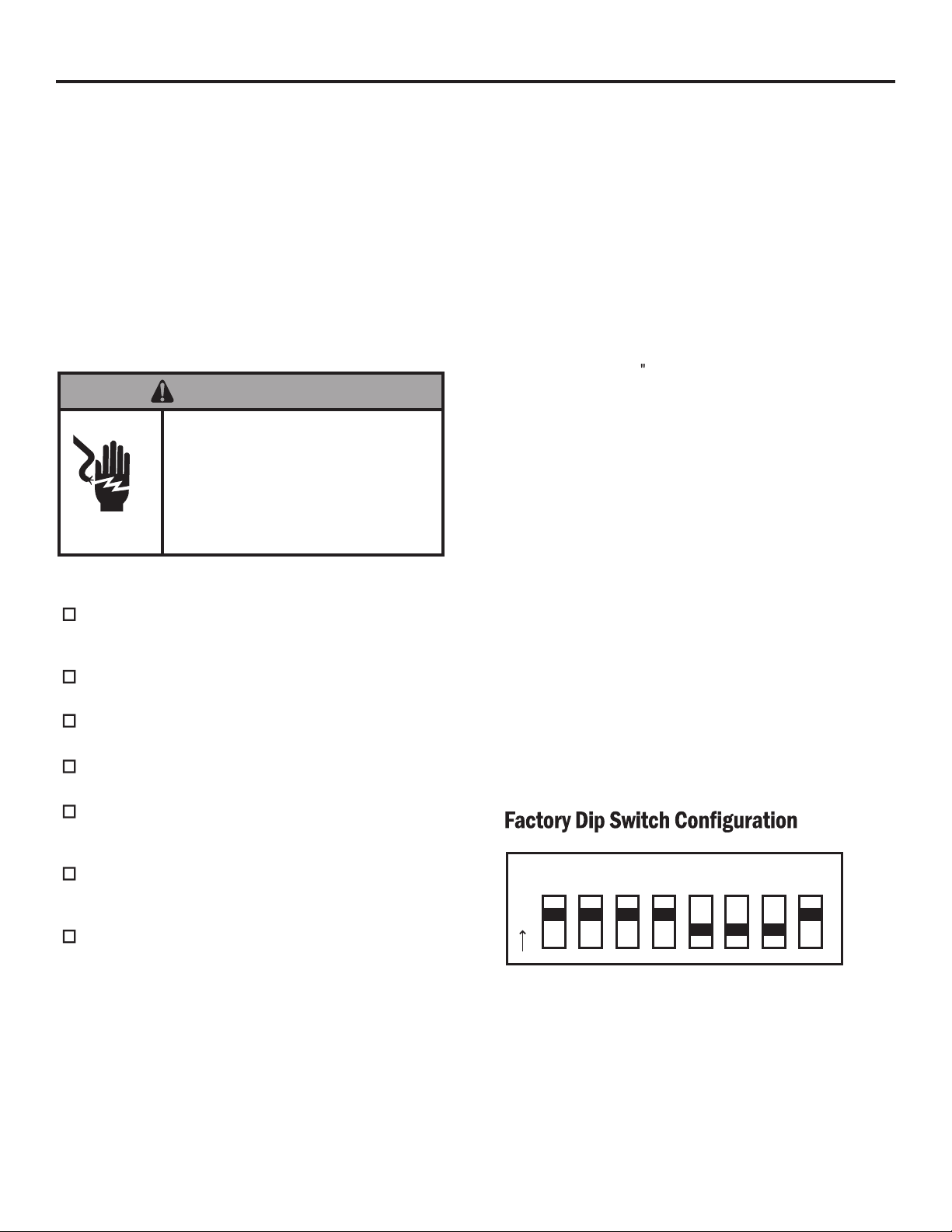

Factory Dipswitch Configuration.................................................................................................

Service & Warranty

Servicing/Chassis Quick Changeouts..............................................................................................

Routine Maintenance .............................................................................................................

Electronic Control Error Code Diagnostics and Test Mode.............................................

Unit Control Panel...........................................................................................................

Error Codes .....................................................................................................................

Accessories ....................................................................................................................

Warranty................................................................................................................................

.............................................. 14

........................................ 14

...................................... 14

..................................... 14

.................................... 14

........................................ 15

............................................... 15

............................................... 16

............................................... 16

............................................... 17

........................................ 18

.............................. 15

Congratulations!

Thank you for your decision to purchase the Friedrich Vert-I-Pak Air Conditioner (VPAK). Your new Friedrich has been carefully

engineered and manufactured to give you many years of dependable, efficient operation, maintaining a comfortable

temperature and humidity level. Many extra features have been built into your unit to assure quiet operation, the greatest

circulation of cool, dry air, and the most economic operation.

General Instructions

This Installation and Operation Manual has been designed to ensure maximum satisfaction in the performance of your unit.

For years of trouble-free service, please follow the installation instructions closely. We cannot overemphasize the importance

of proper installation. We have added new information to the basic instructions to help you achieve success.

Here are some suggestions to help you use your

new Friedrich most efficiently:

1. Carefully read and follow the installation instructions.

2. Clean the filter frequently (See Routine Maintenance,

Page 18).

3. Do not block the air flow to and from the unit.

4. A dirty filter or improperly set controls can affect the

cooling ability and overall performance of the unit.

5. If cooling is weak and you have verified that the filter is

clean and the controls are properly set, the unit may

need service, and you should call your Friedrich service provider to Check the unit.

6. Keep blinds, shades and drapes closed on the sunny

side of the room being cooled for optimum performance.

7. Proper insulation helps your unit maintain the desired

inside temperature.

Your safety and the safety of others are

very important.

We have provided many important safety messages

in this manual and on your appliance. Always read

and obey all safety messages.

This is a safety Alert symbol.

This symbol alerts you to potential

hazards that can kill or hurt you and

others.

All safety messages will follow the

safety alert symbol with the word

“WARNING” or “CAUTION”.

WARNING

Please read this manual thoroughly prior to equipment

installation or operation.

It is the installer’s responsibility to properly apply and

install the equipment. Installation must be in

conformance with the NFPA 70-2008 National Electric

Code or current edition, International Mechanic Code

2009 or current edition and any other applicable local

or national codes.

Failure to do so can result in property damage,

personal injury or death.

WARNING

Refrigeration system under high pressure.

Do not puncture, heat, expose to flame or incinerate.

Only certified refrigeration technicians should service

this equipment.

R410A systems operate at higher pressures than R22

equipment. Appropriate safe service and handling

practices must be used.

Only use gauge sets designed for use with R410A. Do

not use standard R22 gauge sets.

Failure to do so can result in property damage,

personal injury or death.

These words mean:

WARNING

Indicates a hazard which, if not avoided, can result in

severe personal injury or death and damage to product

or other property.

CAUTION

Indicates a hazard which, if not avoided, can result in

personal injury and damage to product or other property.

All safety messages will tell you what the potential

hazard is, tell you how to reduce the chance of injury,

and tell you what will happen if the instructions are not

followed.

NOTICE

Indicates property damage can occur if instructions are

not followed.

1

230/208

230/208

230/208

VEA09K

VEA12K

VEA18K

General Specifications

Vert-I-Pak

®

SERIES

DESIGN SERIES

Chassis Specifications

MODEL:

23 1/8”

23 1/8”

32 1/4”

26” x 28 1/2” x 35”

25 = 2.5 KW

34 = 3.4 KW

23 1/8”

23 1/8”

32 1/4”

26” x 28 1/2” x 35”

ENGINEERING CODE

OPTIONS

-410AR-410AR-410AR

23 1/8”

23 1/8”

32 1/4”

26” x 28 1/2” x 35”

See Charts A & B (page 11)

.3” water .3” water .3” water

NOTES:

Electrical Data

Heater Watts 2500/2050 3400/2780 5000/4090 2500/2050 3400/2780 5000/4090 2500/2050 3400/2780 5000/4090

Voltage

Heating BTU/h 8500/7000 11600/9500 17000/13900 8500/7000 11600/9500 17000/13900 8500/7000 11600/9500 17000/13900

Heating Current (Amps) 10.9/9.9 14.8/13.4 21.7/19.7 10.9/9.9 14.8/13.4 21.7/19.7 10.9/9.9 14.8/13.4 21.7/19.7

Minimum Circuit Ampacity

Branch Circuit Fuse (Am ps ) 15 20 30 15 20 30 15 20 30

LRA - Compressor (Amps) 22 22 22 30 30 30 42 42 42

Cooling Current (Amps) 4.2/4.4 4.2/4.4 4.2/4.4 5.2/5.4 5.2/5.4 5.2/5.4 8 1/8.. 6 8 1/8.. 6 8 1/8.. 6

Basic heater Size 2.5 Kw 3.4 Kw 5.0 Kw 2.5 Kw 3.4 Kw 5.0 Kw 2.5 Kw 3.4 Kw 5.0 Kw

Power Connection

Recommended Branch

Circuit Wire Sizes

* AWG-American Wire Gauge

Important: All 208/230v chassis must be hard wired with properly sized breaker. See nameplate for specific chassis electrica

requirements. See Figure 15, page 13 for unit wiring and wall thermostat wiring. See page 12 for wire size. Use

HACR type breakers to avoid nuisance trips. All field wiring must be done in accordance with NEC and local codes.

