Page 1

Original instructions

UF600

GB

FR

PL

.... 13

.... 27

.... 43

SE

IT

RU

.... 16

.... 31

.... 47

.... 19

DE

.... 35

NL

Appendix A

.... 51

ES

NO

.... 23

.... 39

Page 2

UF600

GB

SE

DE

ES

FR

The introduction pages consist mainly of pictures. For translation of the

English texts used, see the respective language pages.

Introduktionssidorna består huvudsakligen av bilder. För översättning av de

engelska texter som används, se respektive språksidor.

Die Einleitungsseiten bestehen hauptsächlich aus Bildern. Für die Übersetzung

der verwendeten Texte in englischer Sprache, siehe die entsprechenden

Sprachseiten.

Las páginas introductorias contienen básicamente imágenes. Consulte la

traducción de los textos en inglés que las acompañan en las páginas del

idioma correspondiente.

Les pages de présentation contiennent principalement des images. Pour la

traduction des textes en anglais, consultez la page correspondante à la langue

souhaitée.

IT

NL

NO

PL

RU

Le pagine introduttive contengono prevalentemente immagini. Per le

traduzioni dei testi scritti in inglese, vedere le pagine nelle diverse lingue.

De inleidende pagina's bevatten hoofdzakelijk afbeeldingen. Voor een vertaling

van de gebruikte Engelse teksten, zie de pagina's van de resp. taal.

Introduksjonssidene består hovedsakelig av bilder. For oversettelse av de

engelske tekstene, se de respektive språksidene.

Początkowe strony zawierają głównie rysunki. Tłumaczenie wykorzystanych

tekstów angielskich znajduje się na odpowiednich stronach językowych.

Страницы в начале Инструкции состоят в основном из рисунков, схем и

таблиц. Перевод встречающегося там текста приведен в разделе RU.

