OPERATING INSTRUCTIONS

WARNING: To reduce the risk of injury, the user must read and understand the

operating instructions before using this product.

FT1700VCE 21/4 HP Router

1

TABLE OF CONTENTS

Page

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Additional Safety Rules for Routers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Functional Description and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .7

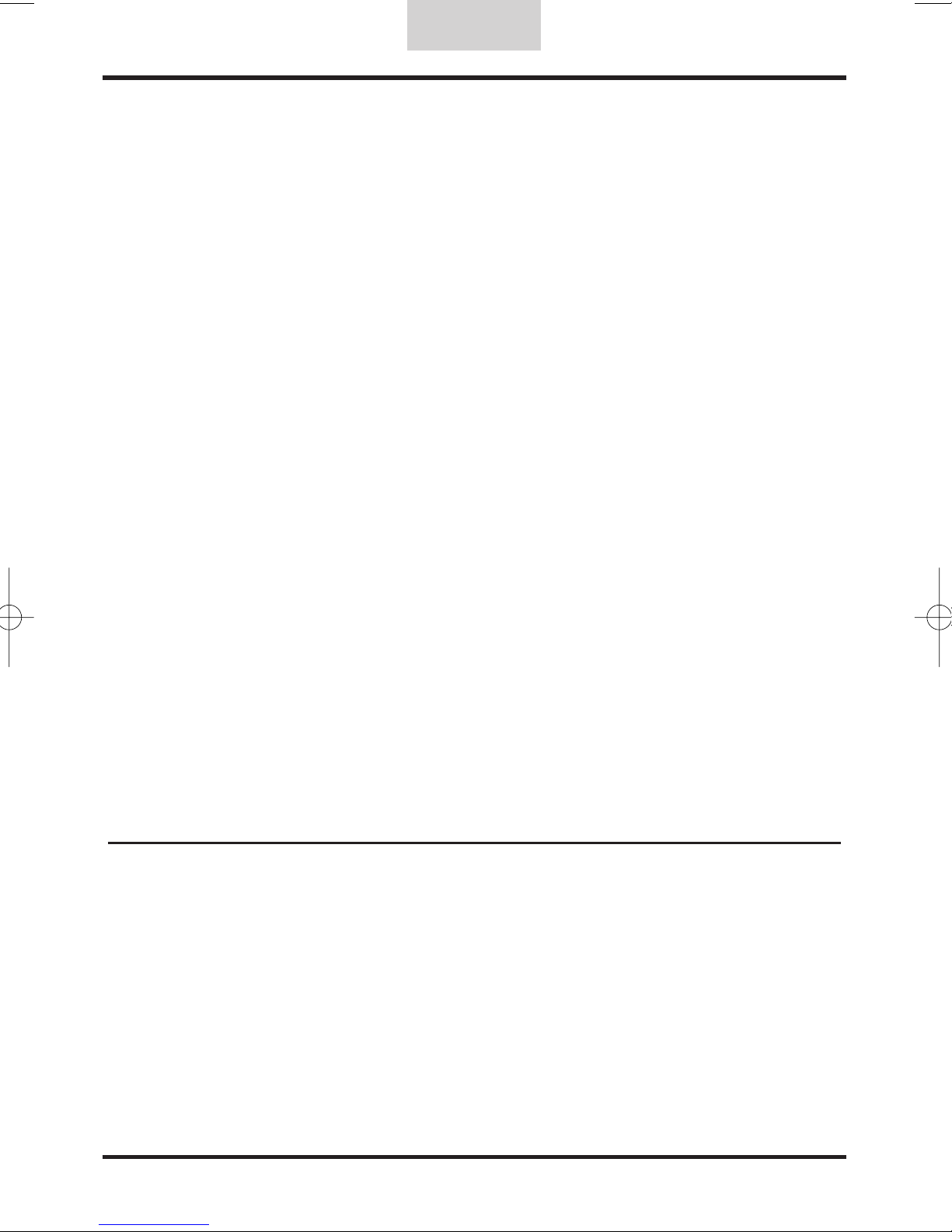

Parts and Feature Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Assembly and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Prior to Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Installing and Removing Router Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Adjusting Depth of Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Mounting Template Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Starting the Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Variable Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Cutting Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Table Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Maintenance & Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Tool Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Ventilation Openings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Inspect Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Inspect Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Service Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Power Tool Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

English

2

TABLE DES MATIÈRES

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Règles générales de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Règles additionnelles de sécurité pour toupie . . . . . . . . . . . . . . . . . . . . . .22

Description fonctionnelle et spécifications . . . . . . . . . . . . . . . . . . . . . . . .24

Diagramme des pièces et caractéristiques . . . . . . . . . . . . . . . . . . . . . . . .24

Symboles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Spécifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Assemblage et utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Avant l’utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Installation et retrait du couteau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Ajuster la profondeur de coupe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Montage des guides pour gabarit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Instructions d’utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Mise en marche de l’outil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Réglage de la vitesse de rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Applications de coupe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Montage sur table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Maintenance et inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Cordon d’alimentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Lubrification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Ouvertures d’aération . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Roulements à bille . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Inspection des accessoires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Inspection des vis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Accessoires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Accessoires standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Points de service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Français

3

TABLA DE CONTENIDOS

Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Reglas de seguridad en general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Reglas adiciónales de seguridad para las Fresadoras . . . . . . . . . . . . . . . .38

Descripcion funcional y especificáciones . . . . . . . . . . . . . . . . . . . . . . . . .40

Diagrama de partes y caracteristicas . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Símbolos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Especificáciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Ensamblaje y Operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Antes de la Operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Instalar y quitar broca fresadora . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Reglaje de la Profundidad de Corte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Montar las plantillas de guiar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Instrucciónes de Operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Empezar la Herramienta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Control de Velocidad Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Applicaciónes de Corte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Montajé de Mesa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Mantenimiento e Inspección . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Servício . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Cable Eléctrico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Lubricación de la herramienta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Aberturas de Ventílación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Rodamientos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Inspección de los Accesorios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Inspección de los tornillos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Accesorios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Estandar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Localizacion de Servício . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Garantia de Herramienta Eléctrica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Español

4

SAFETY

SAVE THESE INSTRUCTIONS

GENERAL SAFETY RULES

1. Work Area

a) Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents

which could result in personal injury.

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks which may ignite the dust of fumes.

c) Keep bystanders, children, and visitors away while operating a power tool. Distractions can

cause you to lose control.

2. Electrical Safety

a) Double Insulated tools are equipped with a polarized plug (one blade is wider than the

other). This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install a

polarized outlet. Do not change the plug in any way. Double Insulation eliminates the need

for the three wire grounded power cord and grounded power supply system.

b) Prevent body contact with grounded surfaces such as pipes, radiators, ranges, and

refrigerators. There is an increased risk of electric shock if your body is grounded.

c) Do not expose power tools to rain. Do not use power tools in damp or wet locations. Water

entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never carry the tool by the cord or yank the cord to pull the plug

from a receptacle. Keep cord away from heat, oil, sharp edges, or moving parts. Replace

damaged cords immediately. Damaged cords increase the risk of electric shock.

e) When operating a power tool outside, use an outdoor extension cord marked "W-A" or "W".

These cords are rated for outdoor use and reduce the risk of electric shock.

3. Personal Safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool.

Do not operate a tool while you are tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power tools may result in serious

personal injury.

b) Dress properly. Do not wear loose clothing or jewelry. Wear protective hair covering to

contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors.

c) Avoid unintentional starting. Be sure switch is off before plugging in. Do not carry tools with

your finger on the switch or plug in tools that have the switch turned on.

d) Form the habit of checking to see that keys and adjusting wrenches are removed from the

tool before turning it on. A wrench or a key that is left attached to a rotating part of the tool

may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. Proper footing and balance

enables better control of the tool in any situation.

f) Use safety equipment. Always wear protective glasses. Also use a face or dust mask if

cutting operation is dusty.

English

WARNING: Read and understand all instructions. Failure to follow all instructions listed below

may result in electric shock,fire, and/or serious personal injury.

5

4. Tool Use and Care

a) Secure your work. Use clamps or a vise to secure and support the work piece to a stable

platform. Securing the work with a clamp or vise will free both hands to operate the tool.

Holding the work by hand or against your body is unstable and may lead to loss of control.

b) Do not force tool. The power tool will do the job better and safer at the rate for which it was

intended.

c) Use the correct tool for your application. Do not use tools for purposes for which they were

not intended.

d) Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with

the switch is dangerous and must be repaired. Have defective switches replaced by an

authorized Freud service center.

e) Disconnect the plug from the power source when not in use, before servicing, and when

changing accessories such as blades, bits, and cutters. Such preventive safety measures

reduce the risk of starting the tool accidentally and causing personal injury.

f) Store idle tools when not in use. Tools should be stored in a dry, high, or locked-up place

and out of the reach of children.

g) Maintain tools with care. Keep cutting tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect tool

cords periodically and, if damaged, have repaired by and authorized Freud service center.

Inspect extension cords regularly and replace if damaged. Keep handles dry, clean, and free

from oil or grease. Properly maintained tools, with sharp cutting edges are less likely to bind

and are easier to control.

h) Check for damaged parts. Before further use of the tool, a guard or other part that is

damaged should be carefully inspected to determine that it will operate properly and

perform its intended function. Check for alignment of moving parts, binding of moving

parts, mounting, and other conditions that may affect the operation of the tool. A guard or

other part that is damaged should be properly repaired or replaced by an authorized Freud

service center unless otherwise indicated elsewhere in this instruction manual.

i) Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may become hazardous when used with

another tool.

5. Service

a) Tool service must be performed only by a Freud authorized service center. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

b) When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric shock or injury. Certain cleaning

agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic parts.

ADDITIONAL SAFETY RULES FOR ROUTERS

• WARNING! Do not rout material containing amianthus. Working with materials containing

amianthus/asbestos and/or silica stones produces a dust which is harmful to health. Protect

yourself from inhaling this dust, in compliance with regulations on accident prevention.

• Tighten collet nut securely to prevent bit from slipping.

• Provide clearance under work piece for router bit when through-cutting.

• Remove any adjusting key or wrench before turning the power tool on. A wrench or key left

attached to a rotating part of the power tool may result in personal injury.

• Never tighten collet nut without a bit installed.

• Avoid "Climb-Cutting" (moving the router with the rotation of the bit) this will increase the

chance for loss of control resulting in possible personal injury.

English

6

• Do not overreach. Keep footing and balance at all times. This enables better control of the

power tool in unexpected situations.

• Do not pierce the motor housing as this could damage the double insulation (use adhesive

labels).

• Always unplug the tool before working on it.

• Always stop the tool by using the on/off switch, not by unplugging it.

• WARNING! Before each use, inspect the plug and cord. Should they need replacing, have

this done by an authorized Freud service technician.

• Always keep the tool cord and extension cord clear of the working range of the tool.

• Only plug in the tool with the switch in the OFF position.

• Hold the tool firmly in both hands and in a stable position or mounted to a router table.

• Adjust the speed for different diameter bits. The larger the bit the slower the speed.

