Page 1

Installation and Operation Manual

Room Air Conditioners

115-Volt:

Q Chassis Models

SQ06, SQ08

115-Volt: EQ08

AUTO

F

C

AUTO FAN

AM

CONTINUOUS

PM

88

ONOFF

SET POINT

SCHEDULE

ROOM TEMP

CHECK $MART

AUTO SPEED

FILTER

SYSTEM

FAN MODE

POWER

FAN SPEED

SCHEDULE

93001011_01

Page 2

Thank you for your decision to purchase the Friedrich High Efciency Air Conditioner. Your new Friedrich has been carefully engineered and manufactured to

give you many years of dependable, efcient operation, maintaining a comfortable temperature and humidity level. Many extra features have been built into

your unit to assure quiet operation, the greatest circulation of cool, dry air, and the most economic operation.

THANK YOU, on behalf of our entire company,

for making such a wise purchase.

FRIEDRICH

AIR CONDITIONING CO.

SAN ANTONIO, TX

MODEL NUMBER

EQ08N11

SERIAL NUMBER

AALY00219

VOLTS

115

103 VOLT MIN.

COOLING:

BTU/HR

7500

EER

9.8

AMPS

6.9

HEATING:

BTU/HR

4000

EER

AMPS

11.2

MAX AMPS:

23.5 OZS.

DESIGN PRESSURES

600 PSIG HS

300 PSIG LS

U.S. PATENTS

D458, 229 S

5,634,346

IF CONNECTED TO

A FUSE PROTECTED

CIRCUIT, USE A 12 A

TIME DELAY FUSE

LISTED 183H

ROOM AIR

CONDITIONER

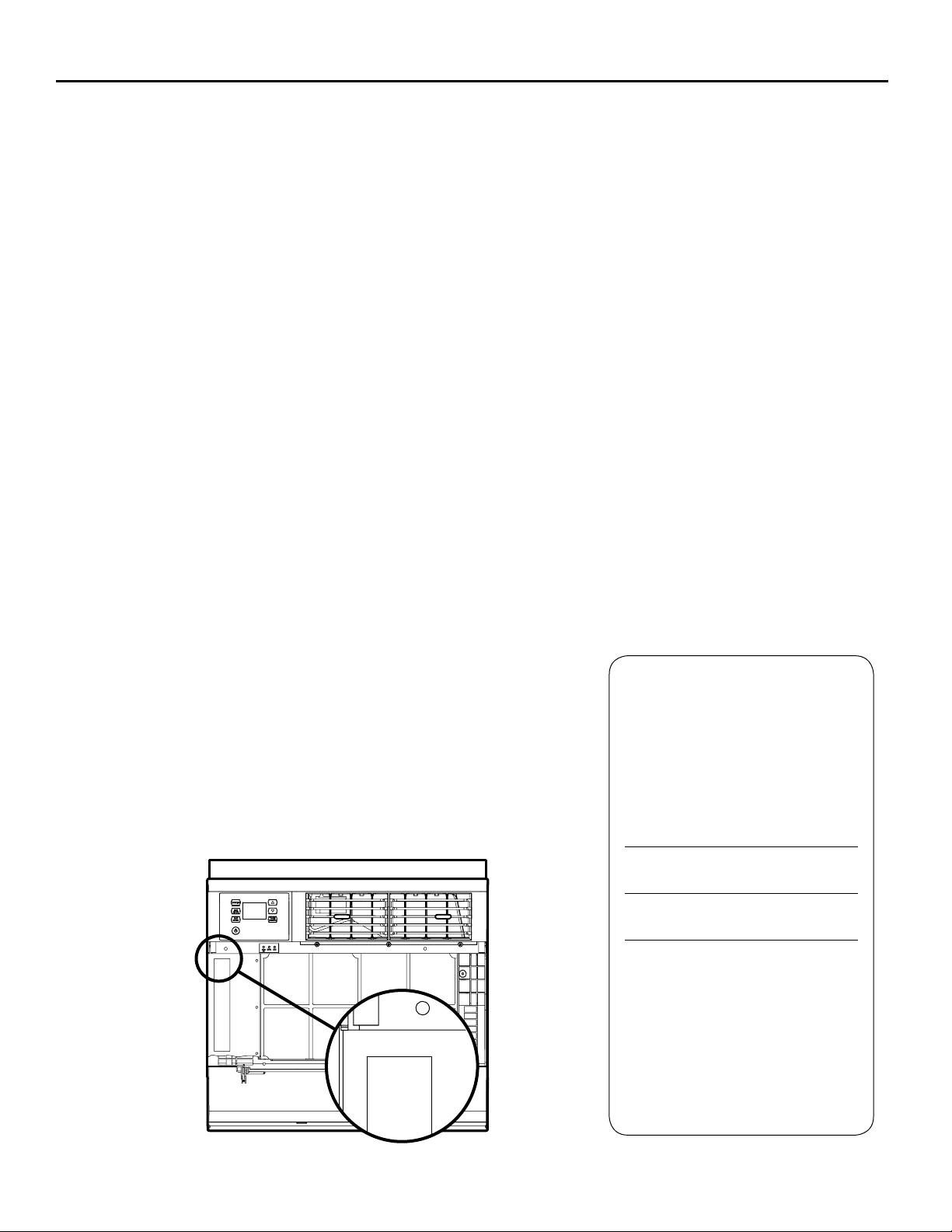

Register your air conditioner

Model information can be found on the name

plate behind the front cover.

Please complete and mail the owner

registration card furnished with this product,

or register online at www.friedrich.com. For

your future convenience, record the model

information here.

MODEL NUMBER

SERIAL NUMBER

PURCHASE DATE

-A

60 HZ/ 1PH

FRIEDRICH

AIR CONDITIONING CO.

SAN ANTONIO, TX

Assembled in Mexico

MODEL NUMBER

EQ08N11-A

SERIAL NUMBER

AALY00219

VOLTS

60 HZ/ 1PH

2

Page 3

Table of Contents

Table of Contents ...................................................................................................................................................................................................................................................................................... 3

Safety Precautions ................................................................................................................................................................................................................................................................................... 4

WARNING: Before Operating Your Unit .............................................................................................................................................................................................................................................. 5

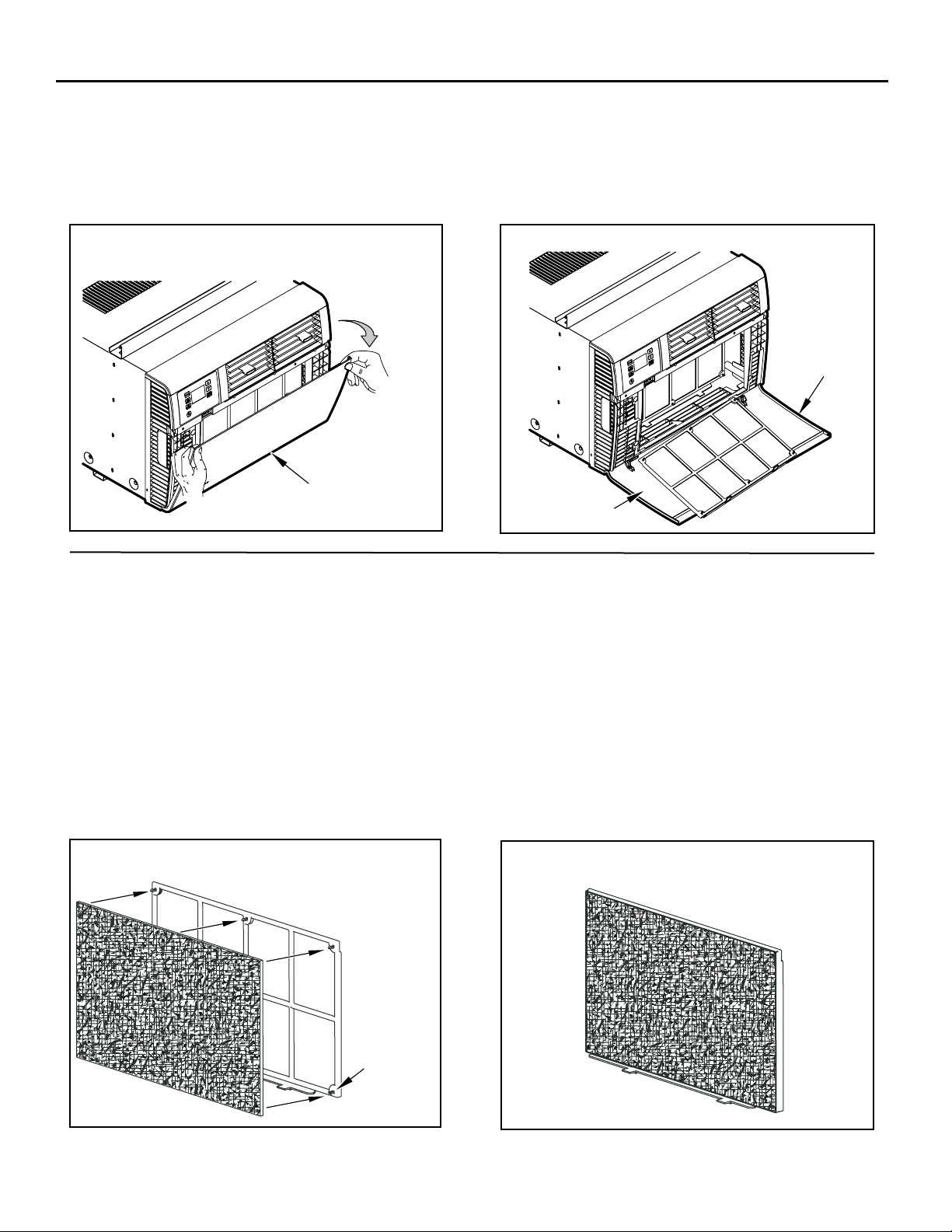

Standard Filter Cleaning / Installation Instructions .............................................................................................................................................................................................................................. 6

Premium Carbon Filter Installation Instructions ................................................................................................................................................................................................................................... 6

Control Panel Operation Instructions .................................................................................................................................................................................................................................................... 7

Remote Control Operation .................................................................................................................................................................................................................................................................... 12

Remote Effectiveness ............................................................................................................................................................................................................................................................................ 12

Airow Selection and Adjustment ........................................................................................................................................................................................................................................................ 14

Installation Instructions & Precautions ................................................................................................................................................................................................................................................ 14

Items required for installation ................................................................................................................................................................................................................................................................ 15

Standard Window Installation ............................................................................................................................................................................................................................................................... 16

Replacement Installation Instructions ................................................................................................................................................................................................................................................. 19

Cord Routing Change ............................................................................................................................................................................................................................................................................20

EntryGuard Security Lock ..................................................................................................................................................................................................................................................................... 21

Thru-the-wall Installation .......................................................................................................................................................................................................................................................................22

Final Inspection & Start-up Checklist .................................................................................................................................................................................................................................................. 24

Routine Maintenance .............................................................................................................................................................................................................................................................................25

Service and Assistance ......................................................................................................................................................................................................................................................................... 25

Available Accessories ............................................................................................................................................................................................................................................................................ 25

Troubleshooting Tips ..............................................................................................................................................................................................................................................................................26

Addendum 1 ............................................................................................................................................................................................................................................................................................ 28

Performance Testing Installation and Test Method (for testing laboratory use) ..................................................................................................................................................................... 30

3

Page 4

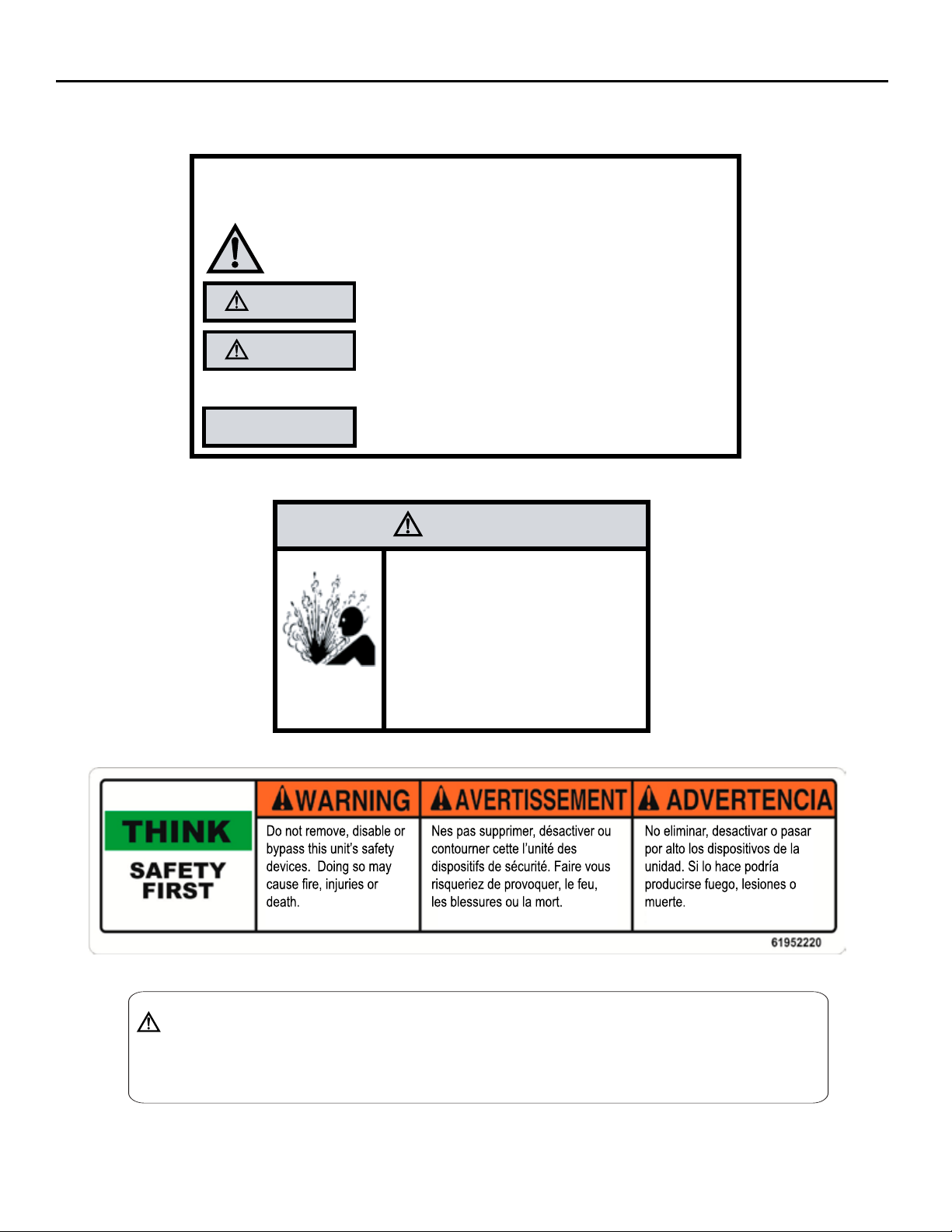

Safety Precautions

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what will happen if the instructions are not followed.

Your safety and the safety of others are very important.

This is a safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING”

or “CAUTION”. These words mean:

WARNING

CAUTION

Indicates a hazard which, if not avoided, can result in severe personal injury or

death and damage to product or other property.

Indicates a hazard which, if not avoided, can result in personal injury and

damage to product or other property.

NOTICE

Indicates property damage can occur if instructions are not followed.

WARNING

Refrigeration system

under high pressure

Do not puncture, heat, expose to flame or

incinerate.

Only certified refrigeration technicians should

service this equipment.

R410A systems operate at higher pressures

than R22 equipment. Appropriate safe

service and handling practices must be used.

Only use gauge sets designed for use with

R410A. Do not use standard R22 gauge sets.

California Safe Drinking Water and Toxic Enforcement Act

WARNING: This product contains chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm. Wash hands after handling.

4

Page 5

WARNING: Before Operating Your Unit

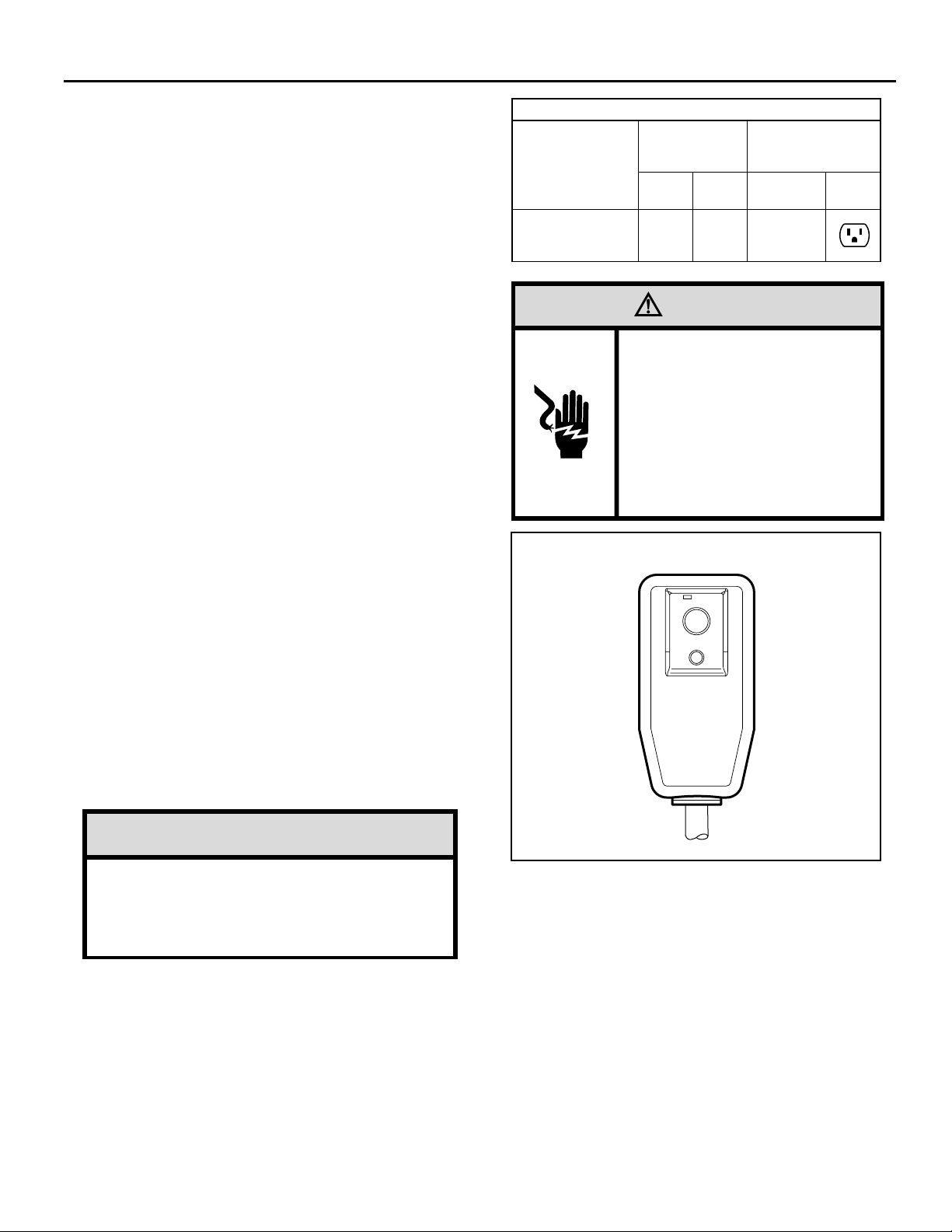

FRR072

Make sure the wiring is adequate for your unit.

