Page 1

GB

Instruction for products with software version 1.2.

Read this instruction before installation and wiring

i

of the product. This product is BTL listed from

software version 1.2-1-00 (BACnet stack 3.0.4).

Consult documentation in all cases where this symbol

is used, in order to nd out the nature of the potential

hazards and any actions to be taken

INSTRUCTION

FCR-230

FCR230

Room controller for controlling fan-coil units

FCR-230 is a room controller intended for controlling fan-coil heaters/

coolers and thermal actuators or 3-point actuators. Installation is

directly on the wall or on an electrical connection box. The fan can be

set to one of three speeds.

FCR-230 has change-over function and can be used for 2-pipe or

4-pipe systems.

For integration into a system, FCR-230 has communication via

RS485 (Modbus, BACnet or EXOline). The device can be congured

using the application Regio tool (version 1.3-1-05 or later), which can

be downloaded from the Regin web site (www.regin.se).

Technical data

Supply voltage 230 V AC ±10 %, 50/60 Hz

Power consumption < 3 W

Ambient temperature 0...50°C

Ambient humidity Max 90 % RH

Storage temperature -20...+70°C

Built-in temperature sensor NTC type, range 0...50°C

Inputs Refer to connection illustrations and

table below

Outputs Relays for fan control, 230 V AC, 3 A

DO4, DO5 for actuators, Triac, 230 V AC,

max. 300 mA

Communication RS485: Modbus, EXOline (using

automatic detection/switching) or BACnet

Modbus 8 bits, 1 or 2 stop bits. Odd, even

(FI) or no parity

Communication speed 9600, 19200, 38400 bps (EXOline, Modbus

and BACnet) or 76800 bps (BACnet only)

Terminal blocks Lift type for a maximum cable area 2.1 mm

Protection class IP20

Pollution degree 2

Overvoltage category 3

Material casing Polycarbonate, PC

Dimensions 102 x 120 x 29 mm

2

Installation

Place the controller in a location that has a temperature representative for

the room. A suitable location is approx. 1.6 m above oor level in a place

with unobstructed air circulation.

Depress the locking tab in the upper edge of the controller with a

screwdriver. Carefully turn the screwdriver until the bottom plate and the

electronics unit are slightly separated (see gure 1). Then use the cutout

that becomes visible in the edge of the bottom plate to open the upper

edge completely (see gure 2). Do the same thing in the lower edge of the

controller.

Figure 1 Figure 2

Lift the electronics unit up from the bottom plate. The bottom plate with

terminals has a number of hole combinations. Select suitable holes and

fasten the bottom plate on the wall or connection box, so that the arrows

on the bottom plate point upwards. Do not tighten the screws too hard!

FCR-230

Note: FCR-230 does not indicate fan breakdown or overheating of the

heating coil. Therefore, all connections must be made externally. An

overheating protection or similar can be used to disconnect the supply

voltage.

Disconnection

FCR-230 should be connected to a switch or circuit breaker in the

building installation. This switch should be in close proximity to the

controller and within easy reach of the operator, and should be

marked as the disconnecting device for the equipment.

Always use the circuit breaker to disconnect the controller from the

mains supply during maintenance of the fan-coil and actuators.

Settings

Control modes

FCR-230 can control heating and cooling in sequence or be set to

seasonal switching between heating and cooling (change-over, see

below).

Change-over function

FCR-230 has an input for change-over that automatically resets the

output DO4 to operate with heating or cooling function. When the controller is used together with a 3-position actuator, output DO5 is also

aected by the change-over function in accordance with the above. A

sensor of type PT1000 can be connected to the input and be mounted

so that it senses the temperature on the supply pipe to the coil.

When the temperature exceeds 28°C, the output function is set to

heating and when the temperature drops below 16°C, the output is

set to cooling. As an alternative, a potential-free contact can be used.

The input function can be set to NO/NC.

To ensure satisfactory functioning when using a sensor, the system

must have continuous primary circuit circulation. When the changeover function is not used, the input must be left disconnected.

When using an electric heater and the change-over function is set to

heating, the sequence of operation for FCR-230 will be heating/heat-

ing and DO5 will be activated rst.

