Page 1

Room Air Conditioners

AUTO

°F°C

AUTO

CONTINUOUS

AUTO

SYSTEM FAN MODE

SCHEDULE FAN SPEED

Installation and Operation Manual

Standard Chassis Models

115-Volt:

208-230-Volt:

115-Volt:

208-230-Volt:

920-198-09 (10-10)

SS08M10, SS10M10, SS12M10, SS14M10

SS12M30, SS15M30, SM18M30, SM21M30

SM24M30, SL28M30, SL36M30

YS10M10

ES12M33, ES15M33, YS12M33, EM18M34,

YM18M34, EM24M34, EL36M35, YL24M35

Page 2

THANK YOU!

your unit to assure quiet operation, the greatest circulation of cool, dry air, and the most economic operation.

AIR CONDITIONING CO.

SAN ANTONIO, TEXAS

ASSEMBLED IN MEXICO

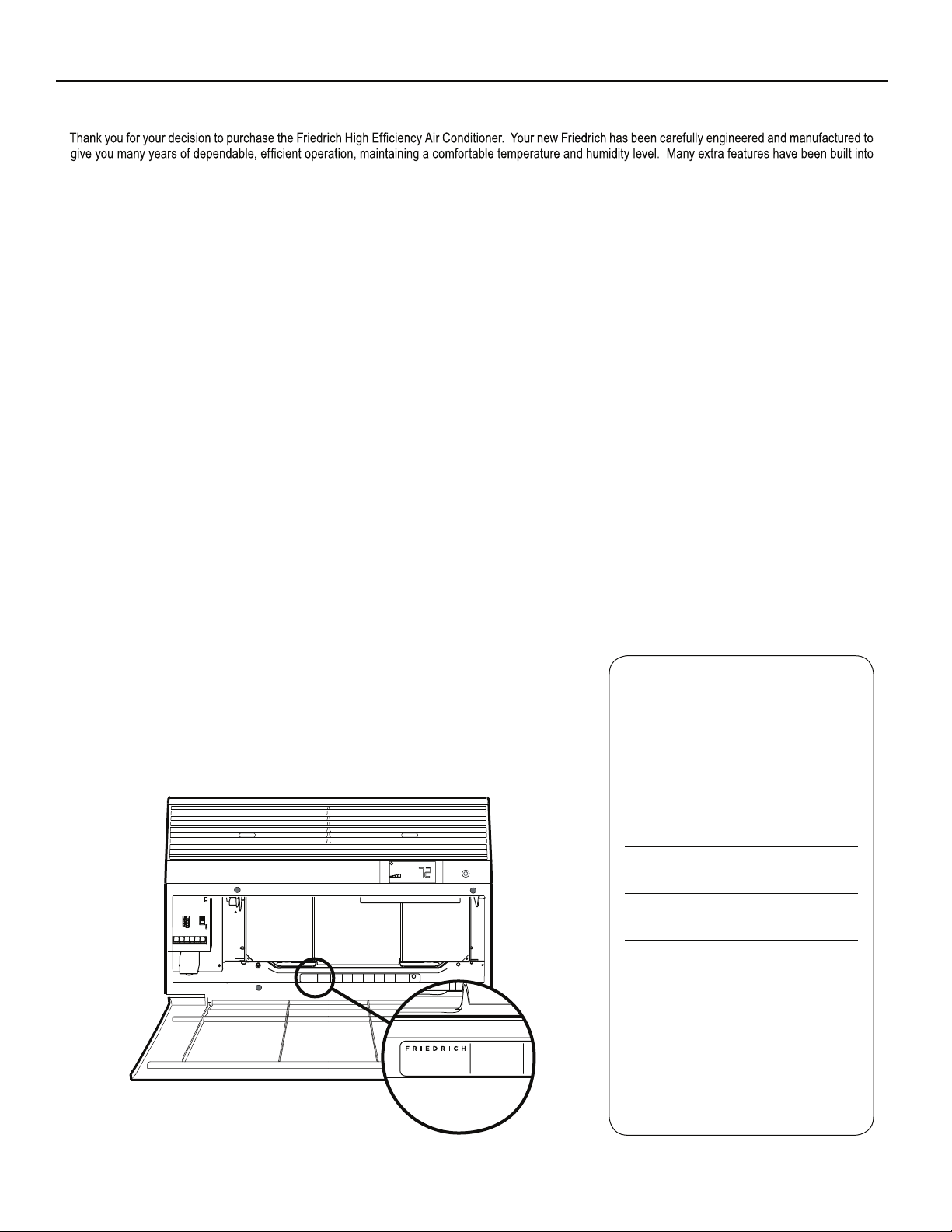

Register your air conditioner

Model information can be found on the name

plate behind the front cover.

Ple a s e c o mplete a n d mail the o w ner

registration card furnished with this product,

or register online at www.friedrich.com (USA

only). For your future convenience, record the

model information here.

MODEL NUMBER

SERIAL NUMBER

PURCHASE DATE

MODEL NUMBER

HEATING

REFRIGERANT

XXXXXXXXX

XXXXXXXXXX

VOLTS 115

COOLING

YS10M10A

60 HZ / 1 PH

BTH/HR 6500

SERIAL NUMBER

VOLTS MIN 108

EER 12.0

LICY00008

AMPS 8.0

FUSE PROTECTED

U

600 PSIG HS

XXXXXXXXX

CIRCUITS USE 15A

300 PSIG LS

XXXXXXXXXX

TIME DELAY FUSE

XXXXXXXXXX

L

X XX

XXXXX

XXXXXXXXXX

AIR CONDITIONING CO.

SAN ANTONIO, TEXAS

ASSEMBLED IN MEXICO

MODEL NUMBER

YS10M10A

SERIAL NUMBER

LICY00008

BTH/HR 6500

30.1 OZ R410A

EER 10.4

AMPS 7.0

2

Page 3

Table of Contents

Safety Precautions ................................................................................................................................................................................................................... 4

Unpacking Instructions............................................................................................................................................................................................................. 5

WARNING: Before Operating Your Unit ..................................................................................................................................................................................6

Standard Filter Cleaning / Installation Instructions .................................................................................................................................................................. 7

Premium Carbon Filter Installation Instructions ....................................................................................................................................................................... 8

Control Panel Operation ........................................................................................................................................................................................................ 10

Add a Remote Thermostat ..................................................................................................................................................................................................... 14

Remote Thermostat Selection ...............................................................................................................................................................................................14

Remote Control Operation ..................................................................................................................................................................................................... 15

Remote Effectiveness ............................................................................................................................................................................................................ 15

.......................................................................................................................................................................................... 17

Installation Instructions .......................................................................................................................................................................................................... 18

Standard Window Installation ................................................................................................................................................................................................ 20

Cord Routing Change ............................................................................................................................................................................................................30

Through-the-Wall Installation ................................................................................................................................................................................................. 32

Programmable Thermostat ....................................................................................................................................................................................................36

Final Inspection & Start-up Checklist..................................................................................................................................................................................... 38

Routine Maintenance ............................................................................................................................................................................................................. 39

Service and Assistance .........................................................................................................................................................................................................39

Available Accessories ............................................................................................................................................................................................................ 39

Troubleshooting Tips .............................................................................................................................................................................................................. 40

Addendum 1 ........................................................................................................................................................................................................................... 42

3

Page 4

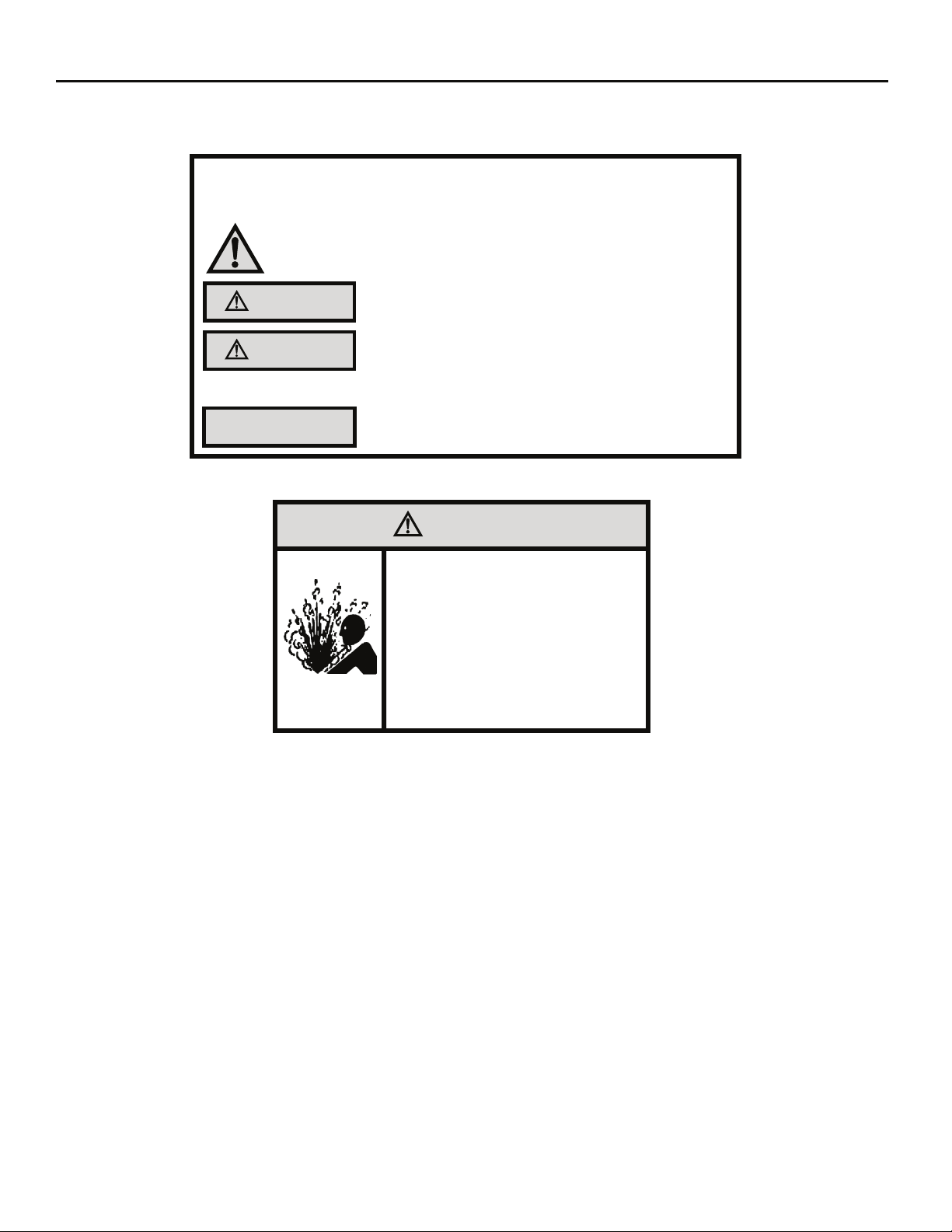

Safety Precautions

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

WARNING

CAUTION

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what will happen if the instructions are not followed.

Your safety and the safety of others are very important.

This is a safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING”

or “CAUTION”. These words mean:

Indicates a hazard which, if not avoided, can result in severe personal injury or

death and damage to product or other property.

Indicates a hazard which, if not avoided, can result in personal injury and

damage to product or other property.

NOTICE

Indicates property damage can occur if instructions are not followed.

WARNING

Refrigeration system

under high pressure

Do not puncture, heat, expose to flame or

incinerate.

Only certified refrigeration technicians should

service this equipment.

R410A systems operate at higher pressures

than R22 equipment. Appropriate safe

service and handling practices must be used.

Only use gauge sets designed for use with

R410A. Do not use standard R22 gauge sets.

4

Page 5

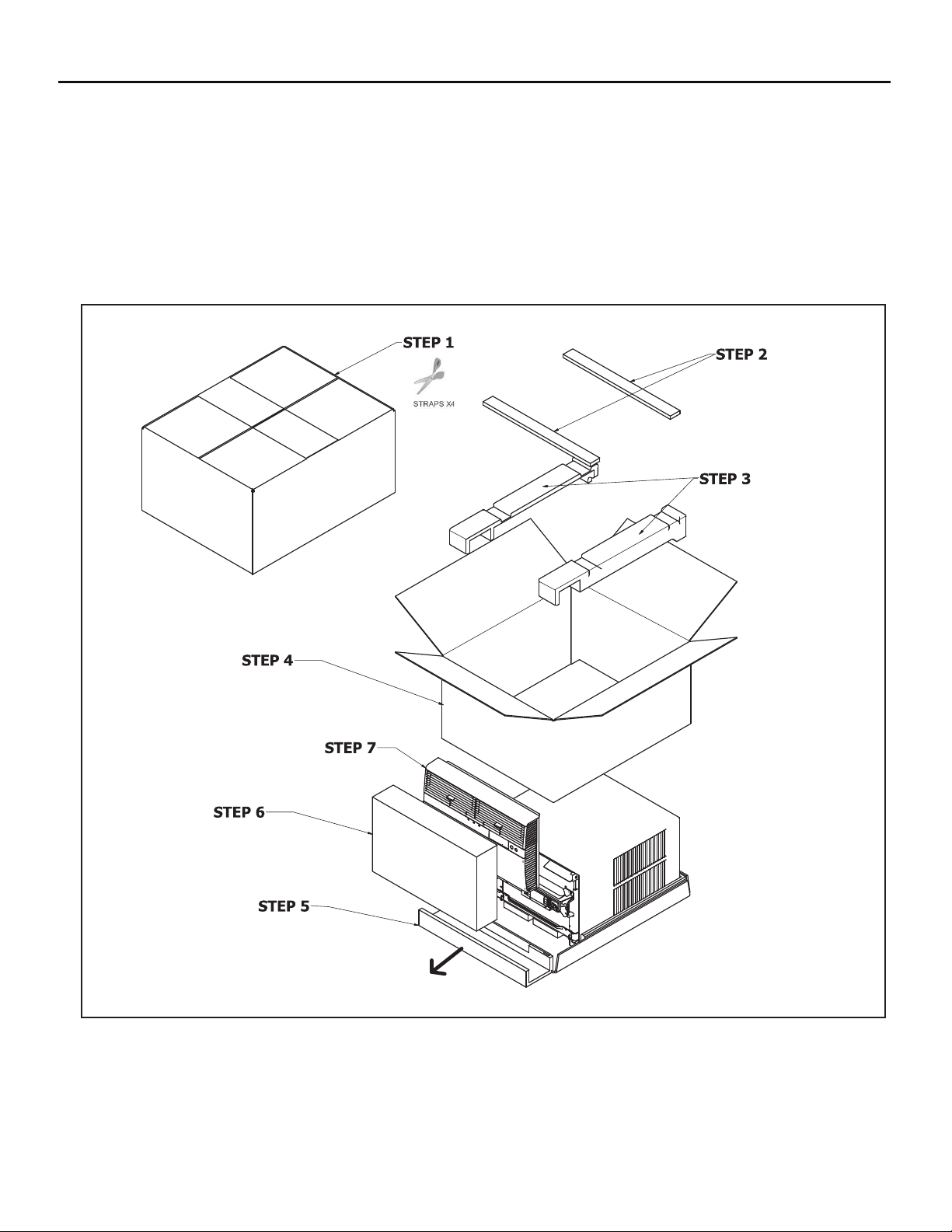

Unpacking Instructions

STEP 5. Slide the foam front support forward

STEP 1. Cut all 4 packing straps.

STEP 2. Remove wooden shipping bar dividers.

STEP 3. Remove top foam pads.

STEP 4. Slowly remove outer box, careful not to loosen decorative front.

STEP 6. Carefully lift decorative front box from foam front support

STEP 7. Remove decorative front and set safely aside

5

Page 6

WARNING: Before Operating Your Unit

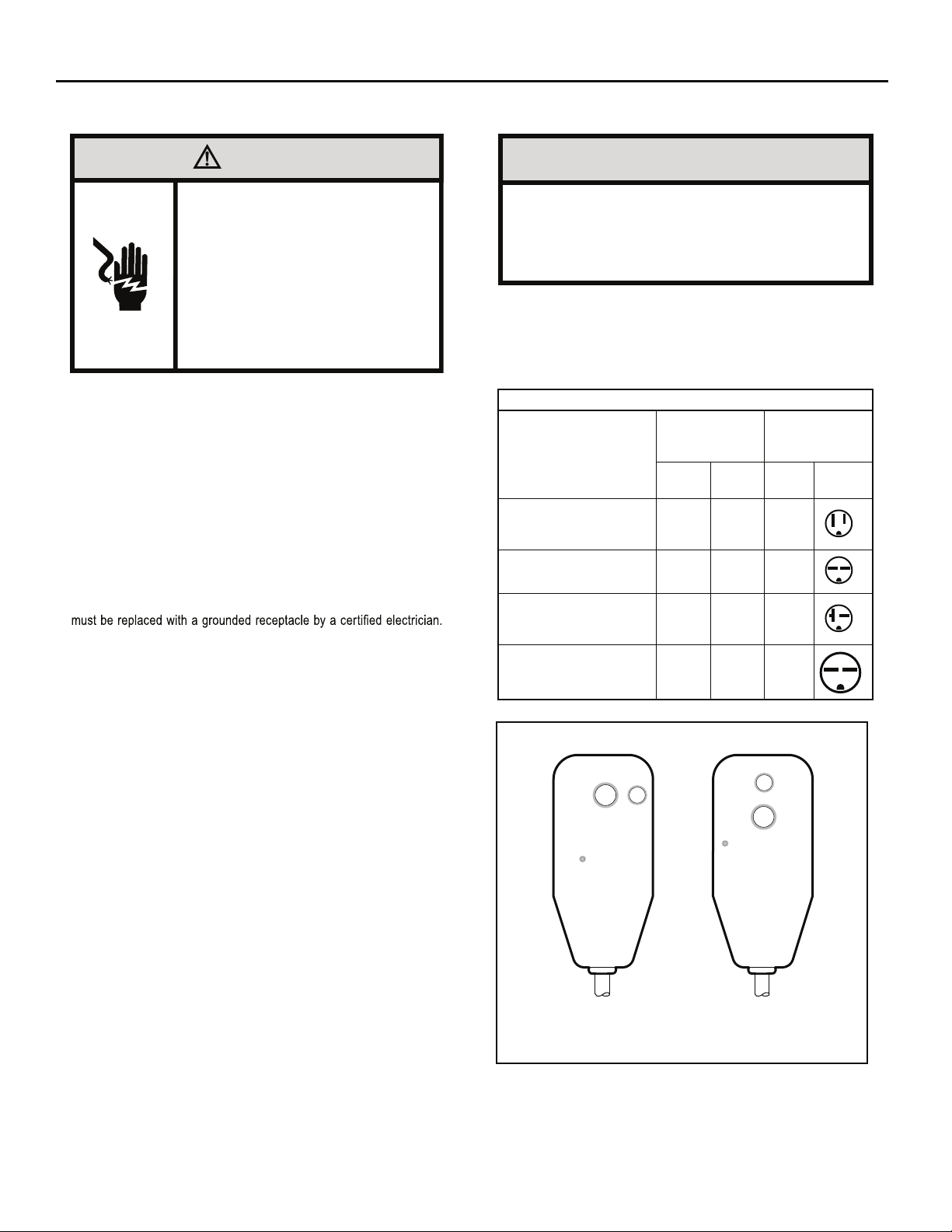

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong oulet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

Make sure the wiring is adequate for your unit.

If you have fuses, they should be of the time delay type. Before you install

or relocate this unit, be sure that the amperage rating of the circuit breaker

or time delay fuse does not exceed the amp rating listed in Table 1.

DO NOT use an extension cord.

The cord provided will carry the proper amount of electrical power to the

unit; an extension cord may not.

Make sure that the receptacle is compatible with

the air conditioner cord plug provided.

Proper grounding must be maintained at all times. Two prong receptacles

The grounded receptacle should meet all national and local codes and

ordinances. You must use the three prong plug furnished with the air

conditioner. Under no circumstances should you remove the ground

prong from the plug.

