Page 1

PTAC

Packaged Terminal Air

Conditioners & Heat Pumps

Installation and Operation Manual

FreshAire

TM

Page 2

2

Tableof Contents

Congratulations········································································································································3

General Instructions

General Specifications

PTAC Installation Recommendations···········································································································5

Wall Sleeve Installation Instructions (PDXWSA)···························································································· 6

Alternate Wall Installations

PXDR10 Drain Kit Installation Instructions (optional for new construction)

External Drain (for new construction or unit replacement)··············································································11

PXGA Standard Grille Installation Instructions····························································································· 12

Chassis Install Preparation

Chassis Installation

Friedrich PTAC Digital Control and Unit Features·························································································19

System Configuration······························································································································ 21

Digital Control User Input Configuration

Digital Control Operation

Remote Control Thermostat Installation······································································································26

··································································································································

·······························································································································

·························································································································

························································

·······················································································································

·································································································································

······································································································

··························································································································

10

16

18

22

24

3

4

7

Remote Thermostat and·························································································································· 26

Low Voltage Control Connections

Final Inspection & Start-up Checklist

Basic Troubleshooting····························································································································· 29

Service & Assistance·······························································································································31

Accessories

···········································································································································

··············································································································

··········································································································

26

28

32

NOTE:

All PTAC 9000units come with a universal 2.5+1.0kW electric heater(standard 20A power cord for 3.5kW ,optional

15A power cord for 2.5kW). All PTAC 12000units come with a universal 3.5+1.5kW electric heater(standard 20A

power cord for 3.5kW,optional 30A power cord for 5kW,optional 15A power cord for 1.5kW).

Page 3

3

Congratulations

Thank you for your decision to purchase Friedrich. Your new Friedrich has been carefully engineered and manufactured to give you many years of

dependable, efficient operation, maintaining a comfortable temperature and humidity level. Many extra features have been built into your unit to assure quiet

operation, the greatest circulation of cool, dry air, and the most economic operation.

This Installation and Operation Manual has been designed to insure maximum satisfaction in the performance of your unit. For years of trouble-free service,

please follow the installation instructions closely. We cannot overemphasize the importance of proper installation.

WARNING

Refrigeration system

under high pressure

Do not puncture, heat, expose to flame or

incinerate.

Only certified refrigeration technicians should

service this equipment.

R410A systems operate at higher pressures

than R22 equipment. Appropriate safe

service and handling practices must be used.

Only use gauge sets designed for use with

R410A. Do not use standard R22 gauge sets.

Here are some suggestions to help you use your

new Friedrich most efficiently:

1. Carefully read and follow the installation instructions.

2. Make sure the unit is the right capacity for the area being cooled.

An undersized unit makes the unit work too hard, using more

electricity than needed and increases wear. An oversized unit

will cycle on and off too rapidly, and therefore cannot control

humidity as well.

3. Clean the filter frequently (See Routine Maintenance, Page 27).

4. Do not block the air flow to and from the unit.

5. A dirty filter or improperly set controls can affect the cooling

ability of the unit.

6. If cooling is weak and you have verified that the filter is clean

and the controls are properly set, the unit may need service and

you should call your Friedrich service provider to check the unit.

7. Keep blinds, shades and drapes closed on the sunny side of the

room being cooled to reduce radiant heat.

8. Proper insulation helps your unit maintain the desired inside

temperature.

9. Whenever possible, shade south and west facing windows.

10. Keep window coverings awayfrom the unit to provide free airflow.

WARNING

Read Installation Operation Manual

Please read this manual thoroughly prior to

equipment installation or operation.

It is the installer’s responsibility to properly

apply and install the equipment. Installation

must be in conformance with the NFPA 70

-2008 National Electric Code or current edition,

International Mechanic Code 2009 or current

edition and any other applicable local or

national codes.

Failure to do so can result in property damage,

personal injury or death.

WARNING

CAUTION

Indicates a hazard which, if not avoided, can result in severe personal injury or

death and damage to product or other property.

Indicates a hazard which, if not avoided, can result in personal injury and

damage to product or other property.

NOTICE

Indicates property damage can occur if instructions are not followed.

General Instructions

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is a safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING”

or “CAUTION”. These words mean:

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what will happen if the instructions are not followed.

Page 4

4

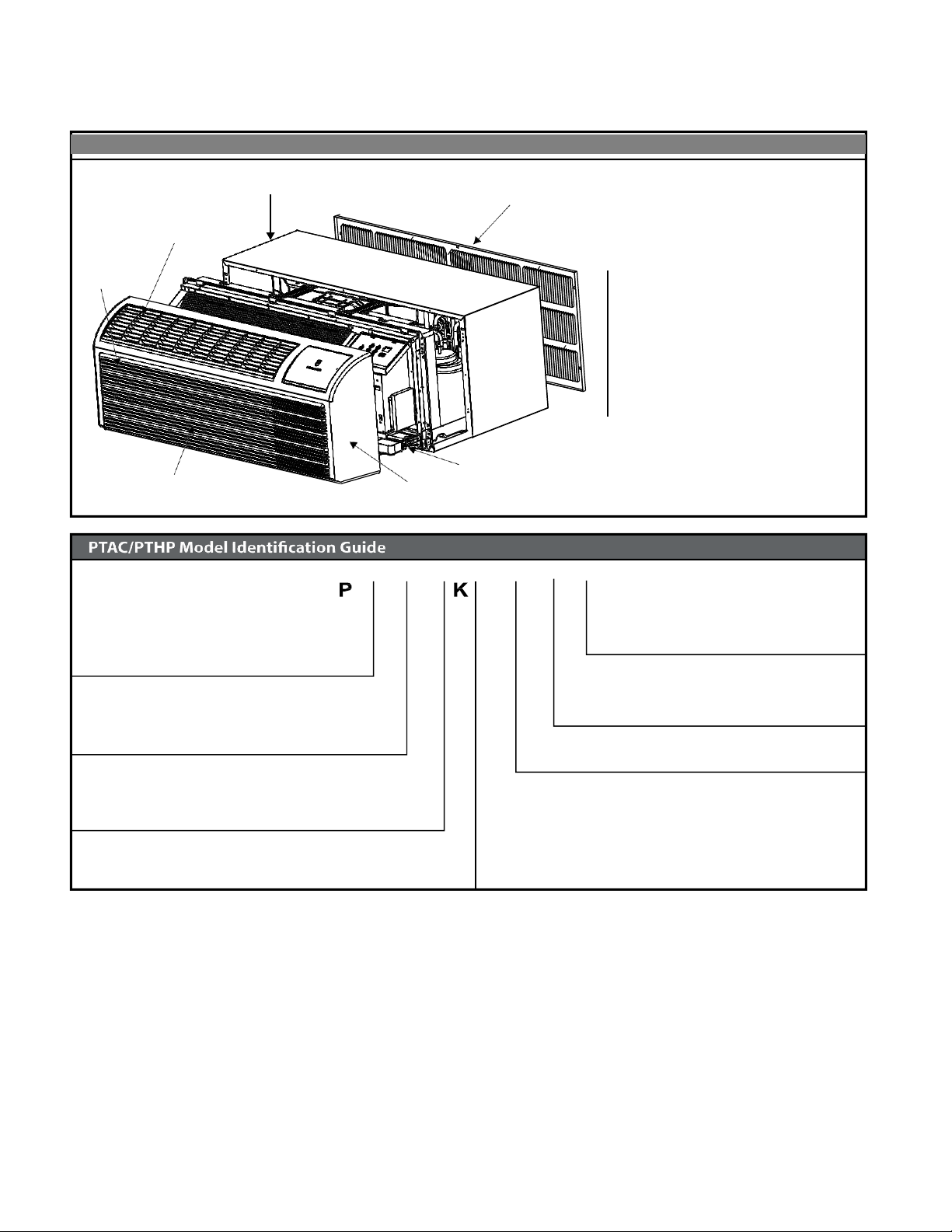

GeneralSpecifications

WALL SLEEVE

DISCHARGE GRILLE

FILTERS

RETURN AIR GRILLE

OUTDOOR GRILLE

CHASSIS

FRONT COVER

PDXWS Wall Sleeve

Dimensions: 16" H x 42" W x

13-¾" D

Front Cover Dimensions:

16" H x 42" W x 7-¾" D

Cut-Out Dimensions:

16-¼" x 42-¼"

MODEL NUMBER

V

H

09

3 F

Series

PV = Friedrich Digital PTAC

System

E = Cooling with electric heat

H = Heat Pump with Auxiliary Heat

Nominal Capacity

Engin eering Digit

Design Series

Chassis

F= FreshAire

07 = 7,000 Btuh

09 = 9,000 Btuh

Voltage

12= 12,000 Btuh

15= 15,000 Btuh

Nominal Heater Size (230V or 265V)

3=3kW

Installation Checklist

. Inspect all components and accessories for damage before and

after installation.

. Remove the cardboard wall sleeve support and grill weatherboard.

. Check for proper wall sleeve installation in accordance with the wall

sleeve installation instructions.

. Check for a subbase kit or other means of structural support which

is required for ALL installations projecting more than 8" into room.

. Install th e recommended Condensate Drain Kits for complete

condensate removal.

. Ensure that chassis and chassis front cover are installed and secured

properly.

. Ensure that drapes,bed,bedspread,furniture,etc DO NOT block

either return or discharge air grilles.

. Inspect the condenser air inlet and outlet for any obstructions

(shrubbery,etc).

. Ensure that 'reset' button is pressed on LCD device(only on cord

connected models).

Typical Unit Components and Dimensions

K = 230/208V - 1 Ph. - 60 Hz.

R = 265V - 1 Ph. - 60 Hz.

A

. Ensure that the chassis is installed in a 16" highx4'' wide wall sleeve

that is no deeper than 13-¾".A baffle kit is required if the sleeve

exceeds that depth.

Page 5

5

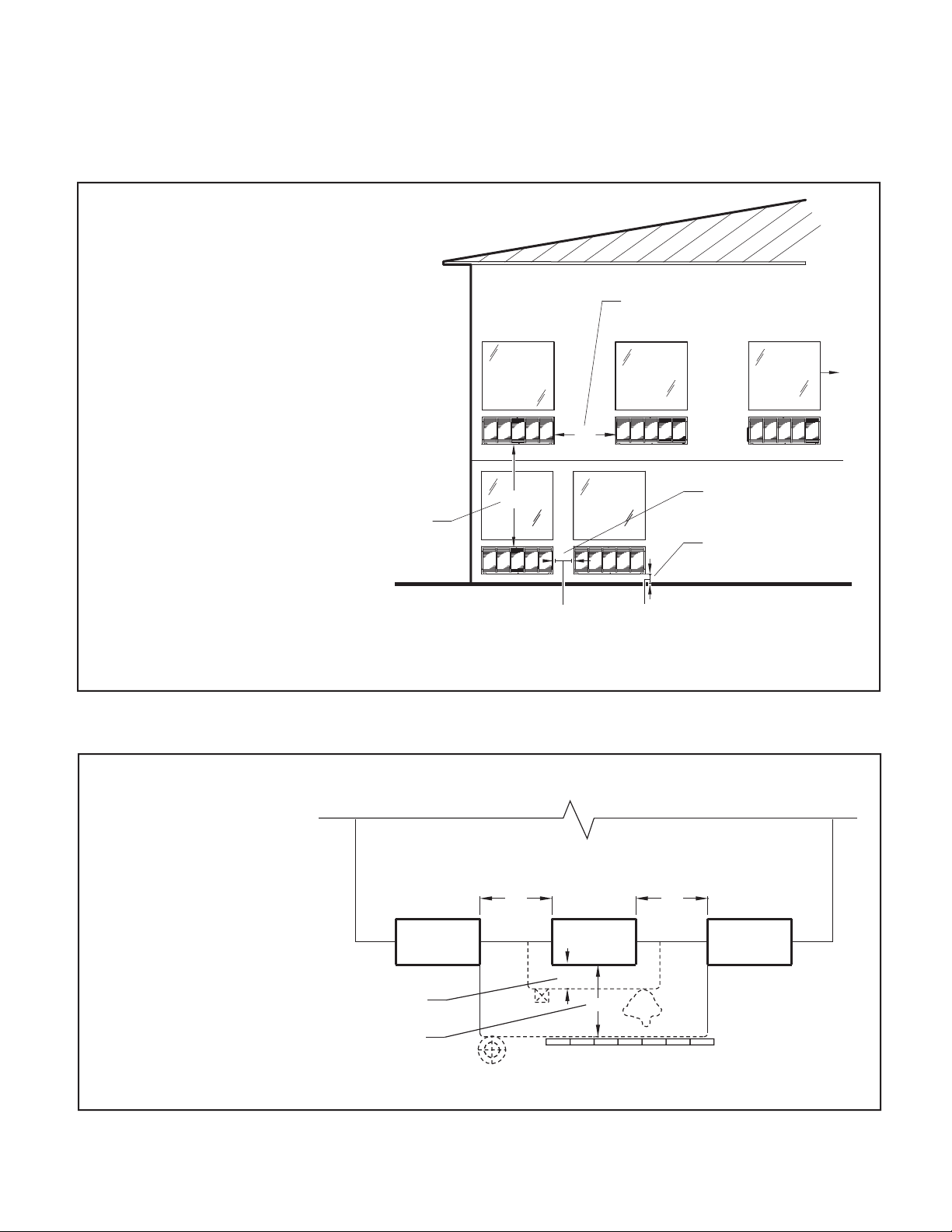

PTACInstallationRecommendations

FRP001

• Fo r mi nor o bs truc t ion s

such as lamp poles or small

shrubbery a clearance of

12" from the outdoor louver

should be maintained.