• Router bits should be handled and kept with the utmost care, in accordance with the

manufacturer's instructions.

• Check the bit carefully before use to make sure it is not damaged or cracked. Replace

cracked or damaged bits immediately.

• Make sure the bits are chucked in the collet in accordance with the manufacturer's

instructions.

• Check that the bit has been properly fitted and secured before using the tool. Start the tool

with no load and run for a few seconds in a safe position. If you notice serious vibration or

any other defect, turn off the tool immediately.

• Use only Freud approved collets and collet nuts to chuck bits.

• Ensure that the material to be worked on is firmly secured before beginning any routing.

• Beware of shavings that fly off during operation. Hold the tool so that chips fly away from

you.

• When working on woods that irritate skin, eyes or respiration, use dust extraction equipment

and wear a mask.

• When working with the tool, always wear safety glasses and hearing protection. Other

personal protection equipment such as dust masks, apron, and non-slip footwear should

also be worn.

• Make sure the tool's air vents are clear of dust and debris. If they require cleaning, first

unplug the tool and vacuum. Do not use metal objects to clean the air vents or you may

damage the tool's internal parts.

• Do not touch the bits when rotating.

• WARNING! The bit keeps moving for a long time after the switch is turned off. Be sure the

bit has stopped rotating before putting the tool down or changing accessories.

DOUBLE INSULATION

To ensure safer operation of this tool, Freud has adopted a double insulation design. "Double

Insulation" means that two physically separated insulation systems have been used to insulate the

electrically conductive materials connected to the power supply from the outer frame handled by

the operator.

To keep the double insulation system effective, follow these precautions:

• Be careful not to pierce the motor housing as this could damage the efficiency of the double

insulation system.

• Only Freud Authorized Service Centers should disassemble or assemble this power tool, and

only genuine Freud replacement parts should be installed.

English

7

DESCRIPTIONS & SPECIFICATIONS

FUNCTIONAL DESCRIPTION

English

A - Micro Adjust Dial

B - Micro Adjusting Knob

C - Variable Speed Control

D - On/Off Switch

E - Side Handles

F - Spindle

G - Collet

H - Fixed Base

I - 22mm Wrench

J

L

Q

M

R

N

O

P

J - Above Table Height

Adjustment Access

K - Depth Adjustment Wrench

L - Above Table Base Clamp Access

M - Base Plate

N - Spindle Lock

(Shaft Lock)

O - Base Clamp

P - Base Release Button

Q - Spindle Lock Access

R - Locking Lever

K

B

A

G

C

F

D

H

E

I

8

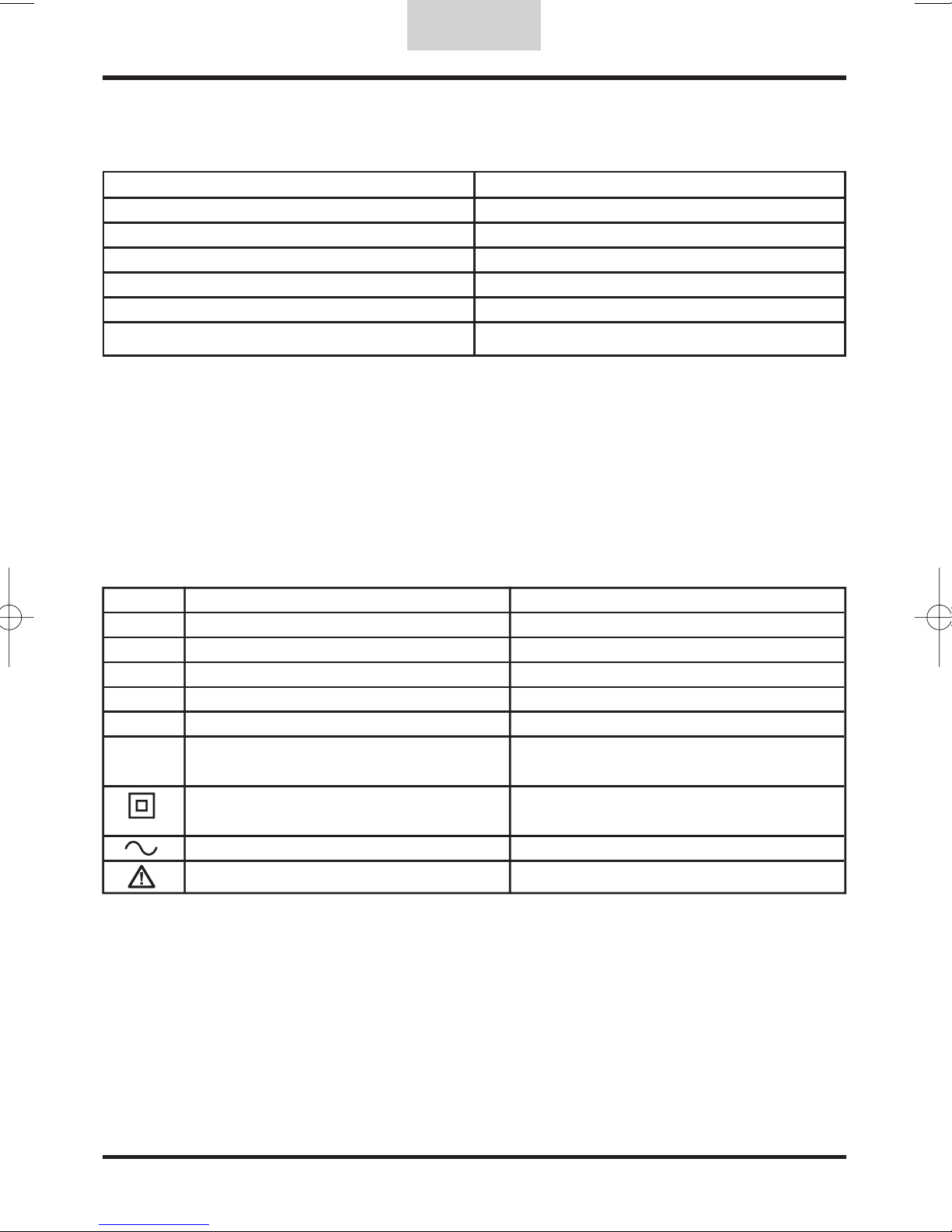

SYMBOLS

Some of the following symbols may be used on your tool. Please study them and learn their

meaning. Proper interpretation of these symbols will allow you to operate the tool better and

more safely.

English

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

n

o No load speed Rotational speed, at no load

.../min Revolutions or reciprocation per minute Revolutions, strokes, surface speed,

orbits, etc. per minute

Class II construction Designates double insulated construction

tools

Alternating current Type or a characteristic of current

Safety Alert Precautions that involve your safety

Power Source Single-Phase, 120V, AC 60Hz

Amps 13

Watts 1500

No-Load Speed 10,000-23,000 RPM

Collet 1/4 inch & 1/2 inch

Max Bit Diameter* 3-1/2 inch (89 mm)

Weight 5.4 lbs

SPECIFICATIONS

* Router bits over 11/2” diameter should be used only with the router mounted in a router table. The router base

plate must be removed to to accept bits larger 21/2” diameter. Consult the router table’s user manual for

maximum bit diameter that can be used in the router table.

9

ASSEMBLY & OPERATION

PRIOR TO OPERATION

1. Check Power Supply

Ensure that the power source to be utilized conforms to the power source requirements

specified on the tool nameplate. Ensure the receptacle being used accepts the plug tightly. If

a faulty receptacle is used, it may cause overheating, resulting in a serious hazard.

2. Check Work Area

Confirm that the work site is placed under appropriate conditions conforming to precautions

prescribed in the safety section of this manual.

3. Before Plugging in the Tool

Ensure that the power tool switch (D) is in the OFF position to prevent the tool from accidental

start up which could cause serious injury.

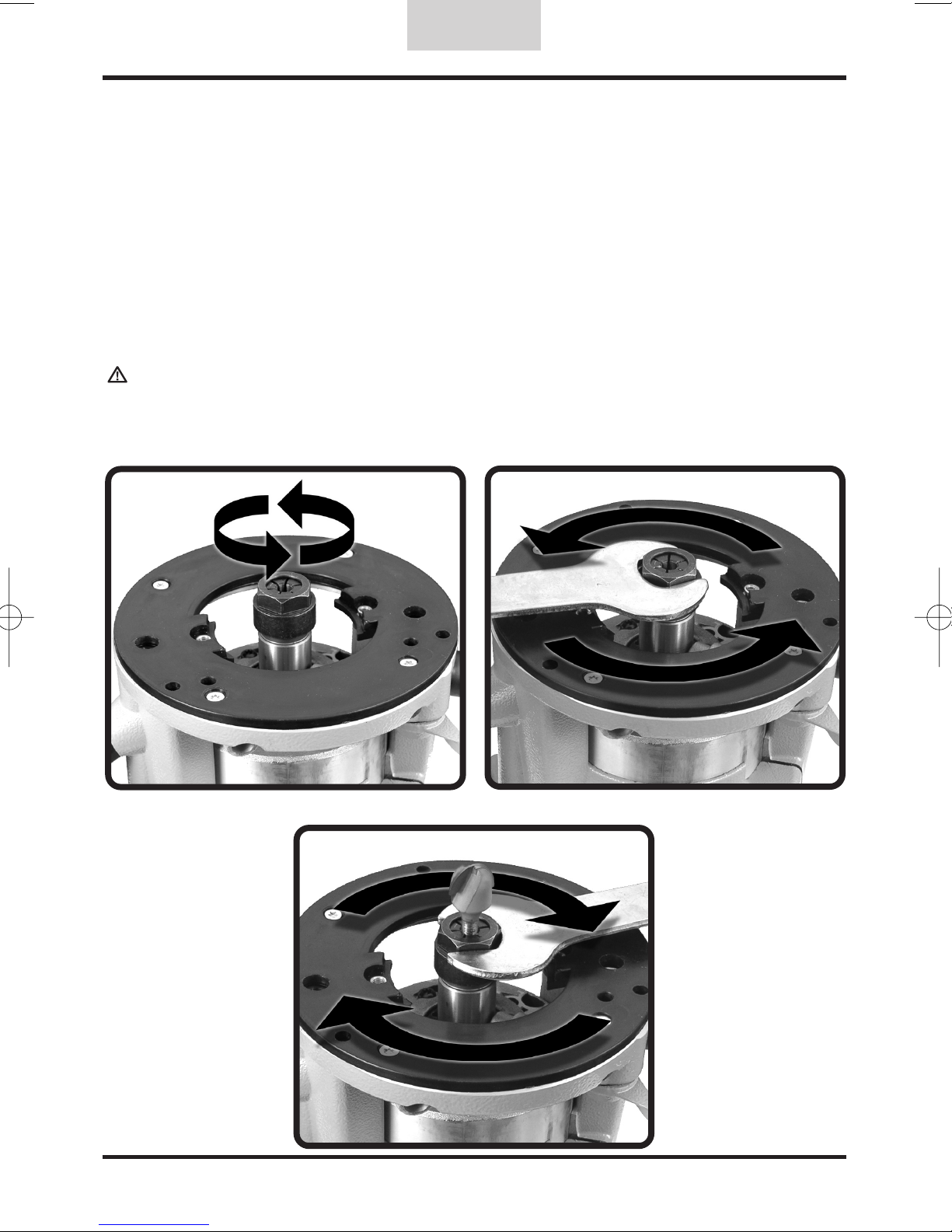

INSTALLING AND REMOVING THE BIT (2 OPTIONS)

WARNING: Disconnect tool from power source. Make sure the correct collet is selected to

match the bit shank diameter before proceeding.

