Page 1

Service & Parts Manual

Dehumidifier

Models D25D, D50D, D70D

Dehumidifie r-2 010 Svc Parts (4-2010)

Important points o n ser vic e, and Flow chart

for inspecting and r epa iri ng the unit

Troubleshooting

Appearance and Con tro l panel

Techn ical specifications

Refrigerator sys tem d iagram

Schematic wiring d iag ram

Exploded view and Pa rts L ist s

Warranty

................. ... ... ... ............................. 13

................. ... ... ... ................... 2

................. ... ... ... .... 4-6

................. ... ... ... 7

................. ... ... ... .... 8

............... 1

................. ... ... . 3

................. .. 9- 12

Page 2

IMPORTANT POINTS ON SERVICE OPERATING SAFETY

Please follow these instructions carefully :

Unplu g t h e u n i t to avoid any danger f r o m e l e ctric shock befor e d i s a s sembling the unit fo r

repai r.

If ther e i s a n y s o und of the refriger a n t c i r culating when in op e r a t i on, avoid touchin g t h e

cooli n g c o i l s.

If you ne e d t o p e r form any welding or s o l d e r ing, be sure you are in a w e l l v e n tilated area.

Only a qu a l i f i ed professional s h o u l d p erform any welding o n t h e u n i t.

When re p a i r i ng the unit, the spec i f i c a tions listed in thi s m a n u a l must be strictly ad h e r e d

to when r e p l a c ing any component s .

When re p l a c i ng any electrical c o m p o n ents they should be fa c t o r y approved units.

Be sure t h a t a n y e lectrical compo n e n t s a re properly wired a n d i n p l a ce.