2

Page 3

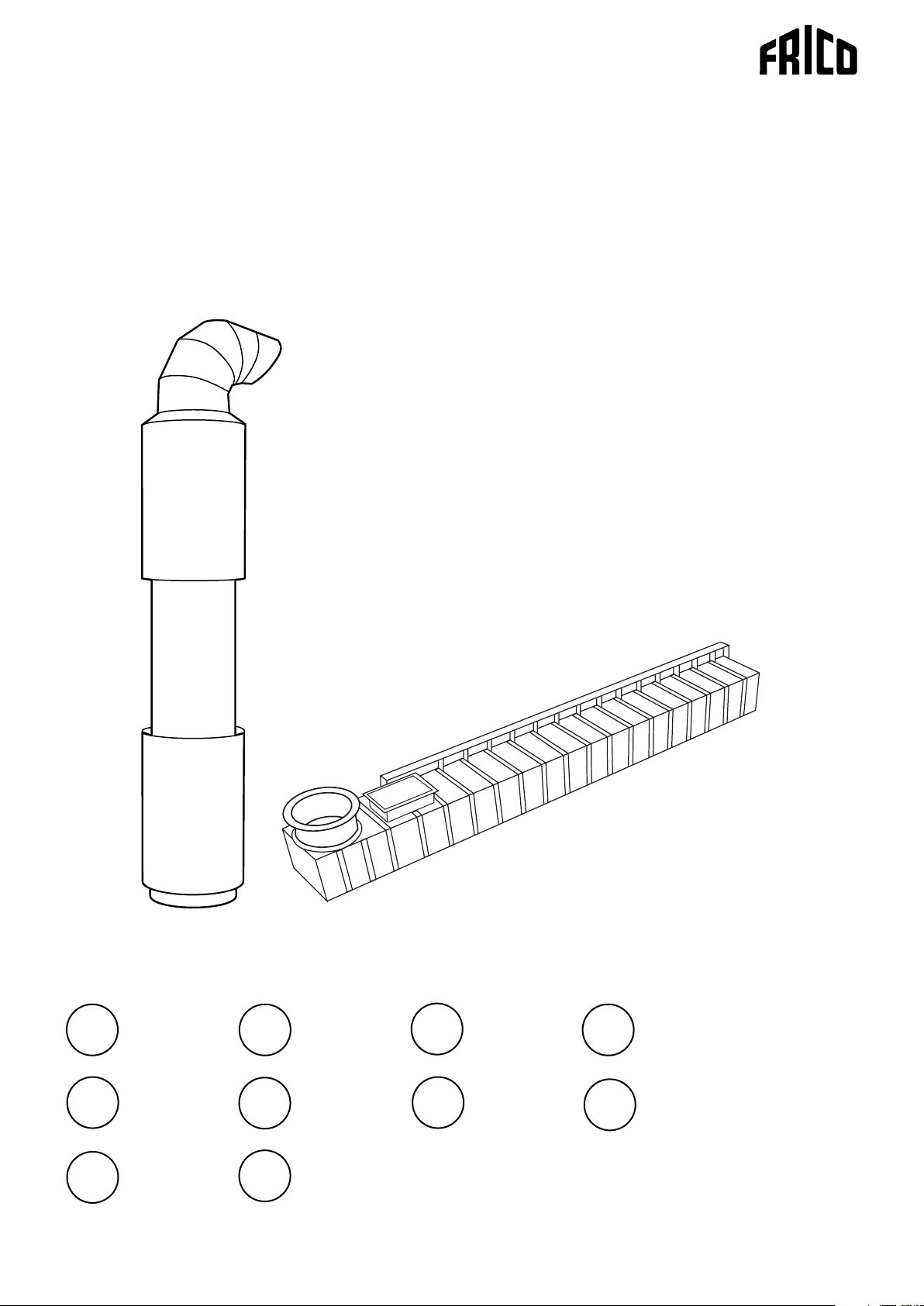

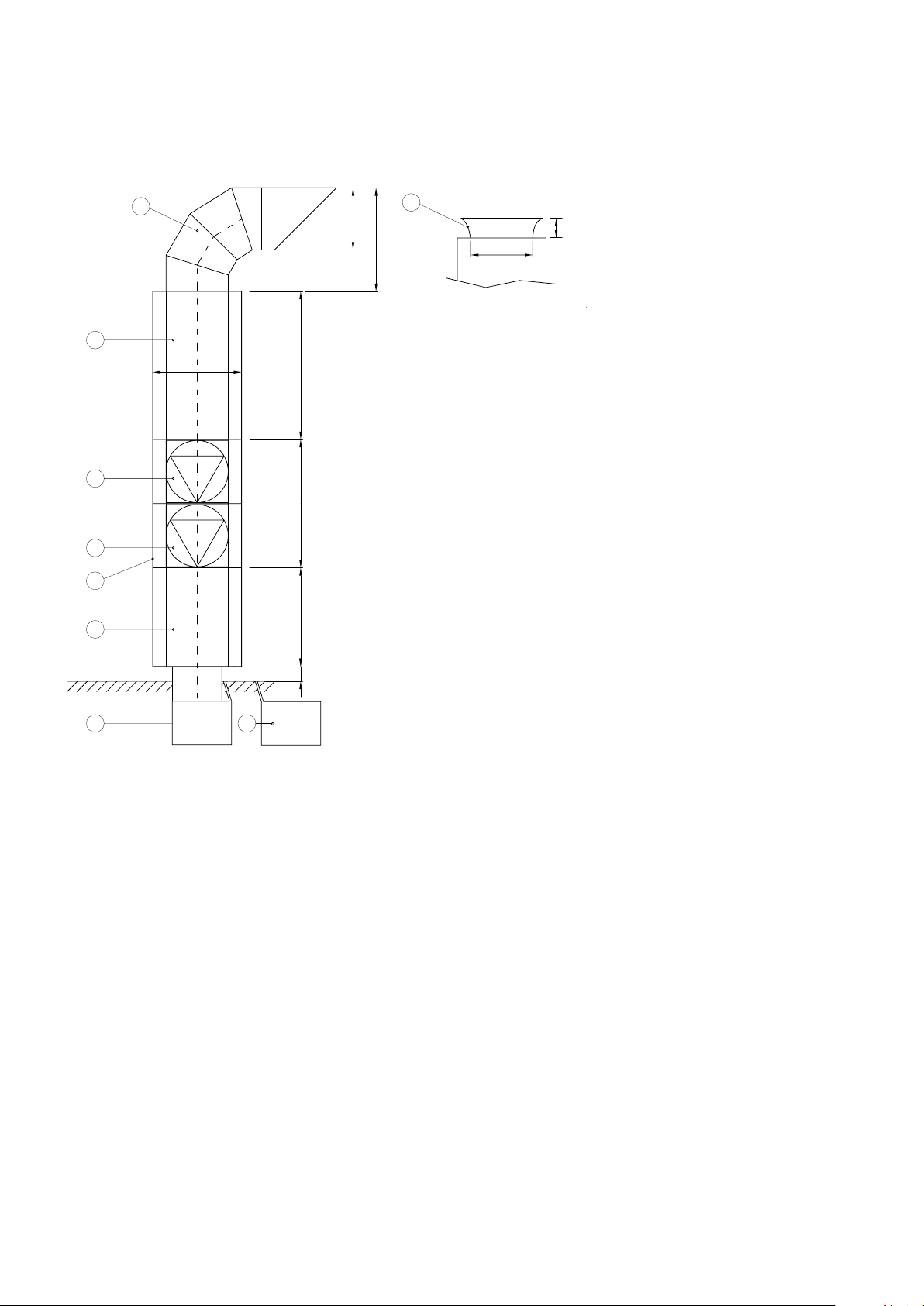

UF600

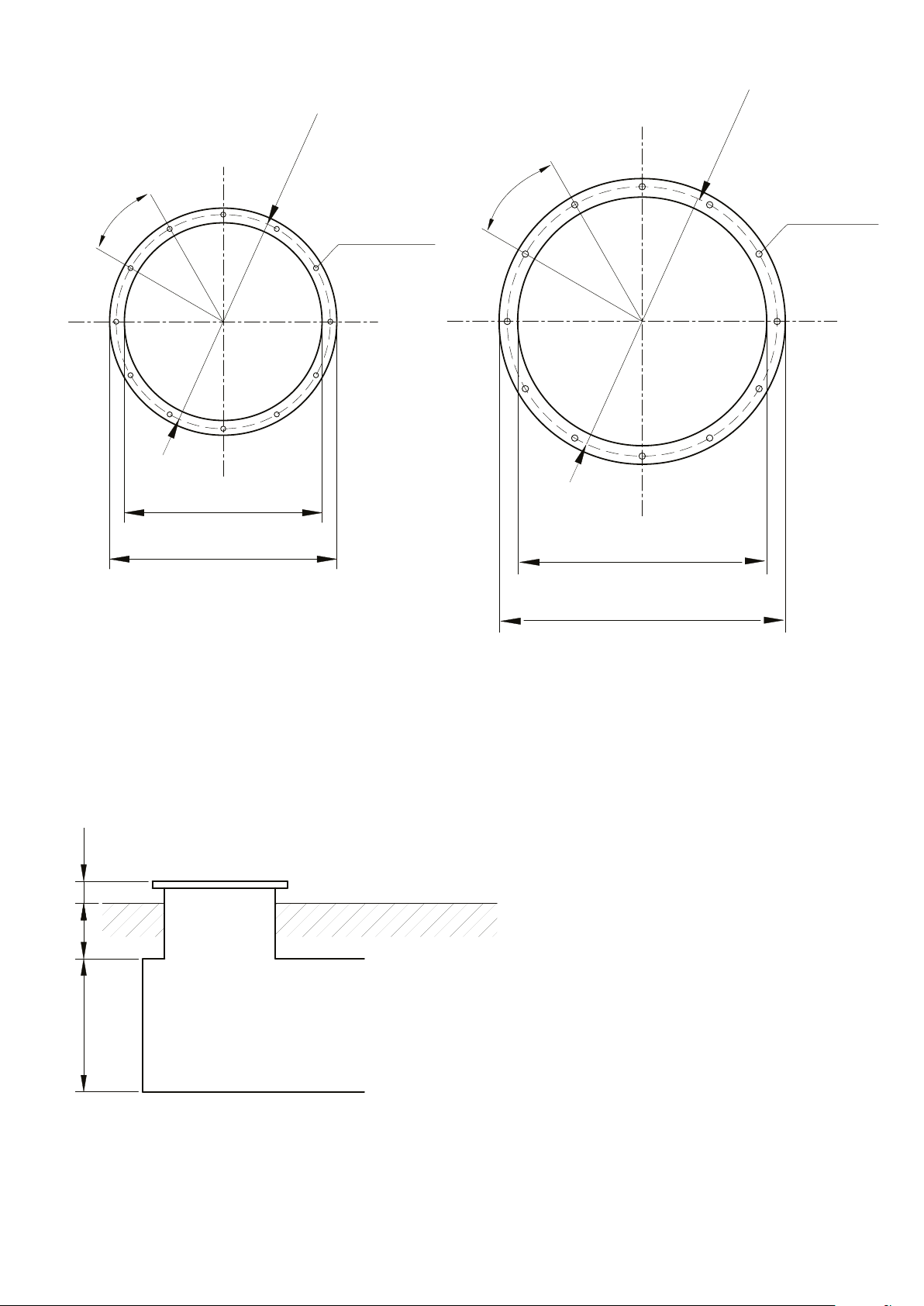

Outdoor installation Indoor installation

1.

