Page 1

INSTALLATION &

OPERATION GUIDE

920-087-04 (8-05)

PTAC

PACKAGED TERMINAL

AIR CONDITIONERS

& HEAT PUMPS

Standard Control

Remote Thermostat

Seacoast Protected

Page 2

920-087-04 (8-05)

TableofContents

Unit Components ...............................................................................................................................................................................................2

Model Number Code..........................................................................................................................................................................................3

Installation Recommendations ..........................................................................................................................................................................4

Friedrich Digital Control Features .................................................................................................................................................................5-6

Drain Kit Installation ........................................................................................................................................................................................7-8

Wall Sleeve Installation .................................................................................................................................................................................9-10

Deep Wall Installation ......................................................................................................................................................................................11

Standard Grille Installation ..............................................................................................................................................................................12

Electrical Rating Tables ...................................................................................................................................................................................13

Power Cord Information ...................................................................................................................................................................................13

Installation Checklist ........................................................................................................................................................................................14

Chassis Installation .....................................................................................................................................................................................14-15

Digital Control User Input Configuration .........................................................................................................................................................16

Operation ..........................................................................................................................................................................................................17

Remote Thermostat and Low Voltage Control Connections .........................................................................................................................18

Desk Control Terminals ...................................................................................................................................................................................19

Auxiliary Fan Control........................................................................................................................................................................................19

FreshAir Vent Control ......................................................................................................................................................................................19

Air Discharge Grille ..........................................................................................................................................................................................19

Start-up Checklist .............................................................................................................................................................................................20

Appendix A: Electrical Wiring for 265 V Models............................................................................................................................................21

Routine Maintenance .......................................................................................................................................................................................22

Basic Troubleshooting Techniques .................................................................................................................................................................23

Digital Control Diagnostics and Test Mode ....................................................................................................................................................24

Accessories ................................................................................................................................................................................................25-26

Warranty ...........................................................................................................................................................................................................27

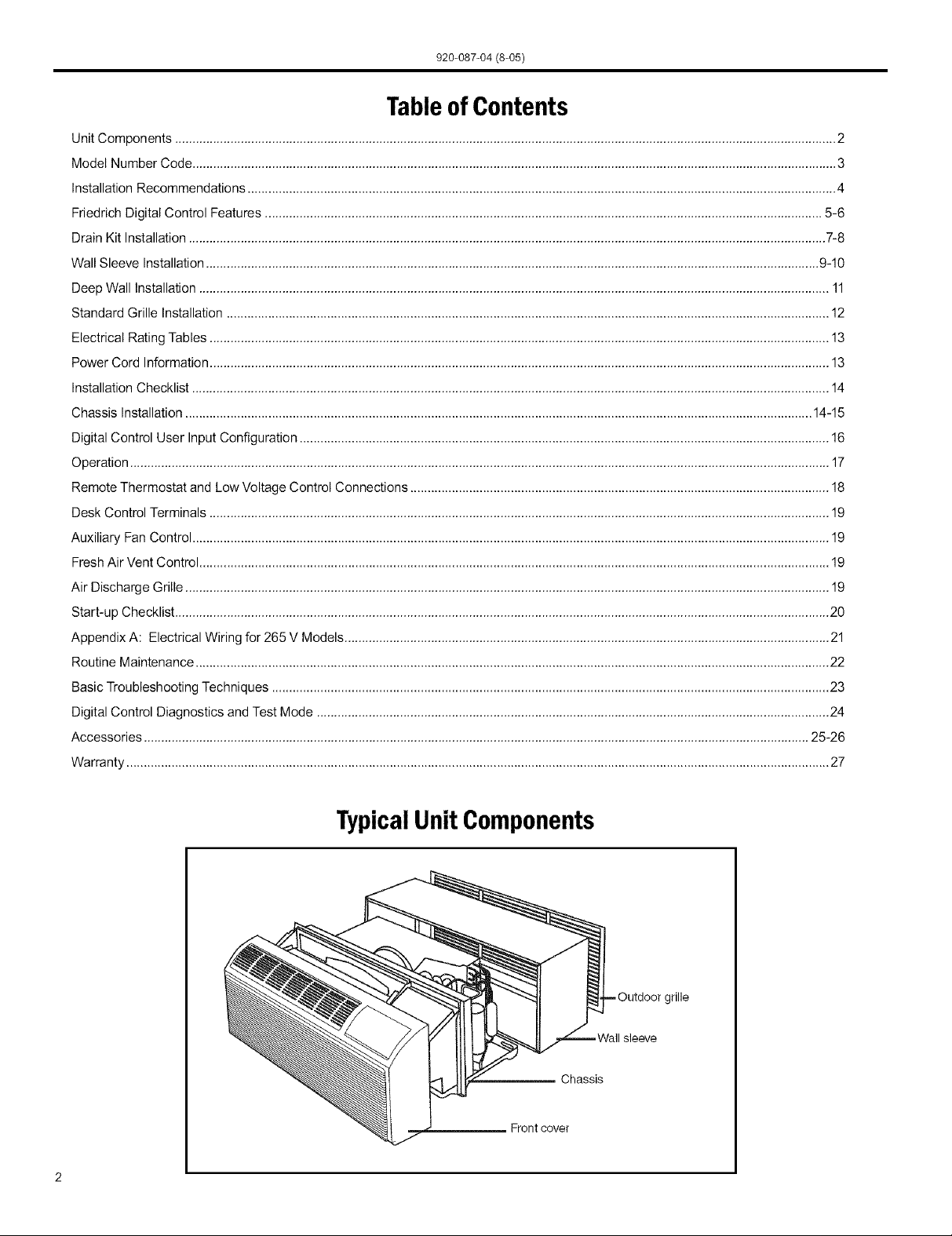

TypicalUnit Components

Chassis

Frontcover

jrille

Page 3

920-087-04 (8-05)

Thank you for your decision to purchase the newly designed Friedrich Packaged Terminal Air Conditioner (PTAC). We are

confident that you will find this unit a quiet and efficient example of Friedrich reliability.

This Installation and Operation Manual has been designed to insure maximum satisfaction in the performance of your unit.

For years of trouble-free service, please follow the installation instructions closely. We cannot overemphasize the importance

of proper installation. We have added new information to the basic instructions to help you achieve success.

Remember, proper installation is not difficult but it is essential.

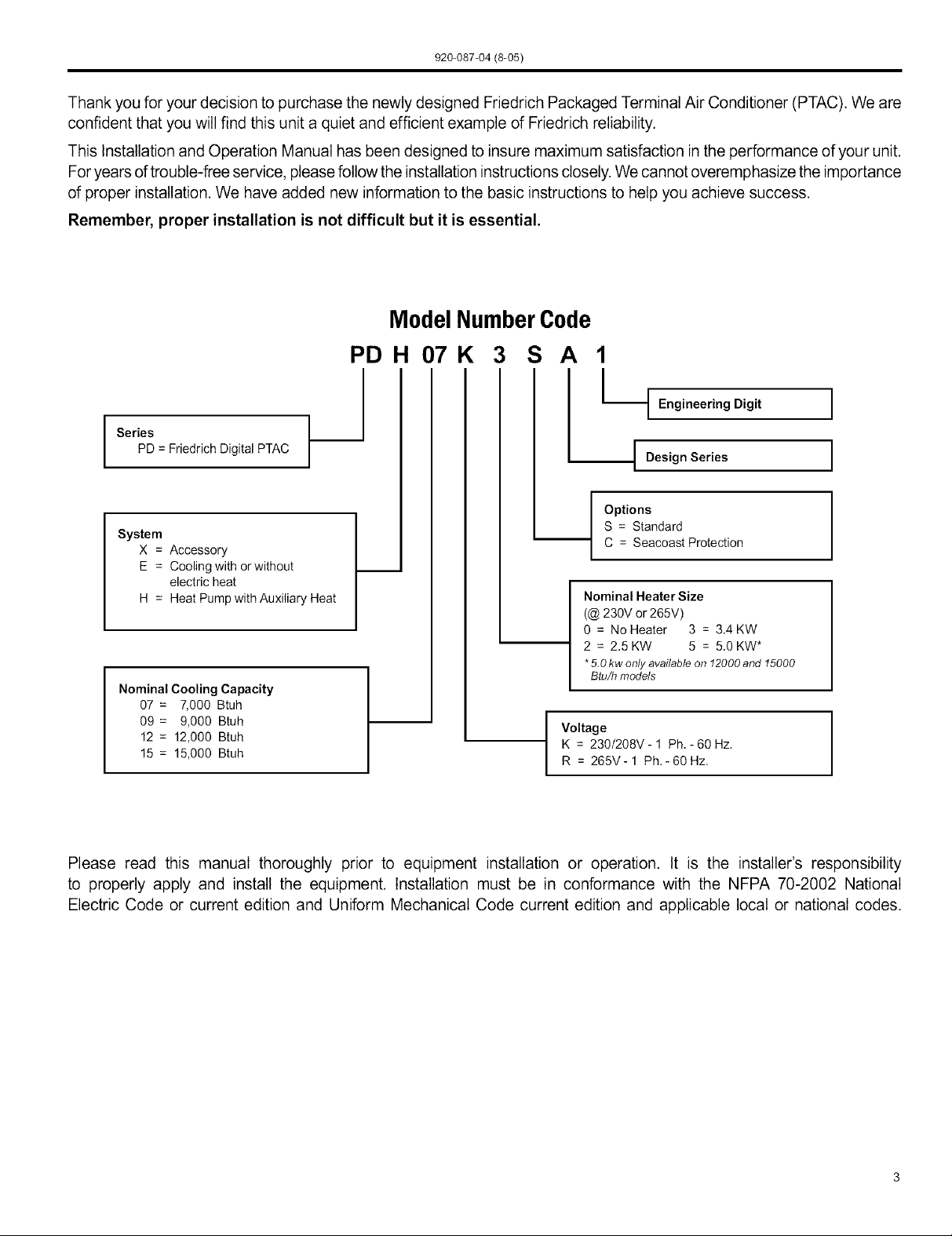

ModelNumberCode

PDH 07K 3 S A 1

I_

Series

PD = Friedrich Digital PTAC

I

System

X = Accessory

E = Cooling with orwithout

electric heat

H = Heat Pump with Auxiliary Heat

Nominal Cooling Capacity

07 = 7,000 Btuh

09 = 9,000 Btuh

12 = 12,000 Btuh

15 = 15,000 Btuh

t Engineering Digit

I DesignSeries

Options

S = Standard

C = Seacoast Protection

Nominal Heater Size

(@ 230V or 265V)

0 = No Heater 3 = 3.4 KW

2 = 2.5 KW 5 = 5.0 KW*

*5.0 kw onlyavailable on 12000and 15000

Btu/h models

Voltage

K = 230/208V - 1 Ph, - 60 Hz.