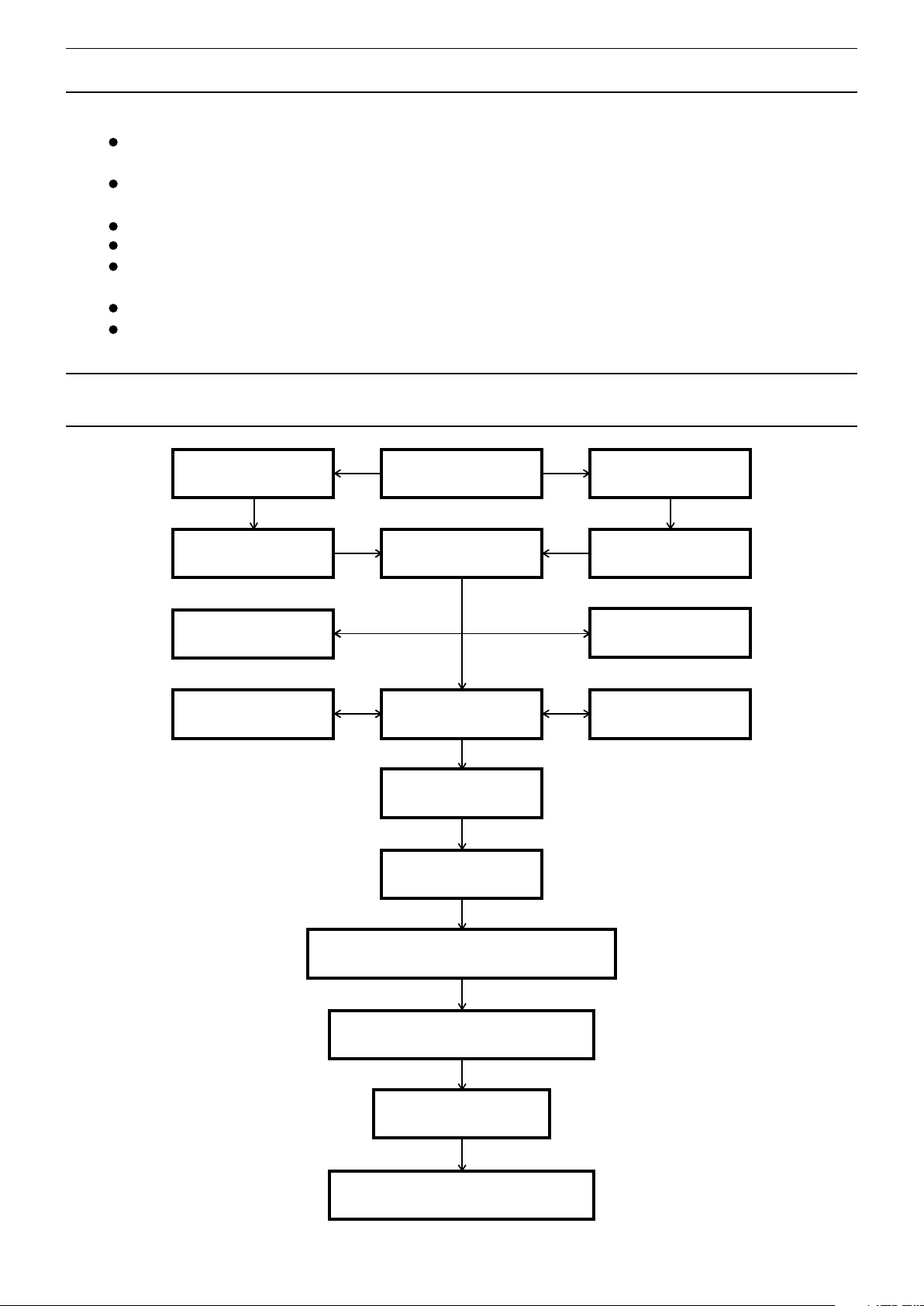

FLOW CHART FOR INSPECTING AND REPAIRING THE UNIT

Electricity sh utdow n

Check fuses on

main switch

Check if air filte r is

clogged

Capacitors are f aulty

Dehumidifier

doesn't work

Can not dehumidi fy

Compressor doe sn't

work

Refrigerant is l eakin g

Maintain

&

repair system

Check if drain buc ket

water level swit ch

is broken

Humidity senso r

is broken

Humidity setti ng on

continuous ope ratio n

Over load protec tor is

faulty

Supply Nitroge n 15Kg/ cm² fro m low

pressure side an d locat e the lea kage

Use oxygen acety lene an d 5% silv er

iron to fill crack s and hol es

Pump vacuum for at

least 15 minutes

After filling wi th

refrigerant pr oceed t o test ru n

- 1 -

Page 3

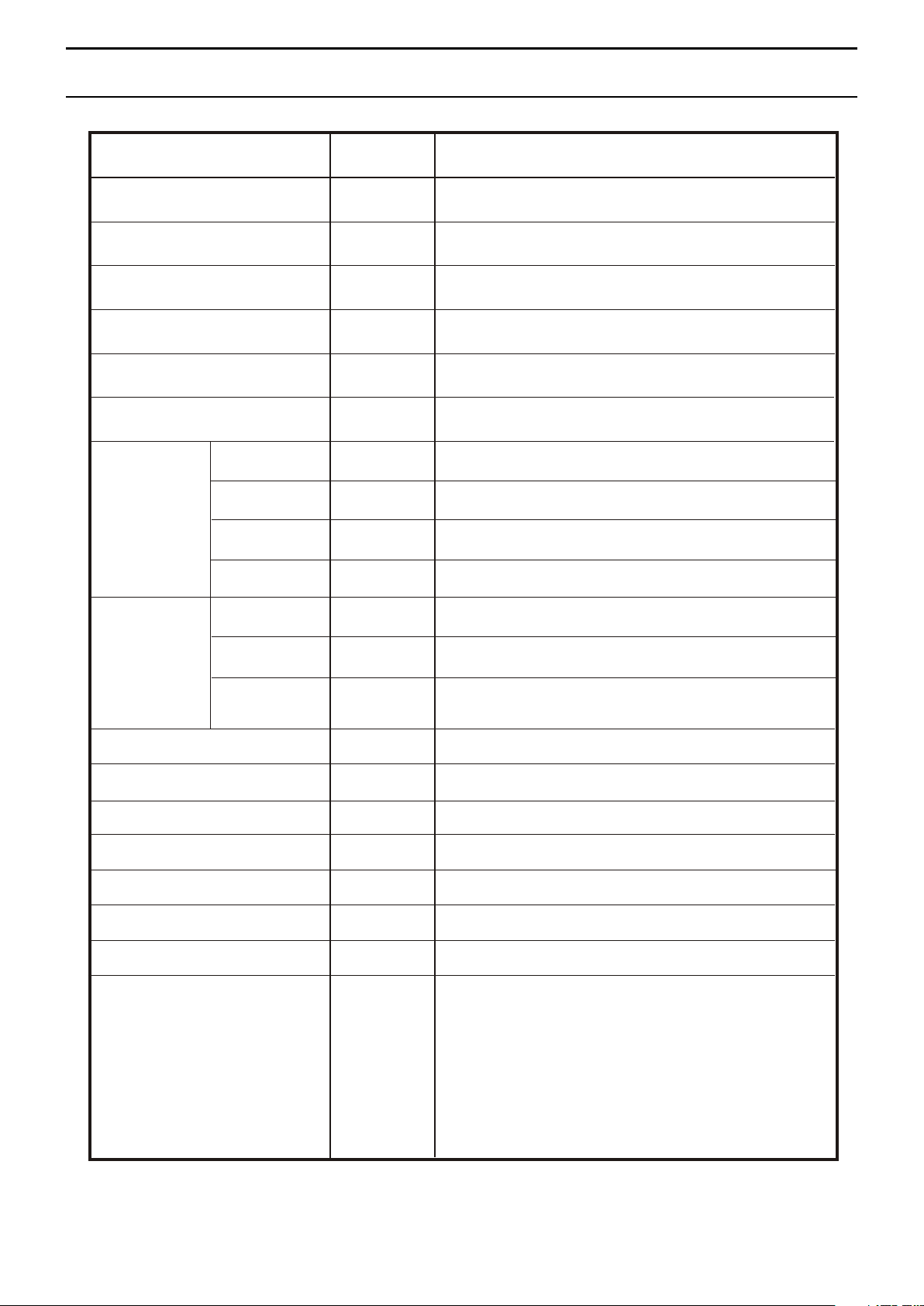

TROUBLE S HOOTING

Problem

Dehumidifier

doesn't work

Fan doesn't work

Compressor

doesn't work

Can not

dehumidify or the

dehumidifcation

volume is too low

Possible causes

Electricity shutdown or low

voltage

Bad plug or wire is broken

Motor is broken

Low voltage

Still under the 3 min

protection

