1

Update: 01.07.2014

EN

Operating instructions

Electrofusion units

FRIAMAT® Prime

FRIAMAT® Basic

FRIAMAT

®

2

Stand/Update: 01.07.2014

EN

Contents Page

1 Preliminary remarks 6

1.1 Safety instructions and hints 6

1.2 Intended use 6

2 Safety 7

2.1 Functional reliability 7

2.2 The operator’s obligations 7

2.3 Sources of danger 8

2.4 Mains operation 8

2.5 Generator operation 9

2.6 Extension cable 10

2.7 Opening the device 10

2.8 Safety measures at the installation site 10

2.9 Emergency 10

3 Basic information 11

3.1 Layout/parts 11

3.2 Type plate 11

3.3 Reader wand 12

3.4 Barcode scanner 12

3.5 Protective cap for data interface 13

3.6 Temperature probe 13

3.7 Fan functionality 13

3.8 Signalling devices 14

3.9 Technical details 14

3.10 Automatic activation of maintenance interval 16

3.11 Transport/storage/dispatch 16

4 “Fusion” sequence 16

4.1 Siting, connection, and startup 16

4.2 Reading in the barcode 17

4.3 Starting the fusion procedure 18

3

EN

Stand/Update: 01.07.2014

Contents Page

5 FRIAMAT Basic 19

5.1 Function keys explained 19

5.2 Display symbols explained 20

5.3 “Basic Settings” menu 20

5.4 “Info” menu 21

5.5 “Emergency Input” menu 21

6 FRIAMAT Prime 22

6.1 Function keys explained 22

6.2 Display layout (main screen) 23

6.3 Function key symbols explained 24

6.4 Function status symbols explained 25

6.5 Main window symbols explained 26

6.6 “Basic Settings” menu 26

6.6.1 Documentation 27

6.6.2 Time 27

6.6.3 Date 27

6.6.4 Language 27

6.6.5 Protocol language 28

6.6.6 Volume 28

6.7 “Emergency Input” menu 28

6.8 “Fusion Sequence” menu 28

6.8.1 Commission number 29

6.8.2 Operator pass 29

6.8.3 Info Text 30

6.8.4 Comment 1 30

6.8.5 Comment 2 30

6.8.6 Subcontractor 31

6.8.7 Traceability 31

6.8.8 Pipe Number 31

6.8.9 Pipe Length 31

6.8.10 GPS Data 31

6.8.11 Seam number 31

6.8.12 Scraper tool 31

4

Stand/Update: 01.07.2014

EN

Contents Page

6.9 “Data” menu 32

6.9.1 Transfer 32

6.9.2 PDF 33

6.9.3 CSV 33

6.9.4 Delete 34

6.10 “Info” menu 34

6.11 “Formatting” menu 34

6.12 Fusion options 35

6.12.1 ID Data 35

6.12.1.1 Commission number 35

6.12.1.2 Operator pass 36

6.12.1.3 Serial number 36

6.12.1.4 Seam number 36

6.12.1.5 GPS 1 – 3 37

6.12.2 Traceability Barcodes / Pipe Number / Pipe Length 38

6.12.3 Info Text, Comment 1, Comment 2, Subcontractor 39

6.12.4 Scraper tool 39

6.13 SUPERVISOR 40

6.13.1 Basic Settings 41

6.13.1.1 Documentation 41

6.13.1.2 Time 41

6.13.1.3 Date 41

6.13.1.4 Data Protection 42

6.13.1.5 Maintenance Date 42

6.13.1.6 Mode 42

6.13.1.7 Language 42

6.13.1.8 Emergency Input 42

6.13.1.9 Energy Display 42

6.13.1.10 Volume 42

5

EN

Stand/Update: 01.07.2014

Contents Page

6.13.2 Fusion Sequence 43

6.13.2.1 Traceability 43

6.13.2.2 Info Text 43

6.13.2.3 Comment 1 43

6.13.2.4 Comment 2 43

6.13.2.5 Subcontractor 44

6.13.2.6 GPS Data 44

6.13.2.7 Seam number 44

6.13.2.8 Serial number 44

6.13.2.9 Commission number 44

6.13.2.10 Operators pass 44

6.13.2.11 Pipe Prepared? Display 44

6.13.3 Factory Settings 45

6.13.4 PIN 45

6.13.5 Display (Resistance) 46

7 Warranty/maintenance/disposal 46

7.1 Warranty 46

7.2 Maintenance and care 46

7.3 Disposal 47

8 Error messages / warnings / info 48

9 Annex 51

9.1 Recommended accessories (options) 51

9.2 Authorised service stations 51

9.3 Updates to these operating instructions 51

6

Stand/Update: 01.07.2014

EN

1 Preliminary remarks

1.1 Safety instructions and hints

In these operating instructions, the following symbols with warnings are used:

Symbol Meaning

WARNING!

Danger to people.

Failure to comply can result in death or serious injury.

CAUTION!

Danger to people.

Failure to comply can result in minor or moderate injury.

NOTE

Danger to objects.

Failure to comply can result in objects damage.

INFORMATION

Application hints and other useful information.

Failure to comply can not result in personal inury or

objects damage.

1.2 Intended use

FRIAMAT fusion units are designed to apply a maximum fusion voltage of

48 V on the following:

•FRIALEN

®

safety fittings with HDPE pressure pipes (SDR 17-7),

•derFRIALEN® XL large pipe installations with HDPE pressure pipes

(SDR 17-7), and

•FRIAFIT® sewage fittings with HDPE sewage pipes (SDR 17-33).

FRIAMAT fusion units can also be used on fittings from other manufacturers

when these components bear a 24 digit barcode complying with ISO

13950:2007-03. The power ratings and technical data of both the fittings and

the FRIAMAT fusion unit must be observed (see also Section 3.9 “Technical

data”).

Intended use also includes adherence to:

•alloftheinstructionsintheseoperatinginstructions,

•thegeneralandspecicprocessingspecicationsforelectrofusion

fittings, and

•theapplicableaccidentpreventionregulations,theenvironmental

regulations, the statutory rules, the pertinent safety provisions, and

all standards, laws, and directives applying in the country of use.

7

EN

Stand/Update: 01.07.2014

2 Safety

2.1 Functional reliability

FRIAMAT fusion units are state of the art, built in accordance with the requirements under ISO 12176-2 and the acknowledged safety standards and fitted

with the required safety devices. Prior to delivery, FRIAMAT fusion units are

tested for correct and safe functioning. Failure to operate or otherwise use the

equipment properly will pose a danger to:

•thehealthoftheoperator,

•theFRIAMATfusionunitorotherpropertyoftheuser,or

•theefciencyofworkwiththeFRIAMATfusionunit.

Safety considerations forbid the following:

•modicationsandchangestotheFRIAMATfusionunitand

•workingwithFRIAMATfusionunitswithbrokenleadseals.Failingto

observe the above makes all warranty claims void.

2.2 The operator’s obligations

Only trained personnel may work with the FRIAMAT fusion unit. In the work

area, the operator is responsible for all third parties. The owner is obliged:

•tomaketheoperatinginstructionsaccessibletotheoperatorand

•toensurethattheseinstructionshavebeenreadandunderstood.

The operating instructions must be kept at all times at the device’s place

of use (ideally in the mesh pocket on the transport box). They must be

accessible to the operator at all times.

8

Stand/Update: 01.07.2014

EN

2.3 Sources of danger

WARNING!

Electric shock from live parts! Danger of death!

- Never leave the FRIAMAT fusion unit unattended.

- Immediately replace damaged housings, connecting lines, and extension

cables. Stop using the FRIAMAT fusion unit.

- Before all care and maintenance work, pull out the plug connecting the

equipment.

- Maintenance and repair work must be performed by authorised FRIATEC

service stations only.

- Supply FRIAMAT fusion units only with the operating voltage specified on

the ratings plate.

- Fit a residual current protective device (RCD) when this is prescribed.

- Do not remove or otherwise put safety installations out of operation.

- Immediately eliminate identified defects.

WARNING!

Danger of fire and explosion from highly flammable materials and

potentially explosive atmospheres!

- Keep away from flammable liquids and gases.

- Do not use in potentially explosive atmospheres (e.g. in areas where

flammable gases, solvent vapours, or ignitable dusts can accumulate).

- Never leave the FRIAMAT fusion unit unattended.

2.4 Mains operation

Out of doors (building sites), power outlets must be fitted with residual

current protective devices (RCDs). The regulations governing RCDs must be

observed here.

NOTE

Before commencing fusion, check the input voltage. The FRIAMAT fusion unit

is designed for an input voltage range of 190–250 V!

9

EN

Stand/Update: 01.07.2014

2.5 Generator operation

NOTE

Only those generators must be used that have been designed for industrial

use on building sites. The operating instructions for the generator must be

observed!

The use of generators must comply with DVGW work sheet GW308, VDE

0100 Part 728, and the specifications and guidelines applying in the country

of use.

INFORMATION

The rated power output required from the generator depends on the level

needed for the largest fusion fitting, the connection conditions, the ambient

conditions, the generator type, and its control characteristics. Generators from

different series exhibit highly diverse control characteristics. The suitability of

a specific generator, therefore, cannot be safeguarded even when it provides

the required rated power output according to its technical data sheet.

In cases of doubt, e.g. when acquiring new equipment, contact our service

hotline +49 (0)621 486-1533!

Use only those generators that operate with frequencies within 44–66 'Hz.

First start the generator, and let it run for half a minute. If necessary, adjust the

no-load voltage, limiting it to the voltage specified in the technical data. The

generator (mains) fuse must be at least 16 A (slow blow).

NOTE

During fusion, do not operate any other consumer from

the same generator!

On finishing fusion work, first pull out the plug connecting the device to the

generator, and then switch off the generator.

10

Stand/Update: 01.07.2014

EN

2.6 Extension cable

When using an extension cable, make sure it has an adequate conductor

cross section:

•2.5mm

2

up to 50 m in length or

•4mm2 up to 100 m in length.

NOTE

Danger of overheating in the extension cable!

The extension cable may be used only when it has been completely unwound and

stretched out.

2.7 Opening the device

WARNING!

Electric shock from live parts! Danger of death!

- Never open the FRIAMAT fusion unit when it is supplied with operating

voltage!

- FRIAMAT fusion units may be opened only by specialised personnel from

an authorised FRIATEC service station!

