Friedrich KQ08J50A-B, SM18J50B-B, SS12J50A-A, EM18J53A-B, EM24J53A-B Service & Parts Manual

...

2003 International

Service & Parts Manual

Room Air Conditioners

50 Hz Models

MODELS

KQ08J50A-B

SS12J50A-A

SM18J50B-B

EX0302 (10-03)

SM24J50B-B

ES12J53A-A

EM18J53A-B

EM24J53A-B

YM18J50A-B

YS12J50A-A

Page 2

Page 3

TABLE OF CONTENTS

General......................................................................................................................................... 4

Specications....................................................................................................................... 4

Operating Data ..................................................................................................................... 6

Installation Instructions For DC-2 Drain Kit ...................................................................... 7

Compressors........................................................................................................................ 8

Component Operation And Testing .............................................................................. 8

Thermal Overload (External)............................................................................................... 9

Fan Motor.............................................................................................................................. 9

Run Capacitor ..................................................................................................................... 10

System Control Switch........................................................................................................ 11

System Control Switch........................................................................................................ 11

System Control Switch........................................................................................................ 12

Thermostat ........................................................................................................................... 13

Thermostat Bulb Location .................................................................................................. 13

Thermostat ........................................................................................................................... 14

Thermostat Adjustment....................................................................................................... 14

Resistor (See Figure 17)...................................................................................................... 15

MoneySaver® Switch........................................................................................................... 15

Heating Element - (See Figure 19)...................................................................................... 16

Defrost Thermostat............................................................................................................ 16

Defrost Bulb Location ......................................................................................................... 17

Solenoid Coil ........................................................................................................................ 17

Check Valve - (Figure 22) .................................................................................................... 17

Valve, Drain Pan (See Figure 23) ........................................................................................ 18

Reversing Valve ................................................................................................................... 18

Electronic Control (See Figure 12) ..................................................................................... 19

Sealed Refrigeration System ............................................................................................. 21

Hermetic Component Replacement ................................................................................... 22

Special Procedures In The Case Of Compressor Motor Burn-out .................................. 22

Rotary Compressor Special................................................................................................ 24

Refrigerant Charge .............................................................................................................. 24

Refrigerant Reverse Cycle

Refrigerant Flow Chart — Heat Pump Models .................................................................. 24

Refrigerant Flow Chart, Cooling Cycle .............................................................................. 24

Refrigerant Flow Chart, Heating Cycle .............................................................................. 24

Routine Maintenance........................................................................................................... 23

Troubleshooting

Troubleshooting Touch Test Chart..................................................................................... 24

Troubleshooting Cooling .................................................................................................... 25

Troubleshooting Heating (Heat Pumps) ............................................................................ 29

Troubleshooting Heating (Cooling/Electric Models) ........................................................ 31

Troubleshooting Heating (Cooling/Electric Models) ........................................................ 33

Wiring Diagrams .................................................................................................................. 35-40

PARTS LISTS

"KQ" Series Chassis Parts List .......................................................................................... 41

"KQ" Series Cabinet Parts List........................................................................................... 42

QuietMaster "SS" & "SM" Series Chassis Parts............................................................... 45

QuietMaster "SS" & "SM" Series Cabinet Parts................................................................ 46

"ES" – "EM" – "YS" – "YM" Series Chassis Parts ............................................................ 50

"ES" – "EM" – "YM" Series Cabinet & Mounting Parts .................................................... 51

