Fresh Breeze GmbH

XCitor

X-Wing Evo

Owner's Manual

Service Booklet

Version 2.1

Date: 26.11.2013

Fresh Breeze GmbH

© Fresh Breeze GmbH

Fresh Breeze GmbH works continuously to develop and further improve all models. You will

appreciate that we must therefore reserve the right to alter any part of the model and its equipment or

technical specifications at any time. No legal commitment can therefore be implied by the information,

illustrations or descriptions in this Manual.

You should therefore regularly visit our website: www.fresh-breeze.de

There you will find additional information relating to your model and any changes to the Manual. The

date and version number of the Manual are given on the first page.

Express written consent from Fresh Breeze GmbH is required for any duplication of this Manual, in whole or

in part (with the exception of short quotations in specialist articles), and in any form or by any means,

whether it be electronic or mechanical.

No claim arises to the product descriptions, common or trade names or other intellectual property by virtue of

the fact that this Manual has been made available.

WARNING

This paratrike must be used within the limits and according to the instructions

in this manual. The manual must be on board during flying.

Read manual before first flight!

Fresh Breeze GmbH

Foreword

Thank you for choosing the XCitor.

The XCitor combines the latest technology with numerous features for your enjoyment

and safety and convenience. To help you get the best out of these features in everyday

use, we recommend that you read this Manual carefully so you can quickly become

familiar with your paratrike in detail.

As well as information on how to use the controls and equipment, the Owner's Manual

contains important notes on care and maintenance. These are relevant to your safety and

will help preserve your paratrike's value. The Manual also offers useful flying tips and

advice, together with some suggestions on how to fly your paratrike.

In addition to this Owner's Manual, the Service Booklet also includes the Service

Schedule for your paratrike. It contains important information on Fresh Breeze service

requirements and lists the trike's fuel consumption figures.

Should you have any further questions regarding your XCitor or if you suspect that your

owner's literature is not complete, please contact your Fresh Breeze dealer or importer.

They are always glad to answer your queries and note any suggestions you may have.

We wish you safe and enjoyable flying with your XCitor.

Fresh Breeze GmbH

Fresh Breeze GmbH

Contents

NOTES ON THIS OWNER'S MANUAL .............................................................................. 9

M

ANUAL

............................................................................................................................ 9

F

RESH BREEZE AND THE ENVIRONMENT

.................................................................................... 9

Respect for nature and the environment .................................................................... 9

Environmentally-friendly recycling............................................................................ 10

XCITOR ........................................................................................................................ 11

01 TECHNICAL EXPLANATION ...................................................................................... 11

G

ENERAL LAYOUT

............................................................................................................... 11

Features .................................................................................................................... 11

T

ECHNICAL DATA

................................................................................................................ 12

P

ERFORMANCE DATA

.......................................................................................................... 12

Air speed ................................................................................................................... 12

Take off distance ....................................................................................................... 12

Landing distance ....................................................................................................... 12

Climb rate.................................................................................................................. 12

Range ........................................................................................................................ 12

Cross wind ................................................................................................................. 12

Noise ......................................................................................................................... 12

Tire pressure.............................................................................................................. 12

Maximum altitude..................................................................................................... 13

Screw tightening torque............................................................................................ 13

O

PERATION LIMITS

............................................................................................................. 13

Permitted Maneuvers................................................................................................ 13

Air speed ................................................................................................................... 13

E

NGINE

............................................................................................................................ 13

Fuel............................................................................................................................ 13

Engine Operation ...................................................................................................... 14

Engine instrumentation............................................................................................. 14

Fresh Breeze GmbH

W

EIGHT, CENTER OF GRAVITY

............................................................................................... 14

02 STANDARD PROCEDURES ....................................................................................... 15

S

ET UP AND TEAR DOWN FOR TRANSPORTATION AND FLYING

...................................................... 15

Safety issues for ground transportation.................................................................... 15

D

AILY INSPECTION

.............................................................................................................. 15

Check prior to flight................................................................................................... 16

Engine ....................................................................................................................... 16

M

AINTENANCE AND CARE

.................................................................................................... 16

P

ERIODICAL CHECKS

............................................................................................................ 17

