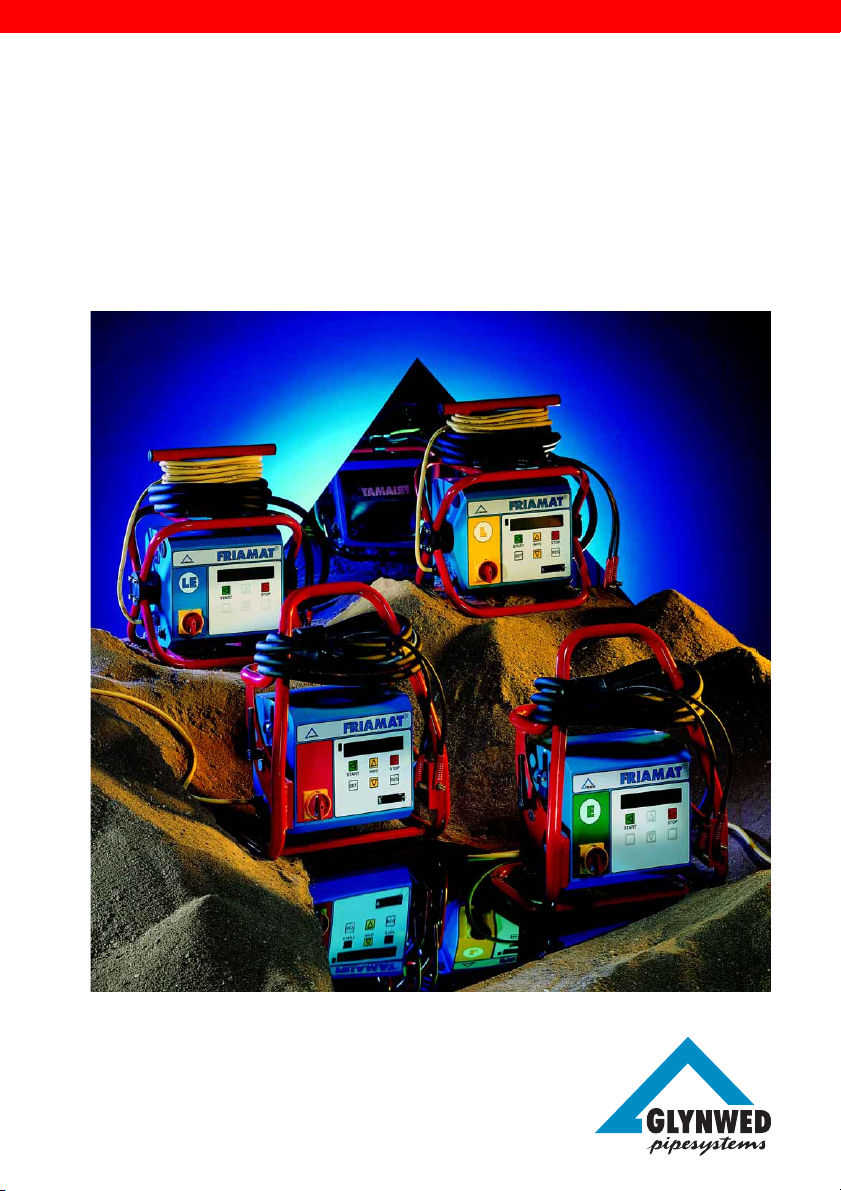

Technical Equipment FRIALEN®/FRIAFIT

Operating Instructions

FRIAMAT® Fusion Units

®

37

Contents Page

1. SAFETY 4

1.1 Dangers 4

1.2 Safety hints and tips 4

1.3 Use in accordance with the requirements 5

1.4 Sources of Danger 6

1.5 Permitted users 6

1.6 Dangers from electrical power 6

1.7 Emissions 7

1.8 Safety precautions on site 8

1.9 Signal equipment 8

1.10 Emergencies 8

2. TECHNICAL DATA / TRANSPORT / COMMISSIONING 9

2.1 Technical data 9

2.2 Transport / storage / despatch 10

2.3 Setting up / connection 10

2.4 Putting into service 10

3. BASIC SETTINGS 11

3.1 Explanation of the function buttons 11

3.2 Date and time 12

3.3 Setting the signal volume 12

3.4 Setting the language 13

4. OPERATION 14

4.1 Construction / components 14

4.2 Functional principles 14

4.3 Fusion operating procedure 14

4.4 Preparation 14

4.5 Reading in the bar code 15

4.6 Starting the fusion process 16

4.7 Display voltage and frequency 17

2

5. AUXILIARY FUNCTION (ONLY FOR DOCUMENTATION UNITS) 18

5.1 Documentation 18

5.1.1 Switching on 18

5.1.2 Switching off 18

5.2 Operator’s Pass 19

5.3 Commission Numbers 20

5.3.1 Specifying and saving a commission number 20

5.3.2 Selecting saved commission numbers 21

5.3.3 Deleting saved commission numbers 21

5.3.4 Altering currently set (activated) commission numbers 22

5.3.5 Deactivating commission numbers 22

5.4 Info-text 22

5.5 Fusion Report 23

5.5.1 Print / delete the whole content of the memory 23

5.5.2 Printing out and deleting individual commission numbers 24

5.5.3 Deleting data without printing out the logs. 25

6. MAINTENANCE / TAKING OUT OF SERVICE 25

6.1 Warranty 25

6.2 Care and Maintenance instructions 25

6.3 Checking the reader wand 26

6.4 Taking out of service 26

7. OPERATING FAULTS 26

7.1 Faults when reading in the bar code 26

7.2 Emergency Input 26

7.3 Overheating 27

7.4 Fusion interruption 27

7.5 Fault messages / Warning messages 28

8. APPENDIX 30

8.1 Recommended accessories (options) 30

8.2 Authorised Service Centres world-wide 31

3

1. Safety

1.1 Dangers

The fusion units of the FRIAMAT® Family are constructed using state of the

art technology and in accordance with recognised safety rules, and are fitted

with the appropriate protective equipment. In addition to this the fusion units

of the FRIAMAT® Family are entitled to carry the TÜV GS Test Symbol as a

result of tests in line with the German Equipment Safety Law.

The fusion units of the FRIAMAT® Family have been checked for function and

for safety before being delivered. Incorrect operation or misuse, however,

can mean potential danger to

- the health of the operator,

- your FRIAMAT® model or other property of the user,

- the efficient operation of your FRIAMAT® model

All personnel who are in any way involved with the commissioning, operation,

maintenance or repair of the FRIAMAT® must

- be suitably qualified and

- comply precisely with these operating instructions.

This affects YOUR safety !

