Friedrich VHA24K25, VEA24K25, VHA24K34, VEA24K34, VHA24K50 Installation & Operation Manual

...Page 1

INSTALLATION &

OPERATION GUIDE

920-159-02 (10-04)

VERT-I-PAK® A-SERIES

SINGLE PACKAGE

VERTICAL AIR

CONDITIONING SYSTEM

24,000 BTU/h

Page 2

920-159-02 (10-04)

Table of Contents

Installation Recommendations ......................................................................................................................................................... 3

I. General Specifi cations

Model Number Identifi cation Guide ................................................................................................................................... 4

VERT-I-PAK Chassis Specifi cations ...................................................................................................................................4

II. Installation

1. Utility Closet Dimensions ................................................................................................................................................... 5

2. Wall Plenum & Architectural Louver Installation ................................................................................................................ 6

3. Electrical Information ..................................................................................................................................................... 7-9

4. Indoor Re turn Air Grille Installation .................................................................................................................................. 10

5. Ductwork Preparation and CFM ....................................................................................................................................... 11

6. Chassis Installation .......................................................................................................................................................... 11

7. Chassis Final Connections (Electrical, Duct, Drain & Wall Thermostat) ............................................................................ 12

8. Final Installation Checklist ............................................................................................................................................... 12

III. Chassis Operation

9. Thermostat Control ..........................................................................................................................................................12

10. Low Ambient Protection for Compressor & Fan ................................................................................................................ 12

11. Heating Defrost (Heat Pump Models only) ........................................................................................................................ 12

12. Fresh Air Door ...................................................................................................................................................................13

13. Condensate Disposal System ..........................................................................................................................................13

IV. Service, Maintenance & Warranty

14. Servicing / Chassis Quick Changeouts ............................................................................................................................. 13

15. Routine Maintenance .......................................................................................................................................................13

16. Warranty .......................................................................................................................................................................... 14

V. Vert-I-Pak Accessories ....................................................................................................................................................15

Please read this manual thoroughly prior to equipment installation or operation. It is the installer’s

responsibility to properly apply and install the equipment. Installation must be in conformance with

the NFPA 70-2002 National Electric Code or current edition and Universal Mechanical Code current

edition and applicable local or national codes.

Proper installation is not diffi cult but it is essential.

2

Page 3

920-159-02 (10-04)

Vert-I-Pak Installation Recommendations

For proper unit performance and maximum operating life please refer to the minimum installation clearances

below.

