Friedrich Metal Products SH15 Installation Manual

Hazardous Duty Room

Air Conditioner

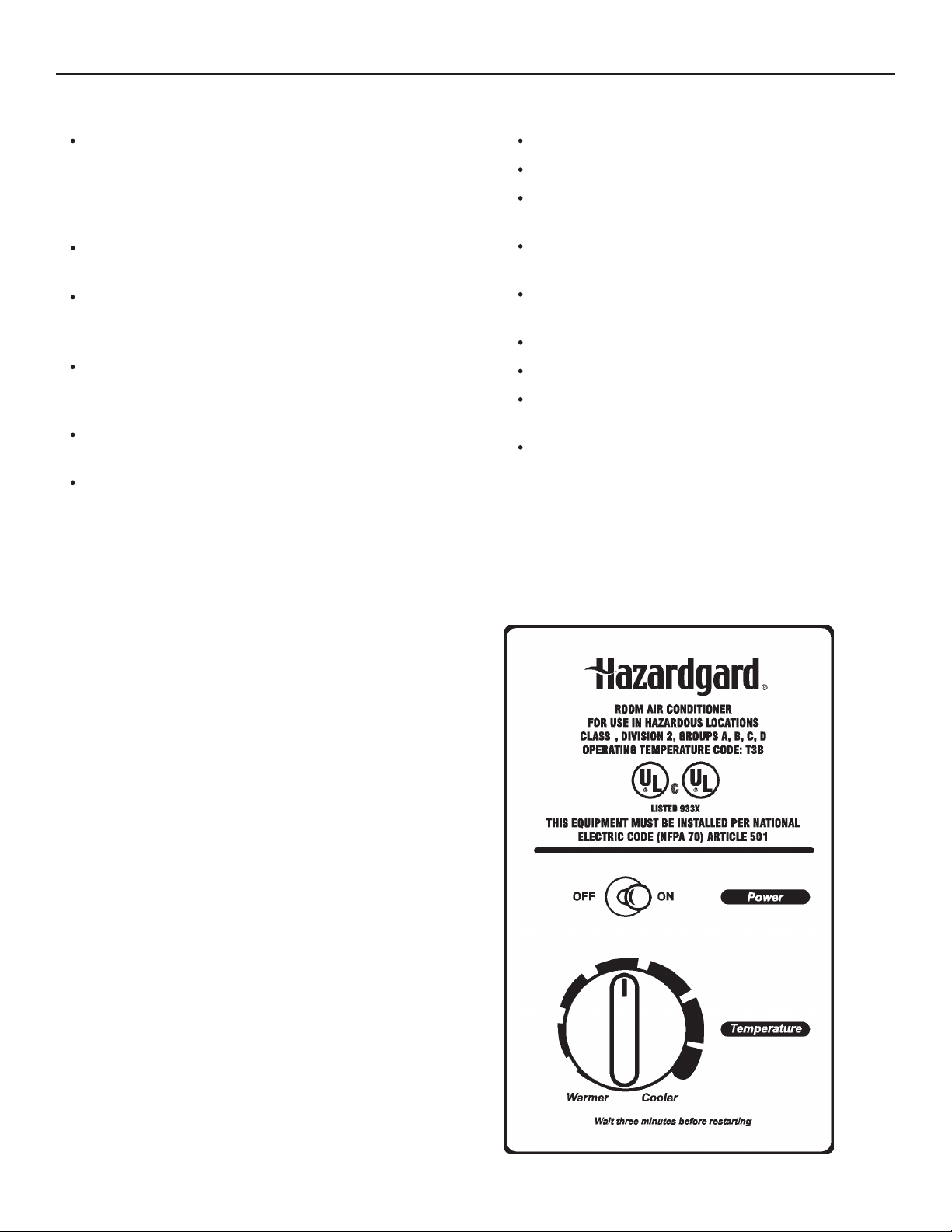

Power

Temperature

Installation & Operation Manual

230-Volt: SH15|SH20

920-024-07 (8/09)

920-024-07

Table of Contents

Operationand Care Instructions

Your Safety and the safety of others................................................................................................................................... 3

General Instructions............................................................................................................................................................ 3

Filter information................................................................................................................................................................ 4

Maintenance Checklist........................................................................................................................................................ 4

Special Features .................................................................................................................................................................. 5

Control Panel ...................................................................................................................................................................... 5

Underwriters Laboratories .................................................................................................................................................. 5

Installation Instructions

Electrical Requirements...................................................................................................................................................... 6

Unpacking the Unit............................................................................................................................................................. 8

Chassis Wiring and Preparation.......................................................................................................................................... 8

Shell Preparation................................................................................................................................................................. 9

Shell Installation ............................................................................................................................................................... 10

Sash Window ............................................................................................................................................................. 10

Through-the-Wall ...................................................................................................................................................... 13

Chassis Installation ........................................................................................................................................................... 16

WARRANTY ................................................................................................................................................................... 18

920-024-07

Congratulations!

Thank you for your decision to purchase the Friedrich Hazardgard (Hazardous Duty Room Air Conditioner). Your new Friedrich

has been carefully engineered and manufactured to give you many years of dependable, efficient operation, maintaining a

comfortable temperature and humidity level. Many extra features have been built into your unit to assure quiet operation, the

greatest circulation of cool, dry air, and the most economic operation.

General Instructions

This Installation and Operation Manual has been designed to insure maximum satisfaction in the performance of your unit. For

years of trouble-free service, please follow the installation instructions closely. We cannot overemphasize the importance of

proper installation. We have added new information to the basic instructions to help you achieve success.

WARNING

Refrigeration system under high pressure.

Do not puncture, heat, expose to flame or incinerate.

Only certified refrigeration technicians should service

this equipment.

R410A systems operate at higher pressures than R22

equipment. Appropriate safe service and handling

practices must be used.

Only use gauge sets designed for use with R410A. Do

not use standard R22 gauge sets.

Here are some suggestions to help you use your

new Friedrich most efficiently:

1. Carefully read and follow the installation instructions.

2. Make sure the unit is the right capacity for the area to be

cooled. An undersized unit makes the unit work too hard,

using more electricity than needed and increases wear. An

oversized unit will cycle on and off too rapidly, and therefore

cannot control humidity as well.

3. When you first turn on your Friedrich, set the thermostat to

its coldest position to cool the room. When the desired

temperature is reached, turn the thermostat control toward

the “warmer” position until you hear a click and the

compressor goes off. The thermostat will then cycle the

compressor to maintain the selected temperature.

4. Clean the filter frequently (See Filter Information)

5. Do not block the air flow to and from the unit. Make sure the

louvers are directed to give even distribution of air

throughout the room. Caution: If air directed into a restricted

area such as a corner, this may cause the unit to cycle on and

off rapidly, which could damage your unit.

6. A dirty filter or improperly set controls can affect the cooling

ability of the unit.

7. If cooling is weak and you have verified that the filter is

clean and the controls are properly set, the unit may be low

on refrigerant, and you should call your Friedrich service

provider to check the unit.

8. Keep blinds, shades and drapes closed on the sunny side of

the room being cooled.

9. Proper insulation helps your unit maintain the desired inside

temperature.

WARNING

Please read this manual thoroughly prior to equipment

installation or operation.

It is the installer’s responsibility to properly apply and

install the equipment. Installation must be in

conformance with the NFPA 70-2008 National Electric

Code or current edition, International Mechanic Code

2009 or current edition and any other applicable local

or national codes.

Failure to do so can result in property damage,

personal injury or death.

10. Whenever possible, shade west-facing windows with

awnings.

11. Keep window coverings away from the unit to provide free

air flow.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual

and on your appliance. Always read and obey all safety messages.

WARNING

CAUTION

and damage to product or other property.

All safety messages will tell you what the potential hazard is, tell you

how to reduce the chance of injury, and tell you what will happen if

the instructions are not followed.

NOTICE

followed.

This is a safety Alert symbol. This symbol alerts you

to potential hazards that can kill or hurt you and

others.

All safety messages will follow the safety alert

symbol with the word “WARNING” or “CAUTION”.

These words mean:

Indicates a hazard which, if not

avoided, can result in severe

personal injury or death and damage

to product or other property.