Every 25 hours........................................................................................................... 17

Every 100 hours......................................................................................................... 17

Every 2 years ............................................................................................................. 17

O

BLIGATION OF REGULAR CHECKS

.......................................................................................... 17

S

TANDARD PROCEDURES, CHECKLISTS, ENGINE START

................................................................ 17

On the panel................................................................................................................ 1

Beside the panel ........................................................................................................ 19

Engine start procedure.............................................................................................. 19

Rolling on the ground................................................................................................ 20

Take off and climb..................................................................................................... 20

Cruise......................................................................................................................... 21

Landing...................................................................................................................... 21

Engine shut off .......................................................................................................... 21

Checklist prior to start ............................................................................................... 21

F

LIGHTS UNDER SPECIAL CONDITIONS

..................................................................................... 22

Rain ........................................................................................................................... 22

Wind.......................................................................................................................... 22

In flight turbulences .................................................................................................. 22

Flights in snowy conditions ....................................................................................... 22

Extreme temperatures .............................................................................................. 22

S

PECIAL REMARKS

.............................................................................................................. 22

03 EMERGENCY PROCEDURES ..................................................................................... 24

E

NGINE FAILURE

................................................................................................................ 24

E

NGINE START DURING FLIGHT

.............................................................................................. 24

S

MOKE OR FIRE ON BOARD

................................................................................................... 24

F

LYING WITH THE ENGINE SHUT OFF

....................................................................................... 25

F

ORCED LANDINGS

............................................................................................................. 25

L

OSS OF DIRECTIONAL CONTROL

............................................................................................ 25

Fresh Breeze GmbH

X-WING EVO................................................................................................................ 26

04 SAFETY.................................................................................................................... 26

S

AFETY NOTICES

................................................................................................................. 26

D

ISCLAIMER, EXCLUSION OF LIABILITY AND OPERATING LIMITS

..................................................... 26

F

OR YOUR SAFETY

.............................................................................................................. 27

T

YPES OF USE

.................................................................................................................... 28

Winch launch............................................................................................................. 28

Aerobatics ................................................................................................................. 28

05 X-WING EVO FEATURES .......................................................................................... 29

D

ESCRIBTION

.................................................................................................................... 29

S

USPENSION SYSTEM

.......................................................................................................... 29

T

ECHNICAL DATA

.................................................................................................................. 1

06 SETTING UP THE X-WING EVO AND TEST-FLYING .................................................... 31

B

EFORE THE FIRST FLIGHT

.................................................................................................... 31

A

DJUSTING THE MAIN BRAKE LINES

........................................................................................ 31

F

IRST FLIGHT

..................................................................................................................... 32

07 FLYING THE X-WING EVO ........................................................................................ 34

PRE-

FLIGHT CHECK AND LAYING OUT THE PARAGLIDER

............................................................... 34

6-

POINT CHECK

.................................................................................................................. 34

U

SE OF THE TRIM SYSTEM

.................................................................................................... 34

T

AKE OFF, CRUISE AND LANDING

........................................................................................... 36

F

LYING UNDER TURBULENT CONDITIONS

................................................................................. 36

L

ANDING WITH ENGINE SHUT OFF

.......................................................................................... 36

L

ANDING WITH HELP OF ENGINE

............................................................................................ 37

N

ORMAL FLIGHT

................................................................................................................ 37

R

APID DESCENTS

................................................................................................................ 37

Spiral dive.................................................................................................................. 37

08 DANGEROUS SITUATIONS AND EXTREME FLYING................................................... 39

D

ANGEROUS SITUATIONS

..................................................................................................... 39

Safety training........................................................................................................... 39

Material stress and damage ..................................................................................... 39

C

OLLAPSING THE PARAGLIDER

............................................................................................... 39

Asymmetric collapse ................................................................................................. 39

Asymmetric collapse with tangling ........................................................................... 40

Fresh Breeze GmbH

Front stall .................................................................................................................. 40

T

YPES OF STALL

.................................................................................................................. 40

Deep stall .................................................................................................................. 41

Full stall ..................................................................................................................... 41

Spin............................................................................................................................ 42

O

THER TIPS FOR DANGEROUS SITUATIONS

............................................................................... 42