500/630

1.

500/630

240/290

810/1015

2.

750/900

14801080/15001000

3.

4.

5.

6.

1. Intake with bird protection grille (or inlet nozzle for

indoor installation)

2. Inlet side silencer

L = 1 480 mm

3. Axial fan 400V

4. Axial fan 400V

5. Motor silencer

6. Silencer pressure side

L = 1 000 mm

7. Floor channel

7.

Outdoor

installation

Fig. 1 Dimensions

150

7.

Indoor installation

3

Page 4

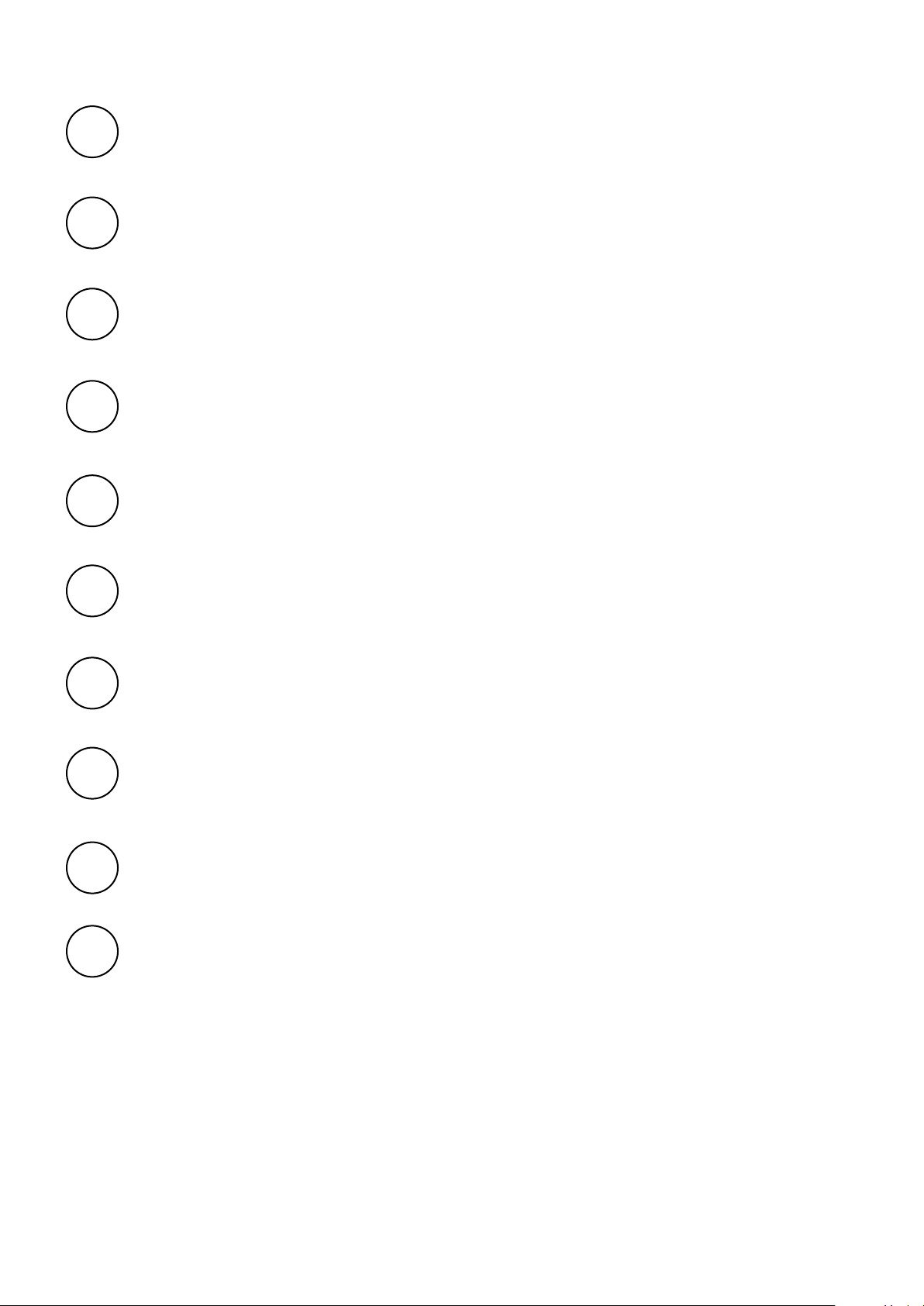

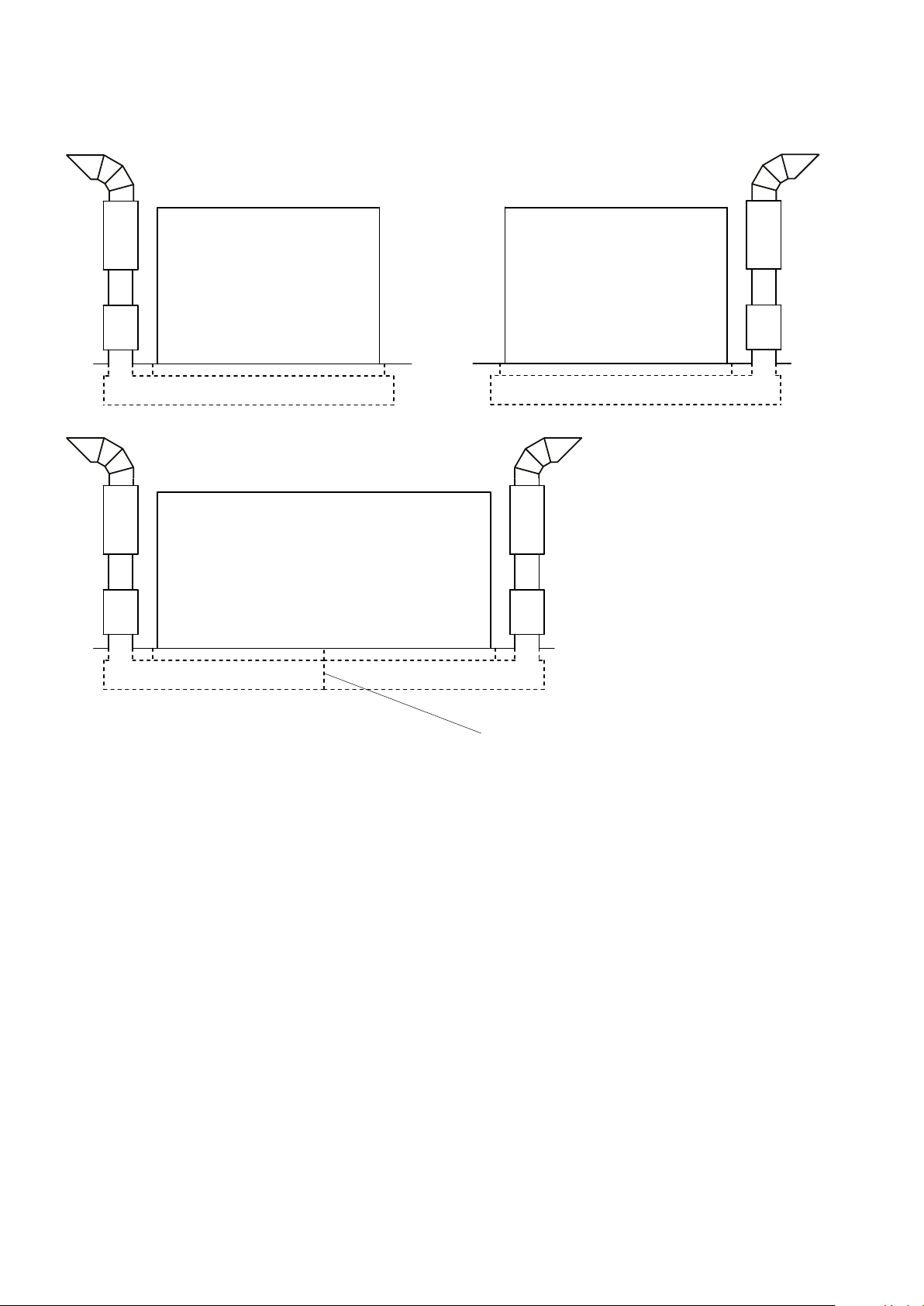

Installation alternatives

UF600

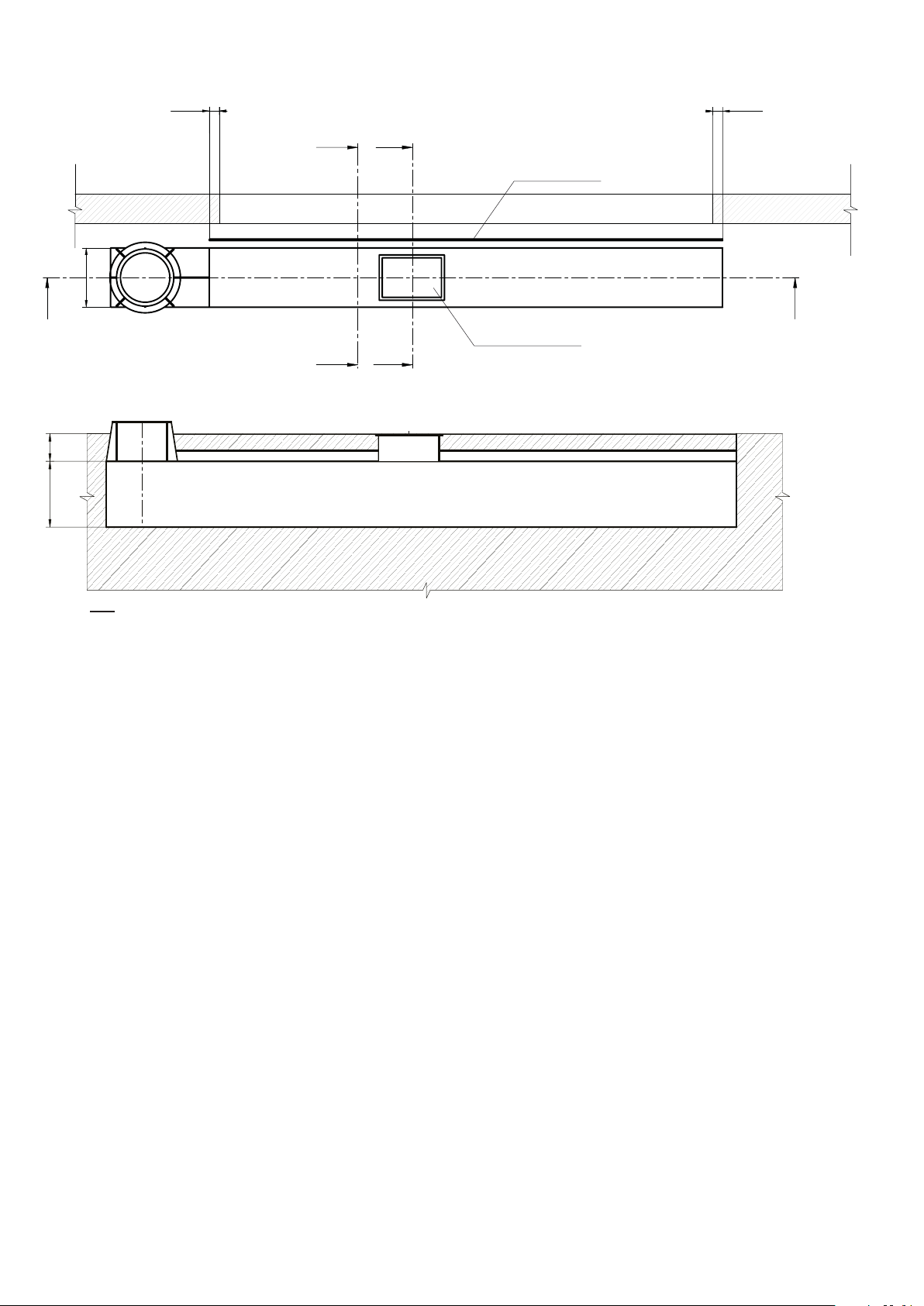

Fig. 2 The positioning of the columns.