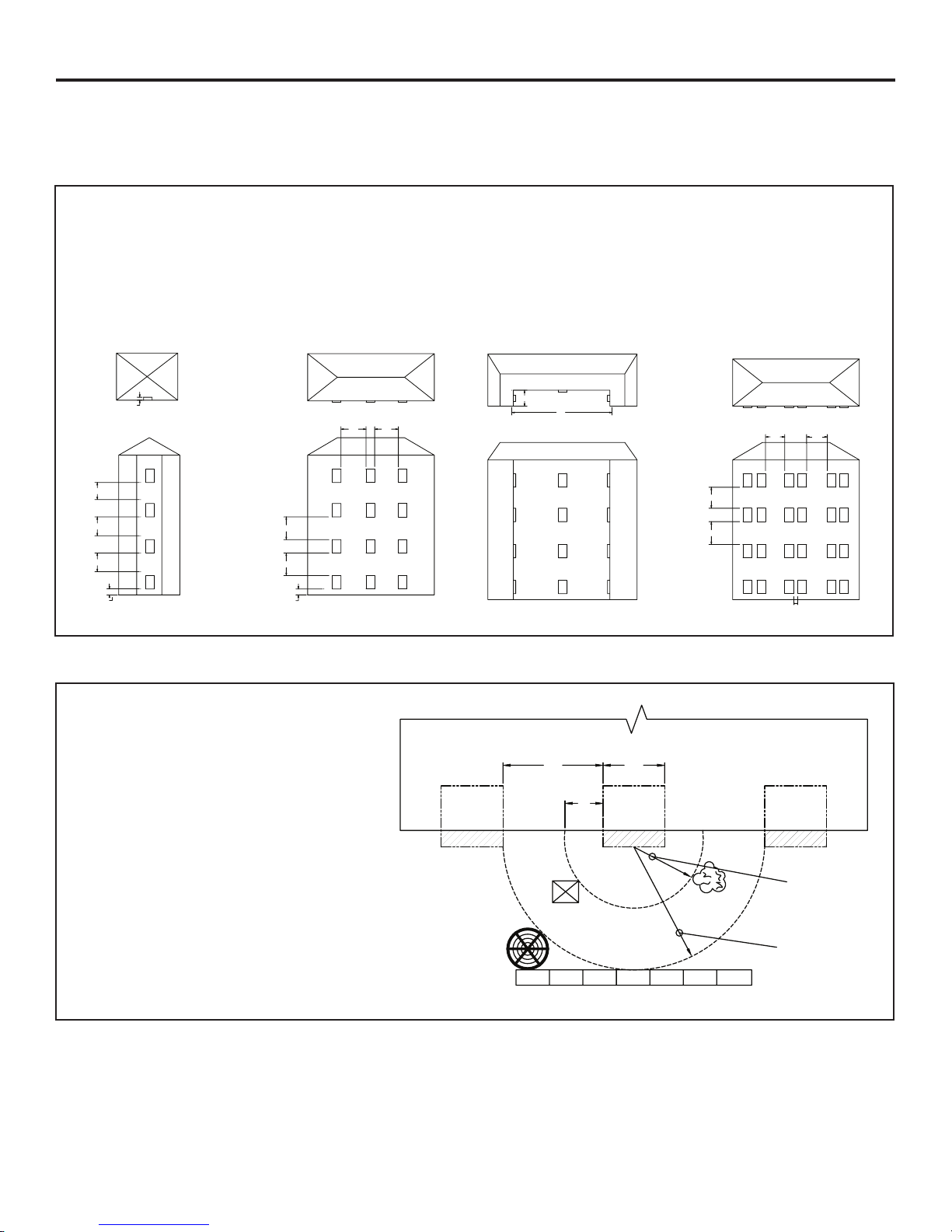

Fig ure 1

VERT-I-PAK® units must be installed on an outside wall. Confi ned spaces and/or covered areas should be

avoided. Units should be installed no closer than 12" apart when two units are side by side. If three of more

units are to operate next to one another allow a minimum of 60" between units or pairs of units. Also, a vertical

clearance of 60" should be maintained between units. Units installed on the bottom fl oor should be mounted

at least 6" off of the ground.

6"

SMALL RECESS OK

60"

60"

60"

60" 60"

60"

60"

B

A

LARGER RECESS OK. IF A> 5xB

60"

60"

60"60"

6"

6"

Fig ure 2

Any time obstructions are present use

the following guidelines for proper

spacing from the VERT-I-PAK louver:

• For minor obstructions such as lamp

poles or small shrubbery a clearance

of 24" from the outdoor louver should

be maintained.

• For major obstructions such as a solid

fence, wall or other heat rejecting

device like a condensing unit, a minimum distance of 72" should be kept.

BUILDING

24"60"

VPAK VPAK VPAK

OUTDOOR

CONDENSING

UNIT

12"

POLE

MAJOR OBSTRUCTION

SHRUB

12"

24"

72"

FENCE

The above suggestions are for reference only and do not represent all possible installations. Please contact the factory

for information regarding affects of other installation arrangements.

By following these simple recommendations you can be confi dent that your Friedrich Vert-I-Pak

of worry-free operation.

®

will provide years

3

Page 4

920-159-02 (10-04)