Deep stall in rain ....................................................................................................... 42

Advertising and adhesives......................................................................................... 43

Overloading............................................................................................................... 43

Sand and salt air ....................................................................................................... 43

Temperature range ................................................................................................... 43

09 STORING AND LOOKING AFTER THE PARAGLIDER................................................... 44

S

TORING THE PARAGLIDER

................................................................................................... 44

Packing the paraglider .............................................................................................. 44

Storing and transporting the glider........................................................................... 45

L

OOKING AFTER THE PARAGLIDER

.......................................................................................... 46

Fabric......................................................................................................................... 46

Lines .......................................................................................................................... 46

Rigid construction ..................................................................................................... 47

Cleaning .................................................................................................................... 47

10 REPAIRS AND INSPECTIONS .................................................................................... 48

T

YPE DESIGNATION

............................................................................................................. 48

R

EPAIRS

........................................................................................................................... 48

Fresh Breeze workshops ............................................................................................ 48

Small repairs to the glider ......................................................................................... 48

R

EGULAR INSPECTIONS

........................................................................................................ 48

Lines .......................................................................................................................... 48

I

NSPECTION

...................................................................................................................... 49

General...................................................................................................................... 49

Inspection periods ..................................................................................................... 49

Validity of inspection................................................................................................. 49

Inspection by the pilot ............................................................................................... 49

11 APPENDIX ............................................................................................................... 50

F

RESH BREEZE WEBSITE

....................................................................................................... 50

Product registration .................................................................................................. 50

A

DDRESSES

....................................................................................................................... 50

O

WNER’S MANUAL VERSIONS

.............................................................................................. 51

Version 2.0 ................................................................................................................ 51

Fresh Breeze GmbH

MAINTENANCE AND SERVICE BOOKLET....................................................................... 52

R

EPAIRS

........................................................................................................................... 52

L

OCATION OF SIGNBOARDS AND FRAME NUMBER

..................................................................... 52

12 X-WING EVO ........................................................................................................... 53

G

LIDER DETAILS

................................................................................................................. 53

P

ILOT DETAILS

/ P

ROOF OF OWNERSHIP

.................................................................................. 53

