Model PXDR10

Installation Instructions

DRAIN KIT

For Use With Packaged Terminal Units

Please read these instructions completely before attempting installation.

NOTE: These instructions apply to the Packaged Terminal Unit Drain Kit ONLY. Refer to Chassis Installation / Operation

Manual and Wall Sleeve Installation Instructions for additional information.

Check kit for parts listed in Table 1.

Table 1 Drain Kit Parts List

QUANTITY

2

1

1

3

4

2

2

NOTE: Determine whether drain will be located within the

wall, on the indoor side, or will drain to the exterior of the

building. Follow appropriate instructions below depending on

your particular type of installation. Make certain that the four

overflow slots at rear of the wall sleeve are not blocked.

COVER PLATE S

MOUNTING PLATE

DRAIN TUBE

MOUNTING PLATE GASKETS

#10 X 1 /2" MOUNTING SCREWS

10-24 X 1/2" MACH. SCREWS

LOCKNUTS

DESCRIPTION

Internal Drain

NOTE: If installing an internal drain, you MUST install drain

kit on wall sleeve before wall sleeve is installed.

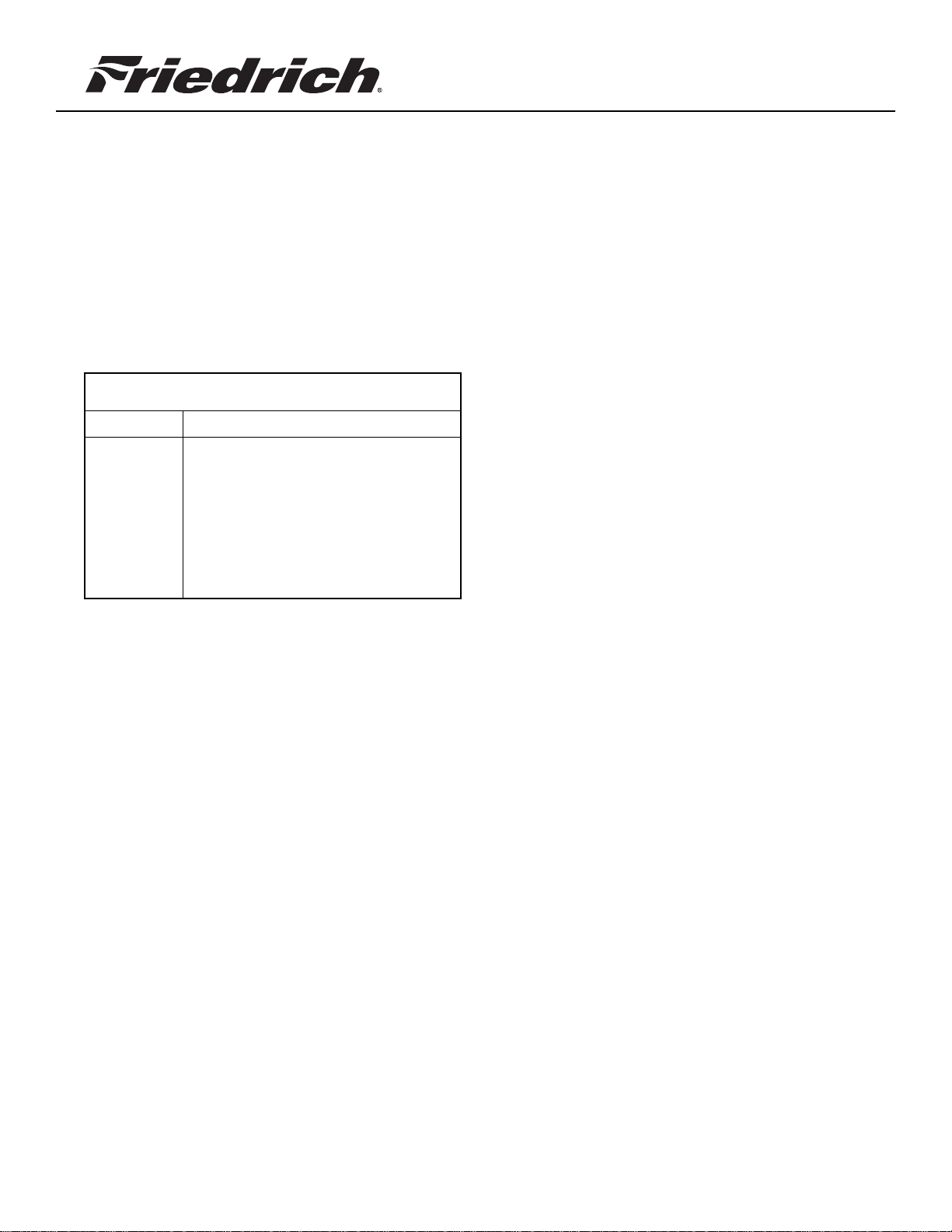

1. Refer to Figure 1 and locate drain within "Primary" area

for best drainage. Maintain at least 1/2" clearance

from embossed area.

5. Use 1/2" I.D. copper tube, PVC pipe, or vinyl hose

(obtained locally) to connect from internal drain tube

to drain system in building.