2.8 Safety measures at the installation site

The connecting and fusion cables must be protected against sharp edges. Do

not expose the FRIAMAT fusion unit to heavy mechanical loads.

FRIAMAT fusion units are splash proof. They may not, however, be immersed

in water.

2.9 Emergency

In emergencies, immediately set the main switch to OFF, and disconnect the

FRIAMAT fusion unit from the voltage supply.

11

EN

Stand/Update: 01.07.2014

3 Basic information

3.1 Layout/parts

1

2

3

4

6

7

8

5

1 Main switch 4 Ventilation slots (air intake)

2 Fusion cable with reader wand or 5 Data interface with (USB)

barcode scanner protective cap

3 Front foil with display and 6 Adapter bag

function keys (Fig shows 7 Power cable

FRIAMAT Prime) 8 Ventilation slots (air outlet)

3.2 Type plate

The type plate lists the details specific to the FRIAMAT fusion unit and

its unique device number. The type plate is found on the rear side of the

device, under the adapter bag.

12

Stand/Update: 01.07.2014

EN

3.3 Reader wand

To read in fusion barcodes and traceability barcodes, place the reader wand

under a slight angle (like a pencil) in front of the barcode on the fitting. Now

move the reader wand quickly over the whole label and a little beyond. Barcodes can be read in from right to left or vice versa. When the barcode has

been read in correctly, the device emits an acoustic signal to confirm this. If

the barcode cannot be read in the first time, repeat the procedure, this time

under a different angle or at a different speed.

NOTE

Protect the tip of the reader wand from dirt and damage!

The condition of the reader wand tip has a direct effect on the legibility of barcodes.

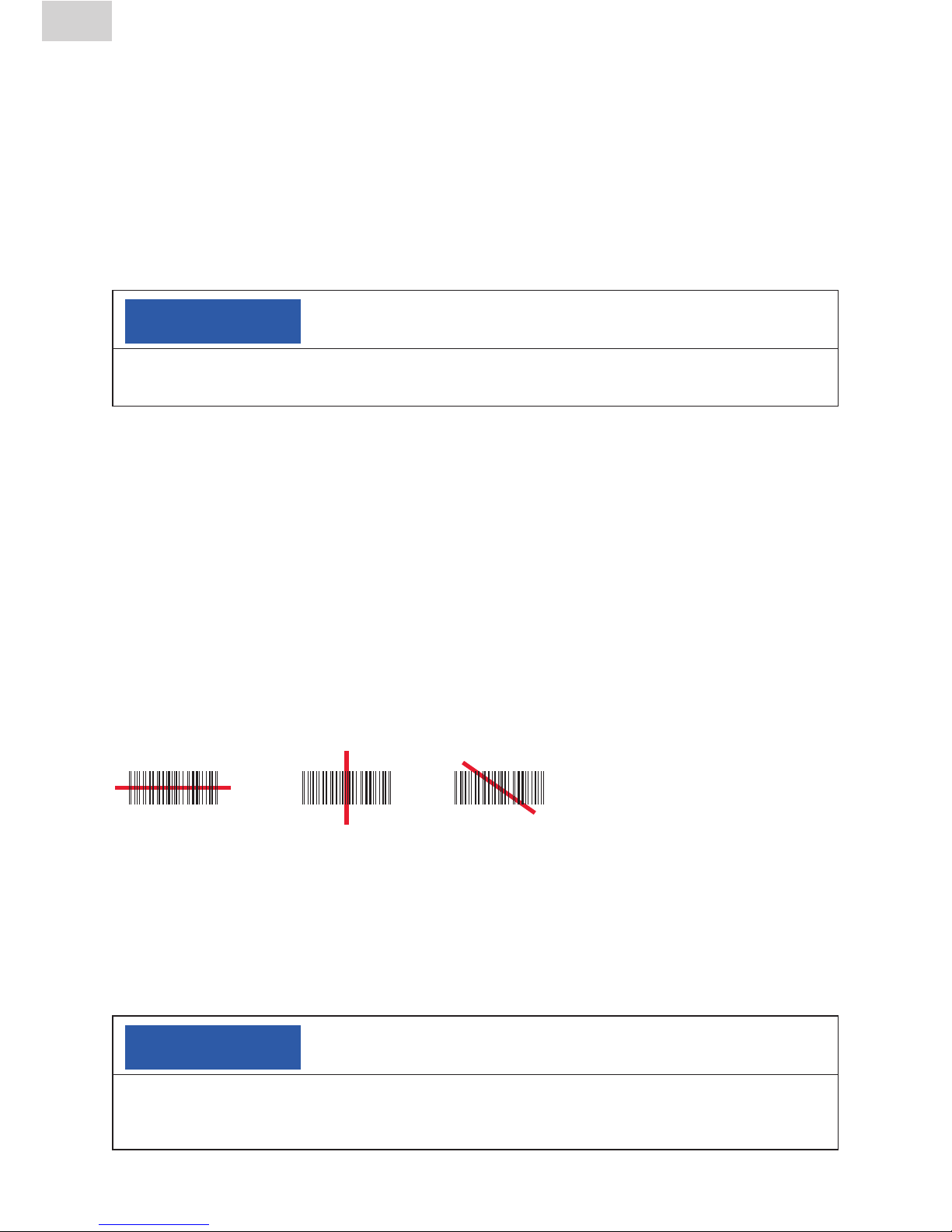

3.4 Barcode scanner

The barcode scanner uses a laser to read in fusion barcodes and traceability

barcodes without physical contact. All you need to do is aim at the barcode

and press the read button. The barcode is scanned by means of a red light

strip that must cross over the whole barcode, whenever possible at the centre. The barcode is not detected properly when the red light strip does not

cross the whole barcode.

The optimal read results are obtained when the scanner is positioned at a

small distance over the barcode.

Good legibility Failed to read Failed to read

Badly printed or slightly damaged barcodes can be read in when the scanner

is placed directly on the barcode and then, with the read button pressed,

moved away. When the barcode is read in successfully, the device emits an

acoustic signal, and a green indicator lamp lights up in the middle of the read

barcode.

NOTE

Protect the reading window from dirt and scratches!

The condition of the reading window has a direct effect on the capabilities of the

FRIAMAT barcode scanner.

13

EN

Stand/Update: 01.07.2014

3.5 Protective cap for data interface

The USB-A port is found directly behind the protective cap. This data interface functions as a service port and, on the FRIAMAT Prime, is also used

to read out and transfer the fusion protocol. The protective cap for the data

interface must be screwed on at all times to prevent contaminants and

moisture from reaching it.

3.6 Temperature probe

FRIAMAT fusion units can be used only on electrofusion fittings bearing a

barcode. When this is read in, the microprocessor controlled FRIAMAT fusion

unit regulates and monitors the supplied energy fully automatically and defines the fusion time as a function of the ambient temperature. This ambient

temperature is continuously measured by the temperature probe on the fusion

cable (silver coloured metal sleeve at the reader wand or scanner bag).

Make sure that both the temperature probe and the fusion fitting are exposed

to the same ambient temperatures. Avoid adverse processing situations, e.g.

where the probe is exposed to intense sunlight and the fitting is in the shade.

The temperature probe must be protected against damage.

3.7 Fan functionality

How the fans function depends on the temperatures measured at the heat

sink inside the FRIAMAT fusion unit. The fans switch ON automatically when

the heat sink reaches a certain temperature. And this not only during, but also

between fusion sessions, or after reactivation, depending on the (previous)

load levels. This safeguards reliable operations in continuous duty and during

fusion on large dimensions.

INFORMATION

Reduce cooling times!

In particular during series fusion work or work on fittings requiring high power

levels, leave the FRIAMAT fusion unit switched ON after each fusion. The fans

can then reduce the heat sink temperature.

14

Stand/Update: 01.07.2014

EN

3.8 Signalling devices

FRIAMAT fusion units confirm certain sequences of operations by emitting an

acoustic signal (1, 2, 3, or 5 beeps). These signals mean the following:

1 beep means: Read barcode confirmed.

2 beeps mean: Fusion procedure ended.

3 beeps mean: Supply voltage too low / too high.

5 beeps mean: Error! See display!

INFORMATION

Adjust the volume!

The volume of these signals can be set to “high” or “low” in the “Basic Settings”

menu. See also Sections 5.3 and 6.2.6.