X-W

ING EVO

– I

NSPECTIONS AND REPAIRS OVERVIEW

.............................................................. 55

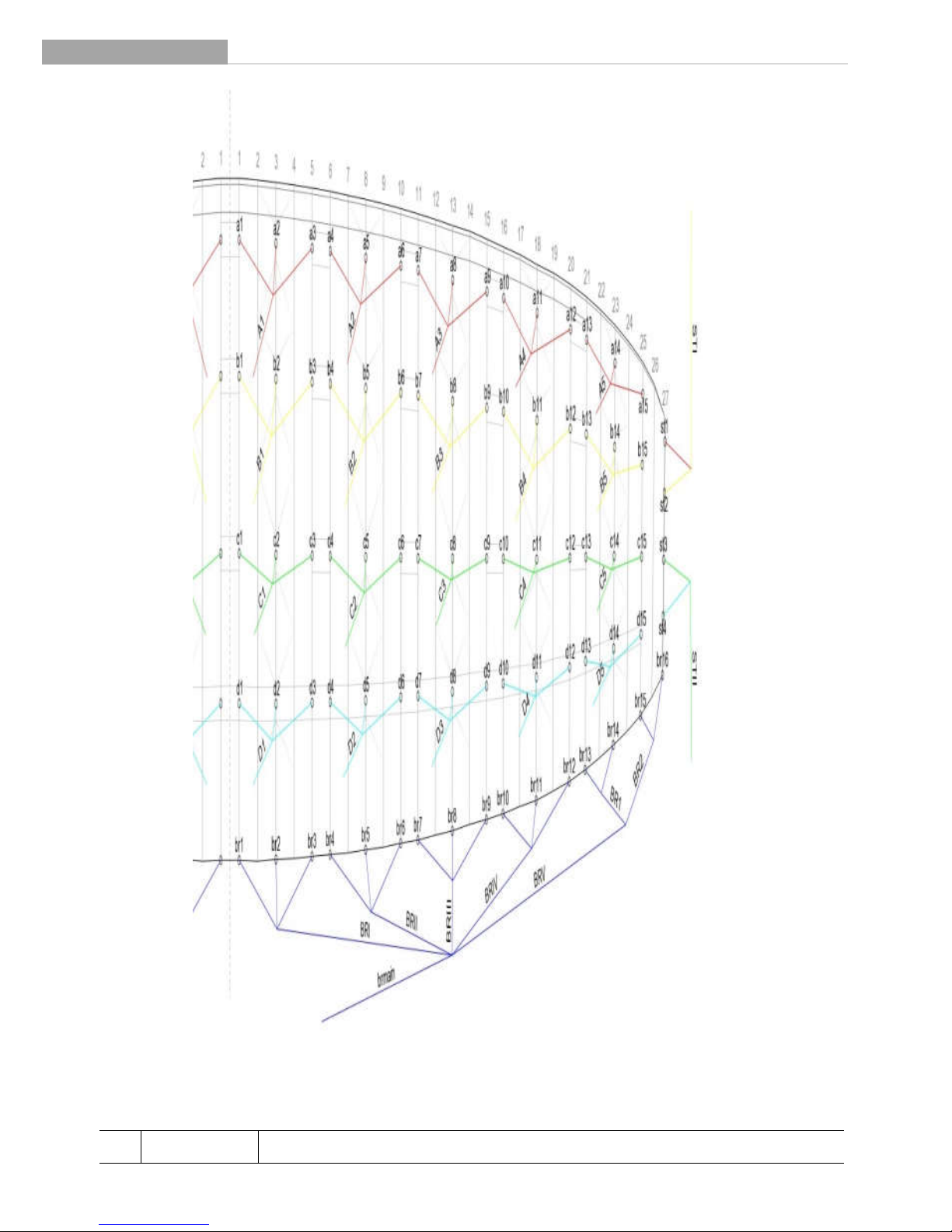

L

INE LAYOUT

..................................................................................................................... 55

M

ATERIAL LIST

.................................................................................................................. 57

L

OAD AND SHOCK TEST REPORT

............................................................................................. 59

13 XCITOR ................................................................................................................... 60

W

EIGHT AND BALANCE

........................................................................................................ 60

Procedure .................................................................................................................. 60

W

EIGHT AND BALANCE SHEET

............................................................................................... 61

E

QUIPMENT LIST

................................................................................................................ 62

XC

ITOR TRIKE

– M

AINTENANCE OVERVIEW

............................................................................. 63

Fresh Breeze GmbH

Notes on this Owner's Manual Section 0 9

Notes on this Owner's

Manual

Manual

This Owner's Manual contains important

information, tips, suggestions and warnings. We

recommend that you familiarise yourself with

your new paratrike by reading this Manual

before your first flight. This will allow you to

acquaint yourself its new functions, to learn the

best way to fly the paratriker in various

situations, and explain how to get the best out of

your XCitor.

The Manual complies with the airworthiness

requirements in LTF NFL II 91/09 and forms

part of the certification.

Please ensure that this Owner's Manual is always

available to anyone else flying the XCitor, i.e.

anyone renting, borrowing or buying the model

from you.

This manual describes the equipment available

for the XCitor at the time of going to print.

Some of the equipment described here will not

be available until a later date, or may only be

available in certain markets.

Some sections of this Owner's Manual do not

apply to all models. If this is the case, a text at

the start of the section indicates which models it

applies to.

Illustrations are intended as a general guide,

and may vary from the equipment fitted in your

XCitor in some details.

At the beginning of this Owner's Manual, you

will find a table of contents showing all the

items described in this manual in the order in

which they appear.

All references to positions such as “left”,

“right”, “front” or “rear” are given as seen facing

in the direction of travel.

* optional equipment

The section is continued on the following

page.

Denotes the end of a section.

® Registered trademarks are marked ®.

However, the absence of this symbol does

not constitute a waiver of the rights

concerning any proprietary name.

⇒

Refers to a “WARNING” within the same

section. If the WARNING symbol is followed

by a page number the warning text referred to is

included in a different section.

WARNING

Texts with this symbol contain

safety information. They warn you of

serious dangers, possibly involving

accident or injury.