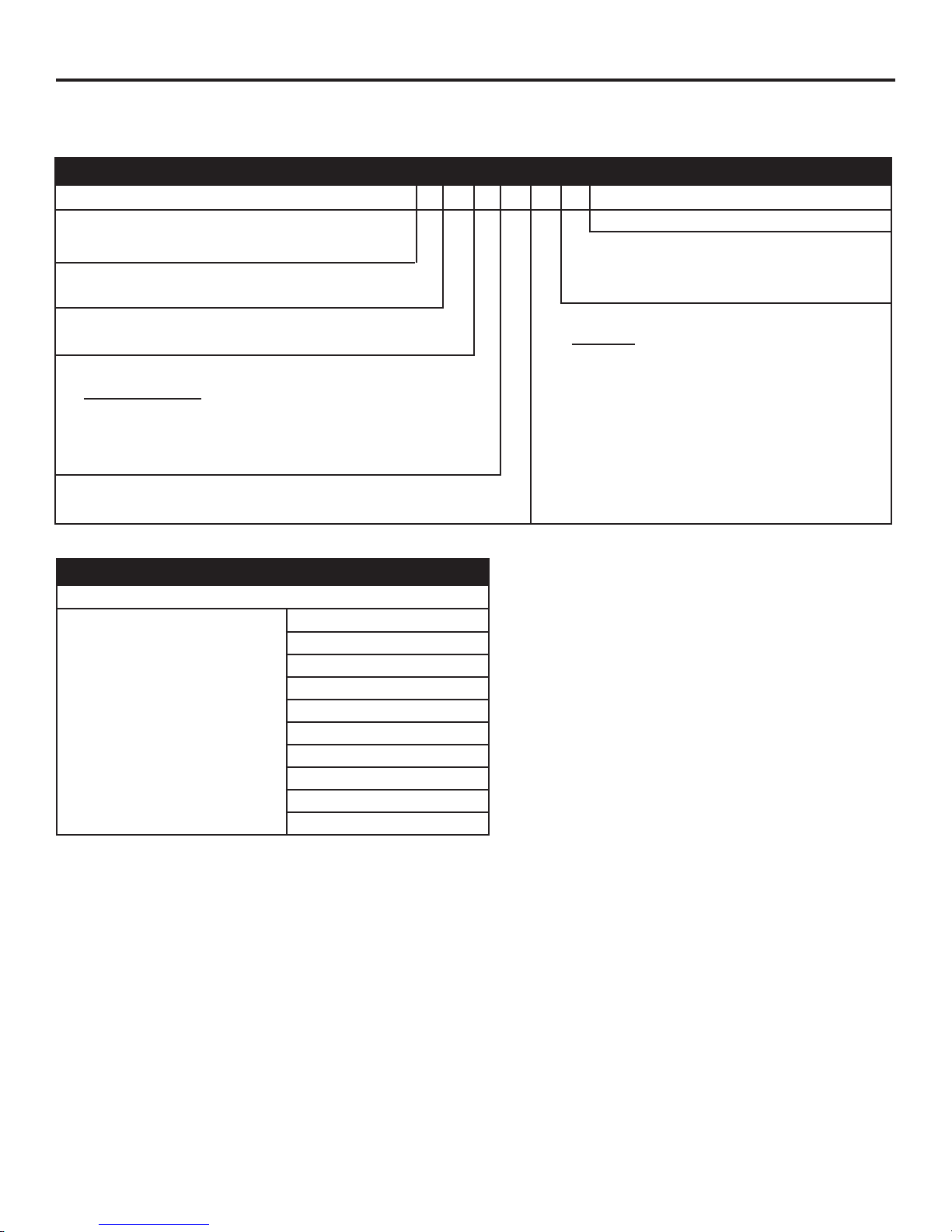

Section I. General Specifi cations

VERT-I-PAK® MODEL IDENTIFICATION GUIDE

MODEL NUMBER V E A 24 K 50 RT A

SERIES

V=Vertical Series

E=Cooling with or without electric heat

H=Heat Pump

EN GI NEER ING CODE

OPTIONS

RT = Stan dard Re mote Op er a tion

SP = Sea coast Pro tect ed

DESIGN SERIES

A = 32" and 47" Cabinet

NOMINAL CAPACITY

A-Series (Btu/h)

09 = 9,000

12 = 12,000

18 = 18,000

24 = 24,000

VOLTAGE

K = 208/230V-1Ph-60Hz

Vert-I-Pak® Chassis Specifications

MODEL: V(E,H)A24

Voltage ( V) 230/208

Refrigerant R-22

Chassis Width 23.125

Chassis Depth 23.125

Chassis Height ** 47.25

Supply Duct Collar *** 10"

Drain Connection 3/4" FPT

Min. Circuit Amps See Nameplate

CFM Indoor See chart, pg. 11

Max. Duct ESP .4 in. water

ELECTRIC HEATER SIZE

A-Series

00 = No electric heat

25 = 2.5 KW

34 = 3.4 KW

50 = 5.0 KW

75 = 7.5 KW

10 = 10 KW

NOTES:

** Height includes 2" duct collar & isolators under unit.

*** Factory collar accepts 10" fl ex duct.

4

Page 5

920-159-02 (10-04)

II. Installation

1) Utility Closet Dimensions

Recommended utility closet dimensions and a typical indoor installation are illustrated in Figure 1. Three inches minimum clearance on

three sides of the unit must be allowed for return airfl ow, installation access and service access. See Figures 1 & 2 for clear anc es and

ref er ence di men sions.

Fig ure 3

Typical Utility Closet

Chassis Shown in Closet, on Optional Platform

Field-supplied

Filter (25" x 20")

29"

VPRG4 Access Panel &

Return Air Filter Grille

58"

Power

Disconnect

Optional field

installed drain pan

(refer to local codes)

Optional Platform

3" Clearance on all

three sides minimum for

service and installation

Rigid Ductwork

Chassis is

shipped with

vibration

isolators

installed

Exterior Wall

Flexible Ductwork

VPAWP1-8/1-14 Wall Plenum

Plenum

VPDP1 drain pan

beneath unit is

required on all

VEA/VHA24 units.

Drain pan must be

installed prior to

chassis installation

Fig ure 4

control box

Top View

electrical

entrance

Vert-I-Pak Chassis 2-ton dimensions:

•

23" wide x 23" deep x 47 1/4" high.

VPAWP1-8/1-14 Wall Plenum cut-out

•

dimensions 24 5/8" wide x 30 7/8" high.

VPRG4 Access Panel cutout dimensions:

•

27" wide by 55 3/4" high.

See Figure 8 (Page 10) for proper

•

chassis installation.

NOTE: Drain pan must be installed in closet prior to chassis

insertion into plenum. See Figure 7 (page 8) for drain pan

installation details.