If you have fuses, they should be of the time delay HACR type. Before you

install or relocate this unit, be sure that the amperage rating of the circuit

breaker or time delay fuse does not exceed the amp rating listed in Table 1.

DO NOT use an extension cord.

The cord provided will carry the proper amount of electrical power to the

unit; an extension cord may not.

Tabl e 1.

MODEL

• SQ06

SQ08 •EQ08

CIRCUIT RATING

OR TIME DELAY

FUSE

AMP VO LT NEMA NO.

15 125 5-15P

REQUIRED WALL

RE CEPTAC LE

Make sure that the receptacle is compatible with the air

conditioner cord plug provided.

This insures proper grounding. If you have a two prong receptacle you

will need to have it replaced with a grounded receptacle by a certied

electrician. The grounded receptacle should meet all national and local

codes and ordinances. Under no circumstances should you remove the

ground prong from the plug. You must use the three prong plug furnished

with the air conditioner.

Test the power cord

All Friedrich room air conditioners are shipped from the factory with a

Leakage Current Detection Interrupter (LCDI) equipped power cord. The

LCDI device meets the UL and NEC requirements for cord connected air

conditioners effective August 2004.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET (See Figure 1).

3. Press TEST, listen for click; the RESET button trips and pops out.

4. Press and release RESET (Listen for click; RESET button latches

and remains in). The power cord is ready for use.

Once plugged in, the unit will operate normally without the need to reset

the LCDI device.

If the LCDI device fails to trip when tested or if the power supply cord is

damaged, it must be replaced with a new power supply cord from the

manufacturer. Contact our Technical Assistance Line at (800) 541-6645.

To expedite service, please have your model number available.

Figure 1

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Unplug unit prior to performing any service.

Always plug into a grounded 3 prong oulet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

RESET

TEST

WARNING:

TEST BEFORE EACH USE!

1.PRESS REST BUTTON.

2.PLUG LCDI INTO POWER

RECEPTACLE.

3.PRESS TEST BUTTON,

RESET BUTTON SHOULD

POP UP.

4.PRESS RESET BUTTON

FOR USE.

DO NOT USE IF ABOVE TEST

FAILS.

WHEN GREEN LIGHT IS ON.

IT IS WORKING

PROPERLY!

NOTICE

Do not use the LCDI device as an ON/OFF switch.

Failure to adhere to this precaution may cause

premature equipment malfunction.

5

Page 6

Standard Filter Cleaning / Installation Instructions

FRR075

FRR076

FRR077

FRR078

STEP 1. Open front cover and remove permanent/washable mesh

lter by grasping the lter grip and pushing the lter holder

up and outward.

Figure 2

FILTER

DOOR

Premium Carbon Filter Installation Instructions

STEP 2. Clean the front mesh frame by washing the dirt from the lter.

Use a mild soap solution if necessary. Allow lter to dry.

STEP 3. Install lter back into the unit. See also “Filter Removal

Procedure” on the inside of the front door.

Figure 3

FILTER

DOOR

FILTER FRAME

INSTRUCTIONS

Please follow the instr uctions below to install the Friedr ich carbon lter. The carbon

lter should be replaced after 300 hours of operation, 3 months, or more often if

needed for maximum effectiveness.

When you replace the carbon lter, clean the washable mesh lter if dirty. Allow

mesh lter to dry before reinserting.

STEP 1. Remove the black plastic lter frame from the unit following the

instructions above or on the inside of the front cover.

STEP 2. Lay the black plastic lter frame on a at surface, with the 6

lter frame hooks facing upward.

Figure 4

FILTER FRAME

HOOKS (6)

Place the carbon lter over the lter frame so that the carbon

lter’s 6 installation holes align with the 6 lter frame hooks.

(Figure 4)

Secure the carbon lter to the lter frame. Make sure that

all 6 lter frame hooks are inserted through all 6 installation

holes of the carbon lter. The installation hooks will hold the

lter securely.

STEP 3. Place the black plastic filter frame with the carbon filter

installed (Figure 5) back into the front of the unit, following

the instructions on the inside of the lter door.

Carbon lter is now ready for use!

Figure 5

6

Page 7

FAN

CONTROL

Control Panel Operation

FRR095

4 Speed

FAN

AUTO FAN

AUTO FAN

C

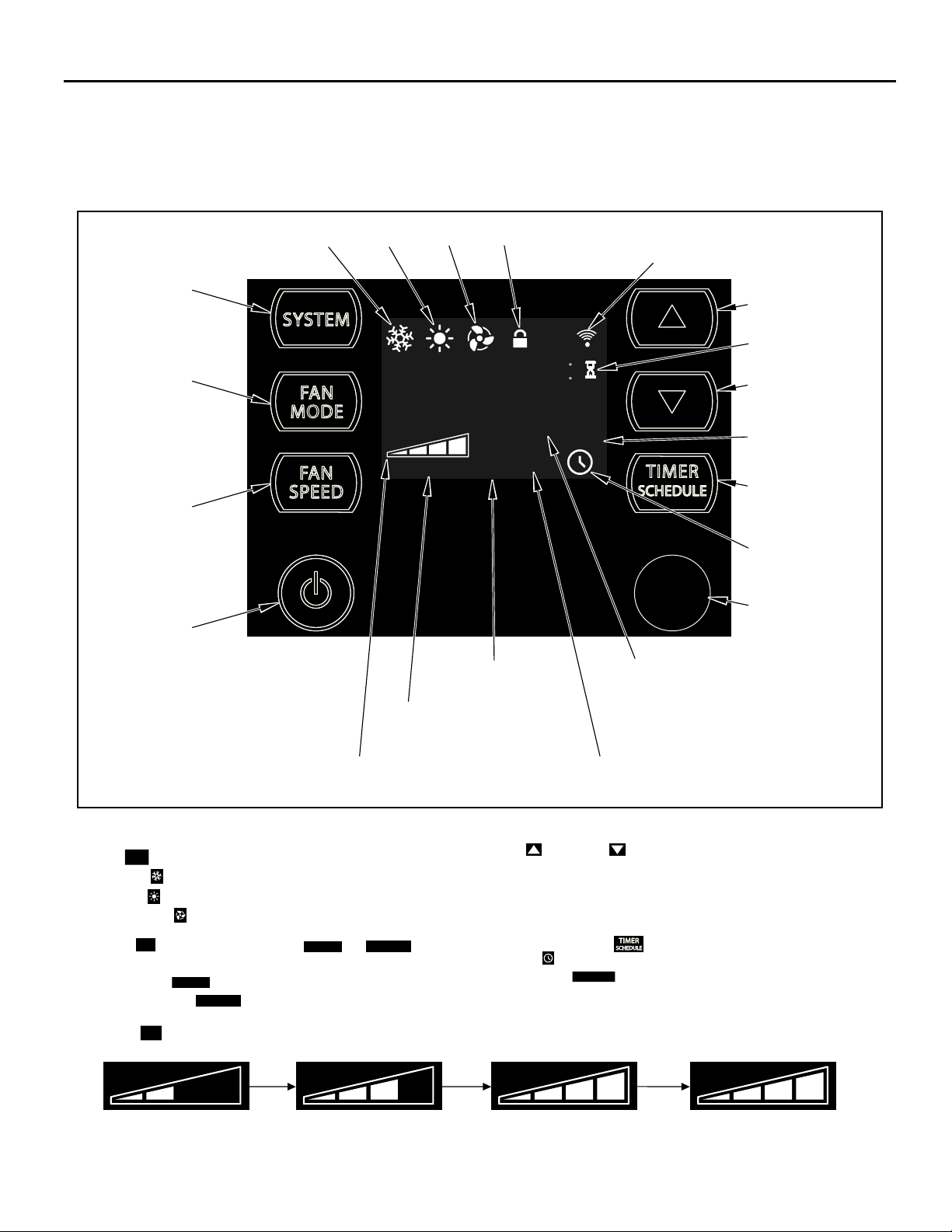

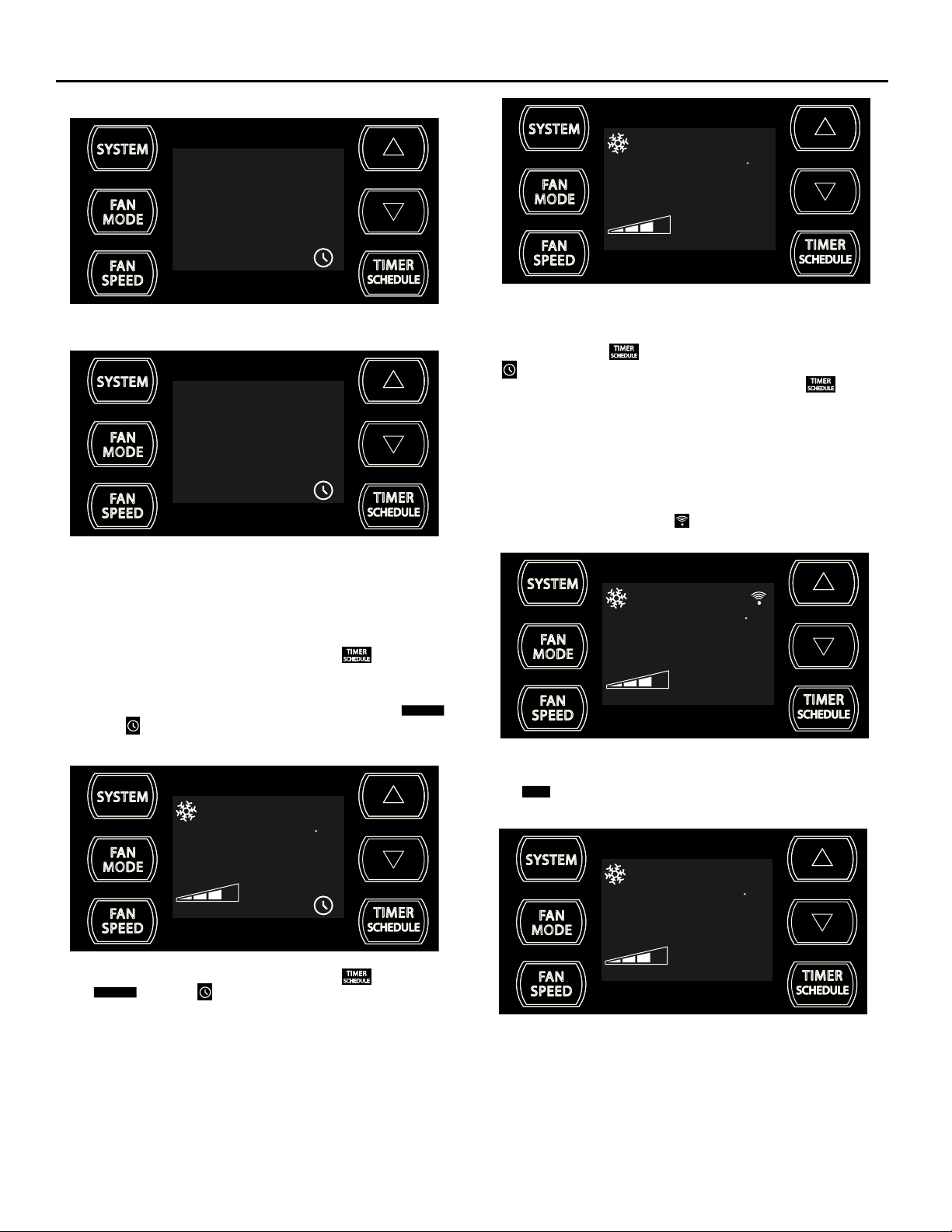

All of the control panel function buttons and mode icons are shown below in Figure 6.

The display backlight has an automatic two (2) step dim function. After 15 seconds of inactivity, the display dims to 20% intensity. After an additional 120

seconds, the display switches off. Touching any button automatically changes the display to full brightness.

Figure 6

SYSTEM

Cycles between:

- COOL

- HEAT (if available)

- FAN ONLY

FAN MODE

Sets fan to either:

- AUTOFAN

-- Cycles automatically

CONTINUOUS

-

-- Runs continuously

FAN SPEED

Sets fan speed:

- LOW

-

MED

- HIGH

TO

- AU

ON / OFF:

Turns unit on/off

COOL

FAN SPEED

Selected fan speed

HEAT

AUTO FA N

CONTINUOUS

ONLY

AUTO SPEED

AUTO SPEED

Automatically selects

best fan cooling speed

LOCKED

88

SET POINT

ROOM TEMP

CHECK$MART

FILTER

FILTER

Check / Clean

WI-FI

CONNECTED (optional)

F

C

AM

PM

ON OFF

SCHEDULE

2 DIGIT DISPLAY

Shows Setting for:

- Set Point Temperature (default)

- Room Temperature

- Clock (AM/PM)

DEMAND RESPONSE EVENT

(optional)

TEMPERATURE

UP

WAIT

TEMPERATURE

DOWN

SCHEDULE ON

TIMER / SCHEDULE

Turns ON or OFF

TIMER ON

IR WINDOW

Do not block

FRR079

Basic Functions

SYSTEM

SYSTEM

FAN MODE

must be in COOL or HEAT operation modes)

FAN SPEED

allows you to select three modes of operation:

COOL

HE AT (if available)

FAN ONLY

MODE

allows you to select between

AUTOFAN

CONTINUOUS

FAN

SPEED

allows you to select between four fan speeds:

: fan cycles on or off with compressor

ONTINUOUS

: fan operates all the time.

LOW MEDIUM HIGH AUTO*

and

UP

and DOWN – changes the system's set point (desired room

temperature). Press once to change 1 degree at a time or hold down

to change at a faster pace. The factory preset lower and upper limits

are 60°F (16°C) and 99°F (37°C) (These buttons are also used for

other functions explained later in this section).

CONTINUOUS

modes.

TIMER SCHEDULE

Timer

(default) or one of the pre-programmed energy management

SCHEDULE

SCHEDULE

options. Pressing this button will activate the selected

TIMER or SCHEDULE. Details are explained in the next section.

*

AUTO selects fan speed needed to satisfy desire set point.

allows you to select between the 24-Hour

AUTO

7

Page 8

Advanced Functions.

FRR097

FRR129

FRR130

FRR128

FRR141

FRR142

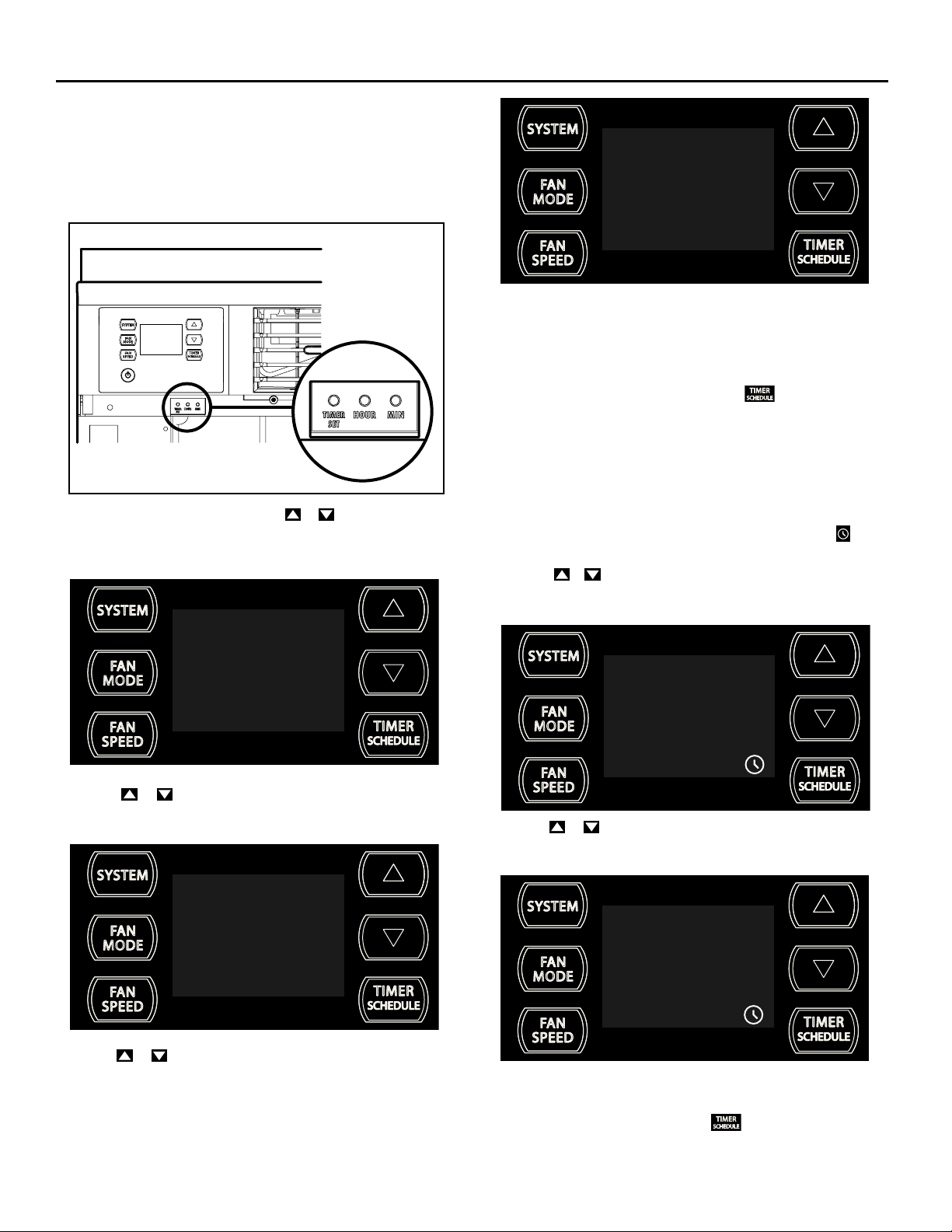

In order to use advanced functions, such as the timer or scheduler, you

must rst set the time and day on your unit.