Test the power cord

All Friedrich room air conditioners are shipped from the factory with a

Leakage Current Detection Interrupter (LCDI) equipped power cord. The

LCDI device on the end of the cord meets the UL and NEC requirements

for cord connected air conditioners.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET (See Figure 1).

3. Press TEST, listen for click; the RESET button trips and pops out.

4. Press and release RESET (Listen for click; RESET button latches

and remains in). The power cord is ready for use.

NOTICE

Do not use the LCDI device as an ON/OFF switch.

Failure to adhere to this precaution may cause

premature equipment malfunction.

Once plugged in, the unit will operate normally without the need to reset

the LCDI device. If the LCDI device fails to trip when tested or if the power

supply cord is damaged, it must be replaced with a new power supply cord

from the manufacturer. Contact our Technical Assistance Line at (800)

541-6645. To expedite service, please have your model number available.

Table 1.

MODEL

SS08M10, SS10M10,

SS12M10, SS14M10,

YS10M10

SS12M30, SS15M30,

SM18M30, SM21M30

SM24M30

, SL28M30,

ES12M33, ES15M33,

YS12M33

SL36M30, EM18M34,

EM24M34,

EL36M35,

YM18M34, YL24M35

Figure 1

RESET

WARNING

TEST BEFORE EACH USE

1. PRESS RESET BUTTON

2. PLUG LCDI INTO POWER

RECEPTACLE

3. PRESS TEST BUTTON,

RESET BUTTON SHOULD

POP UP

4. PRESS TEST BUTTON,

FOR USE

DO NOT USE IF ABOVE TEST

FAILS

WHEN GREEN LIGHT IS ON

IT IS WORKING PROPERLY

CIRCUIT RATING

OR TIME DELAY

AMP VOLT

15 125 5-15R

15 250 6-15R

20 250 6-20R

30 250 6-30R

TEST

FUSE

TEST BEFORE EACH USE

1. PRESS RESET BUTTON

2. PLUG LCDI INTO POWER

RECEPTACLE

3. PRESS TEST BUTTON,

RESET BUTTON SHOULD

POP UP

4. PRESS TEST BUTTON,

FOR USE

DO NOT USE IF ABOVE TEST

FAILS

WHEN GREEN LIGHT IS ON

IT IS WORKING PROPERLY

REQUIRED

WALL

RECEPTACLE

NEMA

NO.

TEST

RESET

WARNING

15/20A LCDI Device 30A LCDI Device

FRR001

6

Page 7

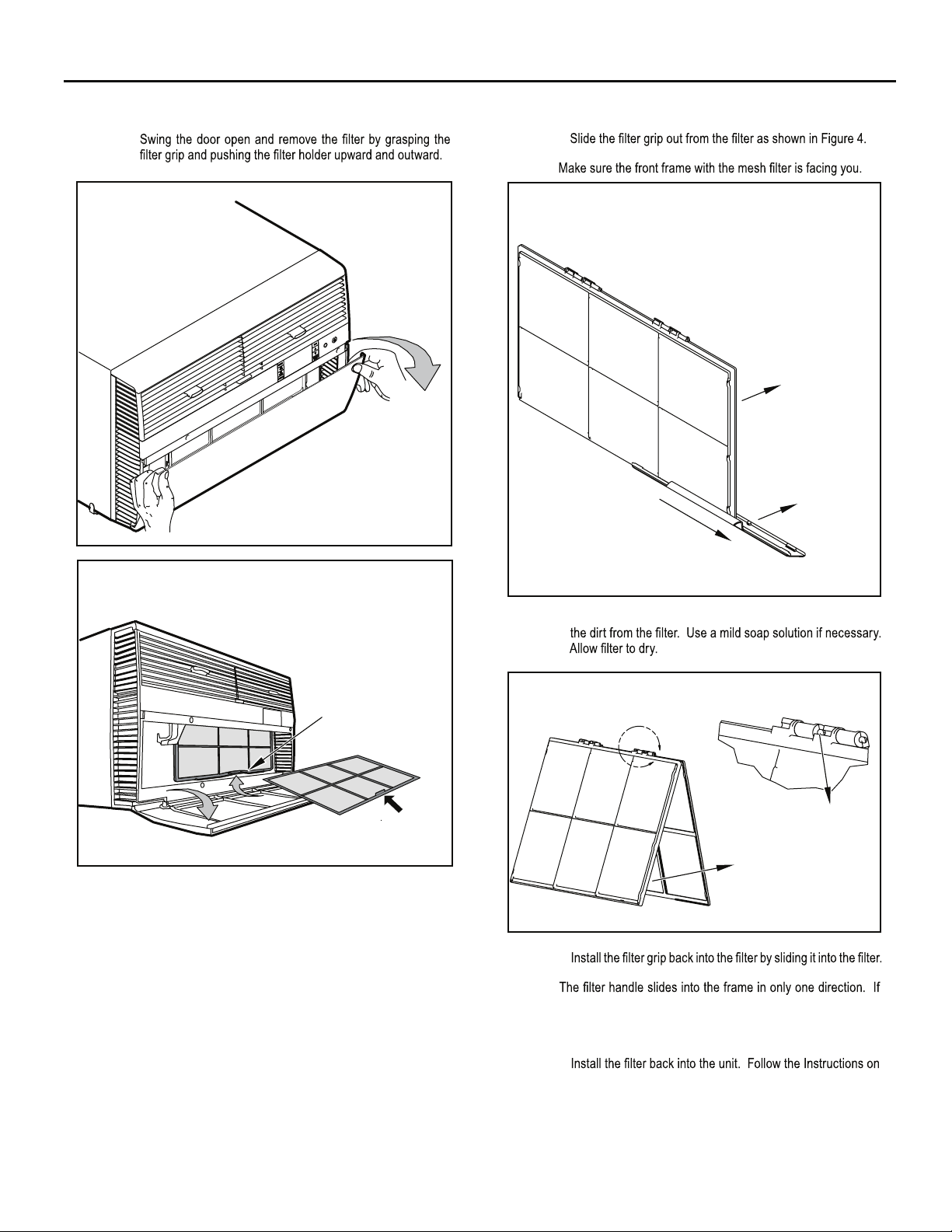

Standard Filter Cleaning / Installation Instructions

STEP 1.

Figure 2

FRR071

STEP 2.

NOTE:

Figure 4

FILTER

FILTER

GRIP

Figure 3

FILTER

GRIP

HANDLE

FRR052

FRR047

STEP 3. Swing the front frame open. Clean the front frame by washing

Figure 5

A

TOP TAB

FRONT

FRAME WITH

STANDARD

MESH FILTER

FRR048

STEP 4.

NOTE:

the tab in the frame stops the handle from sliding in, slide the

handle from the other direction. Do not force the handle into

the frame.

STEP 5.

the inside of the front door.

7

Page 8

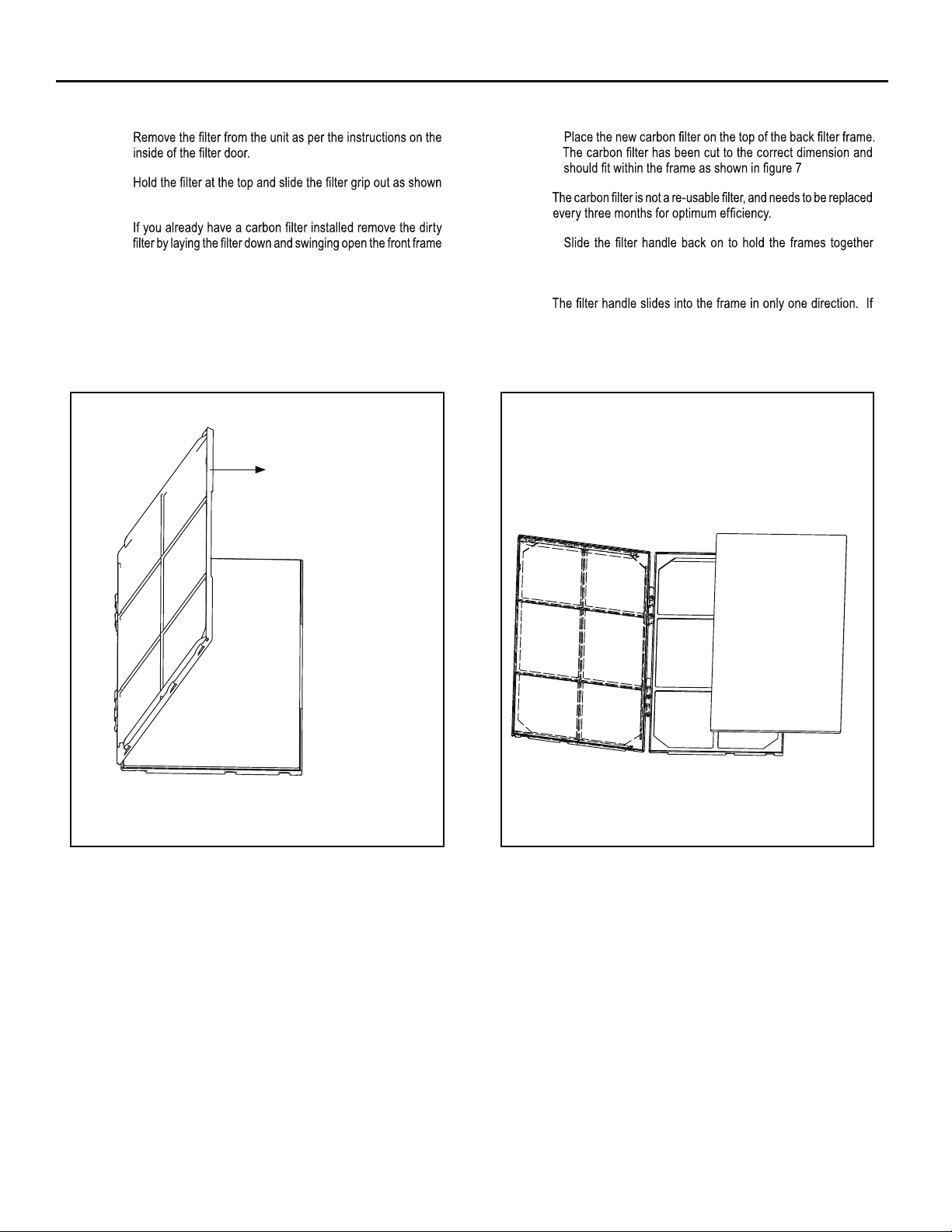

Premium Carbon Filter Installation Instructions

STEP 1.

STEP 4.

STEP 2.

in Figure 4.

STEP 3.

as shown in Figure 6.

NOTE: Make sure the frame with the mesh is facing towards you.

Figure 6

FRONT FRAME WITH

MESH FILTER

NOTE:

STEP 5.

and slide the assembly into the unit as per the instructions

on the door.

NOTE:

the tab in the frame stops the handle from sliding in, slide the

handle from the other direction. Do not force the handle into

the frame.

Figure 7

FRR051FRR05 0

8

Page 9

THIS PAGE INTENTIONALLY LEFT BLANK

9

Page 10

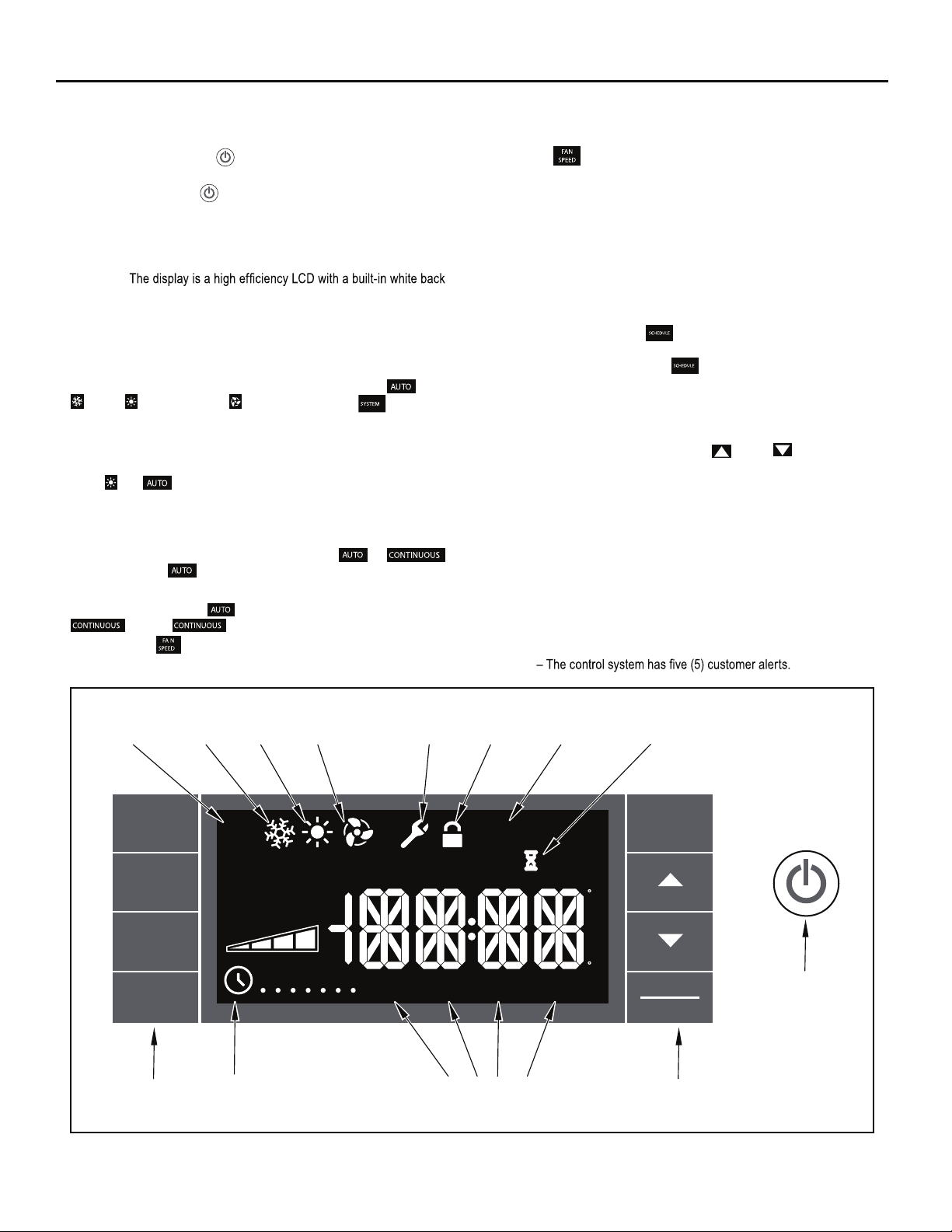

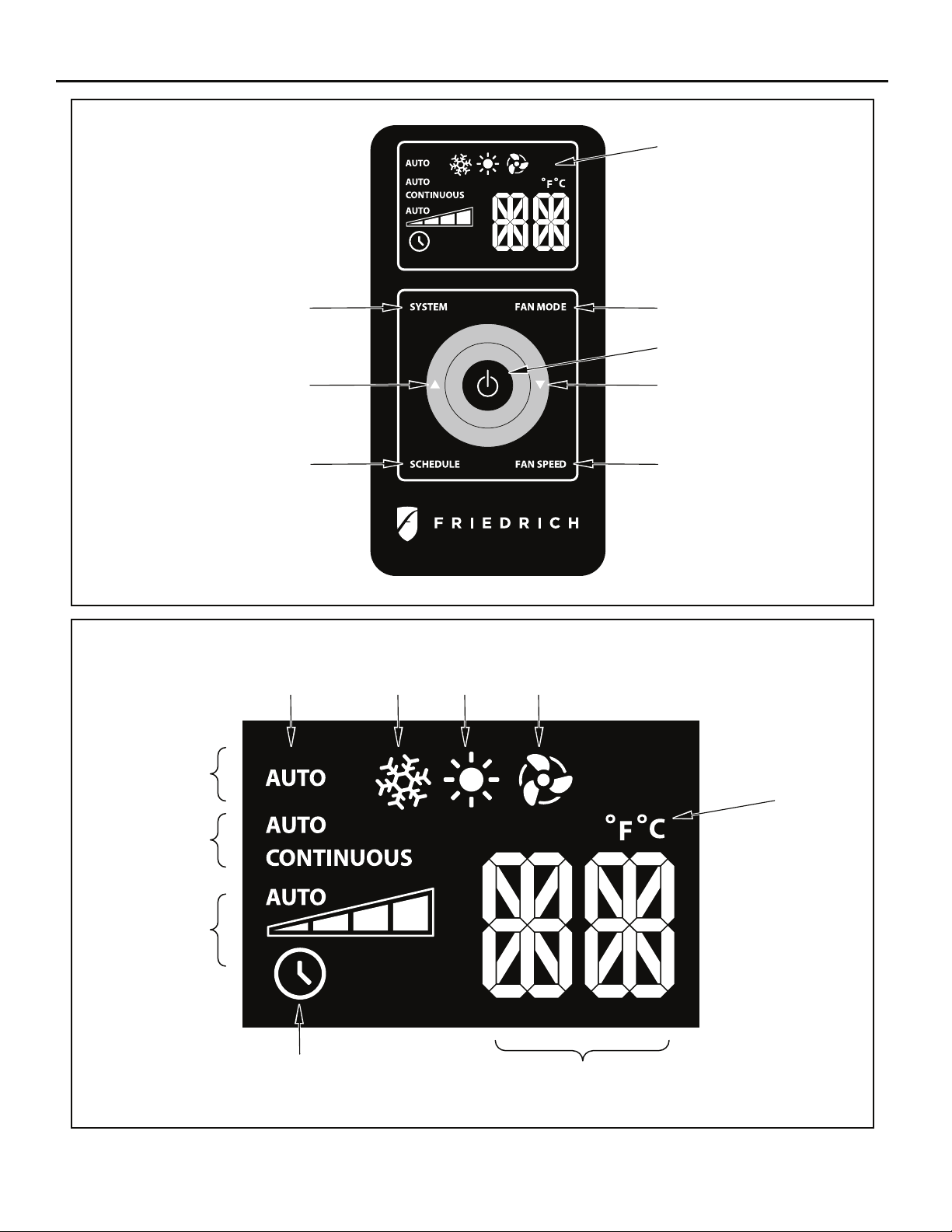

Control Panel Operation

Let’s check out how to control your air conditioner. On the control panel,

just to the left of the POWER , is a liquid crystal display (LCD). All of the

control panel function buttons and mode icons can be viewed in Figure 8.

Power On – Press the

power button will illuminate to indicate the power is on. The backlight on

the power switch will automatically dim to 20% intensity after 15 seconds

of inactivity. The remote control can also be used to turn power ON / OFF

(See Remote Control).

Display –

light. The back light has an automatic two (2) step dim function. After 15

seconds of inactivity, the display dims to 20% intensity. After an additional

120 seconds, the display switches off. Touching buttons will automatically

bring the display to full brightness.

There are four control push buttons on each side of the display.

S

YSTEM Button – Allows the user to sequentially select,

, HEAT , and FAN ONLY operation. Press the button and

the display advances to the next mode. A new icon appears. At the same

time, the mode displays for two (2) seconds, then returns the display to

the temperature set point for modes other than FAN. Note that when the

heating function is not available, the system will automatically skip the

HEAT

and modes.

NOTE: After the compressor stops the fan will continue to operate for 30

seconds.

FAN MODE Button – Selects between automatic

operation. In the mode, the fan only turns on and off when the

compressor operates or the heat function is enabled.

