Friedrich PE07K0SB, PE07K0XA, PE07K0XB, PE07K2CA, PE07K2CB Owner’s Manual

...

WallMaster®PTAC

PackagedTerminalAirConditioners& Heat Pumps

• Standard

• RemoteThermostat

• SeacoastProtected

Installation& OperationManual

920-087-02 (9-03)

920-087-02(9-03)

TableofContents

UnitComponents......................................................................................................................................................................................... 2

P-SeriesAnnouncement/ModelNumberCode............................................................................................................................................ 3

InstallationRecommendations.................................................................................................................................................................... 4

DrainKit Installation ................................................................................................................................................................................ 5-6

Wall SleeveInstallation............................................................................................................................................................................ 7-8

DeepWall Installation .................................................................................................................................................................................. 9

Standard GrilleInstallation ........................................................................................................................................................................ 10

InstallationChecklist................................................................................................................................................................................. 11

Electrical RatingTables.............................................................................................................................................................................. 11

ChassisInstallation............................................................................................................................................................................. 12-13

Standard UnitOperations.......................................................................................................................................................................... 14

TemperatureLimitingThermostat .............................................................................................................................................................. 14

HeatingControl(Heat Pumps& Emergency Heat)..................................................................................................................................... 15

FanCycleSwitch....................................................................................................................................................................................... 15

FreshAirVent Control................................................................................................................................................................................ 15

AirDischargeGrille.................................................................................................................................................................................... 16

Start-up Checklist...................................................................................................................................................................................... 16

AppendixA: RemoteThermostatWiring............................................................................................................................................... 17-18

AppendixB: ElectricalWiringfor 265 V Models........................................................................................................................................ 19

RoutineMaintenance................................................................................................................................................................................ 20

BasicTroubleshootingTechniques............................................................................................................................................................. 21

Accessories......................................................................................................................................................................................... 22-23

Warranty................................................................................................................................................................................................... 24