Set TIME a nd DAY - To adjust the unit's time press and hold the HOUR and

the MIN buttons together for three seconds (Refer to Figure 7).

Figure 7

4

Press TIMER SET button to exit and save the SET TIME and DAY. The

TIMER SET button must be pressed within 15 seconds or the display will

time out and return to the normal operating display.

24-HOUR TIMER

FRIEDRICH

AIR CONDITIONING CO.

SAN ANTONIO, TX

The unit's current hour displays. Use the

hour from 1 - 12, AM or PM. The example shown below is set for 11 AM.

Press TIMER SET (Refer to Figure 7) button to save the hour setting and

display the unit's current minutes.

or buttons to adjust the

AM

11

Use the or buttons to adjust the minutes. The example shown

below is now set for 11:25 AM. Press TIMER SET button to display the

unit's day setting.

The default program for your TIMER SCHEDULE

Timer. (scheduler options explained later in this section)

It allows you to set daily ON and OFF times. For example, you can program

the unit to turn ON at 8:15 am and turn OFF at 1:30 pm everyday. The start

and stop time can be dened, but the unit's system mode, fan speed and

set point cannot and will default to the last setting used.

Set Timer: Setting the Start Time

Press and hold the HOUR button (Figure 7) for 3 seconds. The

and "ON" will appear on the display

Press the

(Figure 7) to save hour setting and go to minutes. The example below is

showing a starting hour of 4 AM.

or button to adjust the hour. Pre ss the TIMER SET button

4

Use the or button to adjust the minutes. Press the TIMER SET

button (Figure 7) within 15 seconds to exit and save the setting. The example

below has been set to turn on at 4:21 AM, once the Timer is activated..

button is a 24- Hour

icon

AM

ON

25

Use the

= Monday, 3 = Tuesday, and so on. The example shown below is set to

4 = Wednesday. Both pre-programmed schedules and customizable

schedules (discussed next) operate off of this setting. It is crucial to set

the day correctly if any schedule is to be used.

8

or buttons to adjust the day from 1 to 7, 1 = Sunday, 2

21

The display will return to normal once the settings are saved.

NOTE: Setting the Timer's start and stop times do not activate the timer.

To activate the timer, you must press the

ON

button.

Page 9

FRR145

FRR146

FRR157

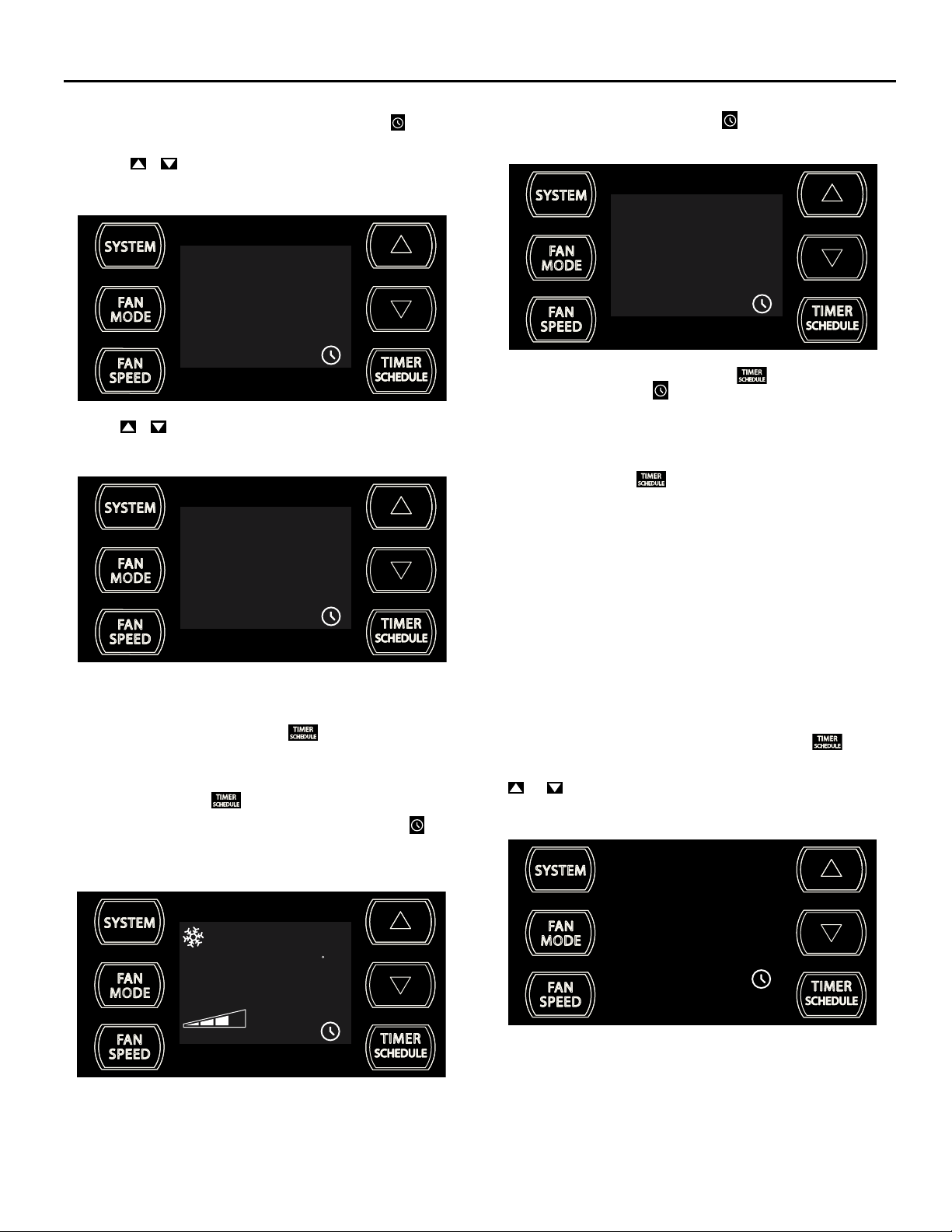

Set Timer: Setting the Stop Time

FRR159

FRR139

Press and hold the MIN button (Figure 7) for 3 seconds. The icon and

"OFF" will appear on the display

Press the

(Figure 7) to save hour setting and go to minutes. The example below is

showing a stop hour of 11 AM.

or button to adjust the hour. Pre ss the TIMER SET button

AM

11

OFF

When the set OFF time occurs or the Timer function is activated during

the OFF time, the unit will turn off, but the

as shown below.

icon will remain illuminated,

Use the

(Figure 7) within 15 seconds to exit and save the setting. The example below

is now set to turn off at 11:55 AM, once the Timer is activated.

The display will return to normal once the settings are saved.

NOTE: Setting the Timer's start and stop times do not activate the timer.

To activate the timer, you must press the

Timer Activated Scenarios

Once the Timer's Start and Stop times have been saved, you can activate

the Timer by pressing the

If the Timer function is activated during the ON time, the Timer icon

illuminates and the unit will continue to run in the existing mode (system

mode, fan mode, fan speed, set temperature, etc.) until the set OFF time

occurs. See the example below:

or button to adjust the minutes. Press the TIMER SET button

55

button..

OFF

button.

To deactivate and shut off the Timer, press the

in the ON or OFF times, the

time, the unit will stay in the current state. If the unit was in an OFF time,

the unit will turn back on in the last state operated.

TIMER and PRE-PROGRAMMED SCHEDULING

The TIMER SCHEDULE

24-Hour Timer - System default. (already covered)

Residential Schedule (option 1) – 40 Hr. Work Week:

This option causes your unit to raise temperatures to 85°F during the typical

work day, lower them again to 78°F prior to the time when most people will

return home, and raise slightly to 82°F overnight.

Commercial Schedule (option 2) - 5-Day Business Week

This option causes your unit to raise temperature to 84°F after typical

working hours and on weekends when commercial spaces are typically

unoccupied.

(Refer to Addendum 1 in the back of this manual for both Residential and

Commercial Schedule Tables.)

Timer/Schedule Select

To select between these 3 options, press and hold the

for 3 seconds. You will then be able to toggle between Timer (default),

Residential Schedule (1) and Commercial Schedule (2) by pressing the

or buttons. See below for images of each option.

24-Hour Timer (system default).

icon disappears. If the unit was in an ON

has three options:

button again. Whether

button

AUTO FA N

79

SET POINT

F

9

Page 10

FRR125

FRR126

Residential Schedule (option 1).

FRR137

FRR138

FRR155

FRR161

SCHEDULE

1

SCHEDULE

Commercial Schedule (option 2).

2

SCHEDULE

To select/save an option, press the TIMER SET button (Figure 7) while

on the desired selection. If there is no button activity for 15 seconds, the

function will time out and leave the original selection.

Once the selection is saved (or timed out), the display reverts to the

normal display.

To activate the selected timer or schedule, press the button

Scheduler Activated Scenarios

If the Schedule function is activated during normal operation, the

and Timer

period schedule parameters, as shown below..

icons illuminates and the unit immediately runs the current

F

AUTO FA N

SCHEDULE

AUTO FA N

79

SET POINT

Timer - Scheduler Control Block

If the unit is operating in the TIMER or SCHEDULE mode, all buttons are

locked out except the

icon begins to blink for 3 seconds. In order to make any changes, you

must rst deactivate the Timer or Schedule by pressing the

FRIEDRICHLINK WI-FI CONTROL

The FriedrichLink Wireless Adapter Accessory (sold separately) allows

you to unlock the full control potential of your Kuhl unit.

You can control, create customized schedules, group units for zone cooling,

and many other options remotely from a smartphone, tablet or computer.

When FriedrichLink is in use, the

system is receiving a Wi-Fi connection.

EXTERNAL CONTROL STATUS

$MART

The

remotely for a Demand Response event.

icon illuminates to indicate that the system is being controlled

but ton. If any other button is pressed, the Timer

icon illuminates to indicate that the

AUTO FA N

79

SET POINT

F

button.

F

79

SET POINT

To deactivate and shut off the Schedule, press the button again.

The

the current state. See example below.

10

and Timer icons will disappear and the unit will stay in

SCHEDULE

AUTO FA N

79

SET POINT

$MART

F

Page 11

FRR133

FRR192

SETTINGS & ALERTS

CHECK

FILTER

FRR118

FAN

FRR120

FAN

FRR116

SPEED

ºF - ºC Select

To switch from degrees Fahrenheit (F) to Celsius (C), press

buttons simultaneously for three seconds.

An “F” will ash for 5 seconds. To change from F to C (or C back to F),

press the

seconds of your desired setting (F or C), the display will revert back to

normal with your desired setting.

or button within those 5 seconds. After the 5 ashing

and

Check Filter Alert

When the lter needs to be cleaned or replaced, the

AUTO FA N

79

SET POINT

CHECK

FILTER

F

icon displays.

f

DIM Function

There are three separate display brightness levels, AUTO, 20% and full

(100%). To change the DIM setting, press the Power button for 3 seconds.

The 1 (shown below) indicates a DIM setting of Auto (factory default). Use

the

or buttons to change the setting.

1

The 2 (not shown, but same placement as "1" above") indicates a DIM

setting of 20%. Press the TIMER SET (Figure 7) button within 15 seconds

to save the setting. Button inactivity for more than 15 seconds causes the

display to time out and return to the normal operating display.

SET POINT

MODE

and for 3 seconds.

F

+ buttons

SPEED

The alert can be dismissed by pressing the

Compressor Lockout Alert

The wait icon

This feature reduces wear and tear on your unit by giving the

compressor adequate time to equalize pressure and prevents

damage that could occur from starting up the unit too quickly after

it stops running.

illuminates when the compressor lockout is active.

AUTO FA N

79

Compressor lockout typically lasts between 2 - 3 minutes. Once

wait icon

Lock Control Panel

To lock the front panel controls, press and hold the

for 3 seconds. The lock icon

clears, normal operation should begin.

illuminates to indicate the locked status.

The 3 (not shown, but same placement as "1" above") indicates a

DIM setting of 100% (full brightness). Press the TIMER SET button

within 15 seconds to save the setting. Button inactivity for more than

15 seconds causes the display to time out and return to the normal

operating display.

AUTO FA N

79

SET POINT

FAN

To unlock, press and hold the

The lock icon disappears to indicate unlocked status.

+ buttons for 3 seconds.

F

11

Page 12

FRR080

Remote Control Operation

AUTO FA N

AUTO FA N

FAN

FAN

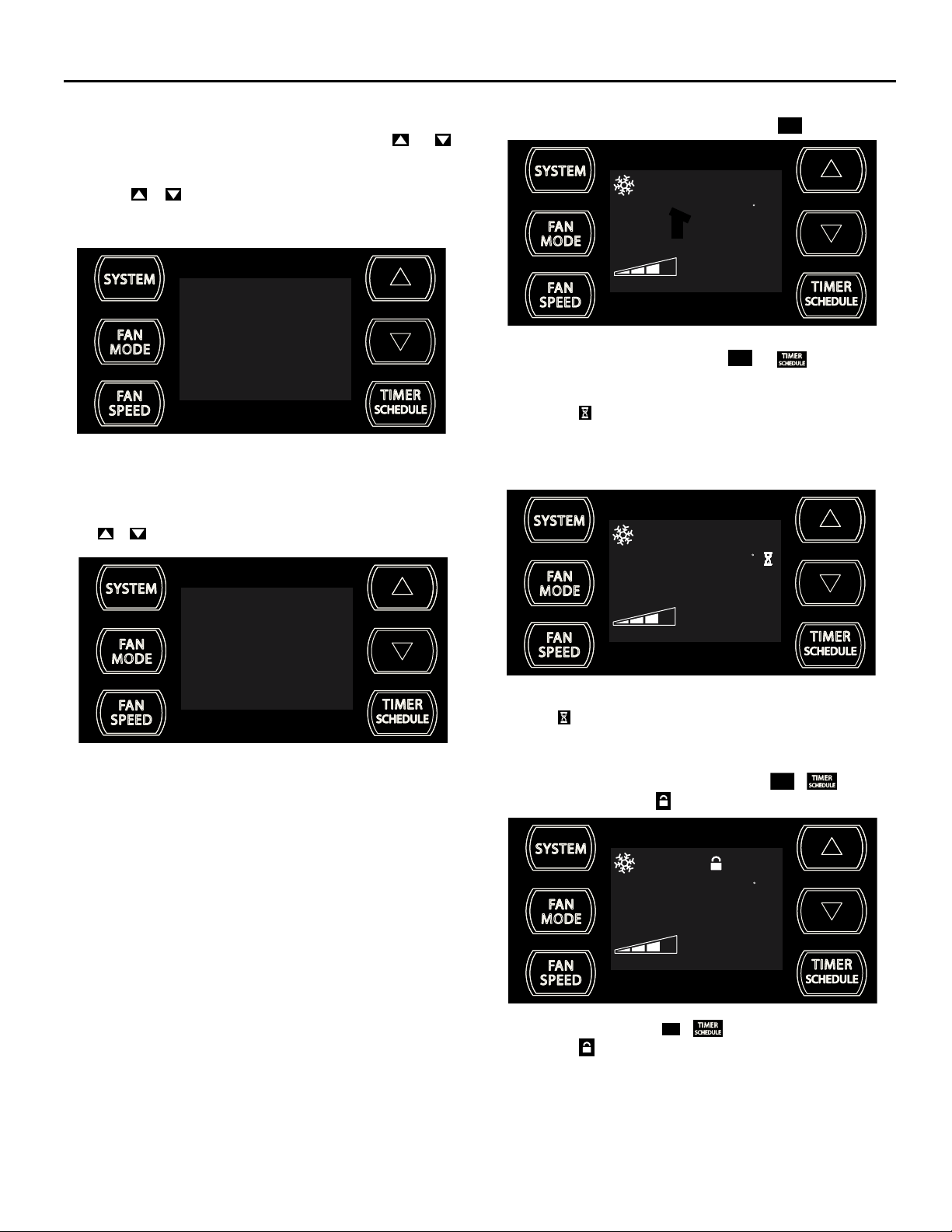

Remote Control - Refer to Figures 9 and 10 during operation description.

Getting Star ted - Install two (2) AA A batteries in the battery compartment

located on the back of the unit.

Operation - The remote control should be within 25 feet of the air conditioner

for operation. (Refer to Figure 8 for effectiveness). Press the power button

to turn the remote on. The remote will automatically power off after 15

seconds if the buttons are not being pressed. The remote must be on to

control the unit.

POWER Button - Turns remote and unit on and off.

SYSTEM Button - Toggle between Cool

FAN ONLY

operation.

FAN MODE Button - Toggle between automatic (

fan operation.

, HEAT (if available), and

CONTINUOUS

) or

SCHEDULE

SCHEDULE Button – Press the

selected timer or schedule function. Pressing the

button to activate the saved/

SCHEDULE

button a second

time deactivates the saved/selected timer or schedule.

UP and DOW N Arrows - Pressing either the

(UP) or (DOWN) button

changes the desired room temperature. These buttons are also used to

navigate between functions explained earlier in this chapter.

Remote Effectiveness

Hand Held Remote - Has an operating range of up to 25 ft. The infrared

remote control signal must have a clear path to transmit the command

to the air conditioning unit. The remote signal has some ability to

"bounce" off of walls and furniture similar to a television remote

control. The diagram below shows the typical operating range of the

control in a standard room with 8 ft. high ceilings.

NOTE:

indicates

determined by your selection on the

is not available in the FAN ONLY Mode, the display

CONTINUOUS

. In the

CONTINUOUS

SPEED

mode, fan speed is

button.

FAN SPEED Button - Toggle between fan speeds or AUTO speed. When

the

but ton is pressed, the fan speed icon (triangle) changes to indicate

SPEED

the new speed level.

