Page 1

Thermozone AC 300

SE

... 12

... 8

NO

FR

... 28

... 24

PL

... 40

... 44

IT

FI

... 20

...16

GB

NL

... 36

... 32

RU

ES

... 48

DE

Page 2

Thermozone AC 300Thermozone AC 300

2

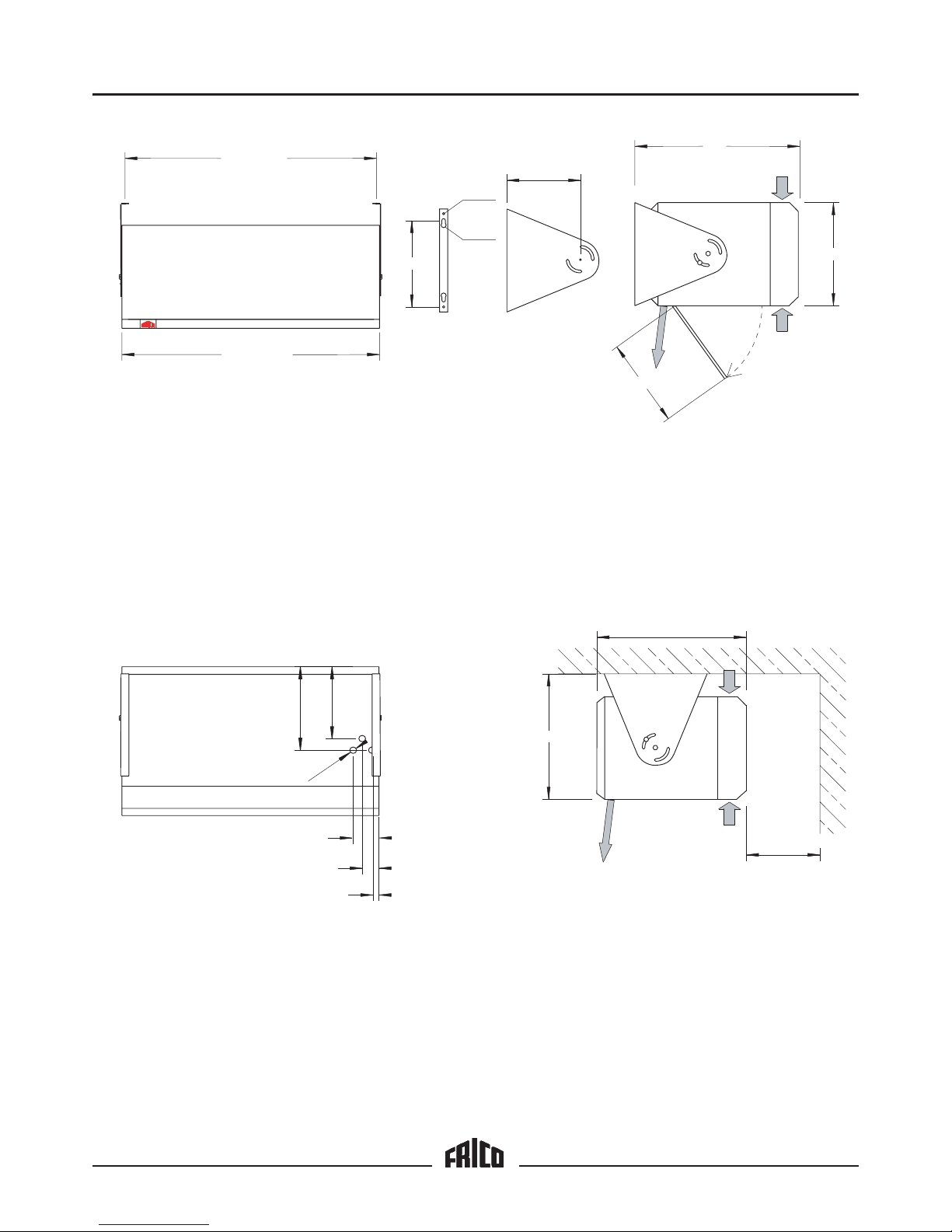

1000 / 1665

335

Ø 11

Ø 20

490

Fig. 1

975 / 1640

640

400

min 300

580

Fig. 3

280

325

24

65

100

3x Ø29

287

Fig.2

360

Thermozone AC 300

Page 3

Thermozone AC 300

3

AC 300

Fig. 4

45

AVMP300

AVMP300

45

AC 300

Thermozone

Thermozone

Page 4

Thermozone AC 300

4

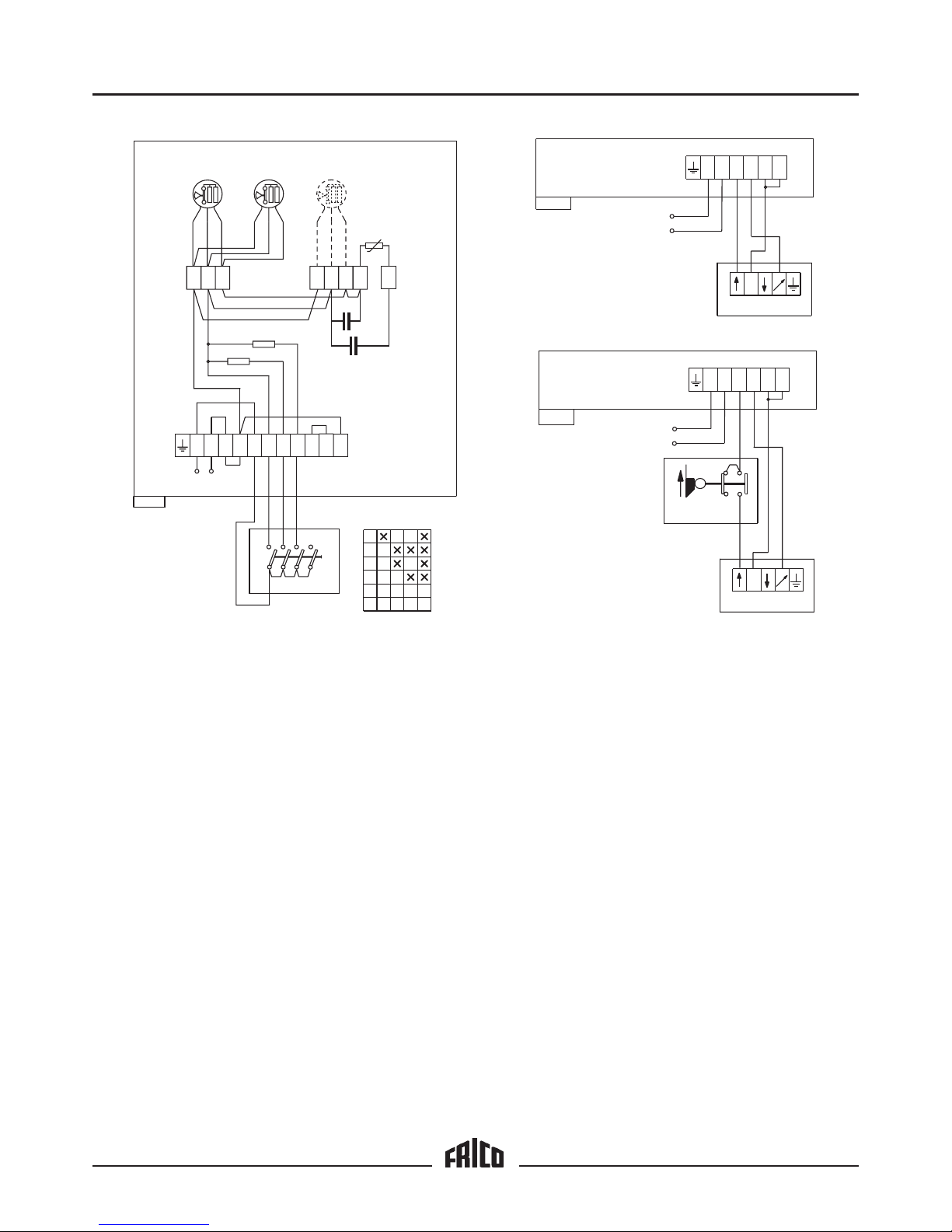

7531

268

ACR 304

0

1357

1

2

3

4

NL

PTC

123456NL

NL

7 8 9

230V~

AC 301, -302 230V~

KS101.1

~

N

2221 AG

AC 301, -302

1234NL

230V~

KS102.2

AGB 304

~

N

2221 AG

AC 301, -302

1234NL

230V~

KS103.2

~

M

˚C

~

M

˚C

~

M

˚C

Page 5

Thermozone AC 300

AC 301, -302

123456NL 9

230V~

AC 301, -302

4569

AC 301, -302

4569

1234

AGB 304

456783

ACR 3042

2

1

KS104.1

5

Page 6

Thermozone AC 300

7531

2468

ACR 304

0

1357

1

2

3

4

5

1

2

6

EV 300

62

13121110

321

400V 3~

LLL

K1

K2

230 V 3~

14

400V 3~ / 230V 3~

AC 308, -312 400V 3(N)~ / 230V 3~

~

M

NL

PTC

123456NL

NL

7 8 9

230V~

1

2

3

2

3

1

Hi

Lo

KRT 2800

KS106.1

~

M

~

M

˚C

˚C ˚C

Diff Hi - Lo 1 - 4 ˚C

˚C

˚C

˚C

6

Page 7

Thermozone AC 300

AC 308, -312

123456NL 7

230V~

AC 308, -312

456

AC 308, -312

456

321

LLL

400V 3~ / 230V 3~

5

1

2

6

EV 300

121314

10

321

LLL

400V 3~ / 230V 3~

121314

10

321

LLL

400V 3~ / 230V 3~

121314

10

1

2

3

2

3

1

Lo

KRT 2800

AGB 304

34 35 36 37 3833

ACR 3042

32

1234

31

KS107.1

Diff Hi - Lo 1 - 4 ˚C

˚C

7

Page 8

Thermozone AC 300

