Page 1

Service Manual

WallMaster® P SERIES

Packaged Terminal Air Conditioners

Packaged Terminal Heat Pumps

· Standard Unit

· Seacoast Protected Unit

· Remote Thermostat Unit

P2K23-DM (4-03)

Page 2

3

Table of Contents

Typical Unit Components .......................................... 4

Introduction................................................................ 4

Unit Identication....................................................... 5

Unit Specications..................................................... 6

PE Series Air Conditioner–Cooling Performance...... 6

PH Series Heat Pump–Heating/Cooling Performance..... 6

PE / Ph Series Electric Heating Data ........................ 6

Sequence Of Operation............................................. 7

Electrical Supply........................................................ 8

Supply Circuit ............................................................ 8

Electrical Rating Tables ............................................. 8

Standard Unit Operation............................................ 9

Temperature Limiting Thermostat.............................. 9

Standard Unit Control Panel...................................... 9

Remote Thermostat Unit Installation ....................... 10

Manual Changeover Thermostat............................. 10

Remote Thermostat Unit Operation..........................11

Room Thermostats...................................................11

Location....................................................................11

Heat Anticipators ..................................................... 12

Calculating Approximate CFM................................. 12

Fan Cycle Switch..................................................... 13

Hot Start Sensor...................................................... 13

Refrigerant Charging ............................................... 13

Method Of Charging ................................................ 13

Undercharged Refrigerant Systems ........................ 14

Overcharged Refrigerant Systems .......................... 15

Restricted Refrigerant Systems............................... 18

Capillary Tube Systems........................................... 17

Reversing Valve Operation ...................................... 17

Electrical Circuit And Coil ........................................ 18

Checking Reversing Valve....................................... 18

Touch Test In Heating/Cooling Cycle....................... 18

Procedure For Changing Reversing Valve .............. 18

Compressor Checks................................................ 19

Locked Rotor Voltage (L.R.V.) Test ......................... 19

Single Phase Connections ...................................... 19

Determine L.R.V. ..................................................... 19

Amperage (L.R.A.) Test ........................................... 19

Single Phase Running And L.R.A. Test ................... 19

External Overload.................................................... 19

Checking The External Overload............................. 19

Single Phase Resistance Test ................................. 20

Compressor Replacement....................................... 20

Capacitors ............................................................... 21

Capacitor Check ..................................................... 21

Capacitor Connections ............................................ 21

System Switch Continuity Check............................ 22

Thermostat Continuity Check .................................. 22

Fan Cycle Switch Continuity Check ........................ 23

Fan Speed Switch Continuity Check ....................... 23

Emergency Heat Switch Continuity Check.............. 24

Routine Maintenance .............................................. 25

Troubleshooting Chart — Cooling .......................... 26

Troubleshooting Chart — Heating.......................... 27

Electrical Troubleshooting Chart ............................. 28

Wiring Diagrams................................................. 29-34

2

Page 3

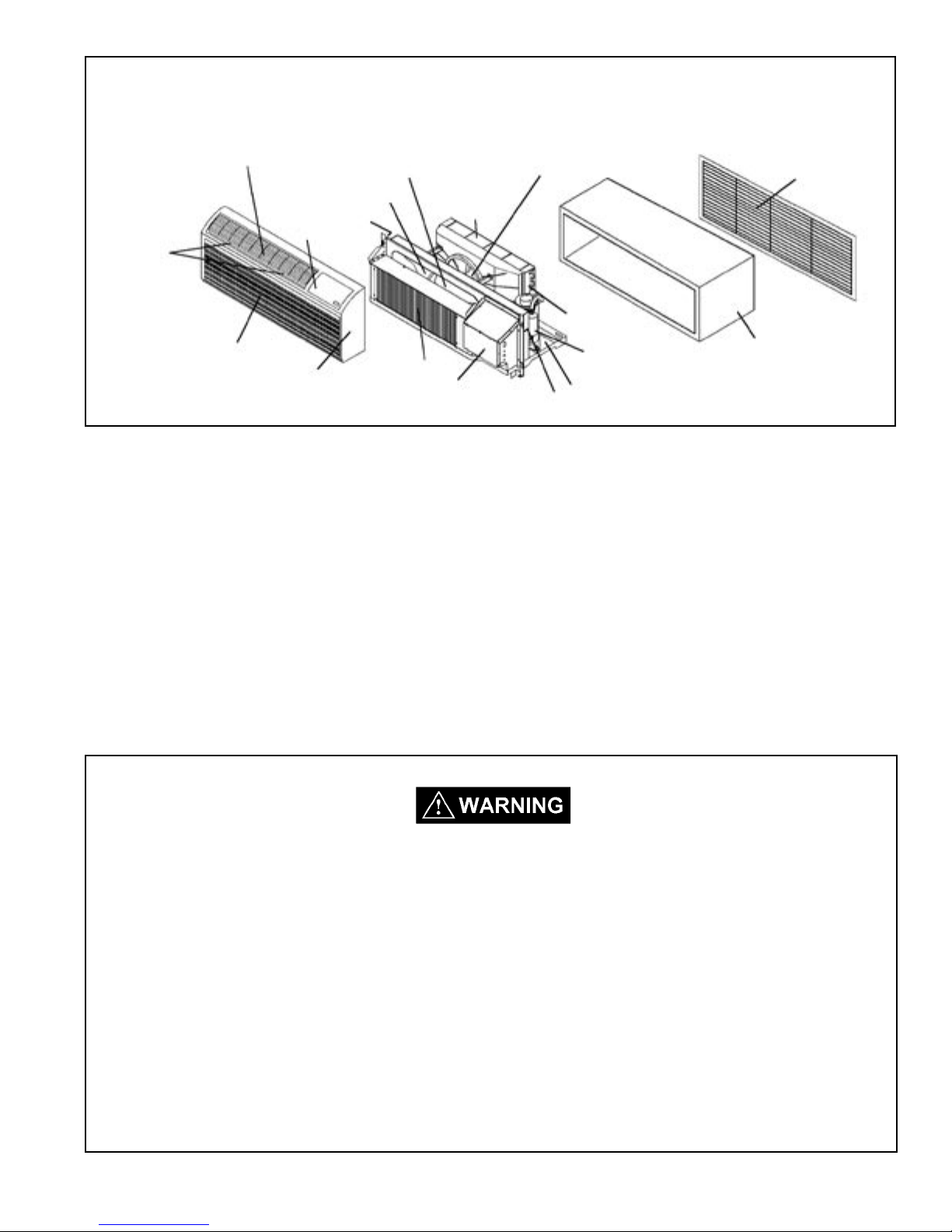

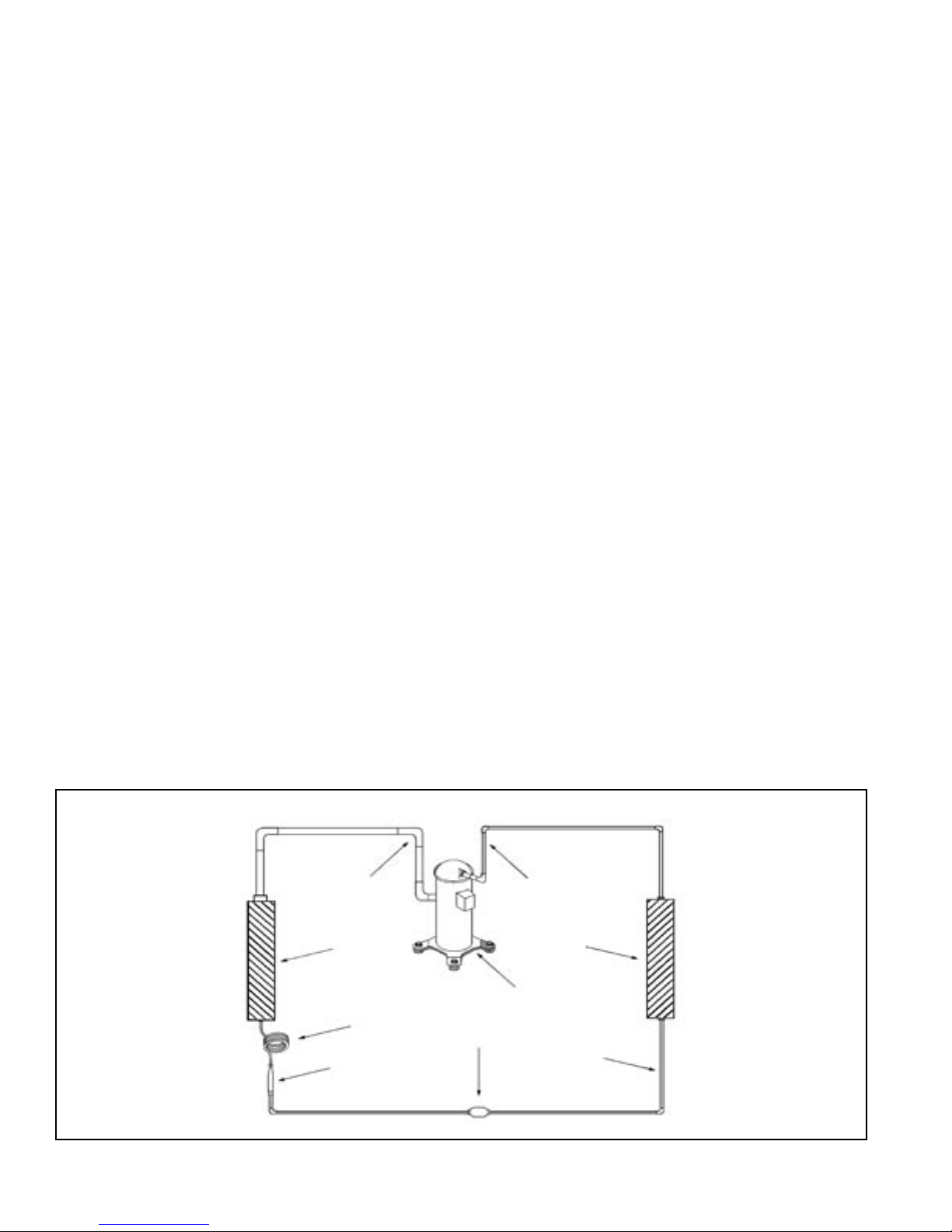

Typical Unit Components

Discharge Air Grille

Filters

Return Air Grille

Blower Wheel

Indoor Blower Housing

Gasket

Control Door

Evaporator Coil

Front Cover

Condenser

Control Panel

Condenser Fan Blade

Shroud

Gasket

Condenser

Coil

Compressor

Basepan

Outdoor Grille

Wall Sleeve

INTRODUCTION

This service manual is designed to be used in conjunction with the installation manuals provided with each air

conditioning system component.

This service manual was written to assist the professional HVAC service technician to quickly and accurately

diagnose and repair any malfunctions of this product.

This manual, therefore, will deal with all subjects in a general nature. (i.e. All text will pertain to all models).

IMPORTANT: It will be necessary for you to accurately identify the unit you are

servicing, so you can be certain of a proper diagnosis and repair. (See

Unit Identication.)

The information contained in this manual is intended for use by a qualied service technician

who is familiar with the safety procedures required in installation and repair, and who is equipped

with the proper tools and test instruments.

Installation or repairs made by unqualied persons can result in hazards subjecting the

unqualied person making such repairs to the risk of injury or electrical shock which can be

serious or even fatal not only to them, but also to persons being served by the equipment.

If you install or perform service on equipment, you must assume responsibility for any bodily

injury or property damage which may result to you or others. Friedrich Air Conditioning

Company will not be responsible for any injury or property damage arising from improper

installation, service, and/or service procedures.

3

Page 4

5

UNIT IDENTIFICATION

Model Number Code

P H 07 K 3 S B 1

Series

P = P series

System

X= Accessory

E= Cooling with or

without electric heat

H = Heat Pump with

Auxiliary Heat

Nominal Cooling Capacity

07 = 7,000 - 7,100 BTUh

09 = 9,000 - 9,100 BTUh

12 = 11,500 - 11,700 BTUh

15 = 14,100 - 14,200 BTUh

Engineering Digit

Design Series

Options

S = Standard

R = Remote Thermostat

C = Seacoast Protection

X = Seacoast Remote

Nominal Heater Size

(@ 230V or 265V)

0 = No Heater

2 = 2.5 KW

3 = 3.4 KW

5 = 5.0 KW

Voltage

K = 230/208V - 1Ph. - 60 Hz.

