Frico Thermocassette HP Series, Thermocassette HP300, Thermocassette HP600, Thermocassette HP305, Thermocassette HP605 Mounting And Assembly Instruction

Page 1

Thermocassette HP

.... 6 ... 14.... 10 .... 12

... 16

FI

GB

RU

.... 8

... 18

FR NO DE SE

Page 2

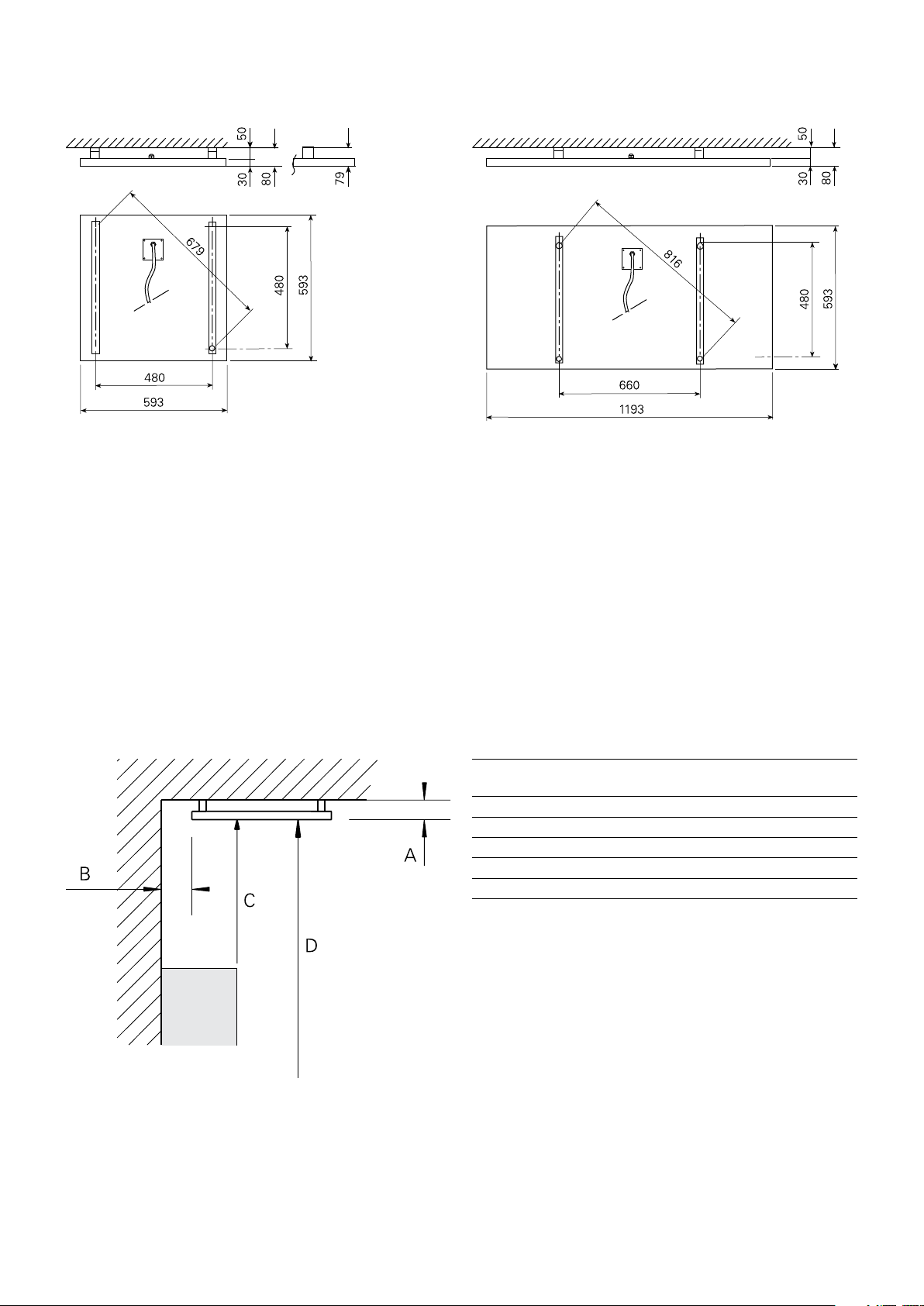

Thermocassette HP

HP305

False ceiling

HP300/600

HP605

Minimum mounting distance

Fig. 1: Minimum mounting distance

Ceiling 80

Wall, long side of the unit 50

Wall, short side of the unit 50

Obstacle 500

Floor 1800

Min.distance

[mm]

