Friant & Associates Interra Installation Manual

Interra Installation Manual

to install the Friant

Interra panel system

Instructions

Friant & Associates, LLC

Table of Contents

Getting Started

Introduction ��������������������������������������������������������������������������������������������������3

General Tools, Staging & Safety ��������������������������������������������������������� 4

Before Installation ��������������������������������������������������������������������������������������5

A/B Style Frames ���������������������������������������������������������������������������������������6

Frame Connection Point Locations ��������������������������������������������������7

Frame Assembly & Connectors

Frame to Frame Assembly ��������������������������������������������������������������������8

Frame to Frame of Dierent Heights �����������������������������������������������9

Stacking Frame Installation �����������������������������������������������������������������10

Stacking Frame to Stacking Frame Installation ������������������������� 11

Door Frame Installation ������������������������������������������������������������������������ 12

Frame to Connector Assembly ���������������������������������������������������������13

Frame to Connector Assembly: 2-Way, 3-Way 4-Way ���������� 14

Stacking Frame to Connector Installation ����������������������������������� 15

Other Connectors & Finished Ends

Wall Strips ����������������������������������������������������������������������������������������������������16

Tile Adapters ���������������������������������������������������������������������������������������������� 17

Wall Start ������������������������������������������������������������������������������������������������������18

Frame Finished End Installation�������������������������������������������������������20

Finished End Change of Height Installation�������������������������������� 21

Trims & Top Caps

A/B Base Trim �������������������������������������������������������������������������������������������24

Top Cap Installation �������������������������������������������������������������������������������29

Glass Top Cap Installation, Center & End Cap ��������������������������30

Tiles

Fabric Tile����������������������������������������������������������������������������������������������������46

Fabric Tile to Floor ���������������������������������������������������������������������������������47

Window Tile �����������������������������������������������������������������������������������������������48

Markerboard Tile ��������������������������������������������������������������������������������������49

Rail Tile ���������������������������������������������������������������������������������������������������������50

Upper Components

Straight Front Half Height Shelf �������������������������������������������������������51

Sliding Door Overhead Cabinet ������������������������������������������������������� 52

Upmount Sliding Overhead Cabinet ���������������������������������������������54

Radius Front Half Height Shelf ��������������������������������������������������������� 55

Pneumatic Overhead Cabinet �����������������������������������������������������������56

Upmount Pneumatic Overhead Cabinet ������������������������������������� 57

Frameless Glass Installation ���������������������������������������������������������������58

Wire Manager ��������������������������������������������������������������������������������������������59

Task Lights ������������������������������������������������������������������������������������������������� 60

Worksurfaces & Legs

Worksurface: Rectangular ������������������������������������������������������������������� 61

Worksurface: Corner ������������������������������������������������������������������������������ 62

Open Metal Leg ���������������������������������������������������������������������������������������63

Square Post Leg ��������������������������������������������������������������������������������������64

Square Metal P-Leg ��������������������������������������������������������������������������������73

Square Metal Leg Triangle Frame ��������������������������������������������������� 74

Triangle Leg with Frame Support Bar ������������������������������������������65

Laminate End Panel �������������������������������������������������������������������������������68

Electrical

Wiring Diagram: Ceiling & Base �������������������������������������������������������32

8-Wire Electrical, Base Feed Installation ������������������������������������� 33

Ceiling Power Pole ����������������������������������������������������������������������������������34

8-Wire Electrical, Baseline Power Retro ��������������������������������������35

Power Connection: 2-Way, 3-Way, 4-Way �����������������������������������36

Beltline Power Retro ����������������������������������������������������������������������������� 40

In Frame Power Jumper ����������������������������������������������������������������������� 41

Beltline Power Connection �����������������������������������������������������������������42

Power Connection: Panel Through Post ��������������������������������������43

Receptacle Installation �������������������������������������������������������������������������44

Base Cover Installation ������������������������������������������������������������������������� 45

Lower Storage

Pedestals �����������������������������������������������������������������������������������������������������69

Lateral Files ������������������������������������������������������������������������������������������������70

Laterals Counterweight Installation ������������������������������������������������ 71

Interra 120° Build-out ���������������������������������������������������������������������������� 72

2

Interra System Installation Manual

Introduction

The Interra System Installation manual provides the necessary instruction

for the safe installation of the Interra System for:

• The Installers with visual and written instructions.

• The End Users to ensure continued safe use of the product when

maintaining and reconfiguring the product.

To ensure proper installation of the product, the Interra System requires

layout and wall supports as specified in this manual. Reconfiguration

of the product and additions to an installation must be performed per

the instructions in this manual to ensure the continued safe use of the

product. Friant & Associates, LLC does not assume any responsibility for

product that is altered in any way.The Interra System is composed of full

and/or partial height Walls, Support Cabinets, Wall Mounted and FreeStanding components, and accessories.

The Interra System is considered to be portable furniture; therefore,

subject to applicable local Fire, Electrical and Building Codes. Check with

local authorities prior to installation.

ELECTRICAL STATEMENT: Friant’s Interra System Electrical Distribution

System is listed with the Underwriters Laboratories, and complies with

the National Electrical Code, ANSI/BIFMA 70. Check with local authorities

prior to installing the product.

NOTE: To ensure proper installation of the product, frames

must be leveled during the installation process.

WARNING: Failure to follow the instructions

in this manual can result in product damage,

personal injury, or death.

Friant | Interra Installation Manual

3

General Tools, Staging & Safety

General Tools

Thefollowingtoolsarenecessaryforeldassemblyandinstallation

of Friant’s Interra product:

• allen wrench 1/4”

• #2 phillips head screwdriver

• #3 phillips head screwdriver

• screwdriver, med slotted

• measuring tape (25’ or more)

• rubber mallet or dead blow mallet

• carpenter’s level (48”)

In addition, the following tools will help speed up installations:

• drill (12v or more)

• set of drill bits

• set of screw bits #2 and #3

• 1/4” allen bit for drill

• wrench open end 10 mm (long handle is best)

• pliers

• carton knife

• ratchet head with 1/4” allen bit

• 6’ step ladder

• material handling carts

Safety

• Please note all warnings, as

these are for your safety�

• Always use proper tools when

installing�

• Keep your work area clean,

clutter-free and safe during

installation�

• Use eye protection when

working under a workstation or

when working with tools�

• Many products weight more

than 35 pounds, so use two or

more people to safely lift, carry

and install the products�

• When using tools, extension

cords or ladders, use them in

accordance to OHSA guidelines�

• Work safe, work smart�

Staging

Inaneorttomakeyourprojectrunmoresmoothly,thefollowingis

recommended:

1. Check in and count all products for accuracy and damage prior to

the delivery truck leaving. Note any damages or shortages on the

Bill of Lading before signing.

2. Notify the factory immediately of any shortages or damages (with

photo to document).

3. Unload all products into a staging area on your job site and sort by

product number.

4. Keep and maintain a clutter-free staging area — it will help speed up

your assembly.

5. Protect all building walls with furniture pads or cardboard where

productisleaningagainstthemorinhightracareas.

Friant | Interra Installation Manual

4

Before Installation

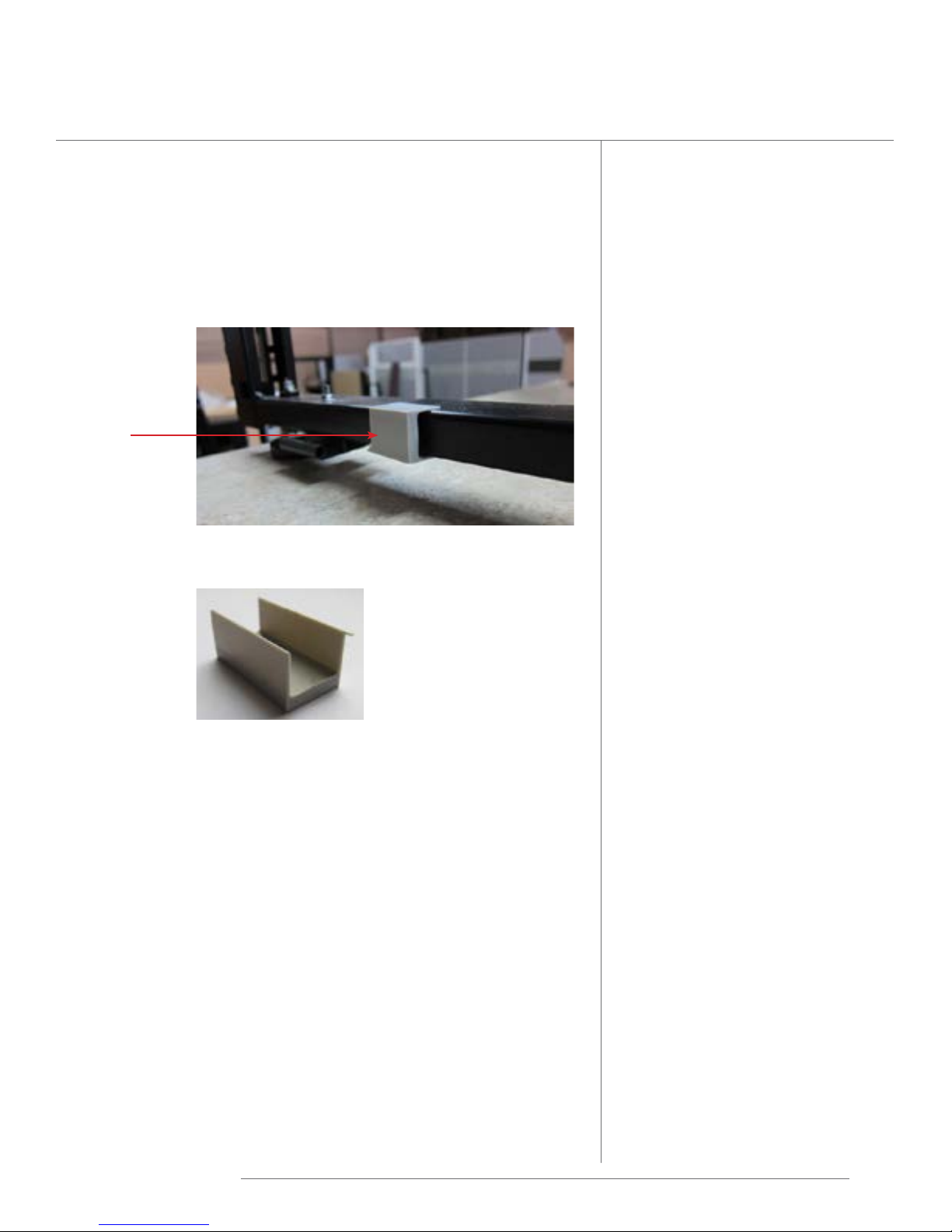

Remove shipping spacers

Some sizes of Interra frames ship with stability bar at the top

corners. All sizes ship with gray plastic spacers at the bottom.