I

R = 265V-1 Ph.-60Hz,

I

I

I

I

Please read this manual thoroughly prior to equipment installation or operation. It is the installer's responsibility

to properly apply and install the equipment. Installation must be in conformance with the NFPA 70-2002 National

Electric Code or current edition and Uniform Mechanical Code current edition and applicable local or national codes.

Page 4

920-087-04 (8-05)

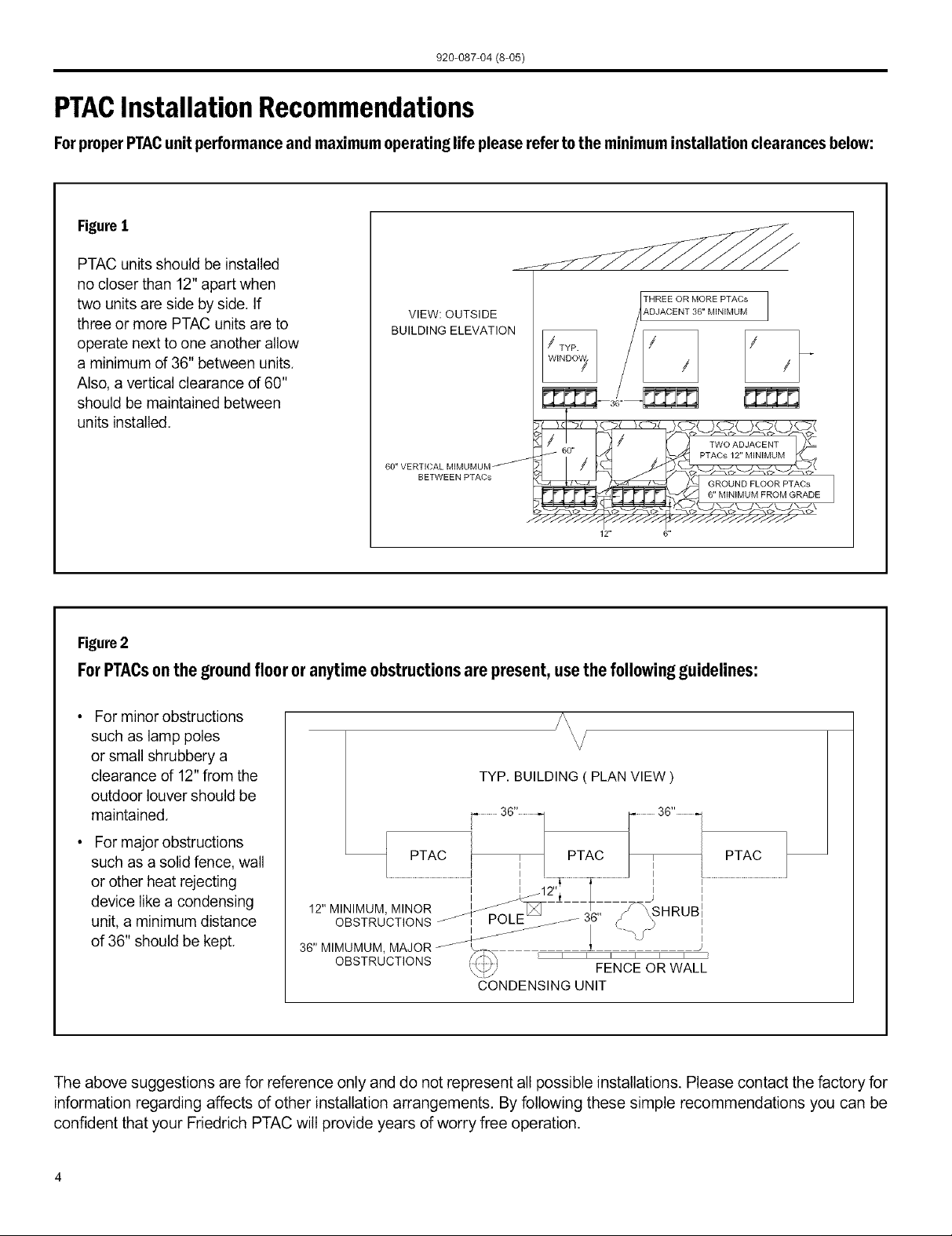

PTACInstallation Recommendations

Forproper PTACunit performance and maximumoperating life please refer to the minimum installation clearances below:

FigureI

PTAC units should be installed

no closer than 12" apart when

two units are side by side. If

three or more PTAC units are to

operate next to one another allow

a minimum of 36" between units.

Also, a vertical clearance of 60"

should be maintained between

units installed.

VIEW: OUTSIDE

BUILDING ELEVATION

BETWEEN PTACs

THREE OR MORE PTACs

A.DJACENT 36" MINIMUM

12"

Figure2

For PTACson the ground floor or anytime obstructions are present, use the following guidelines:

For minor obstructions

such as lamp poles

?\

J \

or small shrubbery a

clearance of 12" from the

TYP. BUILDING ( PLAN VIEW )

outdoor louver should be

maintained.

For major obstructions

such as a solid fence, wall

or other heat rejecting

PTAC PTAC / PTAC

............................................................., i_:,._..................._...........................j ,.............................................................

...............3G,,.............. /_ 3G,,.1

7

J

device like a condensing

unit, a minimum distance

of 36" should be kept.

OBSTRUCTIONS _ POLE_j.J--- 3,_5 ¢_ ._

/_-- JJ / .....',J I

36" MIMUMUM MAJOR _'_ _ 1 J

OBSTRUCTIONS _ FENCEOR WALL

CONDENSINGUNIT

The above suggestions are for reference only and do not represent all possible installations. Please contact the factory for

information regarding affects of other installation arrangements. By following these simple recommendations you can be

confident that your Ffiedrich PTAC will provide years of worry free operation.

Page 5

920-087-04 (8-05)

FriedrichDigital ControlFeatures

The new Friedrich digital PTAChas state of the art features to improve guest comfort, indoor air quality and conserve energy.

Through the use of specifically designed control software for the PTAC industry Ffiedfich has accomplished what other Manufactur-

er's haveonly attempted - a quiet, dependable, affordable and easy to use PTAC.

Below is a list of standard features on every Friedrich PTACand their benefit to the owner.

Digital Temperature Bydigitallymonitoringdesiredroomtemperaturetheroomiscontrolledmorepreciselythanconventionalsystems.Thelarge,easy

Readout toreadLEDdisplaycanshoweitherset-pointor actualroomtemperatureasselectedby owner.

Whentheunitispoweredoff theunitcanbereturneddirectlytoheatingorcoolingmodeby pressingthe 'Heat'or 'Coot'buttons

One-Touch Operation withouttheconfusingpowerupsequenceofsomecontrols.One-touchcontroltakesguessworkoutofunitcontroldeliveringamore

enjoyableexperienceandeliminatingfront-deskcalls.

Individual Mode and ByhavingseparatecontrolbuttonsandindicatorsforbothfanandmodesettingstheFriedrichdigitalcontroleliminatestheconfu-

Fan Control Buttons sionofpreviousdigitalPTACs.Theaccuratetemperaturesettingprovidesgreaterguestcomfortthanothersystems.

Quiet Start/Stop

Fan Delay for"free cooling"byutilizingthealreadycoolindoorcoilto itsmaximumcapacitybyrunningfor30secondsafterthecompressor.

Remote Thermostat Someapplicationsrequiretheuseof a wallmountedthermostat.All newFriedrichPTACsmaybeswitchedfromunitcontrolto

Operation remotethermostatcontroleasilywithouttheneedtoorderaspecialmodeloraccessorykit,

Wireless Remote Guestscanadjustthetemperatureandmodeoftheunitthroughtheused anoptionalhandheldwirelessremote,improvingguest

Control Ready comfortandrelaxation.

Internal Diagnostic ThenewFriedrichdigitalPTACfeaturesa selfdiagnosticprogramthatcanalert maintenancetocomponentfailuresoroperating

Program problems,Theinternaldiagnosticprogramsavespropertiesvaluabletimewhendiagnosingrunningproblems.

Service ErrorCode Theself diagnosisprogramwilIalsostoreerrorcodesinmemoryif certainconditionsoccurandcorrectthemselvessuchasex-

Storage determineiftheunitfacedobscureconditionsorifanerroroccurredandcorrecteditself.

Constant Comfort Theon-boardprocessormonitorstimebetweendemandcycles(heatorcool)andwilIcyclethefanevery9 minutestosamplethe

Room Monitoring statwithoutthecomplicationor costofa wailmountedthermostat.

Electronic Temperature Bylimitingtheoperatingrangethepropertycansaveenergybyeliminating"maxcoot"or"maxheat"situationscommonwitholder

Limiting ofoneanother.

Thefanstartandstopdelayspreventabruptchangesinroomacousticsduetothecompressorenergizingorstoppingimmediately.

Uponcallforcoolingorheatingtheunitfanwillrunforfivesecondspriortoenergizingthecompressor.Also,thefanoffdelayallows

tremehighorlowoperatingconditionsor activationoftheroomfreezeprotectionfeature,Storingerrorcodescanhelpproperties

roomconditionanddetermineifthedesiredconditionsaremet.Thisallowsthe roomtohavesimilarbenefitstoaremotemounted

uncontrolledsystems.Thenewelectroniccontrolallowsownerstoset operatingrangesforbothheatingandcoolingindependently

RoomFreeze

Protection

RandomCompressor

Restart

DigitalDefrost

Thermostat

WhenthePTACsensesthattheindoorroomtemperaturehasfallento40°Ftheunitwillcycleonhighfanandtheelectricstripheat

toraisetheroomtemperatureto 46°Fthencycleoff again.Thisfeatureworksregardlessofthemodeselectedandcanbeturned

off.ThecontrolwillalsostoretheRoomFreezecycleintheservicecodememoryfor retrievalatalaterdate.Thisfeatureensures

thatunoccupiedroomsdo notreachfreezinglevelswheredamagecanoccurtoplumbingandfixtures.

Multiplecompressorsstartingatoncecanoftencauseelectricaloverloadsand prematureunitfailure.The randomrestartdelay

eliminatesmultipleunitsfromstartingatoncefollowingapoweroutageor initialpowerup,The compressordelaywillrangefrom

180to240seconds.

ThenewFriedrichPTACusesadigitalthermostatto accuratelymonitortheoutdoorcoilconditionstoallowtheheatpumpto run

wheneverconditionsarecorrect,RunningthePTACinheatpumpmodesaveenergyandreducesoperatingcosts.Thedigital

thermostatallowsmaximizationofheatpumpruntime.

Page 6

920-087-04 (8-05)

FriedrichDigital ControlFeaturesContinued

Instant Heat Heatpumpmodelswillautomaticallyruntheelectricheatertoquicklybringtheroomuptotemperaturewheninitiallyenergized,

Heat Pump Mode atedwithheatpumpunits.