Figure 8

7.5ft

SIDE VIEW

60°

60°

30°

45°

45°

30°

TOP VIEW

25ft

25ft

4ft

8ft

25ft

60°

60°

45°

45°

30°

30°

6ft

16ft

12

8ft

25ft

25ft

25ft

25ft

25ft

Page 13

FRR081

Figure 9

SYSTEM

TEMPERATURE

UP

FAN SPEED

AUTO FAN

CONTINUOUS

AUTO

SYSTEM

FAN SPEED

88

FAN MODE

POWER

SCHEDULE

DISPLAY

F

C

FAN MODE

POWER

TEMPERATURE

DOWN

SCHEDULE

Figure 10

SYSTEM

MODE

FAN

MODE

FAN

SPEED

COOL

ICON

AUTO FAN

CONTINUOUS

AUTO

HEAT

ICON

FAN ONLY

ICON

88

F

C

SCHEDULE

ICON

°F / °C

ICONs

FRR082

13

Page 14

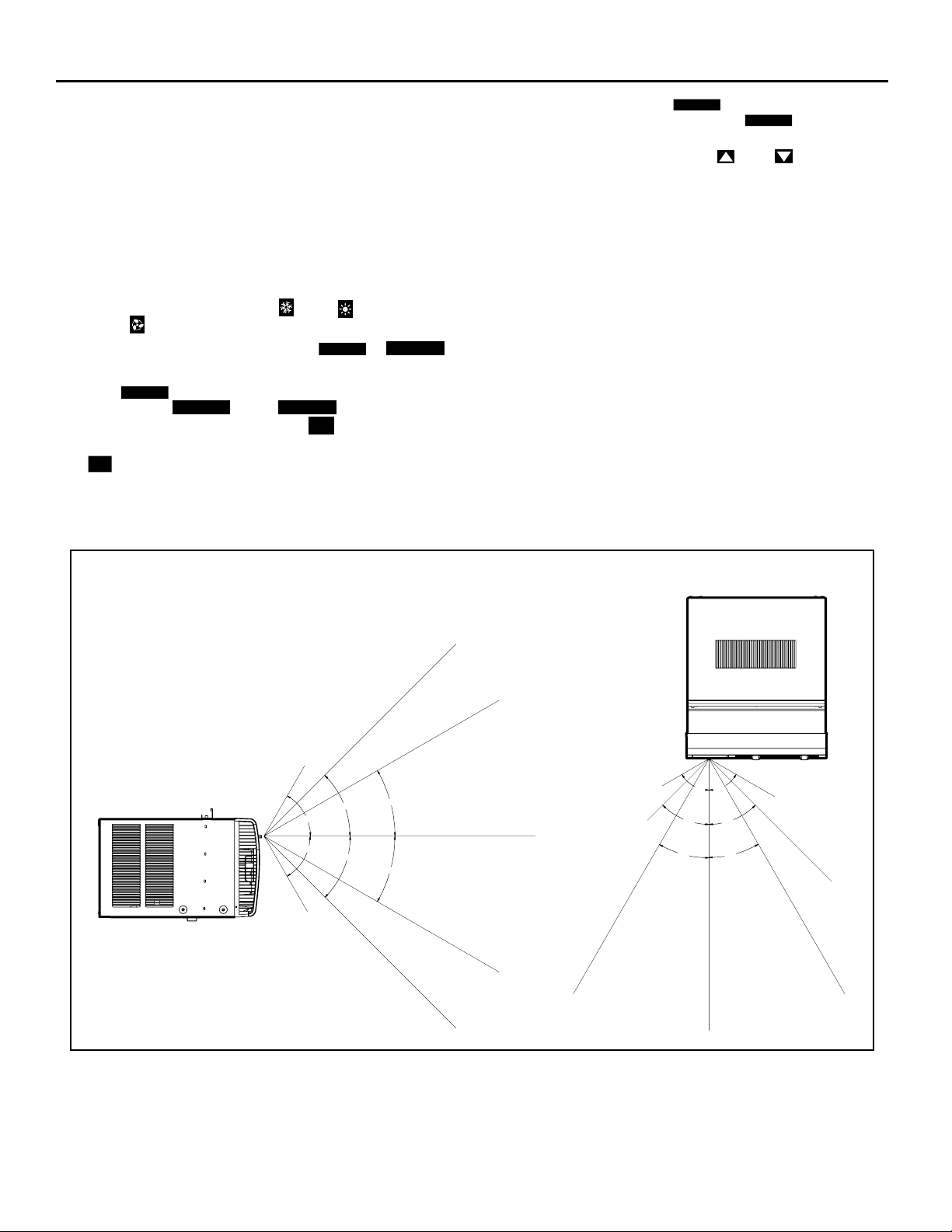

Airflow Selection and Adjustment

FRR083

Air flow direction adjustment

The airow path may be adjusted to distribute air independently from the

left or right side of the discharge opening. Each of the banks of louvers

can be directed left, right, up or down in order to achieve the most optimum

airow positioning.

To adjust airow direction grab the lever in the center of the louver

bank and move it in the direction that you would like the air to be

directed. Please note that it is normal that airow may be stronger

out of one side of the louvers than the other.

Installation Instructions

Figure 11

LEFT AIRFLOW

LEVER

RIGHT AIRFLOW

LEVER

NOTE: This section includes installation instructions for window mount

and thru-the-wall mount methods. Kühl heat/cool units are

designed for permanent thru-the-wall installation. Mounting the

unit in a window will require a window accessory kit, available

through your Friedrich dealer.

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Unplug unit prior to performing any service.

Always plug into a grounded 3 prong oulet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

READ THIS FIRST! Electrical Requirements

IMPORTANT: Before you begin the actual installation of the air conditioner,

be sure your electrical requirements are as described below. Consult an

electrical professional as necessary to insure home wiring is per local

electrical codes.

CIRCUIT PROTECTION – An overloaded circuit will invariably cause

malfunction or failure of an air conditioner, therefore, it is necessar y that the

electrical protection is adequate. Due to momentary high current demand

when your air conditioner is started, use a "TIME DELAY" fuse or a HACR

type circuit breaker. Consult your dealer or power company if in doubt.

Your air conditioner must be connected to a power supply with the same

A.C. voltage and hertz as marked on the unit nameplate. Only alternating

current (A.C.), no direct current (D.C.), can be used.

The power cord has a plug with a grounding prong of approved type

and a matching plug receptacle with ground is required. Refer to page

5 for the correct type of plug receptacle for your model.

14

Page 15

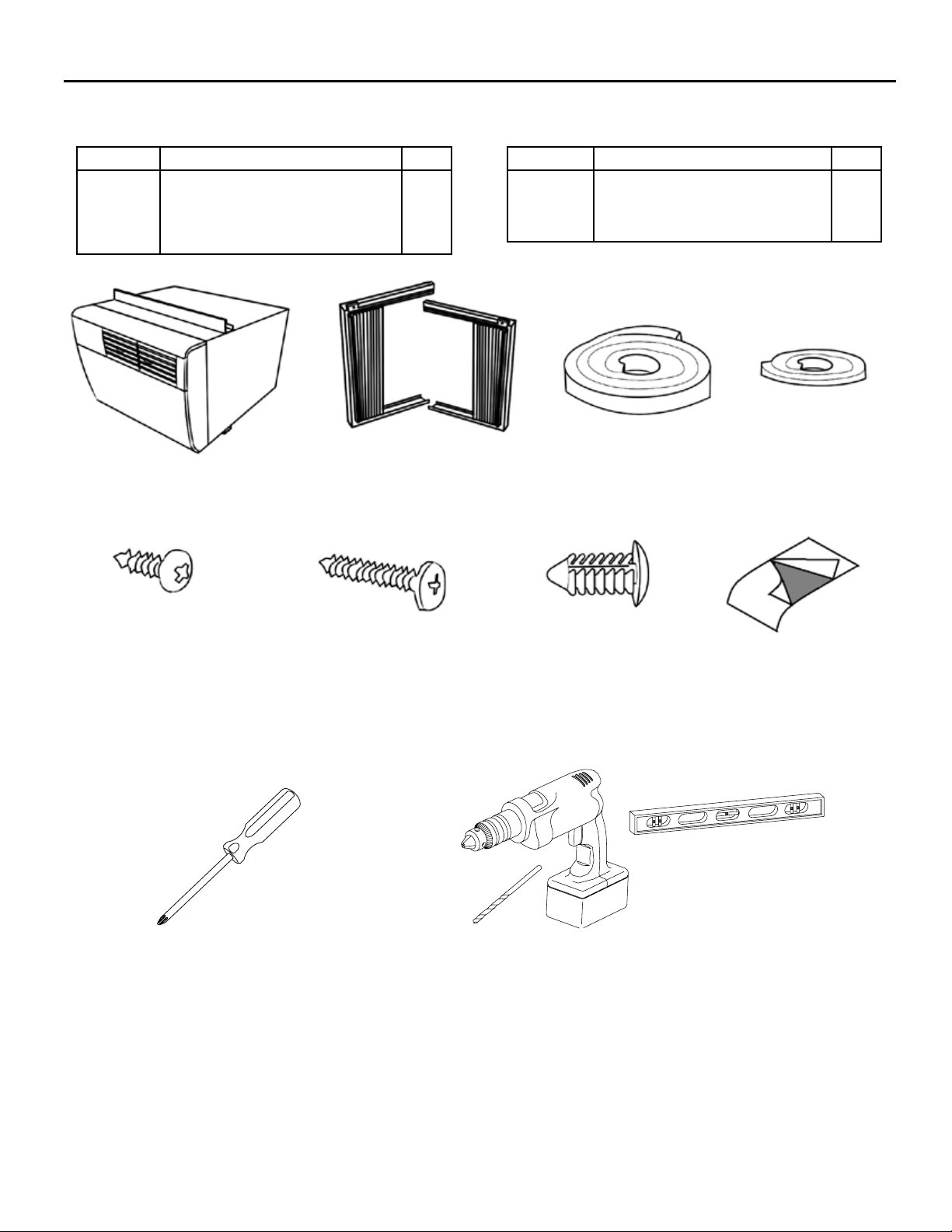

Items required for installation (included in cooling only units, sold separately for heat/cool models)

ITEM NO DESCRIPTION QT Y.

A

B

C

D

Q KÜHL UNIT

Q SIDE CURTAINS (INCLUDES 8 PUSH PINS)

WINDOW SEAL GASKET

SHELL GASKET (ADHESIVE-BACK)

for replacement installations only

A

1

2

1

1

B

ITEM NO DESCRIPTION QT Y.

E

F

G

H

SCREW #8 x ½" (BLUE BAG)

S

REW #8 x 1 ¼" (GREY BAG)

C

SPARE PUSH PINS

*R1 INSULATION PANEL

*Panel not included in EQ08 models,

C

6

5

4

2

D

E F G

Recommended tools required for installation: (not included)

Required for all installations

PHILLIPS SCREWDRIVER

NOTE: Protective clothing and gear should be worn & used while installing the unit (ex: protective eyewear, gloves, boots, etc…)

FOR WINDOW INSTALLATIONS, PROCEED TO THE NEXT PAGE.

Recommended for thru-the-wall installations

LEVEL

POWER DRILL & ⅛” DRILL BIT

H

FOR THRU-THE-WALL INSTALLATIONS, SKIP TO PAGE 22.

15

Page 16

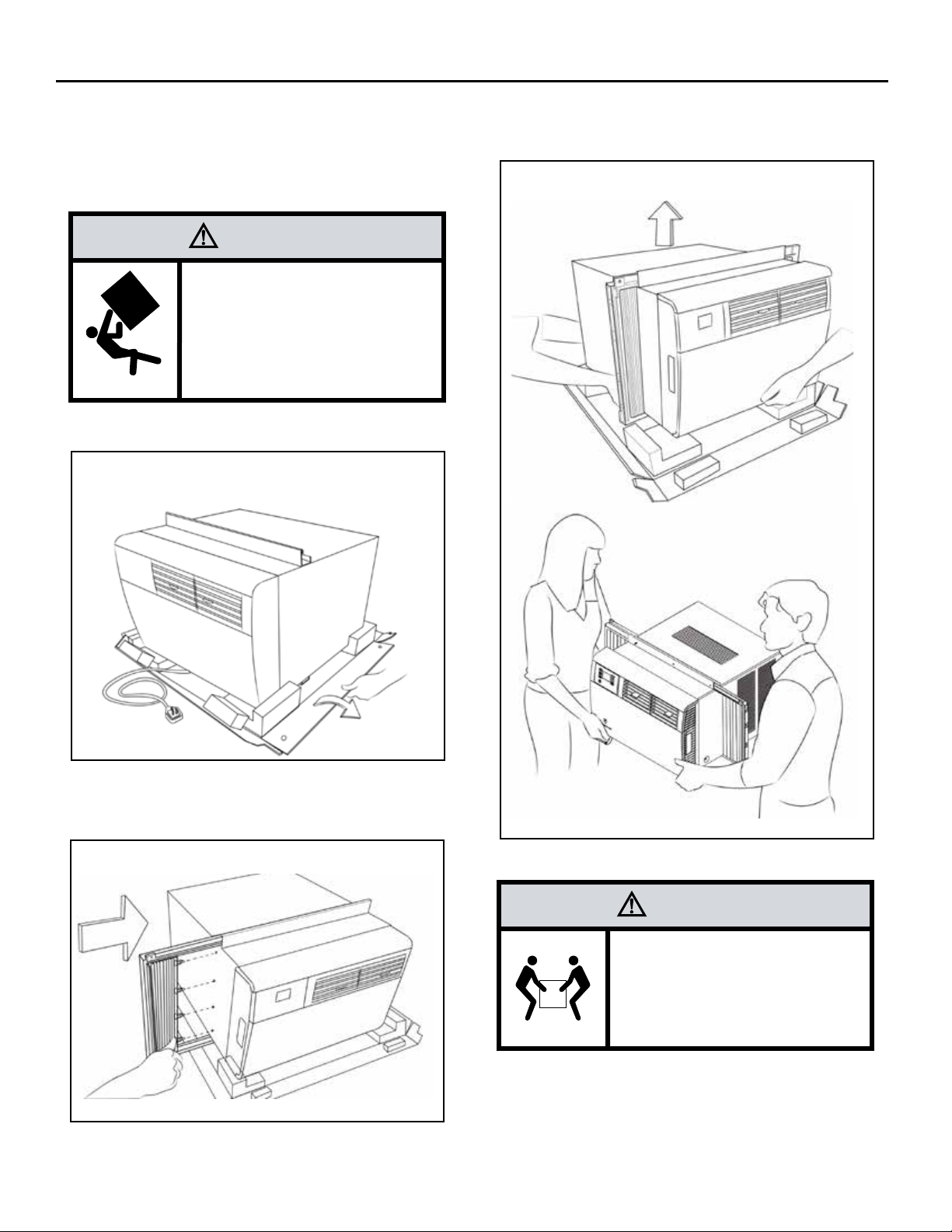

Standard Window Installation

IMPORTANT: Some municipalities or jurisdictions require that window

units are installed by licensed contractors. Check your local codes and

ordinances prior to attempting installation.

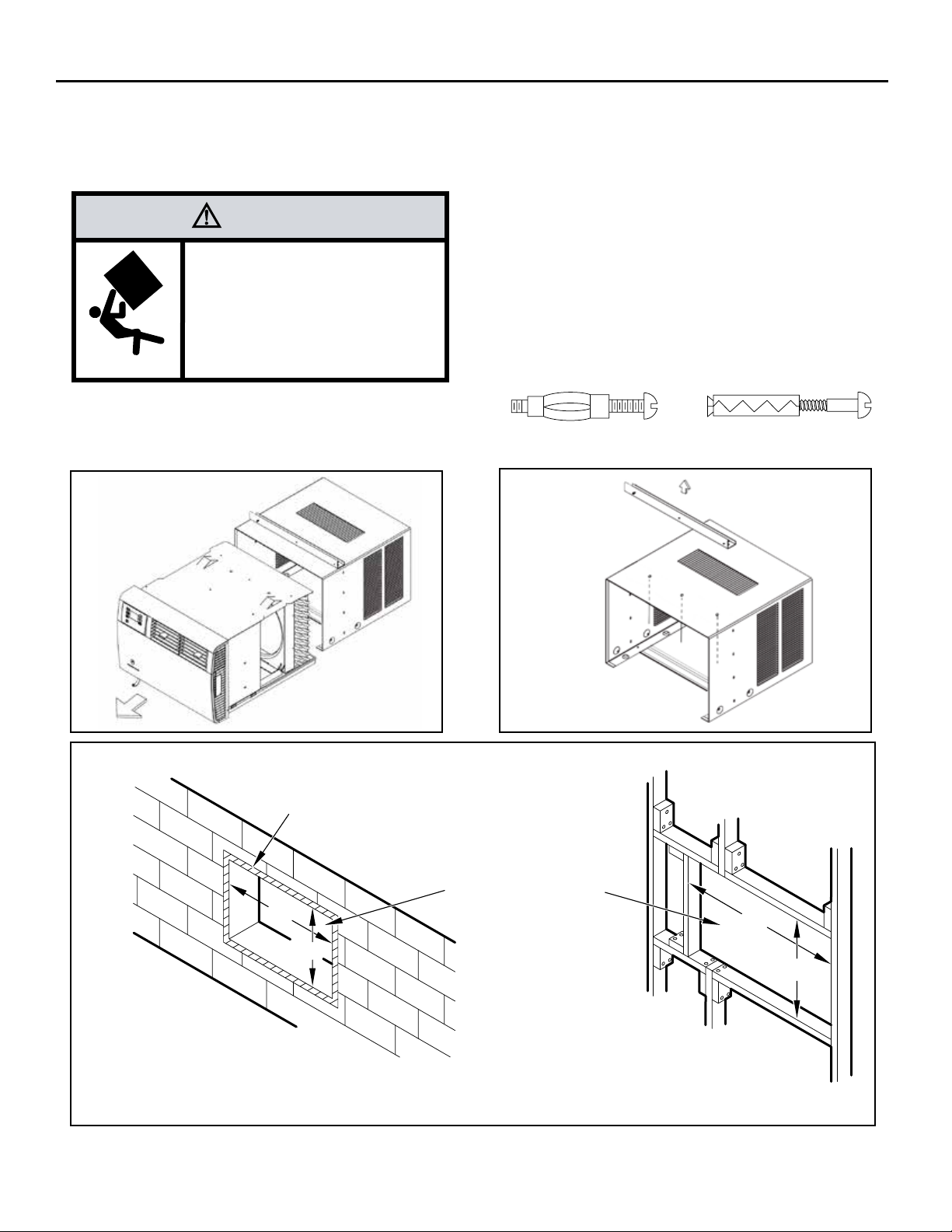

WARNING

Falling Object Hazard

Not following Installation Instructions

for mounting your air conditioner can

result in property damage, injury, or

death.

