Frico HP-300, HP-304, HP-305, HP-604, HP-605 Assembly And Operating Instructions Manual

...Page 1

Thermocassette

HP

SE

NO

... 4

... 6

GB

DE

... 8

... 10

Page 2

Thermocassette HP

2

Page 3

Thermocassette HP

3

Page 4

Thermocassette HP

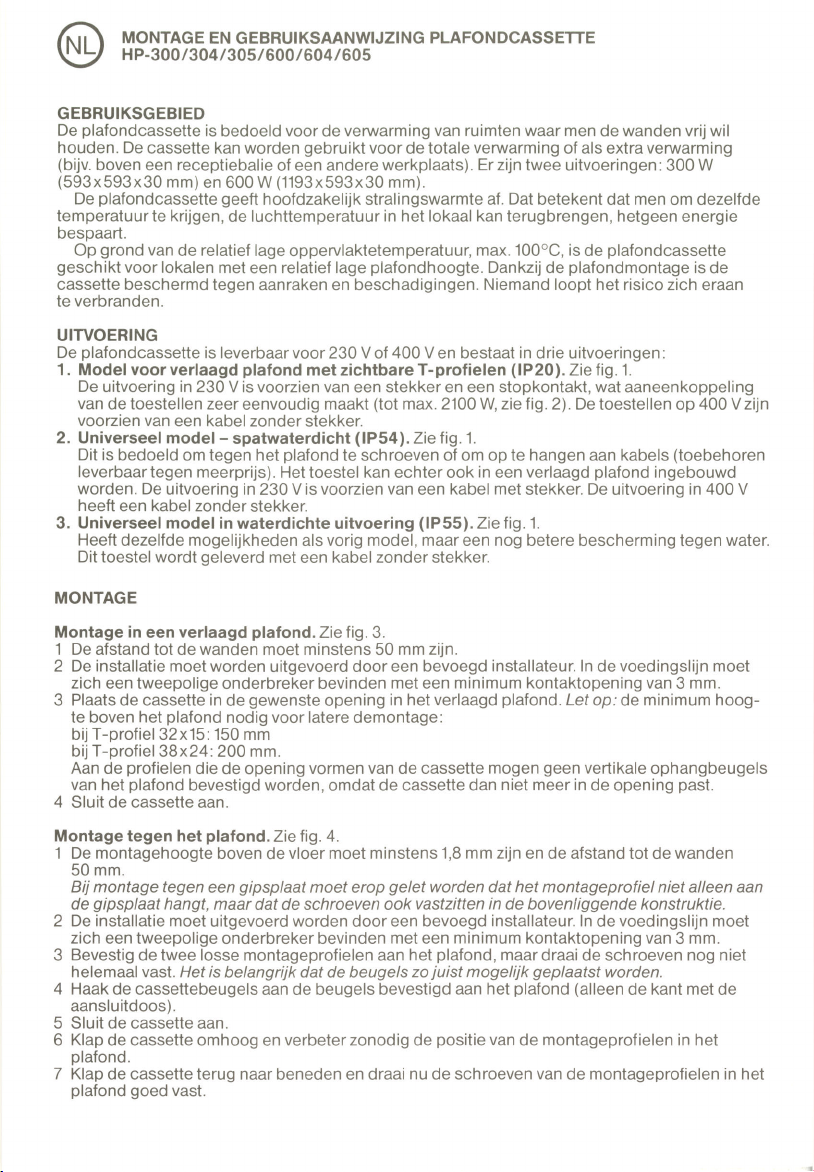

Assembly and operating instructions Thermocassette HP-300/304/305/600/604/605

Area of use

The heating panel is intended for the heating of

rooms requiring free walls. The panel can be used

for complete heating, or as an additional heater

(e.g. over a reception desk or other work place.)