5

Page 6

920-159-02 (10-04)

2) Wall Plenum and Architectural Louver Installation

A. Install the wall plenum (VPAWP1-8/1-14) components in accordance with the in stal la tion instructions provided with each accessory.

IMPORTANT REMINDER: FRIEDRICH WALL PLENUM IS NOT DESIGNED TO CARRY STRUCTURAL

LOADS. PROPER WALL HEADER CONSTRUCTION IS REQUIRED. THE PLENUM RE QUIRES

PROP ER FLASHING, SHIM AND CAULK FOR A WEATH ER RESISTANT INSTALLATION.

B. Ensure that the divider is adjusted properly for the depth of the wall in accordance with the accessory installation manual

Fig ure 5

Wall Ple num & Outdoor Louver In stal la tion

Proper Flashing

Proper Caulking

Proper Header

Outside Wall

Caulk all 8

fl ange cor ners

Inside Wall Plenum

(Part B)

Proper Caulking

Architectural louver VPAL2 mounted

on the outside wall plenum (Part A)

Rough opening dimension 24 5/8" wide x 30 7/8" high.

•

Ensure that the bottom of the plenum is 1 1/2" from the fl oor of the closet. Note: 9,000 / 12,000 / 18,000 installation

•

height may be different. Refer to specifi c installation manual for clarifi cation.

For proper airfl ow, maintain a minimum distance of 12" between Vert-I-Pak units. Consult the factory for any

•

installation or application questions.

6

Proper Flashing

Page 7

3) Electrical Information

Electrical Data

920-159-02 (10-04)

MODEL

VHA/VEA24K25

230/208 230/208 230/208 230/208 230/208 230/208

68 68 68 68 68 68

Cooling Current (A)

MIN. Ckt. Amps (A)

Max Branch Circuit Fust (Amps)

* Single circuit from main box. Based on copper wire, single in su lat ed conductor at 60°C.

NOTE: Use copper conductors ONLY. Wire sizes are per NEC. Check local codes for over seas applications.

13.7/12.4 13.7/12.4 13.7/12.4 13.7/12.4 13.7/12.4 13.7/12.4

17.2/15.9 22.1/20.3 30.7/28.1 44.3/40.3 57.9/52.7 15.6/15.6

25/25 25/25 35/30 45/45 60/60 20/20

HARD WIRED

Recommended Branch

14/14 12/12 8/10 6/6 4/6 14/14

AWG - American Wire Gauge

Voltage ( V)

LRA - Comp. (A)

Power Connection

Circuit Wire Sizes*

VHA/VEA24K34

VHA/VEA24K50

VHA/VEA24K75

VHA/VEA24K10

VHA/VEA24K00

Sample Name plate (see your chassis name plate)

SAMPLE

7

Page 8

IMPORTANT: ALL 208/230V CHASSIS MUST BE HARD WIRED WITH PROPERLY SIZED

BREAKER. SEE NAMEPLATE FOR SPECIFIC CHASSIS ELECTRICAL REQUIREMENTS.

SEE PAGE 9 - FIGURE 8 FOR UNIT WIRING AND WALL THERMOSTAT WIRING. SEE PAGE

7 FOR WIRE SIZE. USE HACR TYPE BREAKERS TO AVOID NUISANCE TRIPS. ALL FIELD

WIRING MUST BE DONE IN ACCORDANCE WITH NEC AND LOCAL CODES.

3) Electrical Information (continued)

Figure 6

Electrical Requirements

Note: All fi eld wiring must comply with NEC and local codes. It

is the responsibility of the installer to insure that the electrical

codes are met.

920-159-02 (10-04)

CAUTION

Wire Size

Fuse /Circuit

Breaker

Grounding

Wire Sizing

Use ONLY wiring size recommended for single

out let branch circuit.

Use ONLY type and size fuse or HACR circuit

breaker indicated on unit's rating plate (See sample

on page 6). Proper current protection to the unit is

the responsibility of the own er.

Unit MUST be grounded from branch circuit to

unit, or through separate ground wire provided on

permanently connec ted units. Be sure that branch

circuit or general purpose outlet is ground ed.

Use recommended wire size given in tables and

install a single branch circuit. All wiring must comply

with local and national codes. NOTE: Use copper

conductors only.

Figure 7

Drain Connection

and Location

Elec tric shock haz ard.

Turn OFF ele c tric pow er be fore service

or in stal la tion.

All electrical connections and wir ing MUST

be in stalled by a qual i fi ed elec tri cian and

con form to the Na tion al Elec tri cal Code and

all local codes which have ju ris dic tion.

Failure to do so can result in prop er ty

damage, per son al injury and/or death.

CAUTION: THE ACCESSORY DRAIN PAN

(VPDP1) MUST BE INSTALLED BEFORE

INSTALLING THE UNIT.

