Page 1

Original instructions

SFS

SE

IT

.... 12

.... 36

GB

NL

.... 17

.... 41

DE

NO

.... 21

.... 46

ES

RU

.... 26

.... 51

FR

PL

.... 31

.... 56

Page 2

SFS

SE

GB

NO

FR

DE

Introduktionssidorna består huvudsakligen av bilder. För översättning av de

engelska texter som används, se respektive språksidor.

The introduction pages consist mainly of pictures. For translation of the

English texts used, see the respective language pages.

Introduksjonssidene består hovedsakelig av bilder. For oversettelse av de

engelske tekstene, se de respektive språksidene

Les pages de présentation contiennent principalement des images. Consulter

la page correspondant à la langue souhaitée.

Die Einleitungsseiten bestehen hauptsächlich aus Bildern. Für die Übersetzung

der verwendeten Texte in englischer Sprache, siehe die entsprechenden

Sprachseiten.

ES

NL

IT

PL

RU

Las páginas introductorias contienen básicamente imágenes. Consulte la

traducción de los textos en inglés que las acompañan en las páginas del

idioma correspondiente.

De inleidende pagina's bevatten hoofdzakelijk afbeeldingen. Voor een vertaling

van de gebruikte Engelse teksten, zie de pagina's van de resp. taal.

Le pagine introduttive contengono prevalentemente immagini. Per le

traduzioni dei testi scritti in inglese, vedere le pagine nelle diverse lingue.

Początkowe strony zawierają głównie rysunki. Tłumaczenie wykorzystanych

tekstów angielskich znajduje się na odpowiednich stronach językowych.

Страницы в начале Инструкции состоят в основном из рисунков, схем и

таблиц. Перевод встречающегося там текста приведен в разделе RU.