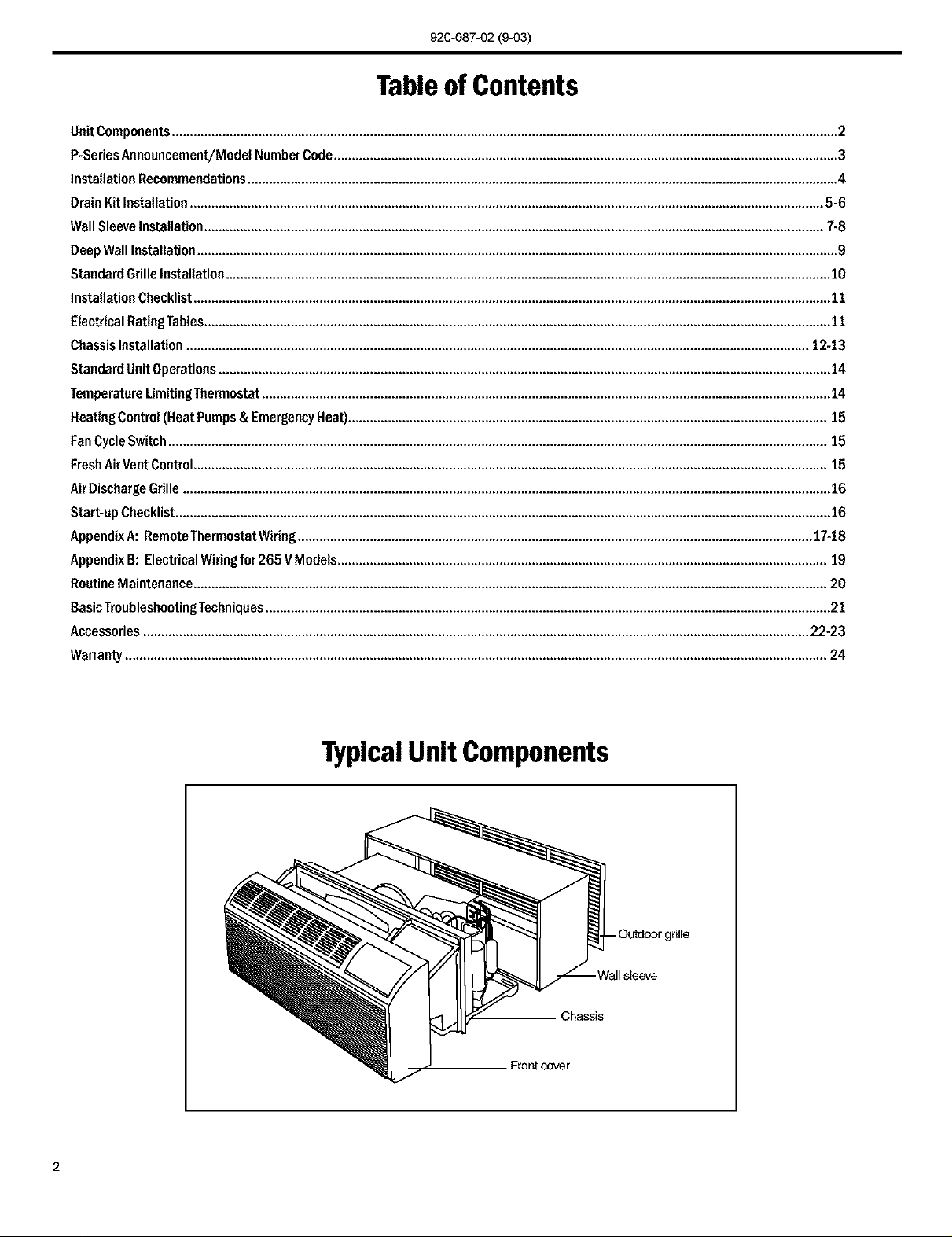

TypicalUnit Components

Chassis

tcover

2

920-087-02 (9-03)

Announcing the FriedrichP-Series PackagedTerminalAir Conditioner.

A new approach to reliability and efficiency. A totally redesigned Friedrich PTAC.

Thank you for your decision to purchase the newly designed Friedrich Packaged Terminal Air Conditioner

(PTAC). We are confident that you will find this unit a quiet and efficient example of Friedrich reliability.

This Installation and Operation Manual has been designed to insure maximum satisfaction in the performance

of your unit. For years of trouble-free service, please follow the installation instructions closely. We cannot

overemphasize the importance of proper installation. We have added new information to the basic instructions

to help you achieve success.

Remember, proper installation is not difficult but it is essential.