TYPICAL BUILDING ( PLAN VIEW )

• For major obstructions such

as a solid fence, wall or

other heat rejecting device

like a condensing unit, a

minimum distance of 36"

should be kept.

PTAC

12" MINIMUM, MINOR

OBSTRUCTIONS

36" MIMUMUM, MAJOR

36"

POLE

PTAC

12"

36"

36"

SHRUB

PTAC

OBSTRUCTIONS

CONDENSING UNIT

FENCE OR WALL

FRP002

The above suggestions are for reference only and do not represent all possible installations.Please contact Friedrich for information regarding affects of other

installation arrangements.By following these simple recommendations youcan be confident that your Friedrich PTACwill provide years ofworry free operation.

For proper PTAC unit performance and maximum operating life refer to the minimum installation clearances

below:

Figure 1

PTAC units should be installed no

closer than 12" apart when two

units are side by side. If three or

more PTAC units are to operate

next to one another allow a

minimum of 36" between units.

Also,a vertical clearance of 60"

should be maintained between

units installed. In the interior of

the room the unit should be

located a minimum of 1/4" from the

floor and a minimum of 36"

from the ceiling.

TYPICAL

WINDOW

36"

THREE OR MORE PTACs

ADJACENT 36" MINIMUM

TWO ADJACENT PTACs

12" MINIMUM

GROUND FLOOR PTACs

6" MINIMUM FROM GRADE

60" VERTICAL

MINIMUM

BETWEEN

PTACs

60"

12"

6"

VIEW: OUTSIDE BUILDING ELEVATION

For PTACs on the ground floor or anytime obstructions are present, use the following guidelines:

Figure 2

Page 6

6

Wall Sleeve Installation Instructions (PDXWSA)

NOTE: Insure that the unit is only installed in a wall structurally adequate to support the unit including the sleeve, chassis and accessories.If the sleeve

projects more than 8" into the room, a subbase or other means of support MUST be used. Please read these instructions completely

before attempting installation.

WARNING

Falling Object Hazard

Not following Installation Instructions for

mounting your air conditioner can result

in property damage, injury, or death.

NOTICE

DO NOT allow any pitch toward the inside.

Flashing on all 4 sides of the opening is recommended.

Potential property damage can occur if instructions are

not followed.

For Deep Wall Installation (Greater than 13 1/4")

See Page 9

The following instructions apply ONLY to walls less than 13 ¼" in depth.

1 The PXDR10 Drain Kit,(optional for new construction) see page 10

if applicable, must be installed before the wall sleeve is installed

into the wall.

2 The External Drain (for new construction or unit replacement) see

page 11 if applicable, must be installed before the wall sleeve is

installed into the wall.

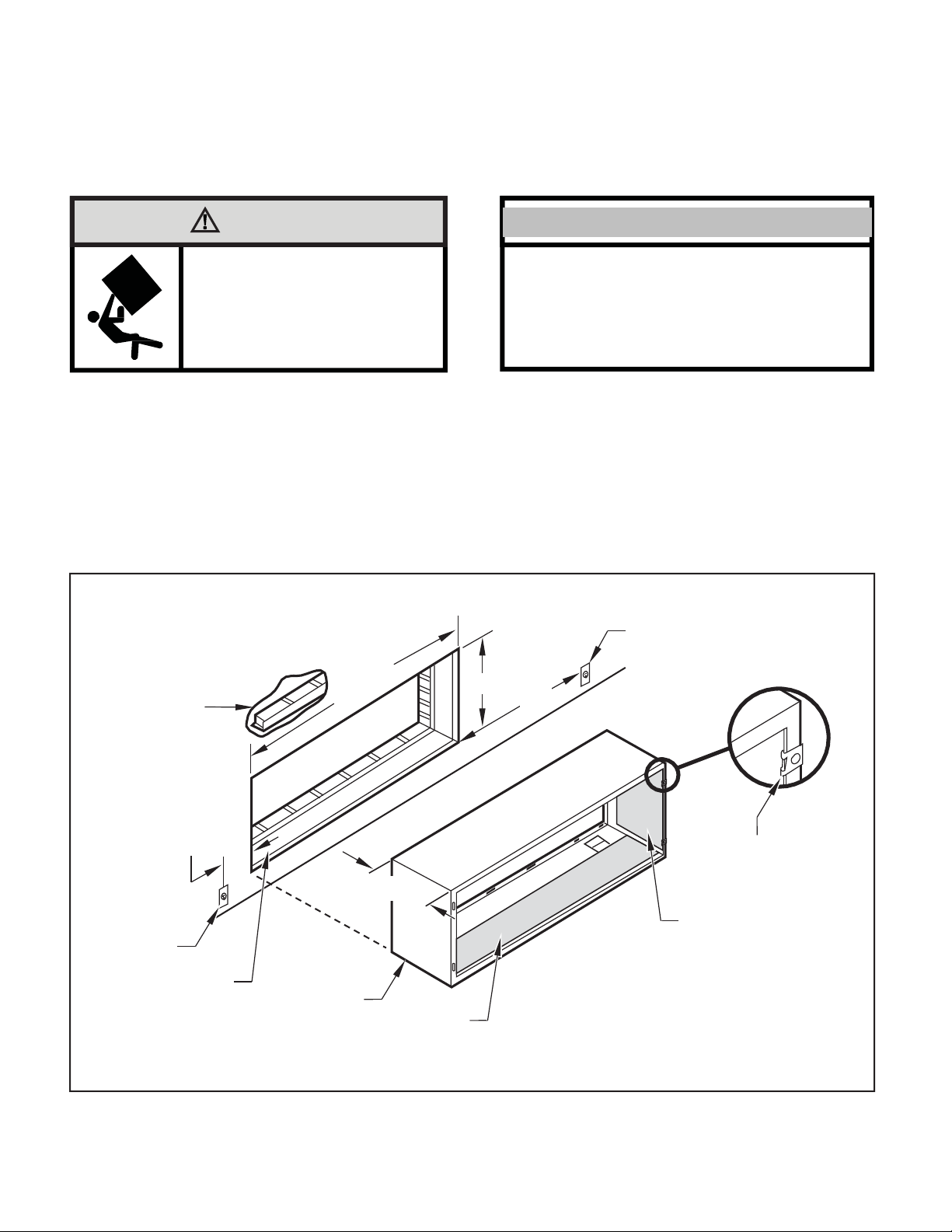

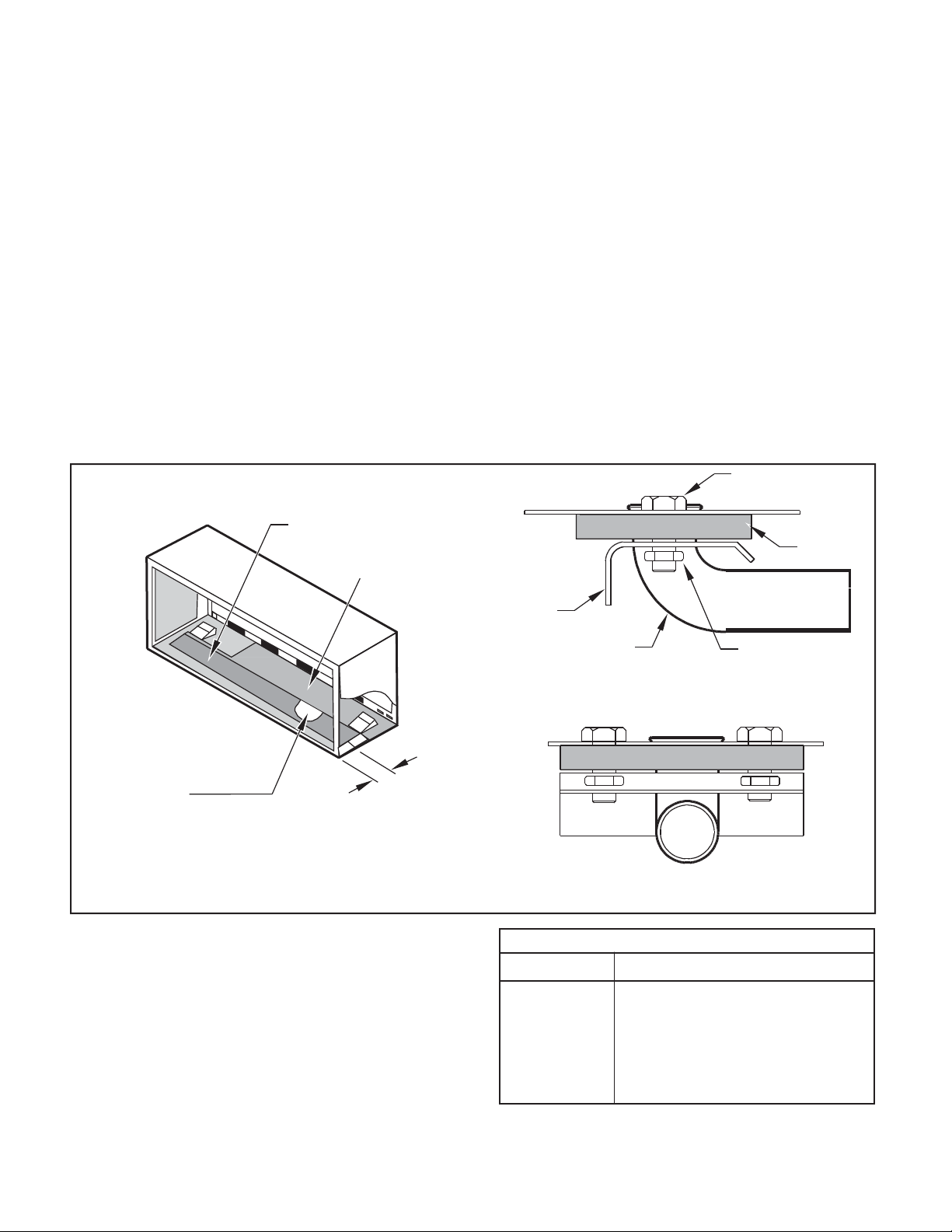

Figure 3

Typical Wall Sleeve Installation

3 Frominside the building, positionthe wall sleeve inthe opening and

push itinto the wall until it protrudes at least ¼” on the outside

(See Figure 9, Page 8).

4 Position the wall sleeve with a slight tilt towards the outside to

facilitate condensate drainage. It should be level side-to-side and

the front should be ¼ bubble higher than the back.

ELECTRICAL

RECEPTACLE

LINTEL TO SUPPORT

MASONRY WALLS

42-¼"

MIN.

16-¼"

60"

MAX.

20"

MAX.

13-¾"

SMOOTH SIDE OF SCREW

CLIP FACING INTO ROOM

ELECTRICAL

RECEPTACLE

INSULATION

WALL OPENING

WALL SLEEVE

INSULATION

NOTE:

All 230/208V units are manufactured with a 60” power cord and all 265V units with a 18” power cord.

