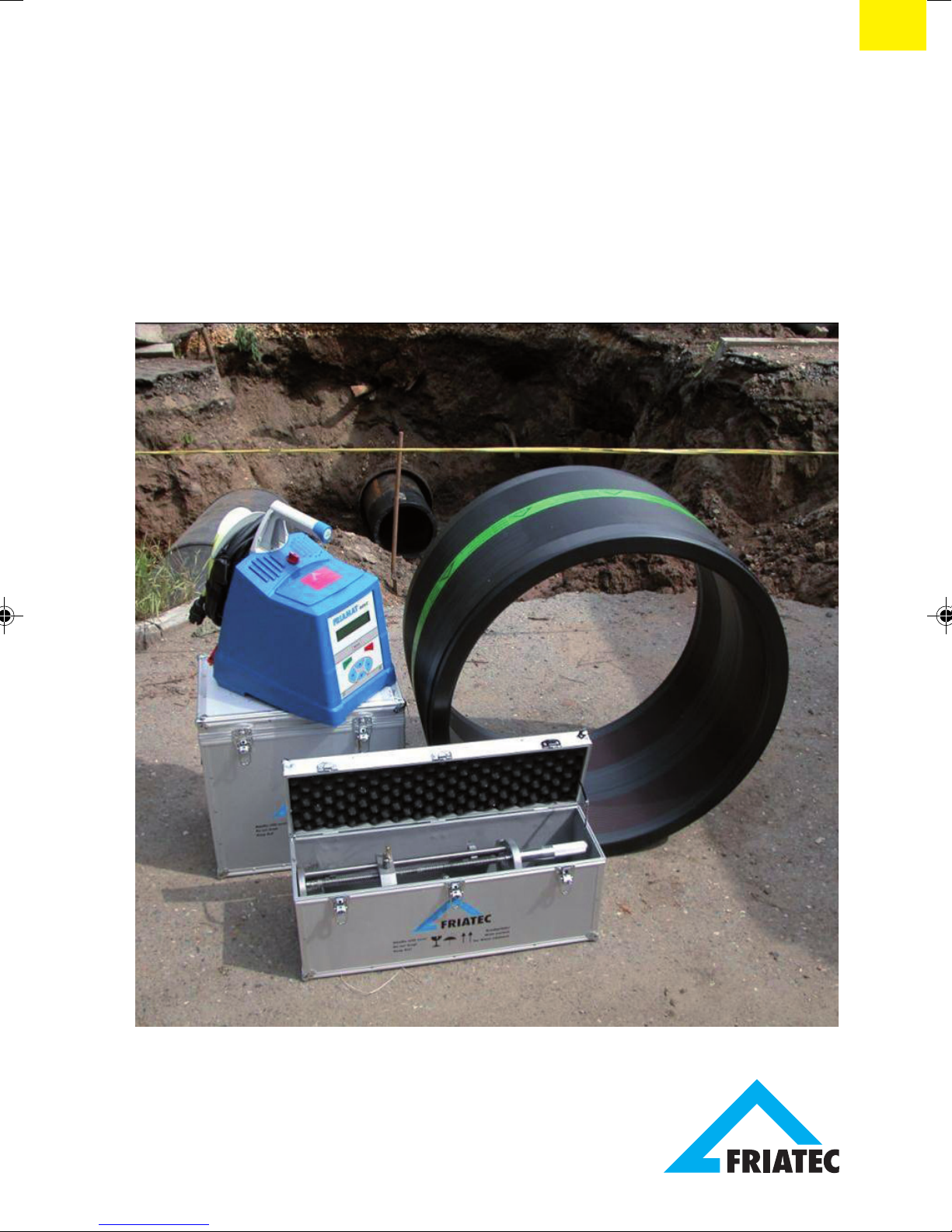

FRIALEN

®

-Large Pipe Technique

for laying large pipes

and relining pipe networks

Fitting Instructions

®

FRIALEN

Large Pipe Technique

Contents Page

FRIALEN® Safety Fittings:

1. Safety 3

2. Areas of Application 3

3. Standard publications and specifications for use 4

4. Couplers from d 250 mm 6

5. Saddle parts - Top Loading 16

6. Pipeline relining 26

7. Update of these assembly instructions 30

For further information on the processing of FRIALEN® Safety Fittings,

please contact:

FRIATEC Aktiengesellschaft

Technical Plastics Division

P.O.B. 710261 · D-68222 Mannheim

Phone +49 621 486-1486

Fax +49 621 479196

Internet: www.frialen.com

Email: info-frialen@friatec.de

Hotline +49 621 486-1486

2

1. Safety

1.1 Safety advice and tips

The following warning symbols are used in these assembly instructions:

DANGER!

Describes impending danger!

Non-observance of this warning may lead to serious damages to health and

objects.

WARNING!

Describes a dangerous situation!

Non-observance of this warning may cause minor injuries or damage to

objects.

IMPORTANT!

Describes advice and other useful information!

2. Areas of Application

FRIALEN® Safety Fittings are used for weld joints at pressure pipes made

of polyethylene in the dimensions SDR 17.6 to SDR 11 for use in gas and

water supply, pressure drainage, industry and landfill construction.

For processing of pipes SDR > 17.6, please call us.

When operating with other media than water and natural gas, please contact

our application engineering department.

IMPORTANT!

The information and processing instructions mentioned on the fitting or

enclosed shall apply predominantly.

3

3. Standard publications and specifications for use

For detailed and up-to-date information on FRIALEN® Safety Fittings, please

see the technical datasheets available on the Internet (www.frialen.com).

Please observe the guidelines of the DVGW standard publications, and of the

DVS, BGR 500 (VBG 50), EN 1555, EN 12201, EN 13244, UVV and

respectively national regulations.

DANGER!

The described sequence of the processes is absolutely to be adhered to.

FRIALEN® Safety Fittings can be used with pipes made of PE 100,

PE 80, PE 63, PE 50 according to DIN 8074/75, EN 1555-2, EN 12201-2,

EN 13244-2, ISO 4437 and ISO 4427.

For PE pipes, a fusion flow rate MFR 190/5 in the range of 0.2 – 1.7g/10 min.

applies.

We recommend using pipes with a limited dimension tolerance range,

tolerance class B.

FRIALEN® Safety Fittings consist of PE 100 and meet the requirements

according to DIN 16963-5, -7, EN 1555-3, EN 12201-3, EN 13244-3,

ISO 8085-3 as well as the DVGW test bases. FRIALEN® Safety Fittings can

be fused with FRIAMAT® Electrofusion Units at ambient temperatures

between - 10 °C and + 45 °C. Fittings from d 710 between 0 °C and + 45 °C.

For material transition joints, the material- or system-specific standards and

installation guidelines apply in addition.

WARNING!

Fusion with other pipe materials such as e.g. PP, PVC etc. is not

possible.

WARNING!

Pipes and moulded components should have settled to a balanced

temperature level between - 10 °C and + 45 °C (Couplers UB d 710 between

0 °C and + 45 °C) when being processed.

4

IMPORTANT!

FRIALEN® Safety Fittings are identified by a batch marking.