1.2 Safety hints and tips

This operating instruction employs the following SYMBOLS with WARNING

NOTES:

DANGER ! Describes an impending threat of danger !

Non-compliance with this instruction can result in severe damage to health

and property.

WARNING ! Describes a dangerous situation !

Non-compliance with this instruction can cause slight injuries or damage to

property

IMPORTANT ! Designates user tips and other useful information

4

1.3 Use in accordance with the requirements

The fusion units of the FRIAMAT® Family are exclusively for use in the fusion

of

- FRIALEN Safety Fittings with HD-PE pressure pipes (SDR 17-7)

and

- FRIAFIT Sewage Fittings with HD-PE sewage pipes (SDR 17 - 32)

Your FRIAMAT® model can also be used with fittings from other manufacturers

as long as they have been provided by the manufacturer with a bar code 2/5

interleaved to ANSI HM 10.8 M - 1983 or ISO CD 13950/08.94.

Using in according with the requirements also includes observing

- all the directions in this Operating Instruction and also

- the guidelines from the DVGW Code of Practice, from the DVS, the UVV

and the appropriate national and local regulations.

IMPORTANT ! Any other usage does not comply with the requirements !

FRIATEC AG accepts no liability for use which does not comply with the

requirements:

- Modifications or alterations are not permitted for safety reasons

- The fusion units of the FRIAMAT® Family must only be opened by an

electrical specialist

- Fusion with fusion units of the FRIAMAT® Family whose lead seals are

broken will render all claims for warranty and liability null and void.

Other examples of uses which contravene the requirements:

- use as a battery charger

- use as a power supply for heaters of any type

5

1.4 Sources of Danger

- Damaged connection leads and extension cables must be replaced

immediately

- Do not either remove safety devices or put them out of action

- Eliminate known faults immediately

- Do not leave your FRIAMAT® model unattended

- Keep away from flammable liquids / gases

- Do not operate in an Ex-environment

1.5 Permitted users

Only trained personnel may work with your FRIAMAT® model. The operator is

responsible for third parties in the working area The user must:

- make the operating instruction available to the operator and

- satisfy himself that the latter has read and understood them

1.6 Dangers from electrical power

- Do not use any damaged connecting cables

- Check the connection leads for damage

- Pull out the power supply plug before all care and maintenance work !

- Only have servicing, maintenance and repairs carried out by authorised

service centres

- Only connect the fusion units of the FRIAMAT® Family to the supply

voltage stated on the rating plate

WARNING ! Distribution points on the construction site: Comply with

the regulations on circuit breakers

Outdoors (on construction sites) sockets must be fitted with earth leakage

circuit breakers. If using generators the DVGW Work Sheet GW 308 and

VDE 0100 Part 728 must be complied with. The generator output rating

required is dependent on the power requirements for the largest fitting being

used, on connection conditions, ambient conditions and the actual generator

type (its control characteristics). Since generators from different model ranges

exhibit very different control characteristics the suitability of a generator

cannot always be guaranteed by the specified rated output alone.

6

In the event of doubt (e.g. when purchasing new) ask the authorised service

centre or request the “Positive Generator List” from FRIATEC AG.

Only use generators whose operating frequency lies within the range from

45 - 66 Hz.

First start the generator and let it run for half a minute. Set the off-load voltage

if necessary and limit it to the voltage specified in the technical data. !

Generator (mains) fuse max. 16 A (slow acting)

IMPORTANT ! Before starting the fusion process always check the input

voltage for your FRIAMAT® model from the Technical

Data (See Section 2.1 and 4.7)

If using an extension cable make sure the cross section is adequate:

- 2.5 mm2 up to 50 m and

-4 mm2 up to 100 m length.

Always unroll the cable fully before use. ! Do not connect any other equipment

to the same generator whilst fusion is taking place ! At the end of the fusion

operation first disconnect the power cable to the generator and then shut off

the generator.

DANGER ! Risk to life ! Never open your FRIAMAT® model whilst it is

connected to the power supply !

The fusion units of the FRIAMAT® Family are must only be opened by

specialist personnel from a recognised service centre !

1.7 Emissions

The (equivalent) continuous noise level from all fusion units of the FRIAMAT

Family is below 70 dB(A). When working in a quiet environment the effect of

the signal tone on the “Loud” setting is very loud. For this reason the signal

tone is adjustable (loud / quiet)

®

7

1.8 Safety precautions on site

IMPORTANT ! All the fusion units of the FRIAMAT® Family are splash

proofed. They must not be, however, dipped in water.

1.9 Signal equipment

The fusion units of the FRIAMAT® Family confirm certain operating processes

with an acoustic signal tone (1, 2, 5 tones or a continuous tone). These

signals have the following meanings:

Signal tone x 1 means: Confirmation of reading in a bar code

Signal tone x 2 means: Fusion process ended.

Signal tone x 3 means: Supply voltage too low / too high.

Signal tone x 5 means: Warning - Fault. Look at the display !

1.10 Emergencies

In an emergency switch the master switch to “OFF” immediately and

disconnect your FRIAMAT® model from the power supply ! The fusion units of

the FRIAMAT® Family can be stopped by:

- operating the master switch

- pulling out the power supply plug

8

2. Technical data / Transport / Commissioning

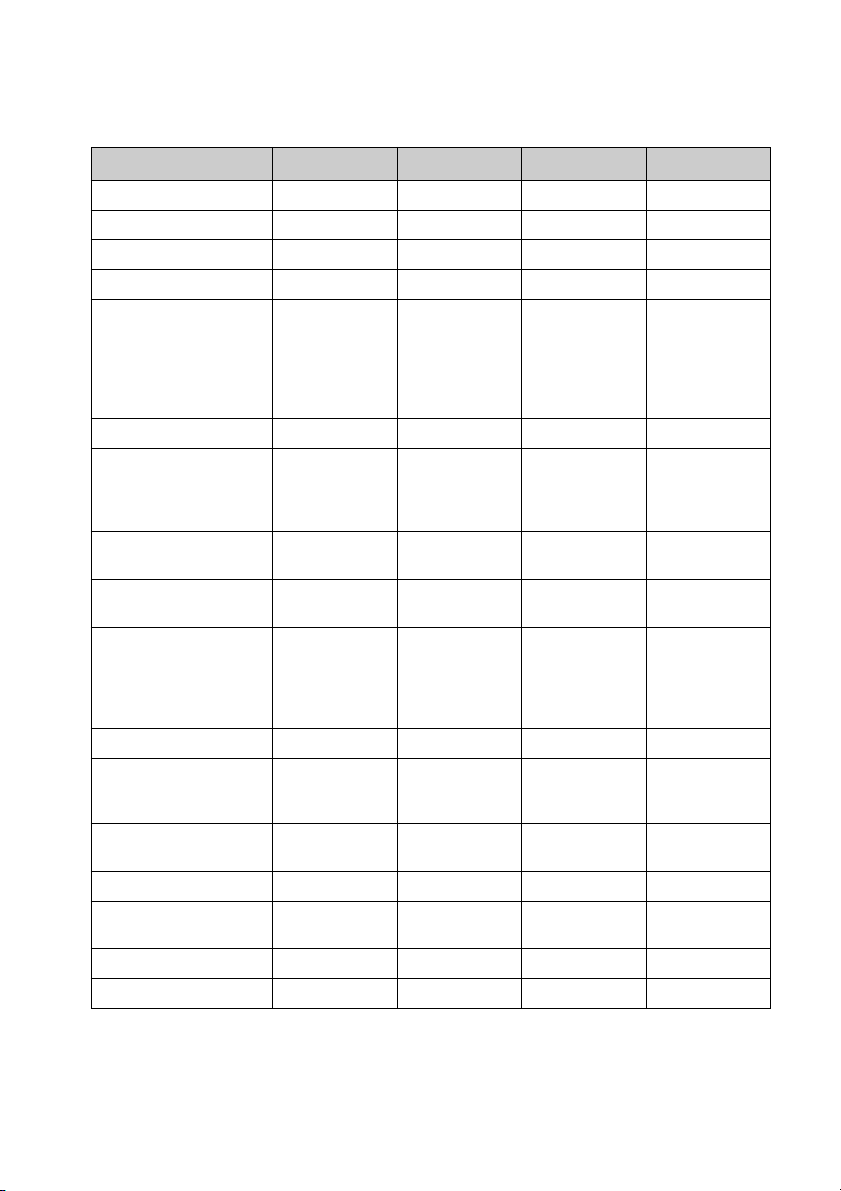

2.1 Technical data

FRIAMAT

®

FRIAMAT®E FRIAMAT®L FRIAMAT®LE

Input voltage range AC 200 V.-. 260 V AC 200 V.-. 260 V AC 200 V.-. 260 V AC 200 V.-. 260 V

Frequency range 44 Hz... 66 Hz 44 Hz... 66 Hz 44 Hz... 66 Hz 44 Hz... 66 Hz

Current consumption AC 16 A max. AC 16 A max. AC 16 A max. AC 16 A max.

Power 3.5 kW 3.5 kW 3.0 kW 3.0 kW

Generator rated output 1~

d20 - d160 AC 2.4 kW AC 2.4 kW AC 2.4 kW * AC 2.4 kW *

d180 - d630 AC 4.0 kW AC 4.0 kW

(mechanical governor)

d180 - d630 AC 4.0 kW AC 5.0 kW

(electronic governor)

Equipment fuse 16 A slow acting 16 A slow acting 16 A slow acting 16 A slow acting

Casing Enclosure class Enclosure class Enclosure class Enclosure class

IP 54 DIN 40 050 IP 54 DIN 40 050 IP 54 DIN 40 050 IP 54 DIN 40 050

Protection class I Protection class I Protection class I Protection class I

DIN 57 700 DIN 57 700 DIN 57 700 DIN 57 700

Connection cable 5 m with 5 m with 5 m with 5 m with

contoured plug contoured plug contoured plug contoured plug

Fusion cable 4 m with Ø 4 mm 4 m with Ø 4 mm 4 m with Ø 4 mm 4 m with Ø 4 mm

fittings plug fittings plug fittings plug fittings plug

Bar code Code 2/5 Code 2/5 Code 2/5 Code 2/5

interleaved to interleaved to interleaved to interleaved to

ANSI HM 10.8M - ANSI HM 10.8M - ANSI HM 10.8M - ANSI HM 10.8M 1983, ISO CD 1983, ISO CD 1983, ISO CD 1983, ISO CD

13950/08.94 13950/08.94 13950/08.94 13950/08.94

Working temperature range -20 °C ... +50 °C** -20 °C ... +50 °C** -20 ° C ... +50 °C** -20 °C ... +50 °C**

Fusion current monitoring Short circuit 110 A Short circuit 110 A Short circuit 110 A Short circuit 110 A

Open circuit Open circuit Open circuit Open circuit

0.25 x I

N

0.25 x I

N

0.25 x I

N

0.25 x I

N

Printer interface Parallel - Parallel -

(D-Sub 25) (D-Sub 25)

Fusion voltage max. AC 48 V max. AC 48 V max. AC 48 V max. AC 48 V

Dimensions 370x280x480 mm 370x280x480 mm 350x260x450 mm 350x260x450 mm

W x D x H

Weight 19 kg 19 kg 14 kg 14 kg

Weight with transport box 23 kg 23 kg 18 kg 18 kg

*: The FRIAMAT®L / LE is only suitable for domestic connections and distribution pipes up to

d110, plus saddle components of all sizes

** : When fusing fittings from other manufacturers always take heed of the details given on the

working temperature range.

9

2.2 Transport / storage / despatch

Your FRIAMAT® model is delivered in a transport box. There are no particular

requirements for unpacking, or for (temporary) storage in the transport box.

Storage temperature - 20 °C to + 70 °C

WARNING ! Do not damage the front face of your FRIAMAT® model !

Always despatch in the transport box.

2.3 Setting up / connection

If protected from rain and wet your FRIAMAT® model can be set up and

operated out of doors.

- Set up the FRIAMAT® on level ground (as near horizontal as possible).

- Ensure that generator is fused with a 16 A minimum (slow acting) fuse.

- Plug the mains plug into the mains socket or connect to the generator.

- If necessary use an extension cable, ensuring that the cross section is

adequate (see section 2.1 “Technical Data”).

- Always comply with the operating instructions for the generator.

WARNING ! Always unroll the cable before use

2.4 Putting into service

WARNING ! Charring ! Dirty contacts can char the plug.

The contact surfaces of the fitting and the fusion plug must always be clean.