Compressor is broken

Filter is dirty

Refrigerant is leaking

Solution

Wait for electricity to be

restored

Repair or replace

Repair or replace

Call the local electricity

company

Wait until if goes back to

function after 3 min

Repair or replace

Clean filter

Detect the leakage and fill with

refrigerant

Loud noise and

vibration

Evaporator is

frosted

Dehumidification

water overflows

Low temp and humidity

Uneven floor

Motor or compressor is loose

Sound of flowing water

Filter is too dirty

Environment temp is too low

Drain bucket is broken

Micro switch is broken

Normal

Move to level place or use

blocks

Tighten screws

Normal, it is the sound when

the refrigerant is flowing

Clean filter

Stop use temporarily

Repair or replace

Repair or replace

- 2 -

Page 4

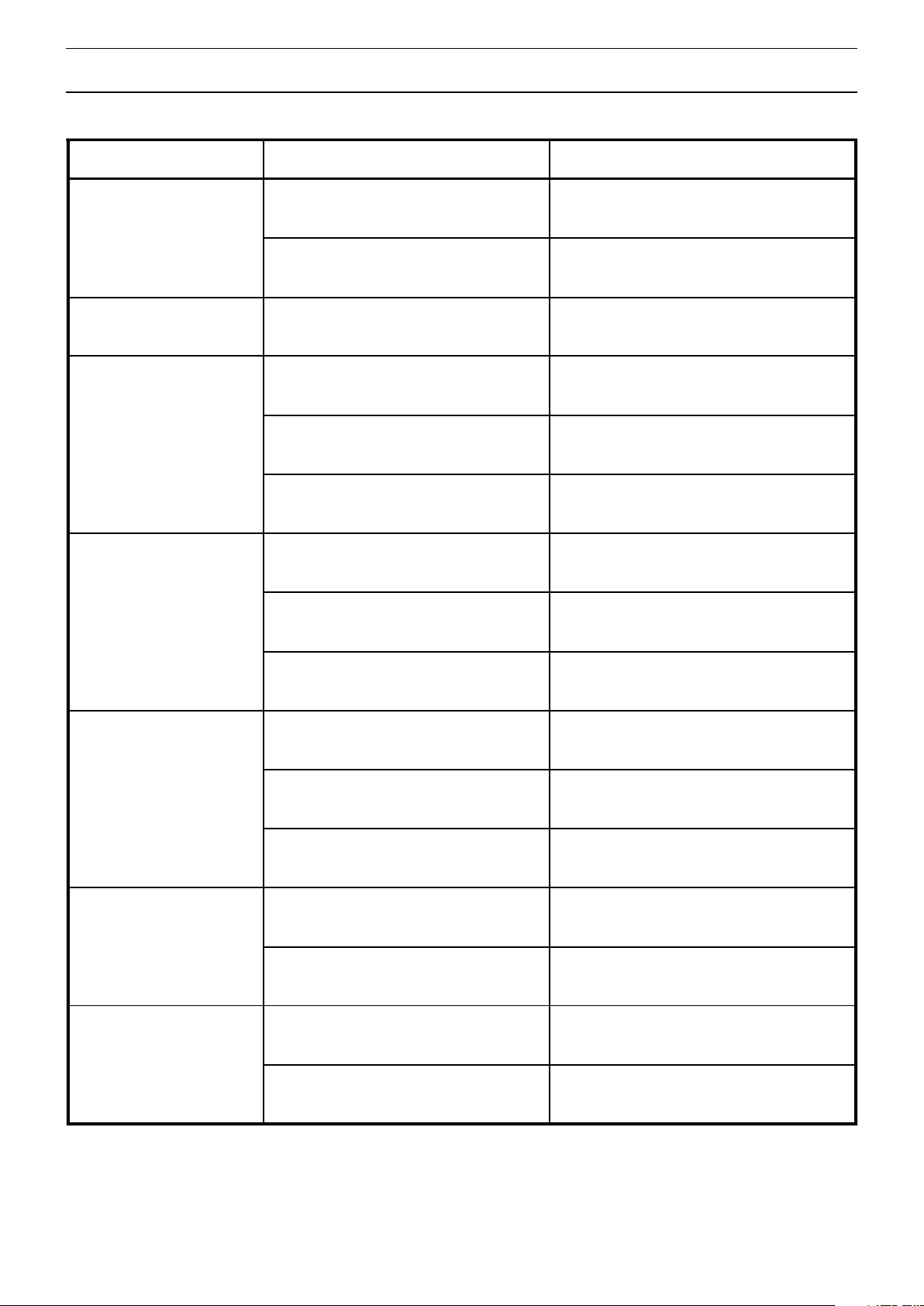

APPEARANCE

CONTROL PANEL

MOIST AIR

INTAK E

DRAIN BUCKET

AIR FILTER

ROLL CASTORS

OUTLET FOR

DEHUMIDIFIED

DRY AIR

HANDLE

CONTINUOUS

DRAINAGE HOLE

Electricity cable

CON TROL PAN EL

BUCKET FULL LAMP

Water tank is full,and

lamp lights.

FAN SPEED

High / L ow

POWER

On / Off

DEFROST LAMP

When l ow t em perature,

unit g et s in to defrosti ng

mode a nd l am p lights.

When unit operates, press

"TIMER" set hours unit will off

after set hours.

When unit stand-by, press

"TIMER" set hours unit will on

after set hours.

Setting timer from 1~24 hours.

To cancel the timer, proceed

as above but set the "timer off"

to zero hours.

TIMERS

CURRENT TEMP / TIMER SET DISPLAY

When machine is running, it displays the current temperature. Press

the "Timer" button to set the machine to shut off automatically after a

specified amount of time. 10 seconds after displaying the timer, the

display will change back to current temperature.

SET HUMIDITY / CURRENT HUMIDITY DISPLAY

When machine is running, it displays the current

humidity. Press "▲" or "▼" to select humidity

setting. The humidity is adjusted in an increment

of 5% by each pressing of "▲" or "▼". Adjustable

range is within 30%RH to 90%RH. 10seconds

after setting humidity, the display will change

back to the current humidity.

Press the ℃/℉

switch buttons,

it will switch at

sequence of

℃ and ℉.