Page 3

Page 5

GENERAL

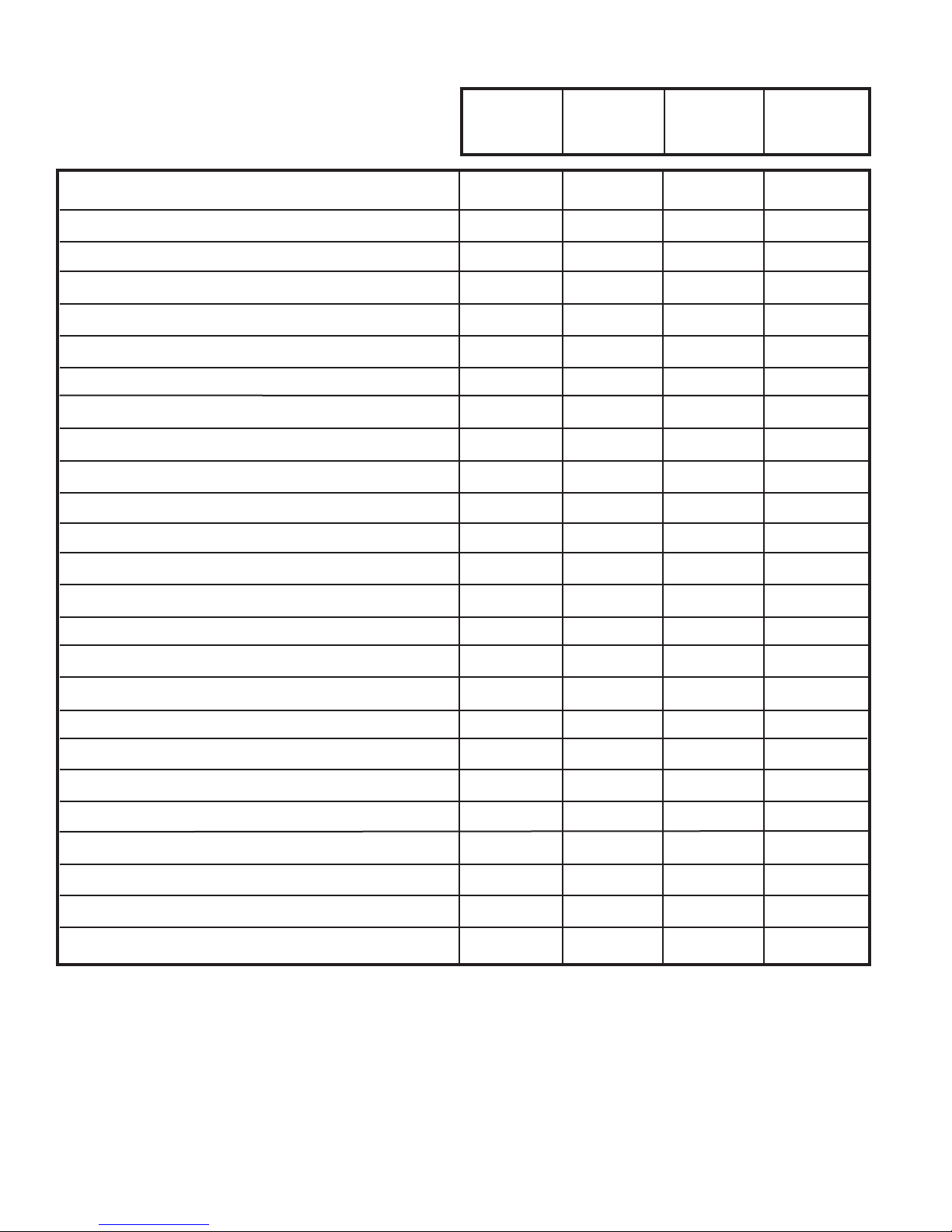

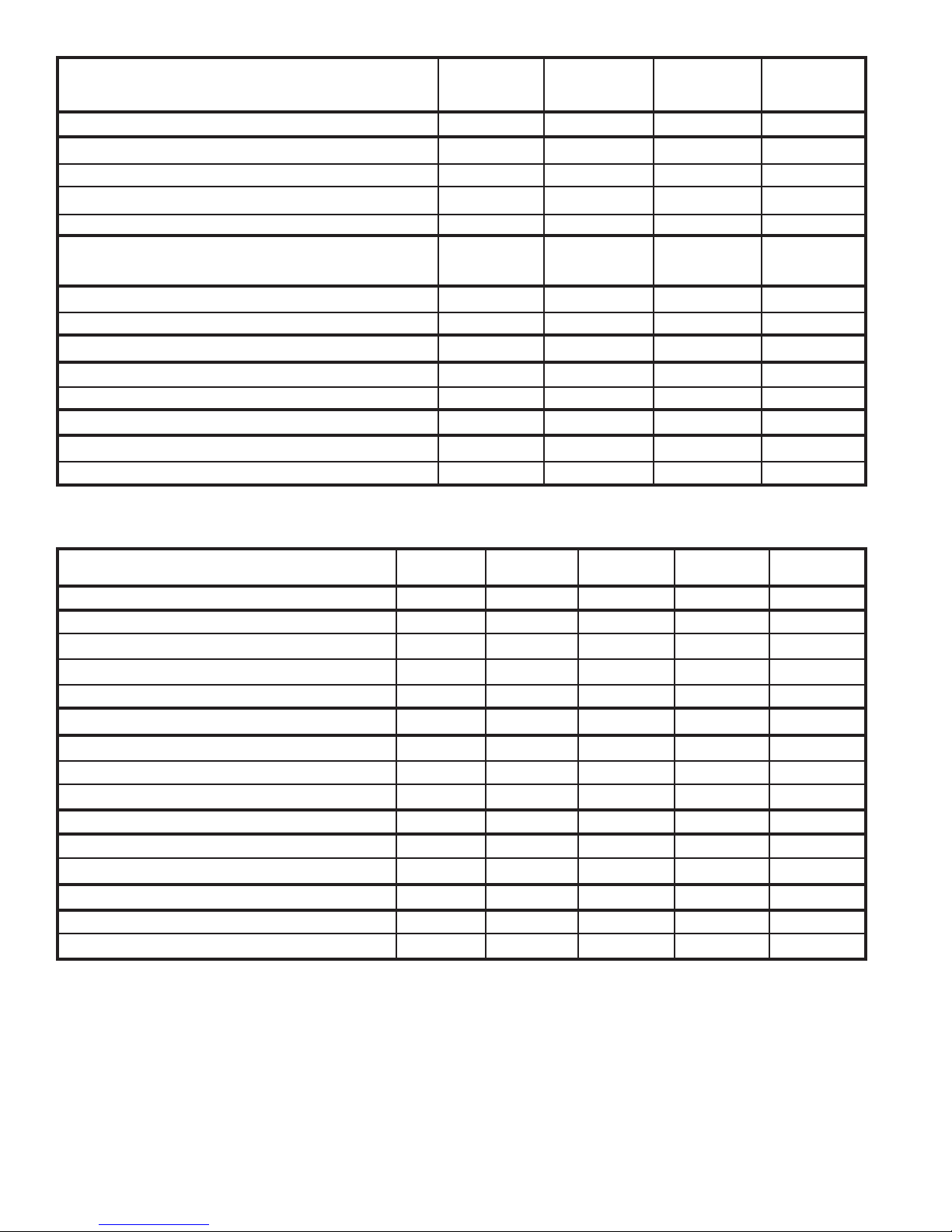

SM18J50BB SM24J50BB KQ08J50AB SS12J50AA

SPECIFICATIONS

Btu/hr 18,000 24,000 8,100 12,000

k.Cal./hr 4,536 6,048 2,041 3,024

E.E.R. - Btu/watt 8.5 8.5 9.5 9.0

E.E.R. - k.Ca./hr. 2.14 2.14 2.39 2.28

Volts 220/240 220/240 220/240 220/240

Amperes 10.2 13.5 3.9 6.5

Total Watts 2120 2825 850 1090

Fuse/Breaker Size (Amps) 15 20 15 15

Fan rpm-High 1200 1200 1300 970

Evaporator Air CFM 450 450 200 320

Evaporator Air M3/Hr 765 765 340 54

Dehumidication-Pts./hr. 5.7 8.5 2.5 3.0

Dehumidication-Lit./hr. 2.70 4.02 1.18 1.41

Width-Inches 25 15/16 25 15/16 19 3/4 25 15/16

Width-MM 659 659 502 659

Height-Inches 17 15/16 17 15/16 14 15 15/16

Height-MM. 456 456 356 405

Depth-Inches 27 3/8 27 3/8 21 3/4 27 3/8

Depth-MM 695 695 543 695

Min. Ext. Into Room-Inches 3 1/16 3 1/16 5 1/2 3 1/16

Min. Ext. Into Room-MM 78 78 140 78

Min. Ext to Outside-Inches 16 15/16 16 15/16 10 3/4 16 15/16

Min. Ext to Outside-MM 430 430 273 430

Shipping Weight-lbs. 150 160 84 122

Shipping Weight-kg 68.0 42.5 38.1 55.3

Page 4

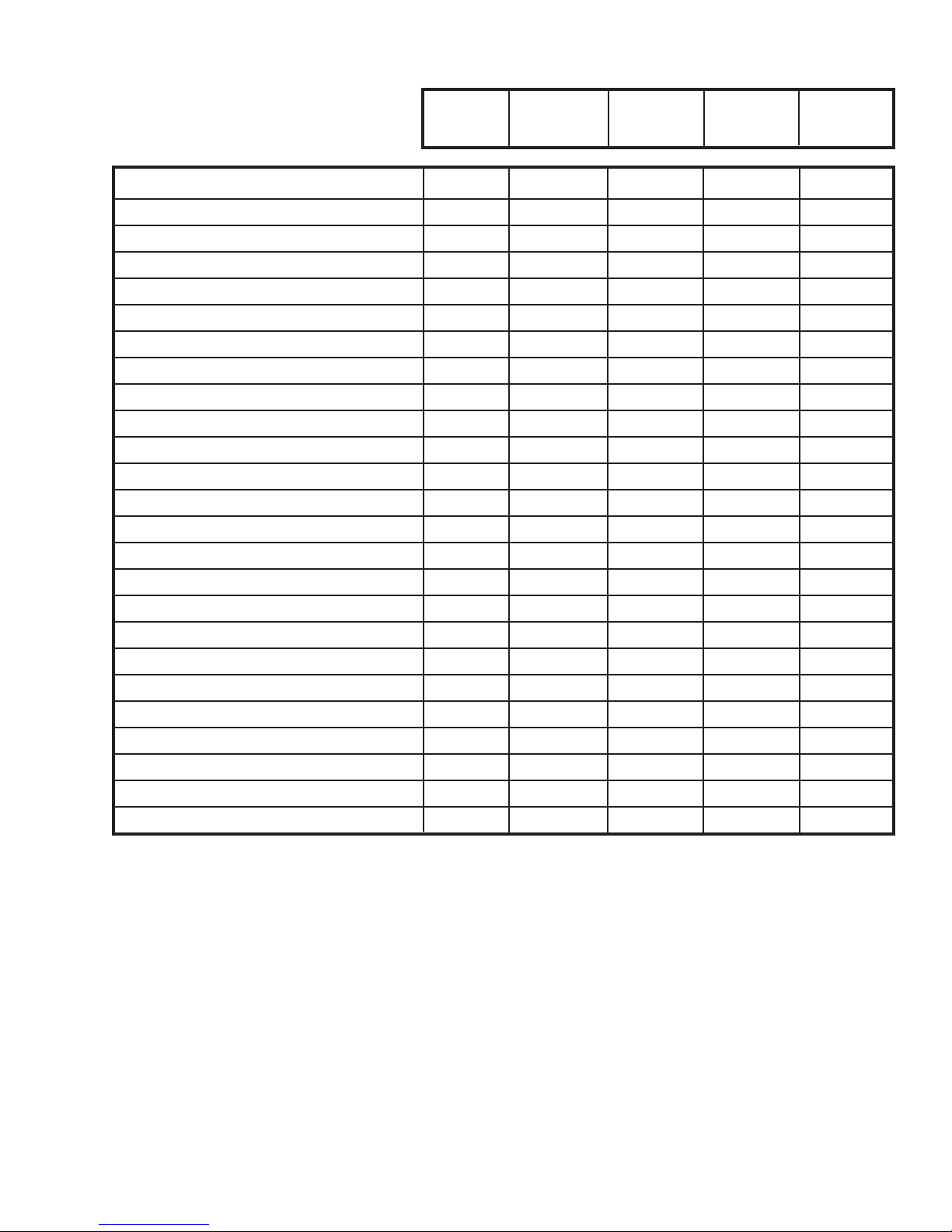

SPECIFICATIONS

YS12J50AA ES12J53AA EM18J53AB YM18J50AB EM24J53AB

Btu/Hr 12,000 12,000 18,000 18,000 24,000

k.Cal./hr 3,024 3,024 4,536 4,536 6,048

E.E.R. - Btu/watt 11.0 9.0 8.5 8.5 8.5

E.E.R. - k.Ca./hr. 2.77 2.28 2.14 2.14 2.14

Volts 220/240 220/240 220/240 220/240 220/240

Amperes 4.9 6.5 10.2 10.2 13.5

Total Watts 1090 1090 2120 2120 2825

Fuse/Breaker Size (Amps) 15 20 20 15 20

Fan rpm - High 970 970 1200 1200 1200

Evaporator Air CFM 320 320 450 450 450

Evaporator Air M3/hr. 544 544 765 765 765

Dehumidication - Pts./hr. 3.0 3.0 5.7 5.7 8.5

Dehumidication - Lit./hr. 1.41 1.41 2.70 2.70 4.02

Width - Inches 25 15/16 25 15/16 25 15/16 25 15/16 25 15/16

Width - MM 659 659 659 659 659

Height - Inches 15 15/16 15 15/16 17 15/16 17 15/16 17 15/16

Height - MM 405 405 456 456 456

Depth - Inches 27 3/4 27 3/8 27 3/8 27 3/8 27 3/8

Depth - MM 695 695 695 695 695

Min. Ext. into Room - Inches 3 1/16 3 1/16 3 1/16 3 1/16 3 1/16

Min. Ext. into Room - MM 78 78 78 78 78

Min. Ext to Outside - Inches 16 15/16 16 15/16 16 15/16 16 15/16 16 15/16

Min. Ext to Outside - MM 430 430 430 430 430

Shipping Weight - lbs. 122 121 150 170 160

Shipping Weight - kg 55.3 55.3 68.0 77.0 72.5

Page 5

Page 7

OPERATING DATA

OPERATING PRESSURES

Suction - PSI 78.0 72.0 68 80.0

Suction - ATM 5.3 4.89 4.62 5.44

Discharge - PSI 296 288 280 280

Discharge - ATM 20.14 19.60 19.05 19.04

ELECTRICAL RATING

(Compressor)

