Service Manual

WallMaster® P SERIES

Packaged Terminal Air Conditioners

Packaged Terminal Heat Pumps

· Standard Unit

· Seacoast Protected Unit

· Remote Thermostat Unit

P2K23-DM (4-03)

3

Table of Contents

Typical Unit Components .......................................... 4

Introduction................................................................ 4

Unit Identication....................................................... 5

Unit Specications..................................................... 6

PE Series Air Conditioner–Cooling Performance...... 6

PH Series Heat Pump–Heating/Cooling Performance..... 6

PE / Ph Series Electric Heating Data ........................ 6

Sequence Of Operation............................................. 7

Electrical Supply........................................................ 8

Supply Circuit ............................................................ 8

Electrical Rating Tables ............................................. 8

Standard Unit Operation............................................ 9

Temperature Limiting Thermostat.............................. 9

Standard Unit Control Panel...................................... 9

Remote Thermostat Unit Installation ....................... 10

Manual Changeover Thermostat............................. 10

Remote Thermostat Unit Operation..........................11

Room Thermostats...................................................11

Location....................................................................11

Heat Anticipators ..................................................... 12

Calculating Approximate CFM................................. 12

Fan Cycle Switch..................................................... 13

Hot Start Sensor...................................................... 13

Refrigerant Charging ............................................... 13

Method Of Charging ................................................ 13

Undercharged Refrigerant Systems ........................ 14

Overcharged Refrigerant Systems .......................... 15

Restricted Refrigerant Systems............................... 18

Capillary Tube Systems........................................... 17

Reversing Valve Operation ...................................... 17

Electrical Circuit And Coil ........................................ 18

Checking Reversing Valve....................................... 18

Touch Test In Heating/Cooling Cycle....................... 18

Procedure For Changing Reversing Valve .............. 18

Compressor Checks................................................ 19

Locked Rotor Voltage (L.R.V.) Test ......................... 19

Single Phase Connections ...................................... 19

Determine L.R.V. ..................................................... 19

Amperage (L.R.A.) Test ........................................... 19

Single Phase Running And L.R.A. Test ................... 19

External Overload.................................................... 19

Checking The External Overload............................. 19

Single Phase Resistance Test ................................. 20

Compressor Replacement....................................... 20