This reads from left to right:

• Production week (KW) (stamp 1+2)

• Production year (stamp 2)

• Material identification letter (stamp 3)

Example:

0

5

4

0

0

3

0

0

1

2

0

9

8

1

0

7

0

6

1

2

5

3

4

K

J

L

I

M

H

A

G

B

F

C

E

D

KW 14/01/E

The FRIALEN® Safety Fittings can be stored and processed for a long time,

provided the general storage specifications are adhered to. When properly

stored (in closed rooms or containers (boxes)) and/or not exposed to UV

radiation as well as effects of weather (humidity etc.), a storage and

processing period of more than 4 years can be assumed.

WARNING!

Improperly stored component parts may not be processed because

this may result in leaking fusion joints.

Traceability

An automatic component traceability is possible when using e.g. traceabilitycapable FRIAMAT® Electrofusion Units with a special barcode (see Figure 9)

which contains the specific data of the fitting, e.g. manufacturer, dimension,

material, batch. These data on component traceability can be electronically

archived together with the fusion process data.

IMPORTANT!

Manual electrofusion units (without barcode reader), e.g. FWS 225, are

no longer state-of-the art. Processing of FRIALEN® Safety Fittings with

these units is thus no longer possible.

3.1 Pressure load-bearing capability

The pressure load-bearing capability of FRIALEN® Safety Fittings made of

PE 100 is expressed in SDR stages.

SDR =

pipe outer diameter d

pipe wall thickness s

5

The design factor C (calculation coefficient for PE components) depends on

the area of application and the specifications (min. 1.25).

Fitting material: PE 100 Water Gas

(FRIALEN® standard)

SDR Stage maximum operating pressure maximum operating pressure

in bar for new: C = 1.25 in bar for new: C = 2

17 10 5

11 16 10

7.4 25 -

The parts are identified and usable with regard to their load-bearing

capability according to the above table.

DANGER !

Fusion with escaping media is not permissible.