FRP003

Page 7

7

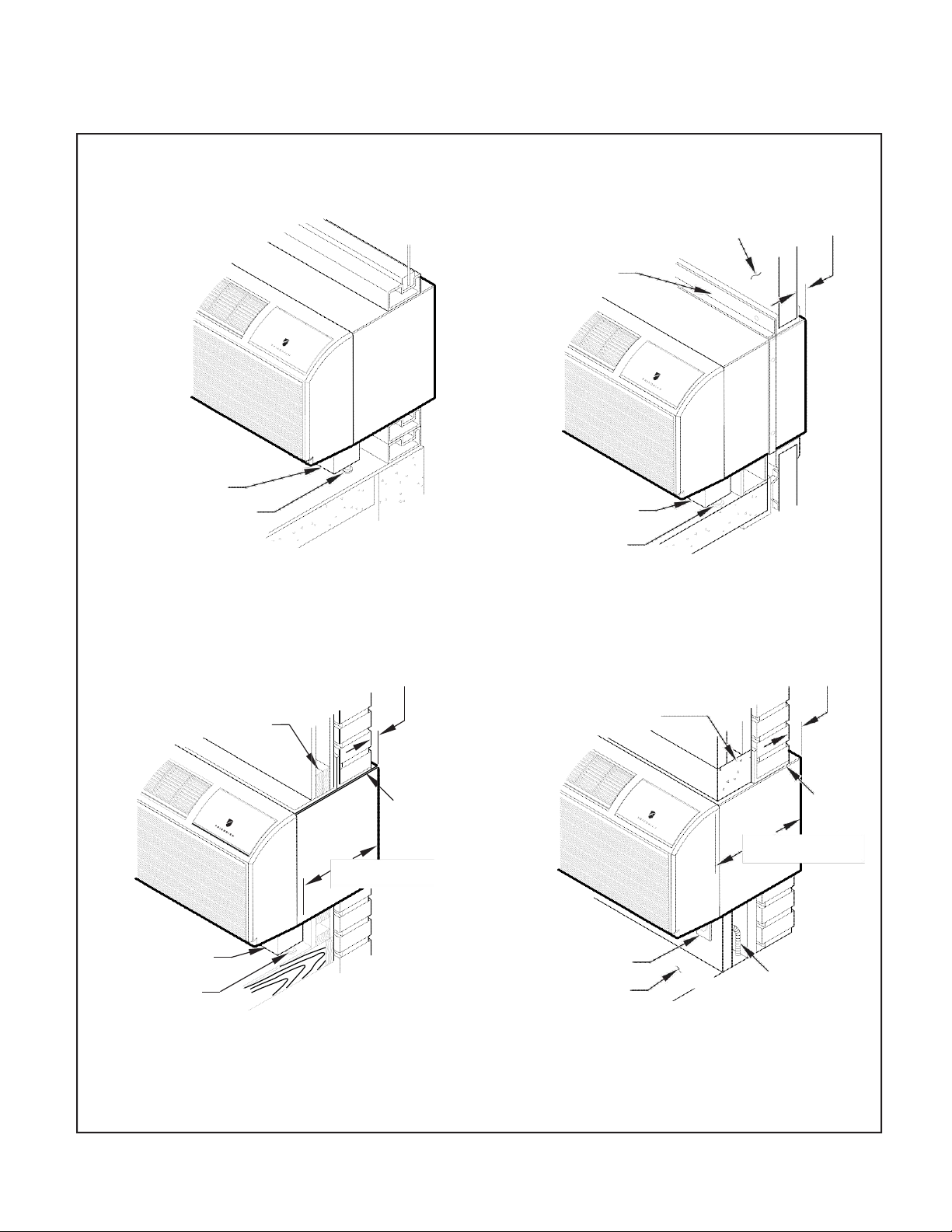

AlternateWall Installations

Figure 4

Panel Wall

Figure 6

CurtainWall

WALL OR

WINDOW

1/4" MIN

PROJECTIO

N

CASE FLANGE

OPTIONAL SUBBASE

LEVELING SCREW

OPTIONAL SUBBASE

FRP004

LEVELING SCREW

FRP006

Figure 5

Frame and Brick Veneer

Figure 7

Block and Brick Veneer

1/4" MIN

PROJECTION

1/4" MIN

PROJECTION

WOOD FRAME

CONCRETE LINTEL

STEEL

LINTEL

13-3/4" MIN.

STEEL

LINTEL

11" MIN.

WITH SUBBASE

WITHOUT SUBBASE

OPTIONAL SUBBASE

LEVELING SCREW

FRP005

RECEPTACLE

FINISHED FLOOR

POWER SUPPLY CONDUIT

(SUPPLIED BY INSTALLER)

FRP007

NOTE: Follow all wall system manufacturer installation instructions. For sunrooms and modular buildings, adhere to their installation instructions for

supporting and sealing sleeve to their frames. All wall and window/wall installations must provide for proper drainage. In applications where the

drain holes on the PTAC wall sleeve are not exposed beyond the wall an internal drain system is recommended. It is the installer's responsibility

to ensure there is adequate drainage for the PTAC unit.

(BY OTHERS)

Page 8

8

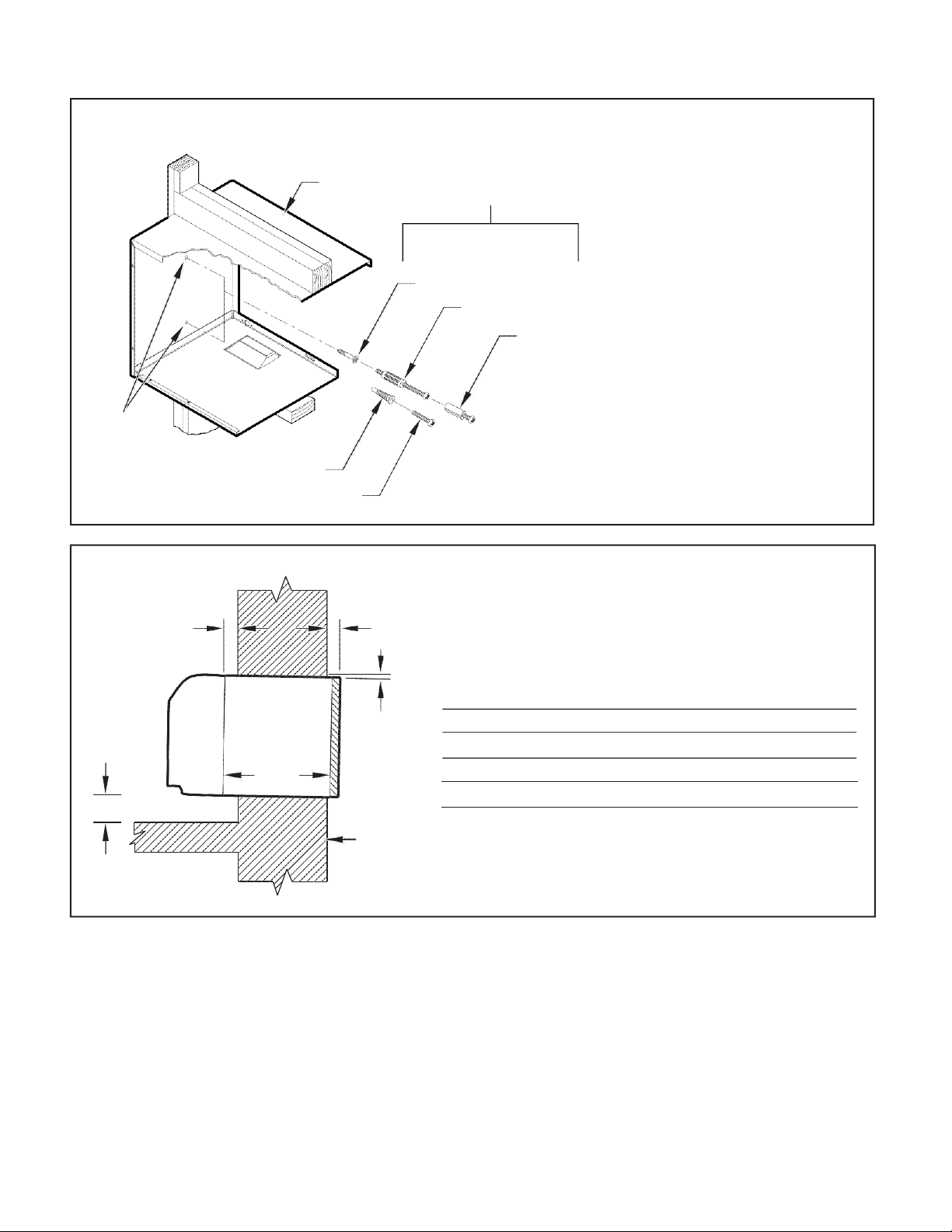

13-¾

"

Figure 8

WALL

SLEEVE

ALTERNATE

FASTENING METHODS

(Field Supplied)

WOOD SCREW

TOGGLE BOLT

NOTE: The Wall Sleeve must be

horizontally level (side-to-side)

and pitched 1/4 bubble to the

outside when installed in an

opening.

The mounting hole location

EXPANSION

ANCHOR BOLT

should be approximately 2-4”

from the top and bottom of the

sleeve.

PLASTIC ANCHORS

SCREWS

FRP008

A ¼" MIN.

A B C

Dimension*

Allow

for wall

finishing

Allow

for floor

finishing

Allow

for proper

drainage

(Minimum) Min. Max.

(Front-to-Back)

C

No Accessories

¼" ¼"

---

---

With Subbase 1-¾" 3-½" 5"

---

With Lateral Duct ¾"

¼"

---

---

Wall Sleeve Tilt

B

---

---

---

¼"

WALL

* If more than one accessory is to be used, use the maximum

dimension. If the wall thickness is more than 13-¾" - (A+ ¼"),

a sleeve extension must be used.

Wall Sleeve Attachment

MOUNTING

HOLES

Figure 9

Dimensions

FRP009

Page 9

9

5. Drill two 3/16" holes through each side of the sleeve approximately

4" from top and 4" from bottom of sleeve. Screw four #10 x 1"

screws (included) or appropriate fasteners for your installation,

through the holes in the sides of the wall sleeve.

6. Apply sealant around the wall sleeve where it projects through the

inside and outside wall surfaces. Apply the sealant to the screw

heads or the tops of the fasteners used in Step #5.

7. If the chassis and exterior grille are to be installed later, leave the

weatherboard and center support in place, otherwise remove and

dispose of them. (See Figure 13, Page 12).