Application area

The Thermozone AC 300 air curtains are

intended for stationary installation above or

at the side of entrance and smaller doors with

a height between 2.5 and 3.5 metres.

The Thermozone AC 300 is supplied with

or without heating elements. Electric heat

can be added to units without heat

afterwards.

The efficiency of the air curtains is

dependent on the difference of air pressure

and temperature (between the rooms that are

separeated by the air curtain) and pressure

caused by wind.

The protection class of AC 300 is IP 24,

drip-proof design.

Operation

The air is drawn in from the upper and under

side of the unit and is blown out at high

velocity across the doorway, providing a

protective air shield. The air shield

minimizes heat and cold air leakage.

When mounted on supplied brackets, the

units can be directed with regard to the size

of load on the door in question. The more

load caused by negativ pressure, temperature

differences and wind, the more should the air

stream be directed outwards.

The air flow is adjusted with a selector

(ACR304 eller ACR3042) to provide maximum protection to the opening.

Units with electric heat can be regulated

with the output selector EV300 in 3 stages

(0 - 1/2 - 1/1) and with a 2-stage thermostat,

KRT 2800.

NOTE! Air pressure imbalance between

rooms separated by air curtains, considerably

reduces the efficiency of the air curtain. The

ventilation should therefore be balanced!

Mounting

a) Above the doorway

• The unit is usually mounted inside the

doorway as close to the opening as

possible with the nozzle closest to the

opening.

• When used above interior freezer doors,