Option 1 – Hand Held Use

a) Open base clamp (O) on the router base (H). - Fig 1a

b) While pressing the router base release button (M), push down the router handles until the

entire collet extends past the base. Rotate Locking Lever (R) until it engages the Spindle

Lock (N) - Fig 1b

English

Fig. 1a Fig. 1b

1

3

2

10

c) Rotate collet until the spindle lock pin engages with the spindle (F). When the locking pin

engages, you will not be able to rotate the spindle. - Fig 1c

d) Using the included 22mm wrench (I), turn the collet nut (G) counterclockwise to loosen the

collet. - Fig 1d

e) Insert the router bit and rotate the collet nut with the 22mm wrench clockwise to

tighten the collet. Always be sure that 80% of the router bit shank is inserted in the collet

- Fig 1e

f) Rotate Locking Lever (R) until it disengages the Spindle Lock (N). Press the router base

release button and slide the router motor out of the base until the router bit is back below

the surface of the router base and close base clamp.

g) Before operating the router, follow directions in the section in this manual titled "Adjusting

Depth of Cut" to properly set your depth of cut.

h) To remove a router bit from the collet, follow steps b,c, and d and then remove the router bit.

WARNING: Failure to disengage the spindle lock or remove the wrench before operating this

power tool could result in injury or damage to the tool.

English

Fig. 1e

Fig. 1c

Fig. 1d

11

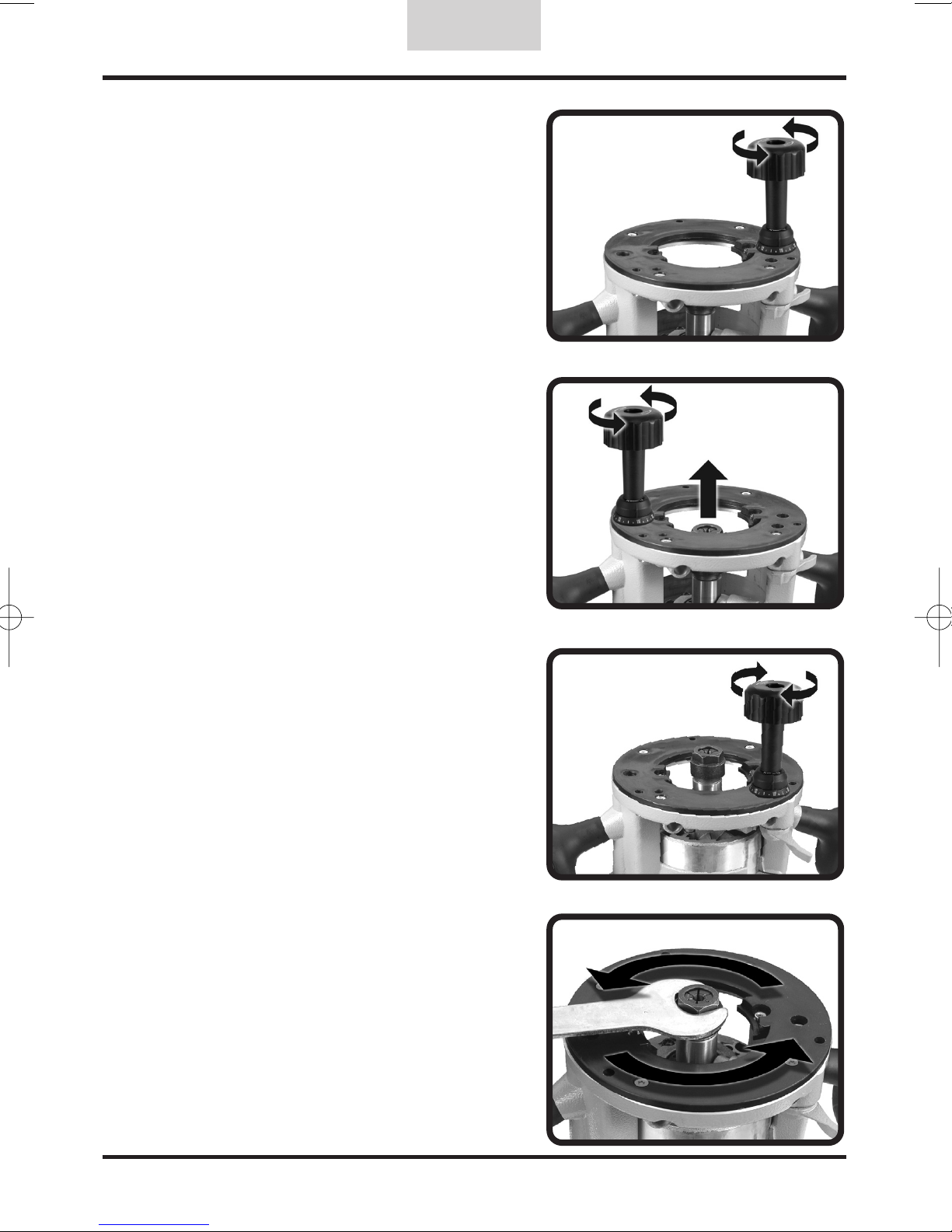

Option 2 – Through The Base Bit Changes

The Freud FT1700 can also be mounted to a router

table.To mount the router, please follow the

instructions included with the router table.

a) Unlock the base by inserting the height

adjustment wrench (K) into the above table base

clamp access hole (L) and turn counter clockwise

until the wrench stops turning. - Fig. 2a

b) Insert the depth adjustment wrench into the

above table height adjustment access hole (J)

and rotate counter clockwise until the collet (G)

extends fully through the base. - Fig. 2b

c) Insert the depth adjustment wrench into the

spindle lock access hole (Q) and rotate clockwise

until it stops. Rotate spindle (F) until spindle lock

pin (N) engages. When the spindle lock pin is

correctly engaged, you will not be able to rotate

the spindle. - Fig. 2c

d) Using the 22mm collet nut wrench (I), turn the

collet nut counter clockwise to loosen the collet.

If a bit is already in the collet, the collet nut will

loosen for approximately 1 turn and then become

tight again. Continue turning the nut counter

clockwise with the wrench until the nut is loose

again. At the point the bit should be released and

easy to remove from the collet. - Fig. 2d

e) To install a router bit, insert the bit into the collet

and with the 22mm wrench rotate the collet nut

clockwise to tighten the collet. Always be sure

that at least 80% of the router bit shank is

inserted in the collet but never allow the bit

shank to “bottom out” in the collet. - Fig. 2e

f) Insert the depth adjustment wrench into the

spindle lock access hole (Q) and rotate counter

clockwise until it stops turning.- Fig. 2f

g) 1. Insert depth adjustment wrench into the

above table height adjustment access hole (J)

and turn clockwise to lower the router bit.

2. Lock the base by inserting the height

adjustment wrench into the above table base

clamp access hole (L) and turn the wrench

clockwise until the wrench stops turning.

- Fig. 2g

h) Before operating the router, follow directions in

the section in this manual titled “Adjusting Depth

of Cut” to properly set your depth of cut.

English

Fig. 2a

Fig. 2b

Fig. 2c

Fig. 2d

12

WARNING: Failure to disengage the spindle lock or remove the wrench before operating this

power tool could result in injury or damage to the tool.

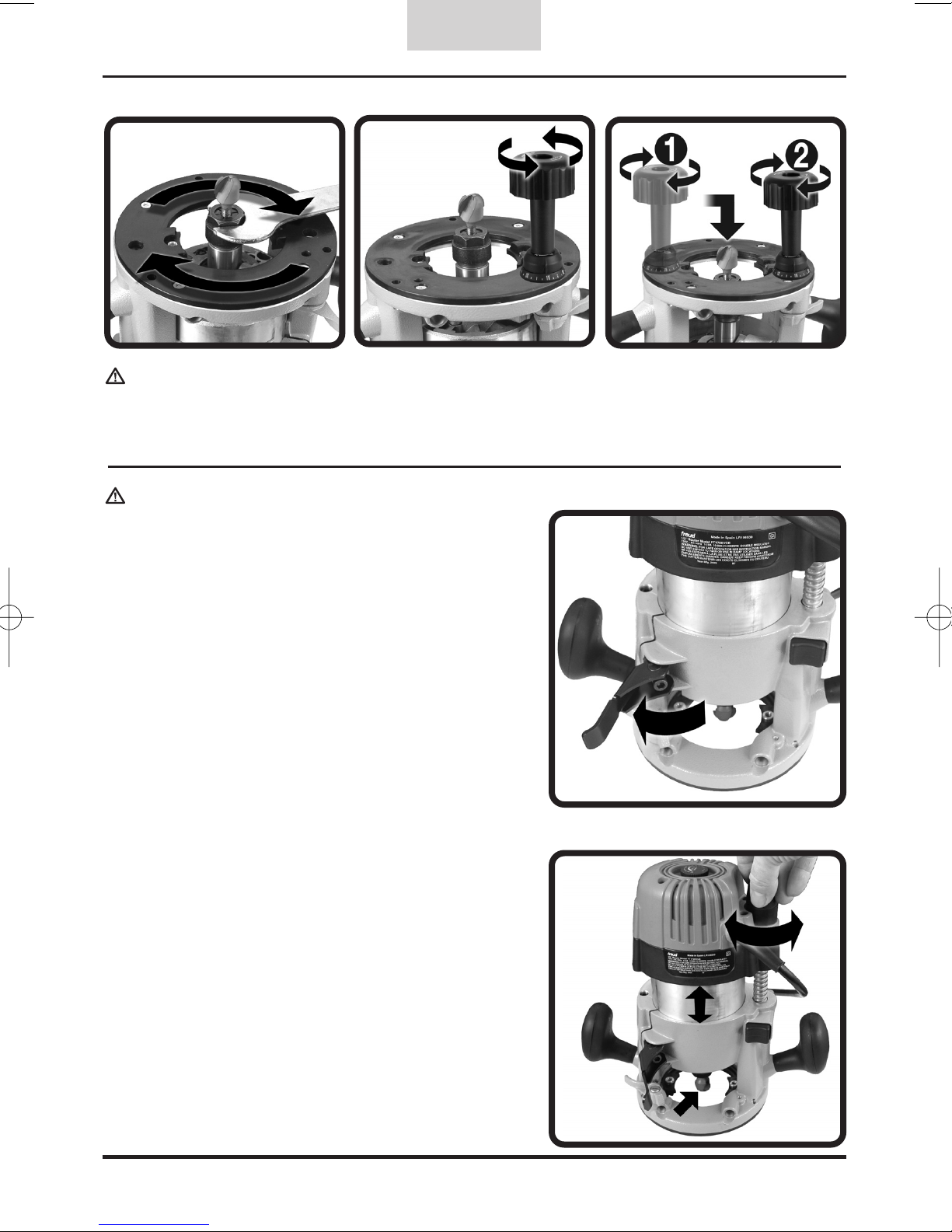

ADJUSTING DEPTH OF CUT (2 OPTIONS)

WARNING! Disconnect tool from power source.