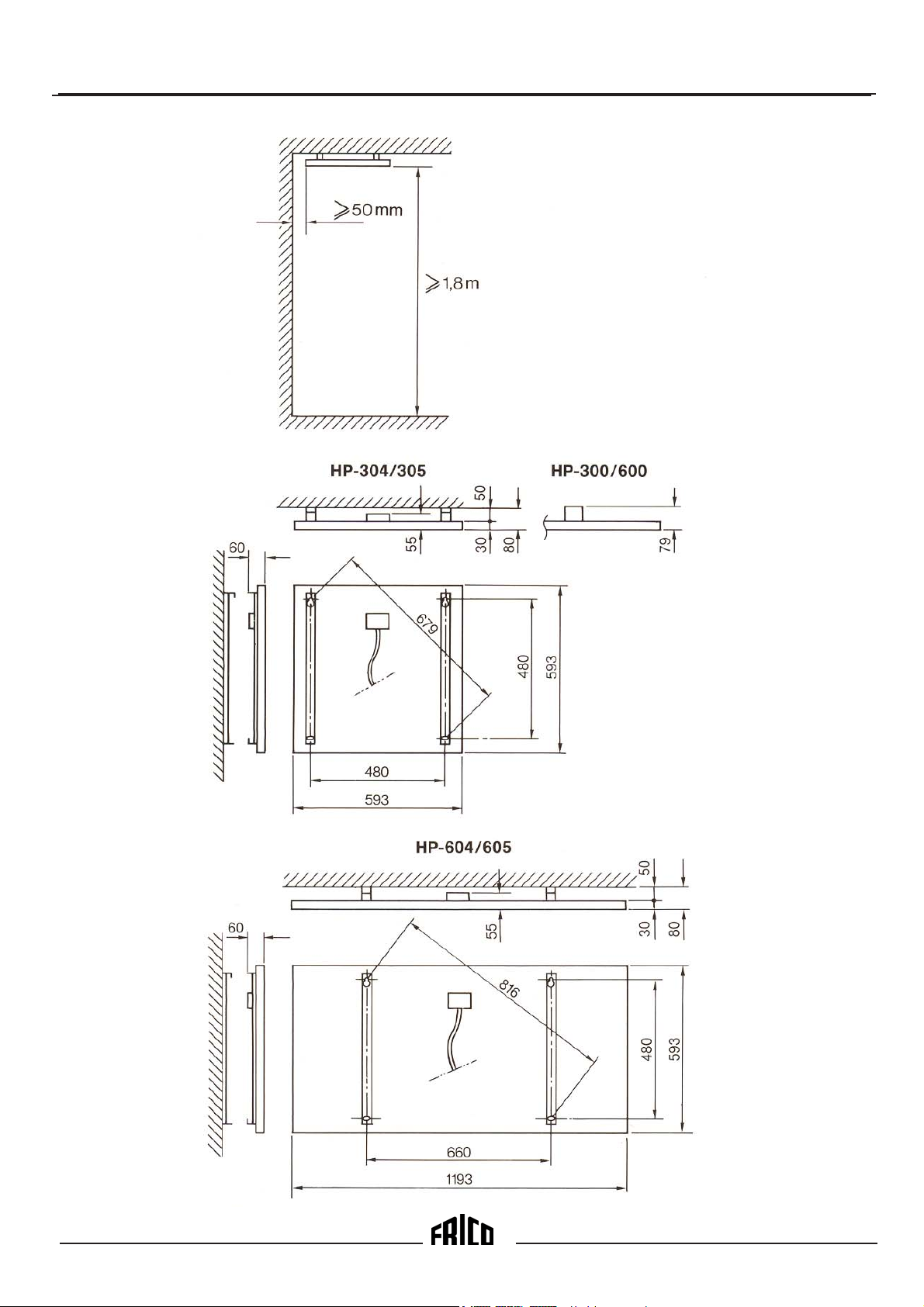

There are two ratings: 300 W(593x593x30 mm)

and 600 W(1193x593x30 mm).

The heating panel provides mainly radiation

heating. This implies that to obtain the same

experienced temperature it is possible to reduce

the air temperature in the room, which saves

energy.

Because of the low surface temperature, max

100°C, the heating panel is suitable for rooms with

relatively low ceiling height. Thanks to the

location, the panel is protected from any physical

contact or damage. There is no risk of being

burned.

Design

The heating panels are available for 230 and 400

V, which are approved by SEMKO in three

versions:

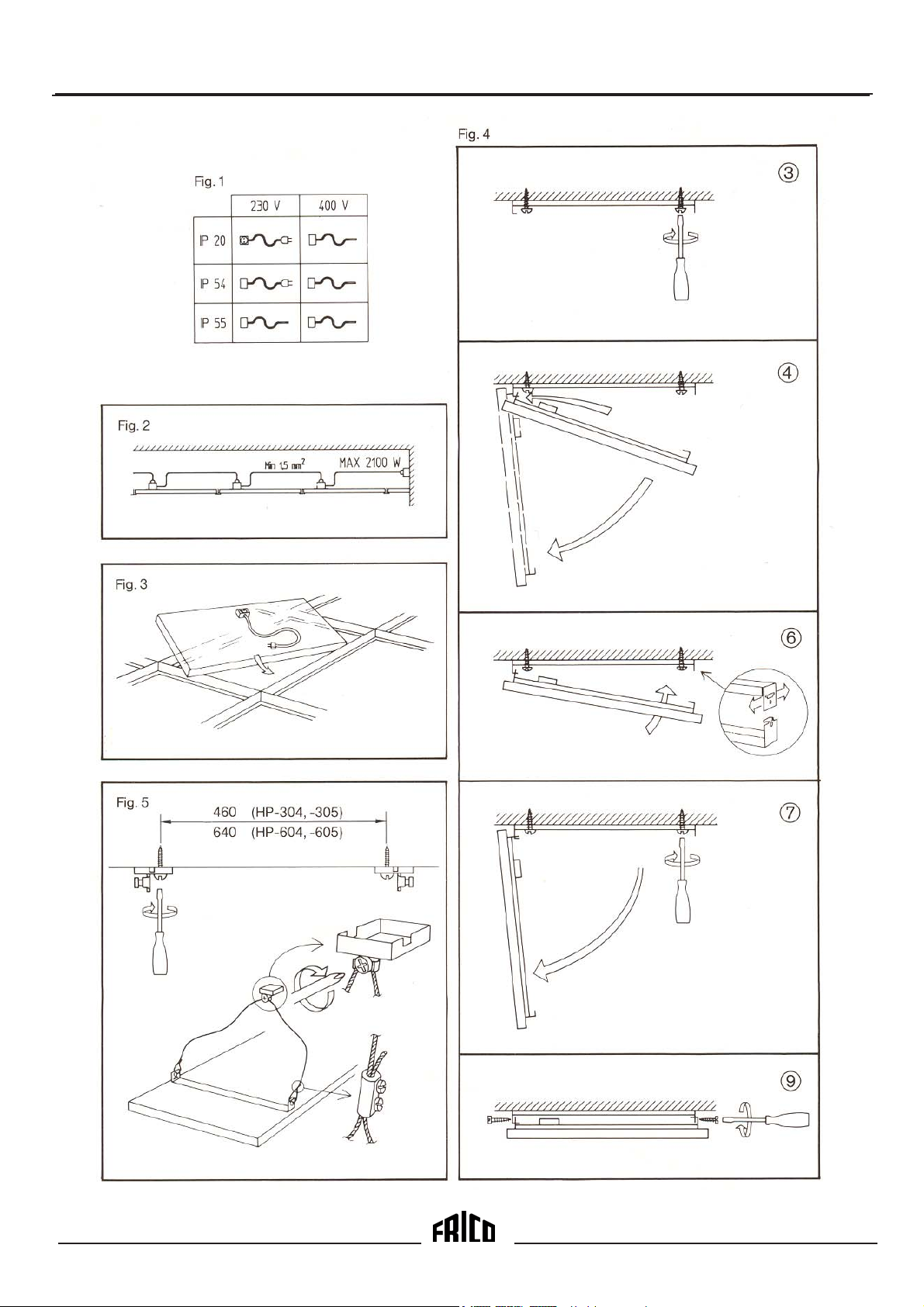

1 . Ceiling model in standard version (IP20).

See fig. 1.

Intended as lay-in panel fpr exposed grid. The

230 V version have cord and socket, which

ensures simple extended connection (max

2100 W from one wall socket. See fig. 2). The

400 V versions are delivered with a cable

without plug.

2 . Universal model in splash-proof design

(IP54). See fig. 1.

Intended for other methods of mounting (can

also be put in exposed grid). Approved for fire

hazard rooms. The 230 V versions have a cord

(without socket). The 400 V versions are

delivered with a cable without plug.

a. Screwed to ceiling with accompanying

mounting brackets.

b. Hanging in wire (with accessory

”Wire mounting kit” 74 701 90).

3 . Universal model in flush-proof design (IP55).

See fig. 1.

Identical with 2, but with better protection

against water. Delivered with cable without

plug.

Mounting

Integrated in ceiling (put in exposed grid).

See fig. 3.

1 . Lateral distance to wall shall be at least

50 mm.

2 . Installation, which is to be preceded by an all-

pole switch, must be carried out by an

authorized electrician (not applicable to

versions with a cord).

3 . Place the cassette in the required ceiling

square. Minimum design height ”H” for

dismounting, T-profile 32x15: 150 mm,

T-profile 38x24: 200 mm.

NOTE! Avoid fixing vertical bars in the T-profile

where a heating panel is to be installed.

The panel fills out the whole square.