In the FAN ONLY Mode,

. In the mode, fans speed is determined by your

selection on the button.

button to turn on the air conditioner. The

Cool

or

is not available. The display indicates

FAN SPEED Button .sdeeps naf neewteb tceles yllaitneuqes ot desU –

Depending on your model, you can select between LOW, MED, HIGH,

When the

button is pressed, the fan speed is temporarily displayed

in the display window, plus a fan speed icon (triangle) changes to indicate

the new speed level. W

hen auto is selected,

fan speed automatically varies

depending on the set temperature on the control panel and the actual

room temperature. Let me explain. Say for example you’re working in

your garage and you need to open the big door for several minutes. The

air conditioner will sense a wide difference between the set temperature

and the actual room temperature when this occurs the system fan speed

increases to MAX. The fan speed decreases (in step) as the temperature

difference decreases. When the set point temperature is reached the FAN

speed returns to the original setting.

SCHEDULE Button – The

button turns the schedule function on

and off. The current day of the week is indicated as a dot underneath

the day symbol. Pressing the

button a second time turns the

schedule function off. The schedule function comes preprogrammed with

recommended energy savings values (Addendum 1). The values may

be changed through the schedule program function (See Programmable

Thermostat).

UP and DOWN arrows – Pressing either

(UP) or (DOWN) button

changes the desired room temperature. The factory preset lower and

upper limits are 60° F (16° C) and 99° F (37° C). These buttons are also

used to navigate between function options when using the User Menu or

Maintenance Mode.

BACK Button .detceles neeb sah meti unem a retfa desu si nottub sihT –

It takes the user back to the previous menu level.

DISPLAY/ENTER Button – This button is used in conjunction with User

menu and Maintenance Mode operation to select items.

This button may also be used alternately to

RATURE

and TIME. If the display is left inactive for 10 seconds it will

display the ROOM TEMPE-

reset to the TEMPERATURE SET POINT.

Alerts

.)sledom sulp looc ro LY ,LE ,LS no ton gnittes xaM .OTUA dna XAM dna

Figure 8

AUTO

MODE

SYSTEM

FAN

MODE

FAN

COOL

MODE

HEAT

MODE

AUTO

AUTO

CONTINUOUS

AUTO

FAN

ONLY

MODE

MAINTENANCE

REQUIRED

OUTDOOR TEMP

% RH

SPEED

M

SCHEDULE

BUTTONS BUTTONS

SCHEDULE

ON/OFF

T W

T F S

S

WAKE

AWAY

SCHEDULE

FRONT

PANEL

LOCK

CHECK

FILTERONOFF

HEAT ->

RETURN NIGHT

PERIODS

FILTER

MAINTENANCE

EXIT

RESET

<- COOLROOM TEMP SET POINT

F

A

M

P

M

C

WAIT

BACK

DISPLAY

ENTER

POWER

FRR002

10

Page 11

CHECK FILTER

appears on screen. The word “ ” appears next to the .nottub

The alert is issued when the fan run .sruoh 005 naht retaerg si emit

This alert may be reset by the user (Refer to Special Functions, Filter Reset).

Maintenance Required – When maintenance is required, a service icon

appears on screen. This icon will not be dismissed until maintenance

has been performed. If the service icon

the icon .noitidnoc lamronba na desnes sah metsys eht ybdnats no si

is established the service icon goes away.

Wait – The WAIT icon .evitca si tuokcol rosserpmoc eht nehw setanimulli

Whenever the compressor shuts off, system pressures must be allowed

to equalize. At this time, an internal timer begins a count-down from up to

240 seconds. If a demand for heat or cool occurs during this count-down

the WAIT icon

displays letting you know that the compressor will not

operate until the count-down has completed. This timer prevents damage

to the unit if it tries to start too quickly after it stops running. Normally the

WAIT icon

is off. Once the timer has cleared, the air conditioner will

heat or cool based on the temperature setting. Electric heat is not affected

by this timer.

Protection Alert (Freeze) – If the room freeze protection is active, the

display indicates this by showing Room Freeze Protection "FRZ". Once

temperature is less than 40° F (4° C), and the air conditioner is equipped with

electric heat, the room freeze protection will activate. The air conditioner

will run high fan and electric heat until the room temperature reaches

46° F (8° C). Pressing the

Low Battery – When the battery is low a warning display

button delays the freeze protection function

will be

inserted before other messages such as “COOL”. If the Low Battery

alert is on, the battery in the control unit must be changed. Refer

to the changing the battery procedure. Once the battery is changed, the

alert message will go off. Refer to Troubleshooting Tips. Under normal

conditions the battery life should be greater than 7 years.

Special Functions

Panel Lock

inadvertent operation. To lock the front panel, press and hold the

buttons for three (3) seconds. A double beep indicates your mode

change was successful and a icon appears on the display. To unlock

the display, press and hold the + .sdnoces )3( eerht rof snottub

The icon will no longer be visible.

Filter Reset –

and holding the button for three (3) seconds. A beep indicates the

system timer was reset and the icon and the word "

no longer be visible.

User Menu Functions – The User Menu Functions allows you to change

the following selections: Set TIME, 12/24 Hour Clock Format, BEEP ON /

OFF, DIM ON / OFF, Emergency Heat (EMHT) ON / OFF, Auto BAND Adjust,

F/ C Select, FRZ ON / OFF, the Automatic Temperature Sensing Feature

and Temp Offset.

To enter the User Menu, press and hold

selection appears. Use the (UP) or (DOWN) buttons to scroll

through the User Menu. Press the button to enter the displayed

function. If left inactive for 15 minutes the User Menu display will no longer

be visible and it returns to normal operation mode display. To manually

exit the User Menu, press the

– The front panel push buttons can be locked to prevent

SCHEDULE

icon displays, the timer may be reset by pressing

" will

RESE T

for 3 seconds, the TIME

button.

+

The hour digits flash first. The user presses the or

to change the hours. To change AM-PM, the hours must be

advanced 12 hours. Press the key to change to the

minutes. To exit the selection process, user presses the

key which will go to the time screen.

The minutes digits flash. The user presses the or

to change the minutes. Press the key to change the days.

To exit the selection process, the user presses the key

which will go to the time screen.

The dot underneath the days of the week begins to blink to

indicate which day it is. If the user has not set the date before,

the dot starts on Monday. If the user is making a correction to

previously set information the dot appears under whichever

day the unit thinks it is. The user can press or to move

the dot left or right (respectively) along the week. The user

presses to loop back to the hours setting. To exit the

selection process, the user presses the key which will go

to the time screen.

Tuesday has been selected. The user presses to loop

back to the hours setting. To exit the selection process and

accept the changes, the user presses the key which will go

to the time screen.

BACK

FRR062

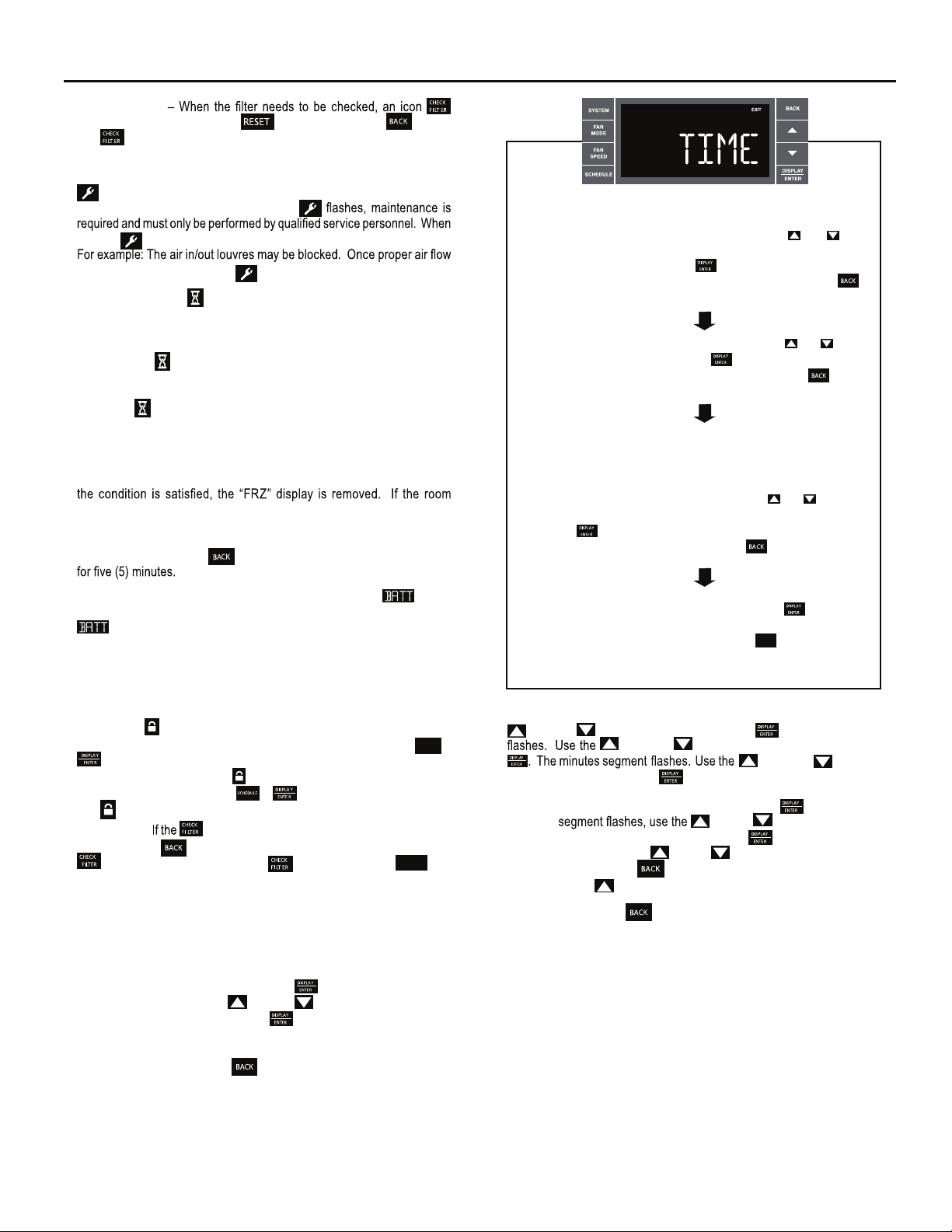

Time Setting – When in the User Menu, on the Control Panel, use the

(UP) and (DOWN) to select TIME. Push , the hours segment

(UP) and hsup neht ,ruoh eht tes ot )NWOD(

(UP) and

to set the minutes, then push

.

NOTE: If the AM or PM indicator is incorrect, push

(DOWN)

until the hours

(UP) or (DOWN) to advance

the hour segment 12 hours, then push

displays. Use the

day. Press the

Press

(UP) to go to the next menu 1224.

NOTE: Pressing the

(UP) or (DOWN) to select the current

key to

save and go back to the TIME screen.

button again will exit the user menu function

. The day of the week

mode. Or simply leave the control inactive for 15 seconds and

the control will return back to normal operation.

11

Page 12

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

BACK

EXIT

DISPLAY

ENTER

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

BACK

EXIT

DISPLAY

ENTER

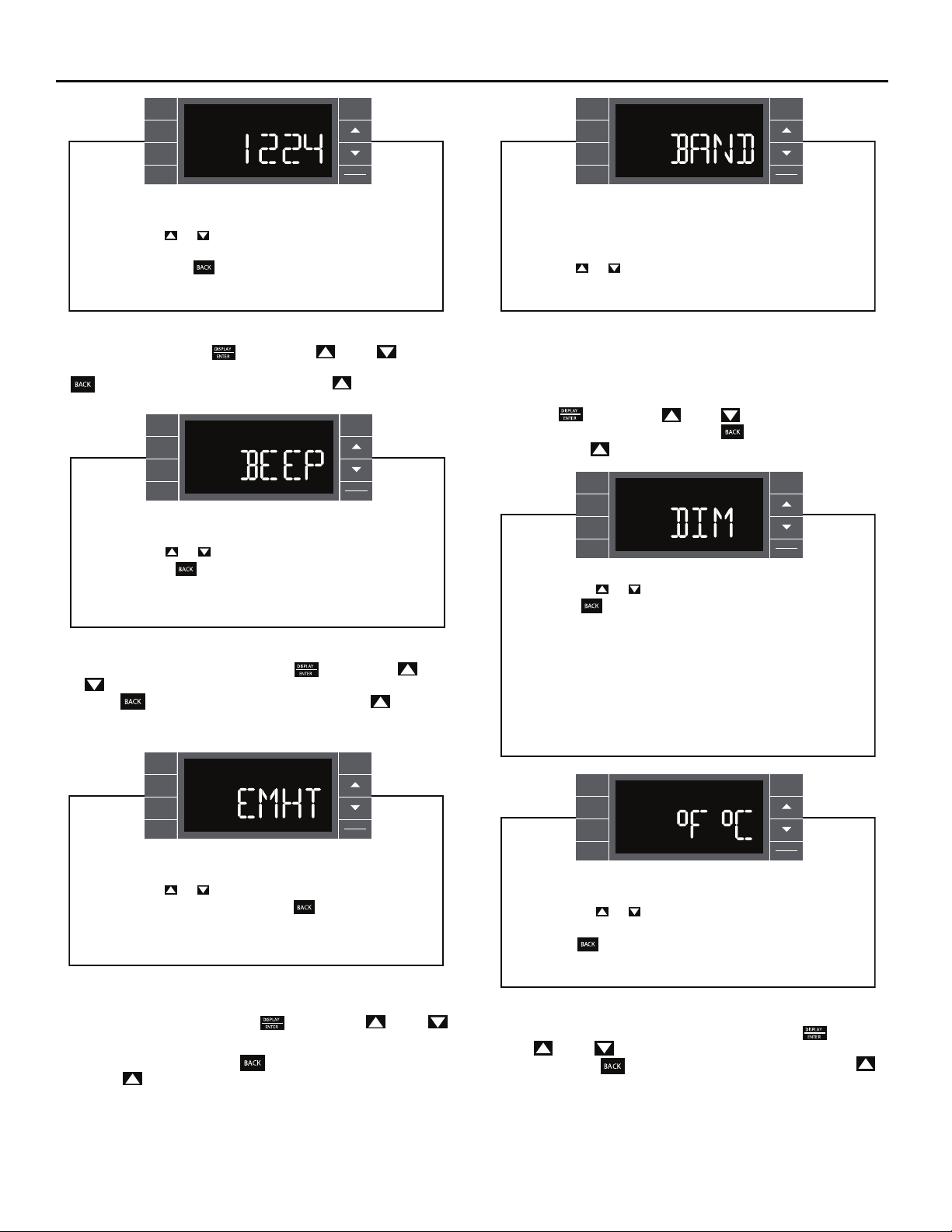

User presses or to toggle the format between 12HR and

24HR display. To exit the selection process and accept the

change, press the key.

FRR063

Clock Type – You may select between a 12 hr and 24 hr clock. When

1224 is displayed press the

key then press (UP) or (DOWN)

to toggle between 12 hr and 24 hr clock. To accept the change, press the

key to return to the 1224 screen. Press the (UP) to go to the

next menu BEEP.

BACK

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

EXIT

DISPLAY

ENTER

User presses or to toggle between Beep On and Beep

Off. Press the key to accept the change and exit the

selection process.

FRR064

Audible Alerts – You can select to have the control beep when entering

menus.

When BEEP is displayed press the

or

(DOWN) to toggle between ON and OFF. To accept the change,

press the

key to return to the BEEP screen. Press the (UP) to go

key then press (UP)

to the next menu EMHT on Kühl+ models or F C for Kühl models.

The menu allows the user to adjust the minimum spread

between the Auto Cool set point and the Auto Heat set point.

Press the or key to adjust. The adjust range is 3 to 10.

FRR066

Auto Changeover ‘Dead Band’ – A buffer Zone between heating and

cooling in which no conditioning occurs. For Kühl+ models with the auto

changeover feature you can select the temperature band between heating

and cooling. From the factory the band is set at 3° F (-16° C). The band is

adjustable from 3° F (-16° C) to 10° F (-12° C). When BAND is displayed

press the key then press (UP) or (DOWN) to toggle between

3 and 10. To accept the change, press the key to return to the BAND

screen. Press the (UP) to go to the next menu F C.

BACK

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

User presses or to select between AUTO, DM 20, OFF.

Press the key to accept the change and exit the

selection process.

The Dim Auto automatically dims the display and then turns it

off after a period of time. The Dim 20 setting behavior is similar

to AUTO, but prevents the display from turning off. Minimum

brightness is 20%. The Dim Off setting forces the display to run

at full brightness.

EXIT

DISPLAY

ENTER

BACK

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

EXIT

DISPLAY

ENTER

User presses or to toggle between Emergency Heat On

and Emergency Heat Off. Press the key to accept the

change and exit the selection process.

FRR065

Emergency Heat – The Kühl+ heat pump models (YS, YM, YL) have

a special feature that is designed to keep the unit providing heat.

When EMHT is displayed press the

key then press (UP) or

.FFO dna NO neewteb elggot ot )NWOD(

To accept the change, press the

Press the

(UP) to go to the next menu BAND

.

In the unlikely event of a compressor failure, the heat pump unit may be

switched to operate in the electric heat mode only until repairs can be

made.

12

FRR067

BACK

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

EXIT

DISPLAY

ENTER

User presses or at the same time to toggle between

Fahrenheit or Celsius as their temperature unit of choice.

Press the key to accept the change and exit the selection

process.

FRR068

Fahrenheit / Celsius Selection – You may select between displaying

temperature in F or C. When F C is displayed press the

key then

press (UP) or (DOWN) to toggle between F and C. To accept the

.neercs THME eht ot nruter ot yek

change, press the key to return to the F C screen. Press the

(UP) to go to the next menu FRZ.

Page 13

BACK

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

EXIT

DISPLAY

ENTER

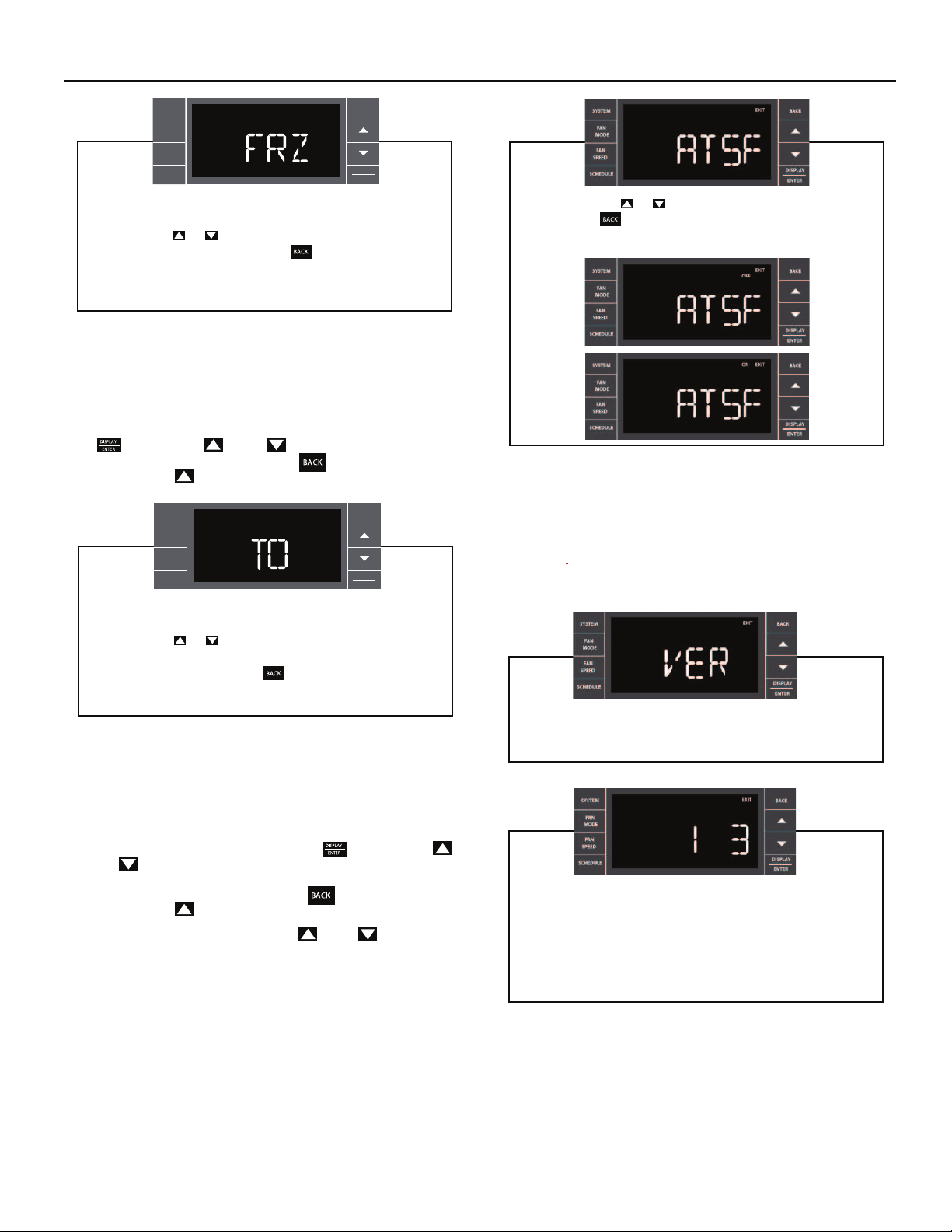

User presses or to select between Freeze Protection On

& Freeze Protection Off. Press the key to accept the

change and exit the selection process.