If a change-over sensor is not connected, the sequence will be heating/heating. If cooling is to be used in the sequence, parameter 2

(change-over mode) must be changed manually.

Operating mode

There are four dierent operating modes. Switching between these

modes is performed locally.

Comfort: is shown in the display. Heating and cooling have a

smaller neutral zone NZC. An occupancy detector can be connected

to the DI in order to select between Comfort and Economy. Switching

between Comfort/Economy and O can also be done via the On/O

button. Comfort/Economy is selected via the parameter list.

1

Page 2

Economy (Standby): “Standby” is shown in the display. The heating and cooling setpoints are freely adjustable. Factory settings:

heating=15°C, cooling=30°C.

O: The controller does not heat or cool and the fan stops (unless

mould protection has been selected or the cool-down function for the

electric heater is running, in which case the fan will still run).

Window: is shown in the display, the controller is o and the fan

stops (unless mould protection has been selected or the cool-down

function for the electric heater is running, in which case the fan will

still run). The window contact is connected to the DI and must be

congured.

Occupancy detection

Parameter 3 determines if the DI is window contact input or

occupancy detection input. An occupancy detector can be connected

to the DI in order to switch between Comfort and Economy mode.

Setpoint

The setpoint is set using the INCREASE and DECREASE buttons.

Parameter 24 determines what is shown in the display. Refer to the

parameter list for details.

