MY-HITE

ADJUSTABLE

TABLE

Model Number : FSQAHTB

Please Read Instructions Before Use

ASSEMBLY INSTRUCTIONS

FRIANT & AS SOC.

4901 E.12 STREET OAKL AND, CA 94601

T:510.535.5113 · FAX:510.535.5237

www.Friant.com/systems/my-hite

081717

page 2 page 15

» Introduction

Friant oers a comprehensive line of oce furniture for every space

and requirement, now including My-Hite, a height adjustable table

that allows for standing or sitting while working.

» User Notes

1. As with all power-operated products, please follow instructions

and handle with care.

2. When moving My-Hite tables, please lif t the tables, do not drag

them.

3. Check that the load on the table does not exceed limits (220lbs

straight, 330lbs corner).

4. Table should be level and aligned at all times.

Thank you for choosing Friant. We appreciate the

trust and confidence you have placed in us and are

committed to providing you the best possible product.

When placing table in final location, be sure there is ample

room for adjustment around ALL sides, and at the highest

(50”) and lowest (24.5”) points the table can reach. Make

sure table will not come into contact with any fixed objects

(fixed tops, storage, shelving, etc.) while adjusting.

Important:

page 14 page 3

» Tools Needed

WARNING:

FAILURE TO FOLLOW THE ASSEMBLY INSTRUCTIONS IN THIS

MANUAL CAN RESULT IN PRODUCT DAMAGE, OR PERSONAL INJURY.

1 2

1. Read instructions

carefully. Check that

no parts are missing.

Single Sided

Wrench

Socket Head

Wrench

Electric Drill

Friant & Ass ociates, LLC do es not assum e any responsib ility for prod uct that is alte red in any way.

2. Caref ully identify each

component, especially

those that are similar.

The most com mon

mistake is mixing

up the order and

placement of parts.

Tools Needed

Follow assembly instructions closely

Do not overload the tables (220 lbs maximum straight, 330 lbs maximum

corner)

The input voltage should be within 108-132V

Use the glides to properly level the table before use

When moving the table, do not tilt the table on one leg or misalignment may

occur

Before first use, perform reset operation

If, after trouble shooting the problem persists, contact Customer Service for

further assistance.

GENERAL TIPS

page 4 page 13

Parts List

TROUBLESHOOTING MY-HITE

Error code Explanation Cause Solution

H01 Motor has

overheated

Overuse 1. Let motor rest for 10 minutes

2. Perform reset operation

if problem persists

3. contact Friant customer service

ASR or

RST (solid

or flashing)

System is

locked

Various Reasons 1. Remove plug from electrical outlet for 15

seconds, then plug unit back in

2. Perform reset operation

if problem persists

3. contact Friant customer service to

replace control panel

No display Control

Panel has

lost power

Disruption in

power supply to

base

1. Remove plug from electrical outlet for 15

seconds, then plug unit back in

2. Perform reset operation

if problem persists

3. contact Friant customer service to

replace control panel

E01,

E02, or

E03

Excessive

weight

distribution

Too much

weight (limit

exceeded)

or

Other problem

1. Check that weight on table does not

exceed limit

2. Perform reset operation

if problem persists

3. contact Friant customer service to

replace control panel

E0 7,

E08, or

E09

Signal

Interruption

Signal is

interrupted

between leg

and computer

1. Perform reset operation

if problem persists

2. contact Friant customer service

CLEAR MAXIMUM & MINIMUM HEIGHT

1. Table can be at ANY HEIGHT but NOT the minimum or maximum.

2. Hold “S” til display flashes. Release button.

3. Press “S” slowly, multiple times - until “555” shows on display.

Note: Display will show other codes, continue to press “S” until “555” shows.

4. Display will then show table height and can now move to any height between

24.5” and 50.1”.