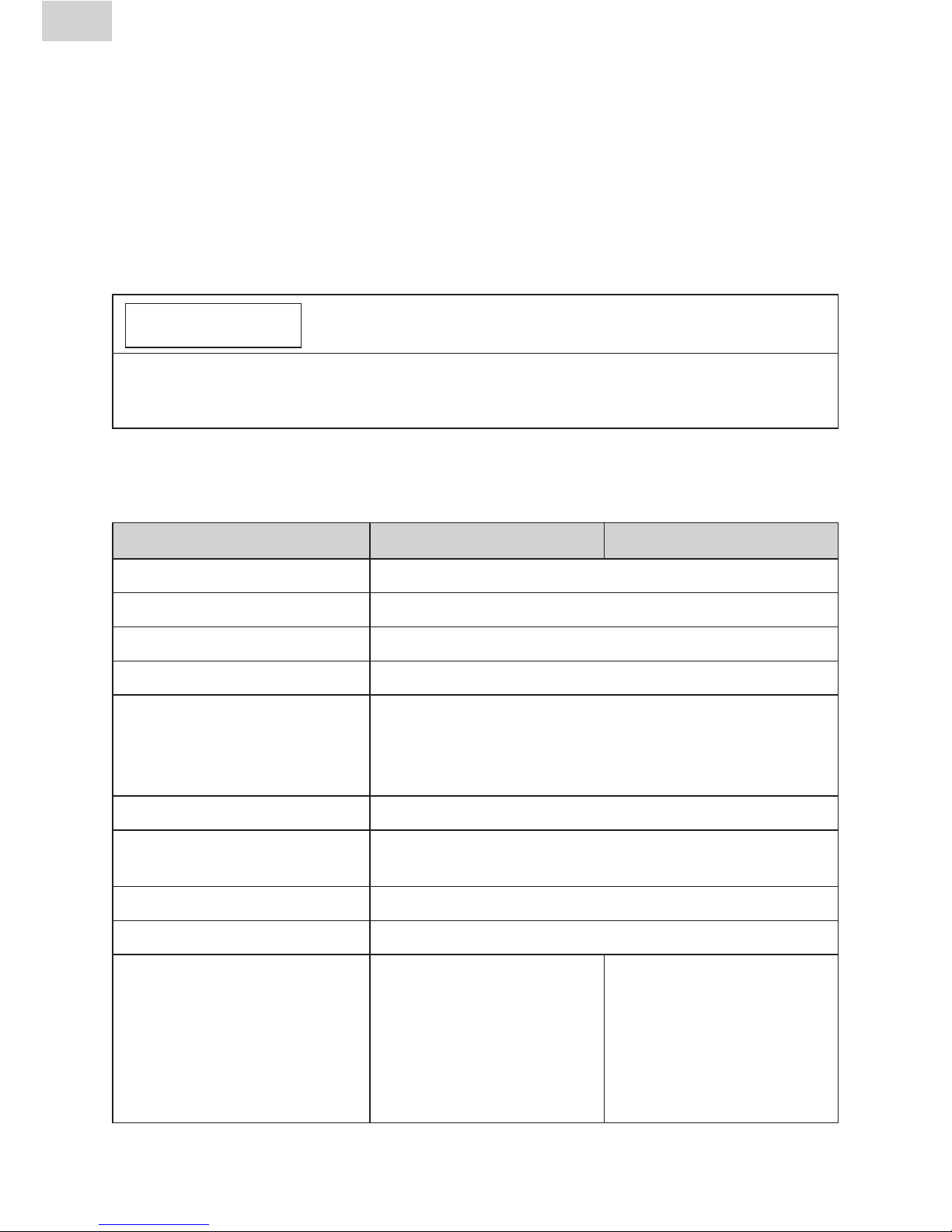

3.9 Technical details

Technical details* FRIAMAT Prime FRIAMAT Basic

Input voltage range AC 190 V – 250 V

Frequency range 44 Hz...66 Hz

Input current AC 16 A max.

Output 3.5 kW

Generator rated

output for fittings

d20–d160

d180–d900 ~ AC 5.0 kW

Unit fuse 16 A slow blow

Housing international protection IP 54 DIN EN 60529

protection class I DIN EN 60335-1

Connecting cable 5 mm with contoured plug

Fusion cable 4 m with fittings plug, ø 4 mm

Barcode type code 2/5 code 2/5

interleaved according to interleaved according to

ANSI HM 10.8 M-1983 ANSI HM 10.8 M-1983

and ISO CD 13950/08.94 and ISO CD 13950/08.94

code 128 according to

ISO 12176-4

15

EN

Stand/Update: 01.07.2014

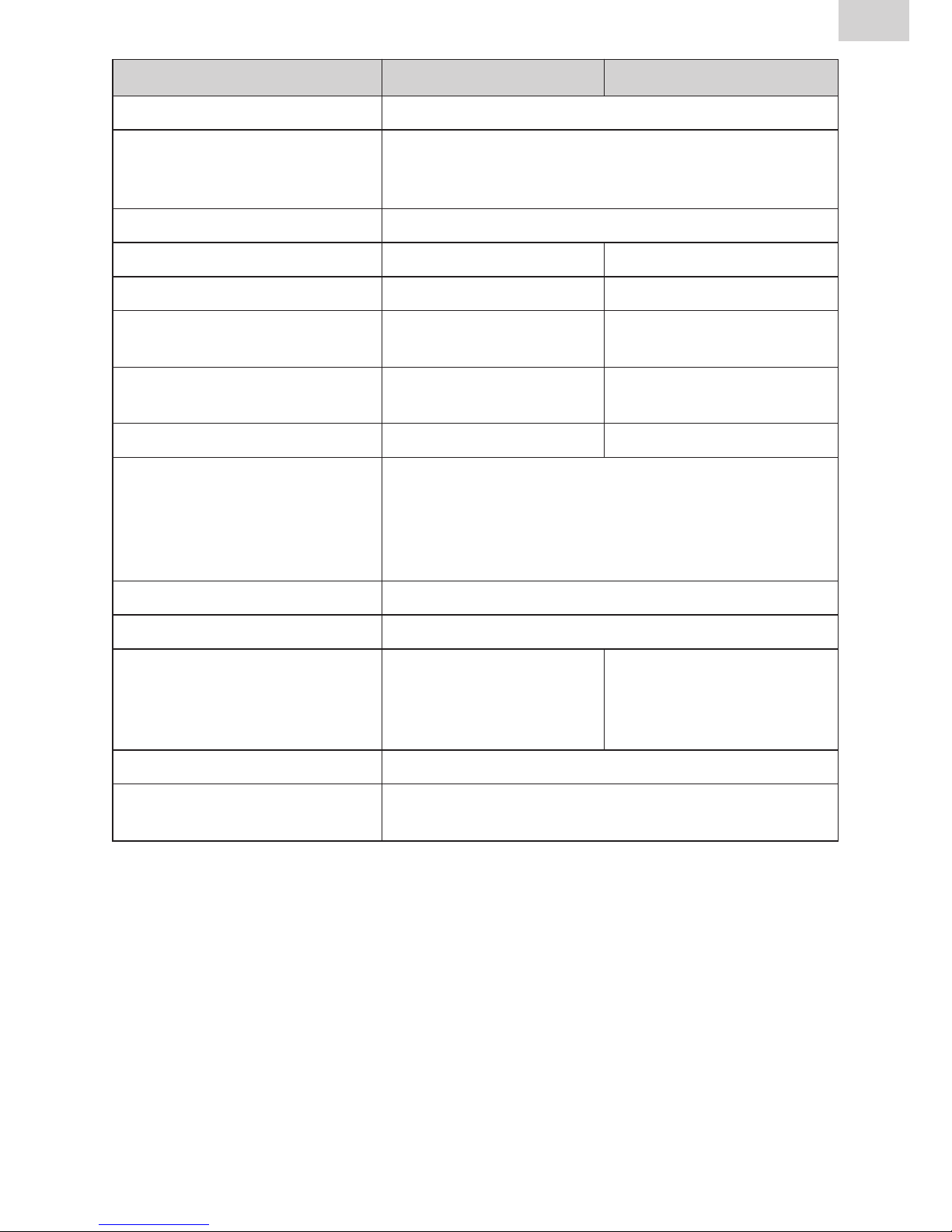

*: Specifications subject to change.

**: Fusion work on fittings from other manufacturers must comply with their respective

working temperature ranges!

Technical details* FRIAMAT Prime FRIAMAT Basic

Operating temperature range** -20°C...+50°C**

Fusion current monitoring short circuit 110 A

short circuit 1.70 x IN

interrupt 0.25 x IN

Fusion voltage max DC 48 V

Data transfer interface USB no

Service port USB USB

Documentation of fusion yes no

and traceability data

Protocol formats FRIATRACE no

format, PDF, CSV

Protocol memory 1000 protocols no

Languages Bulgarian, Croatian, Czech, Danish, Dutch,

English, Estonian, Finnish, French, German,

Hungarian, Italian, Latvian, Lithuanian, Polish,

Portuguese, Romanian, Russian, Slovakian,

Slovenian, Spanish, Swedish, Turkish

Dimensions W x D x H 260 x 500 x 340 mm

Weight approx 12.8 kg

Accessories operating instructions, operating instructions,

transport box, transport box

FRIATEC memory stick,

supervisor pass

Overvoltage classification Category II

Certificate/quality CE, ISO 9001, WEEE Reg. No. DE 49130851, RoHS

16

Stand/Update: 01.07.2014

EN

3.10 Automatic activation of maintenance interval

The maintenance interval stored in the FRIAMAT fusion unit (default: 12

months, see also Section 7.2) is not activated automatically until after the first

fusion.

INFORMATION

The leading maintenance date is always shown on the display and may differ

from the details on the service label attached to the FRIAMAT fusion unit!

3.11 Transport/storage/dispatch

The FRIAMAT fusion unit is delivered in an aluminium transport box. This aluminium transport box keeps it dry and protected against moisture. The aluminium box should always be used to transport the device. The temperature

range for storage is -20 °C to +70 °C.

4 “Fusion” sequence

4.1 Siting, connection, and startup

Before every use, you should check that the FRIAMAT fusion unit is not damaged and operates properly within the specifications. All parts must be correctly installed and all conditions fulfilled. Only then can the device operate

properly.

The FRIAMAT fusion unit can be sited and operated out of doors when it is

protected against rain and moisture.

1. The FRIAMAT fusion unit must be sited on level ground.

2. Prepare the fitting and pipes for fusion in compliance with the assembly

instructions.

3. Make sure that the fitting’s contact pins are accessible for connection to

the fusion plugs.

NOTE

Danger of overheating in the cables!

Before use, all cables must always be unwound completely. This applies to the

device, fusion, and extension cables.

17

EN

Stand/Update: 01.07.2014

4. Connect the device to the power supply (mains or generator). To do so,

insert the device’s plug into the socket.

5. If necessary, use an extension cable. Make sure that the conductor cross

section is adequate (see also Section 2.6).

6. When operating with a generator, make sure that it is fused with at least

16 A (slow blow, see also Section 2.6).

7. When operating with a generator, first start the generator and let it warm

up for 30 s.

8. Switch ON the FRIAMAT fusion unit at its main switch.

NOTE

Danger of scorching!

The contact areas on the fusion plugs and fitting must be clean. Soiled contacts can

cause the plug to overheat, damaging it.

• Ifnecessary,wipecleanofanycontaminants.

• Youmustalwaysprotecttheplugsagainstsoiling.

• Whenadeposithasformedthatcannotberemovedcompletely,thefusionplugs

must be replaced.

• Firstexaminethefusionplugsandthetting’sinsertcontactsforsoiling,then

connect them.

9. Connect the fusion plugs to the contact pins on the fitting.

10. The fusion plugs must be attached completely to the fitting’s pins, i.e. over

their whole internal contact length.

4.2 Reading in the barcode

1. Read in the barcode: use exclusively the barcode affixed to or provided

with the contacted fitting.

2. If the barcode label is missing or damaged, you can use the barcode on an

identical fitting from the same manufacturer and the same charge. In cases

of doubt, contact the fitting manufacturer’s hotline.

NOTE

It is forbidden to read in a replacement barcode on a different fitting!

3. Read in the barcode with a reader wand or barcode scanner (see also

Sections 3.3 and 3.4).