Caution

Texts with this symbol draw your attention to a

possible risk of damage to your paratrike.

Note

Texts with this symbol contain additional

information of a more general nature.

Fresh Breeze and the environment

Protection of the environment, safety and quality

are the three basic values of Fresh Breeze GmbH

and these have implications on everything we

do. We also believe that our customers share our

environmental awareness.

Respect for nature and the

environment

You can easily play a part in protection of the

environment by practising our sport in such a

way that there is no damage to nature and the

areas in which we fly. Take your rubbish away

Fresh Breeze GmbH

10 Section 0 Notes on this Owner's Manual

with you, refrain from making unnecessary noise

and respect the sensitive biological equilibrium

of nature. Consideration for nature is required

even at the launch site!

Flying a paratrike is, of course, an outdoor sport

– protect and preserve our planet’s resources.

Environmentally-friendly recycling

Fresh Breeze gives consideration to the entire

life cycle of its paratrikes, the last stage of which

is recycling in an environmentally-friendly

manner. The synthetic materials used in a

paraglider must be disposed of properly. If you

are not able to arrange appropriate disposal,

Fresh Breeze will be happy to recycle the

paraglider for you. Send the glider with a short

note to this effect to the address given in the

Appendix.

Fresh Breeze GmbH

Technical Explanation Section 1 11

XCitor

01 Technical Explanation

General layout

Features

Paratrike with steerable front wheel

Frame made of T.I.G. welded aluminium

tube

Tandem seater