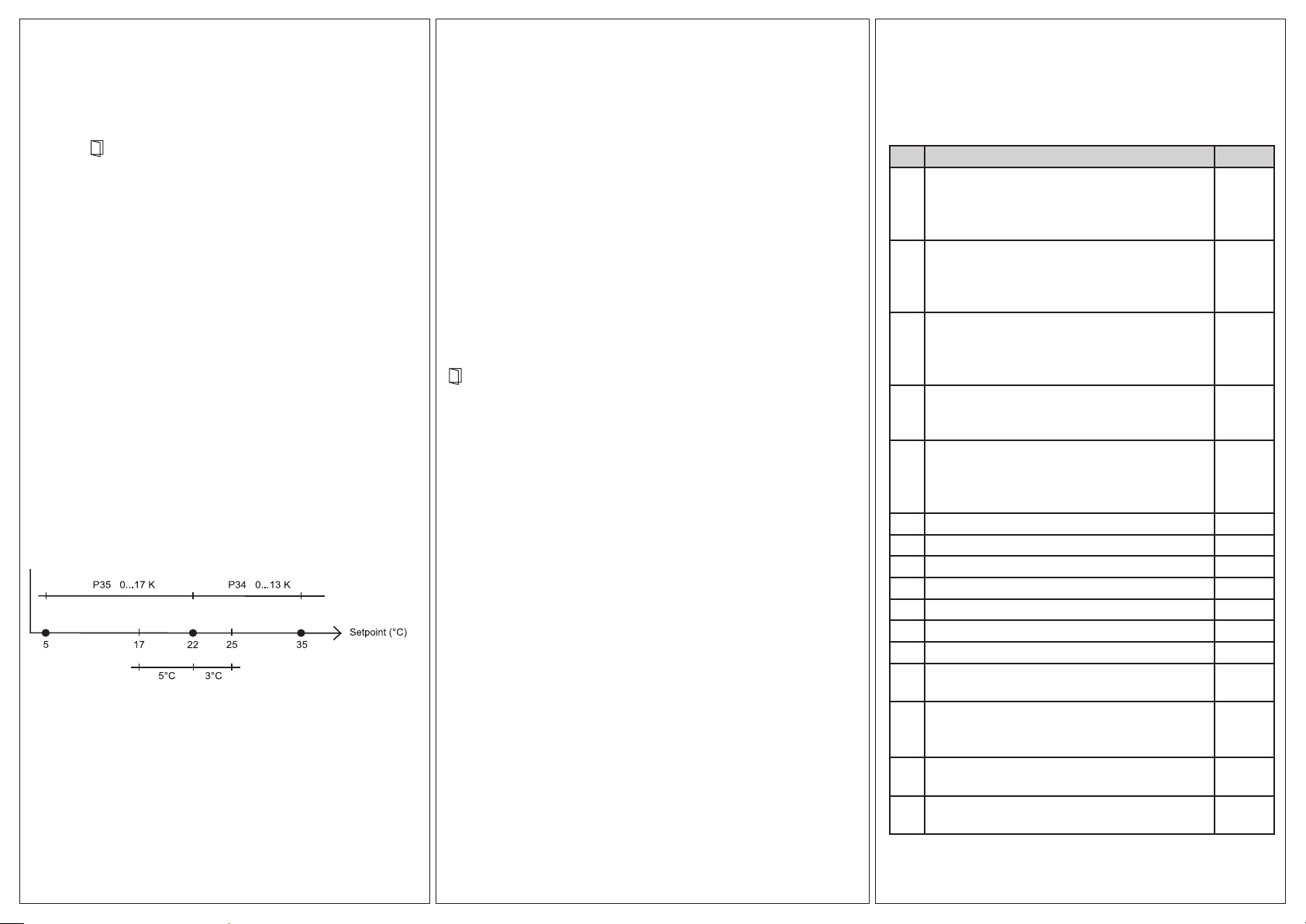

Setpoint limitation

In parameters 34 and 35, it is possible to set the maximum allowed

setpoint increase and decrease respectively.

Example: If P35=5 and P34=3, the setpoint can be changed between

17°C and 25°C (see the picture below).

The basic setpoint can be changed in parameter 64 (factory

setting=22°C).

Figure 3: Example of setpoint limitation

Fan control

The fan can be controlled via FCR-230 with the following modes: Low

speed, Medium speed, High speed, Auto. The current fan speed in

the Auto mode depends on the heating or cooling demand and the

settings for each speed.

When using automatic control, ”AUTO” is shown in the display.

The number of fan speed steps can be selected via parameter 30.

If the parameter is set to 1, the rst fan speed step will be used for fan

control.

Via parameter 31, it is possible to set the fan to the lowest speed level

when Auto mode is selected. If this parameter is set to 1, the fan will run

in all operating modes except O and Window (unless mould protection is

active or the cool-down function for the electric heater is running, in which

case the fan will run in these modes as well).

Manual control of the fan speed

By pressing the fan button, you change the fan speed according to the

sequence IàIIàIIIàAUTO. When using manual control, ”MAN” is shown

in the display.

If the fan has been congured not to be aected by the heating or cooling

demand, ”AUTO” will not be shown when pressing the fan button.

Indications

The display has the following indications:

HEAT Heating control

COOL Cooling control

The open window symbol is shown if this function has

been congured and a window is open.

OFF The controller does not heat or cool

On/O button

By pressing the On/O button, FCR-230 will switch between O mode

and Comfort/Economy mode.

Parameter list

When the controller is in Comfort mode or Window mode, dierent parameter values can be set in a parameter list.

Hold the INCREASE and DECREASE buttons depressed simultaneously

for about 5 seconds until the Service symbol is displayed and then press

the INCREASE button twice.

First the display will show parameter 1. Use the INCREASE and DE-

CREASE buttons to scroll between the parameters and press the On/O

button to select the desired parameter. The parameter number will then

be replaced by the parameter value. The value can be changed using the

INCREASE and DECREASE buttons. If a button is held depressed the

value will start scrolling, rst slowly and then with increasing speed.

To exit the parameter list and go back to the basic display, press the INCREASE button until “EXIT” is shown (one step before parameter 1) and

press the On/O button. You can also exit the parameter list by pressing

down the INCREASE and DECREASE buttons simultaneously.

Parameters

The following parameters can be changed in the parameter list.

Nº = parameter number

FS = factory setting

NO = normally open

NC = normally closed

Nº Description FS

1 Control mode:

2=2-pipe system

3=4-pipe system

4=(Electric heater) N/A

2 Change-over mode:

0=Heating control, 1=Cooling control, 2=Automatic

change-over depending on analogue temperature

sensor or digital input

3 Operating mode when activating digital input 1,

terminal 40/41:

0=Economy mode (occupancy detector)

1=O mode (window contact)

4 Mould protection:

0=Not active

1=Active (fan never stops)

5 Neutral zone at Comfort mode (NZC). If the neu-

tral zone is 2 K, the heating setpoint is equal to the

setpoint minus 1 and the cooling setpoint is equal

to the setpoint plus 1.