These are on the frame for shipping purposes only and must be

removed before installation.

spacer

Spacers on the bottom of the frame can be removed by

pullingthemotheframe.Theydonothavescrews.

Friant | Interra Installation Manual

5

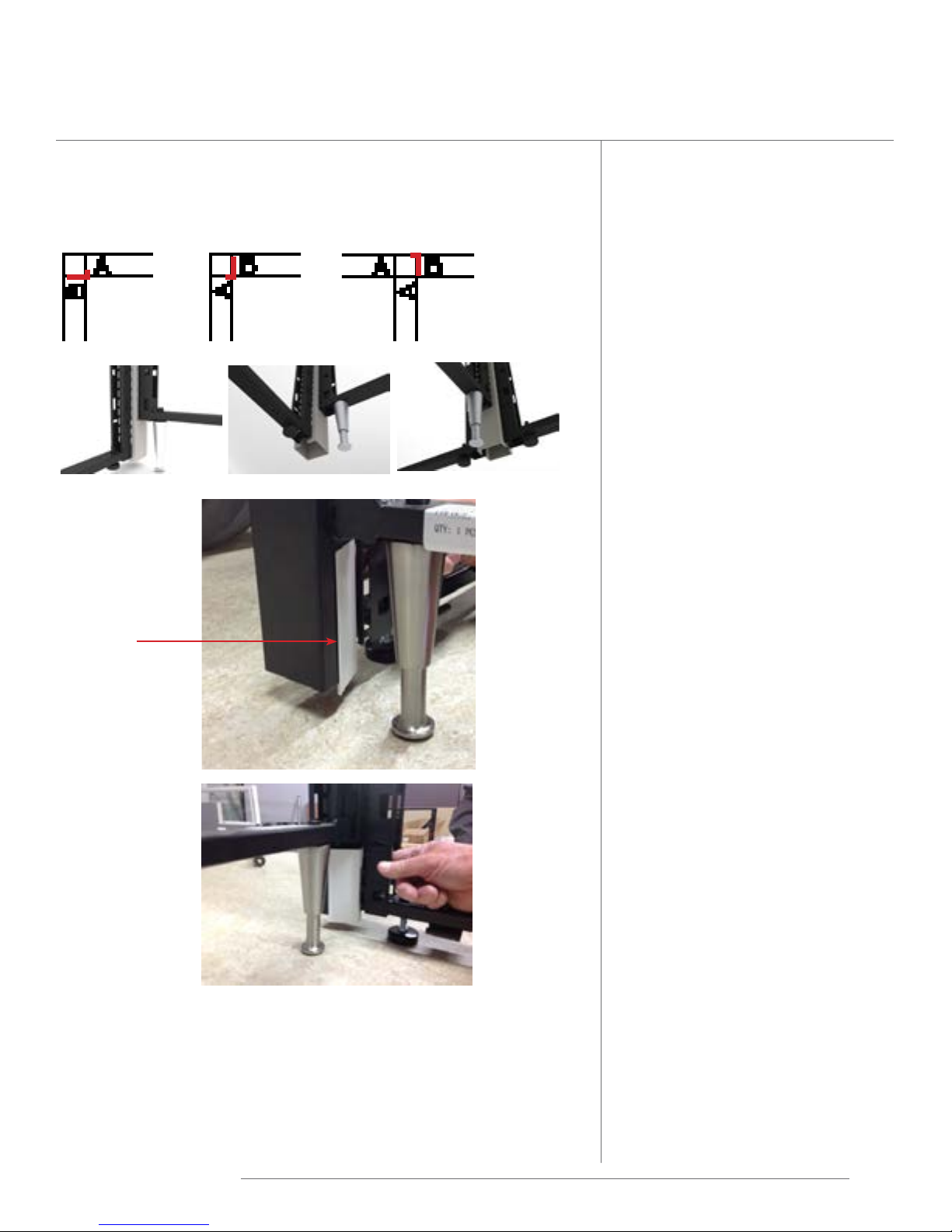

A/B Style Frames

A-Style B-Style

(tiletooorshown)

A-Style Frame

tiletooorstyleorbasecoverstylewithadjustableglides

• Ships assembled with adjustable glides at bottom.

• Be sure that the glides are all the way in the bottom of the frame.

Iftheoorisuneven,glideadjustmentshouldbemadeduring

assembly of the product.

B-Style Frame

open base style with adjustable legs

• Ships unassembled.

• Prior to beginning the installation, attach legs to frame by inserting

the leg and tightening the bolt.

• Leg is adjustable. Be sure the legs are all the way in at their lowest

point.Iftheoorisuneven,glideadjustmentshouldbemadeduring

assembly of the product.

Friant | Interra Installation Manual

6

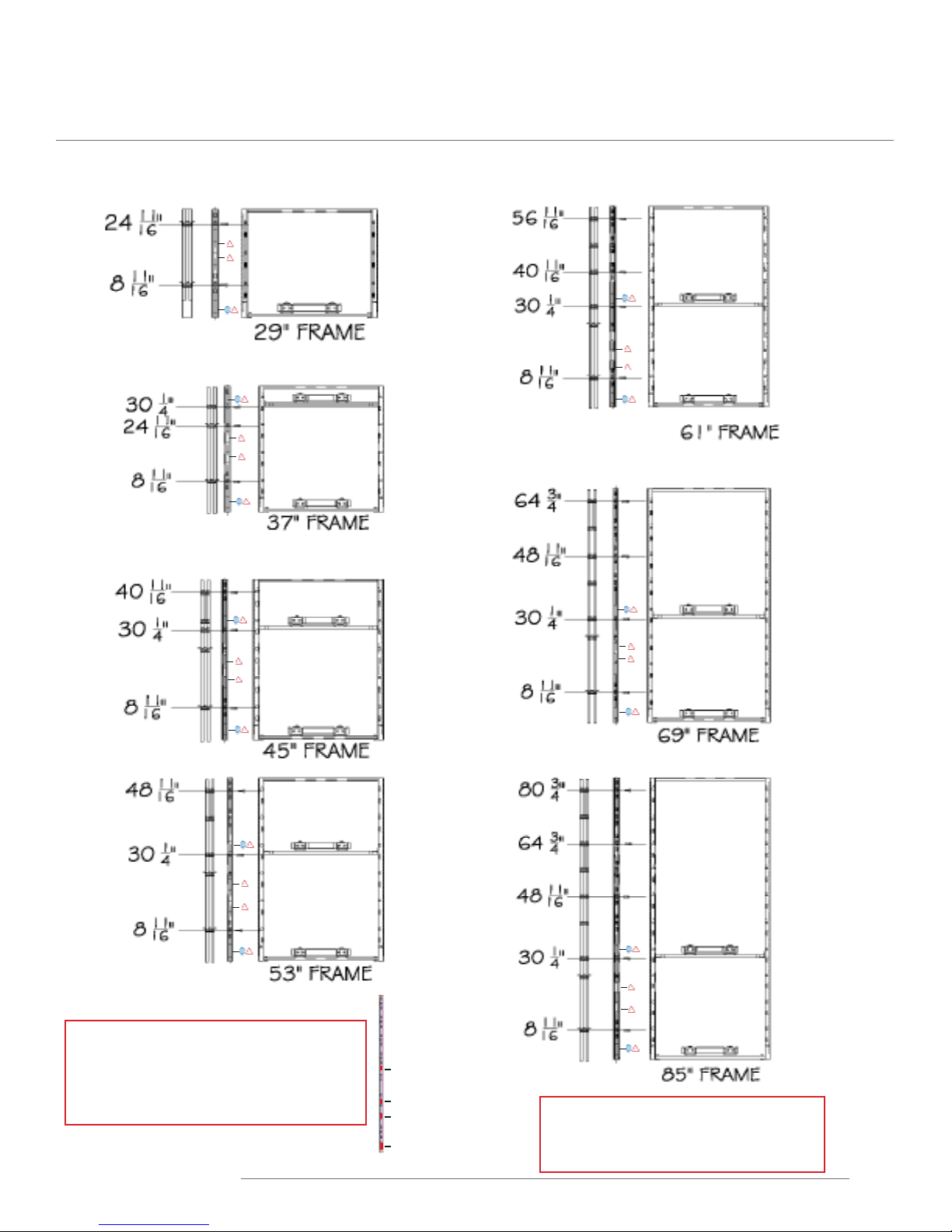

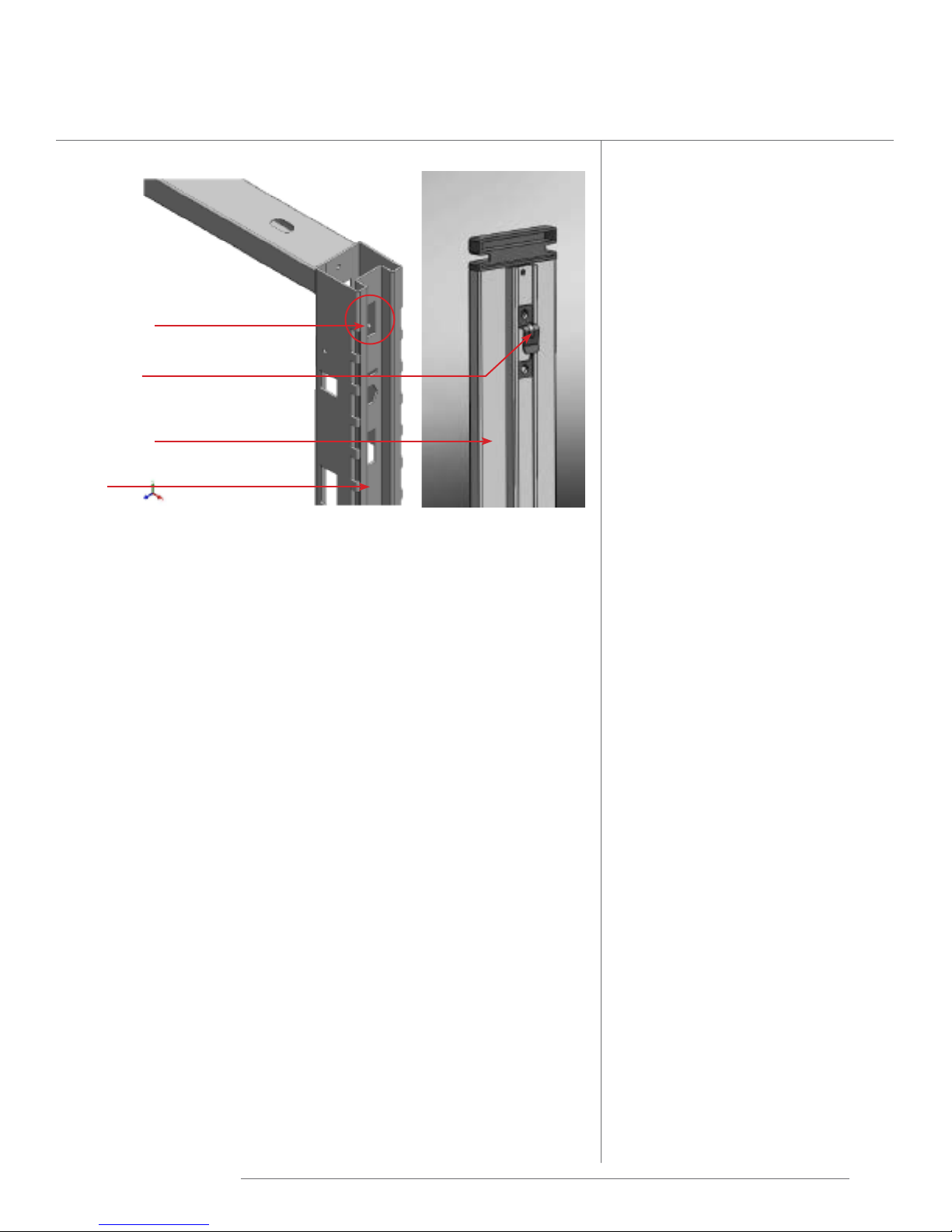

Frame Connection Point Locations

For Frame to Frame or Frame to Connector. Shown below with beltline power.