2

Page 3

SFS

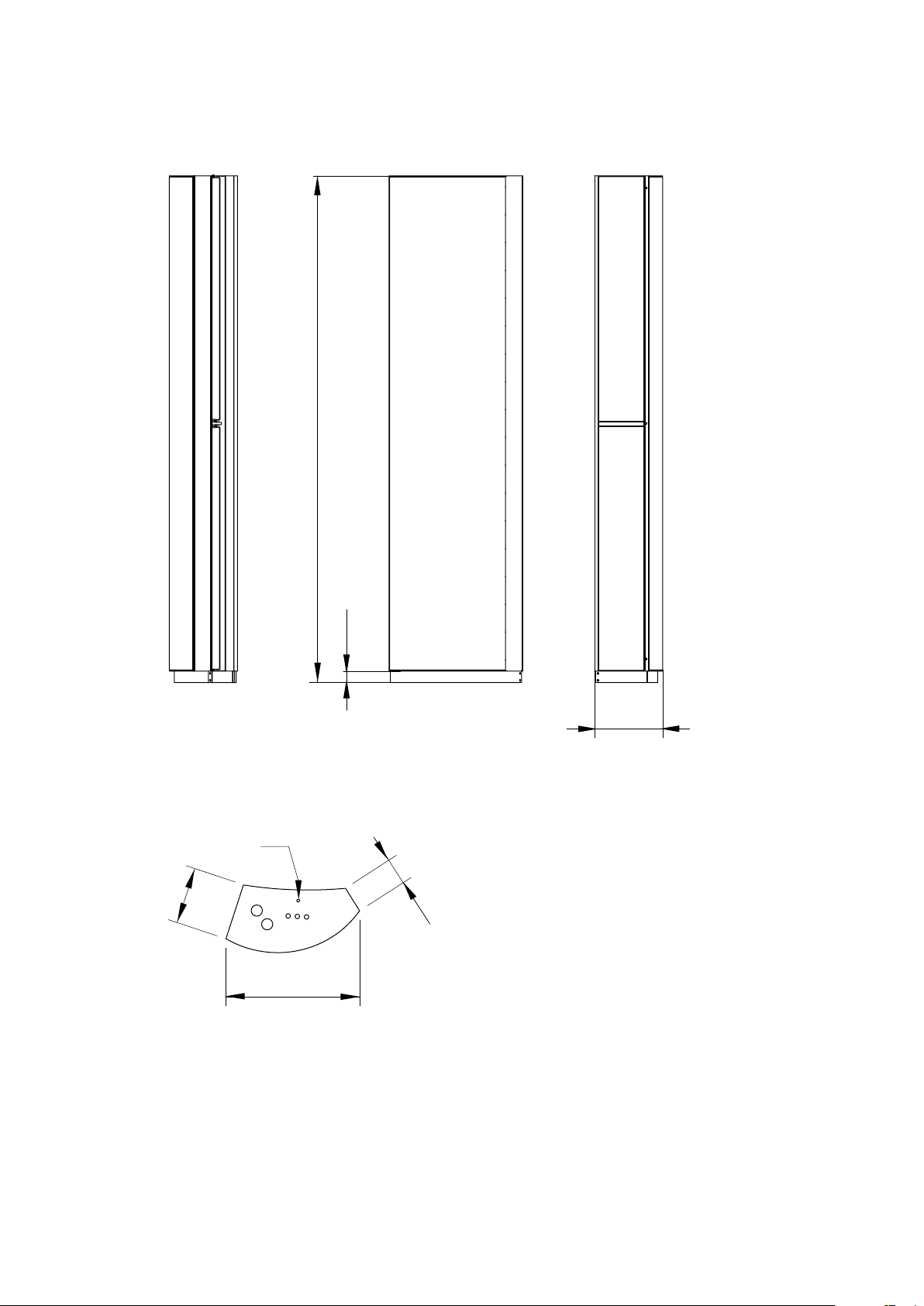

247

2200

M8

50

296

116

581

Fig. 1. Dimensions

3

Page 4

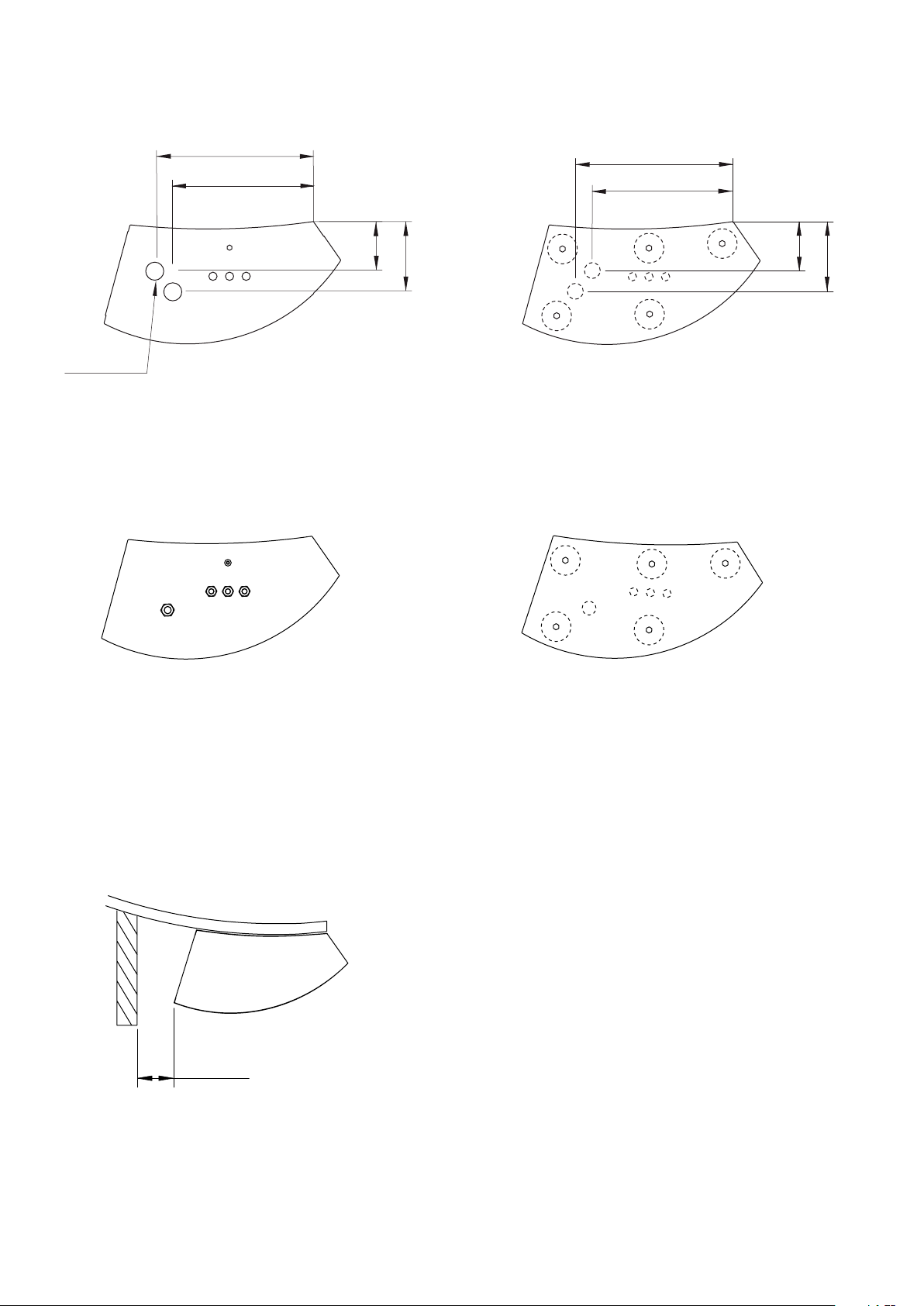

377

339

SFS

380

339

Ø48 (2x)

