Page 1

Service Manual

A SERIES

Single Package

Vertical Air Conditioning System

A – H Suffi x Models

MODELS

V(E,H)A09K25*** V(E,H)A09K34*** V(E,H)A09K50***

V(E,H)A12K25*** V(E,H)A12K34*** V(E,H)A12K50***

V(E,H)A18K25*** V(E,H)A18K34*** V(E,H)A18K25***

V(E,H)A24K25*** V(E,H)A24K34*** V(E,H)A24K50***

V(E,H)A24K75*** V(E,H)A24K10*** V(E,H)A24K00***

VPSERVMN (4-05)

*** Digits vary with model.

Page 2

Table of Contents

Introduction ......................................................................3

Vert-I-Pak Model Number Identifi cation Guide ..............4

Serial Number Identifi cation Guide .................................4

H Suffi x Chassis Specifi cations ......................................5

E and G Suffi x Chassis Specifi cations ............................6

A and D Suffi x Chassis Specifi cations ............................7

Sequence Of Operation ................................................... 8

Electrical Supply ..............................................................9

Supply Circuit ...................................................................9

Supply Voltage .................................................................9

Control (Low) Voltage ......................................................9

Supply Voltage .................................................................9

Electrical Ground .............................................................9

Electrical Rating Tables ...................................................9

Undercharged Refrigerant Systems ..............................17

Overcharged Refrigerant Systems ................................18

Restricted Refrigerant Systems .....................................18

Capillary Tube Systems .................................................19

Reversing Valve — Description/Operation ...................19

Electrical Circuit And Coil ..............................................19

Testing Coil ....................................................................19

Checking Reversing Valves ...........................................20

Touch Testing Heating/Cooling Cycle ..........................20

Procedure For Changing Reversing Valve ....................20

Compressor Checks ......................................................21

Locked Rotor Voltage Test ............................................21

Single Phase Connections ...........................................21

Determine Locked Rotor Voltage .................................21

Electrical Requirements ...................................................9

Room Thermostats ........................................................10

Thermostat Location ......................................................10

Heat Anticipators ..........................................................10

Electrical & Thermostat Wiring Diagrams ................ 11-13

Indoor Blower - Air Flow ................................................14

Condenser Fan Motors ..................................................14

Blower Wheel Inspection ...............................................14

Cooling ........................................................................... 14

Heating (Electric) ..........................................................14

External Static Pressure ................................................14

Checking External Static Pressure ...............................15

Checking Approximate Airfl ow ...................................... 15

Electric Heat Strips ........................................................15

Locked Rotor Amperage Test ........................................21

Single Phase Running & Locked Rotor Amperage .......21

External Overload ..........................................................21

Checking the External Overload ...................................21

Checking the Internal Overload .....................................21

Compressor Single Phase Resistance Test .................22

Compressor Replacement .............................................22

Capacitors ...................................................................... 23

Capacitor Check With Capacitor Analyzer ....................23

Capacitor Connections ..................................................23

Emergency Heat Switch ................................................24

Wiring Diagram Index .............................................. 25-26

9-18 Electrical Troubleshooting Chart – Cooling .........39

2-Ton Electrical Troubleshooting Chart – Cooling .......40

Airfl ow Charts ................................................................16

Refrigerant Charging .....................................................16

Method Of Charging ......................................................17

2

Refrigerant System Diagnosis – Cooling ......................41

Refrigerant System Diagnosis – Heating ...................... 41

Electrical Troubleshooting Chart –Heat Pump .............42

Page 3

Introduction

This service manual is designed to be used in conjunction with the installation manuals provided with each air

conditioning system component. Air conditioning systems consist of BOTH an evaporator (indoor section) and a

condenser (outdoor section) in one closed system, and a room thermostat. When so equipped, accessories such as

electric strip heaters are also considered part of the system.

This service manual was written to assist the professional HVAC service technician to quickly and accurately diagnose

and repair any malfunctions of this product.

This manual, therefore, will deal with all subjects in a general nature. (i.e. All text will pertain to all models).

IMPORTANT: It will be necessary for you to accurately identify the unit you are

servicing, so you can be certain of a proper diagnosis and repair.

(See Unit Identifi cation.)

WARNING

The information contained in this manual is intended for use by a qualifi ed service technician who is familiar

with the safety procedures required in installation and repair, and who is equipped with the proper tools and

test instruments.

Installation or repairs made by unqualifi ed persons can result in hazards subjecting the unqualifi ed person

making such repairs to the risk of injury or electrical shock which can be serious or even fatal not only to them,

but also to persons being served by the equipment.

If you install or perform service on equipment, you must assume responsibility for any bodily injury or property

damage which may result to you or others. Friedrich Air Conditioning Company will not be responsible for any

injury or property damage arising from improper installation, service, and/or service procedures.

3

Page 4

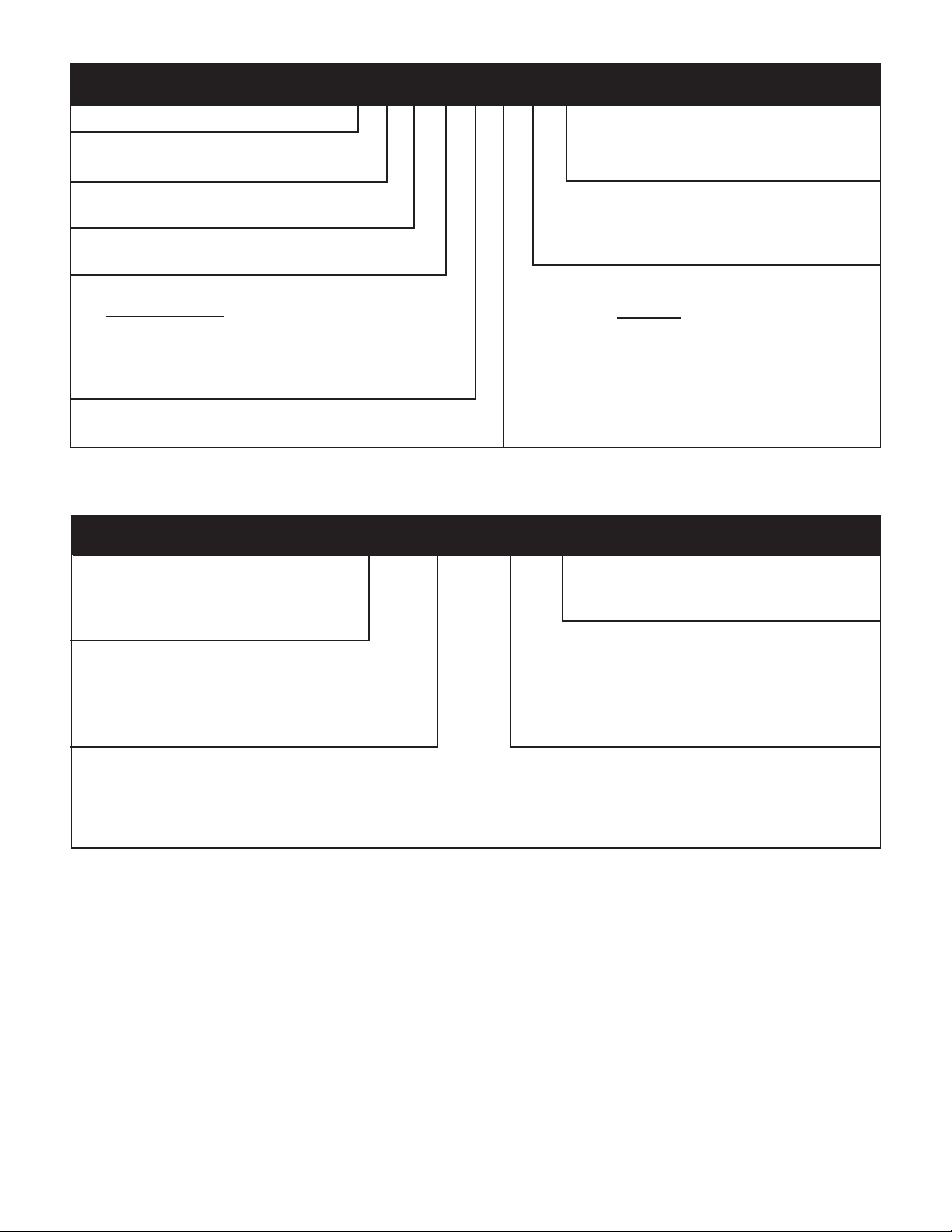

Model Identifi cation Guide

MODEL NUMBER V E A 24 K 50 RT A

SERIES

V=Vertical Series

E=Cooling with or without electric heat

H=Heat Pump

DESIGN SERIES

A = 32" and 47" Cabinet

NOMINAL CAPACITY

A-Series (Btu/h)