FRR069

F

F

Y

R

FRR072

User presses or to select between ATSF On or Off.

Press the key to accept the change and exit the

selection process.

Freeze Protection – The Kühl+ models have a special feature that is

designed to keep the interior space above freezing by energizing the

electric heater anytime the indoor room temperature falls to 40° F (4° C) .

With the freeze protection feature turned on, when the unit senses the

indoor temperature fall to 40° F (4° C) the unit will run the heater and high

fan until the space reaches 46° F (8° C) When FRZ is displayed press

the

key then press (UP) or (DOWN) to toggle between ON

and OFF. To accept the change, press the key to return to the FRZ

screen. Press the (UP) to go to the next menu TO.

BACK

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

EXIT

DISPLAY

ENTER

User presses or to increment/decrement the temperature

offset (TO) for the room temperature sensor. (Maximum offset

= +/- 8 degrees F). Press the key to accept the change

and exit the selection process

FRR070

Temperature Offset – In some cases the built in thermostat on the unit

may not display the temperature as it is felt in the room. This can be caused

by many things including the size of the unit, the heat load on the room or

other factors. Friedrich allows you to select the appropriate temperature

offset to make the temperature readout as accurate as possible for your

application.

In many cases the factory 0° F (-18° C) offset will provide

an accurate temperature readout. To change the offset follow these

instructions. When TO is displayed press the

key then press

(UP) or (DOWN) to toggle between 0° F (-18° C) and 8° F (-13° C) .

In most instances an offset from 0° F (-18° C) to 2° F (-17° C) is all that is

necessary. To accept the change, press the key to return to the TO

screen. Press the (UP) to go to the next menu TIME.

You may cycle through the menus using the

(UP) or (DOWN) keys

to access any of the menus.

FRR073

FRR074

Automatic Temperature Sampling Feature - The automatic temperature

sampling feature maintains a balanced temperature throughout the room

by circulating the air for 30 seconds once every 9 minutes that the unit is

not running and set to cooling or heating mode. By circulating the air the

unit can detect hot or cold area in the room and operate the unit to cool or

warm the room as necessary. This function is only available when the fan

mode is set to ‘AUTO’ and in COOL or HEAT mode. (Heating function only

available on Kuhl+ units)

Y

For display only. No user selectable options.

FRR075

F

F

Firmware Version - When VER is displayed press Display /

Enter key. The firmware version is displayed as left digit

(Major) and right digit (Minor). This version number should be

used along with Model and Serial numbers for service.

FRR076

13

Page 14

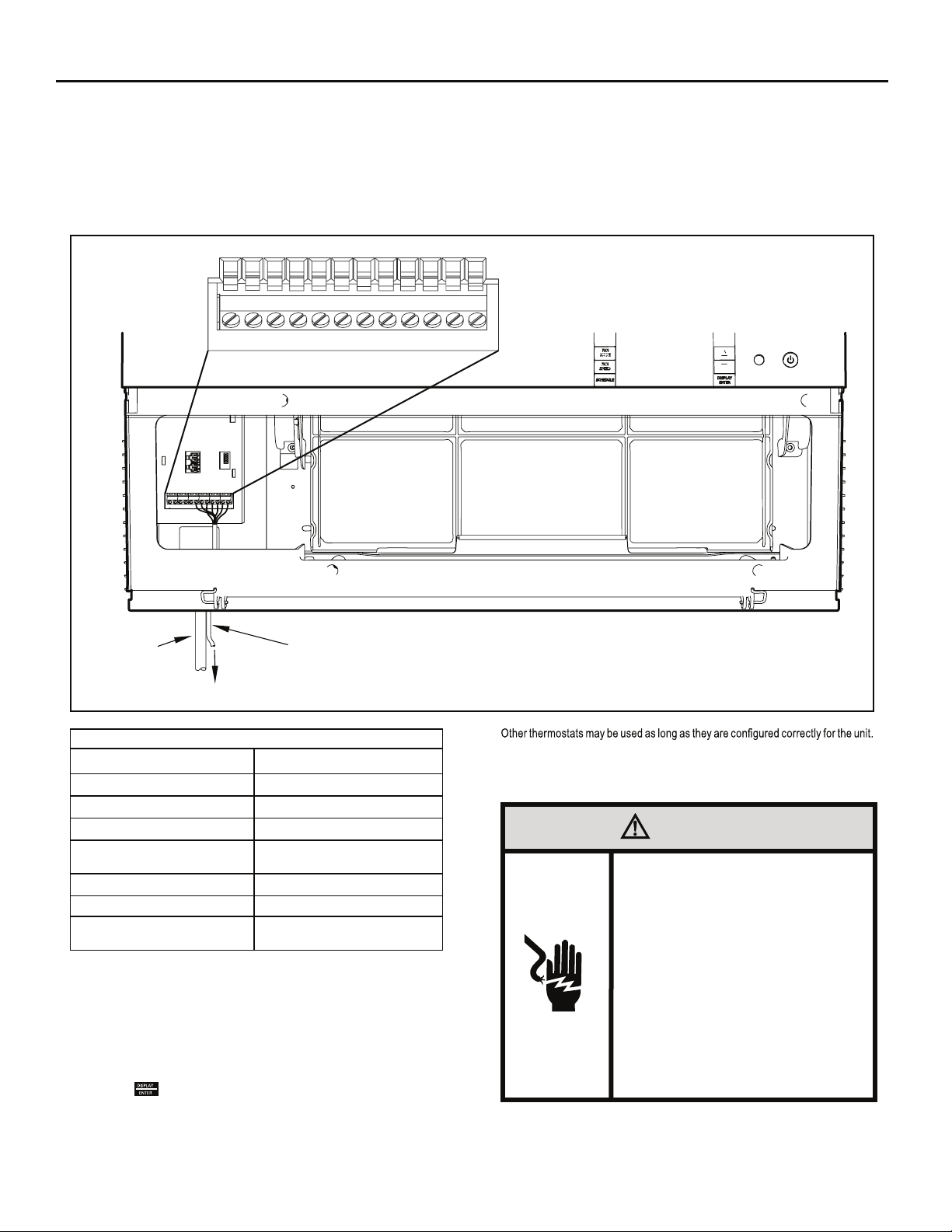

Add a Remote Thermostat

Remote Thermostat – An external thermostat may be added to the air

conditioner to provide remote temperature sensing and control. The

thermostat interface connector is located on the panel behind the front

grille. To enable the remote thermostat operation, remove the jumper

4. Changing modes on the remote thermostat will not illuminate the

Control Panel LCD.

Remote Thermostat Selection

Friedrich recommends the use of either the RT4 or RT5. The RT4 is a

digital display thermostat with single speed fan control. The RT5 features

a digital display, two fan speed selection, battery backup and backlight.

Figure 9

POWER

CORD

THERMOSTAT CONNECTOR

FP

F2

D2

F1

THERMOSTAT WIRE ROUTING USE #18

AWG COLORED THERMOSTAT WIRE

GH

CD1

GL

B

Y

W

R

TO REMOTE THERMOSTAT

Table 2

Terminal Code

between terminals

Inter face Definitions

C

GH

GL

B

Y

W

R

FP & F2

on the terminal block. Connect the thermostat

Wire Connection Function

Common Ground Terminal

Call for High Fan

Call for Low Fan

Call for Heat Pump Reversing Valve

Call for Compressor

Call for Heating

24V Power from Electronic Control to

Wall Thermostat

using Figure 9 and Table 2 as a guide.

If you connect an external thermostat, all Control Panel buttons will be

disabled with the following exception:

1. Maintenance commands (double button press & single button

extended press).

2. The

button for Freeze protection.

3. First Button pushed, illuminate the LCD.

FRR004

For cooling models a single stage cooling thermostat with C, R, G, Y terminals must

be used. For electric heat ‘E’ models a single stage heating and cooling thermostat

with C, R, G, Y, W terminals must be used. For heat pump ‘Y’ models a single

stage heating and cooling thermostat with C, R, G, Y, W, B terminals must be used.

CAUTION

It is the installer’s responsibility to

ensure that all control wiring

connections are made in accordance

with the installation instructions.

Improper connection of the thermostat

control wiring and/or tampering with

the unit’s internal wiring can void the

equipment warranty.

Failure to follow these instructions can

result in personal injury and damage to

product or other property.

14

Page 15

Remote Control Operation

Remote Control – Refer to Figures 11 and 12 during operation description.

Getting Started – Install two (2) AAA batteries in the battery compartment

located on the back of the unit.

Operation – The remote control should be within 25 feet of the air

conditioner for operation (Refer to Figure 10 for effectiveness). Press the

button to turn the remote on. The remote will automatically power off

after 15 seconds if the buttons are not being pressed. The remote must

be on to control the unit.

POWER Button – Turns remote and unit on and off.

SYSTEM Button – Allows the user to sequentially select,

HEAT , and FAN ONLY operation. When the button is pressed, the

Note that when the heating function is not available, the system will

automatically skip the HEAT and AUTO modes.

FAN MODE Button – Selects between automatic (

operation. In the AUTO mode, the fan only turns on and off when the

compressor operates or the heat function is enabled.

NOTE: AUTO is not available in the FAN ONLY Mode, the display

indicates

. In the mode, fan speed is

determined by your selection on the button.

Figure 10

Cool ,

) or

FAN SPEED Button – Used to sequentially select new fan speed, plus

AUTO operation. When the

FAN

button is pressed, the fan speed is

SPEED

temporarily displayed in the display window, plus a fan speed icon (triangle)

changes to indicate the new speed level. Fan speed automatically varies

depending on the set temperature on the control panel and the actual

room temperature. Let me explain. Say for example you’re working in

your garage and you need to open the big door for several minutes. Since

there is a big difference between your set temperature and the actual room

temperature the system fan speed increases to MAX. It remains at this

speed until the room temperature matches the set temperature.

SCHEDULE

SCHEDULE Button

off. Pressing the

– The

SCHEDULE

button a second time turns the schedule function

button turns the schedule function on and

off. Only the schedule icon will be displayed.

.egassem yalpsid a aiv detceles neeb sah edom hcihw setacidni yalpsid

button changes the desired room temperature. The factory preset lower

UP and DOWN Arrows – Pressing either the

(UP) or (DOWN)

and upper limits are 60° F (16° C) and 99° F (37° C). These buttons are

also used to navigate between function options when using the User Menu

or Maintenance Mode.

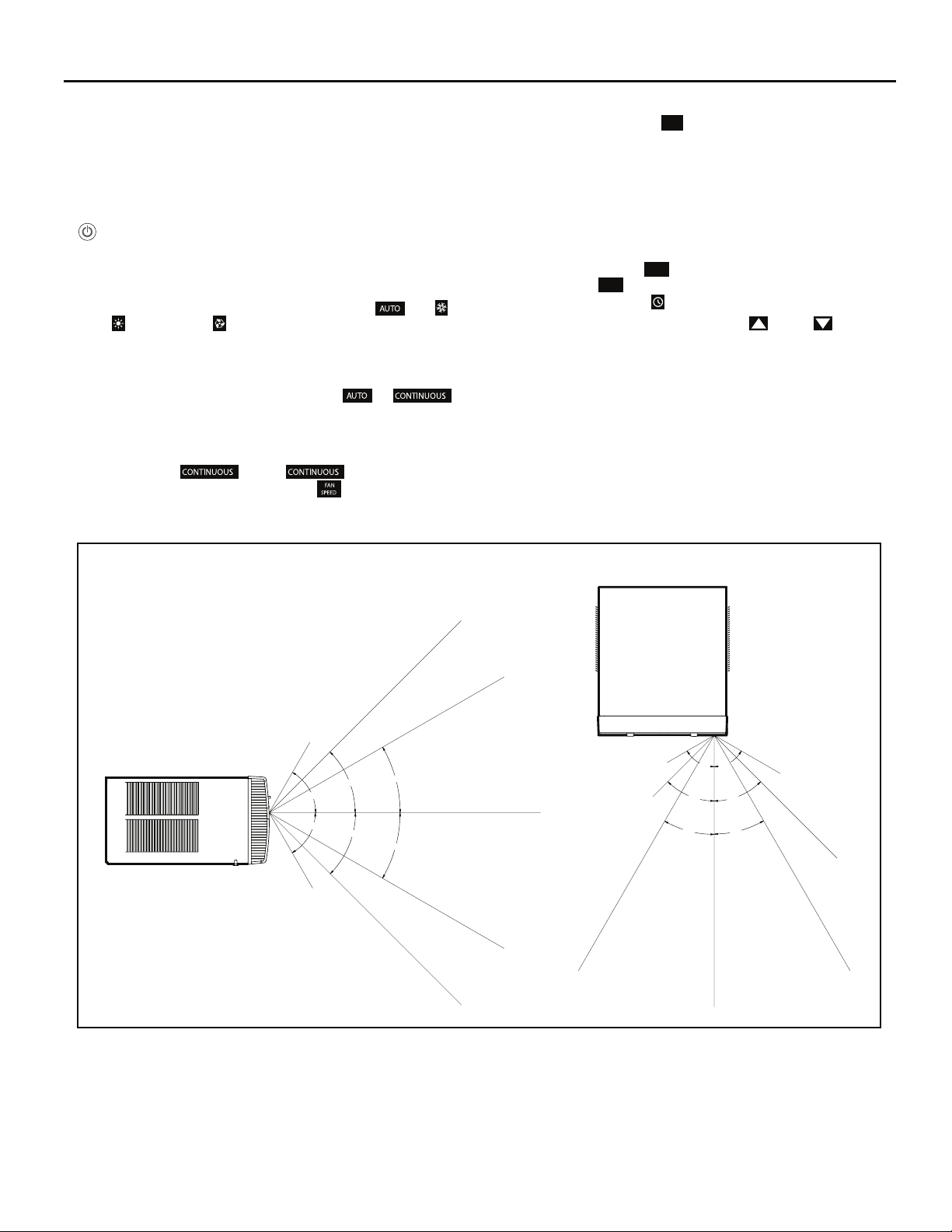

Remote Effectiveness

Hand Held Remote – Has an operating range of up to 25 ft. The infrared

remote control signal must have a clear path to transmit the command to

the air conditioning unit. The remote signal has some ability to "bounce"

off of walls and furniture similar to a television remote control. The diagram

below shows the typical operating range of the control in a standard room

with 8 ft high ceilings.

TOP VIEW

SIDE VIEW

25ft

25ft

7.5ft

45°

60°

60°

8ft

30°

25ft

45°

30°

25ft

25ft

25ft

4ft

8ft

60°

60°

45°

45°

30°

30°

25ft

6ft

16ft

25ft

FRR046

15

Page 16

Figure 11

DISPLAY

Figure 12

SYSTEM

TEMPERATURE

UP

SCHEDULE

AUTO

ICON

COOL

ICON

HEAT

ICON

FAN MODE

POWER

TEMPERATURE

DOWN

FAN SPEED

FRR005

FAN ONLY

ICON

16

SYSTEM

MODE

FAN

MODE

FAN

SPEED

SCHEDULE

ICON

°F / °C

ICONs

2 X 16 SEGMENT

DISPLAY

FRR006

Page 17

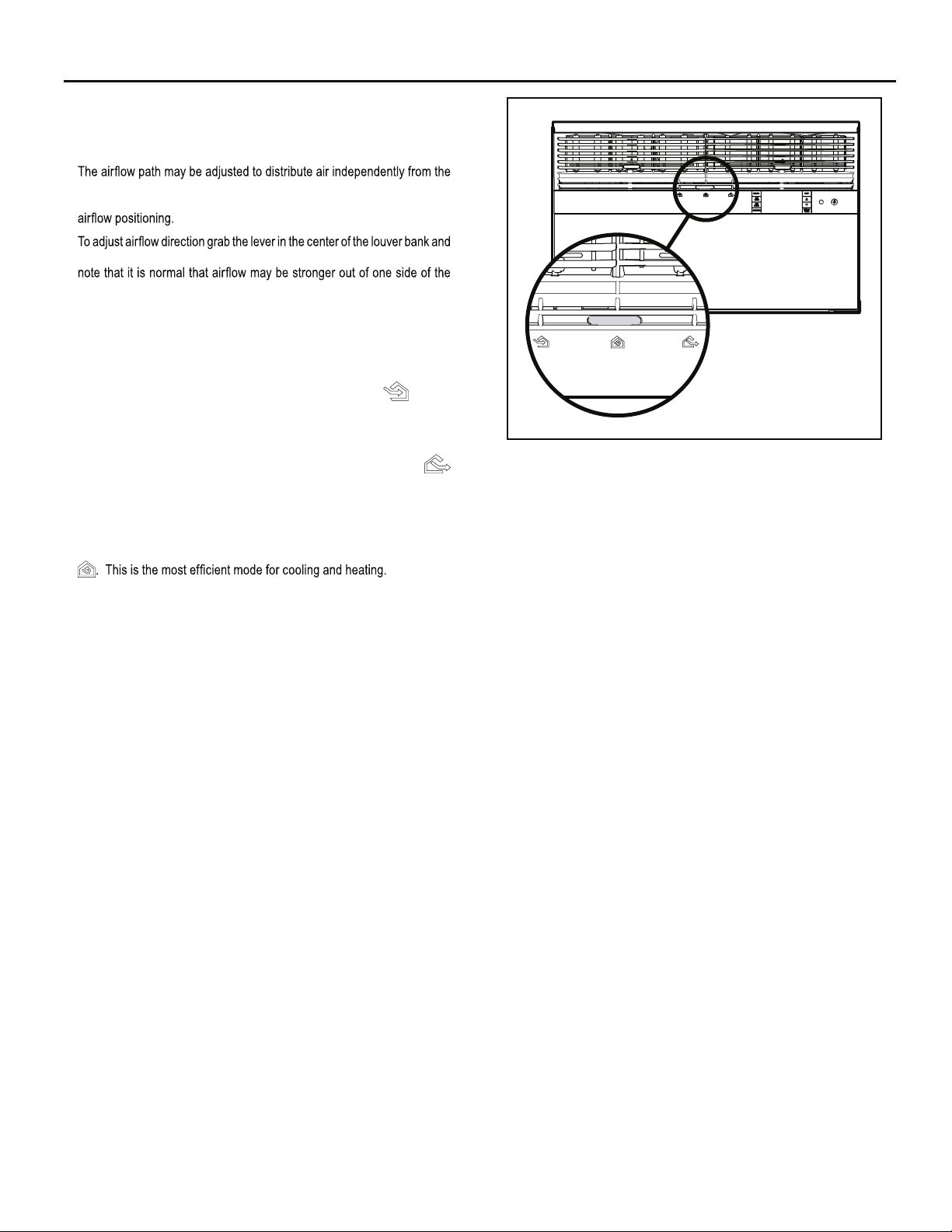

Airflow Selection and Adjustment

Air flow direction adjustment

left or right side of the discharge opening. Each of the banks of louvers

can be directed left, right, up or down in order to achieve the most optimum

move it in the direction that you would like the air to be directed. Please

louvers than the other.