Capacitors ............................................................... 21

Capacitor Check ..................................................... 21

Capacitor Connections ............................................ 21

System Switch Continuity Check............................ 22

Thermostat Continuity Check .................................. 22

Fan Cycle Switch Continuity Check ........................ 23

Fan Speed Switch Continuity Check ....................... 23

Emergency Heat Switch Continuity Check.............. 24

Routine Maintenance .............................................. 25

Troubleshooting Chart — Cooling .......................... 26

Troubleshooting Chart — Heating.......................... 27

Electrical Troubleshooting Chart ............................. 28

Wiring Diagrams................................................. 29-34

2

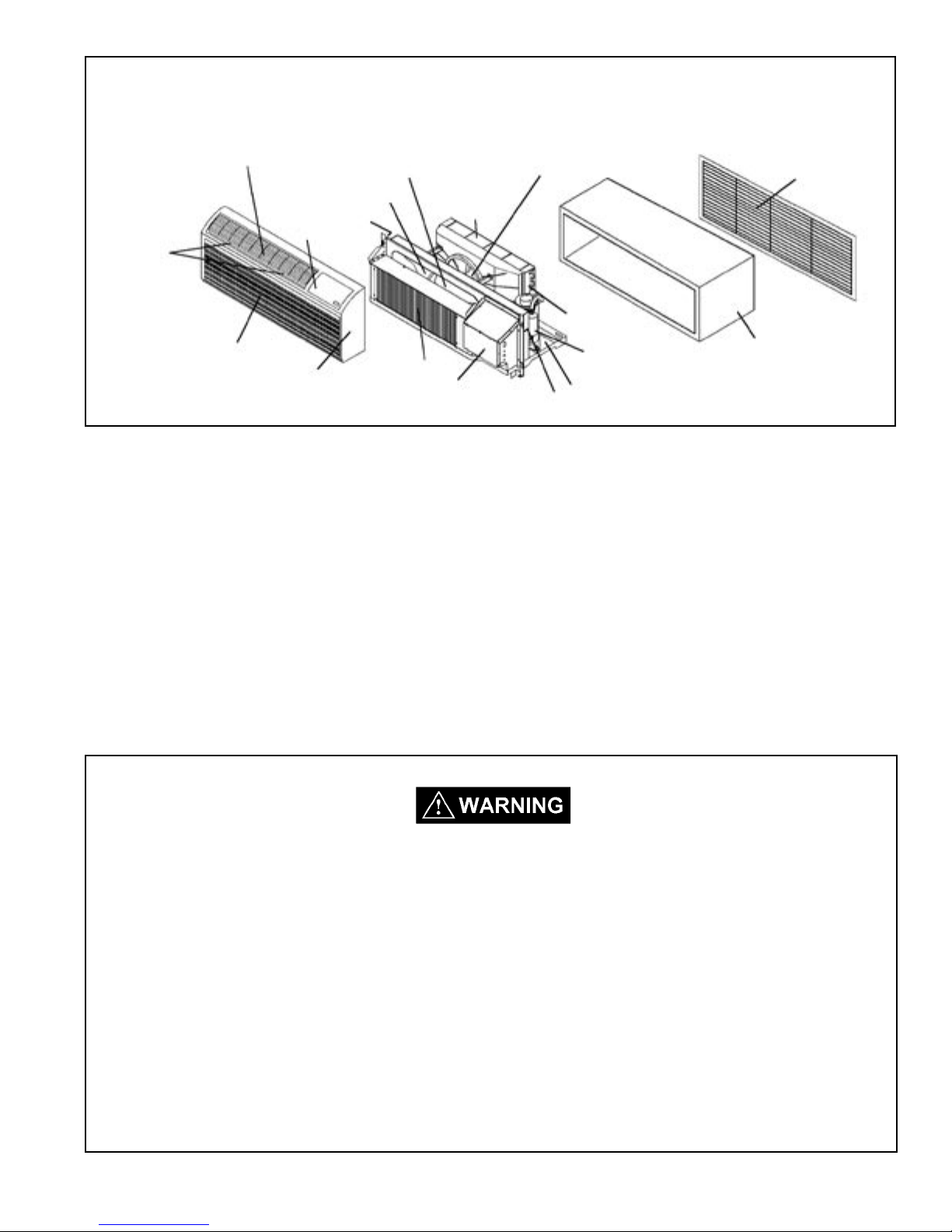

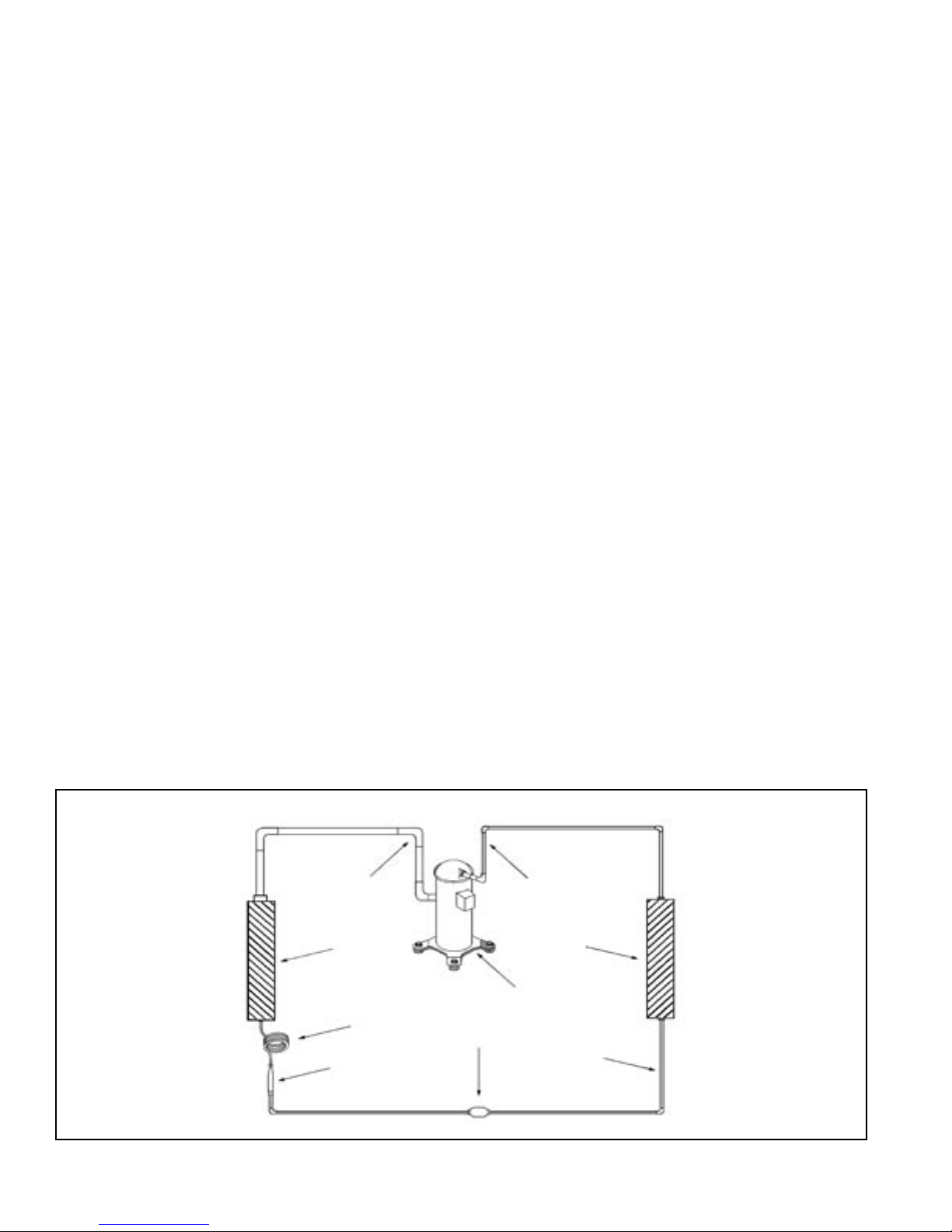

Typical Unit Components

Discharge Air Grille

Filters

Return Air Grille

Blower Wheel

Indoor Blower Housing

Gasket

Control Door

Evaporator Coil

Front Cover

Condenser

Control Panel

Condenser Fan Blade

Shroud

Gasket

Condenser

Coil

Compressor

Basepan

Outdoor Grille

Wall Sleeve

INTRODUCTION

This service manual is designed to be used in conjunction with the installation manuals provided with each air

conditioning system component.

This service manual was written to assist the professional HVAC service technician to quickly and accurately

diagnose and repair any malfunctions of this product.

This manual, therefore, will deal with all subjects in a general nature. (i.e. All text will pertain to all models).

IMPORTANT: It will be necessary for you to accurately identify the unit you are

servicing, so you can be certain of a proper diagnosis and repair. (See

Unit Identication.)

The information contained in this manual is intended for use by a qualied service technician

who is familiar with the safety procedures required in installation and repair, and who is equipped

with the proper tools and test instruments.

Installation or repairs made by unqualied persons can result in hazards subjecting the

unqualied person making such repairs to the risk of injury or electrical shock which can be

serious or even fatal not only to them, but also to persons being served by the equipment.

If you install or perform service on equipment, you must assume responsibility for any bodily

injury or property damage which may result to you or others. Friedrich Air Conditioning

Company will not be responsible for any injury or property damage arising from improper

installation, service, and/or service procedures.

3

5

UNIT IDENTIFICATION

Model Number Code

P H 07 K 3 S B 1

Series

P = P series

System

X= Accessory

E= Cooling with or

without electric heat

H = Heat Pump with

Auxiliary Heat

Nominal Cooling Capacity

07 = 7,000 - 7,100 BTUh

09 = 9,000 - 9,100 BTUh

12 = 11,500 - 11,700 BTUh

15 = 14,100 - 14,200 BTUh

Engineering Digit

Design Series

Options

S = Standard

R = Remote Thermostat

C = Seacoast Protection

X = Seacoast Remote

Nominal Heater Size

(@ 230V or 265V)

0 = No Heater

2 = 2.5 KW

3 = 3.4 KW

5 = 5.0 KW

Voltage

K = 230/208V - 1Ph. - 60 Hz.

R = 265V - 1Ph. - 60 Hz.