Power & data distribution cut outs are

approximately 2.75” tall and are located

approximately 2.5”, 16”, 22”, & 33” from the

bottom of the frame.

in product damage, personal injury, or death.

Friant | Interra Installation Manual

33”

22”

16”

2.5”

WARNING: Failure to follow the

instructions in this manual can result

7

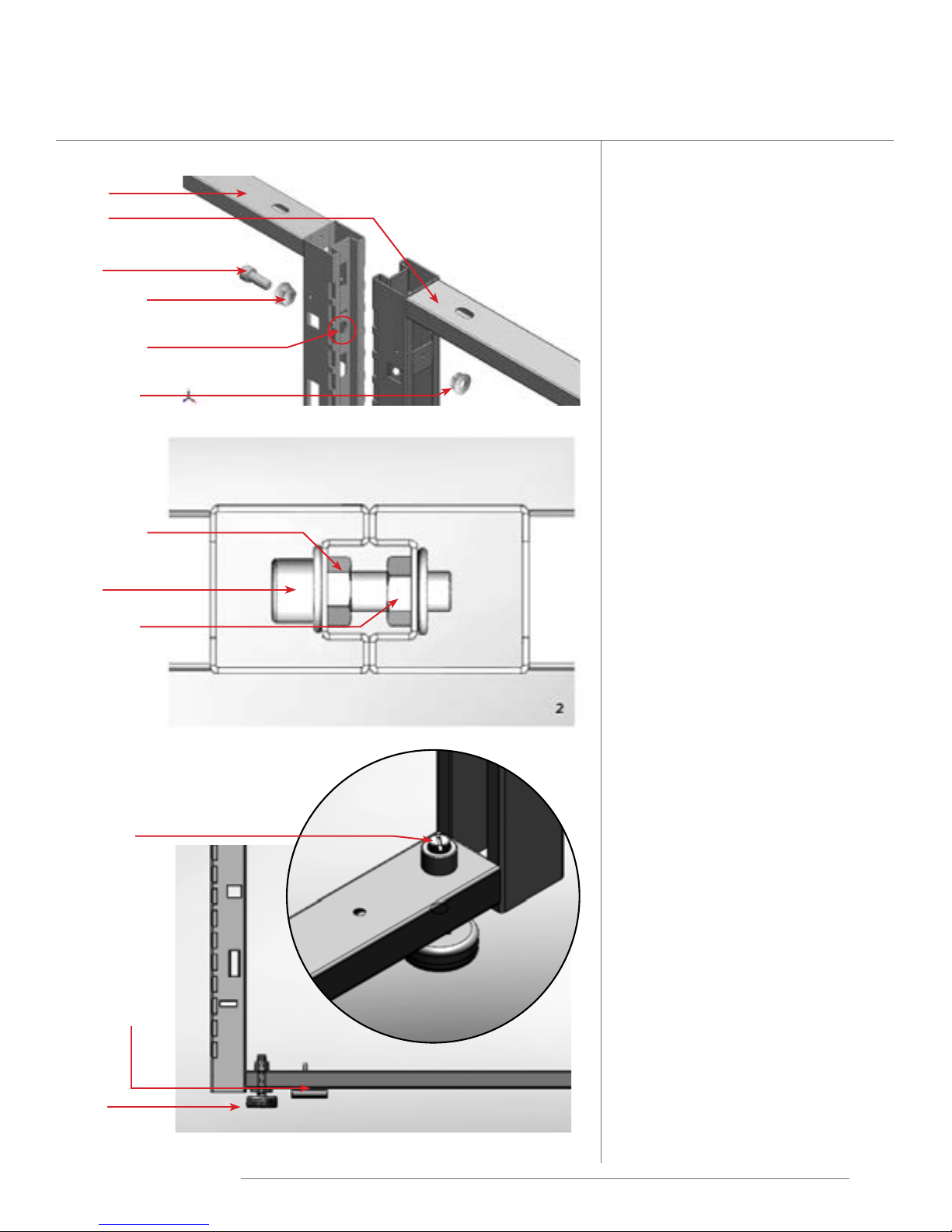

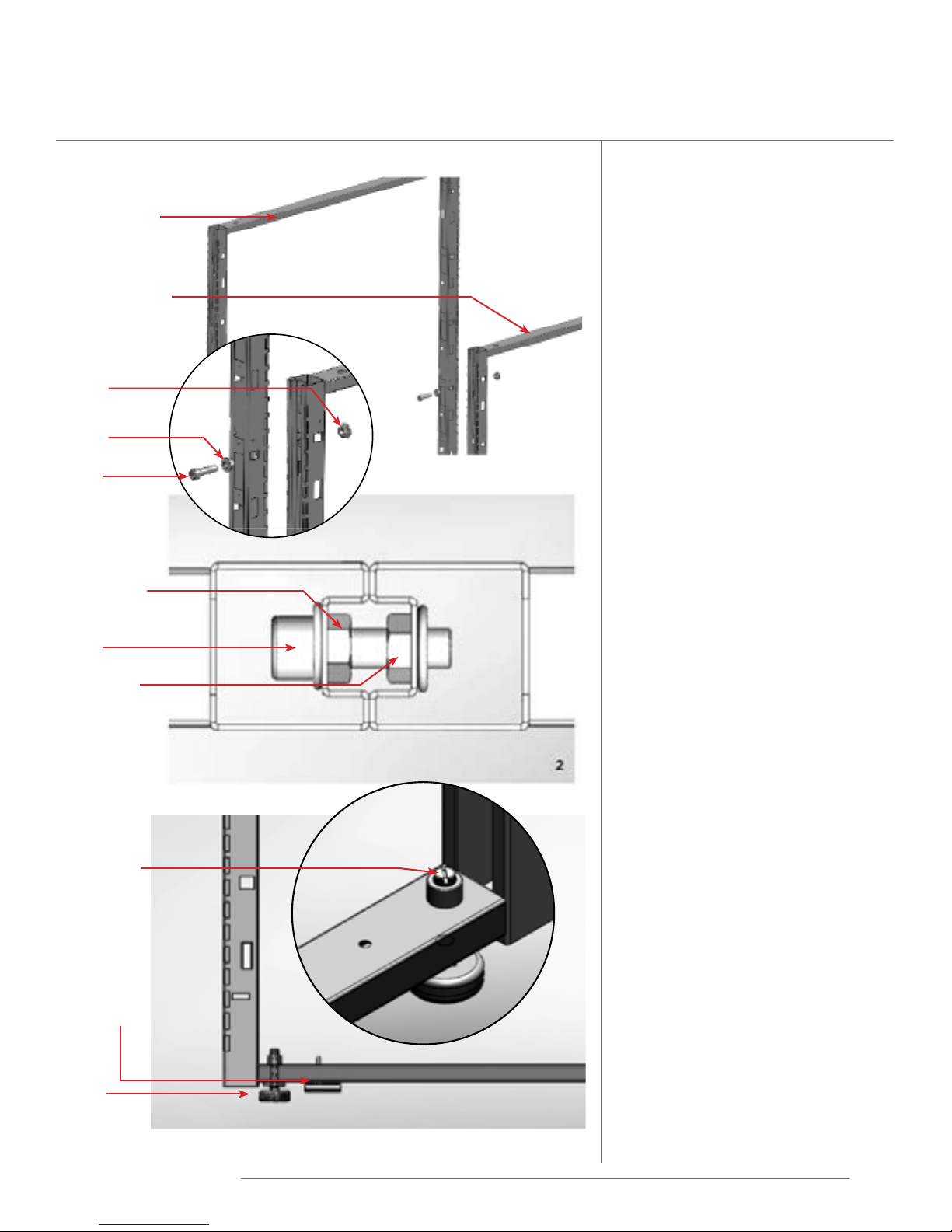

Frame to Frame Assembly

Frame

Frame

Bolt

Alignment

Nut

Hexagonal

Cutout

Threaded

Nut

Alignment

Nut

Bolt

Threaded

Nut

Use Frame to Frame packages to

connect frames of equal or dierent

heights in a straight line� Frame to

Frame package consists of: a bolt,

alignment nut, and threaded nut�

Use the quantity of Frame to Frame

connection packages needed per the

chart below, and see Frame Connection

Point Location page�

Frame Connection points per height:

Height Connections

29” 2

37” 3

45” 3

53” 3

61” 4

69” 4

85” 5

Frame to Frame of the same

height

1� Frames are connected to each other

by means of connecting bolts� A

connecting bolt consists of: a bolt, a

alignment nut and a threaded nut�

Glide

Adjustment

Base cover

holder

Glide

Correct Assembly

2� Bring frames to be connected to-

gether� Insert alignment nut in the

hexagonal cutout in frame number 1�

3� Insert threaded nut in the hexagonal

cutout in frame number 2�

4� Insert bolt through the alignment

nut and secure to threaded nut�

5� Prior to tightening the bolt, insert

the correct number of connecting

bolts, as per the table above and at

the location indicated in the Connection Point Location reference

page�

6� After all connecting bolts are in-

serted, tighten all bolts until all stiles

come securely together�

7� Do not over tighten�

NOTE: To ensure proper installation

of the product, frames must be

leveled during the installation

process.