the unit should be mounted on the warm

side.

• To minimize air leakage between the units,

they should be mounted close to each

other. To reach the wall mounting

screws, a min gap of 50 mm between the

units is required.

• Attach the two (2) wall mounting brackets

securely to the wall or suitable structure.

Attach the air curtain to the brackets

(Fig.1). The units are secured with M10screws in the centre hole of each bracket

and in one of the notches, thus allowing

the whole unit to be turned and the angle

of the air stream to be adjusted.

• Observe the minimum distances given in

fig.3 and also that the units may not be

mounted directly below a power outlet.

b) Standing at the side of the doorway

• When space above the doorway is

limited, the units can be mounted standing

beside the opening, thus creating a sideblowing air stream (fig.4). Mounting plates

AVMP300 are mounted between units and

between the lowest unit and the floor.

• The units are mounted vertically inside the

doorway as close to the edge of the

opening as possible with the nozzle

closest to the opening.

• The mounting plate consists of two parts.

The outer one is secured in the floor (or at

the top of the lower unit) with the supplied

screws. The units are secured with M10screws in the centre hole of each bracket

and in one of the notches, thus allowing

the whole unit to be turned and the angle

of the air stream to be adjusted. The inner

part is mounted on the under side of unit

that is standing on the floor. The plate is

secured with 3 M10-screws in the

prepared screw holes.

• Lift the unit on to the plate and screw the

plates together. Maximum building height

for vertical units is 3.5 metres.

