INSTALLATION

&

OPERATION

[_l,,IoHiI._.,5iIo][_]

WallMaster _Packaged Terminal

Air Conditioners

Packaged Terminal Heat Pumps

• Standard Unit

• Seacoast Protected Unit

• Remote Thermostat Unit

• Central Desk Control Unit

Table of Contents

Page

.

Installation Checklist .................................................................................................... 3

2.

3.

4.

9.

10.

11.

12.

13.

14.

15.

Electrical Requirements ............................................................................................... 3

Chassis Installation ...................................................................................................... 4

Unit Operation ............................................................................................................... 7

Temperature Limiting Thermostat ................................................................................ 7

.

Heating Control ............................................................................................................. 8

Fan Cycle Switch ........................................................................................................... 8

.

Vent Control ................................................................................................................... 8

Air Outlet Louver ........................................................................................................... 9

Startup Checklist ........................................................................................................... 9

Routine Maintenance .................................................................................................. 10

Appendix A: Remote Thermostat ............................................................................... 11

Appendix B: Central Desk Control ............................................................................. 15

Appendix C: Electrical Wiring Options For 265 Volt Models .................................... 17

Warranty ....................................................................................................................... 18

.... il

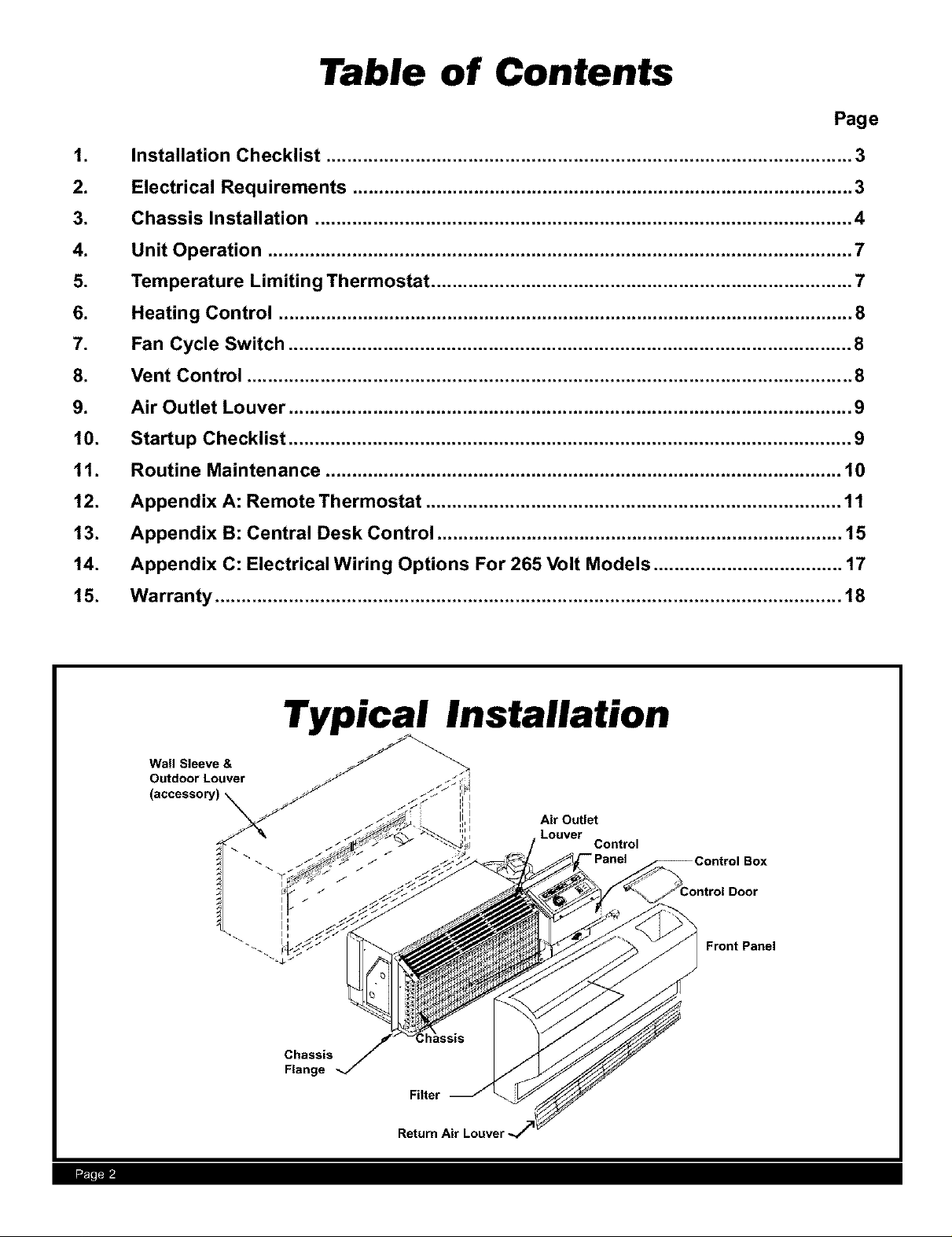

Typical Installation

Air Outlet

Louver

Chassis

Flange

Filter

Return Air Louver-

Control

Box

Front Panel

Installation

Checklist Electric shock hazard.

Turn off electric power before service or installaSor

All electrical connections and circuits are installed in compli-

ance with and conform to the National Electrical Code and lo-

cal codes which have jurisdiction.

_/ Wall sleeve and condensate lines are installed correctly.

_/ Electrical power is disconnected.

_/ Condenser air inlet and outlet MUST be clear and free of obstructions.

_/ Cardboard wall sleeve support and louver weatherboard are removed.

_/ Wall sleeve foam gasket is installed (if applicable).

_/ Subbase kit or other means of structural support is required for ALL installations which project more than 8"

into room.

_/ Unit is installed in a 16"H x42"Wx 11 1/2"D wall sleeve. A sleeve baffle kit is used when installed in a sleeve

greater than 11 1/2" deep.