Friant | Interra Installation Manual

8

Frame to Frame of Dierent Heights

Taller Frame

Shorter Frame

Use Frame to Frame packages to

connect frames of equal or dierent

heights in a straight line� Frame to

Frame package consists of: a bolt,

alignment nut, and threaded nut�

Use the quantity of Frame to Frame

connection packages needed per the

chart below, and see Frame Connection

Point Location page�

Threaded

Nut

Alignment

Nut

Bolt

Alignment

Nut

Bolt

Threaded

Nut

Correct Assembly

Frame Connection points per height:

Height Connections

29” 2

37” 3

45” 3

53” 3

61” 4

69” 4

Frame to Frame of dierent

height

1� Frames are connected to each other

by means of connecting bolts� A

connecting bolt consists of: a bolt, a

alignment nut and a threaded nut�

2� Bring the shorter frame together

with the taller frame and insert

alignment nut in the hexagonal

cutout at the top of the shorter

frame�

3� Insert threaded nut in the hexagonal

cutout in the taller frame�

Glide

Adjustment

Base cover

holder

Glide

Friant | Interra Installation Manual

4� Insert bolt through the alignment

nut and secure to threaded nut in

the taller frame�

5� Prior to tightening the bolt, insert

the correct number of connecting

bolts for the shorter frame, as per

the table above and at the location

indicated in the Connection Point

Location reference page�

6� After all connecting bolts are

inserted, tighten all bolts until all

stiles come securely together�

7� Do not over tighten�

NOTE: To ensure proper installation

of the product, frames must be

leveled during the installation

process.

9

Stacking Frame Installation

Stacking

Frame

Base

Frame

Securing

Plate

Bolt

WARNING: Never install worksurfaces

on Stacking Frames. Never install

more than one Stacking Frame

on top of a base frame. Overhead

shelves and storage can only be

hung on a Stacking Frame when it

is connected to connectors or other

frames.

1� Remove top tile from base panel at

desired location by pulling towards

you to disengage top clips from

the frame� Pull tile up to disengage

bottom hooks from frame� Repeat

for other side of frame�

2� Remove top cap by removing wing

nuts and lifting top cap� Set aside

for reuse on top of Stacking Frame�

3� Position Stacking Frame above

existing frame, aligning the holes

in brackets with the holes in the

frame� Install two (2) bolts through

the securing plates on the Stacking

Frame� Do not tighten�

Bolt secured

into top of

base frame

4� When installing (2) Stacking Frames

side by side, see Stacking Frame to

Stacking Frame installation on page

11�

5� Tighten bolts into top of base frame�

6� Install top cap on Stacking Frame�

7� Reinstall all tiles�

NOTE: If installing Window Tile

on a Stacking Frame, must specify

Window Tile Stacking.

Friant | Interra Installation Manual

10

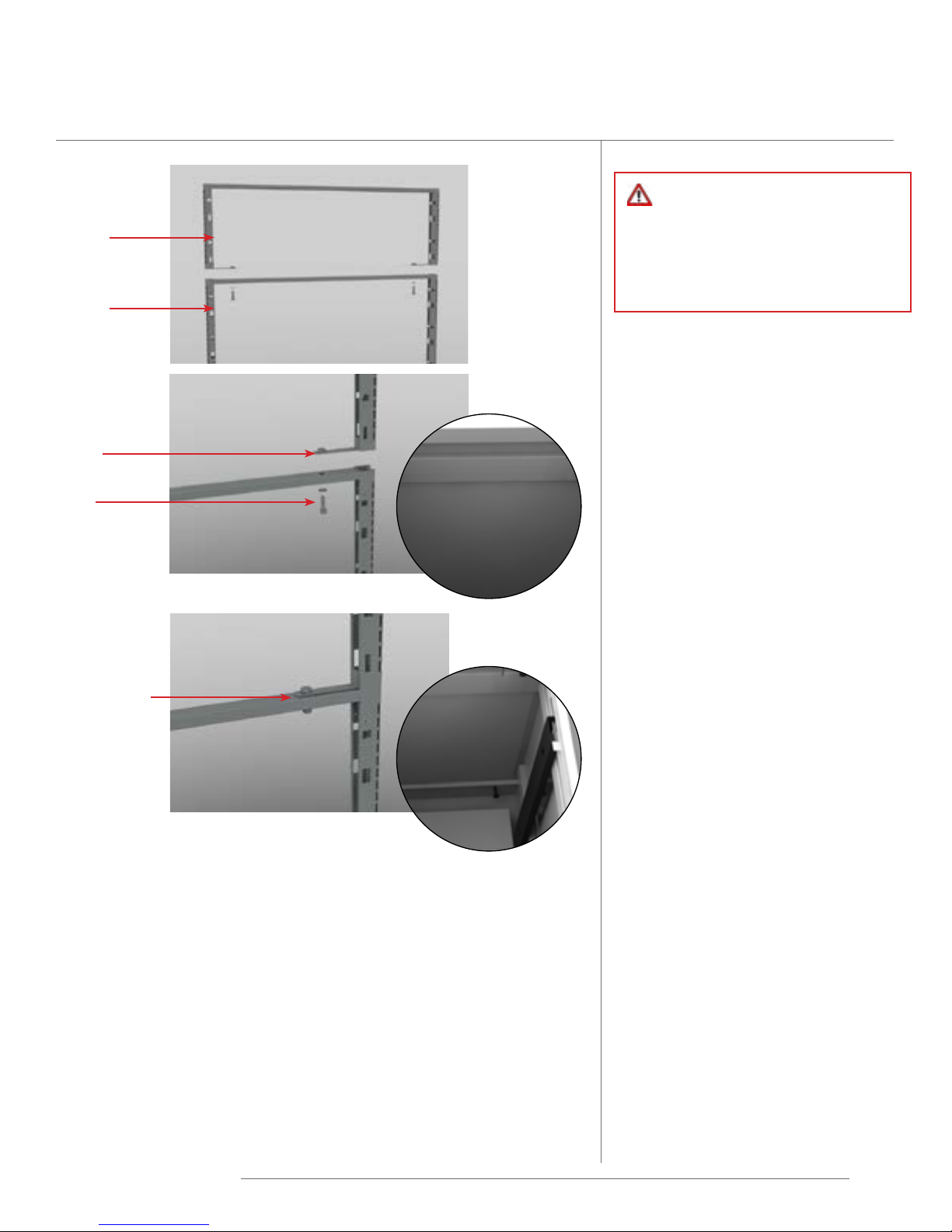

Stacking Frame to Stacking Frame Installation

Frame to Frame of the same

height

1� After securing Stacking Frame

to the base frame (page 8), level

them for attaching together�

2� Stacking Frames are connected

to each other by means of

connecting bolts� A connecting

bolt consists of: a bolt, a

alignment nut and a threaded

nut�

3� Insert alignment nut in the hex-

agonal cutout in frame number 1�

4� Insert threaded nut in the hexag-

onal cutout in frame number 2�

5� Insert bolt through the align-

ment nut and secure to threaded

nut�

6� Prior to tightening the bolt, in-

sert two (2)connecting bolts�

7� After all connecting bolts are

inserted, tighten all bolts until all

stiles come securely together�

8� Do not over tighten�

Friant | Interra Installation Manual

11

Door Frame Installation

Connecting

Bolts

NOTE: Door swing cannot be

changed. If opposite swing

configuration is needed, a new

door is required.

1� Door Frame is factory

assembled for either left of

right hand swing�

2� Place Door Frame at the

proper location with door

swing on the desired side of

frame�

3� Connect Door Frame

to adjacent frame with

connecting bolts� Each door

frame has a total of eight (8)