1. The accessory drain pan has two (2)

provisions (left & right) for connecting an

external condensate drain.

2. A fi eld supplied condensate drain system

must be connected to one of the two 3/4"

FPT connections.

3. The remaining connection must be plugged

using the 3/4" pipe plug (provided) and fi eld

suppled tefl on tape or pipe joint compound.

4. Failure to follow these procedures may

result in serious property damage.

5. This is the primary drain pan. A fi eld supplied

secondary condensate pan may be applied.

Check with local codes.

8

Page 9

3) Electrical Data (continued)

Figure 8

Electrical & Thermostat Wiring Diagrams

RT2

THERMOSTAT

(FRONT)

920-159-02 (10-04)

FOR 208 VOLT MODELS ONLY

MOVE THE WHITE WIRE AS

SHOWN BELOW

BLACK

COM.

208V 240V

WHITE

THERMOSTAT CONNECTIONS

(EAR)

UP

G

R

R

W

Y

WHITE

BROWN

TERM BOARD

BROWN

YELLOW

YWRGBC

TRANSFORMER

24V

BLACK

B

C

RED

RED

c

CAPACITOR

WHITE

HERM

QUICK DISCONNECT

L1

BLACK

BLUE

COM.

TRANSFORMER

24V

208V

L2

WHITE

240V

GREEN

TO MOTOR

MOUNT

RED

WHITE

SEE NOTE #6

RED

GREEN

BLACK

BLACK

BLACK

CONDENSER

MOTOR

RED

BLACK

BLUE

RED

"F"

S

COMP WIRE HARNESS

R

C

"F"

"F"

COMPRESSOR

FAN

BLACK

BLUE

GREEN

RED

YELLOW

WHITE

123

COMPR RELAY

4

LOW AMBIENT

RED

BLACK

WHITE

BROWN

RED

COIL, SOLENOID

RED

BLACK

WHITE

CONTROL

WIRE NUT (RED)

WHITE

RED

PRESSURE

SWITCH

YELLOW

CAPACITOR

YELLOW

FAN

2 4

1 3

BLACK

c

HEATER

2.5 KW & 3.4 KW

5 KW

WHITE

FAN

RELAY

2

BLACK

BROWN

M

ER

H

RED

REV VALVE

4

31

RELAY

WHITE

BLUE

HEAT

RELAY

(2.5KW/3.4KW

2 4

1 3 123

BLACK

BLACK

RED

C

H

L

GREEN

BLOWER

MOTOR

5 KW)

T-STAT

DEFROST

INSULATOR

2-REQ'D

TO MOTOR

MOUNT

WIRE NUT (RED)

SEE NOTE #4

BLACK

7.5 KW & 10 KW

RED

RELAY

2 4

1 3

HEATER

HEAT

(2.5KW/3.4KW

5 KW)

BLACK

BLACK

RED

RED

HEAT

RELAY

(7.5KW/10KW) (7.5KW/10KW)

2

4

1

BLACK

BLACK

HEAT

RELAY

4

3

NOTE: THE DIAGRAM ABOVE ILLUSTRATES THE TYPICAL THERMOSTAT WIRING AND 208

VOLT TRANSFORMER WIRING. SEE THE UNIT CONTROL PANEL FOR THE ACTUAL

UNIT WIRING DIAGRAM AND SCHEMATIC.

9

Page 10

920-159-02 (10-04)

4) Indoor Return Air Grille Installation

There are three Indoor Return Air Grille options as shown in Figure 9. Choose the option that best suits your needs. Use the installation

instructions provided with accessories for installation details.

Figure 9

Return Air Grille Op tions

Option 1

VPRG4

Return Air Grille with Access Panel

A fi eld-supplied (25" x 20") fi lter is

mounted inside the hinged access door.

Option 2

All Vert-I-Pak chassis are shipped with a 20" x 14"

fi lter installed. If an accessory fi lter holder is to be

used, you MUST remove the factory shipped fi lter

from the chassis. Do NOT use two fi lters

VPRG2

Return Air Grille

Unit requires a fi eld-supplied

access door or panel and a

16" x 20" fi lter.

Notes:

A. These are the Friedrich recommended return air grille / fi lter / access panel arrangements. Consult the factory on other

arrangements. Im prop er return air arrangements will cause per for mance problems.

B. Return air arrangements are shown from the front, but can also be installed from the right or left side of the unit.

10

Page 11

920-159-02 (10-04)

5) Indoor Airfl ow Data

The Vert-I-Pak A series units must be installed with a free return air

confi guration. The table below lists the indoor airfl ow at corresponding

static pressures. All units are shipped from the factory and are rated

at low speed.

To change to high speed replace the low speed lead (blue) with the

high speed lead (black) on the blower relay.