6 Heating setpoint when unoccupied 15°C

7 Cooling setpoint when unoccupied 30°C

8 P-band for the room controller 10 K

9 I-time for the room controller 300 s

10 Not used for this model

11 Switch o timer for Comfort mode 0 min

12 Switch on delay for Comfort mode 0 min

13 Sensor connected to AI1, terminal 42/43:

0=Internal sensor, 1=External room sensor

14 Sensor connected to UI1, terminal 43/44:

0=None, 1=Change-over digital, 2=Change-over

analogue

15 Type of digital actuator:

0=Thermal, 1=3-point

16-17Not used for this model

3

0

0

0

0 K

0

0

0

FCR-230

2

Page 3

Nº Description FS

18 Period time for heating actuator with

60 s

thermal actuator

19 Period time for cooling actuator with

60 s

thermal actuator

20 Runtime for heating actuator with increase/de-

120 s

crease actuator

21 Runtime for cooling actuator with increase/de-

120 s

crease actuator

22 Time in hours between exercise of heating actua-

23

tor

23 Time in hours between exercise of cooling actua-

23

tor

24 Setpoint or actual value shown in the display:

0

0=Actual, setpoint when changing the setpoint,

1=Actual, setpoint adjustment when changing the

setpoint, 2=Setpoint, 3=Only the setpoint adjustment

25 Conguration of fan control:

3

0=No control, 1=The fan is controlled by heating

requirement, 2=The fan is controlled by cooling

requirement, 3=The fan is controlled by heating

and cooling requirement

When using an electric heater, this parameter

should only be set to 1 or 3, or the heater may be

overheated.

26 Start signal in % of the controller output, heating

or cooling, for fan speed 1

20 (5

when

using an

electric

heater)

27 Start signal in % of the controller output, heating

60

or cooling, for fan speed 2

28 Start signal in % of the controller output, heating

100

or cooling, for fan speed 3

29 Hysteresis for start/stop of fans in % of the control-

5

ler output. (N/A)

30 Number of fan speeds (N/A) 3

31 Fan speed in the Auto mode:

0

0=The fan speed follows the cooling/heating

output, 1=The fan speed is minimum limited to

the lowest speed

32 Temperature compensation on AI1 0 K

Nº Description FS

33 Temperature compensation for the internal room

0 K

sensor

34 Highest permitted setpoint oset upwards. Set-

13 K

table value=0...13 K. Starting point=22°C.

35 Highest permitted setpoint oset downwards. Set-

17 K

table value=0...17 K. Starting point=22°C.

36 NO/NC digital input 1:

0

0=NO, 1=NC

37 NO/NC universal input 1:

0

0=NO, 1=NC

38 NO/NC digital output 4:

1

0=NO, 1=NC

39 NO/NC digital output 5:

1

0=NO, 1=NC

40 Manual/Auto heating output signal:

2

0=O, 1=Manual, 2=Auto

41 Manual/Auto cooling output signal:

2

0=O, 1=Manual, 2=Auto

42 Heating output signal in manual mode 0

43 Cooling output signal in manual mode 0

44 Model 45 Version Major 46 Version Minor 47 Released or beta version 48 Revision 49 Display backlight low 0

50 Display backlight high 30

51 EXOline PLA address 52 EXOline ELA address 53 Modbus address 254

54 Modbus communication parity bit:

2

0=No parity, 1=Odd parity, 2=Even parity

55 Modbus timeout for character (t1.5) in ms. Should

2 ms

be 1.5 times a character, i.e. at least 2 ms.

56 Modbus answer delay (t3.5) in ms. Should be 3.5

5 ms

times a character, i.e. at least 5 ms.