8. Provide a support lintel if the wall sleeve is installed in a concrete

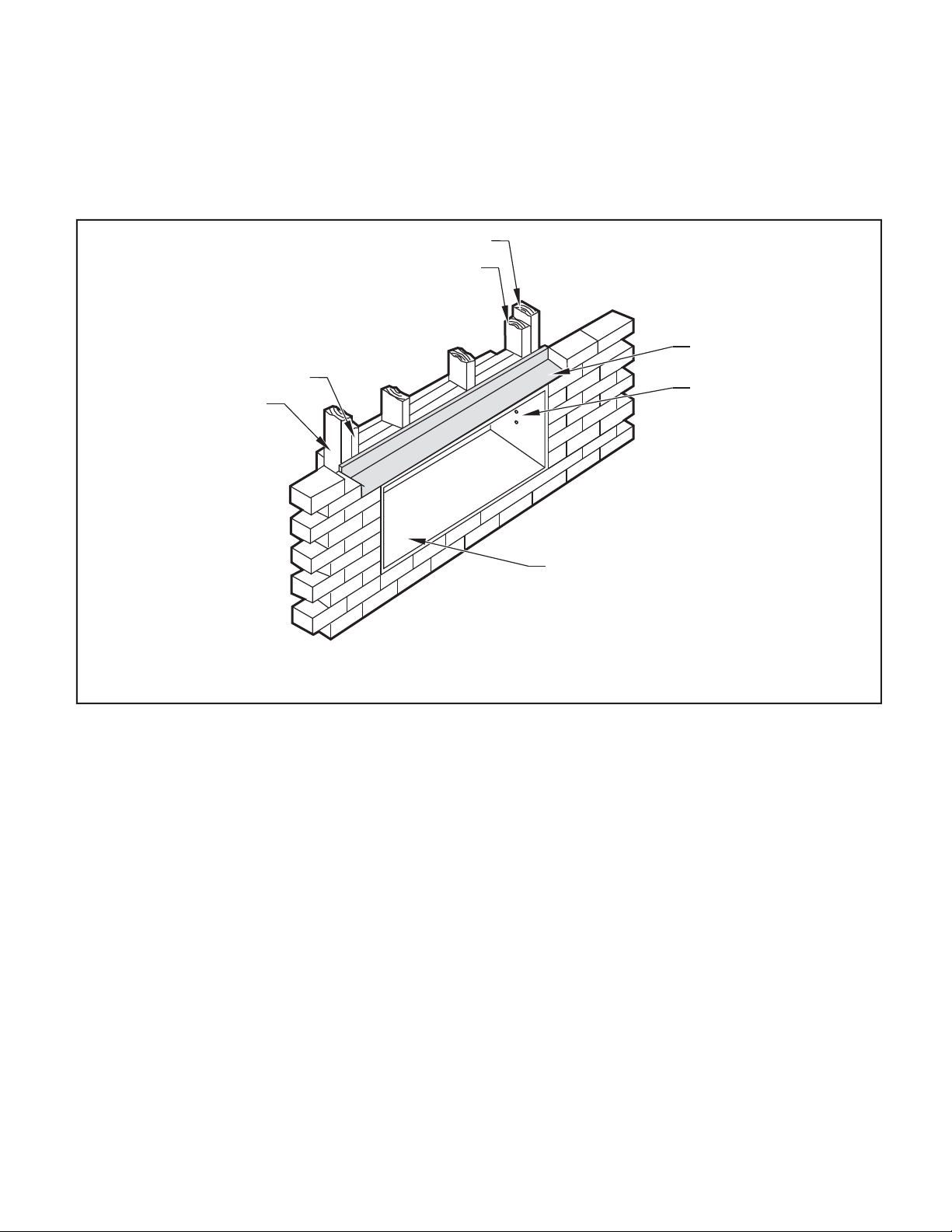

or masonry wall (See Figure 10, Page 9).

Figure 10

Lintel Installation

MAIN STUDS

JACK STUDS

JACK STUDS

MAIN STUDS

LINTEL

MOUNTING

SCREW HOLES

NO HOLES IN BOTTOM OF WALL

SLEEVE UNLESS DRAIN KIT IS USED

NOTE: Construct wall opening to comply with all applicable building codes.

FRP010

One-Piece Deep Wall Sleeve

If the wall is thicker than 13 1/4” a deep wall sleeve or wall sleeve extension

MUST be used. The deep wall sleeve may be special ordered through

your Sales Representative.

Installation (PDXWSEXT)

Page 10

10

PXDR10DrainKitInstallation

Instructions(optionalfornew

construction)

NOTE: Determine whether drain will be located within the wall, on the

indoor side, or will drain to the exterior of the building. Follow

appropriate instructions below depending on your particular

type of installation.

Internal Drain

NOTE: If installing an internal drain, you MUST install a drain kit on

the wall sleeve before the wall sleeve is installed.

1. Refer to Figure 11 and locate the drain within the “Preferred”

area of best drainage.Maintain at least a ½” clearance from the

embossed area.

2. Using the mounting plate with the ½” hole as a template, mark

and drill two, 3/16” mounting holes and a ½” drain hole in the

sleeve bottom.

Figure 11

DrainKitLocationand Installation

OPTIONAL AREA

PREFERRED AREANO FOAM INSULATION

3. Remove the backing from the gasket and mount it on the flat

side of the mounting plate (See Figure 12, Page 11). Insert the

drain tube through the hole in the gasket and mounting plate so the

tube flange will be against the wall sleeve.

4. Position the assembly beneath the drilled holes and secure it with

#10-24 x ½" machine screws and lock nuts provided. Seal the tops

of the screws with silicone caulking.

5. Use ½" I D copper tube, PVC pipe, or vinyl hose (obtained locally)

to connect the internal drain tube tothe drain system in thebuilding.

6. Referring to Figure 12, Detail A, Page 11, locate and assemble

the two cover plates and gaskets over the drain holes at the

rear of the wall sleeve. Attach them with the #10 sheet metal

screws provided. Make certain that the four overflow slots at

the rear of the wall sleeve are not blocked (See drawing of the

back of the sleeve Figure 12, Page 11).

7. If a deep wall extension (PDXWSEXT) is used, after installing the

field supplied flashing,caulk as required. Be sure to caulk around

the flashing and the wall sleeve where the hole was drilled for the

drain tube.

DRAIN TUBE

NUT

IF THE DRAIN MUST BE

REMOVED TO ALLOW ACCESS

3"

FRONT VIEW

FRP011

PXDR10

QUANTITY

DESCRIPTION

2

COVER PLATES

1

MOUNTING PLATE

1

DRAIN TUBE

3

MOUNTING PLATE GASKET

4

#10 X ½” SHEET METAL SCREWS

2

#10-24 X ½ ” MACH. SCREWS

2

#10-24 X ½" LOCKNUTS

LOCATED IN THE OPTIONAL

AREA, THE FOAM INSULATION

MUST BE CUT AWAY AND

TO THE DRAIN.

WALL SLEEVE

SCREW

GASKET

MOUNTING

PLATE

SIDE VIEW

Page 11

11

External Drain (for new

construction or unit

replacement)

When using an external drain system, the condensate is removed through

either of two drain holes on the back of the wall sleeve. Select the drain

hole which best meets your drainage situation and install the drain kit.

Seal off the other with a cover plate.

Drain Tube Installation (See Figure 12)

1. Peel the backing tape off the gaskets and apply the sticky side

to one cover plate and one mounting plate as shown in Details

A and B.

2. Place the drain tube through the gasket and the mounting plate

with the flange toward the wall sleeve.

3. Attach the drain tube assembly to one of the two drain holes at the

rear of the wall sleeve. The large flange on the mounting plate is

positioned at the bottom of the sleeve facing toward the sleeve,

Detail B. When the drain tube is positioned at the desired angle,

tighten the screws.

Cover Plate Installation

4. Mount the foam gasket tothe cover plate. Using two #10 x ½" sheet

metal screws (provided), attach the cover plate to the remaining

drain hole. Make certain the large flange on the plate is positioned

at the bottom of the sleeve.

5. Discard the additional cover plate, gasket, machine screws, and

locknuts.

NOTICE

If the wall sleeve has not been installed, the drain tube

must be rotated to a horizontal position until after the

sleeve is installed. Tighten the mounting plate screws

when the tube is in the proper position. Make certain that

the four overflow slots at the rear of the wall sleeve are not

blocked (See Figure 12).

When sealing the sleeve on the outside of the building, be

careful NOT to let the sealant block the two condensate

drain holes or the four overflow slots at the bottom flange

of the sleeve.

Potential property damage can occur if instructions are

not followed.

Figure 12

Drain Kit Installation

COVER

PLATE

NUT

MOUNTING

PLATE

FOAM

GASKET

DETAIL A

FOAM

GASKET

DETAIL B

SCREWS

½” O.D. TUBE

FRP012

NOTE: The large flange on the mounting plate is positioned at the bottom of the sleeve facing toward the sleeve. The drain tube must be rotated to a

horizontal position to allow for the wall sleeve to be installed into the wall. Once the wall sleeve is installed, return the drain tube to a downward

angle.

OVERFLOW

SLOTS

Page 12

12

PXGA Standard Grille

Quantity

Description

1

6

6

Stamped Aluminum Grille

Plastic Grommets

#8 x –" Sheet Metal Screws

PXGAStandardGrille

Installation Instructions

1. Remove the center support and weatherboard if still installed in

the sleeve.

2. Insert six plastic grommets into the grille openings from the outside

of the grille as shown in Figure 13.

3. Insert two #8 x ⅜" sheet metal screws (provided) in the top two

outside edge plastic grommets, and tighten them half way into

the grommets.

4. Grasp the grille by the attached plastic handles. Pos ition

it w ith t he c ond e nsa te d rai n kno c ko uts f aci ng d own.

From inside the building, maneuver the grille through the wall

sleeve and pull toward you until the screw heads are inserted

into the keyhole slots at the top of the wall sleeve. Tighten the

two screws completely.

5. Insert the remaining screws into the remaining holes and tighten

securely.

WARNING

Falling Object Hazard

Not following Installation Instructions for

mounting your air conditioner can result

in property damage, injury, or death.

Figure 13

WEATHERBOARD

CENTER SUPPORT

WALL

SLEEVE

STANDARD

GRILLE

#8 x 3/8”

SHEET METAL

SCREW

Standard Grille

WALL SLEEVE

STANDARD GRILLE

PLASTIC GROMMETS

PLASTIC HANDLES

FRP013

Page 13

13

FUSE/CIRCUIT

BREAKER

Use ONLY type and size fuse or HACR circuit breaker indicated on unit’s rating plate.

Proper current protection to the unit is the

responsibility of the owner. NOTE: A time

delay fuse is provided with 265V units.

GROUNDING

Unit MUST be grounded from branch circuit through service cord to unit, or through

separate ground wire provided on permanently connected units. Be sure that branch

circuit or general purpose outlet is grounded.The field supplied outlet must match plug on service cord and be within reach of

service cord. Refer to Table 1 for proper

receptacle and fuse type. Do NOT alter

the service cord or plug. Do NOT use an

extension cord.

RECEPTACLE

A.

Table 1 Receptacles and Fuse Types

Voltage

230V

265V

Amps

152030

152030

Heater Size

3.5kw

5kw

5kw

Receptacles

NEMA#

Receptacle

6-15R

6-20R

6-30R

7-15R

7-30R

NEMA#

Plug

6-15P

6-20P

6-30P

7-15P

7-30P

electrician and conform to the National

Code and all local codes which have

jurisdiction.

B. Power Cord Information (230/208V models only)

All Friedrich 230/208V PTAC units are shipped from the factory with a

Leakage Current Detection Interrupter (LCDI) equipped power cord.

The LCDI device meets the UL and NEC requirements for cord connected

air conditioners effective August 2004.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET.

3. Press TEST ( listen for click;Reset button trips and pops out).

4. Press and release RESET (listen for click;Reset button latches

and remains in).The power supply cord is ready for operation.

Figure 14

Typical LCDI Devices

NOTE: The LCDI device is not intended to be used as a switch. Once

plugged in the unit will operate normally without the need to reset the

LCDI.device.

If the LCDI device fails to trip when tested or if the power supply cord is

damaged it must be replaced with a new supply cord obtained from the

product manufacturer,and must not be repaired.

15/20/30A LCDI Device

FRP014

Electrical Rating Tables

All units are equipped with standard power cords.

NOTE: 1.5kW heater only for 12K Btu unit and 2.5kW heater only for 9K Btu unit.

1.5/2.5kw

1.5/2.5kw

WARNING

Electrical Shock Hazard

Turn off electrical power before service

or installation.

ALL electrical connections and wiring

MUST be installed by a qualified

Failure to do so can result in property

damage, personal injury and/or death.

3.5kw

7-20R

7-20P

The field supplied outlet must match plug on

service cord and be within reach of service

cord. Refer to Table 1 for proper receptacle

and fuse type. Do NOT alter the service

cord or plug. Do NOT use an extension

cord.

Page 14

14

TABLE 2

MODEL

HEATER kW

Power Cord Kit

Voltage

Amperage

Receptacle

PVH09K

2.5(optional)

STD

230/208

15

NEMA 6-15r

3.5(default)

STD

230/208

20

NEMA 6-20r

PVH12K

1.5(optional)

STD

230/208

15

NEMA 6-15r

3.5(default)

STD

230/208

20

NEMA 6-20r

5.0(optional)

STD

230/208

30

NEMA 6-30r

PVH09R

2.5(optional)

STD

265/277

15

NEMA 7-15r

3.5(default)

STD

265/277

20

NEMA 7-20r

PVH12R

1.5(optional)

STD

265/277

15

NEMA 7-15r

3.5(default)

STD

265/277

20

NEMA 7-20r

5.0(optional)

STD

265/277

30

NEMA 7-30r

Electrical Wiring for 265 Volt Models

Power Cord Installation

All 265V PTAC/PTHP units come with a factory installed non-LCDI

power cord for use in a subbase.If the unit is to be hard-wired refer to

the instructions below.