09 = 9,000

12 = 12,000

18 = 18,000

24 = 24,000

VOLTAGE

K = 208/230V-1Ph-60Hz

Serial Number Identifi cation Guide

SERIAL NUMBER

L K A V 00001

Decade Manufactured

J = 9 K = Not Used

L = 0

YEAR MANUFACTURED

A = 1 E = 5 J = 9

B = 2 F = 6 K = 0

C = 3 G = 7

D = 4 H = 8

PRODUCTION RUN NUMBER

PRODUCT LINE

R = RAC

P = PTAC

E = EAC

V = VPAK

H = SPLIT

EN GI NEER ING CODE

OPTIONS

RT = Stan dard Re mote Op er a tion

SP = Sea coast Pro tect ed

ELECTRIC HEATER SIZE

A-Series

00 = No electric heat

25 = 2.5 KW

34 = 3.4 KW

50 = 5.0 KW

75 = 7.5 KW

10 = 10 KW

MONTH MANUFACTURED

A = Jan D = Apr G = Jul K = Oct

B = Feb E = May H = Aug L = Nov

C = Mar F = Jun J = Sep M = Dec

4

Page 5

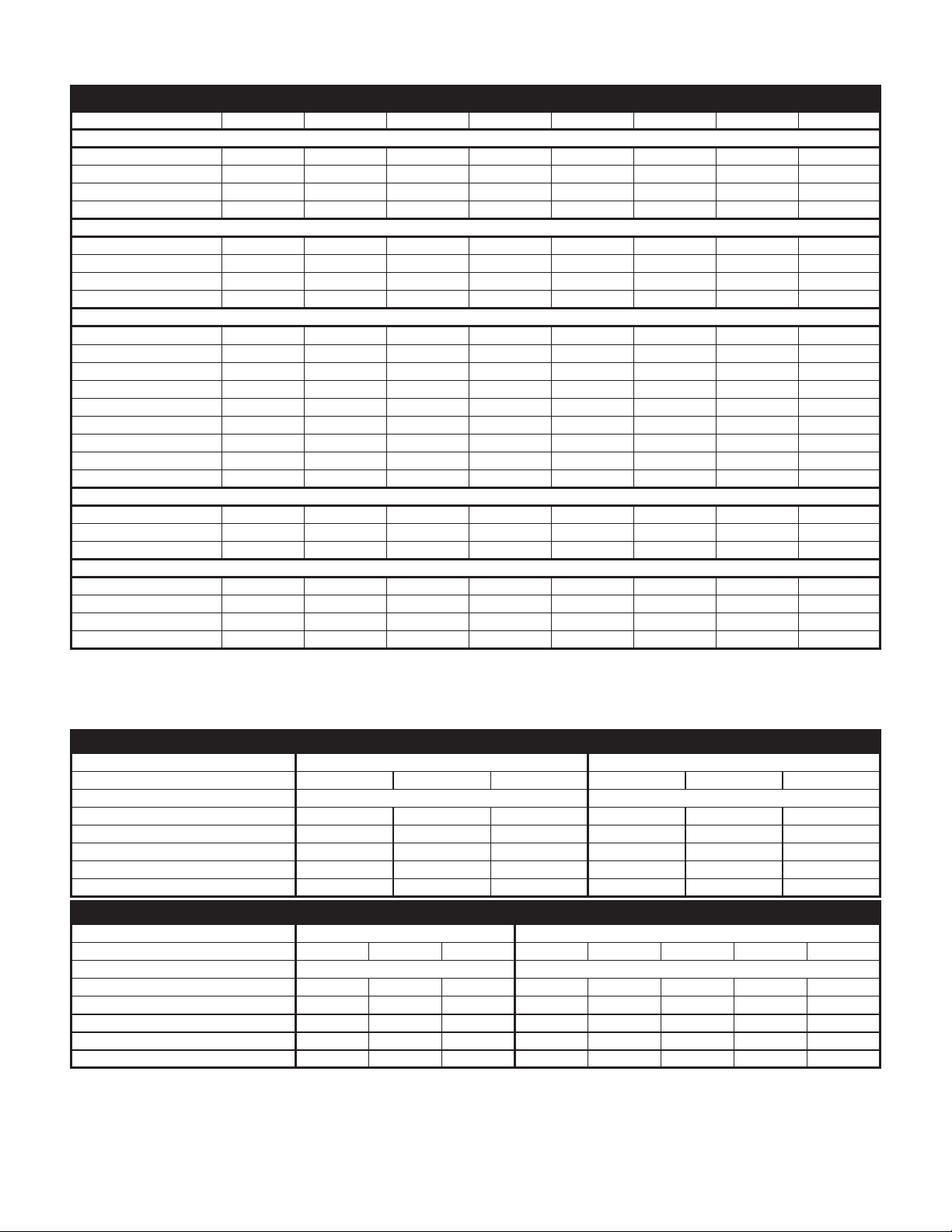

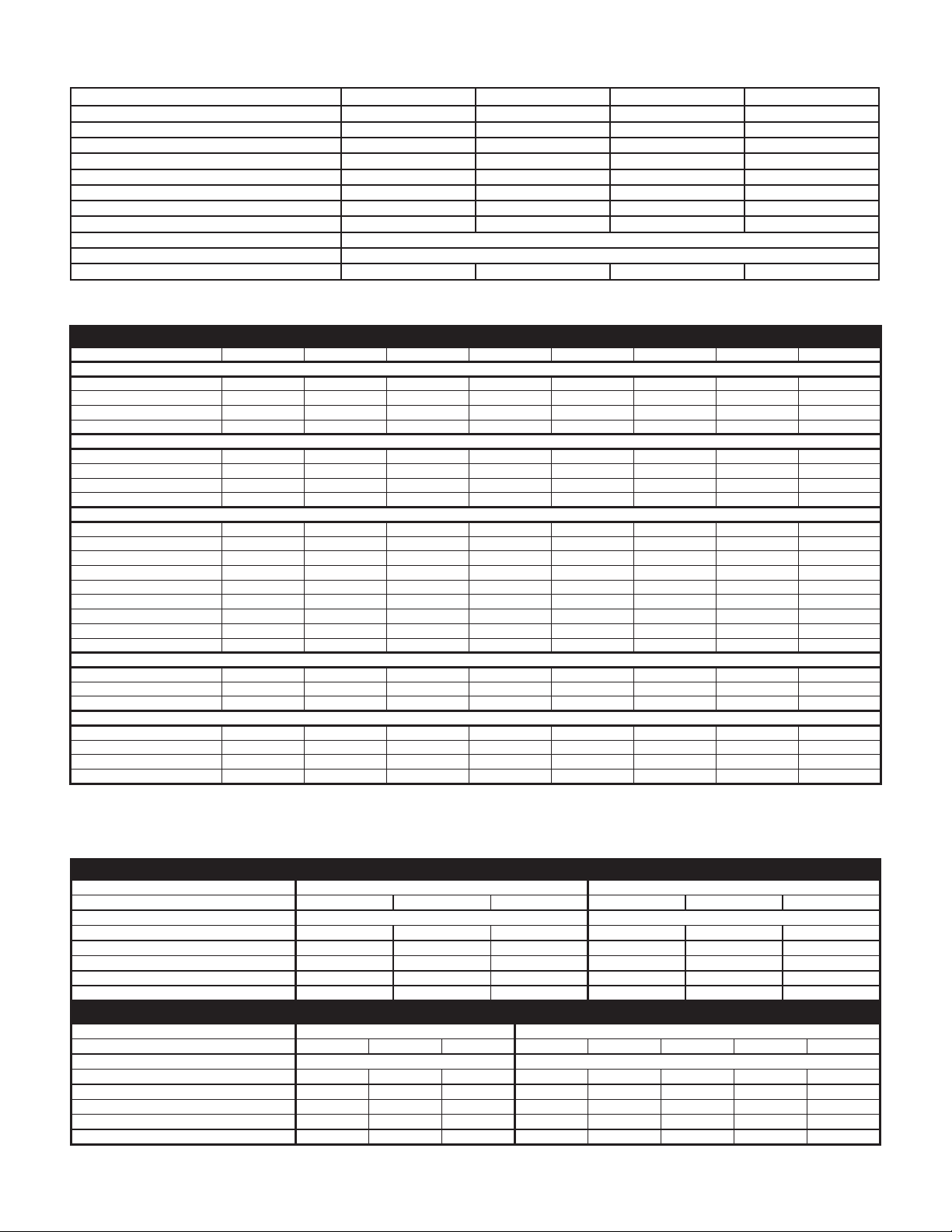

VERT-I-PAK® H SUFFIX CHASSIS SPECIFICATIONS

VEA/VHA9K-24K

VEA09K VEA12K VEA18K VEA24K VHA09K VHA12K VHA18K VHA24K

COOLING DATA

Cooling Btu/h 9500/9300 11800/11500 18000/17800 24000 9500/9300 11800/11500 18000/17800 23500

Cooling Power (W) 880 1093 2070 2526 905 1124 2070 2474

EER 10.8 10.8 8.7 9.5 10.5 10.5 8.7 9.5

Sensible Heat Ratio 0.74 0.72 0.70 0.70 0.74 0.72 0.70 0.70

HEAT PUMP DATA

Heating Btu/h N/A N/A N/A N/A 8500/8300 10600/10400 15700/15500 22500

COP @ 47°F N/A N/A N/A N/A 3.0 3.2 3.0 3

Heating Power (W) N/A N/A N/A N/A 830 971 1705 2200

Heating Current (A) N/A N/A N/A N/A 4.4/4.9 5.5/6.1 9.2/10.2 11.4

ELECTRICAL DATA

Voltage (1 Phase, 60 Hz) 230/208 230/208 230/208 230/208 230/208 230/208 230/208 230/208

Volt Range 253-198 253-198 253-198 253-198 253-198 253-198 253-198 253-198

Cooling Current (A) 4.1/4.3 4.9/5.3 9.2/10.2 11.2/12.4 4.2/4.4 5.0/5.5 9.2/10.2 11.2/12.4

Amps L.R. 21 21 47 68 21 21 47 68

Amps F.L. 3.7 4.5 7.9 10.2 3.7 4.5 7.9 10.2

Indoor Motor (HP) 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4

Indoor Motor (A) 1.2 1.2 1.4 2 1.2 1.2 1.4 2

Outdoor Motor (HP) N/A N/A N/A 1/4 N/A N/A N/A 1/4

Outdoor Motor (A) N/A N/A N/A 2 N/A N/A N/A 2

AIRFLOW DATA

Indoor CFM* 300 350 550 750 300 375 550 750

Vent CFM 60 60 60 80 60 60 60 80

Max. ESP .3" .3" .3" .3" .3" .3" .3" .3"

PHYSICAL DATA

Dimensions (W x D x H) 23 x 23 x 32 23 x 23 x 32 23 x 23 x 32 23 x 23 x 47 23 x 23 x 32 23 x 23 x 32 23 x 23 x 32 23 x 23 x 47

Net Weight (Lbs) 114 124 144 167 114 125 144 167

Shipping Weight (Lbs) 125 135 155 180 125 135 155 180

R-22 Charge 25 29 42 68.5 23.5 27 42 63.5

* Normal Value Wet Coil @ .1" ESP.

ELECTRIC HEAT DATA

VEA/VHA09,12

Heater Watts 2500/2050 3400/2780 5000/4090 2500/2050 3400/2780 5000/4090

Heating Btu/h 8500/7000 11600/9500 17000/13900 8500/7000 11600/9500 17000/13900

Heating Current (Amps) 10.6/9.3 14.5/12.5 20.9/18.2 10.6/9.3 14.5/12.5 20.9/18.2

Minimum Circuit Ampacity 15 19.9 27.9 15 19.9 27.9

Branch Circuit Fuse (Amps) 15 20 30 15 20 30

Basic Heater Size 2.5 Kw 3.4 Kw 5.0 Kw 2.5 Kw 3.4 Kw 5.0 Kw

VEA/VHA18,24

Heater Watts 2500/2050 3400/2780 5000/4090 2500/2050 3400/2780 5000/4090 7500/6135 10000/8180

Heating Btu/h 8500/7000 11600/9500 17000/13900 8500/7000 11600/9500 17000/13900 25598/20939 34130/27918

Heating Current (Amps) 10.6/9.3 14.5/12.5 20.9/18.2 10.9/9.9 14.8/13.4 21.7/19.7 32.6/29.5 43.5/39.3

Minimum Circuit Ampacity 15 19.9 27.9 17.2/15.9 22.1/20.3 30.7/28.1 44.3/40.4 57.9/52.7

Branch Circuit Fuse (Amps) 15 20 30 25/25 25/25 35/30 45/45 60/60

Basic Heater Size 2.5 Kw 3.4 Kw 5.0 Kw 2.5 Kw 3.4 Kw 5.0 Kw 7.5 Kw 10.0 Kw

VE/VHA09 VE/VHA12

Voltage 230/208 230/208

VE/VHA18 VE/VHA24

Voltage 230/208 230/208

5

Page 6

VERT-I-PAK

Model V(E,H)A09 V(E,H)A12 V(E,H)A18 V(E,H)A24

Voltage (V)

Refrigerant

Chassis Width

Chassis Depth

Chassis Height **

Shipping W x D x H

Supply Duct Collar ***

Drain Connection

Min. Circuit Amps

CFM Indoor

Max. Duct ESP

** Height includes 2" duct collar & isolators under unit. *** Factory collar accepts 10" fl ex duct.

®

E & G SUFFIX CHASSIS SPECIFICATIONS

230 / 208 230 / 208 230 / 208 230 / 208

R-22 R-22 R-22 R-22

23.125" 23.125" 23.125" 23.125"

23.125" 23.125" 23.125" 23.125"

32.25" 32.25" 32.25" 47.25"

26" x 28.5" x 35.0" 26." x 28.5" x 35" 26" x 28.5" x 35" 26" x 28.5" x 50"

10" 10" 10" 10"

3/4" FPT 3/4" FPT 3/4" FPT 3/4" FPT

.3 in. water .3 in. water .3 in. water .3 in. water

See Chassis Nameplate

Page 11

VEA/VHA9K-24K

COOLING DATA

Cooling Btu/h 9500/9300 11800/11500 18000/17800 24000 9500/9300 11800/11500 18000/17800 23500

Cooling Power (W) 880 1093 2070 2526 905 1124 2070 2474

EER 10.8 10.8 8.7 9.5 10.5 10.5 8.7 9.5

Sensible Heat Ratio 0.74 0.72 0.70 0.70 0.74 0.72 0.70 0.70

HEAT PUMP DATA

Heating Btu/h N/A N/A N/A N/A 8500/8300 10600/10400 15700/15500 22500

COP @ 47°F N/A N/A N/A N/A 3.0 3.2 3.0 3

Heating Power (W) N/A N/A N/A N/A 830 971 1705 2200

Heating Current (A) N/A N/A N/A N/A 4.4/4.9 5.5/6.1 9.2/10.2 11.4

ELECTRICAL DATA

Voltage (1 Phase, 60 Hz) 230/208 230/208 230/208 230/208 230/208 230/208 230/208 230/208

Volt Range 253-198 253-198 253-198 253-198 253-198 253-198 253-198 253-198

Cooling Current (A) 4.1/4.3 4.9/5.3 9.2/10.2 11.2/12.4 4.2/4.4 5.0/5.5 9.2/10.2 11.2/12.4

Amps L.R. 21 21 47 68 21 21 47 68

Amps F.L. 3.7 4.5 7.9 10.2 3.7 4.5 7.9 10.2

Indoor Motor (HP) 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4

Indoor Motor (A) 1.2 1.2 1.4 2 1.2 1.2 1.4 2

Outdoor Motor (HP) N/A N/A N/A 1/4 N/A N/A N/A 1/4

Outdoor Motor (A) N/A N/A N/A 2 N/A N/A N/A 2

AIRFLOW DATA

Indoor CFM* 300 350 550 750 300 375 550 750

Vent CFM 60 60 60 80 60 60 60 80

Max. ESP .3" .3" .3" .3" .3" .3" .3" .3"

PHYSICAL DATA

Dimensions (W x D x H) 23x23x32 23x23x32 23x23x32 23x23x47 23x23x32 23x23x32 23x23x32 23x23x47

Net Weight (Lbs) 114 124 144 167 114 125 144 167

Shipping Weight (Lbs) 125 135 155 180 125 135 155 180

R-22 Charge 25 29 42 68.5 23.5 27 42 63.5

* Normal Value Wet Coil @ .1" ESP.