VEA/VHA24K

Low High

.1” ESP 750 815

.2” ESP 725 780

.3” ESP 700 745

.4” ESP 675 700

Figure 10

Slide-in View / Chassis Installation

All values listed are inches

W.C. with a wet indoor coil

with fi lter installed.

6) Chassis Installation

NOTE: Prior to installing the chassis, ensure that the drain pan and

line are free from debris.

A. Ensure that the wall ple num is in stalled in ac cor dance with

the VPAWP1-8/1-14 Installation Manual.

B. Ensure that the VPDP1 drain pan is installed correctly (see

page 8). Using the 3/4" plugs supplied with the pan, plug

the unused condensate drain hole. Connect a drain to the

condensate exit location. Be sure to use tefl on tape or

approved pipe sealant on all drain connections and plugs

(see page 8).

C. Place the chassis into the closet with the outdoor side

facing the wall plenum opening.

D. Slide the chassis into the wall plenum until the plenum

divider seal is established and the factory-installed chassis

to plenum gasket has sealed to the top fl ange of the

plenum. (See Figure 10)

Chassis to

plenum gasket

The Vert-I-Pak chassis must be inserted into

the wall plenum so that the plenum divider

gas ket makes contact with the condenser

baffle in the unit. The chassis will fit

ap prox i mate ly 2

NOTE: Prior to installing the chas sis,

ensure that the drain pan and line are free

from debris.

3

/8" into the wall plenum.

23/

8

11

Page 12

920-159-02 (10-04)

7) Chassis Final Connections

With the chassis in place, you are now ready to begin chassis

connections:

A. Move the thermostat switches to "OFF" and "AUTO." This

will keep the ther mo stat from cy cling the chassis until fi nal

connections are com plete.

B. Connect the ductwork onto the 10" collar. Plas tic wireties (fi eld

sup plied) are suggested to se cu re the ductwor k in pla ce. U se

2 wire ties, one for each inner and outer fl ex duct sleeve.

D. For 208 Volt pow er o nly: y ou mu st mo ve t he tran s form er wire

as shown in Fig ure 8, Page 9.

RT2 Digital Thermostat

III. Chassis Operation

E. Review the Fi nal Installation Check list on Page 12 before

re plac ing the pow er quick dis con nect, reconnecting power

to the chassis, plug ging in the re mote ther mo stat har ness, or

op er at ing the chassis.

Electrical shock and moving parts hazard can cause injury

or death. If you have not done so, pull out the disconnect

head found on the front of chas sis before continuing installation! Disconnect external power at the breaker.

8) Final Installation Checklist

Correct line voltage?

Chassis deck level?

Plenum divider baffl e installed?

Wall plenum caulked? Level? Flashing?

HACR type breaker/fuse?

9) Remote Thermostat Control

The chassis requires a simple single stage heat-cool wall thermostat.

Each chassis comes with a terminal strip located in the electrical

control box. All internal chassis wiring (low & high voltage) is factory

ready for 230 Volt operation. For 208 Volt operation a single wire

MUST BE CHANGED ON THE TRANS FORM ER. Refer to Figure

8 on page 9.

10) Low Ambient Protection

Each chassis is equipped with Low Ambient Protection in the form of

a suction line thermostat. This thermostat will prevent compressor

operation at low suction line temperatures. Each chassis is also

equipped with a factory in stalled bellows that will drain water from

the base pan to prevent the fan slinger from freezing during winter

weather.

11) Heating Defrost (Heat Pump Models Only)

All Heat Pumps have a passive heating defrost system. Defrost

occurs as needed and automatically switches to electric heat during

defrost. When the outdoor ambient temperature drops below a 45°F

factory setting, the chassis au to mat i cal ly switch es to electric heat.

As outdoor ambient temperatures rise above 45°F, the chassis

returns to the heat pump mode. The changeover temperature

is user adjustable from approximately 32°F - 55°F. The defrost

thermostat may also be used to lock out the compressor in an

emergency heat situation.

Single circuit only?

Ductwork connected?

Chassis weather seal in place?

Wall thermostat wired correctly?

Chassis inserted into plenum?

12

Page 13

920-159-02 (10-04)

12) Fresh Air Door

The Fresh Air Door is an "intake" system. The fresh air door is

opened via a slide on the front of the chassis located just above

the indoor coil. Move the slide left to open and right to close the

fresh air door. The system is capable of up to 60 CFM of fresh air

@ ~.3" H20 internal static pressure.

13) Condensate Disposal System

The VPDP1 drain pan features two ¾ female PVC fi ttings to

attach a drain connection to on the left or right side of the drain

pan. Condensate piping can be routed to the left, right or beneath

the unit platform.

See page 8 or the drain pan installation manual for more

information.

Part 1: The system’s fi rst stage increases energy

effi ciency utilizing a factory installed fan that slings

the cold condensate onto the hot outdoor coil.