NOTE: It is recommended that the PXSBsubbase assembly, the

PXCJA conduit kit(or equivalent) be installed on all

hardwire units.If installing a flush-floor mounted unit,make

sure the chassis can be removed from the sleeve for

service and maintenance.

Toinstall the line voltage power leads and conduit to

chassis, follow the instructionsbelow. PXCJA

Conduit Kit isrequiredwiththissetup.

1. Follow the removal process of the chassis’s junction box .

2. Prepare the 265V(or 230V)power cord forconnection to the chassis’

power cord connector by cutting the cord to the appropriate length

(referto Figure16 and follow Figure15).Power cord harness selection

shown on Table 2 on page 14.

WARNING

Electrical Shock Hazard

Turn off electrical power before service

or installation.

ALL electrical connections and wiring

MUST be installed by a qualified

electrician and conform to the National

Code and all local codes which have

jurisdiction.

Failure to do so can result in property

damage, personal injury and/or death.

Page 15

15

Figure 15

4.0 IN.

WALL CONNECTION

JUNCTION

BOX

EXPOSE

WIRES

(1.0 IN.)

18.0 IN.

JUNCTION

BOX COVER

COVER

SCREW

S

FRP016

TRIM HARNESS

TO LENGTH

Figure 17

STRIP WIRE ENDS (0.5 IN.)

SPACER

LEADING SIDE FOR

WIRE HARNESS INSERTION

LOCKNUT

TO WALL JUNCTION

FRP015

3. Route the cut ends of harness through the conduit connector

assembly and flex conduit sleeve. Be sure to use the s upplied

conduit bushing to prevent damage to the cord by the con duit.

The cord should pass through the Locknut, Spacer, Chassis

Junction Box, Conduit Connector, Bushing, then the Conduit

Sleeve. See Figure 17.

4. Route the cut ends of the power cord through the elbow connector

at the other end of the conduit. Tighten screws on elbow connect

or to secure conduit sleeve.

5. Fasten and secure the elbow connector to the wall junction box

cover with locknut. Place and mount the wall junction box with

the four wall mounting screws making sure to pass the wall lines

through the junction box. Connect and join all wall lines with the

stripped ends using wire nuts. Tighten both screws of the wall

junction box cover to junction box.

SPACER

BUSHING

CONDUIT

SLEEVE

EXITING SIDE FOR

WIRE HARNESS

CHASSIS

JUNCTION

BOX

CONDUIT

CONNECTOR

FRP017

Figure 16

TO CHASSIS JUNCTION

STRAIGHT

CONNECTOR

GROUND

SCREW

GROUND

WIRE

HARNESS

Page 16

16

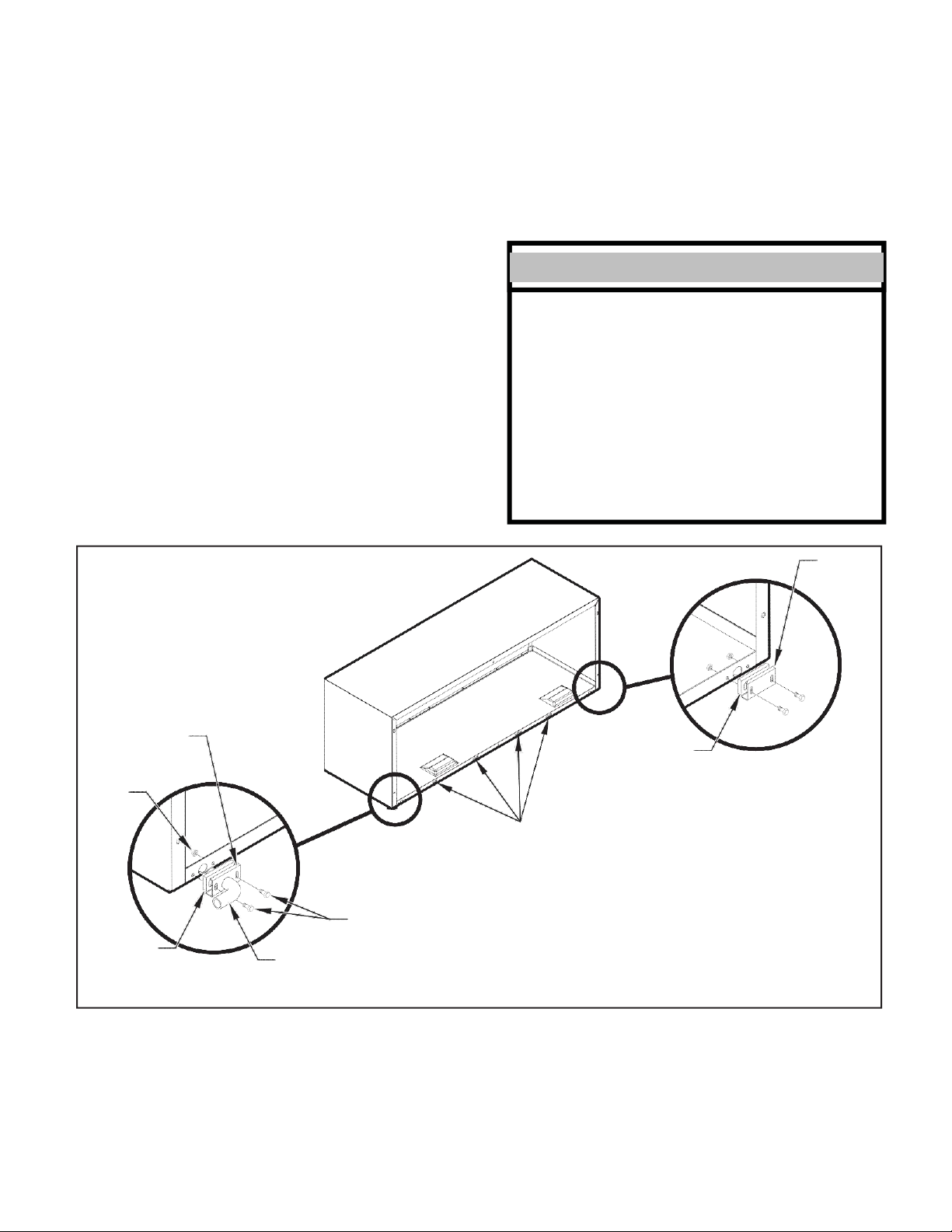

Chassis Install Preparation

1. Remove the weatherboard and center support from the sleeve (if

still in place). Be sure an outdoor grille is attached.

Figure 18

NOTE: To avoid breaking the door orhingepins,do not apply excessive

force when installing.

Figure 19

WALL SLEEVE

PIN

CONTRO

L DOOR

CENTER SUPPORT

FRP018

FRP019

NOTE: Use a wall sleeve adapter kit (PXSE) if installing a P-Series

chassis in a T-Series sleeve.

WARNING

IMPORTANT: When installing a Friedrich PTAC into an existing sleeve,

it is important to ensure that the unit is installed completely. Inspection

of the air seal between the condenser air baffles and around the indoor

mounting flange is recommended.

In some cases additional gaskets or baffling may be required.

Do NOT use in cribs, beds or playpens.

Destroy immediately after opening. This bag

is NOT a toy.

Failure to do so can result in personal injury

and/or death.

2. Remove the front cover contained in a protective plastic bag

from chassis. Remove the bag and dispose of it properly.

a. From the front cover, slide the right control door pin into the

hole on the right side of the front cover.

b. Slide the left door pin into the hole on the left side of the

front cover opening.

c. Snap cover into place.

Checkto besure the wallsleeve,extension (ifused),grille, and drain kitareinstalled properly beforechassis

installation.

INSERT PIN

IN THIS LOCATION

WEATHERBOARD

Suffocation Hazards

Keep bag away from babies and children.

If the control door is not installed, follow these steps:

Page 17

17

CAUTION

Unit Damage Hazard

Failure to follow this caution may result in equipment damage

or improper operation.

3. Carefully remove shipping tape from the front panel and power

vent door. See Figure 20.

Figure 20

SHIPPING TAPE

FRP020

Shipping Tape Location

Figure 21

RemovingFrontPanel

2

1

FRP021

4. Remove front panel,see Figure 21.

Pull out at the bottom to release it from the tabs (1). Then lift up (2).

NOTE: If the unit is mounted flush to the floor, the service cord MUST

be rerouted at the bottom of the front cover on the side closest

to the receptacle. A notch MUST be made in the front cover

side where the cord exits the unit. It is the responsibility of

the installer to create an exit notch.

Page 18

Chassis Installation

1. Lift unit level and slide unit into wall sleeve until seal rests

firmly against front of wall sleeve.

Figure 22

3. Place tabs over top rail. (1)Push inward at bottom until panel

snaps into place(2).

4.

CAUTION

Excessive Weight Hazard

Use two or more people when installing

your air conditioner.

Failure to do so can result in back

or other injury.

SUPPLY

CORD

2. Locate the four supplied chassis mounting screws.Insert the

screws through the chassis mounting flange holes that are

aligned with the speed nuts in the wall sleeve.Tighten all four

screws(two per side).

Copper refrigerant tubes are NOT handles.

Do NOT use tubing to lift or move chassis.

To remove the front cover,pull the bottom end forward and lift it up to

clear the L bracket across the top of the chassis.

5. Plug the cord(if applicable)into the appropriate receptacle.

Restore power to the unit.

SecuringUnit

Reinstall front panel.See Figure 23.

NOTICE

POWER

FRP022

Figure 23

Replacing FrontPanel

1

2

FRP023

18

Page 19

19

Friedrich PTAC Digital Control and Unit Features

The new Friedrich digital PTAC has state of the art features to improve guest comfort, indoor air quality and conserve energy. Through the use of specifically

designed control software for the PTAC industry Friedrich has accomplished what other Manufacturer’s have only attempted – a quiet, dependable, affordable

and easy to use PTAC. Below is a list of features and their benifit to the owner.

ONLY TWO MODELS

BETTER

DEHUMIDIIFICATION

SOFT START

OPERATION

ERV 8 OUTDOOR AIR

M

FILTER

DC INVERTER

REMOTE THERMOSTAT

OPERATION

INTERNAL DIAGNOSTIC

PROGRAM

ELECTRONIC

TEMPERATURE

LIMITING

ROOM FREEZE

PROTECTION

CONDENSATE REMOVAL

SYSTEM

FreshAire PTACs utilize a DC inverter rotary compressor to ensure part load efficiencies and reliable

operation.

Some applications require the use of a wall-mounted thermostat. All new Friedrich PTACs may be

switched from unit control to remote thermostat control easily without the need to order a special model

or accessory kit.

The Friedrich digital PTAC features a self- diagnostic program that can alert maintenance to component

failures or operating problems. The internal diagnostic program saves properties valuable time when

diagnosing running problems.

By limiting the operating range, the property can save energy by eliminating “max cool” or “max heat” situ-

ations common with older uncontrolled systems. The new electronic control allows owners to set operat-

ing ranges for both heating and cooling independently of one another.

When the PTAC senses that the indoor room temperature has fallen to 50°F, the unit will cycle on the

fan (high) and the electric strip heat to raise the room temperature to 55°F, and then cycle off again. This

feature works regardless of the mode selected and can be turned off.

Condenser fan utilizes slinger ring technology to pick up condensate from the base pan and disperse it on

to the condenser coil where it evaporates. This helps to cool the coil and increase the energy efciency

of the unit.

UNIVERSAL ELECTRIC

HEATER

FACTORY RUN-TEST

Unit has a univ

All units are factory run tested to ensure trouble free operation.

ersal power cord with 20 Amp coming standard out of the box.

Page 20

DIGITAL DEFROST

THERMOSTAT

The PV-Series uses a digital thermostat to accurately monitor the outdoor coil conditions to allow the heat

pump to run whenever conditions are correct. Running the PTAC in heat pump mode saves energy and

reduces operating costs. The digital thermostat allows maximization of heat pump run time.

