Friedrich TEC09R50, TEC15K50, THC15R50, THC15R34, THC15R25 Owner’s Manual

...

INSTALLATION

&

OPERATION

[_l,,IoHiI._.,5iIo][_]

WallMaster _Packaged Terminal

Air Conditioners

Packaged Terminal Heat Pumps

• Standard Unit

• Seacoast Protected Unit

• Remote Thermostat Unit

• Central Desk Control Unit

Table of Contents

Page

.

Installation Checklist .................................................................................................... 3

2.

3.

4.

9.

10.

11.

12.

13.

14.

15.

Electrical Requirements ............................................................................................... 3

Chassis Installation ...................................................................................................... 4

Unit Operation ............................................................................................................... 7

Temperature Limiting Thermostat ................................................................................ 7

.

Heating Control ............................................................................................................. 8

Fan Cycle Switch ........................................................................................................... 8

.

Vent Control ................................................................................................................... 8

Air Outlet Louver ........................................................................................................... 9

Startup Checklist ........................................................................................................... 9

Routine Maintenance .................................................................................................. 10

Appendix A: Remote Thermostat ............................................................................... 11

Appendix B: Central Desk Control ............................................................................. 15

Appendix C: Electrical Wiring Options For 265 Volt Models .................................... 17

Warranty ....................................................................................................................... 18

