Room Air Conditioner

Service and Parts

Manual

Slider Casement

SV08 / SV10 / SV12 (01/05)

115Volts • SV08A10A • SV10A10A • SV12A10A

High

Cool

Med

Fan

Off

Mode

Temperature

Med

Cool

Low Cool

Low

Fan

CoolerWarmer

—2—

1. PREFACE

1.1 SAFETY PRECAUTIONS................................2

1.2 INSULATION RESISTANCE TEST.................2

1.3 SPECIFICATIONS...........................................3

1.4 FEATURES......................................................4

1.5 CONTROL LOCATIONS .................................4

2.

DISASSEMBLY INSTRUCTIONS

2.1 MECHANICAL PARTS....................................5

2.1.1 FRONT GRILLE .....................................5

2.1.2 CABINET................................................5

2.1.3 CONTROL BOX .....................................5

2.2 AIR HANDLING PARTS..................................6

2.2.1 AIR GUIDE AND TURBO FAN...............6

2.2.2 FAN ........................................................6

2.2.3 SHROUD................................................7

2.3 ELECTRICAL PARTS......................................7

2.3.1 OVERLOAD PROTECTOR....................7

2.3.2 COMPRESSOR......................................7

2.3.3 CAPACITOR...........................................8

2.3.4 POWER CORD ......................................8

2.3.5 THERMOSTAT.......................................8

2.3.6 ROTARY SWITCH .................................8

2.3.7 MOTOR ..................................................9

2.4 REFRIGERATION CYCLE..............................9

2.4.1 CONDENSER.........................................9

2.4.2 EVAPORATOR.......................................9

2.4.3 CAPILLARY TUBE...............................10

3.

INSTALLATION

3.1 HOW TO INSTALL THE UNIT.......................12

3.2 CHECKING INSTALLATION.........................12

3.3 HOW TO DRAIN............................................12

3.4 WINDOW REQUIREMENTS.........................13

3.5 INSTALLATION KITS CONTENTS ...............13

3.6

HORIZONTAL SLIDING WINDOW INSTALLATION

.....14

3.7 CASEMENT WINDOW INSTALLATION .......15

4.

TROUBLESHOOTING GUIDE

4.1 OUTSIDE DIMENSIONS...............................16

4.2 PIPING SYSTEM...........................................16

4.3 TROUBLESHOOTING GUIDE......................17

5. SCHEMATIC DIAGRAM

5.1 CIRCUIT DIAGRAM ......................................21

5.2 CIRCUIT DIAGRAM ......................................22

6. EXPLODED VIEW..................................23

7. REPLACEMENT PARTS LIST........24

1. PREFACE

This

SERVICE MANUAL provides various service information, including the mechanical and electrical

parts etc. This room air conditioner was manufactured and assembled under a strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 SAFETY PRECAUTIONS

1. When servicing the unit, set the ROTARY SWITCH

or POWER SWITCH to OFF and unplug the power

cord.

2. Observe the original wire insulation.

If a short circuit is found, replace all parts which

have been overheated or damaged by the short

circuit.

3. After servicing the unit, make an insulation resistance test to protect the customer from being

exposed to shock hazards.

1.2

INSULATION RESISTANCE TEST

1. Unplug the power cord and connect a jumper

between 2 pins (black and white).

2. The grounding conductor (green) is to be open.

3. Measure the resistance value with an ohm meter

between the jumpered lead and each exposed

metallic part on the equipment at all the positions

(except OFF) of the ROTARY SWITCH.