R = 265V - 1Ph. - 60 Hz.

PTAC Serial Number Identication Guide

Serial Number

Decade Manufactured

L=0 C=3 F=6 J=9

A=1 D=4 G=7

B=2 E=5 H=8

Year Manufactured

A=1 D=4 G=7 K=0

B=2 E=5 H=8

C=3 F=6 J=9

Month Manufactured

A=Jan D=Apr G=Jul K=Oct

B=Feb E=May H=Aug L=Nov

C=Mar F=Jun J=Sep M=Dec

4

L B L P 00000

Production Run Number

PRODUCT LINE

R=RAC

P=PTAC

E=EAC

V=VPAK

H=Split

Page 5

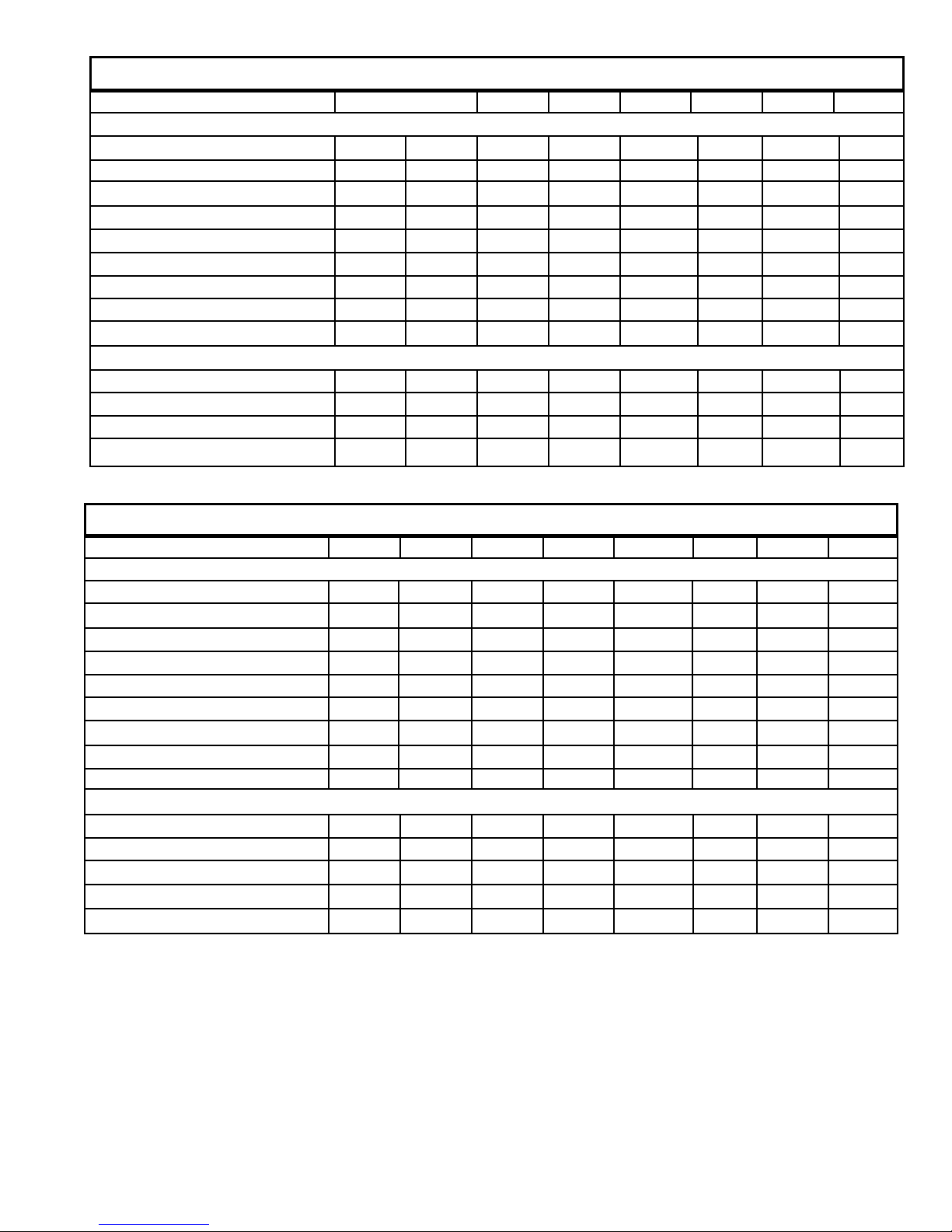

GENERAL INFORMATION – PE SERIES

Model PE07K PE07R PE09K PE09R PE12K PE12R PE15K PE15R

POWER

VOLTAGE (1 PHASE, 60 Hz) 230/208 265 230/208 265 230/208 265 230/208 265

VOLT RANGE 253-198 292-239 253-198 292-239 253-198 292-239 253-198 292-239

POWER (WATTS) 615/598 615 800/783 800 1091/1073 1091 1579/1578 1579

CURRENT (AMPS) 3 3 3.9 3.9 5.1 5.1 6.6 6.6

POWER FACTOR 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.9

AMPS L.R. 18 18 22.2 22.2 26.3 26.3 38 38

AMPS F.L. 3 3 3.9 3.9 5.1 5.1 6.8 6.8

HORSEPOWER 1/15. 1/15. 1/12. 1/12. 1/10. 1/10. 1/10. 1/10.

R-22 CHARGE (OZ) 27 27 30 30 28 28 28 28

PERFORMANCE

COOLING BTUh 7500/7300 7500 9200/9000 9200 12000/11800 12000 15000/14800 15000

INDOOR CFM 250 250 300 300 325 325 350 350

SENSIBLE HEAT RATIO 0.79 0.79 0.76 0.76 0.76 0.76 0.75 0.75

VENT CFM 60 60 60 60 70 70 70 70

GENERAL INFORMATION – PH SERIES

Model PH07K PH07R PH09K PH09R PH12K PH12R PH15K PH15R

POWER

VOLTAGE (1 PHASE, 60 Hz) 230/208 265 230/208 265 230/208 265 230/208 265

VOLT RANGE 253-198 292-239 253-198 292-239 253-198 292-239 253-198 292-239

POWER (WATTS) 590/574 590 791/774 791 1121/1023 1121 1581/1559 1559

CURRENT (AMPS) 3 3 3.9 3.9 5.1 5.1 6.6 6.6

POWER FACTOR 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.9

AMPS L.R. 18 18 22.2 22.2 26.3 26.3 38 38

AMPS F.L. 3 3 3.9 3.9 5.1 5.1 6.8 6.8

HORSEPOWER 1/15. 1/15. 1/12. 1/12. 1/10. 1/10. 1/10. 1/10.

R-22 CHARGE (OZ) 27 27 32 32 34.5 34.5 33 33

PERFORMANCE

COOLING BTUh 7200/7000 7000 9100/8900 9100 12000/11800 12000 14700/14500 14700

REVERSE HEATING BTUh 6400/6200 6400 8100/7900 8100 10800/10600 10800 13500/13300 13500

INDOOR CFM 250 250 300 300 325 325 350 350

SENSIBLE HEAT RATIO 0.79 0.79 0.76 0.76 0.76 0.76 0.75 0.75

VENT CFM 60 60 60 60 70 70 70 70

5

Page 6

7

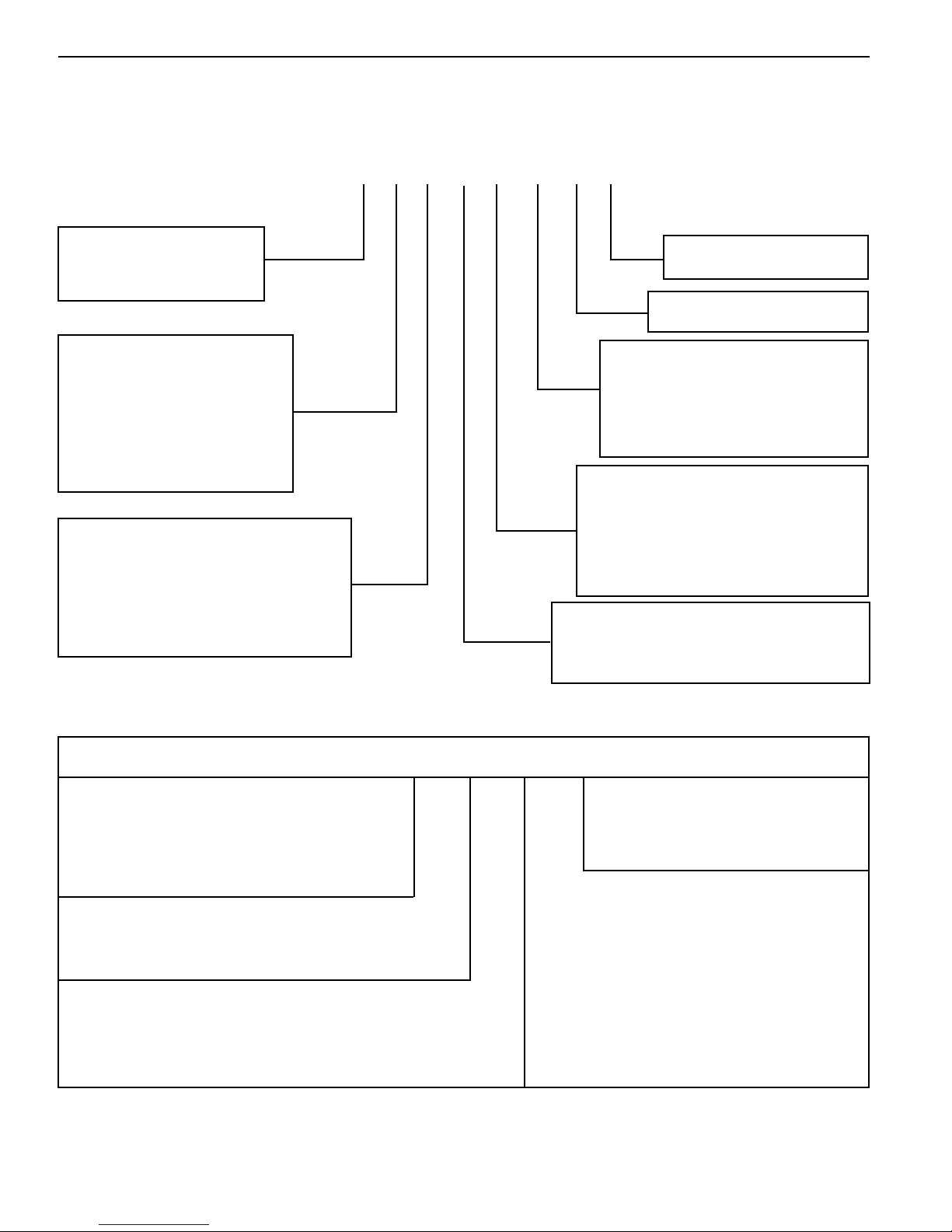

Sequence of Operation

A good understanding of the basic operation of the refrigeration

system is essential for the service technician. Without this

understanding, accurate troubleshooting of refrigeration system

problems will be more difcult and time consuming, if not (in some

cases) entirely impossible. The refrigeration system uses four

basic principles (laws) in its operation they are as follows:

1. "Heat always ows from a warmer body to a cooler body."

2. "Heat must be added to or removed from a substance before

a change in state can occur"

3. "Flow is always from a higher pressure area to a lower

pressure area."

4. "The temperature at which a liquid or gas changes state is

dependent upon the pressure."

The refrigeration cycle begins at the compressor. Starting the

compressor creates a low pressure in the suction line which draws

refrigerant gas (vapor) into the compressor. The compressor then

"compresses" this refrigerant, raising its pressure and its (heat

intensity) temperature.

The refrigerant leaves the compressor through the discharge Line

as a hot High pressure gas (vapor). The refrigerant enters the

condenser coil where it gives up some of its heat. The condenser

fan moving air across the coil's nned surface facilitates the transfer

of heat from the refrigerant to the relatively cooler outdoor air.

When a sufcient quantity of heat has been removed from the

refrigerant gas (vapor), the refrigerant will "condense" (i.e. change

to a liquid). Once the refrigerant has been condensed (changed)

to a liquid it is cooled even further by the air that continues to ow

across the condenser coil.