Read these instructions carefully and completely

before attempting installation. Unit should be

installed by qualified service personnel ONLY.

Failure to do so can result in property damage,

personal injury and/or death.

_/ Ensure that drapes, bed, bedspread, furniture, etc. DO NOT block either return or discharge air louvers.

_/ Condensate Drain Kits should be installed for complete condensate removal.

Electrical

Electric shock hazard.

Turn OFF electric power before service or installation.

All electrical connections and wiring MUST be installed

by a qualified electrician and conform to the National

Electrical Code and all local codes which have juris-

diction.

Failure to do so can result in property damage, per-

sonal injury and/or death.

Wire Size

Fuse/Circuit

Breaker

Grounding

Receptacle

Requirements

Use ONLY wiring size recommended for single out-

let branch circuit.

Use ONLY type and size fuse or HACR circuit

breaker.

Indicated on unit's rating plate (see page 4). Proper current protection to the unit is the responsibility of

the owner. NOTE: A time delay fuse is provided with 265V units.

Unit MUST be grounded from branch circuit through service cord to unit, or through separate ground

wire provided on permanently connected units. Be sure that branch circuit or general purpose outlet is

grounded.

The field supplied outlet must match plug on service cord and be within reach of service cord. Refer to

Table 1 for proper receptacle and fuse type. Do NOT alter the service cord or plug. Do NOT use an

extension cord.

Wire Sizing

Use recommended wire size given in Table 2 and install a single branch circuit. All wiring must comply

with local and national codes. NOTE: Use copper conductors only.

rl'l

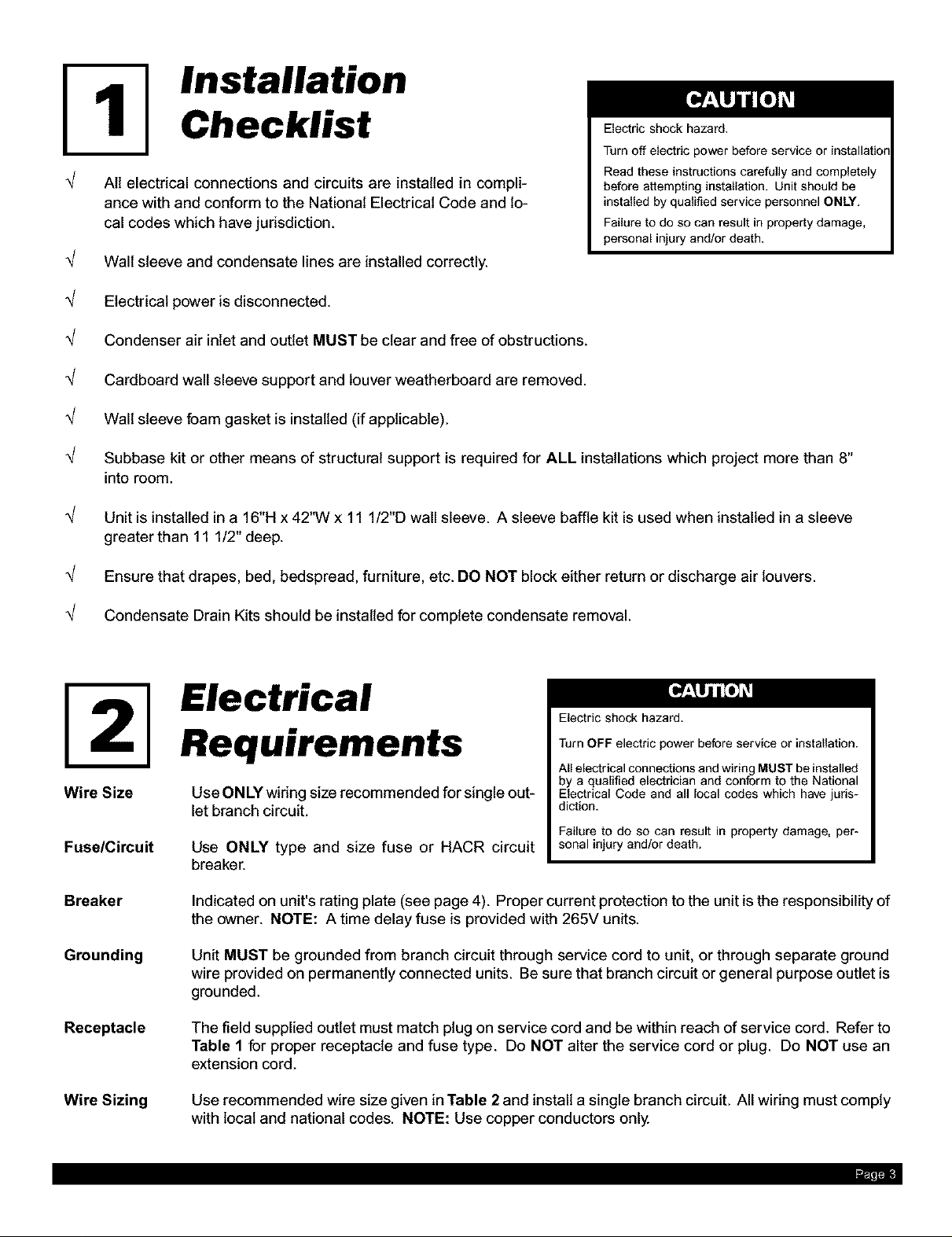

Electrical Rating Tables

All 230/208 volt units are equipped with power cords.

See Appendix C on page 17 for wiring instructions on 265V units.

I NOTE: Use Copper Conductors ONLY. I

Wire sizes are per NEC. Check local codes

for overseas applications.