Even Heat Monitoring sarytheunitwillcycletheelectricheattomaintainthetemperature.Thisfeatureensuresguestcomfortbydeliveringtheheating

Fan Cycle Control ingandquietstart/stopfandelayonlyoperateinfancyclemode)Fancontinuousmodeisusedtokeepconstantairflowcircula-

Emergency Heat Override tanceheater.Thisfeatureensuresthatevenintheunlikelyeventofa compressorfailurethe roomtemperaturecanbemain-

Desk Control Ready lingtheunitfroma remotelocationlikethefrontdeskcan reduceenergyusageand requiresnoadditionalaccessoriesat the

Indoor Coil Frost Sensor theindoorcoilto freeze.Whentheindoorcoilreaches30°Fthecompressorisdiabtedandthefancontinuesto operatebased

thenreturntoheatpumpmode.Thisensuresthattheroomisbroughtuptotemperaturequicklywithouttheusualdelayassoci-

Thedigitalcontrolmonitorsindoorconditionstoensurethattheroomtemperatureiswithinfivedegreesofthesetpoint.If neces-

benefitsof anelectricheaterwhilemaintainingtheefficiencybenefitsofaheatpump.

Theownermaychoosebetweenfancyclingorfancontinuousmodebasedonpropertypreference.(Note:Evenheatmonitor-

tionintheroomduringatItimestheunitis'ON'.Fancyclewillconserveenergybyonlyoperatingthefanwhilethecompressor

orelectricheaterisoperating.

Inthe eventofa compressorfailureinheatpumpmodethecompressormaybelockedout toprovideheatthroughtheresis-

taineduntilthecompressorcanbeserviced.

All FriedrichdigitalPTACshavelowvoltageterminalsreadyto connectadeskcontrolenergymanagementsystem.Control-

PTAC.

Thefrostsensorprotectsthecompressorfromdamageintheeventthatairflowis reducedorlowoutdoortemperaturescause

ondemand,Oncethecoiltemperaturereturnsto 45°Fthecompressorreturnsto operation.

ThenewFriedrichPDseriesunitsfeatureaindoorfansystemdesignthat reducessoundlevelswithoutloweringairflowand

Ultra-Quiet Air System preventingproperaircirculation,

High Efficiency TheFriedrichPTACbenefitsqualitycomponentsandextensivedevelopmenttoensureaquiet,efficientanddependableunit.

Friedrich'ssingIe-motordesignallowsforenhancedoutdoorairflowandsimplifiesthe unitdesignwithouttheneedfor redun-

Single Motor dantcomponents.

Rotary Compressor HighefficiencyrotarycompressorsareusedonallFriedrichPTACsto maximizedurabilityandefficiency.

TheFriedrichPTACfeaturesa24VACterminalfor connectiontoan auxiliaryfanthatmaybeusedtotransferairtoadjoining

Auxiliary Fan Ready rooms.Auxiliaryfanscanprovideconditioningto multipleroomswithoutthe requirementof multiplePTACunits.

Aluminum Endplates AllFriedrichPTACsarebuiltwith.04"endplatesmadefromaluminumasopposedtosteel.Theendplatesaretypicallythemost

Seacoast Protection includesdippingthe entireoutdoorcoilina 7-stepcoatingprocessthatprovidessuperiorprotectiontoonlycoatingthefins of

Top Mounted Anti- All FriedrichPTACreturnairfiltersfeatureananti-microbialelementthathasproventopreventmoldand bacterialgrowthin

microbial Air Filters andareeasilyaccessedfromthetopof theunitwithouttheremovalof thefrontcover.

susceptibleareaforcorrosionandaluminumisfar moreresistantto corrosionthanevencoatedsteel.

OptionalSeacoastprotectionisavailableto protecttheoutdoorcoilfromharshenvironments.TheFriedrichSeacoastprocess

thecoil.

laboratorytesting.PDXFTreplacementfilterkitsfeaturethesameanti-microbialagent.Allfiltersarewashableandreusable

Filtered Fresh Air Intake

FriedrichPTACunitsarecapabieofintroducingupto70CFMofoutsideairintotheconditionedspace.Theoutdoorairpasses

throughawashablemeshfiltertopreventdebrisfromenteringthe airstream.

Page 7

920-087-04 (8-05)

Installation Instructions PXDRIODrainKit

NOTE: Determine whether drain will be located within the wall, on the indoor side, orwill drain to the exterior of the building. Follow

appropriate instructions below depending on your particular type of installation.

Internal Drain (optional for new construction)

NOTE: If installing an internaldrain, you MUST install a drain kit

on the wall sleeve beforethe wall sleeve is installed.

Refer to Figure 3 below and locate the drain within the

"Primary" area for best drainage. Maintain at least a 1!2"

clearance from the embossed area.

,

Using the mounting platewith the 1/2" hole asa template,

mark and drill two, 3/16" mounting holes and a 1/2" drain

hole.

,

Remove the backing from the gasket and mount iton the

flat side of the mounting plate. (See Figure 4.) Insert the

drain tube through the hole in the gasket and mounting

plate so the tube flange will be against the wall sleeve.

,

Position the assembly beneath the drilled holes and

secure it with #10-24 x 1/2" machine screws and lock

nuts provided. Seal the tops of the screws with silicone

caulking.

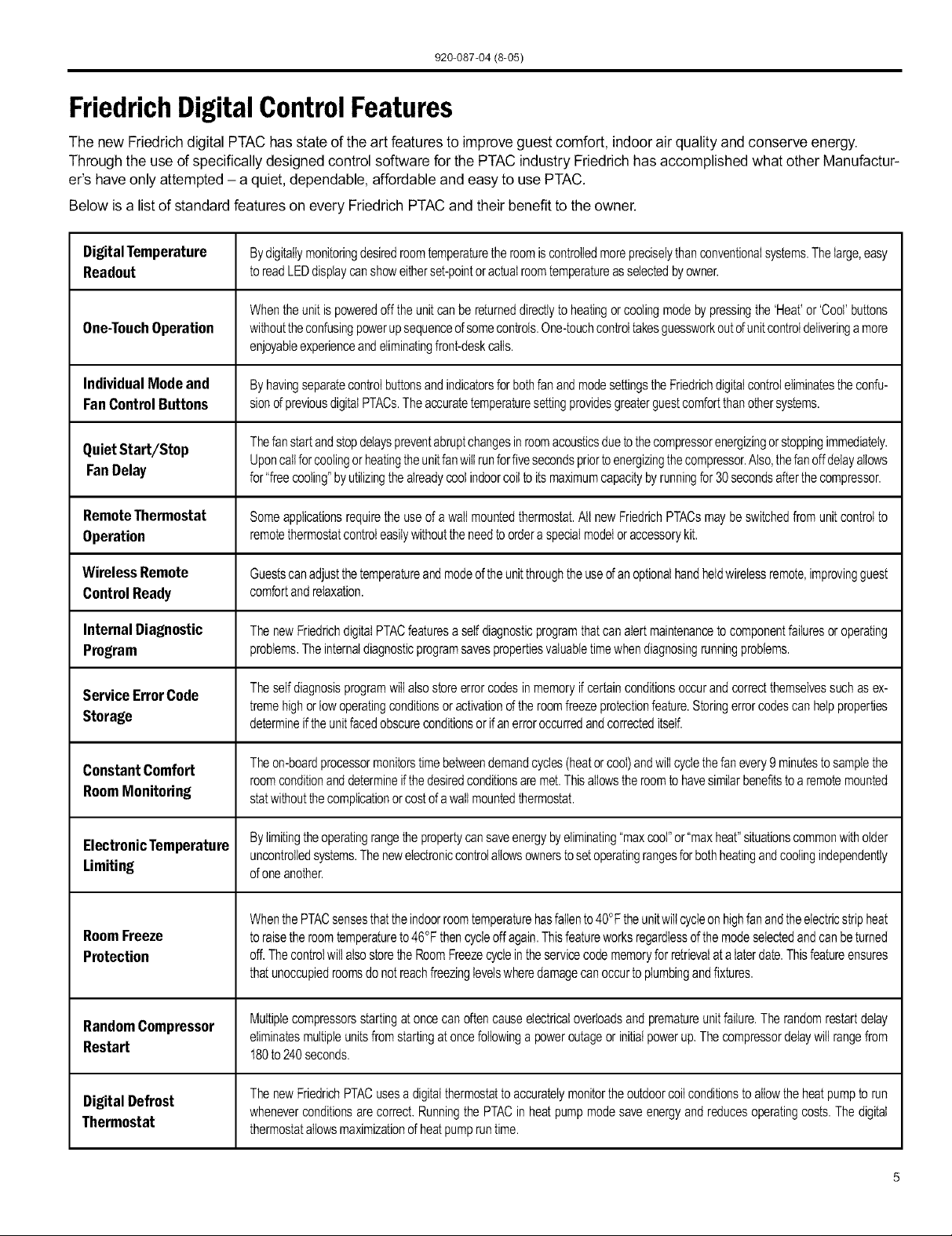

Figure3

DrainKit LocationandInstallation

Primary area - no foam insulation

If the drain must be located in the

secondary area, the foam insulation

must be cut away and removed to

Secondary area

allow access to the drain.

Screw

Wall sleeve

7.6 cm

5,

Use 1/2"I.D.coppertube,PVCpipe,orvinyl hose(obtained

locally)toconnect the internaldraintubetothe drainsystem

in the building.

,

Referring to Detail A on page 6, locate and assemble the

(2) two cover plates and gaskets over the drain holes at

the rear ofthe wall sleeve. Attach them with the#10 sheet

metalscrews provided. Make certainthatthe four overflow

slots at the rear of the wall sleeve are not blocked (See

drawing of the back of the sleeve onpage 6).

,

If a deep wall extension (PXWE) is used, after installing

the field supplied flashing, caulk as required. Be sure to

caulk around the flashing and the wall sleeve where the

hole was drilled for the drain tube.

Gasket 4

Mounting plate -_._/ I Fq---Tq t \\

• Nut_Jl'l I II \\

Drain tube _ I _._

Page 8

920-087-04(8-05)

ExtemalDrain(fornewconstructionor unit replacement)

When using an external drain system, the condensate is removed through either of two drain holes on the back of the wall sleeve.

Select the drain hole which best meets your drainage situation and install the drain kit. Seal off the other with a cover plate.