Indicates a hazard which, if not

avoided, can result in personal injury

Indicates property damage can

occur if instructions are not

3

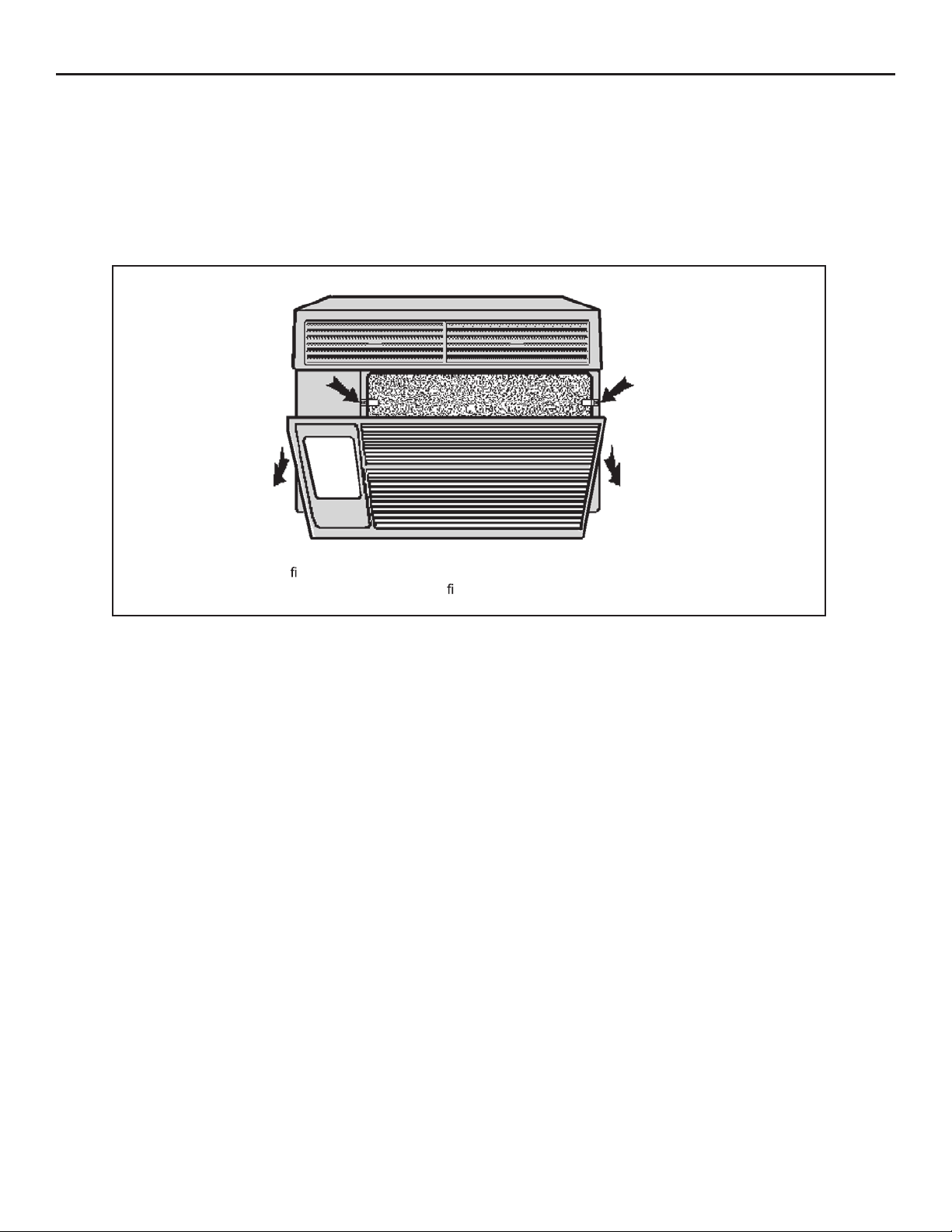

Filter Information

The filter in your Friedrich removes dust, pollen and other

impurities from the air as they are drawn through the unit.

The filter is permanent and reusable, and has a germicidal

treatment which is not affected by washing.

920-024-07

A clogged, dirty filter reduces the air flow through the unit and

reduces its efficiency. You should check the filter every seven

to ten days, depending on the amount your unit is used. Clean

the filter regularly.

FILTER RETAINER CLIPS

The lter can be removed for cleaning by opening the front of

the unit and releasing the

Maintenance Checklist

Won’tCool

If the unit operates, but doesn’t cool, check to see that the controls are properlyset. Inspectthe filterand clean it thoroughly, if

needed. Check to see if the chassis seal gasket is installed (refer

to installation instructions).

Won’tRun

If the unit does not operate at all, check that the power supply

connections are tight. Check for blown fuses or tripped circuit

breakers. Replace blown fuses with the proper size time-delay

fuse.Thenameplateon the unitshows theproperfuse size. After

restoring power, wait three minutes before restarting the unit.

Inside CoilFreezesUp

YourFriedrichHazardgard is designednottofreeze withoutdoor

temperaturesas low as 45°F (7°C). Freezing should only occur

whentheoutsideair isdamp andbelow45°F(7°C). If the indoor

lter from its retaining clips.

coil should iceoverwhile cooling,set thethermostatto thewarmestpositionuntiltheiceonthecoilisgone. Settingthethermostat

toaslightlywarmer positionwillprobablykeepicefromforming

on the coil. A dirty filter will contribute to icing.

Cleaning

The front grille of your Friedrich, as well as the complete cabinet may be cleaned with warm water and a mild detergent. The

coils and base pan should be cleaned periodically for the most

efficient operation. We suggest you call your Friedrich dea

for this service.

Lubrication

Fan motors are factory lubricated and sealed. No lubrication

is required.

ler

4

Hazardgard Special Features

920-024-07

Permanent Split-Capacitor, totally enclosed fan motor to

assure efficient operation even under adverse electrical

conditions. Motorhasaspecialstainlesssteel shaftto resist

corrosion andahermetically sealed overload for arc-free

operation.

High capacity compressorwith internal hermeticallysealed

overload.

Contains transient voltage suppressor to protect

controls against transient voltage spikes. Provides

solid state switches for arc-free operation.

Hot gas bypass low ambient control to permit operation

without freezing at outdoor ambient temperatures as low

as 45°F (7°C).

Environmentally sealed on-off switch and gold plated

contacts in thermostat for corrosion resistance.

Polyester powder finish, over-baked for an attractive,

long-lasting finish.

Friedrich Air Conditioning quality has been proven by more than 25 years of successful experience from the Gulf of Mexico to

the searing sands of the Arabian desert.

Copper tubing/aluminum fin coils.

Galvanized steel cabinet and base pan, all bonderized.

Slide-out chassis for easy installation in window or

through–the–wall.

Extra insulation inside, including completely insulated

plenum chamber for quieter, more efficient cooling.

Entire unit test run in environmental chamber before

crating.

Eight–way air flow control for uniform air circulation.

Condensate drain with exclusive mosquito trap.

15ampcircuitwithtime-delayfuserequired. Accommodates

direct wiring.

Long lasting 3/8" (10 mm) thick air filter, germicidally

treated, easily removed for cleaning.

Control Panel

Function Control (Power)

This switch isadouble pole, single throw toggle switch.

ON - Turns everything on.

OFF - Turns everything off.

Temperature Control

Theknobat the bottomis thethermostatwhich isacross ambient

type used tomaintainthe desiredcomfort level. The thermostat

reacts only toachange in temperature at the bulb location-turn

the knob clockwise to set cooler, counterclockwise for warmer.

Exclusive

Friedrichleads with thefirst ULListed Room Air Conditioners

designed to cool living quarters and other enclosures situated in

hazardous locationswherespecific volatileflammable liquidsor

gases are handled or used with enclosed containers or systems.

Friedrich Hazardgard room air conditioners are designed to

meet the National Electrical Code, Article 500 requirements

forClass I, Division 2, GroupsA, B, C,DHazardous locations,

THIS UNIT IS LISTED BY UNDERWRITERS LABORATORIES FOR USE IN CL

B,C,DHAZARDOUS LOCATIONS. Operating Temperature

Code: T3B.

ASS I, DIVISION 2, GROUPS A,

5

920-024-07

Installation Instructions

Models SH15 and SH20

NOTE: THIS MANUAL INCLUDES INSTALLATION INSTRUCTIONS FOR BOTH WINDOW MOUNT AND THROUGH-

THE-WALL INSTALLATIONS

WARNING

Explosion Hazard

Electrically connect unit in accordance with NEC

Code Article 501. Failure to do so can result in

death, explosion, re, or electrical shock.

Electrical Shock Hazard

Electrical Requirements

ALL FIELD WIRING MUST MEET THE REQUIREMENTS OF THE NATIONAL ELECTRICAL CODE (ANSI/NFPA 70)

ARTICLE 501.

THE FIELD-PROVIDED CIRCUIT PROTECTION DEVICE (HACR CIRCUIT BREAKER OR TIME DELAY FUSE) MUST

NOT EXCEED THE AMPACITY INDICATED ON THE PRODUCT NAMEPLATE.

IMPORTANT: Before you begin the actual installation of your air conditioner, check local electrical codes and the information

below.

Your air conditioner must be connected to a power supply with the same A.C. voltage and frequency (hertz) as marked on the data

plate located on the chassis. Only alternating current (A.C.), no direct current (D.C.), can be used.

An overloaded circuit will invariably cause malfunct

electrical power is adequate. Consult your dealer or power company if in doubt.

The following instructions are for HAZARDGARD models and cabinet sizes listed below.

ion or failure of the air conditioner; therefore, it is extremely important that the

)D x W x H( EZIS TENIBACSPUORG

15

/16" x 25 15/16" x 27 3/8"

SMALL CHASSIS SH15

MEDIUM CHASSIS SH20

epyT gulPrebmuN ledoM

6

15

(405 mm x 660 mm x 695 mm)

15

/16" x 25 15/16" x 27 3/8"

17

(455 mm x 660 mm x 695 mm)