- 3 -

Page 5

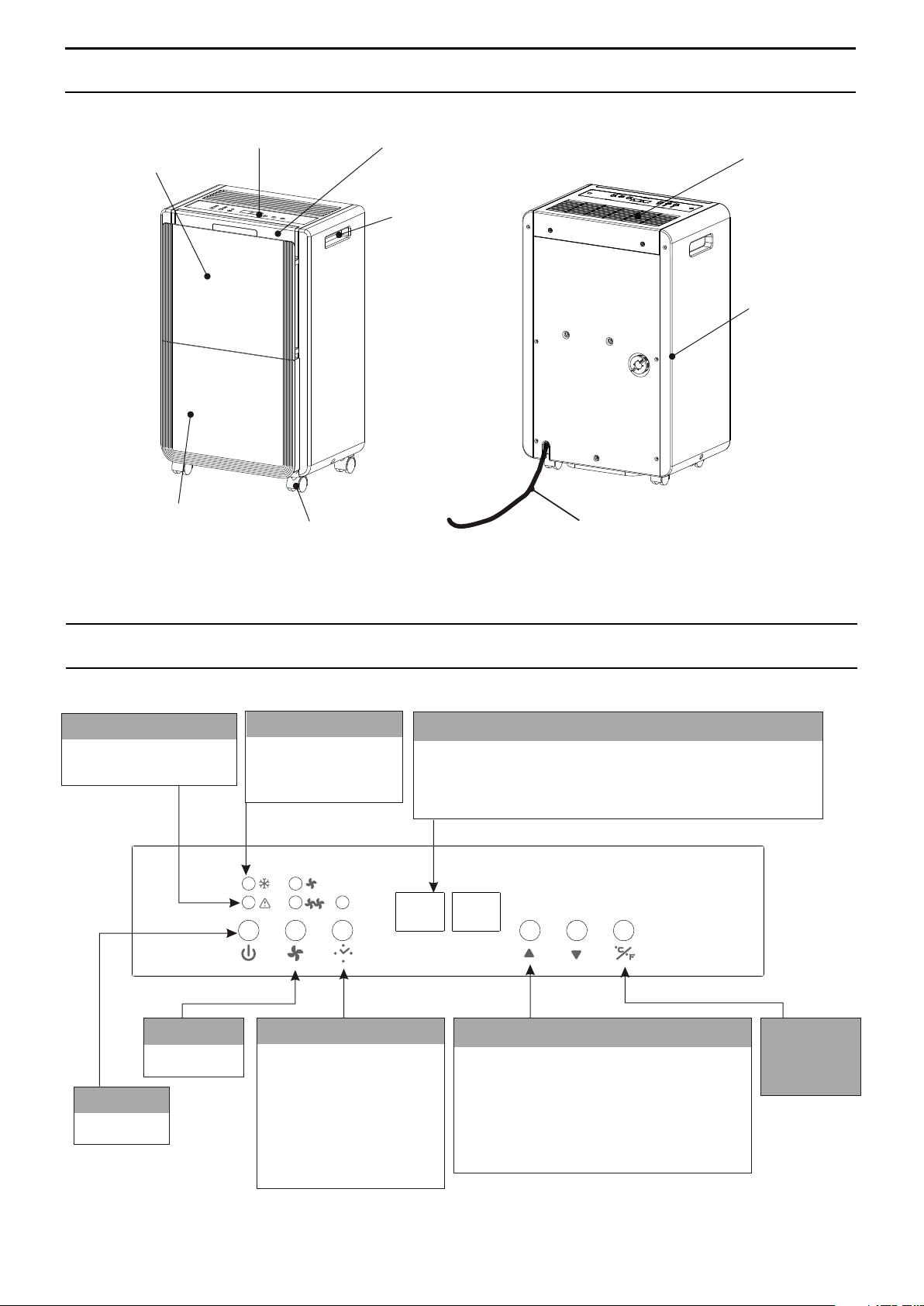

TECHNICAL SPECIFICATIONS

ITEM UNIT

DEHUMIDIFYING CAPACITY

OUTER DIMENSION

RATED VOLTAGE

RUNNING CURRENT

Pint/day

Inches

V/Hz

A

WIRE SPECIFICATION

MODEL

COMPRESSOR

INPUT

POWER

OPERATING

CYCLE

PROTECTOR

W

uF/V

D25D

25 (at 80°F , 60%RH)

13.46(W) * 21.46(H) * 9.84(D)

115 / 60

4.6

10A 125V 18AWG*3C

35D042-A2-ABDA

300

35/300

MRA12228-12095

MODE L

INPU T

FAN MOTOR

CAPILLARY

EVAPORATOR

CONDENSER

REFRIGERANT

WEIGHT

WATER TANK CAPACITY

POWE R

OPER ATING

CYCL E

W

uF/V

Inches

R410A/oz

Lbs

Pint

LS-16T2-04

47

5/250

0.086(O.D.)*0.047(I.D.)*19.685(L)

1R10S21FPI

2R10S21FPI

5.28

32

11

- 4 -

Page 6

TECHNICAL SPECIFICATIONS

ITEM UNIT

DEHUMIDIFYING CAPACITY

OUTER DIMENSION

RATED VOLTAGE

RUNNING CURRENT

Pint/day

Inches

V/Hz

A

WIRE SPECIFICATION

MODEL

OPERATING

uF/V

COMPRESSOR

CYCLE

PROTECTOR

D50D

50 (at 80°F , 60%RH)

14.96(W) * 23.43(H) * 12.01(D)

115 / 60

5.9

10A 125V 18AWG*3C

35D052-A2-ABLL

40/300

MRA12274-12095

MODE L

INPU T

FAN MOTOR

CAPILLARY

EVAPORATOR

CONDENSER

REFRIGERANT

WEIGHT

WATER TANK CAPACITY

POWE R

OPER ATING

CYCL E

W

uF/V

Inches

R410A/oz

Lbs

Pint

LS-16T2-02-N2

47

6/250

0.086(O.D.)*0.047(I.D.)*39.37(L)