4. The value should be over 1MΩ.

CONTENTS

—3—

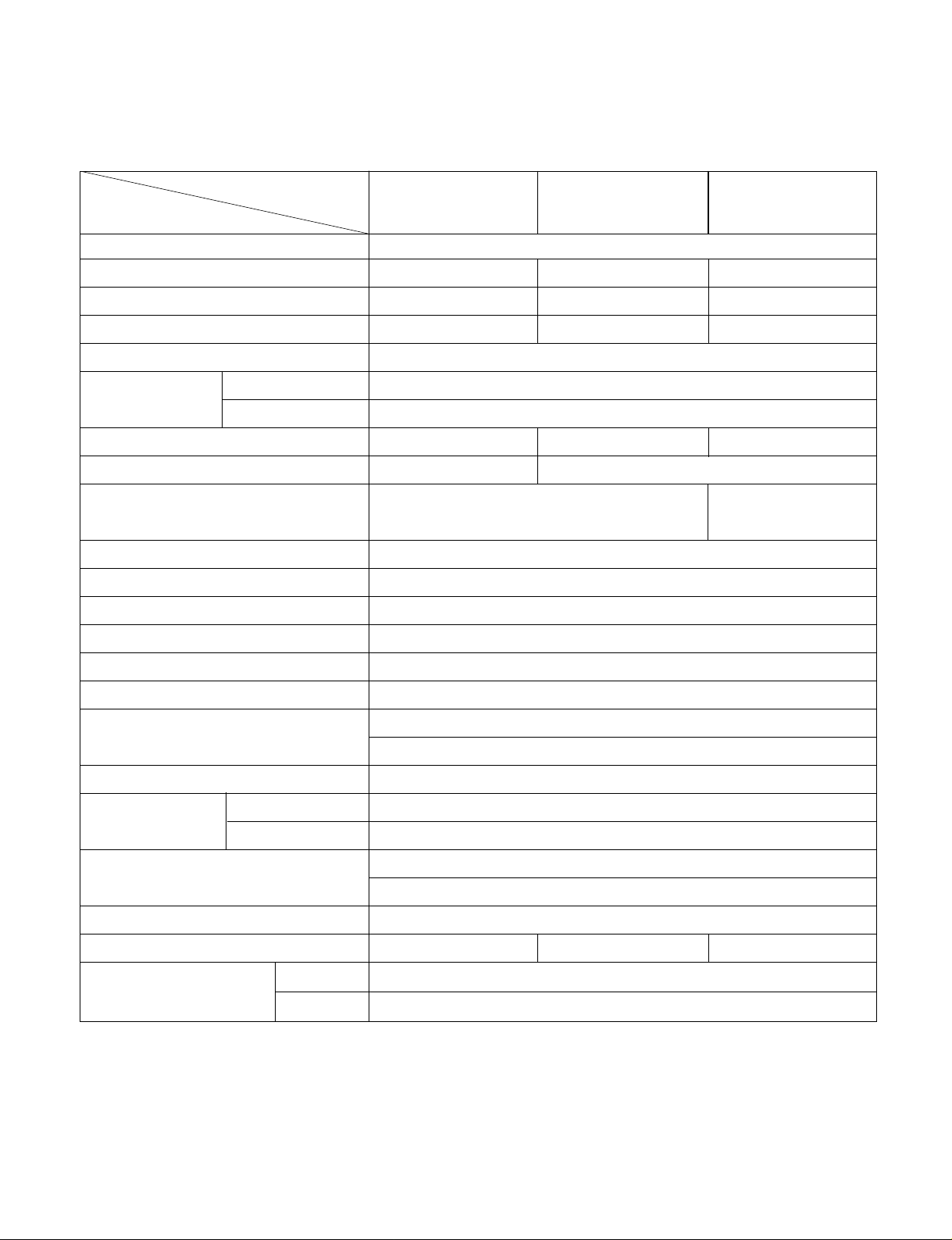

POWER SUPPLY

COOLING CAPACITY (Btu/h)

INPUT (W)

RUNNING CURRENT (A)

E.E.R (BTU/W.h)

INDOOR (°C)

OUTDOOR (°C)

REFRIGERANT (R-22) CHARGE

EVAPORATOR

CONDENSER

FAN, INDOOR

FAN, OUTDOOR

FAN SPEEDS, FAN/COOLING

FAN MOTOR

OPERATION CONTROL

ROOM TEMP. CONTROL

AIR DIRECTION CONTROL

CONSTRUCTION

PROTECTOR

COMPRESSOR

FAN MOTOR

POWER CORD

DRAIN SYSTEM

NET WEIGHT (lbs/kg)