4. A correctly read barcode is confirmed with an acoustic signal.

18

Stand/Update: 01.07.2014

EN

INFORMATION

When an acoustic signal is not emitted, examine the reader wand or barcode

scanner for soiling or damage. If necessary, you can also perform the fusion in

emergency input mode (see Sections 5.5 and 6.3)!

4.3 Starting the fusion procedure

CAUTION!

Danger of burning injury!

In rare cases, hot PE melt can exit when the fusion sequence malfunctions. A safety

distance of at least 1 m must be kept from the fusion site.

NOTE

Do not connect any other consumers during fusion!

Youcanstopthefusionprocedureatanytimebypressingthe(STOP)key

. Fusion can be resumed after the fusion joint has cooled completely

(and all causes of the fault have been eliminated). Observe here the processing instructions from the fitting manufacturer.

Operating steps

1. “Pipe Processed?” appears on the display. When applicable, confirm

this with the (START) key or, on the FRIAMAT Prime, the guide key

O.K.

.

2. Press the (START) key to initiate the fusion procedure. The ambient

temperature is measured, and the resistance of the connected fitting determined. Fusion begins. The duration of fusion can be followed on the

display (the seconds are counted up to the final fusion time).

3. “End of fusion” means: Fusion procedure ended. “t:” and “tc:” mean

nominal and actual fusion time and must agree.

4. Note the fusion parameters on the pipe/fitting. This also serves to prevent

double fusions.

5. Press the (STOP) key to acknowledge the displayed “End of fusion”

with “t:” and “tc:”. On the FRIAMAT Prime, you can also confirm with the

guide key

O.K.

. The fusion procedure has now ended, and the

FRIAMAT fusion unit is ready for the next fusion.

19

EN

Stand/Update: 01.07.2014

5 FRIAMAT Basic

5.1 Function keys explained

1

2 3

4

5

1 Display

The FRIAMAT Basic is fitted with a two-line display.

2 START key

The START key is used to start a fusion procedure, to select sub- or individual menus, and to save settings. This key is also used to confirm messages on the display.

3 STOP key

The STOP key is used to abort a fusion procedure, to close sub- or individual menus, and to cancel an input (without saving).

4 MENU key

The MENU key lies between the direction keys and opens the main menu

with the submenus “Basic Settings”, “Info”, and “Emergency Input”. In the

event of an error, pressing the MENU key displays it in plain text.

5 Direction keys

The direction keys

(

UP/DOWN) can be used to navigate through

the sub- and individual menus. Where this navigation is possible is shown

by the respective symbols on the display (see Section 4.2). The direction

keys ( LEFT/RIGHT) move the cursor on the display to the left or

right when data are being entered, e.g. emergency input, date. The direction keys ( UP/DOWN) selects the character (letter, number, special

character) at this position.

20

Stand/Update: 01.07.2014

EN

5.2 Display symbols explained

Symbol Description

When this symbol appears in the second display line, the

direction keys ( UP/DOWN) can be used to open

further menus.

5.3 “Basic Settings” menu

The “Basic Settings” menu lets you edit the device settings.

TIME

DATE

* LANGUAGE *

VOLUME

1. Press the key.

2. Press the direction keys to open the “Basic Settings” submenu.

3. Press the key.

4. Use the direction keys to open the menu for Time, Date, Language,

and Volume.

5. Press the key.

6. Use the direction keys and to make your changes in this

menu.

7. Press the key to save your changes. Press the key to cancel

without saving.

INFORMATION

Two asterisks appear to the left and right of the top line in the “Language”

menu. This lets you find the language settings menu when, for instance, the language was changed by accident.

21

EN

Stand/Update: 01.07.2014

5.4 “Info” menu

The “Info” menu lets you view the device details.

TIME/DATE

VOLTAGE/FREQUENCY

TEMPERATURE

DEVICE NUMBER

SOFTWARE VERSION

MAINTENANCE DATE

1. Press the key.

2. Press the direction keys to open the “Info” submenu.

3. Press the key.

4. Use the direction keys to open the menu for Time/Date,

Voltage/ Frequency, Temperature, Ambient Temperature, Device Number,

Software Version, Maintenance Date.

5. Press the key.

6. Press the or key to close the menu.

5.5 “Emergency Input” menu

The “Emergency Input” menu lets you enter the fusion barcode manually.

1.

Press the key.

2. Press the direction keys to open the “Emergency Input” submenu.

3. Press the key.

4. The display then shows “Code:” followed by 24 digits of which the first

flashes.

INFORMATION

When this is used for the first time, all digits are set to “0”. Afterwards, the last

barcode entered manually is always shown!

5. Use the direction keys and to enter the digits from the barcode on the fusion fitting.

6. Press the key to confirm your input. Press the key to cancel

without saving.

22

Stand/Update: 01.07.2014

EN

6 FRIAMAT Prime

6.1 Function keys explained

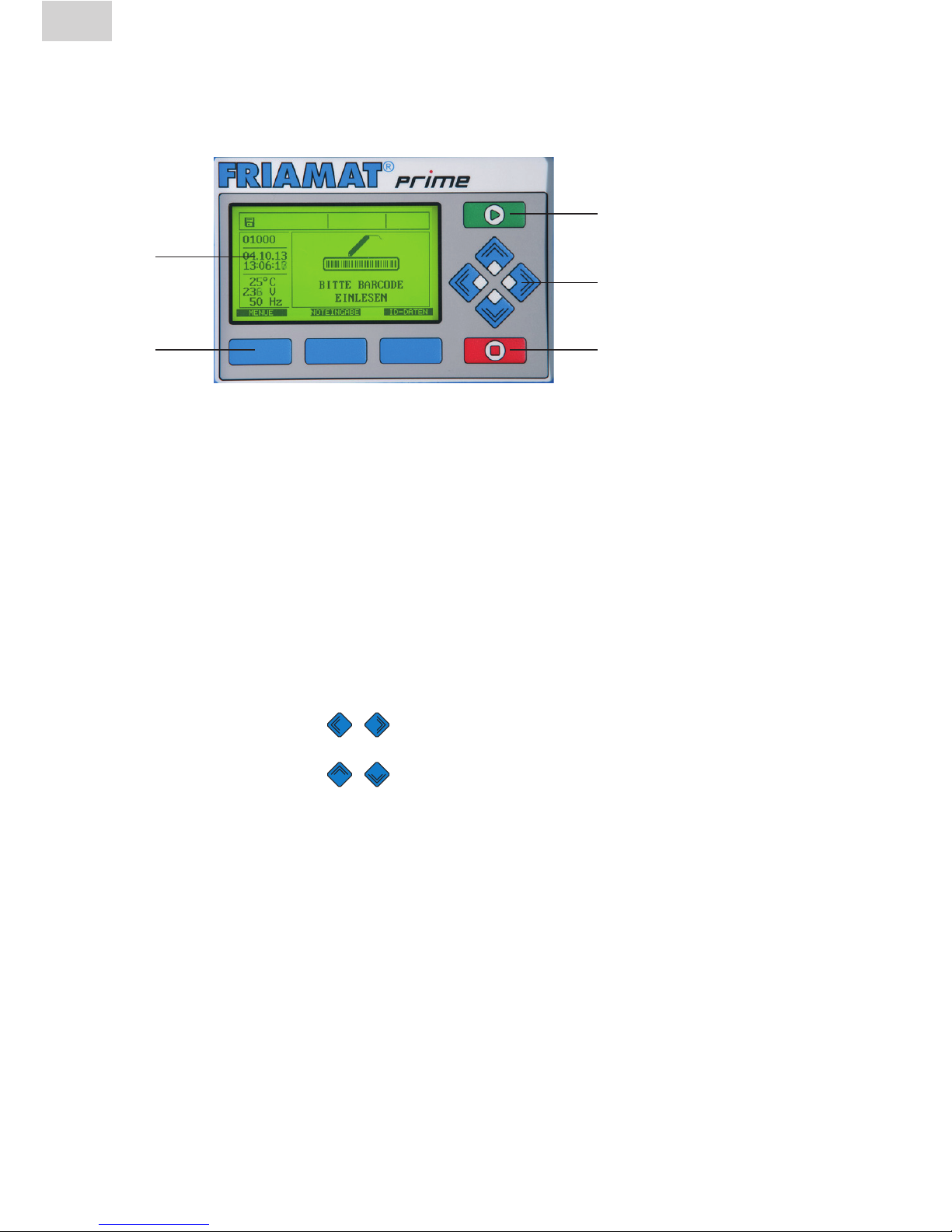

1

2

3

4

5

1 Display

The FRIAMAT Basic is fitted with a graphical maxi display.

2 Guide keys

The three blue guide keys let you access the guide key symbols (see Sec-

tions 5.2 and 5.3) that are shown directly at the top of the graphical maxi

display.

3 START key

The START key is used to start a fusion procedure.

4 Direction keys

The direction keys (

LEFT/RIGHT) move the cursor on the display to

the left or right when data are being entered, e.g. emergency input, date.

The direction keys ( UP/DOWN) selects the character (letter, number, special character) at this position.

5 STOP key

The STOP key is used to abort the fusion procedure and to cancel inputs

(without saving). Cancelling inputs with the STOP key always returns you

to the main screen of the graphical maxi display (reset function).

23

EN

Stand/Update: 01.07.2014

6.2 Display layout (main screen)

1

2

3

4

1 Function status symbols

Symbols appear representing the functions that can be activated at this

time (e.g. documentation, traceability mode). See also Section 6.4. Also

shown is the next due maintenance (see also Section 6.13.1.5).

2 View ambient details

Key ambient details are shown (date, time, ambient temperature, voltage,

and frequency).

3 Main window

The main window presents all inputs and details in each of the menus. See

also Section 6.1.

4 Guide key symbols

This presents the functions that are activated at each of the blue guide

keys. The symbols shown vary depending on the menu selected (see also

Section 6.3).

24

Stand: 01.07.2014

6.3 Function key symbols explained

Symbol Description

MENUE

This opens the main menu.

SELECT

This opens a submenu.

OK

This confirms the information shown in the

main window.

SAVE

This saves the entered data.

CANCEL

This cancels an input without saving. Back to the

previous input step.

FORWARD

This takes you to the next input step.

BACK

This takes you back to the previous input step.

ALL

This selects all.

NEW

This lets you enter new values in text fields (e.g. info

text, commission number, etc.)

CHANGE

This lets you change menu settings and/or text inputs

(e.g. the last ten commission numbers)

SHIFT

In edit mode: this switches between delete and insert.