2

Page 3

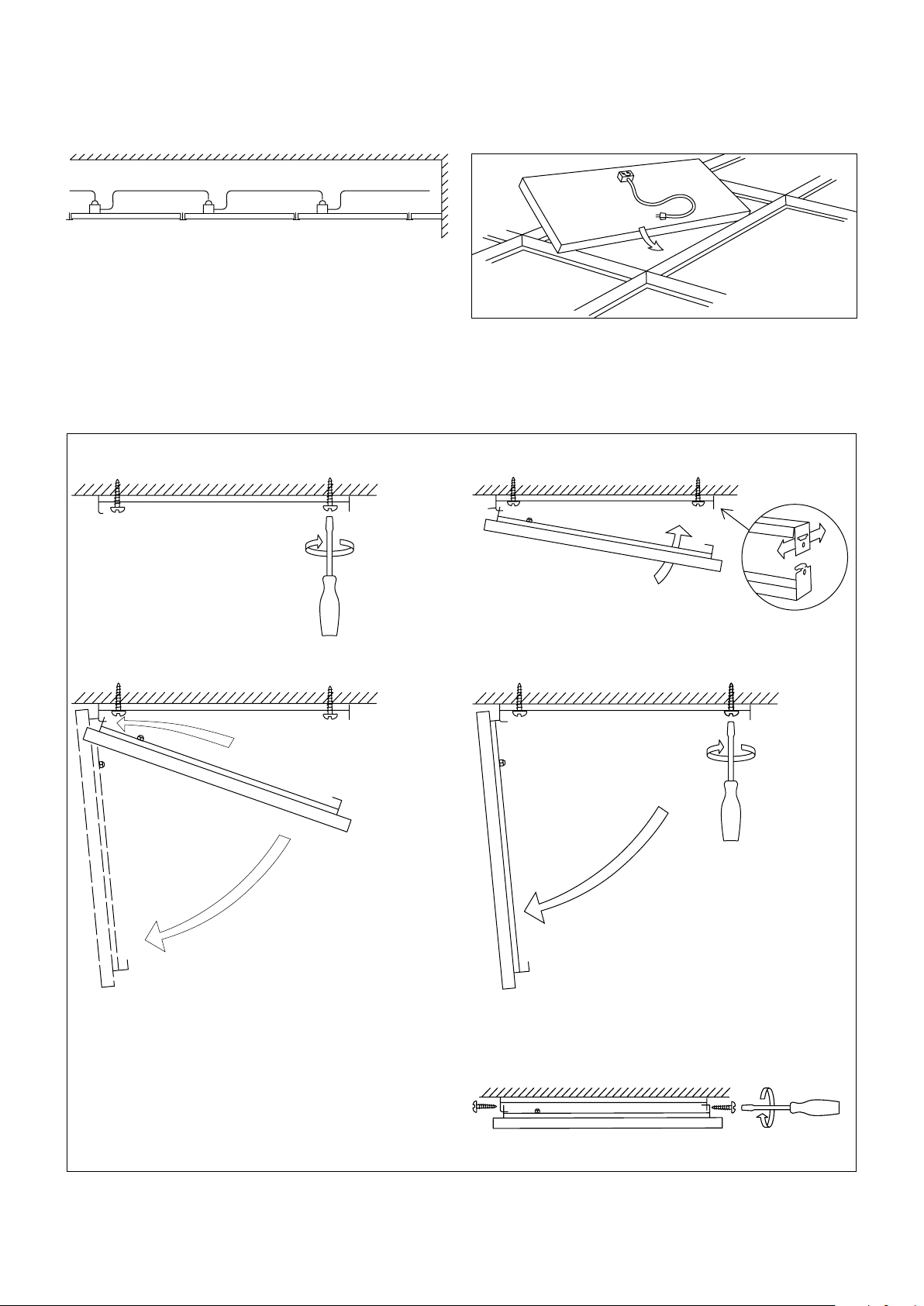

Mounting

Thermocassette HP

Fig. 1

A

Min 1,5 mm²

Max 2100 W

Fig. 2

C

B

D

E

Fig. 3

3

Page 4

Thermocassette HP

20

25

30

15

10

5

Technical specifications |

Type E-nr [SE] EL-nr [NO] Output (1)