15 19.9 28.6 15 19.9 28.6 15 19.9 28.6

HARD WIRED HARD WIRED HARD WIRED

14 12 10 14 12 10 14 12 10

2

VHA0 9K

VHA1 2K

VHA1 8K

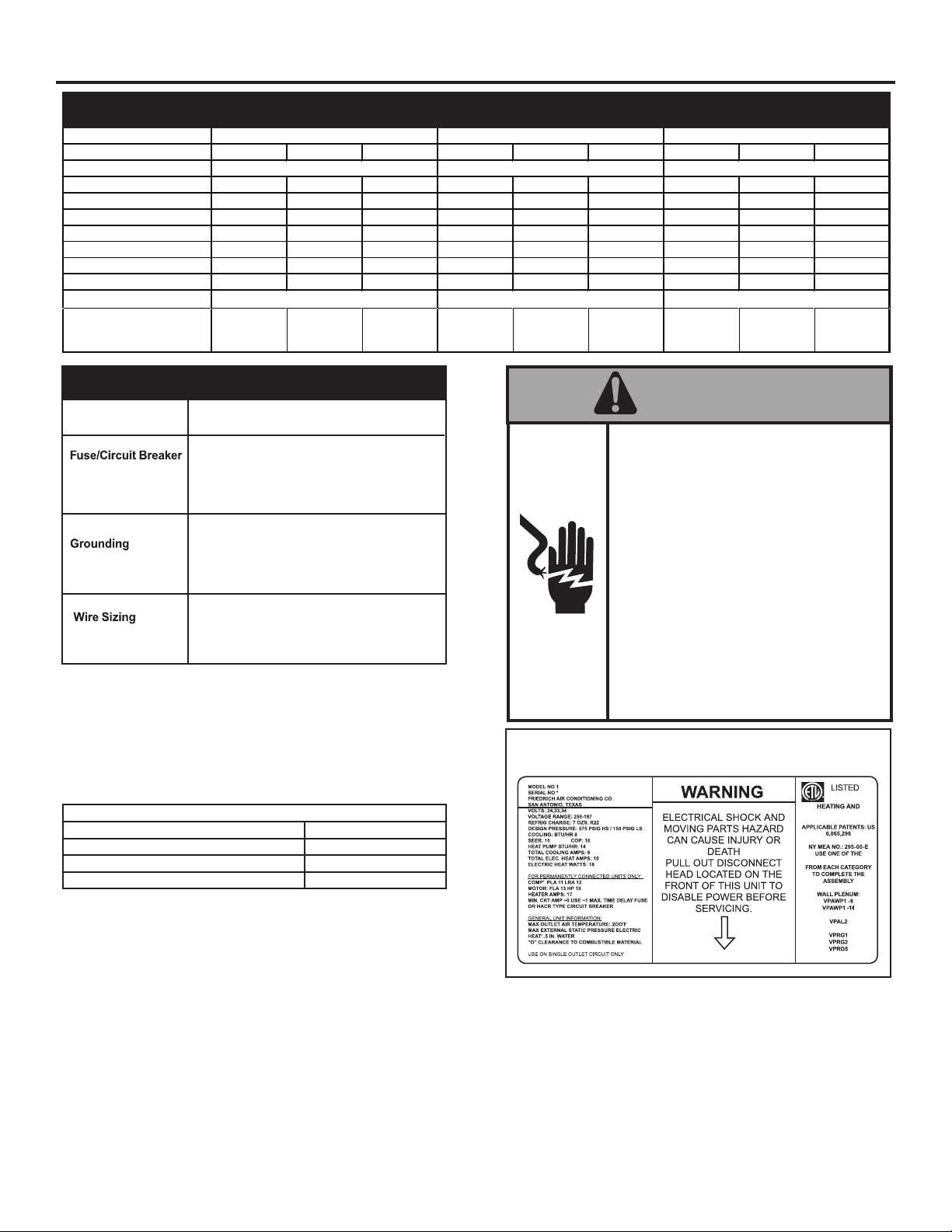

Electrical Data

Heater Watts 2500/2050 3400/2780 5000/4090 2500/2050 3400/2780 5000/4090 2500/2050 3400/2780 5000/4090

Voltage

Heating BTU/h 8500/7000 11600/9500 17000/13900 8500/7000 11600/9500 17000/13900 8500/7000 11600/9500 17 000/13900

Heating Current (Am ps) 10.9/9.9 14.8/13.4 21.7/19.7 10.9/9.9 14.8/13.4 21.7/19.7 10.9/9.9 14.8/13.4 21.7/19.7

Minimum Circuit Ampacity 15 19.9 28.6 15 19.9 28.6 15 19.9 28.6

Branch Circuit Fuse (Am ps ) 15 20 30 15 20 30 15 20 3

LRA - Compress or (Amps ) 18.5 18.5 18.5 26 26 26 42 42 42

Cooling Current (Am ps ) 4.1/4.3 4.1/4.3 4.1/4.3 5.3/5.5 5.3/5.5 5.3/5.5 8.2/8.6 8.2/8.6 8.2/8.6

Basic heater Size 2.5 Kw 3.4 Kw 5.0 Kw 2.5 Kw 3.4 Kw 5.0 Kw 2.5 Kw 3.4 Kw 5.0 Kw

Power Connection

Recommended Branch

Circuit Wire Sizes

* AWG-American Wire Gauge

14 12 10 14 1012 14 12 10

230/208 230/208 208/230

HARD WIRED HARD WIRED HARD WIRED

Electrical Requirements

Wire Size

NOTE: All field wiring must comply with NEC and local

codes. It is the responsability of the installer to insure that

the electrical codes are met.

Use ONLY wire size recommended for

single outlet branch circuit.

Use ONLY type and size fuse or HACR

circuit breaker indicated on unit’s rating

plate (See sample below). Proper over

current protection to the units is the responsibility of the owner.

Unit MUST be grounded from branch circuit

to unit, or through separate ground wire

provided on permanently connected units.

Be sure that branch circuit or general

purpose outlet is grounded.

Use recommended wire size given in tables

and install a single branch circuit. All wiring

must comply with local and national codes.

NOTE: Use copper conductors only.

WARNING

Electrical shock hazard.

Turn OFF electric power before service

or intallation.

Unit must be properly grounded.

Unit must have correct fuse or circuit

breaker protection.

Unit’s supply circuit must have the

correct wire conductor size.

All electrical connections and wiring must

be installed by a qualified electrician and

conform to the National Electrical Code

and all local codes which have jurisdiction.

Failure to do so can result in property

damage, personal injury and/or death.

0

Electrical Rating Table

NOTE: Use copper conductors ONLY. Wire sizes are per

NEC. Check local codes for overseas applications.

Recommended branch circuit wire sizes*

Nameplate maximum circuit breaker size AWG Wire size**

A51

A02

A03

AWG --- American Wire Gauge

* Single circuit from main box.

** Based on 100’ or less of copper, single insulated

conductor at 60° C

41

21

01

Sample Nameplate

S

A

M

P

L

COOLING EQUIPMENT

FOLLOWING ITEMS

E

OUTDOOR GRILLE

120524

INDOOR GRILLE

3

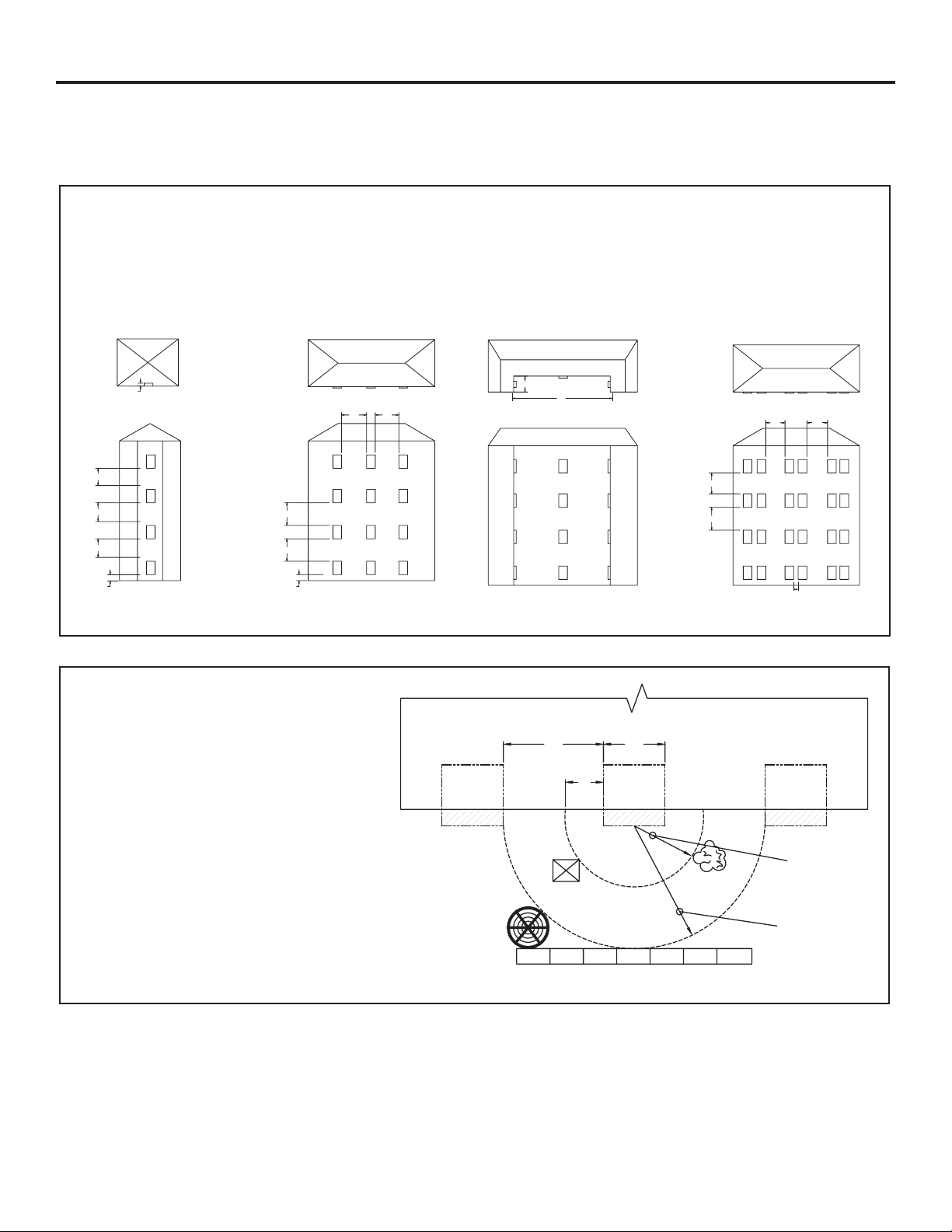

Vert-I-Pak Installation Recommendations

Forproper unit performance andmaximum operating lifeplease refer to the minimum installation clearances

below.

Figure 1

VERT-I-PAK® units must be installed on an outside wall. Confined spaces and/or covered areas should be

avoided. Units should be installed no closer than 12" apart when two units are side by side. If three or more

units are to operate next to one another allow a minimum of 60" between units or pairs of units. Also, a vertical

clearance of 60" should be maintained between units. Units installed on the bottom floor should be mounted at

least 6" off of the ground.

6"

SMALL RECESS OK

60"

60"

60"

6"

60" 60"

60"

60"

6"

B

A

LARGER RECESS OK. IF A> 5xB

60"

60"

60"60"

12"

Figure 2

Any time obstructions are present use the

following guidelines for proper spacing

from the VERTI-I-PAK louver:

• For minor obstruction such as lamp

poles or small shrubbery a clearance of

24” from the outdoor louver should be

maintaned.

• For major obstructions such as a solid

fence, wall or other heat rejecting

POLE

device like a condensing unit, a

minimum distance of 72” should be

kept.