REMOVE

This deletes one or more characters in text inputs.

ADD

This adds one or more characters in text inputs.

DETAILS

This shows the decrypted traceability barcode.

ID-DATA

This assigns data (commission number, operator pass,

serial number, and/or seam number) to the fusion that is

now to be started (see also Section 6.4.3).

25

EN

Stand/Update: 01.07.2014

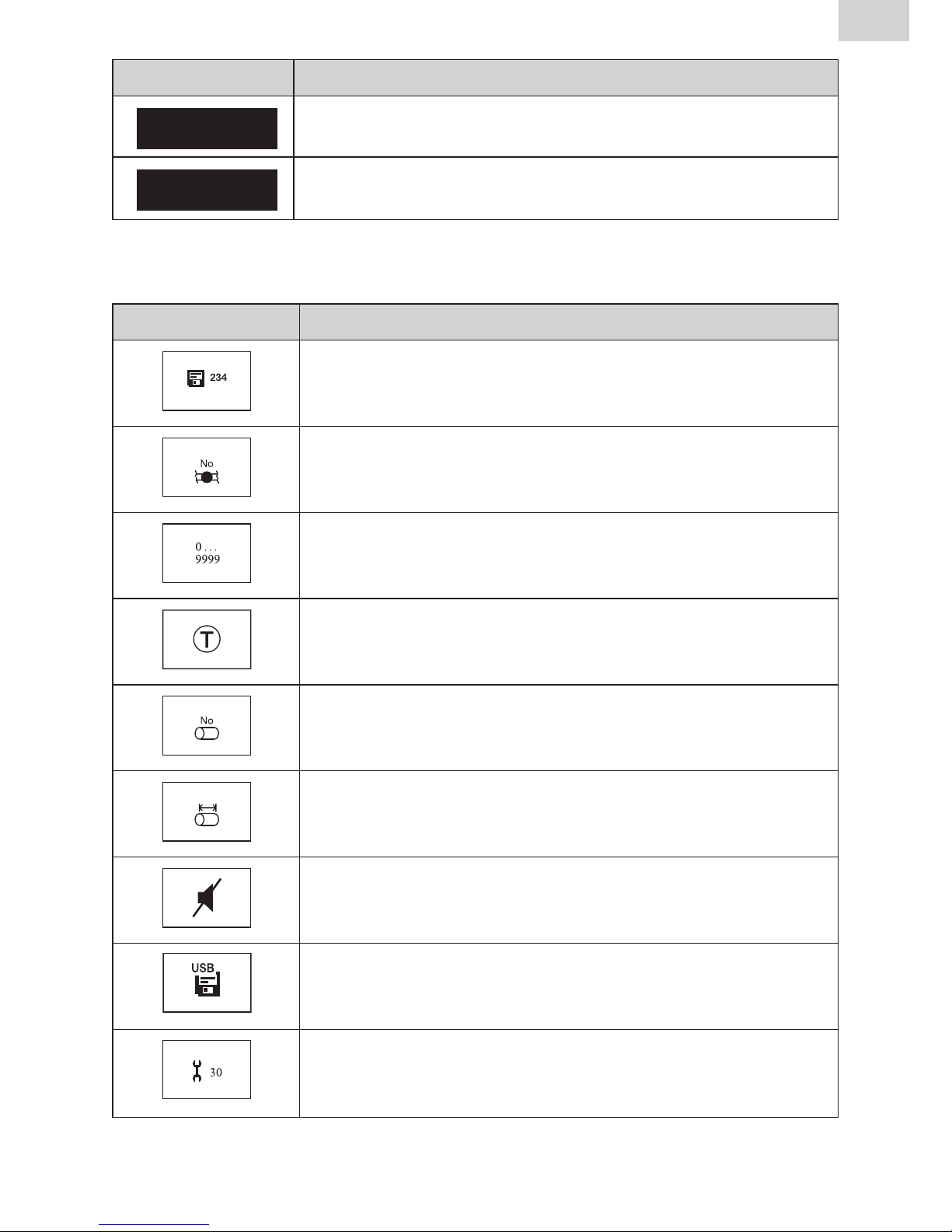

6.4 Function status symbols explained

Symbol Description

Documentation has been activated. The free memory

locations are shown.

Seam numbers can be entered.

The serial numbers are presented in ascending order,

and not according to commission number.

Traceability barcodes can be entered.

Pipe numbers can be entered.

Pipe lengths can be entered.

Acoustic signals have been deactivated.

FRIATEC memory stick has been connected.

Maintenance date: the next due maintenance (in days)

is shown.

Symbol Description

EMERGENCY

INPUT

This lets you enter the barcode manually, e.g. when this

cannot be read in (see also Section 5.10.4).

INFOTEXT

This lets you add additional text information to the

fusion entry (see also Section 6.4.3).

26

Stand/Update: 01.07.2014

EN

6.5 Main window symbols explained

Symbol Description

A ticked box indicates that this menu item or this

function has been activated.

An empty box indicates that this menu item or this

function has not been activated.

6.6 “Basic Settings” menu

The “Basic Settings” menu lets you edit the device settings.

DOCUMENTATION

TIME

DATE

LANGUAGE

PROTOCOL LANGUAGE

VOLUME

1. Press the

MENU

guide key.

2. Press the direction keys to open the “Basic Settings” submenu.

3. Press the

SELECT

guide key.

4. Use the direction keys to open the menu for Documentation, Time,

Date, Language, Protocol Language, and Volume.

5. Press the

SELECT

guide key.

6. Use the direction keys and or the guide key

CHANGE

to make

your changes in this menu.

7. Press the

SAVE

guide key to save your changes. Press the

CANCEL

guide

key to cancel without saving.

27

EN

Stand/Update: 01.07.2014

6.6.1 Documentation

INFORMATION

The FRIAMAT Prime is delivered with deactivated documentation!

The function Documentation stores the fusion parameters. Each of these can

be assigned to an commission number and/or an operator pass. The documentation can be activated or deactivated in the Documentation submenu.

6.6.2 Time

The “Time” submenu lets you set the current time of day.

6.6.3 Date

The “Date” submenu lets you set the current date.

INFORMATION

The date can be changed only when fusion is performed for the first time,

hence activating the maintenance interval. See also Section 3.10!

6.6.4 Language

The “Language” submenu lets you set the display language.

INFORMATION

Two asterisks appear to the left and right of the top line in the “Language”

menu. This lets you find the language settings menu when the language was

changed by accident!

28

Stand/Update: 01.07.2014

EN

6.6.5 Protocol language

The “Protocol language” submenu lets you set the language for the documentation. The log language can be set independently of the display language.

6.6.6 Volume

The “Volume” submenu lets you set the volume to “high” or “low”.

6.7 “Emergency Input” menu

The “Emergency Input” menu lets you enter the fusion barcode manually.

The digits you enter must be taken from the barcode on the fusion fitting.

INFORMATION

When this is used for the first time, all digits are set to “0”. Afterwards, the last

barcode entered manually is always shown!

1. Press the

EMERGENCY

INPUT

guide key.

2. The display then shows “Code:” followed by 24 digits (with the first flashing) or the digits from the barcode last entered manually.

3. Use the direction keys and to enter the digits from the barcode on the fusion fitting.

4. Press the

SAVE

guide key to save your changes. Press the

CANCEL

guide

key to cancel without saving.

6.8 “Fusion Sequence” menu

INFORMATION

The “Fusion Sequence” menu is first activated and hence shown on the display

when documentation has been activated. All submenus are not activated on

delivery (default)!

The “Fusion Sequence” menu lets you select the information to be assigned

to each fusion procedure.

29

EN

Stand/Update: 01.07.2014

COMMISSION NUMBER

OPERATOR PASS

INFO TEXT

COMMENT 1

COMMENT 2

SUBCONTRACTOR

TRACEABILITY

PIPE NUMBER

PIPE LENGTH

GPS DATA

SEAM NUMBER

SCRAPER TOOL

1. Press the

MENU

guide key.

2. Press the direction keys to open the “Basic Settings” submenu.

3. Press the

SELECT

guide key.

4. Use the direction keys to open the menu for commission number,

operator pass, Info Text, Comment 1, Comment 2, Subcontractor,

Traceability, Pipe Number, Pipe Length, GPS Data, Seam number,

Scraper Tool.

5. Press the

SELECT

guide key.

6. Use the direction keys and or the guide key

CHANGE

to make

your changes in this menu.

7. Press the

SAVE

guide key to save your changes. Press the

CANCEL

guide

key to cancel without saving.

6.8.1 Commission number

The work with commission numbers can be activated or deactivated at the

CHANGE

guide key. When “Commission number” is activated, the commission number “#####################” appears on the display’s main

screen next to “ ➔ CODE” in the top line.

6.8.2 Operator pass

INFORMATION

The “Operator pass” menu is first activated and hence shown on the display

when an operator pass is read in for the first time (and documentation is

activated)!

After an operator pass has been read in for the first time, all fusions performed from this time on will be stored under the code for this operator pass.

The FRIAMAT Prime is reconfigured accordingly when another operator pass

is read in.

30

Stand/Update: 01.07.2014

EN

Reading in an operator pass opens the “ID Data” submenu (see also Section

6.8.1).Youcanusethedirectionkeys to view the settings activated on

the FRIAMAT Prime. Press the guide key

OK

to exit the submenu.

The operator pass can be used to lock the FRIAMAT Prime as protection

against unauthorised use. The display on a locked FRIAMAT Prime shows the

prompt “PLEASE ENTER VALID OPERATOR PASS!”.

Locking the device

1. Again read in the current operator pass.

2. Press the

OK

guide key to confirm the prompt “LOCK DEVICE?”.

Alternatively, you can abort the procedure at the

CANCEL

guide key.

3. The FRIAMAT Prime is also locked automatically when an operator pass

has been read in and the date changes, i.e. the FRIAMAT Prime is locked

on the next day. In both of these cases (manual or automatic locking), the

display shows the prompt “PLEASE ENTER VALID OPERATOR PASS!”.

Unlocking the device

1. Read in an operator pass.

2. The valid operator pass appears on the display and must be confirmed

with the guide key

OK

.

6.8.3 Info Text

The “Info Text” submenu lets you decide whether additional text information

can be entered for a fusion.