Table 2

Recommended branch circuit wire sizes*

Table1

AMPS

RECEPTACLE

MANUFACTURER

Hubbell

P&S

GE

Arrow-Hart

TIME-DELAY TYPE

FUSE 30

(or HACR circuitbreaker)

HACR -- Heating, Air conditioning, Refrigeration

* May be used for 15 Amp applications if fused for 15 Amp

NOTE: 265 volt units are permanently connected.

250 V Receptacles and Fuse Types

15 20 *

@

PART NUMBERS

5661 5461

5661 5871

GE4069-1 GE4182-1

5661 5861

15 20

30

9330

5930

GE4139-3

5700

Nameplate

maximum circuit

breaker size

15

20

30

AWG --American Wire Gauge

* Single circuit from main box

** Based on copper wire, single insulated

conductor at 60°C

AWG Wire size**

14

12

10

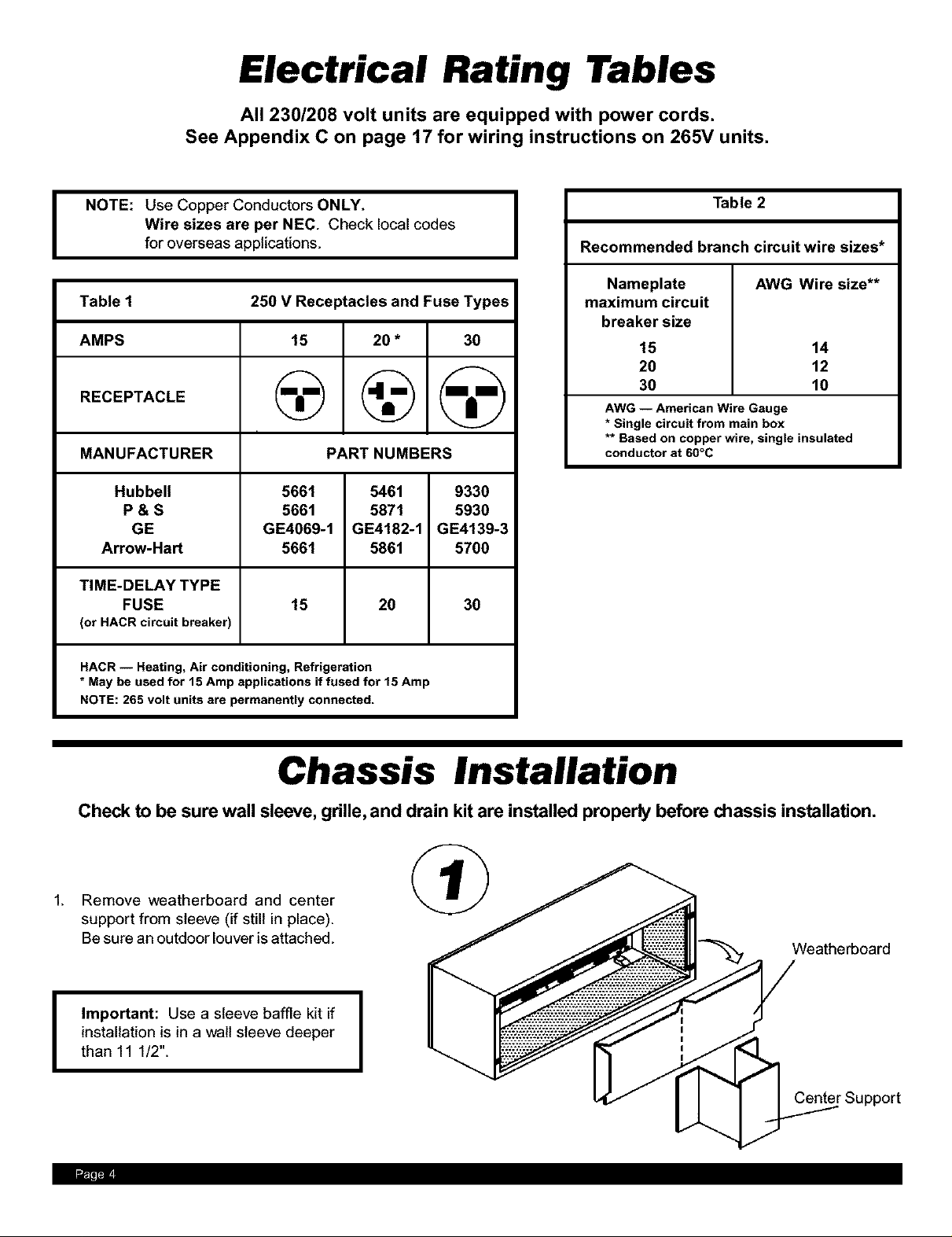

Chassis Installation

Check to be sure wall sleeve, grille, and drain kit are installed properly before chassis installation.

Remove weatherboard and center

support from sleeve (if still in place).

Be sure an outdoor louver is attached.

Important: Use a sleeve baffle kit if

installation is in a walt sleeve deeper

I

than 11 1/2".

