Page 1

Room Air Conditioners

Installation and Operation Manual

Standard Chassis Models

115-Volt:

208-230-Volt:

115-Volt:

208-230-Volt:

93001010_00

SS08, SS10, SS12, SS14, SM15

SS12, SS16, SM18, SM21, SM24

SL22, SL24, SL28, SL36

YS10

ES12, ES16, YS12, EM18

YM18, EM24, EL36, YL24

Page 2

your unit to assure quiet operation, the greatest circulation of cool, dry air, and the most economic operation.

THANK YOU, on behalf of our entire company,

for making such a wise purchase.

AIR CONDITIONING CO.

SAN ANTONIO, TEXAS

ASSEMBLED IN MEXICO

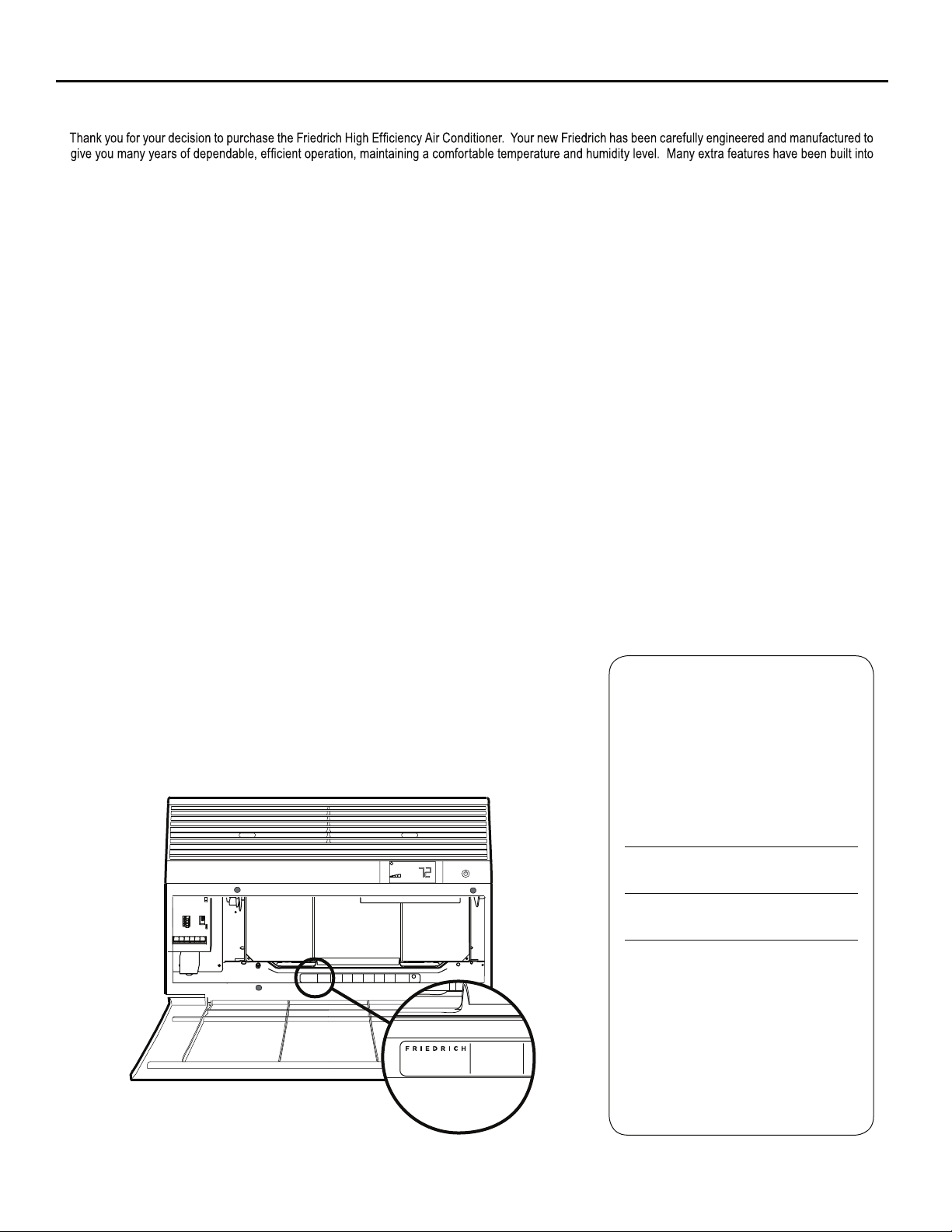

Register your air conditioner

Model information can be found on the name

plate behind the front cover.

Ple a s e c omp l ete an d m ail the o w n e r

registration card furnished with this product,

or register online at www.friedrich.com.

For your future convenience, record the

model information here.

MODEL NUMBER

SERIAL NUMBER

PURCHASE DATE

MODEL NUMBER

HEATING

REFRIGERANT

XXXXXXXXX

XXXXXXXXXX

VOLTS 115

COOLING

YS10M10A

60 HZ / 1 PH

BTH/HR 6500

SERIAL NUMBER

VOLTS MIN 108

EER 12.0

LICY00008

AMPS 8.0

FUSE PROTECTED

U

600 PSIG HS

XXXXXXXXX

CIRCUITS USE 15A

300 PSIG LS

XXXXXXXXXX

TIME DELAY FUSE

XXXXXXXXXX

L

X XX

XXXXX

XXXXXXXXXX

AIR CONDITIONING CO.

SAN ANTONIO, TEXAS

ASSEMBLED IN MEXICO

MODEL NUMBER

YS10N10

SERIAL NUMBER

LICY00008

BTH/HR 6500

30.1 OZ R410A

EER 10.4

AMPS 7.0

2

Page 3

Table of Contents

Safety Precautions ................................................................................................................................................................................................................... 4

Unpacking Instructions............................................................................................................................................................................................................. 5

WARNING: Before Operating Your Unit ..................................................................................................................................................................................6

Standard Filter Cleaning / Installation Instructions .................................................................................................................................................................. 7

Premium Carbon Filter Installation Instructions .......................................................................................................................................................................8

Control Panel Operation ......................................................................................................................................................................................................... 9

New Kühl Control Options ...................................................................................................................................................................................................... 10

Control Panel Operation Instructions ............................................................................................................................................................................................... 11

Remote Control Operation ..................................................................................................................................................................................................... 20

Remote Effectiveness ............................................................................................................................................................................................................ 20

.......................................................................................................................................................................................... 22

Installation Instructions .......................................................................................................................................................................................................... 23

Standard Window Installation ................................................................................................................................................................................................ 25

Cord Routing Change ............................................................................................................................................................................................................34

Through-the-Wall Installation ................................................................................................................................................................................................. 36

Final Inspection & Start-up Checklist..................................................................................................................................................................................... 40

Routine Maintenance .............................................................................................................................................................................................................41

Service and Assistance .........................................................................................................................................................................................................41

Available Accessories ............................................................................................................................................................................................................41

Troubleshooting Tips .............................................................................................................................................................................................................. 42

Addendum 1 ........................................................................................................................................................................................................................... 44

Warranty ..... ........................................................................................................................................................................................................................... 45

3

Page 4

Safety Precautions

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what will happen if the instructions are not followed.

Your safety and the safety of others are very important.

This is a safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING”

or “CAUTION”. These words mean:

WARNING

CAUTION

Indicates a hazard which, if not avoided, can result in severe personal injury or

death and damage to product or other property.

Indicates a hazard which, if not avoided, can result in personal injury and

damage to product or other property.

NOTICE

Indicates property damage can occur if instructions are not followed.

WARNING

Refrigeration system

under high pressure

Do not puncture, heat, expose to flame or

incinerate.

Only certified refrigeration technicians should

service this equipment.

R410A systems operate at higher pressures

than R22 equipment. Appropriate safe

service and handling practices must be used.

Only use gauge sets designed for use with

R410A. Do not use standard R22 gauge sets.

4

Page 5

Unpacking Instructions

STEP 5. Slide the foam front support forward

STEP 1. Cut all 4 packing straps.

STEP 2. Remove wooden shipping bar dividers.

STEP 3. Remove top foam pads.

STEP 4. Slowly remove outer box, careful not to loosen decorative front.

STEP 6. Carefully lift decorative front box from foam front support

STEP 7. Remove decorative front and set safely aside

5

Page 6

WARNING

NOTICE

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong oulet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

Make sure the wiring is adequate for your unit.

If you have fuses, they should be of the time delay type. Before you install

or relocate this unit, be sure that the amperage rating of the circuit breaker

or time delay fuse does not exceed the amp rating listed in Table 1.

DO NOT use an extension cord.

The cord provided will carry the proper amount of electrical power to the

unit; an extension cord may not.

Make sure that the receptacle is compatible with

the air conditioner cord plug provided.

Proper grounding must be maintained at all times. Two prong receptacles

The grounded receptacle should meet all national and local codes and

ordinances. You must use the three prong plug furnished with the air

conditioner. Under no circumstances should you remove the ground

prong from the plug.

Test the power cord

All Friedrich room air conditioners are shipped from the factory with a

Leakage Current Detection Interrupter (LCDI) equipped power cord. The

LCDI device on the end of the cord meets the UL and NEC requirements

f

or cord connected air conditioners.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET (See Figure 1).

3. Press TEST, listen for click; the RESET button trips and pops out.

4. Press and release RESET (Listen for click; RESET button latches

and remains in). The power cord is ready for use.

Do not use the LCDI device as an ON/OFF switch.

Failure to adhere to this precaution may cause

premature equipment malfunction.

Once plugged in, the unit will operate normally without the need to reset

the LCDI device. If the LCDI device fails to trip when tested or if the power

supply cord is damaged, it must be replaced with a new power supply cord

from the manufacturer. Contact our Technical Assistance Line at (800)

541-6645. To expedite service, please have your model number available.

Table 1.

CIRCUIT RATING

OR TIME DELAY

MODEL

FUSE

AMP VOLT

SS08, SS10

SS12, SS14

15 125 5-15R

YS10, SM15

SS12, SS16

SM18, SM21 15 250 6-15R

SL22

SM24

, SL28

ES12, ES16

20 250 6-20R

YS12, SL24

SL36, EM18

EM24,

EL36

30 250 6-30R

YM18, YL24

Figure 1

RESET

TEST

WARNING:

TEST BEFORE EACH USE!

1.PRESS REST BUTTON.

2.PLUG LCDI INTO POWER

RECEPTACLE.

3.PRESS TEST BUTTON,

RESET BUTTON SHOULD

POP UP.

4.PRESS RESET BUTTON

FOR USE.

DO NOT USE IF ABOVE TEST

FAILS.

WHEN GREEN LIGHT IS ON.

IT IS WORKING

PROPERLY!

REQUIRED

WALL

RECEPTACLE

NEMA

NO.

FRR072

6

Page 7

Standard Filter Cleaning / Installation Instructions

STEP 1.

Figure 2

FRR071

STEP 2.

NOTE:

Figure 4

FILTER

FILTER

GRIP

Figure 3

FILTER

GRIP

HANDLE

FRR052

FRR047

STEP 3. Swing the front frame open. Clean the front frame by washing

Figure 5

A

TOP TAB

FRONT

FRAME WITH

STANDARD

MESH FILTER

FRR048

STEP 4.

NOTE:

the tab in the frame stops the handle from sliding in, slide the

handle from the other direction. Do not force the handle into

the frame.

STEP 5.

the inside of the front door.