Part 2: When high outdoor humidity prevents the slinger

from disposing of all the condensate, the excess

condensate overfl ows into the condensate drain

pan and out of the ¾" internal drain connections.

Part 3: If Parts 1 & 2 fail for any reason, excess

condensate overfl ows from a spillway directly into

the wall plenum to the outside of the building. IF

THIS OCCURS, THIS IS YOUR WARNING THAT

THE CHAS SIS OR DRAIN NEEDS SERVICING.

15) Routine Maintenance

Performing Routine Maintenance

With the proper maintenance and care, your system will operate

economically and dependably. Maintenance can be accomplished

easily by referring to the following directions. However, before

performing any maintenance, consider these important safety

precautions:

WARNING: Electrical Shock Hazard. Before attempting any service

work or routine maintenance, turn off all electrical connections to

the unit. Failure to do so may result in property damage, personal

injury and/or death.

CAUTION: Although great care has been taken to minimize sharp

edges in the construction of your unit, be extremely careful when

handling parts or reaching into the unit.

Replace Air Filter

A dirty air fi lter reduces the effi ciency of your Vert-I-Pak and

allows lint and dirt to accumulate on the indoor-air coil. Lint and

dirt on the indoor-air coil can damage your unit and void the

warranty. The air fi lter should be replaced as it becomes dirty.

To replace the fi lter (chassis mounted return air fi lter):

1. Slide the fi lter clear of the fi lter rails.

2. Remove the fi lter.

3. Install new disposable fi lter.

CAUTION: Do not operate your system without a fi lter in place,

nor block the front of the unit return air opening.

IV. Service & Warranty

14) Servicing / Chassis Quick Changeouts

The chassis is designed for quick disconnect and change out. For

minor electrical service, the control box cover lifts straight up after

the screws & disconnect head are removed. For major electrical,

refrigeration and fan service the chas sis may be removed from

utility closet.

To Remove the Chassis from the Closet:

A. Switch the wall Ther mo stat off.

B. Pull the Power Disconnect located in the front of the chassis.

C. Disconnect the thermostat wiring harness.

D. Disconnect the electrical connection.

E. Disconnect the ductwork.

F. Slide the chassis out of the wall ple num.

G. Lift the chassis out of the utility closet.

Electrical shock and moving parts hazard can cause injury

or death. Pull out the disconnect head found on the front

of the chassis before servicing.

Inspect and Clean Indoor-air Coil

Eventually, minor amounts of lint and dirt may pass through the

fi lter and collect on the indoor-air coil. These minor accumulations

can be carefully vacuumed away with a brush attachment on

a vacuum cleaner. Care must be taken to avoid bending the

aluminum fi ns on the coil. Bent fi ns should be straightened using

a special fi n tool available from most HVAC service technicians.

Inspect Outdoor-air Intake and Exhaust

The unit’s outdoor-air intake and outdoor-air exhaust paths must

remain clear. Check the OA exhaust frequently. Keep it free of all

debris, snow, or ice. The OA intake should also be kept free of

obstructions. Blocking the OA exhaust or OA intake opening will

reduce the effi ciency of your unit, could damage it, and may void

your warranty.

Inspect and Clean Condensate Drain

The condensate drain must be routed to a suitable drainage

area. Check the unit condensate drain periodically. Keep it free of

anything that may block or impede the fl ow of condensate water.

If there is any accumulation of foreign matter in the drain pipe, it

should be removed and cleaned. The entire drain line must be

protected from freezing.

16) Warranty

All service work must be done by a qualifi ed servicer. See Warranty

on the next page, and consult your dealer or contractor for details

13

Page 14

920-159-02 (10-04)

Friedrich Air Conditioning Company

P.O. Box 1540

San Antonio, TX 78295

210.357.4400

www.friedrich.com

VERT-I-PAK® A SERIES

SINGLE PACKAGE VERTICAL AIR CONDITIONERS

LIMITED WARRANTY

SAVE THIS CERTIFICATE.

province to province.

In the event that your unit needs servicing, contact your nearest authorized service center. If you do not know the nearest service

center, ask the company that installed your unit or contact us - see address and telephone number above. To obtain service

and/or warranty parts replacement, you must notify an authorized FRIEDRICH Air Conditioning Co. service center, distributor,

dealer, or contractor of any defect within the applicable warranty period.

When requesting service:

Unless specified otherwise herein,

FRIEDRICH VERT-I-PAK A SERIES VERTICAL AIR CONDITIONERS AND HEAT PUMPS

LIMITED WARRANTY - FIRST YEAR (Twelve (12) months from the date of installation).

the material or workmanship will be repaired or replaced free of charge by our authorized service center during the normal

working hours; and

LIMITED WARRANTY - SECOND THROUGH FIFTH YEAR (Sixty (60) months from the date of installation). ON THE

SEALED REFRIGERATION SYSTEM.

will be repaired or replaced free of charge (excluding freight charges) by our authorized service center during normal working

hours. The sealed refrigeration system consists of the compressor, metering device, evaporator, condenser, reversing valve,

check valve, and the interconnecting tubing.