bolts, four (4) on each side�

Connecting

Bolt

Connecting

Bolt

Connecting

Bolt

4� Adjust adjacent frame glides

so door opening is square

with the door� Door frame

must be parallel to the flat

face of the door�

Friant | Interra Installation Manual

12

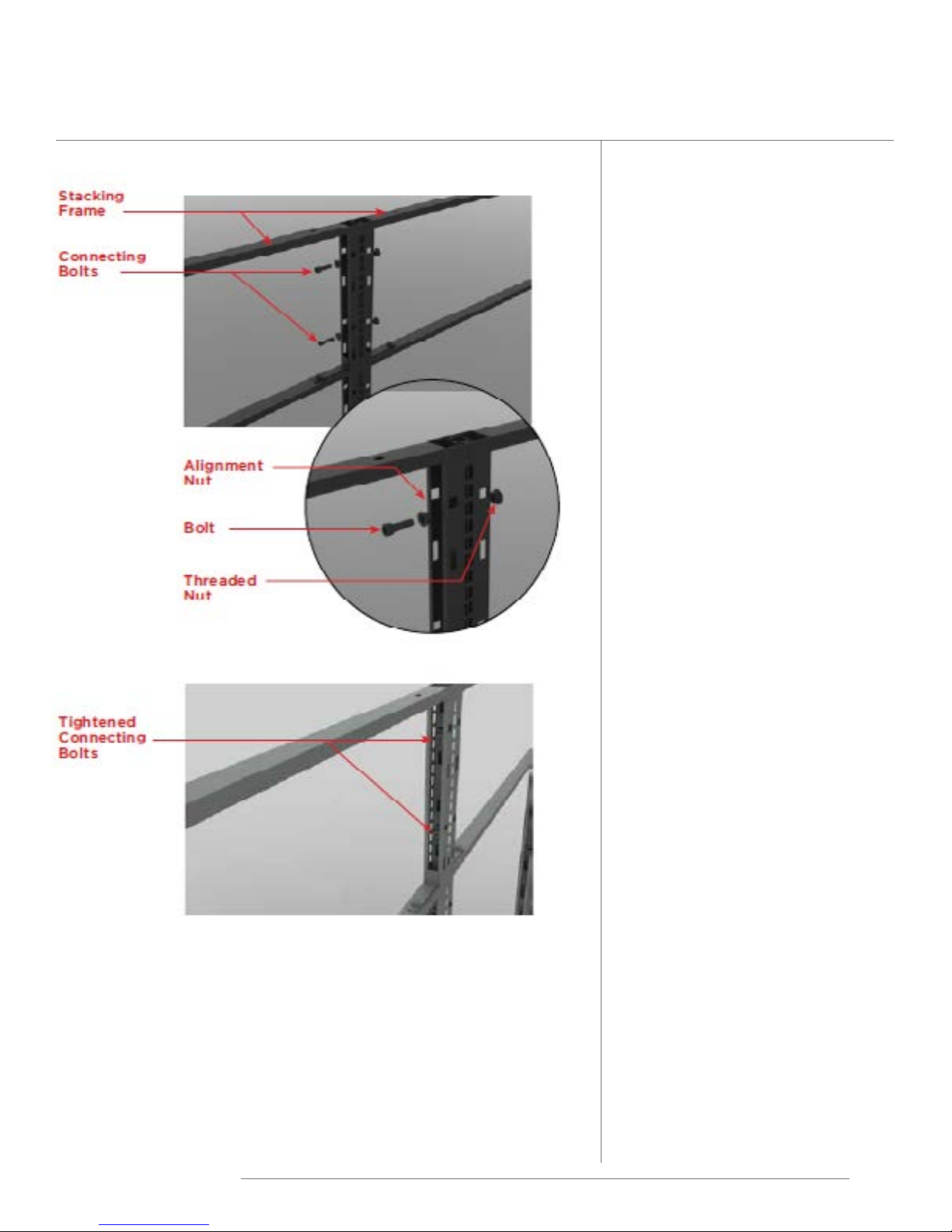

Frame to Connector Assembly

Insertion

Point

Alignment

Tab

Connector

Post

Frame

Frame to Connector

Assembly

Alignment tabs and threaded

inserts are already secured to the

connecting posts�

1� Position frame so that the

alignment tabs at the bottom

of the connector post align with

the corresponding insertion

point on the Frame�

2� Frames are secured to

connector posts by means of

connecting bolts� For frame

to connector assembly, the

connecting bolt consists of a

bolt and a washer as shown in

image to the left� Insert the first

bolt and washer� Tighten bolt

lightly�

Threaded

Insert

Washer

Connecting

Bolt

Glide

Adjustment

Glide

Friant | Interra Installation Manual

3� Continue by inserting the

correct number of connecting

bolts as per the table below,

at the location indicated in the

Connection Point Location

reference page�

4� Prior to tightening all bolts,

ensure that the frame and

connector post are squarely

aligned�

5� Tighten all bolts until stiles and

connector post come securely

together�

See next page for diagram of 2-Way,

3-Way, 4-Way connector post

installation�

Frame Connection points per

height:

Height Connections

29” 2

37” 3

45” 3

53” 3

61” 4

69” 4

85” 5

13

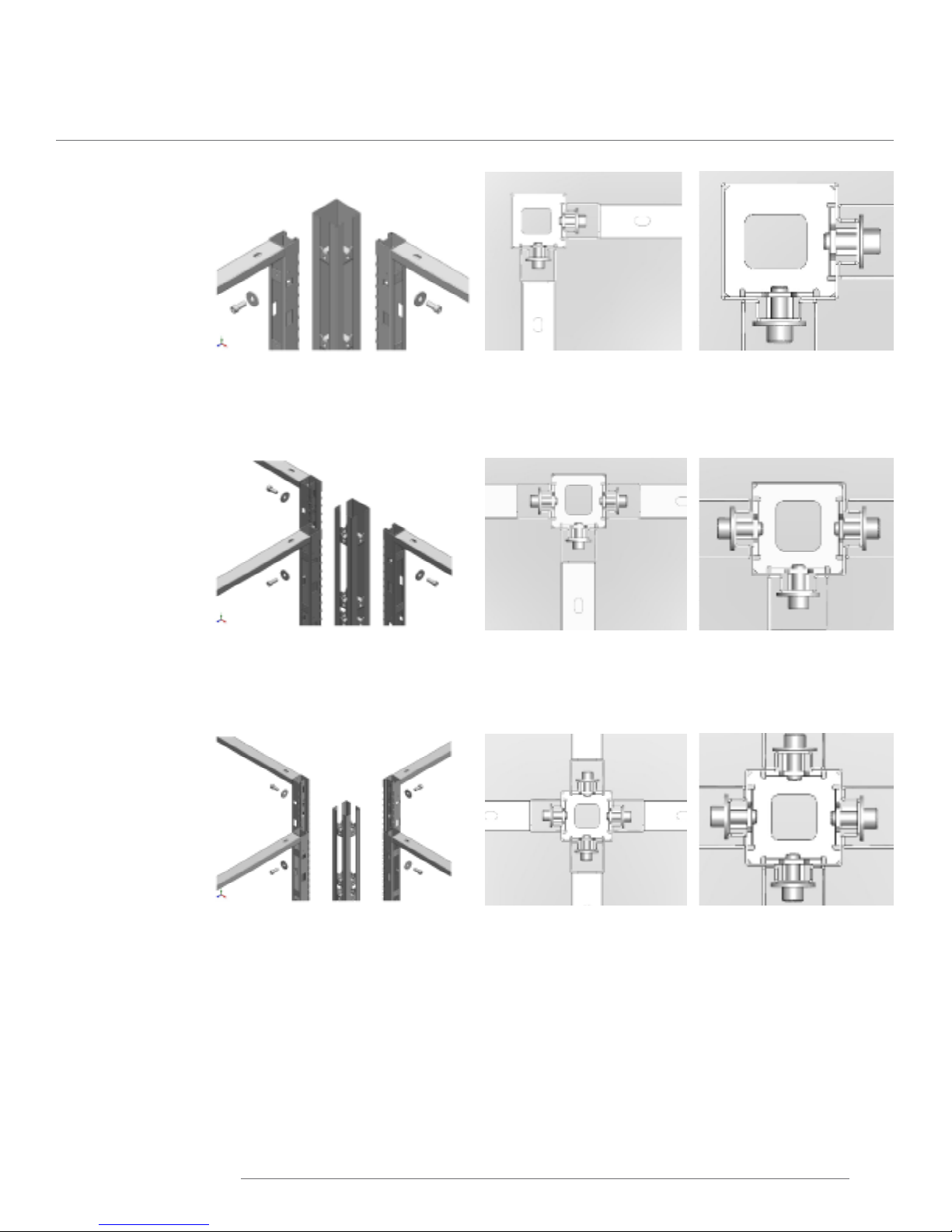

Frame to Connector Assembly: 2-Way, 3-Way, 4-Way

2-Way

3-Way

4-Way

Friant | Interra Installation Manual

14

Stacking Frame to Connector Installation

Stacking Frame to

Connector

1� Stacking Frames are secured to

connector posts by means of

connecting bolts� For Stacking

Frame to connector assembly,

the connecting bolt consists of

a bolt and a washer as shown in

image to the left� Insert the first

bolt and washer� Tighten bolt

lightly�

2� Continue by inserting the

second as shown�

3� Prior to tightening all bolts,

ensure that the frame and

connector post are squarely

aligned�

4� Tighten all bolts until stiles and

connector post come securely

together�

5� Do not over tighten�

Friant | Interra Installation Manual

15

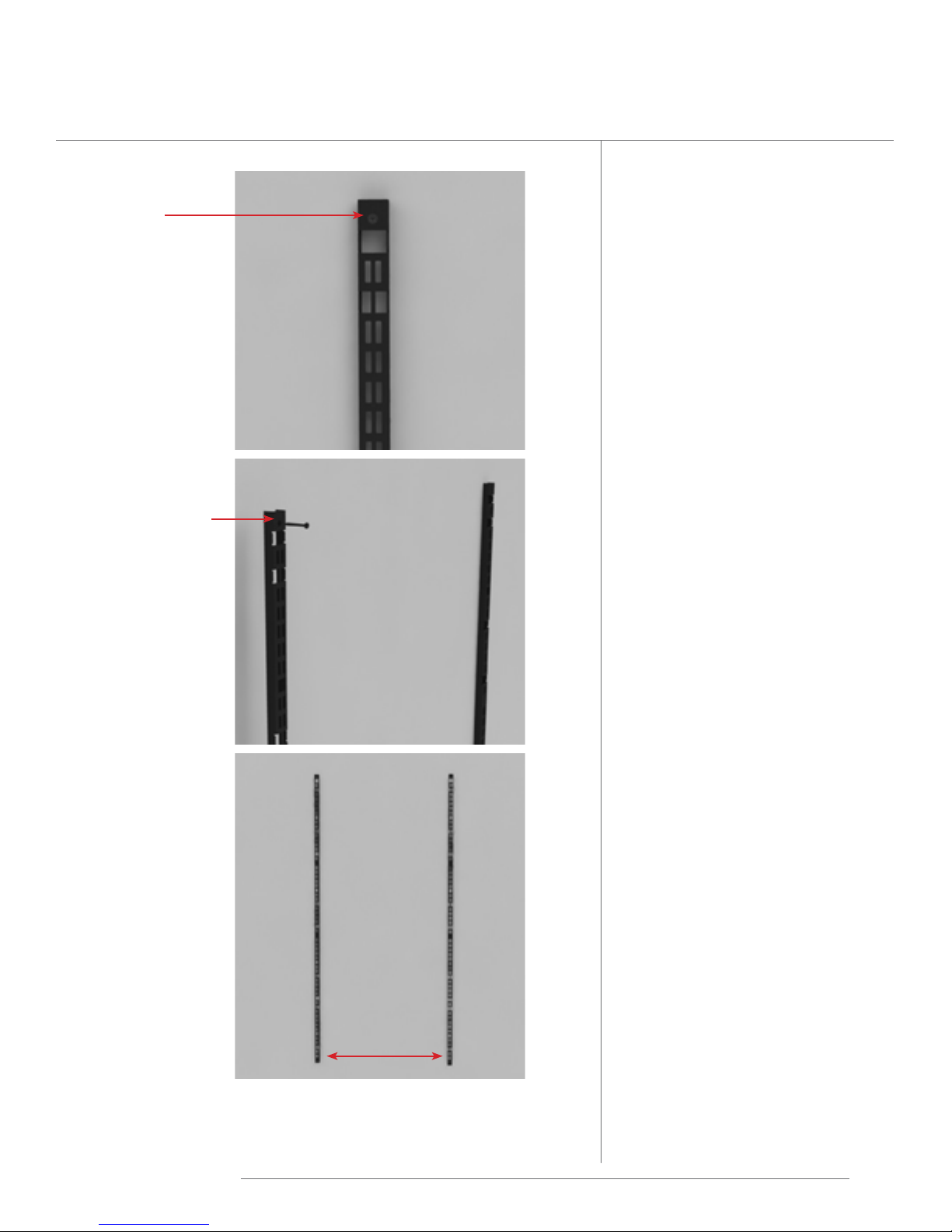

Wall Strip

Wall Strip

secured at

the top hole

NOTE: Wall strips must be installed to

structural walls. Be sure to install wall

strips at studs, if possible.