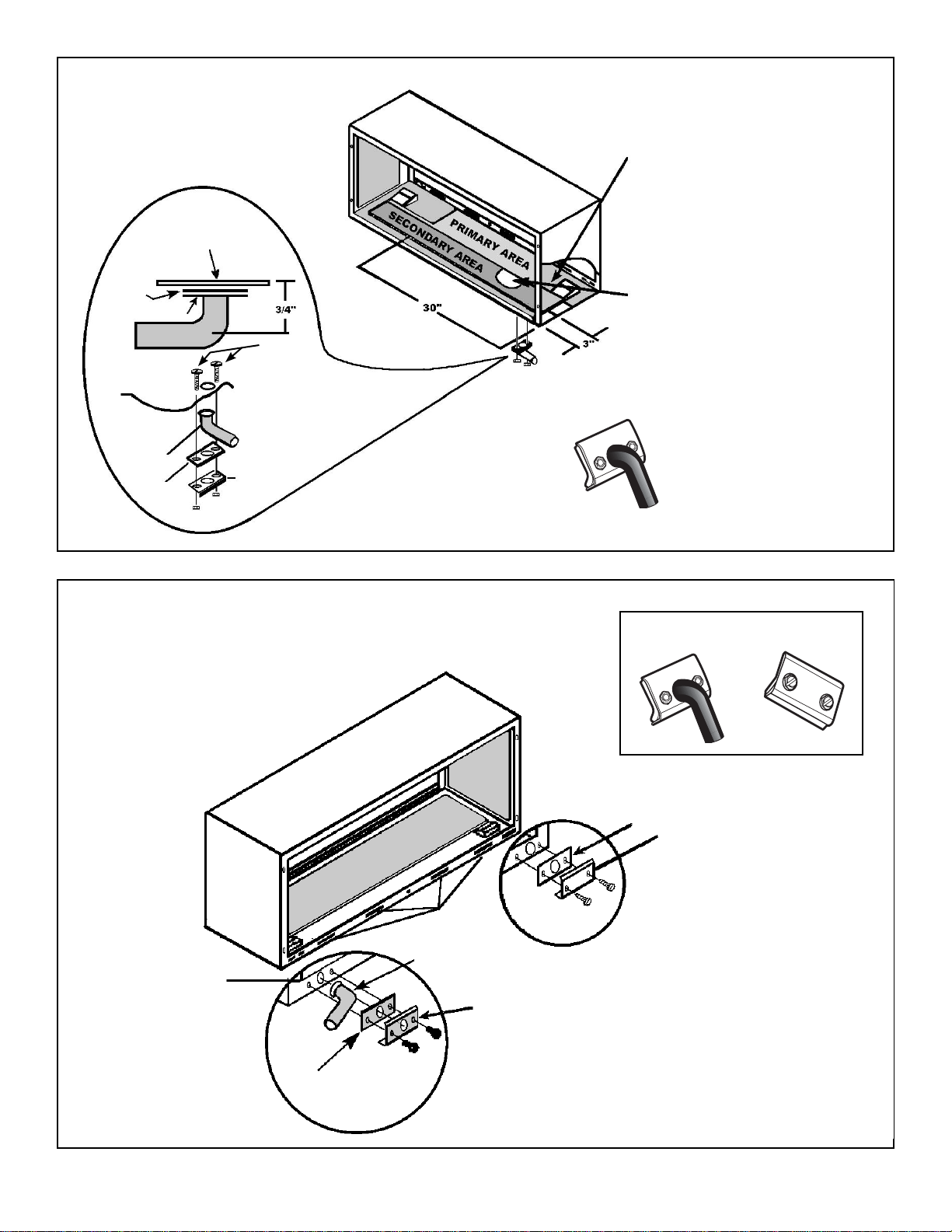

6. Referring to Detail A, locate and assemble (2) two

cover plates and gaskets over drain holes at rear of

wall sleeve. Attach with #10 sheet metal screws

provided.

External Drain

1. Peel backing tape off gaskets and apply sticky side

to one cover plate and one mounting plate as shown

in Details A and B.

2. Place drain tube through gasket and mounting plate

with flange toward wall sleeve.

3. Attach drain tube assembly to one of two drain holes

at rear of wall sleeve. Large flange on mounting plate

is posi t i o n e d at bot tom of slee v e f a cing toward sl e e v e ,

Detail B. When drain tube is positioned at desired

angle, tighten screws.

NOTE: If wall sleeve has not been installed, drain tube

must be rotated to a horizontal position until after sleeve

is installed. Tighten mounting plate screws when tube is

in proper position.

2. Using the mounting plate with the 1/2" hole as a

template, mark and drill two, 3/16" mounting holes

and a 1/2" drain hole.

3. Referring to F i g u r e 2 , r e m ove gasket ba c k i n g t ape an d

apply sticky side of gasket to flat side of mounting

plate. Insert drain tube through hole in gasket and

mounting plate so tube flange will be against the wall

sleeve.

4. Position assembly beneath drilled holes and secure