OUTSIDE DIMENSION (inch)

(W x H x D) (mm)

1Ø115V, 60Hz

8,000 10,000 12,000

840 1,050 1,260

7.7 9.6 11.5

9.5

26.7(DB)* 19.4(WB)**

35(DB)* 23.9(WB)**

460g(16.2 oz) 520g(18.3 oz) 615g(21.7 oz)

2 ROW 16 STACKS, SLIT FIN TYPE

3 ROW 16 STACKS, SLIT FIN TYPE

2 ROW 23 STACKS, 3 ROW 23 STACKS,

LOUVER FIN TYPE LOUVER FIN TYPE

TURBO FAN

AXIAL FAN

2/3

6 POLES

ROTARY SWITCH

THERMOSTAT

VERTICAL LOUVER (RIGHT & LEFT)

HORIZONTAL LOUVER (UP & DOWN)

TOP-DOWN CHASSIS

OVERLOAD PROTECTOR

INTERNAL THERMAL PROTECTOR

3 WIRE WITH GROUNDING

ATTACHMENT PLUG (CORD-CONNECTED TYPE)

DRAIN PIPE SPLASHED BY FAN SLINGER

66/30 77/35 79/36

141/2 x 201/2 x 233/5

368 x 521 x 607

SV08A10A SV10A10A SV12A10A

MODELS

ITEMS

OPERATING

CONDITION

1.3 SPECIFICATIONS

1.3.1 FOR SV08A10A / SV10A10A / SV12A10A

* DB:Dry Bulb

**

WB:Wet Bulb

—4—

1.4 FEATURES

• Designed for COOLING ONLY.

• Powerful and whispering cooling.

• Simple installation and service.

• Low air-intake, top cooled-air discharge.

1.5 CONTROL LOCATIONS

1.5.1 COOLING ONLY MODEL

• VENTILATION

The ventilation lever must be in the CLOSE position

in order to maintain the best cooling conditions.

When fresh air is necessary in the room, set the

ventilation lever OPEN position.

The damper is opened and room air is exhausted.

• TEMPERATURE

Thermostat will automatically control the temperature

of the room. Select a higher grade for a cooler

temperature in the room. The temperature is selected

by moving the knob to the desired position.

• MODE

- Turns air conditioner off.

- Med speed fan operation without cooling.

- Low speed fan operation without cooling.

- Cooling with high speed fan operation.

- Cooling with med speed fan operation.

- Cooling with low speed fan operation.

• Built-in adjustable THERMOSTAT

• Washable one-touch filter

• Compact size

• Reliable and efficient rotary compressor is equipped.

VENTCLOSE

OPEN

High

Cool

Med

Fan

Off

Mode

Temperature

Med

Cool

Low Cool

Low

Fan

CoolerWarmer

Inlet Grille

H

i

g

h

C

o

o

l

M

e

d

F

a

n

O

f

f

M

o

d

e

T

e

m

p

e

r

a

t

u

r

e

M

e

d

C

o

o

l

L

o

w

C

o

o

l

L

o

w

F

a

n

C

o

o

l

e

r

W

a

r

m

e

r

NOTE!

Before using the air conditioner

secure the front grille with two screws

enclosed with the owner’s manual.

1. Open the inlet grille downward and

remove the air filter.