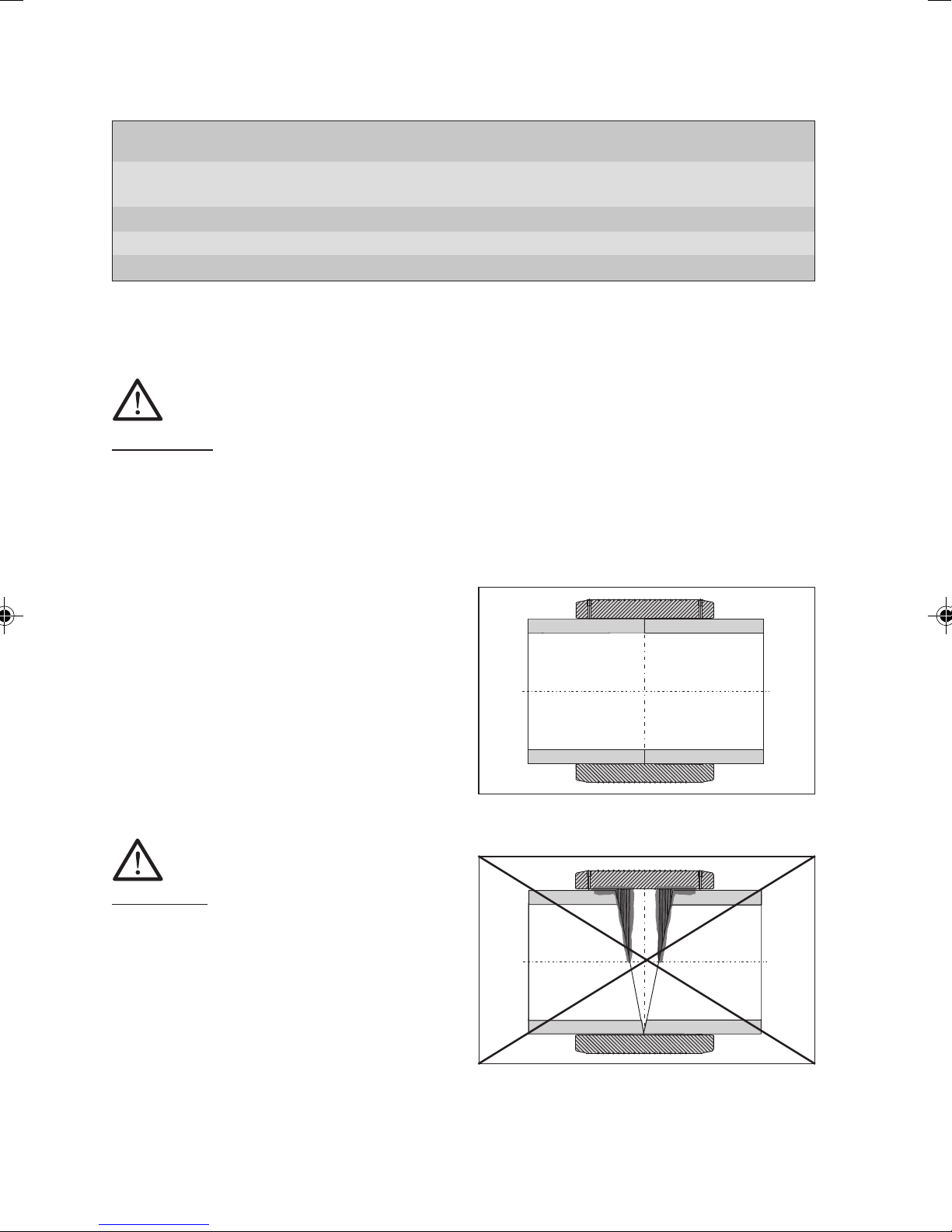

4. Couplers from d 250 mm

4.1 Cutting to length of pipes

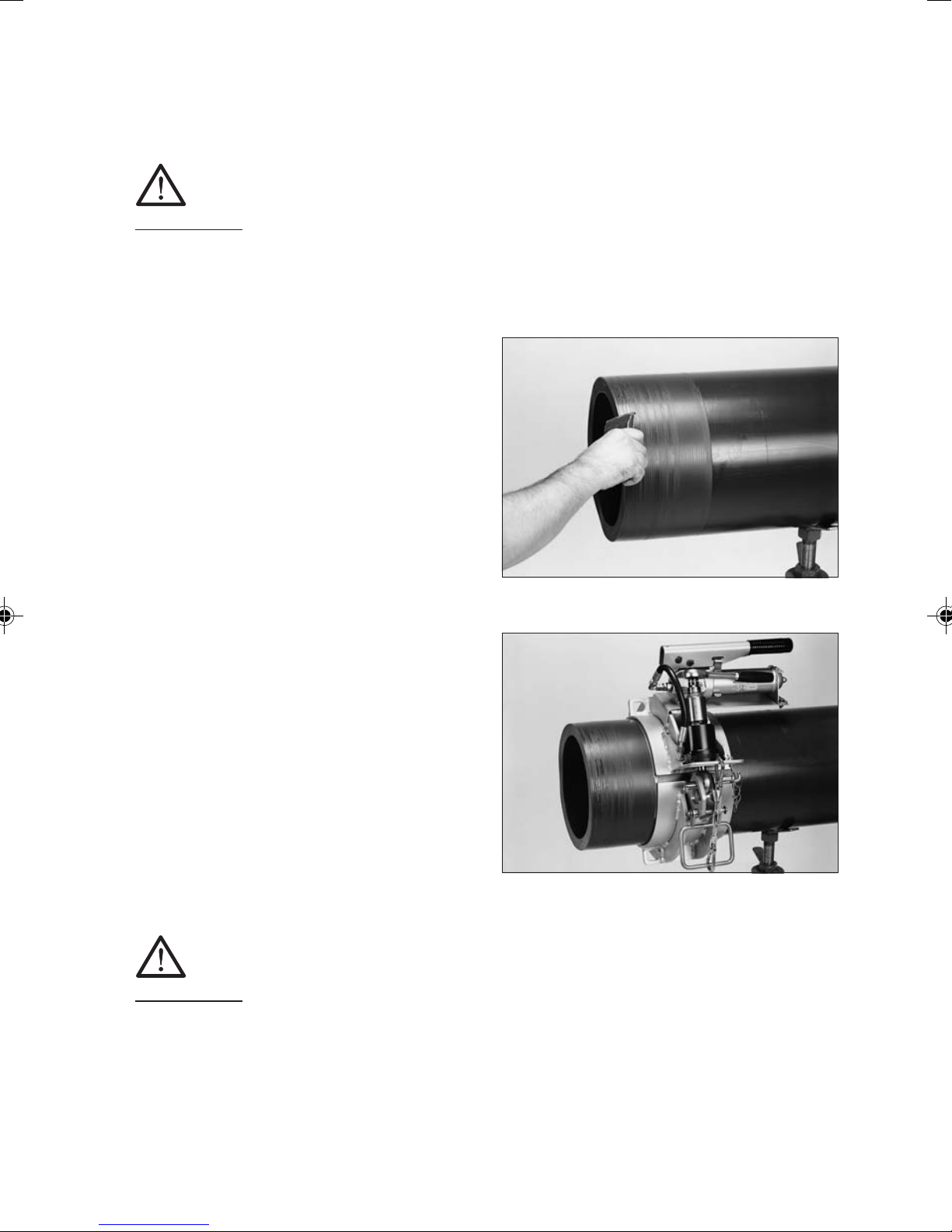

Cut off the pipe in a right angle

to the pipe axis (see Figure 1). A

suitable tool is a PE pipe cutter or a

saw with toothing suitable for

plastics.

Distinctive conical oblique pipeends

must be cut off, if necessary.

DANGER!

A non-rectangular pipe cutting

may cause the heating coil

partially not being covered by the

pipe which may result in

overheating, uncontrolled melt

formation or self-ignition (see

Figure 2).