6.8.4 Comment 1

The “Comment 1” submenu lets you decide whether additional text information can be entered for a fusion.

6.8.5 Comment 2

The “Comment 2” submenu lets you decide whether additional text information can be entered for a fusion.

31

EN

Stand/Update: 01.07.2014

6.8.6 Subcontractor

The “Subcontractor” submenu lets you decide whether additional text information can be entered for a fusion.

6.8.7 Traceability

The “Traceability” submenu lets you enable the FRIAMAT Prime for reading

in, processing, and storing traceability barcodes. Enabling this menu also

activates the submenus “Pipe Number” and “Pipe Length”.

6.8.8 Pipe Number

The “Pipe Number” submenu lets you decide whether an individual pipe

number can be entered for each of the fusion pipes.

6.8.9 Pipe Length

The “Pipe Length” submenu lets you decide whether the length can be

entered for each of the fusion pipes.

6.8.10 GPS Data

The “GPS Data” submenu lets you decide whether the coordinates/location

of the fitting can be entered for a fusion.

INFORMATION

A corresponding device is needed to determine the GPS data!

6.8.11 Seam number

The “Seam number” submenu lets you decide whether a seam number can

be entered for a fusion.

6.8.12 Scraper tool

The “Scraper Tool” submenu lets you decide whether the data (e.g. device

number) of the scraper tool used to prepare for fusion can be entered for a

fusion. The scraper tool must then bear a corresponding barcode.

32

Stand/Update: 01.07.2014

EN

6.9 “Data” menu

INFORMATION

The “Data” menu is first activated and hence shown on the display when

documentation has been activated and the first data record saved!

The “Data” menu lets you define how the fusion and traceability data are

transferred from the FRIAMAT Prime to the PC or laptop.

TRANSFER

PDF

CSV

DELETE

1. Press the

MENU

guide key.

2. Press the direction keys to open the “Basic Settings” submenu.

3. Press the

SELECT

guide key.

4. Use the direction keys to open the menu for Transfer, PDF, CSV,

Delete.

5. Press the

SELECT

guide key.

6. In this menu, use the corresponding guide keys to initiate the data transfer.

Press the

SELECT

guide key to select the data for transfer. Otherwise, you

can transfer all of the saved data with the

ALL

key.

7. Press the

OK

guide key to confirm the end of data transfer.

6.9.1 Transfer

The “Transfer” submenu lets you read out and transfer data from the

FRIAMATPrime.Youmustusethistotransferdatafromamemorystickinthe

FRIAMAT Prime’s USB port (see also Section 8.1). The data are saved to an

FTD file on the memory stick and can be processed with the FRIATRACE

data base software on a PC or laptop.

NOTE

FRIATEC accepts no warranty claims arising from the use of standard USB

sticks. Use the FRIATEC memory stick!

33

EN

Stand/Update: 01.07.2014

6.9.2 PDF

The “PDF” submenu lets you save data to a PDF file on the FRIATEC memory

stick.YoumustusethistotransferdataasaPDFletothememorystickin

the FRIAMAT Prime’s USB port (see also Section 8.1). The PDF files are written

to a subdirectory on the memory stick. This subdirectory is named as follows

(here an example): F+device number (e.g. FR 14 81 001): F1481001

The file names are made up of the current data and a two digit number incremented from 0. For example, the second printout (02) on 24/01/2014 (130201):

14012402.PDF

The PDF files can then be printed out with the right software (e.g. Acrobat

Reader

©

) on a PC or laptop.

6.9.3 CSV

The “CSV” submenu lets you save data to a CSV file on the FRIATEC memory

stick.YoumustusethistotransferdataasaCSVletothememorystickin

the FRIAMAT Prime’s USB port (see also Section 8.1). The CSV files are written to a subdirectory on the memory stick. This subdirectory is named as follows (here an example): F+device number (e.g. FR 14 81 001): F1481001

The file names are made up of the current data and a two digit number incremented from 0. For example, the second printout (02) on 24/01/2014 (130201):

14012402.CSV

The CSV files can then be read in and printed out with the right software (e.g.

Microsoft

©

Excel) on a PC or laptop.

34

Stand/Update: 01.07.2014

EN

6.9.4 Delete

The “Delete” submenu lets you delete all of the saved data.

NOTE

Deleted data are irretrievably lost!

6.10 “Info” menu

The “Info” menu presents some key details of the FRIAMAT Prime: device

number,softwareversion,nextmaintenancedate.Youwillneedthesedetails

when contacting the FRIATEC service station, e.g. when problems occur.

1. Press the

MENU

guide key.

2. Press the direction keys to open the “Info” submenu.

3. Press the

SELECT

guide key.

4. Press the

OK

guide key to close the menu.

6.11 “Formatting” menu

The “Formatting” menu can be used to format USB sticks to FAT 12 or

FAT 16.

The FRIATEC memory stick must be used for transferring data from the

FRIAMAT Prime. Please bear in mind when using a standard USB stick that

this must be formatted to FAT 12 or FAT 16. A FAT 32 or partitioned USB stick

(with master boot record) will cause the error message “ERROR 91” to appear

on the FRIAMAT Prime. Also, the capacity of the USB stick used must not

exceed 2 GB.

NOTE

Formatting deletes all data!

Bear in mind that formatting deletes all data on the memory stick.

35

EN

Stand/Update: 01.07.2014

1. Press the

MENU

guide key.

2. Press the direction keys to open the “Format” submenu.

3. Press the

SELECT

guide key.

4. Selectingthemenuitem“MEMORYSTICK”openstheprompt

“AREYOUSURE?”.

5. Press the

OK

guide key.

6. Press the

OK

guide key to acknowledge the message

“MEMORYSTICKNOWFORMATTED”.

NOTE

Use the FRIATEC memory stick!

FRIATEC accepts no warranty claims arising from the use of standard USB sticks.

6.12 Fusion options

6.12.1 ID Data

INFORMATION

The “ID Data” option is first activated and hence shown on the display when

documentation has been activated!

“ID Data” are data that can be assigned directly to the fusion that is now to

be started: commission number, operator pass, serial number, and seam

number. These additional details are described in the following.

INFORMATION

Commission numbers and seam numbers can be entered only when the documentation and the functions “Commission number” (see Section 6.4.1) or

“Seam Number” (see Section 6.4.11) have been activated!

6.12.1.1 Commission number

1. Press the

ID-DATEN

guide key.

2. Use the direction keys to select “Commission number”.

3. When entering an commission number for the first time, press the

CHANGE

guide key.

4. The first digit starts to flash. Press the direction keys and to

enter the commission number.

5. Press the

SAVE

guide key to save your changes. Press the

CANCEL

guide

key to cancel without saving.

36

Stand/Update: 01.07.2014

EN

When one or more commission numbers have already been entered, you can

choose from “EDIT”, “NEW”, and “SELECT”.

CHANGE

= This lets you edit the commission number entered last.

NEW

= This lets you enter a new commission number.

SELECT

= This lets you select an commission number from the twenty

commission numbers entered last.

6.12.1.2 Operator pass

Pressing the guide key

ID DATA

displays whether and which welder has

been registered. If no operator pass has been activated, the window remains

unchanged.

The welder cannot be edited manually (via key presses). To register a new

welder, you must read in a new operator pass (see Section 6.4.2).

6.12.1.3 Serial number

Pressing the guide key

ID DATA

displays the serial number of the executed

fusions. This number is assigned automatically by the device and cannot be

changed. Normally the serial number is assigned to the activated commission

number.

INFORMATION

The Supervisor function (see Section 6.9) lets you specify other assignments to

the commission number (see Section 6.9.2.9)!

6.12.1.4 Seam number

The “Seam number” menu assigns a user defined number (seam number) to

the fusion.

1. Press the

ID DATA

guide key.

2. Use the direction keys to select “Seam number”.

3. To enter a seam number, press the

CHANGE

guide key.

4. The first digit starts to flash. Press the direction keys and to

enter the seam number.

5. Press the

SAVE

guide key to save your changes. Press the guide key to

cancel without saving.

6. Press the

OK

guide key to close the menu.

37

EN

Stand/Update: 01.07.2014

When a seam number has already been assigned, you can choose between

“CHANGE” and “NEW”.

CHANGE

= This lets you edit the seam number entered last.

NEW

= This lets you enter a new seam number.

6.12.1.5 GPS 1 – 3

INFORMATION

Data can be entered under GPS 1, GPS 2, and GPS 3 only when this has been

activated (see Section 6.4.10)!

The coordinates/location of the fusion (GPS 1, GPS 2, GPS 3) can be entered

in the menu “GPS 1 – 3”. The GPS data are made up of three input fields:

GPS 1 for the geographical longitude, GPS 2 for the geographical latitude, and

GPS 3 for the altitude above sea level. GPS 1 can take a string of thirteen user

definable alphanumerics, GPS 2 twelve, and GPS 3 ten.

INFORMATION

A corresponding device is needed to determine the GPS data!

1. Press the

ID DATA

guide key.

2. Use the direction keys and to select “GPS 1”, “GPS 2”, and

“GPS 3”.

3. To enter GPS coordinates, press the

CHANGE

guide key.

4. The first digit starts to flash. Press the direction keys and to

enter the GPS coordinates.

5. Press the

SAVE

guide key to save your changes. Press the

CANCEL

guide key to cancel without saving.

6. Press the

OK

guide key to close the menu.

38

Stand/Update: 01.07.2014

EN

When GPS coordinates have already been entered, you can choose between

“EDIT” and “NEW”.

CHANGE

= This lets you edit the GPS coordinates entered last.

NEW

= This lets you enter new GPS coordinates.

6.12.2 Traceability Barcodes / Pipe Number / Pipe Length

INFORMATION

Traceability data can be entered only when documentation and the function

“Traceability” and/or “Pipe Number” and/or “Pipe Length” has been activated

(see Section 5.6.7).

Traceability Barcodes is activated when the fusion barcode on the fusion fitting

is read in. The main window prompts you to enter the traceability barcode on

the fitting. When this is to be read in (visualised by a ticked box), you are

prompted to enter the traceability barcode on Component 1. When the pipe

number and/or pipe length is to be entered, this is also displayed for input.

Now you are prompted to enter the traceability barcode on Component 2. The

pipe number and/or pipe length is entered analogously to the above.

Press the function key

OK

to acknowledge the prompt

“Pipe Processed?” when the fusion pipe has been processed properly.