2. Fasten the front grille with screws.

3. Reinstall the air filter.

4. Close the inlet grille.

—5—

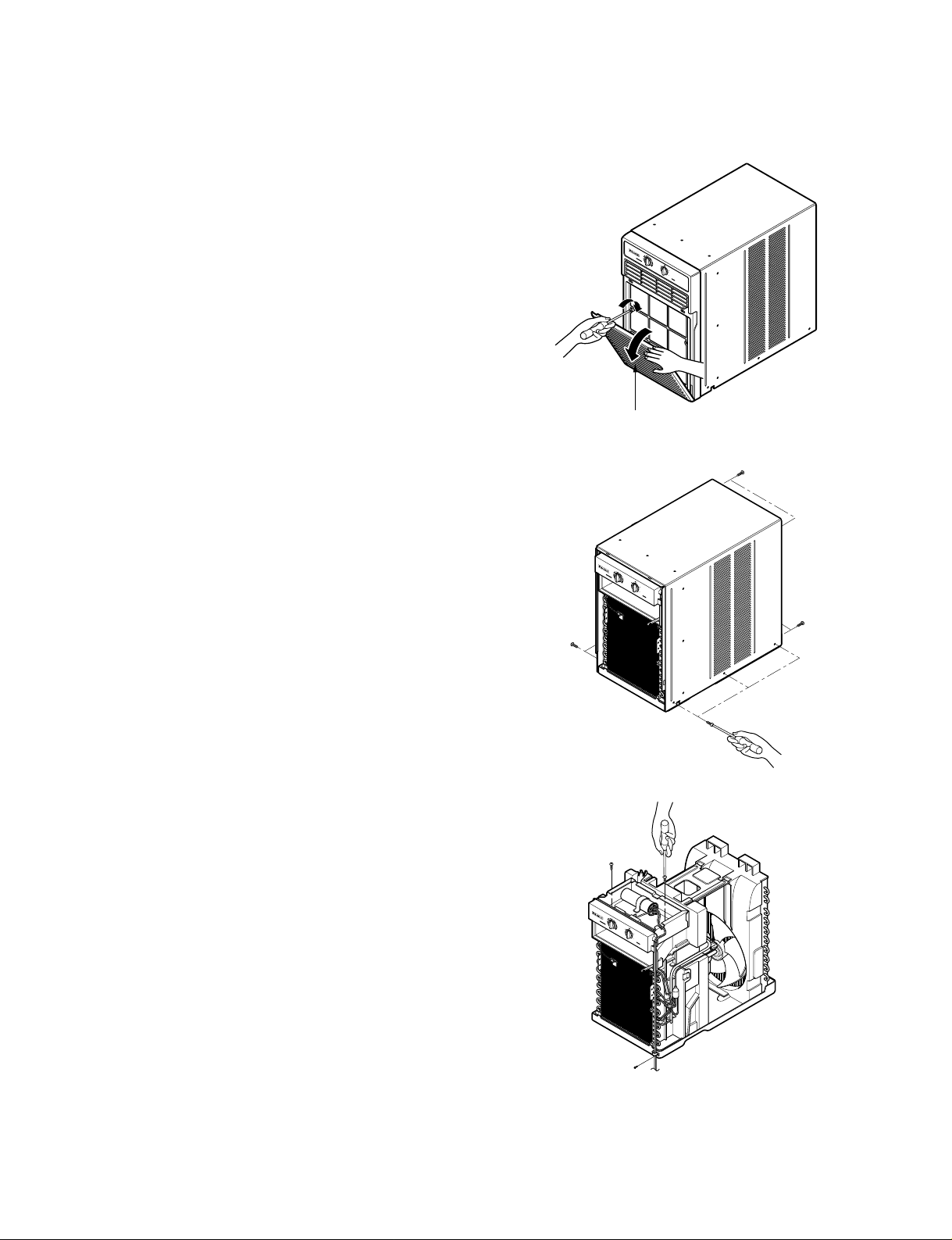

2.1 MECHANICAL PARTS

2.1.1 FRONT GRILLE

1. Open the inlet grille downward and remove the air

filter.

2. Remove the screws which fasten the front

grille.(See Figure 1)

3. Pull the front grille from the right side.

4. Remove the front grille.(There are 4 hooks.)

5. Re-install the components by referring to the

removal procedure, above.