Figure 1

Figure 2

6

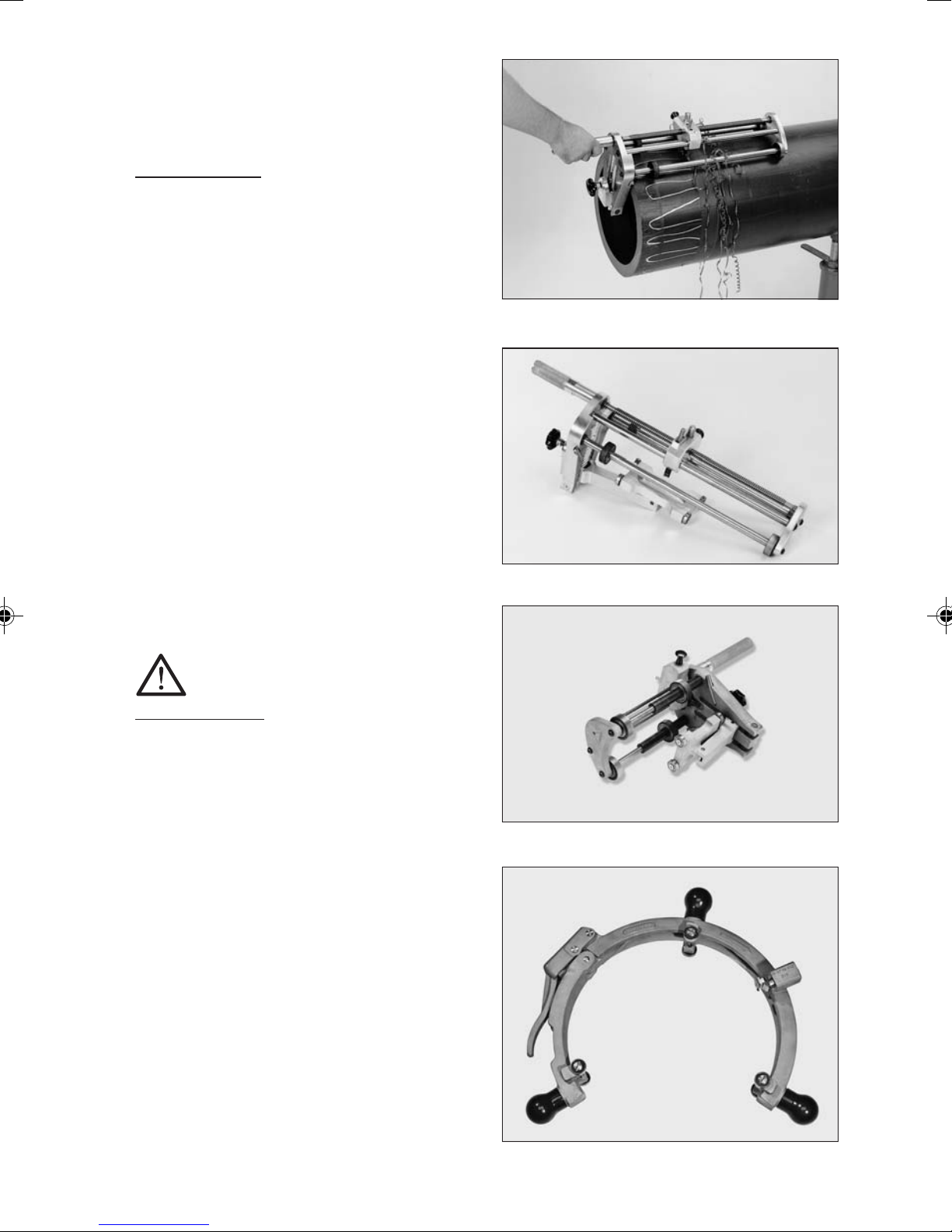

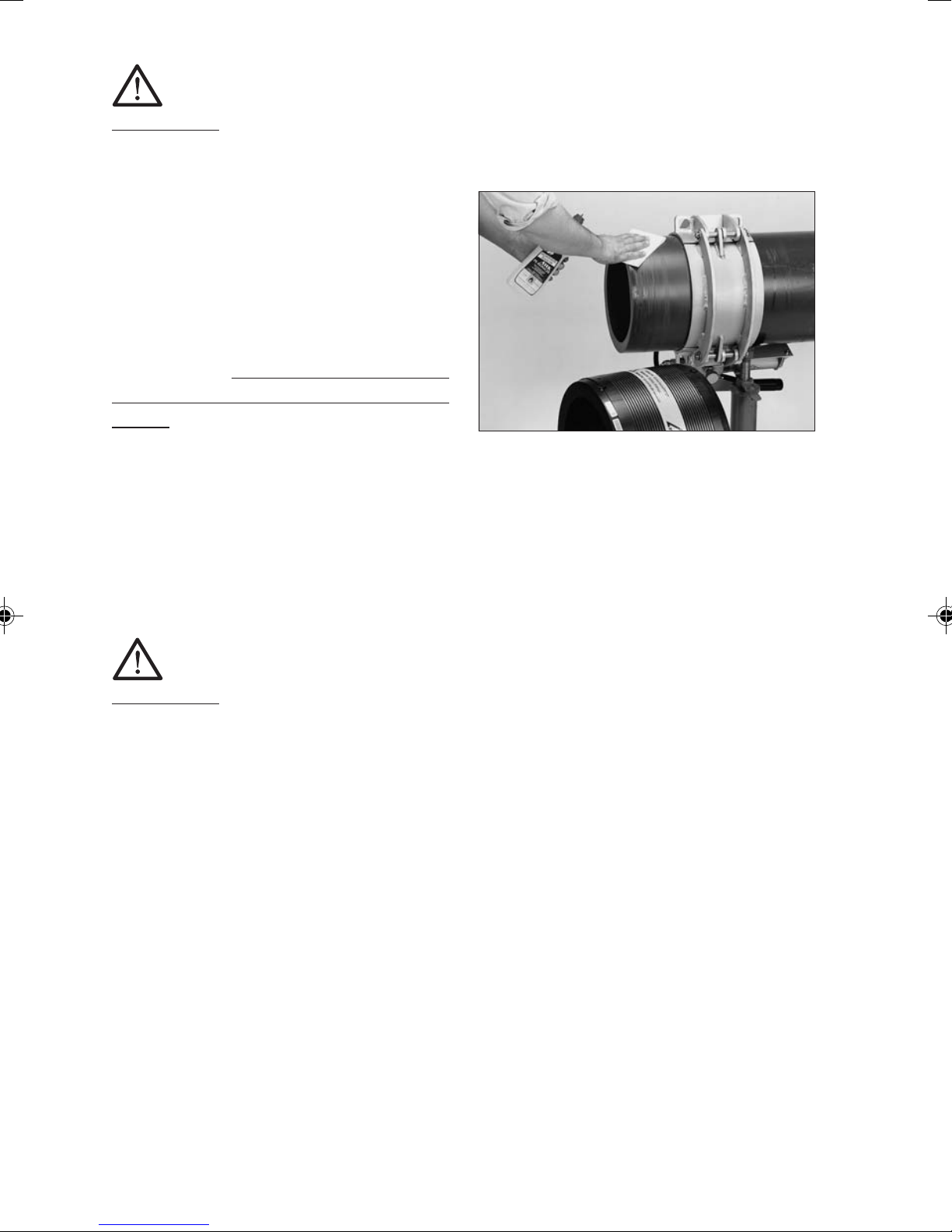

4.2 Measure fusion zone, mark

with a FRIALEN® marker

and remove oxide layer

Fusion zone:

The length of the fusion zone

corresponds to half the length of the

coupler.

At first, remove contaminations from

the pipe. A processing allowance of

approx. + 5 mm in addition of the

insertion depth provides proof after

fusion that the oxide layer has been

removed properly. Using a manual

scraper or FRIALEN® Scraper tools

(see Figure 4 a+b+c), the oxide layer,

which formed during on the surface

of HDPE pipes and spigot fittings

during storage, has to be removed

completely directly before the

assembly.

IMPORTANT!

The Scraper tool FWSG 710 S and

FWSG 710 L have proved themselves for a long time in use

application and serve for the

scraping of pipes in the dimension

area d 250 to d 710.

Figure 3

Figure 4a

Figure 4b

Besides, the FWSG 710 S scrapes

only half a sleeve length, so that it

is possible to scrape spigot

fittings. With the FWSG 710 L the

whole sleeve length is scraped to

make easier the assembly as a

slide-over coupler.

The scraper tools FWSG SE 250,

280 and 315 are proper for both,

preparation of couplers-, and

saddle assembly.

Figure 4c

7

WARNING!

If the oxide layer is not removed completely, inhomogeneous, leaking

fusion joints may result.

WARNING!

The FWSG 710 scraper tool must in all circumstances be used for fittings

from d 710.

A one-time, complete removal is sufficient (min. 0.15 mm).

Damages to the pipe surface as e.g. axial grooves or scratches may not be

located within the fusion zone.

WARNING!

An excessive swarf removal may result in an excessively large annular

gap which either cannot or only insufficiently closed by fusion (for the

remedy see item 4.8).

Please thus regularly check the condition of the blade at the manual

scraper and the wear of the scraper blade at the scraper tool. Worn blades

must be replaced (see FRIALEN® Info No. 1).

Scraper Tool Estimated swarf thickness (mm) Abrasion limit (mm)

FWSG 225 0.25 - 0.35 0.4

FWSG 710 0.30 - 0.40 0.5

FWSG SE 250 - 315 0.25 - 0.35 0.4

Please note that the indicated wearing margin applies to FRIALEN

Safety Fittings. Where appropriate please observe manufacturers’

indications.

Filing or sanding are not permitted because contaminations are

introduced.

For a control of the complete surface removal over the entire surface, we

recommend to apply marking (control) lines (see Figure 3). If during scraping of

the surface non-scraped areas occur at some points (e.g. in case of oval pipes),

these areas are to be reworked.

®

8

The processed zone is to be protected against dirt, soap, grease, subsequently

flowing water and unfavourable effects of weather (e.g. moisture, frost formation).

Do not touch the fusion zone again after scraping.

WARNING!

FRIALEN® Safety Fittings with integrated heating coils guarantee optimal

heat transfer through their exposed heating coils and may thus not be

scraped at the inside of the fitting.

4.3 External and internal

chamfering of the cutting

edge (See Figure 5)

For this purpose, the manual scraper

is a suitable tool. A good chamfer on

the outside diameter of the face of

the pipe will make it easier to fit the

coupler. Remove swarves from

within the pipe.