57 Communication protocol:

0

0=EXOline/Modbus, 1=BACnet MS/TP

58 BACnet MS/TP MAC address

-

0-127=master address, 128-254=slave address

Nº Description FS

59 The 4 low numbers in the BACnet device ID,

-

0-9999

60 The 3 high numbers in the BACnet device ID 61 BACnet MS/TP Max. master 127

62 Communication protocol speed:

0

0=9600 bps, 1=19200 bps, 2=38400 bps,

3=76800 bps (alternative 3 only applies to BACnet)

63 Resets communication parameters (not address-

0

es) to their factory settings:

1=Factory settings (EXOline/Modbus@9600)

64 Basic setpoint. Settable value=5...50°C. 22°C

Recommended settings for Frico convectors:

Nº TKW heat TKW cool TKW change over

2 0 (FS) 1 2

14 0 (FS) 0 (FS) 2

31 0 (FS) 0 (FS) 0 (FS)

Nº SL/SLS R

heat

SL/SLS R

cool

SL/SLS R

change over

2 0 (FS) 1 2

14 0 (FS) 0 (FS) 2

31 1 1 1

Wiring

20

10

POWER

LOGIC

40

Figure 4: Bottom plate connections

30

50

FCR-230

3

Page 4

BLU-BLUE

BIANCO-WHITE

GRIGIO-GREY

VIOLA-VIOLET

V

G

FACTORY WIRING

SAFETY MICRO FLOAT

FAN MOTOR INTERNAL UNIT

DRAIN PUMP

ADDITIONAL WIRING

EELECTRIC VALVE

FS

PS

IFM

VPTK

SUPPLY TERMINAL BLOCK

TB

COLORE CAVI WIRE COLOURS

B

MARRONEBROWN

NEROBLACK

ROSSORED

ORANGE

CWR

O

YELLOW/GREEN

Y/G

A

FCR230

HEATING INPUT SIGNAL ( 230V a.c.)

230V - 1~ - 50Hz

N

L

D04

COOLING INPUT SIGNAL ( 230V a.c.)

33 D05

44 AGnd

41 Al

2 ÷ 10Vd.c.

50 A01

50 AGnd

+

-

AO1

Figure 8: External placement

B

Modbus

EXOline

M

BACnet

Connection of dierent actuators

FILTER

L N PE

AB Y/G

(cool) (heat)

VPTK VPTK

0 V Y

EC fan

When connecting thermal actuators, DO4 is used for heating actuators and DO5 for cooling actuators. If the installation is a 2-pipe

installation and the change-over function is used, the actuator should

be connected to DO4.

When connecting 3-point actuators, DO4 is used for increase signal

and DO5 for decrease signal, even when the change-over function is

used.

TKW

Figure 5: Connection diagram

~ ~ YX Y1 Y2 Y3 Y4 L L N N PE

1TB

Y/G

B

A

O

4 3 2 1

4 3 2 1

G

1CF

1CM

Y/G

B

W

1IFM

W

CR

B

1PS

11

A

G

O

FS

35 35

2LIV 1LIV

C

N L PE

X3

P15V

A+

AP+

P-

W V U TP TP

X2

M1 M2

INVERTER

BLAC

RS232

1PCB

B

C

ECGT1

A

Figure 6: Connection diagram with water heater

M

Modbus

EXOline

BACnet

10 L 230 V AC Line Power supply

11 - Not connected

12 N 230 V AC Neutral Power supply (internally con-

nected to terminal 13)

13 N Fan-coil common /

230 V AC Neutral

Common fan-coil connector (internally connected to

terminal 12)

20 DO1 Fan-coil output 1

Relay, 230 V AC*, 3 A

for fan control

21 DO2 Fan-coil output 2

Relay, 230 V AC*, 3 A

for fan control

22 DO3 Fan-coil output 3

Relay, 230 V AC*, 3 A

for fan control

ECGT1

30 - Not connected

31 DO4 Digital output 4 for

heating/cooling

or opening with

Digital output. 230 V AC, max

300 mA. Max 2 A during 20

ms.

3-point actuator

32 CDO45 Common DO4 & 5 Common connection for

Figure 7: internal placement

FCR-230

digital outputs 4 and 5

4

Page 5

33 DO5 Digital output 5 for

cooling or closing

with 3-point actuator.

40 DI Digital input Potential-free window contact

41 Agnd Analogue ground

42 AI Analogue input External PT1000 instead of

43 UI Universal input Change-over input. Potential-

44 Agnd Analogue ground

50 Agnd Analogue ground

51 - Analogue out A0I EC fan

52 - Not connected

53 A RS485 communication A

54 B RS485 communication B

*The sum of the current through DO1-DO3 is protected by a fuse

Digital output. 230 V AC, max

300 mA. Max 2 A during

20 ms.

or occupancy contact. Con-

gurable for NO/NC.

the internal NTC

free switch (congurable for

NO/NC) or PT1000.