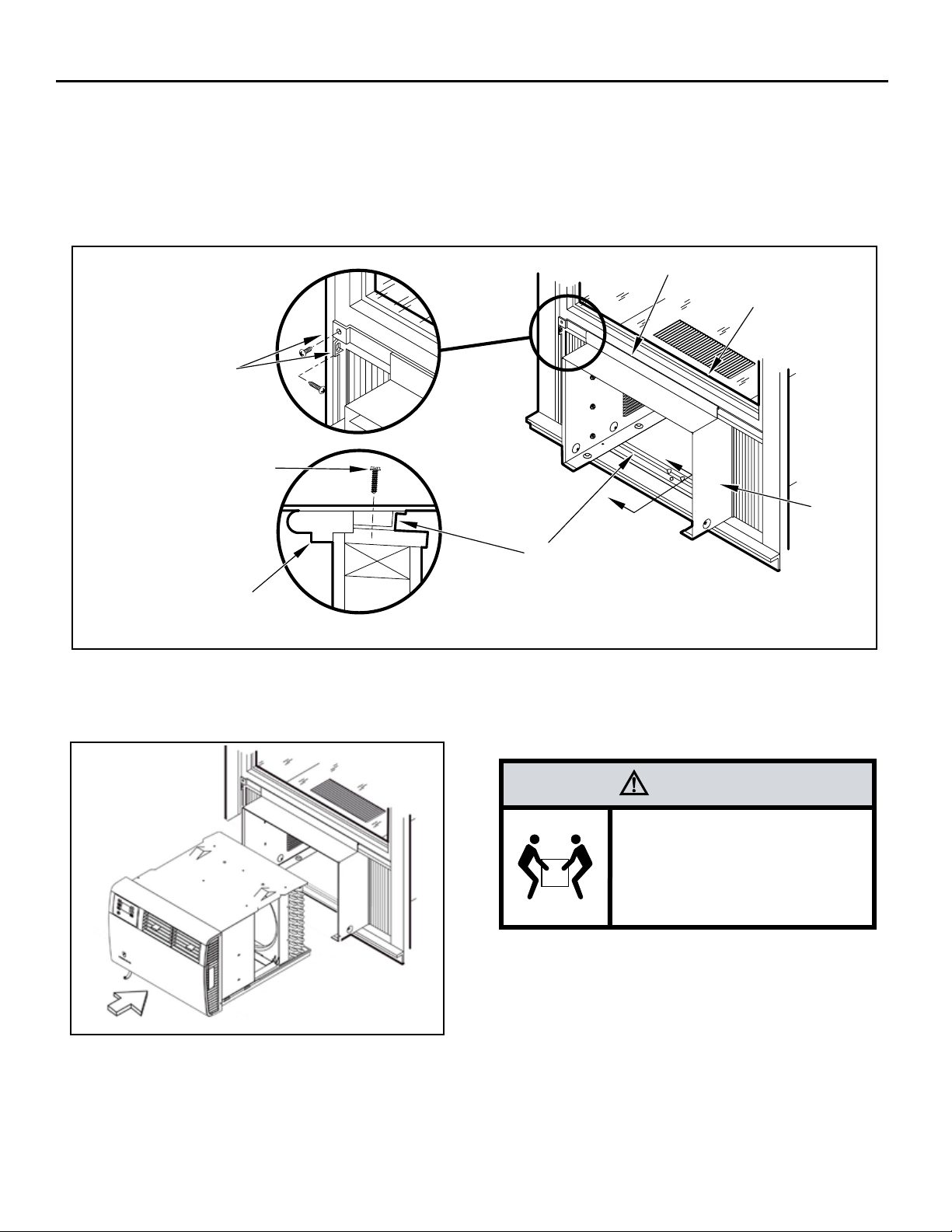

STEP 1. Fold down the sides of the carton bottom tray. (See Figure 12).

Figure 12

STEP 3. Once both curtains have been installed, slide hands

underneath the unit to lift and carry to the window, as shown

in Figure 14 below. Obtain assistance as needed

Figure 14

STEP 2. Install side curtains (B in parts list) on both sides of the unit.

Press in the attached push pins (4 on each side) to secure

curtains to the sleeve. (See Figure 13)

Figure 13

16

CAUTION

Excessive Weight Hazard

Use two or more people when

installing your air conditioner.

Failure to do so can result in

back or other injury.

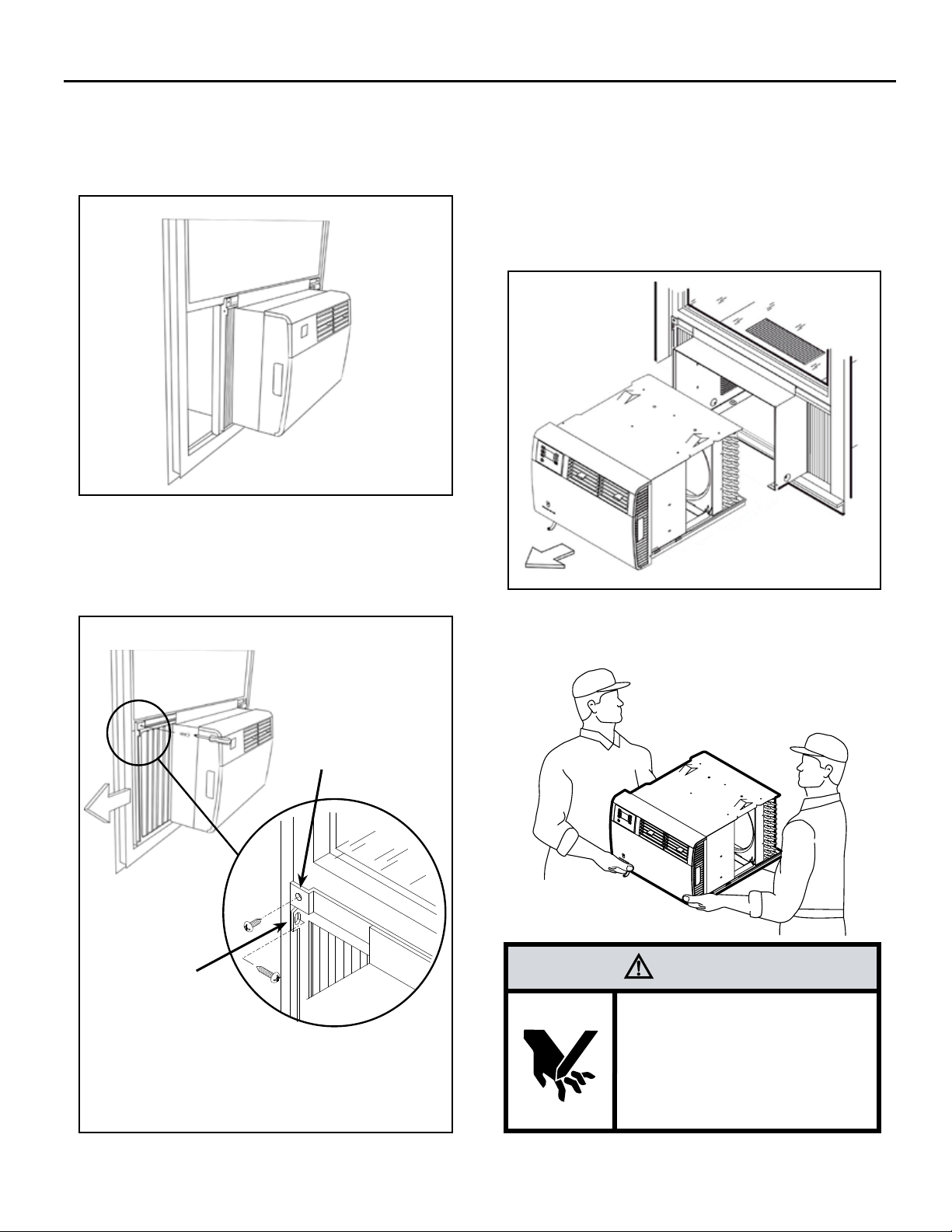

Page 17

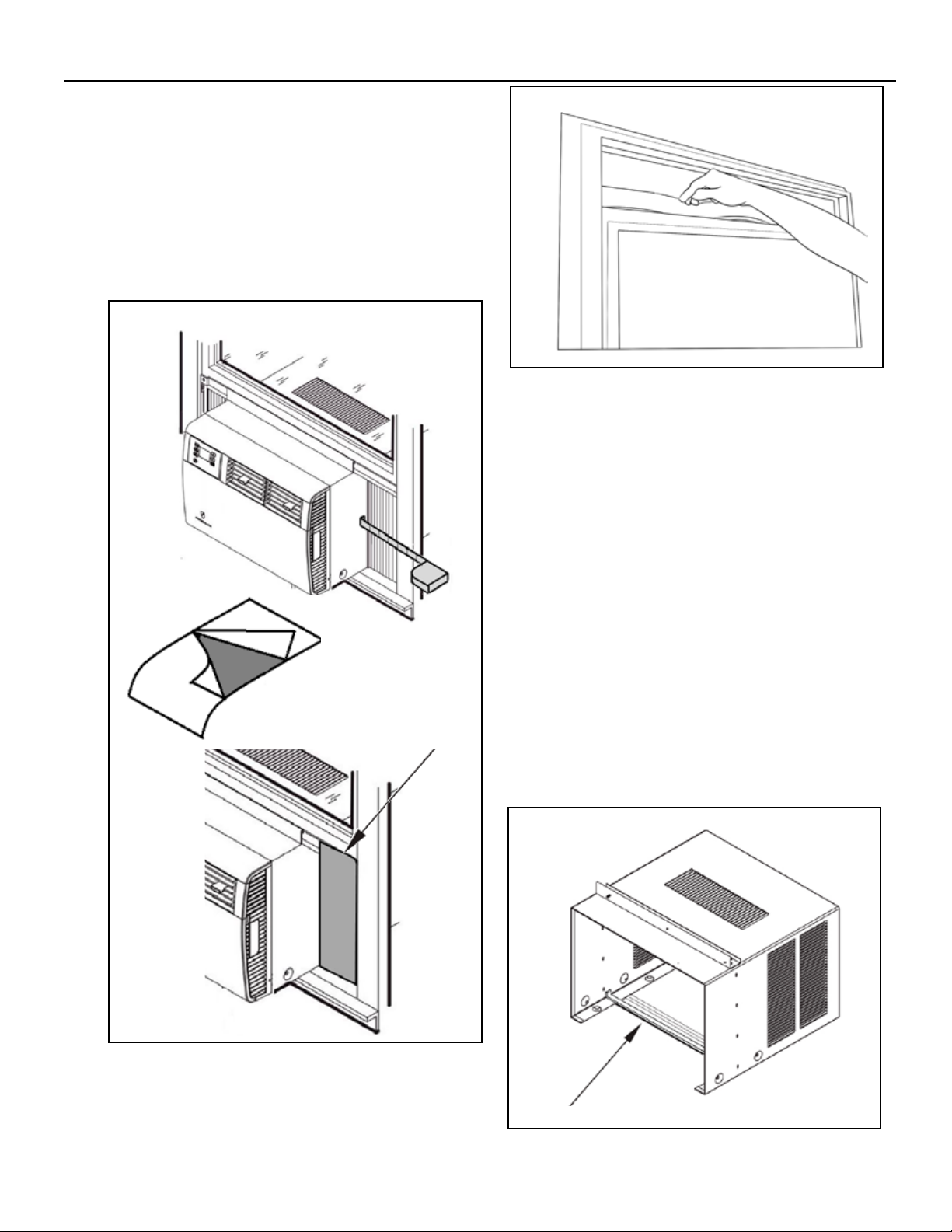

STEP 4. Place unit in window with the bottom support rail up against the

back edge of the window sill. Center and close window sash

onto upper support rail. The unit should be slightly tilt

ed

outside (1/4" tilt). (See Figure 15) NOTE:

Depending on the type of window, install the appropriate

security lock as recommended by manufacturer.

Figure 15

If you desire a more permanent installation, you can secure your

curtains using both screw holes and your unit sleeve directly to

the lower window stool using the instruction Steps 5.1 - 5.3 shown

below. If you choose the standard installation already covered in

Steps 1 - 5, then you can proceed to Step 6 found on Page 18.

STEP 5.1.

Pull unit from sleeve, using the side handles located on

either side of the decorative front. Obtain assistance as

needed. Place unit out of the way on a secure, at surface.

(See Figure 17)

Figure 17

STEP 5. Extend side curtains to ll window. Secure outer top corner

of both curtain (left and right) to window jamb and window

sash using supplied screws. 1/2" screws (Item E in parts list)

and 1 1/4" screws ( Item F: in parts list) have been provided to

accommodate varying window types. (See Figure 16)

Figure 16

SECURE TO WINDOW

SASH THROUGH TOP

SCREW HOLE

SECURE TO

WINDOW JAMB

THROUGH

BOTTOM / SIDE

SCREW HOLE

THIS STEP MUST BE FOLLOWED COMPLETELY TO INSURE

UNIT IS ADEQUATELY SECURED TO WINDOW.

NOTE: WHEN REMOVING UNIT FROM SLEEVE AND CARRYING OR

HANDLING UNIT, OBTAIN ASSISTANCE OR HELP AS NECESSARY

TO SUPPORT UNIT FROM BOTTOM (BASEPAN), MAINTAINING

CLEARANCE FROM ALL OBSTACLES. (See image below)

CAUTION

Cut/Sever

Although great care has been

taken to minimize sharp edges

in the construction of your unit,

use gloves or other hand

protection when handling unit

Failure to do so can result in minor

to moderate personal injury.

17

Page 18

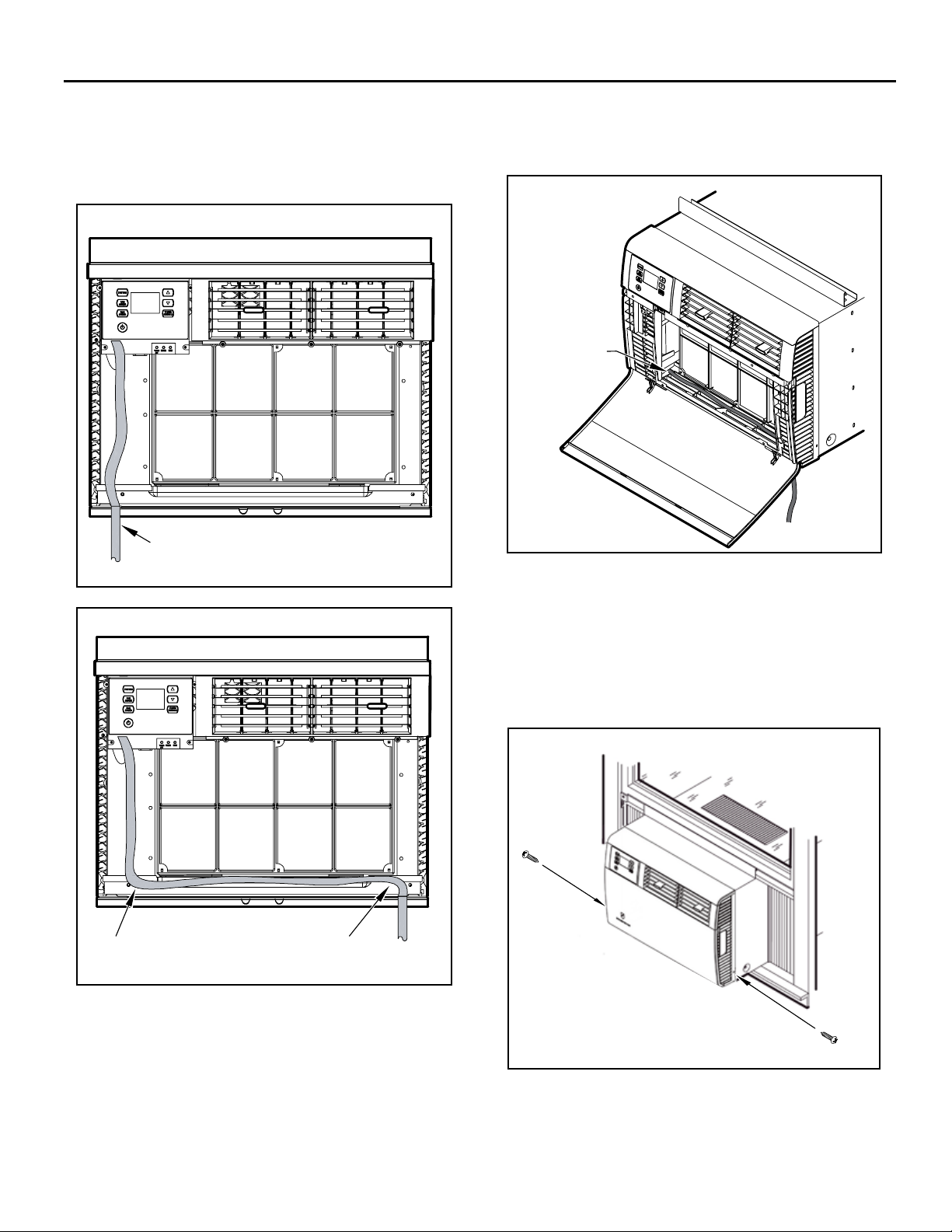

STEP 5.2.

Once unit is removed from sleeve, secure sleeve to window sill through screw hole in the bottom center of sill channel using 1 supplied 1 ¼" screw (F in parts list) . (See Figure 18 A-A)

In Step 5, the window curtains were secured using 1 supplied screw per curtain (2 screws total). For a more permanent application,

you may secure each curtain with an additional screw through the remaining screw hole, insuring each window curtain is secured

to window jamb and sash with 2 screws each (4 screws total). Two sizes of screws (E and F in parts list) have been provided to

accommodate varying window types. (See Figure 18)

NOTE: Securing the curtains using both screw hole locations may not work in certain window types. For those applications, use only

1 screw per curtain and install the appropriate security lock as recommended by window manufacturer.

Figure 18

SECURE CURTAINS

THROUGH REMAINING

HOLES USING EITHER 1/2"

SCREWS (ITEM E: BLUE

BAG) OR 1 1/4" SCREWS

(ITEM F: GREY BAG).

SECURE SILL CHANNEL

TO WINDOW STOOL

USING (1) 1 1/4" SCREW

(ITEM F: GREY BAG).

WINDOW STOOL

STEP 5.3.

Figure 19

Inspect unit prior to inserting back into sleeve. Manually rotate fan to see that it turns freely. Make sure electrical cord is positioned

in the front of unit and out of the way when inserting it back into the sleeve.

Insert unit back into sleeve by positioning onto bottom rails of sleeve and pushing back into place. Obtain assistance as needed.

(See Figure 19)

SECTION A-A

SILL

CHANNEL

SHELL SUPPORT CHANNEL

WINDOW SASH

A

A

SLEEVE

18

CAUTION

Excessive Weight Hazard

Use two or more people when

installing your air conditioner.

Failure to do so can result in

back or other injury.

NOTE: WHEN CARRYING OR HANDLING UNIT, OBTAIN ASSISTANCE

OR HELP AS NECESSARY TO SUPPORT UNIT FROM BOTTOM

(BASEPAN), MAINTAINING CLEARANCE FROM ALL OBSTACLES.