Seen from above - Connection above

Fig. 2 Connections W

118

168

118

168

Seen from above - Connection below

Seen from above - Connection above

Fig. 3 Connections E

min 120

Fig. 4 Minimum mounting distance

Seen from above - Connection below

4

Page 5

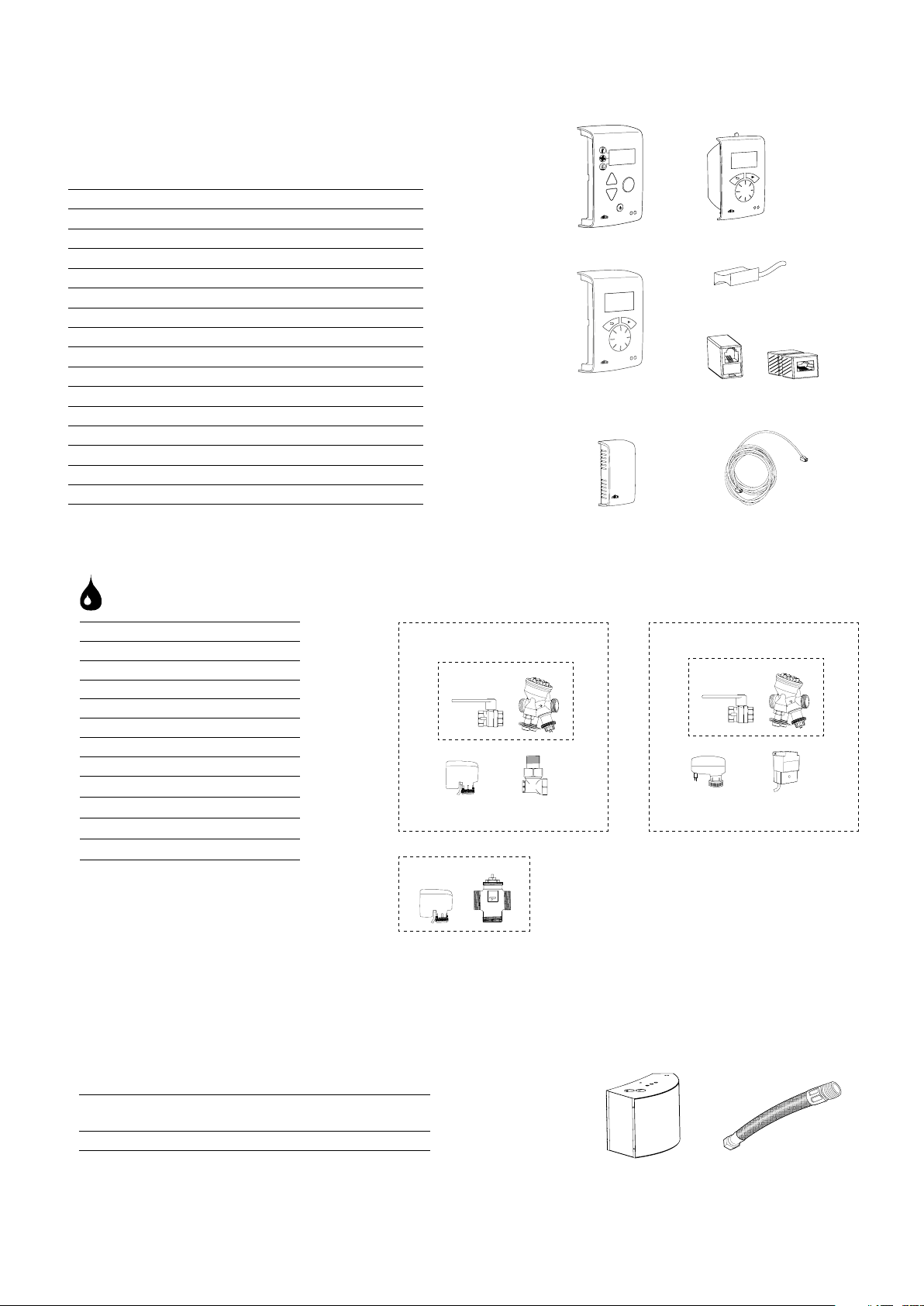

Accessories

SIRe

SIReB

SIReAC

SIReAA

SIReRTX 70x33x23 mm

SIReUR 114x70x50 mm

SIReWTA

SIReCJ4

SIReCJ6

SIReCC603 3 m

SIReCC605 5 m

SIReCC610 10 m

SIReCC615 15 m

SIReCC403 3 m

SIReCC405 5 m

SIReCC410 10 m

SIReCC415 15 m

SFS

C

SIReB

SIReAC/SIReAA

SIReUR

SIReWTA

SIReCJ4/SIReCJ6

VKF15LF

VKF15NF

VKF20

VKF25

VKF32

SD230

BPV10

SDM24

ST23024

VOT15 DN15

VOT20 DN20

VOT25 DN25

DN15

DN15

DN20

DN25

DN32

VLSP

VKF

SD230 BPV10

VOT

SIReRTX

SIReCC

VLP

VKF

SDM24 ST23024

FH1025 Flexible hose (DN25, 1" inside thread) for

easy connection to the pipe system.