Fresh air and exhaust control

Your air conditioner has the ability to bring fresh air into the room or exhaust

stale air out of the room. The control slide is found on the upper part of

the unit (See Figure 13).

TO BRING IN FRESH AIR – Move the lever to the Fresh Air

which allows outside air to enter the room. This is useful in fall and spring as

a means of bringing in fresh outside air when using FAN ONLY . It can also

be used in the summer with the compressor in the Cooling Mode if you wish.

TO EXHAUST IN DOOR AIR – Move the lever to the Exhaust

position. This will allow stale air to be expelled to the outside of the dwelling.

This is especially handy in the spring or fall when indoor air tends to get

stale, or after a social gathering involving smokers, or to remove cooking

odors.

BEST PERFORMANCE – Move the lever to the Re-Circulate Position

position

Figure 13

FRR008

17

Page 18

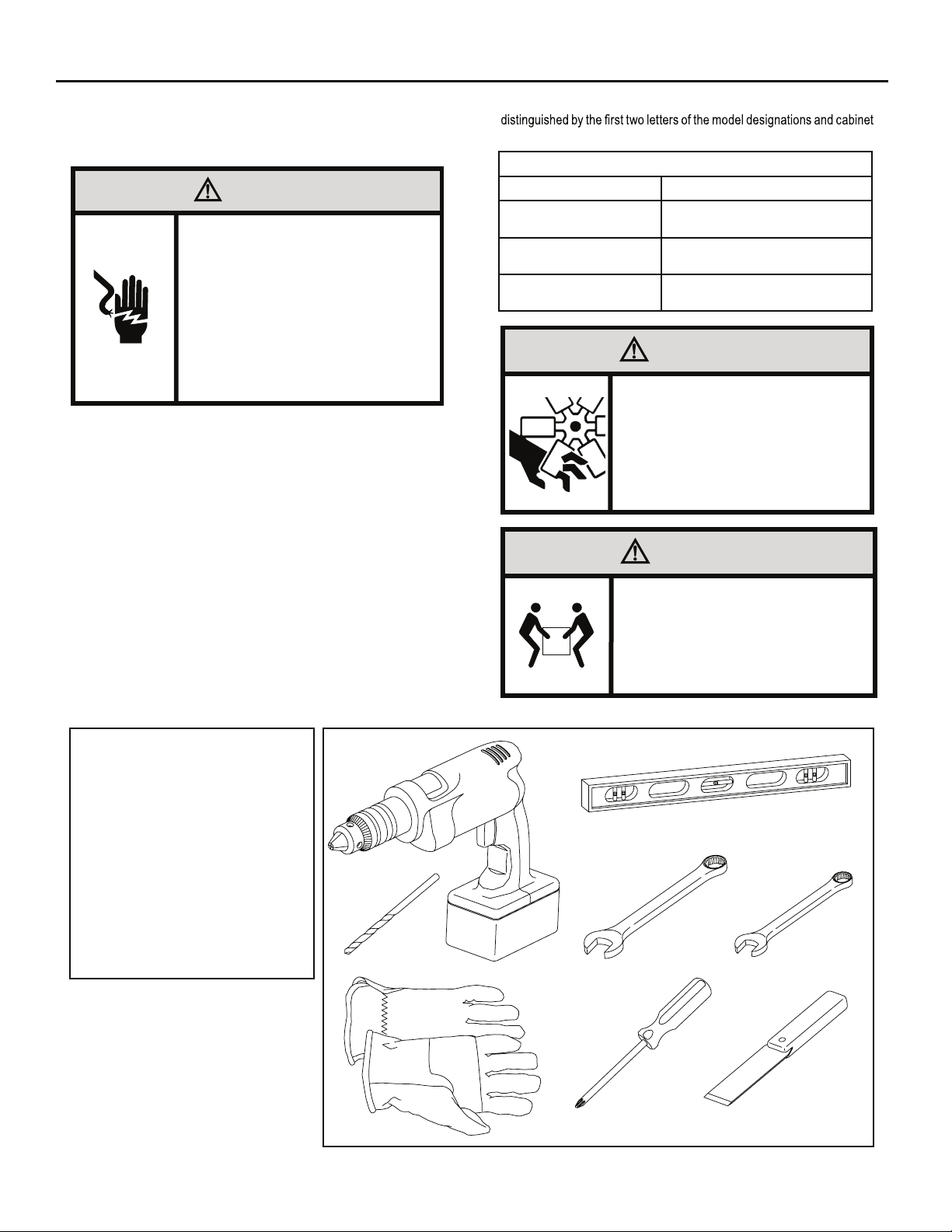

Installation Instructions

READ THIS FIRST! Electrical Requirements

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong oulet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

IMPORTANT: Before you begin the actual installation of your air

Your air conditioner must be connected to a power source with the same

alternating current (A.C.) voltage and amperage as marked on the name

plate located on the chassis. Only A.C. can be used. Direct Current (D.C.)

cannot be used.

CIRCUIT PROTECTION – Use on single outlet circuit only. An overloaded

circuit will invariably cause malfunction or failure of an air conditioner,

therefore, it is necessary that the electrical protection is adequate. Due

to momentary high current demand when the air conditioner starts, use a

"TIME DELAY" fuse or a HACR type circuit breaker. Consult your dealer

or power company if in doubt.

Refer to the electrical name plate located on the air conditioner chassis

(See page 2) to determine the correct fuse or circuit breaker amperage

for your model (See Table 1 on Page 6 for electrical receptacle types).

The power cord has a plug with a grounding prong and a matching

receptacle is required.

The following instructions are for standard chassis model groups

sizes listed in Table 3.

Table 3

MODEL DESIGNATION CABINET SIZE (H x W x D)

SMALL CHASSIS - SS,

ES, YS

MEDIUM CHASSIS - SM,

EM, YM

LARGE CHA SS IS - SL,

EL, YL

15 15⁄16" x 25 15⁄16" x 29" (405 mm x

660 mm x 737 mm)

15

17

⁄16" x 25 15⁄16" x 29" (455 mm x

660 mm x 737 mm)

20 3⁄16" x 28" x 35 1⁄2" (513 mm x 711

mm x 851 mm)

WARNING

MOVING PARTS HAZARDS

* Do not operate unit out of sleeve

or with front grille removed.

.woleb noitamrofni eht dna sedoc lacirtcele lacol kcehc ,renoitidnoc

* Do not place hands in blower or

fan blade areas.

Failure to do so can result in

serious injury.

CAUTION

Excessive Weight Hazard

Use two or more people when

installing your air conditioner.

Failure to do so can result in

back or other injury.

Recommended Tools

1. Power Drill

2. 5/32" Drill Bit

3. Gloves

4. Carpenters Level

5. 5/16" Wrench

6. 1/4" Wrench

7. #2 Phillips Screw Driver

8. Putty Knife or (wood stir stick)

18

4

1

5/16

2

3

ITEMS NOT TO SCALE

5/16

/4

1

1

/4

65

87

Page 19

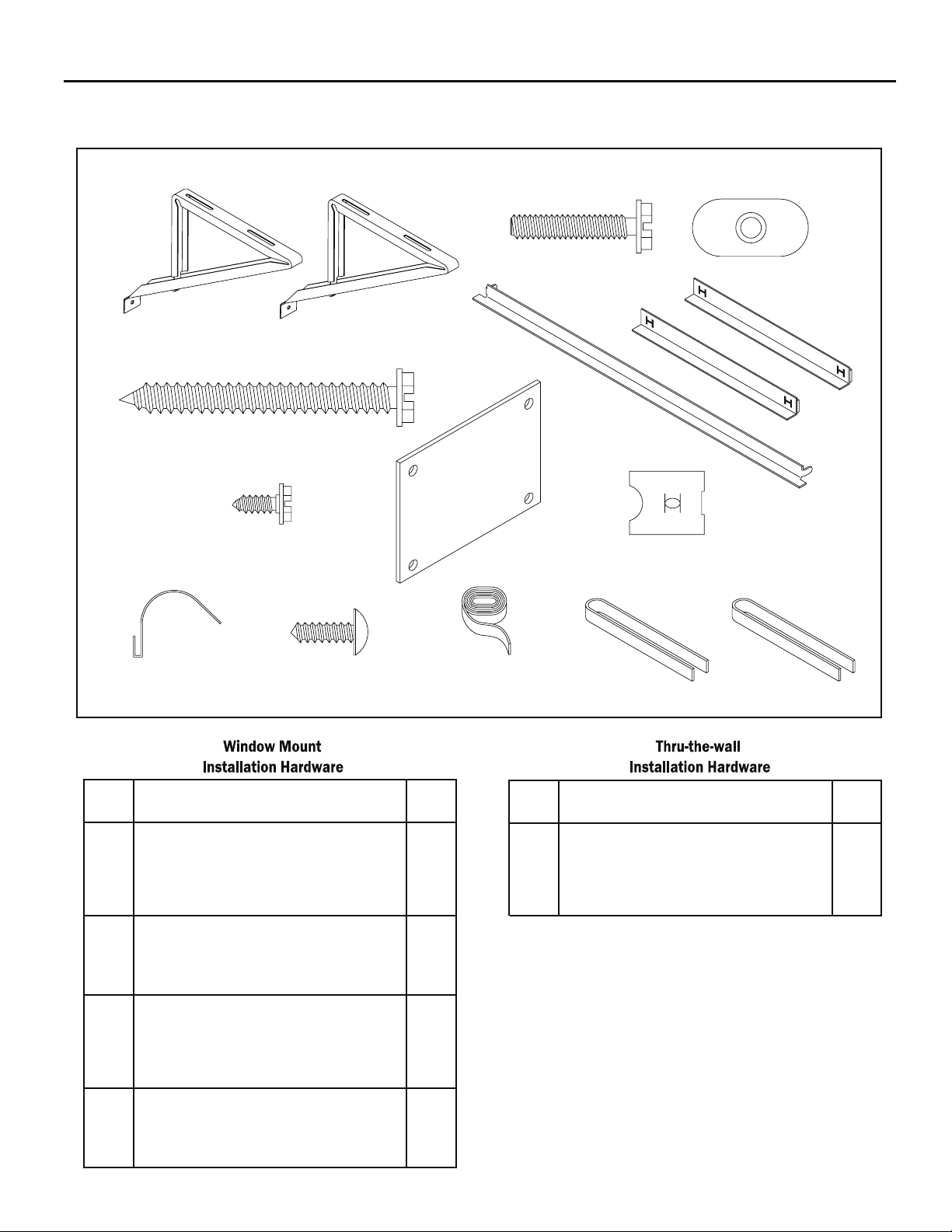

INSTALLATION HARDWARE AND ACCESSORY DETAIL

ITEM 10

ITEMS NOT TO SCALE

ITEM 1

ITEM 4

ITEM 7

ITEM 11

ITEM 12

ITEM 8

ITEM 2

ITEM 5 ITEM 6

ITEM 9

ITEM 13

ITEM 3

ITEM 14

FRR009

ITEM

DESCRIPTION QTY.

NO

WINGBOARD MOUNTING PARTS

8 WINGBOARD (MASONITE) 1

9 "J" TYPE SPEED NUT 4

10 WINGBOARD CLIP (SPRING STEEL) 4

11 SCREW, #8 x ½" PHILLIPS TRUSS HD. 4

WINDOW SEALING

12 SEALING GASKET (VINYL) 1

13 WINDOW SEAL GASKET (DARK FOAM) 1

14 CHASSIS SEAL GASKET (LIGHT FOAM) 1

SHELL MOUNTING PARTS

1 SUPPORT BRACKET 2

2 SCREW, 10-24 x 1" HEX HEAD 4

3 10-24 FLAT WELD NUT 4

4 SCREW, SHEET METAL #12 x 2" 7

WINGBOARD ANGLE MOUNTING

5 WINGBOARD ANGLE, TOP 1

6 WINGBOARD ANGLE, SIDE 2

7 SCREW, SHEET METAL #8 x 3!8" 2

ITEM

DESCRIPTION QTY.

NO

NOTE: Kü h l + models do n o t c ome with wi n d o w mounting

MOUNTING PARTS

4

SCREW, SHEET METAL #12A x 2”

CHASSIS SEAL GASKET (LIGHT FOAM)

14

components. When mounting a cooling and heating model

a window inst allation kit must be purchased separately.

7

1

KWIKS – For all ES and YS models.

KWIKM – For all EM and YM models.

KWIKL – For all EL and YL models.

19

Page 20

Standard Window Installation

NOTE: Hardware and accessories used during installation are shown

on page 18. Each part will be referred as Item No.

Figure 15

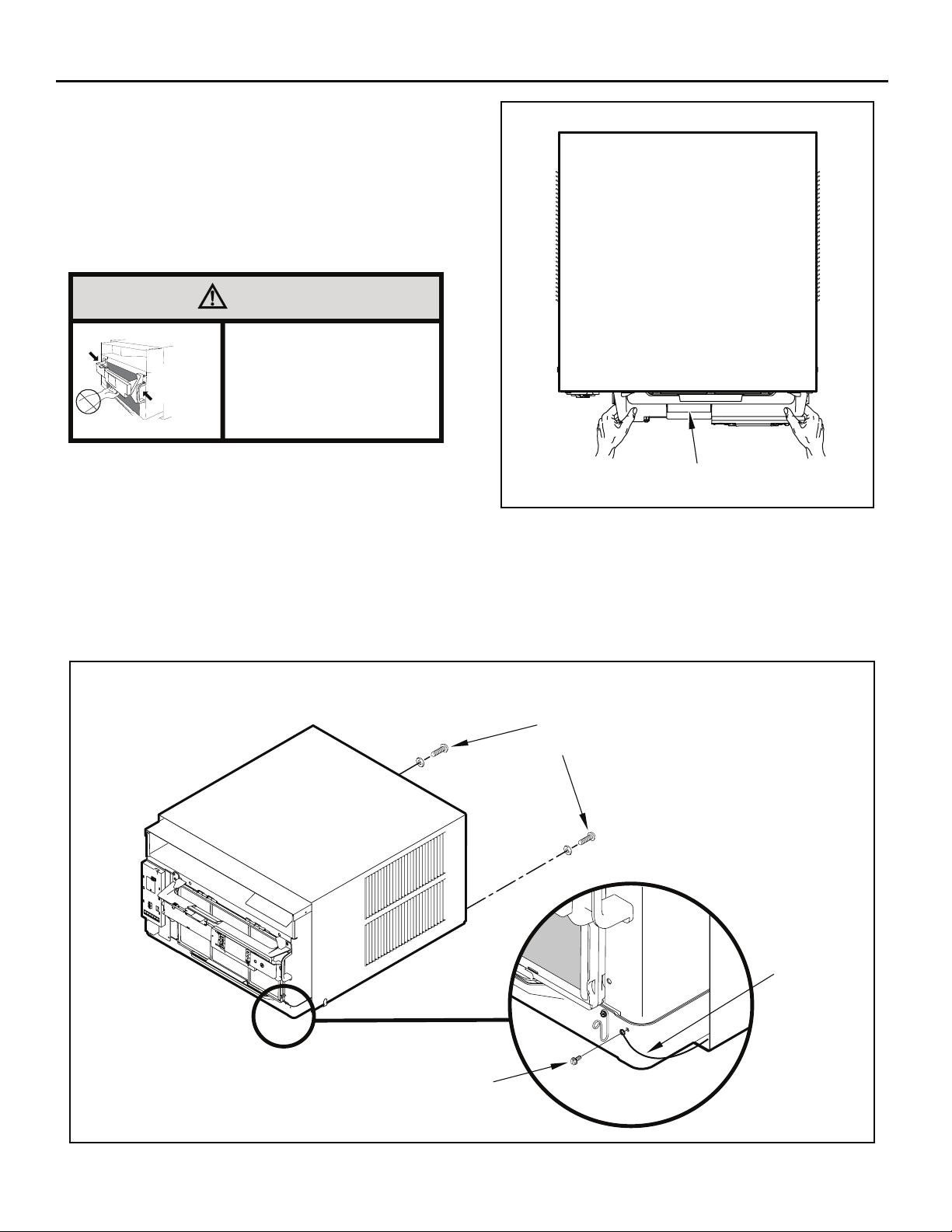

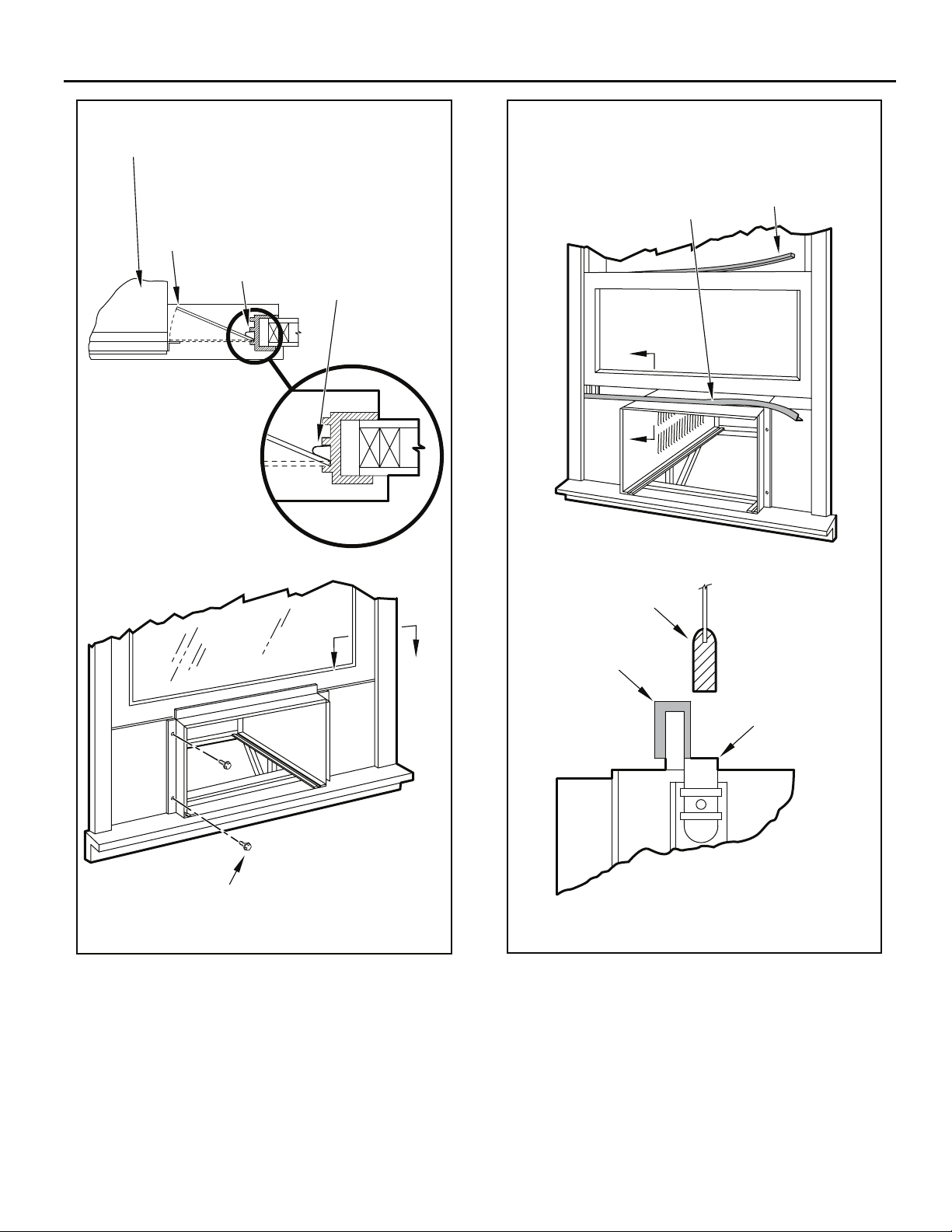

STEP 1. Remove the chassis Entrygard retainer by removing the far

right screw (See Figure 14), save this screw to reattach the

chassis retainer after installation (Step 12). Also, remove and

discard the two retainer screws and washers located at the

rear of the unit (See Figure 14).