Steel wall

4

Page 5

600/750 250

150

Mounting

30°

Ø560

UF600

Ø690

30°

12xØ12mm

12xØ12mm

Fig. 3 Flange sizes

500

590

630

720

Fig. 4 Connection box

5

Page 6

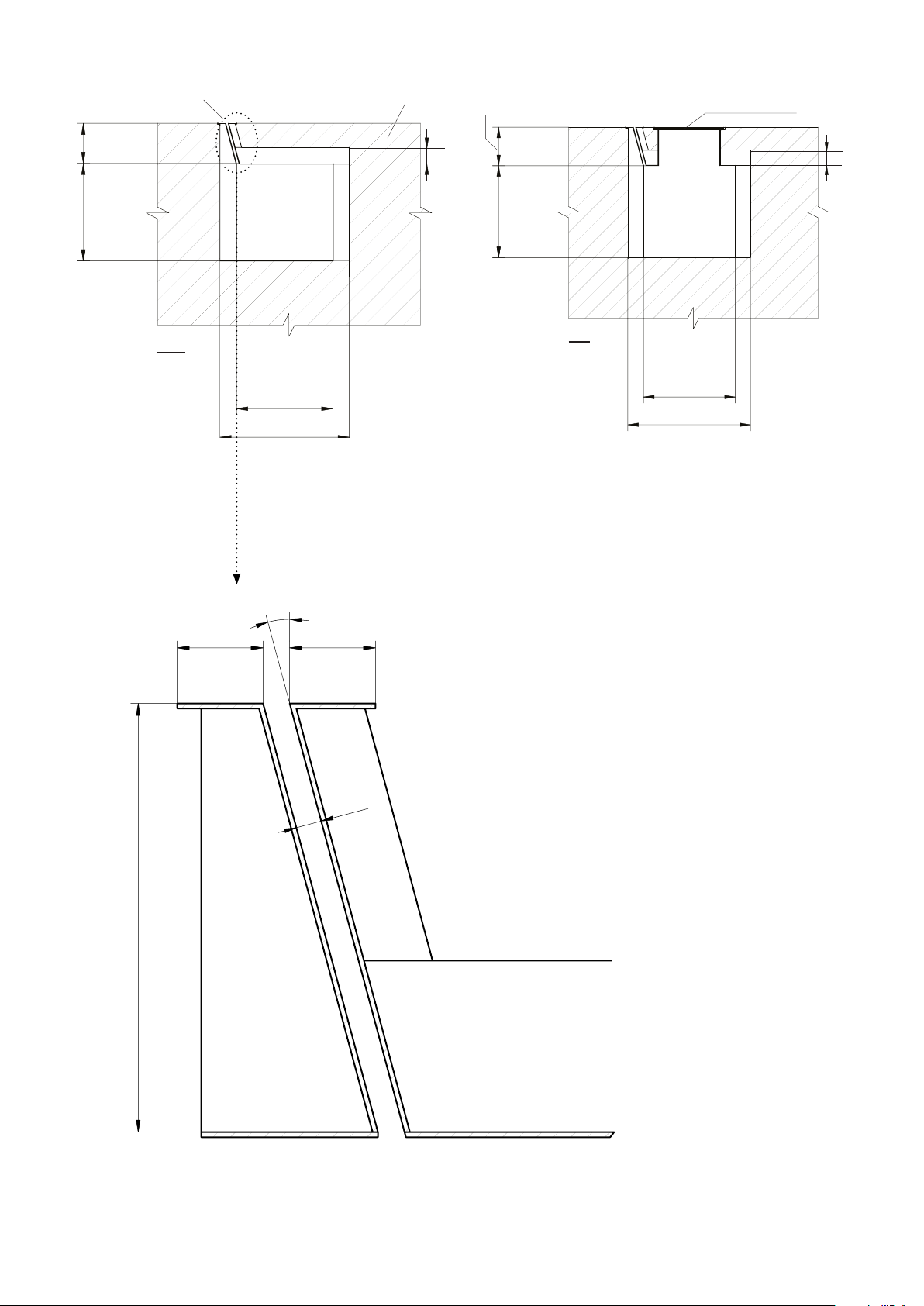

A-A

600

250

Inspection hatch

A

UF600

600/750

150

150

B

B

C

Air outlet slot

A

Inspection hatch

C

Fig. 5.1 Floor channel

6

Page 7

15°

250

Inspection hatch

250

600/750

650/800

B-B

600/750

250

Air outlet slot

Concrete

25

UF600

25

600/750

C-C

600/750

650/800

50 50

Slot width is determined

by Frico.

Fig. 5.2 Floor channel - cross sections

7

Page 8

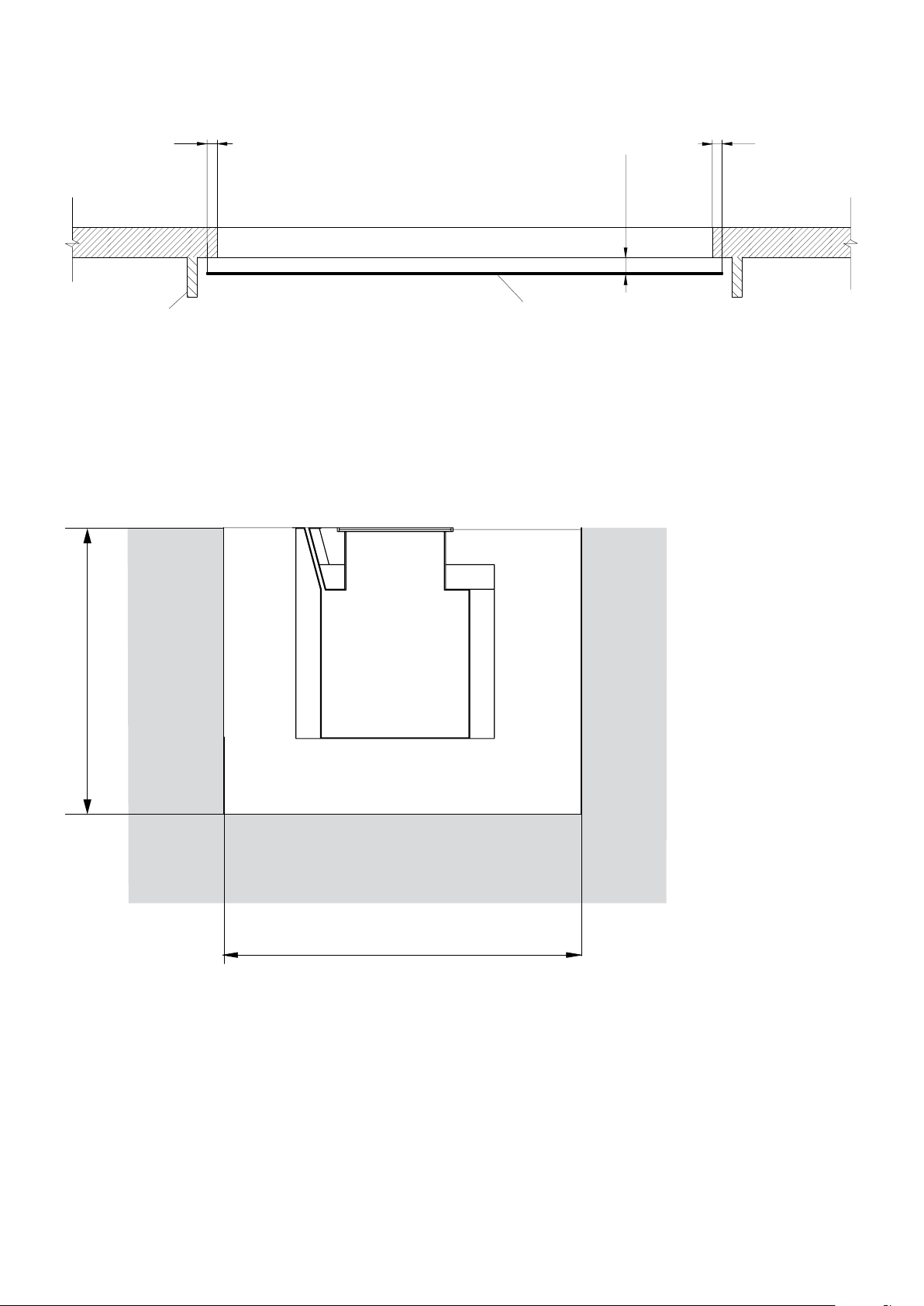

Fig. 6 Air outlet slot

min 150 min 150

x = 250 - 500

Door opening

If x = 300 - 500 => side protection

(If x = 250-300 => no side protection)