Option 1 – Hand Held Use

a. Open the base clamp (O). - Fig. 3a

b. Turn the Micro Adjusting Knob until the bit

contacts the work surface making sure that

the router is level and flat. - Fig. 3b

c. Turn the Micro Adjustment Knob (B) clockwise to

the desired depth. (one complete rotation

varies the bit depth by 1/8").

d. Lock the base clamp (O) prior to operation.

English

Fig. 3a

Fig. 3b

Fig. 2e

Fig. 2f

Fig. 2g

13

Option 2– Through The Base Bit Changes

The Freud FT1700 can also be mounted to a

router table. To mount the router, please follow the

instructions included with the router table.

a) Unlock the base by inserting the height

adjustment wrench (K) into the above table base

clamp access hole (L) and rotate counter

clockwise until the wrench stops turning.

- Fig. 4a

b) Insert the depth adjustment wrench into the

above table height adjustment access hole (J).

Turn the wrench counter clockwise to raise the

bit and clockwise to lower the bit. - Fig. 4b

c) Once the bit is set at the desired depth of cut,

lock the base by inserting the height adjustment

wrench into the above table base clamp access

hole (L) and turn the wrench clockwise until the

wrench stops turning. - Fig. 4c

MOUNTING TEMPLATE GUIDES

WARNING! Disconnect tool from power source.

For template routing, the Freud FT1700 accepts

standard template guides which are available

separately. To use template guides an optional adapter

ring (Freud FT1100) must be attached to the base

plate using the two slotted screws provided. Remove

the slotted screws from the base plate, insert the

adapter ring with the flat side toward the router body.

Install and tighten the screws to secure the adapter

ring. - Fig. 5

The base plate (L) has been centered at the factory,

however, if the base plate has been removed and

remounted some adjustment may be necessary to

center the template guides to the router bit. To adjust,

loosen the four base plate screws that secure the base

plate to the router, reposition the base plate and

tighten the screws.

English

Base Plate

Screw

Adaptor Ring

Screws

Base

Plate Screw

Base Plate

Screw

Base

Plate Screw

Fig. 4a

Fig. 4b

Fig. 4c

Fig. 5

14

WARNING: Make sure that the voltage

from the power supply matches the voltage

specified on the tool. Before plugging in the

tool ensure that the bit is properly inserted

and tightened and that it spins freely.

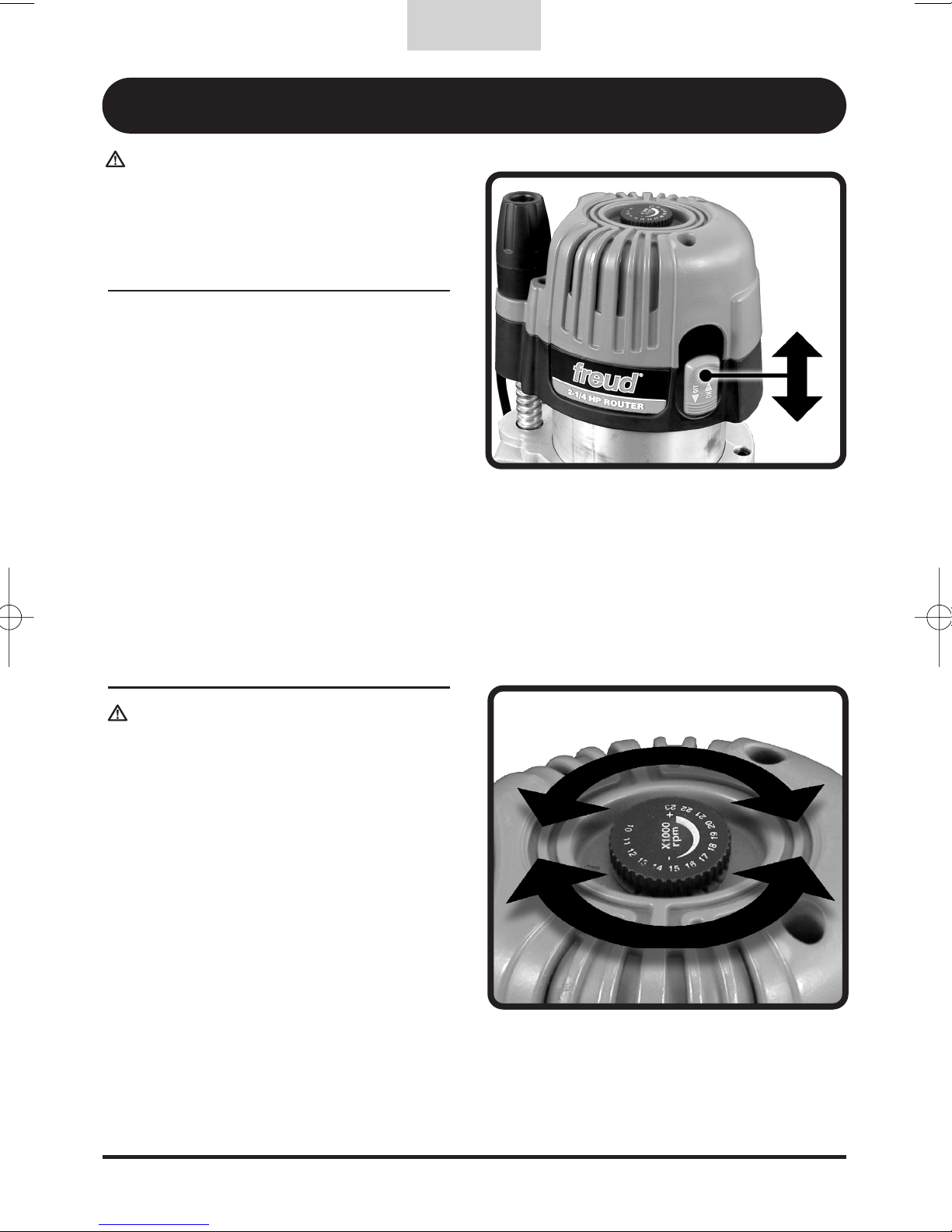

1. Starting the Tool

a) Plug in the tool with the switch in the

OFF position.

b) Hold the router firmly with both

handles with the bit away from you

and positioned so that the bit is not in

contact with the wood or any part of

your body or clothing.

c) Start the tool by sliding the switch in

the direction specified on the tool.

- Fig. 6

d) Turn off the tool by sliding the switch

in the opposite direction.

2. Variable Speed Control

WARNING: Always unplug the router

before making any speed adjustment.

The Freud FT1700 is equipped with an

electronic variable speed control feature.-

Fig. 7

This speed control has an infinite number of

speeds from 10,000 to 23,000 RPM. The

speed is adjusted by turning the speed

control knob (C). Consult the router bit

manufacturer for recommended bit speed.

The electronic speed control keeps constant

speed at all levels. If the motor speed

decreases in use you may be exceeding the

load capacity of the tool. This could cause

damage to the motor by overheating.

Reducing the depth of cut so that more

passes are required and/or slowing the rate

of feed will reduce the power requirements on

the router.

English

Fig. 7

Fig. 6

ON

OFF

OPERATING INSTRUCTIONS

15

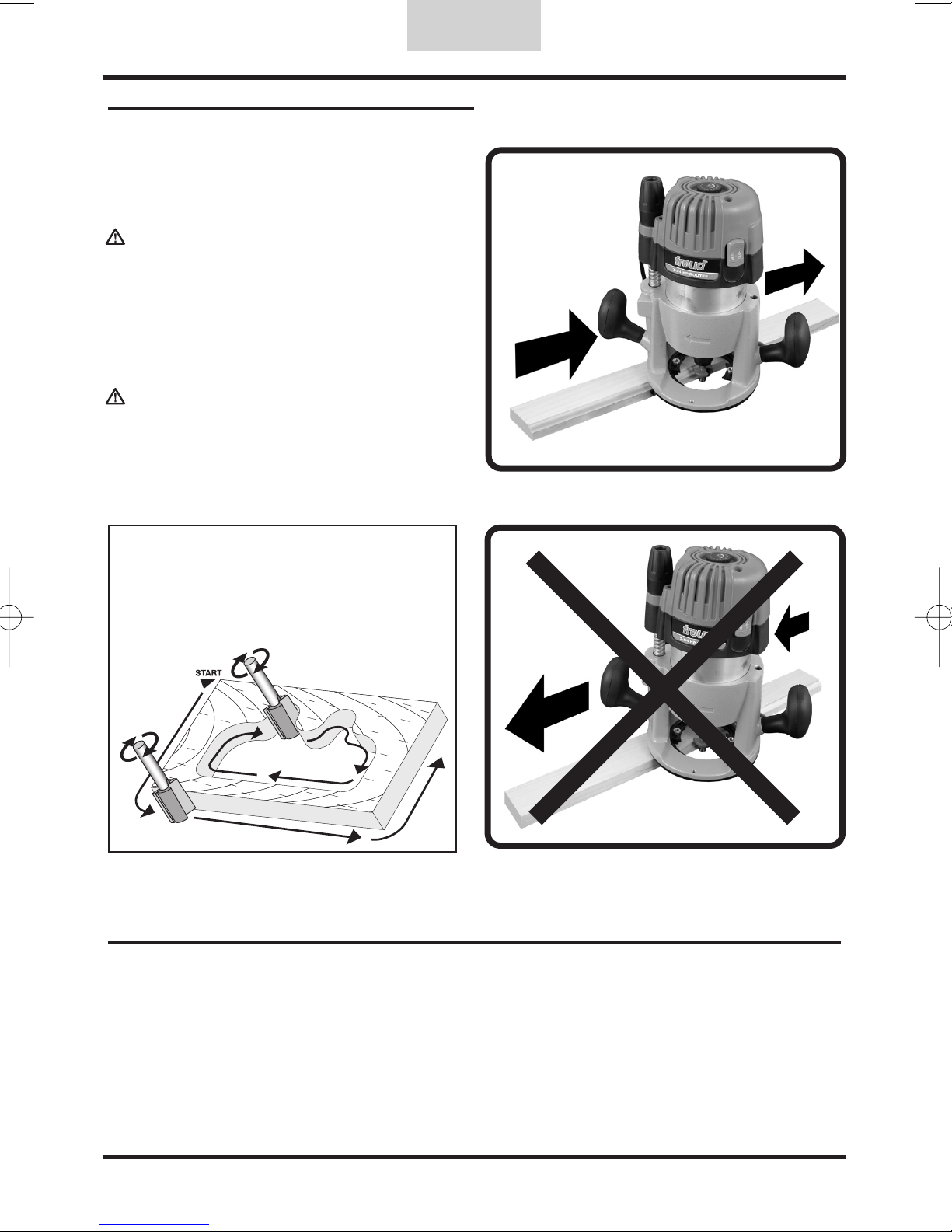

CUTTING APPLICATIONS

Consider the material that you are cutting and

the amount of material that will be removed

before using the tool. Make sample cuts on

scrap wood before cutting the actual work piece.