OUTDOOR

CONDENSING

UNIT

The above suggestions are for reference only and do not represent all possible installations. Please contact Friedrich Air Conditioning

(see contact information on back cover) for information regarding affects of other installation arrangements.

By following these simple recommendations you can be confident that your Friedrich Vert-I-Pack

free operation.

BUILDING

24"60"

12"

MAJOR OBSTRUCTION

KAPVKAPVKAPV

24"

SHRUB

72"

FENCE

®

will provide years of worry-

4

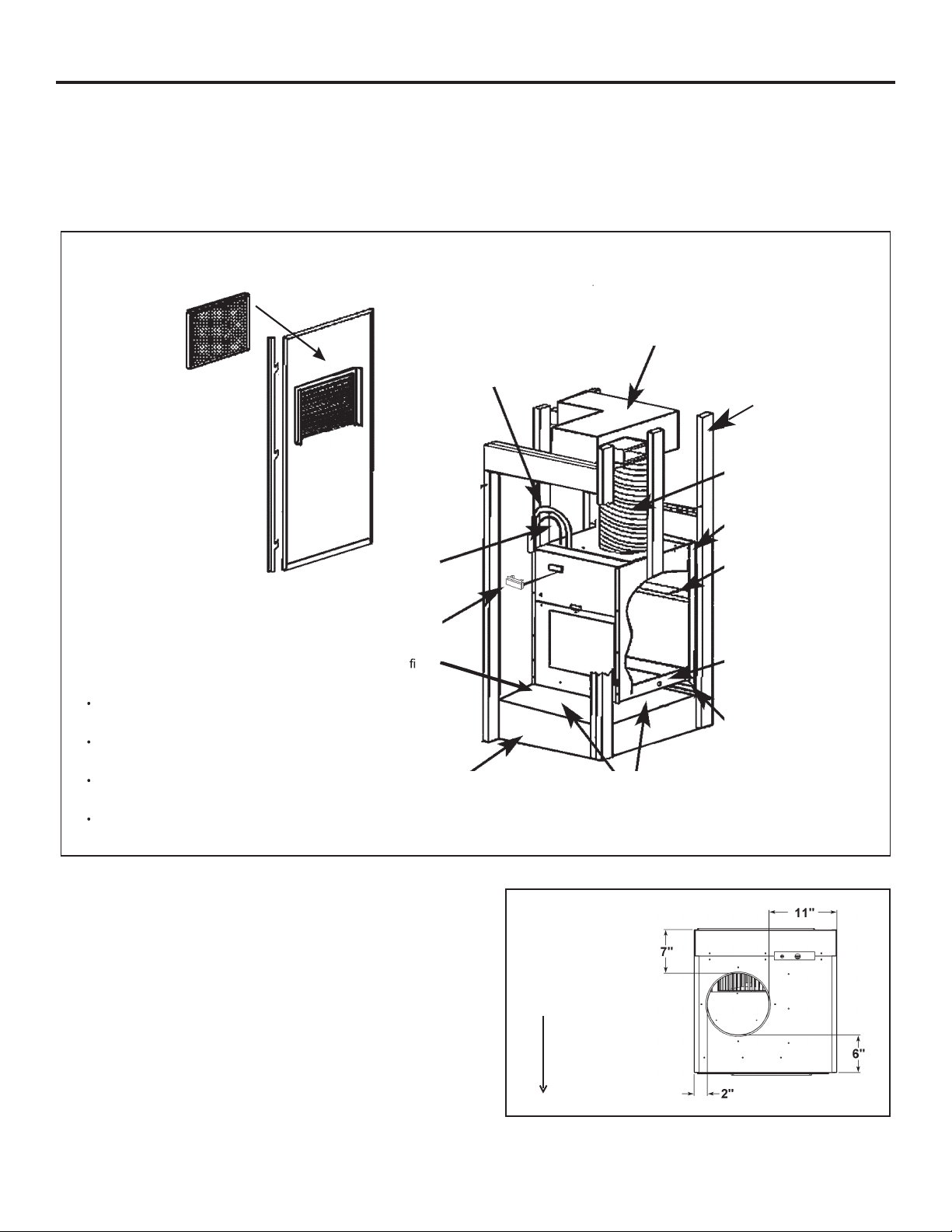

Installation

Utility Closet Dimensions

Recommended utility closet dimensions and a typical indoor installation are illustrated in Figure 3. Three inches minimum clearance

on three sides of the unit must be allowed for return airflow, installation access and service access. See Figures 3 & 4 for cl

and reference dimensions.

earances

Figure 3

25" x 20" Filter

(Field Supplied)

VPRG4 Access Panel and

Return Air Filter Grille

Vert-I-Pak Chassis dimensions:

1

23

/8" wide x 231/8" deep x 321/4" high.

VPAWP1-8/1-14 Wall Plenum cut-out

dimensions 24

VPRG4 Access Panel cutout dimensions:

27" wide by 55

See Figure13, Page 11 for proper chassis

installation.

5

/8" wide x 307/8" high.

3

/4" high.

Typical Utility Closet

Thermostat

Wiring

Power

Disconnect

Recommended eld

installed drain pan

Optional

Platform

Chassis Shown in Closet, on Optional Platform

Rigid Ductwork

Electrical

Connection

Exterior Wall

Flexible Ductwork

VPAWP1-8/1-14

Wall Plenum

Plenum Divider

3/4" FPT Drain

Connection

Chassis installs

3

2

/8" into Plenum

3" Clearance on all three sides

minimum for service and installation.

Figure 4

Top View

Outside

Wall

5

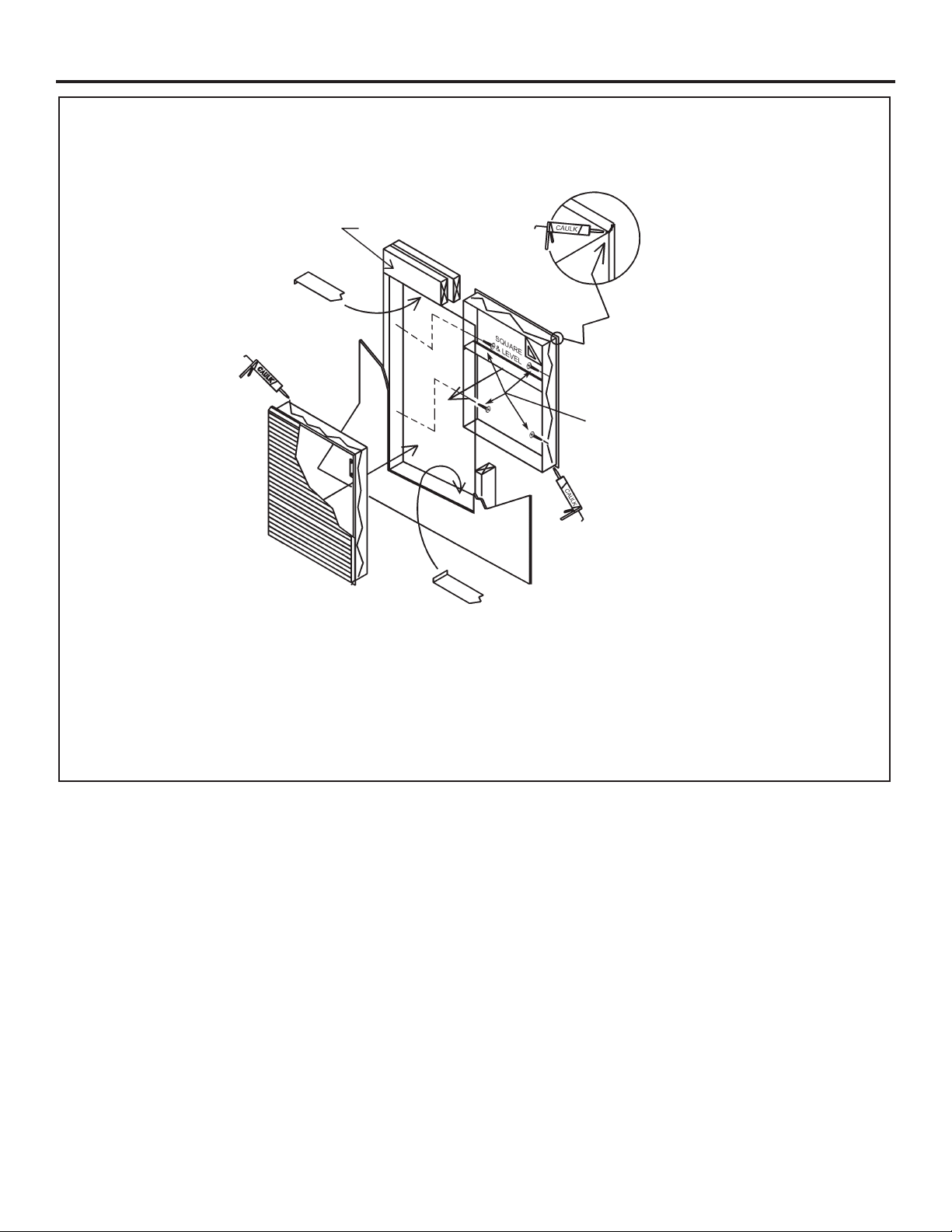

Wall Plenum and Architectural Louver Installation

Install the wall plenum components in accordance with the installation instructions provided.

NOTE: IMPORTANT REMINDER FRIEDRICH WALL PLENUM IS NOT DESIGNED TO CARRY

STRUCTURAL LOADS. PROPER WALL HEADER CONSTRUCTION IS REQUIRED. THE PLENUM

REQUIRES PROPER FLASHING, SHIM AND CAULK FOR A WEATHER RESISTANT INSTALLATION.

YOUR WALL PLENUM WILL WORK ONLY IF INSTALLED CORRECTLY. TAKE NOTICE TO INSTALL

IT IN THE CORRECT ORIENTATION AS SHOWN IN THE ILLUSTRATIONS. ALWAYS FOLLOW

LOCAL AND NATIONAL CODES FOR PROPER INSTALLATION.

Figure 5

Included Parts

There are two parts to a Wall Plenum:

A) 1-Outside Assembly (Part A)

B) 1-Inside Assembly (Part B)

45° Drip

Ledge

Part A

Out-

side Plenum

Part B

Inside

Plenum

Figure 6

Field Supplied Parts

Caulk, Attachment screws and Flashing

are fi eld supplied. Silicone caulk is

recommended.

VPAWP1-8 adjusts for walls 5.5 - 8.0" thick.

VPAWP1-14 adjusts for walls 8 - 14.0" thick.

Both installations are similar.

C

A

ULK

Caulk

Flashing

Shim

PART A CORRECT ORIENTATION:

!