Circuit Rating

Time Delay Fuse

pmA 51-V052xoB noitcnuJ51HS

pmA 51-V052xoB noitcnuJ02HS

920-024-07

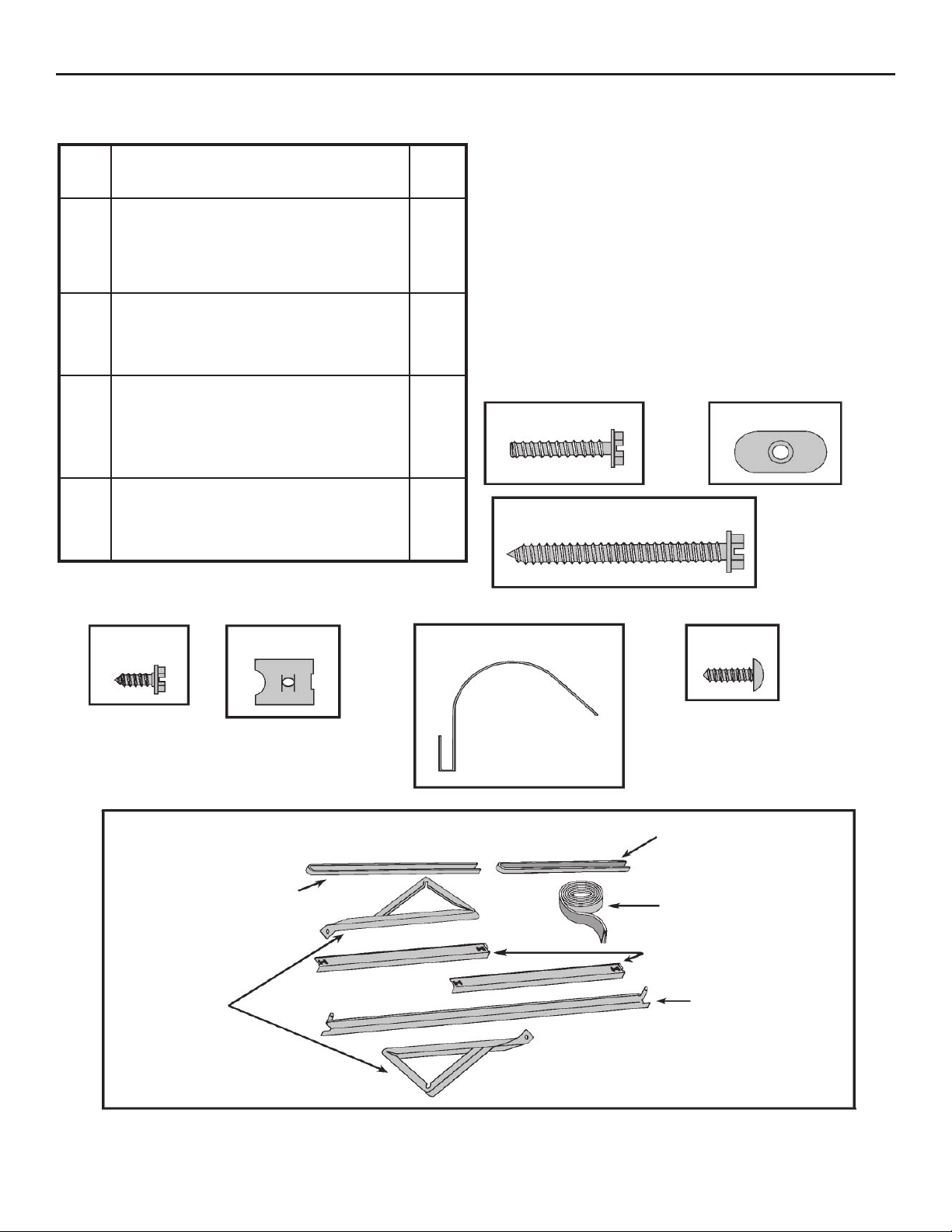

Window Mount Installation Hardware

ITEM DESCRIPTION QTY.

No.

SHELL MOUNTING PARTS

2TEKCARBTROPPUS1

2 SCREW, 10 - 24 x 1" HEX HEAD 4

4TUNDLEWTALF42-013

4 SCREW, SHEET METAL #12A x 2" 7

WINGBOARD ANGLE MOUNTING

5 WINGBOARD ANGLE, TOP 1

6 WINGBOARD ANGLE, SIDE 2

7 SCREW, SHEET METAL #8A x 3/8" 2

WINGBOARD MOUNTING PARTS

8 WINGBOARD (MASONITE) - (NOT SHOWN) 1

4TUNDEEPSEPYT"J"9

10 WINGBOARD CLIP

11 SCREW. #8A x 1/2" PHILLIPS TRUSS HD. 4

(SPRING STEEL) 4

ITEM # 2

ITEM # 3

WINDOW SEALING

12 SEALING GASKET (VINYL) 1

13 WINDOW SEAL GASKET (DARK FOAM) 1

14 CHASSIS SEAL GASKET (LIGHT FOAM) 1

ITEM # 7

ITEM # 9

ACCESSORY DETAIL

ITEM # 14

ITEM # 4

ITEM # 11

ITEM #10

ITEM # 13

ITEM # 12

ITEM # 1

ITEM # 6

ITEM # 5

NOT TO SCALE

7

920-024-07

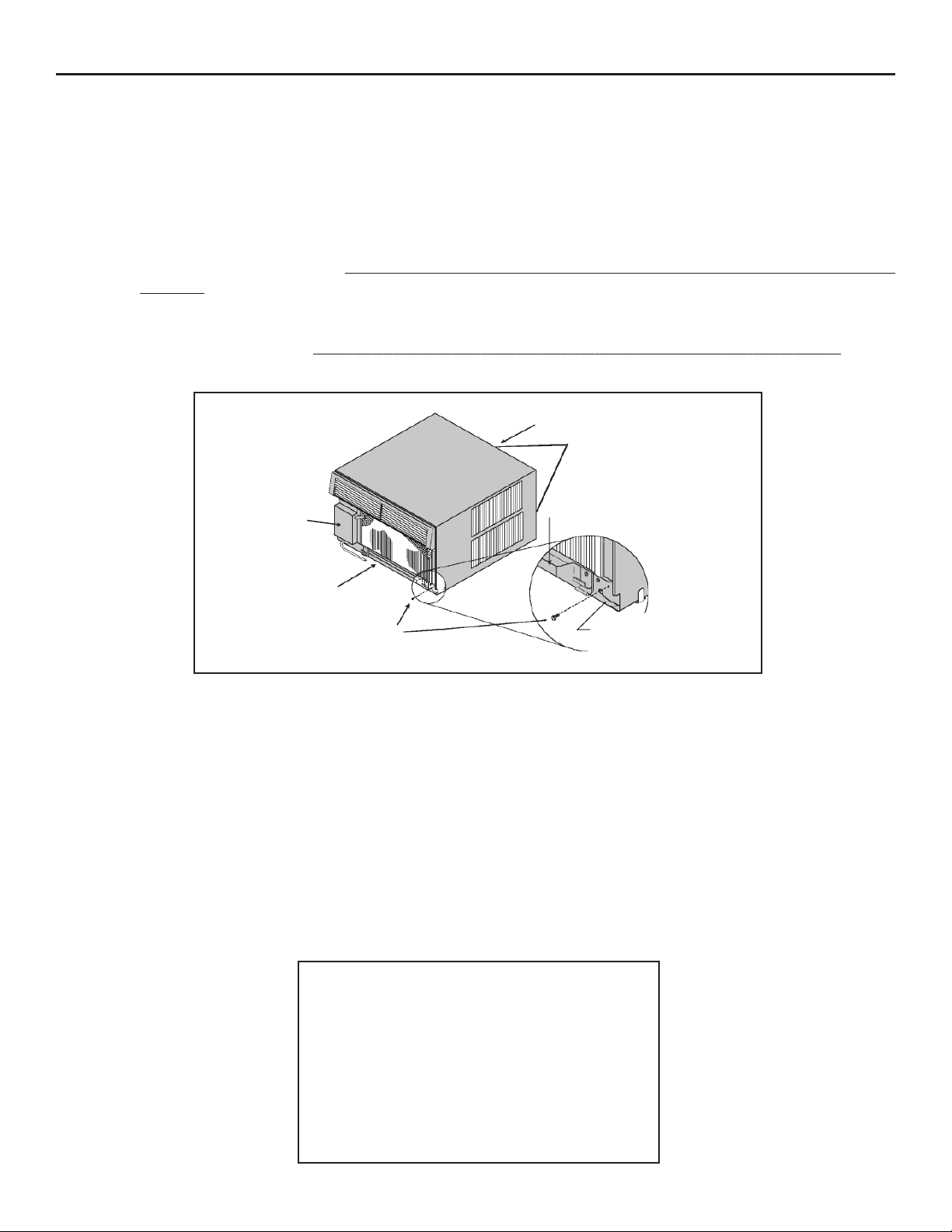

UnpackingThe Unit

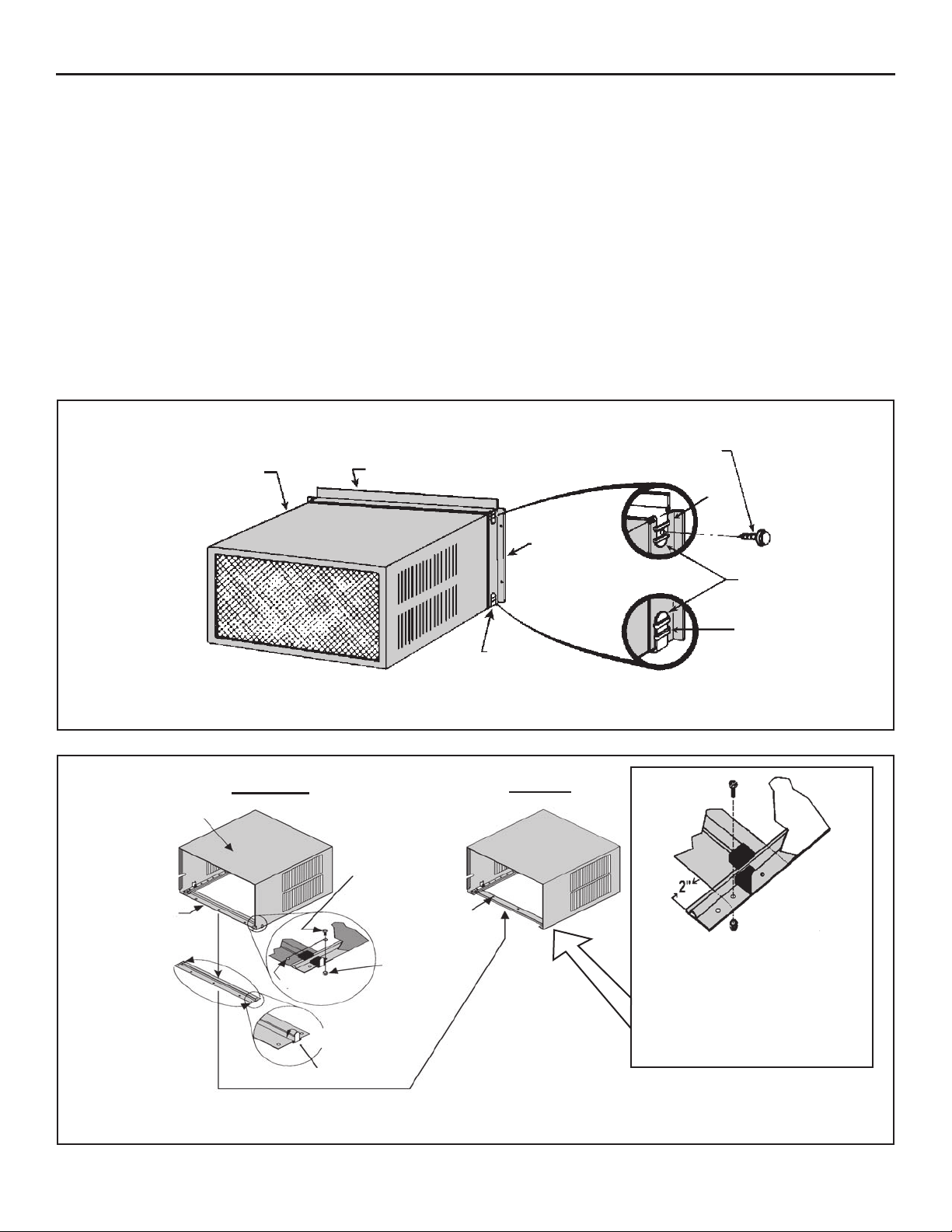

STEP1 Remove decorative plastic return air grille to a safe area away from the unit.