2.1.2 CABINET

1. After disassembling the FRONT GRILLE, remove

the 6 screws which fasten the cabinet at both

sides.(See Figure 2)

2. Remove the 4 screws which fasten the cabinet at

back.

3. Remove the cabinet.

4. Re-install the components by referring to the

removal procedure, above.

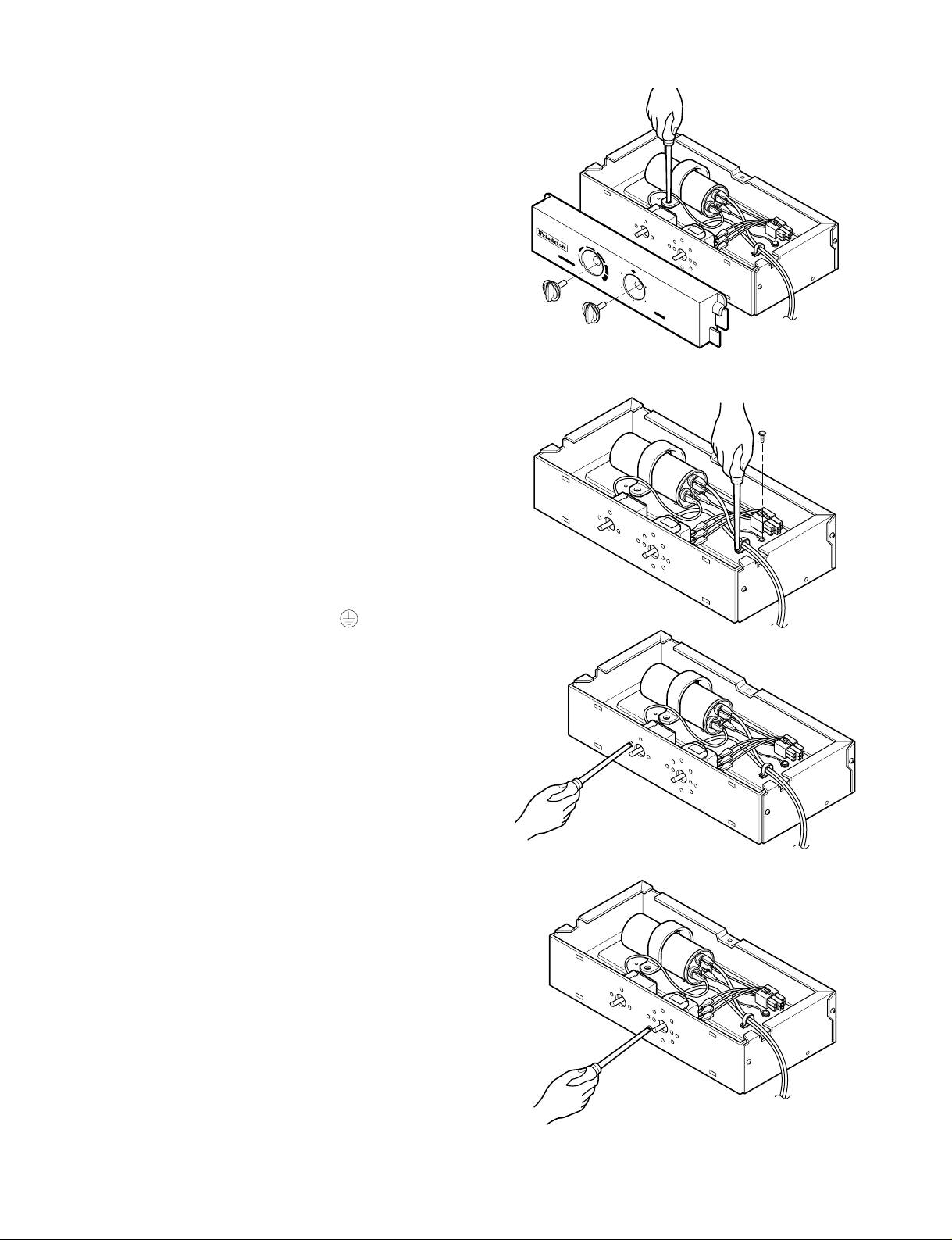

2.1.3 CONTROL BOX

1. Remove the front grille. (Refer to section 2.1.1)

2. Remove the cabinet. (Refer to section 2.1.2)

3. Remove the 1 screw which fasten the power cord.

(See Figure 3)

4. Disconnect the grounding screw from the

evaporator channel.