CAUTION

Handle Use

Use handle on both sides to

eldnaH esU

pull unit from sleeve.

snoitacoL

]sedis htob[

Do not push, pull or lift from

center of support.

STEP 2. Hold the cabinet stationary, then use the hand grips on both

ends of the control unit support bracket to pull the chassis out

of the cabinet (See Figure 15).

STEP 3. Remove the large white foam blocks used to restrain the

compressor during shipment (See Figure 16). Inspect base

pan for dislodged white foam blocks and remove. Do not

remove any other foam parts.

CONTROL UNIT

SUPPORT BRACKET

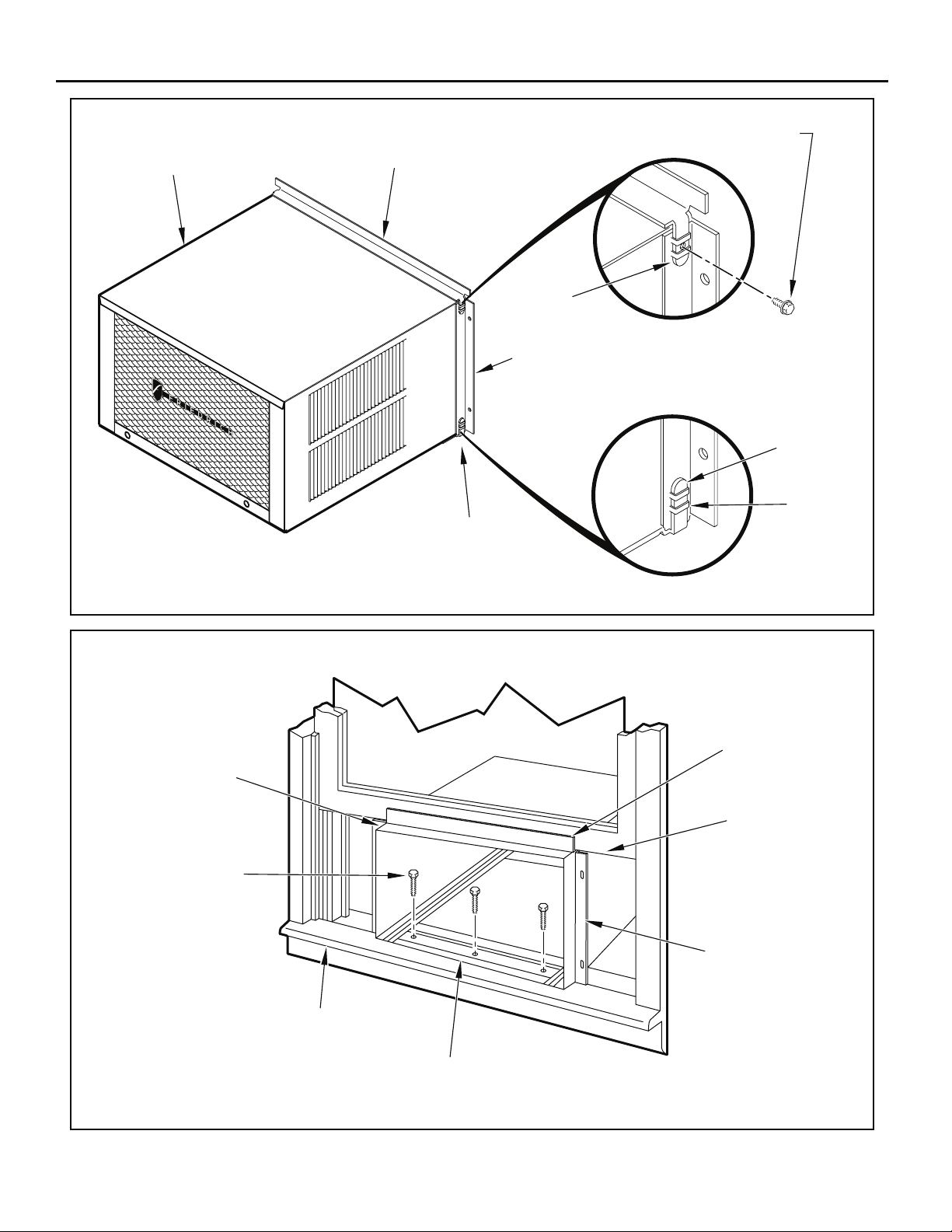

STEP 4. Anchor the side angles (Item 6) by engaging the tabs of the

lower sill plate (See Figure 17, Detail B-2) with the loops of the

side angle. Engage the tabs of the top angle (Item 5) with the

top loops of the side angle (See Figure 17, Detail B-1). Install

two (2) screws (Item 7) to secure the top angle tabs and the

side angle to the cabinet (See Figure 17, Detail B-1).

FRR012

Figure 14

RETAINER SCREWS

AND WASHERS

ENTRYGARD

RETAINER

WIRE

FAR RIGHT

SCREW

20

FRR011

Page 21

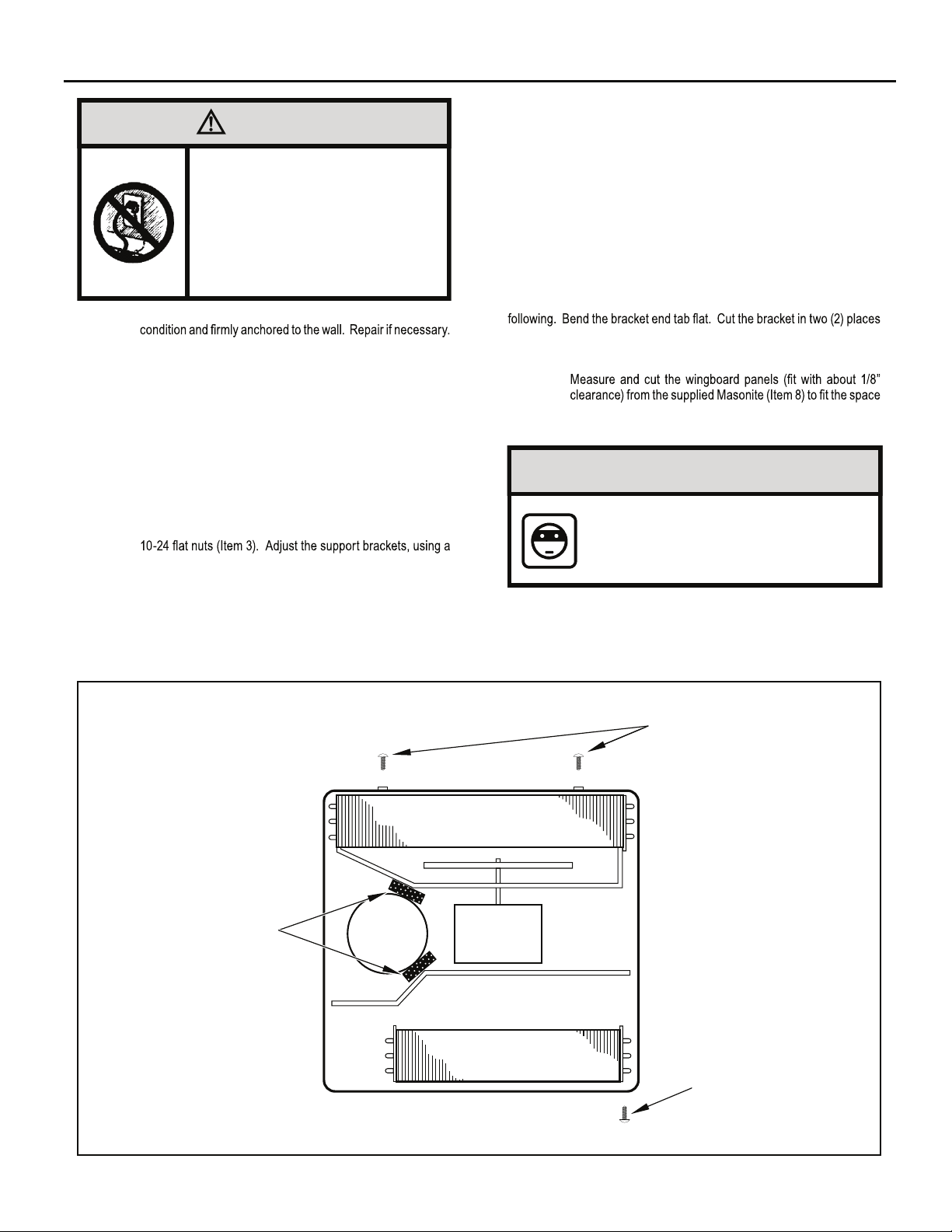

CAUTION

TOP VIEW OF UNIT

Remove Shipping Blocks

Prior to operating the unit remove

the foam shipping blocks.

Failure to do so may result in

damage to the unit which is not

covered by the manufacturer’s

warranty!

STEP 5. Check the window sill and frame to be sure they are in good

STEP 6. CABINET MOUNTING – Raise the lower window 1/4" more

than the height of the cabinet. Carefully slide the cabinet

through the opening until the lower sill plate channel rests

behind the window sill and the top angle rests against the

window (See Figure 18). Center the cabinet within the

opening. Drill three (3) 5/32" diameter pilot holes into window

sill using the holes in the cabinet sill plate as a guide. Install

three (3) #12 x 2" long screws (Item 4) (See Figure 18).

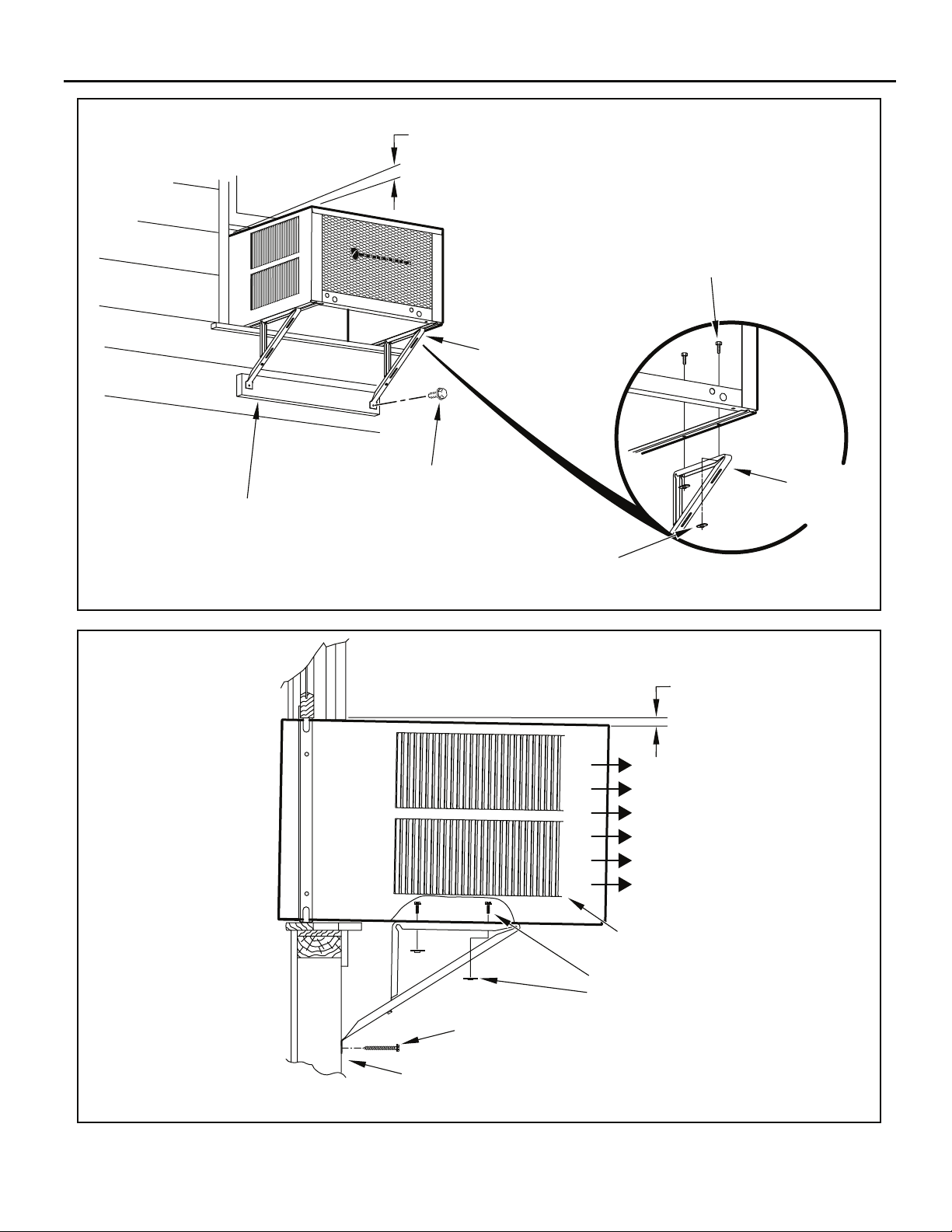

STEP 7. OUTSIDE SUPPORT MOUNTING – Refer to Figures 19 and

20. Assemble the support brackets (Item 1) to the bottom of

the cabinet with four (4) 10-24 1” long screws (Item 2) and four

combination of the elongated holes of the bracket and different

hole locations in the cabinet, to bring the bottom support bracket

pads in contact with the wall. A 1" x 4" or 2" x 4" SPACER

SHOULD BE USED BETWEEN THE WALL AND SUPPORT

THE BRACKETS WHEN INSTALLED ON ALUMINUM OR

VINYL SIDING. Drill 5/32" diameter pilot holes and secure

the brackets to the wall with two (2) 12A x 2" long screws

(Item 4).

Figure 16

NOTE: DO NOT LEVEL the cabinet from front to back. Make sure there

is approximately 3/8” to 1/2” slope (1/8 to 1/4 bubble on level)

toward the outside of the house.

Adjust the support brackets to provide an inside-to-outside slope for excess

condensation drainage (Refer to Standard Window Installation, Figures 19

through 23). Tighten all screws.

Alternate support method A: If you have a wide window sill which prevents

:gniwollof eht yrt ,22 erugiF ni nwohs sa stekcarb eht gnitnuom morf uoy

Using the elongated holes and different hole locations in the cabinet,

.)22 erugiF( thgiew s’tinu eht troppus ot tekcarb eht fo tnemecalp eht tes

Tighten all screws.

Alternate support method B: If the window ledge gap is narrow, try the

as shown in Figure 23. Bend the short piece so it will be vertical when

installed. Adjust the placement as required. Tighten all screws.

STEP 8.

.)42 erugiF( .tenibac dna slennahc edis wodniw eht neewteb

Make sure you include the depth of the window channel.

NOTICE

For YOUR security and safety, YOU must

provide a means of preventing the upper

part of the window from opening.

STEP 9. To assemble the wingboard panels, push on the "J" type speed

nuts (Item 9) and spring steel clips (Item 10) (See Figures 25)

on page 26. Secure each panel with two (2) screws (Item 11).

LEFT SIDE

REMOVE AND DISCARD

FOAM BLOCKS

COMPRESSOR

BACK

FAN MOTOR

EVAPORATOR COIL

FRONT

REMOVE AND DISCARD

SCREWS

RIGHT SIDE

REMOVE AND SAVE

SCREW FOR

RE-INSTALLATION

FRR045

21

Page 22

Figure 17

CABINET

#8 x 3/8” LONG SCREW

(ITEM 7) 2 REQUIRED

TOP ANGLE (ITEM 5)

TAB

Figure 18

DRILL (3) 5/32” DIA.

PILOT HOLES AND

INSTALL (3) #12 x 2”

LONG SCREWS

CENTER

CABINET

IN WINDOW

SIDE TO SIDE

(ITEM 4)

SILL PLATE

TAB

SIDE ANGLE

(ITEM 6)

2 REQUIRED

DETAIL B-2

DETAIL B-1

TAB

LOOP

FRR013

TOP ANGLE

(ITEM 5)

PULL WINDOW

SASH DOWN

BEHIND TOP

ANGLE

22

SIDE ANGLE

(ITEM 6)

WINDOW SILL

LOCATE SILL PLATE GUIDE CHANNEL

JUST BACK OF WINDOW SILL

FRR014

Page 23

Figure 19

3/8” SLOPE DOWN

#10-24 x 1” HEX HD.

SCREW (ITEM 2)

SUPPORT BRACKET

(ITEM 1)

SPACER SHOULD BE USED BETWEEN

WALL AND BRACKET WHEN INSTALLED

ON ALUMINUM OR VINYL SIDING.

Figure 20

#12 x 2” SCREW

(ITEM 4)

SUPPORT

BRACKET

(ITEM 1)

10-24 x FLAT WELD

NUT (ITEM 3)

FRR015

3/8” SLOPE DOWN

CONDENSER

AIR OUTLET

CONDENSER

AIR INLETS

#10-24 SCREW

#10-24 FLAT WELD NUT

#12 x 2” SHEET METAL

SCREW (ITEM 4)

SPACER SHOULD BE USED BETWEEN

WALL AND BRACKET WHEN INSTALLED

ON ALUMINUM OR VINYL SIDING.