SFSEH Extension hood, 100-1000 mm

SFSEH FH1025

5

Page 6

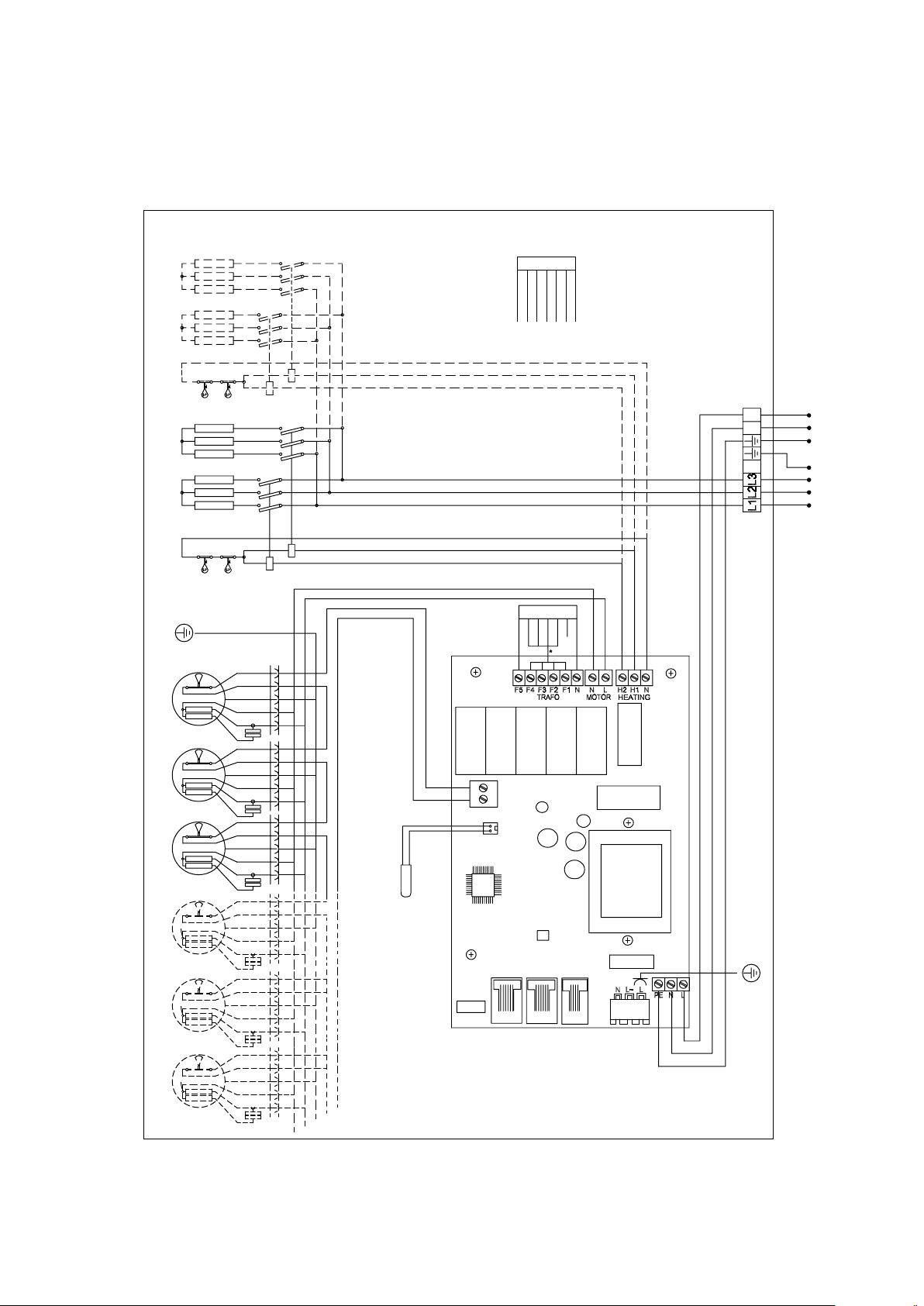

SFS E

SFS

SFS38/56E

SFS23/30E

°C°C°C

SIReB1

Transformer

145V

170V

230V

200V

Yellow

Orange

Red

Brown

Transformer

145V

170V

230V

200V

120V

Black

120V

100V

Green

100V

N

Blue

N

Blue

L

N

230V~

N

400V3~

Grey

Blue

Black

Black

SFS23E

°C°C°C

SFS30/38E

SFS56E

White

White

Motor

Internal

C2

protection

sensor

C1

ROOM

Actuator

230V~

Supply

230V~

6

Page 7

SFS W

SFS

SFS23W

Transformer

230V

200V

Yellow

Orange

Transformer

230V

200V

°C°C°C

°C°C°C

SIReB1

White

White

Motor

protection

sensor

Internal

170V

Red

170V

145V

Brown

145V

120V

120V

Black

100V

Green

100V

N

Blue

N

Blue

Black

SFS30/38W

SFS56W

Actuator

Supply

230V~

C2

C1

ROOM

230V~

230V~

7

Page 8

SIReB Basic

C2

X5

C1

X4

ROOM

X3

Pot.