.... ?1'11

Weatherboard

Center Support

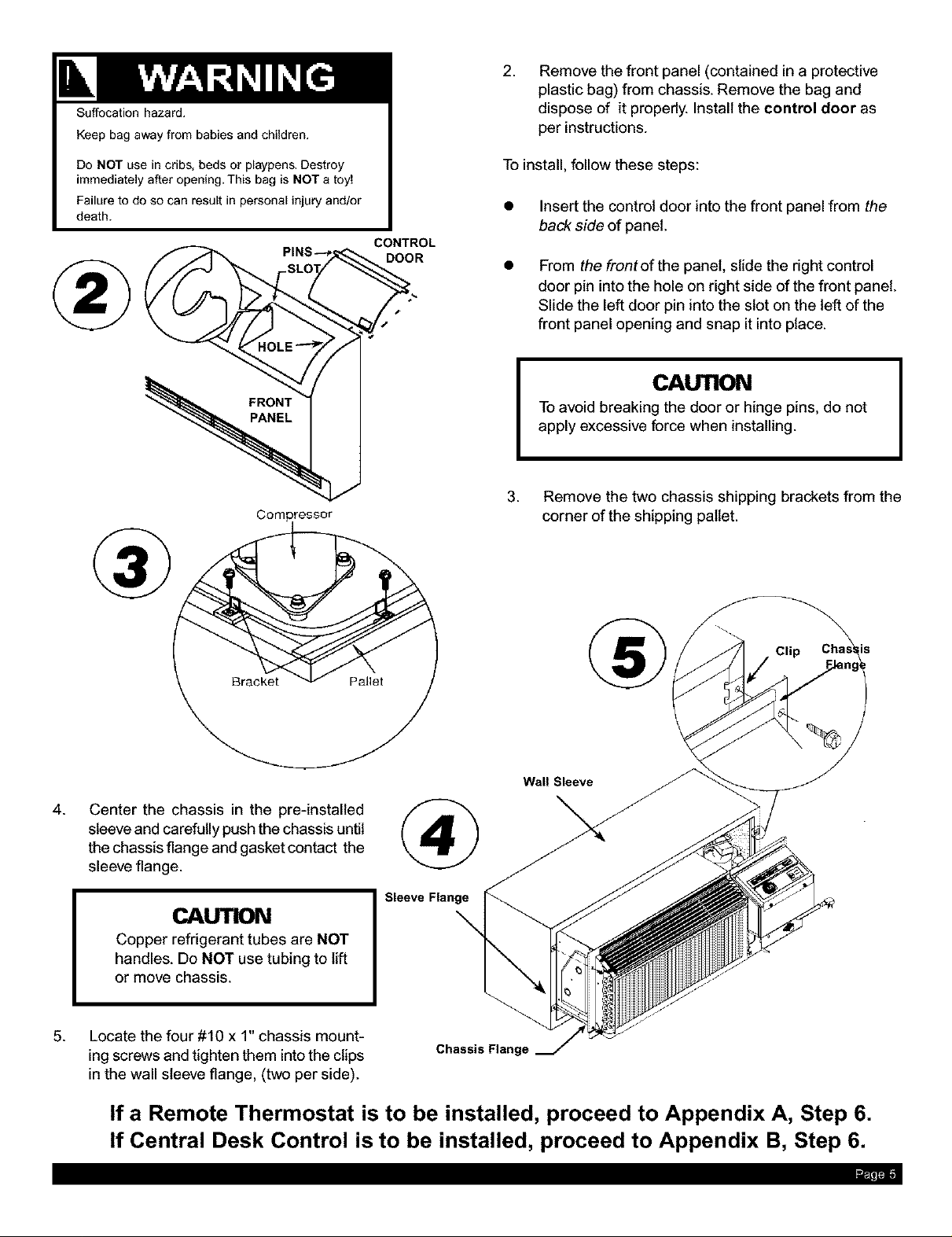

Suffocation hazard.

Keep bag away from babies and children.

2,

Remove the front panel (contained in a protective

plastic bag) from chassis. Remove the bag and

dispose of it properly. Install the control door as

per instructions.

Do NOT use in cribs, beds or playpens, Destroy

immediately after opening. This bag is NOT a toy!

Failure to do so can result in personal injury and/or

death.

PIN'( DOOR

Com#reseor

To install,follow these steps:

• Insert the control door into the front panel from the

back side of panel.

CONTROL

From the frontofthe panel, slide the right control

door pin into the hole on right side of the front panel.

Slide the left door pin into the slot on the left of the

front panel opening and snap it into place.

CAUTION

To avoid breaking the door or hinge pins, do not

apply excessive force when installing.

3. Remove the two chassis shipping brackets from the

corner of the shipping pallet.

4.

Center the chassis in the pre-installed

sleeve and carefully push the chassis until

the chassis flange and gasket contact the

sleeve flange.

CAUTION

Copper refrigerant tubes are NOT

handles. Do NOT use tubing to lift

or move chassis.

. Locate the four #10 x 1" chassis mount-

ing screws and tighten them into the clips

in the wall sleeve flange, (two per side).

If a Remote Thermostat is to be installed, proceed to Appendix A, Step 6.

If Central Desk Control is to be installed, proceed to Appendix B, Step 6.