LOUVER ATTACHMENT

FLANGES TOWARD THE BUILD-

ING OUTSIDE, 45°

DRIP LEDGE AT THE BOTTOM.

PART B CORRECT ORIENTATION:

!

LARGE OPENING TO BOTTOM

3/4" FLANGE TOWARD THE INSIDE

OF THE BUILDING.

Header materials /

wall studs

1" –3" Screws to attach

the plenum assembly

to the wall studs

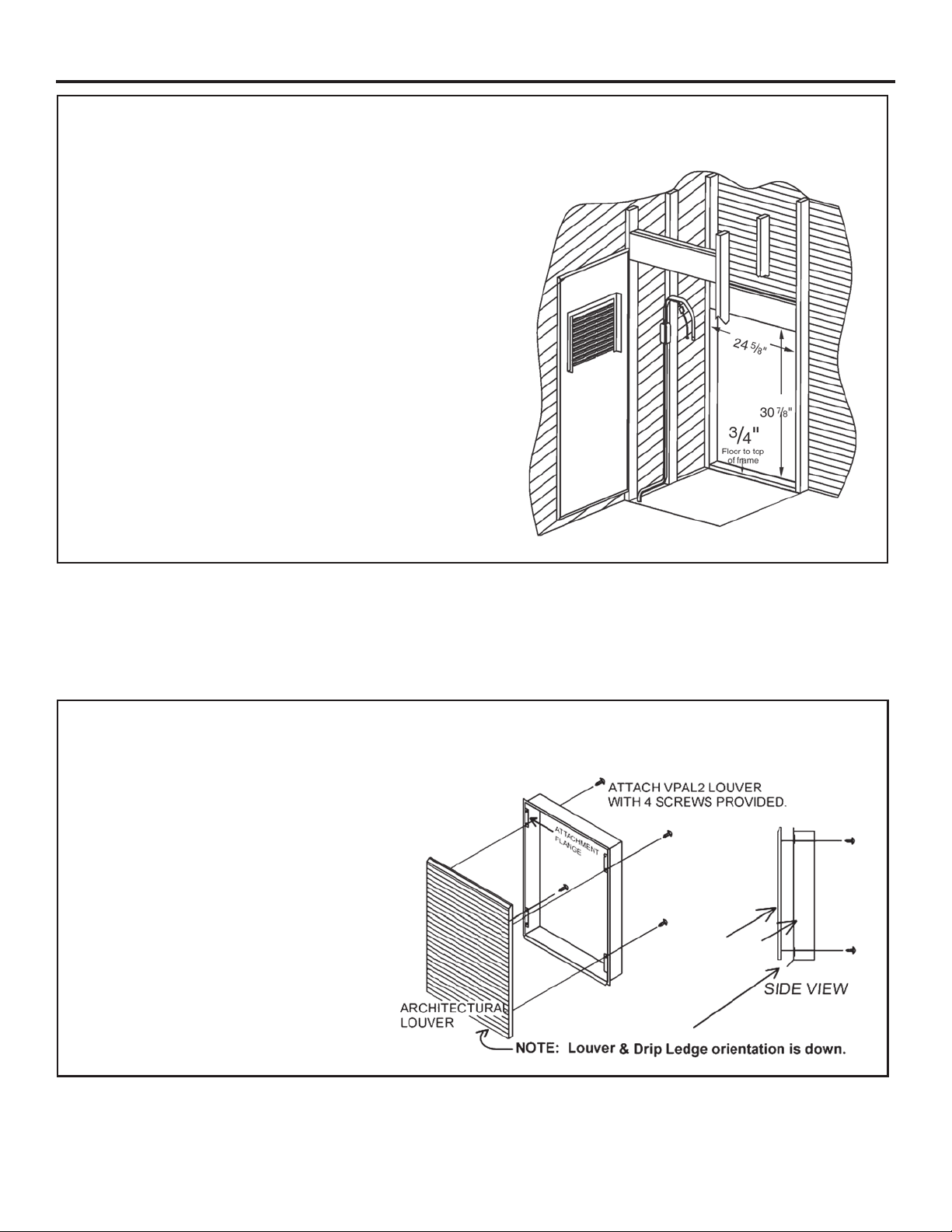

Figure 7

Measure and frame out the outside wall plenum opening

9000 / 12000 / 18000 BTU/h

The plenum cut out dimensions are 24 5/8"

wide x 30 7/8" high. The bottom of the rough

in opening must be 3/4" from the surface the

unit will sit on.

Measure your outside wall as shown in the

illustration. Cut, frame, and square rough

opening. The Wall plenum has a 3/4" break all

the way around to cover the rough cut opening or required shim.

If the installation will utilize an auxiliary drain

pan the drain pan must be a maximum of 3/4”

tall. If the drain pan to be used is taller, the

unit must be raised within the auxiliary pan by

the difference in height of the drain pan and

3/4".

IMPORTANT: THE WALL PLENUM IS NOT DESIGNED TO CARRY STRUCTURAL LOADS. A PROPER

HEADER OPENING MUST BE BUILT INTO THE ROUGH OPENING. THE PLENUM REQUIRES FLASHING, SHIM AND CAULK FOR A WEATHER-RESISTANT INSTALLATION.

IT IS THE RESPONSIBILITY OF THE CONTRACTOR TO PROPERLY INSTALL THE PLENUM AND MEET

BUILDING CODE REQUIREMENTS.

Figure 8

Install Architectural Louver on the Outside Plenum

NOTE: The VPAL2 Architectural

Louver is best installed onto the

Outside Plenum (Part A) prior to

Wall Plenum installation. Louver

installation is easier at this point,

and it will help keep the Wall

Plenum square during installation.

LOUVER

OUTSIDE PLENUM

PART A

7

Figure 9

Plenum Installation

Note: Proper header and wall penetration must conform to all national and local building codes.

Caulk all 8 flange

corners and unused

holes

Proper

Flashing

Proper

Caulking

Architectural louver VPAL2

mounted on the outside

wall plenum (Part A)

Proper Header

Outside

Wall

Inside Wall Plenum (Part B)

Install anchor screws approximately

four inches from the top and bottom

of the plenum. Do not make penetration through the top or bottom of

the plenum

Proper Caulking

Proper Flashing

After the rough cut opening is prepared, you are ready to assemble the two wall plenum parts. Before

caulking and permanent attachment, dry fi t the outside plenum into the rough opening and check for fi t

and level. Caulk (silicone recommended ) the parts well and insert them into the wall as shown.

A) Apply caulk and insert Outside Part A into the hole.

B) Apply caulk and insert Inside Part B into Part A. Be sure that Part A does not back out of the wall hole.

8

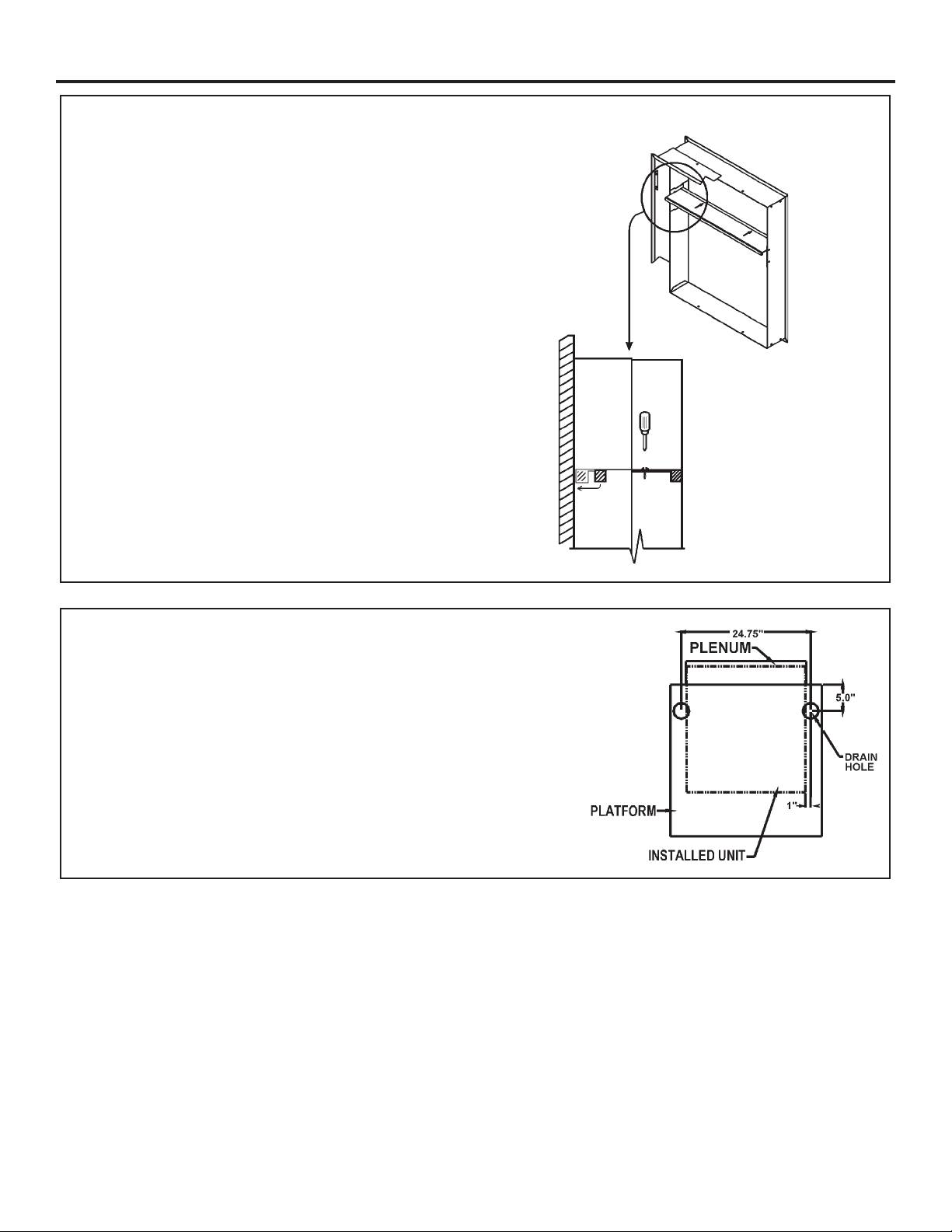

Figure 10

Adjust the Divider

Adjustment

Loosen the two screws located on the top side of the divider.

Slide the top part of the divider toward the outside until the

sealing strip makes contact with the outdoor louver. Tighten

the divider screws to complete the adjustment.

NOTE:

Let the caulk cure completely before installing the

chassis. This completes the plenum installation.