VEA09K VEA12K VEA18K VEA24K VHA09K VHA12K VHA18K VHA24K

ELECTRIC HEAT DATA

VEA/VHA09,12

Heater Watts 2500/2050 3400/2780 5000/4090 2500/2050 3400/2780 5000/4090

Heating Btu/h 8500/7000 11600/9500 17000/13900 8500/7000 11600/9500 17000/13900

Heating Current (Amps) 10.6/9.3 14.5/12.5 20.9/18.2 10.6/9.3 14.5/12.5 20.9/18.2

Minimum Circuit Ampacity 15 19.9 27.9 15 19.9 27.9

Branch Circuit Fuse (Amps) 15 20 30 15 20 30

Basic Heater Size 2.5 Kw 3.4 Kw 5.0 Kw 2.5 Kw 3.4 Kw 5.0 Kw

VEA/VHA18,24

Heater Watts 2500/2050 3400/2780 5000/4090 2500/2050 3400/2780 5000/4090 7500/6135 10000/8180

Heating Btu/h 8500/7000 11600/9500 17000/13900 8500/7000 11600/9500 17000/13900 25598/20939 34130/27918

Heating Current (Amps) 10.6/9.3 14.5/12.5 20.9/18.2 10.9/9.9 14.8/13.4 21.7/19.7 32.6/29.5 43.5/39.3

Minimum Circuit Ampacity 15 19.9 27.9 17.2/15.9 22.1/20.3 30.7/28.1 44.3/40.4 57.9/52.7

Branch Circuit Fuse (Amps) 15 20 30 25/25 25/25 35/30 45/45 60/60

Basic Heater Size 2.5 Kw 3.4 Kw 5.0 Kw 2.5 Kw 3.4 Kw 5.0 Kw 7.5 Kw 10.0 Kw

6

VE/VHA09 VE/VHA12

Voltage 230/208 230/208

VE/VHA18 VE/VHA24

Voltage 230/208 230/208

Page 7

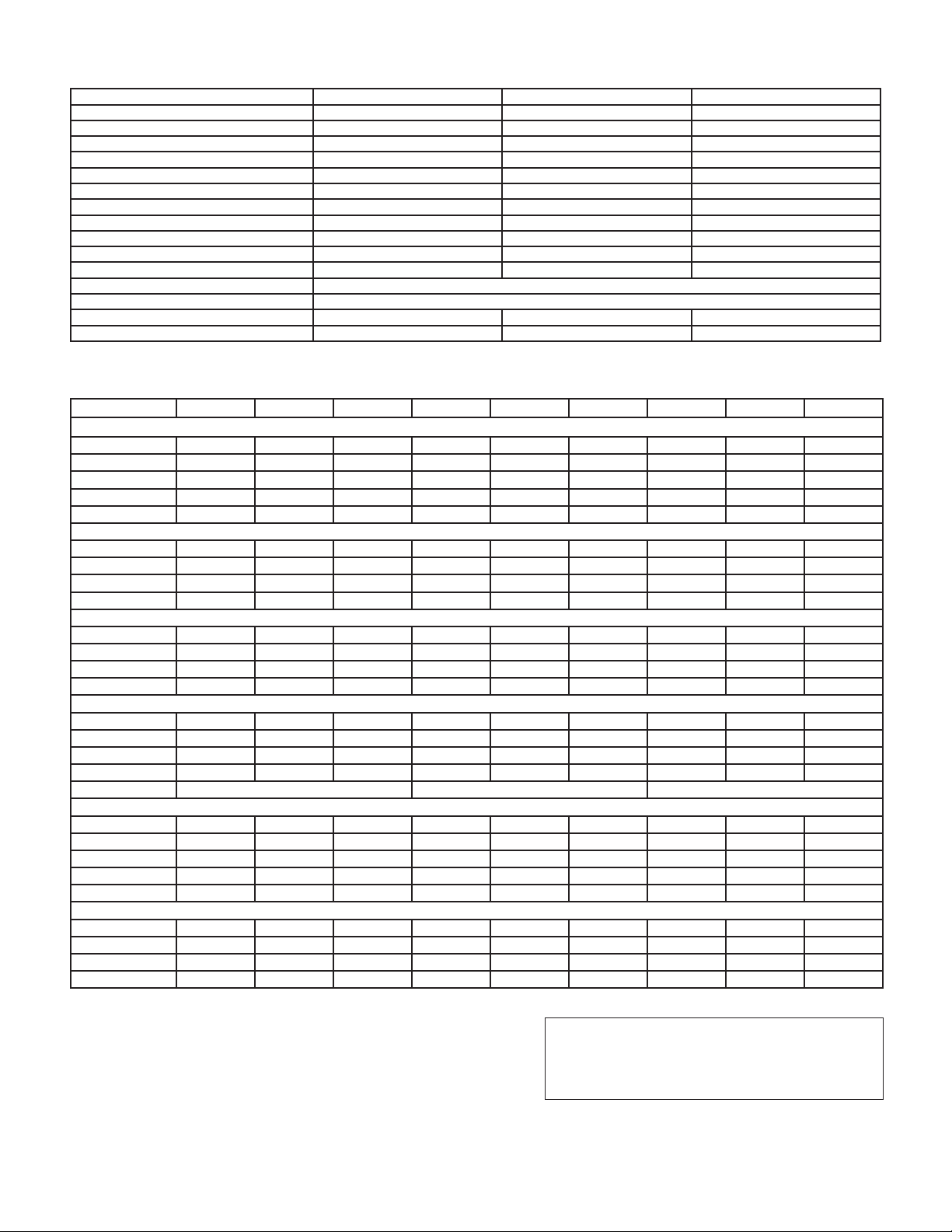

VERT-I-PAK® A - D SUFFIX CHASSIS SPECIFICATIONS

Model V(E,H)A09 V(E,H)A12 V(E,H)A18

Voltage (V) 230 / 208 230 / 208 230 / 208

Refrigerant R-22 R-22 R-22

Chassis Width 23.125" 23.125" 23.125"

Chassis Depth 23.125" 23.125" 23.125"

Chassis Height ** 32.25" 32.25" 32.25"

Shipping W x D x H 26" x 28" x 35" 26" x 28" x 35" 26" x 28" x 35"

Supply Duct Collar *** 10" 10" 10"

Drain Connection 1/2" MPT 1/2" MPT 1/2" MPT

Drain Hose **** 12" long 12" long 12" long

Thermostat Harness 36" long 36" long 36" long

Power Cord 60" long 60" long 60" long

Min. Circuit Amps See Chassis Nameplate

CFM Indoor Page 15

Fan Speeds 222

Max. Duct ESP .3 In. water .3 In. water .3 In. water

NOTES: ** Height includes 2" duct collar & isolators under unit. *** Factory collar accepts 10" fl ex duct.

MODELS V(E,H)A09K25 V(E,H)A09K34 V(E,H)A09K50 V(E,H)A12K25 V(E,H)A12K34 V(E,H)A12K50 V(E,H)A18K25 V(E,H)A18K34 V(E,H)A18K50

Cooling Cap. (Btu/h) 9500/9300 9500/9300 9500/9300 11500/11300 11500/11300 11500/11300 17200/17000 17200/17000 17200/17000

Cooling Power (W) 950 950 950 1200 1200 1200 1911 1911 1911

SEER 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0

Water Removal (Pts/h) 2.1 2.1 2.1 2.8 2.8 2.8 4.0 4.0 4.0

Cooling SHR 0.77 0.77 0.77 0.76 0.76 0.76 0.75 0.75 0.75

Heater Size (KW) 2.5 3.4 5.0 2.5 3.4 5.0 2.5 3.4 5.0

Heating Cap.(Btu/h) 8500/7000 11600/9500 17000/13900 8500/7000 11600/9500 17000/13900 8500/7000 11600/9500 17000/13900

Heating Power (W) 2500/2050 3500/2780 5000/4090 2500/2050 3500/2780 5000/4520 2500/2050 3500/2780 5000/4520

Heating Current (A) 11.9/11.2 15.9/14.6 22.6/20.6 11.9/11.2 15.9/14.6 22.6/20.6 11.9/11.2 15.9/14.6 22.6/20.6

Heating Cap.(Btu/h) 8000/7800 8000/7800 8000/7800 11200/11000 11200/11000 11200/11000 15700/15500 15700/15500 15700/15500

Heating Power (W) 950 950 950 1200 1200 1200 1830 1830 1830

Heating Current (A) 4.4/4.9 4.4/4.9 4.4/4.9 5.2/6.0 5.2/6.0 5.2/6.0 9.0/10.0 9.0/10.0 9.0/10.0

0

COP @ 47

Voltage (V) 230/208 230/208 230/208 230/208 230/208 230/208 230/208 230/208 230/208

LRA - Comp. (A) 2 0 20 20 26.3 26.0 26.3 45 45 45

Cooling Current (A) 4.4/4.9 4.4/4.9 4.4/4.9 5.5/6.1 5.2/6.0 5.2/6.0 7.6 7.6 7.6

MIN. Ckt. Amps (A) 15 20 30 15 20 30 15 20 30

Power Connection POWER CORD POWER CORD POWER CORD WITH OPTION TO HARD WIRE

Refrigerant R-22 R-22 R-22 R-22 R-22 R-22 R-22 R-22 R-22

Unit Width (in.) 23.125 23.125 23.125 23.125 23.125 23.125 23.125 23.125 23.125

Unit Depth (in.) 23.125 23.125 23.125 23.125 23.125 23.125 23.125 23.125 23.125

Unit Height* (in.) 32.25 32.25 32.25 32.25 32.25 32.25 32.25 32.25 32.25

Shipping Weight (lbs.) 125 125 125 135 135 135 155 155 155

Indoor CFM ** 300 300 300 375 375 375 550 550 550

Fresh Air CFM** 60 60 60 60 60 60 60 60 60

Motor 230V, 1/4 HP 230V, 1/4 HP 230V, 1/4 HP 230V, 1/4 HP 230V, 1/4 HP 230V, 1/4 HP 230V, 1/4 HP 230V, 1/4 HP 230V, 1/4 HP

Motor Amps** 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4

F 3.0 3.0 3.0 3.0 3.0 3.0 2.4 2.4 2.4

*Height includes 2" high duct collar and 5/8" isolators under unit.

**Normal Value Dry Coil on High Speed @ .3" ESP.

Due to continuing research in new energy-saving technology,

specifi cations are subject to change without notice.

Capacity rated at standard conditions:

COOLING–

950F DB/750F WB outdoor, 800F DB/670F WB indoor

HEATING– (reverse cycle)

0

F DB/430F WB outdoor, 700F DB/600F WB indoor

47

7

Page 8

Sequence of Operation

A good understanding of the basic operation of the refrigeration

system is essential for the service technician. Without this

understanding, accurate troubleshooting of refrigeration

system problems will be more diffi cult and time consuming,

if not (in some cases) entirely impossible. The refrigeration

system uses four basic principles (laws) in its operation they

are as follows:

1. "Heat always fl ows from a warmer body to a cooler

body."

2. "Heat must be added to or removed from a substance

before a change in state can occur"

3. "Flow is always from a higher pressure area to a lower

pressure area."

4. "The temperature at which a liquid or gas changes state

is dependent upon the pressure."

The refrigeration cycle begins at the compressor. Starting

the compressor creates a low pressure in the suction line

which draws refrigerant gas (vapor) into the compressor.

The compressor then "compresses" this refrigerant, raising

its pressure and its (heat intensity) temperature.

The refrigerant leaves the compressor through the discharge

line as a HOT high pressure gas (vapor). The refrigerant

enters the condenser coil where it gives up some of its

heat. The condenser fan moving air across the coil's fi nned

surface facilitates the transfer of heat from the refrigerant to

the relatively cooler outdoor air.

When a suffi cient quantity of heat has been removed from the

refrigerant gas (vapor), the refrigerant will "condense" (i.e.)

change to a liquid). Once the refrigerant has been condensed

(changed) to a liquid it is cooled even further by the air that

continues to fl ow across the condenser coil.

The Vert-I-Pak design determines at exactly what point

(in the condenser) the change of state (i.e. gas to a liquid)

takes place. In all cases, however, the refrigerant must be

totally condensed (changed) to a liquid before leaving the

condenser coil.

The refrigerant leaves the condenser coil through the liquid

li ne as a WAR M high press ure liquid. It nex t wil l pass throu gh

the refrigerant drier (if so equipped). It is the function of the

drier to trap any moisture present in the system, contaminants,

and LARGE particulate matter.

The liquid refrigerant next enters the metering device. The

metering device is a capillary tube. The purpose of the

metering device is to "meter" (i.e. control or measure) the

quantity of refrigerant entering the evaporator coil.

In the case of the capillary tube this is accomplished (by

design) through size (and length) of device, and the pressure

difference present across the device.

Since the evaporator coil is under a lower pressure (due to

the suction created by the compressor) than the liquid line,

the liquid refrigerant leaves the metering device entering the

evaporator coil. As it enters the evaporator coil, the larger

area and lower pressure allows the refrigerant to expand

and lower its temperature (heat intensity). This expansion is

often referred to as "boiling". Since the unit's blower is moving

Indoor air across the fi nned surface of the evaporator coil,

the expanding refrigerant absorbs some of that heat. This

results in a lowering of the indoor air temperature, hence the

"cooling" effect.

The expansion and absorbing of heat cause the liquid

refrigerant to evaporate (i.e. change to a gas). Once the

refrigerant has been evaporated (changed to a gas), it is

heated even further by the air that continues to fl ow across

the evaporator coil.

The particular system design determines at exactly what

point (in the evaporator) the change of state (i.e. liquid to a

gas) takes place. In all cases, however, the refrigerant must

be totally evaporated (changed) to a gas before leaving the

evaporator coil.

The low pressure (suction) created by the compressor causes

the the refrigerant to leave the evaporator through the suction

line as a COOL low pressure vapor. The refrigerant then

returns to the compressor, where the cycle is repeated.