®

Wall Sleeve

Sleeve Flange

\

Chassis Flange

rl'T

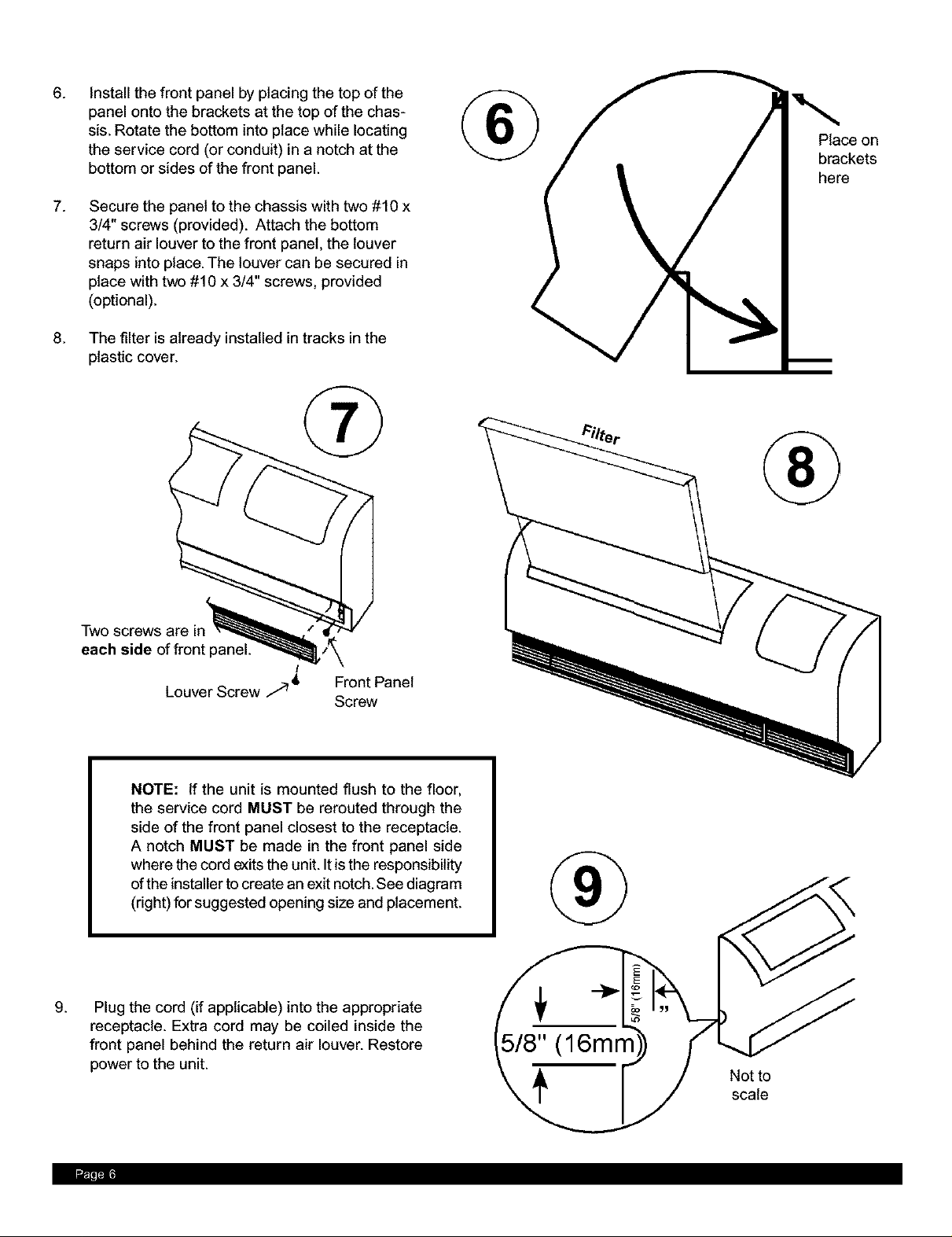

.

Install the front panel by placing the top of the

panel onto the brackets at the top of the chas-

sis. Rotate the bottom into place while locating

the service cord (or conduit) in a notch at the

bottom or sides of the front panel.

7.

Secure the panel to the chassis with two #10 x

3/4" screws (provided). Attach the bottom

return air louver to the front panel, the louver

snaps into place. The louver can be secured in

place with two #10 x 3/4" screws, provided

(optional).

.

The filter is already installed in tracks in the

plastic cover.

® Place on

brackets

here

®

Two

each side of front

!

Louver Screw 9 _ Front Panel

NOTE: If the unit is mounted flush to the floor,

the service cord MUST be rerouted through the

side of the front panel closest to the receptacle.

A notch MUST be made in the front panel side

where the cord exits the unit. It is the responsibility

ofthe installer to create an exit notch. See diagram

(right) for suggested opening size and placement.

g.

Plug the cord (if applicable) into the appropriate

receptacle. Extra cord may be coiled inside the

front panel behind the return air louver. Restore

power to the unit.

Screw

®

5/8" (16mm

Not to

scale

.... 711

Unit Operation

Rotatethe temperaturedial insmallincrements in

the warmer orcooler direction.Movingthe dial

more than 1/4"at atime may overcompensate and

result in an extreme hot or cold situation.

• If Thermostat is installed,

see Appendix A, page 11.

• If Central Desk Control is

installed, see Appendix B,

page 15.

Standard Unit Control Panel

COOL HEAT FAN ONLY OFF

Pushbutton Switch Operation

Control

Cool

Heat

Fan Only

Off

Temp

Fan Speed

Operation

Operates unit on cooling - cooling will not

begin if room temperature is below 60 E

Operates unit on heating. Some models

do not provide this selection.

Circulates air within the room. No heating

or cooling functions.

Shuts system down.

Temperature control - maintains room

temperature at the desired setting.

Counterclockwise - warmer

Clockwise - cooler.

Selects high speed or low speed.

WARNER TEt4 ? C OLER

Temperature Limiting Thermostat

1. Set thermostat knob to center of dial.

2. Remove four screws holding control panel. Pult up on

thermostat knob and remove.

3. Locate the two temperature limiting screws.These screws

are factory installed for a maximum temperature range of

60-90 ° E Each hole in dial plate represents approximately

a 4° change from the adjacent hole.

4. To adjust temperature range, move temperature limiting

screws to desired location.

5. Replace knob when desired range has been set.

6. Replace control panel.

EXAMPLE: To set a maximum temperature range of approxi-

mately 64 to 86° F,move screws to locations shown in diagram

at right.

LOW

Remove Knob

Temperature

L miring Screws

rl'

Heating Control

NOTE: Heat pump models only. Heat pump equipped models use

backup electric resistance heating coils. At extremely low outdoor

ambient temperatures, the heat pump is automatically disabled and the

unit operates solely on electric resistance heat.

O r"_

The heating control is located behind the front panel at the control box

bottom and is accessible through the return air louver opening. Its

function is to allow you to set the temperature range in which the heat

pump operates. This control switches the unit heat operation between

heat pump and electric resistance heat based on the outdoor ambient

COMMANDE DE CHAUFFAGE

temperature. These change over temperatures are based on the

settings of this control. In most cases, the factory setting (at approxi-

mately the one o'clock position) is adequate. Ifyou wish to change the

factory set point, insert a flat bladed screwdriver into the slot and turn counterclockwise to increase the changeover set

point.

In the event of a compressor malfunction, turn the screw to the extreme counterclockwise emergency heat position. The

heater will then cycle using electric resistance heat only. Note that in the emergency heat position, the compressor is locked

out, disabling both heat pump and cooling operations. CALL A SERVICE PERSON.