PART# NAME PIECES

A Side Bracket 2

B Column Leg 2

C Pad 1

D Crossbeam 2

E Center Rails 2

F Control Panel 1

G Control Box 1

H Telescopic Cover Plate 1

I Connector Wires

J Feet 2

K Socket Button Head Bolt

M6*20mm

8

L Socket Button Head Bolt

M6*12mm

16

M Wire Manager 3

N Truss Head Screw

M5*20mm

26

page 12 page 5

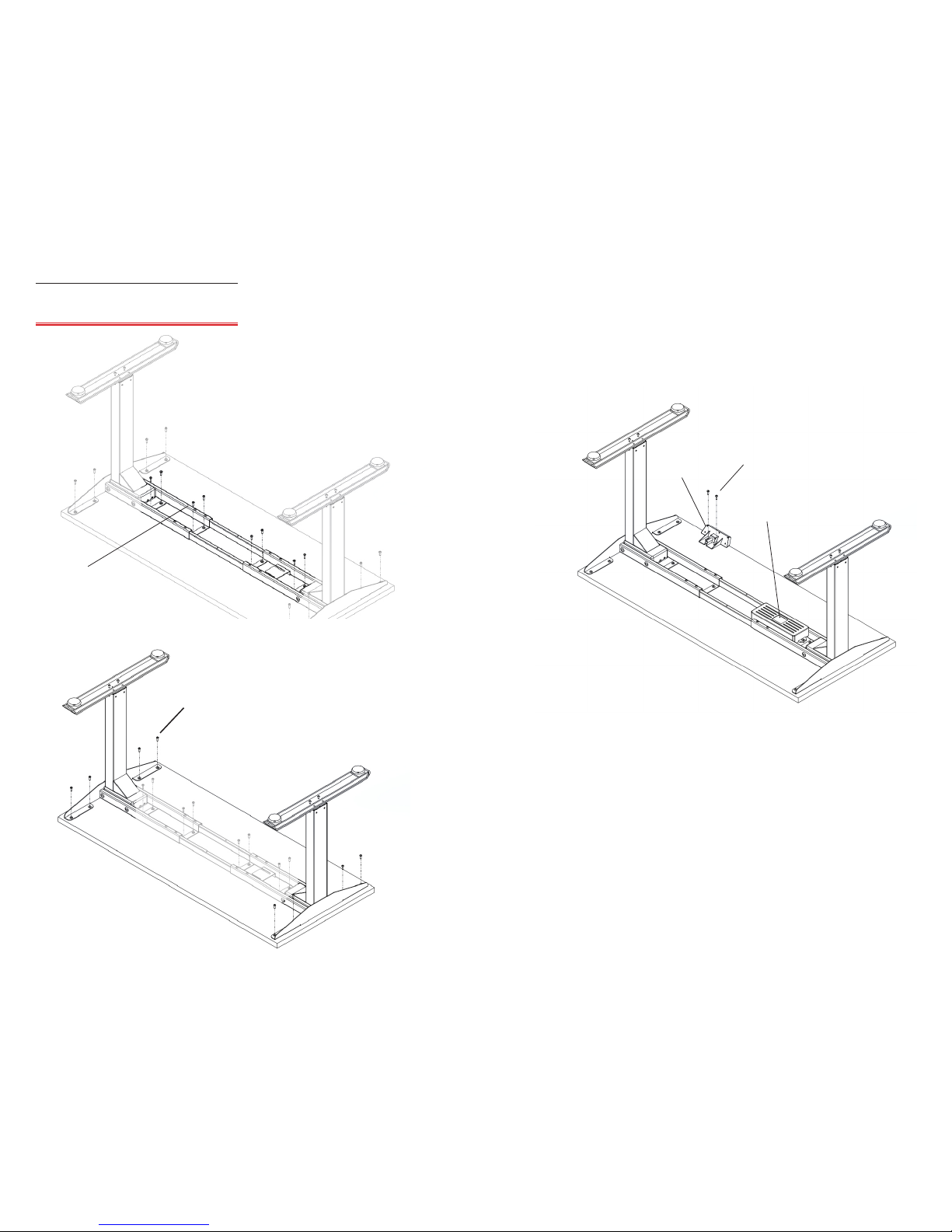

Installation Steps

Step 1: Place worksurface finished

side down on a blanket.

Step 3: Insert D pad under C leg

during assembly process for

proper spacing.

Step 2: Insert A side bracket into

B crossbeam assembly.

Repeat on other side.

B

CROSSBEAM

A

SIDE BRACKET

C

COLUMN LEG

D

PAD

WORKSURFACE

Step 17: It is important to perform the

reset operation below before

you use your My-Hite table

for the first time.