PTAC Serial Number Identication Guide

Serial Number

Decade Manufactured

L=0 C=3 F=6 J=9

A=1 D=4 G=7

B=2 E=5 H=8

Year Manufactured

A=1 D=4 G=7 K=0

B=2 E=5 H=8

C=3 F=6 J=9

Month Manufactured

A=Jan D=Apr G=Jul K=Oct

B=Feb E=May H=Aug L=Nov

C=Mar F=Jun J=Sep M=Dec

4

L B L P 00000

Production Run Number

PRODUCT LINE

R=RAC

P=PTAC

E=EAC

V=VPAK

H=Split

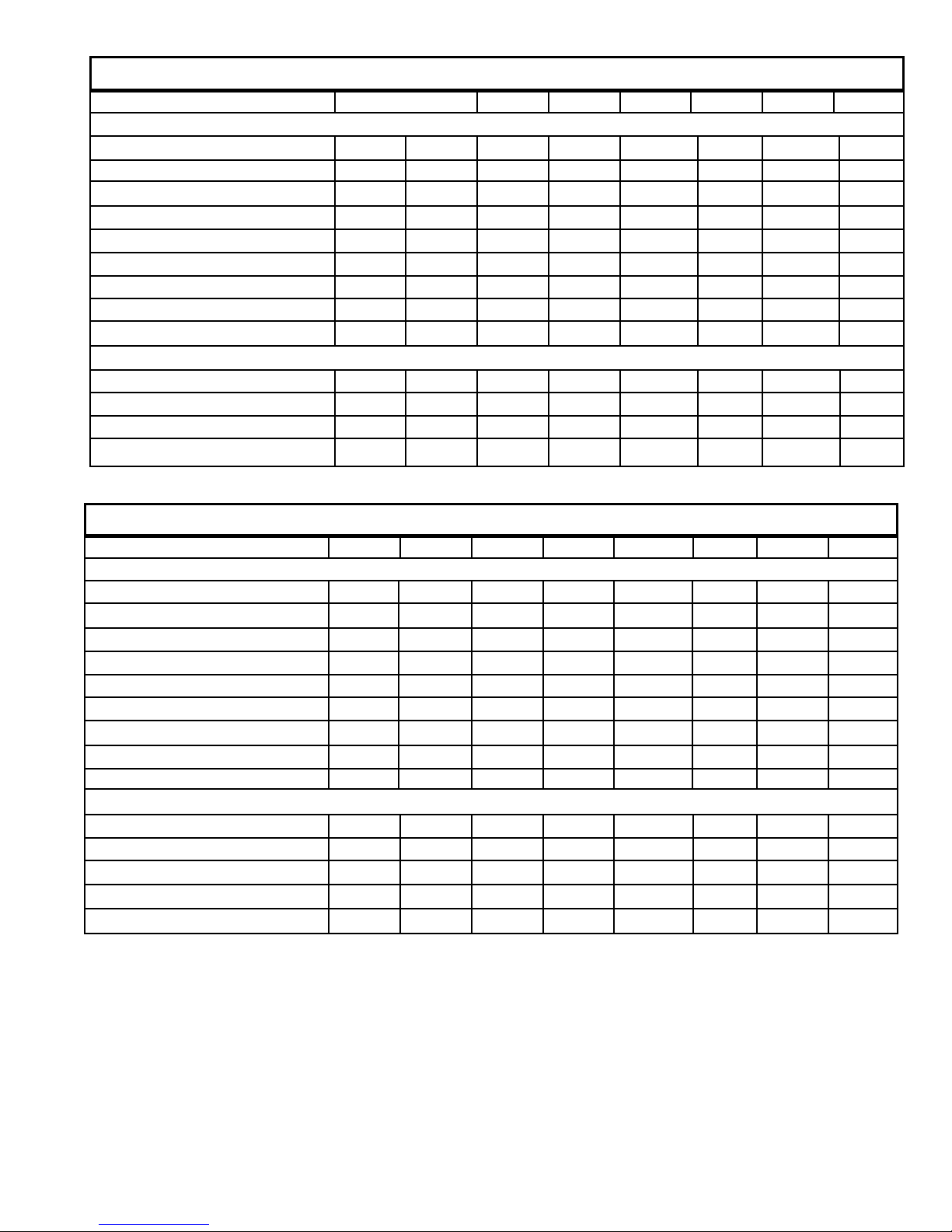

GENERAL INFORMATION – PE SERIES

Model PE07K PE07R PE09K PE09R PE12K PE12R PE15K PE15R

POWER

VOLTAGE (1 PHASE, 60 Hz) 230/208 265 230/208 265 230/208 265 230/208 265

VOLT RANGE 253-198 292-239 253-198 292-239 253-198 292-239 253-198 292-239

POWER (WATTS) 615/598 615 800/783 800 1091/1073 1091 1579/1578 1579

CURRENT (AMPS) 3 3 3.9 3.9 5.1 5.1 6.6 6.6

POWER FACTOR 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.9

AMPS L.R. 18 18 22.2 22.2 26.3 26.3 38 38

AMPS F.L. 3 3 3.9 3.9 5.1 5.1 6.8 6.8

HORSEPOWER 1/15. 1/15. 1/12. 1/12. 1/10. 1/10. 1/10. 1/10.

R-22 CHARGE (OZ) 27 27 30 30 28 28 28 28

PERFORMANCE

COOLING BTUh 7500/7300 7500 9200/9000 9200 12000/11800 12000 15000/14800 15000

INDOOR CFM 250 250 300 300 325 325 350 350

SENSIBLE HEAT RATIO 0.79 0.79 0.76 0.76 0.76 0.76 0.75 0.75

VENT CFM 60 60 60 60 70 70 70 70

GENERAL INFORMATION – PH SERIES

Model PH07K PH07R PH09K PH09R PH12K PH12R PH15K PH15R

POWER

VOLTAGE (1 PHASE, 60 Hz) 230/208 265 230/208 265 230/208 265 230/208 265

VOLT RANGE 253-198 292-239 253-198 292-239 253-198 292-239 253-198 292-239

POWER (WATTS) 590/574 590 791/774 791 1121/1023 1121 1581/1559 1559

CURRENT (AMPS) 3 3 3.9 3.9 5.1 5.1 6.6 6.6

POWER FACTOR 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.9

AMPS L.R. 18 18 22.2 22.2 26.3 26.3 38 38

AMPS F.L. 3 3 3.9 3.9 5.1 5.1 6.8 6.8

HORSEPOWER 1/15. 1/15. 1/12. 1/12. 1/10. 1/10. 1/10. 1/10.

