Page 1

VLSP

.... 2

SE

.... 9

GB

SD230

AV

BPV10

SD230

TAC

AV

BPV10

.... 16

NO

.... 23

DE

.... 30

FR

.... 37

NL

.... 44

ES

.... 51

RU

TAC

Page 2

VLSP

9

GB

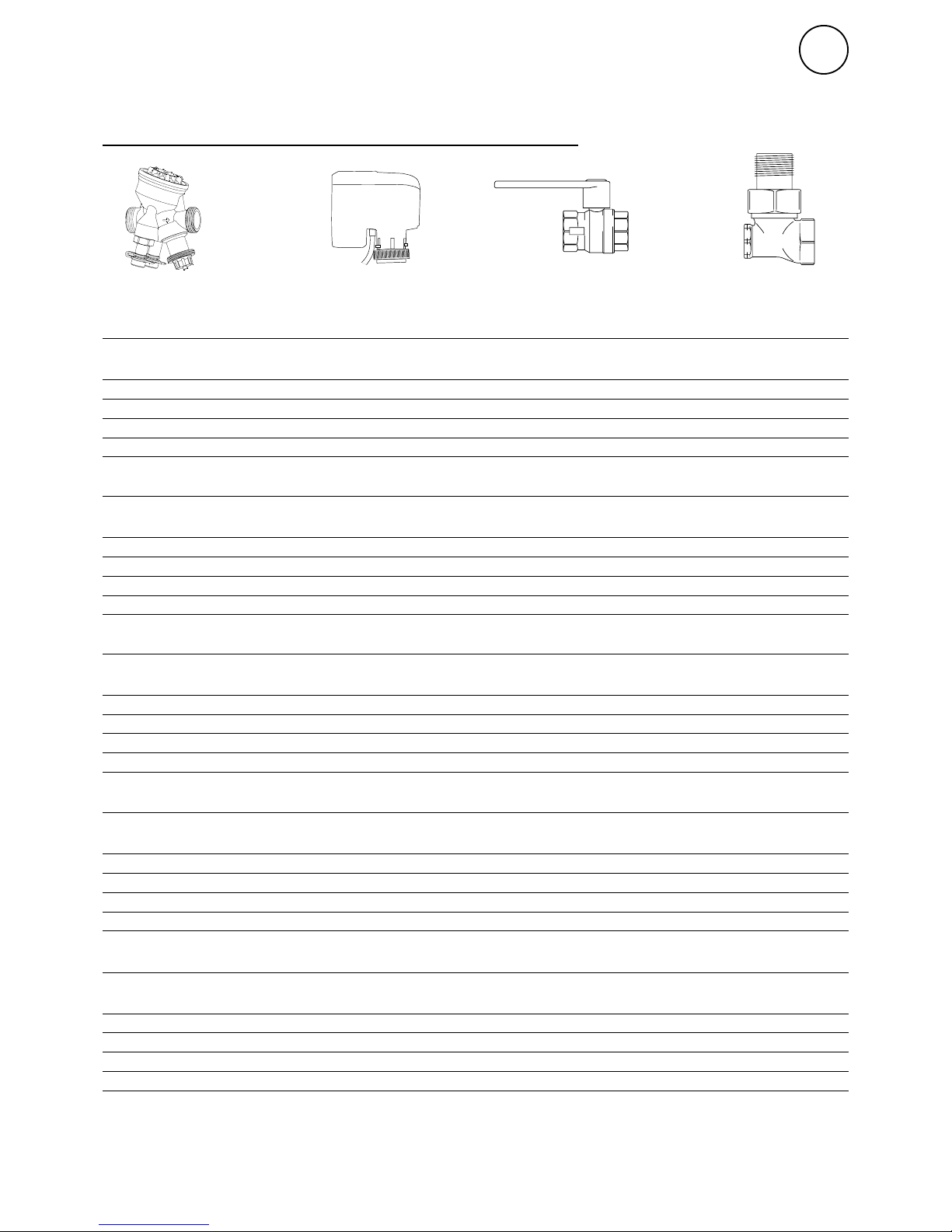

Components

VLSP, pressure independent valve kit on/off

SD230

AV

BPV10

TAC (TA Compact-P)

Type Specification

TAC15LF Two way pressure independent regulation and adjustment valve Low flow, DN15