Thermocassette HP. False ceiling model. Without brackets for false ceiling systems.

[W]

Voltage (2)

[V]

Amperage (3)

[A]

Max. surface

temperature (4)

[°C]

HP300 85 743 62 54 323 35 300 230V~ 1,30 100 5,4

HP600 85 743 64 54 323 36 600 230V~ 2,61 100 10,3

Protection class HP300/600: (IP20), normal design.

CE compliant.

Technical specifications |

Type E-nr [SE] EL-nr [NO] Output (1)

HP305 85 743 82 54 323 39 300 230V~ 1,30 100 5,8

HP605 85 743 84 54 323 41 600 230V~ 2,61 100 10,7

Thermocassette HP. Special model. With brackets.

[W]

Voltage (2)

[V]

Amperage (3)

[A]

Max. surface

temperature (4)

[°C]

Protection class HP305/605: (IP55), jet-proof design.

CE compliant.

Complies with the requirements for flammable areas according to SEMKO 111FF..

(1)

SE: Effekt

GB: Output

NO: Effekt

FR: Puissance

DE: Heizleistung

RU: Мощность

FI: Lämmitysteho

(3)

SE: Ström

GB: Amperage

NO: Strøm

FR: Intensité

DE: Stromstärke

RU: Ток

FI: Virta

(5)

SE: Vikt

GB: Weight

NO: Vekt

FR: Poids

DE: Gewicht

RU: Вес

FI: Paino

Weight (5)

[kg]

Weight (5)

[kg]

(2)

SE: Spänning

GB: Voltage

NO: Spenning

FR: Tension

DE: Spannung

RU: Напряжение

FI: Jännite

(4)

SE: Maximal yttemperatur

GB: Max. surface temperature

NO: Maksimal overflatetemp.

FR: Température de surface

DE: Max. Oberflächentemperatur

RU: Max. температура поверхности

FI: Suurin pintalämpötila

Accessories

ERP

Type E-nr [SE] EL-nr [NO] HxWxD

T10S 85 809 33 54 911 12 80x80x31

TK10S 85 809 34 54 911 13 80x80x31

KRT1900 85 810 12 54 910 50 165x57x60

ERP 85 820 05 54 238 86 153x93x40

ERPS 85 820 10 54 328 90 153x93x40

KRT1900T10S TK10S

[mm]

4

Page 5

Wiring diagrams HP

230V~

230V~

230V~

∼

Internal wiring diagram

Thermocassette HP

HP300, HP600 HP300, HP600

ERP/ T10S/TK10S

Output control

HP

ERP

K

230V~

HP

N

L

3

2

U

4

1

U K

G

G

HP

L

N

HP

L

N

L

N

Control by thermostat

Thermostat

P

N

HP

HP

L

N

HP

L

N

L

N

5

Page 6

GB

Thermocassette HP

Mounting and assembly instruction

General Instructions

Read these instructions carefully before

installation and use. Keep this manual for

future reference.

The product may only be used as set out in

the assembly and operating instructions. The

guarantee is only valid if the product is used

in the manner intended and in accordance

with the instructions.

Area of use

The heating panel is intended for the heating

of rooms requiring free walls. The panel

can be used for complete heating, or as an

additional heater (e.g. over a reception desk

or other work place).

There are two ratings: 300 W and 600 W.

The heating panel provides mainly radiation

heating. This implies that to obtain the

same experienced temperature it is possible

to reduce the air temperature in the room,

which saves energy.

Because of the low surface temperature,

max 100°C, the heating panel is suitable

for rooms with relatively low ceiling height.