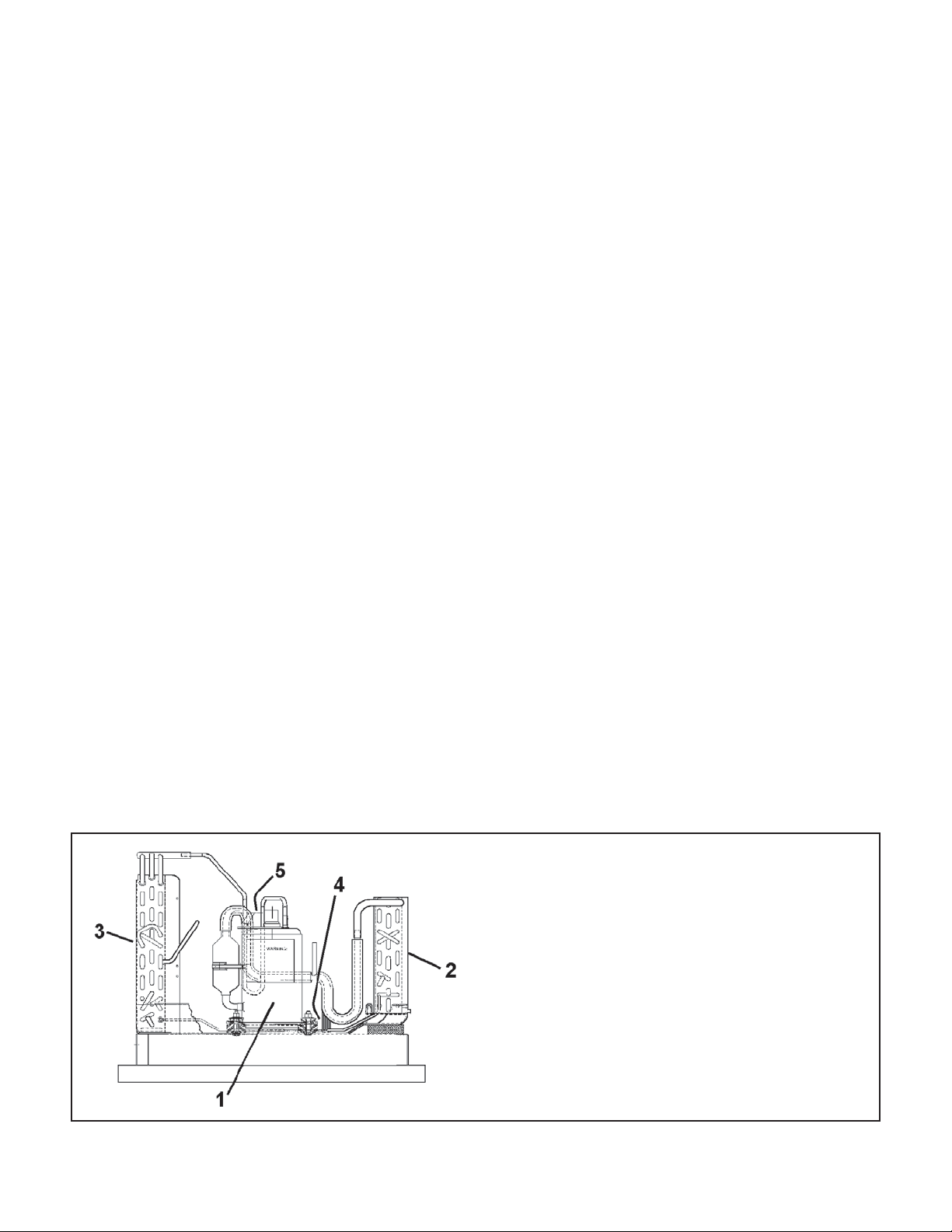

Refrigeration Assembly

1. Compressor

2. Evaporator Coil Assembly

3. Condenser Coil Assembly

4. Capillary Tube

5. Compressor Overload

8

Page 9

Electrical Supply

WARNING: Electrical shock hazard.

Turn OFF electric power at fuse box or service panel

before making any electrical connections and ensure a

proper ground connection is made before connecting line

voltage.

All electrical connections and wiring MUST be installed by

a qualifi ed electrician and conform to the National Electrical

Code and all local codes which have jurisdiction.

Failure to do so can result in property damage, personal

injury and/or death.

Supply Circuit

The system cannot be expected to operate correctly unless

the system is properly connected (wired) to an adequately

sized single branch circuit. Check the installation manual

and/or technical data for your particular unit and/or strip

heaters to determine if the circuit is adequately sized.

Electrical Rating Tables

NOTE: Use copper conductors ONLY

Wire sizes are per NEC. Check local codes for

overseas applications

Supply Voltage

To insure proper operation, supply voltage to the system

should be within fi ve (5) percent (plus or minus) of listed

rating plate voltage.

Control (Low) Voltage

To insure proper system operation, the transformer

secondary output must be maintained at a nominal 24 volts.

The control (low) voltage transformer is equipped with

multiple primary voltage taps. Connecting the primary,

(supply) wire to the tap (i.e., 208 and 240 volts) that most

closely matches the MEASURED supply voltage will insure

proper transformer secondary output is maintained.

Supply Voltage

Supply voltage to the unit should be a nominal 208/230 volts.

It must be between 197 volts and 253 volts. Supply voltage

to the unit should be checked WITH THE UNIT IN

OPERATION. Voltage readings outside the specifi ed range

can be expected to cause operating problems. Their cause

MUST be investigated and corrected.

Electrical Ground

GROUNDING OF THE ELECTRICAL SUPPLY TO ALL

UNITS IS REQUIRED for safety reasons.

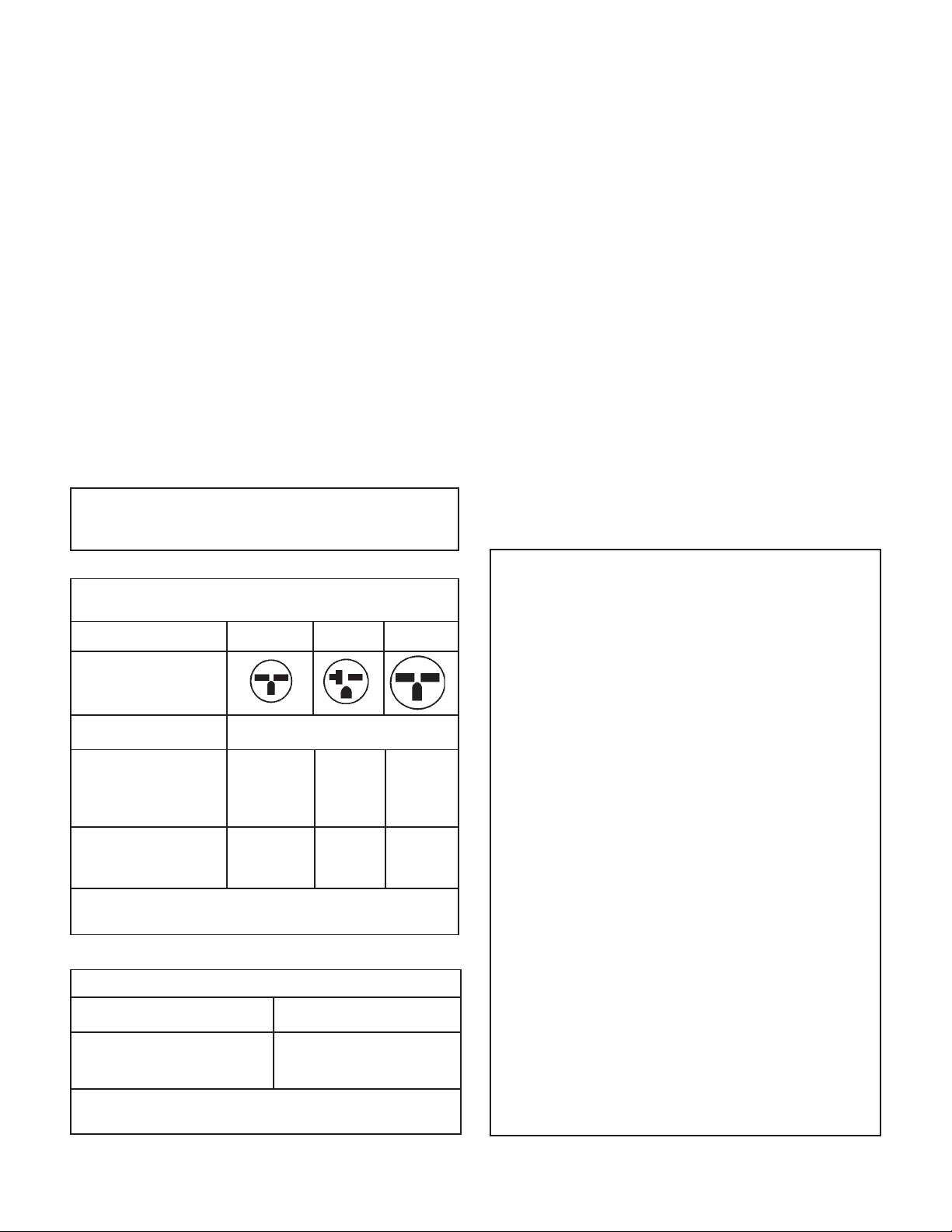

A through D Suffi x

250 V Receptacles and Fuse Types

Units Only

AMPS 15 20 * 30

RECEPTACLE

MANUFACTURER PART NUMBERS

Hubbell 5661 5461 9330

P & S 5661 5871 5930

GE GE4069-1 GE4182-1 GE4139-3

Arrow-Hart 5661 5861 5700

TIME-DELAY TYPE

FUSE 15 20 30

(or HACR circuit breaker)

HACR — Heating, Air Conditioning, Refrigeration

* May be used for 15 Amp applications if fused for 15 Amp

Recommended branch circuit wire sizes*

Nameplate maximum circuit

breaker size

15A 14

20A 12

30A 10

AWG — American Wire Gauge

* Single circuit from main box

** Based on copper wire, single insulated conductor at 60°C

AWG Wire size**

Electrical Requirements

NOTE: All fi eld wiring must comply with

NEC and local codes. It is the

responsibility of the installer to

insure that the electrical codes are

met.

Wire Size Use ONLY w iring size r ecomme nded

for single outlet branch circuit.

Fuse/Circuit Use ONLY type and size fuse or

HACR circuit breaker

Breaker Indicated on unit's rating plate (See

sample on page 6).

Proper current protection to the unit

is the responsibility of the owner.

Grounding Unit MUST be grounded from branch

circuit to unit, or through separate

ground wire provided on permanently

connected units. Be sure that branch

circuit or general purpose outlet is

grounded.

Wire Sizing Use recommended wire size given in

the tables below and install a single

branch circuit. All wiring must comply

with local and national codes. NOTE:

Use copper conductors only.

9

Page 10

Room Thermostats

Room thermostats are available from several different

manufacturers in a wide variety of styles. They range from

the very simple Bimetallic type to the complex electronic

set-back type. In all cases, no matter how simple or

complex, they are simply a switch (or series of switches)

designed to turn equipment (or components) "ON" or "OFF"

at the desired conditions.

An improperly operating, or poorly located room thermostat

can be the source of perceived equipment problems. A

careful check of the thermostat and wiring must be made

then to insure that it is not the source of problems.

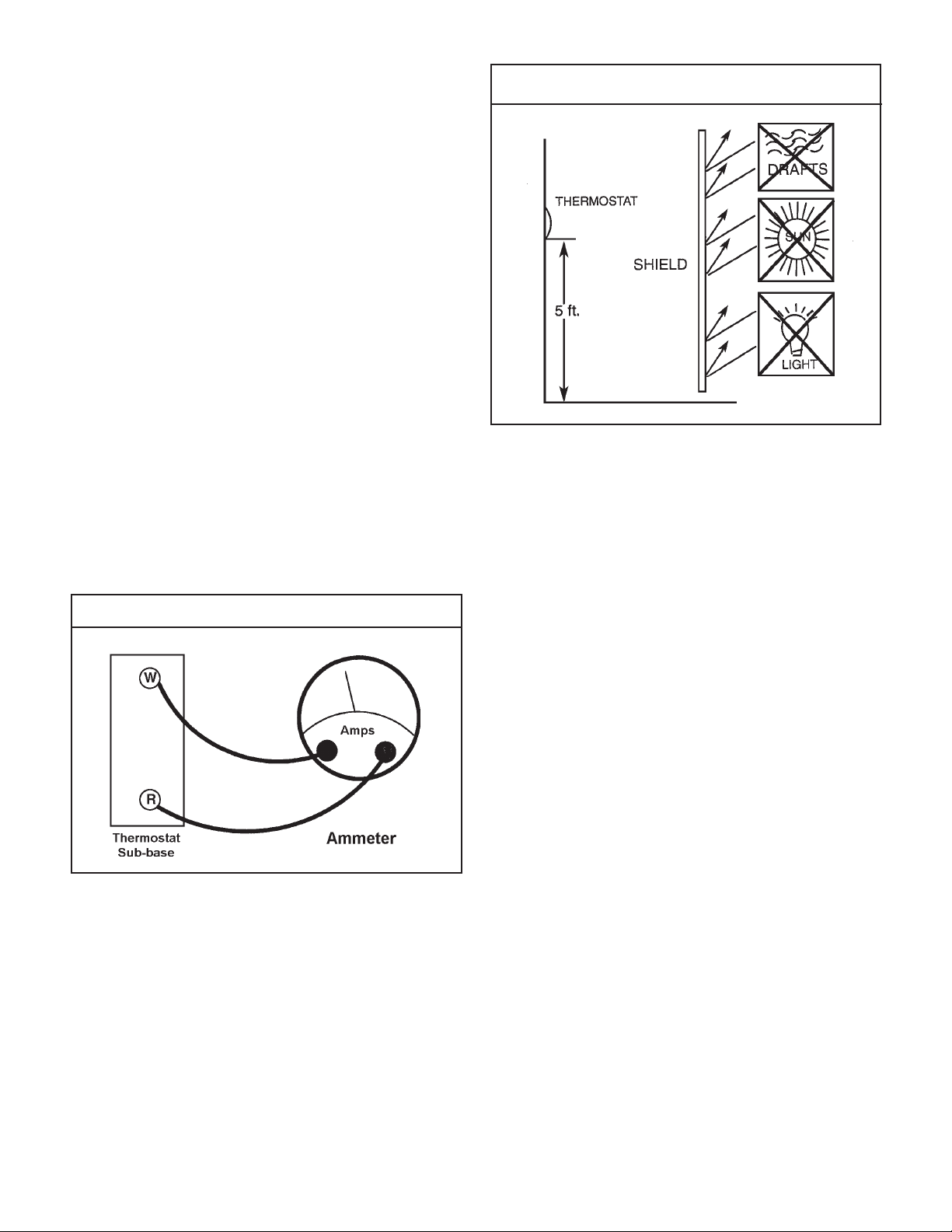

Location

The thermostat should not be mounted where it may be

affected by drafts, discharge air from registers (hot or cold),

or heat radiated from the sun or appliances.