.... il

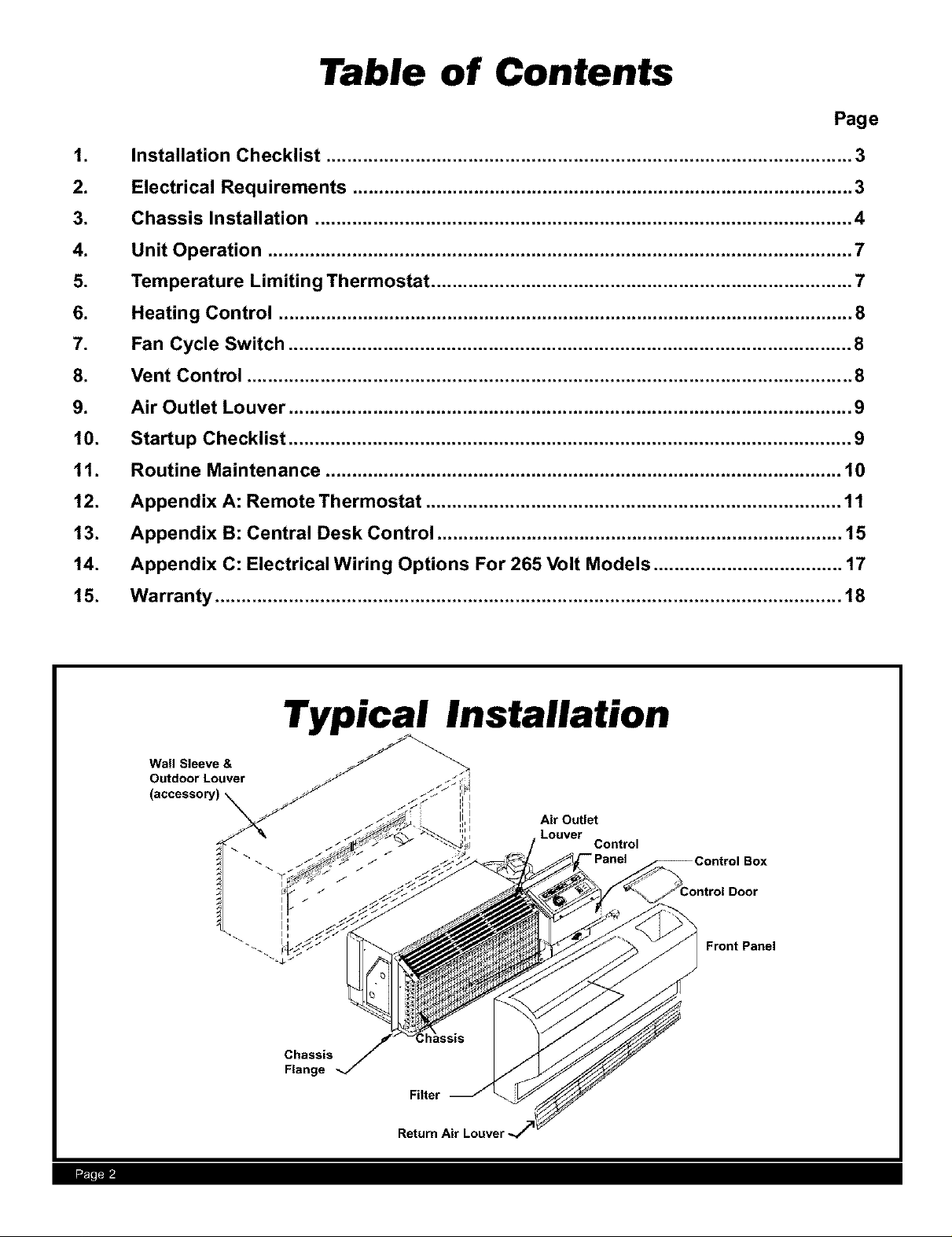

Typical Installation

Air Outlet

Louver

Chassis

Flange

Filter

Return Air Louver-

Control

Box

Front Panel

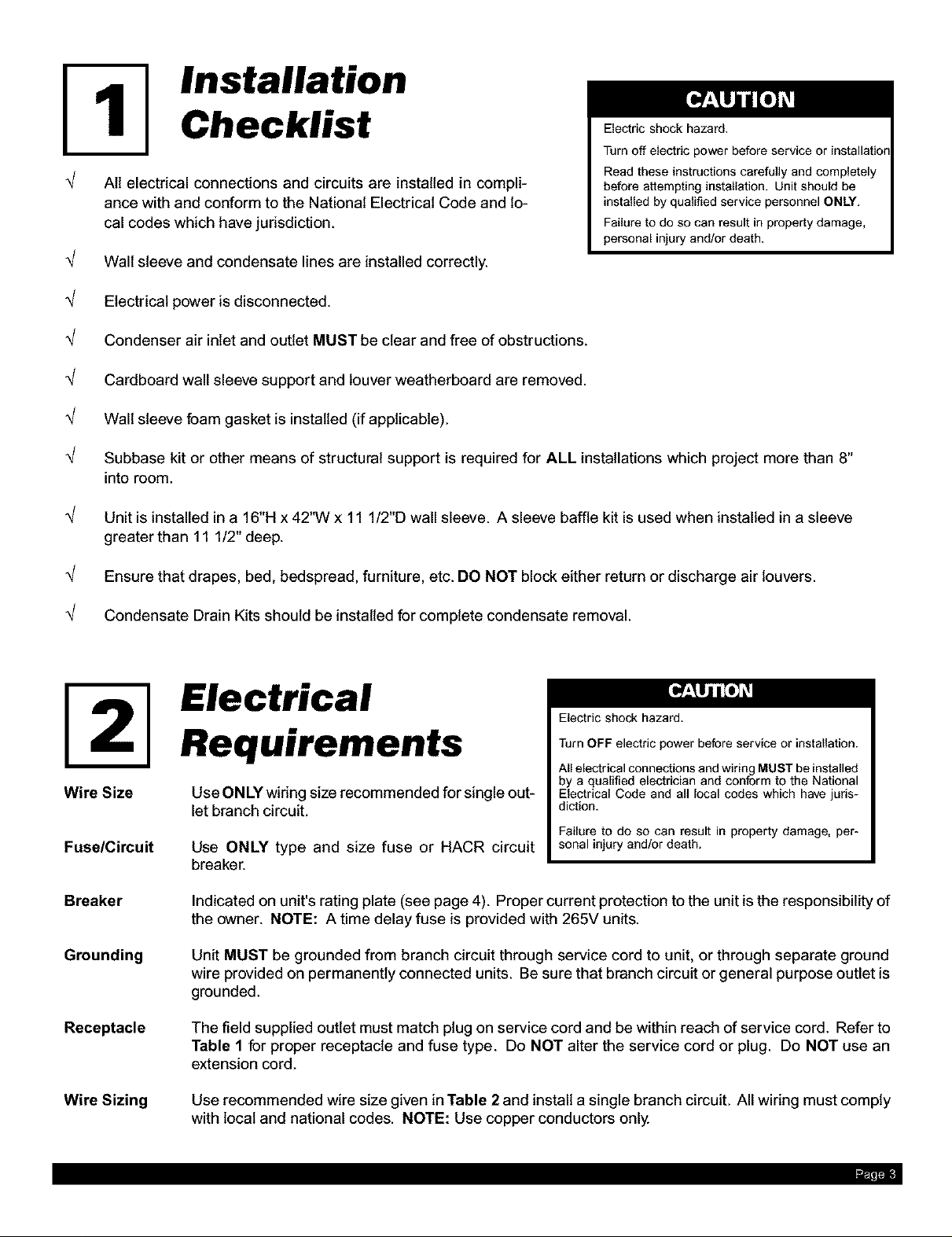

Installation

Checklist Electric shock hazard.

Turn off electric power before service or installaSor

All electrical connections and circuits are installed in compli-

ance with and conform to the National Electrical Code and lo-

cal codes which have jurisdiction.

_/ Wall sleeve and condensate lines are installed correctly.

_/ Electrical power is disconnected.

_/ Condenser air inlet and outlet MUST be clear and free of obstructions.

_/ Cardboard wall sleeve support and louver weatherboard are removed.

_/ Wall sleeve foam gasket is installed (if applicable).

_/ Subbase kit or other means of structural support is required for ALL installations which project more than 8"

into room.

_/ Unit is installed in a 16"H x42"Wx 11 1/2"D wall sleeve. A sleeve baffle kit is used when installed in a sleeve

greater than 11 1/2" deep.

Read these instructions carefully and completely

before attempting installation. Unit should be

installed by qualified service personnel ONLY.

Failure to do so can result in property damage,

personal injury and/or death.

_/ Ensure that drapes, bed, bedspread, furniture, etc. DO NOT block either return or discharge air louvers.

_/ Condensate Drain Kits should be installed for complete condensate removal.

Electrical

Electric shock hazard.

Turn OFF electric power before service or installation.

All electrical connections and wiring MUST be installed

by a qualified electrician and conform to the National

Electrical Code and all local codes which have juris-

diction.

Failure to do so can result in property damage, per-

sonal injury and/or death.

Wire Size

Fuse/Circuit

Breaker

Grounding

Receptacle

Requirements

Use ONLY wiring size recommended for single out-

let branch circuit.

Use ONLY type and size fuse or HACR circuit

breaker.

Indicated on unit's rating plate (see page 4). Proper current protection to the unit is the responsibility of

the owner. NOTE: A time delay fuse is provided with 265V units.

Unit MUST be grounded from branch circuit through service cord to unit, or through separate ground

wire provided on permanently connected units. Be sure that branch circuit or general purpose outlet is

grounded.

The field supplied outlet must match plug on service cord and be within reach of service cord. Refer to

Table 1 for proper receptacle and fuse type. Do NOT alter the service cord or plug. Do NOT use an

extension cord.