R-22 CHARGE (OZ) 27 27 32 32 34.5 34.5 33 33

PERFORMANCE

COOLING BTUh 7200/7000 7000 9100/8900 9100 12000/11800 12000 14700/14500 14700

REVERSE HEATING BTUh 6400/6200 6400 8100/7900 8100 10800/10600 10800 13500/13300 13500

INDOOR CFM 250 250 300 300 325 325 350 350

SENSIBLE HEAT RATIO 0.79 0.79 0.76 0.76 0.76 0.76 0.75 0.75

VENT CFM 60 60 60 60 70 70 70 70

5

7

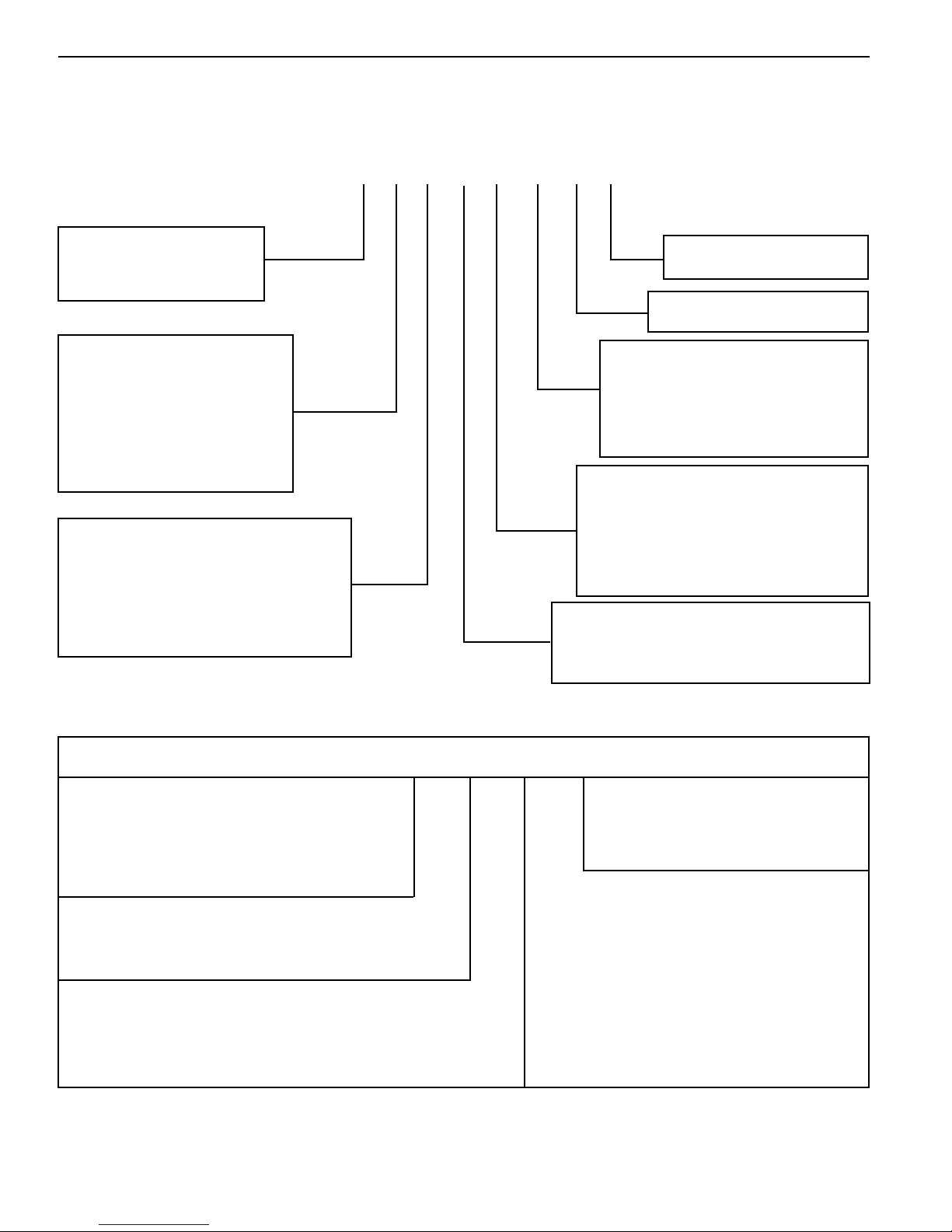

Sequence of Operation

A good understanding of the basic operation of the refrigeration

system is essential for the service technician. Without this

understanding, accurate troubleshooting of refrigeration system

problems will be more difcult and time consuming, if not (in some

cases) entirely impossible. The refrigeration system uses four

basic principles (laws) in its operation they are as follows:

1. "Heat always ows from a warmer body to a cooler body."

2. "Heat must be added to or removed from a substance before

a change in state can occur"

3. "Flow is always from a higher pressure area to a lower

pressure area."

4. "The temperature at which a liquid or gas changes state is

dependent upon the pressure."

The refrigeration cycle begins at the compressor. Starting the

compressor creates a low pressure in the suction line which draws

refrigerant gas (vapor) into the compressor. The compressor then

"compresses" this refrigerant, raising its pressure and its (heat

intensity) temperature.

The refrigerant leaves the compressor through the discharge Line

as a hot High pressure gas (vapor). The refrigerant enters the

condenser coil where it gives up some of its heat. The condenser

fan moving air across the coil's nned surface facilitates the transfer

of heat from the refrigerant to the relatively cooler outdoor air.

When a sufcient quantity of heat has been removed from the

refrigerant gas (vapor), the refrigerant will "condense" (i.e. change

to a liquid). Once the refrigerant has been condensed (changed)

to a liquid it is cooled even further by the air that continues to ow

across the condenser coil.

The PTAC design determines at exactly what point (in the

condenser) the change of state (i.e. gas to a liquid) takes place.

In all cases, however, the refrigerant must be totally condensed

(changed) to a Liquid before leaving the condenser coil.

The refrigerant leaves the condenser Coil through the liquid line

as a warm high pressure liquid. It next will pass through the

refrigerant drier (if so equipped). It is the function of the drier to

trap any moisture present in the system, contaminants, and large

particulate matter.

The liquid refrigerant next enters the metering device. The

metering device is a capillary tube. The purpose of the metering

device is to "meter" (i.e. control or measure) the quantity of

refrigerant entering the evaporator coil.

In the case of the capillary tube this is accomplished (by design)

through size (and length) of device, and the pressure difference

present across the device.

Since the evaporator coil is under a lower pressure (due to the

suction created by the compressor) than the liquid line, the liquid

refrigerant leaves the metering device entering the evaporator coil.

As it enters the evaporator coil, the larger area and lower pressure

allows the refrigerant to expand and lower its temperature (heat

intensity). This expansion is often referred to as "boiling". Since

the unit's blower is moving indoor air across the nned surface

of the evaporator coil, the expanding refrigerant absorbs some of

that heat. This results in a lowering of the indoor air temperature,

hence the "cooling" effect.

The expansion and absorbing of heat cause the liquid refrigerant

to evaporate (i.e. change to a gas). Once the refrigerant has been

evaporated (changed to a gas), it is heated even further by the air

that continues to ow across the evaporator coil.

The particular system design determines at exactly what point (in

the evaporator) the change of state (i.e. liquid to a gas) takes place.

In all cases, however, the refrigerant must be totally evaporated

(changed) to a gas before leaving the evaporator coil.

The low pressure (suction) created by the compressor causes

the refrigerant to leave the evaporator through the suction line

as a cool low pressure vapor. The refrigerant then returns to the

compressor, where the cycle is repeated.

Suction

Line

6

Evaporator

Coil

Metering

Device

Refrigerant

Strainer

Discharge

Line

Compressor

Refrigerant Drier

Condenser

Coil

Liquid

Line

Electrical Rating Tables

All 230/208 volt units are equipped with power cords.