- Remove any existing deposits thoroughly

- Protect the plug from contamination, replacing it if necessary

- Check the fusion plugs and contact sockets on the fitting for dirt, and only

then make the connection

10

3. Basic Settings

3.1 Explanation of the function buttons

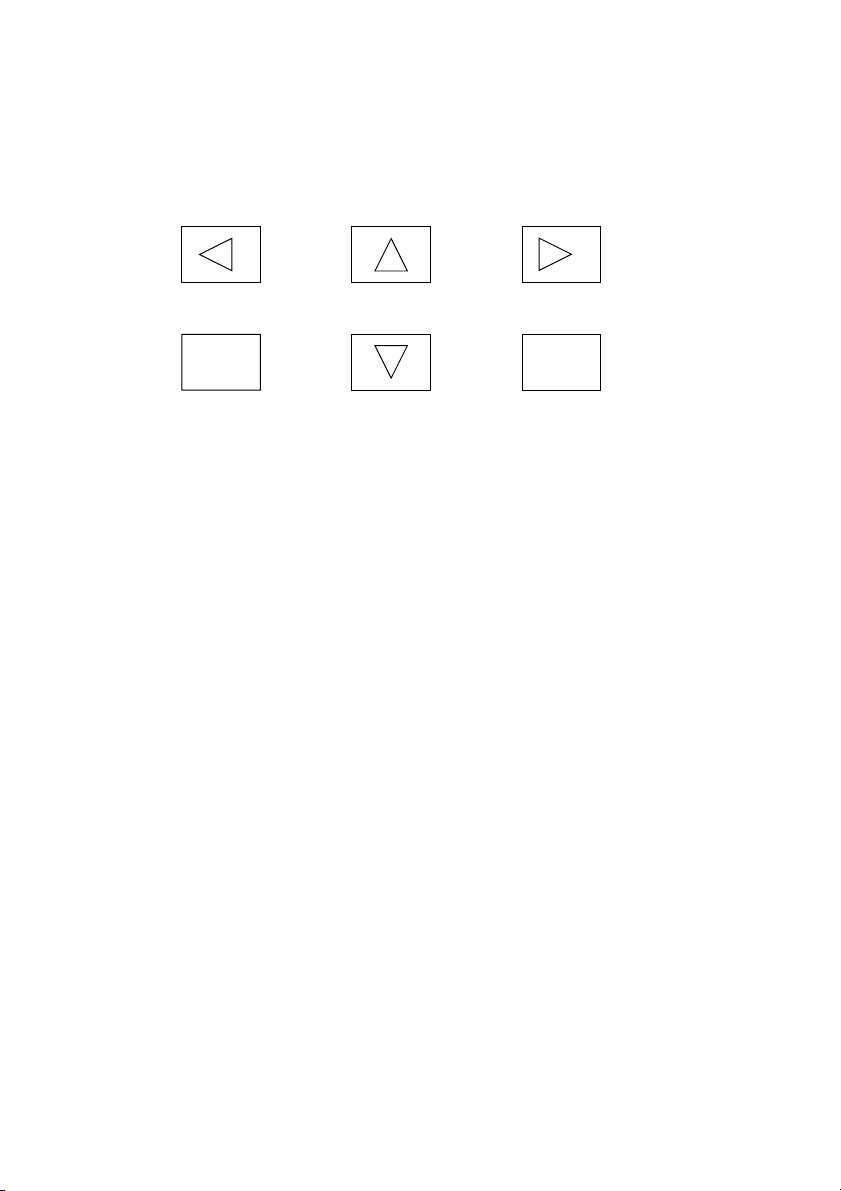

The fusion units of the FRIAMAT® Family have 6 function buttons. Please take

note of the diagram below and the basic explanation of the buttons,

START STOPINFO

SET RESMENU

START: The START button is green in colour. It is used to start a fusion

process, to confirm messages and to call up / select menu functions.

The START button also moves the cursor in the display to the left

when entering characters (e.g. entering notes, date).

STOP: The STOP button is red in colour. It is used to cancel a fusion

process, in some menus to select menu functions and generally to

end menu functions. The STOP button also moves the cursor in the

display to the right when entering characters (e.g. entering notes,

date).

INFO: The INFO button is yellow or grey in colour depending on the

model. It is used to call up current information (voltage / frequency,

date / time, ambient temperature, fusion operator, language) or to

scroll through the individual menus. When entering characters (e.g.

entering notes, date) the setting of the required character is made

with the INFO button.

SET: The SET button is grey in colour. It is used to save settings.

MENU: The MENU button is yellow or grey in colour depending on the

model. It is used to call up the main menu and to scroll through the

individual menus. When entering characters (e.g. entering notes,

date) the setting of the required character is made with the MENU

button.

RES: The RES button is grey in colour. It is used to cancel an input

process.

11

3.2 Date and time

There are two ways of setting date and time.

1. Through the main menu:

Go into the main menu by pressing the MENU button. Now press the

MENU button as many times as it takes for the “Set Date / Time” setting

menu to appear in the display. To set the date / time press the START

button. “FRIAMAT” and the designation of your model will appear in the

top line of the display, whilst the date and time will appear in the bottom

line. The first character will flash. With the INFO / MENU button you can

move one day forward / back. With the START / STOP button you can

move left or right. With the SET button you can confirm and save the new

Date / Time, and with the RES button you can break off without saving.

After pressing the SET or RES button, press the STOP button at the end to

cancel the menu selection.

2. Reading in the TIMER bar code

“FRIAMAT” and the designation of your model will appear in the top line of

the display, whilst the date and time will appear in the bottom line. The first

character (Day) will flash. With the INFO / MENU button you can move one

day forward / back. With the START / STOP button you can move left or

right. With the SET button you can confirm and save the new Date / Time,

and with the RES button you can break off without saving.

FRIAMAT

01.Jul 1999 14:34

3.3 Setting the signal volume

Go into the main menu by pressing the MENU button. Now press the MENU

button as many times as it takes for the “Signal Volume” setting menu to

appear in the display. To set the signal volume press the START button.

“Signal Volume” will appear in the top line of the display, whilst “loud” will

appear on the left in the bottom line and “quiet” on the right. By pressing the

START / STOP button you can adjust the signal volume to loud / quiet. Press

the STOP button at the end to cancel the menu selection.

12

Signal volume

yes continue End

Signal volume

loud quiet

3.4 Setting the language

Go into the main menu by pressing the MENU button. Now press the MENU

button as many times as it takes for the “* Language *” setting menu to

appear in the display (Meaning of the star : See IMPORTANT note in this

section). To set the language press the START button. “* Language *” will

appear in the top line of the display, whilst the actual language set will appear

in the bottom line. Two stars will flash on the right and left to show that you

are in the language setting menu. To change the language select the language

you require with the INFO / MENU button. Press the SET button to end and

save the settings. You can press the RES button to end without saving. Press

the STOP button at the end to end the menu selection.

* Language *

yes continue End

* Language *

* German *

IMPORTANT ! The setting of the language only refers to the one shown

in the display. The language of the documentation

(Report) remains English

IMPORTANT ! In the language setting menu two stars appear, left and

right, in the upper line. These are used to allow the

language setting menu to be recognised when for

example the language has accidentally been set wrongly.

13

4. Operation

4.1 Construction / components

The electronics in your FRIAMAT® model are housed in a splash-proof

casing. The carrying frame is also used to hold the cables. The fusion units of

the FRIAMAT® Family are designed for a maximum fusion voltage of 48 V. The

supply and fusion voltage are isolated from each other by a safety transformer.