Wire Sizing

Use recommended wire size given in Table 2 and install a single branch circuit. All wiring must comply

with local and national codes. NOTE: Use copper conductors only.

rl'l

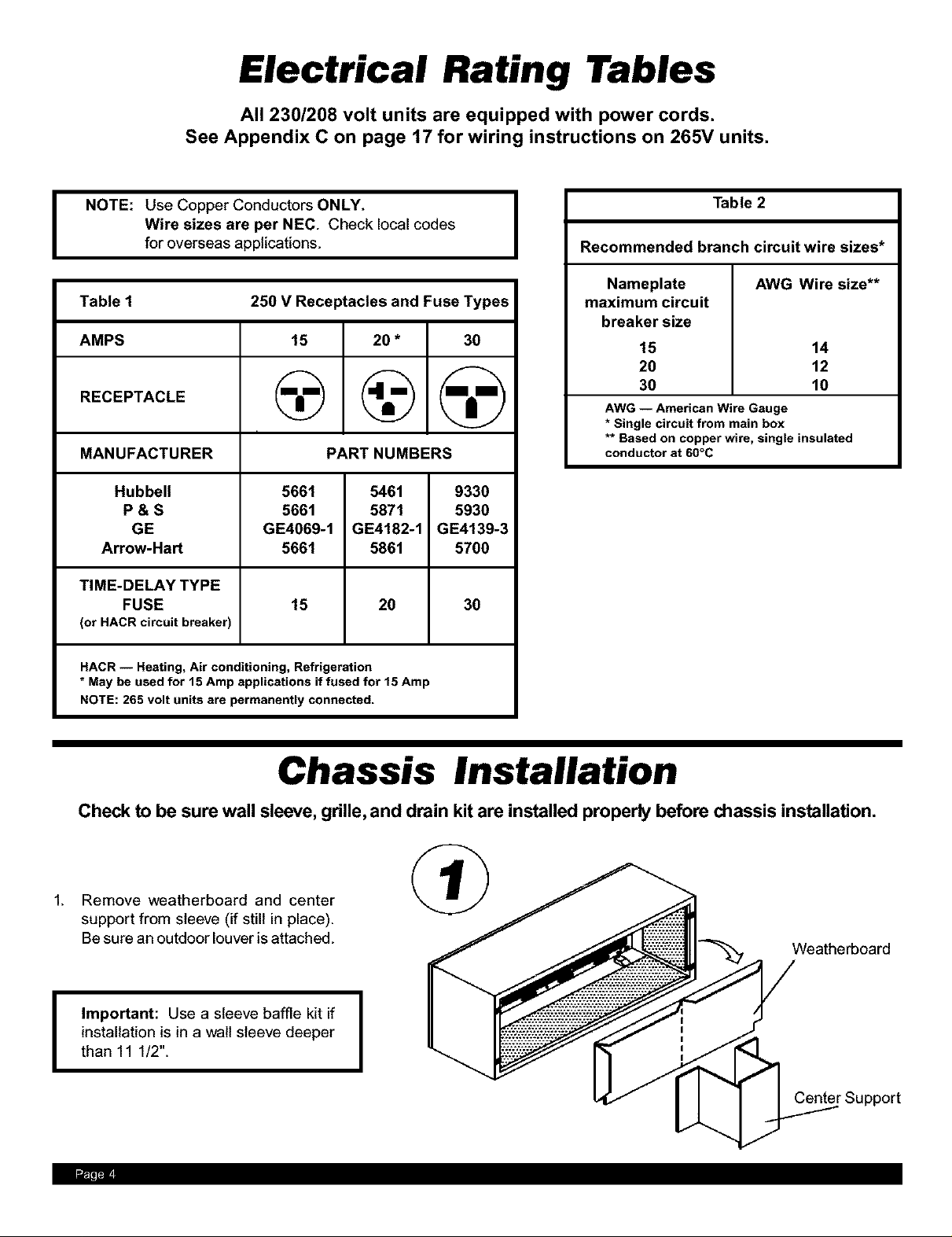

Electrical Rating Tables

All 230/208 volt units are equipped with power cords.

See Appendix C on page 17 for wiring instructions on 265V units.