The PTAC design determines at exactly what point (in the

condenser) the change of state (i.e. gas to a liquid) takes place.

In all cases, however, the refrigerant must be totally condensed

(changed) to a Liquid before leaving the condenser coil.

The refrigerant leaves the condenser Coil through the liquid line

as a warm high pressure liquid. It next will pass through the

refrigerant drier (if so equipped). It is the function of the drier to

trap any moisture present in the system, contaminants, and large

particulate matter.

The liquid refrigerant next enters the metering device. The

metering device is a capillary tube. The purpose of the metering

device is to "meter" (i.e. control or measure) the quantity of

refrigerant entering the evaporator coil.

In the case of the capillary tube this is accomplished (by design)

through size (and length) of device, and the pressure difference

present across the device.

Since the evaporator coil is under a lower pressure (due to the

suction created by the compressor) than the liquid line, the liquid

refrigerant leaves the metering device entering the evaporator coil.

As it enters the evaporator coil, the larger area and lower pressure

allows the refrigerant to expand and lower its temperature (heat

intensity). This expansion is often referred to as "boiling". Since

the unit's blower is moving indoor air across the nned surface

of the evaporator coil, the expanding refrigerant absorbs some of

that heat. This results in a lowering of the indoor air temperature,

hence the "cooling" effect.

The expansion and absorbing of heat cause the liquid refrigerant

to evaporate (i.e. change to a gas). Once the refrigerant has been

evaporated (changed to a gas), it is heated even further by the air

that continues to ow across the evaporator coil.

The particular system design determines at exactly what point (in

the evaporator) the change of state (i.e. liquid to a gas) takes place.

In all cases, however, the refrigerant must be totally evaporated

(changed) to a gas before leaving the evaporator coil.

The low pressure (suction) created by the compressor causes

the refrigerant to leave the evaporator through the suction line

as a cool low pressure vapor. The refrigerant then returns to the

compressor, where the cycle is repeated.

Suction

Line

6

Evaporator

Coil

Metering

Device

Refrigerant

Strainer

Discharge

Line

Compressor

Refrigerant Drier

Condenser

Coil

Liquid

Line

Page 7

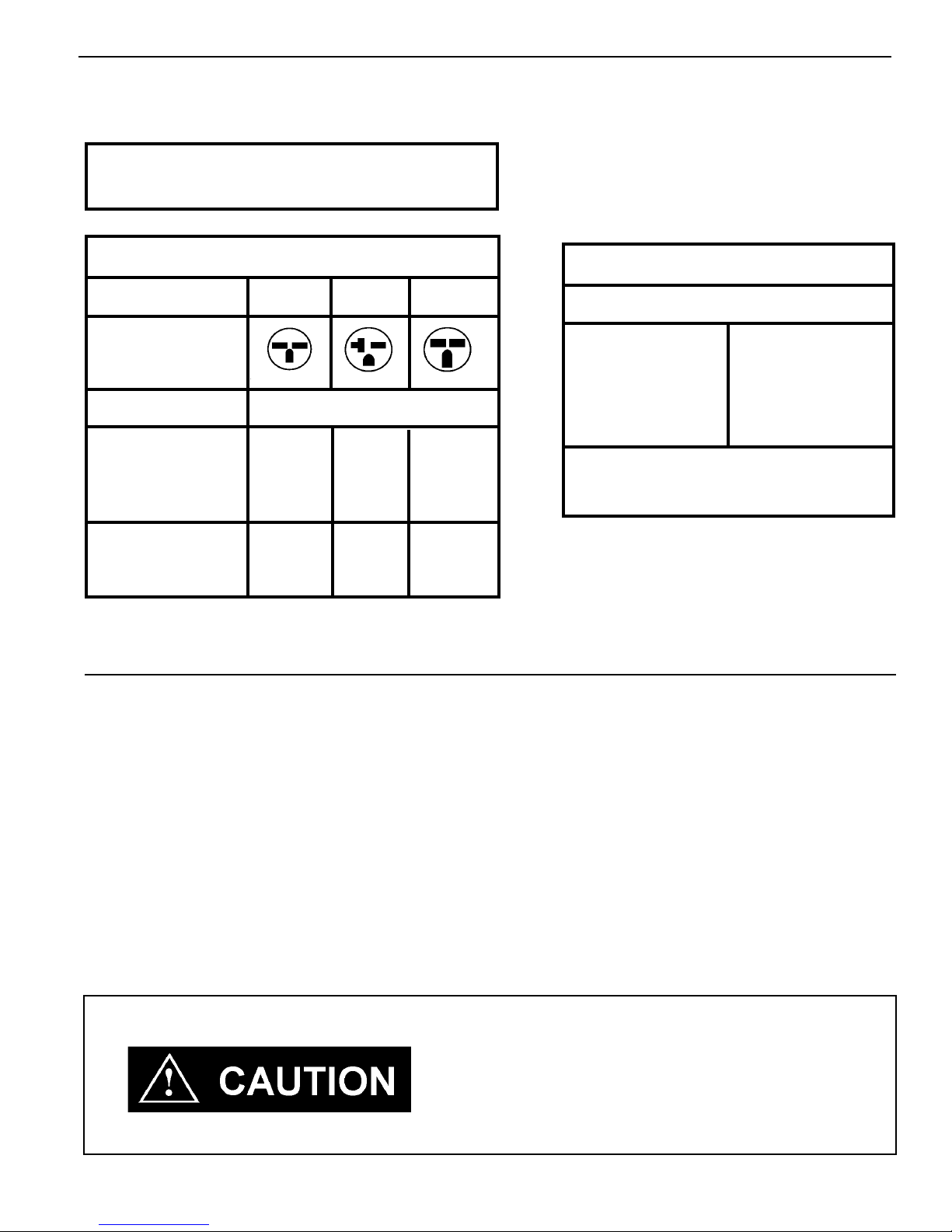

Electrical Rating Tables

All 230/208 volt units are equipped with power cords.

NOTE: Use Copper Conductors ONLY

Wire sizes are per NEC, check local

codes for overseas applications

Table 1 250 V Receptacles and Fuse Types

AMPS 15 20 * 30

RECEPTACLE

MANUFACTURER PART NUMBERS

Hubbell 5661 5461 9330

P & S 5661 5871 5930

GE GE 4069-1 GE4182-1 GE4139-3

Arrow-Hart 5661 5861 5700

TIME-DELAY TYPE

FUSE 15 20 30

(or HACR circuit breaker)

HACR — Heating, Air conditioning, Refrigeration

* May be used for 15 Amp applications if fused for 15 Amp

NOTE: 265 volt units are permanently connected.

Table 2

Recommended branch circuit wire sizes

Nameplate

AWG Wire size**

maximum circuit

breaker size

15 14

20 12

30 10

AWG — American Wire Gauge

* Single circuit from main box

** Based on copper wire, single insulated

conductor at 60°C

Wire Size Use ONLY wiring size recommended for single outlet branch circuit.

Fuse/Circuit Use ONLY type and size fuse or HACR circuit breaker indicated on unit's rating plate. Proper

Breaker current protection to the unit is the responsibility of the owner.

NOTE: A time delay fuse is provided with 265V units.

Grounding Unit MUST be grounded from branch circuit through service cord to unit, or through separate ground

wire provided on permanently connected units. Be sure that branch circuit or general purpose outlet

is grounded.

Receptacle The eld supplied outlet must match plug on service cord and be within reach of service cord.

Refer to Table 1 for proper receptacle and fuse type. Do NOT alter the service cord or plug. Do

NOT use an extension cord.

Wire Sizing Use recommended wire size given in Table 2 and install a single branch circuit. All wiring must

comply with local and national codes. NOTE: Use copper conductors only.

Electric shock hazard.

Turn off electric power before service or installation.

All electrical connections and wiring MUST be installed by a qualied electrician

and conform to the National Electrical Code and all local codes which have

jurisdiction.

Failure to do so can result in property damage, personal injury and/or death.

7

Page 8

9

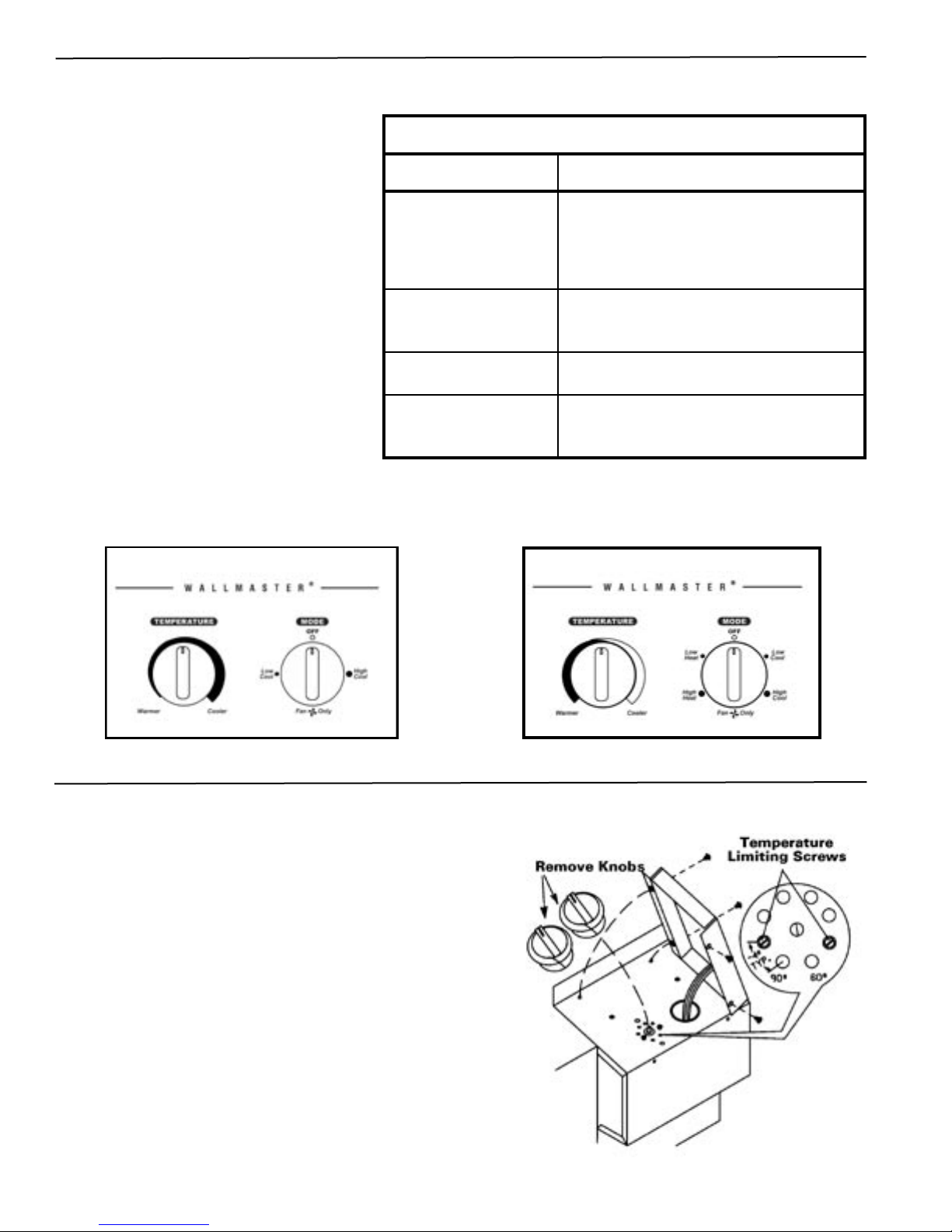

Standard Unit Operation

Rotary Switch Operation

Rota t e the te m p e r a t u r e dial i n small

increments in the warmer or cooler direction.

Moving the dial more than 1/4" at a time may

overcompensate and result in an extreme hot

or cold situation.

Standard Unit Control Panel

Control

Temperature

Low and High Cool

Low and High Heat

Fan Only

Operation

The full-range thermostat maintains room

temperature at the desired setting in both

the heating and cooling modes. Turn the

dial counterclockwise for warmer and

clockwise for a cooler temperature.

Operates the unit on cooling. Cooling

will not begin if the room temperature is

below 60°F.

Operates the unit on heating. Some

models do not provide this selection.