7

Page 8

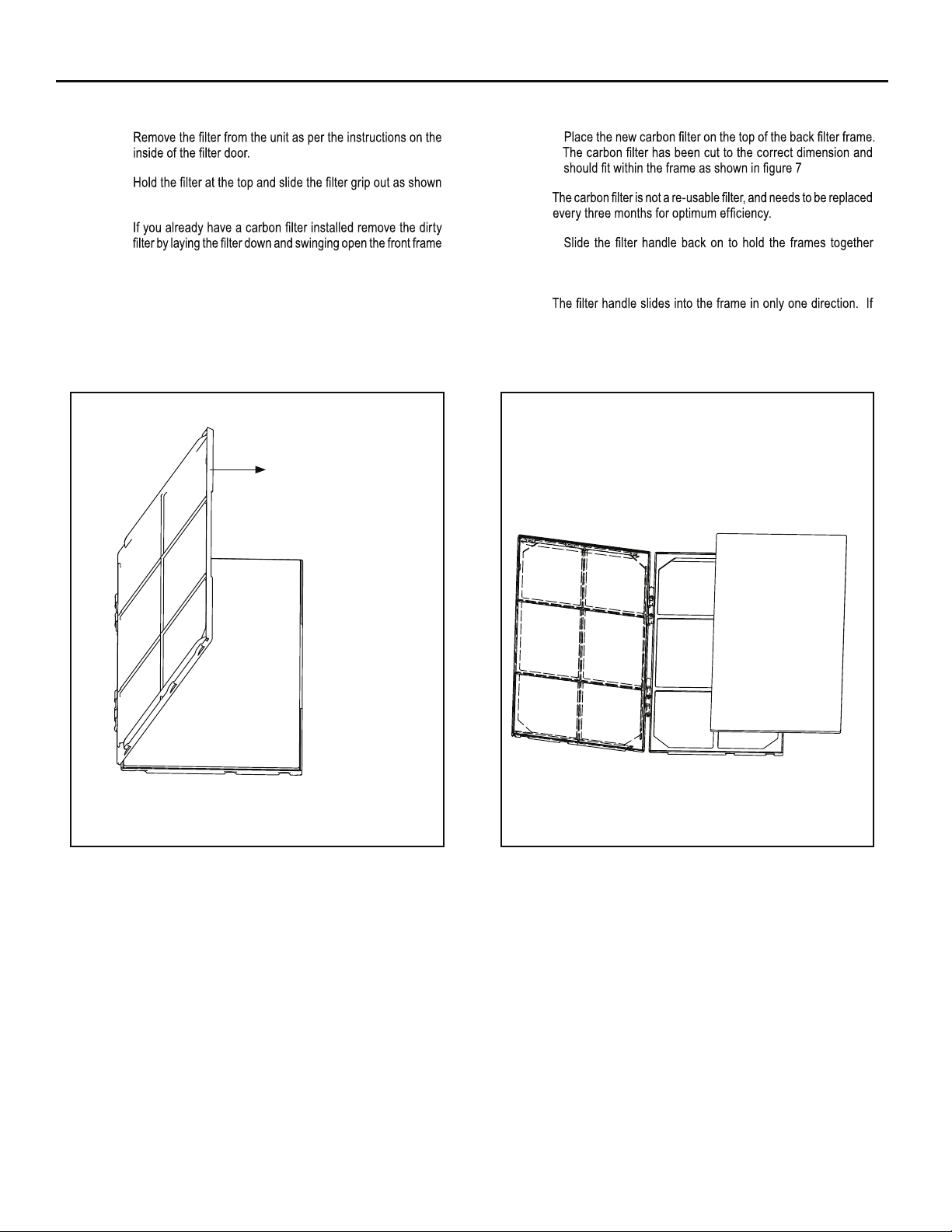

Premium Carbon Filter Installation Instructions

STEP 1.

STEP 4.

STEP 2.

in Figure 4.

STEP 3.

as shown in Figure 6.

NOTE: Make sure the frame with the mesh is facing towards you.

Figure 6

FRONT FRAME WITH

MESH FILTER

NOTE:

STEP 5.

and slide the assembly into the unit as per the instructions

on the door.

NOTE:

the tab in the frame stops the handle from sliding in, slide the

handle from the other direction. Do not force the handle into

the frame.

Figure 7

FRR051FRR050

8

Page 9

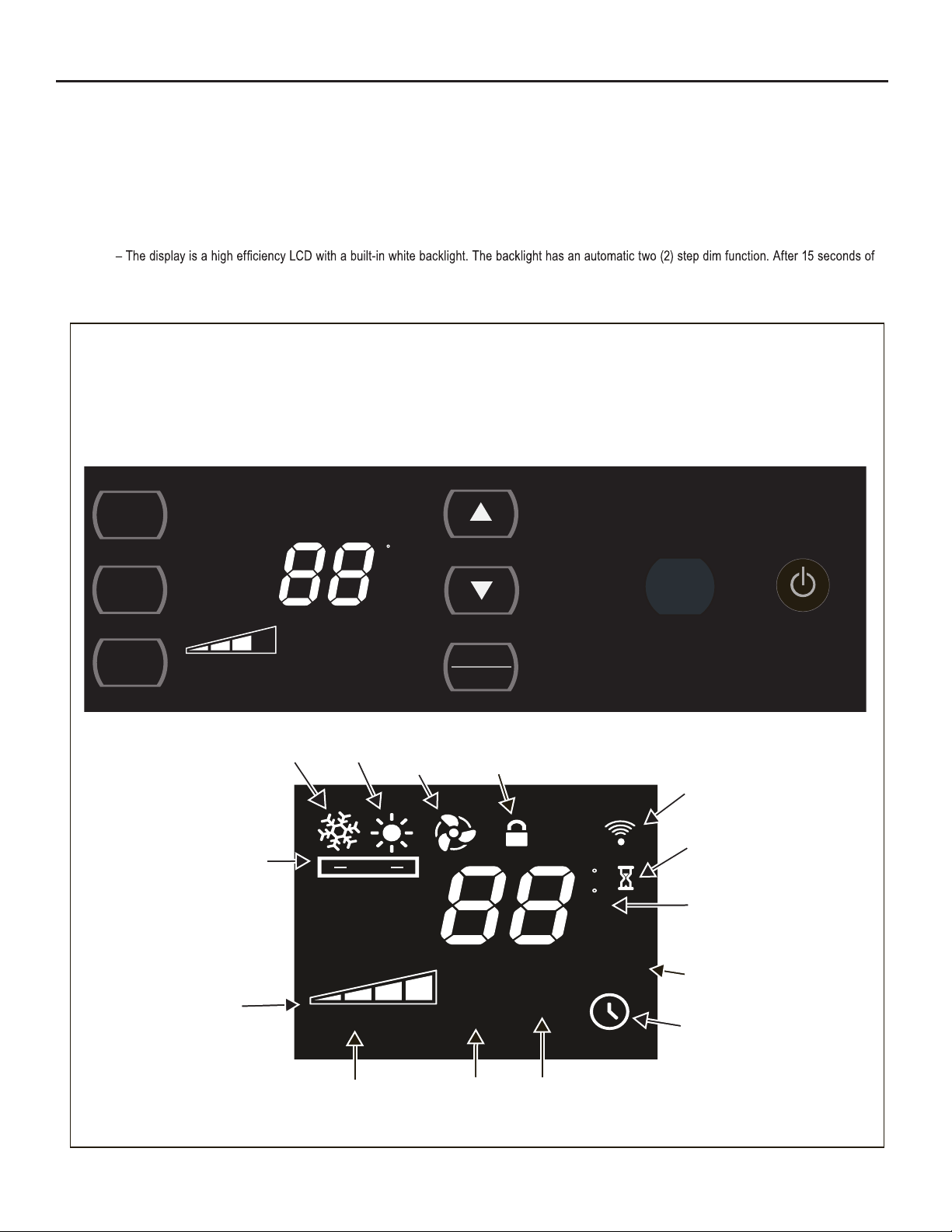

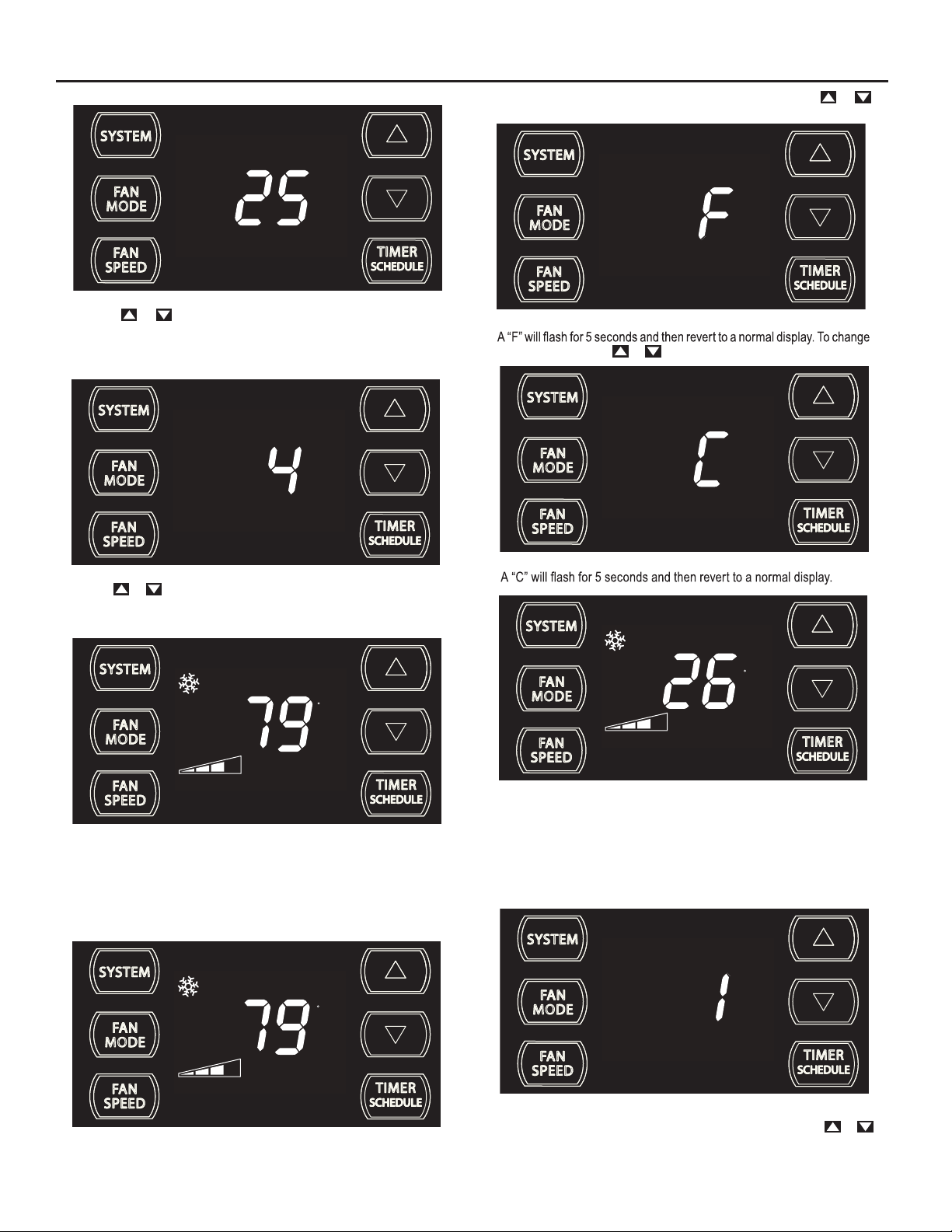

Control Panel Operation

Let’s check out how to control your air conditioner. On the control panel, just above the POWER , is a liquid crystal display (LCD). All of the control panel function

buttons and mode icons can be viewed in Figure 8.

Power On – Press the button to turn on the air conditioner. The power button illuminates to indicate that the power is on. The backlight on the po

we

r switch

will automatically dim to 20% intensity after 15 seconds of inactivity. The remote control can also be used to turn power ON / OFF (See Remote Control).

Display

inactivity, the display dims to 20% intensity. After an additional 120 seconds, the display switches off. Touching any button automatically changes the display

to full brightness.

There are three control push buttons on each side of the display.

