Page 1

Model PDXWS

Installation Instructions

WALL SLEEVE

For Use With Packaged Terminal Units

Please read these instructions completely before attempting installation.

NOTE: These instructions apply to installation of the wall sleeve only through walls structurally adequate to support the unit

(i.e. sleeve, chassis, accessories.) If wall is not structurally adequate, a subbase or other means of support MUST be made.

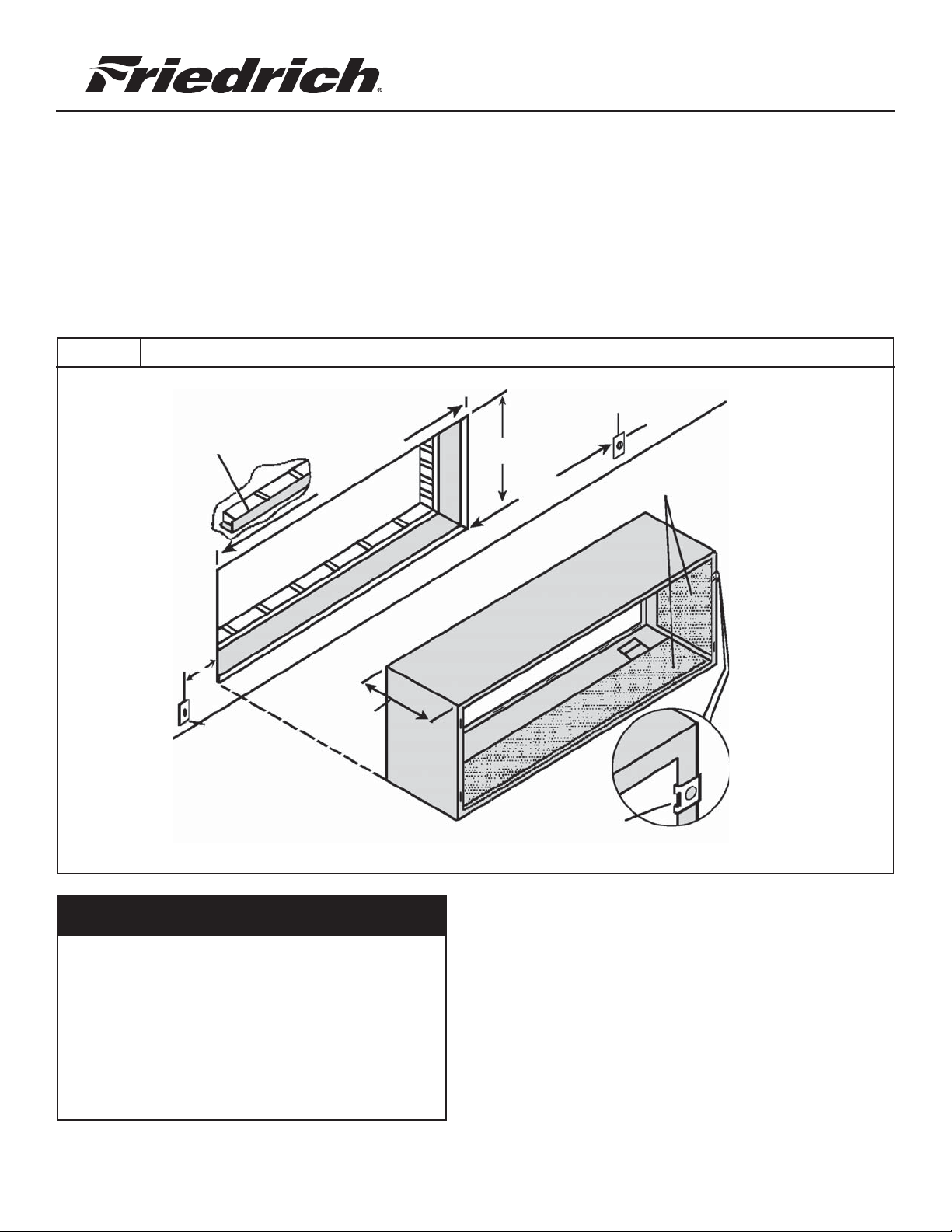

Figure 1. Typical Wall Sleeve Installation

Electrical

Receptacle

Lintel Used To Support

Masonry Walls

42¼"

Minimum

16¼"

Maximum

50"

Insulation

Wall Opening

10" Maximum

13¾"

Electrical

Receptacle

WARNING

Electrical shock hazard.

Turn OFF electric power at fuse box or service panel

before making any electrical connections and ensure a

proper ground connection is made before connecting

line voltage.

Smooth side of

clip on Room side.

Wall Opening

Refer to Figures 1 and 2 for proper dimensions and

location of wall opening and placement of electrical

receptacle.

Failure to do so can result in property damage,

personal injury and/or death.

920-078-01 (12-04)

Page 2

SECTION I

Drain Kit

A field supplied condensate drain kit is required for total

elimination of cooling or heat pump condensate.