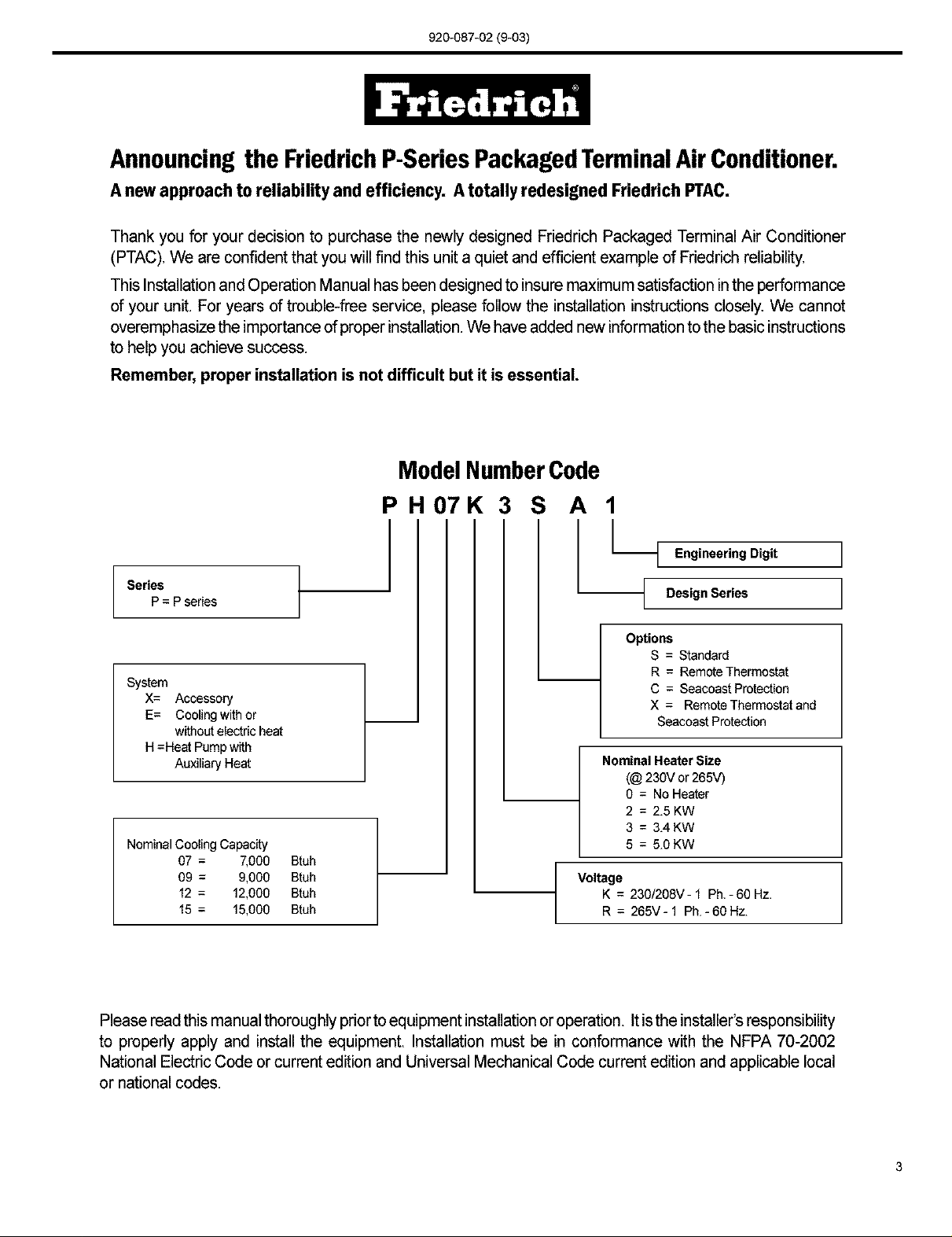

ModelNumberCode

Series

P= Pseries

System

X= Accessory

E= Coolingwith or

withoutelectric heat

H =Heat Pumpwith

Auxiliary Heat

NominalCoolingCapac_y

07 = _000 Btuh

09 = 9,000 Btuh

12 = 12,000 Btuh

15 = 15,000 Btuh

PH07K 3 S A 1

L

I Engineering Digit I

I Designsedes I

Options

S = Standard

R = RemoteThermostat

C = SeacoastProtection

X = RemoteThermostatand

SeacoastProtection

NominalHeaterSize

(@230V or 265V)

0 = NoHeater

2 = 2.5 KW

3 = 3.4 KW

5 = 5.0 KW

Voltage

K = 230/208V-1Ph.-60 Hz.

R = 265V-1Ph.-60 Hz.

Please read this manual thoroughly prior to equipment installation or operation. Itisthe installer's responsibility

to properly apply and install the equipment. Installation must be in conformance with the NFPA 70-2002

National Electric Code or current edition and Universal Mechanical Code current edition and applicable local

or national codes.

3

920-087-02 (9-03)

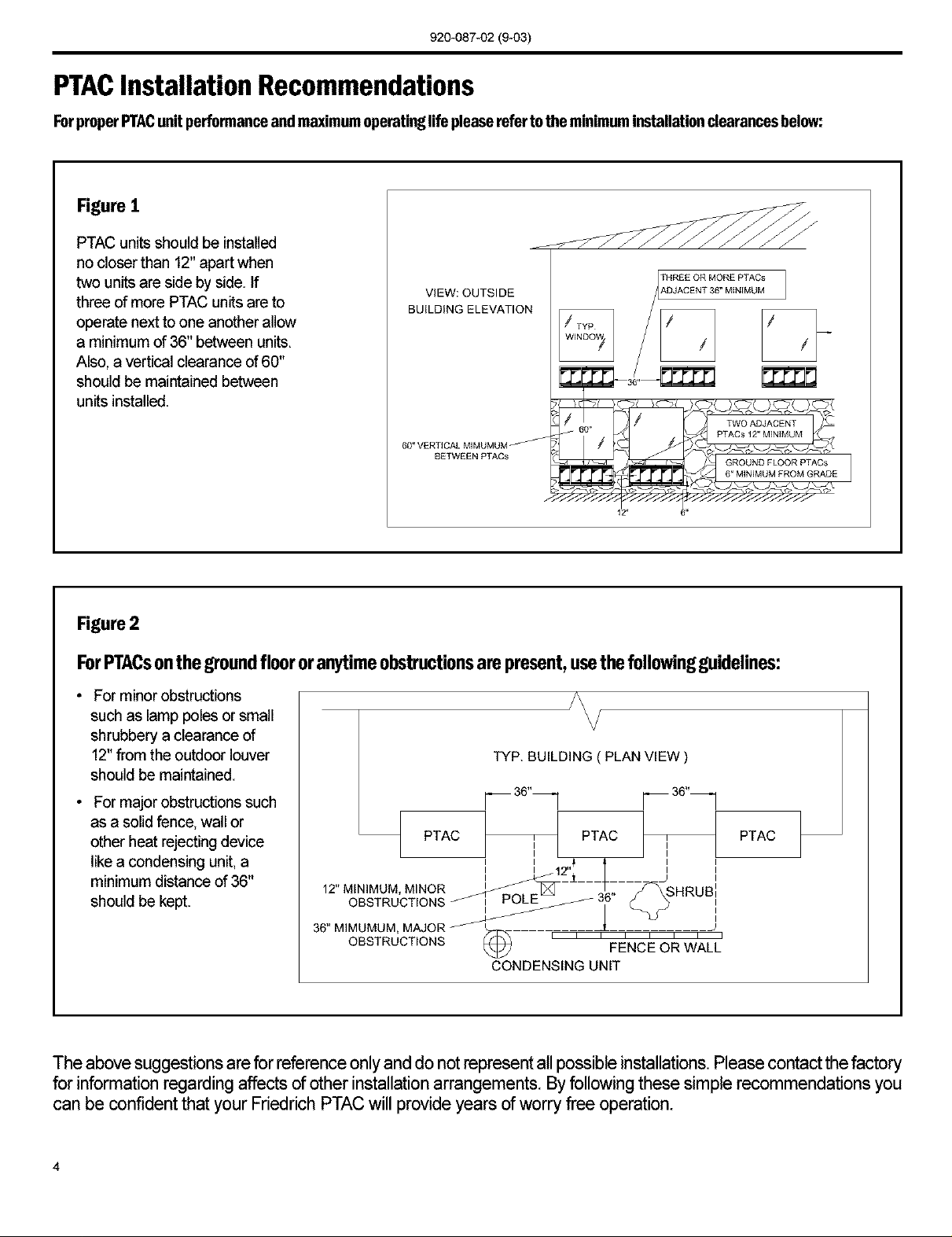

PTACInstallation Recommendations

ForproperPTACunitperformanceandmaximumoperatinglifepleaserefertothe minimuminstallationclearancesbelow:

Figure I

PTAC units should be installed

no closer than 12"apart when

two units are side by side. If

three of more PTAC units are to

operate next to one another allow

a minimum of 36" between units.