OMP6" 04'Z_

HEATING CONTROL

CONTROLDELCALOR

EM_RGENC'¢ HEAT

CHAUFFAGE D'UR_ENCE

DE EME_GENCIA

CYCLE DU

VENTILATEUR

CICLO DEL

VENTILADOR

VENT

AERATION

SALIDA (ESCAPE)

DEL AIRE

Fan Cycle Switch

The fan cycle switch is located behind the front panel at the bottom of the

control box. It is accessible through the return air louver opening. It is

CONTINUOUS

FAN

CYCLE

m

designed to operate the fan either continuously or intermittently with the

compressor or heating elements. When the switch is in the CONTINU-

OUS position, the fan will run continuously when the power switch is on.

With the fan cycle switch in the CYCLE position, the fan will run only when

the compressor or heating elements cycle on.

CYCLE

CICLO

recommended that this switch be set in the continuous position.

I NOTE: For maximum comfort and temperature control, it is

Vent Control

The vent control lever is located behind the front panel at the bottom of the

OPEN

OUVERT

ABIERTA

CLOSED

FERM_

CERRADA

control box. When the lever is up, (OPEN), outside air is mixed with indoor

air. When the lever is down, (CLOSED), no outside air is admitted into

room and room air is recycled through unit.

I NOTE: For peak operating efficiency the vent should remain closed. I

=

I

.... 711

Air Outlet Louver

I

I

I

I

I

The air outlet louver can be redirected to blow air either straight

up or at an angle into the room. To change the airflow direction,

I

\

\

\

remove the front panel, and the two screws on either side of the

louver. Reverse ends of louver and refasten.

Startup Checklist

Check the following:

_/ Unit is installed in compliance with all codes

and ordinances.

_/ Circuit breakers and wire sizes are correct.

_/ Filter is clean and in place.

_/ All panels are in place.

_/ Condenser air inlet and outlet free of obstruc-

tions.

Work area clean and free of debris.

NOTE: Units are to be installed and

checked for proper function by qualified

I

service personnel ONLY.

_/ Operate unit 20 minutes.

_/ Controls operation OK.

_/ Owner or operator instructed on control opera-

tion and routine maintenance.

_/ Name and phone number of service company

attached to unit or noted in telephone directory.

_/ Condensate drain adequate.

_/ Electrical cord is stored properly.

rl'l

11

Routine Maintenance

NOTE: Fan motor and all bearings are i

permanently sealed and do not require oiling.

,IJ Keep air intake filter clean. A dirty filter reduces the efficiency of the system and can cause erratic performance of

controls. It can also result in damage to the heating element and compressor. The unit is provided with a washable

filter that can be cleaned with soap and water. Inspect and clean the filter at least once a month or more often as

conditions dictate. Replace as necessary with a factory approved filter. To replace, slide it up and out through the

front cover immediately in front of the discharge grille opening.

,IJ Do NOT block off outside air flow. Efficient operation of the unit depends on free circulation of air over the indoor and

outdoor coils. Paper, leaves and other debris can reduce efficiency and cause serious damage to the compressor.

,IJ Coils should be inspected periodically for buildup of lint, dirt, leaves, other debris and bent fins. Clean coils with a soft

brush and compressed air or vacuum. Do NOT use sharp objects to clean coils.

,IJ Do NOT operate unit with front panel removed or without filter.

,IJ Ensure that objects such as drapes, furniture, or plants are not blocking free air flow of unit.

,IJ Keep doors and windows closed. Leaving them open will increase the work load on the unit and will result in higher

operating cost and excessive condensate.

,IJ Do NOT operate the unit during construction. Construction dust can clog filter and cause permanent damage to

other components.

I

I

,IJ Apply silicon based lubricant to the belt drive system as needed. DO NOT USE ANY SOLVENT BASED LUBRICANTS

SUCH AS WD-40 TM.

Apply silicon-based

lubricant to belt located

inside access door.

il Tel

Appendix A: Selection, Wiring &

Installation of Remote Thermostat

1. Remote Thermostat Selection & Wiring Guidelines for Packaged Terminal Air

Conditioners

Follow the instructions and recommendations of the thermostat manufacturer for installation and wiring. We do not

recommend aconventional heat pump thermostat with emergency electric heat selection for our heat pump units.

Our units make an automatic decision about turning on emergency heat if the heating demand cannot be met by

the heat pump.

A. Manual Changeover Thermostat

A single stage heat/cool thermostat with a terminal for heat damper operation is required. The recommended

thermostat/subbase is the Honeywell T-87F/Q539J. You can also substitute a thermostat with single stage cooling

and dual stages of heating.

Hone_

TERMINAL LETTER

Y

W

G

R

B

W2

THERMOSTAT TERMINAL

W&Y

Y

B

R

G

n_ell Thermostat Terminal Designation:

OPERATION

Cooling

Heating

Fan

24V common

to the thermostat

Heat Damper

Stage 2 Heating

Durin9 call for cooling.

During call for heating.

Continuous if the slider is inthe "Fan"

)osition, otherwise, intermittent.

Makes contact thru the thermostat

when a call for heating, cooling or fan is

made.

Made continuously during call for

heating.

Made if stage 1 (W) cannot handle the

heating load by itself.

CONTACT MADE

Wiring:

Wire as follows:

JUMPER

Yes

N/A

N/A

N/A

N/A

WIRE TO PTAC TERMINAL

N/A

Y

W

R

G

Manual Changeover Thermostat

Single Stage Cooling/Heating with Heat Damper Terminal

If using a thermostat with single cooling and dual heating

stages, install a jumper between the stage 2 heating terminal

(W2 on Honeywell) & the cooling terminal (Y on the

Honeywell), and wire to terminal "Y" on the UnitTerminal

Board.