I NOTE: Use Copper Conductors ONLY. I

Wire sizes are per NEC. Check local codes

for overseas applications.

Table 2

Recommended branch circuit wire sizes*

Table1

AMPS

RECEPTACLE

MANUFACTURER

Hubbell

P&S

GE

Arrow-Hart

TIME-DELAY TYPE

FUSE 30

(or HACR circuitbreaker)

HACR -- Heating, Air conditioning, Refrigeration

* May be used for 15 Amp applications if fused for 15 Amp

NOTE: 265 volt units are permanently connected.

250 V Receptacles and Fuse Types

15 20 *

@

PART NUMBERS

5661 5461

5661 5871

GE4069-1 GE4182-1

5661 5861

15 20

30

9330

5930

GE4139-3

5700

Nameplate

maximum circuit

breaker size

15

20

30

AWG --American Wire Gauge

* Single circuit from main box

** Based on copper wire, single insulated

conductor at 60°C

AWG Wire size**

14

12

10

Chassis Installation

Check to be sure wall sleeve, grille, and drain kit are installed properly before chassis installation.

Remove weatherboard and center

support from sleeve (if still in place).

Be sure an outdoor louver is attached.

Important: Use a sleeve baffle kit if

installation is in a walt sleeve deeper

I

than 11 1/2".

.... ?1'11

Weatherboard

Center Support

Suffocation hazard.

Keep bag away from babies and children.