Also, a vertical clearance of 60"

should be maintained between

units installed.

VIEW: OUTSIDE

BUILDING ELEVATION

60" VERTICAL M]MUMUM

BETWEEN PTACs

THREE OR MORE PTACs

#,DJACENT 36" MINIMUM

GROUND FLOOR PTACs

6" MINIMUM FROM GRADE

Figure 2

ForPTACsonthegroundfloororanytimeobstructionsarepresent,usethefollowingguidelines:

• For minor obstructions

such as lamp poles or small

shrubbery a clearance of

12"from the outdoor louver

should be maintained.

• For major obstructions such

as a solid fence, wall or

other heat rejecting device

PTAC 7 PTAC r

like a condensing unit, a

minimum distance of 36"

should be kept.

12" MINIMUM, MINOR

OBSTRUCTIONS _ 36"

36" MIMUMUM, MAJOR _

OBSTRUCTIONS _) ' ' ' FENCE OR WALL'

The above suggestions are for reference only and do notrepresent all possible installations. Please contact the factory

for information regarding affects of other installation arrangements. By following these simple recommendations you

can be confident that your Friedrich PTAC will provide years of worry free operation.

TYP. BUILDING ( PLAN VIEW )

-- 36"_] [_ 36"--

I I

I I

I I

I I

CONDENSING UNIT

PTAC

4

920-087-02(9-03)

Installation Instructions PXDRIO DrainKit

NOTE: Determine whetherdrain willbe located within the wall,on the indoor side, orwill drain to the exteriorof the building. Follow

appropriate instructionsbelow depending on yourparticular type of installation.