Circulates air within the room at high

fan speed only. No heating or cooling

functions are active.

COOLING ONLY MODEL

Temperature Limiting Thermostat

1. Set the thermostat knob to center of dial.

2. Remove the four screws holding the control panel. Pull up

on the thermostat knob and remove it.

3. Locate the two temperature limiting screws. These screws

are factory installed for a maximum temperature range of 60°90°F. Each hole in the dial plate represents approximately

a 4° change from the adjacent hole.

4. To adjust the temperature range, move the temperature

limiting screws to the desired location.

5. Replace the knob when the desired range has been set.

6. Replace the control panel.

EXAMPLE: To set a maximum temperature range of

approximately 64° to 86°F, move the screws to

the locations shown in the diagram at right.

8

HEAT/COOL MODEL

Page 9

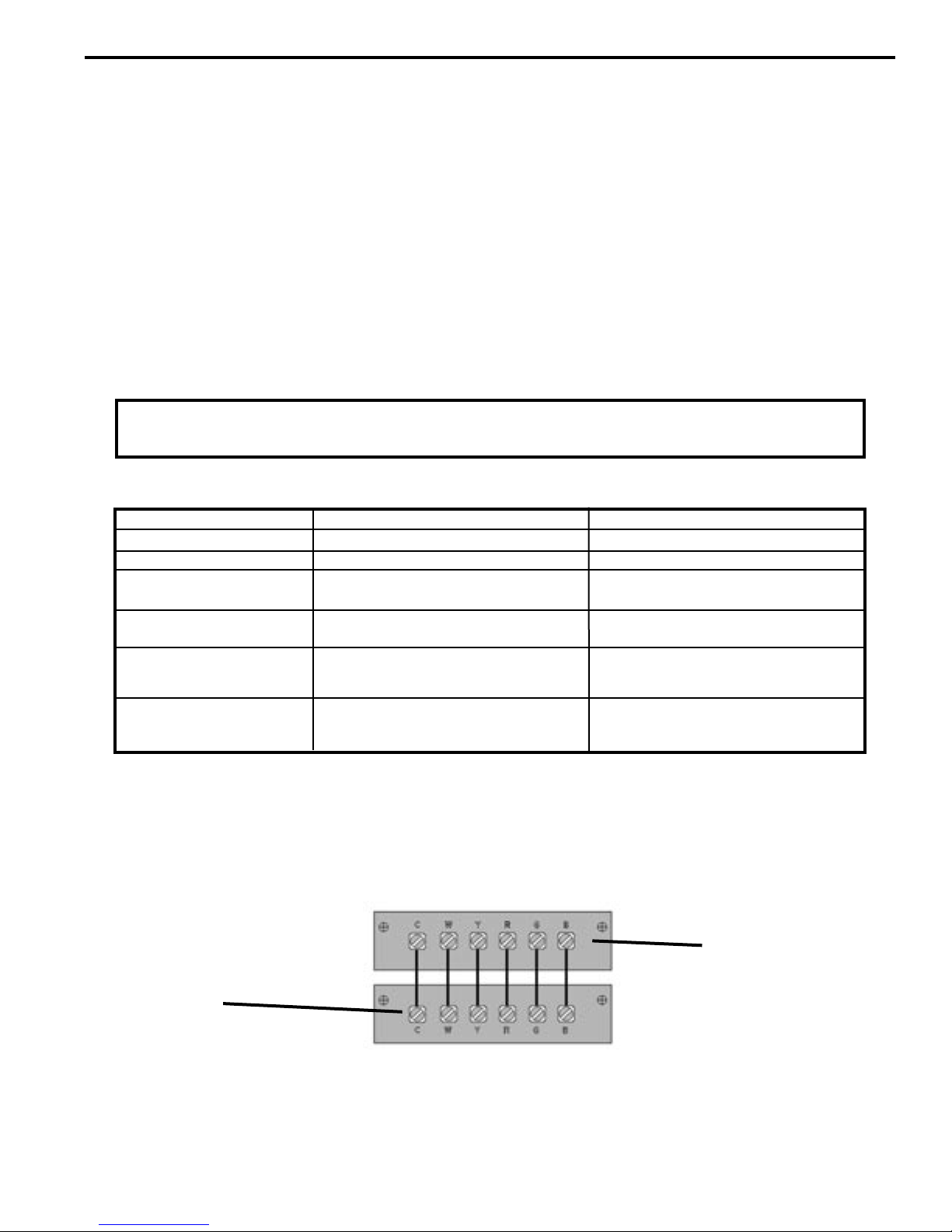

Remote Thermostat Unit Installation

1. Remote Thermostat Selection & Wiring Guidelines for Packaged

Terminal Air Conditioners

Follow the instructions and recommendations of the thermostat manufacturer for installation and wiring. Do not

use a conventional heat pump thermostat with emergency electric heat selection for our heat pump units. Our

units make an automatic decision about turning on electric heat if the heating demand cannot be met by the heat

pump due to low outdoor temperatures.

Manual Changeover Thermostat

For Heat Pump equipped units: A single stage, heat/cool thermostat with a terminal for a reversing valve operation

is required. Terminal "B" should be continuously energized in the heat mode and terminal "G" should be energized

whenever there is a call for heating or cooling. Typically, a heat/cool thermostat designed for use with electric heat

systems will meet the above requirements.

NOTE: This unit is designed for use with a single stage thermostat only. Improper application of the

thermostat may result in property damage, personal injury or death.

Honeywell Thermostat Terminal Designation

TERMINAL LETTER

Y

W

(Heat Pump units Only)

For Non-Heat Pump equipped units: A single stage cooling and heating thermostat is required. Terminal "G"

should be energized whenever a call for heating or cooling is made. Typically a heat/cool thermostat designed

for use with electric heat systems will meet this requirement.

G

C (common)

R

B

OPERATION

Cooling

Heating

Common Terminal

24 V

to the thermostat

Fan

Reversing Valve

CONTACT MADE

During call for cooling.

During call for heating.

Continuous if the slider is in the "Fan"

position, otherwise, intermittent.

For thermostats requiring a common

terminal

Directly from the transformer

Made continuously during call for

heating.

Simplified Wiring Example

Unit Terminal Board

* A-Sufx models do not have a "C" terminal

Terminal "C"

is not used on RT1

thermostat

Terminal "B" is

used for heat pump

models only.

NOTE: It is the installer's responsibility to ensure that all control wiring connections are made in accordance with

the installation instructions. Improper connection of the thermostat control wiring and/or tampering with the unit's

internal wiring can void the equipment warranty and may result in property damage, personal injury or death. Other

manufacturer's PTACs and even older Friedrich models may have different control wire connections. Questions

concerning proper connections to the unit should be directed to the factory.

Thermostat Terminals

9

Page 10

11

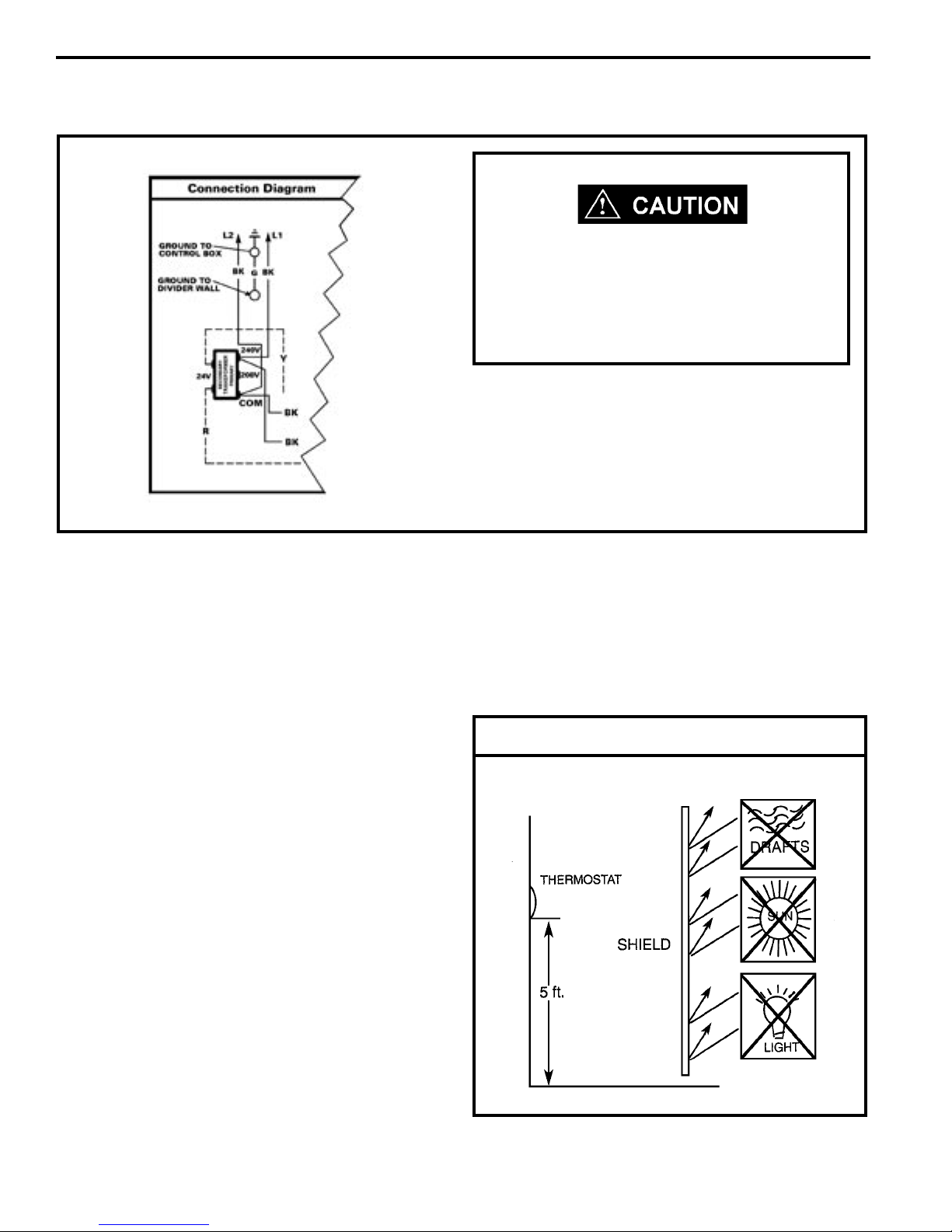

Remote Thermostat 208V Operation

208V 60HZ

If the supply voltage is 208V, the low voltage

transformer MUST be wired for 208V operation.

Failure to do so will result in lower control

voltages to the unit and can damage low voltage

components.

The simplied connection diagram at left shows the

factory congured wiring set for 240V operation. If you

are going to use 208V exclusively, switch the two (2)

black wires on the 240V post of the primary side of the

transformer to the 208V post. This will ensure correct

secondary (low) voltages for the unit. This is only required

on remote thermostat units.

Remote Thermostat Unit Operation

These units are controlled by the use of a remote

thermostat that will cycle the unit to maintain desired

room temperature. See thermostat operating instruction

sheet for details.

The fan speed switch controls high and low speed

fan operation. It is located on the control panel and is

independent of the thermostat.

Room Thermostats

Room thermostats are available from several different

manufacturers in a wide variety of styles. They range

from the very simple Bimetallic type to the complex

electronic set-back type. In all cases, no matter how

simple or complex, they are simply a switch (or series of

switches) designed to turn equipment (or components)

"ON" or "OFF" at the desired conditions.

An improperly operating, or poorly loca ted room

thermostat can be the source of perceived equipment

problems. A careful check of the thermostat and wiring

must be made then to insure that it is not the source of

problems.

the oor in an area of average temperature, with good air

circulation. Close proximity to the return air grille is the

best choice.

Mercury bulb type thermostats MUST be level to control

temperature accurately to the desired set-point. Electronic

digital type thermostats SHOULD be level for aesthetics.

Thermostat Location

Location

The thermostat should not be mounted where it may be

affected by drafts, discharge air from registers (hot or

cold), or heat radiated from the sun or appliances.

The thermostat should be located about 5 Ft. above

10

Page 11

Measuring Current Draw

Heat Anticipators

Heat anticipators are small resistance heaters (wired

in SERIES with the "W" circuit) and built into most

electromechanical thermostats. Their purpose is to prevent

wide swings in room temperature during system operation

in the HEATING mode. Since they are wired in series,

the "W" circuit will open if one burns out preventing heat

operation.