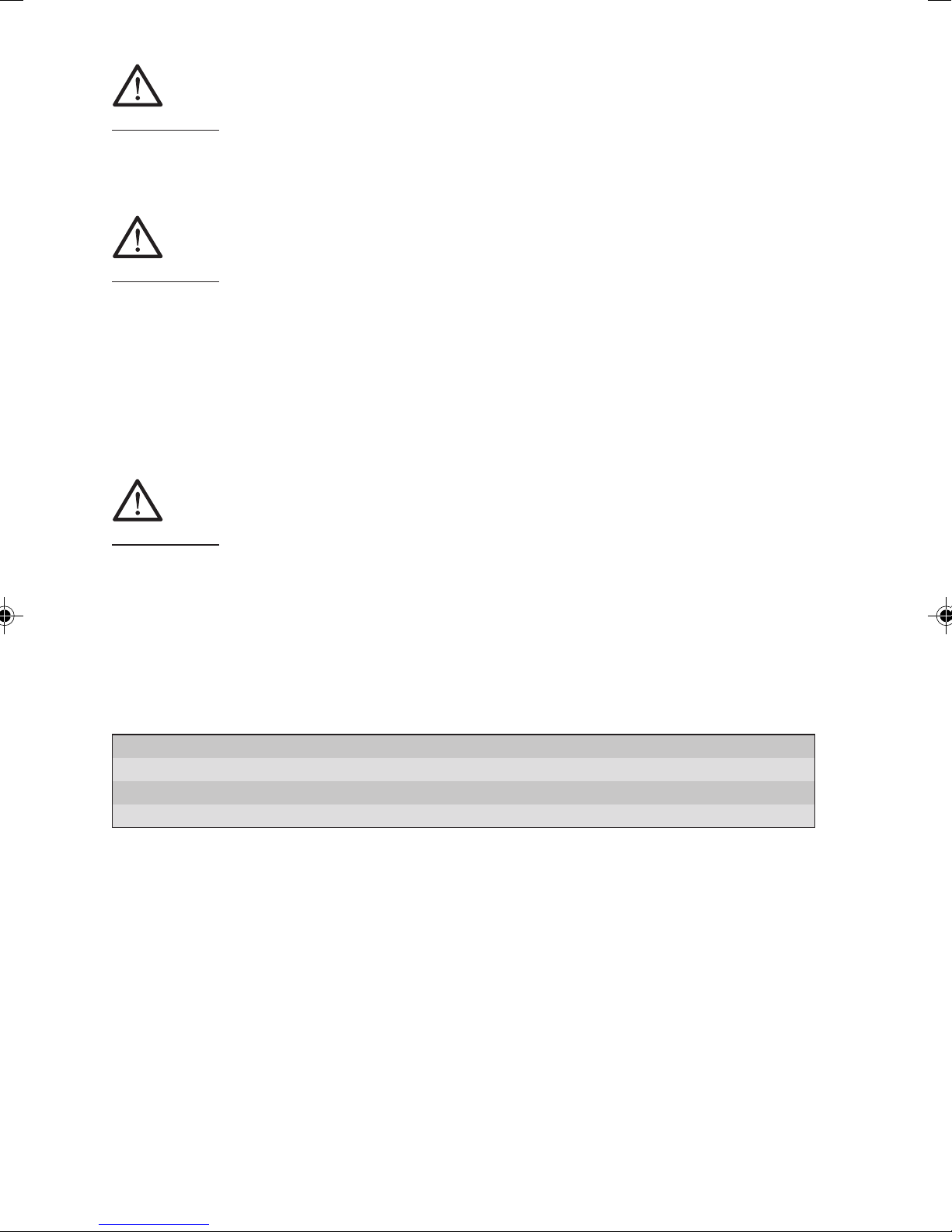

4.4 Restoration of irregular /

Figure 5

oval pipes

Pipes, in particular bundled coils and

drums, may loose their roundness

during storage. If the pipe out-ofroundness in the fusion zone area

exceeds 1.5% of d (outer diameter)

or is > 3.0 mm, these pipes must

be rounded in the fusion zone

area. Please use rounding clamps

for this purpose which are installed

at the end of the fusion zone (See

Figure 6).

Figure 6

WARNING!

For the installation of of fittings from d 710 rounding clamps for the

pipes need to be applied in all circumstances.

With UB couplers d 280 to d 450 the pipe may be adjusted to the coupler

following evaluation of the annular gap (> 1 mm) by using the pre-heating

barcode.

9

WARNING!

The pre-heating barcode must be applied when using fittings from d 500.

4.5 Cleaning

The surfaces of the pipes to be fused

and the interior surfaces of the

FRIALEN® Safety Fittings must be

absolutely clean, dry and free from

any grease. These areas are to be

cleaned with a suitable cleaning

agent and exclusively with ab-

sorbent, lint-free and non-dyed

paper directly before the assembly

and after scraping (see Figure 7).

Figure 7

We recommend PE cleaning agents which meet the requirements of the test

basis DVGW-VP 603, e.g. AHK cleaning agents.

When cleaning, ensure that no contaminations from the unscraped pipe

surface are introduced into the fusion zone.

WARNING!

When using alcoholic cleaning agents, the alcohol percentage must be

at least 99.8% according to DVGW-VP 603.

The cleaning agent must be completely evaporated before starting the

fusion process.

Now, using the FRIALEN® marker, re-mark the line (approx. 120 ° distributed around the circumference) to show the width of the fusion zone on the

pipe since this will have been removed by scraping and cleaning.

The joint surfaces must be clean and dry before installing the fitting. The

cleaned fusion zone should not be touched with bare hands. Moisture in the

area of the joint area, e.g. because of dew or frost, is to be removed using

suitable aids.

The fusion fitting is to be removed from the packaging only directly before

the planned processing. The packaging protects the fittings against external

influences during transport and storage.

10

4.6 Inserting push fit ends or pipe ends into the fitting.

When the FRIALEN® Safety Fittings and pipes are being assembled care

should be taken to ensure that the contact sockets are accessible to allow

connection of the fusion plug. Assembly can be assisted by tapping around the

face with a plastic hammer at the same time. When assembling do not tilt.

The worked insertion end must be pushed into the fitting up to the mark. If

necessary hydraulic rounding clamps should be used (see Figure 6).

Repeated scraping of the outer diameter might be necessary if the tolerance

is big. Repeated scraping may not be performed to remedy installation

problems due to out-of-roundness!

If the fitting cannot be slipped on without using force despite the above

described procedure, a repeated scraping is permitted. (see item 4.4).

A simple control of the high points is possible by installing the coupler and

evaluating the annular gap.

4.7 Ensuring a tension-free assembly of the components

All joints prepared for fusion must be tension-free. Pipes may not be positioned

in the FRIALEN® Safety Fitting under bending stress or self-load. After the

installation on the pipe ends, it must still be possible to move the couplers by

hand.

If required, the piping or the fitting is to be supported or suitable fixing

facilities are to be used. The tension-free fixing of the joint is to be maintained

until the cooling time stated on the barcode and in the table is reached. (see

item 4.9).

Before starting the fusion process, check again based on the markings

whether the position of the pipe insertion end in the FRIALEN® Safety Fitting

has shifted (correct, if required).

WARNING!

A non-tension-free or shifted joint

may result in an impermissible melt

flow and a defective joint during

fusion (see Figure 8).

Figure 8

11

4.8 Pre-heating for reducing the annular gap between coupler and

pipe.

WARNING!

Only use fusion units which have been approved by the manufacturer

with regard to their function for the processing of FRIALEN® Safety

Fittings. See DVS 2207-1.

Use FRIAMAT® fusion units only for FRIALEN® UB d 710!

Preheating barcode (see also instruction leaflet enclosed with the

component part)

The ring gap between the coupler and the pipe can be compensated for

to a certain extent by using a specifically matched preheating barcode

(Figure 9). The maximum bridgeable distance between the coupler and the

pipe may not exceed 3 mm across the entire circumference. For the coupler

mounted and centred at the pipe,

this means: Δ d ≤ 6 mm.

For relining slide-over couplers REM

d110/DN100 and d160/DN150, a

maximum gap of 2 mm applies. The

thermal reduction of tensions in the

joining area has also a positive

effect on the fusion result.

Figure 9

Procedure:

1. Preparation of the joining area corresponding to the FRIALEN® installation

instructions for large pipes and pipe network relining.

2. Centre the coupler on the pipe such that the ring gap across the

circumference is as equal as possible. If required, support the coupler.