STEP2 Remove the installation hardware, wingboard and two (one light colored and one dark colored) gaskets from beneath the

unit, and place them inasafe area away from the unit.

STEP3 Remove the chassis retainer by removing the far right screw in the basepan (see Figure A); save this screw to reattach the

chassis retainer after installatio. Also, remove and discard the two retainer screws and plastic bushi

of the unit.

STEP4 While an assistant holds the cabinet stationary, use the hand pull at the front of the base pan (see Figure A) to pull the

chassis out of the cabinet. Remove white foam blocks used to restrain the compressor during shipment. Inspect

basepan for dislodged white blocks, and remove. Do not remove any other foam.

ngs located at the rear

Figure A

PULL STRAP

HAND PULL

FAR RIGHT SCREW

CABINET

CABINET

RETAINER SCREWS

HAND PULL

CHASSIS RETAINER

Chassis Wiring and Preparation

STEP1

STEP2 Remove and discard theplastic bushingfrom the conduit connectoron the side panel ofthe control compartment. Strip the

Remove the junction box, cover and screw from the shipping position underneath the fan motor. Install one junction box

mounting leg in the upper left position facing the rear of the junction box.

black wires only, approximately 1/2 inch (13 mm).

STEP3 Insert all wires (2 black, 1 green) into the box and thread the box onto the conduit connector until tight. Back off counter

clockwise until the ju

nction box is vertical with the mounting leg at the upper–right position facing the box opening. Be

sure that the shell can fit between this box and the chassis.

PROVIDED HARDWARE

1 JUNCTION BOX FRIEDRICH PN: 613-893-00

2 MOUNTING LEGS RACO INC. PN: 5324-0

2 LEG SCREWS

2 HOLE COVERS

1 GROUND SCREW

BOX COVER FRIEDRICH PN: 613-892-00

GASKET RACO INC. PN: 5173-0

2 SCREWS

1 SHEET METAL SCREW

8

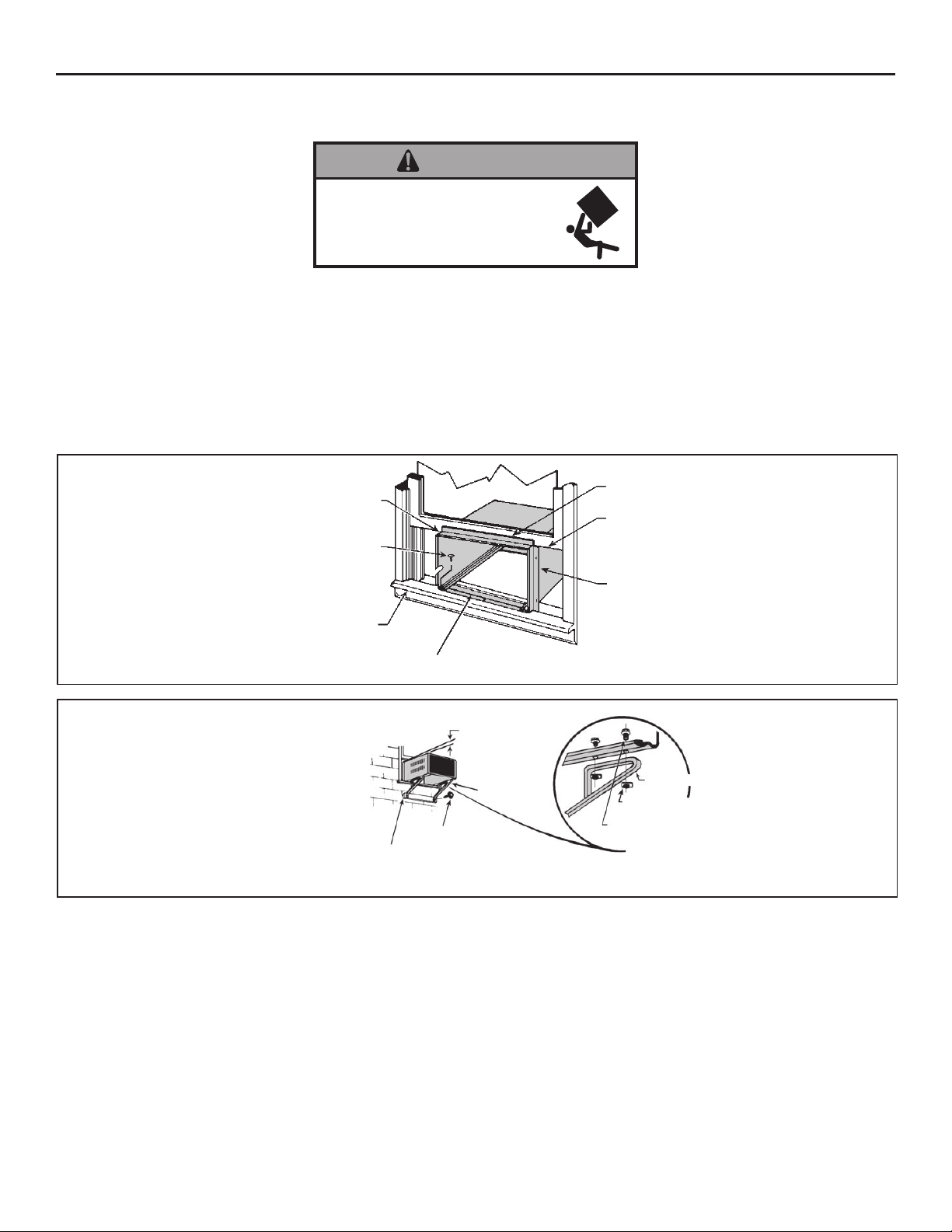

Shell (Cabinet)Preparation

It will be necessary to relocate the sill plate of the cabinet 2"

back from itsshipping position, andthe shell guides 4" forward,

to the forward-most hole in the shell rail. Discard the chassis

retainer wire disconnected in Section II, Step 3. The junction

box mountinglegfromSection VI,Step1,and the field-installed

conduit will retain the chassis in the shell.

IF THIS INSTALLATION ISFORASASHWINDOW–With

the wide flange and pilot holes of the sill plate forward

screws/nuts in the rear holes of the sillplate and third shell hole

from the front (the center of three square holes). Anchor the

side angles(Item #6) byengaging the tabs at eachend of the sill

plate withthe bottom loopsof the side angle. Engage the tabsat

, put the

920-024-07

each end of the topangle(Item#5) with thetop loops of the side

angle. Install two (2) screws (Item #7) to secure the top angle

tabs and the side angle to the rear-most holes in the side of the

cabinet (See Figure B, below).

IF THIS INSTALLATION IS THROUGHAWALL – Turn

the sill plate end to end so that the wide flange with pilot holes

will be over the wall header (towards the rear) and two inches

from the front of the cabinet. Bend the tabs into the channel

of the sill plate,

put the screws/nuts in the front holes of the sill

plate and into the second shell hole from the front. Use one bolt

on each side to secure the sill plate to the cabinet. (See Figure

C, below.)

Figure B

Figure C

CABINET

CABINET

BEFORE

TOP ANGLE (ITEM #5)

SCREW

(2 REQUIRED)

SIDE ANGLE

(ITEM #6) 2

REQUIRED

SILL PLATE

TAB

AFTER

8A X 3/8" LONG SCREW (ITEM #7)

2 REQUIRED

LOOP

Detail B-1

Detail B-2

TAB

LOOP

SILL PLATE

TURN SILL PLATE

END TO END

RETAINER, CHASSIS

(THIS SIDE ONLY)

DETAIL 2

BEND TABS DOWN

NOTE: HOLES

MOVED TO

BACK SIDE

NUT

(2 REQUIRED)

DETAIL 1

Position the sill plate into the

cabinet with the sill plate holes

to the back. Align the plate 2

inches from the front of the

cabinet and secure it with a nut

and bolt in each end.

9

920-024-07

Shell Installation: Sash Window Installations

WARNING

Falling Object Hazard

Not following Installation Instructions

for mounting your air conditioner can

result in property damage, injury, or

death.

STEP1 Check the window sill and frame to be sure they are in good condition and firmly anchored to the wall. Repair if

necessary.

STEP2 CABINETMOUNTING: Raise the lowerwindowsash1/4"more thanthe heightofthe cabinet. Carefullyslidethecabinet

throughthe open window untilthe sill plate channelrests behindthe window sill and thetop support angle restsagainst the

window (See Figure D). Center the cabinet side to side and drill three (3) 5/32" diameter pilot holes into the window sill

using the holes in the cabinet sill plate asaguide. Install three (3) #12A x 2" long screws (Item #4) (See Figure D).

Figure D

CENTER CABINET SIDE TO SIDE IN WINDOW

DRILL 3 5/32" PILOT HOLES AND INSTALL 3

#12A X 2" LONG SCREWS (ITEM #4)

TOP SUPPORT ANGLE

PULL WINDOW SASH DOWN BEHIND

THE TOP SUPPORT ANGLE

SIDE SUPPORT ANGLE

WINDOW SILL

LOCATE THE SILL PLATE GUIDE CHANNEL

JUST BACK OF THE WINDOW SILL.

Figure E

A 1" X 4" OR 2" X 4" SPACER SHOULD BE USED BE-

TWEEN THE WALL AND BRACKET WHEN INSTALLED

ON ALUMINUM, ASBESTOS OR VINYL SIDING.

3/8" (10 MM)

DOWN SLOPE

#12A X 2"

SCREW

(ITEM #4)

SUPPORT

BRACKET

SUPPORT BRACKET (ITEM #1)

10 - 24 FLAT WELDNUT (ITEM #3)

10 - 24 X 1" HEX HEAD SCREW (ITEM #2)

STEP3 OUTSIDESUPPORT MOUNTING: Assemble thesupport brackets (Item #1) to the bottom rails ofthe cabinetwith four

(4) 10-24 1" long screws (Item #2) and four (4) 10–24 flat nuts (Item #3). Adjust the support brackets to bring the bottom

pads in contact with the wall surface. (See Figure E.)