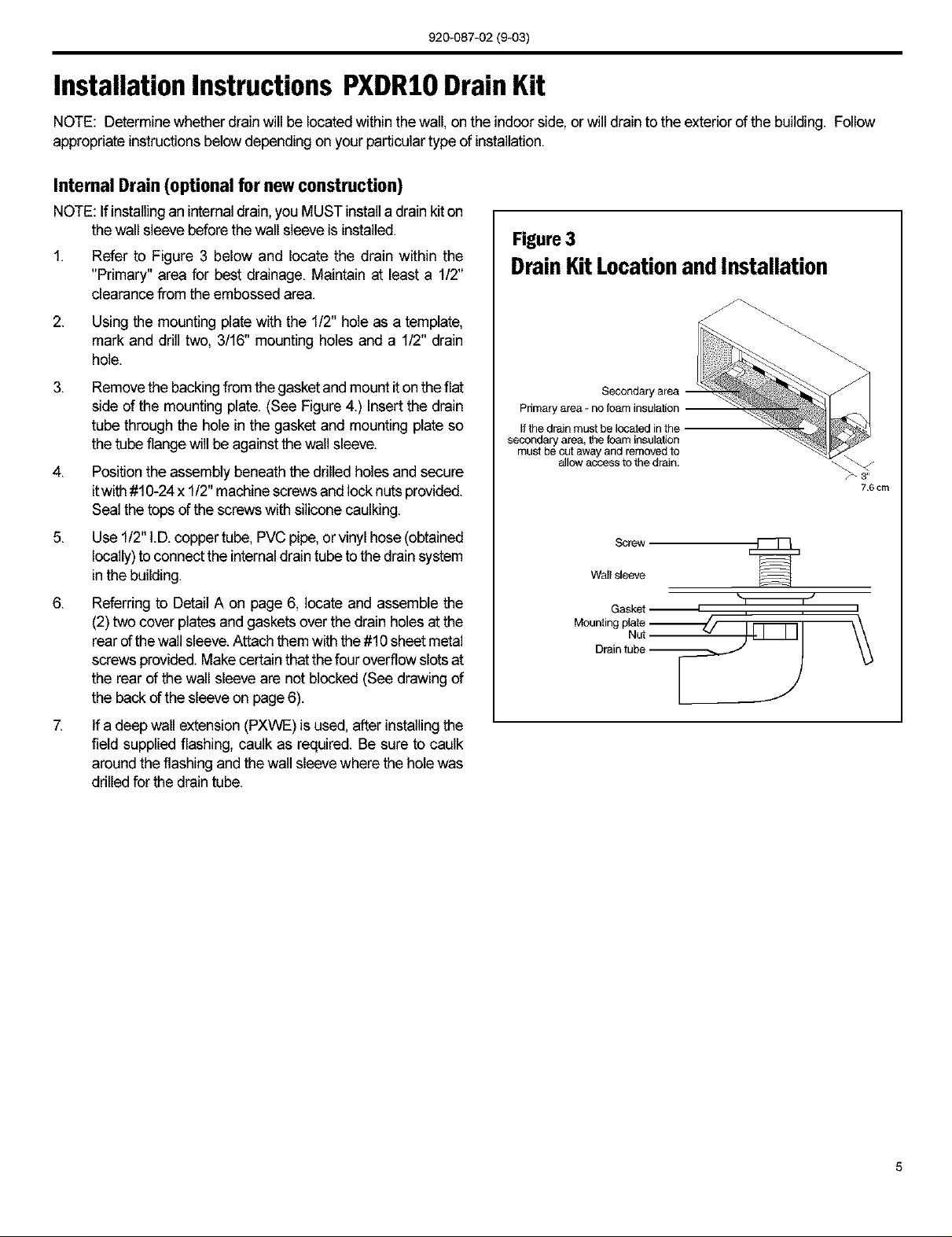

Internal Drain (optional for new construction)

NOTE: Ifinstalling an internaldrain,you MUST installa drainkit on

the wall sleeve before the wall sleeve is installed.

1,

Refer to Figure 3 below and locate the drain within the

"Primary" area for best drainage. Maintain at least a 1/2"

clearance from the embossed area.

2.

Using the mounting plate with the 1/2" hole as a template,

mark and drill two, 3/16" mounting holes and a 1/2" drain

hole.

,

Removethe backingfrom thegasket and mount iton the flat

side of the mounting plate. (See Figure 4.) Insert the drain

tube through the hole in the gasket and mounting plate so

the tube flange will beagainst the wall sleeve.

4. Position the assembly beneaththe drilled holes and secure

itwith #10-24 x 1/2" machine screws and locknuts provided.

Seal the tops of the screws with silicone caulking.

Figure 3

DrainKitLocationandInstallation

Secondary area

Primary area _ no foam insulation --

If the drain must be located in the

secondary area, the foam insulation

must be cut away and removed to

allow access to the drain,

76 cm

5. Use 1/2" I.D.copper tube, PVCpipe, or vinyl hose (obtained

locally) to connect the internaldrain tube to the drain system

in the building.

6. Referring to Detail A on page 6, locate and assemble the

(2) two cover plates and gaskets over the drain holes at the

rear of the wall sleeve.Attach them with the #10 sheet metal

screws provided. Makecertain that the four overflow slotsat

the rear of the wall sleeve are not blocked (See drawing of

the back of the sleeve on page 6).

7. If a deep wall extension (PXWE) is used, after installing the

field supplied flashing, caulk as required. Be sure to caulk

around the flashing and the wall sleevewhere the hole was

drilled for the drain tube.

Screw [_

Wail sleeve

Gasket t t

Mounting plateNut _ j _ I \\

i

)

5

920-087-02 (9-03)