INSTANT HEAT

HEAT PUMP MODE

SEPAR ATE HE AT/COOL

FAN CYCLE

CONTROL

EMERGENCY

HEAT OVERRIDE

CENTRAL DESK

CONTROL

READY(ONLY FOR UNIT

CONTROL)

INDOOR COIL

FROST SENSOR

ULTRAQUIE T

AIR SYSTEM

Heat pump models will automatically run the electric heater to quickly bring the room up to temperature

when initially energized, then return to heat pump mode. This ensures that the room is brought up to

temperature quickly without the usual delay associated with heat pump units.

The owner may choose between fan cycling or fan continuous mode based on property preference. Fan

continuous mode is used to keep constant airflow circulation in the room during all times the unit is ‘ON’. Fan

cycle will conserve energy by only operating the fan while the compressor or electric heater is operating.

ability to set the fan cycling condition independently between heating and cooling mode will increase

user comfort by allowing the choice of only constantly circulating air in the summer or winter time (unlike

other PTAC brands that only allow one selection).

In the event of a compressor failure in heat pump mode, the compressor may be locked out to provide

heat through the resistance heater. This feature ensures that even in the unlikely event of a compressor

failure, the room temperature can be maintained until the compressor can be serviced.

All Friedrich digital PTACs have low voltage terminals ready to connect a central desk control energy

management system. Controlling the unit from a remote location like the front desk can reduce energy

usage and requires no additional accessories on the PTAC unit.

The frost sensor protects the compressor from damage in the event that airflow is reduced or low outdoor

temperatures cause the indoor coil to freeze. When the indoor coil reaches 33°F, the compressor is

disabled and the fan continues

the compressor returns to operation.

The PV-Series units feature an indoor fan system design that reduces soun

airow or preventing proper air circulation.

to operate based on demand. Once the coil temperature returns to 53°F,

d levels without lowering

The

HIGH EFFICIENCY

DUAL MOTOR

ROTARY COMPRESSOR

TOP-MOUNTED

ANTIMICROBIAL

AIR FILTERS

FILTERED FRESH

AIR INTAKE

ALUMINIUM ENDPLATES

R-410A REFRIGERANT

BREAK-PROOF

CONTROL DOOR

The Friedrich PTAC has been engineered so that all functional systems are optimized so that they work

together to deliver the highest possible performance.

The dual-motor design means that the indoor motor can run at slower speeds which reduces sound

levels indoors.

High efciency rotary compressors are used on all Friedrich PTACs to maximize durability and efci ency.

All Friedrich PTAC return air filters feature an antimicrobial element that has proven to prevent mold and

bacterial growth in laboratory testing. PXFTB replacement filter kits feature the same antimicrobial agent.

All filters are washable, reusable and easily accessed from the top of the unit without the removal of the

front cover.

Friedrich PTAC units are capable of introducing up to 40 CFM of outside air into the conditioned space.

The outdoor air passes through a washable mesh screen to prevent debris from entering the airstream.

Outdoor coil endplates made from aluminium reduce corrosion on the outdoor

other coil designs.

Friedrich PTAC units use environmentally-friendly refrigerant.

Break-proof control door design maintains the integrity of the unit.

coil common with

GALVANIZED ZINC

WALL SLEEVE AND

BASE PAN

Galvanized zinc coated steel wall sleeve and steel base pan undergo an 11-step preparation

process,

are powder coated with a polyester finish and cured in an oven for exceptional durability.

20

Page 21

21

System Configuration

Fresh Air Vent Control

To operate the FreshAire module please see Dip switch #3. With dip

switch in the "on" position FreshAire module will be on continuously.

With dip switch in the "OFF" position FreshAire module will be not be

activated.

Adjusting Air

Toadjustairdirection:

1.

Removefrontpanel.SeeFigure21.

2. Remove louverscrewsthat holdlouverinsertinplace(from back side of

frontpanel).SeeFigure 29.

3. Turnlouver insertand rotate180°.SeeFigure 30.

4. Replacelouverinsert.

5.

Replacescrews andfrontpanel.

Figure 26

Backside of Front Panel

LOUVER SCREWS

FRP025

FRP026

AIR DISCHARGE OUTWARD (Default)

AIR DISCHARGE UPWARD

Figure 25

Air Vent Control

POWER-DRIVEN VENT DOOR

Figure 27

Adjusting Louvers

FRP027

Page 22

22

8

Digital Control User Input Configuration

Switch 1-Reserved.

Switch 2-Heat pump enable/disable.

Moving Dip Switch #2 to “OFF” can be set as Emergency Heat

Override. In the unlikely event of a compressor failure, a heat pump unit

may be switched to operate in only the electric heat mode until repairs

can be made.

Switch 3-Electric strip enable/disable.

Switch 4-Reserved.

Switch 5-Room Freeze Protection

Units are shipped from the factory

1 2 3 4 5 6 7

ON

OFF

LOCATION OF

DIP SWITCHES

ON UNIT

FRP028

The adjustable control dip switches are located at the front portion of the digital Smart Center. The inputs are only visible and accessible with the front cover

removed from the PTAC.

Dip SwitchSetting

With the room freeze protection enable.Room Freeze Protection can be

switched off at the owner’s preference by moving Dip Switch 5 to

“OFF”.This feature will monitor the indoor room conditions and in the event

that the room falls below 50°F, the unit will automatically run “heating”.

This occurs regardless of mode.

Switch 6-Electric memory enable/disable

The factory setting is enabled. The smart center will remember user’s

setting. After power cut recovery, the unit will operate the same status as

before power cut. Moving Dip Switch 6 to “OFF”will disable this feature,

smart center will no more remember settings.

Switch 7,Switch 8-Reserved.

Figure 28

Dip Switches

DIP SWITCH

Reserved

Reserved

Electric memory enable/disable

Room freeze protection

Reserved

Electric strip enable/disable

Heat pump enable/disable

Reserved

Switch Description Function Factory setting Option

#1 Reserved / OFF /

#2 Heat pump ON-enable heat pump;

OFF-disable heat pump, run electric heat

only.

#3 Electric strip ON-enable electric heat;

OFF-disable electric heat.

#4 Reserved / OFF /

#5 Room

Protection

#6 Electric memory

enable/disable

#7 Reserved / OFF /

#8 Reserved / OFF /

Freeze

ON-Allows the unit to ensure the indoor room

temperature does not fall below 50℉even

when turned off;

OFF-disable freeze protection.

ON-enable;

OFF-disable.

HP models-ON

Electric heat only-OFF

ON

ON OFF

ON OFF

OFF-Overrides compressor

operation(HP models only)

Factory set. Do not change.

Page 23

23

FreshAire

System

Engagement

Method

Mode

Description

SW3-1

ON / OFF

Fresh-Air Fan runs only when Dip Switch is set to ‘ON’

Fresh-Air Fan NEVER RUNS when Dip Switch is set to

‘OFF’

SW3-2

Cycle /

Continuous

2

FreshAire System

SW3 DIP SWITCH

ON/CON.

1

OFF/CYC.

SW3-2

SW3-1

Fresh-Air Fan runs continuously when SW3-1 is set to

'ON' & SW3-2 is set to 'ON'

Fresh-Air Fan cycles On/Off with the Unit Indoor Fan

when SW3-1 is set to 'ON' & SW3-2 is set to 'OFF'

Page 24

24

Digital Control Operation

Cooling Mode

Emergency Heat Operation

FRP0 29

Heating Mode

After turn on the unit, press the “Heat” button will put the unit into heating

mode.

Heat Pump Models (PVH)

When the “Heat” button is pressed initially the unit may call for electric

strips to bring the room to the set point. When the room temperature falls

2℉below the set point, the unit will turn on the compressor or electric

strip. The fan will run with compressor or electric strips. When the outdoor

ambient temperature falls below 32°F or outdoor coil temperature drops to

5℉, the unit will operate the electric strip instead of heat pump. During

heat pump mode, CPU detects the outdoor coil gets freeze, unit will go to

defrost. During the defrost operation (10min at most), there will be no

heating provide. After finishing defrost, electric heating will come on to

warm the room quickly.

In the event of a compressor failure in heat pump mode, the compressor

may be locked out to provide heat through the electric strip heater

automatically. This feature ensures that even in the unlikely event of a

compressor failure, the room temperature can be maintained until the

compressor can be serviced. If the unit still can’t run electric heater stably,

switch Dip switch 2 to OFF, it controls the emergency heat setting.

Constant Fan

Pressing the “Constant Fan” button will provide constant or cycle fan

operation in cooling or heating modes. The fan speed selection is

made by pressing either “High” or “Low” fan speed button.

Figure 29

Digital Control Panel

Pressing the “Cool” button after turn the unit on will put the unit into

cooling mode. Press “UP” or “DOWN” button to adjust the set point, the

unit will start the compressor and run appropriate frequency to maintain a

comfortable room temperature. The compressor will come on anytime that

the room temperature is 2℉above the set point. The fan will come on with

compressor.

Page 25

25

Settings- Detailed Configurations

This section is about how to set the unit operating parameter, include display temperature unit, Fahrenheit or Celsius, control master, temperature

limit, temperature calibration, display set point or room temperature.

Under OFF mode, hold [Cool] and [Low] two keys at the same time continuously for 5 seconds. This time displays ‘d0’, indicates that system

has entered the senior operation status.

Menu NO.

Function

Parameter value

Explanation

d0

Unit of temperature

F

Fahrenheit(default)

C

Celsius

d1

Control master

P

By control panel(default)

r

By 24V universal remote thermostat

rE

By 12V smart wired controller

d2

Max temperature setting

d3 to 90℉

The Min value is d2 (default 90℉)

d3

Min temperature setting

60℉ to d2

The Max value is d3 (default 90℉)

d4

Indoor

temperature

calibration

-9℃ to 9℃

If unit of temperature is changed, calibration should

be done again. If use the default value, it can be

ignored. (default 0℃/0℉)

-9℉ to 9℉

d5

Temperature

display

selection

0 or 1

0-displays room temperature

1-displays setpoint(default)

[Cool] key is used to switch parameter code and parameter value;

[UP] or [DOWN] keys are used to switch parameter code or set parameter value; [Power] key is used to save

and exit settings.

One example:

Setting target:d0(C),d1(r), d2(88℉),d3(58℉),d4(-1℉),d5(1).

Step1: hold [Cool] and [Low] two keys at the same time continuously for 5 seconds. Display:'d0'

Step2: short press [Cool] key. Display: 'F'(setting d0 has finished)

Step3: short press [Cool] key. Display:'d0'

Step4: short press [UP] key. Display:'d1'

Step5: short press [Cool] key. Display: 'P'

Step6: short press [UP] or [DOWN] key. Display: 'r' (setting d1 has finished)

Step7: short press [Cool] key. Display:'d1'

Step8: short press [UP] key. Display:'d2'

Step9: short press [Cool] key. Display:'90'

Step10: short press [DOWN] key twice. Display:'88' (setting d2 has finished)

Step11: short press [Cool] key. Display:'d2'

Step12: short press [UP] key. Display:'d3'

Step13: short press [Cool] key. Display:'60'

Step14: short press [UP] key twice. Display:'58' (setting d3 has finished)

Step15: short press [Cool] key. Display:'d3'

Step16: short press [UP] key. Display:'d4'

Step17: short press [Cool] key. Display:'0' (setting d4 has finished)

Step18: short press [Power] key to exit.

Page 26

26

Remote Control Thermostat Installation

Install Thermostat

1. Approximately 5 ft from the floor.

2. Close to or in a frequently used room,preferably on an inside wall.

3. On a section of wall without pipes or ductwork.

The Thermostat should NOT be mounted:

1. Close to a window, on an outside wall, or next to a door leading

outside.

2. Where it canbe exposed to directsunlight orheat, suchas the sun,

a lamp,fireplace or any other temperature radiating object which

may cause a false reading.

3. Close to or in the direct airflow of supply registers and/or return

air grilles.

4. Any areas with poor air circulation, such as a corner,behind a

door,or an alcove.