• At the end of the uppermost unit, one of

the supplied mounting consoles (or other

suitable strut) is mounted and then

attached to the wall in order to secure the

top of the tower.

• We recommend that the collision

protection AXP300 is mounted to prevent

the units from being hit by trucks and

similar.

• Mount the air flow selector ACR304 or

ACR3042 withing easy reach for

controlling the air curtains.

• To control units with electric heat, the

output selector EV300 is mounted in

conjunction with the speed selector and a

thermostat (for ex. KRT2800), in such a

place that changes of the temperature

close to the opening, can be quickly

detected.

Installation and Operating Instructions

GB

20

Page 9

Thermozone AC 300

• When mounting vertically, draught can

occur due to rotating air. The mounting of

a narrow wall at the side of the opening

(the side where no units are mounted),

can decrease the rotation.

Electrical installation

The electrical installation should be carried

out by a qualified electrician in conformity

with prevailing regulations. The appliance

should be preceded by a triple pole switch

with at least 3 mm breaking gap.

Different alternatives for air flow

regulation are possible, see wiring diagram

pages 4-7.

The hatch on the underside of the unit is

opened by turning the locking pins 1/4 of a

lap. The connection should be made with a

cable type S05VV-U, A05VV-R or similar.

On the upper side of the unit there are

knock-outs, 2 pcs ø 37 mm and 3 pcs ø 29

mm. The cable-glands used must guarantee

the protection class requirements!

Type Power Voltage Min. area

kW V mm

2

All control 230V 1,5

AC 308 8 230V 3~ 4

AC 308 8 400V 3~ 2,5

AC 312 12 230V 3~ 10

AC 312 12 400V 3~ 4

For the units with electrical heating, the

power and voltage should be supplied in

different connection areas (see wiring

diagram).

In the distribution board it is to be

indicated that ”the air curtains can be

supplied from more than one connection”.

Adjusting the unit and the air stream

Direction and speed of the air stream should

be adjusted with regard to the load on the

door. Pressure forces the air stream to bend

towards the interior of the room (when the

room is heated and the outside is cold). To

withstand the load, the air stream should be

directed outwards. An angel up to 15° can be

recommended. The more load caused by

negativ pressure, temperature differences

and wind, the more should the air stream be

directed outwards.

A baffle on each side of the doorway will

improve the efficiency of the air curtains.

When used above freezer or cooler doors,

the units should be mounted on the warm

side with the air stream directed 0-10°

towards the warm side.

Basic air flow settings

The air flow is set with the air flow selector

so that the speed of the air is 3-4 m/s 1 m

above the floor. The direction of the air

stream and the air speed may need to be

adjusted more exactly depending on the

load on the door.

Trouble shooting

If the fans stand still, check the following:

a) Power supply; check fuses, circuit-breaker,

time switch (if any) that starts and stops

the unit.

b) That the air flow selector is correctly set.

c) That the position limit switch is working

(if any).

If the error cannot be fixed, please contact

qualified service technician.

If there is no heat, check the following:

a) Power supply to electric heater; check

fuses and circuit-breaker (if any).

b) Thermostat settings and actual

temperature.

c) That the output selector (if any) is set

correctly.

d) That the overheat protection has not

been released. If so, please check

description on next page.

Overheating

(applies to units with electric heat)

The Thermozone is equipped with an

overheat protector. If it is released due to

overheating, reset as follows:

a) Disconnect the electricity with the fully

isolated switch.

b) Investigate the matter and repair the

fault.

c) Reset is performed as follows:

• Dismount the service hatch on the

underside of the unit.

• Locate the red buttons.

• Press the buttons until a click is heard

(you do not need to press them

simultaneously).

d) Connect the Thermozone again.

If the error cannot be fixed, please contact

qualified service technician.

GB

21

Page 10

Thermozone AC 300

Security

• Ensure that the area around the intake and

exhaust grille is kept free from material

which could prevent the air to flow through

the unit!

• During operation the surfaces of the unit

are hot!

• The unit must not be covered fully or

partially with clothes, or similar materials,

as overheating can result in a fire risk!

Maintenance

NOTE! Disconnect electricity prior to cleaning

or inspection (units with electric heat can be

supplied from more than one connection).

The fan motors and the other components

require no maintenance other than cleaning

when necessary, however at least once year.

Grille, impeller and elements are vacuum

cleaned or dried clean with a damp cloth.