A 1"x4" or 2"x4" SPACER SHOULD BE USED BETWEEN THE WALL AND THE SUPPORT BRACKETS WHEN

INSTALLED ON ALUMINUM OR VINYL SIDING). Drill 5/32" (4 mm) dia. pilot holes, and secure the brackets to the wall with

two (2) #12Ax2"

long screws (Item #4). Adjust the support brackets to provide an approximate 3/8" (10 mm) down slope towardsthe

outside for drainage. Tighten all screws. (See Figure E).

10

920-024-07

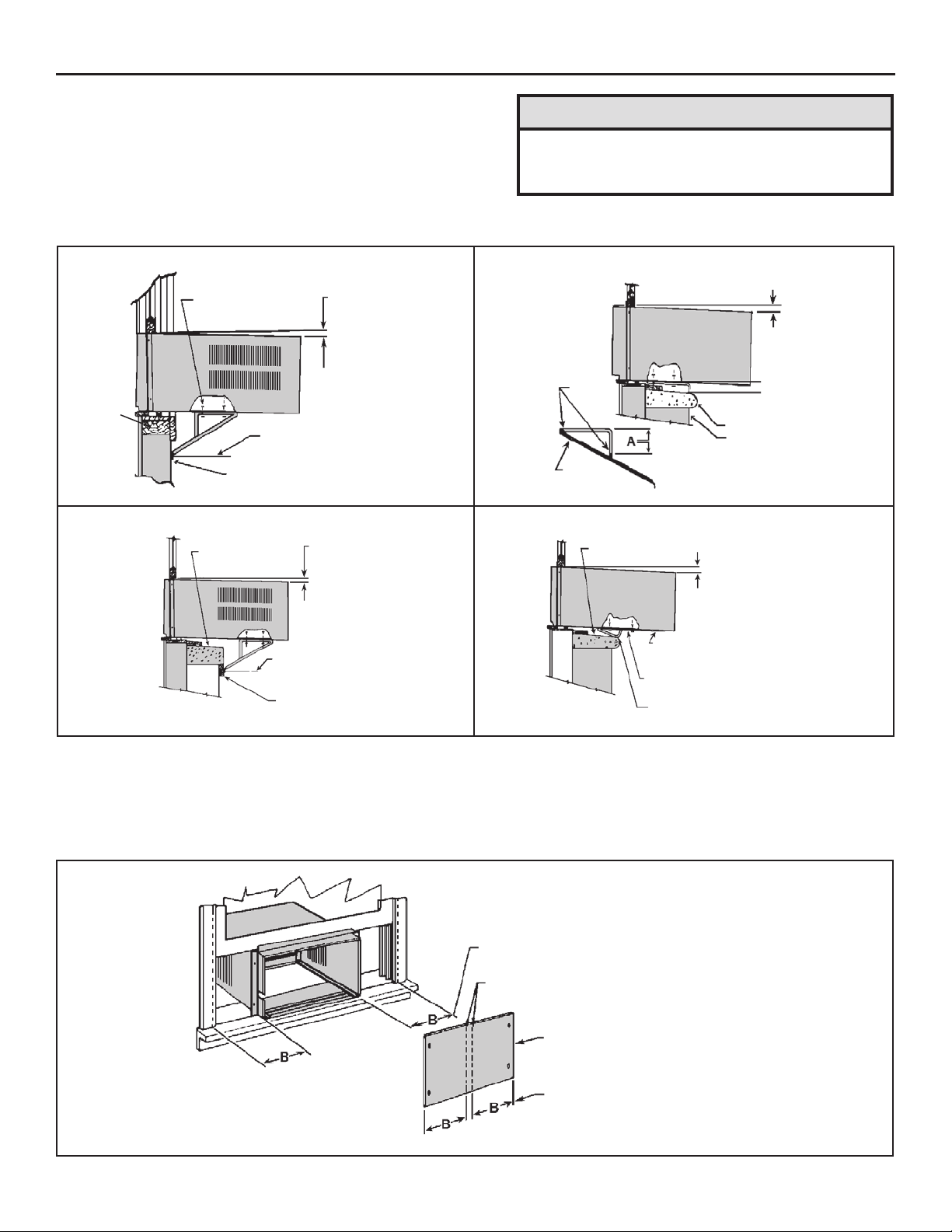

Shell Installation: Thick Wall

The illustrations below show a standard frame construction

installation as well as some suggested ways of adapting the

support bracket to thick walls and large brick ledges.

Typical Installation Sill Plate

Figure 1

10 - 24 SCREW

10 - 24 FLAT NUT

3/8" (10 MM)

SLOPE DOWN

WOOD

LEDGE

#12A X 2" SHEET METAL SCREW

1" X 2" OR 2" X 4" SPACER BETWEEN WALL

AND BRACKET SHOULD BE USED ON ALUMINUM, ASBESTOS OR VINYL SIDING

Figure 3

BRICK LEDGE

3/8" (10 MM)

SLOPE DOWN

NOTICE

Instructions for mounting sleeve with slope must be observed to prevent entry of water into room.

Failure to follow instructions can result in property damage.

Figure 2

CUT

HERE

STONE LEDGE

OUTSIDE WALL

DISCARD

SHADED AREA

Figure 4

STONE LEDGE

CUT TO FIT DIMENSION "A"

AND BEND DOWN TO FOR A

VERTICAL LEG

3/8" (10 MM) SLOPE DOWN

3/8" (10 MM)

SLOPE DOWN

STRAIGHTEN TAB TO LAY FLAT ALONG

#12A X 2" SHEET METAL SCREW

2" X 4" SPACER

THE BOTTOM RAIL OF THE SHELL.

SECURE THE LONGEST SIDE OF

THE BRACKET TO THE SHELL.

ADJUST IN OR OUT TO

REST ON THE LEDGE

STEP4 CUT WINGBOARD PANELS: Measure and cut the wingboard panels from the supplied masonite (Item #8) to fit the

spaces between the side window channels and the sides of the cabinet (See Figure F).

NOTE: AFTER CUTTING PANELS, MAKEATRIAL TEST TO SEE IF THEY FIT THE SPACE WITH ABOUT

1/8" CLEARANCE BEFORE GOING TO STEP 5.

Figure F

MEASURE DISTANCE "B" TO THE INSIDE

OF THE CHANNEL ON EACH SIDE

CUT HERE AND DISCARD THE CENTER

WASTE MATERIAL

WINGBOARD

SUBTRACT 1/8" (3 MM) FROM

DIMENSION "B" AND MEASURE FROM

THE EDGE OF THE WINGBOARD (ITEM

# 8), MARK AND CUT WITH A SAW.

11

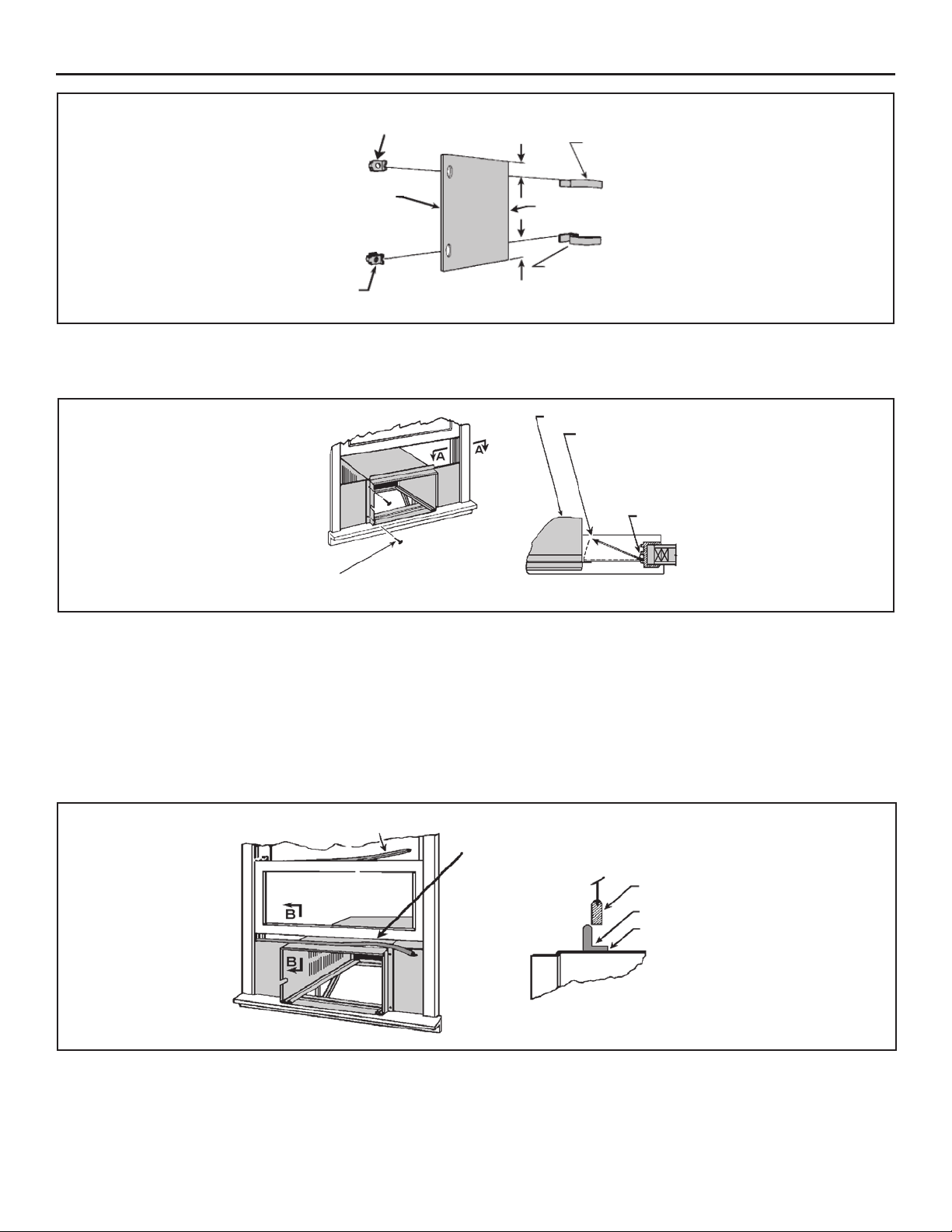

920-024-07

"J" TYPE SPEED NUT (ITEM #9)

Figure G

CUT WINGBOARD PANEL

CENTER THE HOLE IN THE SPEED NUT OVER

THE SLOT IN THE WINGBOARD PANEL

S

TEP5 ASSEMBLE CLIPS TO WINGBOARD PANELS: Assemble "J" type speed nuts (Item #9) and spring steel clips (Item

2 REQUIRED

SPRING STEEL CLIP (ITEM #10)

2 REQUIRED

CUT EDGE

SLIDE CLIP OVER CUT EDGE OF WINGBOARD PANEL

#10) to the edges of the cut wingboard panels (See Figure G).