1� Install the first wall strip,

securing with a screw through

the hole at the top�

2� Ensure that the wall strip is level�

Mark the attachment points on

the wall through the wall strip�

3� Complete attachment to the

wall, by drilling holes at the

attachment points, and securing

with screws�

Second Wall Strip

secured at top

4� Aligning with a level, mark the

location for the second wall

strip� The spacing between wall

strips should be either: 47”, 41”,

35”, 29” or 23”�

5� Repeat steps 2 and 3 to secure

the second wall strip�

distance between

Friant | Interra Installation Manual

Wall Strips

16

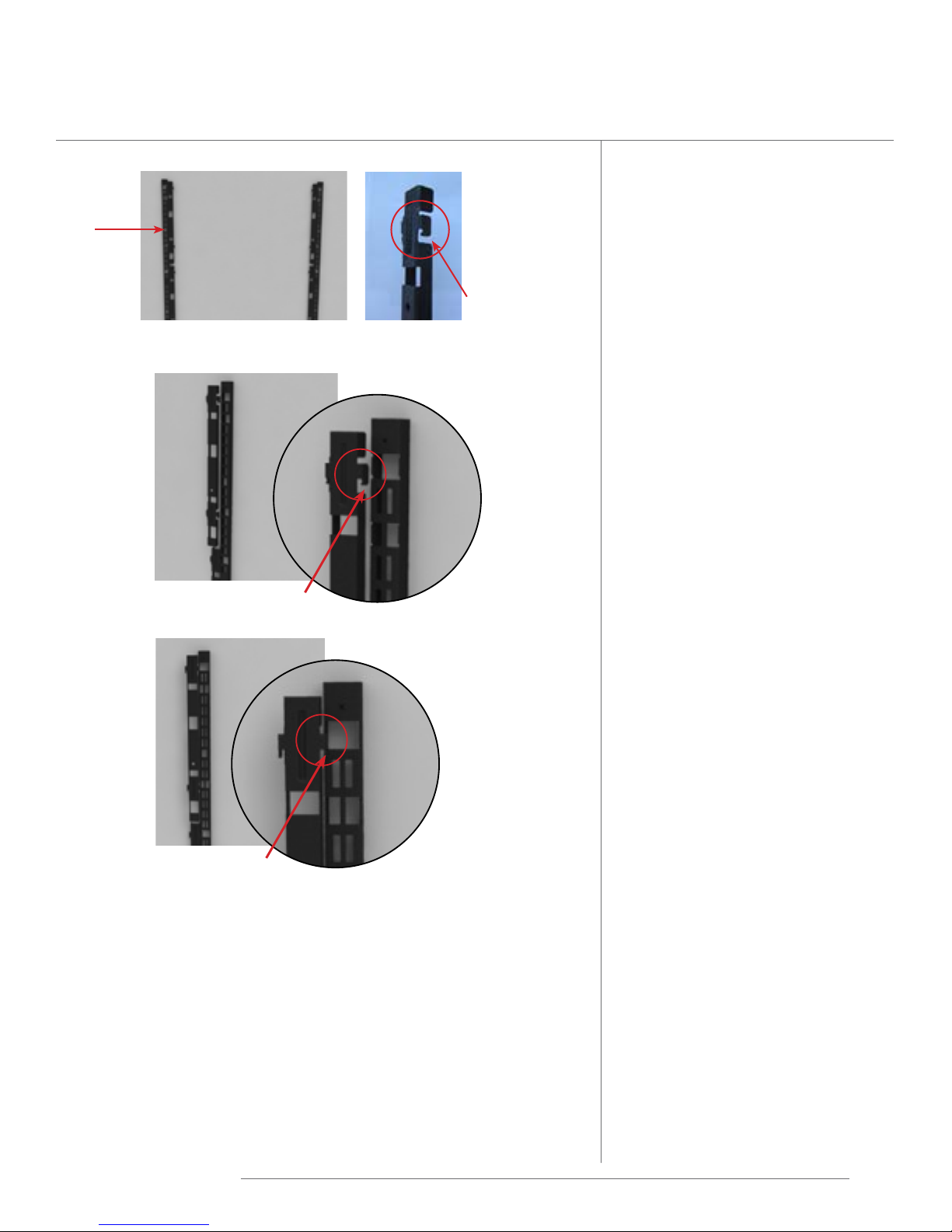

Tile Adapters

Wall

Strips

installed

Inserting Tile Adapter

Tile Adapter hook

Tile Adapter

hook

NOTE: Only available for use with

these tiles: fabric, rail, and perforated

metal.

1� Wall strips should already be

installed�

2� Insert hook of Tile Adapter into

the Wall Strip� Hook should be

oriented as shown in image to

the left�

3� Push Tile adapter to be sure it is

seated securely�

4� For Tile Installation, see pages

45-49�

NOTE: 8” Tile Adapters for use

only at the bottom of a 40” or 56”

wall strip. Not for use in any other

position nor in 64/80” high wall

strips.

Tile Adapter hook

engaged

NOTE: Tile Adapter dimension does

not need to match the tiles installed

(i.e. a 24” tile should be installed on a

32” tile adapter.)

NOTE: When using a 32”H Tile

Adapter, do not use an 8”H tile in the

bottom position.