Unit ID

ACTUATOR

SUPPLY

N L

N

L

PE

L

~

230V~

C2

X5

C1

X4

ROOM

X3

Pot.

Unit ID

ACTUATOR

SUPPLY

N L

N

L

PE

L

~

230V~

C2

X5

C1

X4

ROOM

X3

Pot.

Unit ID

ACTUATOR

SUPPLY

N L

N

L

PE

L

~

230V~

SIReCC6XX (max 50 m)

SIReCC6XX

(max 50 m)

SIReCC6XX

(max 50 m)

SIReUB1

SIReRTX

(optional)

L=2m

SIReB1/B2/B1EC

SIReB1/B2/B1EC

SIReB1/B2/B1EC

SFS E

SFS

Wiring diagrams for SIReAC Competent and SIReAA Advanced, see manuals for SIRe.

8

Page 9

SIReB Basic

SFS W

SFS

SIReB1/B2/B1EC

C2

Pot.

X5

Unit ID

SIReCC6XX

(max 50 m)

SIReB1/B2/B1EC

C2

Pot.

X5

Unit ID

C1

X4

C1

X4

ROOM

X3

ROOM

X3

ACTUATOR

L

N L

~

ACTUATOR

L

N L

~

230V~

SUPPLY

PE

N

L

L=2m

L=1,5m

SIReCC6XX (max 50 m)

230V~

SUPPLY

PE

N

L

SD230

SD230

SIReRTX

(optional)

SIReUB1

SIReCC6XX

(max 50 m)

SD230

SIReB1/B2/B1EC

230V~

Pot.

Unit ID

C2

X5

C1

X4

ROOM

X3

ACTUATOR

L

N L

~

SUPPLY

PE

N

L

Wiring diagrams for SIReAC Competent and SIReAA Advanced, see manuals for SIRe.

9

Page 10

SFS

Output charts water SFS

Supply water temperature: 80 °C

Room temperature: +18 °C

1

Pressure

drop

[kPA]

Type Fan

position

Airflow

3

[m

/h]

Outlet air temperature: +35 °C*

Output

[kW]

Return

water temp.

[°C]

Water

flow

[l/s]

SFS23WL max 2400 14,0 33 0,07 2,0 24,1 47,4 0,29 27,2

min 11 5 0 6,5 27 0,03 0,4 14,2 54,3 0,17 10

SFS30WL max 3250 18,7 29 0,09 1,4 35,3 49,9 0,43 26,2

min 1550 8,8 24 0,04 0,3 21,4 58,4 0,26 9,9

SFS38WL max 3700 21,9 31 0,11 2,0 38,5 48,5 0,47 31,1

min 1700 9,8 24 0,04 0,4 22,9 57,5 0,28 11,4

SFS56WL max 5600 33,0 36 0,18 5,3 49,4 43,8 0,60 50,4

min 2500 14,7 27 0,07 0,8 29,9 53,1 0,37 19,1

Water temperature: 80/60 °C

Room temperature: +18 °C

2

Output*

[kW]

Outlet

air temp.

[°C]

Water

flow

[l/s]

Pressure

drop

[kPA]

Type Fan

position

Airflow

3

[m

/h]

Supply water temperature: 70 °C

Room temperature: +18 °C

Outlet air temperature: +35 °C*

Output

[kW]

Return

water temp.

[°C]

Water

flow

[l/s]

1

Pressure

drop

[kPA]

Water temperature: 70/50 °C

Room temperature: +18 °C

2

Output*

[kW]

Outlet

air temp.

[°C]

Water

flow

[l/s]

Pressure

drop

[kPA]

SFS23WL max 2400 13,6 35 0,09 3,2 19,1 41,3 0,23 1 7, 6

min 11 5 0 6,8 30 0,04 0,7 11,3 46,8 0,14 6,5

SFS30WL max 3250 18,7 32 0,12 2,3 28,2 43,4 0,34 1 7, 1

min 1550 9,1 26 0,05 0,5 1 7, 1 50,4 0,21 6,6

SFS38WL max 3700 21,4 33 0,14 3,2 30,7 42,3 0,37 20,2

min 1700 9,8 26 0,05 0,6 18,4 49,6 0,22 7, 6

SFS56WL max 5600 33,2 41 0,28 11,5 39,3 38,6 0,48 32,6

min 2500 14,2 28 0,08 1,2 23,9 46 0,29 12,5

Type Fan

position

Airflow

3

[m

/h]

Supply water temperature: 60 °C

Room temperature: +18 °C

Outlet air temperature: +35 °C*

Output

[kW]

Return

water temp.