2R12S21FPI

2R12S21FPI

9.32

44

16

- 5 -

Page 7

TECHNICAL SPECIFICATIONS

ITEM UNIT

DEHUMIDIFYING CAPACITY

OUTER DIMENSION

RATED VOLTAGE

RUNNING CURRENT

Pint/day

Inches

V/Hz

A

WIRE SPECIFICATION

MODEL

OPERATING

COMPRESSOR

CYCLE

PROTECTOR

uF/V

A

D70D

70 (at 80°F , 60%RH)

14.96(W) * 23.43(H) * 12.01(D)

115 / 60

7.7

10A 125V 18AWG*3C

41T068-A2-AMLI

40/300

MRA12272-12082

MODE L

INPU T

FAN MOTOR

CAPILLARY

EVAPORATOR

CONDENSER

REFRIGERANT

WEIGHT

WATER TANK CAPACITY

POWE R

OPER ATING

CYCL E

W

uF/V

Inches

R410A/oz

Lbs

Pint

LS-16T2-06

47

6/250

0.086(O.D.)*0.047(I.D.)*31.50(L)

2R12S21FPI

2R12S21FPI

12.03

44

16

- 6 -

Page 8

REFRIGERATOR SYSTEM DIAGRAM

CAPI LLARY TUBE

EVAPORATOR

CONDENSER

COMPRESSOR AS S'Y

DRYER

PTC(HE ATER)

FAN MOTOR

- 7 -

Page 9

SCHEMATIC WIRING DIAGRAM

SCHEMATIC WIRING DIAGRAM

D25D

115V~60Hz

L

BLACK

BLUE

TRANSFORMER

WHITE

BLUE

COMPRESSOR

CN 1

N

N

N

CN 2

CAPACITOR

N

WHITE

E

O

E

S

U

F

T3.15AL 250V

LP

RED

NO

COM.

CN 4

CN 1

CONTROL BOARD

CN 8

CN 2

FAN-L

CN 7

H.sensor

P6

CN 5

FAN-H

P7

CN 3

T.sensor

YELLOW

RED

CAPACITOR

MICRO

SWITCH

WHITE

F/MOTOR

BLACK

BLUE

D6951-870

SCHEMATIC WIRING DIAGRAM

SCHEMATIC WIRING DIAGRAM

115V~60Hz

L

BLACK

CAPACITOR

N

BLUE

WHITE

E

WHITE

BLUE

COMPRESSOR

CN 1

BLUE

N

N1

N2

TRANSFORMER

P

L

O

RED

E

S

U

F

T3.15AL 125V

CN 2

NO

COM.

CN 4

CN 1

CONTROL BOARD

BROWN

FAN-L

CN 8

CN 2

P6 P7

CN 6

CN 7

H.sensor

FAN-H

CN 3

YELLOW

MICRO

SWITCH

T.sensor

RED

WHITE

CAPACITOR

BLUE

D50D, D70D

F/MOTOR

BLUE

- 8 -

D6951-900

Page 10

EXPLODED VIEW

D25D

33

40

42

43

50

44

45

46

47

49

48

28

39

29

51

30

41

34

37

27

38

36

35

21

20

19

18

22

23

24

25

26

31

32

13

11

12

- 9 -

14

15

16

9

17

7

6

5

3

4

10

8

1

2

Page 11

D25D Ser vice Par ts List

Ref #

1

2

3

4

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

Friedrich Par t #

679-041-52

679-042-07

679-041-24

679-041-65

679-041-68

679-041-00

679-041-76

679-042-08

679-041-11

679-041-08

679-041-05

679-041-29

679-041-32

679-041-28

679-041-85

679-041-54

679-041-21

679-041-57

679-041-55

679-041-13

679-041-84

679-041-81

679-041-77

679-041-15

679-041-16

679-041-19

679-041-17

679-041-20

679-041-82

679-041-34

679-041-79

679-041-71

679-041-73

679-041-50

679-041-46

679-041-42

679-041-39

679-041-35

679-041-37

679-042-06

679-042-05

679-041-17

679-042-01

679-041-60

679-041-62

679-041-48

679-041-44

679-042-02

Descript i on

BASE PAN

CASTERS

COMPRESSOR ASS'Y

COMPRESSOR GROMMETS

PLATE

MICRO SWITCH

FIXTURE

BAR

CAPACITOR (35uF/300V)