The thermostat should be located about 5 Ft. above the

fl oor in an area of average temperature, with good air

circulation. Close proximity to the return air grille is the

best choice.

Mercury bulb type thermostats MUST be level to control

temperature accurately to the desired set-point. Electronic

digital type thermostats SHOULD be level for aesthetics.

Measuring Current Draw

Thermostat Location

In order to accomplish this, the heat output from the

anticipator must be the same regardless of the current

fl owing through it. Consequently, some thermostats have

an adjustment to compensate for varying current draw in

the thermostat circuits.

The proper setting of heat anticipators then is important

to insure proper temperature control and customer

satisfaction. A Heat anticipator that is set too low will

cause the heat source to cycle prematurely possibly never

reaching set point. A heat anticipator that is set too high

will cause the heat source to cycle too late over shooting

the set point.

Heat Anticipators

Heat anticipators are small resistance heaters (wired

in series with the "W" circuit) and built into most

electromechanical thermostats. Their purpose is to prevent

wide swings in room temperature during system operation

in the HEATING mode. Since they are wired in series,

the "W" circuit will open if one burns out preventing heat

operation.

The heat anticipator provides a small amount of heat to

the thermostat causing it to cycle (turn off) the heat source

just prior to reaching the set point of the thermostat. This

prevents exceeding the set point.

10

The best method to obtain the required setting for the

heat anticipator, is to measure the actual current draw in

the control circuit ("W") using a low range (0-2.0 Amps)

Ammeter. After measuring the current draw, simply set

the heat anticipator to match that value.

If a low range ammeter is not available, a "Clamp-on" type

ammeter may be used as follows:

1. Wrap EXACTLY ten (10) turns of wire around the jaws

of a clamp-on type ammeter.

2. Connect one end of the wire to the "W" terminal of

the thermostat sub-base, and the other to the "R"

terminal.

3. Turn power on, and wait approximately 1 minute, then

read meter.

4. Divide meter reading by 10 to obtain correct anticipator

setting.

Electronic thermostats do not use a resistance type

anticipator. These thermostats use a microprocessor

(computer) that determines a cycle rate based on a

program loaded into it at the factory.

Page 11

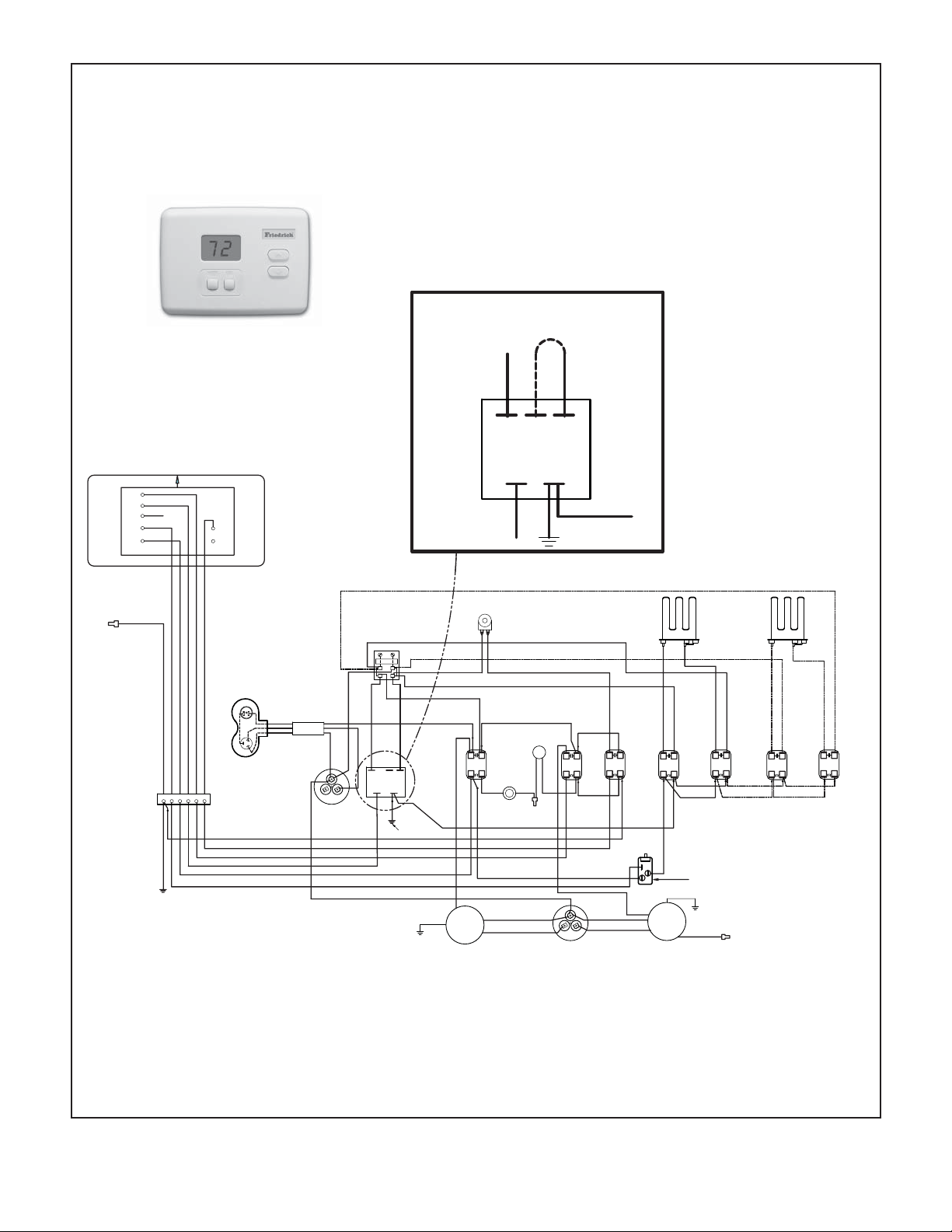

Typical Electrical & Thermostat Wiring Diagrams

VEA/VHA 24K

FOR 208 VOLT MODELS ONLY

MOVE THE WHITE WIRE AS

RT2

THERMOSTAT

(FRONT)

SHOWN BELOW

BLACK

COM.

208V 240V

WHITE

THERMOSTAT CONNECTIONS

(EAR)

UP

G

R

R

W

Y

WHITE

BROWN

TERM BOARD

BROWN

YELLOW

YWRGBC

TRANSFORMER

24V

BLACK

B

C

RED

RED

c

CAPACITOR

HERM

WHITE

QUICK DISCONNECT

L1

BLACK

BLUE

COM.

TRANSFORMER

24V

208V

L2

WHITE

240V

GREEN

SEE NOTE #6

TO MOTOR

MOUNT

WHITE

RED

BLACK

RED

BLACK

BLACK

GREEN

CONDENSER

MOTOR

RED

BLACK

BLUE

RED

"F"

S

COMP WIRE HARNESS

R

C

"F"

"F"

COMPRESSOR

FAN

BLACK

BLUE

GREEN

RED

YELLOW

WHITE

123

COMPR RELAY

4

LOW AMBIENT

RED

BLACK

WHITE

BROWN

RED

COIL, SOLENOID

RED

BLACK

WHITE

CONTROL

WIRE NUT (RED)

WHITE

RED

PRESSURE

SWITCH

YELLOW

CAPACITOR

YELLOW

HEATER

2.5 KW & 3.4 KW

5 KW

WHITE

FAN

RELAY

2

2 4

1 3

BLACK

BLACK

c

FAN

BROWN

HERM

RED

REV VALVE

4

31

RELAY

WHITE

BLUE

HEAT

RELAY

(2.5KW/3.4KW

2 4

1 3 123

BLACK

BLACK

RED

C

H

L

GREEN

BLOWER

MOTOR

5 KW)

T-STAT

DEFROST

INSULATOR

2-REQ'D

WIRE NUT (RED)

SEE NOTE #4

BLACK

TO MOTOR

MOUNT

7.5 KW & 10 KW

RED

RELAY

2 4

1 3

HEATER

HEAT

(2.5KW/3.4KW

5 KW)

BLACK

BLACK

RED

RED

HEAT

RELAY

(7.5KW/10KW) (7.5KW/10KW)

2

4

1

BLACK

BLACK

HEAT

RELAY

4

3

NOTE: THE DIAGRAM ABOVE ILLUSTRATES THE TYPICAL THERMOSTAT WIRING AND 208

VOLT TRANSFORMER WIRING. SEE THE UNIT CONTROL PANEL FOR THE ACTUAL

UNIT WIRING DIAGRAM AND SCHEMATIC.

11

Page 12

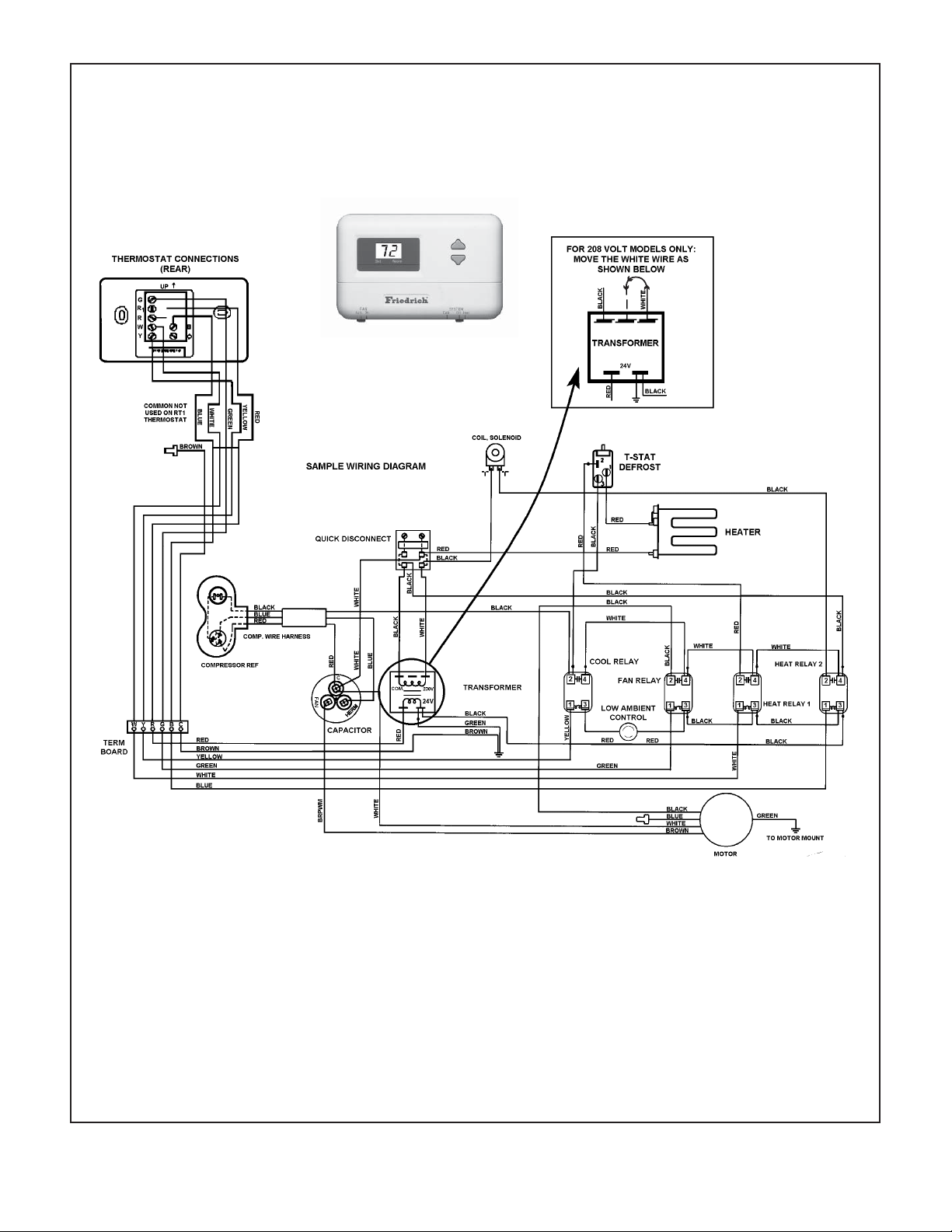

Typical Electrical & Thermostat Wiring Diagrams

G & H Suffi x

COM. 208V 240V

RT1

THERMOSTAT

(FRONT)

12

NOTE: THE DIAGRAM ABOVE ILLUSTRATES THE TYPICAL

THERMOSTAT WIRING AND 208 VOLT TRANSFORMER

WIRING. SEE THE UNIT CONTROL PANEL FOR THE

ACTUAL UNIT WIRING DIAGRAM AND SCHEMATIC.