FIRST TIME USE:

SET MINIMUM HEIGHT

RESET OPERATION

SET MAXIMUM HEIGHT

1. Press the arrow down (V) button to get to desired minimum height.

Note: the arrow down button must be the last button pressed to set the minimum height.

You cannot press the arrow up button when trying to set the minimum height.

2. Hold “S” button til screen display flashes. Immediately press “S” button twice

again.

3. Display will flash “000” and then show the set minimum height.

1. Lower the table to 24.5” by holding arrow down (V) button. Release button.

2. Press the arrow down (V) button again and hold til ASR shows on the display.

3. Release the button and the ASR will flash on the display

4. Hold the arrow down button again. Table will shift up and down slightly as it

resets to 24.5”.

V

1. Press the arrow up ( ) button to get to desired maximum height.

Note: the arrow up button must be the last button pressed to set the maximum height.

You cannot press the arrow down button when trying to set the maximum height.

2. Hold “S” button til screen display flashes. Immediately press “S” button twice

again.

3. Display will flash “999” and then show the set maximum height.

NOTE: If you cannot lower the table to the 24.5” height to perform reset

operation, you may need to clear out the maximum and minimum height

(See instructions below). Once completed, please return to the Reset

Operation instructions.

TO PROGRAM THE MEMORY CONTROL PANEL:

Adjust the table to the desired height, press the S key and one of the three

preset buttons. This position is now saved. Once a preset button is pushed, the

table will automatically move to the preset height. Repeat this procedure for

each preset button.

page 6 page 11

J

SOCKET BUTTON

HEAD BOLT

M6*20mm

I

FOOT

Step 6a: Attach I feet to B column leg

with J 4 socket button head

bolts, M6*20mm.

Step 6b: Tighten bolts securely.

Step 7: Repeat step 6 with other leg.

Step 4: Use 4 socket button head

bolts, M6*12mm to secure

side bracket, column leg and

crossbeam together as shown

in detail.

Step 5: Remove D pad after leg installation, then reuse for assembly of

other leg(s) repeating steps 3 & 4. Remove pad when done.

Make sure the length of the plug-in cord is appropriate to both reach

the outlet, AND for the distance the table will travel up and down.

Range: 24.5” at lowest to 50” highest.

Step 15: Install the G telescopic cover

plates, leaving exit space for

the electrical power cords,

and secure to worksurface

with M 8 truss head screws

M5*20mm

Step 16: Turn table right side up, adjust the glides as necessary, and plug the

power cord into a 110v outlet.

G

TELESCOPIC

COVER PLATE

Insure the length of exposed

power cord is sucient.

M

TRUSS HEAD

SCREWS

M5*20mm

Installation Steps

page 10 page 7

Installation Steps

A

Step 9: Secure D center rails to

C crossbeams with K 8 socket

button head bolt M6*12mm.

C

CROSSBEAM

D

CENTER RAILS

Step 8: Place both leg assemblies on worksurface and insert D center

rails into C crossbeams as shown. Hole on center rails should be

centered between crossbeams. Center leg assemblies on the

worksurface. Make sure your overhang is even on both sides.

K

SOCKET BUTTON

HEAD BOLT

M6*12mm

Base is: A - 38”-68”

Maximum recommended top: 78” wide

Minimum recommended top: 40” wide

Step 14: Connect E control panel to F control box with H connector wires

as shown. Use L wire manager to secure H connector wires to

underside of worksurface.

H

CONNECTOR

WIRES

L

WIRE

MANAGER

Schematic view of the My-Hite wiring:

page 8 page 9

Installation Steps

Step 11: Secure the side bracket to the

worksurface with M 8 truss

head screws M5*20mm.

M

TRUSS HEAD

SCREWS

M5*20mm

M

TRUSS HEAD

SCREWS

M5*20mm

Step 13: Insert the F control box

in-between crossbeam.

Step 12: Secure the E control panel in the desired

location with M 2 truss head screws M5*20mm.

Step 10: Ensure the leg assembly is still

centered, both side-to-side and

front-to-back. Secure the leg

assembly to the worksurface

with M 8 truss head screws

M5*20mm.

M

TRUSS HEAD

SCREWS

M5*20mm

F

CONTROL

BOX

E

CONTROL

PANEL

Loading...

Loading...