3. Close the ring gap with adhesive tape to prevent heat losses.

4. Close open pipe ends (chimney effect).

5. Standard processing:

I. Preheating of first coupler side, record yellow barcode with FRIAMAT

electrofusion unit and start the process; then

II. preheating of second coupler side, record yellow barcode with

FRIAMAT® electrofusion unit and start the process; then

III. first coupler side: check the ring gap: if it is still too large, the

preheating can be repeated 2 x maximum. If ok: Start fusion of first

coupler side, (white barcode), then

IV. second coupler side: check the ring gap: if it is still too large, the

preheating can be repeated 2 x maximum. If ok: Start fusion of

second coupler side, (white barcode)

®

12

WARNING!

Between preheating and fusion, a waiting time is always required to

ensure heating through of the component parts. This waiting time

corresponds approximately to the preheating or fusion time, depending

on the dimension approx. 15-30 minutes. If only one coupler side is to

be processed, the waiting time between preheating and fusion is to be

observed.

If the waiting time is exceeded by more than the double time, the

described process is to be repeated.

4.9 Carrying out the fusion

WARNING!

Only use fusion units which have

been approved by the manufacturer with regard to their function

for the processing of FRIALEN

®

Safety Fittings. See DVS 2207-1.

Use FRIAMAT® fusion units only

for FRIALEN® UB d 710!

Figure 9a

For the fusion of the coupler d 800

please observe our FRIALEN® Info

No. 42.

The fusion parameters are contained in the main barcode affixed to the

FRIALEN® Safety Fitting. When using fully automatic fusion units (e.g.

FRIAMAT®), the parameters are entered into the fusion unit using the reader.

After reading of the barcode (see Figure 9a), the fitting data are to be

compared with the data shown on the unit’s display.

The subordinated barcode contains the data for component traceability (see

information). This barcode is only to be read if the component traceability

function is to be used. This requires suitable fusion units.

The fusable pipe series are listed in the SDR labelling on the label.

The fusion units automatically monitor the fusion process and control the

supplied energy in determined limits.

13

Information:

The fusion parameters are encoded on the barcode label in the form

of a 24-digit figure (top), the data for component traceability in the

form of a 26-digit column of numbers (bottom), and can also be

entered manually into the FRIAMAT® fusion unit using the emergency

entry mode.

Information:

Fusion units FRIAMAT® L and

FRIAMAT® LE are not suitable for

the fusion of large couplers.

For fittings with separate coils (see

Figure 10), each fitting side is to be

fused separately.

For fittings with continuous coil, both

fitting sides are to be fused simultaneously (see Figure 11).

FRIALEN® Safety Fittings are equipped with a swell indicator, this only

gives an indication that fusion has

taken place. This swell indicator

signalises the fusion process, by

changing its colour (red) and by

increase of volume. The proper

progress of the fusion process,

however, is only shown by the

fusion

unit.

After reading of the barcode, the

fitting data are to be compared with

the data shown on the unit’s display.

If they are identical, start fusion.

Please observe the operating instruction of the FRIAMAT® fusion

unit.

Figure 10

Avoid stress on the connecting spot.

14

Figure 11

WARNING!

Keep a distance of one meter to the fusion site during the fusion

process for general safety reasons.

The obtained actual fusion time is

to be compared with the target

fusion time on the unit and to be

noted on the pipe or the FRIALEN

®

Safety Fitting (See Figure 12).

With this identification it is ensured

that no fusion point is overlooked.

In case of doubt, a fusion can be

repeated. But the joint surfaces

must be cooled down to ambient

Figure 12

temperature before each renewed fusion. Please contact for this purpose

your local FRIALEN® sales engineer by phone or the FRIALEN® Hotline.

4.10 Cooling times.

The cooling time is

a) the time which is required to cool down the component to the temperature

which facilitates the movement of the joint. This time is also listed on the

barcode and is identified by CT.

b) the time which is required to cool down the component to the temperature

which facilitates the application of the full test or operating pressure. This is

classified into pressure volumes of up to 8 bar and > 8 bar.

WARNING!

When inserting piping (e.g. relining) it is the cooling time before pressurising which is important.

Diameter Cooling time in minutes for FRIALEN

in mm couplers and fittings

CT Up to pressurising Up to pressurising

until the joint at up to 8 bar at > 8 bar

may be moved

250 – 355 30 75 100

400 – 710 40 95 120

800 90 200 240

®

15

Information:

A piping may only be commissioned after successful pressure test (see

EN 805, EN 12007 and DVGW G 469, W 400). The guidelines of the

DVGW leaflets for pressure tests, the European standards or the

country-specific regulations are to be observed.

Information:

The detachment of the outer armouring wire during the cooling down

stage is caused by the thermal expansion characteristics of the fused

joint and does not present a problem.

5. Saddle parts - Top Loading

FRIALEN® TL saddle parts are used with pipes from SDR 17 to SDR 11

from d 250 mm. The processing occurs with the FRIATOP Clamping Unit

(Figure 15b).

5.1 DAA-TL Pressure Tapping Tees - Top Loading, d 250 - 315 (400)

FRIALEN® DAA-TL Pressure Tapping Tees Top-Loading are suitable for

fitting as branch connectors onto unpressurised or pressurised pipelines.

WARNING!

FRIALEN® pressure tapping valves

≥ d 355 mm may be processed

using only SDR 17 and SDR 17,6

pipes due to tapping technique.

Processing temperature: between

0 °C and 45 °C.

Figure 13

16

5.1.1 Measuring of fusion zone of

the pipes (and the lateral

outlet spigot), marking and

removing oxide layer

The fusion zone: is the area of pipe

covered by the saddle; for a side outlet

it is the insertion depth on the smooth

pipe spigot. The oxide layer in the

area of the fusion zone, which has

formed on the surface of the HDPE

pipes during storage, must be totally

removed with a hand scraper or a

scraper tool (e.g. FWSG SE) immediately before assembly (See Figure

14).

A processing allowance of several

millimetres in addition to the covered

area provides proof after fusion that

the oxide layer has been properly

removed from the pipe.

Figure 14

WARNING!

If the oxide layer is not removed

Figure 14 a

completely, leaking fusion joints

may result.

Worn blades of the scraper tool and manual scraper must be replaced.

A one-time, complete removal is sufficient (min. 0.15 mm). A uniform surface

without flattening and material grates at the pipe diameter should be the

result.

WARNING!

Filing or sanding of the pipe is not permitted because contaminations

are introduced.

17

For a control of the complete surface removal over the entire surface, we

recommend to apply marking (control) lines (see Figure 13). If during scraping

of the surface non-scraped areas occur at some points, these areas are to

be reworked.

The processed zone is to be protected against dirt, soap, grease,

subsequently flowing water and unfavourable effects of weather (e.g.

moisture, frost formation).

5.1.2 Cleaning

The surfaces of the pipes to be fused and the interior surfaces of the

FRIALEN® DAA-TL Pressure Tapping Tees Top-Loading must be

absolutely clean, dry and free from any grease. These areas are to be

cleaned with a suitable cleaning agent and exclusively with absorbent,

lint-free and non-dyed paper directly before the assembly and after

scraping.

We recommend PE cleaning agents which meet the requirements of the test

basis DVGW-VP 603, e.g. AHK cleaning agents.