4.2 Functional principles

Only electrofusion fittings with a bar code can be fused with the fusion units

of the FRIAMAT® Family : Each fitting is assigned a sticker with a bar code.

This contains the information to ensure that fusion is carried out properly. The

computerised command system of your FRIAMAT® model:

- is completely automatic in regulating and checking the metering of the

electrical power

- determines the fusion time depending on the ambient temperature. The

temperature probe in the fusion cable continuously determines the ambient

temperature.

4.3 Fusion operating procedure

So that the FRIALEN Safety Fittings and the FRIAFIT Sewage Fittings will be

properly processed it is essential to adhere to the FRIALEN operating

instructions.

The same applies to fittings from other manufacturers.

4.4 Preparation

IMPORTANT ! Unroll the cable completely !

This applies to mains, fusion and, if applicable, extension

leads. The contact surfaces of the fitting and of the

fusion plugs must be clean; dirty contacts can cause

overheating and charring of the plug. If necessary remove

any existing deposits cleanly

14

Always protect the plug from contamination. If there is a

deposit which cannot be completely removed, the fusion

plugs must be replaced.

- Prepare the fitting and pipes for fusion in accordance with the assembly

instructions

- Ensure that the contact pins on the fitting are accessible for connection of

the fusion plugs

- Connect up the power supply (mains or generator)

- If using a generator start it up first and allow to warm up for 30 seconds

- Switch on the master switch (1)

- Connect the fusion plugs to the contact pins on the fitting

4.5 Reading in the bar code

IMPORTANT ! It is not acceptable to read in the bar code label from

another sort of fitting instead. After ending the read-in

process the reader wand must be replaced in the reader

wand pouch immediately to avoid damage and contamination to the tip of the wand.

If there is a bar code label stuck onto the fitting this should always be used.

If the bar code label on the fitting being fused is illegible due to damage,

an identical fitting from the same manufacturer with a legible bar code

label should be used.

Hold the reader wand slightly slanting and slightly inclined (like a pencil) and

place it on the fitting in front of the bar code. Now move the reader wand

quickly across the whole label and a little beyond. The reading can be done

from left to right or from right to left. When this has been done correctly the

machine will confirm it with a signal tone. If the reading in is not successful

first time try again, if necessary at a different angle or speed.

15

4.6 Starting the fusion process

IMPORTANT ! If there is a malfunction in the fusion process hot molten

PE can be expelled in rare cases.

So:

Keep at a safe distance of at least 1 m from the fusion

point during the fusion process ! Do not connect any

other equipment during the fusion process !

The fusion process can be broken off at any time by pressing the STOP

button. When the fused area has cooled down (and the source of the fault

eliminated if necessary) the fusion process can be repeated (depending on

the fitting manufacturer; please comply with the instructions for use from the

fitting manufacturer in question).

Operating steps: (see also the visual representation on the next page):

1. Press the START button to initiate the fusion process

2. If applicable confirm the display “Pipe processed ?” with the START

button. Next there will be an automatic display of the ambient temperature

and a resistance check on the connected fitting. The fusion process will

start. In the display you can follow the duration of the fusion process (the

complete fusion time will be displayed and counted down to zero in

seconds).

3. Display “End of fusion” means: fusion process finished, ready for the next

fusion. The displays “t:” and “tc:” mean required and actual fusion time

and these must agree.

4. Make a note of the fusion parameters onto the pipe / fitting. This will also

avoid fusing twice

5. To initiate a new fusion process press the START button.

16

FRIA MON 63 mm

START Infotext

FRIA MON 63 mm

Pipe processed ?

End of fusion

t: 53 s tc: 53 s

4.7 Display voltage and frequency

Before or after the fusion: To display the voltage and frequency press the

INFO button. The STOP button will take you back to the basic setting.

During fusion: Pressing the INFO button will display the voltage and frequency,

after 3 seconds the unit will automatically go back to the basic setting.

Voltage: 221.3 V

Frequency: 50.01 Hz

WARNING ! Your FRIAMAT® model is designed for an input voltage

range of 200 - 260 volts. If you are working in the range

from 150 - 200 volts or 260 - 320 volts the actual voltage

and frequency will automatically appear on the display.

You can ignore this warning note by pressing the STOP

button and carry on working but there is a risk that

you will damage the electronics of your FRIAMAT® model.

If the input voltage range is under 150 volts or above

320 volts the actual voltage and frequency will likewise

appear on the display. In this case, however, the warning

indication will remain until you have regulated the input

voltage back into the recommended range and have

acknowledged with the STOP button.

17

5. Auxiliary function (only for documentation units)

5.1 Documentation

Your FRIAMAT® model is supplied with the documentation deactivated

(switched off). The “Documentation” function is used to save the technical

fusion parameters. These can in each case be assigned to a commission

number and/or to an operator pass.

5.1.1 Switching on

This function is activated or deactivated by reading in a DOCUMENTATION

bar code (see plastic card in the accessories pouch). When the function is

activated the display will show the sequential number on the left and the

number of fusions which can still be stored on the right (and if applicable,

above these the appropriate commission number.)

FRIAMAT

2 ➔ Code 499

5.1.2 Switching off

The DOCUMENTATION function can be deactivated by reading in the

DOCUMENTATION bar code again. The safety question of whether this is

required can be acknowledged by pressing the START button or rejected by

pressing the STOP button (breaking off with the STOP button will bring about

a return to the previous state).

Switch off

documentation ?

18

5.2 Operator’s Pass

IMPORTANT ! The operator pass can only be read in with the documen-

tation switched on

Your FRIAMAT® model can be set for use with an operator pass by reading in

the bar code from an operator pass. The operator pass can be ordered from

FRIATEC. When a user code has been read in for the first time all fusions

which are then carried out will be saved under the code for this operator

pass. If another operator pass is read in your FRIAMAT® model will be

switched over to suit.

Your FRIAMAT® model can be cleared for use without an operator pass by

reading in the USER OFF bar code (see plastic card in the accessories

pouch). The question “Deactivate operator?” then appears. This can be

confirmed by pressing the START button or the process can be broken off by

pressing the STOP button.

IMPORTANT ! By means of the operator pass your FRIAMAT® model

can be blocked to protect it from unauthorised use. .

After reading in the current operator pass again the

query will appear “Block the unit?”. This can be confirmed

by pressing the START button or the process can be

broken off by pressing the STOP button. Your FRIAMAT

model will be automatically blocked when the code for an

operator pass is on file and time-wise a change of date

takes place i.e. your FRIAMAT® model will be blocked on

the next day.