Page 19

STEP 6. To minimize air leaks and ensure optimal insulation, install

the included R1 insulation panels.

20 A-C).

First, measure the width from one side of the air condi-tioner

to the end of the side curtain. (See Figure 20A)

Next cut the R1 insulation panel to the measured width and

remove protective cover, exposing adhesive on

back panel (See Figure 20B)

Last, evenly apply the adhesive side of the panel to the top

and botom of the side curtain frame. (See Figure 20C)

Repeat the step above for the other side curtain frame.

Figure 20

(H in parts list) (See Figure

Figure 21

STEP 8.

Now that installation is complete, your unit is ready to operate!

A

Simply plug in the power cord and follow the operation steps

outlined in this manual or your QuickStart Guide.

CIRCUIT PROTECTION - If the air conditioner is circuit protected by a fuse,

use a "TIME DELAY" fuse or HACR type circuit breaker due to momentary

high current demand when your air conditioner is started. Before operating

your unit, verify the ampere rating of the time-delay fuse or circuit breaker

which protects your unit. The ampere rating of the time-delay fuse or circuit

breaker shall be 15 amps

Plug in unit..

Replacement Installation Instructions

B

C

Your new Kühl Q chassis will t in all previous Friedrich Q-size

sleeves. Replacement installation instructions are the same for

both window and thru-the-wall.

Inspect your existing Friedrich Q-size sleeve to ensure it is

properly installed and in good condition.

Remove adhesive backing from supplied shell gasket (D in parts list) and

place along the bottom sill channel, centered, extending up the sides of

the shell. (see Figure 22).

Remove the new Kühl Q chassis from the new sleeve (as outlines

in STEP 5.1 on page 17).and insert into previously installed sleeve.

Obtain assistance as needed.

Figure 22

STEP 7.

Cut the window seal gasket (C in parts list) to match the

window width and insert it between the window sashes

as shown in Figure 21.

SHELL GASKET (ITEM D).

19

Page 20

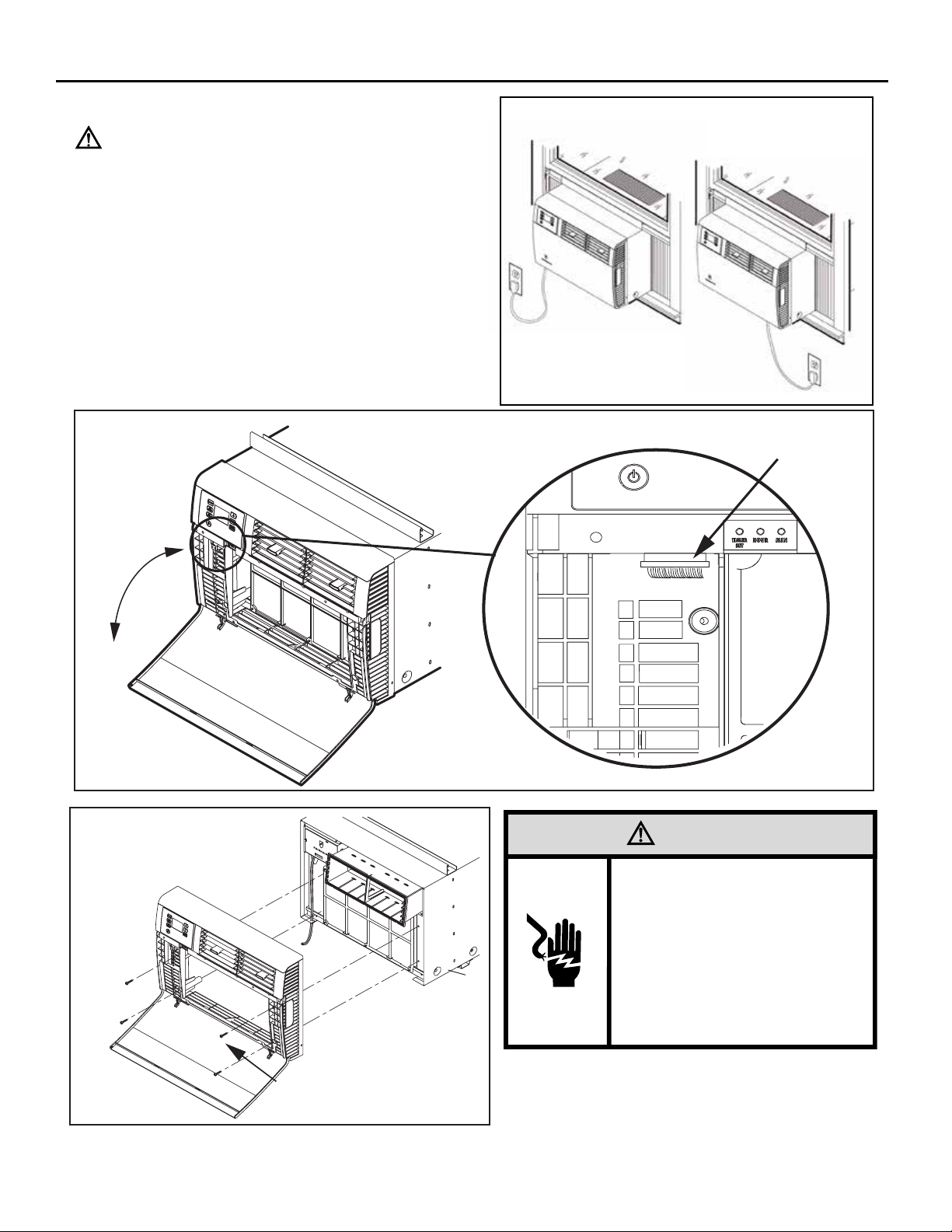

Cord Routing Change

Unplug unit.

Your Kühl Q unit will come with the power cord already installed and routed

to the left side of the unit.

For convenience and optimum appearance the direction of the power

cord can be changed from left to right by following the procedure below.

Select the exit location on the left or right based on proximity to the power

outlet. (See Figure 23)

STEP 1. Remove the decorative front cover. (See A thru D and Figures

24A and 24B below)

A. Open the decorative front cover.

B. Locate and disconnect electronic control power cable harness.

C. Remove 4 screws attaching decorative front cover.

Save to reinstall later..

D. Remove decorative front cover. Store in a safe place to

reinstall later. (no image).

Figure 24A

Figure 23

B.

A.

Figure 24B

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Unplug unit prior to performing any service.

Always plug into a grounded 3 prong oulet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

20

C.

Page 21

FRR099

STEP 2. Route the cord along bot tom inside of the unit (See Figures 25

and 26), under the lower left mounting screw embossments

and exit the cord through right side cord opening (See Figure

26) of the decorative front cover. Decorative front cover will

keep cord in place.

Figure 25

FACTORY SETTING WITH LEFT-SIDE

CORD PLACEMENT

FRR201

STEP 3. Reinstall the 4 screws removed earlier to secure decorative

front cover with cord exiting to the front bottom of the unit. (4

screws RETAINED FROM STEP 1) and re-connect the power

cable harness (disconnected in STEP 1).

Figure 27

CLOSE-UP OF

CORD UNDER

LEFT MOUNTING

SCREW

EMBOSSMENT

Figure 26

NEW CORD ALIGNMENT FOR ROUTING CORD

EXIT TO THE RIGHT OF UNIT

EntryGuard Security Lock

For additional safety, your unit is equipped with EntryGard™ protection,

a feature that helps prevents kick-in intrusions. To engage this feature,

use 2 supplied 1/2" screw (E in parts list) to secure decorative front

cover to sleeve. (See Figure 28 for screw hole locations) .

Figure 28

FRR202

21

Page 22

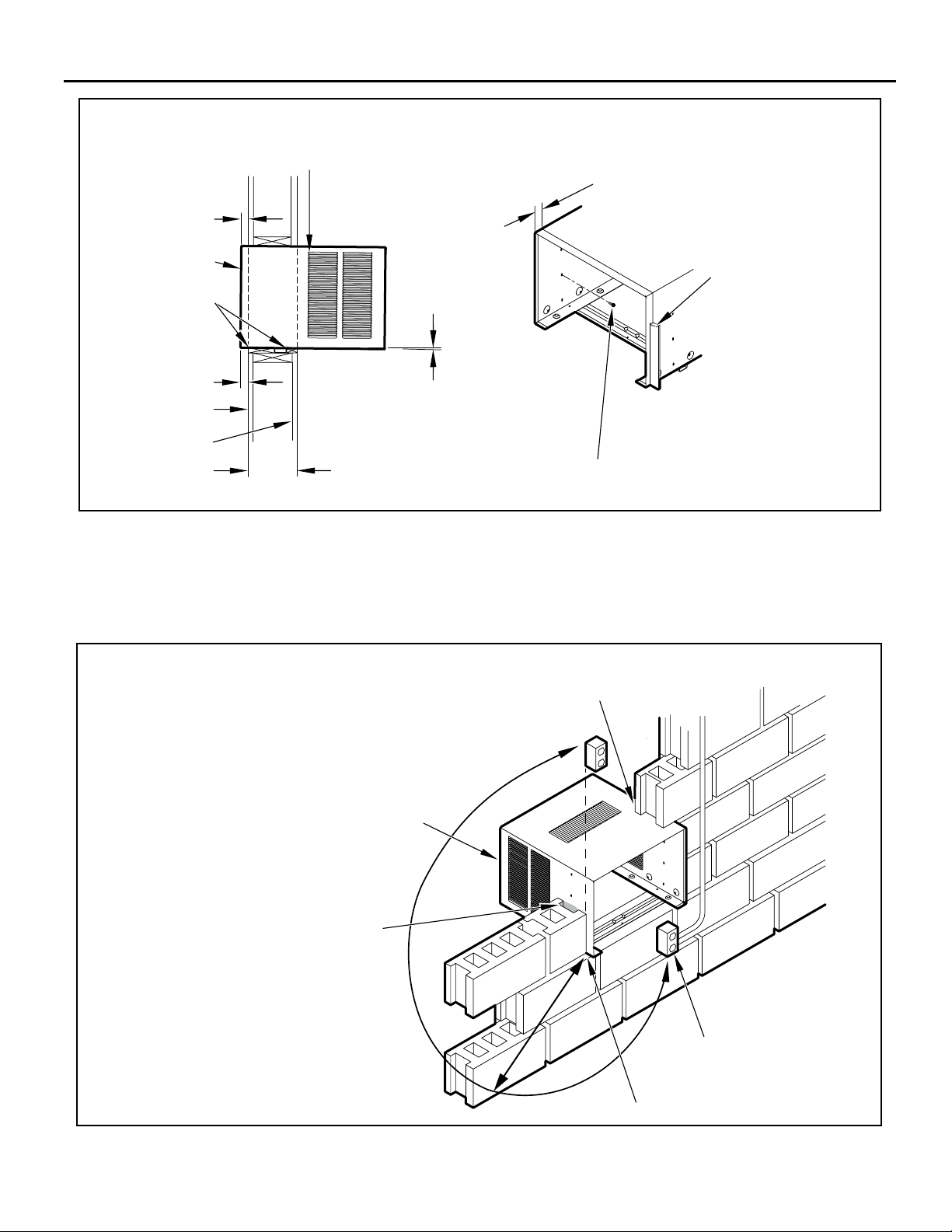

Thru-the-wall Installation

FRR091

EXPANSION ANCHOR BOLT

MOLLY OR TOGGLE BOLT

IMPORTANT: Some municipalities or jurisdictions require that window

units are installed by licensed contractors. Check your local codes and

ordinances prior to attempting installation.

WARNING

Falling Object Hazard

Not following Installation Instructions

for mounting your air conditioner can

result in property damage, injury, or

death.

STEP 3. LAYOUT - Cut and frame in an opening in the desired wall area

using the illustration as a guide. (See Figure 31)

STEP 4. Place the sleeve in the framed opening.

NOTE: Measure and shim void spaces between the side of sleeve and

wood framing before securing to wall.

STEP 5. Position the front edge to extend into the room 3/4" minimum

at top of sleeve and 1" minimum at bottom (See Figure 32).

STEP 6. Secure each side of the sleeve with supplied 1 ¼" screw

(F in parts list) or nails through the holes in the sides.

NOTE: Alternate fasteners which may be used for securing the unit

sleeve to a wall, including masonry walls, are not furnished

(available at local hardware stores).

STEP 1. After removing the unit from shipping carton, slide chassis out

of sleeve. (See Figure 29)

STEP 2. Remove shell channel from top of the sleeve. (See Figure 30)

Figure 29

STEP 1

Figure 31

2” x 8” FRAME

Figure 30

STEP 2

CONCRETE BLOCK CONSTRUCTION FRAME CONSTRUCTION

22

20”

14-1/4”

FINISHED OPENING SIZE

20”

14-1/4”

Page 23

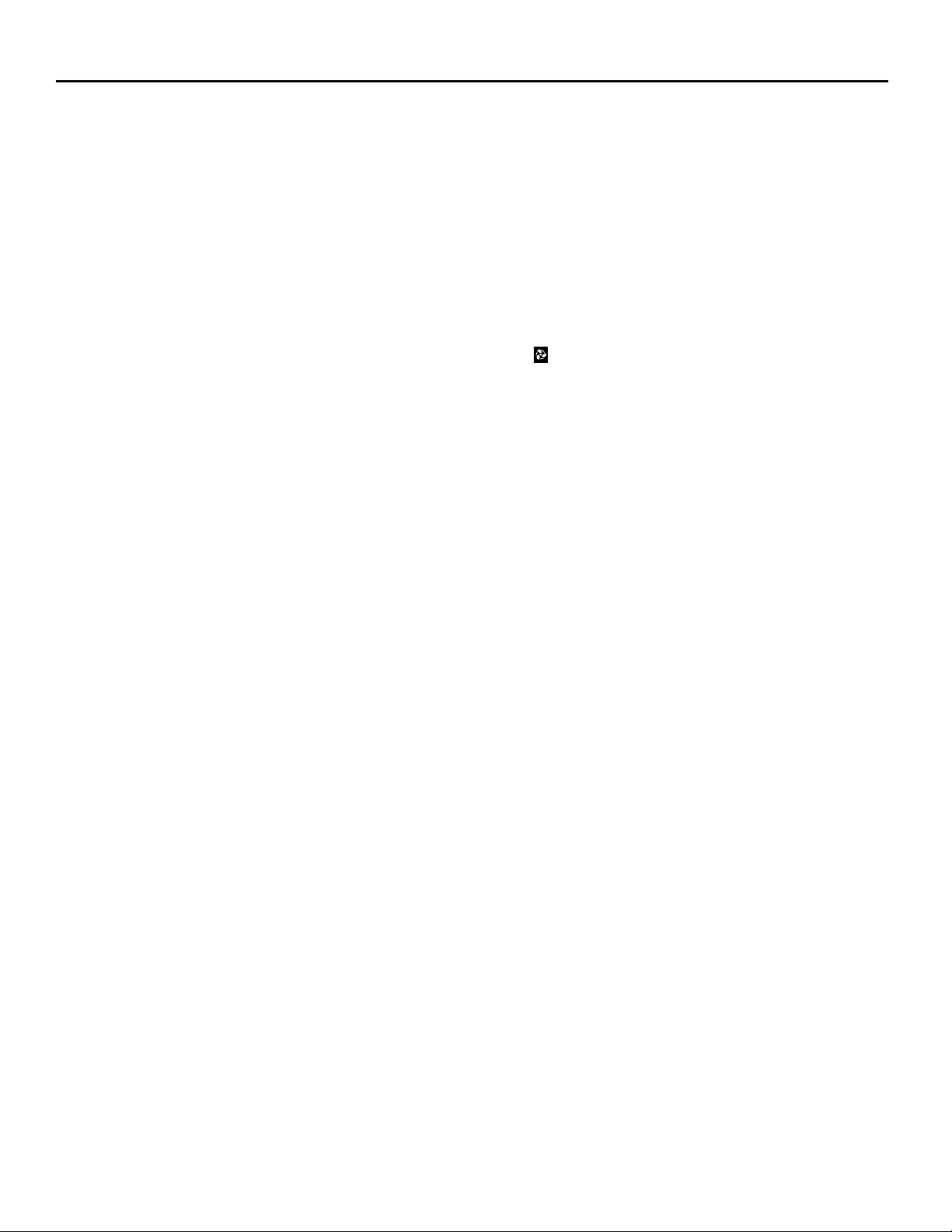

FRR093

FRR092

1”

Figure 32

3/4” MINIMUM

SLEEVE FRONT

THICK LUMBER

FRONT EDGE OF LOUVERS

MUST ALWAYS BE OUTSIDE OF

EXTERIOR WALL SURFACE.

3/4” MINIMUM FRONT

EDGE OF SLEEVE TO

INSIDE WALL SURFACE.

TRIM AROUND THE

SLEEVE WITH A

SUITABLE WOOD

MOULDING AND

FINISH TO SUIT.

CAULK ALL AROUND

SLEEVE ON OUTSIDE

TO INSURE A WEATHER

TIGHT SEAL.

1” MINIMUM

INSIDE WALL

EXTERIOR WALL

MAX. WALL

THICKNESS

ALLOWED 8-1/2”

1/4” SLOPE DOWN.

POSITION AND SECURE

SLEEVE DOWNWARD.

SLOPE OUTSIDE FOR

DRAINAGE.

STEP 7. Cut two pieces of standard 1" lumber (supplied by installer)

to the length and width required. Place in front and back of

bottom sill channel as shown in Figure 32. Secure with nails

(supplied by installer).

STEP 8. Seal all holes in the sleeve with caulking compound (supplied

by installer). (See Figure 33)

Figure 33

SOLID MASONRY CONSTRUCTION

CABINET

1 1/4” SCREWS (F IN PARTS LIST) / 3 EA. SIDE

NAILS MAY BE USED IF DESIRED.

STEP 9. Complete the installation by following STEP 5.3 (Page 18)

and STEP 8 (Page 19) of Standard Window Installation.

R1 Insulation panels and Window seal gasket mentioned in

STEPS 6 - 7 will not be required.

IMPORTANT: Before operating your unit, read CIRCUIT PROTECTION

of Standard Window Instructions, under STEP 8.

CAULK ALL SIDES

MORTAR

NOTE: ELECTRICAL RECEPTACLE LOCATION

FROM POINT “X” MUST BE WITHIN A MAXIMUM

RADIUS OF 69” FOR 115V UNITS.