Amperes (FLA) 10.2 13.5 3.9 6.5

Locked Rotor Amps 52.0 78.0 20.0 32.0

REFRIGERANT, R-22

Charge in oz. 32.0 46.0 18.0 24.0

Charge in kg. 0,907 1,302 0,509 0,655

COMPRESSOR OIL

Charge in Fluid oz. 32 46 18 24

Charge in Liters 0,907 0,360 0,530 0,710

SM18J50BB SM24J50BB KQ08J50AB SS12J50AA

OPERATING DATA ES12J53AA YS12J50AA EM18J53AB YM18J50AB EM24J53AB

OPERATING PRESSURES

Suction PSI 76.5 76.5 78.0 75.5 72.0

Suction - ATM 5.20 5.20 5.3 5.14 4.89

Discharge - PSI 264 264 296 260 288

Discharge - atm 17.96 17.96 20.14 17.69 19.60

ELECTRICAL RATING

(Compressor)

Amperes (FLA) 5.2 4.9 10.2 8.4 13.5

Locked Rotor Amps 32.0 32.0 52.0 52.0 82.0

REFRIGERANT, R-22

Charge in Oz. 24.0 24.0 32.0 33.0 46.0

Charge in kg 0,670 0,670 0,907 0,907 1,302

COMPRESSOR OIL

Charge in Fluid Oz. 15.0 15.0 32.0 32.0 32.0

Charge in Liters 0,444 0,444 0,907 0,907 0,907

Page 6

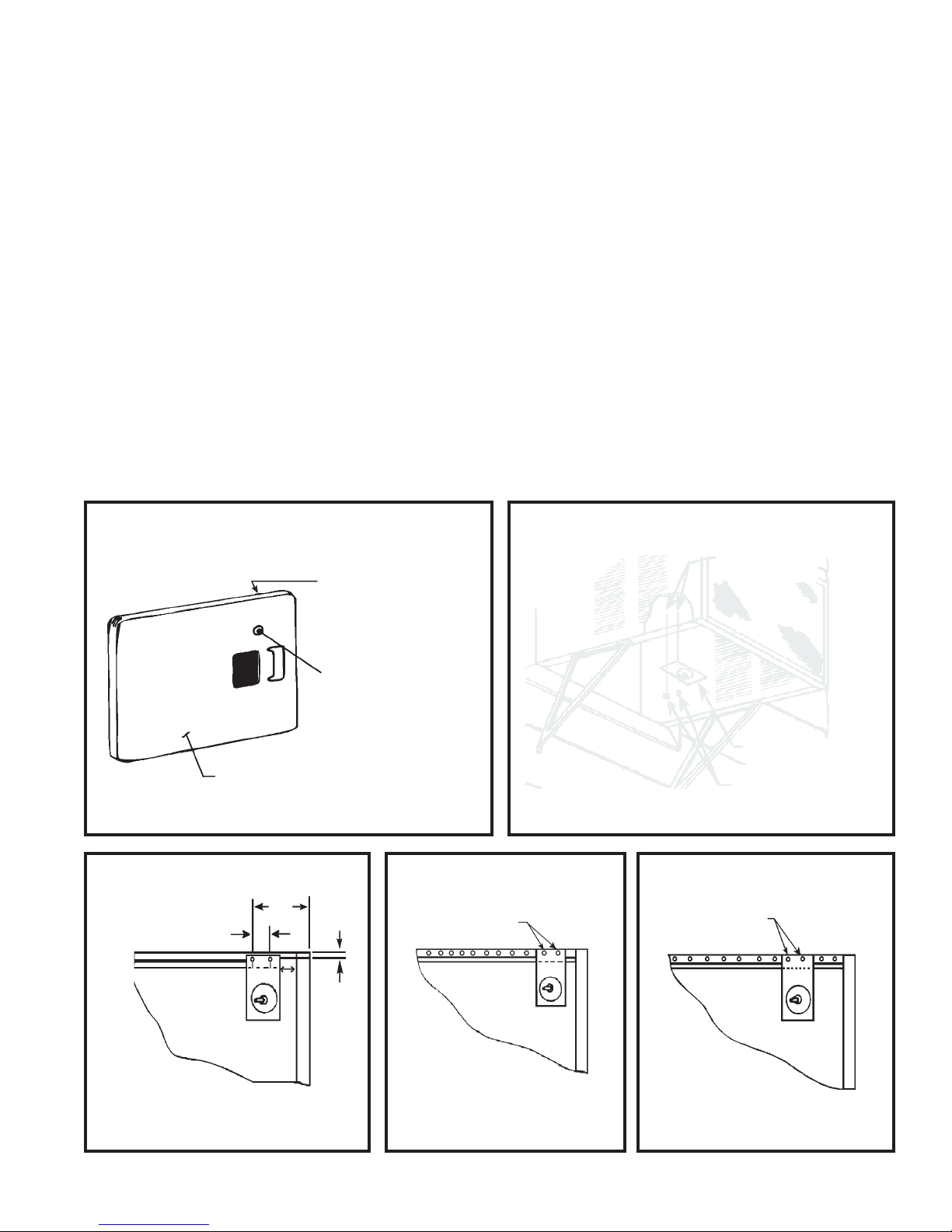

INSTALLATION INSTRUCTIONS FOR DC-2 DRAIN KIT

STEP 1 Before sliding the chassis into the outer shell, turn the chassis on its side and add a drain hole by drilling a

1/2" diameter hole as shown in Figure 1.

STEP 2 DC-2 mounts to the bottom of the outer shell as shown in Figure 2 on the right side as you face the unit. Use

two (2) 10-24 x 3/8" long machine screws and 10-24 hex nuts provided.

STEP 3 SQ, KQ, YQ Models - Drill two 1/4" holes in the outer shell as shown in Figure 3. Also drill a 3/8" diameter

hole in the base pan 3 1/2" from the back and 3 1/2" from the right side.

STEP 4 Small and Medium Chassis Models - Mount in the second and third holes from the rear of the shell. (See

Figure 4.)

STEP 5 Large Chassis Models - Mount in the third and fourth holes from the rear of the shell. (See Figure 5.)

STEP 6 Connect a suitable length of garden hose or other tubing to the end of the drain tube to drain the condensate

away.

FIGURE 1

FIGURE 3

RIGHT SIDE

APPROXIMATE

LOCATION OF EMBOSSMENT. DRILL

1/2 " DIA. HOLE.

BACK OF BASE PAN

6"

2"

3/8"