[°C]

Water

flow

[l/s]

1

Pressure

drop

[kPA]

Water temperature: 60/40 °C

Room temperature: +18 °C

2

Output*

[kW]

Outlet

air temp.

[°C]

Water

flow

[l/s]

Pressure

drop

[kPA]

SFS23WL max 2400 14,1 40 0,17 10,0 14,1 35,2 0,17 10

min 11 5 0 6,6 32 0,06 1,4 8,3 39,3 0,10 3,8

SFS30WL max 3250 18,3 35 0,18 4,9 20,9 36,9 0,25 9,8

min 1550 9,0 28 0,07 0,9 12,8 42,2 0,16 3,9

SFS38WL max 3700 21,4 37 0,23 8,2 22,8 36,1 0,28 11,6

min 1700 9,6 28 0,07 1,0 13,7 41,7 0,17 4,5

SFS56WL max 5600 32,3 45 0,52 39,1 29,1 33,2 0,35 18,4

min 2500 14,4 32 0,13 2,7 1 7, 8 38,9 0,22 7, 3

Type Fan

position

Airflow

3

[m

/h]

Supply water temperature: 55 °C

Room temperature: +18 °C

Outlet air temperature: +35 °C*

Output

[kW]

Return

water temp.

[°C]

Water

flow

[l/s]

1

Pressure

drop

[kPA]

Water temperature: 55/35 °C

Room temperature: +18 °C

2

Output*

[kW]

Outlet

air temp.

[°C]

Water

flow

[l/s]

Pressure

drop

[kPA]

SFS23WL max 2400 13,7 42 0,25 20,1 11,5 32,1 0,14 6,9

min 11 5 0 6,8 35 0,08 2,5 6,8 35,4 0,08 2,6

SFS30WL max 3250 19,2 39 0,30 13,2 1 7, 2 33,5 0,21 6,8

min 1550 9,1 30 0,09 1,4 10,6 38 0,13 2,8

SFS38WL max 3700 22,0 42 0,40 23,0 18,8 32,9 0,23 8,1

min 1700 9,7 30 0,10 1,6 11,3 37,6 0,14 3,2

SFS56WL max 5600 32,2 48 1,16 184,1 23,9 30,5 0,29 12,8

min 2500 14,6 35 0,17 4,9 14,7 35,2 0,18 5,1

1

*

) Recommended outlet air temperature for good comfort and optimized output.

2

*

) Nominal output at given supply and return water temperature.

See www.frico.se for additional calculations.

10

Page 11

SFS

Technical specifications

3 Electrical heat - SFS E (IP20)

Type Output

steps

[kW]

SFS23E08*

SFS30E12*

SFS38E16*

8

2,7/5,4/8,1 1150/2500 21/10

8

3,9/7,8/12 1550/3300 23/11

8

5,4/11/16 1700/3900 28/12

Airflow*1

3

[m

/h]

SFS56E23 7,8/15/23 2500/5900 28/12

2 Water heat - SFS WL, coil for low water temperature (480 °C) (IP20)

Type Output*5

[kW]

SFS23WL*

SFS30WL*

SFS38WL*

8

14 24 1150/2400 21/17 36/29 3,0

8

21 35 1550/3250 24/18 40/32 4,4

8

23 38 1700/3700 23/18 39/30 4,4

SFS56WL 29 49 2500/5600 21/15 35/26 4,4

Output*6

[kW]

Airflow*1

3

[m

/h]

∆t*

[°C]

4

Sound

power*2

[dB(A)]

79 44/63

80 45/64

83 48/67

85 49/69

4,5

∆t*

[°C]

∆t*

[°C]

4,6

Sound

pressure*3

[dB(A)]

Water

volume

[l]

Voltage [V]

Amperage [A]

(control)

Voltage [V]

Amperage [A]

(heat)

230V~/2,7 400V3~/11,7 2200 75

230V~/3,7 400V3~/16,9 2200 80

230V~/5,2 400V3~/23,4 2200 80

230V~/7,8 400V3~/33,8 2200 90

Sound

power*2

[dB(A)]

Sound

pressure*3

[dB(A)]

79 44/63

80 46/64

83 48/67

84 49/68

7

Weight

[kg]

Height*

[mm]

7

Weight

[kg]

Voltage

[V]

Height*

[mm]

Amp.

[A]

230V~ 2,6 2200 75

230V~ 3,6 2200 80

230V~ 4,9 2200 80

230V~ 7, 3 2200 90

*1) Lowest/highest airflow of totally 5 fan steps.

2

*

) Sound power (LWA) measurements according to ISO 27327-2: 2014, Installation type E.

3

*

) Sound pressure (LpA). Conditions: Distance to the unit 5 metres. Directional factor: 2. Equivalent absorption area: 200

m². At lowest/highest airflow.

4

*

) ∆t = temperature rise of passing air at maximum heat output and lowest/highest airflow.

5

*

) Applicable at water temperature 60/40 °C, air temperature, in +18 °C.