NOTE: Use Copper Conductors ONLY

Wire sizes are per NEC, check local

codes for overseas applications

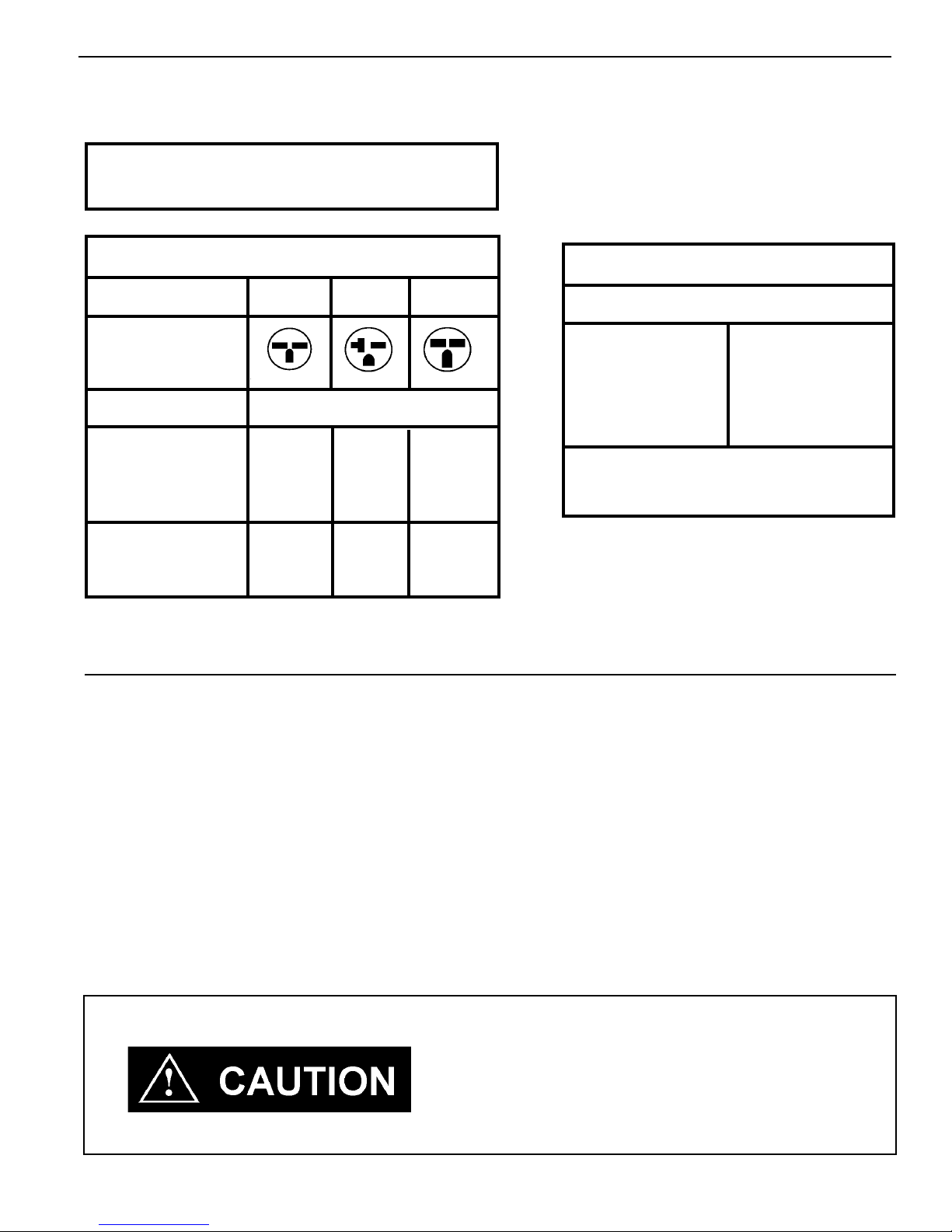

Table 1 250 V Receptacles and Fuse Types

AMPS 15 20 * 30

RECEPTACLE

MANUFACTURER PART NUMBERS

Hubbell 5661 5461 9330

P & S 5661 5871 5930

GE GE 4069-1 GE4182-1 GE4139-3

Arrow-Hart 5661 5861 5700

TIME-DELAY TYPE

FUSE 15 20 30

(or HACR circuit breaker)

HACR — Heating, Air conditioning, Refrigeration

* May be used for 15 Amp applications if fused for 15 Amp

NOTE: 265 volt units are permanently connected.

Table 2

Recommended branch circuit wire sizes

Nameplate

AWG Wire size**

maximum circuit

breaker size

15 14

20 12

30 10

AWG — American Wire Gauge

* Single circuit from main box

** Based on copper wire, single insulated

conductor at 60°C

Wire Size Use ONLY wiring size recommended for single outlet branch circuit.

Fuse/Circuit Use ONLY type and size fuse or HACR circuit breaker indicated on unit's rating plate. Proper

Breaker current protection to the unit is the responsibility of the owner.

NOTE: A time delay fuse is provided with 265V units.

Grounding Unit MUST be grounded from branch circuit through service cord to unit, or through separate ground

wire provided on permanently connected units. Be sure that branch circuit or general purpose outlet

is grounded.

Receptacle The eld supplied outlet must match plug on service cord and be within reach of service cord.

Refer to Table 1 for proper receptacle and fuse type. Do NOT alter the service cord or plug. Do

NOT use an extension cord.

Wire Sizing Use recommended wire size given in Table 2 and install a single branch circuit. All wiring must

comply with local and national codes. NOTE: Use copper conductors only.

Electric shock hazard.

Turn off electric power before service or installation.

All electrical connections and wiring MUST be installed by a qualied electrician

and conform to the National Electrical Code and all local codes which have

jurisdiction.

Failure to do so can result in property damage, personal injury and/or death.