FIGURE 4

3rd AND 4th HOLES

FROM REAR OF

SHELL

FIGURE 2

10–24 x 3/8" LONG

SCREWS

DRAIN PLATE

10–24 NUTS

FIGURE 5

3rd AND 4th HOLES

FROM REAR OF

SHELL

"SQ," "KQ," "YQ" MODELS

BOTTOM VIEW

SMALL AND MEDIUM

CHASSIS MODELS

LARGE CHASSIS MODELS

BOTTOM VIEW

Page 7

Page 9

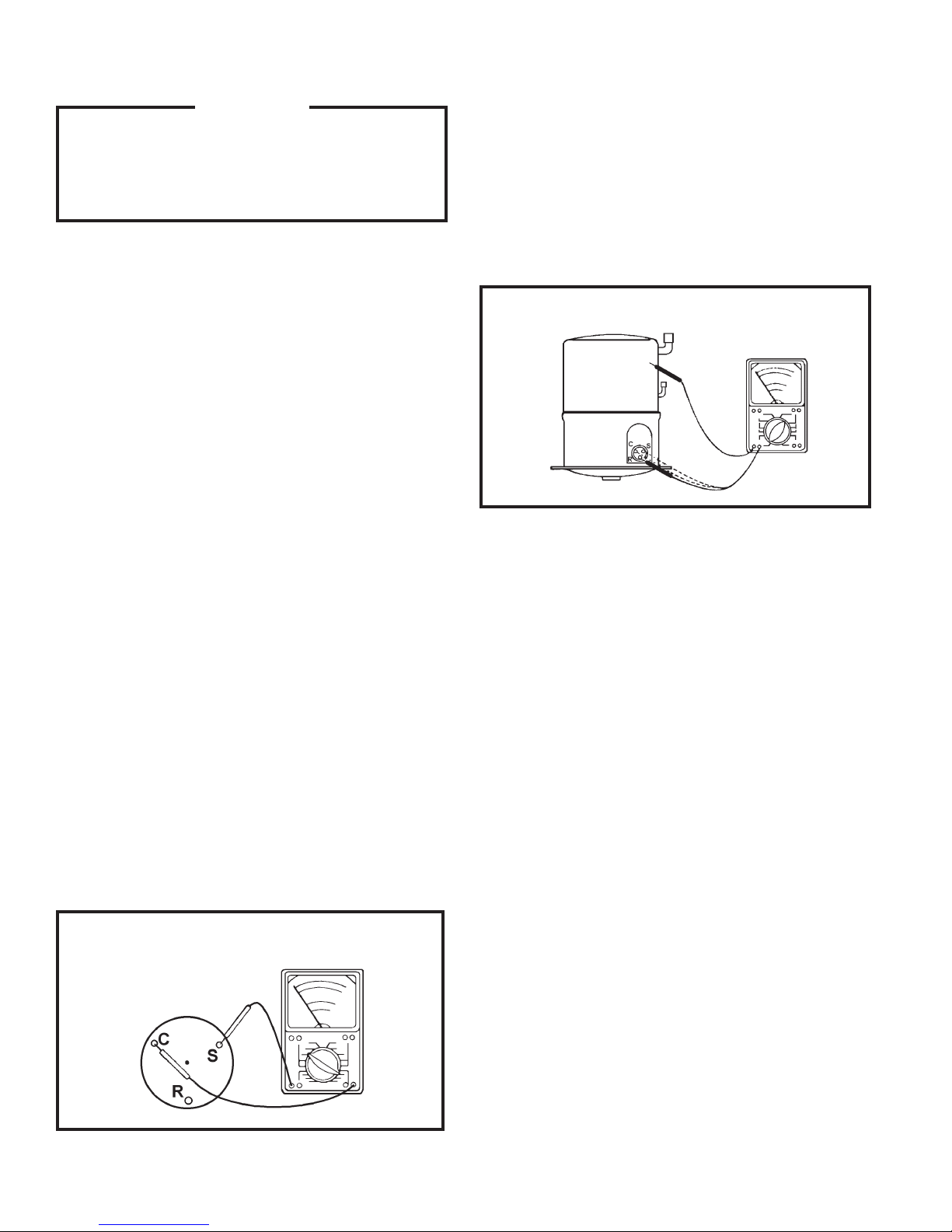

COMPONENT OPERATION AND TESTING

GROUND TEST

WARNING

DISCONNECT ELECTRICAL POWER

TO THE UNIT BEFORE SERVICING OR

TESTING

COMPRESSORS

Compressors are single phase, 220 or 220/240

volt, depending on the model unit. All compressor

motors are permanent split capacitor type, using

only a running capacitor across the start and run

terminal.

All compressors are internally spring mounted

and externally mounted on rubber isolators.

COMPRESSOR WINDING TEST

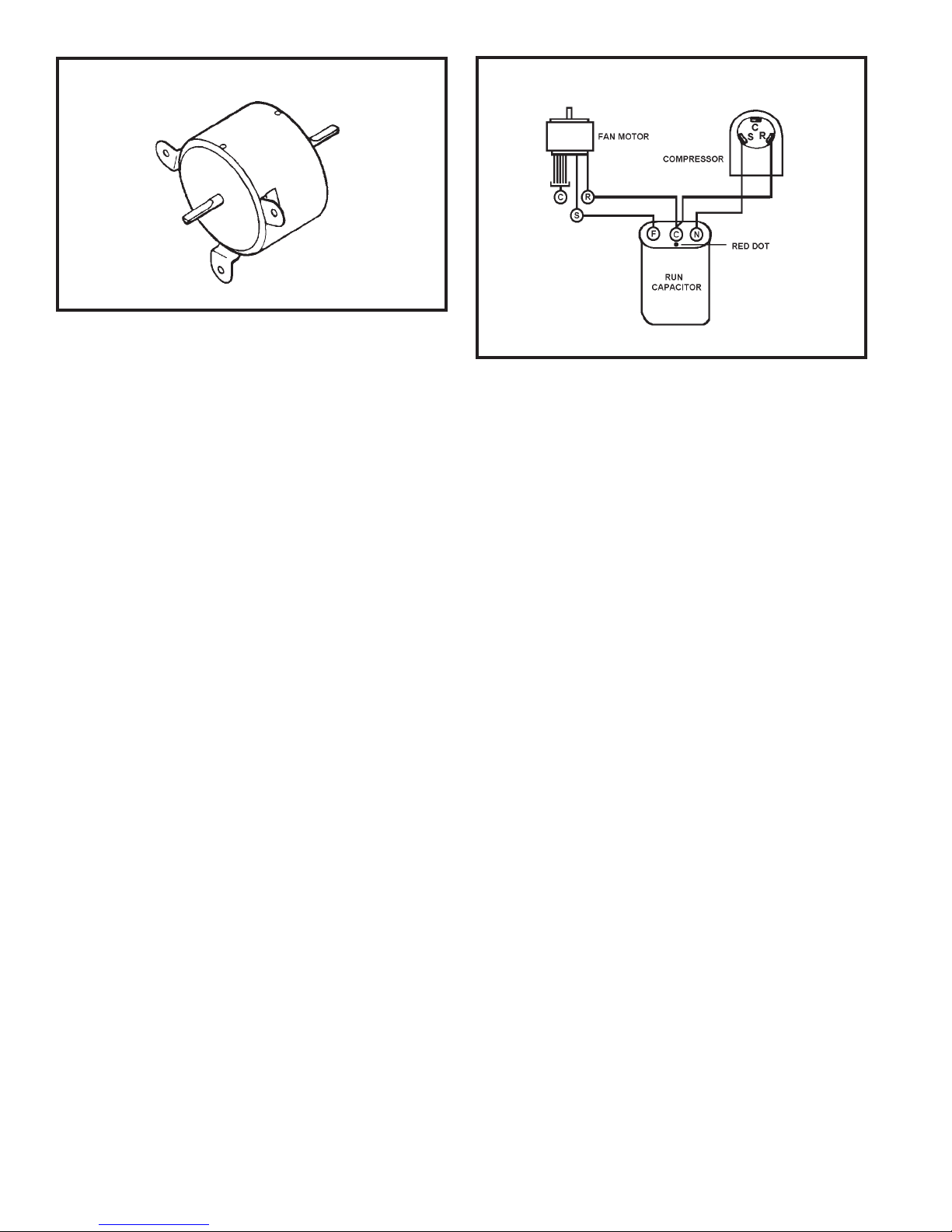

(See Figure 1.)

Remove the compressor terminal box cover

and disconnect the wires from the terminals.

Using an ohmmeter, check continuity across

the following:

Use an ohmmeter set on its highest scale. Touch

one lead to the compressor body (clean point

of contact, as a good connection is a must)

and the other probe in turn to each compressor

terminal. (See Figure 2.) If a reading is obtained,

the compressor is grounded and must be

replaced.

FIGURE 2 TYPICAL GROUND TEST

CHECKING COMPRESSOR EFFICIENCY

The reason for compressor inefficiency is

normally due to broken or damaged suction

and/or discharge valves, reducing the ability of

the compressor to pump refrigerant gas.

1. Terminal "C" and "S" - no continuity - open

winding - replace compressor.

2. Terminal "C" and "R" - no continuity - open

winding - replace compressor.

3. Terminal "R" and "S" - no continuity open

winding - replace compressor.

FIGURE 1 COMPRESSOR WINDING TEST

This condition can be checked as follows:

1. Install a piercing valve on the suction and

discharge or liquid process tube.

2. Attach gages to the high and low sides of the

system.

3. Start the system and run a "cooling or heating

performance test."

If test shows:

A. Below normal high side pressure.

B. Above normal low side pressure.

C. Low temperature difference across the coil.

The compressor valves are faulty - replace

the compressor.

Page 8

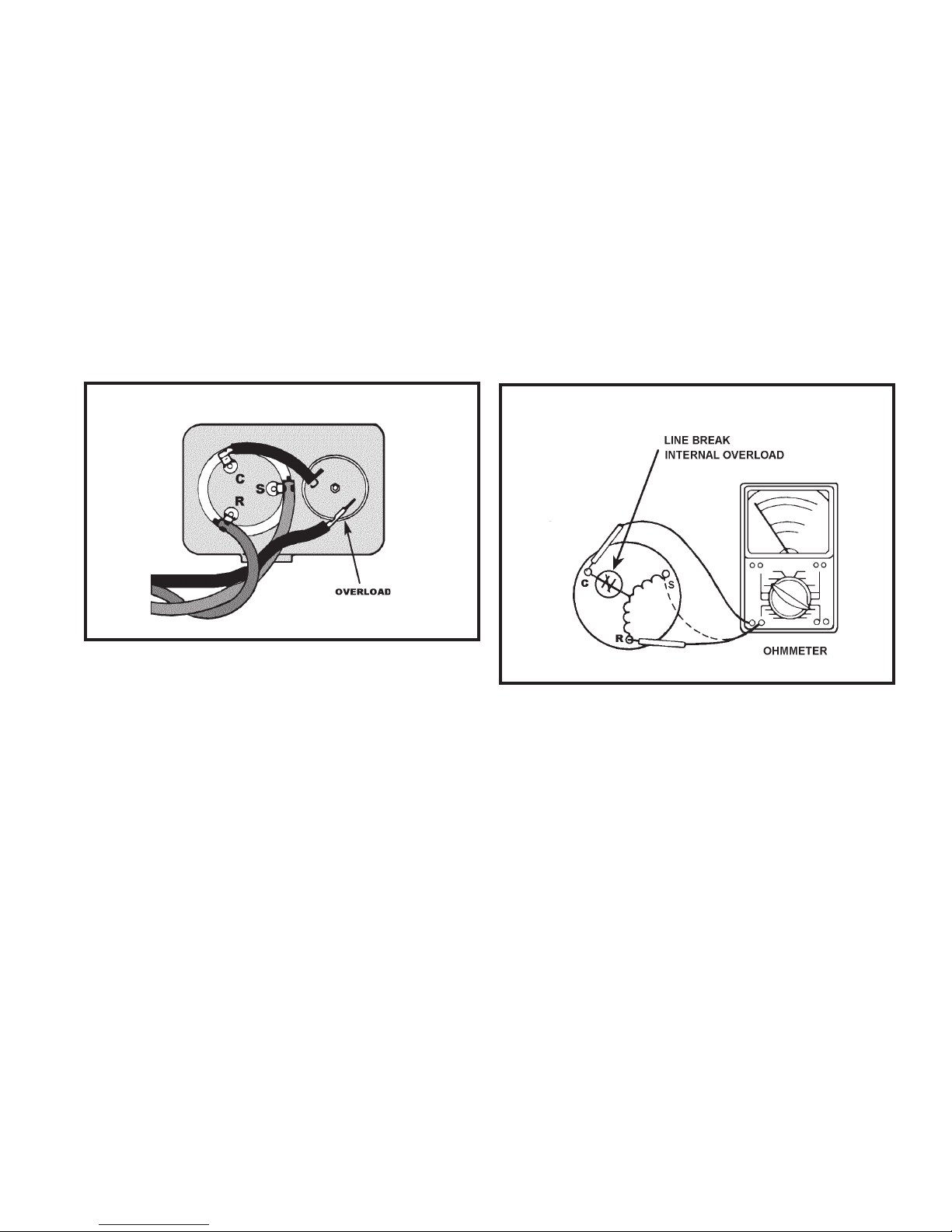

THERMAL OVERLOAD (External)

TERMINAL OVERLOAD (Internal)

Some compressors are equipped with an external

overload which is located in the compressor

terminal box adjacent to the compressor body.