Condensate Disposal Preparation

for 9000 / 12000 / 18000 Models ONLY

IMPORTANT: This step must be performed to ensure that

the chassis installs and seals properly in the wall plenum.

If provisions for condensate disposal are made prior to

chassis installation and the drain is to be located beneath

the platform for the unit, use the accompanying drawing as

a guide for cutout locations. Only one drain per unit is

required.

Condensate Disposal System

The Condensate Disposal System increases energy

efficiency utilizing a factory installed fan that sling the cold

condensate onto the hot outdoor coil.

When high outdoor humidity prevents the slinger from

disposing of all the condensate, the excess condensate

overflows into the condensate drain pan and out of the ¾”

internal drain connections.

NOTE: If the Condensate Disposal System fails to remove

all of the condensate from the unit, any excess condensate

will overflow from a spillway in the rear of the unit directly

into the wall plenum, and drain outside the building. This is

your indication that the chassis or drain requires servicing.

9

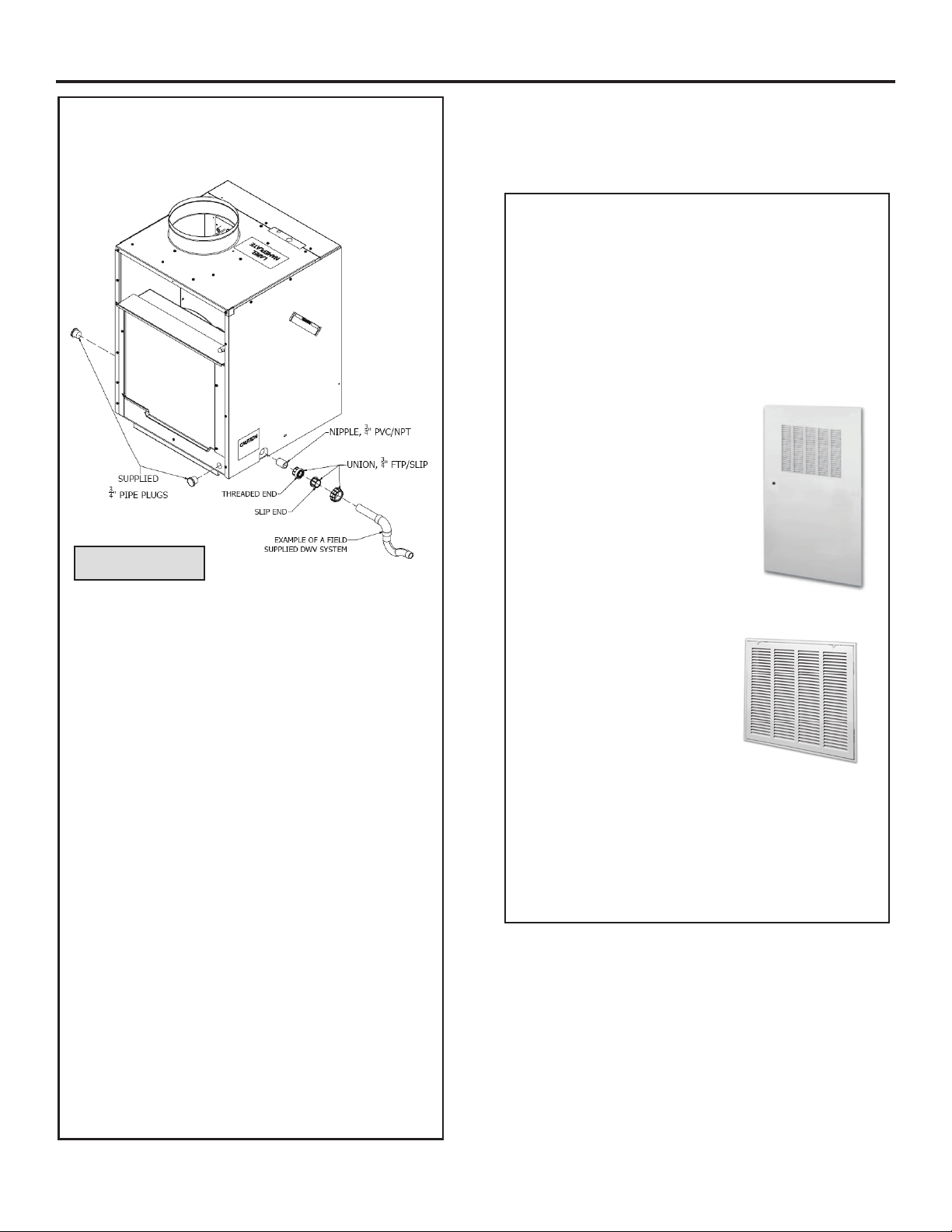

Figure 11

Drain Connection

and Location

NOTICE

1) The unit basepan has three (3) provisions (left, right,

and rear) for connecting an external condensate drain.

2) The supplied drain kit must be connected to one of the

three (left, right, or rear) ¾” FPT connections on the

unit basepan. Use of rear fitting without connection to

DWV system (drain, waste, vent) may result in

staining of the outside wall.

3) Insert the provided ¾” nipple into the determined

connection using field supplied teflon tape or pipe joint

compound.

4) With the threaded end of the supplied ¾” union,

connect to the nipple with teflon tape or pipe joint

compound.

5) Hand-tighten all fittings to prevent damage to unit or

fittings.

6) A field supplied drain system must now be installed to

the slip end of the union. A trap is recommended and

drain connections should be connected to building

DWV system.

7) Pitch the drain line on a ¼” downward slope for every

foot (1’) of lateral horizontal run to the DWV.

8) The remaining two connections must be plugged using

the two ¾” pipe plugs (provided) and field supplied

teflon tape or pipe join compound. Hand-tighten to

prevent damage to unit or fittings.

9) Do not thread metal or copper pipe fittings directly into

unit.

10) Check system for leaks.

11) Failure to follow these procedures may result in

serious property damage.

12) A field supplied secondary condensate pan may be

required. Check with local codes.

10

Indoor Return Air Grille Installation

There are two Indoor Return Air Grille options as shown in

Figure 12. Choose the option that best suits your needs.

Use the installation instructions provided with accessories

for installation details.

Figure 12

Return Air Grille Options

NOTE: All Vert-I-Pak chassis are shipped with a 20” x

14” filter installed. If an accessory filter holder is to be

used, you MUST remove the factory shipped filter from

the chassis. Do NOT use two filters.

Option 1

VPRG4 Return Air Grille

with Access Panel

A field-supplied (25” x 20”) filter is

mounted inside the hinged access

door.

Kit contains hinge bracket for

mounting the door with the return

air openings high or low on the

door for optimal sound attenuation.

It is recommended to install the

door with the hinge on the right

side and the return air openings

high on the door.

Option 2

Field Supplied

Return Air Grille

Must have a minimum of 250

square inches of free area.

NOTES:

There are the Friedrich recommended return air

grille/filter/access panel arrangements. Consult

Friedrich on other arrangements. Improper return air

arrangements will cause performance problems.

Return air arrangements are shown from the front,

but can also be installed from the right or left side of

the unit.

Ductwork

The supply duct system should be designed via a recognized

method such as the equal friction method, or velocity reduction

method, using the appropriate duct calculator(s) for the type(s)

of duct (i.e. metal duct, duct board, or flex duct) being used in

the system. The duct system should be designed for a

maximum friction rate of .30" water column taking into consideration all fittings, registers and/or diffusers. DO NOT operate

unit without a supply duct attached.

The return air to Vert-I-Pak "A" series units MUST NOT be

ducted, and all units MUST have a free return air configuration

to perform properly.

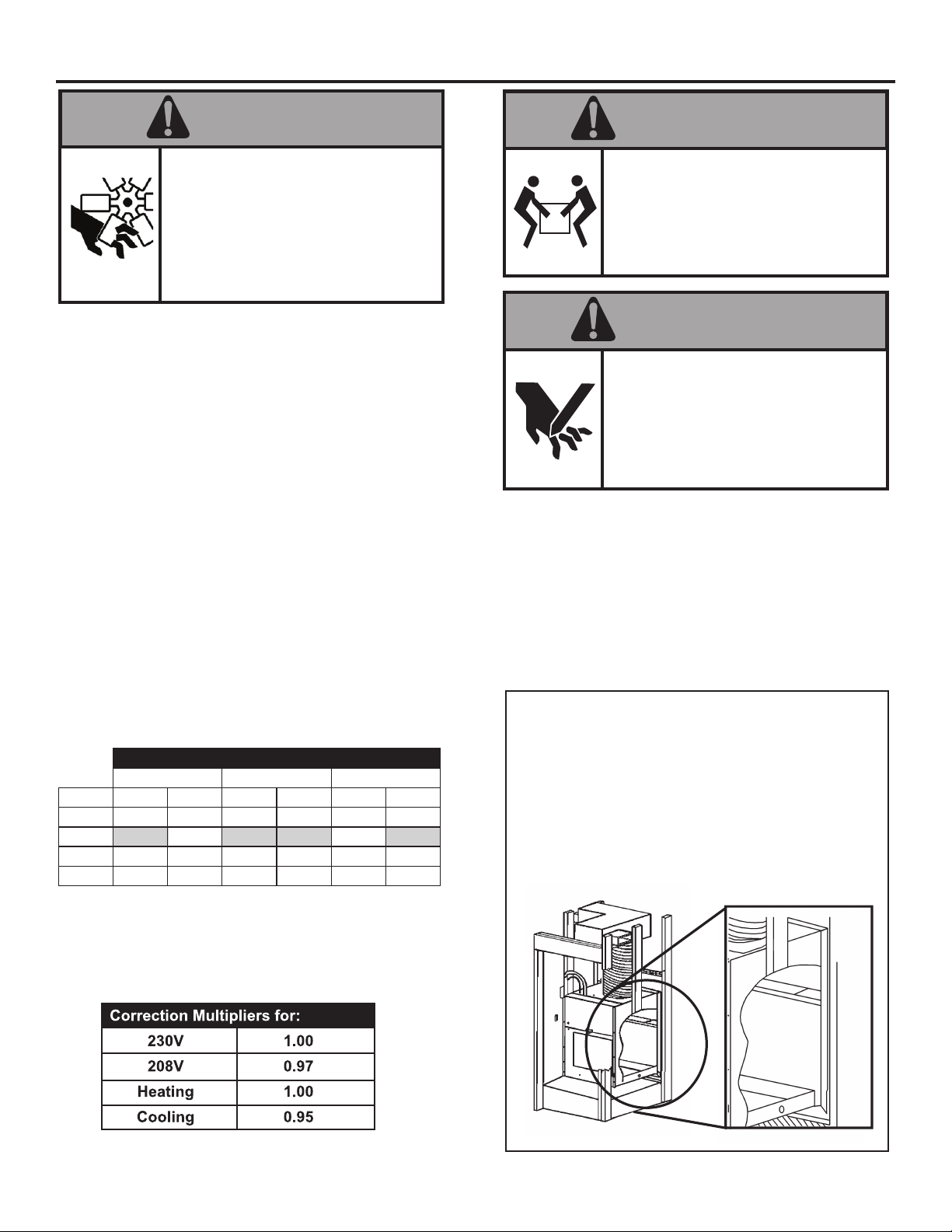

WARNING

CAUTION

Moving parts hazard

Turn off electric power before servicing

this component.