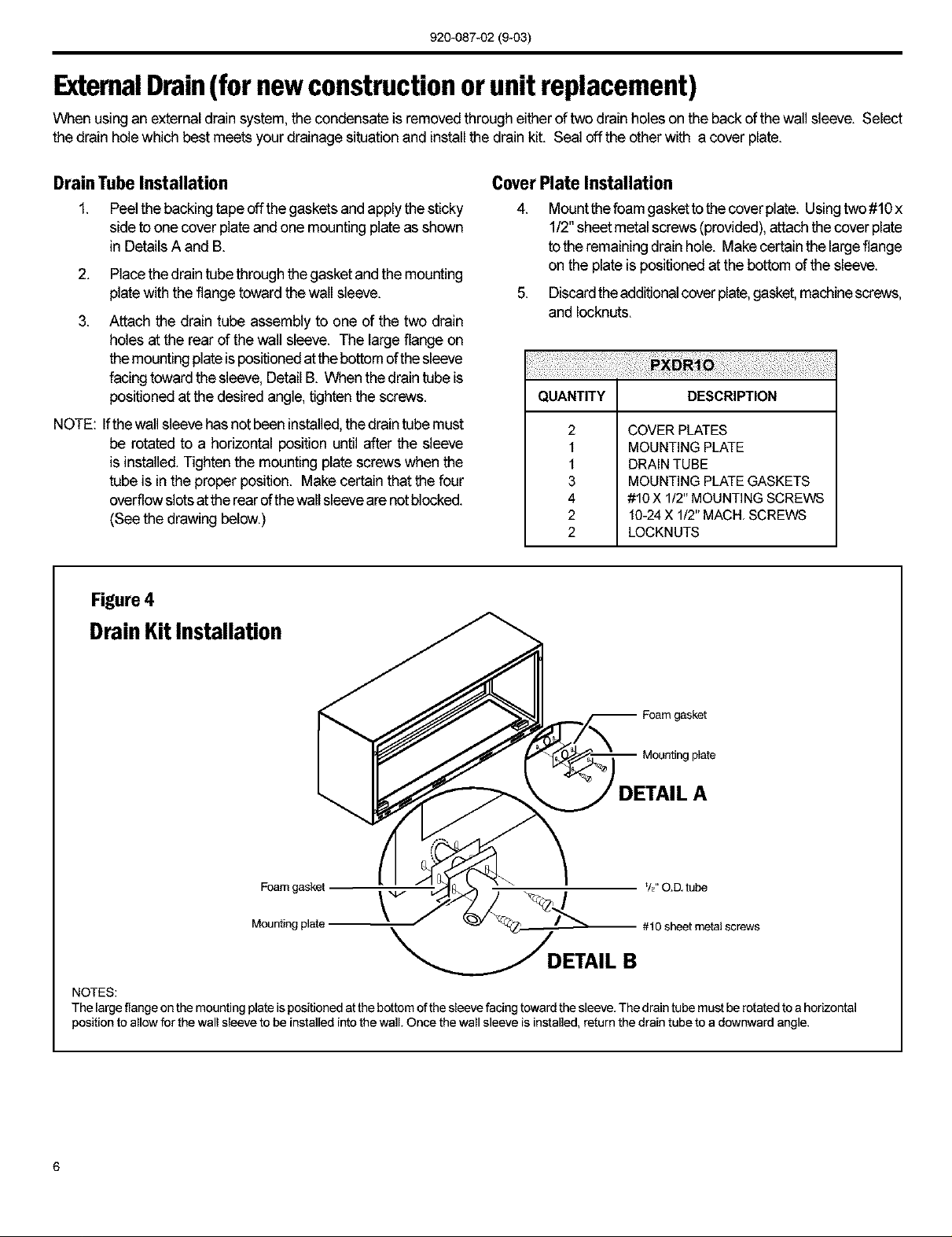

ExtemalDrain(for newconstructionorunit replacement)

When usingan external drain system, the condensate is removedthrough eitherof two drain holes on the back of thewall sleeve. Select

the drain hole which best meets your drainagesituation and install the drain kit. Seal offthe other with a cover plate.

Drain Tube Installation

1. Peelthe backing tape off thegaskets and apply thesticky

side toone cover plateand one mounting plateas shown

in Details A and B,

2. Placethedrain tube throughthe gasketand the mounting

plate with the flange toward the wall sleeve.

3. Attach the drain tube assembly to one of the two drain

holes at the rear of the wall sleeve. The large flange on

themountingplateispositionedatthe bottomofthe sleeve

facing toward thesleeve, Detail B. When thedrain tube is

positioned at the desired angle,tighten the screws.

NOTE: Ifthe wallsleeve hasnot been installed,the draintube must

be rotated to a horizontal position until after the sleeve

is installed. Tighten the mounting plate screws when the

tube is in the proper position. Make certain that the four

overflow slotsat the rearof the wallsleeveare notblocked.

(See the drawing below.)

Figure 4

DrainKitInstallation

Cover Plate Installation

4. Mountthefoamgaskettothecoverplate. Usingtwo#10x

1/2"sheet metal screws (provided),attachthe cover plate

tothe remaining drainhole. Make certain the largeflange

on the plate is positioned at the bottom of the sleeve.

5. Discardtheadditionalcoverplate,gasket,machinescrews,

and Iocknuts.

QUANTITY DESCRIPTION

2

1

1

3

4

2

2

COVER PLATES

MOUNTING PLATE

DRAIN TUBE

MOUNTING PLATE GASKETS

#10 X 1/2" MOUNTING SCREWS

10-24 X 1/2" MACH, SCREWS

LOCKNUTS

gasket

plate

DETAIL A

Foam gasket _ _/2"O.D.tube

Mounting plate #10 sheet metal screws

_DETAIL B

NOTES:

The large flange on the mounting plate is positioned at the bottom of the sleeve facing toward the sleeve. The drain tube must be rotated to a horizontal

position to allow for the wall sleeve to be installed into the wall. Once the wall sleeve is installed, return the drain tube to a downward angle.

6

920-087-02(9-03)