The heat anticipator provides a small amount of heat to

the thermostat causing it to cycle (turn off) the heat source

just prior to reaching the set point of the thermostat. This

prevents exceeding the set point.

If a low range ammeter is not available, a "Clamp-on" type

ammeter may be used as follows:

1. Wrap EXACTLY ten (10) turns of wire around the jaws

of a clamp-on type ammeter.

2. Connect one end of the wire to the "W" terminal of

the thermostat sub-base, and the other to the "R"

terminal.

3. Turn power on, and wait approximately 1 minute, then

read meter.

4. Divide meter reading by 10 to obtain correct anticipator

setting.

Electronic thermostats do not use a resistance type

anticipator. These thermostats use a microprocessor

(computer) that determines a cycle rate based on a program

loaded into it at the factory.

Calculating The Approximate CFM

The approximate CFM actually being delivered can be

calculated by using the following formula:

KILOWATTS x 3413

Temp. Rise x 1.08

In order to accomplish this, the heat output from the

anticipator must be the same regardless of the current

owing through it. Consequently, some thermostats have

an adjustment to compensate for varying current draw in

the thermostat circuits.

The proper setting of heat anticipators then is important to

insure proper temperature control and customer satisfaction.

A heat anticipator that is set too low will cause the heat

source to cycle prematurely possibly never reaching set

point. A heat anticipator that is set too high will cause the

heat source to cycle too late over shooting the set point.

The best method to obtain the required setting for the

heat anticipator, is to measure the actual current draw in

the control circuit ("W") using a low range (0-2.0 Amps)

ammeter. After measuring the current draw, simply set the

heat anticipator to match that value.

DO NOT simply use the Kilowatt Rating of the heater (i.e.

2.5, 3.4, 5.0) as this will result in a less-than-correct airow

calculation. Kilowatts may be calculated by multiplying the

measured voltage to the unit (heater) times the measured

current draw of all heaters (ONLY) in operation to obtain

watts. Kilowatts are then obtained by dividing by 1000.

EXAMPLE: Measured voltage to unit (heaters) is 230 volts.

Measured Current Draw of strip heaters is 11.0 amps.

230 x 11.0 = 2530

2530/1000 = 2.53 Kilowatts

2.53 x 3413 = 8635

Supply Air 95°F

Return Air 75°F

Temperature Rise 20°

20 x 1.08 = 21.6

8635

21.6

= 400 CFM

= CFM

11

Page 12

13

Fan Cycle Switch

NOTE: It is recommended that this switch be set in the continuous position for maximum comfort and

temperature control.

The fan cycle switch is located behind the decorative front

cover below the control box. It is designed to operate the fan

either continuously or intermittently with the compressor or

heating elements. When the switch is in the CONTINUOUS

position, the fan will run continuously when the unit is turned

on. With the fan cycle switch in the CYCLE position, the

fan will run only when the compressor or heating elements

cycle on.

Hot Start Sensor

(Heat Pump Models Only)

Under cold room conditions, the Hot Start Sensor brings

on the heater strips with a call for heat. This is to distribute warm air at the beginning of the heat cycle. Once

the return air has warmed sufciently, the heat pump

mode will begin.

Refrigerant Charging

NOTE: Because The Ptac System Is A Sealed System,

Service Process Tubes Will Have To Be Installed.

First Install A Line Tap And Remove Refrigerant From

System. Make Necessary Sealed System Repairs And

Vacuum System. Crimp Process Tube Line And Solder

End Shut. Do Not Leave A Service Valve In The Sealed

System.

Proper refrigerant charge is essential to proper unit

operation. Operating a unit with an improper refrigerant

charge will result in reduced performance (capacity) and/or

efciency. Accordingly, the use of proper charging methods

during servicing will insure that the unit is functioning as

designed and that its compressor will not be damaged.

Too much refrigerant (overcharge) in the system is just as

bad (if not worse) than not enough refrigerant (undercharge).

They both can be the source of certain compressor failures if

they remain uncorrected for any period of time. Quite often,

other problems (such as low air ow across evaporator,

etc.) are misdiagnosed as refrigerant charge problems. The

refrigerant circuit diagnosis chart will assist you in properly

diagnosing these systems.

Not enough refrigerant (undercharge) on the other hand,

will cause the temperature of the suction gas to increase to

the point where it does not provide sufcient cooling for the

compressor motor. When this occurs, the motor winding

temperature will increase causing the motor to overheat

and possibly cycle open the compressor overload protector.

Continued overheating of the motor windings and/or cycling

of the overload will eventually lead to compressor motor

or

overload failure.

Method Of Charging

The acceptable method for charging the PTAC system is

the Weighed in Charge Method. The weighed in charge

method is applicable to all units. It is the preferred method

to use, as it is the most accurate.

The weighed in method should always be used whenever

a charge is removed from a unit such as for a leak repair,

compressor replacement, or when there is no refrigerant

charge left in the unit. To charge by this method, requires

the following steps:

1. Install a piercing valve to remove refrigerant from the

sealed system. (Piercing valve must be removed from

the system before recharging.)

2. R e c o v e r Re f r i g e r a n t in accordance with EPA

regulations.

3. Install a process tube to sealed system.

4. Make necessary repairs to system.

An overcharged unit will at times return liquid refrigerant

(slugging) back to the suction side of the compressor

eventually causing a mechanical failu re within the

compressor. This mechanical failure can manifest itself

as valve failure, bearing failure, and/or other mechanical

failure. The specic type of failure will be inuenced by the

amount of liquid being returned, and the length of time the

slugging continues.

12

5. Evacuate system to 300 microns or less.

6. Weigh in refrigerant with the property quantity of R-22

refrigerant.

7. Start unit, and verify performance.

8. Crimp the process tube and solder the end shut.

Page 13

NOTE: In order to access the sealed system it will be necessary to install Schrader

type ttings to the process tubes on the discharge and suction of the compressor.

Proper recovery refrigerant procedures need to be adhered to as outlined in EPA

Regulations. THIS SHOULD ONLY BE ATTEMPTED BY QUALIFIED SERVICE

PERSONNEL.

Undercharged Refrigerant Systems

An undercharged system will result in poor performance (low

pressures, etc.) in both the heating and cooling cycle.

Whenever you service a unit with an undercharge of

refrigerant, always suspect a leak. The leak must be

repaired before charging the unit.

To check for an undercharged system, turn the unit on, allow

the compressor to run long enough to establish working

pressures in the system (15 to 20 minutes).

During the cooling cycle you can listen carefully at the exit

of the metering device into the evaporator; an intermittent

hissing and gurgling sound indicates a low refrigerant

charge. Intermittent frosting and thawing of the evaporator

is another indication of a low charge, however, frosting

and thawing can also be caused by insufcient air over

the evaporator.

Checks for an undercharged system can be made at the

compressor . If the compressor seems quieter than normal,

it is an indication of a low refrigerant charge. A check of the

amperage drawn by the compressor motor should show a

lower reading. (Check the Unit Specication.) After the unit

has run 10 to 15 minutes, check the gauge pressures.

Gauges connected to system with an undercharge will

have low head pressures and substantially low suction

pressures.

13

Page 14

15

Overcharged Refrigerant Systems

Com p r e s s or amps will be near norm a l or higher.

Noncondensables can also cause these symptoms. To

conrm, remove some of the charge, if conditions improve,

system may be overcharged. If conditions don’t improve,

Noncondensables are indicated.

Whenever an overcharged system is indicated, always

make sure that the problem is not caused by air ow

problems. Improper air ow over the evaporator coil may

indicate some of the same symptoms as an overcharged

system.

An over charge can cause the compressor to fail, since it

would be "slugged" with liquid refrigerant.

The charge for any system is critical. When the compressor

is noisy, suspect an overcharge, when you are sure that

the air quantity over the evaporator coil is correct. Icing

of the evaporator will not be encountered because the

refrigerant will boil later if at all. Gauges connected to

system will usually have higher head pressure (depending

upon amount of overcharge). Suction pressure should be

slightly higher.

14

Page 15

Restricted Refrigerant System

Troubleshooting a restricted refrigerant system can

be difcult. The following procedures are the more

common problems and solutions to these problems.

There are two types of refrigerant restrictions: Partial

restrictions and complete restrictions.

A partial restriction allows some of the refrigerant to

circulate through the system.

With a complete restriction there is no circulation of

refrigerant in the system.

Restricted refrigerant systems display the same symptoms

as a "low-charge condition."

When the unit is shut off, the gauges may equalize very

slowly.

Gauges connected to a completely restricted system will run

in a deep vacuum. When the unit is shut off, the gauges

will not equalize at all.

A quick check for either condition begins at the evaporator.

With a partial restriction, there may be gurgling sounds

at the metering device entrance to the evaporator. The

evaporator in a partial restriction could be partially frosted

or have an ice ball close to the entrance of the metering

device. Frost may continue on the suction line back to the

compressor.

Often a partial restriction of any type can be found by feel,

as there is a temperature difference from one side of the

restriction to the other.

With a complete restriction, there will be no sound at the

metering device entrance. An amperage check of the

compressor with a partial restriction may show normal

current when compared to the unit specication. With a

complete restriction the current drawn may be considerably

less than normal, as the compressor is running in a deep

vacuum (no load.) Much of the area of the condenser will

be relatively cool since most or all of the liquid refrigerant

will be stored there.

The following conditions are based primarily on a system

in the cooling mode.

15

Page 16

17

Metering Device

Capillary Tube Systems

All units are equipped with capillary tube metering devices.

Checking for restricted capillary tubes.

3. Switch the unit to the heating mode and observe the

gauge readings after a few minutes running time. If

the system pressure is lower than normal, the heating

capillary is restricted.

1. Connect pressure gauges to unit.

2. Start the unit in the cooling mode. If after a few

minutes of operation the pressures are normal,

the check valve and the cooling capillary are not

restricted.

Reversing Valve

Description/Operation

The Reversing Valve controls the direction of refrigerant

ow to the indoor and outdoor coils. It consists of a

pressure-operated, main valve and a pilot valve actuated

by a solenoid plunger. The solenoid is energized during

the heating cycle only. The reversing valves used in the

PTAC system is a 2-position, 4-way valve

The single tube on one side of the main valve body is the

high-pressure inlet to the valve from the compressor. The

center tube on the opposite side is connected to the low

pressure (suction) side of the system. The other two are

connected to the indoor and outdoor coils. Small capillary

tubes connect each end of the main valve cylinder to the

"A" and "B" ports of the pilot valve. A third capillary is a

common return line from these ports to the suction tube

on the main valve body. Four-way reversing valves also

have a capillary tube from the compressor discharge tube

to the pilot valve.

4. If the operating pressures are lower than normal in both

the heating and cooling mode, the cooling capillary is

restricted.

DANGER OF BODILY INJURY OR DEATH

FROM ELECTRICAL SHOCK

The reversing valve solenoid is connected to

high voltage. Turn off electrical power before

disconnecting or connecting high voltage wiring

or servicing valve.

The piston assembly in the main valve can only be shifted

by the pressure differential between the high and low

sides of the system. The pilot section of the valve opens

and closes ports for the small capillary tubes to the main

valve to cause it to shift.

NOTE: System operating pressures must be near

normal before valve can shift.

16

Page 17

Electrical Circuit and Coil

(Reversing valve coil is energized in the heating cycle only).

1. Set controls for heating; valve should shift if there is

pressure in the sealed system.

2. REMOTE THERMOSTAT HEAT PUMP UNITS: Check

for line voltage at the heat relay, terminal #4 and the

reversing valve relay terminal #4. If voltage isn't present,

test the heat relay and the reversing valve relay.

3. STANDARD HEAT PUMP UNITS: Check for line voltage

at system switch terminal #7 and thermostat terminal #2.

If voltage is not present, test the system switch.

Testing Coil

1. Turn off high voltage electrical power to unit.

2. Unplug line voltage lead from reversing valve coil.

3. Check for electrical continuity through the coil. If you

do not have continuity replace the coil.

4. Check from each lead of coil to the copper liquid line as

it leaves the unit or the ground lug. There should be no

continuity between either of the coil leads and ground;

if there is, coil is grounded and must be replaced.