Fan can start automatically.

Failure to do so can result in property

damage, personal Injury and/or death.

Indoor Air Flow Data

Indoor air flow may be determined by measuring the external static pressure (ESP) of the duct system using an

inclined manometer or magnehelic gauge, then consulting

chart “A” to determine actual air flow. Rated air flow for

each unit is obtained at .10” W.C. when operating with a

clean filter and a dry coil (i.e. heating) on the indicated

speed at 230 Volts. Use the air flow correction multipliers

contained in chart “B” to determine accurate air flow under

the listed conditions. Under no circumstances should the

Vert-I-Pak equipment be operated at an external static

pressure in excess of .30” W.C. Operation of the Vert-I-Pak

under these conditions will result in inadequate air flow

leading to poor performance and/or premature component

failure.

For LOW speed operation, connect the fan output terminal

from the thermostat to the GL terminal of the electronic

control. For HIGH speed operation, connect the fan output

terminal from the thermostat to the GH terminal of the

electronic control. For thermostats with two-speed fan

capabilities, connect the LOW speed output to the GL

terminal, and the HIGH speed output to the GH terminal.

Determining the Indoor CFM: Chart A – CFM

Model

VEA12/VHA12 VEA18/VHA18VEA09/VHA09

ESP (")

.00"

.10"

.20"

.30”

Low

340

300

230

140

Highlighted values indicate rated performance point.

Rated performance for VEA12

*

Rated Performance for VHA12

**

High

385

340

280

190

Low

420

350 *

290

250

High

470

420 **

350

300

Low

430

400

340

290

High

480

450

400

330

Excessive Weight Hazard

Use two or more people when installing

your air conditioner.

Failure to so can resut in back or other

injury.

CAUTION

Cut/Sever Hazard

Some edges may be sharp, use gloves

or other hand protection when handling

unit.

Failure to do so can result in minor to

moderate personal injury.

Chassis Installation

Install the following components

A. Ensure that the wall plenum is installed in accordance

with the instructions listed on Pages 6-10.

B. Place the chassis into the closet with the outdoor side

facing the wall plenum opening.

C. Slide the chassis into the wall plenum until the plenum

divider seal is established. (See Figure 13)

Figure 13

Chassis Installation/

Installed View

The Vert-I-Pak chassis must be inserted into the wall

plenum so that the plenum divider gasket makes

contact with the plastic condenser baffle on the unit.

The chassis will fit approximately 2 ⅜" into the wall

plenum.

Correct CFM (if needed):

Chart B – Correction Multipli

ers

11

Remote Thermostat and Low Voltage Control Connections

Remote Thermostat

All Friedrich Vert-I-Pak units are factory configured to be

controlled by using a single stage heat/cool remote wall mounted thermostat. The thermostat may be auto or manual changeover as long as the control configuration matches that of the

Vert-I-Pak unit.

To connect the wall-mounted thermostat:

1. Pull the disconnect switch.

2. Unscrew and remove the control box panel.

3. After selecting which side you want to run your thermostat

wire through, run the wires through the side hole in the box

to reach the connection terminal for the wiring.

4. Make the wire connections, appropriately matching the wires

as shown in the wiring diagram.

5. Once each wire is matched and connected, the unit is now

ready for operation.

6. Reattach the control box cover.

Desk Control Terminals

The Friedrich VERT-I-PAK has built-in provisions for connection to an external switch to control power to the unit. The

switch can be a central desk control system or even a normally open door switch.

For desk control operation, connect one side of the switch to

the D1 terminal and the other to the D2 terminal (See figure

15). Whenever the switch closes, the unit operation will stop.

NOTE: The desk control system and switches must be

field supplied.

Maximum Wire Length for Desk Control Switch

Wire Size Maximum Length

#24 400 ft.

#22 600 ft.

#20 900 ft.

#18 1500 ft.

#16 2000 ft.

NOTE: It is the installer’s responsibility to ensure that all control

wiring connections are made in accordance with the installation

instructions. Improper connection of the thermostat control

wiring and/or tampering with the unit’s internal wiring can void

the equipment warranty and may result in property damage,

personal injury or death. Other manufacturer’s units and even

older Friedrich models may have different control wiring

connections. Questions concerning proper connections to the

unit should be directed to the factory.

Control Board

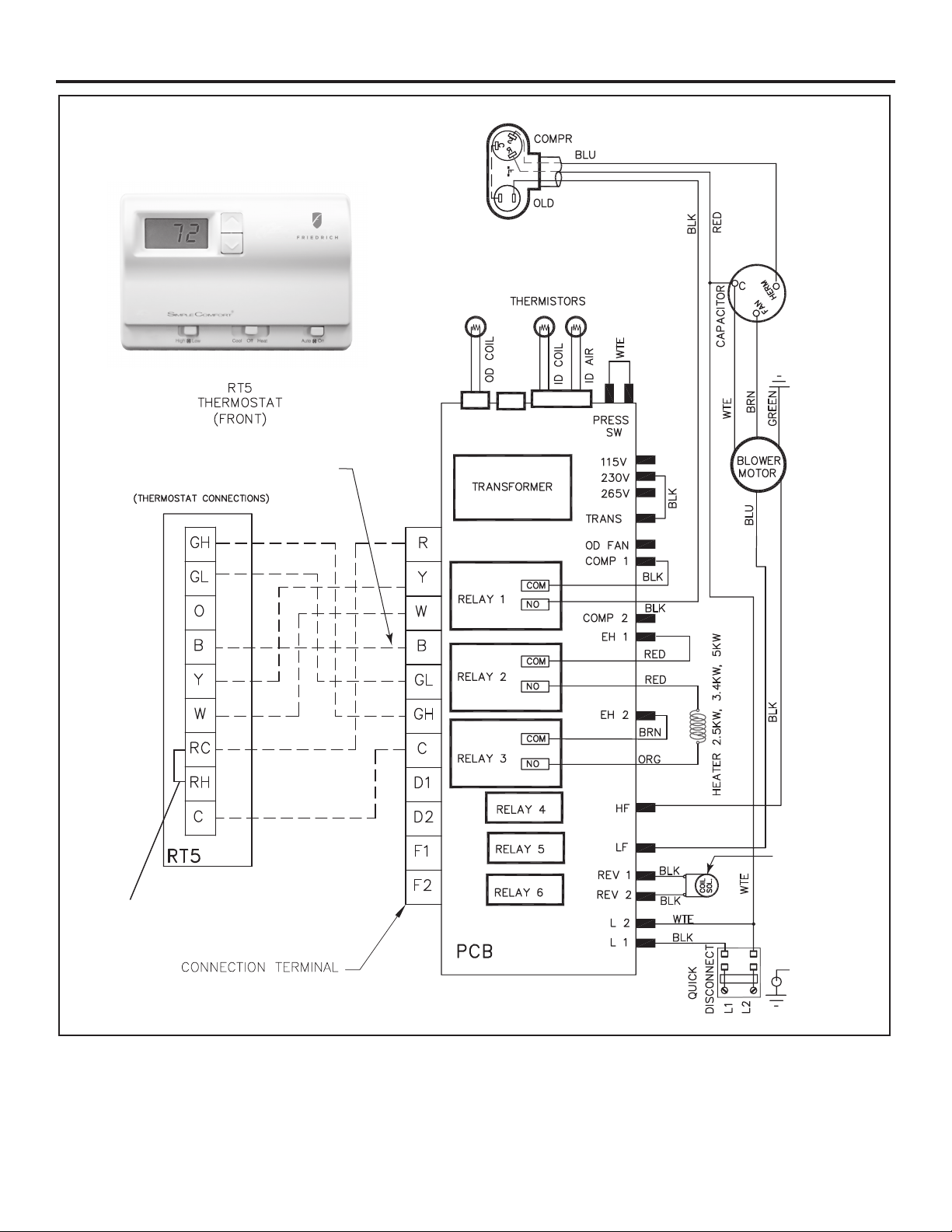

Figure 14

Thermostat Connections

R = 24V Power from Unit

Y = Call for Cooling

W = Call for Heating

B = Reversing Valve Energized in heating mode

GL = Call for Fan (Low Speed)

GH = Call for Fan (High Speed)

C = Common Ground

Auxiliary Fan Control

The Smart Center also has the ability to control a 24VAC relay

to activate an auxiliary, or transfer, fan. The outputs are listed

as F1 and F2 on the control board.

To connect the relay, simply wire one side of the relay to F1

and the other side to F2. Anytime that the fan runs, the

terminals will send a 24VAC signal to the relay. The relay must

be 24VAC, 50mA or less.

NOTE: The relay and auxiliary fans must be field supplied.

12

Figure 15

Electrical & Thermostat Wiring Diagrams

HEAT PUMP ONLY

PRE-INSTALLED JUMPER

NOTE:

THE DIAGRAM ABOVE, ILLUSTRATES THE TYPICAL THERMOSTAT WIRING FOR TWO SPEED FAN

OPERATION. SEE THE UNIT CONTROL PANEL FOR THE ACTUAL UNIT WIRING DIAGRAM AND SCHEMATIC.

HEAT PUMP ONLY

13

Chassis Final Connections

With the chassis in place, you are now ready to begin chassis

connections:

Move the thermostat switches to “OFF” and “AUTO”.

A.

This will keep the thermostat from cycling the chassis

until final connections are complete.

Connect the duct work onto the 10” collar. Plastic wire

B.

ties (field supplied) are suggested to secure the duct

work in place. Use 2 wire ties, one for each inner and

outer flex duct sleeve.

C.

Review the Final Installation Checklist before replacing

the power quick disconnect, reconnecting power to the

chassis or operating the chassis.

Present the owner or operator of the equipment with the

Installation & Operation Manual, all accessory installation

instructions, and the name, address and telephone number

of the Authorized Friedrich Warranty Service Company in

the area for future reference if necessary.

Chassis Operation

Fresh Air Door

The Fresh Air Door is an “intake” system. The fresh air door

is opened via a slide on the front of the chassis located just

above the indoor coil. Move the slide left to open and right to

close the fresh air door. The system is capable of up to 60

CFM of fresh air at .3 H20 internal static pressure.