Figure 8

SYSTEM

Cycles between

AUTO, HEAT,

COOL, or FAN

ONLY

(if equipped)

FAN MODE

Sets fan to either:

- Cycle automatically

-

Run continuously

FAN SPEED

Sets fan speed:

LOW, MED,

HIGH or AUTO

(if equipped)

TEMPERATURE

Increment UP

TEMPERATURE:

Increment DOWN

TIMER / SCHEDULE

Turns ON or OFF

IR WINDOW

Do not block

:

ON / OFF

Turns unit on/off

SYST EM

F

FAN

MODE

SET POINT

FAN

SPEED

AUTO SPEED

TIMER

SCHEDULE

COOL FAN

AUTO

Automatically switches

between cool & heat

FAN SPEED

Selected fan speed

HEAT

AUTO

AUTO FAN

CONTINUOUS

AUTO SPEED

AUTO SPEED

Automatically

selects best fan

cooling speed

ONLY

CONTROL

LOCKED

SET POINT

ROOM TEMP

CHECK

FILTER

FILTER

Check / Clean

F

C

AM

PM

ON OFF

SCHEDULE

$MART

$MART OPERATING

(if equipped)

WI-FI

OPERATING

(if equipped)

WAIT

2 DIGIT DISPLAY

Shows Setting for:

- Set Point (Temperature)

- Room Temperature

- Clock (AM/PM)

SCHEDULE ON

TIMER ON

9

Page 10

New Kühl Control Options

The new Kühl gives you a variety of options for control, programming, and

scheduling including wireless capabilities

Wireless Programming and Control:

. The new FriedrichLink™ Adapter (sold seperately) allows you to conviently

control, program and monitor your air conditioning unit remotely from a

smartphone or computer.

FriedrichLink™ Adapter accessory available through Friedrich authorized

retailers or www.friedrich.com. See FriedrichLink™ Adapter section on

www.friedrich.com for complete details.

Pre-Programmed Scheduling Options:

Your unit’s digital control comes equipped with a 24-hour timer and two preprogrammed 7-day energy management options.

24-Hour Timer

The 24-hour timer allows you to turn the unit off and on at pre-set times by

setting an on and off time on the unit control panel. (See page 12 for details on

timer set-up.)

Pre-programmed Energy Management

Your unit comes from the factory with two (2) Pre-program

Management settings are shown in Addendum 1 (Residential & Commercial

Schedule Table).

Energy Management Schedule Options are:

1. Residential Schedule – 40 Hr. Work Week

2. Commercial Schedule – 5-Day Business Week

med

Energy

The “Residential” (40 Hr. Work Week) Schedule has four (4) time periods: 06:00,

08:00, 18:00, and 22:00. This option will cause your Kühl Q unit to raise the room

temperature temporarily to 85°F during the hours wh

en most people are away

at work, lower them again to 78°F prior to the time when most people will return

home, and then raise slightly to 82°F to maintain a comfortable temperature

overnight.

The “Commercial” (5-Day Business Week) Schedule has two (2) time periods:

07:00 and 18:00. This option will cause your air conditioner to raise temperatures

to 84°F after typical working hours and on weekends when commercial spaces

r

a

e typically unoccupied.

(See Control Panel Operation Instructions Section)

Customizable Programming Options:

Customizable schedules, with up to four temperature adjustments per day, can

either be uploaded to the unit via the air conditioner’s built-in micro USB interface

or conveniently transmitted wirelessly using the new FriedrichLink™ Adapter

accessory, greatly simplifying the programming of one or multiple units.

See Figure 9.

See www.friedrich.com for complete details on

FriedrichLink.

Figure 9

10

FriedrichLink™ Adapter

AIR CONDITIONING CO.

SAN ANTONIO, TEXAS

ASSEMBLED IN MEXICO

MODEL NUMBER

HEATING

REFRIGERANT

XXXXXXXXX

XXXXXXXXXX

VOLTS 115

COOLING

YS10M10A

60 HZ / 1 PH

BTH/HR 6500

SERIAL NUMBER

VOLTS MIN 108

EER 12.0

LICY00008

AMPS 8.0

FUSE PROTECTED

U

L

BTH/HR 6500

EER 10.4

AMPS 7.0

X XX

30.1 OZ R410A

600 PSIG HS

XXXXXXXXX

CIRCUITS USE 15A

XXXXX

300 PSIG LS

XXXXXXXXXX

TIME DELAY FUSE

XXXXXXXXXX

XXXXXXXXXX

Page 11

Control Panel Operation Instructions

SYSTEM - The

modes of operation:

SYSTEM

button allows you to sequentially select up to four

AUTO

- AUTO -

Not available on some models

COOL

HEAT

Not available on some models

FAN ONLY

AUTO MODE

- AUTO -

AUTO FAN

SET POINT

F

COOL MODE

FRR204

FAN ONLY MODE

FRR105

When in the

- AUTO-, COOL or HEAT or FAN ONLY mode,

you can also select FAN MODE, FAN SPEED, TIMER SCHEDULE,

. The SYSTEM MODE does not change.

and

FAN MODE – The

CONTINUOUS

modes.

FAN

MODE

button allows you to select between

AUTO FAN

AUTO FAN (No Cooling Demand)

AUTO FAN

F

and

AUTO FAN

SET POINT

HEAT MODE

AUTO FAN

SET POINT

FAN SPEED - Depending on your model, the

F

When in the

AUTO FAN

mode, the fan only operates when the system has

SET POINT

a demand to cool or heat the room. Note: the fan is off (no fan speed icon),

FRR103

indicating no command for cooling or heating.

AUTO FAN (Cooling Demand)

F

FRR104

N

FAN

SPEED

button allows you to toggle between four or five modes of operation: LOW, MEDIUM, HIGH and AUTO.

System has a demand for cooling. The fan is operating at a medium speed.

AUTO FAN

SET POINT

F

AUTO

FRR112

FRR106

4 Speed

AUTO

3 Speed

When fan speed AUTO FAN mode (SYSTEM mode AUTO, COOL or HEAT) is selected, fan speed automatically varies depending on the difference between

the unit’s set point on the control panel and the actual room temperature. When the system detects a wide difference between the set point and the actual

room temperature the fan speed increases to HIGH for a period of time. The fan speed decreases, in step, as the temperature difference decreases. When the

room temperature matches the system's set point, fan speed returns to the origin

al setting.

11

Page 12

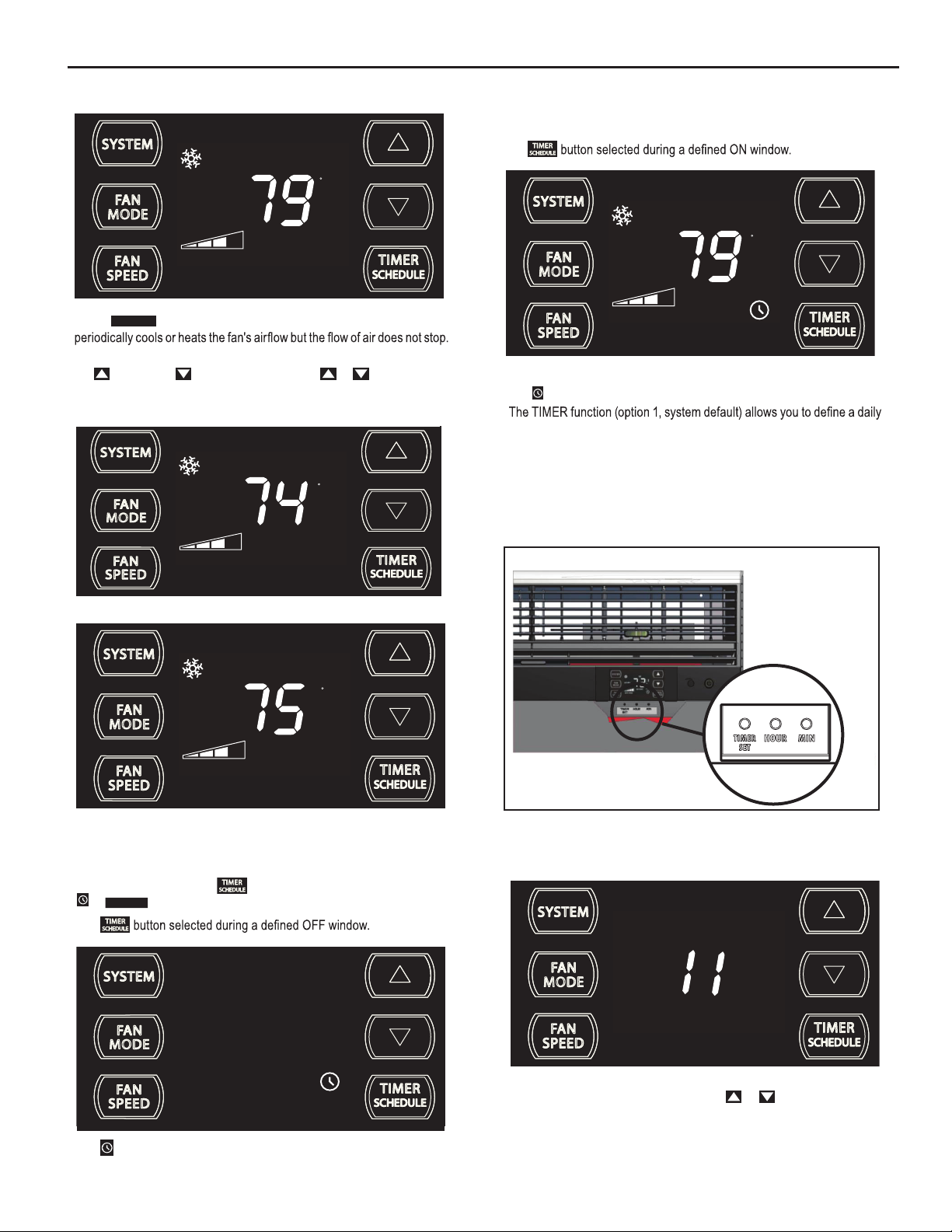

CONTINUOUS

CONTINUOUS

The

F

SET POINT

FRR113

In the

CONTINUOUS

fan mode, the fan operates all the time. The system

UP and DOWN - arrows - Pressing either or button changes

the system's set point (desired room temperature). These buttons are also

used to make system parameter changes later in this manual.

AUTO FAN

SET POINT

F

FRR100

AUTO FAN

F

SET POINT

FRR123

The icon illuminates.

system ON and OFF time window. For example, you can command the

system to turn ON at 8:15 am and turn OFF at 1:30 pm everyday.

The SCHEDULE function allows you to choose either Residential (option

2) or Commercial (option 3). The Residential and Commercial options are

described later in this manual.

OTHER FUNCTIONS

Figure 10

AUTO FAN

SET POINT

F

FRR101

One press equals 1 degree of change. Holding the button down for more

than 0.6 seconds starts the fast increment/decrement change of the set

point.

TIMER SCHEDULE - The

SCHEDULE

or

function.

button allows you to select the TIMER

The

The icon illuminates.

FRR122

12

SET TIME- To adjust the unit's time press and hold the HOUR and the MIN

buttons for three seconds (Refer to Figure 10).

AM

FRR128

The unit's current hour displays. Use the or buttons to adjust the

hour. To change from AM to PM continue to increment (roll) the display.

Press TIMER SET (Refer to Figure 10) button to display the unit's current

minutes.

Page 13

FRR129

Use the or buttons to adjust the minutes. The clock is now set

for 11:25 AM. Press TIMER SET (Refer to Figure 10) button to display the

unit's day setting.