6

*

) Applicable at water temperature 80/60 °C, air temperature, in +18 °C.

7

*

) Standard height. Max. height 3000 mm (extension without fans).

8

*

) Models in the series have different number of motors. In the production the motors will be mounted starting from

the bottom of the unit, because it´s most important to protect at the floor. Therefore it can be empty space above the

motors, at the models that have a smaller number of motors.

Protection class: IP20.

CE compliant.

11

Page 12

Assembly and operating instructions

GB

General Instructions

Read these instructions carefully before

installation and use. Keep this manual for

future reference.

The product may only be used as set out in

the assembly and operating instructions. The

guarantee is only valid if the product is used

in the manner intended and in accordance

with the instructions.

Application area

The SFS air curtain unit is supplied with

electrical heating or hot water heating.

SFS is intended for revolving doors.

SFS is mounted vertically next to the door.

Protection class: IP20.

Operation

Air is drawn in at the side of the unit and

blown out against the entrance, so that it

shields the door opening and minimizes heat

loss. To achieve the optimum curtain effect

the unit must extend the full height of the

door opening.

The grille for directing exhaust air is

adjustable and is normally angled towards the

revolving door to achieve the best protection

against incoming cold air.

The efficiency of the air curtain depends

on the air temperature, pressure differences

across the doorway and any wind pressure.

NOTE! Negative pressure in the building

considerably reduces the efficiency of the air

curtain. The ventilation should therefore be

balanced.

Mounting

The air curtain is mounted to the left of the

door seen from inside. The unit has a curved

design which makes it an integrated part of

the door. The unit can be extended to max

3000 mm (extension without fans). Extension

hood, for heights up to 4 m, is available.

The air curtain is installed on adjustable

feet which makes it possible to compensate

for any surface undulations. The feet

are attached to the floor with fasteners

appropriate to the surface and covered by a

frame. The air curtain must always be secured

at the top.

Ensure that the service hatch is accessible

and can be fully opened.

See Fig. 4.

Electrical installation

The installation, which should be preceded by

an omnipolar switch with a contact separation

of at least 3 mm, should only be wired by a

competent electrician and in accordance with

the latest edition of IEE wiring regulations.

The control system is pre-installed in the air

curtain with an integrated control card. SIRe

is supplied pre-programmed with quick-fit

connections. Modular cables are connected to

the control board. The control card is always

placed at the top of vertical units.

See manual for SIRe.

Unit with water heating

The electrical connection may be done from

above or below, according to ordering key.

Control (230V~) should be connected to a

terminal block.

Unit with electrical heating

The electrical connection may be done from

above or below, according to ordering key.

Control (230V~) and power supply for heat

(400V3~) should be connected to a terminal

block. Modular cables for SIRe control board

should be drawn inside the unit when the

connection is made from the bottom. Bundle

the cables inside the unit to prevent that they

will be drawn into the fans or get in contact

with the heating elements.

The largest cable diameter for the terminal

block is 16 mm². The cable glands used must

meet the protection class requirements. In

the distribution board it is to be indicated

that ”the air curtains can be supplied from

more than one connection”.

See wiring diagrams.

Type Output

[kW]

All Control - 230V~ 1,5

SFS23E08 8,1 400V3~ 2,5

SFS30E12 11,7 400V3~ 4

SFS38E16 16,2 400V3~ 6

SFS56E23 23,4 400V3~ 10

Voltage

motor

[V]

Minimum

area

2

[mm

]

17

Page 13

GB

Number of motors

Models in the series have different number of

motors. In the production the motors will be

mounted starting from the bottom of the unit,

because it´s most important to protect at the

floor. Therefore it can be empty space above

the motors, at the models that have a smaller

number of motors.

Start-up (E)

When the unit is used for the first time or

after a long period of disuse, smoke or odour

may result from dust or dirt that has collected

on the element. This is completely normal

and disappears after a short time.

Connecting the water coil (W)

The installation must be carried out by an

authorised installer.

The water coil has copper tubes with

aluminium fins and is suitable for connection

to a closed water heating system. The heating

coil must not be connected to a mains

pressure water system or an open water

system.

Note that the unit shall be preceded by a

regulating valve, see Frico valve kit.

Water connection can be made from above

and below, according to the order key, via

DN25 (1"), internal thread connections.

When connection is made from below, the

connection is placed in altitude between the

first and second motor. Flexible hoses are

available as an accessory, see accessories

pages.

NOTE: Care must be taken when connecting

the pipes. Use a wrench or similar to hold the

air curtain connections to prevent straining

of the pipes and subsequent water leakage

during connection to water supply pipe-work.

The connections to the heating coil must be

equipped with shut off valves to allow problem

free removal. The battery is equipped with

bleed valves.

Filter (W)

The distance between the coil plates in

combination with the hole diameter of

the intake grille protects against dirt and

blockage. This normally makes a separate

filter unnecessary.