5. If coil tests okay, reconnect the electrical leads .

6. Make sure coil has been assembled correctly.

Reversing Valve in Heating Mode

Touch Test in Heating/Cooling Cycle

The only definite indications that the slide is in the

mid-position is if all three tubes on the suction side of the

valve are hot after a few minutes of running time.

Checking the Reversing Valve

NOTE: You must have normal operating pressures before

the reversing valve can shift.

Check for proper refrigerant charge. Sluggish or sticky

reversing valves can sometimes be remedied by reversing

the valve several time with the airow restricted to increase

system pressure.

To raise head pressure during the cooling season the airow

through the outdoor coil can be restricted . During heating

the indoor air can be restricted by blocking the return air.

Dented or damaged valve body or capillary tubes can

prevent the main slide in the valve body from shifting.

If you determine this is the problem, replace the reversing

valve.

After all of the previous inspections and checks have been

made and determined correct, then perform the "Touch Test"

on the reversing valve.

NOTE: A condition other than those illustrated above, and

on Page 28, indicate that the reversing valve is not shifting

properly. Both tubes shown as hot or cool must be the same

corresponding temperature.

Procedure For Changing Reversing

Valve:

1. Install Process Tubes. Recover refrigerant

from sealed system. PROPER HANDLING OF

RECOVERED REFRIGERANT ACCORDING TO

EPA REGULATIONS IS REQUIRED.

2. Remove solenoid coil from reversing valve. If coil is to

be reused, protect from heat while changing valve.

3. Unbraze all lines from reversing valve.

4. Clean all excess braze from all tubing so that they will

slip into ttings on new valve.

5. Remove solenoid coil from new valve.

6. Protect new valve body from heat while brazing with

plastic heat sink (ThermoTrap) or wrap valve body with

wet rag.

Never energize the coil when

it is removed from the valve

as a coil burnout will result.

7. Fit all lines into new valve and braze lines into new

valve.

17

Page 18

19

Reversing Valve in Cooling Mode

8. Pressurize sealed system with a combination of R-22

and nitrogen and check for leaks, using a suitable leak

detector. Recover refrigerant per EPA guidelines.

9. Once the sealed system is leak free, install solenoid coil

on new valve and charge the sealed system by weighing

in the proper amount and type of refrigerant as shown

on rating plate. Crimp the process tubes and solder the

ends shut. Do not leave Schrader or piercing valves in

the sealed system.

Make sure that the ends of the lead do not touch

the compressor shell since this will cause a short

circuit.

Determine L.R.V.

Start the compressor with the voltmeter attached; then stop

the unit. Attempt to restart the compressor within a couple

of seconds and immediately read the voltage on the meter.

The compressor under these conditions will not start and will

usually kick out on overload within a few seconds since the

pressures in the system will not have had time to equalize.

Voltage should be at or above minimum voltage of 197 VAC,

as specied on the rating plate. If less than minimum, check

for cause of inadequate power supply; i.e., incorrect wire

size, loose electrical connections, etc.

AMPERAGE (L.R.A.) TEST

The running amperage of the compressor is the most

important of these readings. A running amperage higher

than that indicated in the performance data indicates that

a problem exists mechanically or electrically.

Single Phase Running and L.R.A. Test

NOTE: Consult the specication and performance section

for running amperage. The L.R.A. can also be found on

the rating plate.

Select the proper amperage scale and clamp the meter probe

around the wire to the "C" terminal of the compressor.

DANGER OF BODILY INJURY OR

DEATH FROM ELECTRICAL SHOCK

When working on high voltage equipment - turn the

electrical power off before attaching test leads.

Use test leads with alligator type clips - clip to

terminals, turn power on, take reading - turn power

off before removing leads.

Compressor Checks

LOCKED ROTOR VOLTAGE (L.R.V.) TEST

Locked rotor voltage (L.R.V.) is the actual voltage available

at the compressor under a stalled condition.

Single Phase Connections

Disconnect power from unit. Using a voltmeter, attach one

lead of the meter to the run "R" terminal on the compressor

and the other lead to the common "C" terminal of the

compressor. Restore power to unit.

Turn on the unit and read the running amperage on the

meter. If the compressor does not start, the reading will

indicate the locked rotor amperage (L.R.A.).

External Overload

The compressor is equipped with an external overload which

senses both motor amperage and winding temperature.

High motor temperature or amperage heats the overload

causing it to open, breaking the common circuit within the

compressor.

Heat generated within the compressor shell, usually due

to recycling of the motor, is slow to dissipate. It may take

anywhere from a few minutes to several hours for the

overload to reset.

Checking the External Overload

With power off, remove the leads from compressor terminals.

If the compressor is hot, allow the overload to cool before

starting check. Using an ohmmeter, test continuity across

the terminals of the external overload. If you do not have

continuity; this indicates that the overload is open and must

be replaced.

18

Page 19

Many compressor failures are caused by the following

conditions:

1. Improper air ow over the evaporator.

2. Overcharged refrigerant system causing liquid to be

returned to the compressor.

3. Restricted refrigerant system.

4. Lack of lubrication.

5. Liquid refrigerant returning to compressor causing oil

to be washed out of bearings.

6. Noncon dens ables such as air and moisture in

the system. Moisture is extremely destructive to a

refrigerant system.

Recommended procedure for

compressor replacement

NOTE: Be sure power source is off, then disconnect all

wiring from the compressor.

Single Phase Resistance Test

Remove the leads from the compressor terminals and set

the ohmmeter on the lowest scale (R x 1).

Touch the leads of the ohmmeter from terminals common

to start ("C" to "S"). Next, touch the leads of the ohmmeter

from terminals common to run ("C" to "R").

Add values "C" to "S" and "C" to "R" together and

check resistance from start to run terminals ("S" to "R").

Resistance "S" to "R" should equal the total of "C" to "S"

and "C" to "R."

In a single phase PSC compressor motor, the highest value

will be from the start to the run connections (“S” to "R").

The next highest resistance is from the start to the common

connections ("S" to "C"). The lowest resistance is from the

run to common. ("C" to "R") Before replacing a compressor,

check to be sure it is defective.

Check the complete electrical system to the compressor and

compressor internal electrical system, check to be certain

that compressor is not out on internal overload.

Complete evaluation of the system must be made whenever

you suspect the compressor is defective. If the compressor

has been operating for some time, a careful examination

must be made to determine why the compressor failed.

1. Be certain to perform all necessary electrical and

refrigeration tests to be sure the compressor is actually

defective before replacing .

2. Recover all refrigerant from the system though

the process tubes. PROPER HANDLIN G OF

RECOVERED REFRIGERANT ACCORDING TO EPA

REGULATIONS IS REQUIRED. Do not use gauge

manifold for this purpose if there has been a burnout.

You will contaminate your manifold and hoses. Use a

Schrader valve adapter and copper tubing for burnout

failures.

3. After all refrigerant has been recovered, disconnect

suction and discharge lines from the compressor and

remove compressor. Be certain to have both suction

and discharge process tubes open to atmosphere.

19

Page 20

21

4. Carefully pour a small amount of oil from the suction

st ub of t he defec tive co mpresso r into a clean

container.

5. Using an acid test kit (one shot or conventional kit),

test the oil for acid content according to the instructions

with the kit.

6. If any evidence of a burnout is found, no matter how

slight, the system will need to be cleaned up following

proper procedures.

7. Install the replacement compressor.

8. Pressurize with a combination of R-22 and nitrogen

and leak test all connections with an electronic or

Halide leak detector. Recover refrigerant and repair

any leaks found.

Repeat Step 8 to insure no more leaks are present.

9. Evacuate the system with a good vacuum pump

capable of a nal vacuum of 300 microns or less.

The system should be evacuated through both liquid

line and suction line gauge ports. While the unit is

being evacuated, seal all openings on the defective

compressor. Compressor manufacturers will void

warranties on units received not properly sealed. Do

not distort the manufacturers tube connections.

10. Recharge the system with the correct amount of

refrigerant. The proper refrigerant charge will be

found on the unit rating plate. The use of an accurate

measuring device, such as a charging cylinder,

electronic scales or similar device is necessary.

Hazard of shock and electrocution. A capacitor can

hold a charge for long periods of time. A service

technician who touches these terminals can be

injured. Never discharge the capacitor by shorting

across the terminals with a screwdriver.

CAPACITORS

Many motor capacitors are internally fused. Shorting the

terminals will blow the fuse, ruining the capacitor. A 20,000

ohm 2 watt resistor can be used to discharge capacitors

safely. Remove wires from capacitor and place resistor

across terminals. When checking a dual capacitor with

a capacitor analyzer or ohmmeter, both sides must be

tested.

Capacitor Check With Capacitor

Analyzer

The capacitor analyzer will show whether the capacitor is

"open" or "shorted." It will tell whether the capacitor is within

its microfarads rating and it will show whether the capacitor

is operating at the proper power-factor percentage. The

instrument will automatically discharge the capacitor when

the test switch is released

Capacitor Connections

The starting winding of a motor can be damaged by a

shorted and grounded running capacitor. This damage

usually can be avoided by proper connection of the running

capacitor terminals.

From the supply line on a typical 230 volt circuit, a 115 volt

potential exists from the "R" terminal to ground through a

possible short in the capacitor. However, from the "S" or start

terminal, a much higher potential, possibly as high as 400

volts, exists because of the counter EMF generated in the

start winding. Therefore, the possibility of capacitor failure

is much greater when the identied terminal is connected

to the “S" or start terminal. The identied terminal should

always be connected to the supply line, or "R" terminal,

never to the "S" terminal.

Wh en conne cted pro perly, a shorted or grou n ded

running-capacitor will result in a direct short to ground

from the "R" terminal and will blow the line fuse. The motor

protector will protect the main winding from excessive

temperature.

20

Page 21

System Switch Continuity Check

ROTATE SHAFT

(VIEWED FROM THE FRONT)

CLOCKWISE TO

STOP

COUNTER CLOCKWISE

TO ST

OP

READ CONTINUITY BETWEEN

2(C) & 3(L)

2(C) & 1(H)

Thermostat

Rear View

3

2

1

L

C

H

Remove and label all wires from the system switch. Using an ohmmeter checks for continuity can be made. Continuity

reading should be as shown in the table below. Should the switch fail any part of this check it should be replaced.

CONTACTS MADE

Cooling

Only

Models

Cooling /

Heating

Models

OFF

HIGH COOL

FAN ONLY

LOW COOL

CONTACTS MADE

OFF

LOW COOL

HIGH COOL

FAN ONLY

HIGH HEAT

LOW HEAT

NONE

L1 TO 2,3 TO COMP.

4 TO H, COM TO L2

1 TO H COM TO L2

L1 TO 2, 3 TO COMP.

L TO 4, COM TO L2

NONE

L1 TO 2, 5 TO 3, 4 TO 6

L TO 9, COM TO L2

L1 TO2, 5 TO 3, 4 TO 6

H TO 9, COM TO L2

8 TO H, COM TO L2

L1 TO 8

L1 TO 2, 5 TO 1, 7 TO 6

H TO 9, COM TO L2

L1 TO 2, 5 TO 1, 7 TO 6

L TO 9 COM TO L2

Thermostat Continuity Check

Remove and label all wires from the thermostat. To check out the thermostat on cooling the thermostat bulb must be

above 60 degrees. Using an ohmmeter checks for continuity can be made. Continuity reading should be as shown in

the table below. Should the thermostat fail any part of this check it should be replaced.

(Some thermostats may have the terminals identied by the letters C, H and L)

21

Page 22

23

Fan Cycle Switch

Continuity Check

Remove and label all wires from the fan cycle switch. Continuity reading should be as shown in the table below. Should

the fan cycle switch fail any part of this check, it should be replaced.

Fan Speed Switch

Continuity Check

(Remote Models Only)

Remove and label all wires from the fan speed switch. Continuity reading should be as shown in the table below. Should

the fan speed switch fail any part of this check, it should be replaced.