Wire stage 1 heating (Wl on Honeywell) to terminal "W" on

the Unit Terminal Board. The remainder of the wiring is as

shown.

UnitTerminal Board

OR C y ,,m ,30 0 _ 0

" ,JUh PER

ThermostatTerminals ThermostatTerminals

UnitTerminal Board

B. Auto Changeover Thermostat

A single stage thermostat with dual stages of heating and auto changeover is needed. The recommended Thermostat/

Subbase combination is the Honeywell T-874C/Q 674E.

ThermostatTerminal Jumper Wire to PTACTerminal

Y & W2 YES N/A

Y N/A Y

Wl N/A W

R N/A R

G N/A G

Unit Terminal Board

: JUnnpE_

Thermostat Terminals

2. Installation

Follow Steps 1 through 5 (pages 4 and 5), then: ('/R _)

6. Locate the terminal strip on the right side of the control box. Attach

the thermostat subbase wires (field supplied) to the appropriately

labeled terminals as per widng diagram on the side of the chassis.

NOTE: No connections are made to the

"C" Terminal when one of the

manufacturer's thermostat subbases is

used.

Carefully route the wires alongside the conduit

or service cord. Attach the other end of the wires

to the appropriate terminals on the thermostat

subbase. See thermostat directions for proper

widng and mounting of thermostat.

7.

If the filter is not in place, install as shown.

mil*

Appendix A (Continued)

.

Install the front panel by placing the top of the panel

onto the brackets at the top of the chassis. Rotate

the bottom into place while locating the service

cord (or conduit) inthe notch at the bottom or sides

of the front panel.

®

®

g.

Secure the panel to the chassis with two #10 x

3/4" screws (provided). Attach the bottom return

air louver to the front panel. The louver snaps into

place. The louver can be secured in place with

two #10 x 3/4" screws provided (optional).

Front Panel

Screw

Louver Screw /_

NOTE: If the unit is mounted flush to the floor, the service cord

MUST be rerouted through the side of the front panel closest to

the receptacle. A notch MUST be made in the front panel side

where the cord exits the unit. Itis the responsibility of the installer

to create an exit notch. See the diagram for suggested opening

size and placement.

@

Not to scale

10. For 230/208 volt units, plug the cord (if applicable) intoan appropriate receptacle. For 265 volt units see Appendix

C on page 17.The extra cord may be coiled inside the front panel behind the return air louver. Restore power to the

unit.

rl

Appendix A (Continued)

Remote Thermostat 208V Operation

CONNECTION DIAGRAM

CAUTION

If the supply voltage is 208V, the low volt-

age transformer IVlUST be wired for 208V

operation. Failure to do so will result in lower

control voltages to the unit and can dam-

age low voltage components.

The simplified connection diagram at left shows the

factory configured wiring set for 240V operation. If

you are going to use 208V exclusively, switch the

two (2) black wires on the 240V post of the primary

side of the transformer to the 208V post. This will

ensure correct secondary (low) voltages for the unit.

This is only required on the remote thermostat units.

Remote Thermostat Unit Operation

These units are controlled by the use of a remote ther-

mostat that will cycle the unit to maintain desired room

temperature. See thermostat operating manual for de-

tails.

The fan speed switch on the control panel is indepen-

dent of the thermostat and controls the fan speed. If you

wish high speed fan operation, set switch to high. For low

mi,;,-i-ii i

Control

Fan Speed

Switch Operation

Selects high speed or low speed

Operation

Appendix B: Installation of

Central Desk Control

Follow steps 1 through 5 (pages 4 and 5), then:

®

6. Attach two wires from the central desk control to the

terminal board on the right side of the control box.The

central desk control must provide 24 volts AC to this

terminal board in order to switch the unit to the unoc-

cupied mode. When the 24 volts AC is turned off, the

unit returns to the occupied mode.

7.

8.

g.

If filter is not in place, locate and place as shown.

Install the front panel by placing the top of the panel

onto the brackets at top of the chassis. Rotate the

bottom into place while locating the service cord

(or conduit) in the notch at the bottom or sides of

the front panel.

Secure the panel to the chassis with two #10 x

3/4" screws (provided). Attach the bottom return

air louver to the front panel. The louver can be se-

cured in place with two #10 x 3/4" screws provided

(optional).

®

Place on

brackets

here.

(_ Filter

I

Front Panel

(not in place yet)

NOTE: Two screws are in

each side of front panel.

f. ....

Louver Screw _ I

m

_ Evaporator Coil

In//

....,1_- _ Thermostat Bulb

Front Panel

Screw

r

Appendix B (Continued)

NOTE: If the unit is mounted flush to the floor,

the service cord MUST be rerouted through the

side of the front panel closest to the receptacle.

A notch MUST be made in the front panel side

where the cord exits the unit. It is the

responsibility of the installer to create an exit

notch. See diagram for suggested opening size

and placement.

10.

Not to scale

Central Desk Control Operation

Units equipped with Central Desk Control are identical in operation with non-Central Desk Control models,

except in the "Unoccupied Mode" when all functions are disabled.

All conditions are with 24V power ON at Central Desk Control terminal board.

Plug the cord (if applicable) into the appropri-

ate receptacle. Extra cord may be coiled inside

front panel behind the return air louver. Restore

power to the unit.

IMPORTANT: Even if Central Desk Control is energized, the low temperature sensor will not

allow the temperature in the room to fall below 43 ° F. If the temperature falls below 43 ° F,

heat will come on until room temperature reaches 58° E

Appendix B (Continued)

Central Desk Control Low Voltage Wiring Specifications

Length of Run Total Length Wire Gauge

400 feet (120 m) 800 feet (240 m) 22

550 feet (155 m) 1100 feet (330 m) 20

1000 feet (300 m) 2000 feet (600 m) 18

1500 feet (450 m) 3000 feet (900 m) 16

2400 feet (730 m) 4800 feet (1440 m) 14

NOTE: The following points are the MINIMUM requirements needed to operate remote PTACS safely and

within design specifications.