SD230 Actuator on/off 230V 230V~

AV15 Shut off valve DN15

BPV10 By-pass valve DN10

VLSP15LF

Type Specification

TAC15NF Two way pressure independent regulation and adjustment valve Normal flow, DN15

SD230 Actuator on/off 230V 230V~

AV15 Shut off valve DN15

BPV10 By-pass valve DN10

VLSP15NF

Type Specification

TAC20 Two way pressure independent regulation and adjustment valve Normal flow, DN20

SD230 Actuator on/off 230V 230V~

AV20 Shut off valve DN20

BPV10 By-pass valve DN10

VLSP20

Type Specification

TAC25 Two way pressure independent regulation and adjustment valve Normal flow, DN25

SD230 Actuator on/off 230V 230V~

AV25 Shut off valve DN25

BPV10 By-pass valve DN10

VLSP25

Type Specification

TAC32 Two way pressure independent regulation and adjustment valve Normal flow, DN32

SD230 Actuator on/off 230V 230V~

AV32 Shut off valve DN32

BPV10 By-pass valve DN10

VLSP32

Page 3

VLSP

10

GB

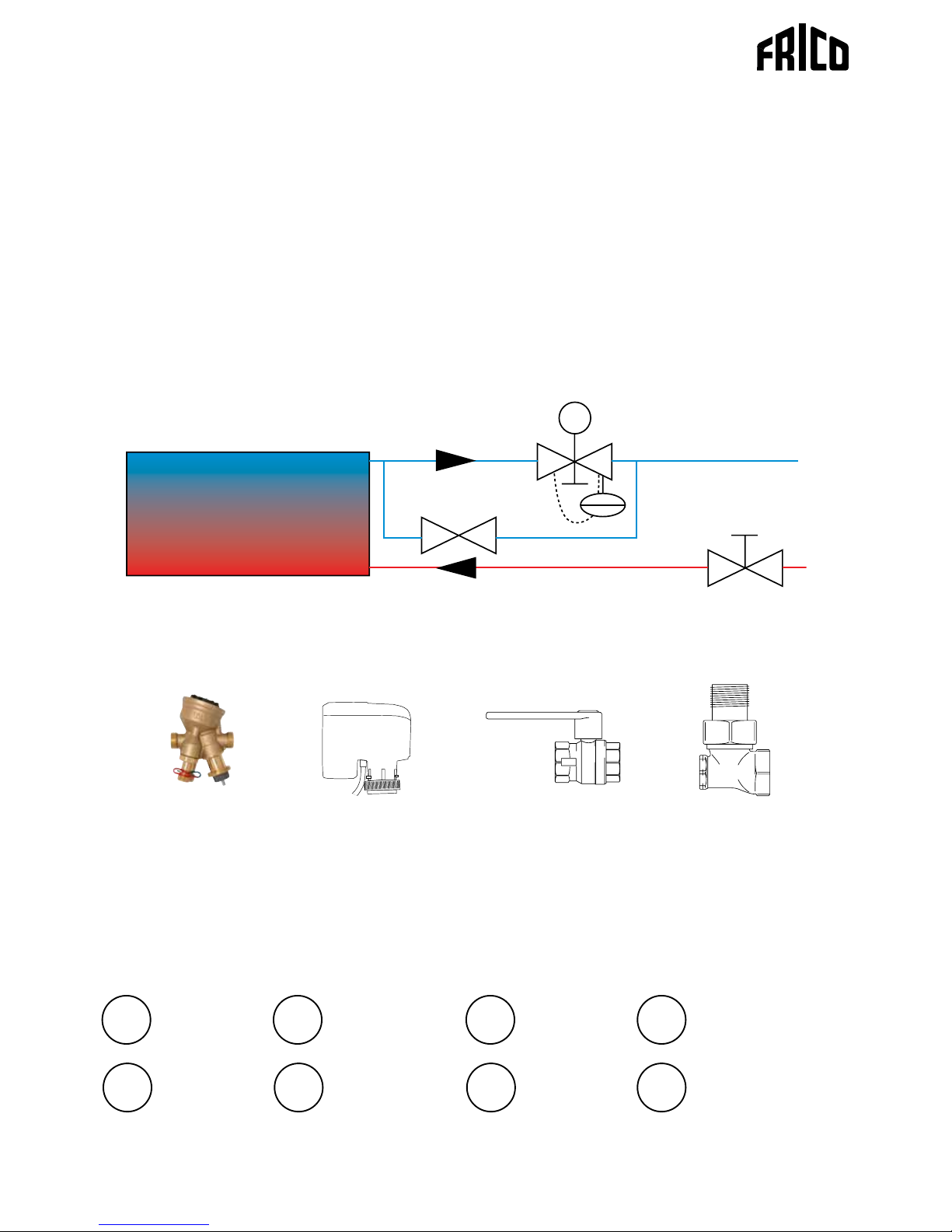

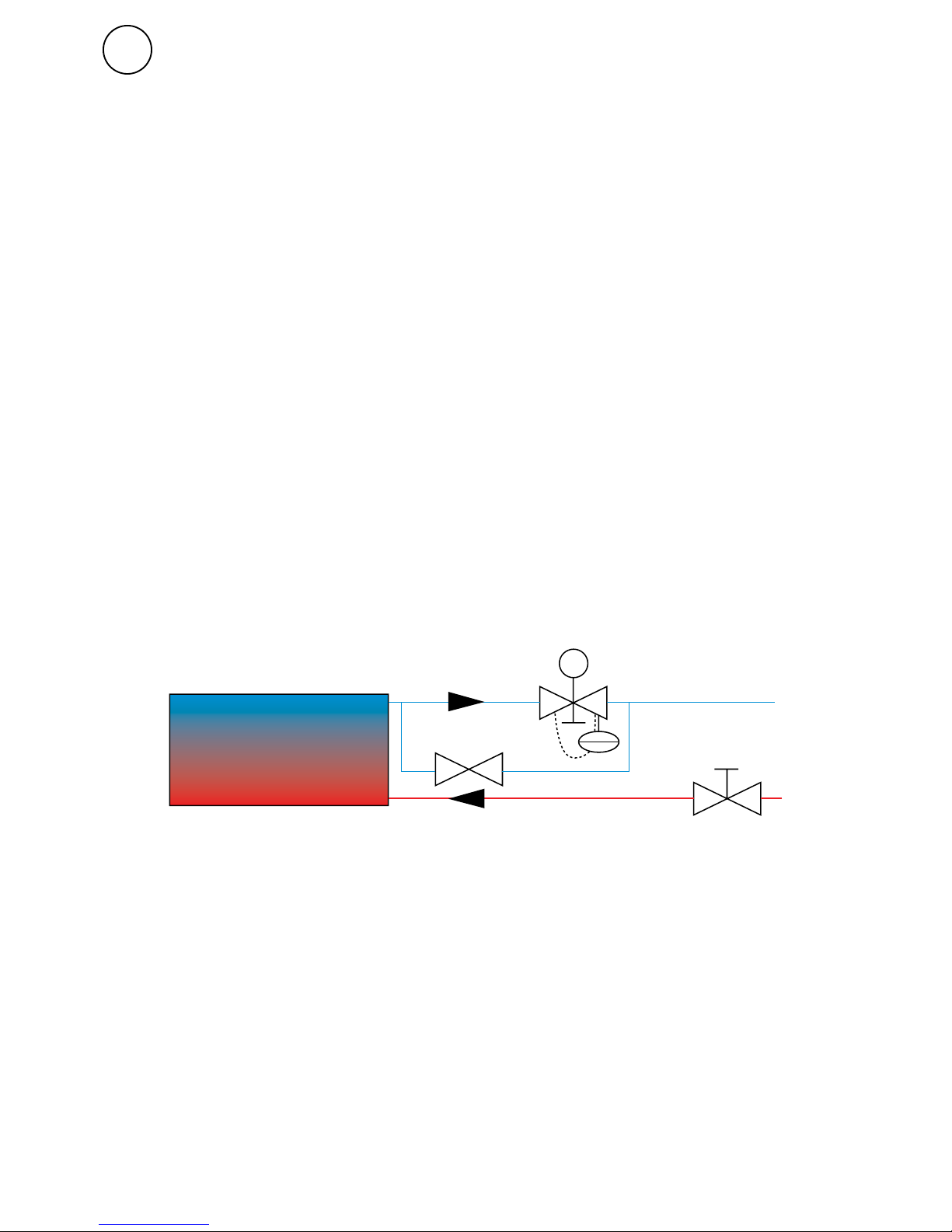

VLSP, pressure independent

valve kit on/off

Two way pressure independent control and

adjustment valve with on/off actuator, shut-off

valve and bypass. DN15/20/25/32. 230V.