COVER

CAPACITOR STRAP

EVAPORATOR ASS'Y

CONDENSER ASS'Y

STRAINER

CAPILLARY TUBE

INNER WALL (MOTOR MOUNT)

FAN MOTOR

BLOWER WHEEL

FAN SHROUD

PLASTIC CAPACITOR (5uF/250V)

CAPACITOR COVER

CAPACITOR MOUNT

CONTROL HOUSING

ELECTRONIC CONTROL BOARD

CONTROL PANEL BOARD

SENSOR

THERMISTOR SENSOR

TRANSFORMER

CONTROL HOUSING COVER

POWER SUPPLY CORD

FIX TUBE

LEFT RAIL

RIGHT RAIL

CONTROL PANEL OVERLAY

DISCHARGE GRILLE

DECORATIVE PANEL

REAR PANEL

LEFT SIDE PLATE

RIGHT SIDE PLATE

SOFT PLUG CAP

SCREW-IN PLUG CAP

WASHER

DRAIN PIPE

DRAIN BUCKET

FLOAT

TANK HANDLE

DECORATING TANK FRONT

AIR FILTER

Qty

1

4

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Notes

- 10 -

Page 12

EXPLODED VIEW

D50D, D70D

51

52

43

44

62

42

63

46

16

47

41

54

53

27

26

25

24

23

45

48

49

60

56

61

55

59

58

57

18

22

7

19

21

20

29

28

30

35

36

37

34

31

39

40

38

12

10

11

8

9

3

4

50

15

13

6

5

14

17

32

33

1

- 11 -

2

Page 13

D50D & D70D Ser vice Par ts List

Ref #

1

2

3

4

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

62

63

Friedrich Par t #

D50D

679-041-53

679-042-07

679-041-25

679-041-67

679-041-69

679-041-00

679-041-76

679-041-12

679-041-06

679-041-09

679-041-78

679-041-82

679-041-15

679-041-16

679-041-20

679-041-19

679-041-18

679-041-75

679-041-01

679-041-66

679-041-04

679-041-03

679-041-07

679-041-00

679-041-02

679-041-83

679-041-10

679-041-30

679-041-33

679-041-28

679-041-86

679-041-59

679-041-56

679-041-22

679-041-58

679-041-14

679-041-81

679-041-84

679-041-34

679-041-80

679-041-70

679-041-72

679-041-40

679-041-47

679-041-51

679-041-43

679-041-74

679-041-45

679-041-36

679-041-38

679-042-05

679-042-06

679-041-61

679-041-41

679-041-63

679-041-64

679-041-49

679-042-03

679-042-01

679-041-27

D70D

679-041-53

679-042-07

679-041-26

679-041-67

679-041-69

679-041-00

679-041-76

679-041-12

679-041-06

679-041-09

679-041-78

679-041-82

679-041-15

679-041-16

679-041-20

679-041-19

679-041-18

679-041-75

679-041-01

679-041-66

679-041-04

679-041-03

679-041-07

679-041-00

679-041-02

679-041-83

679-041-10

679-041-31

679-041-33

679-041-28

679-041-87

679-041-59

679-041-56

679-041-23

679-041-58

679-041-14

679-041-81

679-041-84

679-041-34

679-041-80

679-041-70

679-041-72

679-041-40

679-041-47

679-041-51

679-041-43

679-041-74

679-041-45

679-041-36

679-041-38

679-042-05

679-042-06

679-041-61

679-041-41

679-041-63

679-041-64

679-041-49

679-042-03

679-042-01

679-041-27

Descript i on

BASE PAN

CASTERS

COMPRESSOR ASS'Y

COMPRESSOR GROMM ETS

PLATE

MICRO SWITCH

FIXTURE

CAPAC ITOR (40uF/300V)

CAPAC ITOR STRAP

COVER

CONTROL HOUSING

CONTROL HOUSING COVER

ELECTRONIC CONTR OL BOARD

CONTROL PANEL

TRANSFORMER

SENSOR

THERMISTOR SENSOR

FIX METAL

WATER PUMP

GROMMETS FOR PUMP

PUMP HOSE CONNECTOR

PUSH BUTTON SWITCH FOR PUMP

FIX TU BE

MICRO SWITCH

QUICK CONNECTOR FOR PUMP

DRAIN BUCKET COVER

MICRO SWITCH

EVAPO RATOR ASS'Y

CONDENSER ASS' Y

STRAINER

CAPILLARY TUBE

INNER WALL / MOTOR MOUNT

FAN SHROUD

FAN MOTOR

BLOWER WHEEL

PLASTIC CAPACITOR (6uF/250V)