When installing a condensate drain kit, (either internal or external drain), it is recommended that installation of the drain

kit be completed before installing the wall sleeve. Instructions

for drain kit installation are shipped with the drain kit.

Wall Structure

3. Drill two 3/16" holes through each side of the sleeve

approximately 4" from top and 4" from bottom of sleeve.

Screw four #10 x 1" screws (included) or appropriate

fasteners for your installation, through holes in sides of

opening.

NOTE: Do NOT put any screws or drill any holes in the bottom

of wall sleeve, unless required by the installation of a PXDR10

Condensate Drain Kit.

A subbase or other means of support MUST be used if sleeve

projects more than 8" into room. Refer to subbase installation

instructions for additional information.

Sleeve Installation

For Deep Wall Installation See Section II

The following instructions apply ONLY to walls less than 13

1/4"" in depth.

1. From inside the building, position wall sleeve in opening

and push through the wall so it protrudes at least 1/4"

on the outside, note Figure 2.

2. Position the wall sleeve so that it is positioned with a

slight tilt towards the outside to facilitate condensate

drainage. It should be level side-to-side. DO NOT allow

any pitch toward the inside.

Figure 2. Dimensions

4. Apply sealant around the wall sleeve where it projects

through the inside and outside wall surfaces. Apply

sealant to screw heads or tops of fasteners used in Step

#3.

NOTE: When sealing sleeve on outside of building, be care-

ful NOT to let sealant block the two condensate drain

holes or the four overflow slots at the bottom flange of

the sleeve.

5. If chassis and exterior louver are to be installed later,

leave the weatherboard and center support in place,

otherwise remove and dispose of them.

Dimension* A (Minimum) B

(See Note)

Min. Max.

13¾"

Wall

** To allow for wall/fl oor fi nishing.

¼"

Minimum

No

Accessories

With

Outdoor

Grille

Subbase 1 3/4" 3 1/2" 5"

With

Lateral Duct 3/4" 1/4" —

Caulking

NOTES

* If more than one accessory is to be

used, use the worst case dimension.

If the wall thickness is more than 13 3/4" - (A + 1/4"),

a sleeve extension MUST be used.

**1/4" 1/4" —

Page 3

Figure 3. Lintel Installation

MAIN STUDS

JACK STUD

LINTEL

MOUNTING

SCREW HOLE

No holes are permitted

in the bottom of the

case. (Exception:

PXDR10 Drain Kit)

Note the use of a lintel under the first course of bricks

above the wall sleeve. Do not use the wall sleeve as a lintel. The mounting screw holes shown are to be made by the

installer.

6. Provide a support lintel if the wall sleeve is installed in a concrete or masonry wall. (See Figure 3)

Page 4

SECTION II

Deep Wall Installation

If wall is thicker than allowed in the notes in Figure 2, a sheet

metal wall sleeve extension and flashing MUST be used. See

Figure 4 for guidelines to use in fabricating a wall sleeve extension.

Field Fabricating A Sleeve Extension

The Following points MUST be considered when designing a

wall sleeve extension.

1. Provision must be made to direct excess condensate from

the back of the wall sleeve to the outside of the building.

2. Air baffles must be mounted to properly direct air flow

from the condenser.

3. Wall Sleeve Extension design must allow for the proper

mounting of the louvers.

4. Caulking of all potential sites where condensate or external

water could infiltrate into building is required.

6. Condensate notches are clear of sealant so condensate

flows freely into extension.

NOTE: Improper fabrication of a wall sleeve extension will

impair PTAC performance. Regardless of your final extended

wall sleeve design, provision MUST be made for proper direction of air flow and condensate.

Extension Installation

Size wall sleeve extension to fit frame opening. Secure it to

wall sleeve before installing in the wall. Refer to Figure 4

the

for a

guide for fabrication of a condensate drip panel. Panel MUST

extend the full depth of the wall sleeve and the wall sleeve

extension. Pay particular care in sealing and caulking the panel

where it makes contact with the wall sleeve (see Figure 4.)

After installation in the wall, secure with fasteners through the

sides. Seal around the sleeve extension with exterior caulking.

Using a good grade of silicone sealant, seal all exposed screw

heads. When installation is complete, outside louver may be

attached to wall sleeve extension.

5. Seal strips must be attached to the outside edge of the

vertical baffles.

Figure 4. Extended Wall Sleeve and Sealant Locations

IMPORTANT NOTE: The silicone bead MUST extend 3" up

the side of the two flanges to prevent condensate from

leaking.

Wall Sleeve

Outside Edge

Insulation

Air Baffles

Condensate

Width of wall

Drip

Edge

Drip Panel

(Field

Supplied)

Condensate

Notches

Sealant inside (4)

bottom corners

920-078-01 (12-04)

42 X 16" Frame, 20 gauge minimum,

painted or aluminium

Loading...

Loading...