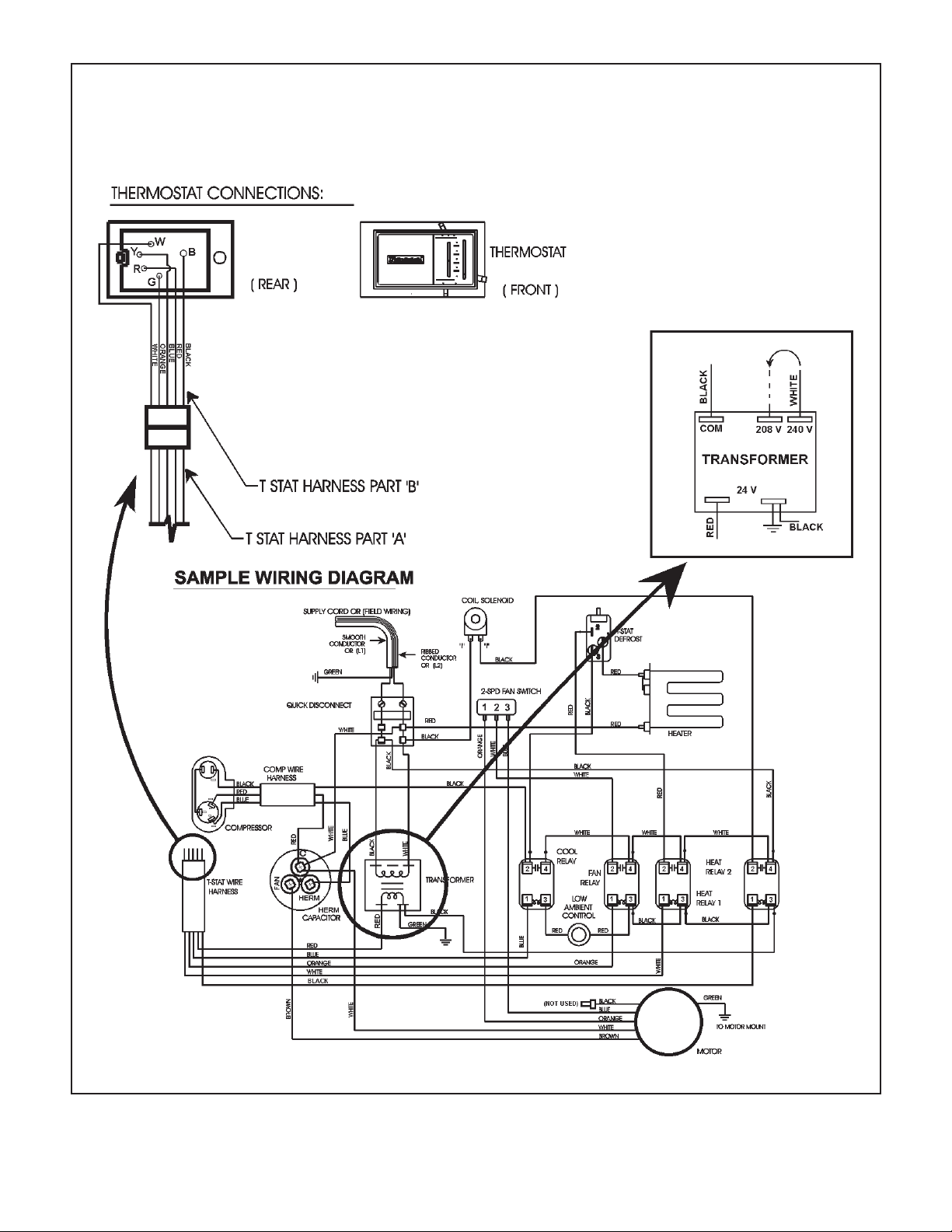

Page 13

Typical Electrical & Thermostat Wiring Diagrams

A – E Suffi x

FOR 208 VOLT MODELS ONLY:

MOVE THE WHITE WIRE AS

SHOWN BELOW.

13

Page 14

Indoor Blower - Airfl ow

The current Vert-I -Pak 9, 12, & 18 use a dual shaft, permanent

split capacitor, single speed motor to drive indoor blower and

outdoor fan. Earlier model VERT-I-Pak units used 2-speed

motors. The Vert-I-Pak 24 uses an individual, single shaft,

permanent split capacitor, single speed motor for the indoor

blower, and a separate motor drives the outdoor fan.

Different size (HP) motors and/or different diameter blower

wheels are used in different models to obtain the required

airfl ow.

Indoor Blower - Airfl ow

The current Vert-I -Pak 9, 12, & 18 use a dual shaft, permanent

split capacitor, single speed motor to drive indoor blower and

outdoor fan. Earlier model VERT-I-Pak units used 2-speed

motors. The Vert-I-Pak 24 uses an individual, single shaft,

permanent split capacitor, single speed motor for the indoor

blower, and a separate motor drives the outdoor fan.

Different size (HP) motors and/or different diameter blower

wheels are used in different models to obtain the required

airfl ow.

Condenser Fan Motors

The current Vert-I-Pak 9, 12, & 18 units use a dual shaft,

permanent split capacitor, single speed motor to drive indoor

and outdoor fan. Earlier models used a 2-speed motor. The

Vert-I-Pak 24 uses and individual, single shaft, permanent

split capacitor, single speed motor for the outdoor fan, with a

separate motor driving the indoor blower.

Blower Wheel Inspection

Visually inspect the blower wheel for the accumulations

of dirt or lint since they can cause reduced airfl ow. Clean

the blower wheel of these accumulations. If accumulation

cannot be removed, it will be necessary to remove the

blower assembly from the unit for proper wheel cleaning.

Cooling

A nominal 400 (350-450 allowable) CFM per ton of airfl ow

is required to insure proper system operation, capacity,

and effi ciency. Factory-set blower speeds should provide

the proper airfl ow for the size (Cooling capacity) of the unit

when connected to a properly sized duct system.

Cooling (VEA/VHA 24)

When the thermostat is set for cooling mode (SYSTEM

switch set to COOL and FAN switch to AUTO) a rise in room

temperature will make It also causes a 24-volt signal on the

“Y” thermostat conductor through the high pressure and low

ambient switches energizing the compressor relay, turning

on the compressor and outdoor fan motor. A 24-volt signal

on the “G” thermostat terminal to the Fan Relay, turning on

the indoor blower motor.

Heating (Electric)

When using electric heaters, select the blower speed that

provides adequate airfl ow across the elements to prevent

overheating and cycling on limit and/or premature failure.

CHECK THE EXTERNAL STATIC PRESSURE, and then

consult the AIR FLOW DATA to determine the ACTUAL air

fl ow delivered for the factory selected fan speed. This will

be especially important on change-outs using an existing

duct system that may not have been properly sized to

begin with.

Heating (VEA/VHA 24)

When the thermostat is set for heating mode (System switch

set to HEAT and FAN switch to AUTO) it will make a 24volt signal on the “B” thermostat terminal to energize the

Reversing Valve Relay. A drop in room temperature, will

make a 24-volt signal on the “W” thermostat terminal to the

Defrost Thermostat, and “G” thermostat terminal to the Fan

Relay. The Defrost Thermostat will determine whether the

unit should run in Heat Pump, or Electric Heat, based on the

outdoor temperature. (See Defrost Thermostat page 24)

External Static Pressure

External Static Pressure can best be defi ned as the pressure

difference (drop) between the Positive Pressure (discharge)

and the Negative Pressure (intake) sides of the blower.

External Static Pressure is developed by the blower as a

result of resistance to airfl ow (Friction) in the air distribution

system EXTERNAL to the VERT-I-PAK cabinet.

Resistance applied externally to the VERT-I-PAK (i.e. duct

work, coils, fi lters, etc.) on either the supply or return side

of the system causes an INCREASE in External Static

Pressure accompanied by a REDUCTION in airfl ow.

External Static Pressure is affected by two (2) factors.

1. Resistance to Airfl ow as already explained.

2. Blower Speed. Changing to a higher or lower blower

speed will raise or lower the External Static Pressure

accordingly.

These affects must be understood and taken into consideration

when checking External Static Pressure/Airfl ow to insure that

the system is operating within design conditions.

Operating a system with insuffi cient or excessive airfl ow

can cause a variety of different operating problems.

Among these are reduced capacity, freezing evaporator

coils, premature compressor and/or heating component

failures. etc.

System air fl o w s hould always be veri fi e d upon co mp letion

of a new installation, or before a change-out, compressor

replacement, or in the case of heat strip failure to insure

that the failure was not caused by improper airfl ow.

14

Page 15

Checking External Static Pressure

The airflow through the unit can be determined by

measuring the external static pressure of the system, and

consulting the blower performance data for the specifi c

VERT-I-PAK.

1. Set up to measure external static pressure at the

supply and return air.

the case of the VERT-I-PAK, the condensate will cause

a reduction in measured External Static Pressure for the

given airfl ow.

It is also important to remember that when dealing with

VERT-l-PAK units that the measured External Static

Pressure increases as the resistance is added externally

to the cabinet. Example: duct work, fi lters, grilles.

2. Drill holes in the supply duct for pressure taps, pilot

tubes or other accurate pressure sensing devices.

3. Connect these taps to a level inclined manometer

or Magnehelic gauges.

4. Ensure the coil and fi lter are clean, and that all the

registers are open.

5. Determine the external static pressure with the

blower operating.

6. Refer to the Air Flow Data for your VERT-I-PAK

system to fi nd the actual airfl ow for factory-selected

fan speeds.

7. If the actual airfl ow is either too high or too low, the

blower speed will need to be changed.

8. Select a speed, which most closely provides the

required airfl ow for the system.

9. Recheck the external static pressure with the

new speed. External static pressure (and actual

airfl ow) will have changed to a higher or lower value

depending upon speed selected. Recheck the actual

airfl ow (at this "new" static pressure) to confi rm

speed selection.

10. Repeat steps 8 and 9 (if necessary) until proper

airfl ow has been obtained.

Checking Approximate Airfl ow

If an inclined manometer or Magnehelic gauge is not

available to check the External Static Pressure, or the

blower performance data is unavailable for your unit,

approximate air fl ow call be calculated by measuring the

temperature rise, then using tile following criteria.

KILOWATTS x 3413

Temp Rise x 1.08

= CFM

Electric Heat Strips

The approximate CFM actually being delivered can be

calculated by using the following formula:

DO NOT simply use the Kilowatt Rating of the heater (i.e.

2.5, 3.4, 5 .0 ) as this wil l r esult in a les s-than-c orrec t airfl ow

calculation. Kilowatts may be calculated by multiplying

the measured voltage to the unit (heater) times the

measured

current draw of all heaters (ONLY) in operation to obtain

watts. Kilowatts are than obtained by dividing by 1000.

EXAMPLE: Measured voltage to unit (heaters) is 230 volts.

Measured Current Draw of strip heaters is 11.0 amps.

230 x 11.0 = 2530

2530/1000 = 2.53 Kilowatts

2.53 x 3413 = 8635

EXAMPLE: Airfl ow requirements are calculated as follows:

(Having a wet coil creates additional resistance to airfl ow.

This addit ional resistance must be taken into consideration

to obtain accurate airfl ow information.

1 ½ TON SYSTEM ( 18,000 Btu)

Operating on high speed @ 230 volts with dry coil

measured external static pressure .20

Air Flow = 500 CFM

In the same SYSTEM used in the previous example but

having a WET coil you must use a correction factor of

.94 (i.e. 500 x .94=470 CFM) to allow for the resistance

(internal) of the condensate on the coil.

It is important to use the proper procedure to check external

Static Pressure and determine actual airfl ow. Since in

Supply Air 95°F

Return Air 75°F

Temper ature Rise 20

20 x 1.08 = 21.6

8635

= 400 CFM

21.6

IMPORTANT: FLEX DUCT CAN COLLAPSE AND

CAUSE AIRFLOW RESTRICTIONS. DO NOT

USE FLEX DUCT FOR: 90 DEGREE BENDS, OR

UNSUPPORTED RUNS OF 5 FT. OR MORE.

°

15

Page 16

Airfl ow Charts A – D Suffi x

Chart A CFM @ 230 Volts - DRY COIL

Model

Fan Speed

ESP (in water)

—

V(E,H)A09/A12 V(E,H)A18

>

—

High

>

CFM

0.00 N/A 427 N/A 517

0.10 411 387 510 480

0.20 373 347 500 470

0.30 327 310 490 460

Low

CFM

High

CFM

Low

CFM

Ductwork Preparation

Pull the fl ex duct tight. Extra fl ex duct slack can greatly

increase static pressure

Explanation of charts

Chart A is the nominal dry coil VERT-I-PAK CFMs. Chart

B is the correction factors beyond nominal conditions.

Chart A – CFM

Model 18000 12000 / 9000

.00 520 420

.10 510 410

.20 500 370

.30 490 330

Chart B – Correction Multipliers

Correction Multipliers for:

230V 1.00

208V 0.97

Heating 1.00

Cooling 0.95

Chart B Correction Factors

To Correct for:

230 Volts 1.00

208 Volts 0.97

Dry Coil 1.00

Wet Coil 0.94

Chart C – VE/VHA CFM

.1" ESP 750 815

.2" ESP 725 780

.3" ESP 700 745

.4" ESP 675 700

All value s listed are inches W.C. with a wet

indoor coil with fi lt er inst alled.

Correction

Factor

VEA/VHA24K

Low High

Refrigerant Charging

Note: Because the earlier model Vert-I- Paks are sealed

systems, service process tubes will have to be installed.