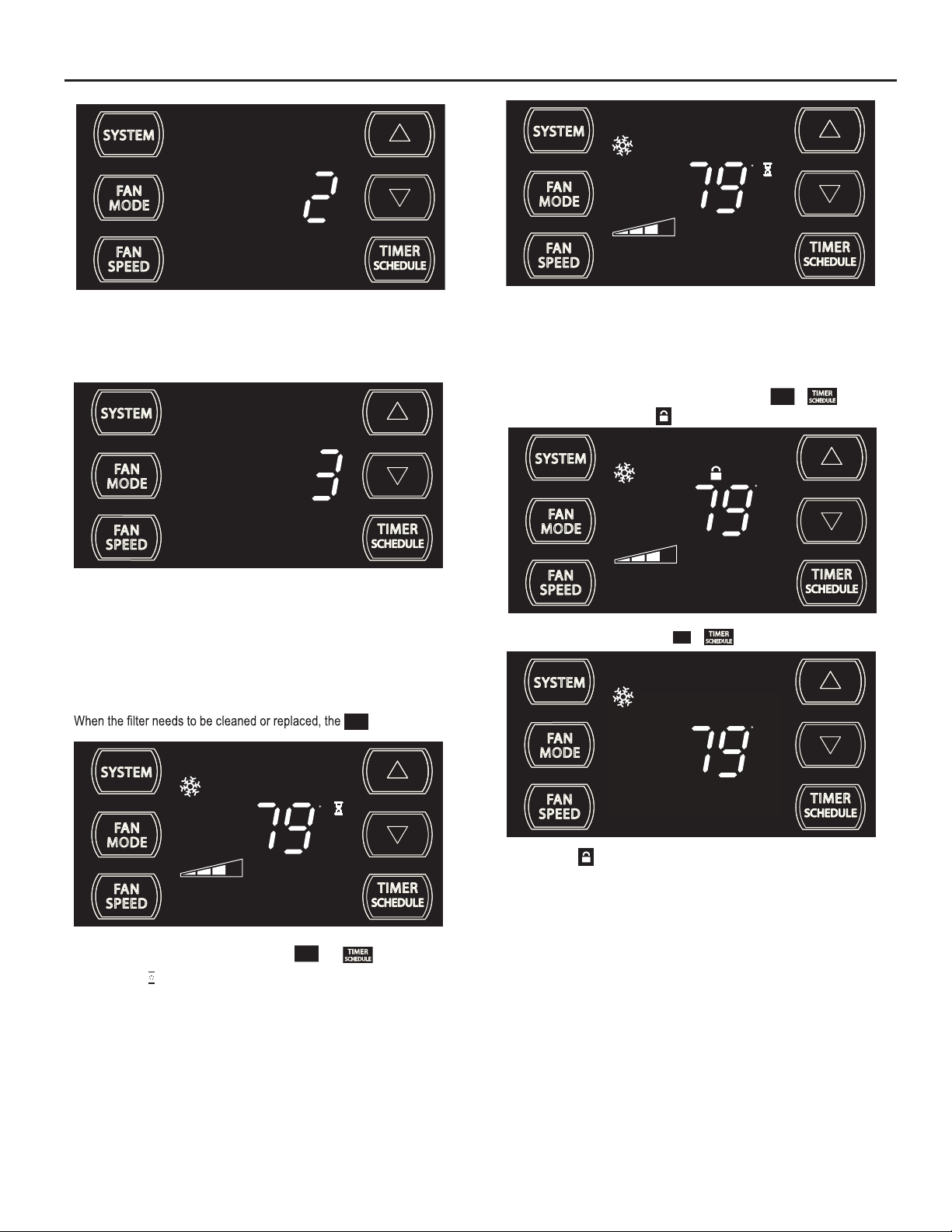

To switch from degrees Fahrenheit (F) to Celsius (C), press &

buttons for three seconds.

FRR133

from F to C, press the or button within 5 seconds.

FRR130

Use the or buttons to adjust the day (1 to 7). The day setting is up

to

you the user. If you set the current day = 1, and today is Tuesday,

then Day 1 = Tuesday.

AUTO FAN

SET POINT

F

FRR131

Press TIMER SET (Refer to Figure 10) button to exit and save the SET

TIME function. The TIMER SET button must be pressed within 15 second.

Button inactivity for more than 15 seconds causes the display to time out

and return to the normal operating display.

ºF - ºC Select

AUTO FAN

F

FRR134

AUTO FAN

SET POINT

C

FRR135

The ºF icon goes away and the ºC icon illuminates on the normal display.

DIM Function

There are three separate display brightness levels, AUTO, 20% and full

(100%). To change the DIM setting, press the Power button for three

seconds.

SET POINT

FRR132

FRR192

The 1 indicates a DIM setting of Auto (factory default). Use the or

buttons to change the setting.

13

Page 14

AUTO FAN

F

SET POINT

FRR193

The 2 indicates a DIM setting of 20%. Press the TIMER SET button within

15 seconds to save the setting. Button inactivity for more than 15 seconds

causes the display to time out and return to the normal operating display.

FRR194

The 3 indicates a DIM setting of 100% (full brightness). Press the TIMER

SET (Refer to Figure 10) button within 15 seconds to save the setting.

Button inactivity for more than 15 seconds causes the display to time out

and return to the normal operating display.

Alerts

CHECK

icon displays.

FILT ER

This means there is a compressor demand but the system is not ready

FRR120

for the compressor to operate. For example a short power outage, the

compressor will not restart until the internal pressures of the compressor

are at the proper level.

Lock Control Panel

To lock the front panel controls, press and hold the

for 3 seconds. The lock icon

AUTO FAN

To unlock, presses and hold the

AUTO FAN

illuminates to indicate the locked status.

SET POINT

FAN

SPEED

+ buttons for 3 seconds.

FAN

SPEED

F

F

+ buttons

16

FRR1

AUTO FAN

SET POINT

FILTER

The alert can be dismissed by pressing the

F

FAN

MODE

and for 3 seconds.

FRR118

The wait icon illuminates when the compressor 3 minute time delay is

active.

14

SET POINT

The lock icon disappears to indicate unlocked status.

FRR117

Page 15

External Control Status

$MART

The

remotely from a source such as a smart grid.

icon illuminates to indicate that the system is being controlled

When selected the unit

3. Commercial Schedule (Selection #2) -

follows a preprogrammed set of operational parameters that covers 7

days of the week with 2 time windows during each day. Each time window

has it's own set of 6 operating parameters. Refer to Addendum 1.

AUTO FAN

79

SET POINT

AUTO FAN

79

SET POINT

The icon illuminates to indicate that the system is receiving a Wi-Fi

connection.

ADVANCED FUNCTIONS

Let me put in plain words many of your unit's advanced functions (Timer,

Schedule, Error Mode, Test Mode, and Maintenance Menu). The functions

mentioned in the following section may or may not be available depending

on the air conditioner model.

Timer/Schedule Select

F

$MART

FRR125

F

FRR126

1

To change the selection, press and hold the TIMER/SCHEDULE

button for 3 sec.

If the Schedule function is available, the system displays the

SCHEDULE

icon. The display indicates the schedule function that is active.

To change to an alternate schedule (2 or 3), press the

If the Schedule function is not available, the Timer icon

SCHEDULE

the

To save and exit this selection, press the TIMER SET button for 3

seconds (Figure 10).

If there is no button activity for 15 seconds, the function will time out and

leave the original selection. Once the selection is saved or timed out, the

display reverts to the normal display.

icon.

2

SCHEDULE

FRR137

or button.

shows without

SCHEDULE

+ noci

AUTO FAN

79

SET POINT

The control system has three Timer/Schedule functions:

1.

Timer (factory default) - Allows you to command the unit to turn

ON and OFF at time you program within a 7 day window. Setting

the start, stop and day window can be found later in this manual.

2.

Residential Schedule (Selection #1) - When selected the unit

follows a preprogrammed set of operational parameters that

covers 7 days of the week with 4 time windows during each day.

Each time window has it's own set of 6 operating parameters.

Refer to Addendum 1.

F

FRR136

FRR138

After pressing the or button, within 15 second of pressing the

button for 3 seconds, the display indicates a change to Timer/Scheduler

2. To save and exit this selection, press the TIMER SET button (Figure 10).

AUTO FAN

79

SET POINT

The display reverts to the normal display.

F

FRR136

15

Page 16

AUTO FAN

FRR146

79

SET POINT

F

FRR139

To turn on the timer or schedule selected, press and release the

button and the selected system will operate in the mode (1, 2 or 3).

Modify the TIMER Function

Timer Start Time

AUTO FAN

79

SET POINT

The display shows a normal system. Press and hold the HOUR button

(Figure 10) for 3 seconds. Note the Timer start-stop times may be set even

when the system is in the Timer or Schedule mode.

4

F

FRR140

AM

ON

FRR143

The display returns to normal once the settings are saved.

Timer Stop Time

AUTO FAN

79

SET POINT

The display shows a normal system. Press and hold the MIN button (Figure

10) for 3 seconds. Note the Timer start - stop times may be set even when

the system is in the Schedule mode.

11

F

FRR144

AM

OFF

FRR141

Use the or button to adjust the hour. Press the TIMER SET button

(Figure 10 10) to adjust the minutes.

21

Use the or button to adjust the minutes. Press the TIMER SET

button (Figure 10) within 15 seconds to exit and save the setting. The timer

is now set to start at 4:21 AM.

16

ON

FRR142

FRR145

Use the or button to adjust the hour. Press the TIMER SET button

(Figure 10) to adjust the minutes.

55

Use the or button to adjust the minutes. Press the TIMER SET

button (Figure 10) within 15 seconds to exit and save the setting. The timer

is now set to stop at 11:55 AM.

OFF

Page 17

FRR148

SET POINT

F

AUTO FAN

79

SCHEDULE

FRR149

Schedule ON Scenarios

AUTO FAN

79

SET POINT

The display returns to normal once the settings are saved.

Timer - Scheduler Control Block

AUTO FAN

79

SET POINT

If the unit is operating in the TIMER or SCHEDULE mode, and then you

press any button except the button, the Timer icon begins

to blink. All button action is blocked. The Timer icon stops blinking after 3

seconds.

F

FRR147

F

SCHEDULE

AUTO FAN

79

SET POINT

The display shows a normal system.

If the Schedule function is turned ON during normal operation, the

and Timer

current period schedule parameters.

F

SCHEDULE

FRR154

SCHEDULE

FRR153

eht snur yletaidemmi metsys lortnoc ehT .setanimulli snoci

AUTO FAN

79

SET POINT

You must turn the active Timer or Schedule mode OFF before making

changes. Once the changes are made, press the button to

re-activate Timer or Schedule mode.

Timer or schedule mode is re-activated.

F

FRR150

17

Page 18

Timer ON Scenarios

Scenario 1

AUTO FAN

79

SET POINT

The display shows a normal operating system.

If the Timer function is turned ON during the Off time, the icon

illuminates. The control system immediately turns the unit OFF.

Scenario 2

F

FRR156

FRR157

AUTO FAN

79

SET POINT

If the Timer function is turned ON during the ON time, the Timer

illuminates. The control system continues to run.

Scheduler OFF Scenarios

Scenario 1

AUTO FAN

79

SET POINT

The display shows the unit in Schedule mode.

F

F

SCHEDULE

FRR159

noci

FRR160

AUTO FAN

79

SET POINT

The display shows a normal operating system.

18

F

FRR158

If the Schedule function is turned OFF during a schedule’s active state

(not off), the Timer and icons turn off. The control stays in the

current state.

The display shows a normal operating system.

Scenario 2

The display shows the unit in Schedule mode during an in-active (OFF)

period.

AUTO FAN

SCHEDULE

79

SET POINT

F

FRR161

SCHEDULE

FRR162

Page 19

AUTO FAN

F

AUTO FAN

F

79

SET POINT

FRR163

If the Schedule function is turned OFF during an in-active (OFF) period,

the Timer

known non-schedule state.

Timer OFF Scenarios

The display shows the unit in Timer mode during an in-active (OFF) period.

and

SCHEDULE

icons turn off. The unit wakes up in the last

FRR166

79

SET POINT

FRR167

If the Timer function is turned OFF during an in-active (OFF) period, the

Timer

If the Timer function is turned OFF during the ON time. The Timer icon

turns off. The control stays in the current state.

icon turns off. The display shows a normal system.

AUTO FAN

AUTO FAN

79

SET POINT

F

F

FRR168

79

The display shows a normal system.

SET POINT

FRR169

19

Page 20

Remote Control Operation

Remote Control - Refer to Figures 12 and 13 during operation description.

Getting Started - Install two (2) AAA batteries in the battery compartment

located on the back of the unit.

Operation - The remote control should be within 25 feet of the air

conditioner for operation. (Refer to Figure 11 for effectiveness). Press the

power button to turn the remote on. The remote will automatically power

of

f aft

er 15 seconds if the buttons are not being pressed. The remote must

be on to control the unit.

POWER Button - Turns remote and unit on and off.

SYSTEM Button - Allows the user to sequentially select the

following: AUTO - AUTO -, COOL

operations. When the button is pressed, the display indicates which mode

has been selected via a display message.Note that when the heating

function is not available, the system will

FAN MODE Button - Selects between automatic (

operation. In the

AUTO FAN

mode, the fan only turns on and off when the

compressor operates or the heat function is enabled.

NOTE:

AUTO FAN

indicates

is not available in the FAN ONLY Mode, the display

CONTINUOUS

. In the

determined by your selection on the

HEAT

,

, and FAN ONLY

automatically skip the HEAT mode.