FRR016

23

Page 24

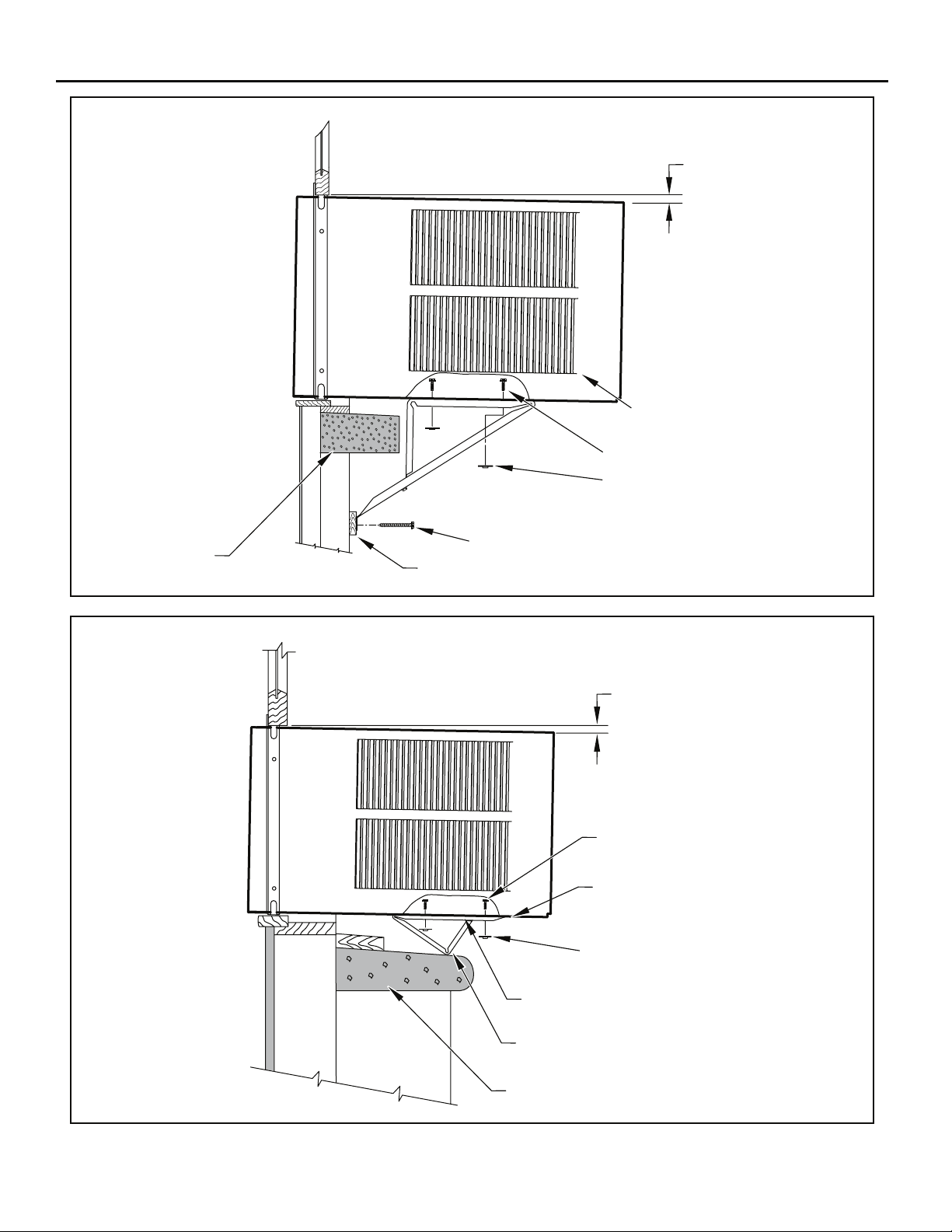

Figure 21

STONE LEDGE

3/8” SLOPE DOWN

CONDENSER

AIR INLETS

#10-24 SCREW

#10-24 FLAT WELD NUT

#12 x 2” SHEET METAL

SCREW (ITEM 4)

SPACER

FRR017

Figure 22

3/8” SLOPE DOWN

#10-24 SCREW

STRAIGHTEN TAB TO LAY FLAT

ALONG THE BOTTOM RAIL OF

THE SHELL

#10-24 FLAT WELD NUT

SECURE THE LONGEST SIDE OF

THE BRACKET TO THE SHELL

ADJUST IN OR OUT TO REST

ON THE LEDGE

24

STONE LEDGE

FRR018

Page 25

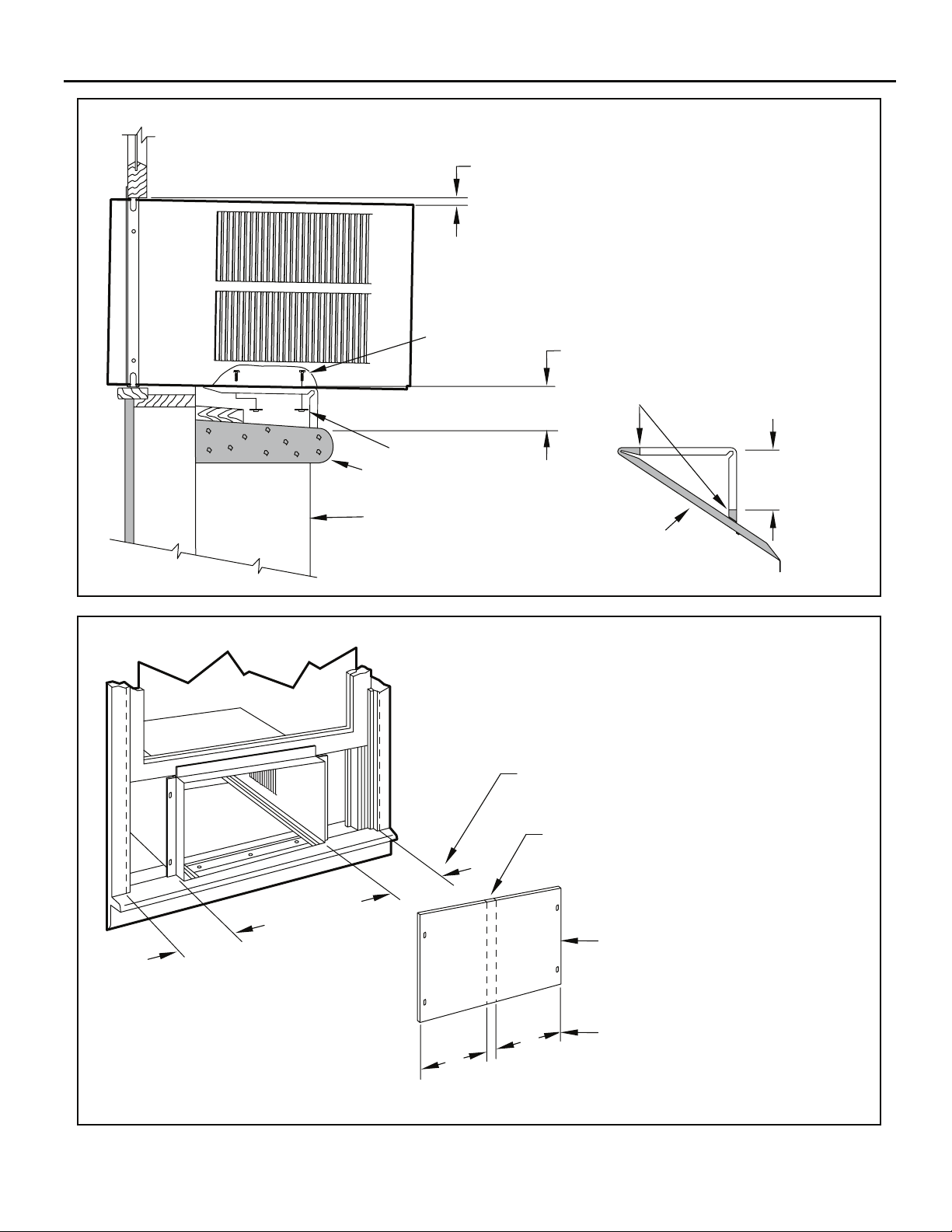

Figure 23

3/8” SLOPE DOWN

Figure 24

#10-24 SCREW

#10-24 FLAT WELD NUT

STONE LEDGE

OUTSIDE WALL

DIMENSION “A”

CUT

HERE

CUT TO FIT DIMENSION “A”

AND BEND DOWN TO FORM

A VERTICAL LEG.

A

DISCARD

SHADED AREA

MEASURE DISTANCE “B” TO INSIDE OF THE

CHANNEL ON EACH SIDE.

FRR019

B

B

B

CUT HERE AND DISCARD CENTER WASTE

MATERIAL.

WINGBOARD

B

SUBTRACT 1/8” FROM DIMENSION “B” AND

MEASURE FROM THE EDGE OF THE WINGBOARD (ITEM 8), MARK, SCORE AND CUT

WITH APPROPRIATE CUTTING TOOL.

FRR020

25

Page 26

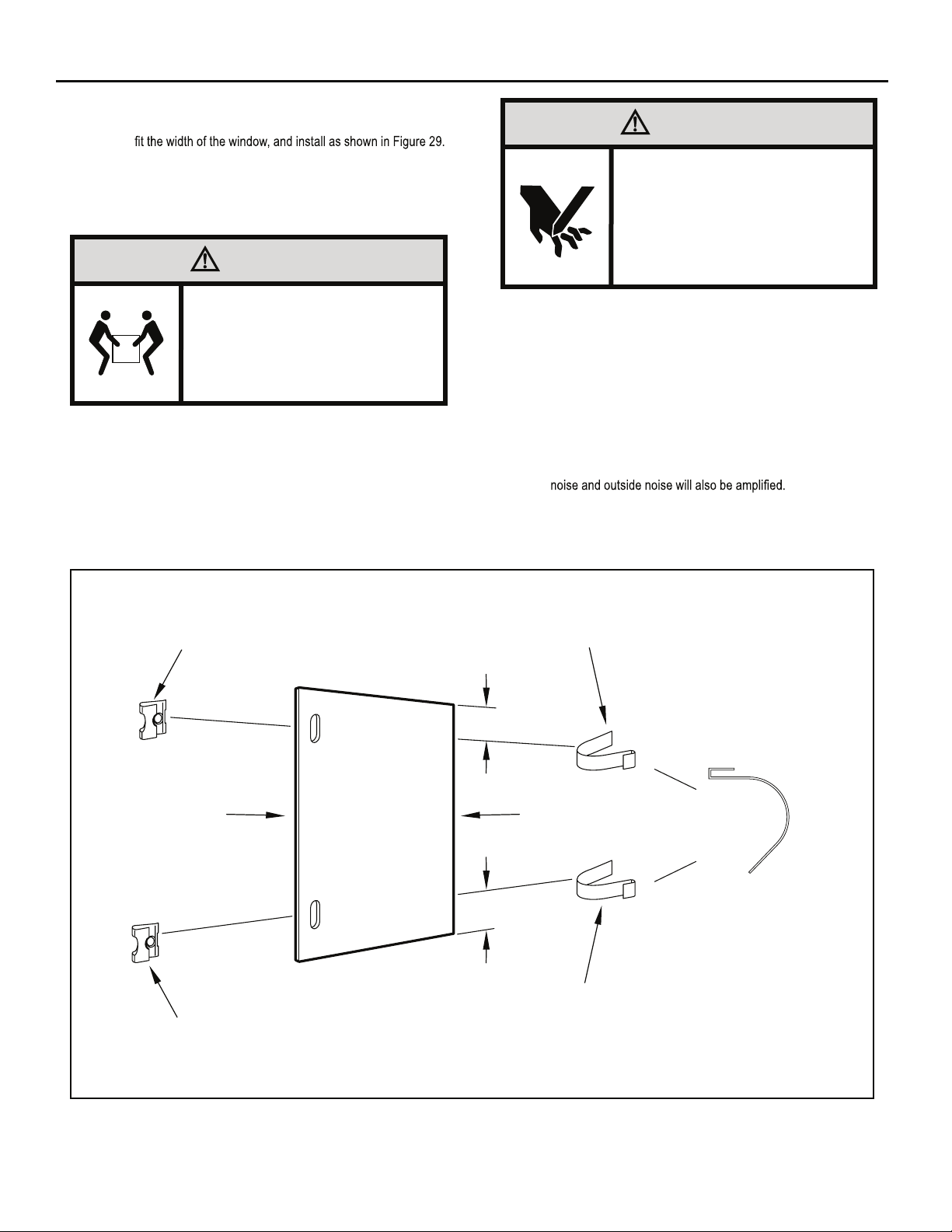

STEP 10. INSTALL THE WINDOW SEALING GASKETS – Measure

and cut the vinyl window seal gasket (grey color, Item 12) to

CAUTION

Figure 25

Pull the window sash down behind the gasket. Measure and

cut the dark foam window seal gasket (Item 13) and install it

between the upper glass panel and the top part of the lower

window sash (Figure 29).

CAUTION

Excessive Weight Hazard

Use two or more people when

installing your air conditioner.

Failure to do so can result in

back or other injury.

“J” TYPE SPEED NUT

(ITEM #9) 2 REQUIRED

Cut/Sever

Although great care has been

taken to minimize sharp edges

in the construction of your unit,

use gloves or other hand

protection when handling unit

Failure to do so can result in minor

to moderate personal injury.

STEP 11. Carefully team lift the chassis and set it into the cabinet. Slide

the chassis stopping approximately 3" from full insertion. Insert

the chassis seal gasket (Item 14) one inch deep between the

.82 egap no nwohs sa )92 erugiF eeS( tenibac eht dna sissahc

A paint stir stick or ruler might be helpful here. Begin inserting

the gasket at either bottom corner and go up the side, across

the top, and down the opposite side. Then push the chassis

all the way into the cabinet.

NOTE: If the chassis seal gasket is not installed or installed improperly,

the operation of the unit will be negatively affected. Operational

STEP 12. Reattach the entry guard chassis entry guard retainer wire with

the same screw retained in Step 1 (See Figure 14).

SPRING STEEL

CLIP (ITEM 10)

2 REQUIRED

26

CUT

WINGBOARD

PANEL

CENTER THE HOLE IN THE

SPEED NUT OVER THE SLOT

IN THE WINGBOARD PANEL

3"

CUT EDGE

3"

SLIDE CLIP OVER CUT EDGE

OF WINGBOARD PANEL

ROTATED 90°

FRR021

Page 27

FRR023

TOP OF CABINET

Figure 27Figure 26

PLACE WINGBOARD PANEL IN WINDOW JAM

TO COMPRESS THE SPRINGS INSIDE THE

RUNNERS, AND SWING THE WINGBOARD

PANELS INTO PLACE AS INDICATED BY THE

DASHED LINES.

WINDOW JAM

CLIP (ITEM 10)

SECTION A-A

INSERT VINYL WINDOW SEAL

GASKET OVER TOP ANGLE

TO WINGBOARD (ITEM 12)

B

B

LOWER WINDOW SASH

INSERT FOAM WINDOW

SEAL GASKET (ITEM 13)

A

SECURE THE SIDE WINGBOARD PANELS TO

THE SIDE ANGLES WITH FOUR (4) #8 x 1/2” LONG

SCREWS (ITEM 11), TWO ON EACH SIDE.

A

FRR022

VINYL

WINDOW

GASKET

TOP WINGBOARD ANGLE

SECTION B-B

27

Page 28

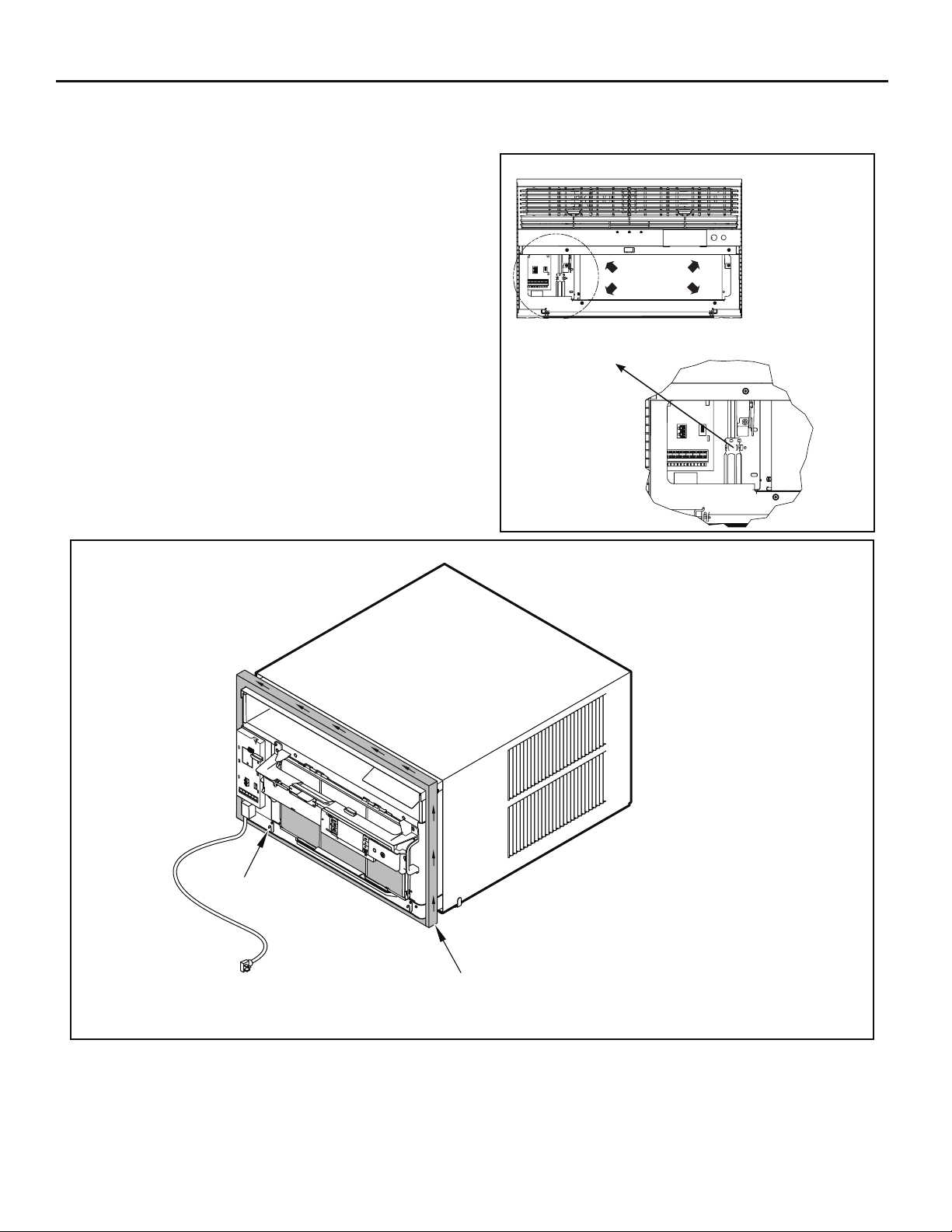

OPTIONAL: The factory assembles the supply cord so that it exits the left

side of the unit at the bottom. At the consumer’s discretion,

To do this, route the supply cord to the right side. Pull the

supply cord taunt through the loops (Refer to Cord Routing

Change, Figure 30) and route the cord down.

Use Tool Provided

.tinu eht fo edis thgir eht tixe ot detuor eb nac droc ylppus eht

Please use the provided tool to attach the decorative front to the chassis.

Figure 28

STEP 13.

To attach and prevent damage to the front grille align the

cord notch over the cord and center the fresh air lever, then

align and tighten the four (4) captive screws as indicated by

the arrows in Figure 28. Before closing the front panel, be

sure the filter is in place. Make sure curtains do not block

the side air intakes.

STEP 14. Refer to the Control Panel Operation section for instructions.

STEP 15. You are now ready to control the comfort level of the room.

Figure 29

USE HAND TOOLS

DO NOT O VER T IGHTE N

B

LOCATION OF GRILLE

REMOVAL TOOL

FRR05 3

28

POWER CORD

CLIP

NOTE: WHEN INSTALLING THE CHASSIS

SEAL GASKET; BEGIN AT EITHER BOTTOM

CORNER AND GO UP THE SIDE & ACROSS

THE TOP & DOWN THE OPPOSITE SIDE.

CHASSIS SEAL

GASKET (ITEM 14)

FRR024

Page 29

THIS PAGE INTENTIONALLY LEFT BLANK

29

Page 30

Cord Routing Change

FRR054

Unplug unit.

STEP 16. Carefully pull out electrical control panel 1", but not all the way.

Figure 32

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong oulet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

For convenience and optimum appearance the direction that the power cord

exits the unit may be changed from left to right by following the procedure

below. Select the exit location on the left or right based on proximity to

the power outlet.

Figure 30

ELECTRICAL

CONTROL PANEL

1 INCH

FRR056

STEP 17. Pull electrical cord strain relief downward until free and rotate

90 degrees to the right.

Figure 33

NOTE:

DECORATIVE FRONT REMOVED USE TOOL PROVIDED.

(SEE FIGURE 28 FOR LOCATION OF TOOL).

Remove 3 screws as shown from the electrical control panel. Save to

reinstall later.

Figure 31

ELECTRICAL CONTROL

PANEL SCREWS (3)

FRR055

90°

ELECTRICAL CORD

STRAIN RELIEF

FRR057

STEP 18. Push electrical cord strain relief back upward into the electrical

control panel.

Figure 34

ENSURE THE ELECTRICAL CORD STRAIN RELIEF IS

FLUSH WITH THE TOP OF ELECTRICAL CONTROL PANEL

FRR058

30

Page 31

STEP 19. Carefully push electrical control panel back into chassis.

Figure 35

ELECTRICAL

CONTROL PANEL

FRR059

STEP 20. Reinstall the 3 screws removed earlier to secure electrical

control panel.

Figure 36

STEP 21. If running power cord to the right of the unit install the cord

into the cord retainer clips along the bottom front of the unit.