7

9

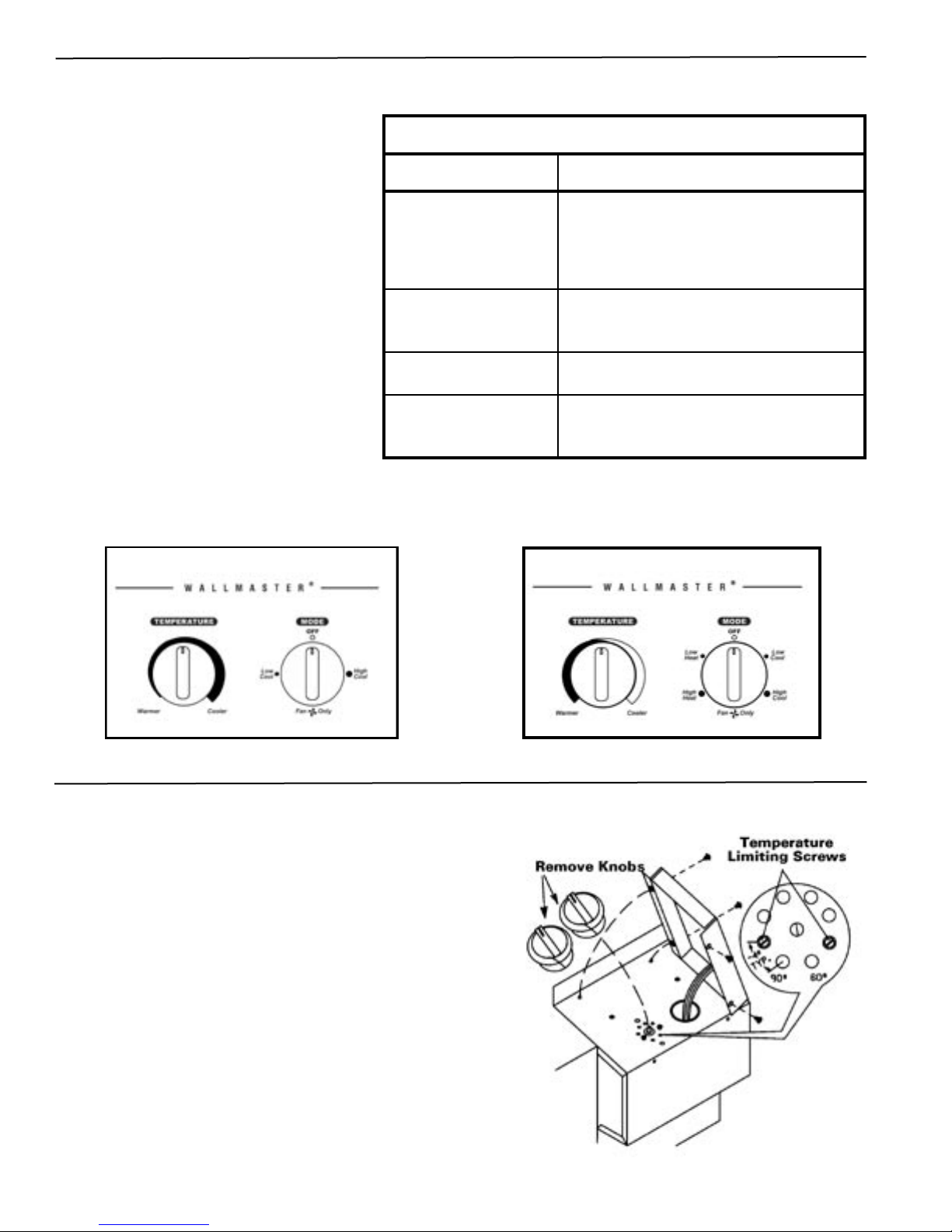

Standard Unit Operation

Rotary Switch Operation

Rota t e the te m p e r a t u r e dial i n small

increments in the warmer or cooler direction.

Moving the dial more than 1/4" at a time may

overcompensate and result in an extreme hot

or cold situation.

Standard Unit Control Panel

Control

Temperature

Low and High Cool

Low and High Heat

Fan Only

Operation

The full-range thermostat maintains room

temperature at the desired setting in both

the heating and cooling modes. Turn the

dial counterclockwise for warmer and

clockwise for a cooler temperature.

Operates the unit on cooling. Cooling

will not begin if the room temperature is

below 60°F.

Operates the unit on heating. Some

models do not provide this selection.

Circulates air within the room at high

fan speed only. No heating or cooling

functions are active.

COOLING ONLY MODEL

Temperature Limiting Thermostat

1. Set the thermostat knob to center of dial.

2. Remove the four screws holding the control panel. Pull up

on the thermostat knob and remove it.

3. Locate the two temperature limiting screws. These screws

are factory installed for a maximum temperature range of 60°90°F. Each hole in the dial plate represents approximately

a 4° change from the adjacent hole.

4. To adjust the temperature range, move the temperature

limiting screws to the desired location.

5. Replace the knob when the desired range has been set.

6. Replace the control panel.

EXAMPLE: To set a maximum temperature range of

approximately 64° to 86°F, move the screws to

the locations shown in the diagram at right.

8

HEAT/COOL MODEL

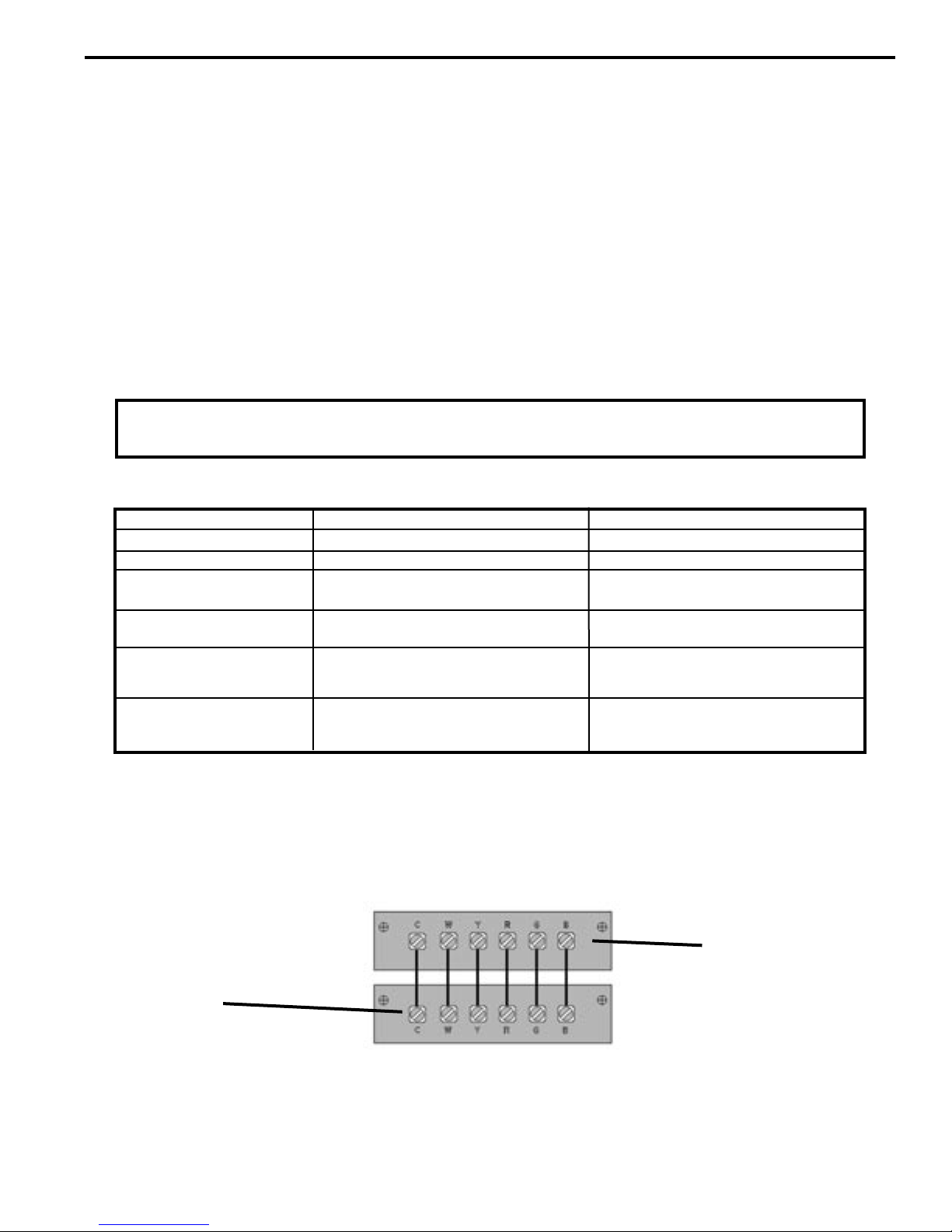

Remote Thermostat Unit Installation

1. Remote Thermostat Selection & Wiring Guidelines for Packaged

Terminal Air Conditioners

Follow the instructions and recommendations of the thermostat manufacturer for installation and wiring. Do not

use a conventional heat pump thermostat with emergency electric heat selection for our heat pump units. Our

units make an automatic decision about turning on electric heat if the heating demand cannot be met by the heat

pump due to low outdoor temperatures.