(See Figure 3:) The overload is wired in series

with the common motor terminal. The overload

senses both motor amperage and compressor

temperature. H igh motor tempe rature or

amperage heats the disc causing it to open and

break the circuit to the common motor terminal.

FIGURE 3 EXTERNAL OVERLOAD

Some model compressors are equipped with an

internal overload. The overload is embedded

in the motor windings to sense the winding

temperature and/or current draw. The overload

is connected in series with the common motor

terminal. Should the internal temperature

and/or current draw become excessive, the

contacts in the overload will open, turning off

the compressor. The overload will automatically

reset, but may require several hours before the

heat is dissipated.

FIGURE 4 INTERNAL OVERLOAD

Heat generated within the compressor shell is

usually due to:

1. High amperage

2. Low refrigerant charge.

3. Frequent recycling.

4. Dirty Condenser.

TERMINAL OVERLOAD - TEST

(Compressor - External Type)

1. Remove overload.

2. Allow time for the overload to reset

before attempting to test.

3. Apply ohmmeter probes to the terminal

on the overload wires. There should be

continuity through the overload.

CHECKING INTERNAL OVERLOAD

(See Figure 4.)

1. With no power to the unit, remove the leads

from the compressor terminals.

2. Using an ohmmeter, test continuity between

terminals "C–S" and "C–R." If not continuous,

the compressor overload is open and the

compressor must be replaced.

FAN MOTOR

A single phase permanent split capacitor motor is

used to drive the evaporator blower and condenser

fan. A self-resetting overload is located inside the

motor to protect against high temperature and

high amperage conditions.

Page 9

Page 11

FIGURE 5 FAN MOTOR

FAN MOTOR-TEST

FIGURE 6 RUN CAPACITOR HOOK–UP

1. Determine that the capacitor is serviceable.

2. Disconnect the fan motor wires from the fan

speed switch or system switch.

3. Apply "live" test cord probes on the black wire

and the common terminal of the capacitor.

Motor should run at high speed.

4. Apply "live" test cord probes on the red wire

and common terminal of the capacitor. Motor

should run at low speed.

5. Apply "live" test cord probes on each of the

remaining wires from the speed switch or

system switch to test intermediate speeds.

RUN CAPACITOR

A run capacitor is wired across the auxiliary and

main winding of a single phase permanent split

capacitor motor such as the compressor and fan

motors. A single capacitor can be used for each

motor or a dual rated capacitor can be used for

both.

The capacitor’s primary function is to reduce the

line current while greatly improving the torque

characteristics of a motor. The capacitor also

reduces the line current to the motor by improving

the power factor of the load. The line side of the

capacitor is marked with a red dot and is wired to

the line side of the circuit. (See Figure 6.)

CAPACITOR – TEST

1. Remove the capacitor from the unit.

2. Check for visual damage such as bulges,

cracks, or leaks.

3. For dual rated capacitors, apply an ohmmeter

lead to the common (C) terminal and the other

probe to the compressor (HERM) terminal. A

satisfactory capacitor will cause a deection

on the pointer, then gradually move back to

innity.

4. R everse th e leads of t he probe a nd

momentarily touch the capacitor terminals.

The deection of the pointer should be two

times that of the rst check if the capacitor is

good.

5. Repeat steps 3 and 4 to check the fan motor

capacitor.

NOTE: A shorted capacitor will indicate a low

resistance and the pointer will move more to the

"0" end of the scale and remain there as long as

the probes are connected. An open capacitor will

show no movement of the pointer when placed

across the terminals of the capacitor.

Page 10

SYSTEM CONTROL SWITCH

("KQ" Models Only - Figure 7)

3. "Low Cool" Position -0 between terminals "L1"

and "L" and "C."

The KQ model unit uses a ve position control

switch to regulate the operation of the unit. The

function of each position (clockwise rotation) is

as follows:

1. "Off" - Turns everything off.

2. "Hi Fan" - Maximum circulation of ltered room

air (no cooling).

3. "Low Fan" - Fan runs slower for less circulation

of ltered room air.

4. "Low Cool" - Fan runs slow for quiet operation

when maximum cooling is not needed.

5. "Hi Cool" - Highest fan speed for maximum

cooling.

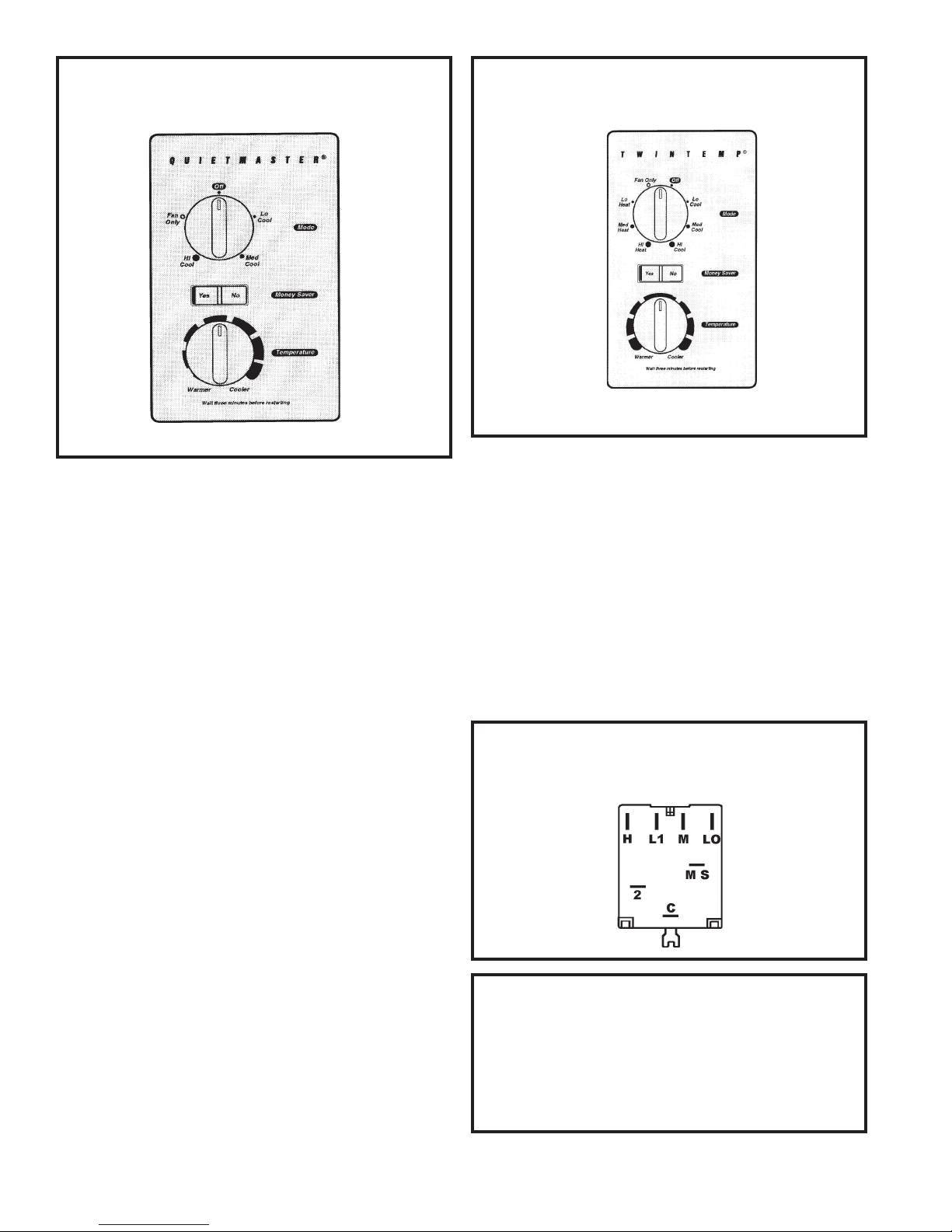

FIGURE 7 SYSTEM CONTROL PANEL

4. "Hi Cool" Position - between terminals "L1"

and "H" and "CC."