WARNING! Always clamp your work piece

securely before making any cuts.

The router bit rotates in a clockwise direction

when viewed from the top of the router. On

external edge treatments move the router

counter clockwise from left to right. - Fig. 8a

WARNING! Avoid climb cutting (moving the

router clockwise with the rotation of the bit.

- Fig. 8b. Climb cutting increases the potential of

loosing control of the router and possible injury.

TABLE MOUNTING

The Freud FT1700 can also be mounted to a router table. To mount the router, please follow the

instructions included with the router table.

English

Fig. 8b

INCORRECT

Fig. 8a

CORRECT

Tip: When creating an edge treatment on all

four edges, begin with the end grain of the

board first. If tear out occurs at the end of

this cut it will be removed when the cut is

made along the edge or with the grain.

16

MAINTENANCE & INSPECTION

Service

It is recommended that all service on your Freud tool be performed by an

Freud Authorized service center. Service by unauthorized service personnel

may result in misplaced internal components resulting in risk of tool

malfunction and personal injury to the tool user.

Power Cord

Check that the power cord is in good condition. If it is not, have it replaced

immediately at a Freud Authorized service center.

Tool Lubrication

All power tools require care and attention. Every couple of years, or when

needed, it is recommended you take the tool to an Freud Authorized service

center for a general cleaning and lubrication.

Ventilation Openings

Make sure the air vents are always kept clean and free of obstacles. If

clogged, vacuum out obstruction. It is recommended that you blow off the

entire tool with compressed air after each use.

Bearings

Every two years, or when needed, the bearings should be inspected by a

Freud Authorized service technician. Bearings that become very noisy should

be replaced at once to avoid overheating or motor failure.

Inspect Accessories

Regularly inspect your router bits. Using worn accessories will diminish the

efficiency of the work and could damage the tool's motor.

Inspect Screws

Regularly inspect all screws in your power tool and make sure they are

properly tightened. Loose screws should be retightened immediately.

English

17

To locate a Freud Authorized Service Center near you, call: 1-800-334-4107

Or visit our web site at: www.freudtools.com

In Canada call: 1-800-263-7016

Or visit the Canadian site for a full list of service centers at: www.freud.ca

Standard Accessories

• Collet Nut Wrench

• Depth Adjustment Wrench

• 1/4" and 1/2" Collets

• Vacuum Adaptor

• Carrying Case

English

ACCESSORIES

Service Locations

18

NORTH AMERICAN POWER TOOL WARRANTY

FREUD LIMITED POWER TOOL WARRANTY

90 DAY MONEY BACK GUARANTEE

If within the first 90 days from the date of original purchase you are not completely satisfied with your Freud

power tool for any reason you may return the tool (in its original packaging and complete with all accessories) to

the place of purchase with proof of purchase (e.g. dated sales receipt) for a full refund.

FREUD LIMITED FIVE YEAR POWER TOOL WARRANTY

Freud warrants to the original consumer purchaser that each new Freud power tool shall be free from defects in

material and workmanship for a period of five (5) years from the purchase date. When warranty service is

requested, proof of purchase (e.g. dated sales receipt) is required. Should the power tool fail within ninety (90)

days from the date of purchase, it will be repaired or replaced AT THE CUSTOMER'S OPTION subject to the

guidelines below. Thereafter, upon verification of failure or malfunction, at Freud's option, Freud will repair or

replace the power tool, subject to the guidelines below. This warranty does not cover damage incurred from

repair or attempted repair by anyone other than Freud's authorized personnel, normal wear and tear, abuse, lack

of maintenance, or accidents.

FREUD WARRANTY GUIDELINES

1. In the event of failure or malfunction, return the product, properly packaged and postage prepaid, to Freud at

the address listed below or to an authorized Freud service station. For technical advice, instructions on returns,

or a list of authorized repair stations, please contact us at (U.S.) 1-800-334-4107 (Canada) 1-800-263-7016.

2. All implied warranties for Freud power tools (INCLUDING MERCHANTABILITY AND FITNESS FOR

PARTICULAR PURPOSE) are limited to the period of three years from the purchase date by the original

consumer purchaser. Some states do not allow limitations on how long an implied warranty lasts, so the above

limitation may not apply to you.

3. A warranty claim shall be limited to repair or replacement as stated in Freud's Limited Power Tool Warranty,

and in no event shall Freud be liable for any other direct, indirect, incidental or consequential damages, costs or

expenses. INCIDENTAL AND CONSEQUENTIAL DAMAGES ARE EXCLUDED UNDER ALL WARRANTIES. Some

States do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

4. Freud's warranties give you specific legal rights, and you may also have other rights which vary from State to

State.

5. Freud's warranties shall not be deemed to have failed their essential purpose while Freud is willing to repair or

replace defective products.

6. Freud assumes no liability for defects or damage caused by abuse or misuse of any product or unauthorized

service of any product. The product must have been used for its recommended purpose and not modified or

changed. Normal wear and tear is not covered under Freud's warranties.

7. Any legal action for breach of warranty must be commenced within one year after the claim has arisen.

8. All warranties are expressly limited to the original consumer purchaser. All warranties and other rights of the

purchaser shall be governed under the laws of the State of North Carolina without regard to conflict of law

principles.

To obtain service under Freud Limited Power Tool Warranty, contact an authorized repair station or:

Freud America, Inc.

(Attn: Technical Service)

218 Feld Avenue

High Point, North Carolina 27263

1-800-334-4107

Freud Canada

(Attn: Technical Service)

7450 Pacific Circle

Mississauga, Ontario L5T 2A3

Canada

1-800-263-7016

(c) Copyright 2007, Freud America, Inc. All rights reserved.

English

19

NOTES:

English

20

NOTICE TECHNIQUE D’UTILISATION

Français

AVERTISSEMENT : Pour réduire les risques de blessure, l’utilisateur doit lire et comprendre

les consignes d’utilisation avant d’utiliser ce produit.

Toupie 2-1/4 HP FT1700VCE

21

SÉCURITÈ

AVERTISSEMENT! Lire attentivement et comprendre toutes les instructions. Le non respect

des instructions peut entraîner des risques de décharge électrique, d’incendie et (ou) de blessure

corporelle grave.

CONSERVER CES INSTRUCTIONS

RÈGLES GÉNÉRALES DE SÉCURITÉ

1. Aire de travail

a) Garder l’aire de travail propre et bien éclairée. L’encombrement et un mauvais éclairage sont

propices aux accidents pouvant causer des blessures corporelles.

b) Ne pas utiliser d’outils mécaniques dans un milieu déflagrant tel qu’en présence de liquide

inflammable, de gaz ou de poussière. Les outils mécaniques génèrent des étincelles qui

peuvent enflammer la poussière ou les vapeurs.

c) Garder éloignés les tiers, les enfants et les visiteurs pendant l’utilisation d’un outil

mécanique. Les distractions peuvent entraîner une perte de contrôle par l’utilisateur.

2. Règles de sécurité en matière d’alimentation

a) Les outils à double isolation sont dotés d’une fiche polarisée (une branche de la fiche est

plus large que l’autre). Ce type de fiche ne peut être branché que d’une seule façon dans

une prise de courant polarisée. Si la fiche ne peut être insérée complètement dans la prise,

inverser la fiche. Si la fiche ne peut toujours pas être correctement insérée, communiquer

avec un électricien qualifié et lui demander d’installer une prise de courant polarisée. Ne

jamais changer la fiche, d’aucune façon. La double isolation élimine le besoin d’utiliser un

cordon d’alimentation à trois fils et d’une source d’alimentation avec mise à la terre.

b) Éviter le contact corporel avec les surfaces mises à la terre telles que les tuyaux, les

radiateurs, les cuisinières et les réfrigérateurs. Le contact corporel avec les surfaces mises à

la terre augmente le risque de décharge électrique.

c) Ne pas exposer les outils mécaniques à la pluie. Ne pas utiliser les outils mécaniques dans

un endroit humide ou détrempé. L’eau entrant en contact avec un outil mécanique augmente

le risque de décharge électrique.

d) Prendre soin du cordon d’alimentation. Ne jamais transporter un outil en le tenant par le

cordon d’alimentation et ne jamais tirer sur le cordon pour retirer la fiche d’une prise. Tenir le

cordon à l’écart de la chaleur, de l’huile, des arêtes vives et des pièces en mouvement.

Remplacer immédiatement un cordon d’alimentation endommagé. Un cordon d’alimentation

endommagé augmente le risque de décharge électrique.

e) À l’extérieur, utiliser une rallonge électrique de catégorie « W-A » ou « W ». Ces rallonges

sont certifiées pour utilisation à l’extérieur et réduisent les risques de décharge électrique.

3. Sécurité personnelle

a) Demeurer vigilant, être attentif à ce que l’on fait et faire preuve de bon sens lorsqu’on utilise

un outil mécanique. Ne pas utiliser un outil lorsqu’on est fatigué ou sous l’influence de

drogues, d’alcool ou de médicaments. Un moment d’inattention peut être source de graves

blessures corporelles.

b) Porter des vêtements adéquats. Ne pas porter de vêtements amples ou de bijoux. Porter un

filet protecteur pour contenir les cheveux longs. Tenir les cheveux, vêtements et gants à

l’écart des pièces en mouvement. Les vêtements amples, les bijoux ou les cheveux longs

peuvent être happés par les pièces en mouvement. Des gants de caoutchouc et des

chaussures antidérapantes sont recommandés pour les travaux extérieurs.

c) Éviter les mises en marche non intentionnelles. S’assurer que l’interrupteur est à la position

(ARRÊT) avant de brancher un outil. Ne pas transporter un outil avec un doigt sur

l’interrupteur et éviter de brancher un outil dont l’interrupteur est à la position Marche.

d) Prendre l’habitude de s’assurer que les clés de réglage sont retirées avant de mettre l’outil

en marche. Une clé oubliée près d’une pièce mobile ou rotative peut causer des blessures

corporelles.

e) Garder son équilibre. Garder une pose des pieds adéquate et son équilibre en tout temps.

Une pose des pieds adéquate et un bon équilibre assurent un meilleur contrôle de l’outil, en

Français

22

toute situation.

f) Utiliser l’équipement de sécurité adéquat. Toujours porter des lunettes de protection. Utiliser

un masque facial ou anti-poussières si l’activité de coupe génère de la poussière.