2,

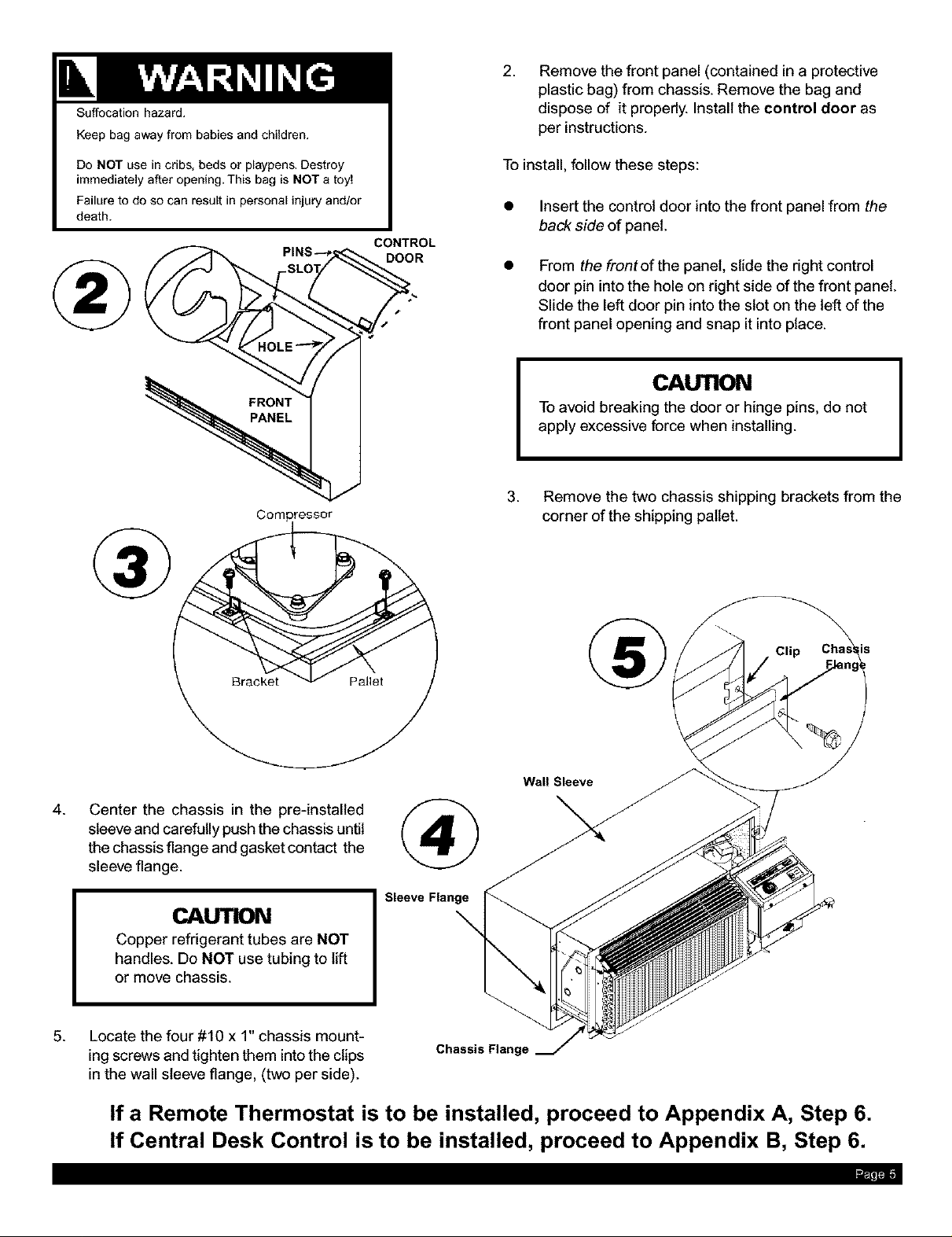

Remove the front panel (contained in a protective

plastic bag) from chassis. Remove the bag and

dispose of it properly. Install the control door as

per instructions.

Do NOT use in cribs, beds or playpens, Destroy

immediately after opening. This bag is NOT a toy!

Failure to do so can result in personal injury and/or

death.

PIN'( DOOR

Com#reseor

To install,follow these steps:

• Insert the control door into the front panel from the

back side of panel.

CONTROL

From the frontofthe panel, slide the right control

door pin into the hole on right side of the front panel.

Slide the left door pin into the slot on the left of the

front panel opening and snap it into place.

CAUTION

To avoid breaking the door or hinge pins, do not

apply excessive force when installing.

3. Remove the two chassis shipping brackets from the

corner of the shipping pallet.

4.

Center the chassis in the pre-installed

sleeve and carefully push the chassis until

the chassis flange and gasket contact the

sleeve flange.

CAUTION

Copper refrigerant tubes are NOT

handles. Do NOT use tubing to lift

or move chassis.

. Locate the four #10 x 1" chassis mount-

ing screws and tighten them into the clips

in the wall sleeve flange, (two per side).

If a Remote Thermostat is to be installed, proceed to Appendix A, Step 6.

If Central Desk Control is to be installed, proceed to Appendix B, Step 6.