POINT “X”

ELECTRICAL

RECEPTACLE

23

Page 24

Final Inspection & Start-up Checklist

u Inspect and ensure that all components and accessories have been

installed properly and that they have not been damaged during the

installation progress.

u Check the condensate water drain(s) to ensure that they are adequate

for the removal of condensate water, and that they meet the approval

of the end user.

u Ensure that all installation instructions concerning clearances around

the unit have been adhered to. Check to ensure that the unit air lter,

indoor coil, and outdoor coil are free from any obstructions.

u Ensure that the circuit breaker(s) or fuse(s) and supply circuit wire

size have been sized correctly. If the unit was supplied with a power

supply cord, insure that it is stored properly.

u Ensure that the entire installation is in compliance with all applicable

national and local codes and ordinances having jurisdiction.

u Secure components and accessories, such as a decorative front

cover.

u Start the unit and check for proper operation of all components in

each mode of operation.

u Instruct the owner or operator of the units operation, and the

manufacturer's Routine Maintenance.

This is a warm weather appliance

Your air conditioner is designed to cool in warm weather when the outside

temperature is above 60°F (15.6°C) and below 115°F (46.1°C), so it won't

cool a room if it is already cool outside.

Condensation is normal

Air conditioners actually pump the heat and humidity from your room to the

outside. Humidity becomes water, and your air conditioner will use most

of the water to keep the outside coil cool. If there is excessive humidity,

there may be excess water that will drip outside. This is normal operation.

Frosting

This usually occurs because of insufcient airow across the coils, a dirty

lter, cool damp weather, or all of these. Set the SYSTEM mode to FAN

ONLY

and the frost will disappear. Setting the thermostat a little warmer

will probably prevent the frosting from recurring.

Noises

All air conditioners make some noise. Friedrich units are designed to

operate as quietly as possible. An air conditioner mounted in a wall is quieter

than one mounted in a window. It is important to ensure that the chassis

seal gasket (Item 14) is properly installed (refer to installation instructions).

NOTE: A log for recording the dates of maintenance and/or service is

u Present the owner or operator of the equipment with the Installation

recommended.

& Operation Manual, all accessory installation instructions, and the

name, address and telephone number of the Authorized Friedrich

Warranty Service Company in the area for future reference if

neces sary.

24

Page 25

Routine Maintenance

To ensure proper unit operation, the air lters should be cleaned at least

monthly, and more frequently if conditions warrant. The unit must be turned

off before the lters are cleaned.

To Remove, Wash and Replace Filter

Lower front panel (See Figure 2). Use handle on lter to ex lter up and

out of retainer. Remove lter from unit (See Figure 3). Clean lter monthly

or more frequently if needed. Refer to accessories section for lter options.

Coils & Chassis

NOTE: Do not use a caustic coil cleaning agent on coils or base pan.

Use a biodegradable cleaning agent and degreaser. The use

of harsh cleaning materials may lead to deterioration of the

aluminum ns or the coil end plates.

The indoor coil and outdoor coils and base pan should be inspected

periodically (annually or semi-annually) and cleaned of all debris (lint, dirt,

leaves, paper, etc.) as necessary. Under extreme conditions, more frequent

cleaning may be required. Clean the coils and base pan with a soft brush

and compressed air or vacuum. A pressure washer may also be used,

however, you must be careful not to bend the aluminum n pack. Use a

sweeping up and down motion in the direction of the vertical aluminum n

pack when pressure cleaning coils.

Service and Assistance

Before calling for service, please check the “Troubleshooting Tips” section on the following page. This may help you to nd the answer to your

problem, avoid unnecessary service calls, and save you the cost of a

service call if the problem is not due to the product itself.

You can nd the name of your local Authorized Ser vice Provider by visiting

our web site at www.friedrich.com.

If you require further assistance

You can call the Customer Support Call Center at 1-800-541-6645.

Before calling, please make sure that you have the complete model and

serial number, and date of purchase of your equipment available. By

providing us with this information, we will be better able to assist you.

Our specialists are able to assist you with:

u Specications and Features of our equipment.

u Referrals to dealers, and distributors.

u Use and Care Information.

u Recommended maintenance procedures.

u Installation information.

u Referrals to Authorized Service Providers and Parts depots.

NOTE: It is extremely important to ensure that none of the electrical

and/or electronic parts of the unit get wet. Be sure to cover all

electrical components to protect them from water or spray.

Decorative Front

The decorative front and discharge air grille may be cleaned with a mild

soap or detergent. Do NOT use solvents or hydrocarbon based cleaners

such as acetone, naphtha, gasoline, benzene, etc., to clean the decorative

front or air discharge grilles.

Use a damp (not wet) cloth when cleaning the control area to prevent

water from entering the unit, and possibly damaging the electronic control.

Fan Motor & Compressor

The fan motor & compressor are permanently lubricated, and require no

additional lubrication.

Wall Sleeve

Inspect the inside of the wall sleeve and drain system per iodically (annually

or semi-annually) and clean as required. Under extreme conditions, more

frequent cleaning may be necessary. Clean both of these areas with an

antibacterial and antifungal c leaner. Rinse bot h items thoroughly with water

and ensure that the drain outlets are operating correctly. Check the sealant

around the sleeve and reseal areas as needed.

Available Accessories

Carbon Filter Kits

Each kit contains three (3) lters.

KWCFQ - Carbon lter kit for "Q" chassis models.

Window Installation Kits

(Standard in Kühl Models without Heat)

KWIKQA

FriedrichLink™ Adapter Accessory:

KWIFI - FriedrichLink™ Adapter Accessory for wireless control and

additional programming options

Decorative Color Front Panel Kits: (limited availability)

KWBGEQA - Q Model Decorative Front Cover in Classic Beige

KWBLKQA - Q Model Decorative Front Cover in Black Onyx

KWBLUQA - Q Model Decorative Front Cover in Cobalt Blue

KWPNKQA - Q Model Decorative Front Cover in Pink Diamond

KWREDQA - Q Model Decorative Front Cover in Deep Red

KWWHTQA - Q Model Decorative Front Cover in Designer White

See www.friedrich.com for additional accessories for your unit.

25

Page 26

Troubleshooting Tips

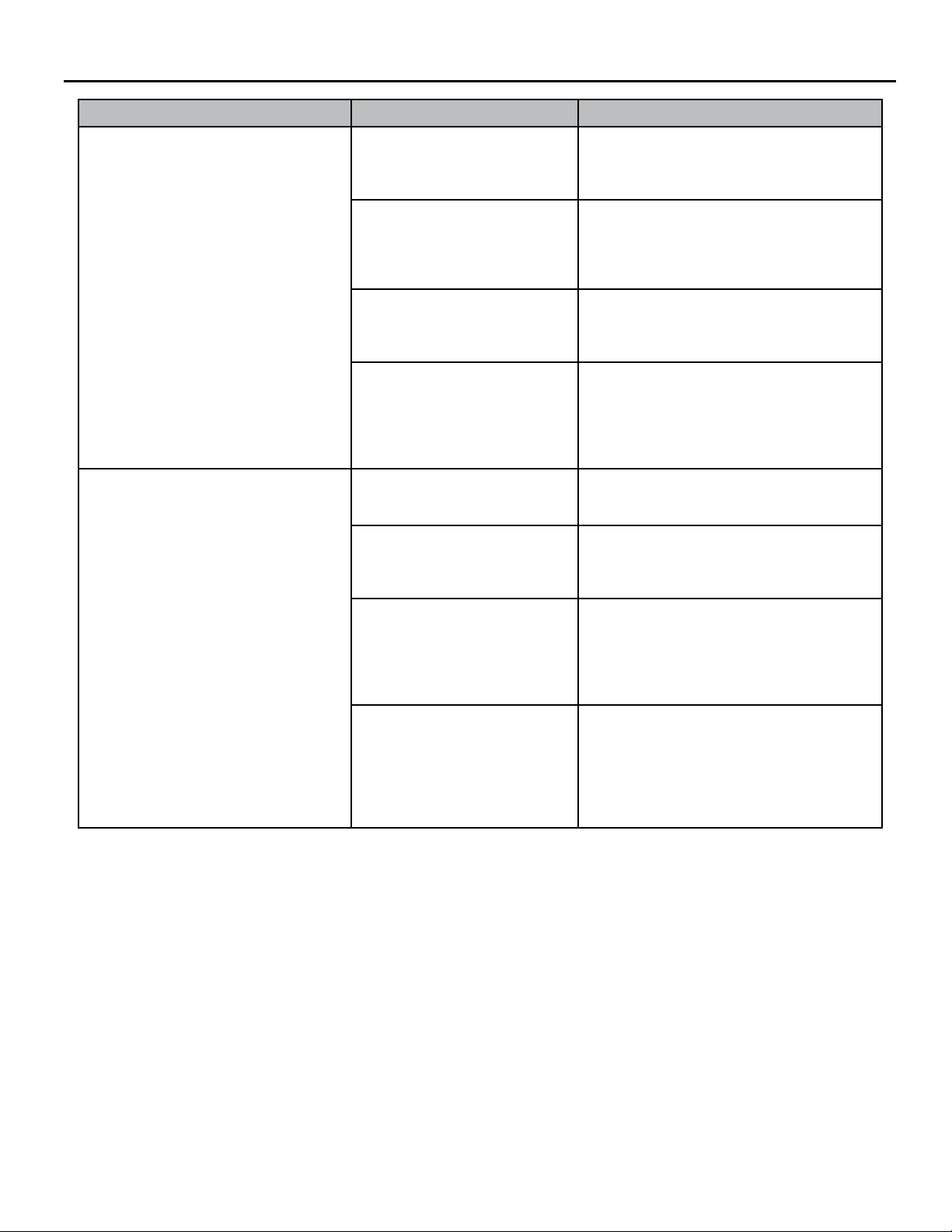

COMPLAINT CAUSE SOLUTION

Unit does not operate.

Unit Trips Circuit Breaker or Blows Fuses.

LCDI Power Cord Trips (Reset Button Pops Out).

Unit Does Not Cool/Heat Room Sufciently, Or

Cycles On And Off Too Frequently.

● The unit is turned to the off position,

or the thermostat is satised.

● The LCDI power cord is unplugged. ● Plug into a properly grounded 3 prong receptacle.

● The LCDI power cord has tripped

(Reset button has popped out).

● The circuit breaker has tripped or

the supply circuit fuse has blown.

● There has been a local power

failure.

● Other appliances are being used on

the same circuit.

● An extension cord is being used. ● Do NOT use an extension cord with this or any

● The circuit breaker or time-delay

fuse is not of the proper rating.

● The LCDI power cord can trip (Reset

button pops out) due to disturbances

on your power supply line.

● Electrical overload, overheating, or

cord pinching can trip (Reset button

pops out) the LCDI power cord.

NOTE: A damaged power supply cord must be replaced with a new power supply cord obtained

from the product manufacturer and must not be repaired.

● The return/discharge air grille is

blocked.

● Windows or doors to the outside are

open.

● The temperature is not set at a cool

enough/warm enough setting.

● The lter is dirty or obstructed. ● Clean the lter, (See Routine Maintenance), or

● The indoor coil or outdoor coil is

dirty or obstructed.

● There is excessive heat or moisture

(cooking, showers, etc.) in the room.

● The temperature of the room you

are trying to cool is extremely hot.

● Turn the unit to the on position and raise or lower

temperature setting (as appropriate) to call for

operation.

See “Electrical Rating Tables” on pg. 6 for the

proper receptacle type for your unit.

● Press and release RESET (listen for click; Reset

button latches and remains in) to resume operation.

● Reset the circuit breaker, or replace the fuse as

applicable. If the problem continues, contact a

licensed electrician.

● The unit will resume normal operation once power

has been restored.

● The unit requires a dedicated outlet circuit, not

shared with other appliances.

other air conditioner.

● Replace with a circuit breaker or time-delay fuse

of the proper rating. See “Electrical Rating Tables”

on pg. 6 for the proper circuit breaker/fuse rating

for your unit. If the problem continues, contact a

licensed electrician.

● Press and release RESET (listen for click; Reset

button latches and remains in) to resume normal

operation.

● Once the problem has been determined and

corrected, press and release RESET (listen for

click; Reset button latches and remains in) to

resume normal operation.

● Ensure that the return and/or discharge air paths

are not blocked by curtains, blinds, furniture, etc.

● Ensure that all windows and doors are closed.

● Adjust the Temperature control to a cooler or

warmer setting as necessary.

remove obstruction.

● Clean the coils, (See Routine Maintenance), or

remove obstruction.

● Be sure to use exhaust vent fans while cooking

or bathing and, if possible, try not to use heat

producing appliances during the hottest part of the

day.

● Allow additional time for the air conditioner to cool

off a very hot room.

26

Page 27

COMPLAINT CAUSE SOLUTION

Unit Does Not Cool/Heat Room Sufciently, Or

Cycles On And Off Too Frequently (continued).

Unit Runs Too Much.

● The outside temperature is below

60°F (16° C).

● The digital control is set to fan

cycling mode.

● The air conditioner has insufcient

cooling capacity to match the heat

gain of the room.

● The air conditioner has insufcient

heating capacity to match the heat

loss of the room.

● This may be due to an excessive

heat load in the room.

● It may also be due to an improperly

sized unit.

● This may be normal for higher

efciency (EER) air conditioners.

● You may notice that the discharge

air temperature of your new air

conditioner may not seem as cold

as you may be accustomed to from

older units. This does not, however,

indicate a reduction in the cooling

capacity of the unit.

● Do not try to operate your air conditioner in the

cooling mode when the outside temperature is

below 60°F (16° C). The unit will not cool properly,

and the unit may be damaged.

● Since the fan does not circulate the room air

continuously at this setting, the room air does not

mix as well and hot (or cold) spots may result.

Using the continuous fan setting is recommended

to obtain optimum comfort levels.

● Check the cooling capacity of your unit to ensure it

is properly sized for the room in which it is installed.

Room air conditioners are not designed to cool

multiple rooms.

● Check the heating capacity of your unit. Air

conditioners are sized to meet the cooling load,

and heater size is then selected to meet the

heating load. In extreme northern climates, room

air conditioners may not be able to be used as a

primary source of heat.

● If there are heat producing appliances in use in the

room, or if the room is heavily occupied, the unit will

need to run longer to remove the additional heat.

● Be sure to use exhaust vent fans while cooking

or bathing and, if possible, try not to use heat

producing appliances during the hottest part of the

day.

● The use of higher efciency components in your

new air conditioner may result in the unit running

longer than you feel it should. This may be more

apparent, if it replaced an older, less efcient,

model. The actual energy usage, however, will be

signicantly less when compared to older models.

● The energy efciency ratio (EER) and cooling

capacity rating (Btu/h) listed on the unit’s rating

plate are both agency certied.