®

Read in

operator

Block the

unit ?

Deactivate

operator ?

19

In both cases (manual or automatic blocking) the note “Read in Operator” will

appear in the display. Your FRIAMAT® model can be cleared for use by

reading in an operator pass

5.3 Commission Numbers

For simple administration of up to 20 different commission numbers your

FRIAMAT® model has a commission number specification menu.

5.3.1 Specifying and saving a commission number

Go into the main menu by pressing the MENU button. Now press the MENU

button as many times as it takes for the “commission no.” setting menu to

appear in the display. To get into the “Change/Specify commission nos.”

setting menu press the START button. By pressing the STOP button you will

go into the specification setting menu in which you can enter and save up to

20 commission nos. If you press the START button the current commission

no. will appear. The first character of the commission no. will flash. This can

be increased by pressing the INFO button or decreased by pressing the

MENU button. With the START / STOP button you can move left or right

within the commission no. With the SET button the commission no. set will be

saved and taken into the Specification Menu, and with the RES button you

can break off the process without saving.

Another method for getting into the “Change/Specify Commission Nos.”

setting menu is to read in the COMMISSION CODE (see plastic card in the

accessories pouch).

Commission No.

Change Specification

Commission No.

New Selection Delete

Commission No.

12 Dossenheimer Way

20

5.3.2 Selecting saved commission numbers

As described in Section 5.3.1, go into the “Change/Specify commission

nos.” setting menu.

By pressing the STOP button you will go into the commission no. specification

menu. If you press the INFO / MENU button the stored commission nos. will

be displayed.

The displayed commission no. is selected by pressing the START or SET

button. The process can be broken off using the STOP or RES button.

Pressing the STOP button again will take you back to the basic setting.

Commission No.

New Selection Delete

5.3.3 Deleting saved commission numbers

As described in Section 5.3.1, go into the “Change/Specify commission

nos.” setting menu. By pressing the STOP button you will go into the

commission no. specification menu. If you press the STOP button you will go

into the Deletion menu.

The displayed Commission No. will be deleted from the commission no.

specification menu by pressing the START button. Pressing the STOP button

will display the next commission no. The fusions which have been saved

under this commission no. will be retained together with the commission no.,

but the commission no. will no longer be available in the commission no.

specification menu.

To leave the Deletion menu press the STOP button as many times as it takes

to get back to the basic setting.

Commission No.

12 Dossenheimer Way

21

5.3.4 Altering currently set (activated) commission numbers

As described in Section 5.3.1, go into the “Change/Specify commission

nos.” setting menu.

After you press the START button the currently set commission no. will

appear. The first character will flash. This can be increased by pressing the

INFO button or decreased by pressing the MENU button. With the START /

STOP button you can move left or right within the commission no. With the

SET button the commission no. set will be saved, and with the RES button

you can break off the process without saving. By pressing the STOP button

again you can go back to the basic setting.

IMPORTANT ! The altered commission no. will not be available in the

commission no specification menu.

Commission No.

12 Dossenheimer Way

5.3.5 Deactivating Commission Nos.

The “Commission No” option will be deactivated by reading in the

COMMISSION OFF CODE (see plastic card in the accessories pouch).

FRIAMAT

2 ➔ Code 498

5.4 Info-text

With the documentation switched on there is a facility to assign an individual

additional text (2x16 characters) to each individual fusion process in the

report. After reading in the fitting bar code press the INFO / MENU button.

The last text entered will appear. The first character will flash. This can be

increased by pressing the INFO button or decreased by pressing the MENU

button. With the START / STOP button you can move left or right within the

Info text. With the SET button the Info-text set will be saved and with the RES

button you can break off the entry process.

22

FRIA MON 63 mm

START Infotext

Kuntz Generator

Type 4500 xs

IMPORTANT ! The additional text has to be newly entered for each

fusion as otherwise no text will appear in the report. If the

START button is pressed directly after reading in the

fitting bar code no additional text will be appended to the

fusion.

5.5 Fusion Report

5.5.1 Print / delete the whole content of the memory

IMPORTANT ! Only printers with a parallel interface can be used. No

printers must be connected during the fusion process.

The fusion report stored in the memory can be printed out. For this the printer

or the Memory Box (optional) has to be connected to the fusion unit. The

printer must be set to “ON-LINE”.

Go into the “Print” setting menu via the Main Menu. Alternatively you can get

into this menu by reading in the PRINT code (see plastic card in the

accessories pouch). After this there will be a query on whether individual, all

or no fusions should be printed out. A complete print-out arranged in

commission number order is started by pressing the START button. A new

page is started for each commission number.

When the complete print-out has finished there will be a query as to whether

the report memory should be deleted. If you want to delete all data press the

START button: the query “Are you sure?” will appear.

23

IMPORTANT ! If the START button is pressed the data will be irretrievably

deleted ! If the STOP button is pressed the data will not

be deleted !

Print

All None Selection

Print

All None Selection

Delete

Are you sure ?

5.5.2 Printing out and deleting individual commission numbers

Go into the “Print” setting menu as described in Section 5.5.1. Pressing the

STOP button will display the first commission number. The commission

number displayed can be printed by pressing the START button and then the

query will appear on whether the data is to be deleted. Pressing the START

button will delete the data, pressing the STOP button will bypass the delete

function and the next commission no. will be displayed. This procedure can

be broken off with the RES button.

24

Print

All None Selection

12 Dossenheimer Way

Print Next

12 Dossenheimer Way

Delete Next

5.5.3 Deleting data without printing out the reports.

Go into the “Print” setting menu as described in Section 5.5.1. By pressing

the INFO button bypass the Print Menu and go directly into the Delete Menu.

The deletion of all or individual data is carried out as already described in

Section 5.5.1. and 5.5.2.

Print

All None Selection

Delete

All None Selection

12 Dossenheimer Way

Delete Next

6. Maintenance / taking out of service

We recommend that you have your FRIAMAT® model serviced once a year

(see list of all authorised Service Stations in section 8.2.). Include all

connection adapters for checking at the maintenance intervals.

6.1 Warranty

The warranty period for the fusion units of the FRIAMAT® Family is 24 months

provided that your FRIAMAT® model undergoes a paid service within the first

14 months. Otherwise the warranty period will be 12 months.

6.2 Care and Maintenance instructions

WHAT ? WHEN ? WHO ?

Clean the reader wand and Daily Operator

check for damage

Check the function Weekly Operator

Clean the contacts Weekly Operator

Factory Maintenance Annually Authorised Service Centres

(see section 8.2)

25

6.3 Checking the reader wand

If the reading is not confirmed after reading in a bar code several times

the reader wand can be checked by reading in the TEST code (see plastic

card in the accessories pouch). “TEST CODE” will appear in the display for

4 seconds.