4. Connect the panel.

Bracket mounting. See fig. 4.

1. Mounting height above floor shall be at least

1.8 m, and lateral distance to wall at least 50

mm. When mounting in gypsum board, make

sure that the mounting brackets are anchored in

the beam behind. During long-term high

temperatures the strength of the board is

reduced.

2 . Installation, which is to be preceded by an all-

pole switch, must be carried out by an

authorized electrician (not applicable to

versions with a cord).

3 . Measure, drill and screw the two loose brackets

to the ceiling. Do not tighten the screws yet. It is

important that the holes come at right angles,

cross measure.

4 . Hook the panel brackets to the ones on the

ceiling (only the side nearest to the connection

box). Allow panel to hang vertical.

5. Connect the panel.

6 . Swing up the panel, and adjust the lateral

position of the ceiling mounted brackets.

7 . Swing down the panel and tighten the screws in

the ceiling.

8 . Swing up the panel again and hook the panel

bracket ends in the ceiling brackets. NOTE!

Make sure that the brackets do not become

unhooked at the other end.

9 . Secure the panel with a screw (enclosed on

delivery) at each hanging point.

8

Page 5

Thermocassette HP

Wire hung. See fig.5.

1. Mounting height above floor shall be 1.8 m,

and lateral distance to wall at least 50 mm.

2 . Installation, which is to be preceded by an all-

pole switch, must be carried out by an

authorized electrician (not applicable to version

with a cord).

3 . Measure, drill and screw in the wire

attachments envloesed in

”Wire mounting kit” 74 701 90 to the ceiling

4 . Insert one wire end in each screw hole in the

bracket ends on the panel, and fix with a screw

terminal

5 . Hang up the panel bt hanging one wire on the

screw in each wire attachment in the ceiling.

Tighten the screws.