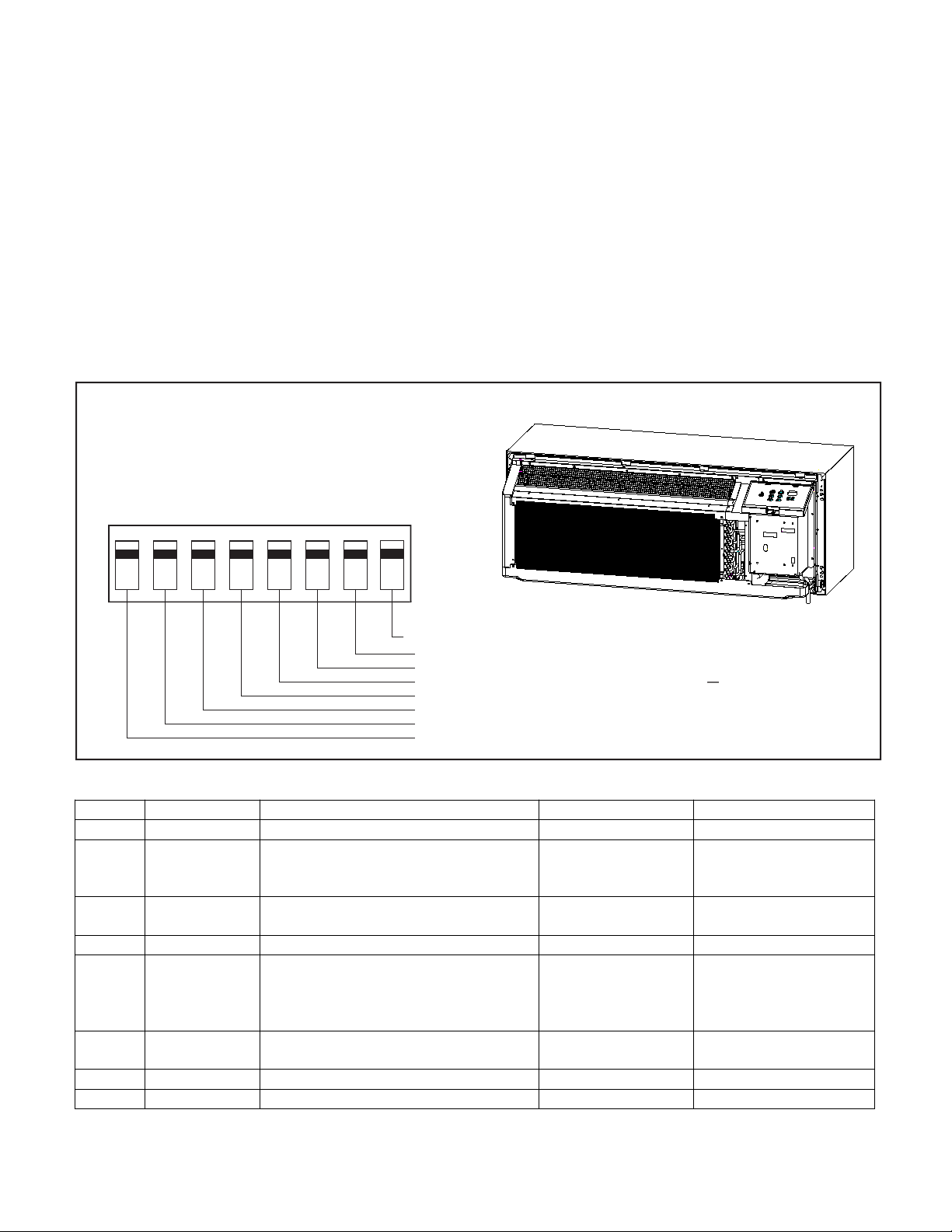

Remote Thermostat and

Low Voltage Control

Connections

RemoteThermostat

All Friedrich PV model PTAC units are factory configured to be controlled

by either the chassis mounted Smart Center or a 24V remote wall mounted

thermostat.The thermostat may be auto or manual changeover as long as

the control configuration matches that of the PTAC unit.

NOTE: All PV models require a single stage cool, dual stage heat

thermostat with an B reversing valve control.The Friedrich RT6

thermostat can be configured for either model.

To control the unit with a wall mounted thermostat

follow the steps below:

1. Unplug the unit before doing any work

2. Remove the low voltage terminal block from the unit.

3. Connect the corresponding terminals from the wall thermostat to

the terminal block

4. Plug the terminal block on the unitk.

5. Restore power to the unit.

6.

GL = Call for Low Fan

GH = Call for High Fan

C = Common Ground

*If only one G terminal is present on thermostat connect to GL for low

speed fan or to GH for high speed fan operation.

Under OFF mode, set menu NO.'d1' to “r”, details refer to the

previous section "Settings- Detailed Configurations" on page 25.

7. The unit is now controlled by the wall thermostat only.

If the accessory escutcheon kit (PDXRTA) is to be used, install

8.

it over the existing control panel.

NOTE:The unit control panel no longer controls the unit. To restore the control

panel, set menu NO.'d1' back to "P", details refer to the previous section "Settings-

Detailed Configurations" on page 2 .

ThermostatConnections

R = 24V Power from Unit

Y = Call for Cooling

W = Call for Heating

B = Reversing Valve Energized in Heating Mode

Figure 30

Control board with optional PDXRTB escutcheon kit

installed

FRP0 30

Page 27

27

Front Desk Control Terminal

WARNING

Electrical Shock Hazard

Turn off electrical power before service

or installation.

ALL electrical connections and wiring

MUST be installed by a qualified

electrician and conform to the National

Code and all local codes which have

jurisdiction.

Improper connection of the thermostat

control wiring and/or tampering with the

units internal wiring may result in property

damage, personal injury or death.

(ONLY FOR UNIT CONTROL)

The Friedrich PV model PTAC has built-in provisions for connection to an

external switch to control power to the unit. The switch can be a central

desk control system.

For front desk control operation, connect one side of the normal open

switch to the R terminal and the other to the FD terminal.

The control logic as below:

(a). Turn ON unit: short R and FD then release for one time within 5s.

(b). Turn OFF unit: short R and FD then release for twice within 5s.

(c). Force unit shut down for one time: short R and FD short over 5s.

NOTE: After forced shut down, you can turn on the unit again by control

panel.

NOTE: The desk control system and switches must be field supplied.

Energy Management

Sometimes known as Front Desk Control, an input is provided so that the

unit can be manually disabled from a remote location. If the unit detects

24Vac on this input, it will automatically turn itself off.If no voltage is

detected on the input , the unit will run normally.

NOTE: It is the installer's responsibility to ensure that all control wiring

connections are made in accordance withthe installation

instructions.Improper connection of the thermostat control

wiringand/or tampering with the unit's internal wiring can

void the equipment warranty.Other manufacturer's PTACs

and even older Friedrich models may have different control

wire connections.Questions concerning proper connections

to the unit should be directed to Friedrich.

Page 28

28

Final Inspection & Start-up Checklist

Inspect and ensure that all components and accessories have been

installed properly and that they have not been damaged during the

installation process.

Check the condensate water drain(s) to ensure they are adequate for

the removal of condensate water, and that they meet the approval of

the end user.

Ensure that all installations concerning clearances around the unit

have been adhered to.Check to ensure that the unit air filter, indoor

coil, and outdoor coil are free from any obstructions.

Ensure that the entire installation is in compliance with all applicable

national and local codes and ordinances that have jurisdiction.

Secure components andaccessories, such asthe chassis, decorative

front cover and control door.

Start the unit and check for proper operation of all components in

each mode of operation.Instruct the owner or operator of this units

operation,andthe manufacturer’srecommended routine maintenance

schedule.

NOTE: A log for recording the dates of maintenance and/or service

is recommended.

Present the owner or operator of the equipment with the Installation

& Operation manual, all accessory installation instructions, and the

name, address and telephone number of the Authorized Friedrich

Warranty Ser vice Company in the area for future reference if

necessary.

WARNING

Electrical Shock Hazard

Unplug Unit or turn off electrical power

to unit prior to performing maintenance

procedures

Failure to do so can result in electrical

shock or death

Front Panel Air Filter

To ensure proper unit operation, the air filters should be cleaned at least

monthly, and more frequently if conditions warrant.The unit must be

turned off before the filters are cleaned.

To remove the air filters,filter grasp the top of the filters and lift out of the

front cabinet.Reverse the procedure to reinstall the filters.

Clean the filters with a mild detergent in warm water, and allow them to

dry thoroughly before reinstalling.

Fresh Air Filter

The fresh air filter should be cleaned or replaced after 3 months of use

for maximum effectiveness The unit must be turned off before the filters

are replaced.

To replace the fresh air filters,drag the unit from wall sleeve and pull the

tape sticked to fresh air filter.

Coils & Chassis

NOTE: Do not use a caustic coil cleaning agent on coils or base pan.

Use a biodegradable cleaning agent and degreaser.The use of harsh

cleaning materials may lead to deterioration of the aluminum fins or the

coil end plates.

The indoor coil and outdoor coils and base pan should be inspected pe-

riodically (annually or semi-annually) and cleaned of all debris (lint, dirt,

leaves,paper, etc )as necessary. Under extreme conditions, more frequent

cleaning may by required.Clean the coils and base pan with a soft brush

and compressed air or vacuum.A pressure washer may also be used,

however, you must be careful not to bend the aluminium fin pack.Use a

sweeping up and down motion in the direction of the vertical aluminium

fin pack when pressure cleaning coils.

NOTE: It is extremely important to insure that none of the electrical

and/or electronic parts of the unit get wet. Be sure to cover all electrical

components to protect them from water or spray.

Decorative Front

The decorative front and discharge air grille may be cleaned with a mild

soap or detergent.Do NOT use solvents or hydrocarbon based cleaners

such asacetone, naphtha, gasoline, benzene, etc , toclean the decorative

front or air discharge grilles.

Use a damp (not wet) cloth when cleaning the control area to prevent

water from entering theunit, and possibly damaging theelectronic control.

Fan Motor & Compressor

The fan motor & compressor and are permanently lubricated, and require

no additional lubrication.

Wall Sleeve

Inspect theinside ofthe wall sleeveand drain system periodically (annually

or semi-annually) and clean as required.

Under extreme conditions, more frequent cleaning may be necessary.

Clean both of these areas with an antibacterial and antifungal cleaner.

Rinse both items thoroughly with water and ensure that the drain outlets

are operating correctly. Check the sealant around the sleeve and reseal

areas as needed.

Routine Maintenance

To ensure proper unit operation and life expectancy the following maintenance procedures should be performed on a regular basis.

Page 29

29

Basic Troubleshooting

Malfunction

Possible Reasons

S olution

Start Failure

power line bad, units don’t have power

supply.

Check the indicator LED on the LCID power head,

it should be lit up, if not, push the RESET button,

if still don’t have voltage, but power grid has

output, you need to change the power cord.

Power cord protection trip.

Check the power cord if somewhere is broken,

push the RESET button. If not solved, replace the

power cord.

Power cord isn’t fixed well.

Check that whether power cord is fixed well.

PCB fuse is broken.

Check if any load (in fan, out fan, reversing valve,

power transformer) is short circuit. Eliminate the

error and replace the fuse with the same type.

Bad contact between main board and

control panel.

Check the contact wires, make sure all contact

well.

Compressor delay start.

It’s normal, compressor will start after 3 minutes

Power fail protection.

When power on, because of auto-restart, unit

will delay starting in 120~240s

Unit in protection mode.

Please check the ERROR CODE

Main board or Control panel is bad.

Replace the main board or control panel

Control panel do not work

When the unit is switch to 24V remote

thermostat or 12V smart controller, the

control panel will not be functioning.

If you need to use control panel to take control,

you need to switch the control master. See the

SENIOR SETTINGS section.

Indoor fan/outdoor fan not function or run

slowly

Fan is locked by something or the power

wires are not fixed well; fan capacitor is not

fixed well; fan capacitor is out of service life.

Disconnect the power cord, check whether the

fan can run smooth by hand or other tools,

whether motor wire is fixed well. For the slow

running speed, you could change a new

capacitor.

Something may block the indoor/outdoor air

outlet.

Make sure that there is no obstacle at the

indoor/outdoor air outlet.

Make sure that the grill is suitable for the unit,

inappropriate grill will cause the compressor

being protected; make sure that the grill has

more than 70% turn over.

Set unsuitable temperature.

Set higher/lower temperature by the control board.

NOTE: temperature setting restriction will restrict

the setting temperature. See the SENIOR

SETTINGS section.

Indoor air filter is dirty.

Should clean the filter every month at least.

Room is hot/cold.