27

Page 28

Addendum 1

e6

dL

t7

dL

t6

dL

t7

dL

t6

dM

t6

e1

dM

t6

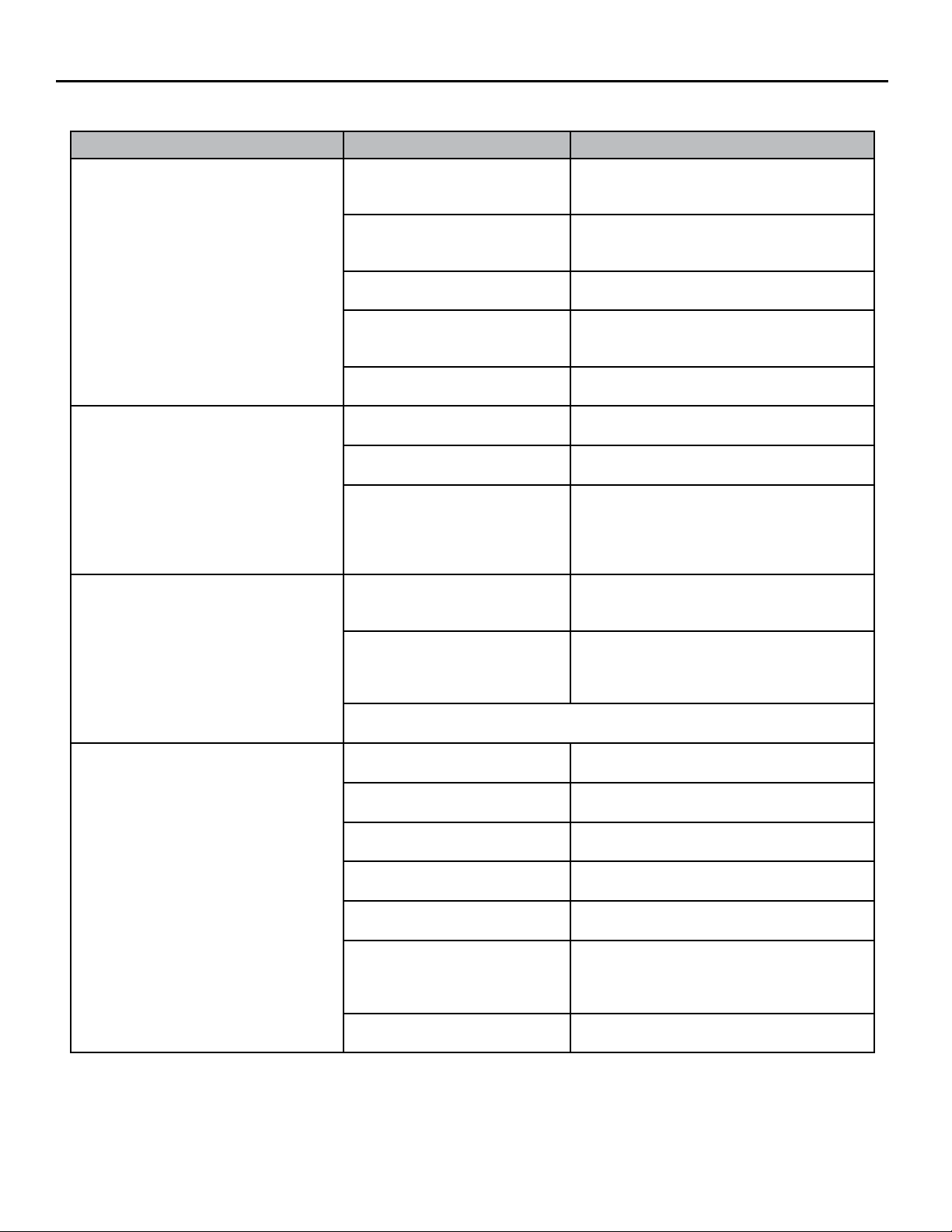

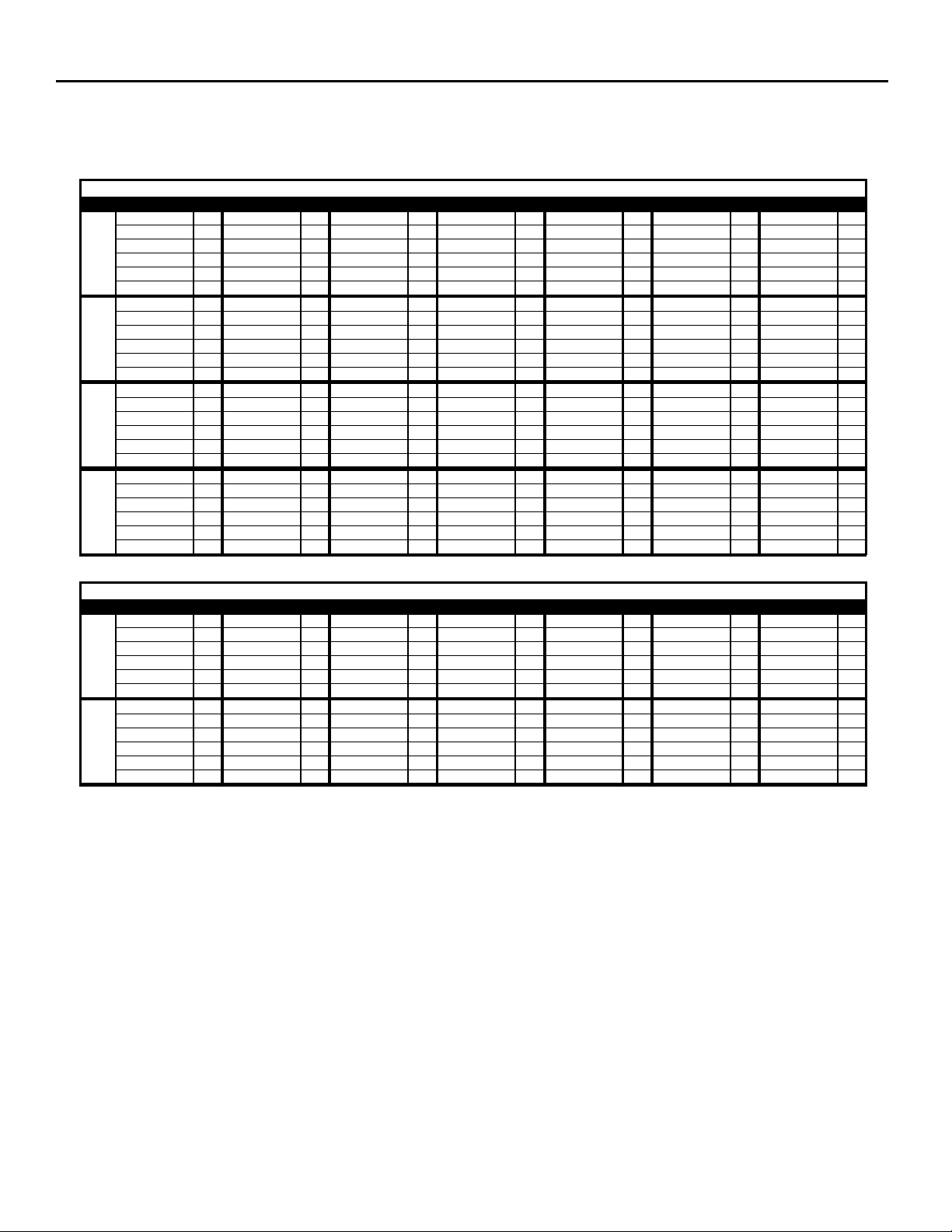

Schedule Table with Energy Saving Values

PeriodSun Mon Tues Wed ThurFri Sat

Start Time 600Start Time 600Start Time 600Start Time 600Start Time600 Start Time600 Start Tim

System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool

Fan Mode AutoFan Mode AutoFan Mode AutoFan ModeAutoFan Mode Auto Fan Mode Auto Fan Mode Auto

1

Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan Spee

Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78

Set Point Heat70 Set Point Heat70 Set Point Heat70 Set Point Heat70 Set Point Heat70 Set Point Heat70 Set Point Hea

Start Time 800Start Time 800Start Time 800Start Time 800 Start Time800 Start Time800 Start Time 800

System Mode Cool System Mode Cool System Mode Cool System ModeCoolSystem Mode Cool System Mode Cool System Mode Cool

Fan Mode AutoFan Mode AutoFan Mode AutoFan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto

2

Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan Spee

Set Point Cool 85 Set Point Cool 85 Set Point Cool 85 Set Point Cool 85 Set Point Cool 85 Set Point Cool 85 Set Point Cool 85

Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Hea

Start Time 1800Start Time 1800Start Time 1800Start Time 1800Start Time 1800Start Time 1800Start Time 1800

System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool

Fan Mode AutoFan Mode AutoFan Mode AutoFan ModeAutoFan Mode Auto Fan Mode Auto Fan Mode Auto

3

Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan Spee

Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78

Set Point Heat70 Set Point Heat70 Set Point Heat70 Set Point Heat70 Set Point Heat70 Set Point Heat70 Set Point Hea

Start Time 2200Start Time 2200Start Time 2200Start Time 2200Start Time 2200Start Time 2200Start Time 2200

System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool

Fan Mode AutoFan Mode AutoFan Mode AutoFan ModeAutoFan Mode Auto Fan Mode Auto Fan Mode Auto

4

Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan SpeedLow Fan Spee

Set Point Cool 82 Set Point Cool 82 Set Point Cool 82 Set Point Cool 82 Set Point Cool 82 Set Point Cool 82 Set Point Cool 82

Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Hea

Commercial Schedule

PeriodSun Mon TuesWed ThurFri Sat

Start Time 700Start Time 700Start Time 700Start Time 700Start Time700 Start Time700 Start Time 700

System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool

Fan Mode AutoFan Mode AutoFan Mode AutoFan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto

Residenal Schedule

1

Fan SpeedMed Fan SpeedMed Fan SpeedMed Fan SpeedMed Fan SpeedMed Fan SpeedMed Fan Spee

Set Point Cool 84 Set Point Cool 75 Set Point Cool 75 Set Point Cool 75 Set Point Cool 75 Set Point Cool 75 Set Point Cool 84

Set Point Heat62 Set Point Heat70 Set Point Heat70 Set Point Heat70 Set Point Heat70 Set Point Heat70 Set Point Hea

Start Time 1800Start Time 1800Start Time 1800Start Time 1800Start Time 1800Start Time 1800Start Tim

System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool

Fan Mode AutoFan Mode AutoFan Mode AutoFan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto

2

Fan SpeedMed Fan SpeedMed Fan SpeedMed Fan SpeedMed Fan SpeedMed Fan SpeedMed Fan Spee

Set Point Cool 84 Set Point Cool 84 Set Point Cool 84 Set Point Cool 84 Set Point Cool 84 Set Point Cool 84 Set Point Cool 84

Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Heat62 Set Point Hea

00

ow

0

ow

2

ow

0

ow

2

ed

2

800

ed

2

28

Page 29

Friedrich Air Conditioning Company

10001 Reunion Place, Suite 500

San Antonio, TX 78216

1-800-541-6645

www.friedrich.com

ROOM AIR CONDITIONERS

LIMITED WARRANTY

FIRST YEAR

ANY PART: If any part supplied by FRIEDRICH fails because of a defect in workmanship or material within twelve months from date of original

purchase, FRIEDRICH will repair the product at no charge, provided room air conditioner is reasonably accessible for service. Any additional labor

cost for removing inaccessible units and/or charges for mileage related to travel by a Service Agency that exceeds 25 miles one way will be the

responsibility of the owner. This remedy is expressly agreed to be the exclusive remedy within twelve months from the date of the original purchase.

SECOND THROUGH FIF TH YEAR

SEALED REFRIGERANT SYSTEM: If the Sealed Refrigeration System (dened for this purpose as the compressor, condenser coil, evaporator coil, revers-

ing valve, check valve, capillary, lter drier, and all interconnecting tubing) supplied by FRIEDRICH in your Room Air Conditioner fails because of a defect

in workmanship or material within sixty months from date of purchase, FRIEDRICH will pay a labor allowance and parts necessary to repair the Sealed

Refrigeration System; PROVIDED FRIEDRICH will not pay the cost of diagnosis of the problem, removal, freight charges, and transportation of the air

conditioner to and from the Service Agency, and the reinstallation charges associated with repair of the Sealed Refrigeration System. All such cost will be

the sole responsibility of the owner. This remedy is expressly agreed to be the exclusive remedy within sixty months from the date of the original purchase.

APPLICABILITY AND LIMITATIONS: This warranty is applicable only to units retained within the Fifty States of the U.S.A., District of Columbia, and Canada.

This warranty is not applicable to:

1. Air lters or fuses.

2. Products on which the model and serial numbers have been removed.

3. Products which have defects or damage which results from improper installation, wiring, electrical current characteristics, or maintenance; or caused by

accident, misuse or abuse, re, ood, alterations and/or misapplication of the product and/or units installed in a corrosive atmosphere, default or delay

in performance caused by war, government restrictions or restraints, strikes, material shortages beyond the control of FRIEDRICH, or acts of God.

OBTAINING WARRANT Y PERFORMANCE: Service will be provided by the FRIEDRICH Authorized Dealer or Service Organization in your area. They are listed

in the Yellow Pages. If assistance is required in obtaining warranty performance, wr ite to: Room Air Conditioner Service Manager, Friedrich Air Conditioning Co.

LIMITATIONS: THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES. Anything in the warranty notwithstanding, ANY IMPLIED WARRANTIES

OF FITNESS FOR PARTICULAR PURPOSE AND/OR MERCHANTABILITY SHALL BE LIMITED TO THE DURATION OF THIS EXPRESS WARRANTY.

MANUFACTURER EXPRESSLY DISCLAIMS AND EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGE FOR BREACH OF

ANY EXPRESSED OR IMPLIED WARRANTY.

NOTE: Some states do not allow limitations on how long an implied warranty lasts, or do not allow the limitation or exclusion of consequential or incidental

damages, so the foregoing exclusions and limitations may not apply to you.

OTHER: This warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

PROOF OF PURCHASE: Owner must provide proof of purchase in order to receive any warranty related services.

All service calls for explaining the operation of this product will be the sole responsibility of the consumer.

All warranty service must be provided by an Authorized FRIEDRICH Service Agency, unless authorized by FRIEDRICH prior to repairs being made.

29

Page 30

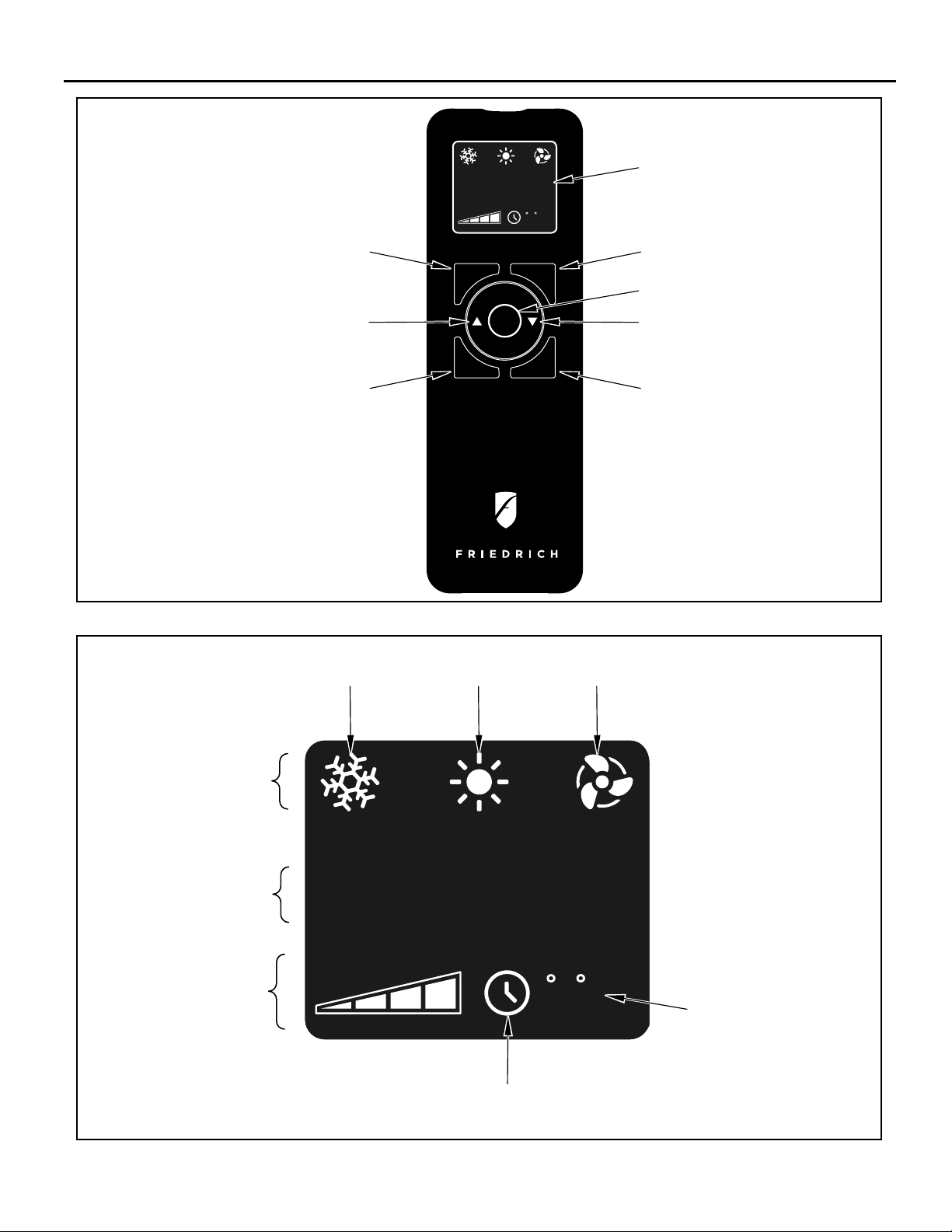

Kühl Q Chassis

®

Performance Testing Installation and Test Method

The following instructions only apply to laboratory test procedures and do not apply to actual product installation

and operation.

ANSI/ASHRAE Standard 16-1983 (RA 2009) Method of Testing for Rating Room Air Conditioners and Packaged

Terminal Air Conditioners shall be adhered to when testing for obtaining cooling capacity and airflow quality for

rating this room air conditioning unit.

Maximum cooling capacity must be achieved in accordance with the following instructions:

For maximum capacity and efficiency, air shall be sampled 4 to 6 inches away from the intake of the unit. See images below:

FRONT VIEW

BACK VIEW

Indoor Sampling Device

Indoor

Sampling

Device

FRONT VIEW

Indoor Sampling

TOP VIEW

Outdoor

Sampling

Device

Device

4.0” – 6.0”

Outdoor Sampling

Device

4.0” – 6.0”

30

Outdoor Sampling

Device

The indoor and outdoor air sampling devices must comply with:

ASHRAE 41.1-1986 (RA 2006) - Method for Temperature Measurement

ASHRAE 41.6-1994 (RA 2006) - Method for Measurement of Moist Air Properties

NOTE: Images of the sampler are for display purposes and not to scale

4.0” – 6.0”

Indoor Sampling Device

Page 31

Kühl Q Chassis

®

Performance Testing Installation and Test Method continued

Test Unit Installation

As per ANSI/ASHRAE Standard 16-1983 (RA 2009), section 4.2.2, this air conditioner shall be installed per the

instructions specified in this Installation & Operation Manual.

Test Unit Settings

Louver position:

• Louvers shall be kept in the recessed position (not extended)

• Louvers shall be centered (not directed left or right) and pointed upward.

Fan speed:

• Fan shall be set to the highest speed setting

• HIGH

System Operation:

• Unit shall be operating in “Cool” Mode

31

Page 32

Friedrich Air Conditioning Co.

10001 Reunion Place, Suite 500 • San Antonio, Texas 78216

1-800-541-6645

www.friedrich.com

Printed in the U.S.A.

93001011_01

Page 33

Unidades de Aire Acondicionado

AUTO

F

C

AUTO FAN

AM

CONTINUOUS

PM

88

ONOFF

SET POINT

SCHEDULE

ROOM TEMP

CHECK $MART

AUTO SPEED

FILTER

SYSTEM

FAN MODE

POWER

FAN SPEED

SCHEDULE

Modelos Q Chassis

Manual de Instalación y Funcionamiento

Kühl

Kühl +

Frío & Calor Eléctrico

93001011_01

115-Voltios: SQ06, SQ08

115-Voltios: EQ08

Page 34

Gracias por su decisión de comprar el Aire Acondicionado de Alta Eficiencia Friedrich. Su nuevo Friedrich ha sido cuidadosamente diseñado y

fabricado para darle muchos años de funcionamiento confiable y eficiente, manteniendo una temperatura y nivel de humedad confortables. Se

han incorporado muchas características adicionales a la unidad para garantizar un funcionamiento silencioso, la mayor circulación de aire frío y

seco, y el funcionamiento más económico.

GRACIAS, a nombre de toda nuestra empresa,

por hacer una compra tan inteligente.

FRIEDRICH

AIR CONDITIONING CO.

MODEL NUMBER

SERIAL NUMBER

VOLTS

COOLING:

BTU/HR

EER

AMPS

HEATING:

BTU/HR

EER

AMPS

MAX AMPS:

23.5 OZS.

DESIGN PRESSURES

U.S. PATENTS

IF CONNECTED TO

A FUSE PROTECTED

CIRCUIT, USE A 12 A

TIME DELAY FUSE

CONDITIONER

Registre su aíre acondicionado

La información del modelo se puede encontrar en la

placa de identificación detrás de la tapa frontal.

Favor de llenar y enviar la tarjeta de registro

proporcionada c

línea en www.friedrich.com. Para su futura

comodidad, registre la información del modelo aquí.

NÚMERO DE MODELO

NÚM

ERO

SAN ANTONIO, TX

EQ08N11-A

AALY00219

60 HZ/ 1PH

115

103 VOLT MIN.

7500

9.8

6.9

4000

11.2

600 PSIG HS

300 PSIG LS

D458, 229 S

5,634,346

LISTED 183H

ROOM AIR

FRIEDRICH

AIR CONDITIONING CO.

SAN ANTONIO, TX

Assembled in Mexico

MODEL NUMBER

EQ08N11-A

SERIAL NUMBER

AALY00219

VOLTS

60 HZ/ 1PH

FECHA DE COMPRA

on este producto, o registrarse en

DE SERIE

32

Page 35

Índice

Índice ......................................................................................................................................................................................................................... 3 3

Medidas de Seguridad ............................................................................................................................................................................................... 3 4

ADVERTENCIA: Antes de Operar su Unidad ............................................................................................................................................................ 35

Limpieza del Filtro Estándar / Instrucciones de Instalación ....................................................................................................................................... 36