®

Wall Sleeve

Sleeve Flange

\

Chassis Flange

rl'T

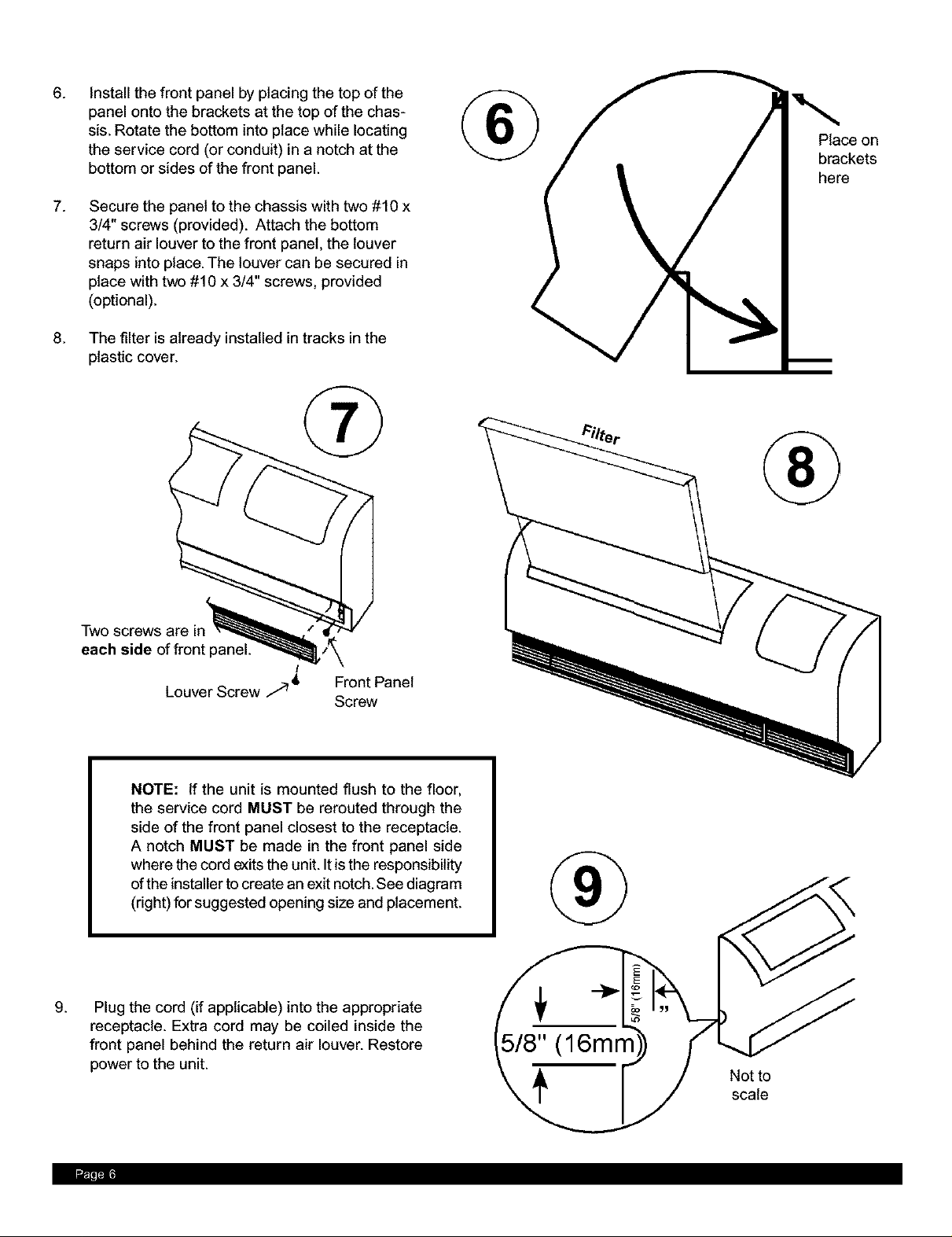

.

Install the front panel by placing the top of the

panel onto the brackets at the top of the chas-

sis. Rotate the bottom into place while locating

the service cord (or conduit) in a notch at the

bottom or sides of the front panel.

7.

Secure the panel to the chassis with two #10 x

3/4" screws (provided). Attach the bottom

return air louver to the front panel, the louver

snaps into place. The louver can be secured in

place with two #10 x 3/4" screws, provided

(optional).

.

The filter is already installed in tracks in the

plastic cover.

® Place on

brackets

here

®

Two

each side of front

!

Louver Screw 9 _ Front Panel

NOTE: If the unit is mounted flush to the floor,

the service cord MUST be rerouted through the

side of the front panel closest to the receptacle.

A notch MUST be made in the front panel side

where the cord exits the unit. It is the responsibility

ofthe installer to create an exit notch. See diagram

(right) for suggested opening size and placement.

g.

Plug the cord (if applicable) into the appropriate

receptacle. Extra cord may be coiled inside the

front panel behind the return air louver. Restore

power to the unit.

Screw

®

5/8" (16mm

Not to

scale

.... 711

Loading...

Loading...