4. Utilisation et maintenance de l’outil

a) Fixer la pièce sur laquelle on travaille. Utiliser des serres ou des pinces étau pour fixer la

pièce sur un support stable. L’utilisation de serres ou de pinces étau permet d’utiliser les

deux mains pour manier l’outil. Tenir la pièce à la main ou l’appuyer contre son corps est

une procédure instable qui peut engendrer une perte de contrôle.

b) Ne pas forcer l’outil. L’outil mécanique offre un meilleur rendement et est plus sécuritaire

lorsqu’il est utilisé à l’intensité pour laquelle il a été conçu.

c) Utiliser l’outil approprié au travail. Ne pas utiliser un outil mécanique pour un travail pour

lequel il n’a pas été conçu.

d) Ne pas utiliser l’outil si l’interrupteur ne peut en contrôler la mise en marche ou l’arrêt. Tout

outil ne pouvant être contrôlé au moyen de son interrupteur est dangereux et doit être

réparé. Un interrupteur défectueux doit être remplacé à un centre de service Freud autorisé.

e) Débrancher la fiche de la source d’alimentation quand l’outil n’est pas utilisé, avant sa

maintenance et avant de remplacer ou de changer un accessoire tel qu’une lame, un foret

ou un couteau. Le respect des mesures de sécurité préventives réduit le risque de mise en

marche accidentelle de l’outil et de blessure corporelle.

f) Ranger les outils non utilisés. Les outils doivent être rangés dans un endroit sec, élevé ou

verrouillé et hors de portée des enfants.

g) Prendre soin de ses outils. Garder les outils de coupe aiguisés et propres pour assurer un

meilleur rendement et une meilleure sécurité. Suivre les instructions pour lubrifier l’outil et

changer les accessoires. Inspecter régulièrement le cordon d’alimentation. Un cordon

d’alimentation endommagé doit être remplacé à un centre de service Freud autorisé.

Inspecter périodiquement les rallonges électriques et remplacer les rallonges endommagées.

Tenir les poignées sèches et propres, exemptes d’huile ou de graisse. Les outils

correctement entretenus, dotés de lames bien aiguisées, sont moins susceptibles de bloquer

et plus faciles à contrôler.

h) Vérifier la présence de pièces endommagées. Avant de continuer à utiliser l’outil, un

protecteur ou autre élément endommagé doit être inspecté pour déterminer s’il peut

fonctionner correctement et assurer sa fonction. Vérifier l’alignement des pièces mobiles, le

montage et les autres composants qui peuvent avoir une incidence sur l’utilisation de l’outil.

Un protecteur ou autre composant endommagé doit être réparé ou remplacé à un centre de

service Freud autorisé, à moins d’indication contraire dans le présent manuel d’utilisation.

i) N’utiliser que les accessoires recommandés par le fabricant pour le modèle d’outil utilisé. Des

accessoires adaptés à un outil donné peuvent être source de danger s’ils sont utilisés avec

un autre outil.

5. Service

a) Le service doit être assuré uniquement par un centre de service Freud autorisé. Le service

ou la maintenance exécuté par du personnel non qualifié peut entraîner des risques de

blessure.

b) Pour la maintenance d’un outil, n’utiliser que des pièces de remplacement identiques. Suivre

les instructions figurant à la section Maintenance du présent manuel. L’utilisation de pièces

non autorisées ou le non respect des instructions relatives à la maintenance peut entraîner

des risques de décharge électrique ou de blessure corporelle. Certains produits de

nettoyage tels que l’essence, le tétrachlorure de carbone, l’ammoniac, etc., peuvent

endommager les pièces en plastique.

RÈGLES DE SÉCURITÉ ADDITIONNELLES POUR TOUPIE

• AVERTISSEMENT! Ne pas défoncer de matériaux contenant de l’amiante. La poussière

dégagée lors de la défonce de matériaux contenant de l’amiante et (ou) de la silice contient

des produits chimiques dangereux pour la santé. Éviter d’inhaler cette poussière et se

conformer aux règles de prévention des accidents.

• Bien serrer l’écrou du collet pour éviter que le couteau glisse hors de son logement.

• Pour les coupes de part en part, laisser un espace suffisant sous le matériau coupé pour

permettre le passage du couteau.

• S’assurer que les clés de réglage sont retirées avant de mettre l’outil en marche. Une clé

Français

23

attachée à une pièce rotative de l’outil peut causer des blessures corporelles.

• Ne jamais serrer l’écrou du collet si aucun couteau n’est installé.

• Ne jamais faire une coupe de droite à gauche, cela augmente le risque de perdre le contrôle

de l’outil et peut causer des blessures corporelles.

• Ne jamais travailler à bout de bras. Garder une pose des pieds adéquate et son équilibre en

tout temps pour assurer un meilleur contrôle de l’outil dans les situations imprévues.

• Ne pas perforer le boîtier de cet outil mécanique, cela pouvant détruire le dispositif

d’isolation contre les décharges électriques (utiliser des étiquettes adhésives).

• Toujours débrancher l’outil avant de changer un couteau ou de travailler sur l’outil.

• Pour arrêter l’outil, utiliser toujours l’interrupteur Marche/Arrêt plutôt que de le débrancher.

• AVERTISSEMENT! Avant chaque utilisation, vérifier la fiche et le cordon d’alimentation. S’ils

doivent être remplacés, s’adresser à un centre de service Freud autorisé.

• Toujours tenir le cordon d’alimentation et la rallonge électrique à l’écart de la zone de travail.

• Avant de brancher l’outil, toujours s’assurer que l’interrupteur est à la position Arrêt.

• Toujours tenir fermement l’outil à deux mains et maintenir une position stable ou utiliser une

table pour toupie.

• Régler la vitesse en fonction du diamètre du couteau. Plus le couteau est gros, moins la

vitesse est élevée.

• Les couteaux à toupie doivent être manipulés et entreposés avec le plus grand soin,

conformément aux instructions du fabricant.

• Vérifier soigneusement les couteaux avant de les utiliser pour s’assurer qu’ils ne sont pas

endommagés ou fissurés. Remplacer immédiatement un couteau endommagé ou fissuré.

• S’assurer que le couteau est inséré dans le mandrin conformément aux instructions du

fabricant.

• Avant d’utiliser l’outil, s’assurer que le couteau est correctement inséré et solidement fixé.

Mettre en marche l’outil libre de charge et le laisser tourner quelques secondes en position

sécuritaire. Arrêter immédiatement l’outil si des vibrations anormales sont ressenties ou si un

défaut est décelé.

• Utiliser seulement les collets et écrous de collet approuvés par Freud pour le montage des

couteaux dans le mandrin.

• Avant de procéder à la coupe, s’assurer que le matériau à couper est solidement fixé.

• Se protéger des rognures qui sont éjectées pendant la coupe. Tenir l’outil de façon à ce que

les copeaux soient expulsés dans la direction opposée à l’utilisateur.

• Pour la coupe de matériaux qui peuvent irriter la peau, les yeux ou les voies respiratoires,

utiliser l’équipement de dépoussiérage et porter un masque.

• Pour utiliser l’outil, toujours porter des lunettes de sécurité et des protecteurs auriculaires.

Les autres équipements de sécurité personnelle tels que les masques anti-poussière, les

tabliers et les chaussures antidérapantes doivent être également portés.

• S’assurer que les ouvertures d’aération sont libres de poussière et de débris. Si elles doivent

être nettoyées, débrancher d’abord l’outil et utiliser un aspirateur. Pour éviter d’endommager

les pièces internes de l’outil, ne jamais utiliser d’objets métalliques pour les nettoyer.

• Ne pas toucher aux couteaux quand ils tournent.

• AVERTISSEMENT! Les couteaux continuent à tourner longtemps après que l’interrupteur ait

été mis à la position Arrêt. S’assurer que le couteau a cessé de tourner avant de déposer

l’outil ou de changer les accessoires.

DOUBLE ISOLATION

Pour assurer une utilisation sécuritaire de cet outil, Freud a adopté une solution de conception à

double isolation. « Double isolation » signifie que deux systèmes d’isolation physiquement séparés

ont été utilisés pour isoler le matériel conducteur d’électricité raccordé à l’alimentation du corps

extérieur tenu par l’utilisateur.

Pour préserver l’efficacité du système à double isolation, suivre les précautions suivantes :

• S’assurer de ne pas percer le boîtier du moteur, cela peut nuire à l’efficacité du système à

double isolation.

• Seuls les centres de service Freud autorisés doivent désassembler et assembler cet outil

mécanique et seules des pièces de rechange Freud d’origine doivent être installées.

Français

24

DESCRIPTION ET SPÉCIFICATIONS

Français

DESCRIPTION FONCTIONNELLE

A – Molette de réglage

micrométrique

B – Poignée de réglage

micrométrique

C – Cadran de réglage des

vitesses

D – Interrupteur Marche/Arrêt

E – Poignées de guidage

F – Arbre de rotation

G – Collet

H – Base fixe

I – Clé 22 mm

J

N

O

P

J – Accès au réglage de la

hauteur au-dessus de la table

K – Clé de réglage de la profondeur

L – Accès au réglage de la hauteur

au-dessus de la table

M – Semelle

N – Verrou de l’arbre de rotation (arrêt

pour essieu)

O – Bride de fixation de la base

P – Bouton de dégagement de la base

Q – Accès au blocage du mandrin

R – Levier de blocage

K

B

A

G

C

F

D

H

E

I

L

Q

M

R

25

Français

SYMBOLES

Certains des symboles suivants peuvent être utilisés sur l’outil. Étudier ces symboles et apprendre

leur signification. L’interprétation correcte de ces symboles permet d’utiliser l’outil plus

efficacement et de façon plus sécuritaire.

Symbole Nom Désignation / Explication

V Volts Tension (potentiel)

A Ampères Courant

Hz Hertz Cadence (cycles par seconde)

W Watt Puissance

n

o

Vitesse à vide Vitesse de rotation à vide

.../min Révolutions ou va-et-vient par minute Révolutions, courses, vitesse périphérique,

orbites, etc. par minute

Conception de classe 2 Désigne un outil à double isolation

Courant alternatif (c.a.) Type ou caractéristique du courant

Avertissement de sécurité

Précautions relatives à la sécurité de

l’utilisateur

Alimentation Monophasée 120V, c.a., 60HZ

Intensité 13 ampères

Puissance 1500 watts

Vitesse à vide 10 000 – 23 000 tr/min

Collet 1/4" po et 1/2” po

Diamètre maximal pour couteau 3-1/2" po (89 mm)

Poids 5,4 lbs

SPÉCIFICATIONS

* Pour utiliser des couteaux dont le diamètre est supérieur à 1-1/2" po, la toupie doit être montée sur

une table pour toupie. Pour les couteaux dont le diamètre est supérieur à 2-1/2" po, la semelle de la

toupie doit être enlevée. Voir le manuel d’instruction du fabricant de la table pour toupie pour le

diamètre maximal des couteaux pouvant être utilisés avec la table pour toupie.

26

ASSEMBLAGE ET UTILISATION

AVANT L’UTILISATION

1. Vérifier la source d’alimentation

S’assurer que la source d’alimentation est conforme aux spécifications figurant sur la plaque

signalétique de l’outil. S’assurer que la prise de courant est bien adaptée à la fiche. Une prise

défectueuse peut causer une surchauffe et constituer une source de grave danger.

2. Vérifier l’aire de travail

S’assurer que l’aire de travail est conforme aux précautions énoncées à la section Sécurité du

présent manuel.

3. Avant de brancher l’outil

S’assurer que l’interrupteur de l’outil mécanique

(D) est à la position ARRÊT pour éviter une mise

en marche accidentelle pouvant causer de graves

blessures corporelles.