FIGURE 8 SYSTEM CONTROL SWITCH

SYSTEM CONTROL SWITCH

("SS," "SM" & "SL" Models)

("KQ" Models Only)

SYSTEM CONTROL SWITCH - TEST

Part No. 604-416-06 (See Figure 8)

Turn knob to phase of switch being tested. There

must be continuity as follows:

1. "Hi Fan" Position - between terminals "L1"

and "H."

2. "Low Fan" Position - between terminals "L1"

and "L."

A ve position control switch is used to regulate

the operation of the fan motor and compressor.

The compressor can be operated with the fan

operating at low, medium or high speed. The

fan motor can also be operated independently on

medium speed. See Switch Section as indicated

on decorative control panel. (See Figure 9.)

SYSTEM CONTROL SWITCH - TEST

Disconnect leads from the control switch. (See

Figure 10.) There must be continuity as follows:

1. "Off " Posit ion - no continuit y between

terminals.

2. "Low Cool" Position - between terminals "L1"

and "C," "LO" and "MS."

3. "Med Cool" Position - between terminals "L1"

and "C," "M" and "MS."

Page 11

Page 13

FIGURE 9 SYSTEM CONTROL PANEL

("SS" & "SM" Models Only)

FIGURE 11 SYSTEM CONTROL PANEL

(Heat Pump & Electric Heat Models)

4. "Hi Cool" Position - between terminals "L1"

and "C," "H" and "MS."

5. "Fan Only" Position - between terminals "L1"

and "2."

SYSTEM CONTROL SWITCH

(Heat Pump & Electric Heat Models)

An eight position control switch is used to regulate

the operation of the fan motor and compressor.

The compressor can be operated with the fan

operating at low, medium or high speed in the

cooling or heating mode. The fan motor can also

be operated independently on medium speed.

See Switch Section as indicated on the decorative

control panel. (See Figure 11.)

1. "Off" Position - Everything is off.

speed, compressor or electric heater is on.

6. "Med Heat" Position - fan operates on medium

speed, compressor or electric heater is on.

7. "Lo Heat" Position - Fan operates on low

speed, compressor or electric heater is on.

8. "Fan Only" Position - Fan operates on medium

speed.

FIGURE 10 SYSTEM CONTROL SWITCH

("SS" & "SM" Models Only)

2. "Low Cool" Position - Fan operates on low

speed, compressor is on.

3. "Med Cool" Position - Fan operates on medium

speed, compressor is on.

4. "Hi Cool" Position - Fan operates on high

speed, compressor is on.

5. "Hi Heat" Position - Fan operates on high

Page 12

NOTE: Heat pump models with electric

heat - in the heat position, the heating

element will be energized only when

the outdoor temperature is below the

operating range of the heat pump.

FIGURE 12 SYSTEM CONTROL SWITCH

(Heat Pump & Electric Heat Models)

SYSTEM CONTROL SWITCH - TEST

Disconnect the leads from the control switch.

Turn the control to the position being tested.

(See Figure 12). There must be continuity as

follows:

THERMOSTAT

("KQ" Models) - (See Figure 13)

The thermostat (part number 613-503-10) is

used to cycle the compressor on, and maintain

the temperature at the comfort level desired. The

thermostat has a range from 63o ± 2o F to 90o ±

4o F, with a differential of 5o F. Turning the knob

clockwise, lowers the indoor room temperature

setting, while turning the knob counterclockwise

raises the indoor temperature.

FIGURE 13 THERMOSTAT ("KQ" Models Only)

1. " Off " Posit ion - no con tinuity bet ween

terminals.

2. "Low Cool" Position - between terminals "C"

and "3," "C2" and "2," "LO" and "M/S," "AR"

and "5."

3. "Med Cool" Position - between terminals "C"

and "3," "C2" and "2," "M" and "M/S," "AR" and

"5."

4. "Hi Cool" Position - Between terminals "C"

and "3", "C2" and "2," "H" and "M/S," "AR

and "5."

5. "Hi Heat" Position - between terminals "C" and

"1", "C2" and "4," "H" and "M/S," "AR" and

"5."

6. "Med Heat" Position - between terminals "C"

and "1," "C2" and "4," "M" and "M/S," "AR" and

"5."

7. "Lo Cool" Position - between terminals "C" and

"1," "C2" and "4," "LO" and "M/S," "AR" and

"5."

TEST:

Remove the wires, turn the thermostat to its

coldest position. Check for continuity between

the two terminals. Turn the thermostat to its

warmest position, check continuity to see of the

contacts open. NOTE: The temperature must be

in the range listed to check the thermostat.

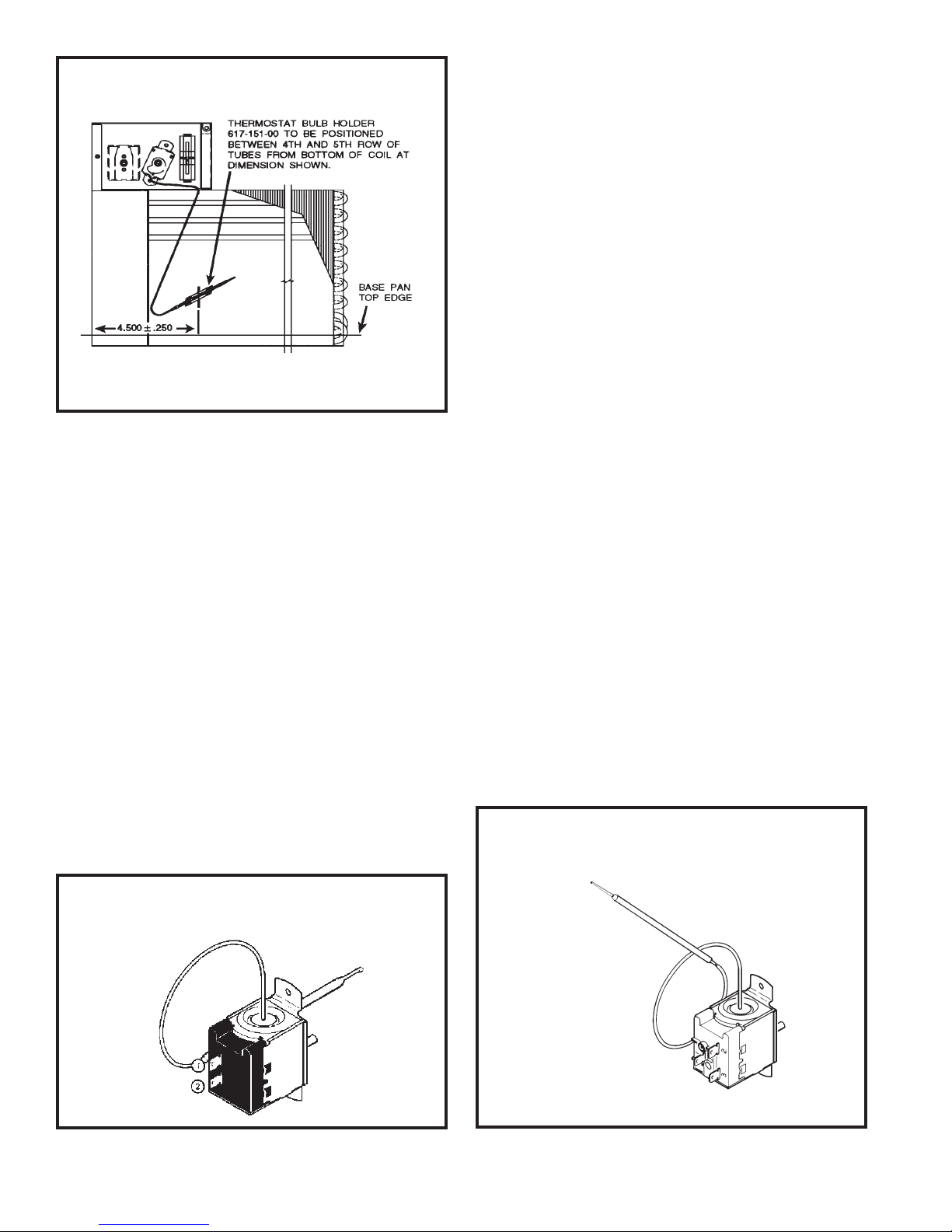

THERMOSTAT BULB LOCATION

("KQ" Models) - (See Figure 14)

The position of the bulb is important in order for

the thermostat to function properly. (See Figure

14.) The bulb of the thermostat should be located

approximately 45o to a maximum of 60o from

horizontal. Also, do not allow the thermostat bulb

to touch the evaporator coil.

8. "Fan Only" Position - between terminals "L1"

and "M."

Page 13

Page 15

FIGURE 14 THERMOSTAT BULB LOCATION

("KQ" Models Only)

THERMOSTAT

("SS" & "SM" Models) - (Figure 15)

A cross ambient thermostat is used on all standard

chassis units. In addition to cycling the unit in

a heating or cooling operation, the thermostat

will terminate the cooling cycle in the event ice

forms on the evaporator coil. In this case the

thermostat functions as a de-icing control. A

resistor (anticipator) is positioned within a plastic

block to supply a small amount of heat to the bulb

area to prevent long "off cycles" in the "Cool-Fan

Auto" (MoneySaver) position. (See Figure 15.) A

current feedback through the fan motor windings

during "off cycle" periods completes the circuit to

the resistor.