CAPAC ITOR MOUNT

CAPAC ITOR COVER

POWER SUPPLY CORD

FIX TU RE

LEFT RAIL

RIGHT RAIL

REAR PANEL

DISCHARGE GRILLE

CONTROL PANEL OVERLAY

DECORATIVE PANEL

STRIKE

DECORATING PLATE FOR BASE

LEFT SIDE PLATE

RIGHT SIDE PLATE

SCREW IN PLUG CAP

SOFT PLUG CAP

DRAIN BUCKET

DECORATIVE TANK FRONT

FLOAT

FLOAT CAP

TANK HA NDLE

AIR FILTER

DRAIN PIPE

WASHER

Qty

1

4

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Notes

- 12 -

Page 14

Friedrich Air Conditioning Company

P.O. Box 1540

San Antonio, TX 78295

210.357.4400

www.fnedrich.com

DEHUMIDIFIERS

LIMITED WARRANTY

FIRST YEAR

ANY PART: If any part supplied by FRIEDR ICH fails because of a de fect in wo rkmanship or mate rial within twelv e mon ths from

date of o riginal pur chase, FRIE DRICH will re pair the prod uct at no charg e, provid ed the provid ed the produc t is transpor ted to a Friedr ich

Autho rized Serv ice Cent er for reoair. ALL transp ortation charges are the sole respo nsibility of the owner. this remedy is expressl y

agreed to be the exclusi ve r em ed y wi th in t we lv e months from the date of the original purchase.

SECOND THROUGH FIF TH YEAR

SEALED REFRIGERANT SYSTEM: If the Sealed Refrigeration System (defined for this purpose as the compressor, condenser

coil, dehumidifying coil, capillary, filter drier, and all interconnecting tuing) supplied by FRIEDRICH in your dehumidifier fails

because of a defect in workmanship or material within sixty months from date of purchase, FRIEDRICH will pay a labor allowance

and parts necessary to repair the Sealed Refrigeration System; PROVIDED FRIEDRICH will not pay the cost of diagnosis of the

problem, removal, freight charges, and transportation of the dehumidifier to and from the Service Agency, and the reinstallation

charges associated with repair of the Sealed Refrigeration System. All such cost will be the sole responsibility of the owner. This

remedy is expressly agreed to be the exclusive remedy within sixty months from the date of the original purchase.

APPLICABILITY AND LIMITATIONS: This warranty is applicable only to units retained within the Fifty States of the U.S.A., District

of Columbia, and Canada. This warranty is not applicable to:

1.

Air filters or fuses.

2.

Products on which the model and serial numbers have been removed.

3.

Products which have defects or damage which results from improper installation, wiring, electrical current

characteristics, or maintenance; or caused by accident, misuse or abuse, fire, flood, alterations and/or misapplication

of the product and/or units installed in a corrosive atmosphere, default or delay in performance caused by war,

government restrictions or restraints, strikes, matenal shortages beyond the control of FRIEDRICH, or acts of God.

OBTAINING WARRANTY PERFORMANCE: Service will be provided by the FRIEDRICH Authorized Dealer or Service

Organization in your area. They are listed in the Yellow Pages. If assistance is required in obtaining warranty performance, write

to: Room Air Conditioner Service Manager, Friedrich Air Conditioning Co., P.O. Box 1540, San Antonio, TX 78295-1540.

LIMITATIONS: THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES. Anything in the warranty

notwithstanding, ANY IMPLIED WARRANTIES OF FITNESS FOR PARTICULAR PURPOSE AND/OR MERCHANTABILITY

SHALL BE LIMITED TO THE DURATION OF THIS EXPRESS WARRANTY. MANUFACTURER EXPRESSLY DISCLAIMS AND

EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGE FOR BREACH OF ANY EXPRESSED OR

IMPLIED WARRANTY.

NOTE: Some states do not allow limitations on how long an implied warranty lasts, or do not allow the limitation or exclusion of

consequential or incidental damages, so the foregoing exclusions and limitations may not apply to you.

OTHER: This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

PROOF OF PURCHASE: Owner must provide proof of purchase in order to receive any warranty related services.

All service calls for explaining the operation of this product will be the sole responsibility of the consumer.

All warranty service must be provided by an Authorized FRIEDRICH Service Agency, unless authorized by FRIEDRICH prior to

repairs being made.

(2-1 0)

- 13 -

Loading...

Loading...