Springy landing gear, 150 mm travel, cable

operated front brake

Two stroke in-line engine Hirth 3503 with

electric ignition, motor management and

electronic injection system

Four-blade propeller 1665 mm, Type HTC

CCQW-3B-167,5-CG 4 Blade

Paraglider: technical description see

X-Wing Evo section

Fig. 1: 3D side views of XCitor

Fresh Breeze GmbH

12 Section 1 Technical Explanation

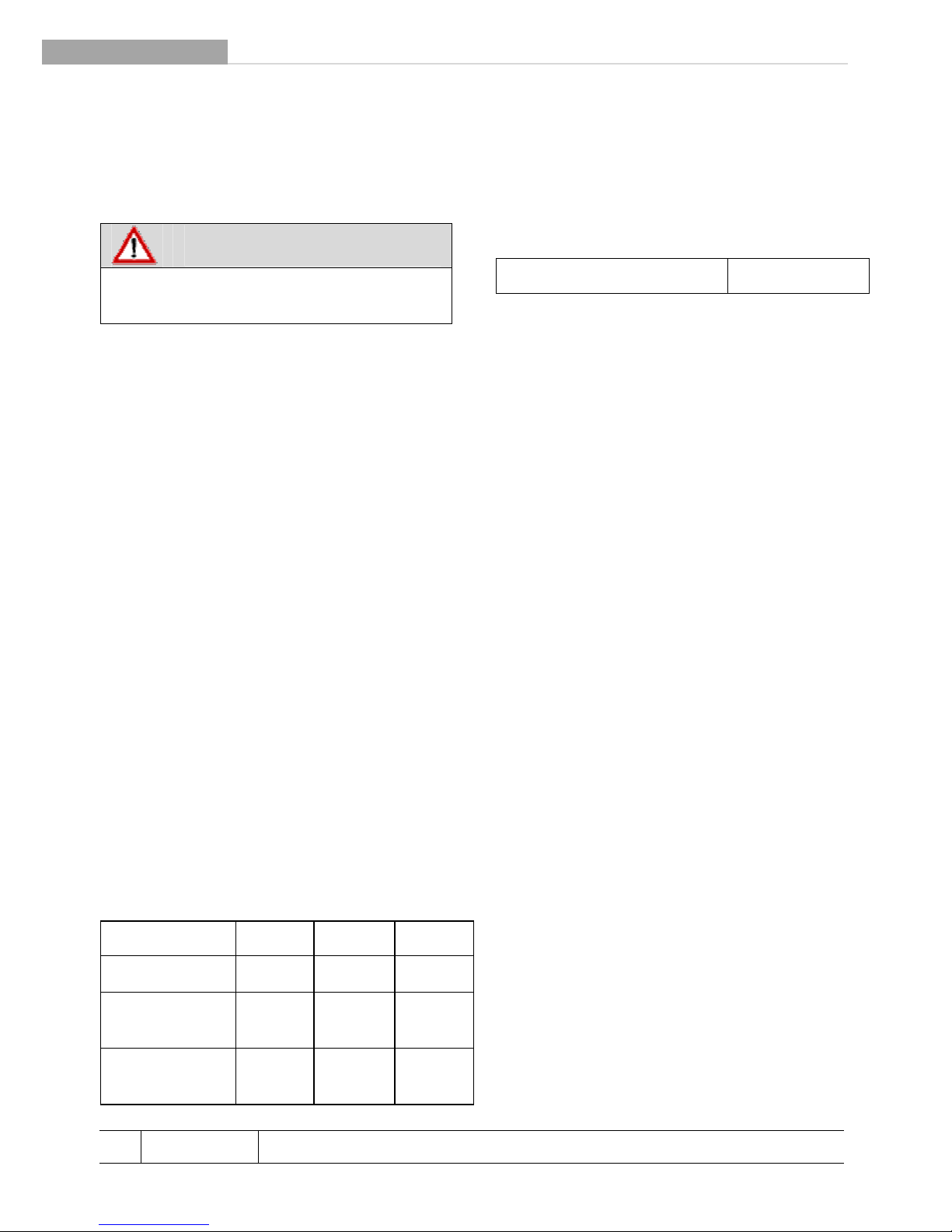

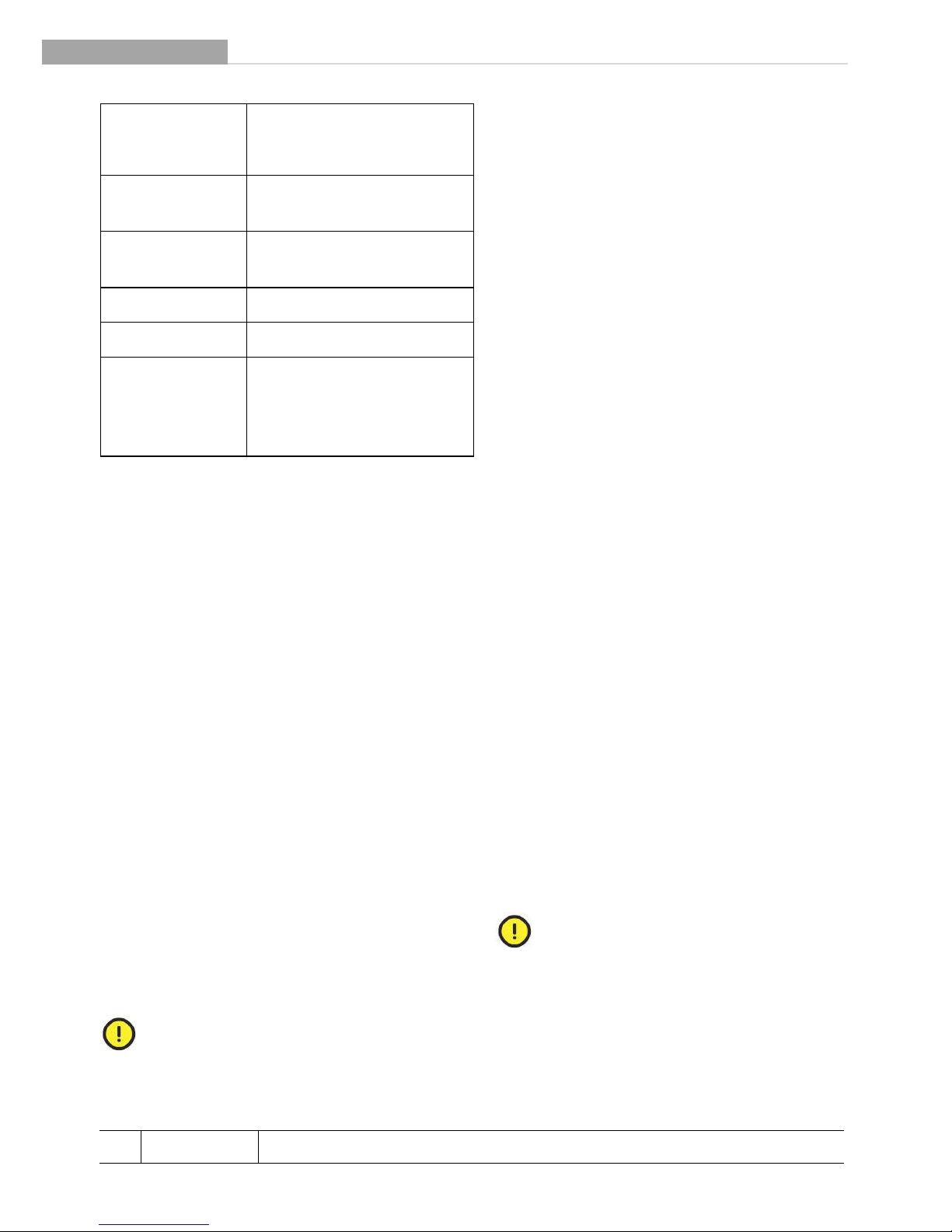

Technical data

Length 3,17m

Height 2,00m

Width 1,91m

Empty weight 168kg

Payload 200 kg

Take off-weight (max.) 383 kg

Fuel capacity 28 L

Performance data

The following figures were achieved in flight

tests. They are based on a good general shape of

the trike, the wing and the engine and that the

pilot has an average skills.

They are valid under standard conditions (mean

sea level, standard pressure, 15°C, no wind,

maximum take off weight 383 kg, even runway

with short grass in a good shape). Higher

altitude, higher temperatures and lower air

pressure reduce those performance figures.

Air speed

Minimum speed 30 km/h

Manoeuvre speed 65 km/h

Permitted maximum speed 73 km/h

Take off distance

Take off distance 20-150 m (depends

on load and wind

speed)

Take off distance about a

15m obstacle

200m

Landing distance

Landing distance 10 - 30 m with

brakes

Landing distance about a

15m obstacle

150 m

Climb rate

single 4,0 m/sec

tandem 2,5 m/sec

Range

The range is depending on the fuel consumption,

which is much higher at higher air speeds.

The best consumption can be achieved flying

slightly faster than the best gliding speed. This

gives a range of ca. 200 km at an air speed of 65

km/h.

Cross wind