INSTALLATION ET RETRAIT DES COUTEAUX

(2 CHOIX)

Avertissement! Débrancher l’outil de la source

d’alimentation. Avant de procéder, s’assurer que le

collet choisi est approprié au diamètre de la tige du

couteau.

(Choix 1) – Utilisation manuelle

a) Sur la base du routeur (H), ouvrir la bride de

fixation (O). – Fig. 1a

b) Presser sur le bouton de dégagement de la base

(M) et pousser les poignées de guidage

vers le bas jusqu’à ce que le collet dépasse de la

base. Tourner le levier de blocage (R) jusqu’à ce

que le système de blocage du mandrin (N) soit

engagé. – Fig. 1b

c) Tourner le collet jusqu’à ce que la tige de

verrouillage s’engage dans l’arbre de rotation (F).

Une fois la tige engagée, il n’est plus possible de

tourner l’arbre. – Fig. 1c

d) Au moyen de la clé 22 mm (I) fournie, tourner

l’écrou du collet (G) dans le sens anti-horaire

pour desserrer le collet. – Fig. 1d

Français

Fig. 1a

Fig. 1b

Fig. 1c

1

3

2

27

e) Insérer le couteau et, au moyen de la clé 22 mm,

tourner l’écrou du collet dans le sens horaire

pour resserrer le collet. Toujours s’assurer qu’au

moins 80 % de la tige du couteau est inséré

dans le collet. – Fig. 1e

f) Tourner le levier de blocage (R) jusqu'à ce que le

système de blocage du mandrin (M) soit dégagé.

Presser le bouton de dégagement de la base,

sortir le moteur de la base jusqu’à ce que le

couteau revienne sous la surface de la base et

fermer la bride de fixation de la base.

g) Avant d’utiliser la toupie, suivre les instructions

figurant à la section Réglage de la profondeur de

coupe du présent manuel.

h) Pour enlever un couteau du collet, suivre les

étapes b, c, et d puis retirer le couteau.

AVERTISSEMENT! Avant d’utiliser l’outil, s’assurer

de désengager le verrou de l’arbre de rotation et de

retirer la clé de serrage pour éviter les blessures

corporelles ou d’endommager l’outil.

(Choix 2) – Utilisation avec la table de toupie

La toupie Freud FT1700 peut aussi être montée sur une

table pour toupie. Pour le montage, voir les instructions

fournies avec la table pour toupie.

a) Pour ouvrir la base, insérer la molette

d’ajustement de la hauteur (K) dans le trou de

déblocage de la base situé au dessus de la table

(L) et tourner en sens inverse des aiguilles d’une

montre jusqu’à ce que la molette ne puisse plus

tourner. – Fig. 2a

b) Insérer la molette d’ajustement de la profondeur

dans le trou d’accès d’ajustement de la hauteur

par le dessus de la table (J) et tourner en sens

inverse des aiguilles d’une montre jusqu’à ce que

le collet (G) dépasse complètement au dessus de

la base. – Fig. 2b

c) Insérer la molette d’ajustement de la profondeur

dans le trou d’accès du blocage du mandrin (Q)

et tourner dans le sens des aiguilles d’une

montre jusqu’à l’arrêt complet de la molette.

Tournez le mandrin (F) jusqu’à ce que la cheville

de blocage du mandrin (N) soit engagée. Quand

la cheville de blocage est bien engagée, il est

impossible de tourner le mandrin. – Fig. 2c

d) Utiliser la clé à mandrin de 22mm (I) et tourner

l’écrou en sens inverse des aiguilles d’une montre

Français

Fig. 2a

Fig. 2b

Fig. 1d

Fig. 1e

28

pour desserrer le collet. Si une mèche est déjà

insérée dans le collet, l’écrou se desserrera

après un tour et se serrera de nouveau.

Continuez de tourner l’écrou en sens inverse des

aiguilles d’une montre avec la clé à mandrin

jusqu’à ce que l’écrou soit complètement

desserré. À ce point, la mèche devrait être

relâchée et facile à retirer du collet. – Fig. 2d

e) Pour installer une mèche de toupie, insérer la

mèche dans le collet, et avec la clé à mandrin de

22mm tournez l’écrou dans le sens des aiguilles

d’une montre. Il faut toujours s’assurer que 80 %

de la tige de la mèche de toupie soit insérée dans

le collet sans jamais laisser la tige toucher le

fond du collet. – Fig. 2e

f) Insérer la molette d’ajustement de la profondeur

dans le trou d’accès du blocage du mandrin (Q)

et tourner en sens inverse des aiguilles d’une

montre jusqu’à l’arrêt de la molette. – Fig. 2f

g) 1. Insérer la molette d’ajustement de la

profondeur dans le trou d’accès d’ajustement de

la hauteur par le dessus de la table (J) et tourner

dans le sens des aiguilles d’une montre pour

baisser la mèche de toupie. 2. Bloquer la base

en insérant la molette d’ajustement de la hauteur

dans le trou de blocage, par le dessus de la table

(L) et tourner dans le sens des aiguilles d’une

montre jusqu’à ce que la molette ne puisse plus

tourner. – Fig. 2g

h) Avant d’utiliser la toupie, assurez vous de suivre

les directives dans la section du manuel ‘Ajuster

la profondeur de coupe afin de bien régler la

profondeur de coupe.

AVERTISSEMENT! Avant d’utiliser l’outil, s’assurer

de désengager le verrou de l’arbre de rotation et de

retirer la clé de serrage pour éviter les blessures

corporelles ou d’endommager l’outil.

Français

Fig. 2c

Fig. 2d

Fig. 2e

Fig. 2f

Fig. 2g

29

AJUSTER LA PROFONDEUR DE COUPE

AVERTISSEMENT! Débrancher l’outil de la source

d’alimentation.

(Choix 1) – Utilisation manuelle

a) Ouvrir la bride de fixation de la base (O). –Fig. 3a

b) En s’assurant que la toupie est bien à plat et au

niveau, tourner la poigné de réglage

micrométrique (B) jusqu’à ce que le couteau

entre en contact avec la surface de travail.

- Fig. 3b

c) Tournée la poignée de réglage micrométrique

dans le sens horaire jusqu’à la position désirée

(une rotation complète déplace le couteau de 1/8

de pouce).

d) Fermer la bride de fixation de la base (O).

(Choix 2) – Utilisation avec la table de toupie

a) Pour ouvrir la base, insérer la molette

d’ajustement de la hauteur (K) dans le trou de

déblocage de la base situé au dessus de la table

(L) et tourner en sens inverse des aiguilles d’une

montre jusqu’à ce que la molette ne puisse plus

tourner. – Fig. 4a

b) Insérer la molette d’ajustement de la profondeur

dans le trou d’accès d’ajustement de la hauteur

par le dessus de la table (J). Tourner la molette

dans le sens inverse des aiguilles d’une montre

pour monter la mèche et tourner en sens des

aiguilles d’une montre pour baisser la mèche.

– Fig. 4b

c) Quand la mèche est ajustée à la profondeur de

coupe désirée, bloquer la base en insérant la

molette d’ajustement de la hauteur dans le trou

de blocage, par le dessus de la table (L) et

tourner dans le sens des aiguilles d’une montre

jusqu’à ce que la molette ne puisse plus tourner.

–Fig. 4c

Français

Fig. 3a

Fig. 3b

Fig. 4a

Fig. 4b Fig. 4c

30

MONTAGE DES GUIDES POUR GABARIT

AVERTISSEMENT! Débrancher l’outil de la

source d’alimentation.

Pour le toupillage avec gabarit, la toupie Freud

FT1700 accepte les guides pour gabarit standards

vendus séparément. Pour utiliser les guides pour

gabarit, un anneau adaptateur (FT1100) offert en

option doit être fixé à la semelle au moyen de deux

vis à filets interrompus (fournies). Enlever les vis à

filets interrompus de la semelle et placer l’anneau

adaptateur, le côté plat face au corps de la toupie.

Mettre les vis et les serrer pour fixer l’anneau.

– Fig. 5

La semelle (L) a été centrée en usine. Cependant, si

la semelle a été enlevée puis replacée, certains

ajustements peuvent être requis pour centrer le

guide autour du couteau. Pour ajuster, desserrer les

quatre vis qui fixent la semelle à la toupie,

repositionner la semelle et serrer les vis.

INSTRUCTIONS D’UTILISATION

AVERTISSEMENT! S’assurer que la tension de

la source d’alimentation correspond à celle indiquée

sur l’outil. Avant de brancher l’outil, s’assurer que le

couteau est correctement inséré et fixé et qu’il

tourne librement.

Démarrage de l’outil

a) Brancher l’outil, l’interrupteur à la position

Arrêt.

b) Tenir fermement la toupie avec les deux

mains, le couteau à l’écart de l’utilisateur et

placé de façon à ce qu’il ne touche pas à

la surface de travail, au corps de

l’utilisateur ou aux vêtements.

c) Démarrer l’outil en glissant l’interrupteur

dans la direction indiquée sur l’outil. – Fig. 6

d) Arrêter l’outil en glissant l’interrupteur dans

la direction opposée.

Réglage de la vitesse de rotation

AVERTISSEMENT! Toujours débrancher la

toupie avant de régler la vitesse.

La toupie Freud FT1700 est munie d’un dispositif

électronique de réglage de la vitesse de rotation.

– Fig. 7

Ce dispositif permet de sélectionner un nombre

quasi infini de vitesses allant de 10 000 à 23 000

tr/min. Pour ajuster la vitesse, tourner le cadran de

réglage de la vitesse (C). Voir les instructions du

fabricant des couteaux pour la vitesse

recommandée.

Le dispositif électronique de réglage de la vitesse

maintient une vitesse constante. Si la vitesse du

moteur diminue pendant l’utilisation, il est possible

que la capacité de charge de l’outil ait été excédée.

Le cas échéant, le moteur peut surchauffer et être

endommagé. Pour réduire la charge, réduire la

profondeur de coupe et faire plusieurs passes et (ou)

ralentir la coupe.

Français

Fig. 5

Fig. 6

ON

OFF

Vis de la

semelle

Vis de l’anneau

adaptateur

Vis de la

semelle

Vis de la

semelle

Vis de la

semelle

Fig. 7

31

APPLICATIONS DE COUPE

Avant d’utiliser l’outil, prendre en compte le

type de matériau et la quantité de matériau à

retirer. Avant de procéder à la coupe, faire

des coupes d’essai sur du matériau de rebut.

AVERTISSEMENT! Toujours bien fixer la

pièce à couper avant de procéder.

Vu du dessus de la toupie, le couteau tourne

dans le sens horaire. Pour les coupes sur les

bords extérieurs, déplacer la toupie dans le

sens anti-horaire, de gauche à droite.

– Fig. 8a

AVERTISSEMENT! Ne jamais faire une

coupe de droite à gauche (dans le sens de

rotation de la toupie) – Fig. 8b. Cela

augmente le risque de perte le contrôle de

l’outil et peut causer des blessures

corporelles

MONTAGE SUR TABLE

La toupie Freud FT1700 peut aussi être montée sur une table pour toupie. Pour le montage, voir

les instructions fournies avec la table pour toupie.