Manual Changeover Thermostat

For Heat Pump equipped units: A single stage, heat/cool thermostat with a terminal for a reversing valve operation

is required. Terminal "B" should be continuously energized in the heat mode and terminal "G" should be energized

whenever there is a call for heating or cooling. Typically, a heat/cool thermostat designed for use with electric heat

systems will meet the above requirements.

NOTE: This unit is designed for use with a single stage thermostat only. Improper application of the

thermostat may result in property damage, personal injury or death.

Honeywell Thermostat Terminal Designation

TERMINAL LETTER

Y

W

(Heat Pump units Only)

For Non-Heat Pump equipped units: A single stage cooling and heating thermostat is required. Terminal "G"

should be energized whenever a call for heating or cooling is made. Typically a heat/cool thermostat designed

for use with electric heat systems will meet this requirement.

G

C (common)

R

B

OPERATION

Cooling

Heating

Common Terminal

24 V

to the thermostat

Fan

Reversing Valve

CONTACT MADE

During call for cooling.

During call for heating.

Continuous if the slider is in the "Fan"

position, otherwise, intermittent.

For thermostats requiring a common

terminal

Directly from the transformer

Made continuously during call for

heating.

Simplified Wiring Example

Unit Terminal Board

* A-Sufx models do not have a "C" terminal

Terminal "C"

is not used on RT1

thermostat

Terminal "B" is

used for heat pump

models only.

NOTE: It is the installer's responsibility to ensure that all control wiring connections are made in accordance with

the installation instructions. Improper connection of the thermostat control wiring and/or tampering with the unit's

internal wiring can void the equipment warranty and may result in property damage, personal injury or death. Other

manufacturer's PTACs and even older Friedrich models may have different control wire connections. Questions

concerning proper connections to the unit should be directed to the factory.

Thermostat Terminals

9

11

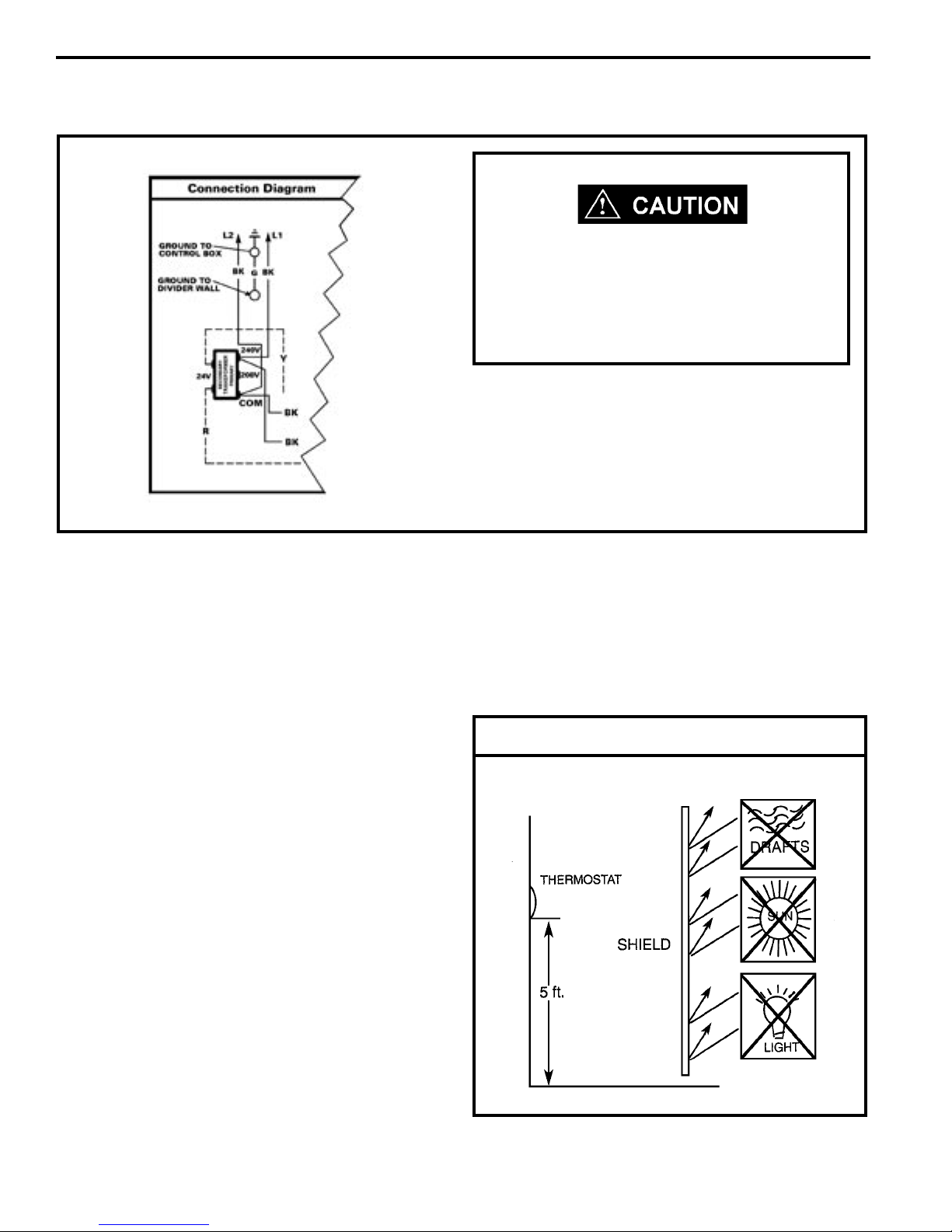

Remote Thermostat 208V Operation

208V 60HZ

If the supply voltage is 208V, the low voltage

transformer MUST be wired for 208V operation.

Failure to do so will result in lower control

voltages to the unit and can damage low voltage

components.

The simplied connection diagram at left shows the

factory congured wiring set for 240V operation. If you

are going to use 208V exclusively, switch the two (2)

black wires on the 240V post of the primary side of the

transformer to the 208V post. This will ensure correct

secondary (low) voltages for the unit. This is only required

on remote thermostat units.

Remote Thermostat Unit Operation

These units are controlled by the use of a remote

thermostat that will cycle the unit to maintain desired

room temperature. See thermostat operating instruction

sheet for details.

The fan speed switch controls high and low speed

fan operation. It is located on the control panel and is

independent of the thermostat.