The valve set consists of the following:

• TAC, pressure independent regulation and

adjustment valve

• SD230, actuator on/off 230V

• AV, shut off valve

• BPV10, bypass valve

The shut off valve (AV) consists of a ball valve

which is either open or closed and is used to

shut off the flow, when servicing for example.

The regulation and adjustment valve (TAC)

can be used to finely adjust or shut off the

water flow manually. TAC is independent

of the available differential pressure, which

contributes to stable and accurate regulation

(ensures the correct flow to the heater even if

the differential pressure in the rest of the pipe

system changes). The water flow is set using

the gray adjustment knob on the valve

If the valve (TAC) is closed, a low flow

passes through the by-pass valve (BPV10) so

that there is always hot water in the water

coil. This is to provide quick heat supply

when a door is opened but also to provide a

degree of frost protection.

The actuator (SD) controls the heat supply

on/off. In unpowered mode SD230 is open.

The valve set is available in 4 different

valve dimensions, DN15 (1/2"), DN20 (3/4"),

DN25 (1") and DN32 (1 1/4"). The by-pass

valve is DN10 (3/8").

Used with SIRe Basic and Competent or

supplemented with suitable thermostat.

SD230

TAC

BPV10

Page 4

VLSP

11

GB

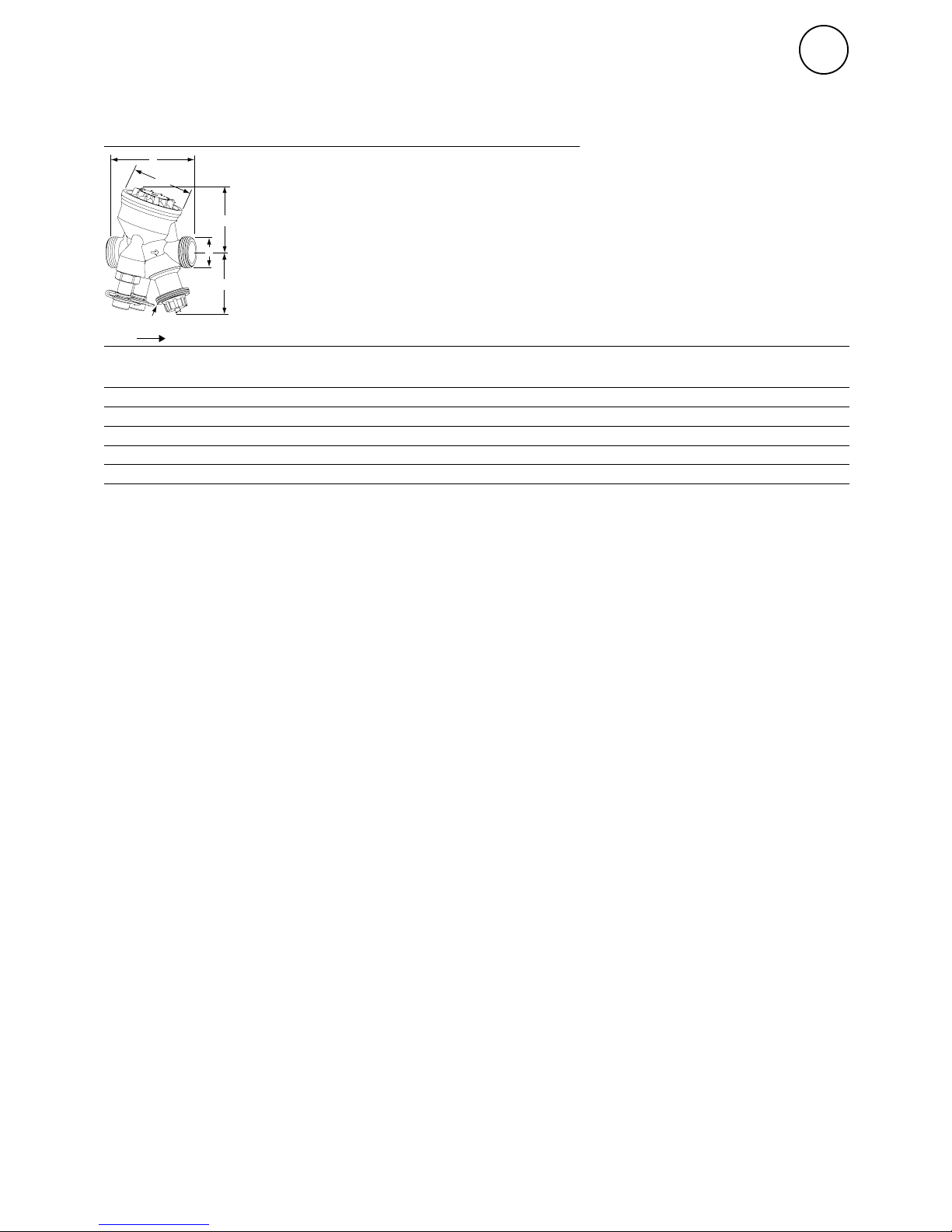

Two way pressure independent regulation and adjustment valve TAC (TA

Compact-P)

Type DN Flow D Da

*1

L

[mm]H1[mm]H2[mm]B[mm]

Vikt

[kg]

TAC15LF 15 Low flow G3/4 M30x1,5 74 55 55 54 0,54

TAC15NF 15 Normal flow G3/4 M30x1,5 74 55 55 54 0,54

TAC20 20 Normal flow G1 M30x1,5 85 64 55 64 0,69

TAC25 25 Normal flow G1 1/4 M30x1,5 93 64 61 64 0,79

TAC32 32 Normal flow G1 1/2 M30x1,5 11 2 78 61 78 1,5

Pressure class: PN16

Max. working temperature: 90 °C

Min. working temperature: 0 °C

Lift: 4 mm

*1

) Connection to actuator.

Dimensions and technical specifikations

Material

AMETAL® is a dezincification resistant alloy.

Media:

Water or neutral fluids, water-glycol

mixtures.

Flow range

:

The flow (q

max

) can be set within the

range:

DN 15 LF: 44-245 l/h

DN 15 NF:88-470 l/h

DN 20: 210-1150 l/h

DN 25: 370-2150 l/h

DN 32: 800 - 3700 l/h

q

max

= l/h at each setting and fully open