WARNING

Electrical Shock Hazard

Pull out electrical disconnect on front of

the chassis and turn off all power to the

unit before servicing.

Failure to do so can result in property

damage, personal injury and/or death.

Final Installation Checklist

Inspect and ensure that all components and accessories have been installed properly and that they have

not been damaged during the installation process.

Ensure that all installation instructions concerning

clearances around the unit have been adhered to.

Check to ensure that the unit air filter, indoor coil, and

outdoor coil are free from any obstructions.

Ensure that the circuit breaker(s) or fuse(s) and supply

circuit wire size have been sized correctly.

Check the condensate water drain(s) to ensure that

they are adequate for the removal of condensate

water, and that they meet approval of the end user.

Low Ambient Compressor Cut Out

Each chassis is equipped with low ambient protection in the

form of a thermistor, which will prevent compressor operation at low suction temperature.

oom Freeze Protection

R

Units are shipped from the factory with the room freeze

protection disabled. Room Freeze Protection can be

switched on at the owner’s preference by moving Dip Switch

6 to ‘ON’. This feature will monitor the indoor room

conditions and in the event that the room falls below 40ºF

the unit will cycle on high fan with the electric heater. This

occurs regardless of mode.

Emergency Heat Operation

In the event of a compressor failure in heat pump mode the

compressor may be locked out to provide heat through the

resistance heater. This feature ensures that even in the

unlikely event of a compressor failure the room temperature

can be maintained until the compressor can be serviced.

Moving dip switch 7 to ‘ON’ controls the emergency heat

setting.

Ensure that the entire installation is in compliance with

all applicable national and local codes and ordinances

having jurisdiction.

Secure all access panels (i.e. front cover and/or control

box), apply power to the unit, then start the unit, and

check for proper operation in each mode. Instruct the

owner or operator regarding the unit’s operation, and

the recommended routine maintenance schedule.

NOTE: Maintaining a log for recording the dates of maintenance and/or service is recommended, and should be

suggested to the owner or operator of the equipment.

14

1 2 3 4 5 6 7 8

O

N

Service & Warranty

Servicing / Chassis Quick Changeouts

The chasis is designed for quick disconnect and change out.

For minor electrical service, the control box cover lifts

straight up after the screws & disconnect head are removed.

For major electrical, refrigeration and fan service the chassis

may be removed from utility closet.

To Remove the Chassis from the Closet

A. Switch the wall thermostat off.

B. Pull the Power Disconnect located in the fron

C. Disconnect the power coming into the unit from the main

breaker panel or the closet mounted disconnect.

D. Disconnect the electrical connection.

E. Disconnect the duct work.

F. Slide the chassis out of the wall plenum.

G. Lift the chassis out of the utility closet.

:

t of the chassis

.

WARNING

Electrical Shock Hazard

Pull out electrical disconnect on front of

the chassis and turn off all power to unit

before servicing.

Failure to do so can result in property

damage, personal injury and/or death.

Routine Maintenance

Performing Routine Maintenance

With the proper maintenance and care, your system will

operate ecomomically and dependably. Maintenance can be

accomplished easily by referring to the following directions.

However, before performing any maintenance, see above

stated WARNING.

CAUTION

Cut/Sever Hazard

Some edges may be sharp, use gloves

or other hand protection when handling

unit.

Failure to do so can result in minor to

moderate personal injury.

Replace Air Filter

A dirty air filter reduces the efficiency of your Vert-I-Pak and

allows lint and dirt to accumulate on the indoor-air coil. Lint

and dirt on the indoor-air coil can damage your unit.

The air filter should be replaced as it becomes dirty.

To replace the filter (chassis mounted return air filter):

1. Slide the filter clear of the filter rails.

2. Remove the filter.

3. Install new disposable filter.

NOTE:

FILTER IN PLACE OR BLOCK THE FRONT OF THE UNIT

RETURN AIR OPENING.

DO NOT OPERATE YOUR SYSTEM WITHOUT A

Inspect and Clean Indoor-air Coil

Eventually, minor amounts of lint and dirt may pass through

the filter and collect on the indoor-air. These minor

accumulations can be carefully vacuumed away with a

brush attachment on a vacuum claner. Care must be taken

to avoid bending the aluminum finns on the coil. Bent fins

should be straightened using a special fin tool avalable from

most HVAC supply depots.

In

spect Outdoor-Ai r (OA) Intake and Exhaust

The unit’s outdoor-air intake and outdoor-air exhaust paths

must remain clear. Check the OA exhaust frequently. Keep

it free of all debris, snow, or ice. The OA intake should also

be kept free of obstructions. Blocking the OA exhaust or OA

intake opening will reduce the efficiency of your unit and

could damage it.

Inspect and Clean Condensate Drain

The condensate drain must be routed to a suitable drainage

area. Check the unit condensate drain periodically. Keep it

free of anything that may block or impede the flow of

condensate water. If there is any accumulation of foreign

matter in the drain pipe, it should be removed and cleaned.

The entire drain line must be protected from freezing.

Warranty

All warranty service work must be done by an authorized

servicer. See Product Warranty, and consult your dealer or

contractor for details.

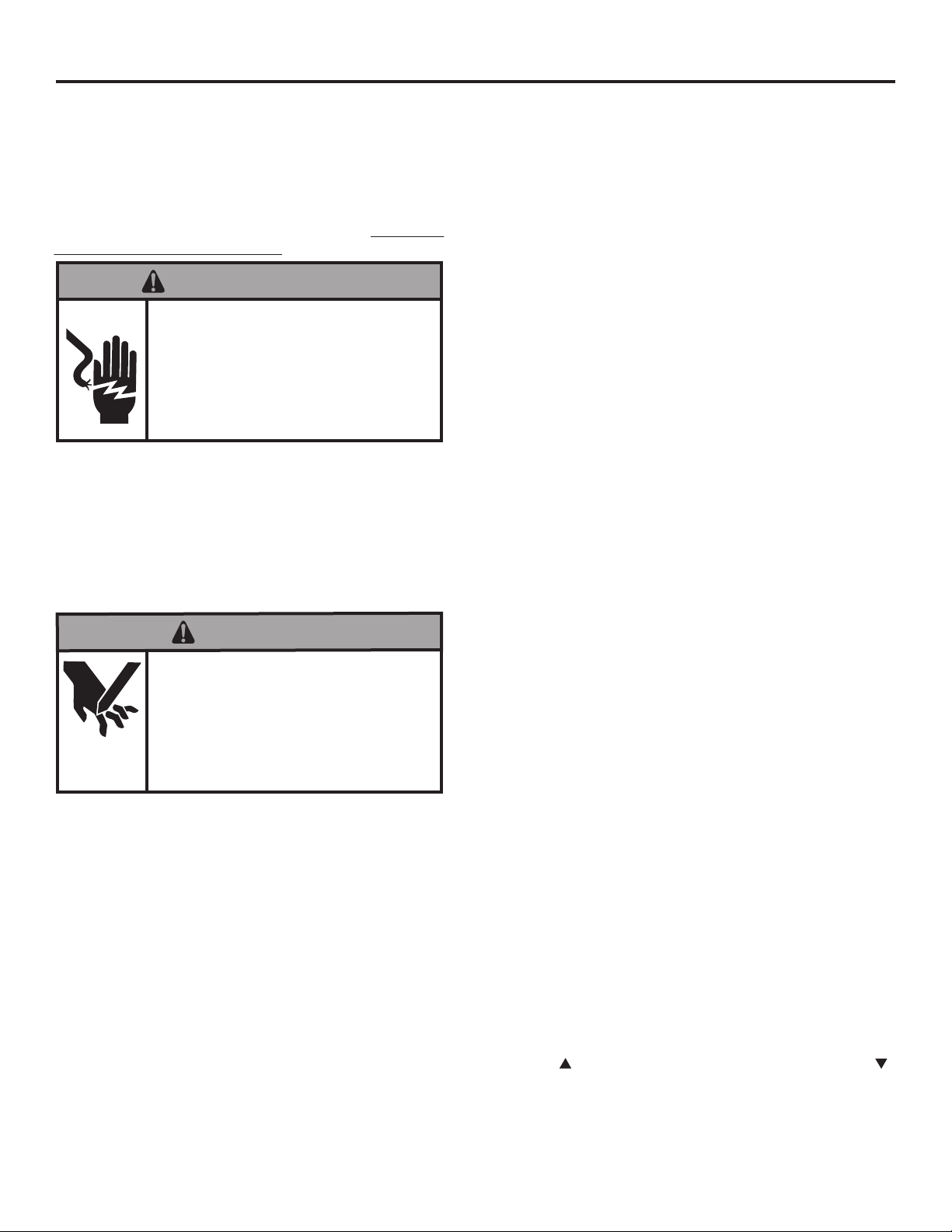

Electronic Control Error Code

Diagnostics and Test Mode

Error Code Diagnostics

The VPAK electronic control continuously monitors the

Vert-I-Pak unit operation and will store error codes if certain

conditions are witnessed. In some cases the unit may take

action an shut the unit off until conditions are corrected.

To access the error code menu press ‘HEAT’ and

‘HIGH FAN’ buttons simultaneously for three seconds, If

error codes are present they will be displayed. If multiple

codes exist you can toggle between error codes using the

temp up button. To clear all codes press the temp down

button for three seconds while in the error code mode. To

exit without losing codes press the ‘Low Fan’ button.

15

Unit Control Panel

With the remote thermostat escutcheon installed, the button locations to access the diagnostics mode can be located as

shown below.

* Heat and high fan - access error code

Temp

Temp

Cool

Fan only

High fan

Heat

Power

Low fan

* Temp up and temp down - toggle between error

codes

* Low fan - exit error code mode without losing stored

error codes

* Temp down - clears all error codes.