It gives you specific rights, you may also have other rights which may vary from state to state and

please have the model

the following applies:

Any part of the sealed refrigeration system that is defective in material or workmanship

and serial number from your unit readily available.

Any part found to be defective in

These warranties apply only while the unit remains at the original site and only to units installed inside the continental

United States, Alaska, Hawaii, Puerto Rico and Canada. The warranty applies only if the unit is installed and operated in

accordance with the printed instructions and in compliance with applicable local installation and building codes and

good trade practices. For international warranty information, contact the Friedrich Air Conditioning Company International Division.

Any defective part to be replaced must be made available to

proof must be presented to establish the date of install, otherwise the beginning date of this certificate will be considered to be our

shipment date plus sixty days. Replacement parts can be new or remanufactured. Replacement parts and labor are only

warranted for any unused portion of the unit’s warranty.

We will not be responsible for and the user will pay for:

1. Service calls to:

A) Instruct on unit operation. B) Replace house fuses or correct house wiring. C) Clean or replace air filters. D) Remove

the unit from its installed location when not accessible for service required. E) Correct improper installations.

2. Parts or labor provided by anyone other than an authorized service center.

3. Damage caused by:

A) Accident, abuse, negligence, misuse, riot, fire, flood, or acts of God. B) Operating the unit where there is a corrosive

atmosphere containing chlorine, fluorine, or any damaging chemicals (other than in a normal residential environment). C)

Unauthorized alteration or repair of the unit, which in turn affects its stability or performance. D) Failing to provide proper

maintenance and service. E) Using other than a “Seacoast Protected” unit in a coastal environment. F) Using an

incorrect power source. G) Faulty installation or application of the unit.

We shall not be liable for any incidental, consequential, or special damages or expenses in connection with any use or

failure of this unit. We have not made and do not make any representation or warranty of fitness for a particular use or

purpose and there is no implied condition of fitness for a particular use or purpose. We make no expressed warranties

except as stated in this certificate. No one is authorized to change this certificate or to create for us any other

obligation or liability in connection with this unit. Any implied warranties shall last for one year after the original

purchase date.

above limitations or exclusions may not apply to you. The provisions of this warranty are in addition to and not a modification of

or subtraction from the statutory warranties and other rights and remedies provided by law.

Some states and provinces do not allow limitations on how long an implied warranty or condition lasts, so the

FRIEDRICH

in exchange for the replacement part. Reasonable

In case of any questions regarding the provisions of this warranty, the English version will govern.

14

(10-04)

Page 15

920-159-02 (10-04)

IV. Vert-I-Pak Accessories

MODEL DESCRIPTION PHOTO

WALL PLENUM Two-part sleeve that telescopes in and out

1

from 5

/2" to 8" in depth. The wall plenum sits inside the

VPAWP1-8

exterior wall penetration.

3

DIMENSIONS: 30

/8" high x 241/8" wide.

CUTOUT DIMENSIONS: 30

7

/8" high x 245/8" wide.

VPAWP1-14

VPAL2

VPSC2

RT2

VPRG4

Same as VPAWP1-8, but telescopes 8" to 14" as required.

ARCHITECTURAL LOUVER Extruded aluminum louver that

attaches to the outdoor section of the wall plenum.

1

DIMENSIONS: 31

/16" high x 259/16" wide.

Same as VPAL2 but can be ordered in a special color to

match the exterior wall.

DIGITAL THERMOSTAT Digital electronic thermostat with

"one touch" adjustment. Mounts to wall for control of unit.

ACCESS PANEL / RETURN AIR GRILLE – Serves as an

access panel to chassis and interior return air grille. A

field-supplied (25" x 20") filter is mounted inside the hinged

access door.

DIMENSIONS: 58" high x 29" wide.

CUTOUT DIMENSIONS: 55

3

/4" high x 27" wide.

RETURN AIR GRILLE – Interior return air grille that hinges

VPRG2

to allow a field supplied (16" x 20") filter to slip inside. Must

be used when an access door / panel already exists in

closet.

DIMENSIONS: 18

VPDP1

DRAIN PAN for VEA/VHA24 models. Drain pan may be

installed prior to chassis for easy installation/removal.

7

/16" high x 223/8" wide.

15

Page 16

Use Factory Certifi ed Parts.

FRIEDRICH AIR CONDITIONING CO.

Post Office Box 1540 · San Antonio, Texas 78295-1540

4200 N. Pan Am Expressway · San Antonio, Texas 78218-5212

(210) 357-4400 · Fax (210) 357-4480

www.friedrich.com

Printed in the U.S.A.

920-159-02 (10-04)

Loading...

Loading...