Service, repairs and maintenance

For all service, repair and maintenance first

carry out the following:

1. Disconnect the power.

2. The service hatch is opened by unscrew off

the screws in the side of the unit.

Maintenance

Unit with water heating:

The appliance filter should be cleaned

regularly to ensure the air curtain effect and

the heat emission from the device. How often

depends on local circumstances. A clogged

filter is not a risk, but the appliance function

can fail. Vacuum the intake grille regularly

from outside when dust is visible, for example

as a part of the cleaning routine.

All units:

Since fan motors and other components are

maintenance free, no maintenance other than

cleaning is necessary. The level of cleaning

can vary depending on local conditions.

Undertake cleaning at least twice a year. Inlet

and exhaust grilles, impeller and elements

can be vacuum cleaned or wiped using a

damp cloth. Use a brush when vacuuming

to prevent damaging sensitive parts. Avoid

the use of strong alkaline or acidic cleaning

agents.

Basic setting fan speed

The fan speed when the door is open is set

using the control. Note that the air flow

direction and fan speed may need fine

adjustment depending on the loading of the

door.

18

Page 14

GB

Overheating

The air curtain unit with electric heater is

equipped with an overheat protector. If it is

deployed due to overheating, reset as follows:

1. Disconnect the electricity with the fully

isolated switch.

2. Allow the electrical coil to cool.

3. Determine the cause of overheating and

rectify the fault.

4. Connect the air curtain again.

All motors are equipped with an integral

thermal safety cut-out. This will operate,

stopping the air curtain should the motor

temperature rise too high. The cut-out

will automatically reset when the motor

temperature has returned to within the

motor’s operating limits.

Temperature control

Temperature control of SIRe maintains the

exhaust temperature. If the temperature

should exceed anyway the overheating alarm

goes off. For more information see the manual

for SIRe.

Fan replacement

1. Determine which of the fans is not functioning.

2. Disconnect the cables to the relevant fan.

3. Remove the screws securing the fan and lift

the fan out.

4. Install the new fan as above in reverse order.

Replacing heating elements/heating

package (E)

1. Mark and disconnect the cables to the heating

elements/package

2. Remove the mounting screws securing the

heating elements/package in the unit and lift

the heaging elements/package out.

3. Install the new heating elements/package in

reverse order to the above.

Replacing the water coil (W)

1. Shut off the water supply to the unit.

2. Disconnect the connections to the water coil.

3. Remove the mounting screws securing the

coil in the unit and lift the coil out.

4. Install the new coil in reverse order to the

above.

Draining the water coil (W)

The drain valve is on the underside of the

coil. It can be accessed via the service hatch.

Trouble shooting

If the fans are not working or do not blow properly,

check the following:

• That the intake grille/filter is not dirty.

• Functions and settings of the SIRe control

system, see manual for SIRe.

If there is no heat, check the following:

• Functions and settings of the SIRe control

system, see manual for SIRe.

For units with electrical heating, also check the following:

• Power supply to electric heater coil; check

fuses and circuit-breaker (if any).

• That the overheat protection for the motors

has not been deployed.

For units with water coil, also check the following:

• That the water coil is air free.

• That there is enough water flow.

• That incoming water is heated enough.

If the fault cannot be rectified, please contact

a qualified service technician.

Residual current circuit breaker (E)

When the installation is protected by means

of a residual current circuit breaker, which

trips when the appliance is connected,

this may be due to moisture in the heating

element. When an appliance containing a

heater element has not been used for a long

period or stored in a damp environment,

moisture can enter the element.

This should not be seen as a fault, but is

simply rectified by connecting the appliance

to the main supply via a socket without a

safety cut-out, so that the moisture can be

eliminated from the element. The drying

time can vary from a few hours to a few days.

As a preventive measure, the unit should

occasionally be run for a short time when it is

not being used for extended periods of time.

19

Page 15

GB

Safety

• For all installations of electrically heated

products should a residual current circuit

breaker 300 mA for fire protection be used.

• Keep the areas around the air intake

and exhaust grilles free from possible

obstructions!

• The unit may have hot surfaces during

operation and when cooling down!

• The unit must not be fully or partially

covered with clothing, or similar materials,

as overheating can result in a fire risk! (E)

• Lifting equipment must be used to lift the

unit.

• This appliance can be used by children

aged from 8 years and above and persons

with reduced physical, sensory or mental

capabilities or lack of experience and

knowledge if they have been given

supervision or instruction concerning use of

the appliance in a safe way and understand

the hazards involved. Children shall not

play with the appliance. Cleaning and user

maintenance shall not be made by children

without supervision.

20

Page 16

Page 17

Page 18

Page 19

Main offi ce

Frico AB Tel: +46 31 336 86 00

Box 102

SE-433 22 Partille mailbox@frico.se

Sweden www.frico.se

For latest updated information and information

about your local contact: www.frico.se

Art.no 208030, 2017-01-03 HH/SÄ/SÅ

Loading...

Loading...