5. Remove the 2 screws which fasten the control

box.(See Figure 3)

6. Remove the housing which connects motor wire

in the control box.

7. Remove three leads which connect compressor.

8. Discharge the capacitor by placing a 20,000 ohm

resistor across the capacitor terminals.

9. Raise the control box upward completely.

10. Re-install the components by referring to the

removal procedure, above.

(Refer to the circuit diagram found on pages

21~22 in this manual and on the control box.)

Inlet Grille

H

i

g

h

C

o

o

l

M

e

d

F

a

n

O

f

f

M

o

d

e

T

e

m

p

e

r

a

t

u

r

e

M

e

d

C

o

o

l

L

o

w

C

o

o

l

L

o

w

F

a

n

C

o

o

l

e

r

W

a

r

m

e

r

H

i

g

h

C

o

o

l

M

e

d

F

a

n

O

f

f

M

o

d

e

T

e

m

p

e

r

a

t

u

r

e

M

e

d

C

o

o

l

L

o

w

C

o

o

l

L

o

w

F

a

n

C

o

o

l

e

r

W

a

r

m

e

r

H

i

g

h

C

o

o

l

M

e

d

F

a

n

O

f

f

M

o

d

e

T

e

m

p

e

r

a

t

u

r

e

M

e

d

C

o

o

l

L

o

w

C

o

o

l

L

o

w

F

a

n

C

o

o

l

e

r

W

a

r

m

e

r

2. DISASSEMBLY INSTRUCTIONS

— Before the following disassembly, set POWER SWITCH to OFF and disconnect the power cord.