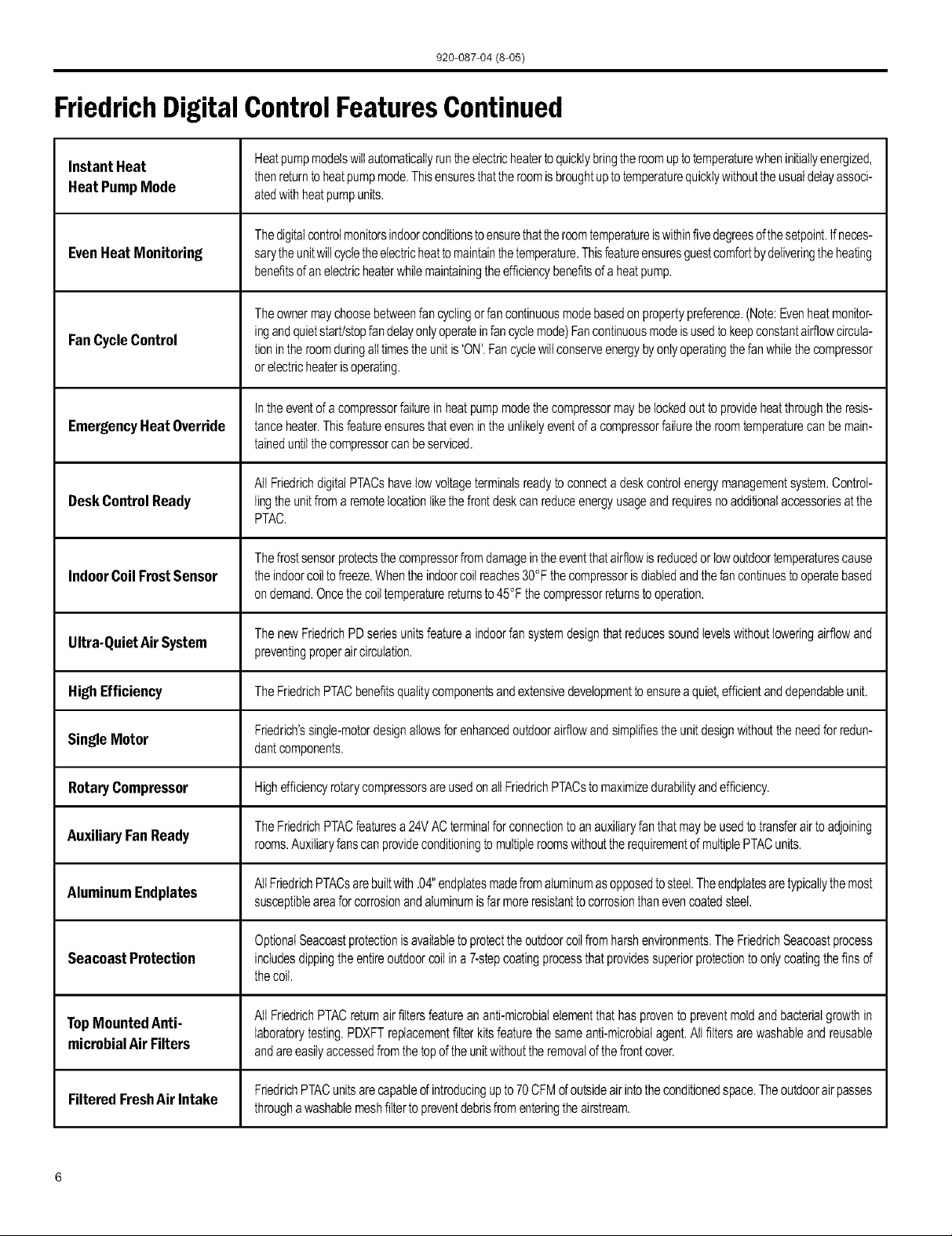

Drain Tube Installation

1. Peel the backing tape off the gaskets and apply the

sticky side to one cover plate and one mounting plate

as shown in DetailsA and B.

2. Placethe draintubethroughthegasket andthemounting

plate with theflange toward the wall sleeve.

Attach the draintube assembly to one of the two drain

holes at the rear of the wall sleeve. The large flange

on the mounting plateis positioned atthe bottom ofthe

sleeve facing toward the sleeve, Detail B. When the

drain tube ispositioned atthe desired angle, tighten the

screws.

NOTE:

If the wall sleeve has not been installed, the drain tube

must be rotated to a horizontal position until after the

sleeve is installed. Tighten the mounting plate screws

when the tube is in the proper position. Make certain

that thefour overflow slots at the rear ofthe wall sleeve

are not blocked. (See the drawing below.)

Figure4

DrainKit Installation

Cover Plate Installation

4. Mount the foam gasket to the cover plate. Using two

#10 x 1!2" sheet metal screws (provided), attach the

cover plate to the remaining drain hole. Make certain

the largeflange on the plate is positioned at the bottom

of the sleeve.

5. Discard the additional cover plate, gasket, machine

screws, and Iocknuts.

QUANTITY DESCRIPTION

2

1

1

3

4

2

2

COVER PLATES

MOUNTING PLATE

DRAIN TUBE

MOUNTING PLATE GASKETS

#10X 1/2" MOUNTING SCREWS

10-24 X 1/2" MACH. SCREWS

LOCKNUTS

-- Foam gasket

Mounting plate

DETAIL A

I V2" O.D. tube

Foam gasket _ /

Mounting plate # 10 sheet metal screws

DETAI L B

NOTES:

The large flange on the mounting plate is positioned at the bottom of the sleeve facing toward the sleeve. The drain tube must be rotated to a horizontal

position to allow for the wall sleeve to be installed into the wall. Once the wall sleeve is installed, return the drain tube to a downward angle.

Page 9

920-087-04 (8-05)

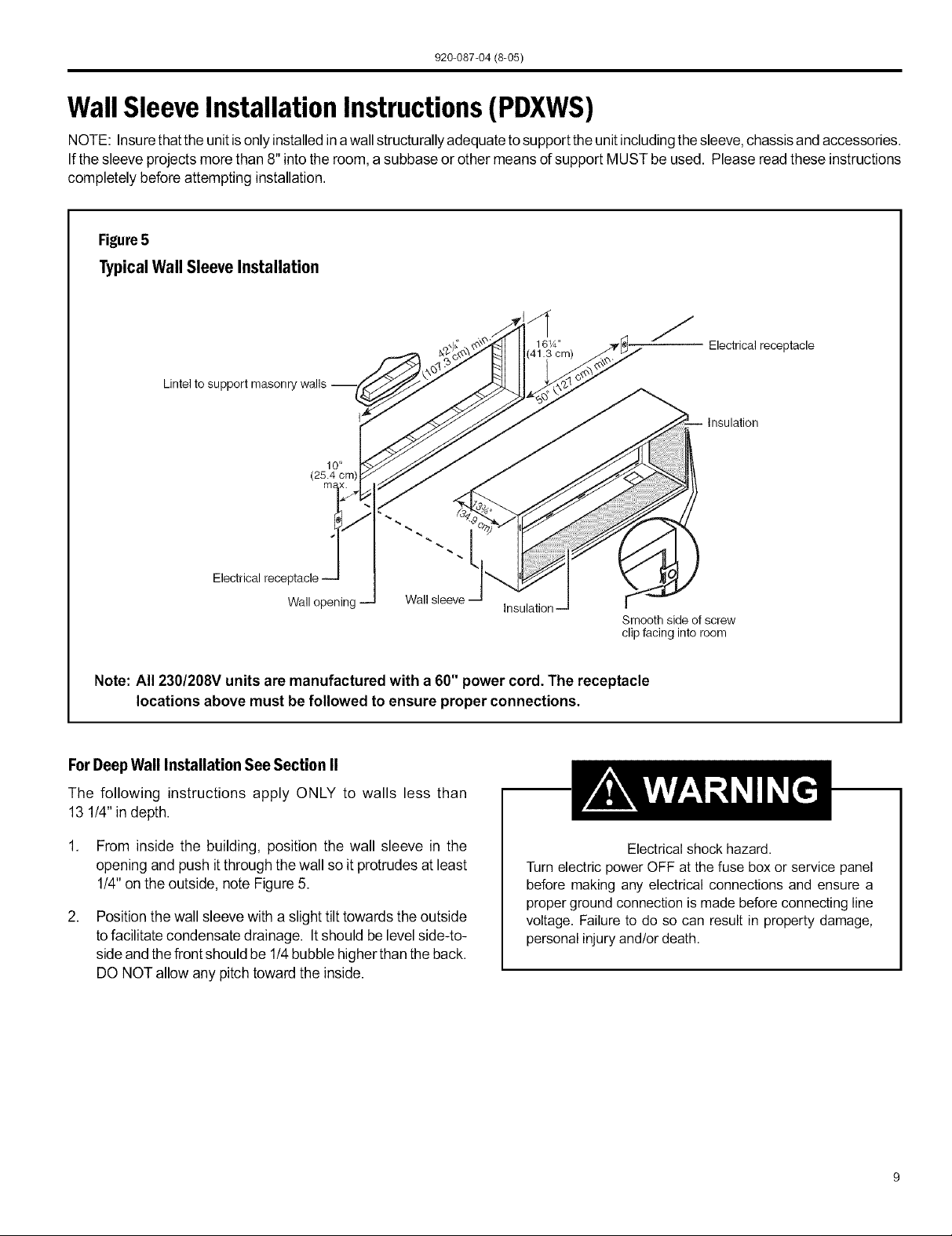

WallSleeveInstallation Instructions(PDXWS)

NOTE: Insurethatthe unitis onlyinstalledin awallstructurally adequatetosupport the unitincludingthesleeve,chassisand accessories.

If the sleeve projects more than 8" into the room, a subbase or other means of support MUST be used. Please read these instructions

completely before attempting installation.

Figure5

Typical Wall Sleeve Installation

16W' Electrical receptacle

Lintel to support masonry

10 _

(25.4 cm)

m_

Electrical

Wall opening

Wall sleeve --

insulation--

Note: All 230/208V units are manufactured with a 60" power cord. The receptacle

locations above must be followed to ensure proper connections.

ForDeep Wall Installation See Section II

The following instructions apply ONLY to walls less than

13 1/4" indepth.

J

Smooth side of screw

clip facing into room

1. From inside the building, position the wall sleeve in the

opening and push itthrough the wall so it protrudes at least

1/4"on the outside, note Figure 5.

,

Position the wall sleeve with a slight tilt towards the outside

tofacilitate condensate drainage. Itshould be levelside-to-

sideand thefront should be 1!4bubble higherthan theback.

DO NOT allow any pitch toward the inside.

Electrical shock hazard.

Turn electric power OFF at the fuse box or service panel

before making any electrical connections and ensure a

proper ground connection is made before connecting line

voltage. Failure to do so can result in property damage,

personal injury and/or death.

Page 10

Figure6

Dimensions

B

T

(6.4 cm)

rain.