Room Thermostats

Room thermostats are available from several different

manufacturers in a wide variety of styles. They range

from the very simple Bimetallic type to the complex

electronic set-back type. In all cases, no matter how

simple or complex, they are simply a switch (or series of

switches) designed to turn equipment (or components)

"ON" or "OFF" at the desired conditions.

An improperly operating, or poorly loca ted room

thermostat can be the source of perceived equipment

problems. A careful check of the thermostat and wiring

must be made then to insure that it is not the source of

problems.

the oor in an area of average temperature, with good air

circulation. Close proximity to the return air grille is the

best choice.

Mercury bulb type thermostats MUST be level to control

temperature accurately to the desired set-point. Electronic

digital type thermostats SHOULD be level for aesthetics.

Thermostat Location

Location

The thermostat should not be mounted where it may be

affected by drafts, discharge air from registers (hot or

cold), or heat radiated from the sun or appliances.

The thermostat should be located about 5 Ft. above

10

Measuring Current Draw

Heat Anticipators

Heat anticipators are small resistance heaters (wired

in SERIES with the "W" circuit) and built into most

electromechanical thermostats. Their purpose is to prevent

wide swings in room temperature during system operation

in the HEATING mode. Since they are wired in series,

the "W" circuit will open if one burns out preventing heat

operation.

The heat anticipator provides a small amount of heat to

the thermostat causing it to cycle (turn off) the heat source

just prior to reaching the set point of the thermostat. This

prevents exceeding the set point.

If a low range ammeter is not available, a "Clamp-on" type

ammeter may be used as follows:

1. Wrap EXACTLY ten (10) turns of wire around the jaws

of a clamp-on type ammeter.

2. Connect one end of the wire to the "W" terminal of

the thermostat sub-base, and the other to the "R"

terminal.

3. Turn power on, and wait approximately 1 minute, then

read meter.

4. Divide meter reading by 10 to obtain correct anticipator

setting.

Electronic thermostats do not use a resistance type

anticipator. These thermostats use a microprocessor

(computer) that determines a cycle rate based on a program

loaded into it at the factory.

Calculating The Approximate CFM

The approximate CFM actually being delivered can be

calculated by using the following formula:

KILOWATTS x 3413

Temp. Rise x 1.08

In order to accomplish this, the heat output from the

anticipator must be the same regardless of the current

owing through it. Consequently, some thermostats have

an adjustment to compensate for varying current draw in

the thermostat circuits.

The proper setting of heat anticipators then is important to

insure proper temperature control and customer satisfaction.

A heat anticipator that is set too low will cause the heat

source to cycle prematurely possibly never reaching set

point. A heat anticipator that is set too high will cause the

heat source to cycle too late over shooting the set point.

The best method to obtain the required setting for the

heat anticipator, is to measure the actual current draw in

the control circuit ("W") using a low range (0-2.0 Amps)

ammeter. After measuring the current draw, simply set the

heat anticipator to match that value.

DO NOT simply use the Kilowatt Rating of the heater (i.e.

2.5, 3.4, 5.0) as this will result in a less-than-correct airow

calculation. Kilowatts may be calculated by multiplying the

measured voltage to the unit (heater) times the measured

current draw of all heaters (ONLY) in operation to obtain

watts. Kilowatts are then obtained by dividing by 1000.

EXAMPLE: Measured voltage to unit (heaters) is 230 volts.

Measured Current Draw of strip heaters is 11.0 amps.

230 x 11.0 = 2530

2530/1000 = 2.53 Kilowatts

2.53 x 3413 = 8635

Supply Air 95°F

Return Air 75°F

Temperature Rise 20°

20 x 1.08 = 21.6

8635

21.6

= 400 CFM

= CFM

11

13

Fan Cycle Switch

NOTE: It is recommended that this switch be set in the continuous position for maximum comfort and

temperature control.

The fan cycle switch is located behind the decorative front

cover below the control box. It is designed to operate the fan

either continuously or intermittently with the compressor or

heating elements. When the switch is in the CONTINUOUS

position, the fan will run continuously when the unit is turned

on. With the fan cycle switch in the CYCLE position, the

fan will run only when the compressor or heating elements

cycle on.

Hot Start Sensor

(Heat Pump Models Only)

Under cold room conditions, the Hot Start Sensor brings

on the heater strips with a call for heat. This is to distribute warm air at the beginning of the heat cycle. Once

the return air has warmed sufciently, the heat pump

mode will begin.

Refrigerant Charging

NOTE: Because The Ptac System Is A Sealed System,

Service Process Tubes Will Have To Be Installed.

First Install A Line Tap And Remove Refrigerant From

System. Make Necessary Sealed System Repairs And

Vacuum System. Crimp Process Tube Line And Solder

End Shut. Do Not Leave A Service Valve In The Sealed

System.

Proper refrigerant charge is essential to proper unit

operation. Operating a unit with an improper refrigerant

charge will result in reduced performance (capacity) and/or

efciency. Accordingly, the use of proper charging methods

during servicing will insure that the unit is functioning as

designed and that its compressor will not be damaged.

Too much refrigerant (overcharge) in the system is just as

bad (if not worse) than not enough refrigerant (undercharge).

They both can be the source of certain compressor failures if

they remain uncorrected for any period of time. Quite often,

other problems (such as low air ow across evaporator,

etc.) are misdiagnosed as refrigerant charge problems. The

refrigerant circuit diagnosis chart will assist you in properly

diagnosing these systems.

Not enough refrigerant (undercharge) on the other hand,

will cause the temperature of the suction gas to increase to

the point where it does not provide sufcient cooling for the

compressor motor. When this occurs, the motor winding

temperature will increase causing the motor to overheat

and possibly cycle open the compressor overload protector.

Continued overheating of the motor windings and/or cycling

of the overload will eventually lead to compressor motor

or

overload failure.

Method Of Charging

The acceptable method for charging the PTAC system is

the Weighed in Charge Method. The weighed in charge

method is applicable to all units. It is the preferred method

to use, as it is the most accurate.

The weighed in method should always be used whenever

a charge is removed from a unit such as for a leak repair,

compressor replacement, or when there is no refrigerant

charge left in the unit. To charge by this method, requires

the following steps:

1. Install a piercing valve to remove refrigerant from the

sealed system. (Piercing valve must be removed from

the system before recharging.)

2. R e c o v e r Re f r i g e r a n t in accordance with EPA

regulations.

3. Install a process tube to sealed system.

4. Make necessary repairs to system.

An overcharged unit will at times return liquid refrigerant

(slugging) back to the suction side of the compressor

eventually causing a mechanical failu re within the

compressor. This mechanical failure can manifest itself

as valve failure, bearing failure, and/or other mechanical

failure. The specic type of failure will be inuenced by the

amount of liquid being returned, and the length of time the

slugging continues.

12

5. Evacuate system to 300 microns or less.

6. Weigh in refrigerant with the property quantity of R-22

refrigerant.

7. Start unit, and verify performance.

8. Crimp the process tube and solder the end shut.

Loading...

Loading...