Low Voltage Directive (LVD) standards / EMC emissions &

immunity standards

This product conforms to the EMC and LVD requirements in the

European harmonised standards EN 60730-1:2000 and EN 60730-29:2002 and carries the CE mark.

RoHS

This product conforms to the Directive 2011/65/EU of the European

Parliament and of the Council.

Contact

Frico AB, Industrivägen 41, 433 61 Sävedalen, Sweden

Tel: +46 31 336 86 00, Fax: +46 31 26 28 60

www.frico.net, mailbox@frico.se

SE

i

Instruktion för produkter med mjukvaruversion 1.2.

Läs denna instruktion innan produkten monteras

och ansluts. Produkten är BTL-godkänd fr.o.m.

mjukvaruversion 1.2-1-00 (BACnet-stack 3.0.4).

Följ alltid de anvisade säkerhetsföreskrifterna i

dokumentationen för att förebygga risken för brand,

elstöt och personskador

INSTRUKTION

FCR-230

Rumsregulator för styrning av fan-coil-enheter

FCR-230 är en rumsregulator avsedd att styra fan-coil-värmare/kylare och

termiska ställdon eller 3-punktsställdon. Montage sker direkt på vägg eller

eldosa. Fläkthastigheten kan regleras i tre steg.

FCR-230 har change-over-funktion och kan användas för 2-rörs- eller

4-rörssystem.

FCR-230 har kommunikation via RS485 (Modbus, BACnet eller EXOline)

för inbyggnad i system. Apparaten kan kongureras via verktyget Regio

tool (version 1.3-1-05 eller senare), som kan laddas ner kostnadsfritt från

Regins hemsida (www.regin.se).

Tekniska data

Matningsspänning 230 V AC ±10 %, 50/60 Hz

Egenförbrukning < 3 W

Omgivningstemperatur 0...50°C

Omgivande fuktighet Max. 90 % RH

Lagringstemperatur -20...+70°C

Inbyggd temperaturgivare Typ NTC, mätområde 0...50°C

Ingångar Se inkopplingsbilder och tabell nedan

Utgångar Reläer för äktstyrning, 230 V AC, 3 A

DO4, DO5 för ställdon, Triac, 230 V AC,

max. 300 mA

Kommunikation RS485: Modbus, EXOline (automatisk

detektering/omkoppling) eller BACnet

Modbus 8 bitar, 1 eller 2 stoppbitar. Udda, jämn

(FI) eller ingen paritet

Kommunikationshastighet 9600, 19200, 38400 bps (EXOline, Modbus

och BACnet) eller 76800 bps (endast

BACnet)

Skruvplint Av hisstyp för kabelarea max 2,1 mm

Skyddsklass IP20

Nedsmutsningsgrad 2

Överspänningskategori 3

Material hölje Polycarbonat, PC

Mått 102 x 120 x 29 mm

2

Installation

Montera regulatorn på en plats med för rummet representativ temperatur. Lämplig placering är ca 1,6 m över golvet, utan omgivande

hinder för luftcirkulation.

Tryck in låshaken i överkanten av regulatorn med en skruvmejsel.

Vrid försiktigt på mejseln tills bottenplattan och elektronikenheten

delar något på sig (se gur 1). Använd sedan det hack som blir synligt

i kanten av bottenplattan för att öppna överkanten helt (se gur 2).

Gör samma sak i underkanten av regulatorn.

Figur 1 Figur 2

Lyft ur elektronikenheten ur bottenplattan. Bottenplattan med

anslutningskontakter har ett antal hålbilder. Välj passande hålbild

och skruva fast bottenplattan på vägg eller eldosa, så att pilarna i bottenplattan pekar upp. Dra inte skruvarna för hårt!

OBS: FCR-230 har ingen indikering som visar om äkten går sönder

eller om värmebatteriet är överhettat. Därför måste alla kopplingar

FCR-230

5

Loading...

Loading...