valve plug.

Differential pressure (DpV):

Max. differential pressure (DpV

max

):

400 kPa = 4 bar

Min. differential pressure (DpV

min

):

DN15, DN20 = 15 kPa = 0,15 bar

DN25, DN32 = 23 kPa = 0,23 bar

(Valid for position 10, fully open. Other

positions will require lower differential

pressure.)

DpV

max

= The maximum allowed pressure

drop over the valve, to fulfi ll all stated

performances.

DpV

min

= The minimum recommended

pressure drop over the valve, for proper

differential pressure control.

L

D

H2

M30x1.5*

ØB

H1

Da

Valve body: AMETAL®

Valve insert: AMETAL®

Valve plug: Stainless steel

Spindle: Stainless steel

Spindle seal: EPDM O-ring

Dp insert: PPS

Membrane: EPDM and HNBR

Springs: Stainless steel

O-rings: EPDM

Page 5

VLSP

12

GB

Measuring

Measuring q

1. Remove any actuator.

2. Connect IMI TA* balancing instrument to

the measuring points.

3. Input the valve type, size and setting and

the actual flow is displayed.

Measuring DH

1. Remove any actuator.

2. Close the valve according to “Shut-off”.

3. Bypass the Dp part by opening the bypass

spindle ≈1 turn anticlockwise, with a 5 mm

Allen key.

4. Connect IMI TA* balancing instrument to

the measuring points and measure.

Important! Close the bypass spindle after the

measurement is completed.

Leakage rate:

Leakage flow ≤ 0,01% of max. q

max

(setting 10)

and correct flow direction.

(Class IV according to EN 60534-4).

Connection:

Male thread according to ISO 228.

Marking

TA, IMI, PN 16, DN and flow direction

arrow. Grey setting wheel: TA-COMPACT-P

and DN. For low flow version also LF.

Application

The regulation and adjustment valve (TAC)

can be used to finely adjust or shut off the

water flow manually. TAC is independent

of the available differential pressure, which

contributes to stable and accurate regulation

(ensures the correct flow to the heater even if

the differential pressure in the rest of the pipe

system changes). The water flow is set using

the gray adjustment knob on the valve.

Functions

• Control

• Pre-setting (max. flow)

• Differential pressure control

• Measuring (DH, T, q)

• Shut-off

Noise

In order to avoid noise in the installation

the valve must be correctly installed and the

water de-aerated.