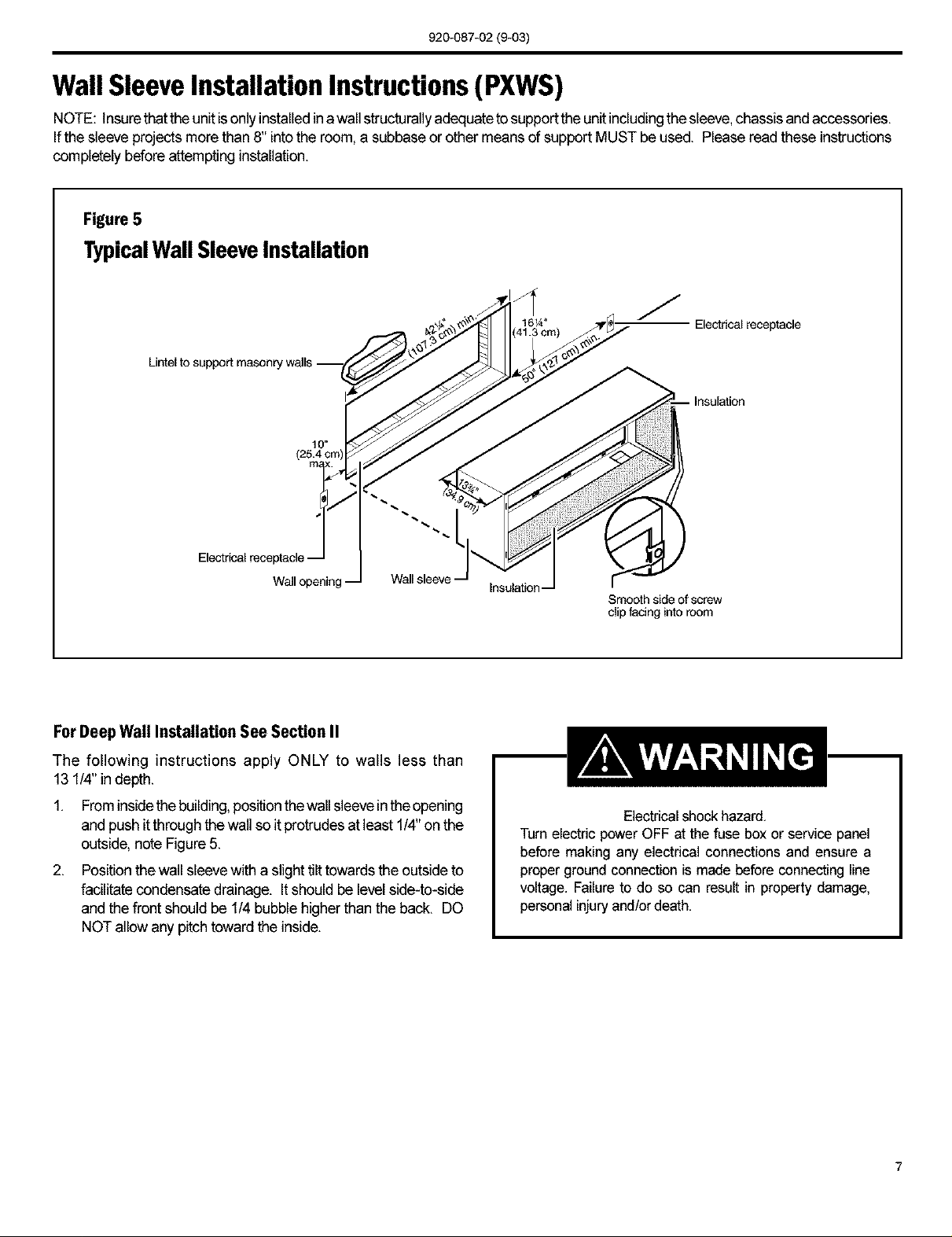

WallSleeveInstallation Instructions(PXWS)

NOTE: Insurethat theunit is only installed inawall structurallyadequatetosupport the unitincludingthe sleeve,chassis andaccessories.

Ifthe sleeve projects more than 8" intothe room, a subbase or other means of support MUST be used. Please read these instructions

completely before attempting installation.

Figure 5

TypicalWall Sleeve Installation

Lintel to support masonry walls .--_.b_//_

10"

(25.4 cm

Electrical receptacle -

Wall opening Wall sleeve

ForDeep Wall Installation See Section II

1 1_ _ /]

/

41._m) _\_'[_ -- -- Electrical receptacle

Insulation --

Smoothsideofscrew

slip facing into room

The following instructions apply ONLY to walls less than

13 1/4" in depth.

1. Frominside thebuilding,positionthewall sleevein theopening

and push it throughthe wall so itprotrudes at least 1/4"onthe

outside, note Figure 5.

2. Position thewall sleeve with a slight tilt towards the outsideto

facilitate condensate drainage. It should be levelside-to-side

and the front should be 1/4 bubble higher than the back. DO

NOT allow any pitch towardthe inside.

Electricalshock hazard.

Turnelectric power OFFat the fuse box or service panel

before making any electrical connections and ensure a

proper ground connectionis made before connecting line

voltage. Failureto do so can result in property damage,

personalinjuryand/ordeath.