Français

Fig. 8b

INCORRECT

Fig. 8a

CORRECT

Truc : Pour l’ajustement des bords sur les

quatre côtés, commencer par le bout de

bois. Si des écornures se produisent à la fin

de cette coupe, elles seront éliminées avec

la coupe effectuée sur la rive (dans le sens

du grain).

Commencer

32

MAINTENANCE ET INSPECTION

Service

Il est recommandé que toute activité de maintenance de l’outil Freud soit

exécutée par un centre de service Freud autorisé. Les interventions effectuées

par du personnel non autorisé peuvent engendrer des défauts de mise en

place ou d’assemblage des composants internes causant un défaut de

fonctionnement de l’outil et constituant un risque de blessure corporelle pour

l’utilisateur.

Cordon d’alimentation

S’assurer que le cordon d’alimentation est en bon état. Un cordon

d’alimentation endommagé doit être immédiatement remplacé à un centre de

service Freud autorisé.

Lubrification

Tous les outils mécaniques requièrent soins et attention. Tous les deux ans, ou

au besoin, nous recommandons de laisser l’outil à un centre de service Freud

autorisé pour un nettoyage complet et sa lubrification.

Ouvertures d’aération

S’assurer que les ouvertures d’aération demeurent propres et non obstruées.

Nettoyer à l’air comprimé les ouvertures bouchées. Il est recommander de

nettoyer l’outil à l’air comprimé après chaque utilisation.

Roulements à bille

Tous les deux ans, ou au besoin, les roulements à bille doivent être inspectés

par un technicien Freud autorisé. Les roulements à bille bruyants doivent être

remplacées pour éviter la surchauffe et les pannes de moteur.

Inspection des accessoires

Inspecter régulièrement les accessoires utilisés avec la toupie. Des

accessoires endommagés ou émoussés réduisent l’efficacité de l’outil et

peuvent endommager son moteur.

Inspection des vis

Inspecter périodiquement toutes les vis pour s’assurer qu’elles sont bien

serrées. Les vis mal serrées doivent être immédiatement resserrées.

Français

33

Points de service

Pour connaître le centre de service Freud autorisé le plus près, composer le

numéro sans frais 1-800-334-4107 ou visiter notre site Web à l’adresse

www.freudtools.com.

Au Canada, composer le 1-800-263-7016 ou visiter notre site Web canadien

pour obtenir la liste complète de nos centres de service : www.freud.ca.

Accessoires standards :

• Clé pour écrou du collet

• Clé pour réglage de la profondeur de coupe

• Collets 1/4" et 1/2" pouce

• Adaptateur pour balayeuse

• Boîtier de transport

Français

ACCESSOIRES

34

Français

GARANTIE LIMITÉE POUR OUTIL MÉCANIQUE FREUD

GARANTIE DE 90 JOURS OU ARGENT REMIS

Si, dans les quatre-vingt-dix (90) jours suivant l’achat initial, vous n’êtes pas entièrement satisfait de

votre outil mécanique Freud, pour quelque raison que ce soit, vous pouvez le retourner, dans son

emballage d’origine et avec tous les accessoires, au magasin où vous l’avez acheté. Pour obtenir un

remboursement complet, présentez une preuve d’achat (par exemple, un reçu daté).

GARANTIE LIMITÉE DE CINQ ANS

Freud garantit à l’acheteur initial que chaque nouvel outil mécanique Freud demeure exempt de défaut

de fabrication et matériel pour une période de cinq (5) ans à compter de la date d’achat. Une preuve

d’achat (par exemple, un reçu daté) est requise pour les réparations sous garantie. Si l’outil s’avère

défectueux dans les quatre-vingt-dix (90) jours suivant la date d’achat, il sera remplacé ou réparé, AU

CHOIX DU CLIENT, conformément aux modalités ci-dessous. Passée la période de 90 jours, Freud,

après vérification du défaut de fonctionnement, à son choix, réparera ou remplacera l’outil,

conformément aux modalités ci-dessous. La présente garantie ne couvre pas les dommages causés par

les réparations effectuées ou tentées par qui que ce soit d’autre que le personnel Freud autorisé ou

résultant de l’usure normale, d’une utilisation abusive, d’un manque de maintenance ou d’un accident.

MODALITÉS DE LA GARANTIE FREUD

1. En cas de bris ou de défaut de fonctionnement, retourner le produit, adéquatement emballé et port

payé, à Freud à l’adresse indiquée ci-dessous ou à un point de service Freud autorisé. Pour obtenir des

conseils techniques, des instructions pour le retour ou la liste des points de service autorisés, composez

le 1-800-334-4107 aux États-Unis ou le 1-800-263-7016 au Canada.

2. Toutes les garanties implicites applicables aux outils mécaniques Freud (INCLUANT LA QUALITÉ

MARCHANDE ET L’ADAPTATION À UN USAGE PARTICULIER) sont limitées aux trois (3) années suivant

la date de l’achat initial. Certains États ou provinces n’autorisant pas les restrictions relatives à la durée

des garanties implicites, la présente restriction peut ne pas s’appliquer.

3. Toute réclamation au titre de la garantie se limite à la réparation ou au remplacement, tel qu’énoncé à

la garantie limitée Freud relative aux outils mécaniques. En aucun cas Freud peut-elle être tenue

responsable d’autres dommages, coûts ou dépenses directs, indirects ou consécutifs. LES PERTES

INDIRECTES ET LES DOMMAGES CONSÉCUTIFS SONT EXCLUS DE TOUTE GARANTIE. Certains

États ou provinces n’autorisant pas les restrictions relatives aux pertes indirectes et dommages

consécutifs, la présente restriction peut ne pas s’appliquer.

4. Les garanties Freud accordent au titulaire des droits spécifiques reconnus par la loi. Selon l’État ou la

province, le titulaire peut jouir d’autres droits qui peuvent varier d’un État ou province à l’autre.

5. Les garanties Freud ne peuvent être réputées avoir failli à leur objet premier alors que Freud est

disposée à réparer ou remplacer les produits défectueux.

6. Freud n’assume aucune responsabilité ou obligation quant aux défauts ou dommages causés par

l’utilisation abusive ou la mauvaise utilisation d’un produit ou par les interventions de maintenance non

autorisées. Le produit doit avoir été utilisé aux fins recommandées et ne pas avoir été modifié de

quelque façon que ce soit. Les garanties Freud ne couvrent pas l’usure normale d’un produit.

7. Toute poursuite pour inobservation de garantie doit être entreprise dans l’année suivant le dépôt de la

réclamation.

8. Toutes les garanties sont expressément limitées au consommateur acheteur initial. Toutes les

garanties et autres droits de l’acheteur sont régis en vertu des lois de l’État de la Caroline du Nord,

abstraction faite des principes inhérents aux conflits de lois.

Pour obtenir du service en vertu de la garantie limitée pour outil mécanique Freud, communiquez

avec un point de service autorisé ou avec :

Freud America, Inc.

(Attn: Technical Service)

218 Feld Avenue

High Point, North Carolina 27263

1-800-434-4107

Freud Canada

(Attn: Technical Service)

7450 Pacific Circle

Mississauga, Ontario L5T 2A3

Canada

1-800-263-7016

© Copyright 2007, Freud America, inc. Tous droits réservés.

GARANTIE EN AMÉRIQUE DU NORD

35

NOTES:

Français

36

INSTRUCCIONES DE OPERACIÓN

Español

ATENCION: Para reducir el riesgo de accídentes, el usuario debe leer y comprender las

Instrucciónes de Operación antes de usar este producto.

FT1700VCE 21/4 HP FRESADORAS

37

SEGURIDAD

ATENCIÓN: Lea y entienda todas las instrucciones. El no leer las instrucciones de abajo puede

resultar en choque eléctrico, fuego y/o heridas serias.

GUARDE ESTAS INSTRUCCIONES

REGLAS GENERALES DE SEGURIDAD

1. Area de trabajo

a) Mantenga su área de trabajo limpia y bien alumbrada. Las mesas de trabajo llenas de cosas

y las áre as oscuras invitan accidentes que pueden resultar en heridas corporales.

b) No opere herramientas eléctricas en atmósferas explosivas, tales como en la presencia de

líquidos inflamables, gases o polvo. Las herramientas eléctricas crean chispas que pueden

prender fuego en presencia de polvo o gases.

c) Mantenga a los transeúntes, niños y visitantes alejados mientras opera una herramienta

eléctrica. Las distracciones pueden ocasionarle pérdida del control.

2. Seguridad Eléctrica

a) Las herramientas con aislamiento doble están equipadas con un cable polarizado (una hoja

del en chufe es más grande que la otra). Este enchufe encajará en la toma polarizada de

electricidad de una sola manera. Si el enchufe no encaja bien en el tomacorrientes, voltee

el enchufe. Si todavía no en caja,contacte a un electricista calificada para instalar un toma

corrientes polarizado. No altere el en chufe de ninguna forma. El aislamiento doble elimina

la necesidad de un cable de tres líneas con po lo a tierra y del sistema que provee polo a

tierra.

b) Prevenga el contacto corporal con superficies que tocan el suelo tales como tuberías,

radiadores, registros y refrigeradores. Existe un incremento del riesgo de choque eléctrico si

su cuerpo está en contacto con el suelo.

c) No exponga las herramientas eléctricas a la lluvia. Tampoco las utilice en lugares húmedos

o moja dos. El agua que entre en la herramienta aumentará el riesgo de choque eléctrico.

d) No abuse del cable. Nunca cargue la herramienta por el cable o jale el cable para halar el

enchufe de un receptáculo. Mantenga el cable alejado del calor, aceite, bordes afilados o

partes móviles. Reemplace los cables dañados inmediatamente. Los cables dañados

aumentan el riesgo de choque eléctrico.

e) Al operar una herramienta eléctrica afuera, use un cable de extensión marcado “W-A” o

“W”. Estos cables están clasificados para uso exterior y reducen el riesgo de choque

eléctrico.

3. Seguridad Personal

a) Permanezca alerta, observe lo que está haciendo y use el sentido común al operar una

herramienta eléctrica. No opere una herramienta cuando esté cansado o bajo la influencia

de drogas, alcohol o medicamentos. Un momento de desatención al operar una herramienta

eléctrica puede resultar en heridas corporales serias.

b) Use ropa apropiada. No utilice ropa floja o joyas. Use un protector de pelo para cubrir el

cabello largo. Mantenga su pelo, ropa y guantes alejados de las partes móviles. La ropa

floja, joyas o cabello largo pueden atascarse en las partes móviles. Guantes de hule y

calzado antideslizante son recomenda dos para trabajar en exteriores.

c) Evite el encendido inintencionado. Asegúrese que el interruptor esté apagado antes de

conectarlo. No cargue herramientas con el dedo en el interruptor o conecte herramientas

que tienen el interruptor encendido.

d) Forme el hábito de chequear para ver si las llaves de ajuste fueron removidas de la

herramienta antes de ser encendida. Una llave que fue dejada en una parte rotatoria de la