Thanks to the location, the panel is protected

from any physical contact or damage. There

is no risk of being burned.

Design

1. Ceiling model: Intended as lay-in panel for

exposed grid. With cord, socket and plug,

which ensures simple extended connection

(max 2100 W from one wall socket).

2. Universal model in flush-proof design

(IP55): With better protection against

water. Delivered with cable without plug

and brackets.

One or more units have to be connected to

power line with a differential circuit breaker

rated at 30 mA. The cable section has to be at

2

least 1,5 mm

.

Units with cable and plug can be interconnected using the sockets on the back of

the heaters. The maximum power in interconnection is 2100 W.

If the units are to be extra insulated, then

this insulation must not exceed a value of

2

R=5 m

K/W.

Mounting

Integrated in ceiling (put in exposed grid)

See fig. 2

1. Lateral distance to wall shall be at least

50 mm.

2. The heater(s) should only be wired by a

competent electrician, and in accordance

with existing national regulations. The

appliance should be preceded by an all

pole switch in accordance with existing

regulations (not applicable to versions with

a cord and plug).

3. Place the cassette in the required ceiling

square. Minimum design height ”H” for

dismounting, T-profile 32x15: 150 mm,

T-profile 38x24: 200 mm. NOTE! Avoid

fixing vertical bars in the T-profile where a

heating panel is to be installed. The panel

fills out the whole square.

4. Connect the panel.

5. The second last page in this mounting

instruction is to be filled out and fixed

adjacent to the distribution board and it

has to contain (drawing) the locations of

the heating units.

Bracket mounting

See fig. 3

1. Mounting height above floor shall be at

least 1,8 m, and lateral distance to wall at

least 50 mm. When mounting in gypsum

board, make sure that the mounting

brackets are anchored in the beam behind.

During long-term high temperatures the

strength of the board is reduced.

2. The heater(s) should only be wired by a

competent electrician, and in accordance

with existing national regulations. The

appliance should be preceded by an all

8

Page 7

Thermocassette HP

pole switch in accordance with existing

regulations (not applicable to versions with

a cord and plug).

3. Measure, drill and screw the two loose

brackets to the ceiling. Do not tighten the

screws yet. It is important that the holes

come at right angles, cross measure. (fig.

3A)

4. Hook the panel brackets to the ones on the

ceiling (only the side nearest to the cable

gland). Allow panel to hang vertical. (fig.

3B)

5. Connect the panel.

6. Swing up the panel, and adjust the lateral

position of the ceiling mounted brackets.

(fig. 3C)

7. Swing down the panel and tighten the

screws in the ceiling. (fig. 3D)

8. Swing up the panel again and hook the

panel bracket ends in the ceiling brackets.

NOTE! Make sure that the brackets do not

become unhooked at the other end.

9. Secure the panel with a screw (enclosed

on delivery) at each hanging point. (fig.

3E)

10.The second last page in this mounting

instruction is to be filled out and fixed

adjacent to the distribution board and it

has to contain (drawing) the locations of

the heating units.

GB

Replacement of cable for HP305 or HP605

1. Because of limitations in the IP55 category

the cable cannot be changed.

2. If the cable is damaged the unit has to be

scrapped.

Safety

This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they

have been given supervision or instruction

concerning use of the appliance by a person

responsible for their safety. Children should

be supervised to ensure that they do not play

with the appliance.

9

Page 8

Page 9

Page 10

Page 11

Place this drawing adjacent to the distribution board

OBS!

– do not restrict the thermal emission of the heated ceiling;

– do not affix materials other than those recommended

– do not insert nails or screws

HP300, 300W, 220-240V

HP305, 300W, 220-240V

HP600, 600W, 220-240V

HP605, 600W, 220-240V

Drawing of the installation

Page 12

Main offi ce

Frico AB Tel: +46 31 336 86 00

Box 102 Fax: +46 31 26 28 25

SE-433 22 Partille mailbox@frico.se

Sweden www.frico.se

For latest updated information and information

about your local contact: www.frico.se

Item no: 204773, 20100601 HH

Loading...

Loading...