TEST

Remove the wires from the thermostat. Turn the

thermostat to its coldest position. Check to see

if there is continuity between the two terminals.

Turn the thermostat to its warmest position.

Check continuity to see of the thermostat contacts

open. Note: The temperature must be within

the range listed to check the thermostat. Refer

to the troubleshooting section in this manual for

additional information on thermostat testing.

THERMOSTAT ADJUSTMENT

("SS" & "SM" Models)

No attempt should be made to adjust the

thermostat. Due to the sensitivity of the internal

mechanism and the sophisticated equipment

required to check the calibration, it is suggested

that the thermostat be replaced rather than

calibrated.

THERMOSTAT - (FIGURE 16)

(Heat Pump & Electric Heat Models Only)

A cross ambient thermostat is used on all heat

pump and electric heat units. In addition to

cycling the unit in a heating or cooling operation,

the thermostat will terminate the cooling cycle

in the event ice forms on the evaporator coil, in

this case the thermostat functions as a de-ice

control.

RANGE: Cooling Model Thermostat

o

60o F ( ± 2

FIGURE 15 THERMOSTAT

("SS" & "SM" Models Only)

Page 14

) to 92o F( ±4o )

FIGURE 16 THERMOSTAT

(Heat Pump & Electric Heat Models)

618-224-00

A resistor (anticipator) is positioned within a

plastic block to supply a small amount of heat

to the bulb area to prevent long "off cycles" in

the "Cool-Fan Auto" (MoneySaver) position.

(See Figure 16.) A current feedback through

the fan motor windings during "off" cycle periods

completes the circuit to the resistor.

In the heating cycle, the heat anticipator is

energized to supply a small amount of heat during

the "on" cycle. This will open the contacts in

the thermostat prematurely to maintain a closer

differential between the "cut-in" and "cut-out"

temperature. The heat anticipator is energized

in the heating mode regardless if the fan is placed

in the automatic (MoneySaver) or constant run

position.

RANGE: Cooling Model Thermostat

60o F ( ± 2o ) to 92o F( ±4o )

RESISTOR (See Figure 17)

(Heat Anticipator)

Failure of the resistor will cause prolonged "off"

and "on" cycles of the unit. When replacing a

resistor, be sure and use the exact replacement.

Resistor ratings are as follows:

115 Volt --5,000 ohms 3 watt

230 Volt-- 20,000 ohms 3 watt

FIGURE 17 RESISTOR

TEST

Cooling/Heating Models: Remove the wires from

the thermostat and check continuity between

terminal "2" (common) and "3" for cooling.

Check between terminals "2" (common) and

"1" for heating. Also check that contacts in the

thermostat open after being placed in either

position. NOTE: The temperature must be within

the range listed to check the thermostat. Refer

to the troubleshooting section in this manual for

additional information on thermostat testing.

THERMOSTAT ADJUSTMENT

(Heat Pump & Electric Heat Models Only)

No attempt should be made to adjust the

thermostat. Due to the sensitivity of the internal

mechanism and the sophisticated equipment

required to check the calibration, it is suggested

that the thermostat be replaced rather than

calibrated. The thermostat bulb must be straight

to insure proper performance.

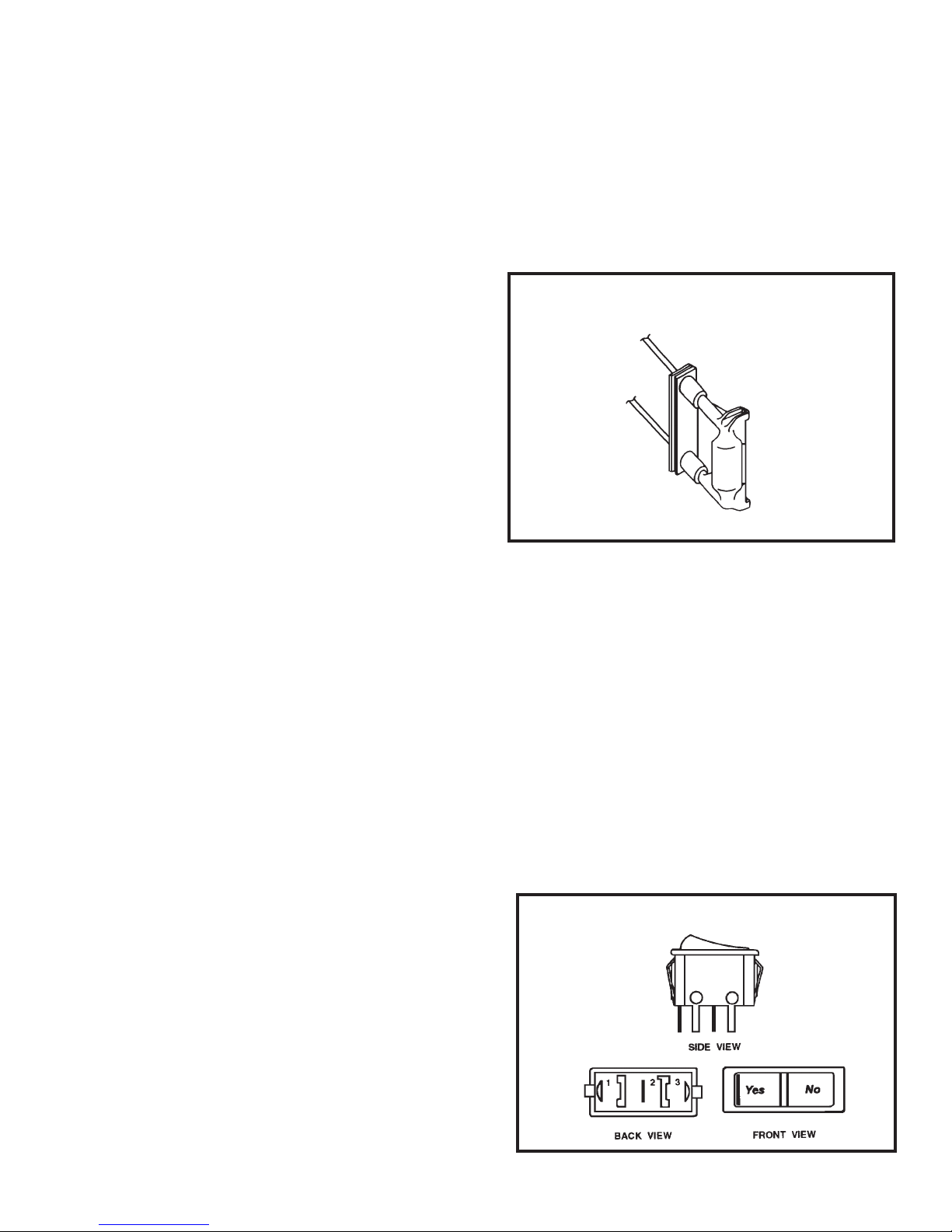

MONEYSAVER® SWITCH

(Rocker Switch) - (See Figure 18)

This rocker switch can be depressed to either

YES or NO. In the YES position you will get

the most economical operation. Both the fan

and compressor will cycle on and off together,

maintaining the selected temperature at a more

constant level and reducing the humidity more

efciently in the cooling mode. This control will

only operate when the unit is in a cooling or

heating mode. In the NO position, the fan will

run constantly as long as the unit is in the cooling

or heating mode.

FIGURE 18 ROCKER SWITCH

Page 15

Page 17

TEST:

Disconnect the leads from the switch. Depress

the switch to the function being tested.

1. When YES is selected, there should be

continuity between terminals "1" and "2."

2. When NO is selected, there should be

continuity between terminals "2" and "3."