Friant | Interra Installation Manual

17

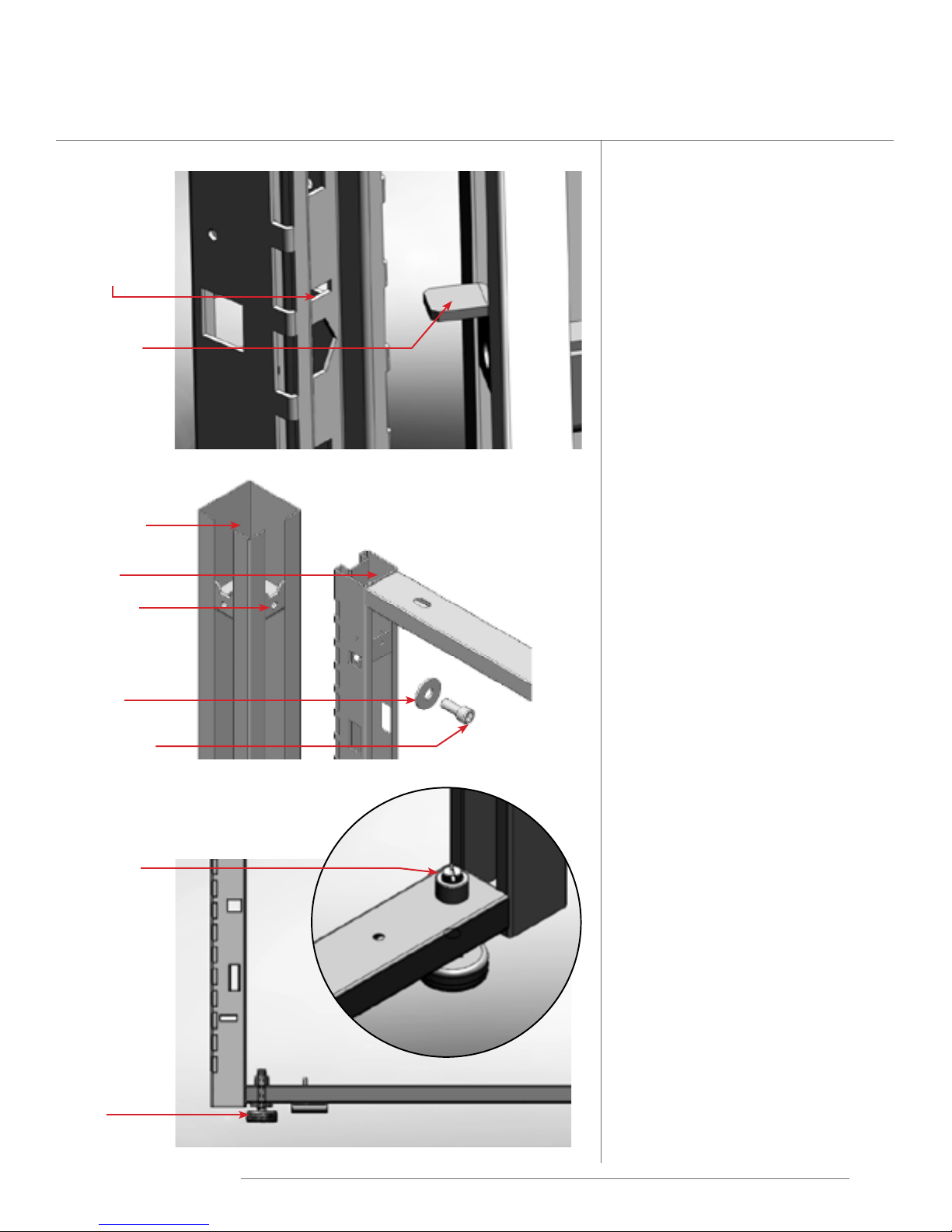

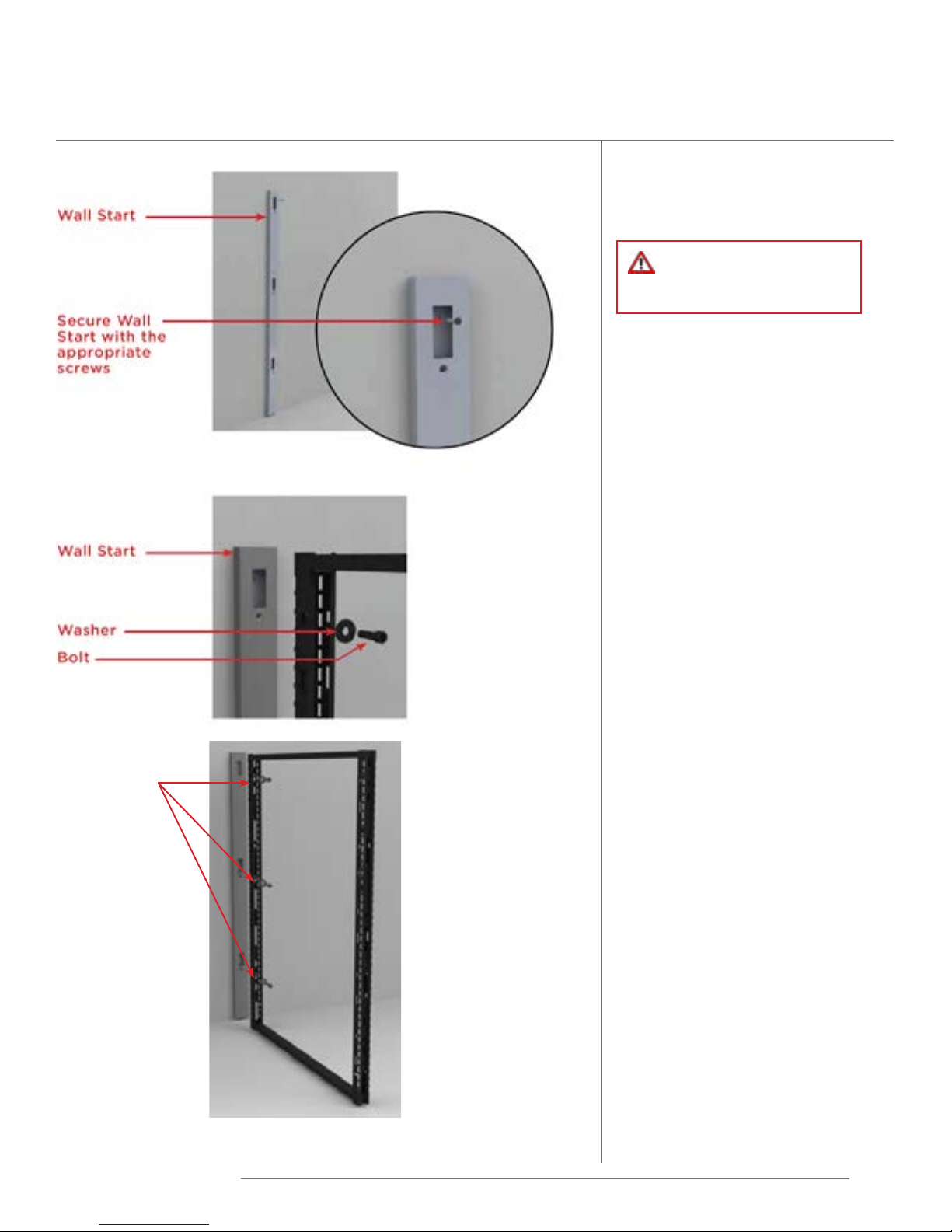

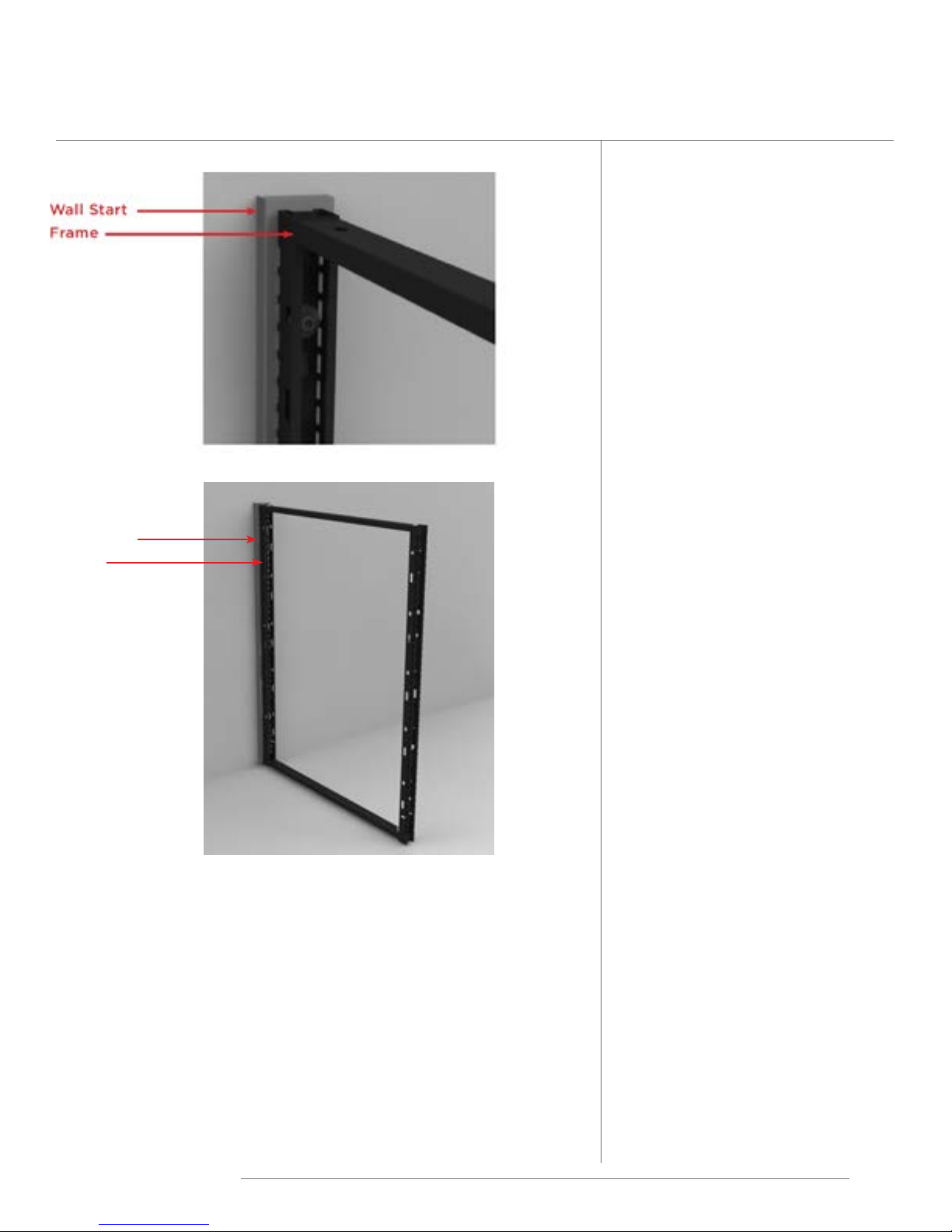

Wall Start

NOTE: Wall Start applications

require some additional tools. Most

important are a good tape measure,

level, drill and appropriate screws for

the type of wall attaching to.

WARNING: The wall

should be reinforced to

prevent damage or injury.

1� Locate on your plan the wall

start� Measure the wall, and

very lightly with a pencil, mark

the location of the wall start�

2� Take a panel and level it to

the wall to determine the

mounting height of the wall

start� Lightly mark the wall at

the top of the panel�

3� Locate the top 2 holes of the

wall start and mark on the

wall for positioning�

Connection

Points

Correct number of bolts

inserted at locations for

this example of a 53”H

frame is 3.

4� Level the wall start and repeat

this step on the middle and

bottom�

5� Secure the wall start to the

wall using the appropriate

screws for the type of wall it

will be attached to�

6� Frames are secured to wall

start by means of connecting

bolts� For frame to wall start

assembly the connecting

bolt consists of a bolt and a

washer as shown in image to

the left�

7� Insert the first bolt and

washer� Tighten bolt lightly�

8� Continue by inserting the

correct number of connecting

bolts at the location indicated

as per the table below, at

the location indicated in the

Connection Point Location

reference page�

Friant | Interra Installation Manual

Frame Connection points per

height:

18

Wall Start

Wall Start

Frame

Height Connections

29” 2

37” 3

45” 3

53” 3

61” 4

69” 4

85” 5

9� Prior to tightening all bolts,

ensure that the frame and wall

start are squarely aligned�

10� Tighten all bolts until stiles

and wall start come securely

together�

11� Do not over tighten�

Friant | Interra Installation Manual

19

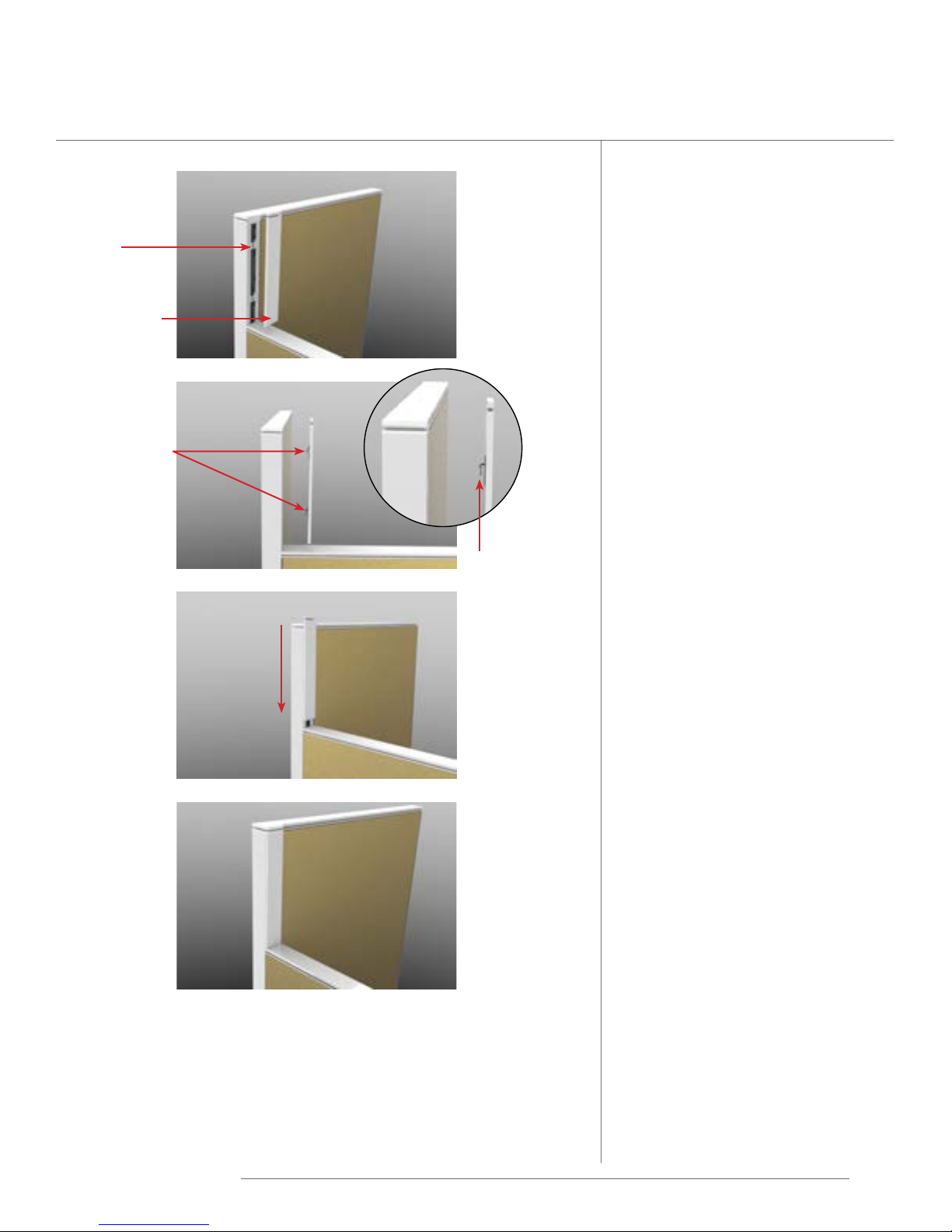

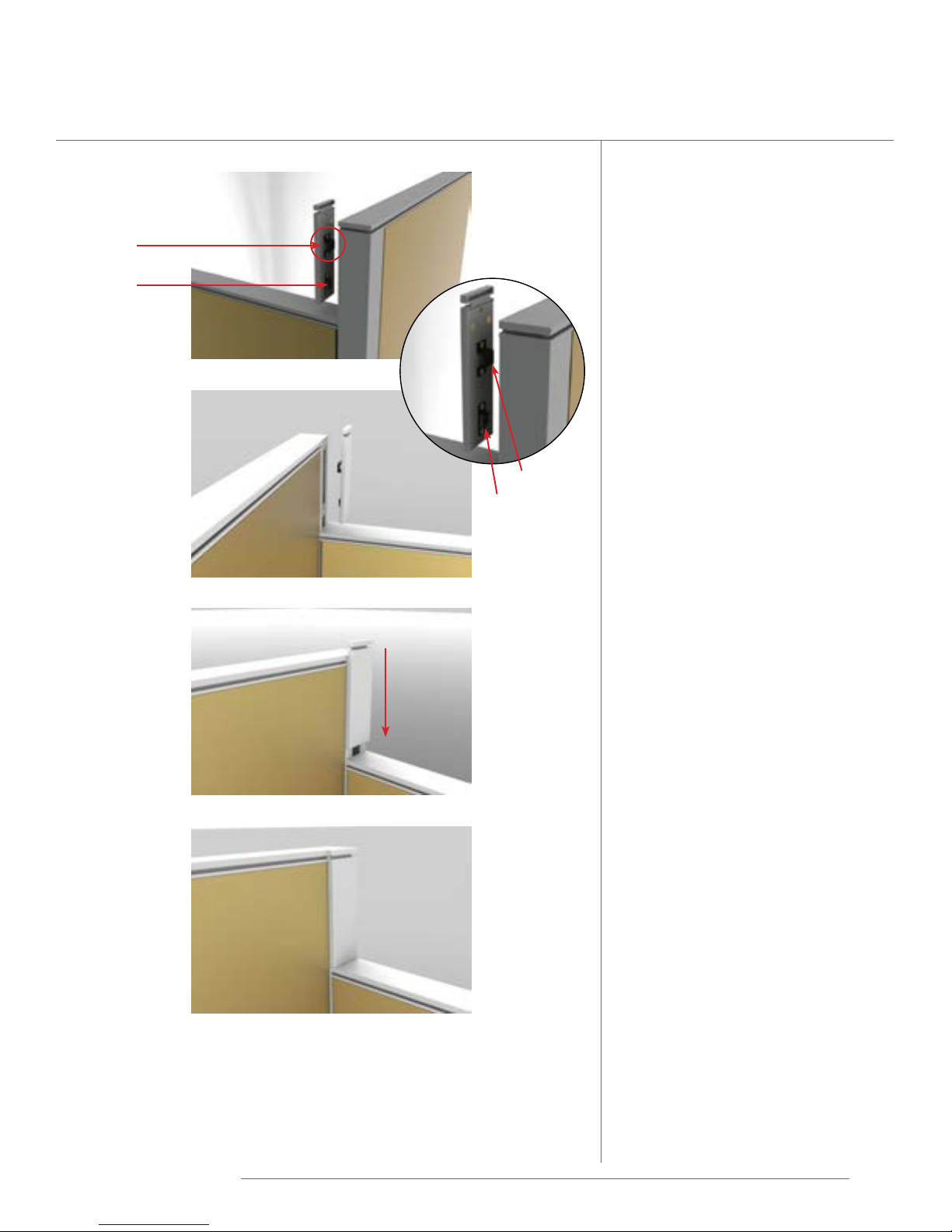

Frame Finished End Installation

Rectangular

Slot

Extended

Tab

Finished

End

Frame Finished End

NOTE: Frame Finished End must

be installed prior to installing the

frame Top Caps.

1� Position the Finished End

onto the frame channel so

the extended tabs at the top

and bottom pass through

the rectangular slots on the

side of the frame�

2� Hold the Finished End tight

against the frame and slide

the Finished End down�

Frame

3� To remove Finished End

from the frame, pull the

Finished End up until it

disengages from the frame�

NOTE: After installation of the

Frame Top Cap, should you need to

remove the Finished End, you will

first need to loosen and lift the Top

Cap in order to pull the Finished

End off.

NOTE: If Finished End is loose,

remove Finished End, tighten the

extended tab by pressing down on

it and reinstall.

Friant | Interra Installation Manual

20

Finished End Change of Height Installation

Finished End Change of

Height for Connectors

Welded

Connection

Plate

Finished End

Change of

Height

Extended Tabs

slide down

to engage

Extended Tab

1� Position the Finished End

Change of Height onto the

connector so the extended

tabs at the top and bottom

pass through the opening

and align with the welded

connection plate�

2� Hold the Finished End

Change of Height tight

against the connector and

slide the Finished End

Change of Height down�

3� To remove Finished End

Change of Height from the

connector, pull the Finished

End Change of Height up

until it disengages from the

connector�

NOTE: If Finished End Change

of Height is loose, remove the

Finished End Change of Height,

tighten the extended tabs by

pressing down on it, and reinstall.

Friant | Interra Installation Manual

21

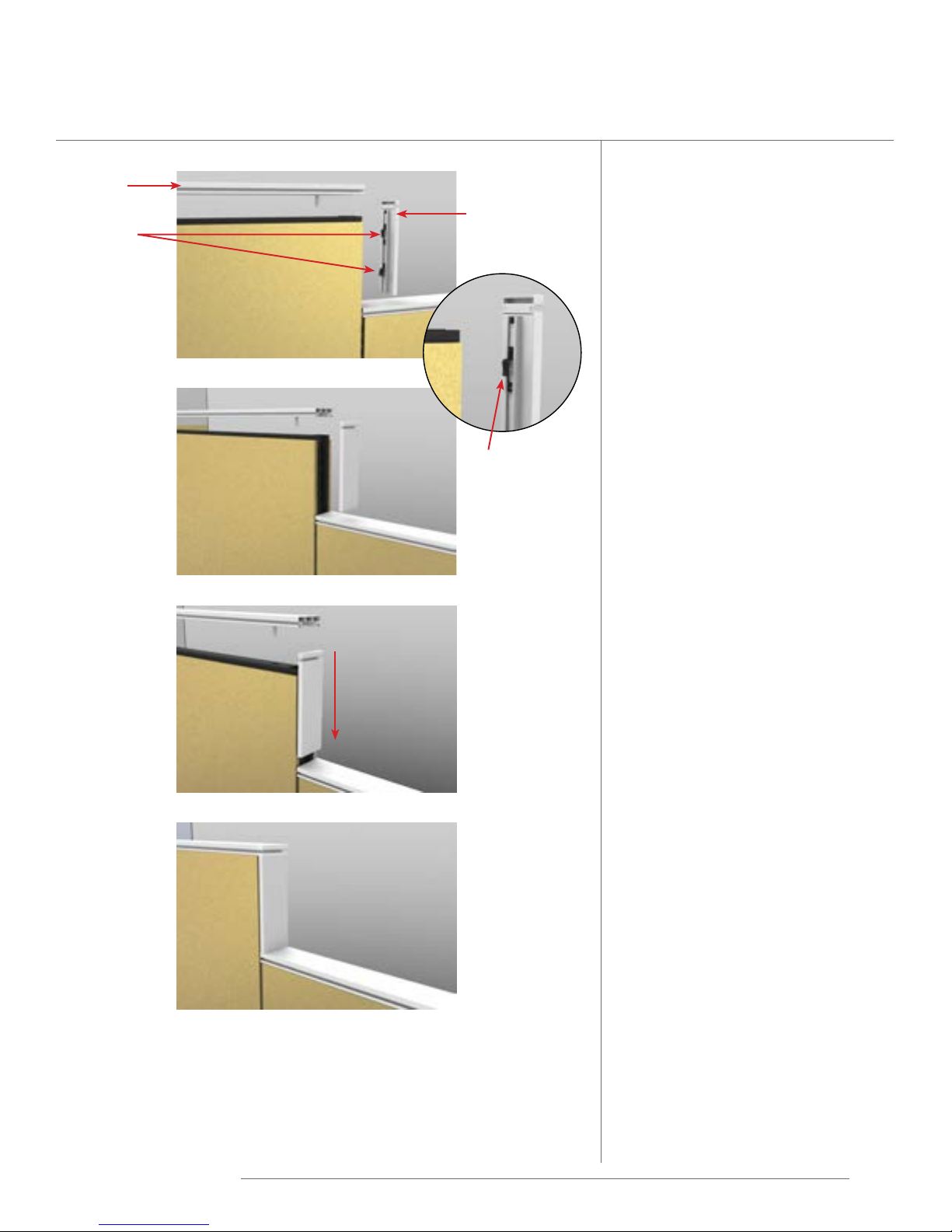

Finished End Change of Height Installation

Top Cap

Extended

Tabs

Finished End

Change of

Height

Extended Tab

Finished End Change of

Height for Frame to Frame

NOTE: Finished End Change of

Height for Frame to Frame must

be installed prior to installing the

frame Top Caps.

1� Position the Finished End

Change of Height onto

the frame channel so the

extended tabs at the top

and bottom pass through

the rectangular slots on the

side of the frame�

2� Hold the Finished End

Change of Height tight

against the frame and slide

the Finished End Change of

Height down�

3� To remove Finished End

Change of Height from the

frame, pull the Finished End

Change of Height up until it

disengages from the frame�

slide down

to engage

NOTE: After installation of the

Frame Top Cap, should you need to

remove the Finished End, you will

first need to loosen and lift the Top

Cap in order to pull the Finished

End off.

NOTE: If Finished End Change

of Height is loose, remove the

Finished End Change of Height,

tighten the extended tabs by

pressing down on it, and reinstall.

Friant | Interra Installation Manual

22

Finished End Change of Height Installation

Finished End Change of

Height 8”, for Connectors

29”H to 37”H

Magnet

Extended

Tab

Magnet

Extended Tab

1� Position the Finished

2� Hold the Finished End

End Change of Height

onto the connector so

the extended tab at the

bottom passes through the

opening and align with the

welded connection plate,

and magnet holds to the

connector�

Change of Height tight

against the connector and

slide the Finished End

Change of Height down�

slide down

to engage

3� To remove Finished End

Change of Height from the

connector, pull the Finished

End Change of Height up

until it disengages from the

connector�

NOTE: If Finished End Change

of Height is loose, remove the

Finished End Change of Height,

tighten the extended tab by

pressing down on it, and reinstall.

Friant | Interra Installation Manual

23

A/B Base Trim

For use at a 2-Way or

3-Way 90°

When an A-style frame meets a

B-styleframeinaconguration,

an A/B Base Trim is necessary to

cover the exposed frame at the

base. The A/B Base trims snap

into place with little pressure.

FIABBT-2

1� Insert A/B Base Trim inside

connector, long side first�

2� Align u-shaped channel with

edge of connector�

u-shaped

channel

3� Rotate A/B Base Trim

outward until it clicks�

Friant | Interra Installation Manual

24

Loading...

Loading...