6.4 Taking out of service

IMPORTANT ! The fusion units of the FRIAMAT® Family contain various

components which make it necessary to ensure that it is

disposed of properly. Your FRIAMAT® model can be

disposed of at the factory or at one of the Authorised

Service Centres

7. Operating faults

7.1 Faults when reading in the bar code

If the reading in is not confirmed by an acoustic signal the reader wand

should be checked for dirt or physical damage. If the reader wand is

defective there is still the facility to carry out the fusion using the Emergency

Input Mode (see below).

7.2 Emergency Input

Go into the “Emergency Input” setting menu via the Main Menu. “Emergency

Input” will appear in the top line of the display, whilst in the bottom line you

will see “Yes” on the left, “Continue” in the centre and “End” on the right.

When the START button is pressed “Code” and 24 characters will appear,

with the first character flashing. This can be increased by pressing the INFO

button or decreased by pressing the MENU button. With the START / STOP

button you can move left or right within the Emergency Input menu. The

figures to be entered should be read off the bar code of the fitting being

fused. After entering the numbers for the bar code you have to confirm the

entry by pressing the SET button - by pressing the RES button you can break

off the process. The fusion process is started by pressing the START button.

Code: 36 18 09 01 06

38 35 08 99 05 47 00

26

7.3 Overheating

If used continuously for long periods your FRIAMAT® model could overheat.

To avoid damage to the unit a temperature monitor has been fitted, and on

the basis of this your FRIAMAT® model will calculate, before the fusion

process, whether the temperature rise anticipated due to the fusion process

is acceptable. If the calculated temperature does not lie within the permitted

range the message “Allow the unit to cool down” will appear on the display.

Since the power consumption of various electrofusion fittings will differ there

may be a possibility of fusing a different fitting.

7.4 Fusion interruption

If the fusion is broken off because, e.g. the power supply has been interrupted

during a fusion run, the fusion can be repeated after removing the cause of

the problem and after allowing the fitting to cool down completely (this is

dependent on the fitting manufacturer; always comply with the instructions

for use from the fitting manufacturer in question).

27

7.5 Fault messages / Warning messages

If irregularities occur during the fusion process then your FRIAMAT® model

will show suitable fault messages in the display

Fault messages

No. Text in display Meaning / causes Remedy

1 - - 2 Temperature Ambient temperature If necessary set up a tent

outside range outside the permitted

range

3 Resistance Electrical resistance of Check contacts for firm

outside tolerance the fitting is outside seating / dirt

the tolerance Clean contacts if necessary

If necessary replace fitting

4 Fitting winding Short circuit in the wire Replace fitting, send in

short circuit winding of the fitting for examination

5 Fitting winding Current flow interrupted Check the connection of

open circuit the fusion plug on the fitting.

If OK replace the fitting and

send in for examination

6 Voltage outside Unacceptable deviation Inform Authorised Service

tolerance of the fusion voltage Centre

7 Fault in the Malfunction in the Make a note of the fault

a..z operating system FRIAMAT® hardware or classification (a...z) and

software inform Authorised Service

Centre

8 Mains voltage Mains voltage outside Extension cable too long or

outside range the permitted range its cross section too small.

during fusion Check the voltage and

connection conditions of

the generator

9 Frequency outside Frequency outside the Check the frequency of the

range permitted range during generator voltage

fusion

10 Fusion interrupted Fusion broken off by -

pressing the STOP button

28

More Fault messages

No. Text in display Meaning / causes Remedy

11 - - -

12 - - 13 Mains failure Supply voltage inter- Check connection

rupted or too low conditions

14 - - -

15 Power rating Power consumption of -

exceeded the fitting exceeds the

rating of the FRIAMAT

®

An example of what is shown on the display:

Fault 3 INFO ?

Resistance

outside tolerance

By pressing the INFO button you will get information on the fault in plain

language

Warning messages :

Text in display Instruction / Remedy

Faulty or damaged bar code Use a new bar code from an identical

fitting or correct the manually entered code

Memory full Print out the log

Memory empty If the memory is empty no printout

is possible

Printer not ready Check whether the output device (printer,

Memory Box, PC with FRIATOOL II) is

connected correctly

29

More warning messages :

Text in display Instruction / Remedy

Let the unit cool down Protective function which prevents

overheating of the equipment. Switch off

the unit and allow it to cool down until

the warning message is no longer

displayed after switching on.

Service date exceeded Inform Authorised Service Centre.

Have the equipment serviced.

Voltage .... V; Frequency .... Hz Readjust generator then acknowledge

with the STOP button (See Section 4.7)

No text, just a continuous acoustic Supply voltage too low

tone

N.B. Double fusion If a fitting is to be fused twice the contact

plugs of the fusion unit must be pulled off

the fitting after the first fusion and the

fitting allowed to cool down (see the

instructions for use from the fitting

manufacturer)

8. Appendix

8.1 Recommended accessories (options)

- Memory Box to transfer fusion data

- FRIATOOL II for electronic processing of the fusion data

- Operator pass

- Scanner

- Remote start pass

- Fusion cable extension

- Infrared remote control

30

8.2 Authorised Service Centres world-wide

FRIATEC AG

Niederlassung Mannheim

Steinzeugstraße

D-68229 Mannheim

Tel.: 0621 / 486-1533

Fax: 0621 / 486-2030

FRIATEC AG Bohnenschäfer

Niederlassung Wittenberg Westberger Weg 86a

Waldstraße D-59065 Hamm

D-06886 Wittenberg Tel.: 0 23 81 / 6 42 43

Tel.:0 34 91 / 61 53 22 Fax: 0 23 81 / 6 08 41

Fax: 0 34 91 / 61 53 12

Axel Jülicher GmbH KS - Kirsch

Hahnenstraße 19 Schweißtechnik

D-28309 Bremen Reetzerstraße 12

Tel.: 04 21 / 87 8-0 D-31515 Wunstorf

Fax: 04 21 / 87 8 11 Tel.: 0 50 31 / 90 96 23

Fax: 0 50 31 / 7 72 37

Hansen & Reinders DIWA Schweißtechnik GmbH

GmbH & Co. KG Heidelberger Straße 11

Manderscheidtstraße 48 D-01189 Dresden

D-45141 Essen Tel.: 03 51 / 4 01 65 37

Tel.: 02 01 / 89 10 90 Fax: 03 51 / 4 01 65 17

Fax: 02 01 / 21 62 10

Friedrich Rütz Meyer Elektronic

Reinbeker Redder 102 Elmendorfer Straße 9-10 A

D-21031 Hamburg D-26160 Bad Zwischenahn

Tel.: 0 40 / 7 39 21 60 Tel.: 04 40 3 / 97 15-0

Fax: 0 40 / 7 30 40 41 Fax: 04 40 3 / 97 15 17

FRIATEC GmbH FRIATEC S.A.R.L.