Wall

920-087-04 (8-05)

A B

Dimension* Allow Allow for floor finishing

for wall

finishing

(Minimum) Min. Max

No Accessories ¼" ¼"

(6.4 mm)* (6.4 mm) ---

With Su bbase 1¾" 3W' 5"

(4.5 cm) (8.9cm) (12.7cm)

With Lateral Duct ¾" ¼"

(1.9 cm) (6.4 mm) ---

* If more than one accessory is to be used, use the maximum

dimension. If the wall thickness is more than 13¾" (35cm) -

(A + ¼" [6.4 mm]), a sleeve extension must be used.

Drill two 3/16" holes through each side of the sleeve

approximately 4" from top and 4" from bottom of sleeve.

Screw four #10 x 1" screws (included) or appropriate

fasteners for your installation,through the holes in the sides

of the wall sleeve.

,

Apply sealant around the wall sleeve where it projects

through the inside and outside wall surfaces. Apply the

sealant to thescrew heads or the tops of thefasteners used

in Step #3.

NOTE: When sealing the sleeve on the outside of the

building, be careful NOT to let the sealant block the two

condensate drain holes or the four overflow slots at the

bottom flange of the sleeve.

Figure7

LintelInstallation Mainstuds

Jack studs

Main

Ifthechassis and exterior grilleareto beinstalled later,leave

the weatherboard and center support in place, otherwise

remove and dispose of them.

Provide a support lintel if the wall sleeve is installed in a

concrete or masonry wall. (See Figure 7.)

Lintel

Mounting screw holes

No holes in bottom of wall

sleeve unless drain kit is used

NOTE: Construct wall opening to comply with all applicable

building codes.

10

Page 11

920-087-04 (8-05)

Section II - DeepWall Installation (PXWE)

If thewall isthicker thanallowed in the notes in Figure 6, a sheet

metal wall sleeve extension and flashing MUST be used.

Installation Instructions for the PXWE- 4" Wall

Sleeve Extension

The following points MUST be considered when installing awall

sleeve extension:

1 Provision must be made to direct excess condensate from

the back of the wall sleeve into the extension then outside

the building or to a drainage system.

2. Air baffles must be mounted to properly direct air flow to

and from the condenser.

3. Thewall sleeve extension design mustallow for the proper

mounting of the grille.

4. Caulking is required at all sites where condensate or

external water could potentially infiltrate intothe building.

5. Fabricateand install metalflashing inwall to serveas adrip

panel. Referto drawing for more information.

6. Condensate notches and overflow slotsmust bekept clear

of sealant and gaskets so condensate can flow freely into

the wall sleeve extension.

NOTE: Improper fabrication or installation of a wall sleeve

extension will impair PTAC performance.

Extension Installation

Secure the wall sleeve extension to the wall sleeve before

installing itin the wall. Referto Figure8 fora guide forfabrication

of acondensate drip panel.The panel MUST extend thefulldepth

of the wall sleeve and the wall sleeve extension.

Pay particular care in sealing and caulking the panel where it

makescontact withthewall sleeve(seeFigure8).After installation

in thewall, secure withfasteners through the sides. Use agood

grade of silicone sealant around the sleeveextension. Seal all

exposed screw heads. When the installation is complete, the

outside grille should be attached to the wall sleeve extension.

Figure8

WallSleeveExtensionSealant Locations _ION__ s

IMPORTANT NOTE: The silicone bead MUST extend 3" J w=. _l ..... _.

_') up the side of the two flanges to prevent condensate / _X'e'n"si'on _ "_,

from leaking. _!' r_ear _an_ r,_n/._

Wall Sleeve I _._ _lll_i='_" l

Outside Edge Sealant

Insulation

Drip

Width of Wall Edge Notches (4)

Wall Sleeve Extension, 42" X 16" Frame, 20 gauge minimum, painted or aluminium

I Wall Sleeve _.llf,[/'_) •

Silicone Bead 7-_

I Drip Panel L

Sealant around perimeter

Wall Sleeve

Extension

i Sealant inside (4)

bottom corners

Page 12

920-087-04 (8-05)

InstallationInstructionsModel PXGAStandardGrille

1. Removethe center support andweatherboard ifstill installed

in the sleeve.

2. Insert six plastic grommets into the grille openings from the

outside of the grille as shown in Figure 9.

3. Insert two#8 x 3/8" sheet metal screws (provided) in the top

two outside edge plasticgrommets,and tightenthem halfway

intothe grommets.

4. CAUTION: Bodily injury can be caused bygrilles falling from

a building during installation. It is recommended that a safety

line be attached to the grille and an anchor point inside the

buildina durina installation.

Figure9

Standard Grille

5. Grasp the grille by the attached plastic handles. Position

itwith the condensate drain knockouts facing down. From

inside the building, maneuver the grille through the wall

sleeve and pull toward you until the screw heads are

inserted intothe keyhole slotsat the top of the wall sleeve.

Tighten the two screws completely.

6. Insert the remaining screws into the remaining holes and

tighten securely.

Quantity Description

1 Stamped Aluminum Grille

6 Plastic Grommets

6 #8 x 3/8"Sheet Metal Screws

Wall sleeve

-- Weatherboard

-- Center support

!

Plastichandles Plastic

grommets

12

Page 13

920-087-04 (8-05)

A. Electrical RatingTables

All 230/208 voltunitsareequippedwithpowercords.SeeAppendixBon page19 forwiringinstructionson265V units.

NOTE: Use Copper Conductors ONLY. Wire sizes are per NEC, check local codes for overseas applications.

Table 1 250 V Receptacles and Fuse Types

AMPS 15 20* 30

RECEPTACLE (_ @ @

TIME-DELAY TYPE FUSE

(or HACR circuit breaker)

HACR - Heating, Air Conditioning, Refrigeration

* May be used for 15 Amp applications iffused for 15Amp

NOTE: 265 volt units are hard wired.

Table 2 Recommended branch circu# wire sizes*

NAMEPLATE / MAXIMUM

CIRCUIT BREAKER SIZE

15 14

20 12

30 10

AWG -American Wire Gauge

* Single circuit from main box

** Based on copper wire, single insulated conductor at 60°C

ELECTRIC SHOCK HAZARD! rum dfelectricpowerbeforeserviceorinstallation.

AllelectricalconnectionsandwiringMUSTbe installedbya qualifiedelectricianand

conformtothe NationalBectricatCodeand all local codeswhichhavejurisdiction.

Failuretodoso canresultinpropertydamage,personalinjuryand/ordeath.

15 20 30

AWG WIRE SIZE**

WIRE SIZE

FUSE/CIRCUIT

BREAKER

GROUNDING

RECEPTACLE

WIRE SIZING

Use ONLY wiring size recommended for

single outlet branch circuit.

Use ONLY type and size fuse or HACR cir-

cuit breaker indicated on unit's rating plate.

Proper current protection to the unit is the

responsibility of the owner. NOTE: A time

delay fuse is provided with 265V units.

Unit MUST be grounded from branch circuit

through service cord to unit, or through sep-

arate ground wire provided on permanently

connected units. Be sure that branch circuit

or general purpose outlet is grounded. The

field supplied outlet must match plug on

service cord and be within reach of service

cord. Refer to Table 1 for proper receptacle

and fuse type. Do NOT alter the service cord

or plug. Do NOT use an extension cord.

The field supplied outlet must match plug on

service cord and be within reach of service

cord. Refer to Table 1 for proper receptacle

and fuse type. Do NOT alter the service cord

or plug. Do NOT use an extension cord.

Use recommended wire size given in Table

2 and install a single branch circuit. All wiring

must comply with local and national codes.

NOTE: Use copper conductors only.

B.PowerCordInformation(230/208V modelsonly)

All Friedrich230/208V PTACunitsareshippedfrom thefactorywith

a Leakage Current Detection Interrupter(LCDI)equipped power

cord. The LCDI device meets the UL and NEC requirementsfor

cordconnected air conditionerseffectiveAugust2004.

Totest your powersupply cord:

1. Plug powersupplycord intoa grounded3 prongoutlet.

2. PressRESET.

3. Press TEST (listenfor click; Resetbuttontrips and popsout).

4. Press and release RESET (listen for click; Reset button

latchesand remains in).The power supplycord is readyfor

operation.

FigurelOa

15/20A I.CDI Device

2"

4 ,t ,i

NOTE: The LCDI device is not intended to be used as a switch.

Once pluggedinthe unitwill operatenormallywithoutthe needto

resettheLCDI device.IftheLCDIdevicetripsand requiresresetting

the causeof the trip should be identified priorto further use ofthe

PTAC.

If the devicefails to trip whentested or if the powersupply cord is

damaged itmustbe replacedwith a newsupplycordobtainedfrom

the productmanufacturer,andmust not be repaired.

FigurelOb

30A I.CDI Device

1

13

Page 14

InstallationChecklist

920-087-04 (8-05)

[] Inspect all components and accessories for damage

before and after installation.

[] Remove the cardboard wall sleeve support and grille

weatherboard.

[] Check for proper wall sleeve installation in accordance

with the wall sleeve installation instructions.

[] Check for a subbase kit or other means of structural

support which is required for ALL installations projecting

more than 8" into room.

[] Install the recommended Condensate Drain Kitsfor

complete condensate removal.

[] Ensure that the chassis is installed ina 16" high x 42"wide

wall sleeve that is no deeper than 133/4". A baffle kit is

required ifthe sleeve exceeds that depth.

[] Ensure that drapes, bed, bedspread, furniture, etc. DO

NOT block either return or discharge air grilles.

[] Inspect the condenser air inlet andoutlet for any

obstructions (shrubbery, etc.)

[] Ensure that'reset' button is pressed on LCD device (only

on cord connected models)

Section III - ChassisInstallation

Checktobesurethewallsleeve,extension(ifused),grille,anddrainkitare installedproperlybeforechas.,isinstallation.

1. Removetheweatherboardandcentersupportfromthesleeve

(ifstillin place).Be sure an outdoorgrille is attached.

NOTE: Toavoid breaking the door or hinge pins, do not apply

excessive force when installing

Pins

®

Wall sleeve

--Weatherboard

Center support

IMPORTANT:Useawall sleeveadapterkit(PXSE)if

installinga P-Series chassis ina T-Seriessleeve.

Suffocation hazard

Keep bag away from babies and children.

Do NOT use in cribs, beds or playpens. Destroy

immediately after opening. This bag is NOT a toy.

Failure to do so can result in personal injury and/or death

2. Removethe front covercontained in a protectiveplasticbag

from chassis. Remove the bag anddispose of itproperly.

If the control door is not installed, follow these steps:

From the front of the cover, slide the right control door pin

into the hole on the right side of the front cover. Slide the

left door pin into the hole on the left side of the front cover

opening and snap it into place.

14

" Control

Door

i

J

Front Panel

3. Remove the two chassis shipping brackets from the ends

of the shipping pallet.