CONTINUOUS

) or

CONTINUOUS

FAN

SPEED

AUTO FAN

mode, fan speed is

button.

FAN SPEED Button - Used to sequentially select new fan speed, plus

AUTO operation. When the

FAN

button is pressed, the fan speed icon

SPEED

(triangle) changes to indicate the new speed level. Fan speed automatically

varies depending on the set temperature on the control panel and the actual

room temperature. For example if there is a big difference between your

set temperature and the actual room temperature, the system fan speed

increases to HIGH. It remains at this speed until the room temperature

matches the set temperatur

SCHEDULE Button – The

e

.

SCHEDULE

button turns the schedule function

on and off. Press the Schedule button once to turn on the Schedule

(Residential, Commercial, Timer, or Customized) that has already been

selected on your unit. Pressing the

SCHEDULE

button a second time turns

the schedule function off.

UP and DOWN Arrows - Pressing either the

(UP) or (DOWN)

button changes the desired room temperature. The factory preset lower

and upper limits are 60°F (16°C) and 99°F (37°C). These buttons are also

used to navigate between function options when using the User Menu or

Maintenance Mode.

Remote Effectiveness

Hand Held Remote - Has an operating range of up to 25 ft. The infrared

remote control signal must have a clear path to transmit the command to

the air conditioning unit. The remote signal has some ability to "bounce"

off of walls and furniture similar to a television remote control. The diagram

below shows the typical operating range of the control in a standard room

with 8 ft high ceilings.

Figure 11

SIDE VIEW

TOP VIEW

25ft

25ft

7.5ft

30°

45°

60°

60°

45°

30°

8ft

25ft

25ft

25ft

4ft

8ft

60°

60°

45°

45°

30°

30°

6ft

16ft

25ft

20

25ft

25ft

FRR080

Page 21

FRR081

Figure 12

SYSTEM

TEMPERATURE

UP

FAN SPEED

AUTO

AUTO FAN

CONTINUOUS

AUTO

SYSTEM

FAN SPEED

POWER

F

C

FAN MODE

SCHEDULE

DISPLAY

FAN MODE

POWER

TEMPERATURE

DOWN

SCHEDULE

Figure 13

SYSTEM

MODE

FAN

MODE

FAN

SPEED

COOL

ICON

AUTO

AUTO FAN

CONTINUOUS

AUTO

HEAT

ICON

SCHEDULE

ICON

FAN ONLY

ICON

F

C

°F / °C

ICONs

FRR082

21

Page 22

Airflow Selection and Adjustment

Air flow direction adjustment

left or right side of the discharge opening. Each of the banks of louvers

can be directed left, right, up or down in order to achieve the most optimum

move it in the direction that you would like the air to be directed. Please

louvers than the other.

Fresh air and exhaust control

Your air conditioner has the ability to bring fresh air into the room or exhaust

stale air out of the room. The control slide is found on the upper part of

the unit (See Figure 14).

TO BRING IN FRESH AIR – Move the lever to the Fresh Air

which allows outside air to enter the room. This is useful in fall and spring as

a means of bringing in fresh outside air when using FAN ONLY . It can also

be used in the summer with the compressor in the Cooling Mode if you wish.

TO EXHAUST INDOOR AIR – Move the lever to the Exhaust

position. This will allow stale air to be expelled to the outside of the dwelling.

This is especially handy in the spring or fall when indoor air tends to get

stale, or after a social gathering involving smokers, or to remove cooking

odors.

BEST PERFORMANCE – Move the lever to the Re-Circulate Position

position

Figure 14

FRR008

22

Page 23

Installation Instructions

READ THIS FIRST! Electrical Requirements

WARNING

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong oulet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

IMPORTANT: Before you begin the actual installation of your air

conditioner, check your local electrical codes and the information below.

Your air conditioner must be connected to a power source with the same

alternating current (A.C.) voltage and amperage as marked on the name

plate located on the chassis. Only A.C. can be used. Direct Current (D.C.)

cannot be used.

CIRCUIT PROTECTION – Use on single outlet circuit only. An overloaded

c

ircuit will invariably cause malfunction or failure of an air conditioner,

therefore, it is necessary that the electrical protection is adequate. Due

to momentary high current demand when the air conditioner starts, use a

"TIME DELAY" fuse or a HACR type circuit breaker. Consult your dealer

or power company if in doubt.

Refer to the electrical name plate located on the air conditioner chassis

(

See page 2) to determine the correct fuse or circuit breaker amperage

for your model (See Table 1 on Page 6 for electrical receptacle types).

The power cord has a plug with a grounding prong and a matching

receptacle is required.

The following instructions are for standard chassis model groups

sizes listed in Table 3.

Table 3

MODEL DESIGNATION CABINET SIZE (H x W x D)

SMALL CHASSIS - SS,

ES, YS

MEDIUM CHASSIS - SM,

EM, YM

LARGE CHASSIS - SL,

EL, YL

15

15

⁄16" x 25 15⁄16" x 29" (405 mm x

660 mm x 737 mm)

15

17

⁄16" x 25 15⁄16" x 29" (455 mm x

660 mm x 737 mm)

3

⁄16" x 28" x 35 1⁄2" (513 mm x 711

20

mm x 851 mm)

WARNING

MOVING PARTS HAZARDS

* Do not operate unit out of sleeve

or with front grille removed.

* Do not place hands in blower or

fan blade areas.

Failure to do so can result in

serious injury.

CAUTION

Excessive Weight Hazard

Use two or more people when

installing your air conditioner.

Failure to do so can result in

back or other injury.

Recommended Tools

1. Power Drill

2. 5/32" Drill Bit

3. Gloves

4. Carpenters Level

5. 5/16" Wrench

6. 1/4" Wrench

7. #2 Phillips Screw Driver

8. Putty Knife or (wood stir stick)

4

1

5/16

2

3

ITEMS NOT TO SCALE

5/16

1/4

1

/4

65

87

23

Page 24

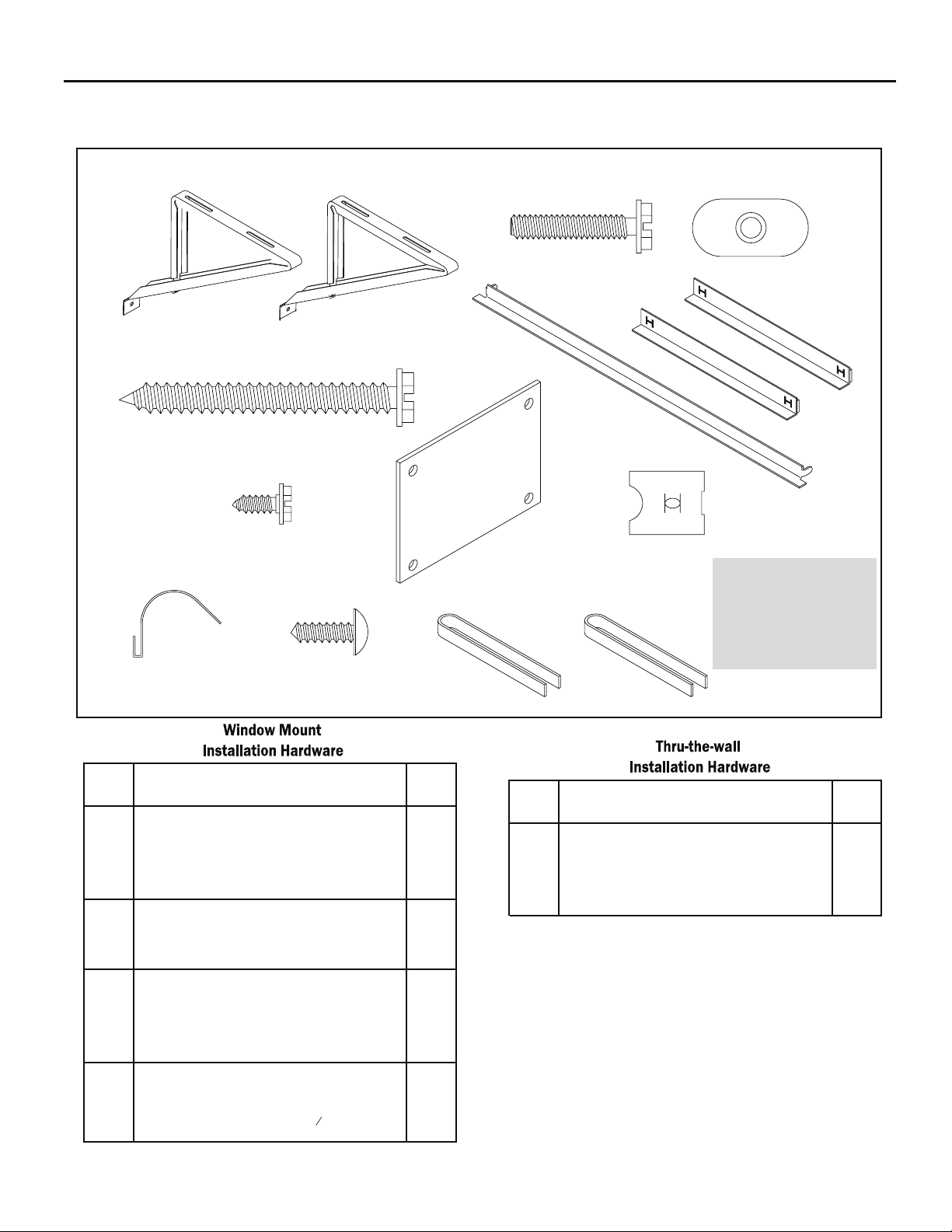

INSTALLATION HARDWARE AND ACCESSORY DETAIL

ITEM 10

ITEMS NOT TO SCALE

ITEM 4

ITEM 7

ITEM 1

ITEM 11

ITEM 2

ITEM 5 ITEM 6

ITEM 8

ITEM 12 ITEM 13

ITEM 3

ITEM 9

ITEM 14

FRR009

ITEM

DESCRIPTION QTY.

NO

WINGBOARD MOUNTING PARTS

10 WINGBOARD CLIP (SPRING STEEL) 4

11 SCREW, #8 x ½" PHILLIPS TRUSS HD. 4

WINDOW SEALING

12 WINDOW SEAL GASKET (DARK FOAM) 1

13 CHASSIS SEAL GASKET (LIGHT FOAM) 1

SHELL MOUNTING PARTS

1

2 SCREW, 10-24 x 1" HEX HEAD

3

4 SCREW, SHEET METAL #12 x 2" 7

WINGBOARD ANGLE MOUNTING

5

6 WINGBOARD ANGLE, SIDE 2

7 SCREW, SHEET METAL #8 x

24

3

8

" 2

ITEM

DESCRIPTION QTY.

NO

1WINGBOARD (MASONITE)

4"J" TYPE SPEED NUT

NOTE: K ühl + models do not come w i t h window mou nting

2SUPPORT BRACKET

4

410-24 FLAT WELD NUT

1WINGBOARD ANGLE, TOP

MOUNTING PARTS

4

SCREW, SHEET METAL #12A x 2”

CHASSIS SEAL GASKET (LIGHT FOAM)

14

components. When mounting a cooling and heating model

a window installation kit must be purchased separately.

KWIKS – For all ES and YS models.

KW

IKM – For all EM and YM models.

KWIKL – For all EL and YL models.