NOTE: Hold buttons down for three seconds

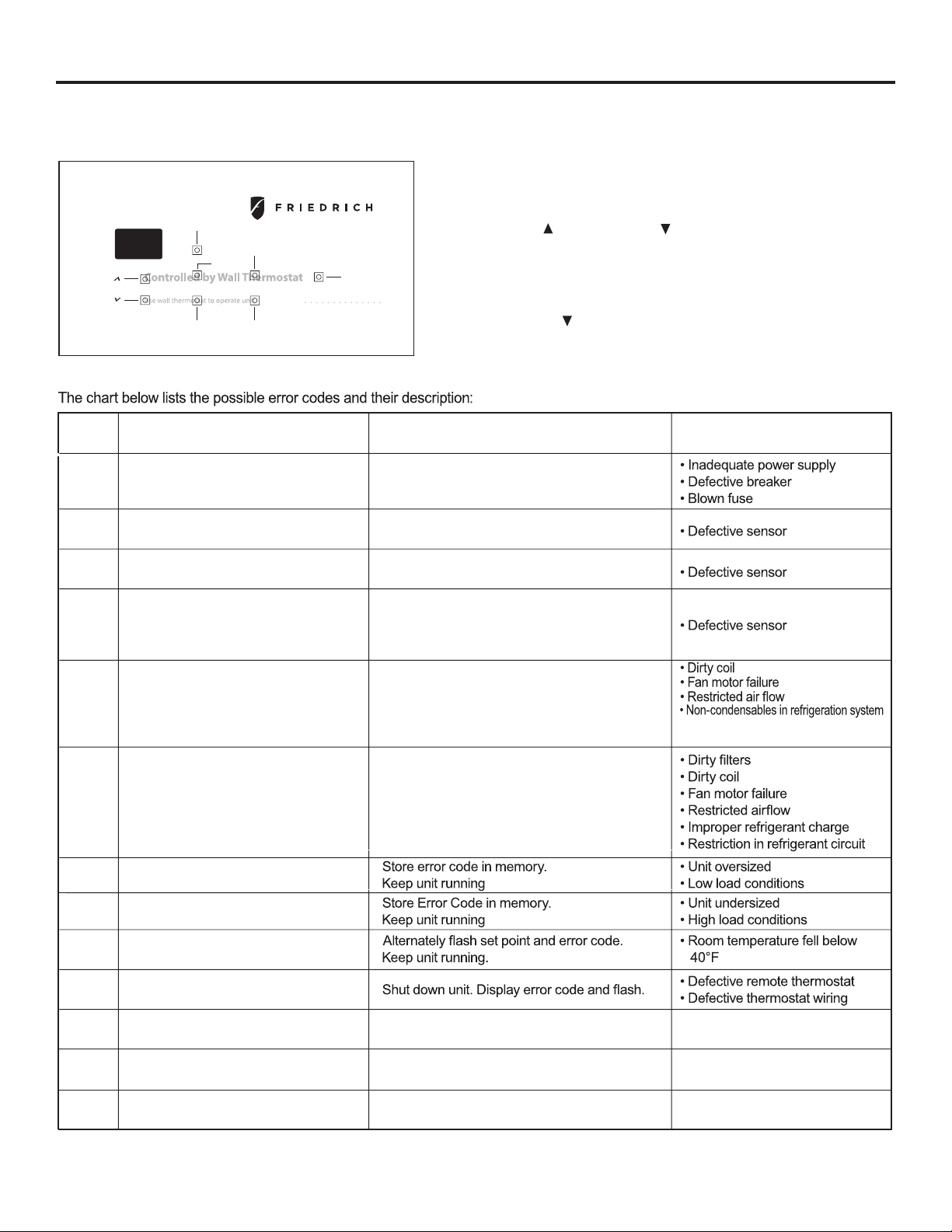

Error Codes

Error

Code

02

03

04

05

06

07

08

09

Code Translation Action Taken by Unit Possible Cause

An extreme low voltage condition

exists <198V for 230V units and

<239 for 265V units

Return air thermistor sensor open

or short circuit

Indoor coil thermistor sensor open

or short circuit

Outdoor coil thermistor sensor

open or short circuit

If outdoor Coil Temperature >175°F

for 2 consecutive minutes. (Heat

Pump models only)

Indoor coil temperature <30°F for

2 consecutive minutes

Unit cycles (Heat or Cool demand)

>9 times per hour

Unit cycle (Heat or Cool demand)

< 3 times per hour

Shut down unit. Display Error code and

flash. Once voltage rises to normal level

system power is restored.

Set return air sensor = 75°F. Alternately flash

set point and error code. Leave unit running.

Set ID coil temp = 40°F. Alternately flash set

point and error code. Leave unit running.

Set OD coil temp = 20°F. Alternately flash

set point and error code. Automatically

change over to Electric Heat Mode only.

Leave unit running.

Alternately flash set point and error code.

Shut unit down for 5 minutes, then try

again 2 times. If it fails the 3rd time, shut

down unit to prevent high head pressure.

Alternately flash set point and error code.

Continue fan operation while the compressor

is locked out until the indoor coil thermistor

reaches 45° F, then energize the compressor. However, compressor must still wait a

lockout time of 180 to 240 seconds.

• Improper Installation

• Divider baffle not extended

16

10

11

12

13

14

Room Freeze Protection triggered

No Signal to “GL” or ”GH” terminal

(Remote Thermostat mode only)

Not Applicable

Not Applicable

Not Applicable

Accessories

VPAWP1-8

VPAWP1-14

VPAL2

WALL PLENUM Two-part sleeve that telescopes in and out

"

from 5 ½

to 8" in depth. The wall plenum sits inside the

exterior wall penetration.

DIMENSIONS: 30 ⅜

"

high x 24 " wide.

COUTOUT DIMENSIONS: 30

Same as VPAWP1-8, but telescopes 8

1

8

7

"

high x 24 " wide.

8

5

8

"

to 14" as required.

ARCHITECTURAL LOUVER Extruded aluminum louver that

attaches to the outdoor section of the wall plenum.

DIMENSIONS: 31

1

"

high x 25 " wide.

16

9

16

OTOHP NOITPIRCSED LEDOM

VPSC2

RT4

RT5

VPRG4

Same as VPAL2 but can be ordered in a special color to match

the exterior wall.

DIGITAL REMOTE WALLL THERMOSTAT Single stage

thermostat, used on VERT-I-PAK units. Hard wired with single

speed fan. Direct replacement for RT2.

DIGITAL REMOTE WALL THERMOSTAT Single stage

thermostat. Features high/low fan speed switch. Thermostat is

hard wired and can be battery powered or unit powered.

Features backlit display and multiple configured modes.

ACCESS PANEL / RETURN AIR GRILLE –

Serves as an access

panel to chassis and interior return air grille. A field-supplied (25"

x 20") filter is mounted inside the hinged access door.

Kit contains hinge bracket for mounting the door with the return air

openings high or low on the door for optimal sound attenuation. For

9,000 / 12,000 / 18,000 Btu models, it is recommended to install

the door with the hinge on the right side and the return air

openings high on the door. For 24,000 Btu models, it is recommended to install the hinge on the left side with the return air

openings low on the door.

DIMENSIONS: 58" high x 29" wide.

COUTOUT DIMENSIONS: 55 " high x 27" wide.

3

/

4

17

Friedrich Air Conditioning Company

10001 Reunion Place, Suite 500

San Antonio, Tx 78216

1-800-541-6645

www.friedrich.com

VERT-I-PAK® A SERIES

SINGLE PACKAGE VERTICAL AIR CONDITIONERS

LIMITED WARRANTY

SAVE THIS CERTIFICATE.

province.

In the event that your unit needs servicing, contact your nearest authorized service center. If you do not know the nearest service center,

ask the company that installed your unit or contact us - see address and telephone number above. To obtain service and/or warranty parts

replacement, you must notify an authorized FRIEDRICH Air Conditioning Co. service center, distributor, dealer, or contractor of any defect

within the applicable warranty period.

When requesting service:

Unless specified otherwise herein,

FRIEDRICH VERT-I-PAK A SERIES VERTICAL AIR CONDITIONERS AND HEAT PUMPS

LIMITED WARRANTY - FIRST YEAR (Twelve (12) months from the date of installation).

or workmanship will be repaired or replaced free of charge by our authorized service center during the normal working hours; and

LIMITED WARRANTY - SECOND THROUGH FIFTH YEAR (Sixty (60) months from the date of installation). ON THE SEALED

REFRIGERATION SYSTEM.

replaced free of charge (excluding freight charges) by our authorized service center during normal working hours. The sealed refrigeration

system consists of the compressor, metering device, evaporator, condenser, reversing valve, check valve, and the interconnecting tubing.

These warranties apply only while the unit remains at the original site and only to units installed inside the continental United

States, Alaska, Hawaii, Puerto Rico, Mexico and Canada. The warranty applies only if the unit is installed and operated in accordance with

the printed instructions and in compliance with applicable local installation and building codes and good trade practices. For

international warranty information, contact the Friedrich Air Conditioning Company - International Division.

Any defective part to be replaced must be made available to

presented to establish the date of install, otherwise the beginning date of this certificate will be considered to be our shipment date plus sixty

days. Replacement parts can be new or remanufactured. Replacement parts and labor are only warranted for any unused portion of the

warranty.

unit’s

We will not be responsible for and the user will pay for:

1. Service calls to:

A) Instruct on unit operation. B) Replace house fuses or correct house wiring. C) Clean or replace air fil

from its installed location when not accessible for service required. E) Correct improper installations.

2. Parts or labor provided by anyone other than an authorized service center.

3. Damage caused by:

A) Accident, abuse, negligence, misuse, riot, fire, flood, or acts of God. B) Operating the unit where there is a corrosive atmosphere

containing chlorine, fluorine, or any damaging chemicals (other than in a normal residential environment). C) Unauthorized

alteration or repair of the unit, which in turn affects its stability or performance. D) Failing to provide proper maintenance and

service.

We shall not be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of

this unit. We have not made and do not make any representation or warranty of fitness for a particular use or purpose and there

is no implied condition of fitness for a particular use or purpose. We make no expressed warranties except as stated in this

certificate. No one is authorized to change this certificate or to create for us any other obligation or liability in connection with

this unit. Any implied warranties shall last for one year after the original purchase date.

limitations on how long an implied warranty or condition lasts, so the above limitations or exclusions may not apply to you. The provisions of

this warranty are in addition to and not a modification of or subtraction from the statutory warranties and other rights and remedies provided

by law.

Performance of Friedrich’s Warranty obligation is limited to one of the following methods:

1. Repair of the unit

2. A refund to the customer for the prorated value of the unit based upon the remaining warranty period of the unit.

3. Providing a replacement unit of equal value

E) Using an incorrect power source. F) Faulty installation or application of the unit.

It gives you specific rights, you may also have other rights which may vary from state to state and province to

please have the model

the following applies:

Any part of the sealed refrigeration system that is defective in material or workmanship will be repaired or

and serial number

FRIEDRICH

from your unit readily available.

Any part found to be defective in the material

in exchange for the replacement part. Reasonable proof must be

ters. D) Remove the unit

Some states and provinces do not allow

The method of fulfillment of the warranty obligation is at the sole discretion of Friedrich Air Conditioning

In case of any questions regarding the provision

18

s of this warranty, the English version will govern.

(10-06)

920-075-12 (5-10)

Loading...

Loading...