®

Compressor

Chassis

shipping bracket

Shipping pallet

IMPORTANT: When installinga FriedrichP-Series PTAC intoan

existing sleeve, it is important to ensure that the unit is installed

completely. Inspectionofthe airseal betweenthe condenserair

baffles andaround the indoor mounting flange is recommended.

In somecases additional gaskets or baffling may be required.

Page 15

920-087-04 (8-05)

4. Centerthe chassis in the pre-installed sleeve andcarefully

pushthe chassis untilthe chassisflange andgasket contact

the sleeveflange.

®

Wall sleeve

j Wall sleeve flange

Chassis flange

and gasket

NOTE: Ifthe unit is mounted flush to the floor, the service cord

MUST be rerouted at the bottom of the front cover on the side

closest to the receptacle. A notch MUST be made in the front

cover sidewhere thecord exits the unit. Itis the responsibility of

the installertocreate anexit notch. See diagram8 for suggested

opening size and placement.

them into the quick nuts located on the chassis to secure

the cover. If the unit has been placed such that there is no

room to insert thethumbscrews from the bottom, request a

Side Mounting kit (Part No. PXSM) from Friedrich. Locate

the service cord or conduit in the notch atthe bottom right

of the front cover.

®

7. Ifthe filters are not already installed in tracks in the plastic

cover, slidethem into place.

8. Plugthecord (ifapplicable)into theappropriate receptacle.

Extra cord may be coiled inside the front cover behind the

return air grille. Restore power to the unit.

®

®

Screw clips

mounting screw

5. Locatethe four#10 x 1"chassis mounting screws. Tighten

thescrews intothe clips - adjacentto thealignment dimples

on the mounting brackets on the wall sleeve flange (two

per side).

6. Install the front cover assembly (including the discharge

grille) by placing the top of the cover onto the 90° angle

bracketalong the top of the chassis. Rotatethe bottom into

place and insert the included thumb screws into the slots

located at the bottom back corners of the cover. Tighten

Ifa remotethermostatis to beinstalled, proceedto page 18, Step 1, Fora 265 V unit,proceedto AppendixA,Step 1.

Chassis

flange

To remove the front cover, remove the thumbscrews

at the bottom back corners of the cover (or sides).

Pull the bottom end forward and lift it up to clear the

L bracket across the top of the chassis,

®

Not to scale

15

Page 16

920-087-04 (8-05)

DigitalControlUserInput Configuration

The adjustable control dip switches are located at the lower left hand portion of the digital Smart Center. The inputs are only visible

and accessible with the front cover removed from the PTAC.

Dip Switch Setting

1) Electronic Temperature Limiting - Switches 1-4

The digital control is set from the factory to allow a tempera-

ture range between 60°F and 90°F in both heating and cooling

mode. Dip Switches 1-4 can be used to set high and low limits

for either heating or cooling or both.

From the factory all four switches are in the up 'ON' position.

The charts to the right show the available electronic limiting

ranges.

2) Fan Cycle Control - Switch 5

All PTACs are shipped from the factory with Dip Switch 5 in the

'OFF' position to cycle the fan only when there is ademand for

the compressor or heater.As an option the fan may be set to

'continuous' mode by switching Dip Switch 5 to 'ON' position to

run the fan continuously while the unit is powered on.

Toensure that the room temperature is maintained evenly while

in fan cycle mode the Even Temp Load Anticipation feature is

enabled. Quiet Fan Belay is also enabled in fan cycle mode to

lessen the acoustical change between compressor start up and

shut off by running the fan for 5 seconds before each demand

cycle, and 30 seconds after cooling or 15seconds after heating

cycles.

3) Room Freeze Protection - Switch 6

Unitsare shippedfrom thefactory with the room freeze protection

disabled. Room Freeze Protection can be switched on at the

owner's preference by movingDip Switch 6 to 'ON'. This feature

will monitor the indoorroom conditions and in the event that the

room falls below 40°F the unit will cycle on high fan with the

electric heater.This occurs regardless of mode.

Heating RangeSwitches 1 & 2

Temperature

Range

Low High

60 90

60 87

60 84

60 81

CoolingRange Switches 3 & 4

Ternperatu re

Range

Low High

60 90

63 90

66 90

69 90

Figure11

Factory DipSwitch Configuration

12345678

Dip

Switch

1 2

On On

Off On

Off Off

On Off

Dip

Switch

3 4

On On

On Off

Off Off

Off On

4) Emergency Heat Override - Switch 7

In the unlikely event of a compressor failure a heat pump unit

may be switched to operate in only the electric heat mode until

repairs can be made. Moving Dip Switch 7to 'ON'.

Note: PTAC must be disconnected from power supply

when making any configuration changes.

16

Page 17

DigitalControlOperation

920-087-04 (8-05)

TemperatureDisplay

The Ffiedfich digital PTACisshipped from the factory to display

the desired room temperature on the LED readout.

The unit can be configured to display the room temperature by

simultaneously pressing the 'Cool' and 'High Fan' buttons

for three seconds the display will show an 'F,"for one seconds

to acknowledge the change. The unit will display the setpoint

whenever the 'Temp' A or v buttons are pressed and then

switch back to room temperature.

Torevertback todisplayingthe setpointonly press the'Ceor and

'LowFan' buttonsfor three seconds simultaneously,the unitwill

display an'S' for one seconds to acknowledge the change.

°Fvs. °C Display

The unit is factory configured to display all temperatures in

degrees Fahrenheit (°F). To switch to degrees Celsius press

the 'Fan Only' and 'Low Fan' buttons simultaneously for three

seconds. The display will show a 'C' as acknowledgement of

the change.

Torevert backto oFpress the 'Fan Only' and 'Low Fan' buttons

simultaneously forthree seconds. The display will show an 'F'as

acknowledgement of the change.

CoolingMode

Pressingthe 'Cool' buttonwhile the unitis inany mode, including

off, will put the unit into cooling mode. Adjust the temperature

readout to the desired room temperature and the unit will cycle

the compressor on and off to maintaina comfortable room. The

compressor will come on anytime that the room temperature

is 1.8°F above the desired temperature. The fan operation is

dependentonthefan modeselected, eithercontinuousorcycling.

See page 16 for fan cycle control.

Heating Mode

Pressing the 'Heat' buttonwhile theunit isin anymode, including

off,will put the unit into heating mode.

Heat Pump Models (PDH)

When the 'Heat' button is pressed initially the unit will energize

the electric resistance heat to quickly bring the room to the

set temperature. When the desired room temperature falls

1.8°F below the desired set temperature the unit will cycle the

compressor onand operate asa heat pumpto maintaintheroom

temperature while running more efficiently than resistance heat

only models. If the room temperature should fall more than 5°F

from the set temperature the unit will run the resistance heater.

Thefan operation isdependent onthe fan mode selected, either

continuous or cycling. Dip switch 5controls the fan mode, see

page 16 for setting.

Whenthe outdoorcoiltemperaturefalls below 30°Ffor morethan

2 minutesthe unitwill operate the resistanceheaters and not the

compressor. When the outdoor coil temperature reaches 45°F

the compressor will be allowed to operate again.

Figure12

DigitalControlPanel

Temp

Heat/Cool Models (PDE)

After pressingthe 'Heat'button,adjust thetemperaturereadoutto

the desiredroomtemperatureand theunit willcycletheresistance

heat on and off to maintain a comfortable room. The heater will

come on anytime that the room temperature is 1.8°F below the

desired temperature. Thefan operation is dependent on the fan

modeselected, eithercontinuous orcycling. Dip switch 5controls

the fan mode, see page 16for setting.

EmergencyHeat Operation

In the event of a compressor failure in heat pump mode the

compressor may be locked out to provide heat through the

resistance heater. This feature ensures that even in the unlikely

event of a compressor failure the room temperature can be

maintained until the compressor can be serviced. Dip switch 7

controls the emergency heat setting, see page 16.

Mode Fan

sMAnr CENTER

Fan Mode

Fan Only

Pressing the 'Fan Only' button will run the fan to allow for air

circulation in the room without operating the compressor or

heater regardlessofthe room or set temperature.The fan speed

selection is made by pressing either the 'High Fan' or 'Low

Fan' button.

Cycle/Continuous

The owner may choose between fan cycling or fan continuous

mode based on property preference. (Note: Even heat

monitoring and quiet start/stop fan delay only operate in fan

cycle mode) Fan continuous mode is used to keep constant

airflow circulation in the room during alltimes the unit is 'ON'.

Fan cycle will conserve energy by only operating the fan while

the compressor or electric heater is operating. Dip switch 5

controls the fan mode, see page 16 for setting.

17

Page 18

920-087-04 (8@5)

RemoteThermostatand LowVoltageControlConnections

Remote Thermostat

All Friedrich PD model PTAC units arefactory configured to be

controlled byeither the chassis mounted Smart Center ora 24V

single stage remote wall mounted thermostat. The thermostat

may be auto or manual changeover as long as the control

configuration matches that of the PTAC unit.

To control the unit with a wall mounted thermostat follow

the steps below:

1) With thefront cover removedlocatethelowvoltage terminal

strip at the lower portion of the Smart Center.

2) Remove thejumper betweenthe 'GI2and GH' terminals.

3) The control is now configured for control bya wall thermo-

stat. The Smart Center will no longer control the unit.

4) If desired the accessory escutcheon kit (PDXRT) is to be

used, install it over the existing control panel.

Note:Torevert backtothe Smart Centercontrolofthe unitreplace

the jumper wire between the 'GI2 and 'GH' terminals that was

removed in step 1.

Thermostat Connections

C = Common Ground

W = Call for Heating

Y = Callfor Cooling

R = 24V Powerfrom Unit

GL = Call for Low Fan

GH = Callfor High Fan

B = Reversing Valve Energized in heating mode

(PDH Models Only)

*If only one G terminal is present on thermostat connect to GL

for lowfan or to GH for high fan operation.

Figure13

Control board with optional PDXRTescutcheon kit installed

{oo st o byWa l ® mostat

U;sewu 1o operate _t

18

Page 19

920-087-04 (8-05)

Desk ControlTerminals

The Friedrich PD model PTAC has built-in provisions for

connection to an externalswitch to control power tothe unit.The

switch can be a central desk control system or even a normally

open door switch.

For deskcontrol operation connect one side of the switch to the

D1 terminal and the other to the D2 terminal (See figure 13).

Whenever the switch closes the unit operation will stop.

Maximum Wire Length for Desk Control Switch

Wire Size

#24

#22

#2O

#18

#16

Maximum Length

400 ft.

6OOft.

9OOft.

1500 ft.

2000 ft.

Note: The desk

control system and

switches must be

field supplied.

G.FreshAirVentControl

The vent control lever is located behind the front cover on the

left side of the unit. The unit is shipped in the closed position

with a locking screw in place. The screw must be removed to

operate the lever. When the lever is back, (OPEN), outside air

is mixedwith indoor air. When the lever is forward, (CLOSED),

no outside air isadmitted into the room and room airis recycled

through the unit.