7

1

Page 25

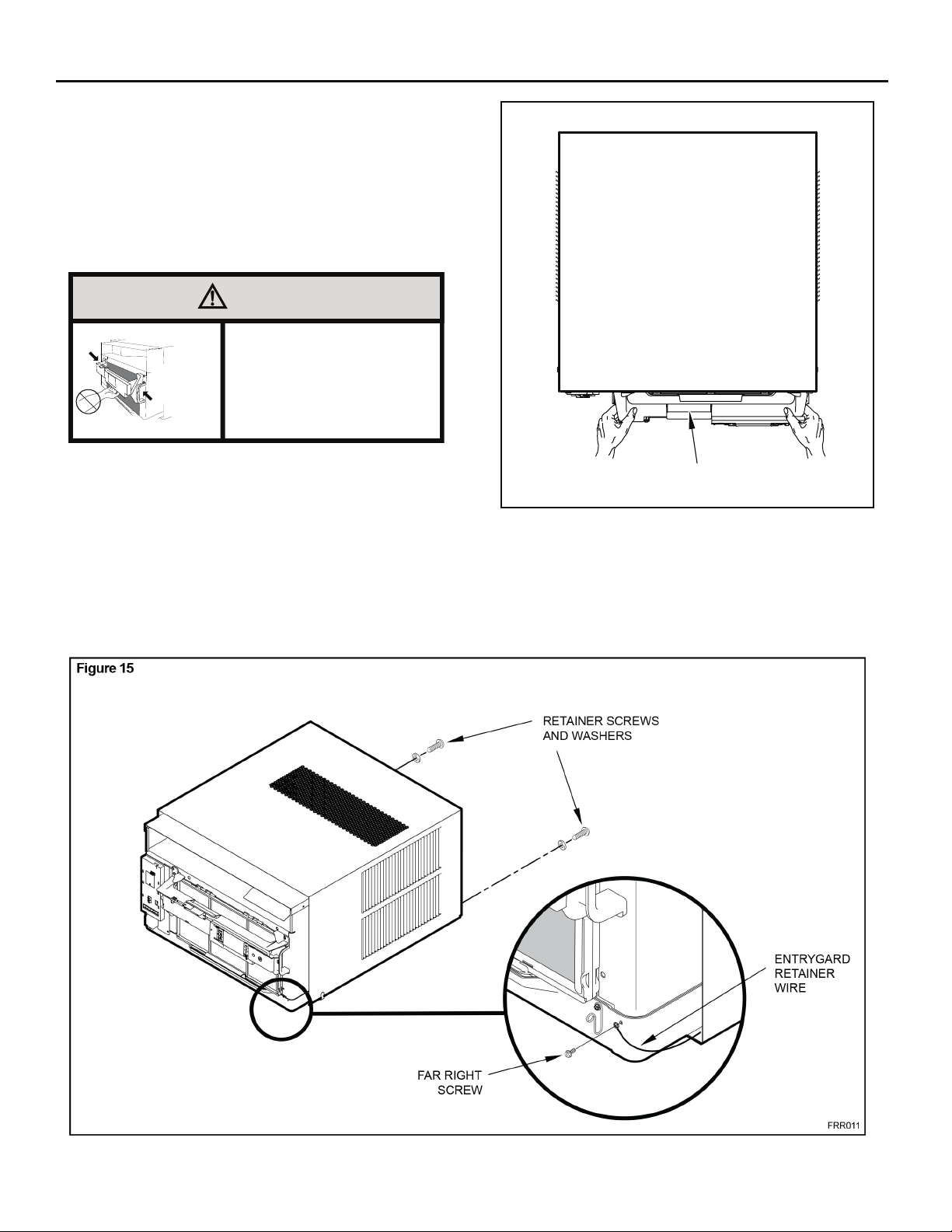

Standard Window Installation

Figure 16

NOTE: Hardware and accessories used during installation are shown

STEP 1. Remove the chassis Entrygard retainer by removing the far

on page 23. Each part will be referred as Item No.

right screw (See Figure 15), save this screw to reattach the

chassis retainer after installation (Step 12). Also, remove and

discard the two retainer screws and washers located at the

rear of the unit (See Figure 15).

CAUTION

Handle Use

Use Handle

Locations

(both sides)

STEP 2. Hold the cabinet stationary, then use the hand grips on both

STEP 3. Remove the large white foam blocks used to restrain the

ends of the control unit support bracket to pull the chassis out

of the cabinet (See Figure 16).

compressor during shipment (See Figure 17). Inspect base

pan for dislodged white foam blocks and remove. Do not

remove any other foam parts.

Use handle on both sides to

pull unit from sleeve.

Do not push, pull or lift from

center of support.

CONTROL UNIT

SUPPORT BRACKET

STEP 4. Anchor the side angles (Item 6) by engaging the tabs of the

l

ower sill plate (See Figure 18, Detail B-2) with the loops of the

side angle. Engage the tabs of the top angle (Item 5) with the

top loops of the side angle (See Figure 18, Detail B-1). Install

two (2) screws (Item 7) to secure the top angle tabs and the

side angle to the cabinet (See Figure 18, Detail B-1).

FRR012

25

Page 26

CAUTION

TOP VIEW OF UNIT

Remove Shipping Blocks

Prior to operating the unit remove

the foam shipping blocks.

Failure to do so may result in

damage to the unit which is not

covered by the manufacturer’s

warranty!

STEP 5. Check the window sill and frame to be sure they are in good

STEP 6. CABINET MOUNTING – Raise the lower window 1/4" more

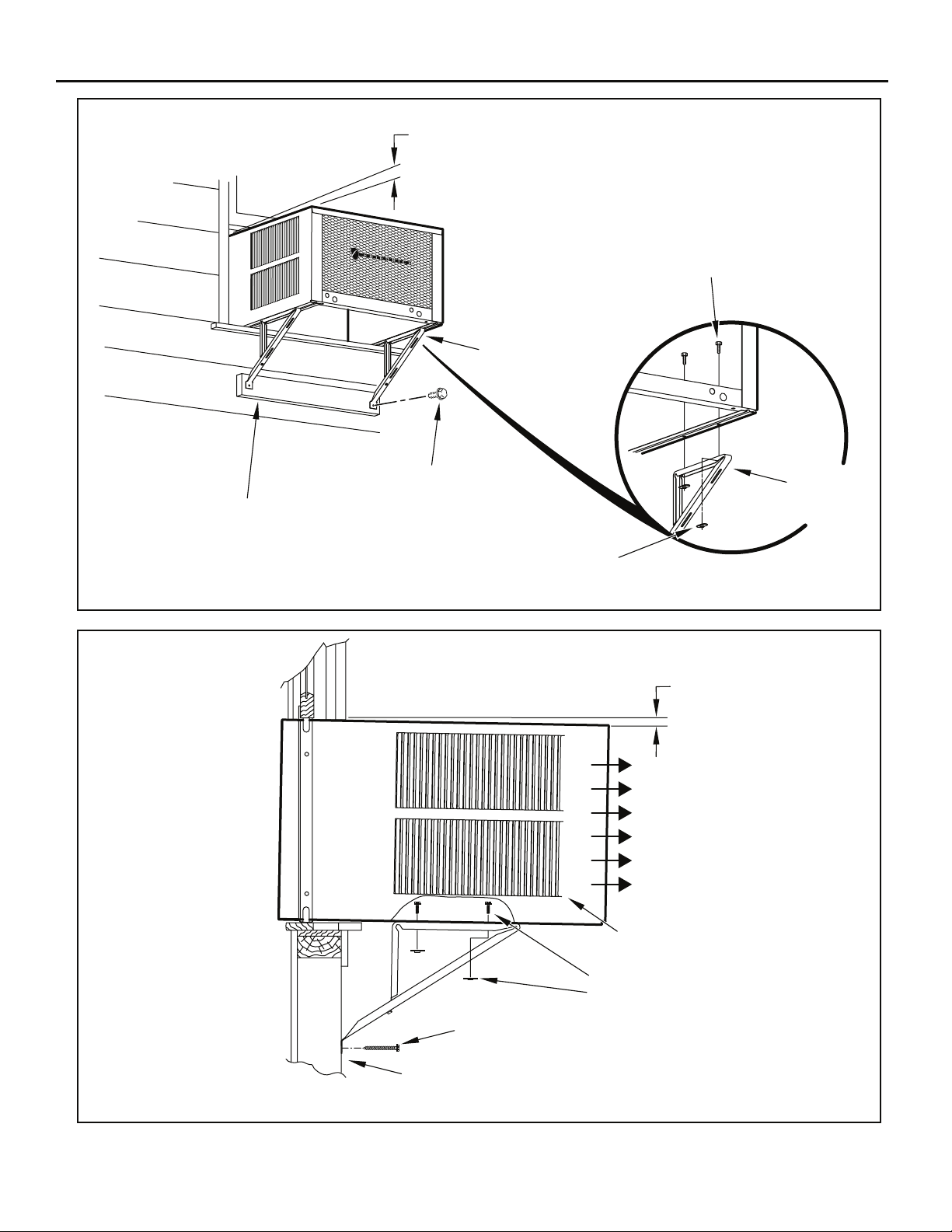

STEP 7. OUTSIDE SUPPORT MOUNTING – Refer to Figures 20 and

Figure 17

than the height of the cabinet. Carefully slide the cabinet

through the opening until the lower sill plate channel rests

behind the window sill and the top angle rests against the

window (See Figure 19). Center the cabinet within the

opening. Drill three (3) 5/32" diameter pilot holes into window

sill using the holes in the cabinet sill plate as a guide. Install

t

hree (3) #12 x 2" long screws (Item 4) (See Figure 19).

21. Assemble the support brackets (Item 1) to the bottom of

the cabinet with four (4) 10-24 1” long screws (Item 2) and four

combination of the elongated holes of the bracket and different

hole locations in the cabinet, to bring the bottom support bracket

pads in contact with the wall. A 1" x 4" or 2" x 4" SPACER

SHOULD BE USED BETWEEN THE WALL AND SUPPORT

THE BRACKETS WHEN INSTALLED ON ALUMINUM OR

VINYL SIDING. Drill 5/32" diameter pilot holes and secure

the brackets to the wall with two (2) 12A x 2" long screws

(Item 4).

NOTE: DO NOT LEVEL the cabinet from front to back. Make sure there

Adjust the support brackets to provide an inside-to-outside slope for excess

condensation drainage (Refer to Standard Window Installation, Figures 20

through 24). Tighten all screws.

Alternate support method A: If you have a wide window sill which prevents

you from mounting the b

U

set the placement of the

Tighten all screws.

Alternate support method B: If the window ledge gap is narrow, try the

as shown in Figure 24. Bend the short piece so it will be vertical when

installed. Adjust the placement as required. Tighten all screws.

STEP 8.

is approximately 3/8” to 1/2” slope (1/8 to 1/4 bubble on level)

toward the outside of the house.

sing the elongated holes and different hole locations in the cabinet,

between t

Make sure you include the depth of the window channel.

rackets as shown in Figure 23, try the following:

bracket to support the unit’s weight (Figure 23).

he window side channels and cabinet. (Figure 25).

NOTICE

For YOUR security and safety, YOU must

provide a means of preventing the upper

part of the window from opening.

STEP 9. t "J" eht no hsup ,slenap draobgniw eht elbmessa oT ype speed

nuts (Item 9) and spring steel clips (Item 10) (See Figures 26)

on page 31. Secure each panel with two (2) screws (Item 11).

26

LEFT SIDE

REMOVE AND DISCARD

FOAM BLOCKS

COMPRESSOR

BACK

FAN MOTOR

EVAPORATOR COIL

FRONT

REMOVE AND DISCARD

SCREWS

RIGHT SIDE

REMOVE AND SAVE

SCREW FOR

RE-INSTALLATION

FRR045

Page 27

27

Page 28

Figure 20

3/8” SLOPE DOWN

#10-24 x 1” HEX HD.

SCREW (ITEM 2)

SUPPORT BRACKET

(ITEM 1)

SPACER SHOULD BE USED BETWEEN

WALL AND BRACKET WHEN INSTALLED

ON ALUMINUM OR VINYL SIDING.

Figure 21

#12 x 2” SCREW

(ITEM 4)

SUPPORT

BRACKET

(ITEM 1)

10-24 x FLAT WELD

NUT (ITEM 3)

FRR015

3/8” SLOPE DOWN

CONDENSER

AIR OUTLET

28

CONDENSER

AIR INLETS

#10-24 SCREW

#10-24 FLAT WELD NUT

#12 x 2” SHEET METAL

SCREW (ITEM 4)

SPACER SHOULD BE USED BETWEEN

WALL AND BRACKET WHEN INSTALLED

ON ALUMINUM OR VINYL SIDING.