Figure 1

Figure 3

Figure 2

—6—

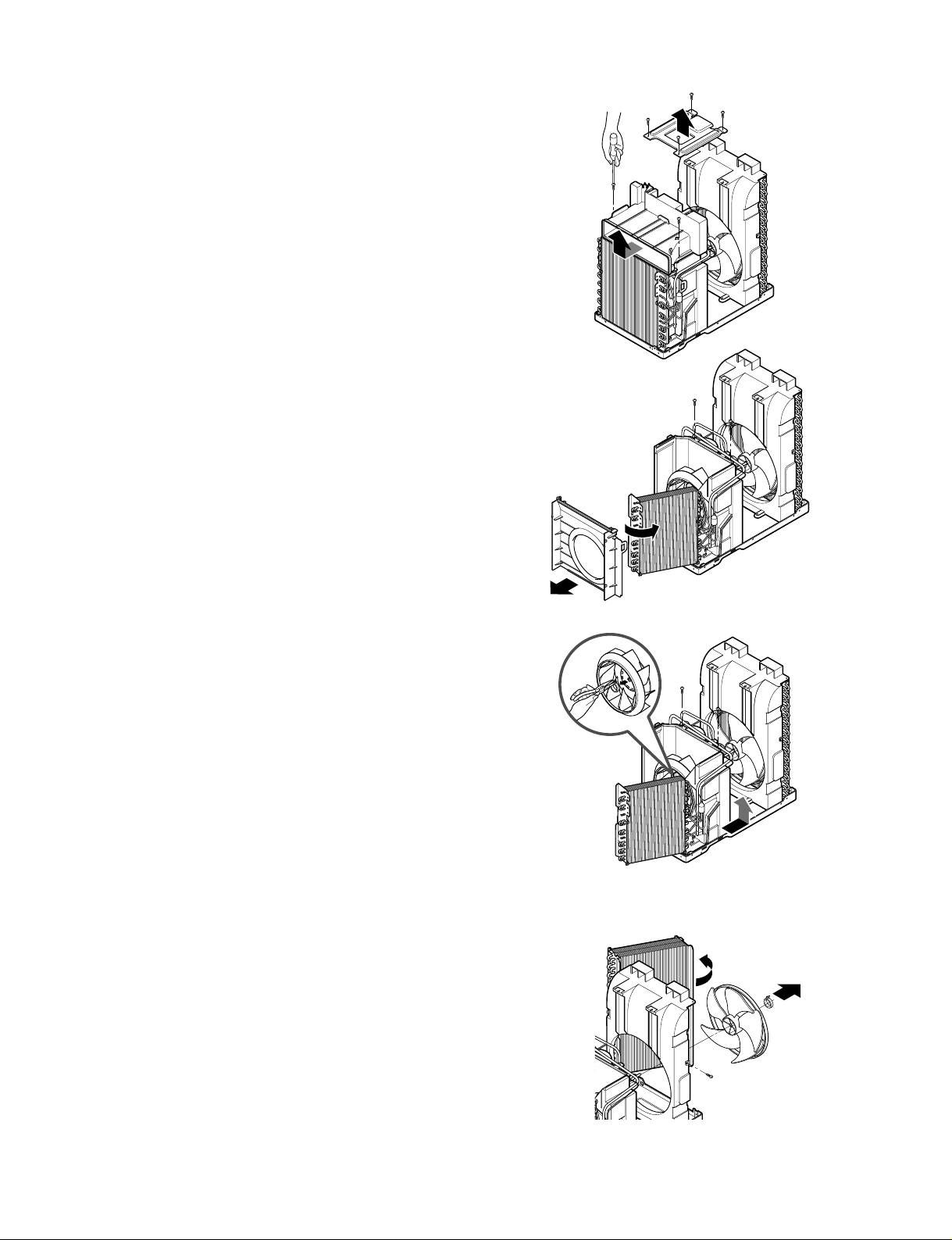

2.2 AIR HANDLING PARTS

2.2.1 AIR GUIDE AND TURBO FAN

1. Remove the front grille. (Refer to section 2.1.1)

2. Remove the cabinet. (Refer to section 2.1.2)

3. Remove the control box. (Refer to section 2.1.3)

4. Remove the 4 screws which fasten the brace.

5. Remove the brace.

6. Remove the 2 screws which fasten the upper air

guide. (See Figure 4)

7. Remove the upper air guide.

8. Remove the 2 screws which fasten the

evaporator.

9. Move the evaporator forward while pulling it

upward slightly. (See Figure 5)

10. Remove orifice by pulling two taps.

11. Remove the clamp with a hand plier which

secures the turbo fan.

12. Remove the turbo fan. (See Figure 6)

13. Remove the motor. (Refer to section 2.3.7)

14. Remove the 2 screws which fastens the lower air

guide from the base pan.

15. Remove the 2 screws which fasten the motor

mount from the base pan.

16. Remove the 2 screws which fasten the lower air

guide and motor mount.

17. Move the lower air guide backward and pull out

from the base pan. (Move the lower air guide

carefully.)

18. Re-install the components by referring to the

removal procedure, above.

2.2.2 FAN

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the brace (Refer to section 2.2.1)

3. Remove 6 screws which fasten the condenser.

4. Move the condenser to the right carefully.

5. Remove the clamp which secures the fan with a pair of

hand pliers.

6. Remove the fan. (See Figure 7)

7. Re-install by referring to the removal procedure.

Figure 4

Figure 5

Figure 6

Figure 7

—7—

2.2.3 SHROUD

1. Remove the fan. (Refer to section 2.2.2)

2. Remove the shroud. (See Figure 8)

3. Re-install the components by referring to the

removal procedure, above.

2.3 ELECTRICAL PARTS

2.3.1 OVERLOAD PROTECTOR

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the nut which fastens the terminal cover.