Air outlet slot

~1100/1250

UF600

Fig. 7 Pit for embedment

8

~1100/1250

Page 9

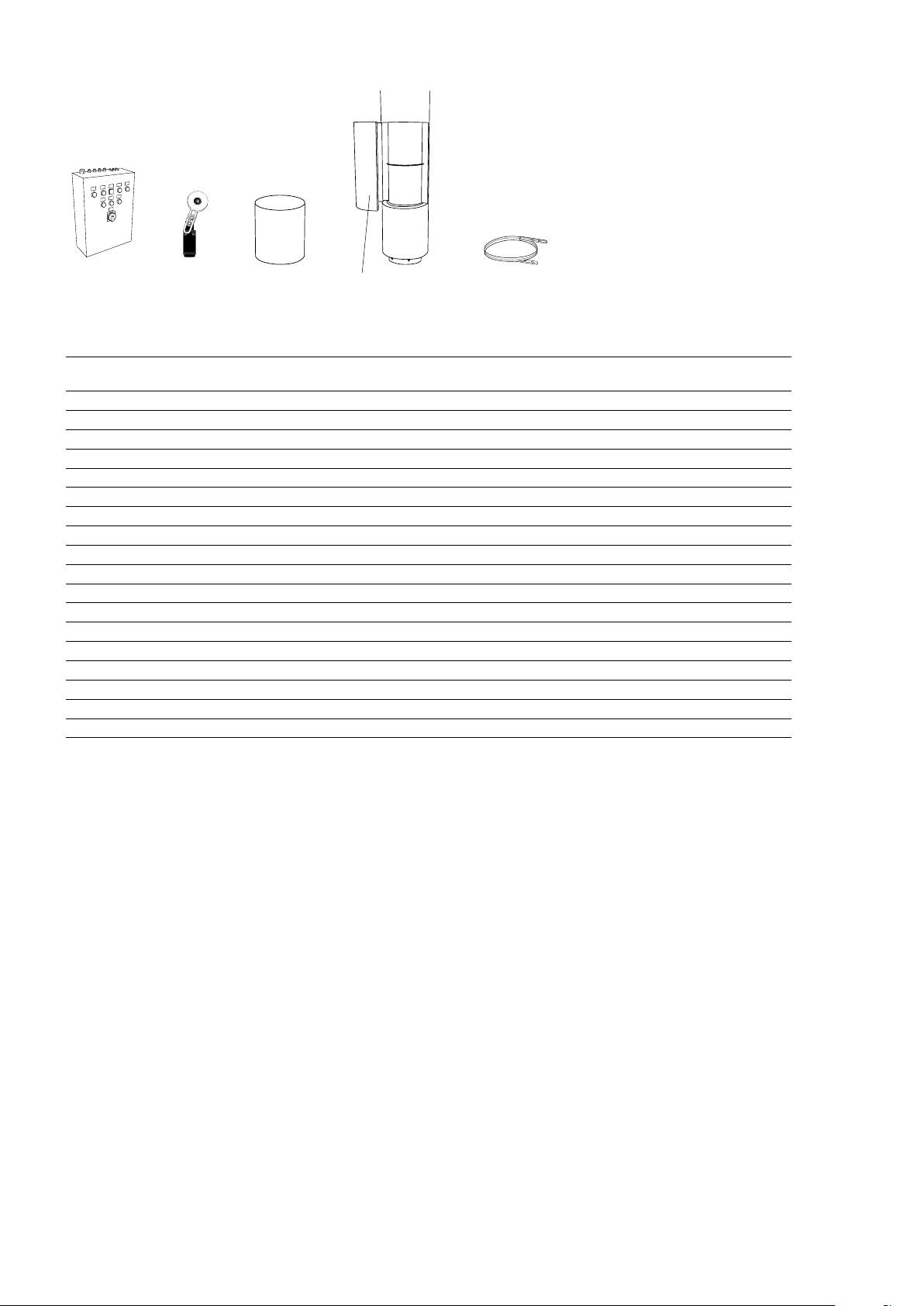

Accessories

UF600

UFC600 AGB304

Type Description HxWxD

UFC601 Control box UF601 600x600x210

UFC602 Control box UF602 600x600x210

UFC603 Control box UF603 600x600x210

UFC604 Control box UF604 800x600x210

UFC605 Control box UF605 800x600x210

AGB304 Position limit switch, IP44

UFEH505 Pillar extension, Ø500 mm, for UF601 L: 500

UFEH510 Pillar extension, Ø500 mm, for UF601 L: 1000

UFEH515 Pillar extension, Ø500 mm, for UF601 L: 1500

UFEH520 Pillar extension, Ø500 mm, for UF601 L: 2000

UFEH605 Pillar extension, Ø630 mm, for UF602-605 L: 500

UFEH610 Pillar extension, Ø630 mm, for UF602-605 L: 1000

UFEH615 Pillar extension, Ø630 mm, for UF602-605 L: 1500

UFEH620 Pillar extension, Ø630 mm, for UF602-605 L: 2000

UFMS750 Motor silencer Ø750 mm, for UF601

UFMS900 Motor silencer Ø900 mm, for UF602-605

UFS750 Securing strip Ø750 mm, for UF601

UFS900 Securing strip Ø900 mm, for UF602-605

UFMSUFEH UFS

[mm]