22

Page 23

Emergency Heat Switch (Defrost Thermostat)

Continuity Check

Electric Heat Switch Operation ( Heat Pumps Only)

The electric heat switch is a dual function control and is shown on the wiring diagram as a defrost thermostat. It may

be adjusted using a screwdriver. As the control shaft is rotated counter clockwise a detent will be encountered. Turning

the control past the detent will lock out the compressor and acts as an emergency heat switch. Turning the control shaft

clockwise will lower the change over point for compressor operation. The control it self is a double throw, single pole switch

operated by a bellows and a gas lled capillary tube. The capillary tube senses a combination of outdoor coil temperature

and outdoor air temperature. As the combined temperatures reach a point that the outdoor coil is iced, where heat

pump operation is no longer efcient, the control shuts off the compressor and turns on the electric heat. At its lowest

setting the cut off point is approximately 25 degrees, the highest setting is 52 degrees, with a 10 degree differential. It

is possible, under certain conditions, for the unit to cycle between compressor and electric heat operation.

Electric Heat Switch Check Out

The switch may be checked out with an ohmmeter. Remove and label the three wires from the switch. Terminal 2 is

common and the contacts make to Terminal 3 on temperature rise and to Terminal 1 on temperature fall. With the

control set in the emergency heat position continuity should be read between Terminal 2 and Terminal 1 regardless of

coil temperature. As the control shaft is rotated clockwise, through the adjustment range, continuity will be read between

Terminal 2 and Terminal 3, providing the temperature of the capillary tube is above 25º (± 5%). If the temperature at the

capillary tube is above approximately 52 degrees it may be necessary to place the end of the capillary tube in ice water

to determine if the control is sensing temperature changes. Should the control lose the gas charge in the capillary tube

it will fail to the electric heat position and the compressor will not operate.

(Some thermostats may have the terminals identied by the letters C, H and L)

L

C

H

SWITCH

POSITION

TEMPERATURE

AT CAPILLARY

CONTINUITY READ

EMERGENCY HEAT N/A 1(H) and 2(C) = Electric Heat

ANYWHERE IN

ADJUSTMENT RANGE

ABOVE

SET POINT

2(C) and 3(L) = Compressor

ANYWHERE IN

ADJUSTMENT RANGE

BELOW

SET POINT

1(H) and 2(C) = Electric Heat

23

Page 24

25

Routine Maintenance

NOTE: Units are to be inspected and serviced by qualied service personnel only.

1. Clean the unit air intake lter at least every 300 to 350 hours of operation. Clean the lters with a mild detergent in

warm water and allow to dry thoroughly before reinstalling.

2. The indoor coil (evaporator coil), the outdoor coil (condenser coil) and base pan should be inspected periodically

(yearly or bi-yearly) and cleaned of all debris (lint, dirt, leaves, paper, etc.). Clean the coils and base pan with a soft

brush and compressed air or vacuum. If using a pressure washer, be careful not to bend the aluminium n pack.

Use a sweeping up and down motion in the direction of the vertical aluminum n pack when pressure cleaning

coils. Cover all electrical components to protect them from water or spray. Allow the unit to dry thoroughly before

reinstalling it in the sleeve.

NOTE: Do not use a caustic coil cleaning agent on coils or base pan. Use a biodegradable cleaning agent and

degreaser.

Inspect the indoor blower housing, evaporator blade, condenser fan blade, and condenser shroud periodically (yearly

or bi-yearly) and clean of all debris (lint, dirt, mold, fungus, etc.) Clean the blower housing area and blower wheel

with an antibacterial / antifungal cleaner. Use a biodegradable cleaning agent and degreaser on condenser fan

and condenser shroud. Use warm or cold water when rinsing these items. Allow all items to dry thoroughly before

reinstalling them.

3. Periodically (at least yearly or bi-yearly): inspect all control components, both electrical and mechanical, as well

as the power supply. Use proper testing instruments (voltmeter, ohmmeter, ammeter, wattmeter, etc.) to perform

electrical tests. Use an air conditioning or refrigeration thermometer to check room, outdoor and coil operating

temperatures. Use a sling psychrometer to measure wet bulb temperatures indoors and outdoors.

4. Inspect the surrounding area (inside and outside) to ensure that the units' clearances have not been compromised

or altered.

5. Inspect the sleeve and drain system periodically (at least yearly or bi-yearly) and clean of all obstructions and debris.

Clean both areas with an antibacterial and antifungal cleaner. Rinse both items thoroughly with water and ensure

that the drain outlets are operating correctly. Check the sealant around the sleeve and reseal areas as needed.

6. Clean the front cover when needed. Use a mild detergent. Wash and rinse with warm water. Allow it to dry thoroughly

before reinstalling it in the chassis.

Discharge Air Grille

Filters

Return Air Grille

Blower Wheel

Indoor Blower Housing

Gasket

Control Door

Front Cover

Evaporator Coil

Control Panel

Condenser Fan Blade

Condenser

Shroud

Gasket

Condenser

Coil

Compressor

Basepan

Outdoor Grille

Wall Sleeve

24

Page 25

Troubleshooting Chart — Cooling

REFRIGERANT SYSTEM

DIAGNOSIS COOLING

Low Suction Pressure High Suction Pressure Low Head Pressure High Head Pressure

Low Load Conditions High Load Conditions Low Load Conditions High Load Conditions

Low Air Flow Across High Air Flow Across Refrigerant System Low Air Flow Across

Indoor Coil Indoor Coil Restriction Outdoor Coil

Refrigerant System Reversing Valve not Reversing Valve not

Restriction Fully Seated Fully Seated

Undercharged Overcharged Undercharged Noncondendsables (air)

in System

Moisture in System Defective Compressor Defective Compressor

Overcharged

25

Page 26

27

Troubleshooting Chart — Heating

REFRIGERANT SYSTEM

DIAGNOSIS – HEATING

Low Suction Pressure High Suction Pressure Low Head Pressure High Head Pressure

Low Airow

Across Outdoor Coil

Refrigerant System

Restriction

Undercharged Overcharged

Moisture in System

Outdoor Ambient Too High

for Operation in Heating

Reversing Valve not

Fully Seated

Defective Compressor Defective Compressor

Refrigerant System

Restriction

Reversing Valve not

Fully Seated

Undercharged

Outdoor Ambient Too High

For Operation In Heating

Low Airow Across

Indoor Coil

Overcharged

Non-condensables (air) in

System

26

Page 27

Electrical Troubleshooting Chart

HEAT PUMP

HEAT PUMP

SYSTEM COOLS WHEN

HEATING IS DESIRED.

Is Line Voltage

Present at the Solenoid

Valve?

YES

Is the Solenoid Coil Good?

YES

Reversing Valve Stuck

Replace the Reversing Valve

NO

NO

Is the Selector Switch

Set for Heat?

Replace the Solenoid Coil

27

Page 28

29

Wiring Diagram PTAC Models PE ( 07, 09, 12, 15 ) KOOSA-1

Wiring Diagram PTAC Models PH ( 07, 09, 12, 15 ) K (2, 3, 5 ) SA-1

28

Page 29

Wiring Diagram PTAC Models PH ( 07, 09, 12, 15 ) KOOSA-1

Wiring Diagram PTAC Models PE ( 07, 09, 12, 15 ) K ( 2, 3, 5 ) SA-1

29

Page 30

31

Wiring Diagram PTAC Models PH ( 07, 09, 12, 15 ) K ( 2, 3, 5 ) RA-1

Wiring Diagram PTAC Models PE ( 07, 09, 12, 15 ) K ( 2, 3, 5 ) RA-1

30

Page 31

Wiring Diagram PTAC Models PE ( 07, 09, 12, 15 ) KOORA-1

Wiring Diagram PTAC Models PE ( 07, 09, 12, 15 ) R00SA-1

31

Page 32

33

Wiring Diagram PTAC Models PE ( 07, 09, 12, 15 ) R ( 2, 3, 5 ) SA-1

Wiring Diagram PTAC Models PH ( 07, 09, 12, 15 ) R ( 2, 3, 5 ) SA-1

32

Page 33

Wiring Diagram PTAC Models PE ( 07, 09, 12, 15 ) R ( 2, 3, 5 ) RA-1

Wiring Diagram PTAC Models PH ( 07, 09, 12, 15 ) R ( 2, 3, 5 ) RA-1

33

Page 34

35

Wiring Diagram PTAC Models PE (07, 09, 12, 15) K005 S-1

FAN

HERM

c

S

C

R

1(H)

3(L)

2(C)

4

L

3

CO

M

H

L1

L2

1

2

COMP

1

3

2

RED

BLACK

FAN

CAPACITO

R

BROWN

YELLOW

TO INNERWALL

GREE

N

SMOOTH

RIBBED

SUPPLY CORD

TO CONTROL BO

X

RED

BLU

E

COMPRESSOR

MOTOR

BLACK

RED

BLACK

INDOOR

BLUE

RED

BLACK BLAC

K

YELLO

W

SYSTEM

SWITCH

FAN CYCLE

HEAT

T-STAT

SWITCH

ANTICIPATOR

BLU

E

260-400-00

REVPART NO.

ORANGE

ORANGE

BLUE

L1 TO 2, 3 TO COMP,

1 TO H COM TO L2

4 TO H, COM TO L2

L1 TO 2, 3 TO COMP,

WIRING DIAGRAM PTAC MODELS

NONE

OFF

L TO 4, COM TO L2

LOW COOL

FAN ONLY

HI COOL

CONTACTS MADE

HAZARD DISCONNECT POWER

BEFORE SERVICING

DANGER: ELECTRICAL SHOCK

4

1

5

2

OPTIONAL FIELD DESK CONTROL WIRING

DESK CONTROL RELAY

00

WHITE WIRE

(SUPPLIED)

(SUPPLIED)

BLACK WIRE

TO UNIT SWITCH

TERMINAL "L2"

TERMINAL "L1"

TO UNIT SWITCH

CORD

VOLT WIRES.

FIELD SUPPLIED 24

WIRING HARNESS &

RIBBED WIRE

SMOOTH WIRE

POWER

FAN

5

HERM

c

3

4

1

C(2)

L(3)

H(1)

S

C

R

H(1)

L(3)

C(2)

9

5

L

6

COM

H

L1

L2

31

8

2

7

4

1

3

2

RED

BLACK

FAN

HEATER

SOLENOID

CAPACITOR

HOT START

SENSOR

BROWN

RED

BROWN

YELLOW

TO INNERWALL

GREEN

SMOOTH

RIBBED

SUPPLY CORD

TO CONTROL BOX

BROWN

HOT START

RELAY

BLACK

RED

BLUE

DEFROST

BROWN

BROWN

RED

COMPRESSOR

COIL

T-STAT

MOTOR

BLACK

RED

BLACK

INDOOR

RED

BLUE

RED

BLACK BLACK

YELLOW

BLUE

TAN

SYSTEM

SWITCH

FAN CYCLE

HEAT

T-STAT

SWITCH

ANTICIPATOR

BLUE

WHITE

RED

BLUE

260-401-10

REVPART NO.

ORANGE

ORANGE

BLACK

BLACK

L TO 9, COM TO L2

L1 TO 2, 5 TO 1, 7 TO

6

H TO 9, COM TO L2

L1 TO 2, 5 TO 1, 7 TO

6

8 TO H, COM TO L2,

H TO 9, COM TO L2

L1 TO 2, 5 TO 3, 4 TO

6

L TO 9, COM TO L2

L1 TO 2, 5 TO 3, 4 TO

6

WIRING DIAGRAM PTAC MODELS

NONEOFF

L1 TO

8

LOW HEAT

HI HEAT

FAN ONLY

HI COOL

LOW COOL

CONTACTS MADE

HAZARD DISCONNECT POWER

BEFORE SERVICING

DANGER: ELECTRICAL SHOC

K

DESK CONTROL RELAY

OPTIONAL FIELD DESK CONTROL WIRING

CORD

SMOOTH WIRE

RIBBED WIRE

VOLT WIRES.

FIELD SUPPLIED 24

WIRING HARNESS &

4

1

5

2

POWER

TERMINAL "L1"

TERMINAL "L2"

TO UNIT SWITCH

(SUPPLIED)

BLACK WIRE

(SUPPLIED)

WHITE WIRE

TO UNIT SWITCH

00

Wiring Diagram PTAC Models PH (07, 09, 12, 15) K (2, 3, 5) SB-1

34

Page 35

Wiring Diagram PTAC Models PE (07, 09, 12, 15) K (2, 3, 5) SB-1

FAN

HERM

c

S

C

R

1(H)

3(L)

2(C)

9

5

L

6

COM

H

L1

L2

31

8

2

7

4

1

3

2

RED

BLACK

FAN

HEATER

CAPACITOR

TAN

RED

BROWN

YELLOW

TO INNERWALL

GREEN

SMOOTH

RIBBED

SUPPLY CORD

TO CONTROL BOX

RED

BLUE

COMPRESSOR

MOTOR

BLACK

RED

BLACK

INDOOR

RED

BLUE

RED

BLACK BLACK

YELLOW

BLUE

SYSTEM

SWITCH

FAN CYCLE

HEAT

T-STAT

SWITCH

ANTICIPATOR

BLUE

260-403-00

REVPART NO.