* www.imi-hydronic.com/

Page 6

VLSP

13

GB

Setting

1. Turn the setting wheel to desired value, e.g. 5.0.

Sizing

1. Choose the smallest valve size that can

obtain the design flow with some safety

margin, see “q

max

values”. The setting

should be as open as possible.

2. Check that the available DpV is within the

working range 15-400 kPa or 23-400 kPa.

Measuring accuracy

Maximum flow deviation at different settings.

*) Setting (%) of fully open valve.

Shut-off

1. Turn the setting wheel clockwise to X.

0

2

4

6

8

10

12

14

16

18

20

22

24

02040608

0100

[%] *

± %

10 30 50 70 90

q

max

values

1 2 3 4 5 6 7 8 9 10

DN15LF 44 71 97 123 148 170 190 210 227 245

DN15 88 150 200 248 295 340 380 420 450 470

DN20 210 335 460 575 680 780 890 990 1080 11 5 0

DN25 370 610 830 1050 1270 1490 1720 1870 2050 2150

DN32 800 1220 1620 2060 2450 2790 3080 3350 3550 3700

Position

q

max

= l/h at each setting and fully open valve plug.

LF = Low flow

Page 7

VLSP

14

GB

Closing force

Working range: X (closed - fully open) =

11,6 - 15,8

Closing force: Min. 125 N (max. 500 N)

The maximum recommended pressure drop

over a valve and actuator combination for

close off (DpV

close

) and to fulfill all stated

performances (DpV

max

).

kPa*

DN15 400

DN20 400

DN25 400

DN32 400

*) Closing force 125 N.

DpV

close

= The maximum pressure drop that

the valve can close against from an opened

position, with a specified force (actuator)

without exceeding stated leakage rate.

DpV

max

= The maximum allowed pressure

drop over the valve, to fulfill all stated

performances.

Ø22

10

X

M30x1,5

Shut off valve (AV15/20/25/32)

Dimensions and technical specifikations

A

B

C

D

Application

The shut off valve is used to shut off the water

flow to the unit and consists of a ball valve

which is either open or closed. The shut off

valve have no adjustment function and is only

used for maintance and service.

Type DN A

[mm]B [mm]C [mm]D [mm]

Weight

[kg]

AV15 15 119 57 25 57 0,2

AV20 20 130 57 32 70 0,3

AV25 25 140 62 42 85 0,3

AV32 32 178 81 57 104 0,5

Page 8

VLSP

15

GB

By-passvalve (BPV10)

Dimensions and technical specifikations

Type HxWxD

[mm]

Weight

[kg]

BPV10 63x45x28 0,17

Application

The by-pass valve is used when a small

amount flow of water should pass by the unit

at all times. The purpose of this is that the

water should always stay hot in the watercoil,

in cases when a door opens and a quick heat

supply is needed.

This kind of valve has the dimension

DN10 (3/8").

When mounting the plug inside the

valve must be screwed entirely at first

and then screwed back a whole lap. In cases

where the distance between inlet and the

unit is far away, open the plug even more by

screwing the plug backwards.

Actuator (SD230)

Dimensions and technical specifikations

Application

The electrical actuator in combination

with the valve is used for regulating the heat

supply to the unit. It's function is to open or

close the valve (on/off). In unpowered mode

SD230 is open.

The electrical actuator can be mounted and

rotated after that the valve has been installed.

For regulating the actuator in

combination with valve complement with

SIRe or appropiate thermostat.

Action

On/Off-regulation, linear

motion

Supply voltage 230V, 50-60 Hz

Power consumption <1,5 VA in operation

<0,5 VA in the end position

Stroke force 100 N

Stroke length 6,5 mm

Full stroke time "On" Nominal 3 s

Full stroke time "Off" Nominal 12 s

Protection class IP54

Screw-nut M30x1,5

Cable length 1,5 m

Isolation class II

Surrounding temp. 0-60 °C

Type HxWxD

[mm]

Weight

[kg]

SD230 81x88x56 0,2

!

SPST

L

N

BLACK

BROWN

BLUE

max. 40 m

BROWN

BLACK

L

N

BLUE

SPST

CONTROLLER

Page 9

Page 10

Page 11

Main offi ce

Frico AB Tel: +46 31 336 86 00

Box 102

SE-433 22 Partille mailbox@frico.se

Sweden www.frico.se

For latest updated information and information

about your local contact: www.frico.se

Art no: E4593, 20161026 HH

Loading...

Loading...