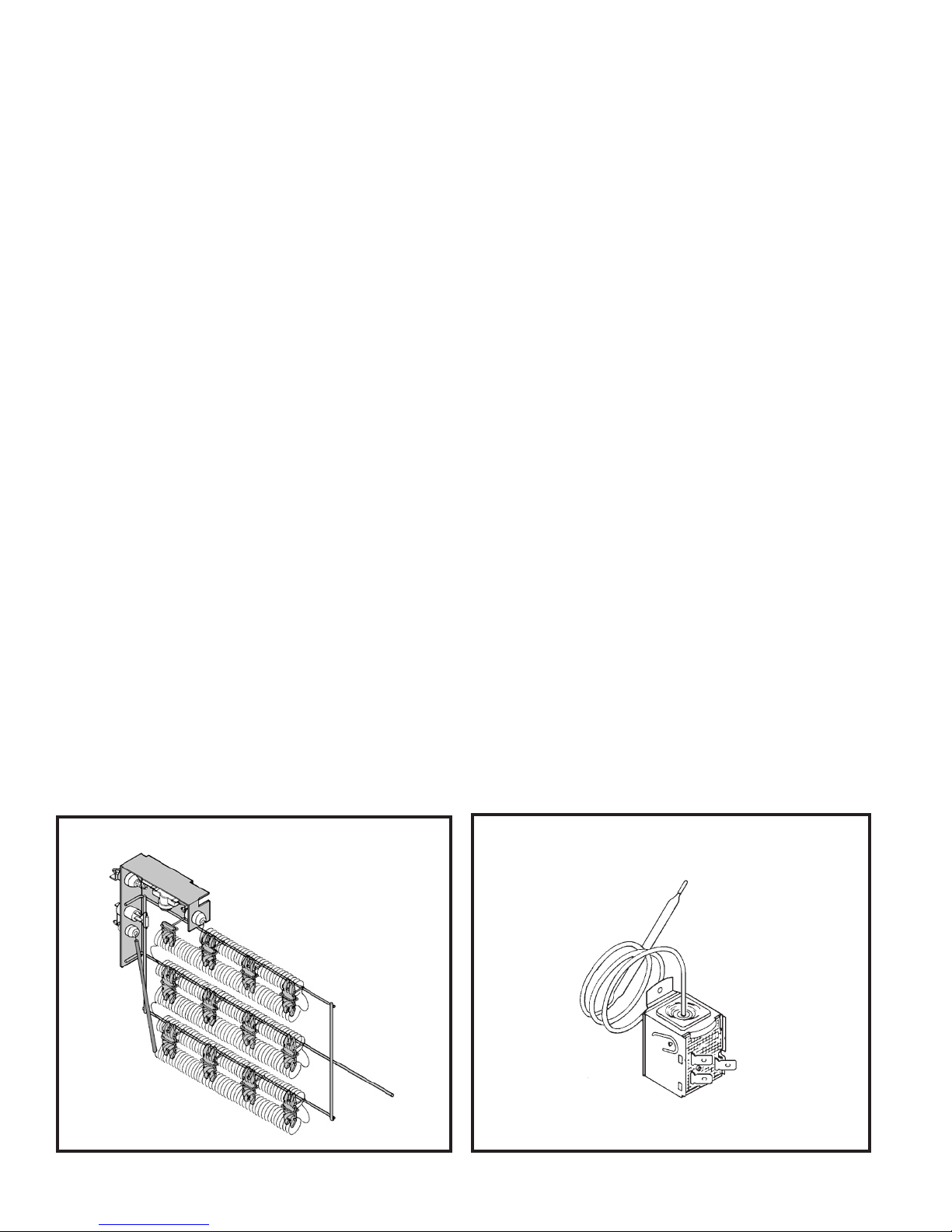

HEATING ELEMENT - (See Figure 19)

The control is designed to open at 110°F ± 6°F.

Test continuity below 110°F and for open above

110°F.

The heating element for the "Y" model is energized

by an outdoor thermostat. The outdoor thermostat

is adjusted at a predetermined temperature to

bring on the heating element and turn off the

compressor. The room thermostat will then

control the cycling of the element when the

selected indoor temperature is reached.

All electric heat models are equipped with a 3.3

KW heating element.

The heating element contains a fuse link and a

heater limit switch. The fuse link is in series with

the power supply and will open and interrupt the

power when the temperature reaches 161.6°F,

or a short circuit occurs in the heating element.

Once the fuse link separates, a new fuse link

must be installed. NOTE: Always replace with

the exact replacement.

The heater element has a high limit control. This

control is a bimetal thermostat mounted in the top

of the heating element.

Should the fan motor fail or lter become clogged,

the high limit control will open and interrupt

power to the heater before reaching an unsafe

temperature condition.

Testing of the elements can be made with

an ohmmeter across the terminals after the

connecting wires have been removed. A cold

resistance reading of approximately 14.5 ohms

for the 3.3 KW heater, should be registered.

DEFROST THERMOSTAT

(Heat Pump Models Only)

This thermostat (Figure 20) is single pole-double

throw with contacts between terminals "2" and "3"

closing on temperature rise and contact between

terminals "2" and "1" closing on temperature

fall.

This control is a dual purpose control that acts as

an outdoor thermostat and defrost control.

When the sensing bulb, attached to the condenser

FIGURE 19 HEATING ELEMENT

Page 16

FIGURE 20 DEFROST THERMOSTAT

(Heat Pump Models)

613-503-13

coil, senses enough icing on the outdoor coil, it

will interrupt power to the compressor until the

coil temperature reaches above 43 degrees, then

the unit will resume operating in the reverse cycle

mode.

The fan motor will not turn off when defrost occurs,

and the 4-way valve will not reverse.

DEFROST BULB LOCATION

(Heat Pump Models Only)

1. Disconnect power to the unit.

2. Disconnect the coil leads.

3. Attach the probes of an ohmmeter to each coil

lead and check for continuity.

WARNING: Do not start the unit with the solenoid

coil removed from the valve, or do not remove the

coil after the unit is in operation. This will cause

the coil to burn out.

The defrost control bulb must be mounted

securely and in the correct location to operate

properly (See Figure 21).

SOLENOID COIL

(Heat Pump Models Only)

The solenoid coil is an electromagnetic type coil

mounted on the reversing valve and is energized

during the operation of the compressor in the

heating cycle.

Should the reversing valve fail to shift during the

heating cycle, test the solenoid coil. Also, refer

to the Touch Test Chart on Page 25.

TO TEST:

FIGURE 21 DEFROST THERMOSTAT

BULB LOCATION

(All Heat Pump Models)

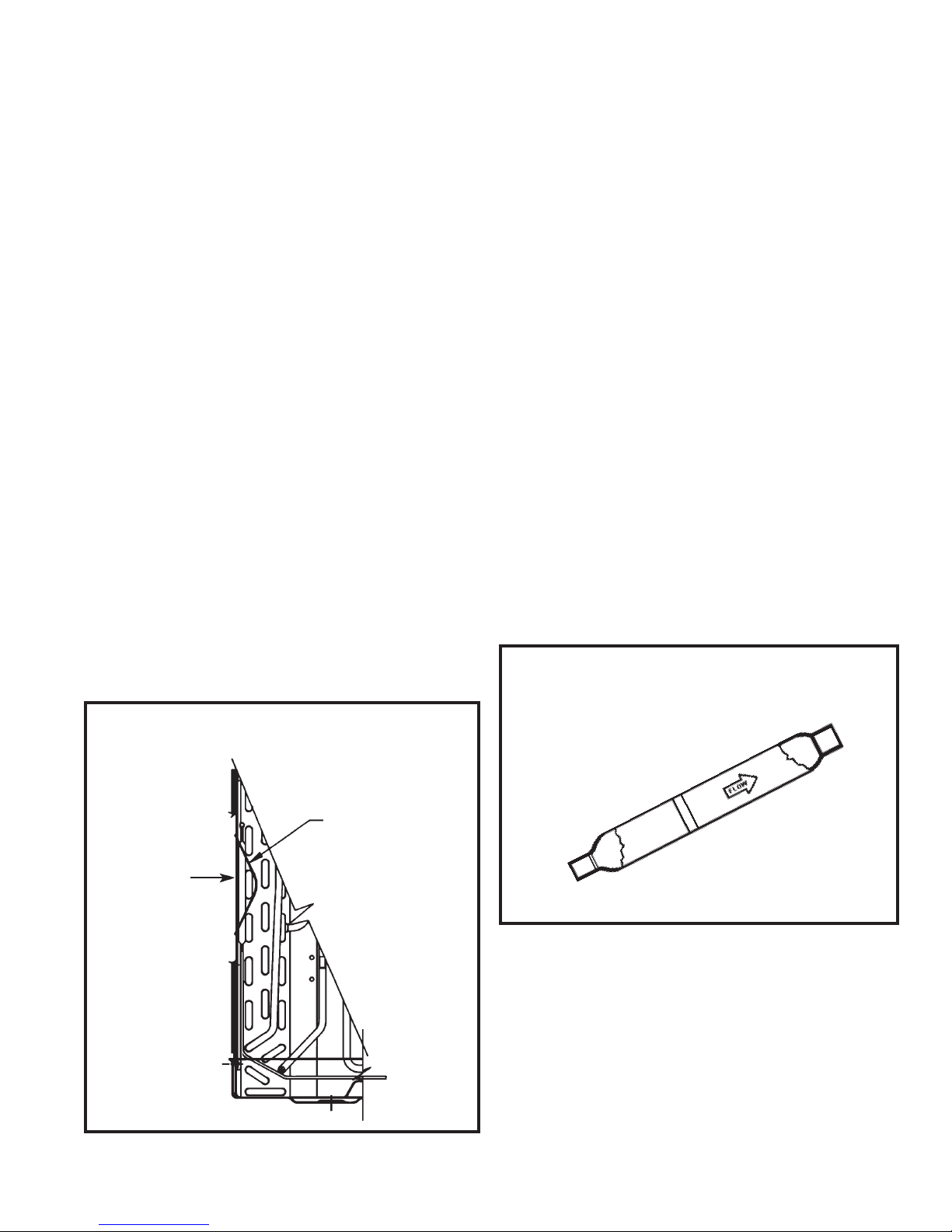

CHECK VALVE - (Figure 22)

(Heat Pump Models Only)

A one-way check valve is installed in the capillary

tube circuit to allow the ow of refrigerant through

both tubes in the evaporator during the cooling

mode.

In the heating mode, one capillary is closed by

the check valve to allow ow through one capillary

only to the condenser.

FIGURE 22 ONE–WAY CHECK VALVE

(Heat Pump Models)

SLIDE BULB

END OF THERMOSTAT DEFROST UNDER

RETAINER AS

SHOWN

RETAINER

618-244-00

NOTE: The slide (check) inside the valve is made

of teon. Should it become necessary to replace

the check valve, place a wet cloth around the

valve to prevent overheating during the brazing

operation. The ow arrow on the valve must point

towards the evaporator.

Page 17

Loading...

Loading...