When cleaning, ensure that no contaminations from the unscraped pipe

surface are introduced into the fusion zone.

WARNING!

When using alcoholic cleaning agents, the alcohol percentage must be

at least 99.8% according to DVGW-VP 603.

The cleaning agent must be completely evaporated before starting the

fusion process.

Subsequently, re-apply marking line for the fusion zone width with the

FRIALEN® marker because this line was removed during scraping and

cleaning. The joint surfaces must be clean and dry before installing the

fitting. The cleaned fusion zone should not be touched with bare hands.

Moisture in the area of the joint area, e.g. because of dew or frost, is to be

removed using suitable aids.

18

The fusion fitting is to be removed

from the packaging only directly

before the planned processing. The

packaging protects the fittings

against external influences during

transport and storage.

5.1.3 Assembly

- Place the saddle onto the prepared

surface of the pipe.

- Fit the adapter of the FRIATOP

clamping device (Figure 15a).

- Fit the clamping device as directed

in the Operating Instructions (Figure

15b).

WARNING!

For pressure tapping tees and

pressure tapping valves, the

factory drill setting may not be

changed before starting the fusion

process.

Figure 15a

5.1.4 Carrying out of fusion

When fusing Pressure Tapping

Tees to media-carrying pipings, the

following operating pressures may

not be exceeded until the pipe has

cooled down completely:

Figure 15b

19

Pipe material PE 80 PE 100

SDR 17 11 17 11

Maximum permissible working pressure in bar

Gas pipe 2 5 5 10

Water pipe 8 12.5 10 16

WARNING!

Only use fusion units which are authorised by their manufacturer to

process FRIALEN® Safety Fittings as part of their function. See DVS

2207-1.

The fusion parameters are contained in the main barcode affixed to the

FRIALEN® Safety Fitting. When using fully automatic fusion units (e.g.

FRIAMAT®), the parameters are entered into the fusion unit using the reader.

After reading of the barcode, the fitting data are to be compared with the

data shown on the unit’s display. If they are identical, start fusion. Please

observe the operating instruction of the FRIAMAT® fusion unit.

The fusion units automatically monitor the fusion process and control the

supplied voltage in determined limits.

The swell indicator only indicates to the performed fusion process. The

proper fusion process is, however, only indicated by the fusion unit!

WARNING!

Keep a distance of one meter to the fusion site during the fusion

process for general safety reasons.

The obtained ACTUAL fusion time is to be compared with the target

fusion time on the unit and to be noted on the pipe or the FRIALEN

Safety Fittings.

With this identification it is ensured that no fusion point is overlooked.

After the fusion process has finished always maintain the jointing

pressure for a 10 minute cooling period!

®

20

5.1.5 Tapping and application of the test and operating pressure

The following waiting times are to be observed:

Diameter Cooling time in minutes for FRIALEN

in mm Saddle fittings

Up to pressurisation CT

via outlet Up to

tapping

≥ 250 50 60

®

The cooling time CT stated on the components corresponds to the cooling

time until tapping.

WARNING!

If the waiting times are not observed, leaking fusion joints may result. The

general installation instructions must be observed before tapping.

5.1.6 Tapping of Pressure

Tapping Tees

Remove blanking plug. Turn the drill

down up to the lower stop using the

matching FRIALEN® activating key

(SW 19) (See Figure 16).

Turn the drill backwards up to the

upper stop. Position the blanking

plug and turn down the FRIALEN

®

activating key until the collar of the

plug slightly touches the front face

of the drill spigot.

Subsequently, turn back the plug

half a turn to relieve the O-ring

tension.

WARNING!

If the collar is excessively tightened, the plug may break or the hexagonal seat may be overwound. In this case, the plug has to be replaced.

We recommend closing the tapping dome with a fusion cap K. The

required scraping and cleaning are to be performed (see items 4.2 - 4.8).

Figure 16

21

5.1.7 Tapping of DAV-TL pressure tapping valves d 250 - 315 (400)

(Figure 17)

WARNING!

Because of tapping requirements,

the FRIALEN-pressure tapping

valves ≥ d 355 can only be installed

on pipes with SDR 17.

Installation, fusion and cooling times

as 5.1.3 et seq.

Tap by turning square spanner

clockwise up to lower end position.

The valve is now closed. In order to

open the valve, the tap must be moved

Figure 17

anti-clockwise up to the end position.

After arriving the end position turn

back approx. half a rotation.

The metal end points for the ‘open shut’ positions of the valve lead to a

distinctly noticeable increase in the activating force. As sealing takes place

in the closed position using a radially injected O-ring, it is not necessary to

apply a great deal of pressure when closing the valve.

Install the FRIALEN Installation Kit EBS on the 14 mm square of the DAV-TL

and secure the splint against pull out. Set the required overlapping height on

telescoping frame. Telescoping frame may be adjusted by sliding scale and

will stop securely at any point. The FRIALEN® EBS is technically perfectly

adapted to the FRIALEN® DAV-TL.

22

5.2 VAM-RG-TL Valve Tapping Saddles d 250 - 315 (560)

5.2.1 Assembly

The preparation of the installation

and the fusion process is made

analogue to the FRIALEN® Pressure

Tapping Tee (see 5.1.1 to 5.1.4).

WARNING!

The fusion range of the saddle

covers the dimensions d 250 up

to d 560. If necessary application

Figure 18

technology restrictions must be considered by drill tool (usually

applicable until d 315 SDR 11).

Restrictions concerning the application must be considered, e.g. length

of drilling tool. Details of these components, given by manufacturer,

have to be regarded.

The cooling times are to be observed (see item 5.1.5 Pressure Tapping Tee).

The fitting is drilled using a suitable close-off device or fitted with a valve in

accordance with the relevant Fitting Instructions from the different valve

manufacturers. The preparation and conduct of the pressure test are carried

out in accordance with the details given by the valve manufacturer.

The threaded components fitted at the factory must be secured with a

spanner to prevent them from twisting.

Care should be taken to ensure that the insulation work is carried out in

accordance with the regulations (DVGW Standard Publication).

5.3 SPA-TL Shut off Saddles

Top-Loading d 250 - 315 (560)

5.3.1 Assembly

WARNING!

The fusion dimensions of the component includes d 250 - d560. If

necessary application technological restrictions have to be regarded.

For example by borer tool or balloon, normally applicable up to d 315

SDR 11. Details of these components, given by manufacturer, have to

be regarded. Processing temperature: between 0 °C and 45 °C.

23

FRIALEN® Shut-off Saddles (see

Figure 19) are prepared for

installation and fused analogue to

FRIALEN® Pressure Tapping Tees

(see Chapters 5.1.1 – 5.1.4). The

tapping of the pipe can be made

after cooling down (see item 5.1.5)

and observing the installation instructions of the tapping/shut-off

saddle installation equipment of the

relevant manufacturer.

Installing the brass plug

The plug is to be installed up to the

stop; the O-ring must seal in the

dome. The required torque of

approx. 150 Nm can be achieved

through a lever. A visual control

takes place (Figure 20). A torque

screwdriver is not necessary.

Figure 19

After fitting the brass plug either the

plastic nut must be screwed on or a

FRIALEN® cap for Shut off Saddles must be fused on, ensuring that

the usual scraping and cleaning

work is carried out (see Figure 21).