FRR016

Page 29

Figure 22

STONE LEDGE

3/8” SLOPE DOWN

CONDENSER

AIR INLETS

#10-24 SCREW

#10-24 FLAT WELD NUT

#12 x 2” SHEET METAL

SCREW (ITEM 4)

SPACER

FRR017

Figure 23

3/8” SLOPE DOWN

#10-24 SCREW

STRAIGHTEN TAB TO LAY FLAT

ALONG THE BOTTOM RAIL OF

THE SHELL

#10-24 FLAT WELD NUT

SECURE THE LONGEST SIDE OF

THE BRACKET TO THE SHELL

ADJUST IN OR OUT TO REST

ON THE LEDGE

STONE LEDGE

FRR018

29

Page 30

Figure 24

3/8” SLOPE DOWN

#10-24 SCREW

#10-24 FLAT WELD NUT

STONE LEDGE

OUTSIDE WALL

DIMENSION “A”

CUT

HERE

DISCARD

SHADED AREA

CUT TO FIT DIMENSION “A”

AND BEND DOWN TO FORM

A VERTICAL LEG.

A

FRR019

30

Page 31

STEP 10. INSTALL THE R1 INSULATION PANEL – To

minimize air leaks and ensure optimal insulation, install the

included R1 insulation panel. (14 in parts list) (See Figure 28

A-C).

First, measure the width from one side of the cabinet/sleeve

(covering the side angles where the wingboard was just

secured) to the end of the wingboard. (See Figure 28A)

Next cut the R1 insulation panel to the measured width and

remove protective cover, exposing adhesive on back panel

(See Figure 28B)

Last, evenly apply the adhesive side of the panel across the

entire height and width from side angle to wingboard panel.

(See Figure 28C)

Repeat the steps above for the other wingboard panel.

STEP 11. INSTALL THE WINDOW SEALING GASKETS – Measure

and cut the dark foam window seal gasket (Item 12) and

install it between the upper glass panel and the top part of

the window sash (Figure 29).

CAUTION

Cut/Sever

Although great care has been

taken to minimize sharp edges

in the construction of your unit,

use gloves or other hand

protection when handling unit

Failure to do so can result in minor

to moderate personal injury.

STEP 12. Carefully team lift the chassis and set it into the cabinet. Slide

the chassis stopping approximately 3" from full insertion. Insert

the chassis seal gasket (Item 13) one inch deep between the

chassis and

33.

inserting the gasket at either bottom corner and go up the

side, across the top, and down the opposite side. Then push

the chassis all the way into the cabinet.

the cabinet (See Figure 31) as shown on page

A paint stir stick or ruler might be helpful here. Begin

Figure 26

CAUTION

Excessive Weight Hazard

Use two or more people when

installing your air conditioner.

Failure to do so can result in

back or other injury.

“J” TYPE SPEED NUT

(ITEM #9) 2 REQUIRED

CUT

WINGBOARD

PANEL

NOTE: If the chassis seal gasket is not installed or installed improperly,

the operation of the unit will be negatively affected. Operational

STEP 13. Reattach the entry guard chassis entry guard retainer wire with

the same screw retained in Step 1 (See Figure 15).

SPRING STEEL

CLIP (ITEM 10)

2 REQUIRED

3"

CUT EDGE

CENTER THE HOLE IN THE

SPEED NUT OVER THE SLOT

IN THE WINGBOARD PANEL

3"

SLIDE CLIP OVER CUT EDGE

OF WINGBOARD PANEL

ROTATED 90°

FRR021

31

Page 32

Figure 27

TOP OF CABINET

PLACE WINGBOARD PANEL IN WINDOW JAM

TO COMPRESS THE SPRINGS INSIDE THE

RUNNERS, AND SWING THE WINGBOARD

PANELS INTO PLACE AS INDICATED BY THE

DASHED LINES.

Figure28

INSERT FOAM WINDOW

SEAL GASKET (ITEM 12)

WINDOW JAM

CLIP (ITEM 10)

SECTION A-A

A

A

I

C

SECURE THE SIDE WINGBOARD PANELS TO

THE SIDE ANGLES WITH FOUR (4) #8 x 1/2” LONG

SCREWS (ITEM 11), TWO ON EACH SIDE.

32

FRR022

SECTION B-B

Page 33

OPTIONAL: e ti taht os droc ylppus eht selbmessa yrotcaf ehT xits the left

side of the unit at the bottom. At the consumer’s discretion,

the supply cord can be routed to exit the right side of the unit.

To do this, route the supply cord to the right side. Pull the

supply cord taunt through the loops (Refer to Cord Routing

Change, Figure 31) and route the cord down.

Use Tool Provided

Please use the provided tool to attach the decorative front to the chassis.

Figure 29

STEP 14.

To attach and prevent damage to the front grille align the

cord notch over the cord and center the fresh air lever, then

align and tighten the four (4) captive screws as indicated by

the arrows in Figure 29. Before closing the front panel, be

sure the filter is in place. Make sure curtains do not block

the side air intakes.

STEP 15. Refer

to the Control Panel Operation section for instructions.

STEP 16. You are now ready to control the comfort level of the room.

USE HAND TOOLS

DO NOT O VER T IGHTE N

B

LOCATION OF GRILLE

REMOVAL TOOL

FRR053

33

Page 34

34

Page 35

35

Page 36

Through-the-Wall Installation

The following instructions apply to wood, masonry, brick, concrete or cinder

block wall construction.

STEP 1. Follow steps 1, 2, 3, and 4 of the "STANDARD WINDOW

STEP 2. CABINET PREPARATION – Remove the sill plate

INSTALLATION" instructions beginning on page 25.

from the

cabinet by removing two (4) nuts and screws (Figure 39).

Note that the chassis retainer is secured by a right side nut

and screw (Detail A, Figure 39). Bend the tabs of the sill plate

down into its channel at both ends of the plate or cut them off

(Detail B, Figure 39) Rotate the sill plate 180° (end-to-end,

Detail B, Figure 39) and reinstall. Reverse the orientation of

the nuts and screws, so that the head of the screws are on the

underside of cabinet facing up

C, Figure 39). Ensure that the chassis retainer is reinstalled

as shown in the detail.

and the nuts are on top (Detail

NOTICE

The outside cabinet condenser air intake louvers

MUST NOT BE BLOCKED by extra thick walls.

STEP 3. WALL PREPARATION – The maximum wall thickness

permissible without special construction is determined by

the model size to be installed. Observe the maximum wall

thickness shown in Figure 40. Walls exceeding the maximum

thickness shown in the chart, should be altered as shown in

Figure 40.

B

Table 3

FINISHED

DIMENSION

A 16 3⁄16" 18 3⁄16" 20 3⁄8"

B 26

SMALL

CHASSIS

3

⁄16" 26 3⁄16" 28 1⁄4"

MEDIUM

CHASSIS

size.

A

LARGE

CHASSIS

STEP 4. CHECKING WIRING AND PLUMBING – Check for wiring and

STEP 5. OPENING CONSTRUCTION – Depending upon size of unit

plumbing inside and outside of the wall to be sure none will be

damaged when the

to be installed, lay out the hole dimensions per Table 3. Cut

construction is typical frame or 2” x 4” studding with brick or

stone veneers, locate the opening next to one of the studs.

For masonry, concrete or cinder block walls, locate opening

for your convenience (See Figures 41, 42, and 43).

cabinet framework is being constructed.

36

Page 37

37

Page 38

38

Page 39

STEP 6. Slide the cabinet into the hole far enough to allow the

guide-channel of the sill plate to contact the inside wall surface

(Figure 21).

STEP 7. Drill three (3) 5/32” diameter pilot holes (use the sill-plate holes

as a guide) into the frame and install three (3) #12 x 2" long

screws (Item 4) (Figure 21).

NOTE: Alternate fasteners are required when securing the sill plate or

support brackets to material other than wood (cinde

r block, brick,

masonry or concrete). These items can be purchased at your

local hardware store.

NOTE: DO NOT LEVEL the cabinet from front to back. Make sure there

is approximately 3/8” to 1/2” slope (1/8 to 1/4 bubble on the level)

toward the outside of the house.

STEP 8. Drill two (2) 5/32" diameter pilot holes in each cabinet side

at the locations shown (Figure 21) and install four (4) #12 x

2" screws (Item 4). Provided

that Step 5 (hole construction)

provides a sturdy mount with solid vertical studs, support

brackets may not be required. The installation must support

the weight of the unit plus an additional weight of 400 pounds

on the rear of the cabinet. If support brackets (Item 1) are

available, they can be installed as shown in Figure 21.

EXPANSION ANCHOR BOLT

MOLLY OR TOGGLE BOLT

Figure 44

TRIM MOULDING

SCREW #12 x 2"

LONG (USE 3)

(ITEM 4)

SILL PLATE GUIDE CHANNEL

STEP 9. Complete the installation by following steps 12 through 15

of “STANDARD WINDOW INSTALLATION” ins

tru ctions,

page 25.

CAULK ALL SIDES WEATHER TIGHT

INSIDE AND OUTSIDE

3/8" SLOPE DOWN

3"

4"

NOTE: SUPPORT BRACKET MAY BE

OMITTED FROM THROUGH-THE-WALL

INSTALLATIONS IF THE CABINET IS

SECURED AS FOLLOWS. DRILL TWO

HOLES IN EACH SIDE AND INSTALL 4

FASTENERS (2 EACH SIDE). USE #12 x 2"

SCREWS, (ITEM 4).

TOGGLE BOLTS OR EXPANSION BOLTS

MAY BE REQUIRED.

CABINET

INSIDE WALL SURFACE

SUPPORT BRACKETS

SCREW #12 x 2" LONG

DRILL 5/32" DIA. PILOT HOLES.

FRR031

39

Page 40

Final Inspection & Start-up Checklist

Inspect and ensure that all components and accessories have been

installed properly and that they have not been damaged during the

installation progress.

Check the condensate water drain(s) to ensure that they are adequate

for the removal of condensate water, and that they meet the approval

of the end user.

Ensure that all installation instructions concerning clearances around

indoor coil, and outdoor coil are free from any obstructions.

Ensure that the circuit breaker(s) or fuse(s) and supply circuit wire

size have been sized correctly. If the unit was supplied with a power

supply cord, insure that it is stored properly.

Ensure that the entire installation is in compliance with all applicable

national and local codes and ordinances having jurisdiction.

Secure components and accessories, such as a decorative front

cover.

Start the unit and check for proper operation of all components in

each mode of operation.

Instruct the owner or operator of the units operation, and the

manufacturer's Routine Maintenance.

NOTE: A log for recording the dates of maintenance and/or service is

recommended.

Present the owner or operator of the equipment with the Installation

& Operation Manual, all accessory installation instructions, and the

name, address and telephone number of the Authorized Friedrich

Warranty Service Company in the area for future reference if

necessary.

Heat pumps operate differently

If your unit is a "Y", or heat pump model, there are some things that you

will want to be aware of. Some functions of a heat pump differ from your

unit when it is used for heating:

It is normal for

1. ice to form on the outdoor coil of the heat pump.

Moisture in the outside air, passing over the coil when very cold,

will form ice.

2. If the outdoor temperature drops below 37° F (3° C), your heat

p

ump will automatically turn on the electric resistance heat. When

the temperature rises to 40° F (4° C), the compressor will resume

the heat pump operation. If your unit is a 115 volt model (YS10),

it is designed for use in warmer climates and does not have an

electrical heat feature, and will not provide adequate heat below

37° F (2.8° C).

Control Panel Battery Change Procedure

Remove the grille, by loosening four (4) captive screws (See Figure 45). In

the upper left corner, remove one (1) screw on the battery retaining door

(See Figure 46). Remove and replace the battery (CR2450). Reinstall

the battery retaining door. Align the grille guide pins then tighten the four

Clean or replace it as necessary.

Figure 45

This is a warm weather appliance

Your air conditioner is designed to cool in warm weather when the outside

temperature is above 60° F (15.6° C) and below 115° F (46.1° C), so it

cool a room if it is already cool outside. If you want to cool a room in the

spring or fall, select the FAN ONLY

air control to Fresh Air. This will bring in a supply of cooler outside air.

mode and set the Fresh Air/Exhaust

won't

Condensation is normal

Air conditioners actually pump the heat and humidity from your room to the

outside. Humidity becomes water, and your air conditioner will use most

of the water to keep the outside coil cool. If there is excessive humidity,

there may be excess water that will drip outside. This is normal operation.

Frosting

ONLY and the frost will disappear. Setting the thermostat a little warmer

will probably prevent the frosting from recurring.