First install a line tap and remove refrigerant from system.

The H suffi x model Vert-I-Paks have factory installed ser-

vice values. Make necessary sealed system repairs and

vacuum system. Weigh in charge according to the unit data

plate. Crimp process tube line and solder end shut. Do

not leave a service valve in the sealed system.

Proper refrigerant charge is essential to proper unit

operation. Operating a unit with an improper refrigerant

charge will result in reduced performance (capacity) and/or

effi ciency. Accordingly, the use of proper charging methods

during servicing will insure that the unit is functioning as

designed and that its compressor will not be damaged.

Too much refrigerant (overcharge) in the system is just as

bad (if not worse) than not enough refrigerant (undercharge).

They both can be the source of certain compressor

failures if they remain uncorrected for any period of time.

Quite often, other problems (such as low air fl ow across

evaporator, etc.) are misdiagnosed as refrigerant charge

16

problems. The refrigerant circuit diagnosis chart will assist

you in properly diagnosing these systems.

An overcharged unit will at times return liquid refrigerant

(slugging) back to the suction side of the compressor

eventually causing a mechanical failure within the

compressor. This mechanical failure can manifest itself

as valve failure, bearing failure, and/or other mechanical

failure. The specifi c type of failure will be infl uenced by the

amount of liquid being returned, and the length of time the

slugging continues.

Not enough refrigerant (Undercharge) on the other hand,

will cause the temperature of the suction gas to increase

to the point where it does not provide suffi cient cooling for

the compressor motor. When this occurs, the motor winding

temperature will increase causing the motor to overheat

and possibly cycle open the compressor overload protector.

Continued overheating of the motor windings and/or cycling

of the overload will eventually lead to compressor motor

or overload failure.

Page 17

Method Of Charging

The acceptable method for charging the Vert-I-Pak system

is the Weighed in Charge Method. The weighed in charge

method is applicable to all units. It is the preferred method

to use, as it is the most accurate.

2. Recover Refrigerant in accordance with EPA

regulations.

3. Install a process tube to sealed system.

The weighed in method should always be used whenever

a charge is removed from a unit such as for a leak repair,

compressor replacement, or when there is no refrigerant

charge left in the unit. To charge by this method, requires

the following steps:

1. Install a piercing valve to remove refrigerant from the

sealed system. (Piercing valve must be removed from

the system before recharging.)

4. Make necessary repairs to system.

5. Evacuate system to 300 microns or less.

6. Weigh in refrigerant with the property quantity of

R-22 refrigerant.

7. Start unit, and verify performance.

8. Crimp the process tube and solder the end shut.

NOTE: In order to access the sealed system it will be necessary to install Schrader type

fi ttings to the process tubes on the discharge and suction of the compressor. Proper

recovery refrigerant procedures need to be adhered to as outlined in EPA Regulations.

THIS SHOULD ONLY BE ATTEMPTED BY QUALIFIED SERVICE PERSONNEL.

Undercharged Refrigerant Systems

An undercharged system will result in poor performance

(low pressures, etc.) in both the heating and cooling

cycle.

Whenever you service a unit with an under charge of

refrigerant, always suspect a leak. The leak must be

repaired before charging the unit.

To check for an undercharged system, turn the unit on,

allow the compressor to run long enough to establish

working pressures in the system (15 to 20 minutes).

During the cooling cycle you can listen carefully at the exit

of the metering device into the evaporator; an intermittent

hissing and gurgling sound indicates a low refrigerant

charge. Intermittent frosting and thawing of the evaporator

is another indication of a low charge, however, frosting

and thawing can also be caused by insuffi cient air over

the evaporator.

Checks for an undercharged system can be made at the

compressor . If the compressor seems quieter than normal,

it is an indication of a low refrigerant charge. A check of the

amper age drawn by the compressor motor should show a

lower reading. (Check the Unit Specifi cation.) After the unit

has run 10 to 15 minutes, check the gauge pressures.

Gauges connected to system with an under charge will

have low head pressures and substantially low suction

pressures.

17

Page 18

Overcharged Refrigerant Systems

Compressor amps will be near normal or higher.

Noncondensables can also cause these symptoms. To

confi rm, remove some of the charge, if conditions improve,

system may be overcharged. If conditions don’t improve,

Noncondensables are indicated.

Whenever an overcharged system is indi cated, always

make sure that the problem is not caused by air fl ow

problems. Improper air fl ow over the evaporator coil may

indicate some of the same symptoms as an overcharged

system.

An over charge can cause the compressor to fail, since it

would be "slugged" with liquid refrigerant.

The charge for any system is critical. When the compressor

is noisy, suspect an overcharge, when you are sure that

the air quantity over the evaporator coil is correct. Icing

Restricted Refrigerant Systems

A quick check for either condition begins at the evaporator.

With a partial restriction, there may be gurgling sounds

at the metering device entrance to the evaporator. The

evaporator in a partial restriction could be partially frosted

or have an ice ball close to the entrance of the metering

device. Frost may continue on the suction line back to the

compressor.

of the evapora tor will not be encountered because the

refriger ant will boil later if at all. Gauges connected to

system will usually have higher head pressure (depending

upon amount of overcharge). Suction pressure should be

slightly higher.

Often a partial restriction of any type can be found by feel,

as there is a temperature difference from one side of the

restriction to the other.

With a complete restriction, there will be no sound at the

metering device entrance. An amperage check of the

compressor with a partial restriction may show normal

current when compared to the unit specifi cation. With a

complete restriction the current drawn may be considerably

less than normal, as the compressor is running in a deep

vacuum (no load.) Much of the area of the condenser will

be relatively cool since most or all of the liquid refrigerant

will be stored there.

The following conditions are based primar ily on a system

in the cooling mode.

Troubleshooting a restricted refrigerant system can

be diffi cult. The following proce dures are the more

common problems and solutions to these problems.

There are two types of refrigerant restrictions: Partial

restrictions and complete restrictions.

A partial restriction allows some of the refrigerant to

circulate through the system.

With a complete restriction there is no circulation of

refrigerant in the system.

18

Restricted refrigerant systems display the same symptoms as

a "low-charge condition." When the unit is shut off, the gauges

may equal ize very slowly. Gauges connected to a completely

re stricted system will run in a deep vacuum. When the unit

is shut off, the gauges will not equalize at all.

Page 19

Metering Device - Capillary Tube Systems

All units are equipped with capillary tube metering devices.

Checking for restricted capillary tubes.

1. Connect pressure gauges to unit.

2. Start the unit in the cooling mode. If after a few minutes

of operation the pressures are normal, the check valve

and the cooling capillary are not restricted.

Reversing Valve Description/Operation

The Reversing Valve controls the direction of refrigerant

flow to the indoor and outdoor coils. It consists of a

pressure-operated, main valve and a pilot valve actuated

by a solenoid plunger. The solenoid is energized during

the heating cycle only. The reversing valves used in the

Vert-I-Pak system is a 2-position, 4-way valve

The single tube on one side of the main valve body is the

high-pressure inlet to the valve from the compressor. The

center tube on the opposite side is connected to the low

pressure (suction) side of the system. The other two are

connected to the indoor and outdoor coils. Small capillary

tubes connect each end of the main valve cylinder to the

"A" and "B" ports of the pilot valve. A third capillary is a

common return line from these ports to the suction tube

on the main valve body. Four-way reversing valves also

have a capillary tube from the compressor discharge tube

to the pilot valve.

The piston assembly in the main valve can only be shifted

by the pressure differential between the high and low sides

of the system. The pilot section of the valve opens and

closes ports for the small capillary tubes to the main valve

to cause it to shift.

NOTE: System operating pressures must be near

normal before valve can shift.

WARNING

3. Switch the unit to the heating mode and observe the

gauge readings after a few minutes running time. If

the system pressure is lower than normal, the heating

capillary is restricted.

4. If the operating pressures are lower than normal

in both the heating and cooling mode, the cooling

capillary is restricted.

Electrical Circuit and Coil

(Reversing valve coil is energized in the heating cycle only).

1. Set controls for heating; valve should shift.

2. Check for line voltage at the heat relay, terminal #2

and L2 at the quick disconnect. If line voltage is not

present check the power supply.

Testing Coil

1. Turn off high voltage electrical power to unit.

2. Unplug line voltage lead from reversing valve coil.

DANGER OF BODILY INJURY OR DEATH

FROM ELECTRICAL SHOCK

The reversing valve solenoid is connected to

high voltage. Turn off electrical power before

disconnecting or connecting high voltage wiring

or servicing valve.

3. Check for electrical continuity through the coil. If you

do not have continuity replace the coil.

4. Check from each lead of coil to the copper liquid line as

it leaves the unit or the ground lug. There should be no

continuity between either of the coil leads and ground;

if there is, coil is grounded and must be replaced.

5. If coil tests okay, reconnect the electrical leads .

6. Make sure coil has been assembled cor rectly.

19

Page 20

Checking Reversing Valve

NOTE: You must have normal operating pressures before

the reversing valve can shift.

Check for proper refrigerant charge. Sluggish or sticky

reversing valves can sometimes be remedied by reversing

the valve several time with the airfl ow restri cted to inc re ase

system pressure.

To raise head pressure during the cooling season the airfl ow

through the outdoor coil can be restricted . During heating

the indoor air can be restricted by blocking the return air.

Dented or damaged valve body or capillary tubes can

prevent the main slide in the valve body from shifting.

If you determine this is the problem, replace the reversing

valve.

After all of the previous inspections and checks have been

made and determined correct, then perform the “Touch

Test” on the reversing valve.

CAUTION

Never energize the coil when it is removed

from the valve, as a coil burnout will result.

Touch Test in Heating/Cooling Cycle

The only defi nite indications that the slide is in the mid-position is if all three tubes on the suction side of the valve are

hot after a few minutes of running time.

NOTE: A condition other than those illustrated above, and

on page 19, indicate that the reversing valve is not shifting

properly. Both tubes shown as hot or cool must be the same

corresponding tempera ture.

Procedure For Changing Reversing Valve

1. Install Process Tubes. Recover refrigerant from sealed

system. PROPER HANDLING OF RECOVERED

REFRIGERA NT ACCORDING TO EPA REGULATIONS

IS REQUIRED.

2. Remove solenoid coil from reversing valve. If coil is to

be reused, protect from heat while changing valve.

3. Unbraze all lines from reversing valve.

4. Clean all excess braze from all tubing so that they will

slip into fi ttings on new valve.

5. Remove solenoid coil from new valve.

6. Protect new valve body from heat while brazing with

plastic heat sink (Thermo Trap) or wrap valve body with

wet rag.

Reversing Valve in Heating Mode

Reversing Valve in Cooling Mode

7. Fit all lines into new valve and braze lines into new

valve.

8. Pressurize sealed system with a combina tion of R-22

and nitrogen and check for leaks, using a suitable leak

detector. Recover refrigerant per EPA guidelines.

9. Once the sealed system is leak free, install solenoid

coil on new valve and charge the sealed system by

weighing in the proper amount and type of refrigerant

as shown on rating plate. Crimp the process tubes

and solder the ends shut. Do not leave schrader or

piercing valves in the sealed system.

20

Page 21

WARNING

DANGER OF BODILY INJURY OR DEATH

FROM ELECTRICAL SHOCK

When working on high voltage equipment - turn the

electrical power off before attaching test leads.

Use test leads with alligator type clips - clip to terminals,

turn power on, take reading - turn power off before

removing leads.

Compressor Checks

Locked Rotor Voltage (L.R.V.) Test

Locked rotor voltage (L.R.V.) is the actual voltage available

at the compressor under a stalled condition.

Single Phase Connections

Disconnect power from unit. Using a voltmeter, attach one

lead of the meter to the run "R" terminal on the compressor

and the other lead to the common "C" terminal of the compressor. Restore power to unit.

CAUTION

Make sure that the ends of the lead do not touch the

compressor shell since this will cause a short circuit.

Determine L.R.V.

Start the compressor with the voltmeter attached; then

stop the unit. Attempt to restart the compressor within a

couple of seconds and immediately read the voltage on the

meter. The compressor under these conditions will not start

and will usually kick out on overload within a few seconds

since the pressures in the system will not have had time to

equalize. Voltage should be at or above minimum voltage

of 197 VAC, as specifi ed on the rating plate. If less than

mini mum, check for cause of inadequate power supply; i.e.,

incorrect wire size, loose electrical connections, etc.

Amperage (L.R.A.) Test

The running amperage of the compressor is the most

important of these readings. A running amperage higher

than that indicated in the performance data indicates that

a problem exists mechanically or electrically.

Single Phase Running and L.R.A. Test

NOTE: Consult the specifi cation and perform ance section

for running amperage. The L.R.A. can also be found on

the rating plate.

Select the proper amperage scale and clamp the

meter probe around the wire to the "C" terminal of the

compressor.

Turn on the unit and read the running am perage on the

meter. If the compressor does not start, the reading will

indicate the locked rotor amperage (L.R.A.).

External Overload

Some compressors are equipped with an exter nal overload

which senses both motor amperage and winding temperature.

High motor tempera ture or amperage heats the overload

causing it to open, breaking the common circuit within the

compressor.

Heat generated within the compressor shell, usually due

to recycling of the motor, is slow to dissipate. It may take

anywhere from a few minutes to several hours for the

overload to reset.