Press the key to start fusion.

INFORMATION

The traceability data are input automatically, i.e. the display presents the

entered data in succession until fusion can be started.

You can use the guide keys

FORWARD

and

BACK

to switch at any time between

the prompts “Fitting”, “Component 1”, “Component 2”, “Pipe Processed?”, and

“Start”. Use the direction keys to switch between prompt.

39

EN

Stand/Update: 01.07.2014

6.12.3 Info Text, Comment 1, Comment 2, Subcontractor

INFORMATION

Data can be entered under INFO TEXT, COMMENT 1, COMMENT 2, and/or

SUBCONTRACTOR only when these have been activated (see Section 6.4.3

to 6.4.6)!

After the fusion barcode has been read in, “INFO TEXT” appears on the display.

1. Press the

INFOTEXT

guide key.

2. Use the direction keys to select “INFO TEXT”, “COMMENT 1”,

“COMMENT 2”, and/or “SUBCONTRACTOR”.

3. Press the

INPUT

guide key.

4. The first digit starts to flash. Press the direction keys and to

enter the data.

5. Press the

SAVE

guide key to save your changes. Press the

CANCEL

guide key to cancel without saving.

6. Press the

OK

guide key to close the menu.

INFORMATION

The additional text must be entered for each fusion if it is to appear in the log.

No additional text is added to the fusion data when the START key is pressed

directly after the fitting barcode has been read in.

6.12.4 Scraper tool

INFORMATION

Data can be entered under SCRAPER TOOL only when this has been activated

(see Section 6.4.12).

When the data are being entered to start fusion, the prompt “PIPE PROCESSED?” is followed by the prompt “SCRAPER TOOL: PLEASE READ IN

BARCODE”. When the scraper tool bears a barcode, this can be read in. The

data are then assigned to the fusion in the log.

40

Stand/Update: 01.07.2014

EN

6.13 SUPERVISOR

The SUPERVISOR menu lets you configure the FRIAMAT Prime properties

and functions. Device functions can be enabled or locked specifically for the

user, and the sequence of operations specified for the building site. A special

pass (SUPERVISOR pass) is needed to configure the Supervisor menu.

INFORMATION

The settings and menus locked under SUPERVISOR are no longer displayed

for the user on the building site (e.g. when documentation has been activated,

yet locked against user access, the “Documentation” menu no longer appears

on the display)!

The “SUPERVISOR” menu first opens when the barcode is read in on the

SUPERVISOR pass. A four digit PIN must be entered here. The default PIN is

“0000”. The PIN can be changed at any time under the “Supervisor” menu

(see Section 6.9.4).

BASIC SETTINGS

FUSION SEQUENCE

FACTORYSETTINGS

PIN

DISPLAY(RESISTANCE)

1. Read in the SUPERVISOR pass.

2. Enter the four digit PIN. Press the

SAVE

guide key to confirm the dis-

played PIN. Press the

CHANGE

guide key to change the PIN.

3. Press the

OK

guide key to open the Supervisor menu.

41

EN

Stand/Update: 01.07.2014

6.13.1 Basic Settings

The “Basic Settings” Supervisor menu lets you edit the device settings.

DOCUMENTATION

TIME

DATE

DATA PROTECTION

MAINTENANCE DATE

MODE

LANGUAGE

EMERGENCYINPUT

ENERGYDISPLAY

VOLUME

1. Press the direction keys to open the “Basic Settings” submenu.

2. Press the

SELECT

guide key.

3. Use the direction keys to open the menu for Documentation, Time,

Date, Data Protection, Maintenance Date, Mode, Language, Emergency

Input, Energy Display, and Volume.

4. Press the

SELECT

guide key.

5. Use the direction keys and or the guide key

CHANGE

to make

your changes in this menu.

6. Press the

SAVE

guide key to save your changes. Press the

CANCEL

guide

key to cancel without saving.

6.13.1.1 Documentation

The documentation can be activated or deactivated in the “DOCUMENTATION”

submenu. This setting can be locked against user access.

6.13.1.2 Time

The “TIME” submenu can be used to protect the time against user changes.

6.13.1.3 Date

The “DATE” submenu can be used to protect the date against user changes.

42

Stand/Update: 01.07.2014

EN

6.13.1.4 Data Protection

The “DATA PROTECTION” submenu can be used to protect data against user

deletion. Or it can let the user delete the data after they have been printed out

or transferred out of the device.

6.13.1.5 Maintenance Date

In the “MAINTENANCE DATA” submenu, you can decide whether the warn-

ing “Maintenance date exceeded” is to be deactivated or the device no longer

executes fusions when this date is exceeded. In the latter case, you can set a

period from 0 to max 99 days during which the device continues to operate

after the maintenance date has been exceeded. This setting is displayed to the

user after the maintenance date has been exceeded (a spanner with the number of days the device will continue to operate).

6.13.1.6 Mode

The “MODE” submenu can be used to set various date and time formats as

well as temperature units.

6.13.1.7 Language

The “LANGUAGE” submenu fixes the language, i.e. the user cannot set another language.

6.13.1.8 Emergency Input

The “EMERGENCY INPUT” submenu can disable the option of entering the

barcode digits manually.

6.13.1.9 Energy Display

In the “ENERGY DISPLAY” submenu, you can decide whether the energy

consumed by the fusion procedure is to be displayed or not.

6.13.1.10 Volume

The “VOLUME” submenu can be used to set the volume of the acoustic signal

(ON/OFF, HIGH/LOW). Also, the selected settings can be locked against user

access.

43

EN

Stand/Update: 01.07.2014

6.13.2 Fusion Sequence

In the “Fusion Sequence” Supervisor menu, you can define the data that can

be assigned to the fusion that is now to be started.

TRACEABILITY

COMMISSION NUMBER NUMBER

INFO TEXT

SEAM NUMBER

SERIAL NUMBER

OPERATORS PASS

PIPEPREPARED?DISPLAY

1. Press the direction keys to open the “Fusion Sequence” submenu.

2. Press the

SELECT

guide key.

3. Use the direction keys to open the menu for Traceability, Commission number, Info Text, Seam number, Serial Number, Operator pass, and

Pipe Processed? Display.

4. Press the

SELECT

guide key.

5. Use the direction keys and or the guide key

CHANGE

to make

your changes in this menu.

6. Press the

SAVE

guide key to save your changes. Press the

CANCEL

guide

key to cancel without saving.

6.13.2.1 Traceability

The option of entering traceability barcodes, pipe numbers, and pipe lengths

can be activated or deactivated in the “TRACEABILITY” submenu. Also, the

selected settings can be locked against user access.

6.13.2.2 Info Text

Text entries can be activated or deactivated in the “INFO TEXT” submenu.

Also, the selected settings can be locked against user access.

6.13.2.3 Comment 1

Text entries can be activated or deactivated in the “COMMENT 1” submenu.

Also, the selected settings can be locked against user access.

6.13.2.4 Comment 2

Text entries can be activated or deactivated in the “COMMENT 2” submenu.

Also, the selected settings can be locked against user access.

44

Stand/Update: 01.07.2014

EN

6.13.2.5 Subcontractor

Text entries can be activated or deactivated in the “SUBCONTRACTOR” submenu. Also, the selected settings can be locked against user access.

6.13.2.6 GPS Data

Coordinate entries can be activated or deactivated in the “GPS DATA” sub-

menu. Also, the selected settings can be locked against user access.

6.13.2.7 Seam number

Entering seam numbers can be activated or deactivated in the

“SEAM NUMBER” submenu. Also, the selected settings can be locked

against user access.

6.13.2.8 Serial number

In the “SERIAL NUMBER” submenu, you can decide whether the serial number (assigned by the device) is assigned to the commission number (within the

commission number, beginning with “1”) or independently of it, i.e. consecutively.

6.13.2.9 Commission number

Work with commission numbers can be activated or deactivated in the

“ Commission number” submenu. In addition, you can specify whether the

commission number is to be entered every time the device is switched ON

and/or before each fusion. Also, the selected settings can be locked against

user access.

6.13.2.10 Operators pass

Work with an operator pass can be activated or deactivated in the

“ OPERATOR PASS” submenu. In addition, when an operator pass has been

activated, you can deactivate the default setting that the operator pass must

be read in again on a change of date (i.e., in activated mode, the device is first

locked the next day until an operator pass has been read in).

In addition, you can also specify whether the operator pass is to be entered

every time the device is switched ON and/or before each fusion. Also, the selected settings can be locked against user access.

6.13.2.11 Pipe Prepared? Display

In the “PIPE PREPARED? DISPLAY”, you can activate or deactivate the

warning shown before fusion starts.

45

EN

Stand/Update: 01.07.2014

6.13.3 Factory Settings

The “Factory Settings” Supervisor menu lets you reset all user settings to

their default values (state on delivery).

NOTE

All settings and text entries are irretrievably lost when reset to their default

values!

1. Press the direction keys to open the “Factory Settings” submenu.

2. Press the

OK

guide key.

3. Press the

SELECT

guide key to reset all settings to their default values, or

the

CANCEL

guide key to abort.

6.13.4 PIN

In the “PIN” supervisor menu, you can change the default value “0000” for

accessing the “SUPERVISOR” menu.

1. Press the direction keys

to open the “PIN” submenu.

2. Press the

SELECT

guide key.

3. Press the

CHANGE

guide key.

4. Use the direction keys and to enter the new four digit PIN.

The old PIN is shown above.

5. Press the

SAVE

guide key to save your changes. Press the

CANCEL

guide

key to cancel without saving.

46

Stand/Update: 01.07.2014

EN

INFORMATION

The entered PIN should be noted down and kept in a safe place together with

the SUPERVISOR pass. In the event of a lost PIN, contact our service hotline

+49 (0)621 486-1533!

6.13.5 Display (Resistance)

In the “DISPLAY (RESISTANCE)” Supervisor menu, you can decide whether

the actual measured resistance is to be displayed before the start of fusion on

the fitting.

1. Press the direction keys

to open the “Display (Resistance)” sub-

menu.

2. Press the

SELECT

guide key.

3. Use the direction key

CHANGE

to make your changes in this menu.

4. Press the

SAVE

guide key to save your changes. Press the

CANCEL

guide

key to cancel without saving.

7 Warranty/maintenance/disposal

7.1 Warranty

FRIAMAT fusion units come with a 24 month warranty.