Noises

All air conditioners make some noise. Friedrich units are designed to

operate as quietly as possible. An air conditioner mounted in a wall is

quieter than one mounted in a window. It is important to ensure that the

chassis seal gasket (Item 13) is properly installed (refer to installation

instructions).

USE HAND TOOLS

DO NOT OVER TIGHTEN

1. USE HAND TOOLS WHEN INSTALLING AND

REMOVING FRONT PANEL.

DO NOT OVERTIGHTEN SCREWS.

2. DISCONNECT POWER AND FOLLOW ALL

LABELED WARNINGS WHEN FRONT PANEL

IS REMOVED.

Figure 46

FRR010

40

Page 41

Routine Maintenance

monthly, and more frequently if conditions warrant. The unit must be turned

To Remove, Wash and Replace Filter

Coils & Chassis

NOTE:

The indoor coil and outdoor coils and base pan should be inspected

periodically (annually or semi-annually) and cleaned of all debris (lint, dirt,

leaves, paper, etc.) as necessary. Under extreme conditions, more frequent

cleaning may be required. Clean the coils and base pan with a soft brush

and compressed air or vacuum. A pressure washer may also be used,

pack when pressure cleaning coils.

Do not use a caustic cleaning agent on coils or base pan..

Use a biodegradable cleaning agent and degreaser. The use

of harsh cleaning materials may lead to deterioration of the

Service and Assistance

Before calling for service, please check the “Troubleshooting Tips” section

avoid unnecessary service calls, and save you the cost of a service call

if the problem is not due to the product itself. If you have checked the

“Basic Troubleshooting” section and still need help, it is available as follows:

our web site at www.friedrich.com.

If you require further assistance

You can call the Customer Support Call Center at 1-800-541-6645.

Before calling, please make sure that you have the complete model and

serial number, and date of purchase of your equipment available. By

providing us with this information, we will be better able to assist you.

Our specialists are able to assist you with:

Referrals to dealers, and distributors.

Use and Care Information.

Recommended maintenance procedures.

Installation information.

Referrals to Authorized Service Providers and Parts depots.

42

43

NOTE: It is extremely important to insure that none of the electrical

and/or electronic parts of the unit get wet. Be sure to cover all

electrical components to protect them from water or spray.

Decorative Front

Use a damp (not wet) cloth when cleaning the control area to prevent

water from entering the unit, and possibly damaging the electronic control.

The decorative front and the cabinet can be cleaned with warm water

and a mi

ld liquid detergent. Do NOT use solvents or hydrocarbon based

cleaners such as acetone, naphtha, gasoline, benzene, etc.

The indoor coil can be vacuumed with a dusting attachment if it appears

to be dirty. DO NOT BEND FINS. The outdoor coil can be gently

sprayed with a hose if you can get to it. If not, you might call your dealer

for a more thorough cleaning when needed.

vacuuming with a dust attachment or by cleaning in the sink using warm

reinstalling. Use caution the coil surface can be sharp.

Fan Motor & Compressor

The fan motor & compressor are permanently lubricated, and require no

additional lubrication.

Wall Sleeve

Inspect the inside of the wall sleeve and drain system periodically (annually

or semi-annually) and clean as required. Under extreme conditions, more

frequent cleaning may be necessary. Clean both of these areas with an

antibacterial and antifungal cleaner. Rins

water and ensure that the drain outlets are operating correctly. Check the

sealant around the sleeve and reseal areas as needed.

e both items thoroughly with

Available Accessories

DC-2 Drain Kit – Part No. 01900235

In some installations, excess condensate water caused by extremely humid

conditions, may result in an undesirable water drip such as on a patio or

over an entryway. MODEL DC-2 DRAIN KIT (Part No. 01900-235) can be

installed to drain excess condensation to an alternate location.

Carbon Filter Kits

The kits vary depending on the chassis size (small, medium, large). Each

KWCFS

KWCFM

KWCFL

FriedrichLink™ Adapter Accessory:

KWIFI - FriedrichLink™ Adapter Accessory for wireless control and

additional programming options

Decorative Color Front Panel Kits:

The kits vary depending on the chassis size (small, medium, large.)

KWBGE(S/M/L)A- S/M/L Decorative Front Cover in Classic Beige

KWBLK(S/M/L)A - S/M/L Decorative Front Cover in Black Onyx

K

WBLU(S/M/L)A - S/M/L Decorative Front Cover in Cobalt Blue

KWPNK(S/M/L)A

KWRED(S/M/L)A

KWWHT(S/M/L)A

Window Installation Kits (Standard in Kühl Models without Heat)

KWIKS – For all ES and YS models.

KWIKM – For all EM and YM models.

KWIKL – For all EL and YL models.

See www.friedrich.com for additional accessories for your unit.

- S/M/L Decorative Front Cover in Pink Diamond

- S/M/L Decorative Front Cover in Deep Red

- S/M/L Decorative Front Cover in Designer White

41

Page 42

Troubleshooting Tips

COMPLAINT CAUSE SOLUTION

Unit does not operate.

Unit Trips Circuit Breaker or Blows Fuses.

LCDI Power Cord Trips (Reset Button Pops Out).

Unit Does Not Cool/Heat Room Sufciently, Or

Cycles On And Off Too Frequently.

● The unit is turned to the off position,

or the thermostat is satised.

● The LCDI power cord is unplugged. ● Plug into a properly grounded 3 prong receptacle.

● The LCDI power cord has tripped

(Reset button has popped out).

● The circuit breaker has tripped or

the supply circuit fuse has blown.

● There has been a local power

failure.

● Other appliances are being used on

the same circuit.

● An extension cord is being used. ● Do NOT use an extension cord with this or any

● The circuit breaker or time-delay

fuse is not of the proper rating.

● The LCDI power cord can trip (Reset

button pops out) due to disturbances

on your power supply line.

● Electrical overload, overheating, or

cord pinching can trip (Reset button

pops out) the LCDI power cord.

NOTE: A damaged power supply cord must be replaced with a new power supply cord obtained

from the product manufacturer and must not be repaired.

● The return/discharge air grille is

blocked.

● Windows or doors to the outside are

open.

● The temperature is not set at a cool

enough/warm enough setting.

● The lter is dirty or obstructed. ● Clean the lter, (See Routine Maintenance), or

● The indoor coil or outdoor coil is

dirty or obstructed.

● There is excessive heat or moisture

(cooking, showers, etc.) in the room.

● The temperature of the room you

are trying to cool is extremely hot.

● Turn the unit to the on position and raise or lower

temperature setting (as appropriate) to call for

operation.

See “Electrical Rating Tables” on pg. 6 for the

proper receptacle type for your unit.

● Press and release RESET (listen for click; Reset

button latches and remains in) to resume operation.

● Reset the circuit breaker, or replace the fuse as

applicable. If the problem continues, contact a

licensed electrician.

● The unit will resume normal operation once power

has been restored.

● The unit requires a dedicated outlet circuit, not

shared with other appliances.

other air conditioner.

● Replace with a circuit breaker or time-delay fuse

of the proper rating. See “Electrical Rating Tables”

on pg. 6 for the proper circuit breaker/fuse rating

for your unit. If the problem continues, contact a

licensed electrician.

● Press and release RESET (listen for click; Reset

button latches and remains in) to resume normal

operation.

● Once the problem has been determined and

corrected, press and release RESET (listen for

click; Reset button latches and remains in) to

resume normal operation.

● Ensure that the return and/or discharge air paths

are not blocked by curtains, blinds, furniture, etc.

● Ensure that all windows and doors are closed.

● Adjust the Temperature control to a cooler or

warmer setting as necessary.

remove obstruction.

● Clean the coils, (See Routine Maintenance), or

remove obstruction.

● Be sure to use exhaust vent fans while cooking

or bathing and, if possible, try not to use heat

producing appliances during the hottest part of the

day.

● Allow additional time for the air conditioner to cool

off a very hot room.

42

Page 43

COMPLAINT CAUSE SOLUTION

Unit Does Not Cool/Heat Room Sufciently, Or

Cycles On And Off Too Frequently (continued).

Unit Runs Too Much.

● The outside temperature is below

60°F (16° C).

● The digital control is set to fan

cycling mode.

● The air conditioner has insufcient

cooling capacity to match the heat

gain of the room.

● The air conditioner has insufcient

heating capacity to match the heat

loss of the room.

● This may be due to an excessive

heat load in the room.

● It may also be due to an improperly

sized unit.

● This may be normal for higher

efciency (EER) air conditioners.

● You may notice that the discharge

air temperature of your new air

conditioner may not seem as cold

as you may be accustomed to from

older units. This does not, however,

indicate a reduction in the cooling

capacity of the unit.

● Do not try to operate your air conditioner in the

cooling mode when the outside temperature is

below 60°F (16° C). The unit will not cool properly,

and the unit may be damaged.

● Since the fan does not circulate the room air

continuously at this setting, the room air does not

mix as well and hot (or cold) spots may result.

Using the continuous fan setting is recommended

to obtain optimum comfort levels.

● Check the cooling capacity of your unit to ensure it

is properly sized for the room in which it is installed.

Room air conditioners are not designed to cool

multiple rooms.

● Check the heating capacity of your unit. Air

conditioners are sized to meet the cooling load,

and heater size is then selected to meet the

heating load. In extreme northern climates, room

air conditioners may not be able to be used as a

primary source of heat.

● If there are heat producing appliances in use in the

room, or if the room is heavily occupied, the unit will

need to run longer to remove the additional heat.

● Be sure to use exhaust vent fans while cooking

or bathing and, if possible, try not to use heat

producing appliances during the hottest part of the

day.

● The use of higher efciency components in your

new air conditioner may result in the unit running

longer than you feel it should. This may be more

apparent, if it replaced an older, less efcient,

model. The actual energy usage, however, will be

signicantly less when compared to older models.

● The energy efciency ratio (EER) and cooling

capacity rating (Btu/h) listed on the unit’s rating

plate are both agency certied.

43

Page 44

Addendum 1

Schedule Table with Energy Saving Values

Period Sun Mon Tues Wed Thur Fri Sat

Start Time 600 Start Time 600 Start Time 600 Start Time 600 Start Time 600 Start Time 600 Start Time 600

System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool

Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto

1

Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low

Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78

Set Point Heat 70 Set Point Heat 70 Set Point Heat 70 Set Point Heat 70 Set Point Heat 70 Set Point Heat 70 Set Point Heat 70

Start Time 800 Start Time 800 Start Time 800 Start Time 800 Start Time 800 Start Time 800 Start Time 800

System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool

Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto

2

Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low

Set Point Cool 85 Set Point Cool 85 Set Point Cool 85 Set Point Cool 85 Set Point Cool 85 Set Point Cool 85 Set Point Cool 85

Set Point Heat 62 Set Point Heat 62 Set Point Heat 62 Set Point Heat 62 Set Point Heat 62 Set Point Heat 62 Set Point Heat 62

Start Time 1800 Start Time 1800 Start Time 1800 Start Time 1800 Start Time 1800 Start Time 1800 Start Time 1800

System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool

Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto

3

Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low

Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78 Set Point Cool 78

Set Point Heat 70 Set Point Heat 70 Set Point Heat 70 Set Point Heat 70 Set Point Heat 70 Set Point Heat 70 Set Point Heat 70

Start Time 2200 Start Time 2200 Start Time 2200 Start Time 2200 Start Time 2200 Start Time 2200 Start Time 2200

System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool

Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto Fan Mode Auto

4

Fan Speed Low Fan Speed L

Set Point Cool 82 Set Point Cool 82 Set Point Cool 82 Set Point Cool 82 Set Point Cool 82 Set Point Cool 82 Set Point Cool 82

Set Point Heat 62 Set Point Heat 62 Set Point Heat 62 Set Point Heat 62 Set Point Heat 62 Set Point Heat 62 Set Point Heat 62

ow Fan Speed Low

Fan Speed Low Fan Speed Low Fan Speed Low Fan Speed Low

Commercial Schedule

Period Sun Mon Tues Wed Thur Fri Sat

Start Time 700 Start Time 700 Start Time 700 Start Time 700 Start Time 700 Start Time 700 Start Time 700

System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool System Mode Cool