with #10-24 x 1/2" machine screws and lock nuts

provided. Seal tops of screws with silicon caulking.

920-120-00 (1-05)

4. Using two #10 x 1/2" sheet metal screws (provided),

attach cover plate to remaining drain hole. Make

certain large flange on plate is positioned at bottom

of sleeve, Detail A.

5. Discard additional cover plate, gasket, machine

screws, and locknuts.

6. Check unit for proper operation. Refer to Installation

/ Operation Manual for additional information.

Figure 1

Figure 2

Wall Sleeve bottom

Foam

Gasket

Mounting Plate

Tube

Sleeve

Bottom

1/2" O.D.

Tube

Gasket

Screws

Mounting

Plate

Primary Area: Condensation from

the chassis collects in the sleeve in

this area. The Primary Area is the

preferred installation location.

If the drain must be located in the

secondary area, the foam insulation

must be cut away and removed to

allow access to the drain.

PXDR10 DRAIN KIT

Note: The cover plate and external drain tube

assembly may be placed on either side of the

wall sleeve. Before tightening the screws,

make sure the tubes' position will allow

the wall sleeve to fi t through the wal l.

Figure 3

Back of wall sleeve

Overfl ow

Slots

1/2" O.D. Tube

Mounting Plate

PXDR10 DRAIN KIT

Foam Gasket

Cover plate

DET AIL A

Foam Gasket

DETAIL B

920-120-00 (1-05)

Loading...

Loading...