Figure H

TOP OF CABINET

PLACE WINGBOARD PANEL IN WINDOW JAM TO

COMPRESS THE SPRINGS INSIDE THE RUNNERS,

AND SWING THE PANEL INTO PLACE INDICATED

BY THE DOTTED LINE.

WINDOW JAM

SECURE THE SIDE WINGBOARD PANELS TO

THE SIDE ANGLES WITH FOUR (4) #8X1/2"

LONG SCREWS (ITEM #11), TWO ON EACH SIDE.

SECTION A - A

STEP6 INSTALL SIDE WINGBOARD PANELS: Be sure that the cabinet has been secured to the window sill and the outside

support brackets have been installed as shown in FiguresDandEon Page 10. Raise the window sash and install the right

and left side wingboard panels (See Figure H).

STEP7 INSTALL WINDOW SEALING GASKETS: Measure and cut the vinyl window seal gasket (grey color, Item #12) to fit

the width of the window and install as shown in Figure I. Pull the window sash down behind the gask

et. Measureand cut

the dark foamwindow sealgasket (Item #13) and install it between the upper glass panel andthe top part of the lower sash

(See Figure I).

Figure I

VINYL WINDOW SEAL GASKET ITEM #12)

FOAM WINDOW SEAL GASKET (ITEM # 13)

LOWER WINDOW SASH

VINYL WINDOW SEAL GASKET

TOP WINGBOARD ANGLE

SECTION B - B

NOTE: FOR REASONS OF SECURITY,THE CUSTOMER MUST PROVIDE A MEANS OF PREVENTING THE WINDOW

FROM OPENING.

STEP8 When possible, caulk the outside of the installation with industrial type caulking to prevent air and water leaks.

12

920-024-07

Shell Installation: Through-the-wall Installations

WARNING

Falling Object Hazard

Not following Installation Instructions

for mounting your air conditioner can

result in property damage, injury, or

death.

Wall Preparation

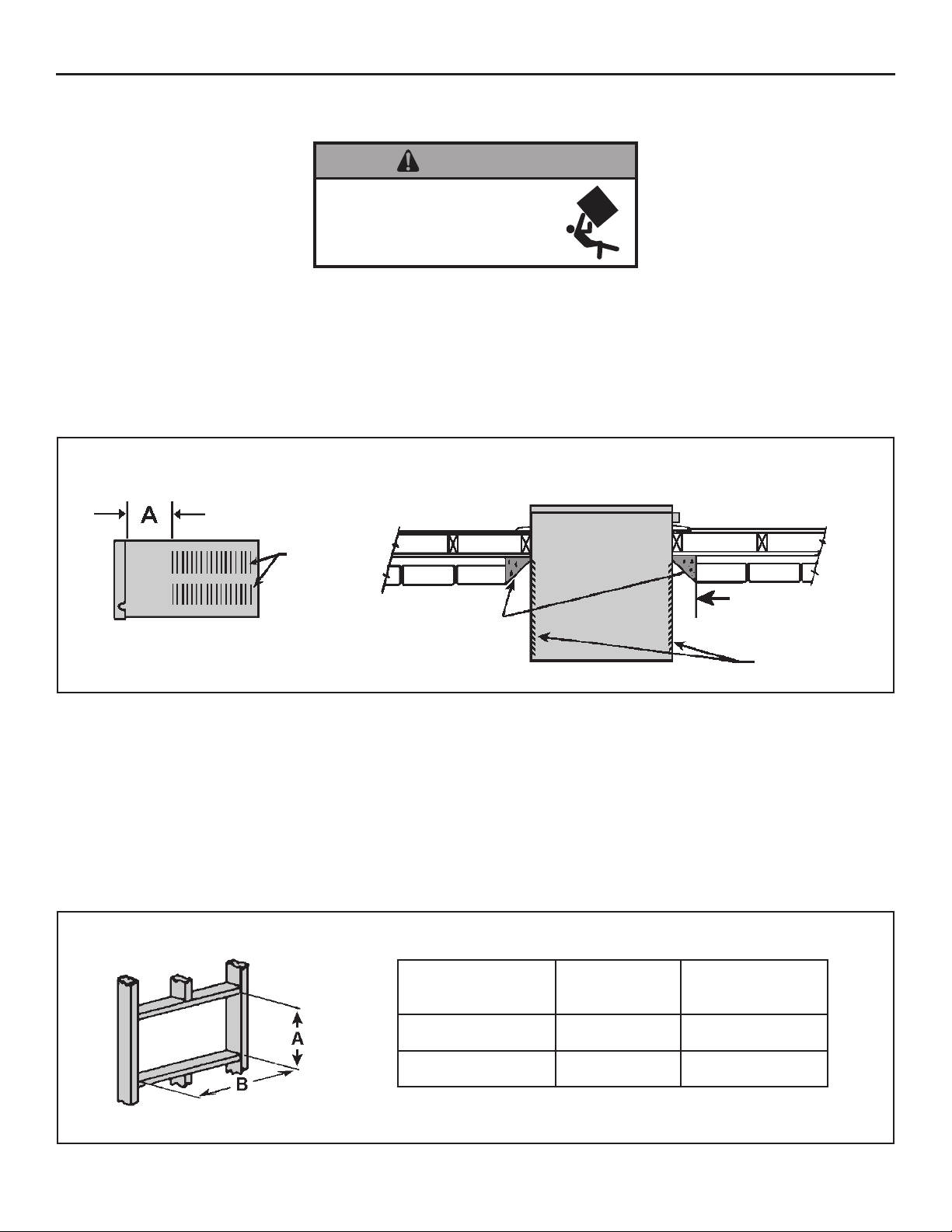

The maximum wall thickness permissible without special construction is determined by the model size to be installed. THE OUT-

SIDE CABINET CONDENSER AIR INTAKE LOUVERS MUST NOT BE BLOCKED BY EXTENDING INSIDE THE WALL

AREA. Observe the maximum wall thickness shown as dimension "A" in Figure J.

Special Instructions For Extra Thick Walls

For installation in walls exceeding the maximum thickness shown as dimension A, the following suggested construction

may apply. (See Figure J).

Figure J

15 1/8 " (384 MM)

MAXIMUM WALL THICKNESS

CONDENSER

AIR INTAKE

LOUVERS

TOP VIEW SHOWING BEVELED SIDES

FOR AIR INTAKE. WALL BELOW

UNIT MUST ALSO BE BEVELED TO

ASSURE PROPER TILT ANGLE.

EXTRA THICK WALL CONSTRUCTION

Top View

2" (51 MM) MINIMUM

BOTH SIDES

CONDENSER AIR

INTAKE LOUVERS

STEP1 CHECKING WIRING AND PLUMBING: Check all wiring and plumbing inside and outside the wall to be sure none

will be broken where the hole is to be cut.

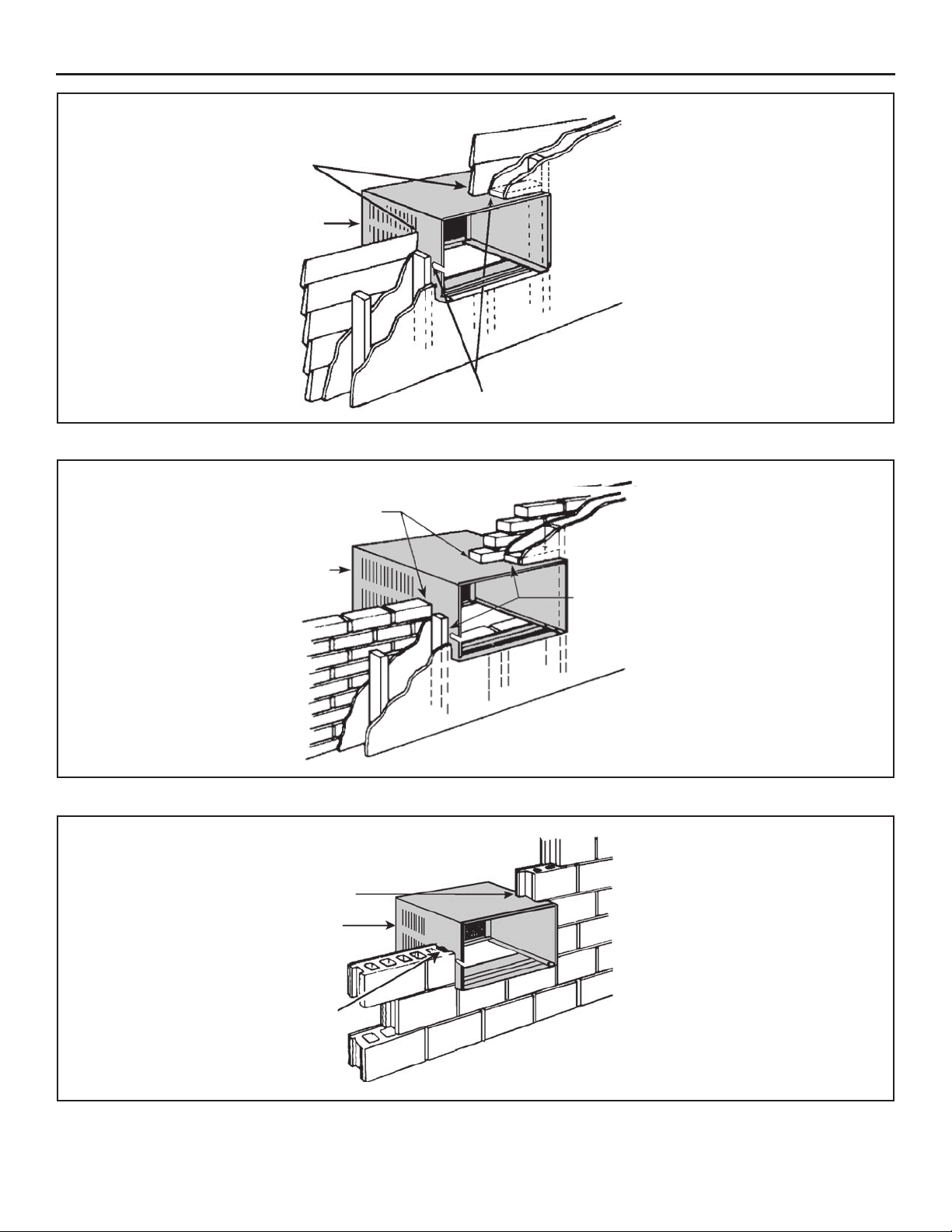

STEP2 HOLE CONSTRUCTION: Depending on the size of the unit to be installed, layout the hole dimensions in accordance

with the chart below (See Figure K). Cut and frame in the hole to the finished dimensions. Use

2"x4" material for framing and follow the suggested typical installations in Figure L,MorNon Page 14.