9

Page 10

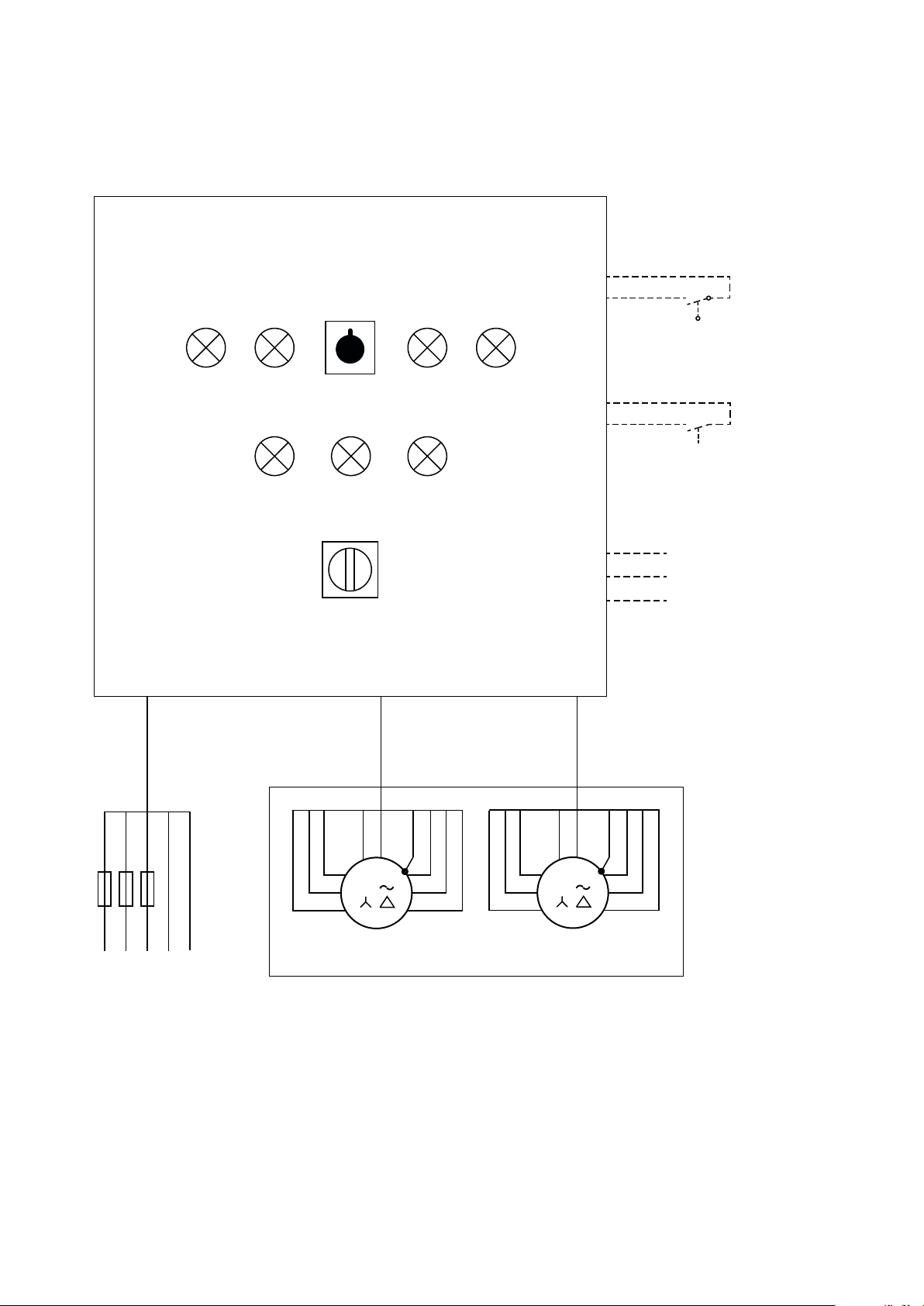

Wiring diagrams UF600

Internal wiring diagram

UF600

UF600

∆-connection

U2 V2

W2

U1 V1

W1

L1 L2 L3 PE

M

~

Y ∆

400V~

Y-connection

U2 V2

W2

TK

U1 V1

TK

TK

L1 L2 L3 PE

W1

TK

TK

TK

∆-connection

U2 V2

W2

U1 V1

L1 L2 L3 PE

W1

M

~

Y ∆

400V~

Y-connection

U2 V2

W2

TK

U1 V1

TK

TK

L1 L2 L3 PE

W1

TK

TK

TK

10

Page 11

UFC600

(Pot. free contact max 5 A)

UF600

UFC600

Fan 1 Fan 2

On FaultOn

Fault

On/Off/Auto

L3L2L1

Main switch

AGB304

Door contact 230V

External

on/off 230V

Alarm

Indication

Common

L1 L2 L3 NPE

400V3~

UF600

TK TK

W1

V1

3

U1

PE

V2

W2

U2

TK TK

W1

V1

3

U1

PE

V2

W2

U2

11

Page 12

Technical specifications

1 Ambient, no heat - UF600 (IP54)

UF600

Type for indoor

installation

UF601 Indoor UF601 Outdoor 2x4 30 400V3~ 2x7,1 600x600 500 750

UF602 Indoor UF602 Outdoor 2x7,5 35 400V3~ 2x13,7 750x750 630 900

UF603 Indoor UF603 Outdoor 2x11 38 400V3~ 2x22 750x750 630 900

UF604 Indoor UF604 Outdoor 2x15 38 400V3~ 2x28,5 750x750 630 900

UF605 Indoor UF605 Outdoor 2x18,5 40 400V3~ 2x33,7 750x750 630 900

*) Depends on the design of the floor channel.

Type for

outdoor

installation

Output

[kW]

Air

velocity*

[m/s]

Voltage

[V]

Amperage

[A]

Dimensions

floor channel

[mm]

Diameter

fans

[mm]

Diameter

silencer

[mm]

Dimensioning

Door width [m]

3 m 4 m 5 m 6 m 7 m 8 m 10 m

3 m UF601 UF601 UF601 UF601

4 m UF602 UF602 UF602

5 m UF603 UF603 UF604 UF605

6 m UF604 UF605 UF605

Door height [m]

Other door sizes on request. For larger openings, two pillars are required. Please contact Frico.

12

Page 13

GB

Assembly and operating instructions

General Instructions

Read these instructions carefully before

installation and use. Keep this manual for

future reference.

The product may only be used as set out in

the assembly and operating instructions. The

guarantee is only valid if the product is used

in the manner intended and in accordance

with the instructions.

Application area and function

UF600 creates a very effective air barrier

when air at high speed is pushed out through

a narrow channel situated in the floor inside

the door opening. An air barrier directed

upwards from the floor gives the best possible

protection against cold air flowing into the

premises.

UF600 consists of a pillar with inlet hood,

silencers and fans, as well as a floor channel

with its slot at floor level. The pillar is placed

outside (or inside) the door on either side of

the opening. The floor channel is cast in floor.

Its width is adapted to the specific door.

Ambient Temperature limits: -20 °C –55 °C.

Protection class: IP54.

Operation

The air is drawn in through the air inlet at

the top of the unit and blown out through

a narrow air outlet slot in the floor. The

air is distributed at high velocity across

the whole doorway, providing a protective

air shield. The air shield minimises cold

draughts and reduces heat loss through

open doorways. The air outlet slot is angled

outwards 15° to achieve the best protection.

För bästa skydd är det lämpligt att ställa in

olika öppningslägen för dörren för att inte

behöva öppna den mer än nödvändigt. The

efficiency of the air curtain depends on

the air temperature, pressure differences

across the doorway and any wind pressure.