Let unit run a little longer that room temperature

will be lower/higher.

Heat leakage between indoor and outdoor.

Block the leakage place.

Indoor coil not cold/heat.

Charge the refrigerant.

Unit has noise

Some moving parts of the unit get loose

fixing or cause bad vibration.

Something in the air way.

Make sure that all moving parts are assembled

well, and nothing is in the air way.

Bad smell when heating

The dust on the E-heater is heating.

The bad smell will disappear a little later.

Not cooling/heating adequately

Page 30

30

Malfunction

Possible Reasons

Solution

Outlet temperature is not always

cooling/heating

Outlet temperature is not high enough when

heating by heat pump.

When outdoor ambient temp is low, the heat

pump will not be able to offer enough heat. Soon

after that, the E-heater will come on to heat.

Fan stops when cooling/heating.

It is normal when the CONSTANT FAN is OFF.

Youcan enable the CONSTANT FAN.

Outdoor is dripping water

Not install the drain pipe kit.

Install the drain pipe kit.

Indoor is dripping water

Wall sleeve is not installed correctly.

Install the wall sleeve according to the

installation manual.

Indoor coil freeze

Outdoor temperature is too low in cooling

mode.

Filter is dirty.

Clean the filter to recover the normal air flow

Error code and solutions

ERROR CODE

Meaning

Solutions

E1

Communication failure between indoor

unit and outdoor unit

Check the communication cables; make sure they are firmly connected. If

the cables are broken, replace them.

E2

Indoor Temp Sensor Open/short

Check the plug is firmly connected. If the sensor is broken, replace it.

E3

Indoor Coil Sensor Open/short

Check the plug is firmly connected. If the sensor is broken, replace it.

E4

1.

Indoor Air Outlet Sensor Open/Short

2.

Outlet Air Over Heat In Electric

Heating Mode

1.

Check the plug is firmly connected. If the sensor is broken, replace it.

2.

In E-Heating mode, check if any obstacles around the air path, remove

them. Make sure the air flow is not blocked.

E5

IPM(DC-INVERTER) Protection (Include

Heat sink Over Heat)

1.

Check the wiring of compressor to the IPM (U/V/W) terminals is

correctly connected. Wrong phase connection is not allowed.

2.

Remove obstacles in the air path that resists heat interchange.

E6

Outdoor Temp Sensor Open/Short

Check the plug is firmly connected. If the sensor is broken, replace it.

E7

Outdoor Coil Sensor Open/Short

Check the plug is firmly connected. If the sensor is broken, replace it.

EC

Compressor Fail Starting/DC-Inverter Fail

1. Check the DIP switch SW2 on the main board (3-position, in red color)

is correctly matched with the unit capacity, refer to the wiring diagram.

Make sure the compressor power cord is firmly and correctly connected.

EH

EEPROM Error

Check the EEPROM chip on the main board is firmly plugged. If still not

solve, replace the main board.

EF

Power Cord Error For 9KBTU, 30A Is

NOT Allowed

Change the power cord to 15A or 20A.

P1

Cooling/Heat Pump Over Load,

Outdoor/Indoor Coil Over Heat

Make sure indoor and outdoor unit vents are not blocked. Clear the air

filter and the condenser after a long time use.

P2

IPM Over Heat Or Over Current

Protection

1.

Make sure indoor and outdoor unit vents are not blocked.

2.

Check the DIP switch SW2 on the main board (3-position, in red color)

is correctly match with the unit capacity, refer to the wiring diagram.

3.

Make sure the compressor power cord is firmly and correctly connected.

P4

Compressor Discharge Over Heat

Protection

1.

Make sure indoor and outdoor unit vents are not blocked.

2.

Check the DIP switch SW2 on the main board (3-position, in red color)

is correctly match with the unit capacity, refer to the wiring diagram.

P7

DC Over/Under Voltage Protection

Make sure the power supply is within the requirement (AC208/230V -

10%+10%)

When outdoor temperature is drop to 55°F(12.8℃)

or below, it will cause that indoor coil freeze. Open

the fresh air door, and running at fan mode.

Page 31

31

Service & Assistance

Before calling for service, please check the "Basic Troubleshooting" section above.This may help you to find the answer to your problem, avoid

unnecessary service calls, and save you the cost of a service call if the

problem is not due to the product itself. If you have checked the "Basic

Troubleshooting" section and still need help, here is a list of available

services:

You can find the name of you local Authorized Service Provider by visiting

our web site at www.friedrich.com.

If you require further assistance you can call the Customer Support Call

Center at 1-800-541-6645.

Before calling, please make sure that you have the complete model and

serial number,and date of purchase of your equipment available. By providing us with this information we will be better able to assist you.

Our specialists are able to assist you with:

* Inspect and ensure that all components and accessories have been

installed properly and that they have not been damaged during the

installation.

* Specifications and Features of our equipment.

* Referrals to dealers, and distributors.

* Use and Care information.

* Recommended maintenance procedures.

* Installation information.

* Referrals to Authorized Service Providers and Parts depots.

Page 32

32

Accessories

New Construction Accessories

PDXWSA

PDX WSEX T18

PDXWSEXT24

PDXWSEXT

PXSE

PXGA

PXAA

PXBG

PXSC

WALL SLEEVE Galvanized zinc coated steel is prepared in an 11-

step process, then powder coated with a polyester nish and cured

in an oven for exceptional durability. The wall sleeve is insulated for

sound absorption and thermal efciency, 16" H x 42" W x 13 3/4" D.

DEEP WALL SLEEVE For walls up to 17 1/2" D.

DEEP WALL SLEEVE For walls up to 23 1/2" D.

CUSTOM DEEP WALL SLEEVE One piece extended wall sleeve for walls

from 13 1/4" to 25 1/2" D are available by special order.

Deep wall sleeve PDXWSE XT18 shown with weather panel

SLEEVE EXTENSION RETROFIT KIT Galvanized zinc coated steel, 2 3/8"

sleeve extension attached to the room side of the sleeve to allow for the

installation of a PZ-Series Friedrich PTAC in a T-Series sleeve.

GRILLE Standard, stamped aluminium, anodized to resist chalking and oxidation.

ARCHITECTURAL GRILLES C on si st of h e a v y- ga ug e 606 3 -T5 a l u minum

alloy: 42" W x 16" H x 1 1/8" D

PXAA – Clear, extruded aluminum

PXBG – Beige acrylic enamel

PXSC – Also available in custom colors.

PDXWSA

PXG

A

PXDR10

PXCJA

PDXDA A

DEA

PDX

CONDENSATE DRAIN KIT Attaches to the bottom of the wall sleeve for in-

ternal draining of condensate or to the rear wall sleeve ange for external

draining. Recommended on all units to remove excess condensate. Packaged in quantities of ten.

CONDUIT KIT WITH JUNCTION BOX Hard wir e conduit kit with junctio n b ox

for 208/230V and 265 V unit s (subbase not required). Kit includes a

means of quick disconnect for easy removal of the chassis. *Required

for 265V installations.

LATERAL DUCT ADAPTER Attaches to the Friedrich PTAC/PTHP unit to direct up to 35% of the total air ow to a second room. The unit-mounted duct

plenum features a front-mounted aluminum grille that has two positions

to provide the most optimal air direction. The air may be directed to either

the left or the right of the unit through the supplied 3

plenum. Plenum may be cut to length by the installer. Kit includes duct

plenum, front grille, 47" duct extension, duct discharge grille, duct end cap

and all necessar y mounting hardware.

1

LATERAL DUCT EXTENSION Additional 3

use with the L ATERAL DUCT ADAPTER. A maximum of 3 duct extensions total may be used. Note: Ducted airow is reduced as duct length is

increased.

/2 H" x 7" W x 47" L plenum for

1

/2 H" x 7 W" x 47" L

PXA A

Page 33

33

New Construction Accessories

PXFTB

REPLACEMENT FILTER PACK These are original equipment return air

lters. They are reusable and can be cleaned by vacuuming, washing, or

blowing out, and are sold in convenient ten-p acks. (Two lters per chassis).

PXSBA DECORATIVE SUBBASE Pr ovides unit support for wall s le ss than si x inches

thick. Includes leveling legs, side filler panels and mounting brackets fo r el ec tr ical acces sories. Accepts circuit breake r, power disconnect

switch, or conduit kit.

PXSB ELECTRICAL SUBBASE Prov ides unit suppor t for wall s less than six inches

thick. Includes leveling legs, side ller panels, mounting brackets, a plugin receptacle and field-wiring access. The subbase also includes electrical knockouts for a power disconnect switch or circuit breaker.

PXSB23020 Electrical Subbase - 230V 15 & 20A

RT6

RT6P

PXSB23030

PXSB26515

PXSB26520

PXSB26530

DIGITAL REMOTE THERMOSTATS

RT6 Wired single stage cool, single stage heat for PDE models or single

Electrical Subbase - 230V 30A

Electrical Subbase - 265V 15A

Electrical Subbase - 265V 20A

Electrical Subbase - 265V 30A

stage cool, dual stage heat for PDH model thermostat features high/low

fan speed switch. Thermostat is hard wired and can be battery powered or

unit powered. Features backlit display and multiple congur ation modes.

For use on Friedrich PTACs and Vert-I-Paks.

RT6P Wireless single stage cool, single stage heat for PDE models or single stage cool, dual stage heat for PDH model thermostat features high/

low fan speed switch. Thermostat is hard wired and can be battery powered or unit powered. Features backlit display and multiple conguration

modes. For use on Friedrich PTACs and Ver t-I-Paks.

PFAXWC1 WIRELESS WALL-MOUNTED CONTROLLER (battery powered).

WRT1 WIRELESS DIGITAL REMOTE THERMOSTAT Single stage cool, single

stage heat for PDE models or single stage cool, dual stage heat for PDH

model thermostat features high/low fan speed switch. Thermostat is

wireless and is battery powered. Features backlit display and multiple

conguration modes. For use on Friedrich PTACs and Vert-I-Paks.

PDXRTB REMOTE THERMOSTAT ESCUTCHEON KIT This kit contains ten escutch-

eons th at can be pla ced over the factor y contr ol buttons when a remote wall

mounted thermostat is used. The escutcheon directs the guest to the wall

thermostat for oper ation and retains the LED window to disp lay error codes

and diagnostic information.

EMRT1

EMWRT1

ENERGY MANAGEMENT THERMOSTATS

EMRT1

Wired thermostat with occupancy sensor.

EMWRT1

Wireless thermostat with occupancy sensor.

EMOCT

Online connection kit.

EMRAF EMRHCF

Remote access fee. Remote humidity control fee.

Page 34

34

Friedrich Air Conditioning Co.

10001 Reunion Place, San Antonio, TX 78216

800.541.6645

PACKAGED TERMINAL AIR CONDITIONERS

LIMITED WARRANTY

We will not be responsible for and the user will pay for:

1. Service calls to:

2. Parts or labor provided by anyone other than an authorized service center.

3. Damage caused by:

1. Repair of the unit

2. A refund to the customer for the prorated value of the unit based upon the remaining warranty period of the unit.

3. Providing a replacement unit of equal value

www.friedrich.com

PV-SERIES

SAVE THIS CERTIFICATE.It gives you specific rights.You may also have other rights which may vary from state to state and province to province.

In the event that your unit needs servicing, contact your nearest authorized service center. If you do not know the nearest service center, ask the company

that installed your unit or contact us - see address and telephone number above. To obtain service and/or warranty parts replacement, you must notify an

authorized FRIEDRICH Air Conditioning Co. service center, distributor, dealer, or contractor of any defect within the applicable warranty period.

When requesting service: please have the model and serialnumber from your unit readily available.

Unless otherwise herein, the following applies:

FRIEDRICH PACKAGED TERMINALAIR CONDITIONERSAND HEAT PUMPS

LIMITED WARRANTY - FIRST YEAR (Twelve (12) months from the date of installation). Any part found to be defective in the material or workmanship

will be repaired or replaced free of charge by our authorized service center during the normal working hours; and

LIMITED WARRANTY - SECOND THROUGH FIFTH YEAR (Sixty (60) months from the date of installation). ON THE SEALED REFRIGERATION

SYSTEM. Any part of the sealed refrigeration system that is defective in material or workmanship will be repaired or replaced free of charge (excluding freight