NOTE: IF THE WALL CONSTRUCTION IS TYPICAL FRAME OR 2 X 4 STUDDING WITH BRICK OR STONE VENEERS,

LOCATE THE HOLE NEXT TO ONE OF THE STUDS. FOR MASONRY, CONCRETE OR CINDER BLOCK WALLS,

LOCATE THE HOLE FOR CONVENIENCE.

Figure K

HOLE SIZE REQUIREMENTS

FINISHED SMALL MEDIUM

DIMENSION CHASSIS CHASSIS

A 16-3/16" 18-3/16"

B 26-3/16" 26-3/16"

SH15

CHASSIS

NOTE: THESE DIMENSIONS ARE FOR FINISHED HOLE SIZE

SH20

CHASSIS

13

920-024-07

Figure L

Figure M

CAULK ALL SIDES

WEATHER CABINET

WEATHER CABINET

CAULK ALL SIDES

FRAME WALL

CONSTRUCTION

SHIM THE VOID SPACE AT THE TOP AND

SIDES WITH WOOD AS REQUIRED

BRICK VENEER

CONSTRUCTION

Figure N

SHIM VOID SPACES AT TOP AND

SIDES WITH WOOD AS REQUIRED

SOLID MASONRY

CONSTRUCTION

CAULK ALL SIDES

CABINET

MORTAR

14

920-024-07

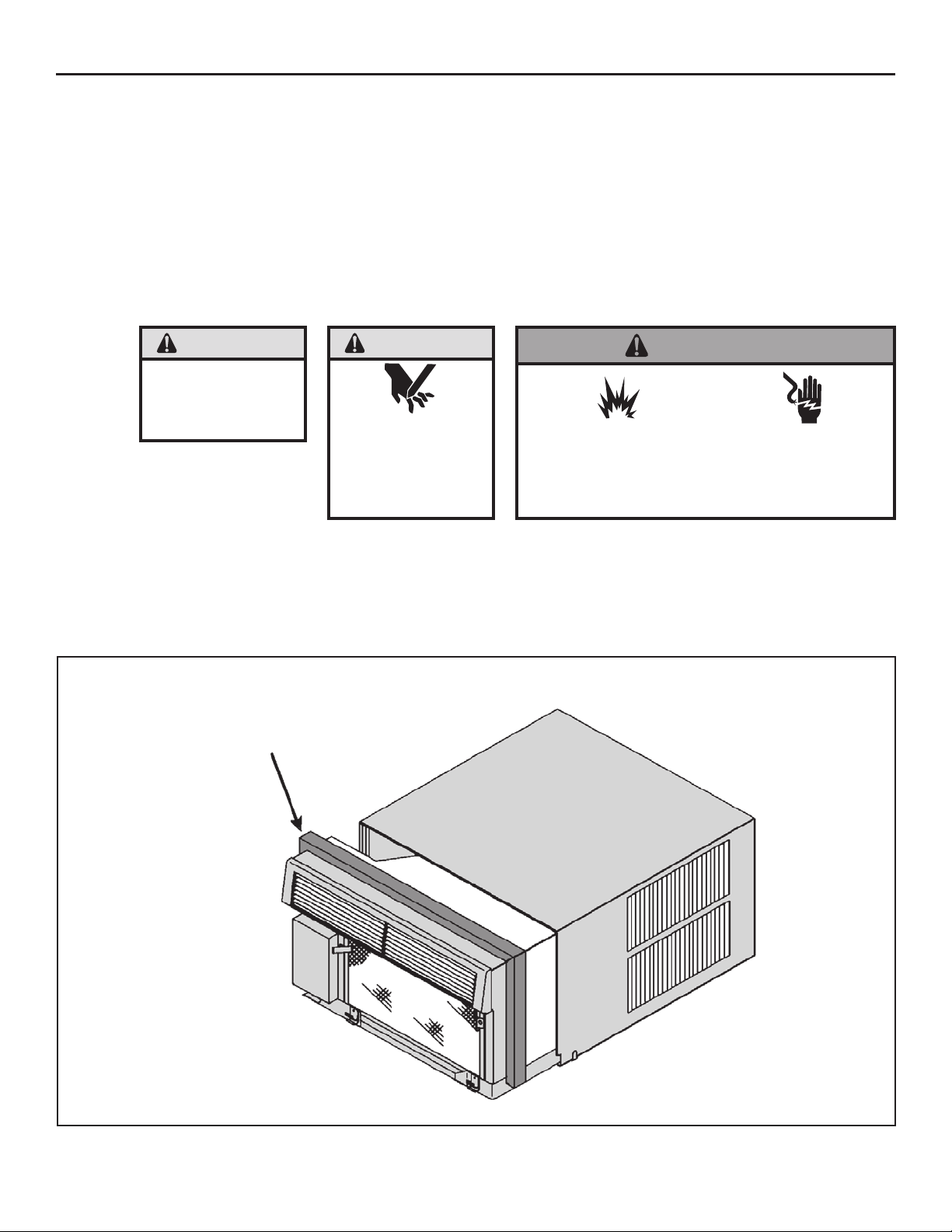

Chassis Installation

STEP 1 Slide the chassis into the cabinet stopping approximately 3" from full insertion. Stuff the chassis seal gasket (Item #14) one

inch deep between the chassis and the cabinet (See Figure P). Begin at either bottom corner and go up the side, across the

top, and down the opposite side. Make sure that the gasket is behind the conduit connector (furthest from you). Push the

chassis into the shell the remaining distance so that the plastic front shrouds the front edge of the shell. Fasten the junction

box mounting foot to the shell with the sheet metal screw.

If chassis seal gasket is not installed, the operation of the unit will be negatively affected. Also, the operation noise and

outside noise will be amplifi ed.

NOTE:

Figure P

CAUTION

Excessive Weight Hazard

Use two or more people when

installing your air conditioner.

Failure to do so can result in

back or other injury.

CAUTION

Cut/Sever

Although great care has been

taken to minimize sharp edges

in the construction of your unit,

use gloves or other hand

protection when handling unit.

Failure to do so can result in minor

to moderate personal injury.

WARNING

Explosion Hazard

Electrically connect unit in accordance with NEC

Code Article 501. Failure to do so can result in

death, explosion, fire, or electrical shock.

Electrical Shock Hazard

Field wiring must be provided to this junction box in accordance with NATIONAL ELECTRIC CODE (NFPA 70, 2008

or current edition) ARTICLE 501. Field and equipment grounds are to be terminated at the post in the junction box with

the green screw provided. Equipment power leads are to be connected with the fi eld supply by means of wire nuts (not

provided). Install the gasket and cover plate onto the junction box.

CHASSIS SEAL GASKET

16

920-024-07

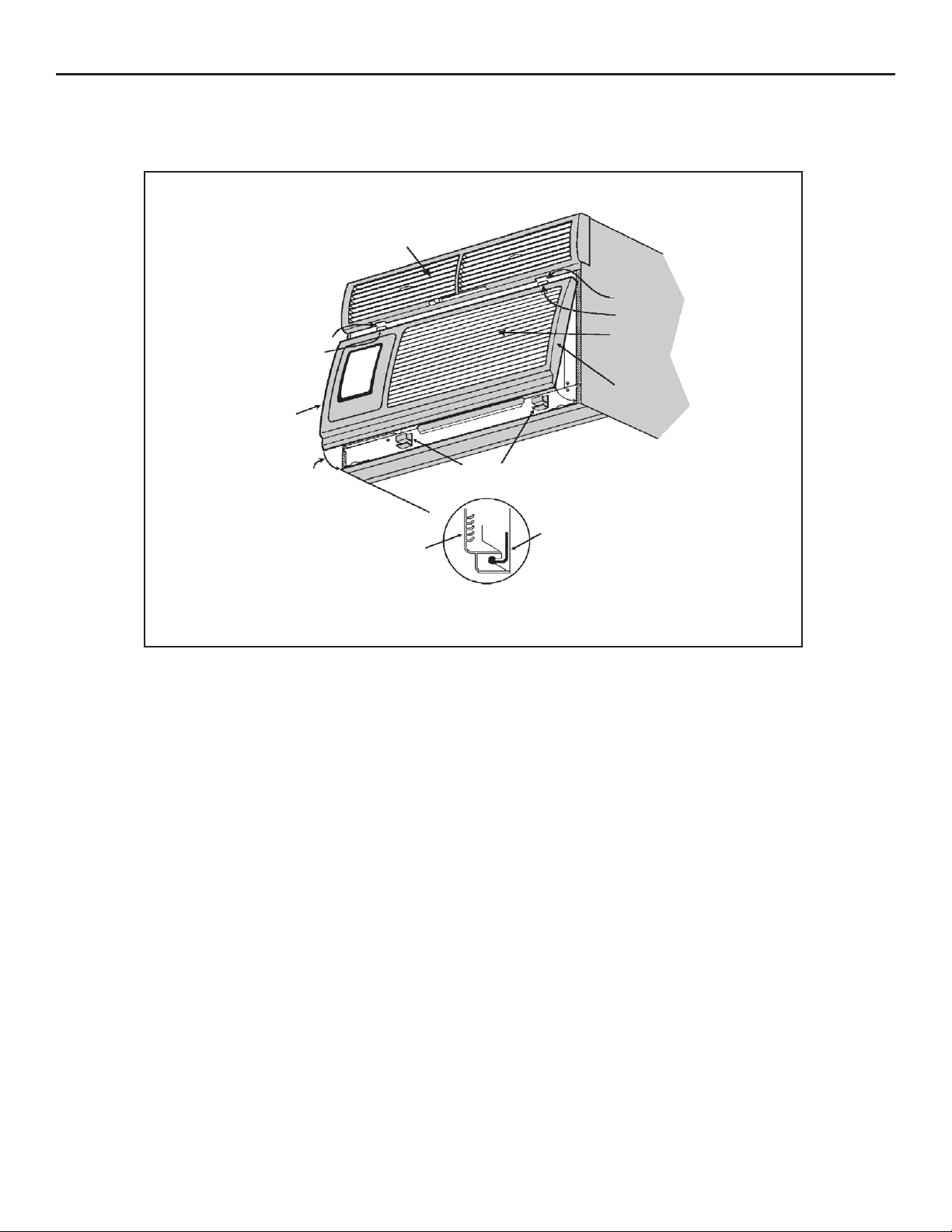

STEP2 Besure that the filter is in place then install the return air grille(See Figure Q). The topof thereturn airgrille can be butted