Figure 37

CORD RETAINER

CLIPS

POWER

CORD

ELECTRICAL CONTROL PANEL SCREWS (3)

(RETAINED FROM STEP 1)

FRR060

FRONT

GRILLE

FRR061

31

Page 32

Through-the-Wall Installation

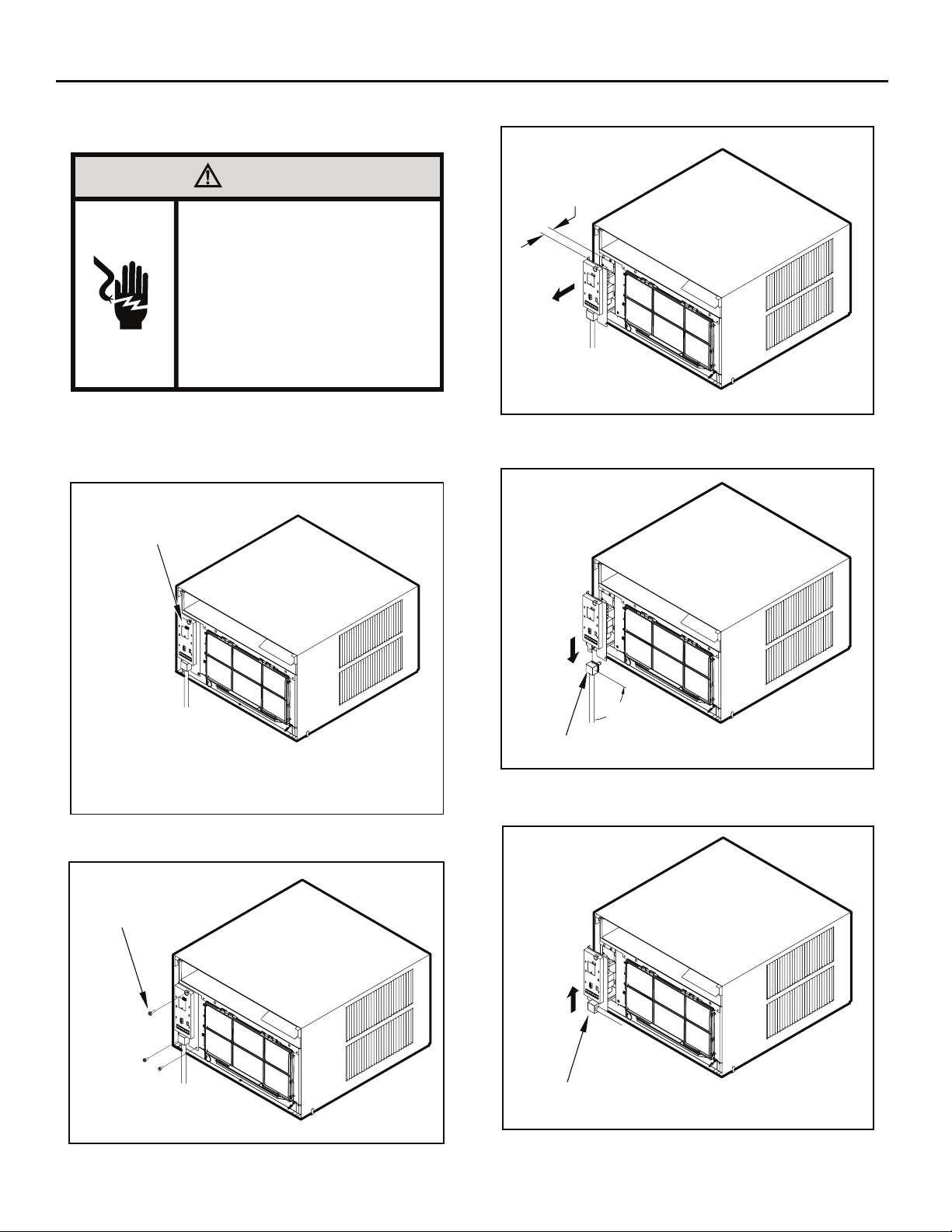

The following instructions apply to wood, masonry, brick, concrete or cinder

block wall construction.

STEP 1. Follow steps 1, 2, 3, and 4 of the "STANDARD WINDOW

INSTALLATION" instructions beginning on page 20.

STEP 2. CABINET PREPARATION – Remove the sill plate from the

Note that the chassis retainer is secured by a right side nut

and screw (Detail A, Figure 38). Bend the tabs of the sill plate

down into its channel at both ends of the plate or cut them off

(Detail B, Figure 38) Rotate the sill plate 180° (end-to-end,

Detail B, Figure 38) and reinstall. Reverse the orientation of

the nuts and screws, so that the head of the screws are on the

underside of cabinet facing up and the nuts are on top (Detail

C, Figure 38). Ensure that the chassis retainer is reinstalled

as shown in the detail.

NOTICE

The outside cabinet condenser air intake louvers

MUST NOT BE BLOCKED by extra thick walls.

STEP 3. WAL L PREPAR ATION – The maximum wall thickness

permissible without special construction is determined by

the model size to be installed. Observe the maximum wall

thickness shown in Figure 39. Walls exceeding the maximum

thickness shown in the chart, should be altered as shown in

Figure 39.

STEP 4. CHECKING WIRING AND PLUMBING – Check for wiring and

plumbing inside and outside of the wall to be sure none will be

damaged when the cabinet framework is being constructed.

.)83 erugiF( swercs dna stun )4( owt gnivomer yb tenibac

A

B

Table 4

FINISHED

DIMENSION

A 16 3⁄16" 18 3⁄16" 20 3⁄8"

B 26 3⁄16" 26 3⁄16" 28 1⁄4"

SMALL

CHASSIS

MEDIUM

CHASSIS

LARGE

CHASSIS

size.

STEP 5. OPENING CONSTRUCTION – Depending upon size of unit

to be installed, lay out the hole dimensions per Table 4. Cut

construction is typical frame or 2” x 4” studding with brick or

For masonry, concrete or cinder block walls, locate opening

for your convenience (See Figures 40, 41, and 42).

32

.sduts eht fo eno ot txen gninepo eht etacol ,sreenev enots

Page 33

Figure 38

CABINET

BEFORE AFTER

SCREW

(4 REQUIRED)

CABINET

SILL PLATE

TURN SILL PLATE

END TO END

Figure 39

A

MAXIMUM WALL THICKNESS

CONDENSER AIR

INTAKE LOUVERS

NOTE: HOLES IN SILL

PLATE MOVED TO

BACK SIDE

DETAIL A

NUT

(4 REQUIRED)

DETAIL B

BEND TABS DOWN

NOTE: SCREW AND NUT

ORIENTATION NOW REVERSED.

TOP VIEW

NUT

(4 REQUIRED)

DETAIL C

SCREW

(4 REQUIRED)

FRR026

CONDITIONED

ROOM SIDE AIR

MODEL A

SMALL CHASSIS 7-3/8”

MEDIUM CHASSIS 7-3/8”

LARGE CHASSIS 15-1/8”

TOP VIEW SHOWING

BEVELED SIDES FOR

AIR INTAKE.

WALL BELOW UNIT MUST

BE BEVELED ALSO.

NOTE: CONDENSER AIR INLETS AND OUTLETS

MUST BE UNOBSTRUCTED TO AVOID THE

RECIRCULATION OF REJECTED HEATED AIR.

2" MINIMUM

BOTH SIDES

CONDENSER AIR

INTAKE LOUVERS

CONDENSER AIR

OUTLET / REJECTED

HEATED AIR

FRR027

33

Page 34

Figure 40

Figure 41

CAULK ALL SIDES

INSIDE AND OUTSIDE

CABINET

SHIM TO FILL IN VOID AT THE

TOP AND SIDES WITH WOOD

AS REQUIRED.

ELECTRICAL RECEPTACLE

(SEE FIG. 42 FOR LOCATION NOTE)

FRR028

CAULK ALL SIDES

INSIDE AND OUTSIDE

CABINET

SHIM TO FILL IN VOID AT THE

TOP AND SIDES WITH WOOD

AS REQUIRED.

ELECTRICAL RECEPTACLE

(SEE FIG. 42 FOR LOCATION NOTE)

FRR029

Figure 42

MORTAR

CABINET

CAULK ALL SIDES

INSIDE AND OUTSIDE

POINT “X”

POINT “Y”

From Point "X" Small/Medium Large

115V 69” N/A

230V 45” 45”

From Point "Y" Small/Medium Large

115V 45” N/A

230V 21” 20”

ELECTRICAL

RECEPTACLE

FRR030

34

Page 35

STEP 6. Slide the cabinet into the hole far enough to allow the

guide-channel of the sill plate to contact the inside wall surface

(Figure 20).

STEP 7. Drill three (3) 5/32” diameter pilot holes (use the sill-plate holes

as a guide) into the frame and install three (3) #12 x 2" long

screws (Item 4) (Figure 20).

NOTE: Alternate fasteners are required when securing the sill plate or

support brackets to material other than wood (cinder block, brick,

masonry or concrete). These items can be purchased at your

local hardware store.

EXPANSION ANCHOR BOLT

MOLLY OR TOGGLE BOLT

Figure 43

NOTE: DO NOT LEVEL the cabinet from front to back. Make sure there

is approximately 3/8” to 1/2” slope (1/8 to 1/4 bubble on the level)

toward the outside of the house.

STEP 8. Drill two (2) 5/32" diameter pilot holes in each cabinet side

at the locations shown (Figure 20) and install four (4) #12 x

2" screws (Item 4). Provided that Step 5 (hole construction)

provides a sturdy mount with solid vertical studs, support

brackets may not be required. The installation must support

the weight of the unit plus an additional weight of 400 pounds

on the rear of the cabinet. If support brackets (Item 1) are

available, they can be installed as shown in Figure 20.

STEP 9. Complete the installation by following steps 12 through 15

of “STANDARD WINDOW INSTALLATION” instructions,

page 20.

TRIM MOULDING

4"

SCREW #12 x 2"

LONG (USE 3)

(ITEM 4)

SILL PLATE GUIDE CHANNEL

INSIDE WALL SURFACE

CAULK ALL SIDES WEATHER TIGHT

INSIDE AND OUTSIDE

3/8" SLOPE DOWN

3"

NOTE: SUPPORT BRACKET MAY BE

OMITTED FROM THROUGH-THE-WALL

INSTALLATIONS IF THE CABINET IS

SECURED AS FOLLOWS. DRILL TWO

HOLES IN EACH SIDE AND INSTALL 4

FASTENERS (2 EACH SIDE). USE #12 x 2"

SCREWS, (ITEM 4).

TOGGLE BOLTS OR EXPANSION BOLTS

MAY BE REQUIRED.

CABINET

SUPPORT BRACKETS

SCREW #12 x 2" LONG

DRILL 5/32" DIA. PILOT HOLES.

FRR031

35

Page 36

Programmable Thermostat

Your unit’s digital control features an advanced 7 day programmable

thermostat feature that can be used to turn the unit on or off or even

change modes and maintain temperatures throughout the day.

Factory settings are shown in addendum 1 (Schedule Table with Energy

Saving Values). These values can be changed by following the procedures

in the preceding paragraphs. Basic options are: Four (4) day groups.

1. Monday through Friday.

2. Saturday and Sunday only.

3. Monday through Sunday.

4. Individual days (Mon thru Sun).

Each of the day groups have four (4) time periods: WAKE (06:00), AWAY

(08:00), RETURN (18:00), and NIGHT (22:00).

The start time for each of the time periods can be changed. In addition,

each time period can have its own temperature and fan mode.

For example, let’s say you are in a cool climate region. You leave for work

at 08:00 and return home around 18:30. You can set the temperature lower

while you are away from your home. At 18:00, you set the temperature

higher for the RETURN period so the room is nice and comfortable when

you arrive.

Set Schedule Sequence – 1 Wake Period

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

Press and hold

AUTO

AUTO

<- COOLSET POINT

for three (3) seconds to enter the schedule setting

mode and returns to normal display without saving any settings that might

have been changed. To exit and save the changes, press and hold

for three (3) seconds. All changed parameters will be saved. The

key allows the user to back up through the menus.

SYSTEM

FAN

MODE

FAN

SPEED

M

T F S

S

SCHEDULE

T W

WAKE

the schedule icon blinks. The display begins with all weekday (MTWTF)

dots lit. Changes made will apply equally to all weekdays.

BACK

F

DISPLAY

ENTER

FRR032

BACK

A

M

DISPLAY

ENTER

FRR033

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

M

T F S

T W

S

WAKE

BACK

A

M

DISPLAY

ENTER

FRR034

The user can select a different day group by pressing . If the user

continues to press , the system will cycle through all the day groups

in the following order: MTWTF SS Mon, Tues, Wed, Thur, , Fri,

Sat, Sun.

Note the last day group is each individual day. In other words, the user can

adjust each of the four (4) time period start times per day. This is a real

helpful feature if you have an adjustable work shift. Each day group begins

showing the start time for the wake time period.

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

M

T F S

T W

S

WAKE

BACK

A

M

DISPLAY

ENTER

FRR035

To change the time, press (UP) or (DOWN) to increment/decrement

the time by 15 minute jumps. Once the correct time is set, press to

advance to the next step.

Set Schedule Sequence – 2 Wake Period

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

CONTINUOUS

M

T W

T F S

S

WAKE

Now you can adjust the settings for SYSTEM, FAN MODE, FAN SPEED

and TEMPERATURE.

SYSTEM

FAN

MODE

FAN

SPEED

SCHEDULE

CONTINUOUS

M

T W

T F S

S

WAKE

<- COOLSET POINT

Press , , or to change the perspective option. Use the

(UP) or (DOWN) to adjust the cool setpoint.

BACK

F

DISPLAY

ENTER

FRR036

BACK

F

DISPLAY

ENTER

FRR037

36

Page 37

FRR038

If the system mode is set to AUTO (Heat-Cool Unit only), a 2nd temperature

labeled “Heat !! Set Point” displays. Use (UP) or (DOWN) arrows

to increment /decrement the heat temperature. The other parameters

The temperature range for AUTO mode must remain a minimum of 3

degrees apart at all times. If the high or low temperature is adjusted too

close to its counterpart, that temperature not being directly changed will

increase/decrease as needed to maintain the 3 degree spread. The user

presses

to advance to the next time period.

FRR039

If the user selects FAN-Only mode, the word FAN displays for 2 seconds.

In this mode you may adjust the FAN SPEED. The FAN SPEED options

are: LOW, MED, HIGH or MAX*. Fan speed depends on your unit's

model. The MAX* Setting is available on all SS and SM models.

Set Schedule – Away, Return, Night Periods

Each of the additional periods (Away, Return, Night) are programmed

.neercs siht no degnahc eb tonnac )EDOM NAF ,DEEPS NAF ,METSYS(

identical to the programming for the Wake period. The appropriate

sequence.

Once the user has programmed all four (4) time periods, the program goes

to the next day or day group by pressing SCHEDULE. For example, if

individual days are being programmed, the program will go from Mon to

Tues leading the user through 4 periods for Tues until it reaches the end of

the week.

NOTE: Day group sequence is as follows: Monday through Friday

(weekday), Saturday – Sunday (weekend), Monday through

Sunday (7-day), and individual days Mon !!Tue !!Wed !!Thru

!! !! !!

Note that by pressing SCHEDULE repeatedly the process follows a

continuous loop until the user decides to exit.

When the user has completed setting start times and options (or at any

point in the process) they can press to toggle to the next day (or set of

days), or they can press and hold for 3 seconds to save their changes

and exit the set schedule mode. Once programmed you can SAVE and

EXIT or select another day group by pressing SCHEDULE.

FRR042

FRR040

If the user wants the air conditioner to power down for a period of time,

pressing

hibernation until the next scheduled period. This feature is available during

FRR041

If the user should decide they don’t want to use any or all four time

periods for the day, they can set any period to be pressing This will

blank out the options and display the word SKIP. This can be undone by

pressing again. The digital control defaults to the time period setting

inmediately prior to the user advancing to SKIP. to

continue on to the next time period. SKIP

previous time period, it will terminate at the

Press

,

continue

continues the settings of the

start of the next time period

P is not selected.where SKI

Schedule Mode Completed.

FRR043

37

Page 38

Final Inspection & Start-up Checklist

u Inspect and ensure that all components and accessories have been

installed properly and that they have not been damaged during the

installation progress.

u Check the condensate water drain(s) to ensure that they are adequate

for the removal of condensate water, and that they meet the approval

of the end user.

u Ensure that all installation instructions concerning clearances around

indoor coil, and outdoor coil are free from any obstructions.

u Ensure that the circuit breaker(s) or fuse(s) and supply circuit wire

size have been sized correctly. If the unit was supplied with a power

supply cord, insure that it is stored properly.

u Ensure that the entire installation is in compliance with all applicable

national and local codes and ordinances having jurisdiction.

u Secure components and accessories, such as a decorative front

cover.

u Start the unit and check for proper operation of all components in

each mode of operation.

u Instruct the owner or operator of the units operation, and the

manufacturer's Routine Maintenance.

NOTE: A log for recording the dates of maintenance and/or service is

recommended.

u Present the owner or operator of the equipment with the Installation

& Operation Manual, all accessory installation instructions, and the

name, address and telephone number of the Authorized Friedrich

Warranty Service Company in the area for future reference if

necessary.

Heat pumps operate differently

If your unit is a "Y", or heat pump model, there are some things that you

will want to be aware of. Some functions of a heat pump differ from your

unit when it is used for heating:

1. .pmup taeh eht fo lioc roodtuo eht no mrof ot eci rof lamron si tI

Moisture in the outside air, passing over the coil when very cold,

will form ice.

2. If the outdoor temperature drops below 37° F (3° C), your heat

pump will automatically turn on the electric resistance heat. When

the temperature rises to 40° F (4° C), the compressor will resume

the heat pump operation. If your unit is a 115 volt model (YS10),

it is designed for use in warmer climates and does not have an

electrical heat feature, and will not provide adequate heat below

37° F (2.8° C).

Control Panel Battery Change Procedure

Remove the grille, by loosening four (4) captive screws (See Figure 44). In

the upper left corner, remove one (1) screw on the battery retaining door

(See Figure 45). Remove and replace the battery (CR2450). Reinstall

the battery retaining door. Align the grille guide pins then tighten the four

Clean or replace it as necessary.

Figure 44

This is a warm weather appliance

Your air conditioner is designed to cool in warm weather when the outside

temperature is above 60° F (15.6° C) and below 115° F (46.1° C), so it won't

cool a room if it is already cool outside. If you want to cool a room in the

spring or fall, select the FAN ONLY

air control to Fresh Air. This will bring in a supply of cooler outside air.

mode and set the Fresh Air/Exhaust

Condensation is normal

Air conditioners actually pump the heat and humidity from your room to the

outside. Humidity becomes water, and your air conditioner will use most

of the water to keep the outside coil cool. If there is excessive humidity,

there may be excess water that will drip outside. This is normal operation.

Frosting

ONLY and the frost will disappear. Setting the thermostat a little warmer

will probably prevent the frosting from recurring.

Noises

All air conditioners make some noise. Friedrich units are designed to

operate as quietly as possible. An air conditioner mounted in a wall is

quieter than one mounted in a window. It is important to ensure that the

chassis seal gasket (Item 14) is properly installed (refer to installation

instructions).

US E HAN D TOOLS

DO NO T OV ER TI G HT EN

1. USE HAND TOOLS WHEN INSTALLING AND

REMOVING FRONT PANEL.

DO NOT OVERTIGHTEN SCREWS.

2. DISCONNECT POWER AND FOLLOW ALL

LABELED WARNINGS WHEN FRONT PANEL

IS REMOVED.

Figure 45

FRR010

38

Page 39

Routine Maintenance

monthly, and more frequently if conditions warrant. The unit must be turned

WARNING

Wall Sleeve

Inspect the inside of the wall sleeve and drain system periodically (annually

or semi-annually) and clean as required. Under extreme conditions, more

frequent cleaning may be necessary. Clean both of these areas with an

antibacterial and antifungal cleaner. Rinse both items thoroughly with

water and ensure that the drain outlets are operating correctly. Check the

sealant around the sleeve and reseal areas as needed.

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong oulet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

To Remove, Wash and Replace Filter

Coils & Chassis

NOTE: .nap esab ro slioc no tnega gninaelc lioc citsuac a esu ton oD

Use a biodegradable cleaning agent and degreaser. The use

of harsh cleaning materials may lead to deterioration of the

The indoor coil and outdoor coils and base pan should be inspected

periodically (annually or semi-annually) and cleaned of all debris (lint, dirt,

leaves, paper, etc.) as necessary. Under extreme conditions, more frequent

cleaning may be required. Clean the coils and base pan with a soft brush