Birostraße 13 Z.A. La Grande Borne

A-1230 Wien F-77140 Darvault/Nemours

Tel.: 00 43 / 61 057 Tel.: 00 33 1 64 45 23 33

Fax: 00 43 / 61 057 5 Fax: 00 33 1 64 45 23 20

31

FRIATEC S.A.U. IBERGAS-Comercio

Cuesta del Rio, s/n Cabo Ruivo

E-28860 Paracuellos del P-1800 Lisboa

Jarama/Madrid Tel.: 00 35 1 1 8 68 72 06 18

Tel.: 00 34 9 6 58 22 50 Fax: 00 35 1 1 8 68 45 71

Fax: 00 34 9 6 58 27 53

TUMAB Scanotherm

Box 50 Møllebakken 4

S-26821 Svalöv DK-6091 Bjert

Tel.: 00 46 4 18 16 385 Tel.: 00 45 75 57 29 66

Fax: 00 46 4 18 41 193 9 Fax: 00 45 75 57 24 95

VIGOTEC SA FRIATEC B.V.

Industrielaan 15 Steenpad 5

B-1740 Ternat NL-4797 Willemstad

Tel.: 00 32 2 58 27 11 0 Tel.: 00 31 168 47 36 51

Fax: 00 32 2 58 22 0 32 Fax: 00 31 168 73 2 00

FRIATEC s.r.o. FRIATEC Sp.z.o.o.

V Korytech 23 ul. Gdanska 40

CZ-10600 Praha 10 PL-70660 Szczecin

Tel.: 00 42 0 2 72 76 03 36 Tel.: 00 48 91 46 23 245

Fax: 00 42 0 2 72 76 45 69 Fax: 00 48 91 46 23 245

FRIATEC s.r.o. FRIATEC-KFT

Nitrianska 2 To 4.3.

SK-91700 Trnava H-2045 Torokbalint

Tel.: 00 42 18 05 55 14 626 Tel.: 00 36 23 33 78 41

Fax: 00 42 18 05 55 13 307 Fax: 00 36 23 33 78 42

MIVA spol. S.r.o. FRIATEC S.R.L.

Teplicskà cesta 10 Via Aldo Moro, 10

SK-05201 Spisska Nova ves I-20080 Carpiano

Tel.: 00 42 96 54 21 590 Tel.: 00 39 2 98 50 90 34

Fax: 00 42 96 54 21 590 Fax: 00 39 2 98 85 90 33

FRIATEC Incorporated FRIATEC Plasmec Pty. Ltd.

426 Fairforest Way 24 Appel Road

Greenville, SC 29609/USA Kramerville, Sandton

Tel.: 18 64 28 68 800 RSA-2144 Wendywood

Fax: 18 64 23 42 050 Tel.: 00 27 11 444 13 21

Fax: 00 27 11 444 28 40

32

IPS Pty. Ltd. ETA Plus Ltd.

Locked Bag 106 49 Cottle Park Drive

AUS-Kingsgrove NSW 2208 NZ-Lower Hutt

Tel.: 00 61 25 54 39 77 Tel.: 00 64 58 90 145

Fax: 00 61 25 02 25 61 Fax: 00 64 58 90 146

Jar Tai Trading Ltd. STR Marketing Ltee.

8 Lane 402, Ming-Sheng Rd. P.O. Box 98

Taichung / Taiwan Port Louis / Mauritius

Tel.: 00 88 64 32 25 005 Tel.: 00 23 02 12 99 72

Fax: 00 88 65 32 20 911 Fax: 00 23 02 12 99 98

Ukrgasifikazia Yug UAB DS1

3, Pedagogicheskaya Ul. Gedimino g 30

270009 Odessa / Ukraine 4050 Trakai / Litauen

Tel.: 00 38 04 82 68 54 83 Tel.: 00 37 03 85 23 16

Fax: 00 38 04 85 68 40 05 Fax: 00 37 03 85 11 33

Elektrakip Benapartner Sdn Bhd

ul. Kabuschkina 80 No. 25, Jalan TPJ 8/1

BY-220118 Minsk Taman Perindustrian Jaya

Tel.: 00 37 00 17 22 40 95 38 47200 Subang Selangor

Fax: 00 37 00 17 22 45 67 67 Darul Ehsan / Malaysia

Tel.: 00 60 37 54 54 66

Fax: 00 60 37 54 54 67

T S J S U I

Techniques in Safe Jointing Southern Gas Co. Ltd.

Av. General Paz 62 State Life Building No.3

RA-1702 Ciudadela Dr. Ziauddin Ahmed Road No. 318

Buenos Aires 75530 Karachi / Pakistan

Tel.: 00 54 14 88 94 87 Tel.: 00 92 25 73 134

Fax: 00 54 16 57 45 02 Fax: 00 92 25 73 074

Akfel Mühendislik Caldervale Technology Ltd.

Ic Ve Dis. Tic Ltd. Sti Grange Road,

Bagdat Cad. Hasan Amir SK. Batley

Dursoy is Merkezi No. 4/13 GB-WF 17 6LN West Yorkshire

TR-81030 Kiziltoprak Istanbul United Kingdom

Tel.: 00 90 21 64 14 87 78 Tel.: 00 44 19 24 42 25 70

Fax: 00 90 21 64 14 87 80 Fax: 00 44 19 24 42 25 85

33

Plant & Site Ltd. Ferdinand Wehrli

Gatehouse Warehousing Schulgasse 174

2 Harper Lane CH-8215 Hallau

Shenley Tel.: 00 41 / 5 26 81 18 87

GB-Wd7 9 HA, St.Albans Herts Fax: 00 41 / 5 26 81 18 87

United Kingdom

Tel.: 00 44 17 27 82 66 93

Fax: 00 44 17 27 82 27 31

FRIATEC Rheinhütte do Brasil

Av. Manoel Inácio Peixoto 2150

BRA-36770 Cataguases MG

Tel.: 00 55 32 69 46 207

Fax: 00 55 32 69 46 241

34

35

Technical Equipment FRIALEN®/FRIAFIT

®

36

FRIATEC Aktiengesellschaft

Technical Plastics Division

P.O.B. 7102 61 · D-68222 Mannheim

Phone (06 21) 486-0

Fax (06 21) 479196

Internet: http://www.friatec.de

e-mail: info-frialen@friatec.de

A member of GLYNWED Pipesystems

Loading...

Loading...