7.2 Maintenance and care

In accordance with DVS 2208 Part 1 and BGV A3 (“Electrical systems and

equipment”), nonstationary electrical equipment must be subjected to repeat

tests at least once a year. This maintenance can be performed at FRIATEC

or one of its authorised service stations (see Section 8.2).

47

EN

Stand/Update: 01.07.2014

Also all connection adapters must be submitted for tests on the maintenance

dates.

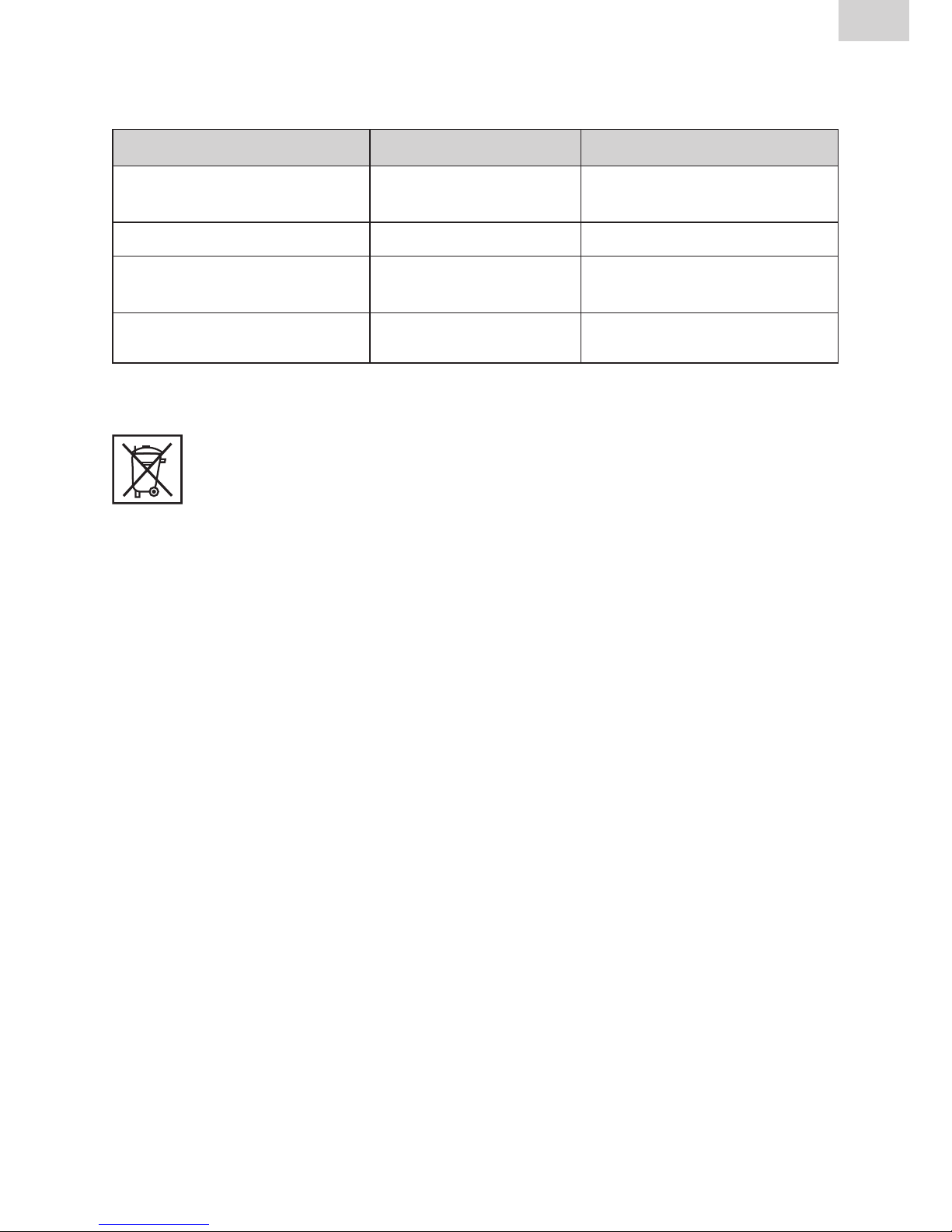

What? When? Who?

Clean the wand, and Daily Operator

check for damage.

Check function. Before every use Operator

Check and, if necessary, Before every use Operator

clean contacts.

Factorymaintenance Yearly FRIATECAGorauthorised

service stations

7.3 Disposal

The European Directive 2002/96/EC on waste electrical and electronic equipment (WEEE) regulates the disposal of used electrical

and electronic products. The WEEE Directive 2005 was implemented

as the ElektroG on the German disposal sector. Under these laws,

waste electrical and electronic equipment must be introduced to a proper

disposal or recycling process. FRIAMAT fusion units fall under this European

Directive and can be submitted for disposal to FRIATEC AG or one of its authorised service stations.

Further regulations, standards, and directives applying in the country of use

must be observed.

48

Stand/Update: 01.07.2014

EN

8 Error messages / warnings / info

Irregularities during fusion cause error messages or warnings to appear on the

display of the FRIAMAT fusion unit.

INFORMATION

On the FRIAMAT Basic, press the Menu key to view the displayed error

message in plain text!

INFORMATION

Should the FRIAMAT fusion unit output an error message or warning that is

not listed in the following and that cannot be explained or remedied despite

the plaintext description, contact our service hotline +49 (0)621 486-1533!

Error messages

No. Displayed text Meaning/causes Remedy

02 Temperature Ambienttemperatureoutside Youmayhavetotent

out of range of permitted range over or shield the

fusion area.

03 Resistance outside Fitting’s electrical resistance Check that contacts sit

of tolerance outside of tolerance. firmly and are clean. If

necessary, clean contacts and replace the

fitting.

04 Fitting’s wire turn Short circuit in the fitting’s Replace fitting, and

short circuited wire turn. send it in for analysis.

05 Fitting’s wire turn Current flow interrupted Check the connection

interrupted between the fusion

plug and the fitting. If

OK, replace fitting, and

send it in for analysis.

06 Voltage outside Deviation in fusion voltage Notify authorised

of tolerance too high. service station.

49

EN

Stand/Update: 01.07.2014

No. Displayed text Meaning/causes Remedy

08 Operating voltage Operating voltage outside of Extension too long,

out of range permitted range during fusion. or cross section too

small. Check voltage

and connection conditions on the generator.

09 Frequency out of Frequency outside of per- Check frequency of

range mitted range during fusion. generator voltage.

10 Fusion stop Fusion stopped at STOP key. –

13 Operating voltage Supply voltage interrupted Check connection

failure (e.g. power failure during conditions.

fusion) or too low.

14 Power too low Fitting’s power input is too low. Contact the FRIATEC

The FRIAMAT cannot provide service hotline:

such a low power. +49 (0)621 486-1533

15 Power exceeded The fitting’s power input Contact the FRIATEC

exceeds the capacity of the service hotline:

FRIAMAT. +49 (0)621 486-1533

23 Generator error Generator possibly not Contact the FRIATEC

suitable for fusion. service hotline:

+49 (0)621 486-1533

xy* System error Contact the FRIATEC

service hotline:

+49 (0)621 486-1533

*: Error messages whose numbers do not appear in the above table.

50

Stand/Update: 01.07.2014

EN

Warnings/info

Displayed text Tip/remedy

Attention! Double fusion! If you intend double fusion on a fitting, you

must disconnect the fusion unit’s pins from

the fitting after the first fusion, and let it cool

down (see the processing instructions issued by the fitting manufacturer).

Please read in the fusion barcode first. Only FRIAMAT Prime: This appears when

the fitting’s traceability barcode was read in

first by accident.

Please read in a valid traceability Only FRIAMAT Prime: This appears when

barcode. the fitting’s fusion barcode was read in first

by accident.

Please read in a valid operator pass. Only FRIAMAT Prime: This appears when a

operator pass is to be read in (e.g. device

locked) and/or a different (incorrect) barcode was read in.

Please read in a valid commission Only FRIAMAT Prime: This appears when

number. an commission number is to be read in

(e.g. device configured to read before every

fusion) and/or an incorrect value was entered or a different (incorrect) barcode was

read in.

Defect/incorrect barcode Use a new barcode on an identical fitting, or

correct the entered code manually.

Device blocked Only FRIAMAT Prime: When maintenance

date exceeded (see Section 6.13.1.5).

Let the device cool down. Protective function that prevents the device

from overheating. Switch OFF the device,

and let it cool down until the warning no

longer appears after reactivation.

Fusion stop Fusion stopped at STOP key.

End of fusion Fusion finished.

Voltage …V; Only FRIAMAT Basic: Adjust generator,

frequency …Hz and acknowledge at STOP key.

Memory empty Only FRIAMAT Prime: Printout not possible

from empty memory.

51

EN

Stand/Update: 01.07.2014

Displayed text Tip/remedy

Memory full Only FRIAMAT Prime: Print out log.

Maintenance date exceeded Notify authorised service station.

Have the device serviced.

9 Annex

9.1 Recommended accessories (options)

Article name Order no. Description

Memory stick 624023 For saving and transferring fusion data and

writing the print log to a PDF or CSV file (only

FRIAMAT Prime).

SUPERVISOR pass 623101 For custom configurations of menu functions

(only FRIAMAT Prime).

FRIATRACE IV 613280 For the electronic processing of fusion data

(only FRIAMAT Prime).

Operator pass 623101 For identifying the welder and protecting

FRIAMAT fusion units from unauthorised

access. The details entered on the operator

pass (welder’s name and number) are transferred to the fusion log (only FRIAMAT Prime).

9.2 Authorised service stations

Please contact the FRIATEC AG service hotline +49 (0)621 486-1533 for

service stations worldwide.

9.3 Updates to these operating instructions

The technical information contained in these operating instructions is examined regularly for currency. The date of the last revision is specified on every

page.

The latest operating instructions can be viewed on the internet at

www.friatools.de. The download section can be accessed via the navigation

bar. This provides our updated operating instructions in the form of PDF

documents. We shall also be pleased to send you these.

52

Stand: 01.07.2014

FRIATEC Aktiengesellschaft

Division Technical Plastics

P.O.B. 71 02 61 · D-68222 Mannheim

Telefon +49 621 486-1533

Telefax +49 621 486-2030

info-friatools@friatec.de

www.friatools.com

2481/1 · Update: 01.07.2014

Loading...

Loading...