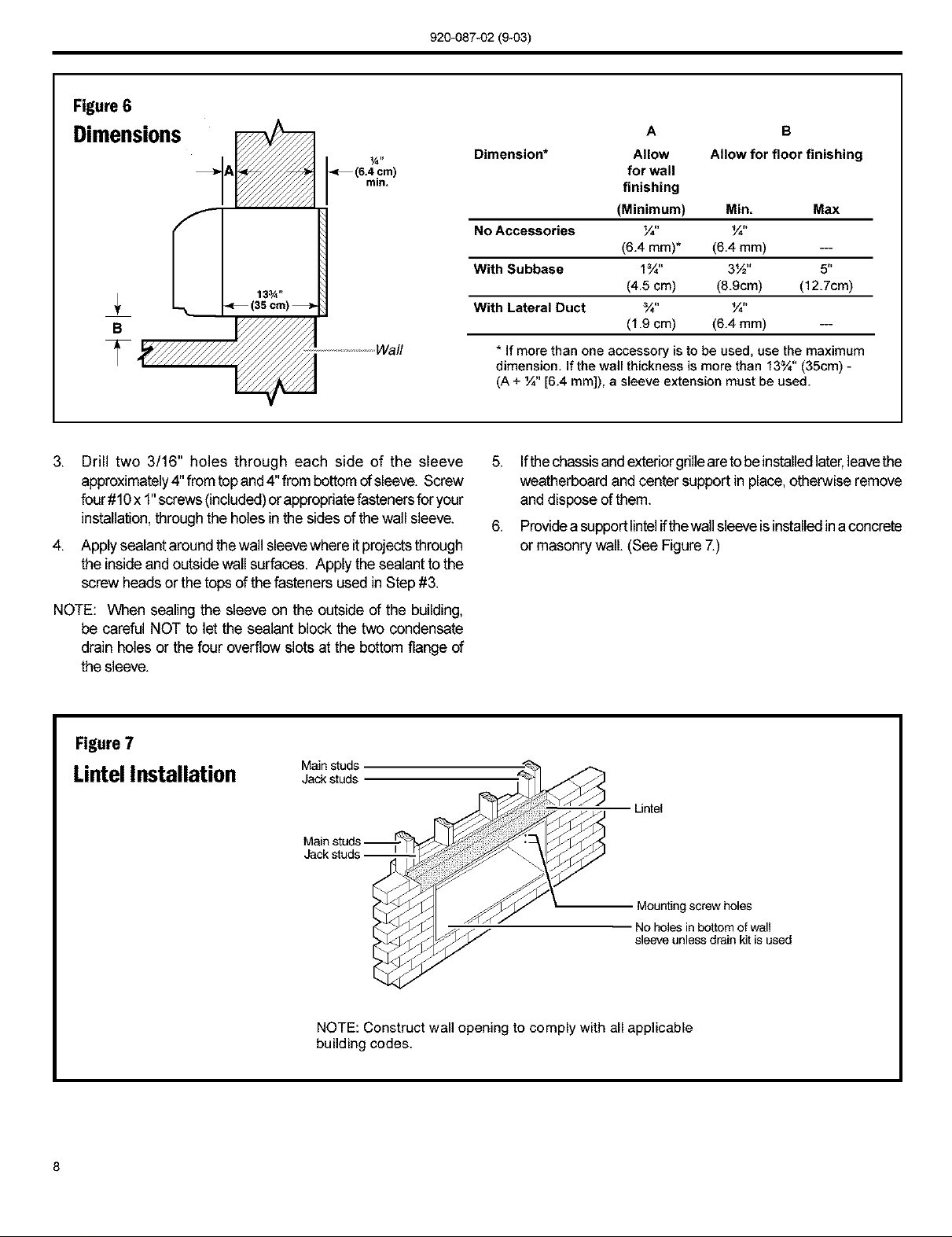

Figure 6

Dimensions

S

'_7€/////_ _ 6.4 cm

A

13¾ _

920-087-02 (9-03)

A B

Dimension*

in.

No Accessories ¼" ¼"

With Subbase 1¾" 3½" 5"

With Lateral Duct ¾" ¼"

Allow Allow for floor finishing

for wall

finishing

(Minimum) Min. Max

(6.4 ram)* (6.4 mm) ---

(4.5 cm) (8.9cm) (12.7cm)

(1.9 cm) (6.4 mm) ---

_ ...........Wall

,

Drill two 3/16" holes through each side of the sleeve

approximately4" from top and4"from bottomof sleeve. Screw

four#10x 1"screws (included)or appropriatefastenersfor your

installation, through the holes inthe sides of the wall sleeve.

4. Apply sealant around thewall sleevewhere itprojectsthrough

the insideand outside wall surfaces. Apply the sealant tothe

screw headsor the tops of the fasteners used in Step #3.

NOTE: When sealing the sleeve on the outside of the building,

be careful NOT to let the sealant block the two condensate

drain holes or the four overflow slots at the bottom flange of

the sleeve.

Rgure 7

LintelInstallation Jack studs

Main studs

* If mere than one accessory [sto be used, use the maximum

dimension. If the wail thickness is more than 13¾" (35cm) -

(A + ¼" [6.4 mm]), a sleeve extension must be used.

5. Ifthe chassisandexteriorgrilleareto beinstanedlater,leavethe

weatherboard and center support in place,otherwise remove

and dispose of them.

6. Providea supportlintelifthewall sleeve isinstalledina concrete

or masonry wall. (See Figure 7.)

Untel

Jack stud

Mounting screw holes

No holes in bottom of wall

sleeve unless drain kit is used

NOTE: Construct wall opening to comply with all applicable

building codes.

8

Loading...

Loading...