NOTE! Negative pressure in the building

considerably reduces the efficiency of the air

curtain. The ventilation should therefore be

balanced.

Mounting - see Appendix A

The UF600 unit is assembled according to this

manual and bolted together with supplied bolt

kit. The floor channel design choosen is cast

into the floor complete with air outlet slot,

inspection hatch and connection box. The air

outlet slot should extend approximately 150

mm outside the door edges. The UF600 unit

is connected to the connection box with the

flange shown in this manual, see fig. 3.

Pillar extension can be ordered as accessory.

The UF600 unit should be fastened in ceiling

or wall to avoid the risk of tipping if the unit

is hit by a vehicle. UF600 should also be

protected with collision protection.

If the air outlet slot is more than 300 mm

away from the door opening the floor channel

should be prolonged or side protection should

be mounted on both sides of the door to

increase air curtain effect. Standard max load

on floor channel is 7 ton, up to 20 ton for

special orders.

Electrical installation

The air curtain should only be wired by a

competent electrician, and in accordance

with the latest edition of IEE wiring

regulations. The connection is via the

terminal box fitted on the outside of the fan

housing.

See wiring diagrams.

Service, repairs and maintenance

For all service, repair and maintenance first

disconnect the power supply.

The level of cleaning can vary depending on

local conditions. Undertake cleaning at least

twice a year.

Periodically check the following according to

official requirements, however at least once a

year:

• Screw connections, specifically the rotor

fitting.

• Is there dirt in the fan wheel? If so, remove

it.

• Have accumulations formed the rotor? If so,

remove them.

• Functions and settings of the control box

UFC600.

Page 14

GB

• Operating current.

• The floor channel should regularly be

cleaned through the inspection hatch.

NOTE! The power supply must always be

disconnected before disassembling any part

of the unit.

Overheating

All motors are equipped with an integral

thermal safety cut-out. This will operate,

stopping the air curtain should the motor

temperature rise too high. The cut-out

will automatically reset when the motor

temperature has returned to within the

motor’s operating limits.

Control box UFC600 is equipped with motor

protection for each one of the fan motors. If

there is an overload the motor protection will

deploy, stopping the air curtain. The motor

protection must be reset manually. If the

motor protection is deployed, please check

the fuses and if the air inlet is blocked.

Trouble shooting

If the fans are not working or do not blow properly,

check the following:

• Operating power supply to the unit;

check fuses, circuit-breaker, time switch/

thermostat (if any) that starts and stops the

unit.

• Functions and settings of the control box

UFC600.

• That the position limit switch is working.

• That the overheat protection for the motors

has not been deployed.

• That the intake grille/filter is not dirty.

• That the air outlet slot is not blocked.

If the fault cannot be rectified, please contact

a qualified service technician.

Start-up current

The external fusing must be adapted to the

motor start-up current.

Safety

- Do not cover surfaces of the air curtain or

obstruct air inlet, as this can cause excessive

temperatures that can be hazardous and may

cause fan motor malfunction.

- Do not block the air outlet slot.

- The air velocity will be too high for people

to go through the air flow. People should not

enter the opening without protection from a

vehicle etc.

Control options

Control box UFC is available as accessory.

Accessories

UFC, control box

Y/D-start with time delay between the motors.

Possibility to use with door switch or position

limit switch or external on/off. Integrated

motor protection for each fan. Alarm and

running indication.

AGB304, position limit switch

Starts the air curtain when the door is

opened and stops it when the door is closed.

Alternating contact 4 A, 230 V~. IP44.

UFEH, pillar extension

For indoor mounting the air intake should

be above the door opening, therefore an

extension of the pillar is sometimes necessary.

This is placed between the inlet hood and the

upper silencer.

UFMS, motor silencer

Additional motor silencer which gives a lower

sound level and a uniform tower.

Drainage

If there is a risk of large amounts of water

running into the floor channel, a drainage

pipe should be connected to the existing 1”

connection (internal thread).

Do not connect the drainage to the sewage

(risk of blowing out water lock).

UFS, securing strip

The securing strip is mounted round the

upper silencer and fixed to the outside wall to

avoid the risk of tipping.

Page 15

GB

Explanation of pages 1-12

Fig. 1 Dimensions

1. Intake with bird protection grille (or inlet nozzle

for indoor installation)

2. Inlet side silencer

L = 1 480 mm

3. Axial fan 400V

4. Axial fan 400V

5. Motor silencer

6. Silencer pressure side

L = 1 000 mm

7. Floor channel

Installation alternatives

Fig. 2 The positioning of the columns

The fan pillar can be positioned on either side

of the door. For large doors, two fan pillars

are often required. They should be positioned

one on each side. When two units are placed

on each side of the doorway, the floor channel

has to be divided by a steel wall in the middle

to prevent the fans from working against each

other.

Mounting

Fig. 3 Flange sizes

The pillar is connected to the connection

box with flange according to the picture. The

UF600 flange comes with Ø12 mm holes.

Fig. 4 Connection box

The connection box is where the pillar is

connected to the floor channel. Please contact

Frico for more information.

Fig. 5, 5.1 Floor channel, - cross sections

The floor channel box is a steel construction

that is cast into the concrete floor. The outlet

opening is at floor level, as close to the floor

opening as possible. The length of the box and

the angle and column width is determined at

the project planning stage.

The channel can be made in one piece or

delivered in sections which are then welded

together on location and include air outlet

slot, connection box and inspection hatch.

Measurements are suggestions. The air outlet

slot should extend minimum 150 mm outside

the door edges on each side. Please contact

Frico for more information.

Fig. 6 Air curtain slot

To compensate for the inward-directed

pressure force, the air curtain slot is directed

at an outward angle of about 15°. The air

curtain slot should be at least 300 mm wider

than the door opening. If the air outlet slot

is more than 300 mm away from the door

opening the floor channel should be prolonged

or side protection should be mounted on both

sides of the door to increase air curtain effect.

Fig. 7 Pit for embedment

Page 16

Appendix A

UF600

51

Page 17

1

UF600

2

52

Page 18

3

4

UF600

5

53

Page 19

6

UF600

7

8

54

Page 20

9

UF600

10

11

55

Page 21

12

UF600

13

56

Page 22

14

UF600

15

16

57

Page 23

17

UF600

18

19

58

Page 24

20

21

UF600

59

Page 25

22

UF600

23

60

Page 26

24

UF600

61

Page 27

Page 28

Page 29

Main offi ce

Frico AB Tel: +46 31 336 86 00

Box 102

SE-433 22 Partille mailbox@frico.se

Sweden www.frico.se

For latest updated information and information

about your local contact: www.frico.se

20170914 HH/LE

Loading...

Loading...