against the bottom of the discharge plenum. Snap thegrille into place by pushing the grille up andonto the unit's latches at

the bottom. (See Detail 4).

Figure Q

Discharge Air Plenum

DETAIL 2

Slot

Tab

Slot

Tab

Return Air Grille

DETAIL 1

DETAIL 1

DETAIL 3

Return air grille

Latches

DETAIL 4

Side view

(Cutaway)

Latch

STEP3 You have completed your installation. Conductareview of your installation to insure that the unit is safely and securely

installed.

17

920-024-07

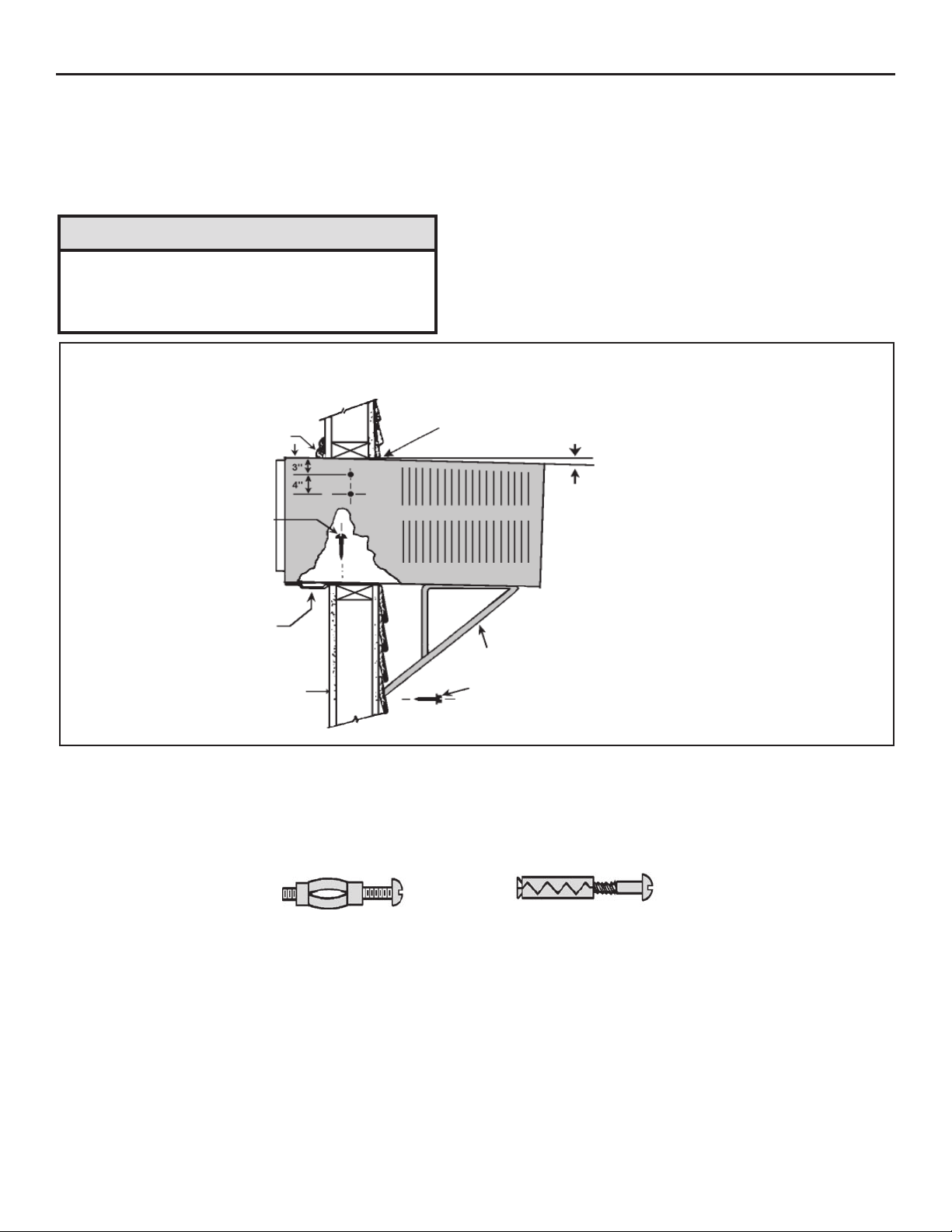

STEP3 Slide the cabinet into the hole far enough to allow the guide-channel of the sill plate to contact the inside wall surface (See

Figure O).

STEP4

Drill three (3) 5/32" diameter pilot holes through holes in sill-plate into the framing and install three (3) #12 x 2" long

screws (Item #4) (See Figure O).

NOTICE

Instructions for mounting sleeve with slope must be observed to

prevent entry of water into room.

Potential property damage can occur if instructions are not

followed.

Figure O

TRIM MOULDING

SCREW #12A X 2" LONG

USE 3

TYPICAL INSTALLATION

CAULK ALL SIDES AIR TIGHT

3/8" (10 MM) SLOPE DOWN

NOTE: SUPPORT BRACKETS MAY BE OMITTED FROM

THROUGH-THE-WALL INSTALLATIONS IF THECABINET IS

SECURED AS FOLLOWS. DRILL 2 HOLES IN EACH SIDE

AND INSTALL 4 FASTENERS (2 EACH SIDE).

USE #12A X 2" (51 MM) SCREWS, TOGGLE BOLTS OR

EXPANSION ANCHOR BOLTS AS SHOWN IN STEP 5.

SILL PLATE GUIDE CHANNEL

SUPPORT BRACKETS (ITEM 1) (SEE NOTE ABOVE)

INSIDE WALL SURFACE

SCREW #12 X 2" LONG, USE ONE IN EACH

BRACKET. DRILL 5/23 (4 MM) DIA. PILOT HOLES.

NOTE: ALTERNATE FASTENERS WHICH MAY BE USED FOR SECURING THE SILL PLATE IN THE WALL, AND THE

SUPPORT BRACKETS TO THE OUTSIDE WALL ARE NOT FURNISHED, BUT ARE AVAILABLE ATALOCAL

HARDWARE STORE.

MOLLY OR TOGGLE BOLT EXPANSION ANCHOR BOLT

STEP5 Drilltwo (2)5/32"(4 mm) dia. pilot holes ineach side at the locations shown(FigureO) and install four (4)#12x2"screws

(Item #4). If the hole construction in Step2providesasturdy mount with solid vertical studs, no support brackets are

required. The installation must support the we

ight ofthe unit plus an additional weight of 400 pounds (185 kg) onthe rear

of the cabinet. The support brackets may be used for through-the-wall installations as shown in Figure O, for additional

support.

STEP6 If desired, trim around the cabinet on the roomside with a suitable frame molding furnishedby the installer (See Figure O).

15

Friedrich Air Conditioning Company

P.O. Box 1540

San Antonio, TX 78295

210.357.4400

www.friedrich.com

HAZARDGARD

®

ROOM AIR CONDITIONERS

LIMITED WARRANTY

LIMITED ONE YEAR PARTS WARRANTY

1. Limited warranty – One year. Friedrich warrants that it will provide a replacement for any part of this HazardGard Room Air

Conditioner found defective in material or workmanship for a period of one (1) year from the date of original purchase.

2. Limited warranty – One year. The Friedrich warranty also covers the cost of labor for repairing any compressor, condenser,

evaporator or inter-connecting tubing found defective within the warranty period, providing the unit is returned to an authorized

Friedrich Repair Station located within the Continental United States.

The Friedrich warranty does not cover:

(1) Any charges for removal, transportation or reinstallation of the unit; (2) the cost of labor to replace parts other than those

described above; and (3) does not apply to any HazardGard Room Air Conditioner that has been subject to (a) accident, misuse,

flood, fire, or neglect; (b) repairs or alterations outside of the Friedrich Authorized Dealer or Service Center so as to affect adversely

its performance and reliability; or (c) any repairs or servicing as a result of using parts not sold or approved by Friedrich.

LIMITATIONS: This warranty is a LIMITED warranty. Anything in the warranty notwithstanding, IMPLIED WARRANTIES

FOR PARTICULAR PURPOSE

WARRANTY. MANUFACTURER EXPRESSLY DISCLAIMS AND EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL OR

INCIDENTAL DAMAGES FOR BREACH OF ANY EXPRESSED OR IMPLIED WARRANTY.

Performance of Friedrich’s Warranty obligation is limited to one of the following methods:

AND MERCHANTABILITY SHALL BE LIMITED TO THE DURATION OF THE EXPRESS

1. Repair of the unit

2. A refund to the customer for the prorated value of the unit based upon the remaining warranty period of the unit.

3. Providing a replacement unit of equal value

The method of fulfillment of the warranty obligation is at the sole discretion of Friedrich Air Conditioning.

(11-09)

18

Loading...

Loading...