6. Connect the panel.

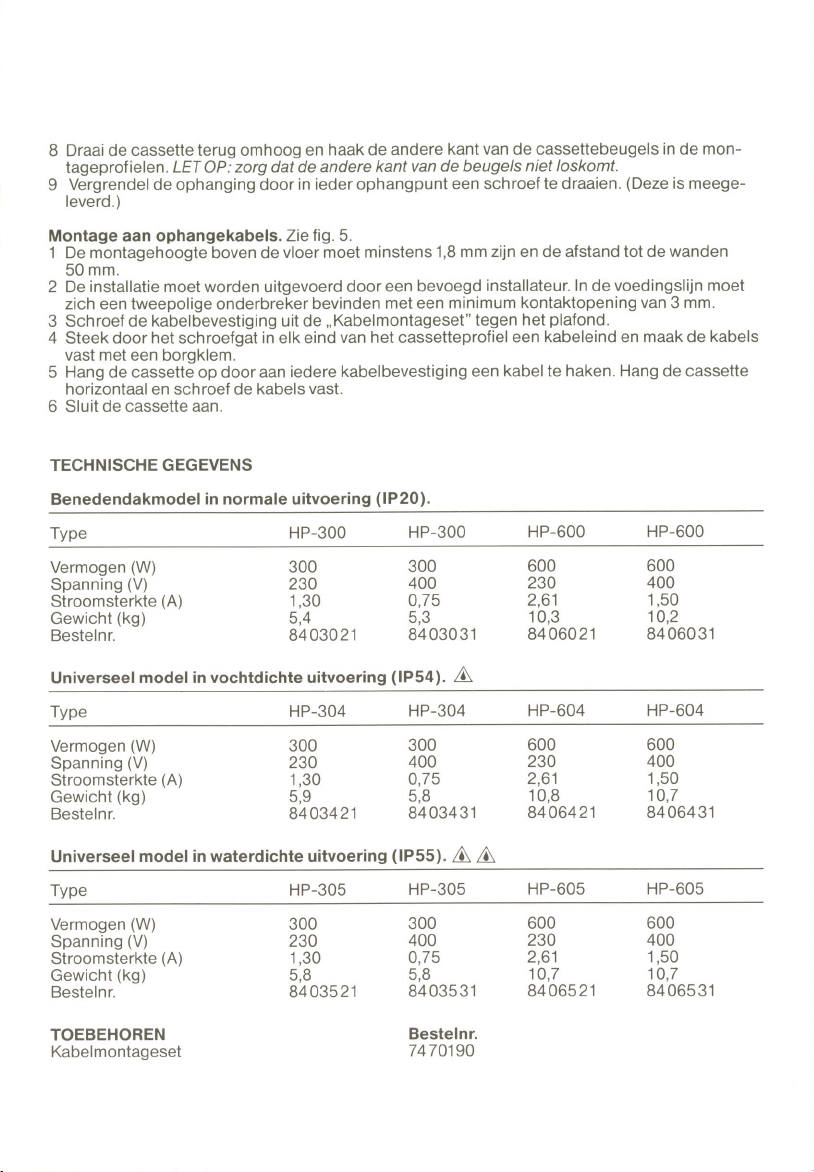

Technical Data

Ceiling model - standard version IP20

Typ HP-300 HP-300 HP-600 HP-600

Power (W) 300 300 600 600

Voltage (V) 23 0 400 230 40 0

Current (A) 1,30 0,75 2,61 1,50

Weight (kg) 5,4 5,3 10,3 10,2

Order nr. 84 030 21 84 030 31 84 060 21 84 060 31

Universal model - waterproof version IP54

Typ HP-304 HP-304 HP-604 HP-604

Power (W) 300 300 600 600

Voltage (V) 23 0 400 230 40 0

Current (A) 1,30 0,75 2,61 1,50

Weight (kg) 5,9 5,8 10,8 10,7

Order nr. 84 034 21 84 034 31 84 064 21 84 064 31

Universal model - waterproof version IP55

Typ HP-305 HP-305 HP-605 HP605

Power (W) 300 300 600 600

Volatage (V) 2 30 400 230 400

Current (A) 1,30 0,75 2,61 1,50

Weight (kg) 5,8 5,8 10,7 10,7

Order nr. 84 035 21 84 035 31 84 065 21 84 065 31

Accessories E- nr. Order nr.

Wire mounting kit 85 744 90 74 701 90

9

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Thermocassette HP

Tillverkardeklaration/

EU-försäkran om överensstämmelse

Vi

Frico AB

Box 102

S-433 22 Partille

Intygar härmed att följande produkter:

Rumsvärmare: Thermocassette

Typ: HP 300, HP 304, HP 344 och HP 305.

HP 600, HP 604, HP 644 och HP 605.

Uppfyller kraven enligt följande direktiv:

EC Electromagnetic Compatibility (EMC)

Directive 89/336 /EEC & 92/31 EEC

EC Lågspänningsdirektivet(LVD) 73/23/EEC

Och tillverkad enligt följande standarder:

Declaration of Conformity

We

Frico AB

Box 102

S-433 22 Partille

under own responsibility hereby declare that the

following product(s)

Room heaters: Ceiling-cassettes

Type: HP 300, HP 304, HP 344 and HP 305.

HP 600, HP 604, HP 644 and HP 605.

which is(are) covered by this declaration of

conformity comply with the

EC Electromagnetic Compatibility (EMC)

Directive 89/336 /EEC & 92/31 EEC

EC Low Voltage Directive (LVD) 73/23/EEC

EMC: EN 55014: 1993

EN 60555-2/3: 1991

EN 55 104

LVD: CCA HD 251 S3:1982 incl. Am. 1-3

CCA HD 251 S1:1987 incl. Am. 1-4

Partille , 15 December 1995

Mats Careborg

Teknisk Chef

and is(are) manufactured in accordance with the

following stated harmonised standard(s) or other

normative document(s).

EMC: EN 55014: 1993

EN 60555-2/3: 1991

EN 55 104

LVD: CCA HD 251 S3:1982 incl. Am. 1-3

CCA HD 251 S1:1987 incl. Am. 1-4

Partille , 15 December 1995

Mats Careborg

Technical Manager

12

Page 13

Main office

FRICO AB Tel: +46 (0)31 336 86 00

Box 102 Fax: +46 (0)31 26 28 25

S-433 22 Partille e-mail: mailbox@frico.se

SWEDEN http://www.frico.se

France

FRICO FRANCE Tel: +33 (0)4 72 42 99 42

7, rue de la libération Fax: +33 (0)4 72 42 99 49

F-69 270 Fontaines sur Saone e-mail: info@frico.fr

FRANCE

Norway

FRICO AS Tel: +47 (0)23 37 19 00

Postboks 82, Alnabru Fax: +47 (0)23 37 1910

N-0614 Oslo e-mail: mailbox@frico.no

NORWAY http://www.frico.no

For latetest updated information, see: www.frico.se

Russia

FRICO representative office in Russia

1 st Golutvinsky per., 3 Tel: +7 095 238 63 20

Moscow 109180 Fax: +7 095 238 64 20

RUSSIA e-mail: frico@orc.ru

Loading...

Loading...