NOTE: The vent should remain closed for peak operating efficiency.

Auxiliary Fan Control

The Smart Center also has the ability to control a 24VAC relay

to activate an auxiliary, or transfer, fan. The outputs are listed as

F1and F2on the control board.

To connect the relay,simply wire one side of the relay to F1and

the othersideto F2.Anytime thatthe PTACfan runstheterminals

will send a 24VACsignal to the relay.The relay must be 24 VAC,

50mA or less.

Note: The relay and auxiliary fans must befield supplied.

NOTE: It isthe installer's responsibility to ensure that all control

wiring connections are made in accordance with the installation

instructions. Improperconnection ofthethermostat control wiring

and/or tampering with the unit's internal wiring can void the

equipment warranty and may resultinproperty damage, personal

injury or death. Other manufacturer's PTACs and even older

Friedrich models may have different control wire connections.

Questions concerning proper connections to the unit should be

directed to the factory.

OPEN CLOSED

OUVERT FERME

ABIERTA CERRADA

FRESH AIR DOOR IS FACTORY

SHIPPED IN CLOSED POSITION.

REMOVE TOP SCREW ON LEVER

TO OPEN DOOR.

250-453-01

VENT

AERATION

SALIDA (ESCAPE)

DEL AiRE

H.Air DischargeGrille

Moving parts hazard,

Turn off electric power before

servicing this component.

Failure to do so can result in property

damage, personal injury and/or death.

Theair dischargegrille canbe redirectedto blowaireitherstraightuporatan angle intotheroom. Tochangethe airflowdirection,remove

thefront cover, locateand removethe six grill retainingscrews. Reversethe ends of the grille and refasten the grille to the cover.

19

Page 20

I.Start-upChecklist

920-087-04 (8-05)

F! Inspect all components and accessories for

damage before and after installation.

[] Check installation for compliance with all national

and local codes and ordinances.

[] Read and follow all manufacturer's installation

instructions.

[] Check that circuit breaker(s) and electrical wire

sizes are correct. If the unit is supplied with a

power supply cord, insure that it is stored properly.

[] Check the condensate water drain outlet(s) to

make sure they are in compliance with all national

and local codes, that they are adequate for the

removal of condensate water, and that they meet

the approval of the end user.

[] Strictly follow installation instructions concerning

clearances around the unit,

[] Secure components and accessories, such as the

control door and front cover.

[] Check the unit air filter, condenser coil and

evaporator coil for any obstructions,

[]

Check for proper operation of all components.

[]

Instruct the owner or operator of the units

operation, and the manufacturer's

recommended routine maintenance schedule,

NOTE: It is highly recommended that a maintenance

schedule log book be prepared for recording

the dates and times of service.

[] Operate the unit for twenty minutes, Record

the unit's indoor/outdoor intake and discharge

temperatures, amperage draw, and power voltage.

[] Assemble the Warranty Certificate, the Operation

and Installation Manual, all accessory installation

instructions and the name, address and telephone

number of the Authorized Friedrich Warranty

Service Company in the area for the owner or

operator,

NOTE: Units are to be installed, inspected, and checked byqualified service personnel only.

20

Page 21

920-087-04 (8-05)

AppendixA: ElectricalWiringfor265 VoltModels

NOTE: Itis recommended thatthe PXSB subbase assembly,the PXCJ conduit kit and the PXDS disconnect switch be installedon all

hardwired units. Ifinstalling aflush-floor mounted unit, make provisionsfor allthe line voltage power leads and conduit to beremoved

for ease of maintenance and service to the chassis.

Toinstall the line voltage powerleads and conduit to the chassis, follow the instructions below.

1. Remove thefour control boxretainingscrews (A)and open

the control box.

2. Pullthechassispowerleadwires (B) (locatedonthebottom-

rightside of the controlbox)through the plasticbushing so

they are located inside the control box.

3. Remove the plastic bushing.

4. Routethe linevoltage power leads through the holewhere

the plasticbushingwas located,and secure itsconduit (use

a 1!2" straight conduit connector, with the Iocknut on the

insideof the control box.)

Figure15

LineVoltageConnections

5. Make the appropriate electrical connections within the

control box, then secure the box on the chassis. Detailed

instructions are included with the installation instructions

for the conduit kit (PXCJ).

6. Route the line voltage power conduit from the control

box straight down the right front to the bottom side of the

chassis. Thiswillallow thefront cover tobe installedwithout

interference with the electrical conduit.

Inside back of control

panel cover.

Screws

Screws

Fuse holder

21

Page 22

920-087-04 (8-05)

J.RoutineMaintenance

NOTE: Units areto be inspected and serviced by qualified service personnel only.

1. Cleanthe unitair intakefilter atleast every300 to350 hours

of operation. Cleanthefilters with a milddetergent inwarm

water and allow to dry thoroughly before reinstalling.

2. The indoorcoil (evaporatorcoil),the outdoor coil(condenser

coil) andbase panshould beinspected periodically (yearly

or bi-yearly)andcleaned ofalldebris(lint,dirt, leaves,paper,

etc.). Clean the coils and base pan with a soft brush and

compressed airor vacuum. Ifusing a pressure washer, be

careful notto bend thealuminium fin pack. Use asweeping

upand down motionin the directionof thevertical aluminum

fin pack when pressure cleaning coils. Cover all electrical

components to protect them from water orspray.

Before reinstalling the chassis in the sleeve, inspect the

indoor blowerhousing, blower wheel, condenser fan blade,

and condenser shroud periodically (yearly orbi-yearly) and

clean of all debris (lint, dirt, mold, fungus, etc.) Clean the

blowerhousing area and blowerwheel with an antibacterial

/ antifungal cleaner. Use a biodegradable cleaning agent

and degreaser on condenser fan and condenser shroud.

Use warm or cold water when rinsing these items. Allow

the unit to dry thoroughly, inspect all gasket material for

deterioration (replace as necessary), and then reinstall the

chassis in the sleeve.

Periodically (at least yearly or bi-yearly): inspect all control

components, both electrical and mechanical, aswell asthe

power supply. Use proper testing instruments (voltmeter,

ohmmeter, ammeter, wattmeter, etc.) to perform electrical

tests. Usean air conditioning or refrigeration thermometer

to check room, outdoor and coil operating temperatures.

Useaslingpsychrometertomeasurewet bulbtemperatures

indoors and outdoors.

,

Inspectthe surroundingarea (inside and outside)to ensure

that the units' clearances have not been compromised or

altered.

Inspect the sleeve and drain system periodically (at least

yearly or bi-yearly)andclean ofall obstructions and debris.

Clean both areas with an antibacterial and antifungal

cleaner. Rinse both itemsthoroughly withwater andensure

that the drain outlets are operating correctly. Check the

sealant around the sleeve and reseal areas as needed.

,

Clean the front cover when needed. Use a mild detergent.

Wash and rinse with warm water. Allow them to dry

thoroughly before reinstalling them in the chassis.

NOTE: Do not use a caustic coil cleaning agent on coils

or base pan. Use a biodegradable cleaning agent and

degreaser.

Figure16

Components

Condenser Fan Blade

Indoor Blower

Discharge Air Grille

Filters

Return Air Control Panel

Grille Evaporator Coil

Indoor Blower

Housing

Condenser Gasket

Condenser Shroud

Outdoor Grille

3ressor Wall Sleeve

22

Page 23

920-087-04 (8-05)

K.BasicTroubleshootingTechniques

Being familiar with the sequence of operation on Standard Controlled Operating Units or the operation of the Remote Thermostat

Controlled Units is important. The following questions and answers may help to identify performance problems.

EnvironmentalEffects- CoolingMode

Isunitsizedtoroomsizeareaand heatloaddemand?

The number of people in the room, numberof electrical devices,

solar gains, etc. are all variable items that can affect proper

sizing of the unit. Friedrich recommends that you consult with

an applications engineer for proper sizing.

Isthe outdoortemperature60°F orbelow?

The unit is designed for outdoor temperatures above 60°R

Isthe indoortemperature80°For above?

Ambient indoor temperatures of80°F or abovewill take a longer

period of run time to cool down the area. Long run times may

indicate that the unit isundersized.

Isindoorhumidityhigh?

This condition will cause the unit to operate longer to remove

humidity before noticingany cooling effect.

Hasthe heat load been increasedby additional devicessuch

as computerequipment, orhasthe roomarea been increased

wherethe unitis located?

If conditions havechanged, the unit maynot beable tocool and

condition as effectively as previously planned.

Environmental Effects- Heating Mode

Isunitproperlysizedtoroomarea andheat loaddemand?

The number of people inthe room,number of electrical devices,

solar gains, etc. are all variable items that can affect proper

sizing of the unit. Friedrich recommends that you consult with

an applications engineer for proper sizing.

Isthe outdoortemperaturo70°For above?

The unit is designed for outdoor temperatures below 70°R

Is the indoor temperature 60°F or below? Ambient indoor

temperatures of 60°F or below will take a longer period of run

time to heat the area. Long run times may indicate that the unit

is undersized.

Hasthe roomareabeenincreasedwherethe unitislocated?

If thearea where the unit is located has beenincreased, the unit

may not provideadequate heat.

Insufficient Maintenance and Inspection

Installationerrorsarethemostcommoncauseofpoorperformance.

Pleasefollow installationinstructions carefully. If other problems

exist, see Maintenance and Inspection Troubleshooting Guide

below.

Maintenance and Inspection Troubleshooting Guide

CAUSE RESULT

System is not serviced or inspected Can result in premature component failures, poor performance and

regularly (semiannually or annually), increased operating costs.

Air filters are not cleaned regularly and May result in poorcooling, icing and water problems aswell as

become blocked with particles, component failures and increased operating costs.

Condenser coil not maintained

properly (blocked with particles).

Evaporator coil not maintained properly May result in poor cooling, icing and water problems, and increased

(blocked with particles), operating costs.

Components that show signs of fatigue May result in multiple service calls, poor performance and

- not replaced, increased operating costs.

Condensate drains and drain lines not May result in water and odor problems.

maintained.

May result in poor cooling, component failures and increased costs.

23

Page 24

920-087-04 (8-05)

DigitalControlDiagnosticsandTestMode

Diagnostics

The Friedrich Smart Center continuously monitors the PTAC unit

operation and will store service codes if certain conditions are

witnessed. In some cases the unit may take action and shut the

unit off until conditions are corrected.