5.4 SA-TL Spigot Saddles

Top-Loading d 250 - 560

5.4.1 Assembly

The preparation of the installation

and the fusion process is made

analogue to the FRIALEN® Pressure

Tapping Tee (see 5.1.1 - 5.1.5).

Figure 20

Figure 21

24

Figure 22

WARNING!

The tapping is made with commercially available tapping units in an

unpressurised state with or under pressure using shut-off valves.

We recommend the tapping unit of the company of Hütz + Baumgarten,

Remscheid (www.huetz-baumgarten.de), especially designed for this

purpose.

Please ask our FRIALEN® Application Engineering Department.

The manufacturer’s installation instructions are to be observed.

5.5 VSC-TL Repair Saddle

Top-Loading d 250 - 560

5.5.1 Assembly

For localised damage to the pipe at a

single point the damaged spot can be

sealed off with a plug and then fused

with the repair Saddle Top-Loading.

The preparation of the installation

and the fusion process of the

Figure 23

individual half shells is made

analogue to the FRIALEN® Pressure

Tapping Tee (see 5.1.1 - 5.1.5).

WARNING!

Care must be taken to ensure that during assembly the damaged or

deformed point on the pipeline lies in the centre of the heating element.

Fusion with escaping media is not permissible.

25

5.6 AKHP-TL Tapping Ball Valves d 250 - d 560

AKHP-TL Tapping Ball Valves allow

the drilling of unpressurised or

pressurised pipelines.

WARNING!

The fusion zone of the component

includes the dimensions d 250d 560. If necessary application

technological restrictions have to

Figure 24

be regarded. For example by borer

tool or balloon, normally applicable up to d 315 SDR 11. Details of these

components, given by manufacturer, have to be regarded.

5.6.1 Assembly

The preparation of the installation and the fusion process of the tapping ball

valve AKHP is made as saddle component analogue to the FRIALEN

Pressure Tapping Tee (see items 5.1.1 - 5.1.5).

®

INFORMATION:

For a leakage-free tapping of pressurised pipings, we recommend the

tapping unit of the company of Hütz + Baumgarten, Remscheid

(www.huetz-baumgarten.de). Please ask our Application Engineering

Department.

The telescopic FRIALEN-actuation key BS is particularly designed for the

technical and geometrical requirements of the KHP ball valve.

6. Pipeline relining

6.1 Procedures and areas of application

Defective old pipelines made of cast iron, steel or other conventional materials

can be renovated by drawing in an HDPE pipe, as an alternative to laying new

pipes.

Standard pipes are used for the relining process and are joined using

suitable FRIALEN® Safety Fittings.

26

For the so-called close-fit process (lining with precisely fitting pipes),

however, the pipes which are used have a cross section which has been

changed in the manufacturing process (e.g. U-liners) or on the building site

itself (e.g. Swage lining). The outside diameter of these pipes is matched to

the inside diameter of the old pipeline and thus deviates from the standard.

The ends of each renovated section of pipeline can be fused with FRIALEN

REM Relining Slide-over Couplers.

At points where it is scheduled to fuse on a coupler or a saddle the relining

pipe should be sized to the nominal inside diameter during the reshaping by

fitting half shells.

6.2 REM Relining Adapter Couplers

One end of the REM Relining Adapter Coupler (Figure 25) is matched to

the dimensions of the pipes used for

this process. The other end corresponds to the standard pipe size. This

allows renovated sections of pipeline

to be connected using fitted pieces of

standard pipe. The fittings are used

like slide-over couplers.

Figure 25

®

6.3 Fitting and fusion

6.3.1 Relining using HDPE standard pipes

When joining standard pipes the appropriate FRIALEN® Safety Fittings are

used. The fitting and fusion is carried out in a similar fashion to that in

item 2. For couplers > d 250 mm preheating in accordance with item 4.8 is

recommended when there are larger annular gaps.

6.3.2 Close-fit relining

After the renovation the HDPE pipes used will often exhibit deviations both in

their diameter and from the ideal round shape in the area of the proposed

joint. Depending on the characteristics of the pipe the joint can be made using

a preheating code, and also in conjunction with a support sleeve or a pipe

expander tool.

27

6.3.3 Pre-heating: Procedure see

item 4.8

6.3.4 Support sleeve

In case of larger deviations in shape

or size on the ends of the pipes in the

area of the joint the use of support

sleeves is recommended (Figure 26).

The fitting can then be used as a

slide-over coupler.

For fitting the support sleeve a suitable

pipe expander tool has to be employed

(Figure 27). Before using the pipe

expander tool deviations in shape

must be taken into account. The

expander shells should be positioned

to give an optimum rounding effect.

Figure 26

Pipe expander tool

The design of the support sleeve is

dependent on the medium flowing,

the material and the pipe size.

Figure 27

The fitting of coupler and sleeve will

be made easier if the pipe tolerances

are taken into account when deciding

on the size. The use of preheating in

accordance with item 6.3.3 will

then be essential.

6.3.5 Use of a pipe expander tool

as a temporary support

sleeve

Figure 28

If a support sleeve is not wanted the

coupler can be fused using a suitable

pipe expander tool, matched to the

size of the pipe. Use of the preheating barcode (see item 6.3.3) is particularly

important to reduce the stresses in the pipe. The tool must remain in place

during the fusion process and until the cooling period has passed.

28

6.4 Cooling times

For cooling times item 4.10 is applicable.

6.5 Relining fittings and clips

(top loading)

When fitting saddle components

(Figure 29) care must be taken with

any ovality or flattening of the HDPE

pipe. In order to achieve a uniform

Figure 29

surface pressure, and thus a proper

fusion, the radius of curvature on the inner liner at the site of the proposed

joint must correspond to the diameter range d of the moulded component

being used. If necessary the saddle must be brought into line either axially or

radially.

The assembly of the saddle components occurs according to items 5.1.1

to 5.1.6

Before the renovation the old pipe should be cut away at the point where a

moulded saddle component is to be fused to the inner liner pipe. The pipe

diameter will be brought to size at the proposed jointing point by fitting half

shells.

When fitting a house connection at some later point access to the inner liner is

gained by using a window cutter to get through the old pipe.

29

7. Update of these assembly instructions

Further operating and assembly instructions are available:

- FRIALEN® Safety Fittings for House Service

and Supply pipings up to d 225

- FRIAFIT® Sewage System

- FRIAMAT® Electrofusion Units

- FRIATOOLS® Scraper Tools

- FRIATOP Clamping Unit

- FWFIT Clamping and Tapping Tool

These technical statements are regularly revised to be up-to-date. The date

of the last revision is stated on the document. For an updated version of the

operating instructions, please visit our website www.frialen.com on the

Internet. You will find the “Download” page on the navigation bar. This page

contains our updated operating instructions as pdf documents. We will also

mail them to you on request.

30

31

FRIATEC Aktiengesellschaft · Technical Plastics Division

P.O.Box 71 02 61 · D-68222 Mannheim

Phone: +49 621 486-1486 · Fax: +49 621 479196

E-Mail: info-frialen@friatec.de · www.frialen.com

32

2104/8e · II.08 · Update: 26.02.08

Loading...

Loading...