Open the inspection hatch to reach elements

and impellers.

Safety cut-out

(applies to units with electric heat)

If the installation is protected by means of a

safety cut-out, which trips when the appliance

is connected, this may be due to moisture in

the heating element. When an appliance

containing a heater element, has not been

used for a long period and is stored in a

damp environment, moisture can enter the

element. This should not be seen as a fault,

but is simply rectified by connecting the

appliance to the mains supply via a socket

without a safety cut-out, so that the moisture

can be driven out of the element.

The drying time can vary from a few hours

to a few days. As a preventive measure the

Thermozone should occasionally be run for a

short time when it is not being used for an

extended period of time.

The garantee is only valid if the

Thermozone units are used in the manner

intended by the manufacturer and in

accordance with the installation and

maintenance instructions.

GB

22

Manufacturer

Our products are manufatured in accordance

with applicable international standards and

regulations.

Frico AB

Box 102

SE-433 22 PARTILLE

SVERIGE

The manufacturer hereby declares that the

following products

AC301, AC302, AC308, AC312,

comply with the following EC-directives.

EC Declaration of Conformity

Defined by the EC Low Voltage Directive

73/23/EEC.

The following harmonised standards are in

use:

SS-EN 60 335-1: 1988, A2, A5, A6,

A51- A54, A56

SS-EN 60 335-2-30: 1992, A51, A52

Complete technical documentation is

available.

EC Declaration of Conformity

Defined by the EC Electromagnetic

Compatibility Directive 89/336/EC och

92/31/EC.

The following harmonised standards are in

use:

SS-EN 50 082-1: 1992

SS-EN 60 555-2/3: 1991

Complete technical documentation is

available.

Partille, 19 januari 1998

Mats Careborg

Technical Manager

Page 11

Thermozone AC 300

Type AC301 AC302 AC308 AC312

Power [kW] 0,4 0,6 8 12

Voltage, motor / manouvre [V] 230~ 230~ 230~ 230~

Voltage, heat output [V] - - 400V3~ 400V3~

Amperage, motor / manouvre [A] 1,6 2,4 1,6 2,4

Amperage heat output [A] - - 11,5 17,3

Air flow [m

3

/h] 900 / 1800 1300 / 2700 900 / 1800 1300 /2700

Temperature rise of passing

air at full output [°C] - - 27 / 13 27 / 13

Sound level [dB(A)] 44 / 62 45 / 63 44 / 62 45 / 63

Weight [kg] 39 57 44 64

Length [mm] 1000 1670 1000 1670

Protection class IP 24 IP 24 IP 24 IP 24

Accessories Type Measures (BxLxD)

Air flow selector (4-step)*

1

ACR 304 80x100x90 mm

Air flow selector high/low *

1

ACR 3042 150x200x105 mm

Air flow regulator (stepless), AC 301-302 *

2

2221AG 85x170x63 mm

Output selector 0 – 1/2 – 1/

1

EV 300 80x100x90 mm

Position limit switch AGB 304

2-step thermostat KRT 2800 60x165x60 mm

Mounting plate for vertical mounting AVMP 300

False ceiling grille (1192 x 192) 22003

False ceiling grille (1515 x 192) 22004

*1 Regulation for a max of 5 units

*2 Regulation for a max of 2 units

23

GB

Page 12

Thermozone AC 300

Main office

FRICO AB Tel: +46 (0)31 336 86 00

Box 102 Fax: +46 (0)31 26 28 25

S-433 22 Partille e-mail: mailbox@frico.se

SWEDEN http://www.frico.se

Norway

FRICO AS

Postboks 82, Alnabru Tel: +47 (0)2 272 38 44

N-0614 Oslo Fax: +47 (0)2 272 38 39

NORWAY e-mail: mailbox@frico.no

http://www.frico.no

France

FRICO FRANCE Tel: +33 (0) 4 72 42 99 42

7, rue de la libération Fax: +33 (0) 4 72 42 99 49

F-69 270 Fontaines sur Saone e-mail: info@frico.fr

FRANCE

Russia

FRICO representative office in Russia

1 st Golutvinsky per., 3 Tel/Fax: +7 095 238 63 20

Moscow 109180 e-mail: frico@trankm.ru

RUSSIA

Artno. 201401 01-01-17

For latetest updated information, see: www.frico.se

Loading...

Loading...