Checking the External Overload

With power off, remove the leads from com pressor

terminals. If the compressor is hot, allow the overload

to cool before starting check. Using an ohmmeter, test

continuity across the terminals of the external overload. If

you do not have continuity; this indicates that the over load

is open and must be replaced.

Internal Overload

Some compressors are equipped with an internal overload

which senses both motor amperage and winding temperature.

High motor temperature or amperage heats the overload

causing it to open, breaking the common circuit within the

compressor. Heat generated within the compressor shell,

usually due to recycling of the motor, is slow to dissipate. It

may take anywhere from a few minutes to several hours for

the overload to reset.

Checking the Internal Overload

A reading of infi nity (∞) between any two terminals MAY

indicate an open winding. If, however, a reading of infi nity

(∞) is obtained between C & R and C & S, accompanied

by a resistance reading between S & R, an open internal

overload is indicated. Should you obtain this indication,

allow the compressor to cool (May take up to 24 hours) then

recheck before condemning the compressor. If an open

internal overload is indicated, the source of its opening must

be determined and corrected. Failure to do so will cause

repeat problems with an open overload and/or premature

compr essor f ailure. Some p ossibl e cause s of an open i nte rn al

overload include insuffi cient refrigerant charge, restriction in

the refrigerant circuit, and excessive current draw.

21

Page 22

Single Phase Resistance Test

Remove the leads from the compressor terminals and set the

ohmmeter on the lowest scale (R x 1).

Touch the leads of the ohmmeter from terminals common to

start ("C" to "S"). Next, touch the leads of the ohmmeter from

terminals common to run ("C" to "R").

Add values "C" to "S" and "C" to "R" together and check resistance from start to run terminals ("S" to "R"). Resistance "S"

to "R" should equal the total of "C" to "S" and "C" to "R."

In a single phase PSC compressor motor, the highest value

will be from the start to the run connections (“S” to "R"). The

next highest resistance is from the start to the common connections ("S" to "C"). The lowest resistance is from the run to

common. ("C" to "R") Before replacing a compressor, check

to be sure it is defective.

Check the complete electrical system to the compressor and

compressor internal electrical system, check to be certain that

compressor is not out on internal overload.

Complete evaluation of the system must be made whenever

you suspect the compressor is defective. If the compressor

has been operating for sometime, a careful examination must

be made to determine why the compressor failed.

Many compressor failures are caused by the following conditions.

1. Improper air fl ow over the evaporator.

2. Overcharged refrigerant system causing liquid to be returned to the compressor.

Recommended Procedure for

Compressor Replacement

NOTE: Be sure power source is off, then disconnect all

wiring from the compressor.

1. Be certain to perform all necessary electrical and refrigeration tests to be sure the compressor is actually defective

before replacing .

2. Recover all refrigerant from the system though the process

tubes. PROPER HANDLING OF RECOVERED RE-

FRIGERANT ACCORDING TO EPA REGULATIONS IS

REQUIRED. Do not use gauge manifold for this purpose

if there has been a burnout. You will contaminate your

manifold and hoses. Use a Schrader valve adapter and

copper tubing for burnout failures.

3. After all refrigerant has been recovered, disconnect suction

and discharge lines from the compressor and remove compressor. Be certain to have both suction and discharge

process tubes open to atmosphere.

4. Carefully pour a small amount of oil from the suction stub

of the defective compressor into a clean container.

5. Using an acid test kit (one shot or conven tional kit), test

the oil for acid content according to the instructions with

the kit.

6. If any evidence of a burnout is found, no matter how

slight, the system will need to be cleaned up following

proper procedures.

3. Restricted refrigerant system.

4. Lack of lubrication.

5. Liquid refrigerant returning to compressor causing oil to

be washed out of bearings.

6. Noncondensables such as air and moisture in the system.

Moisture is extremely de structive to a refrigerant system.

7. Install the replacement compressor.

8. Pressur ize with a combinati on of R-22 and n it rogen a nd

leak test all connections with an electronic or Halide

leak detector. Recover refrigerant and repair any leaks

found.

Repeat Step 8 to insure no more leaks are present.

9. Evacuate the system with a good vacuum pump capable

of a fi nal vacuum of 300 microns or less. The system

should be evacuated through both liquid line and suction

line gauge ports. While the unit is being evacuated, seal

all openings on the defective compressor. Compressor

manufacturers will void warranties on units received not

properly sealed. Do not distort the manufacturers tube

connections.

10. Recharge the system with the correct amount of refrigerant. The proper refrigerant charge will be found on the unit

rating plate. The use of an accurate measuring device,

such as a charging cylinder, electronic scales or similar

device is necessary.

22

Page 23

WARNING

HAZARD OF SHOCK AND ELECTROCUTION. A

CAPACITOR CAN HOLD A CHARGE FOR LONG

PERIODS OF TIME. A SERVICE TECHNICIAN WHO

TOUCHES THESE TERMINALS CAN BE INJURED.

NEVER DISCHARGE THE CAPACITOR BY SHORTING

ACROSS THE TERMINALS WITH A SCREWDRIVER.

Capacitors

Many motor capacitors are internally fused. Shorting the

terminals will blow the fuse, ruin ing the capacitor. A 20,000

ohm 2 watt resistor can be used to discharge capacitors

safely. Remove wires from capacitor and place resistor

across terminals. When checking a dual capacitor with

a capacitor analyzer or ohmmeter, both sides must be

tested.

Capacitor Check With Capacitor Analyzer

The capacitor analyzer will show whether the capacitor is

"open" or "shorted." It will tell whether the capacitor is within

its microfarads rating and it will show whether the capacitor

is operating at the proper power-factor percentage. The

instrument will automatically discharge the capacitor when

the test switch is released

Capacitor Connections

The starting winding of a motor can be damaged by a

shorted and grounded running capacitor. This damage

usually can be avoided by proper connection of the running

capacitor terminals.

From the supply line on a typical 230 volt circuit, a 115 volt

potential exists from the "R" terminal to ground through a

possible short in the capacitor. However, from the "S" or

start terminal, a much higher potential, possibly as high as

400 volts, exists because of the counter EMF generated

in the start winding. Therefore, the possibility of capacitor

failure is much greater when the identifi ed terminal is connected to the “S" or start terminal. The identifi ed terminal

should always be connected to the supply line, or "R"

terminal, never to the "S" terminal.

When connected properly, a shorted or grounded running-capacitor will result in a direct short to ground from

the "R" terminal and will blow the line fuse. The motor

protector will protect the main winding from excessive

tem perature.

23

Page 24

Emergency Heat Switch (Defrost Thermostat) Continuity Check

Electric Heat Switch Operation

(Heat Pumps Only)

The electric heat switch is a dual function control and is

shown on the wiring diagram as a defrost thermostat.

It may be adjusted using a screwdriver. As the control

shaft is rotated counter clockwise a detent will be

encountered. Turning the control past the detent will lock

out the compressor and acts as an emergency heat switch.

Turning the control shaft clockwise will lower the change

over point for compressor operation. The control it self is

a double throw, single pole switch operated by a bellows

and a gas fi lled capillary tube. The capillary tube senses

a combination of outdoor coil temperature and outdoor air

temperature. As the combined temperatures reach a point

that the outdoor coil is iced, where heat pump operation

is no longer effi cient, the control shuts off the compressor

and turns on the electric heat. At its lowest setting the cut

off point is approximately 25 degrees, the highest setting

is 52 degrees, with a 10 degree differential. It is possible,

under certain conditions, for the unit to cycle between

compressor and electric heat operation.

Electric Heat Switch Check Out

The switch may be checked out with an ohmmeter.

Remove and label the three wires from the switch.

Terminal 2 is common and the contacts make to Terminal

3 on temperature rise and to Terminal 1 on temperature

fall. With the control set in the emergency heat position

continuity should be read between Terminal 2 and Terminal

1 regardless of coil temperature. As the control shaft is

rotated clockwise, through the adjustment range, continuity

will be read between Terminal 2 and Terminal 3, providing

the temperature of the capillary tube is above 25º (± 5%). If

the temperature at the capillary tube is above approximately

52 degrees it may be necessary to place the end of the

capillary tube in ice water to determine if the control is

sensing temperature changes. Should the control lose the

gas charge in the capillary tube it will fail to the electric heat

position and the compressor will not operate.

24

SWITCH POSITION TEMPERATURE AT CAPILLARY CONTINUITY READ

EMERGENCY HEAT N/A 1 and 2 = Electric Heat

ANYWHERE IN

ADJUSTMENT RANGE

ANYWHERE IN

ADJUSTMENT RANGE

ABOVE SET POINT 2 and 3 = Compressor

BELOW SET POINT 1 and 2 = Electric Heat

Page 25

Wiring Diagram Index

MODEL DIAGRAM PAGE

VEA09K00 RTA ................... 80004910 ...................28

VEA09K00RTB ................. 80004910 ...................28

VEA09K00RTE ................. 80004910 ...................28

VEA09 K00RTG ................. 8000492 2 ...................34

VEA09 K00RTH ................. 80004922 ...................34

VEA09K25 RTA ................ 80004911 ....................30

VEA09K25RTB ................. 80004911 ....................30

VEA09K25RTE ................. 80004911 ....................30

VEA09 K25RTG ................. 8000 4923 ................... 35

VEA09 K25RTH ................. 8000 4923 ...................35

VEA09K34RTA .................. 80004911 ....................30

VEA09K34RTB ................. 80004911 ....................30

VEA09K34RTE ................. 80004911 ....................30

VEA09 K34RTG ................. 800 04923 ...................35

MODEL DIAGRAM PAGE

VEA12K34RTG .................. 80004920 ...................32

VEA12K34RTH .................. 800 04 920 ................... 32

VEA12K50RTA .................. 80004911 ....................30

VEA12K50RTB .................. 800 04911 ....................30

VEA12K50RTE .................. 800 04911 ....................30

VEA12K50RTG .................. 80004920 ...................32

VEA12K50RTH .................. 800 0 492 0 ...................32

VEA18K00RTA .................. 80 004910 ................... 28

VEA18K00RT B .................. 8 00 04910 ................... 28

VEA18K00RTC .................. 800 0 4910 ................... 28

VEA18K00RTD .................. 80004910 ...................28

VEA18K00RT E .................. 8 00 04910 ................... 28

VEA18K00RTG ................. 80004919 ...................31

VEA18K00RTH .................. 80004919 ...................31

VEA09K34RTH ................. 80004923 ...................35

VEA09K50RTA .................. 80004911 ....................30

VEA09K50RTB ................. 80004911 ....................30

VEA09K50RTE ................. 80004911 ....................30

VEA09 K50RTG ................. 80 004923 ................... 35

VEA09 K50RTH ................. 800 04923 ...................35

VEA12K00RTA .................. 80004910 ................... 28

VEA12K00RTB .................. 800 04910 ................... 28

VEA12K00RTE .................. 800 04910 ................... 28

VEA12K00RTG .................. 80004919 ...................31

VEA12K00RTH .................. 800 0 4 919 ................... 31

VEA12K25RTA .................. 80 004911 ....................30

VEA12K25RT B .................. 8 000 4911 ....................30

VEA12K25RT E .................. 8 000 4911 ....................30

VEA12K25RTG ................. 80004920 ...................32

VEA12K25RTH .................. 80004920 ...................32

VEA18K 25RTA .................. 80 004911 ....................30

VEA18K 25RTB .................. 800 04911 ....................30

VEA18K25RTC .................. 80004911 ....................30

VEA18K25RTD ................. 80004911 ....................30

VEA18K 25RTE .................. 800 04911 ....................30

VEA18K25RTG ................. 80004920 ...................32

VEA18K25RTH ................. 80004920 ...................32

VEA18K34RTA .................. 80004911 ....................30

VEA18K34RTB .................. 80 004911 ....................30

VEA18K34RTC .................. 800 04911 ....................30

VEA18K34RTD .................. 80004911 ....................30

VEA18K34RTE .................. 80 004911 ....................30

VEA18K34RTG ................. 80004920 ...................32

VEA18K34RTH .................. 80004920 ...................32

VEA18K50RTA .................. 80 004911 ....................30

VEA18K50RT B .................. 8 000 4911 ....................30

VEA12K34RTA .................. 80004911 ....................30

VEA12K34RTB .................. 800 04911 ....................30

VEA12K34RTE .................. 800 04911 ....................30

VEA18K50RTC .................. 800 04 911 ....................30

VEA18K50RTD .................. 80004911 ....................30

VEA18K50RT E .................. 80 00 4911 ....................30

25

Page 26

MODEL DIAGRAM PAGE MODEL DIAGRAM PAGE

VEA18K50RTG ................. 80004920 ...................32

VEA18K50RTH .................. 80004920 ...................32

VEA24K00RTH ................. 80110500 ....................37

VEA24K10RTH ................. 80108800 ...................38

VEA 24K25RTH ................. 8010880 0 ...................38

VEA24K34RTH ................. 80108800 ...................38

VEA24K50RTH ................. 80108800 ...................38

VEA24K75RTH ................. 80108800 ...................38

VHA09K25RTA ................. 800004912 .................29

VHA09K25RTB ................. 8 00004912 .................29

VHA09K25RTE ................. 800004912 .................29

VHA09 K25RTG ................. 800004924 .................36

VHA09 K25RTH ................. 800004924 .................36

VHA09K34RTA ................. 800004912 .................29

VHA09K34RTB ................. 800004912 .................29

VHA09K34RTE ................. 800004912 .................29