1. Central Desk Control panel switches and transformers are field supplied. Switches should be SPST,

minimum rating of 0.5 amps inductive at 24 volts.

2. Units will not operate with switches closed. 24V supplied to the unit will DISABLE unit. See chart at left.

3. Minimum VA rafing of transformer is 9.8VA per unit. (9.8 X # of units determine totalVA needed for entire

installation).

4. Low voltage transformer is limited to maxVA per NEC 725-31.This may require multiple transformers for

large installations.

5. Consult the table at left for minimum wire gauges needed for any given low voltage wire run.

Appendix C. Electrical Wiring Options

For All 265V Models

265 volt units come shipped with a junction box under the control box. Remove the junction box cover and attach a 90°

electrical elbow and a 1/2" flexible conduit (separate accessory or field supplied). If not already in place, route the conduit

down through the floor taking care that hole in the floor is located directly below the notch in front panel. Make appropriate

electrical connections within the junction box, and reattach the junction box cover to the control box.

Wiring Diagram

Junction Box

Cover

1/2" Flexible

Conduit

(Accessory or

Rating Plate

Fuse Holder

_pire Nuts (Field

plied) /

Field Supplied)

conduit, make provisions to allow conduit to be removed

I NOTE: When installing a flush-floor mounted unit with

in case of future service needs to chassis.

Friedrich Air Conditioning Co.

P.O. Box 1540

San Antonio, Texas 78295-1540

(210) 357-4400

WALLMASTER ®PACKAGED TERMINAL PRODUCTS

(T Series)

AIR CONDITIONERS AND HEAT PUMPS

SAVETHIS CERTIFICATE. It gives you specific legal rights, and you may also haveother rights which may vary from state to state and

province to province.

In the event your unit needs servicing, contact your nearest authorized service center.When requesting service, please have the model

and serial number from your unit readily available. If you do not know the nearest service center, ask the company that installed your

unit or contact us - see address and telephone number above.

Unless specified otherwise herein,the following applies:

PACKAGEDTERMINALAIR CONDITIONERSAND HEATPUMPS

LIMITED WARRANTY-- FIRSTYEAR (Eighteen 18) months fromoriginal date of purchaseor twelve (12) months from installation). Any

defectinthe unit's materials or workmanship willbe repaired or replaced free of chargeby ourauthorizedservice centerduring normal working

hours; and

LIMITEDWARRANTY -- SECONDTHROUGH FIFTHYEAR (Sixty-six (66) months from the date of purchase or sixty (60) months from the

date of installation, whichever comes first) ON THE SEALED REFRIGERATION SYSTEM ANDTHE FLEX-DRIVE ® SYSTEM. Any part of

the seated refrigeration system,for theT Series,andthe Flex-Drive_System thatisdefective inmaterial or workmanshipwill berepaired or replaced

by our authorized service center during normal working hours.The sealed refrigeration system consists of the compressor, metering device,

evaporator,condenser, reversingvalve,check valve and interconnectingtubing. The Flex-DriveSystem® consists ofthe polyurethane beltand the

blower pulleys.

These warranties apply only while the unit remains at the original site and only to units installed inside the continental United States,

Alaska, Hawaii, Puerto Rico and Canada. The warranty applies only if the unit is installed and operated in accordance with the printed

instructions and in compliance with applicable local installation and building codes and good trade practices.

For International warranty information, contact the Friedrich Air Conditioning Company - International Division.

Reasonable proof mustbe presentedto establishthe original purchase date,otherwise the beginning date ofthis certificate willbeconsidered to be

our shipment date plus sixty days. Replacement parts can be new or remanufactured. Replacement parts and labor are only warranted for any

unused portionof the unit'swarranty. If the unit's normal use is for personal,family or household purposes, then freight and/or handling charges

associated with therepair and replacement pursuantto this warranty will be our responsibility

We will not be responsible for and the user will pa, for:

1. Service calls to:

(a) instruct on unit operation, (b) replace house fuses or correct house wiring, (c) clean or replace air filters, (d) remove the unit from

inaccessible locations, and/or (e) correct improper installations.

2. Parts orlabor provided byanyone other than an authorized service center.

3. Damages caused by:

(a) accident, abuse, negligence, misuse, riot, fire, flood, orActs of God, (b) operating the unit where there is a corrosive atmosphere

containing chlorine,fluorine, oranyother damaging chemicals (otherthan in a normal residentialenvironment), (c)unauthorized alteration

or repair ofthe unit,which inturn affects its stability orperformance,(d) failingto provideproper maintenance andservice, (e) usingother

than a "Seacoast Protected" unit ina coastal environment, (f)using an incorrect _owersource, (g) faulty installation or application of the

unit.

We shall not be liable for any incidental, conse( uential, or special damages or expenses in connection with any use or failure of this

unit. We have not made and do not make any representation or warranty of fitness for a particular use or purpose and there is not

implied condition of fitness for a particular use or purpose.We make no express warranties except as stated in this certificate. No one

is authorized to change this certificate or to create for us any other obligation or liability in connection with this unit. Any implied

warranties shall last for one year after the original purchase date. Some states and )rovincesdo not allow the exclusion or limitation of

incidental or consequential damages or do not allow limitations on how tong an impliedwarranty or condition lasts, so the above limitations or

exclusions may not apply to you.The provisions of this warranty are in addition to and not a modification of or subtraction from the statutory

warranties and other rights and remediesprovidedb' law.

In case of questions regarding the provisionsof this warranty, the English version will govern.

Friedrich Air Conditioning Co.

4200 North Pan Am Expressway * RO. Box 1540

San Antonio, Texas 78295-1540 • U.S.A.

Phone: (210) 357-4400

Fax: (210) 357-4480

rl'l-

Loading...

Loading...