Toaccess theerror code menu press the 'Heat' and 'High Fan'

buttons simultaneously for three seconds. If error codes are

present they will be displayed. If multiple codes exist you can

toggle between messages using the temp A button. To clear

TestMode

For service and diagnostic use only, the built-in timers and

delays on the PTAC may be bypassed by pressing the 'Cool'

and 'Low Fan' buttons simultaneously for three seconds while

in any mode to enter the test mode. TEwill bedisplayed when

entering test mode, and DEwill be displayed when exiting. The

testmode willautomatically beexited 30 minutesafter entering it

or bypressing the 'Cool' and 'Low Fan' buttons simultaneously

for three seconds.

all codes press the temp v button for three seconds while in

the error code mode. To exitwithout changing codes press the

'Low Fan' button.

The chart below lists the possible error codes and their description:

Error

Code

n., NOT USED NONE

UI

An extreme low voltage condition Shut down unit. Display Error code and flash. • Inadequate power supply

02 exists <198Vfor 230V units and Once voltage rises to normal level system power • Defective breaker

<239V for 265V units, isrestored. • Blown fuse

03 Return airthermistor sensor open Set return air sensor = 75°F. Alternate flash set • Defective sensor

or short circuit pointand error code. Leave unit running.

Code Translation Action Taken by Unit Possible Cause

o,_I Indoorcoil thermistor sensor open Set ID coiltemp = 40°F. Alternate flash set point • Defective sensor

Or short circuit and error code. Leave unit running.

Outdoor coil thermistor sensor SetOD coil temp =20°F. Alternate flash set point

n.g open Or short circuit and error code. Automatically change over to • Defective sensor

IfO.D. coil Temperature > 175 Deg

06

Ffor 2consecutive minutes. (Heat

Pump models only)

I.D coil temperature <30 Deg F for

n"/

u/

2 consecutive minutes.

08 Ifunit cycles (Heat or Cool Alternate flash set point and error code. Keep unit • Unit oversized

demand)> 9 times per hour running. • Low load conditions

nS, If unit cycles (Heat or Cool Alternate flash set pointand error code. Keep unit • Unit undersized

demand)< 3 times per hour running. • High load conditions

Electric heat Modeonly. Leave unit running.

Alternate flash set point and error code. Shut unit

down for 5 minutes, then try again 2 times, iffails

the 3rd time, then shut down unit.

Alternate flash set point and error code. Continue

fan operation while the compressor is locked out

untilthe indoor coil thermistor reaches 45° F,and

then energize the compressor. However, com-

pressor must still wait a lockout time of 180to 240

seconds.

• Dirty coil

• Fan motor failure

• Restricted air flow

• Non-condensables in

refrigeration system

• Dirty filters

• Dirty coil

• Fan motor failure

• Restricted airflow

• Improper refrigerant charge

• Restriction in refrigerant circuit

.,n Room Freeze Protection triggered

u running.

24

Alternate flash set point and error code. Keep unit • Room temperature fell below 40°F

Page 25

920-087-04 (8-05)

FriedrichPTACAccessories

MODELNUMBER DESCRIPTION PHOTO

WALL SLEEVE zinccoated steel isprepared inan eleven-step

process, then powder coated with a polyester finish and cured

PDXWS

in an ovenfor exceptional durability. Thewall sleeve isinsulated

for sound absorption and thermal efficiency.

16" High x 42" Wide x 13¾" Deep.

PDXWS

PXGA

PXAA

PXDB

PXSC

PXDR10

PXWE

PXSB

GRILLE standard, stamped aluminium, anodized to resist

chalking and oxidation.

ARCHITECTURAL GRILLES Consist of heavy-gauge

6063-T5 aluminum alloy:

PXAA- Clear, extruded aluminum

PXDB- Dark bronze acrylic enamel

PXSC- Also available in custom colors.

CONDENSATE DRAIN KIT Attaches to the bottom ofthe wall

sleeveforinternaldrainingof condensate orto the rearwallsleeve

flangefor externaldraining. Recommended on allunitstoremove

excess condensate. Packaged in quantities of ten.

DEEPWALL SLEEVE EXTENSION Afour inchdeep anodized

aluminiumextensionthatattachestothe outsideofthewallsleeve

when the wall is greater than eleven inches thick (9½" when a

subbase is used, 10 inches when a lateral duct is used).

DECORATIVE SUBBASE Provides unit support for walls less

than six inches thick. Includes leveling legs, side filler panels

and mounting brackets for electrical accessories. Accepts

circuit breaker, power disconnect switch, or conduit kit.

PXDB

PXDR10

PXWE

PXS_

RT2

PDXRT

DIGITAL REMOTE THERMOSTAT Digital electronic

thermostat with "one touch" adjustment. Mounts to wall for

control of unit.

PDXRT - REMOTE THERMOSTAT ESCUTCHEON KIT

This kit contains 10 escutcheons that can be placed over

the factory control buttons when a remote wall mounted

thermostat is used. The escutcheon directs the guest to the

wall thermostat for operation and retains the LED window to

display error codes and diagnostic information.

RT2

PDXRT

25

Page 26

920-087-04 (8-05)

MODELNUMBER DESCRIPTION PHOTO

SLEEVE EXTENSION RETROFIT KIT Zinccoated steel,

PXSE

2.4" sleeve extension attached to the room side of the

sleeve to allow for the installation of a P-Series Friedrich

PTAC in a T-Series sleeve.

PXSE

LATERAL DUCTADAPTER Attaches to the PTAC/PTHP

unitand provides a transition to direct up to 35% of the total

PDXDA

CFM toa secondary room, either left orright ofthe unit. Kit

includesduct plenum withdischarge grilleand internalbaffle,

adapter and end cap.

LATERAL DUCT EXTENSION A three foot insulated

PDXDE

plenum that attaches to the left or right side of the duct

adapter. The extension can be cutto length bythe installer.

PDXDA

Maximum allowable straight extension is fifteen feet.

PXDL

PDXFT

PXCJ

PXPC

15/2o/3o

CONTROL DOOR LOCK KIT Locks control door to

prevent tampering by unauthorized users

PXDL

REPLACEMENT FILTER PACK These are original

equipment return air filters. They are reusable and can be

cleanedby vacuuming,washing, or blowingout,and aresold

in convenient ten packs. (Two filters per chassis)

PDXFT

CONDUIT KITWITH JUNCTION BOX Hardwire conduitkit

with junction box for208/230V and 265V units(subbase not

required). Kitincludesa meansofquickdisconnectforeasy

removal ofthe chassis. *Required for 265V installations.

PXCJ

POWERCORDRETROFITReplacesLCDtpowercordon 230V

modelswhenunit is usedwitha subbase.PXPC15isusedwith

15 amp 2.5 kWunits. PXPC20isused with 20 amp 3.4 kW

units.PXPC30is usedwith 30 amp5.0 kWunits.

PXPC30

DESIGNATOR DESCRIPTION

S STANDARD UNIT Standard PTAC/PTHP chassis. Can be230/208V or 265V, electric or heat pump.

SEACOAST PROTECTION Additional protection for PTAC/PTHP units in a coastal or corrosive

C environment. The entire outdoor coil is submerged ina speciallyformulated enamel coating, then oven-

curedfor a tough,corrosion-resistantfinish.

26

Page 27

920-087-04 (8-05)

Friedrich Air Conditioning Company

P.O. Box 1540

San Antonio, TX 78295

210.357.4400

www.friedrich.com

PD-SERIES

PACKAGED TERMINAL AIR CONDITIONERS

LIMITED WARRANTY

SAVE THIS CERTIFICATE. It gives you specific rights, you may also have other rights which may vary from state to state and province to

province.

In the event that your unit needs servicing, contact your nearest authorized service center. If you do not know the nearest service center,

ask the company that installed your unit or contact us - see address and telephone number above. When requesting service: please have

the model and serial number from your unit readily available.

Unless specified otherwise herein, the following applies: PACKAGED TERMINAL AIR CONDITIONERS AND HEAT PUMPS

LIMITED WARRANTY - FIRST YEAR (Eighteen (18) Months from the original date of purchase or twelve (12) months from

installation). Any defect in the unit's material or workmanship will be repaired or replaced free of charge by our authorized service center

during the normal working hours; and

LIMITED WARRANTY - SECOND THROUGH FIFTH YEAR (Sixty-six (66) months from the date of purchase) ON THE SEALED

REFRIGERATION SYSTEM. Any part of the sealed refrigeration system on the P-series that is defective in material or workmanship will be

repaired or replaced free of charge (excluding freight charges) by our authorized service center during normal working hours. The sealed

refrigeration system consists of the compressor, metering device, evaporator, condenser, reversing valve, check valve, and the

interconnecting tubing.

These warranties apply only while the unit remains at the original site and only to units installed inside the continental United

States, Alaska, Hawaii, Puerto Rico and Canada. The warranty applies only if the unit is installed and operated in accordance

with the printed instructions and in compliance with applicable local installation and building codes and good trade practices. For

international warranty information, contact the Friedrich Air Conditioning Company - International Division.

Reasonable proof must be presented to establish the original purchase date, otherwise the beginning date of this certificate will be

considered to be our shipment date plus sixty days. Replacement parts can be new or remanufactured. Replacement parts and labor are

only warranted for any unused portion of the unit's warranty.

We will not be responsible for and the user will pay for:

1. Service calls to:

A) Instruct on unit operation. B) Replace house fuses or correct house wiring. C) Clean or replace air filters. D) Remove

the unitfrom inaccessible locations. E) Correct improper installations.

2. Parts orlabor provided by anyone other than an authorized service center.

3. Damage caused by:

A) Accident, abuse, negligence, misuse, riot, fire, flood, or acts of God. B) Operating the unit where there is a corrosive

atmosphere containing chlorine, fluorine, or any damaging chemicals (other than in a normal residential environment). C)

Unauthorized alteration or repair of the unit, which in turn affects its stability or performance. D) Failing to provide proper

maintenance and service. E) Using other than a "Seacoast Protected" unit in a coastal environment. F) Using an

incorrect power source. G) Faulty installation or application of the unit.

We shall not be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of

this unit. We have not made and do not make any representation or warranty of fitness for a particular use or purpose and there

is no implied condition of fitness for a particular use or purpose. We make no expressed warranties except as stated in this

certificate. No one is authorized to change this certificate or to create for us any other obligation or liability in connection with

this unit. Any implied warranties shall last for one year after the original purchase date. Some states and provinces do not allow

limitations on how long an implied warranty or condition lasts, so the above limitations or exclusions may not apply to you. The provisions of

this warranty are in addition to and net a modification of or subtraction from the statutory warranties and other rights and remedies provided

by law.

In case of any questions regarding the provisions of this warranty, the English version will govern.

(12-04)

27

Page 28

FriedrichAir ConditioningCo.

PostOfficeBox 1540 •SanAntonio,Texas78295-1540

4200 N. PanAm Expressway• SanAntonio,Texas78218-5212

(210) 357-4400 • FAX (210)357-4480

www.friedrich.com

Printed in the U,S,A. 920-087-04 (8-05)

Loading...

Loading...