3. Remove the terminal cover. (See Figure 9)

4. Remove all the leads from the overload protector.

5. Remove the overload protector.

6. Re-install the components by referring to the

removal procedure, above.

2.3.2 COMPRESSOR

1. Remove the cabinet. (Refer to section 2.1.2)

2. Discharge the refrigerant system using a Freon

TM

Recovery System.

If there is no valve to attach the recovery system to

install one (such as a WATCO A-1) before venting

the FreonTM. Leave the valve in place after

servicing the system.

3. Remove the overload protector. (Refer to section

2.3.1)

4. After purging the unit completely, unbraze the

suction and discharge tubes at the compressor

connections.

5. Remove the 3 nuts and the 3 washers which

fasten the compressor to the base pan.

6. Remove the compressor. (See Figure 10)

7. Re-install the components by referring to the

removal procedure, above.

Figure 8

Figure 9

Figure 10

—8—

2.3.3 CAPACITOR

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the screw and the clamp which fasten the

capacitor.

3. Disconnect all the leads of capacitor terminals.

4. Re-install the components by referring to the

removal procedure, above. (See Figure 11)

2.3.4 POWER CORD

1. Remove the cabinet. (Refer to section 2.1.2)

2. Disconnect the grounding screw from the control

box.

3. Disconnect the 2 receptacles.

4. Remove a screw which fastens the cord clip.

(See Figure 12)

5. Remove the power cord.

6. Re-install the component by referring to the

removal procedure, above.

(Use only one ground-marked hole for ground

connection.)

7. If the supply cord of this appliance is damaged, it

must be replaced by the same cord that can be

obtained from an authorized parts dealer.

2.3.5 THERMOSTAT

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the 2 screws which fasten the thermostat.

3. Disconnect 2 leads of thermostat terminals.

4. Remove the thermostat.

5. Re-install the components by referring to the above

removal procedure. (See Figure 13)

2.3.6 ROTARY SWITCH

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the 2 screws which fasten the rotary

switch.

3. Disconnect all the leads of the rotary switch

terminals.

4. Remove the rotary switch.

5. Re-install the components by referring to the

above removal procedure. (See Figure 14)

Figure 11

Figure 12

Figure 13

Figure 14

T

e

m

p

e

r

a

t

u

r

e

Med

Fan

Warmer

Off

Cooler

High

Cool

Low

Fan

Low Cool

Med

Cool

M

o

d

e

—9—

2.3.7 MOTOR

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the turbo fan. (Refer to section 2.2.1)

3. Remove the fan. (Refer to section 2.2.2)

4. Remove the 4 screws which fasten the motor from

the Motor Mount. (See Figure 15)

5. Remove the motor.

6. Re-install the components by referring to the

removal procedure, above.(See Figure 15)

2.4 REFRIGERATING CYCLE

2.4.1 CONDENSER

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the 4 screws which fasten the brace.

3. Remove the 4 screws which fasten the condenser

and shroud. (See Figure 16)

4. Remove the 2 screws which fasten the condenser

and base pan.

5. After discharging the refrigerant completely,

unbraze the interconnecting tube at the condenser

connections.

6. Remove the condenser.

7. Re-install the components by referring to notes on

p10. (See Figure 16)

2.4.2 EVAPORATOR

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the control box.(Refer to section 2.1.3)

3. Remove the upper air guide. (Refer to section

2.2.1)

4. Remove the 2 screws which fasten the evaporator

to the lower air guide.

5. Carefully move the evaporator sideways.

(Refer to section 2.2.1)

6. After discharging the refrigerant completely,

unbraze the interconnecting tube at the evaporator

connections.

7. Remove the evaporator.

8. Re-install the components by referring to notes on

page 10. (See Figure 17)

Figure 15

Figure 16

Figure 17

Discharge the refrigerant system using a

FreonTMRecovery System.

If there is no valve to attach the recovery

system to install one (such as a WATCO A-1)

before venting the FreonTM. Leave the valve in

place after servicing the system.

CAUTION

Loading...

Loading...