BLACK

ORANGE

ORANGE

L TO 9, COM TO L2

L1 TO 2, 5 TO 1, 7 TO

6

H TO 9, COM TO L2

L1 TO 2, 5 TO 1, 7 TO

6

8 TO H, COM TO L2,

H TO 9, COM TO L2

L1 TO 2, 5 TO 3, 4 TO

6

L TO 9, COM TO L2

L1 TO 2, 5 TO 3, 4 TO

6

WIRING DIAGRAM PTAC MODELS

NONEOFF

L1 TO

8

LOW HEAT

HI HEAT

FAN ONLY

HI COOL

LOW COOL

CONTACTS MADE

HAZARD DISCONNECT POWER

BEFORE SERVICING

DANGER: ELECTRICAL SHOC

K

00

DESK CONTROL RELAY

OPTIONAL FIELD DESK CONTROL WIRING

4

1

5

2

CORD

SMOOTH WIRE

RIBBED WIRE

VOLT WIRES.

FIELD SUPPLIED 24

WIRING HARNESS &

POWER

TERMINAL "L1"

TERMINAL "L2"

TO UNIT SWITCH

(SUPPLIED)

BLACK WIRE

(SUPPLIED)

WHITE WIRE

TO UNIT SWITCH

24V

240V

208V

COM

HERM

YELLOW

RED

FAN

2

1

BLACK

RED

MOTOR

TERM BOARD

PURPLE

YELLOW

BLUE

ORANGE

W

3

Y

R

G B

HEATING

HEATER

FAN SPEED

BLUE

COIL

SOLENOI

D

1

4

2

6

3

CAPACITOR

SENSOR

HOT START

BROWN

TAN

BROWN

WHITE

FAN

BROWN

YELLO

W

c

RELAY

DEFROST

T-STAT

COOLING RELAY

TO INNERWALL

RED

TRANSFORMER

RIBBED

SMOOTH

BLACK

BLACK

FAN

WHITE

BLUE

BLACK

4

1

2

3

BROWN

5

3

1

4

PURPLE

1

2

3

4

BROWN

RE

D

YELLOW

BROWN

L(3)

C(2)

SUPPLY CORD

TO CONTROL BOX

GREEN

SUCTION LINE

THERMOSTAT

BLACK

BLACK

H(1)

COMPRESSOR

C

R

S

HOT START

BLACK

BLU

E

RED

REV

260-404-10

PART NO.

1

3

4

2

WHITE

RED

BLACK

BLACK

BLACK

BLAC

K

BLAC

K

SWITCH

RELAY

REV VALVE

RELA

Y

BLUE

COM

24V

COM

RELAY

WIRING DIAGRAM PTAC MODELS

HAZARD DISCONNECT POWER

BEFORE SERVICING

DANGER: ELECTRICAL SHOCK

4

1

5

2

DESK CONTROL RELAY

OPTIONAL FIELD DESK CONTROL WIRING

00

C

BLACK

TO TRANSFORMER MOUNT SCREW

GREEN

GREEN

VOLT WIRES.

FIELD SUPPLIED 24

WIRING HARNESS &

RIBBED WIRE

SMOOTH WIRE

POWER

CORD

(SUPPLIED)

BLACK WIRE

(SUPPLIED)

WHITE WIRE

To Unit

Transformer

(230V)

(COM)

Wiring Diagram PTAC Models PH (07, 09, 12, 15) K (2, 3, 5) RB-1

35

Page 36

37

Wiring Diagram PTAC Models PE (07, 09, 12, 15) R00RB-1

HERM

2

1

W

3

Y

R

G B

FAN

c

4

1

2

3

1

2

3

4

C

R

S

C

24V

277V

COM

COM

FAN

BLACK

RED

MOTOR

TERM BOARD

PURPLE

ORANGE

SWITCH

BLUE

CAPACITOR

BROWN

YELLOW

COOLING RELAY

RED

YELLOW

TRANSFORMER

BLACK

BLACK

FAN RELAY

BLACK

PURPLE

SUCTION LINE

THERMOSTAT

BLACK

BLACK

COMPRESSOR

BLUE

RED

REV

260-405-10

PART NO.

BLUE

TO INNERWALL

GREEN

TO CONTROL BOX

GREEN

BLACK

FUSE

WHITE

BLACK

BLACK

BLACK

FAN SPEED

WIRING DIAGRAM PTAC MODELS

HAZARD DISCONNECT POWER

BEFORE SERVICING

DANGER: ELECTRICAL SHOCK

RED

DESK CONTROL RELAY

OPTIONAL FIELD DESK CONTROL WIRING

2

5

4

1

00

BLACK

GREEN

TO TRANSFORMER MOUNT SCREW

GREEN

(SUPPLIED)

BLACK WIRE

(Existing)

WHITE WIRE

FIELD SUPPLIED 24

VOLT WIRES.

WIRING HARNESS &

(Existing)

Black Line

White Line

(Supplied)

Transformer

(277V)

To Uni

t

(COM)

To Fuse

Terminal

HERM

YELLOW

RED

FAN

2

1

BLACK

RED

MOTOR

TERM BOARD

PURPLE

YELLOW

BLUE

ORANGE

W

3

Y

R

G B

HEATING RELAY

HEATER

SWITCH

BLUE

1

3

CAPACITOR

YELLOW

TAN

FAN

BROWN

YELLOW

c

COOLING RELAY

TO INNERWALL

RED

TRANSFORMER

RIBBED

SMOOTH

BLACK

BLACK

FAN RELAY

BLACK

4

1

2

3

PURPLE

1

2

3

4

SUPPLY CORD

TO CONTROL BOX

GREEN

SUCTION LINE

THERMOSTAT

BLACK

BLACK

COMPRESSOR

C

R

S

BLUE

RED

REV

260-406-01

PART NO

.

2

BLUE

BLACK

BLACK

FAN SPEED

4

WIRING DIAGRAM PTAC MODELS

HAZARD DISCONNECT POWER

BEFORE SERVICING

DANGER: ELECTRICAL SHOCK

OPTIONAL FIELD DESK CONTROL WIRING

WHITE WIRE

(SUPPLIED)

BLACK WIRE

(SUPPLIED)

WIRING HARNESS &

FIELD SUPPLIED 24

VOLT WIRES.

DESK CONTROL RELAY

SMOOTH WIRE

RIBBED WIRE

POWER

CORD

4

5

1

2

To Unit

Transformer

(COM)

(230V)

00

C

BLACK

TO TRANSFORMER MOUNT SCREW

GREEN

24V

240V

208V

COM

COM

GREEN

Wiring Diagram PTAC Models PH (07, 09, 12, 15) K (2, 3, 5) RB

36

Page 37

Wiring Diagram PTAC Models PE (07, 09, 12, 15) K00RB-1

HERM

2

1

W

3

Y

R

G B

FAN

c

4

1

2

3

1

2

3

4

C

R

S

COM

C

24V

240V

208V

COM

FAN

BLACK

RED

MOTOR

TERM BOARD

PURPLE

ORANGE

SWITCH

BLUE

CAPACITOR

BROWN

YELLOW

COOLING RELAY

TO INNERWALL

RED

YELLOW

TRANSFORMER

RIBBED

SMOOTH

BLACK

BLACK

FAN RELAY

PURPLE

SUPPLY CORD

TO CONTROL BOX

GREEN

SUCTION LINE

THERMOSTAT

BLACK

BLACK

COMPRESSOR

BLUE

RED

REV

260-407-01

PART NO.

BLUE

RED

BLACK

BLACK

FAN SPEED

WIRING DIAGRAM PTAC MODELS

HAZARD DISCONNECT POWER

BEFORE SERVICING

DANGER: ELECTRICAL SHOCK

OPTIONAL FIELD DESK CONTROL WIRING

DESK CONTROL RELAY

4

5

1

2

00

BLACK

GREEN

GREEN

TO TRANSFORMER

MOUNT SCRE

W

(SUPPLIED)

BLACK WIRE

(SUPPLIED)

WHITE WIRE

VOLT WIRES.

FIELD SUPPLIED 24

WIRING HARNESS &

RIBBED WIRE

SMOOTH WIRE

POWER

CORD

To Uni

t

Transformer

(230V)

(COM)

FAN

HERM

c

S

C

R

H(1)

L(3)

C(2)

4

L

3

COM

H

L1

L2

1

2

COMP

1

3

2

RED

BLACK

FAN

CAPACITOR

BROWN

YELLOW

TO INNERWALL

GREEN

FUSE

TO CONTROL BOX

RED

BLUE

COMPRESSOR

MOTOR

BLACK

RED

BLACK

INDOOR

BLUE

RED

BLACK BLACK

YELLO

W

SYSTEM

SWITCH

FAN CYCLE

HEAT

T-STAT

SWITCH

ANTICIPATOR

BLUE

260-408-00

REVPART NO.

WHITE

BLACK

BLACK

GREEN

BLUE

ORANGE

ORANGE

L1 TO 2, 3 TO COMP,

1 TO H COM TO L2

4 TO H, COM TO L2

L1 TO 2, 3 TO COMP,

WIRING DIAGRAM PTAC MODELS

NONEOFF

L TO 4, COM TO L2

LOW COOL

FAN ONLY

HI COOL

CONTACTS MADE

HAZARD DISCONNECT POWER

BEFORE SERVICING

DANGER: ELECTRICAL SHOCK

OPTIONAL FIELD DESK CONTROL WIRING

DESK CONTROL RELAY

5

1

4

2

00

WIRING HARNESS &

FIELD SUPPLIED 24

VOLT WIRES.

(Supplied)

(Existing)

White Line

Black Line

(Existing)

TERMINAL "L2"

TO UNIT SWITCH

TO UNIT SWITCH

TERMINAL "L1"

WHITE WIRE

BLACK WIRE

(SUPPLIED)

Terminal

To Fuse

Wiring Diagram PTAC Models PE (07, 09, 12, 15) R00SB-1

37

Page 38

39

Wiring Diagram PTAC Models PE (07, 09, 12, 15) R (2, 3, 5) SB-1

FAN

HERM

c

S

C

R

H(1)

L(3)

C(2)

9

5

L

6

COM

H

L1

L2

31

8

2

7

4

1

3

2

RED

BLACK

FAN

HEATER

CAPACITOR

TAN

RED

BROWN

YELLOW

RED

BLUE

COMPRESSOR

MOTOR

BLACK

RED

BLACK

INDOOR

RED

BLUE

RED

BLACK BLACK

YELLOW

BLUE

SYSTEM

SWITCH

FAN CYCLE

HEAT

T-STAT

SWITCH

ANTICIPATOR

BLUE

260-409-00

REVPART NO.

BLACK

TO INNERWALL

GREEN

TO CONTROL BOX

GREEN

BLACK

FUSE

WHITE

BLACK

ORANGE

ORANGE

L TO 9, COM TO L2

L1 TO 2, 5 TO 1, 7 TO 6

H TO 9, COM TO L2

L1 TO 2, 5 TO 1, 7 TO 6

8 TO H, COM TO L2,

H TO 9, COM TO L2

L1 TO 2, 5 TO 3, 4 TO 6

L TO 9, COM TO L2

L1 TO 2, 5 TO 3, 4 TO 6

WIRING DIAGRAM PTAC MODELS

NONEOFF

L1 TO 8

LOW HEAT

HI HEAT

FAN ONLY

HI COOL

LOW COOL

CONTACTS MADE

HAZARD DISCONNECT POWER

BEFORE SERVICING

DANGER: ELECTRICAL SHOCK

OPTIONAL FIELD DESK CONTROL WIRING

4

1

5

2

DESK CONTROL RELAY

00

TO UNIT SWITCH

TERMINAL "L1"

(Existing)

TERMINAL "L2"