The maximum allowed cross wind component

during take off and landing is 8 km/h.

Noise

The XCitor fulfils the German noise

requirements for ultralight paratrikes which

means that it is quieter than 60 dB(A) flying in

150 m altitude.

Tire pressure

Rear wheels 2,0Bar

Front wheel 1,5 Bar

Fresh Breeze GmbH

Technical Explanation Section 1 13

Maximum altitude

The maximum altitude depends on the load and

temperature. It is defined by a climb rate smaller

than 0.5 m/sec. This height is roughly 3000 m.

Screw tightening torque

Propeller HTC CCQW-3B166,5-CG 4-Blade

24 Nm for M8

Operation Limits

This chapter contains information about the

operational limits for the safe use of the XCitor.

These data are the result of flight tests as well as

of theoretical calculations.

Beside this limits check also carefully the limits

of the X-Wing Evo in Section 04 Safety

Flying under icing conditions are not permitted.

No flying under squally wind conditions or at

high wind speeds of more than 20 km/h (=5,6

m/sec), or if rain comes up.

Permitted Maneuvers

The XCitor is designed for safe loads between +

4 G maximum and + 0,5 G minimum load.

WARNING

The XCitor is – as any other ultralight

airplane – not certified for aerobatics.

Any aerobatic manoeuvres as wells as roll

angles of more than 60° during e.g. curves

or spirals are NOT PERMITTED!

Air speed

The given values are standing for the Indicated

Air Speed (IAS), referring to the air speed

sensor located in the front section of the trike.

Max. allowed speed 73 km/h

Max. travel speed 70 km/h

Maneuver speed 65 km/h

Min. recommended

approach speed

40 km/h

Minimum speed 35 km/h

The maximum allowed speed must not be

exceeded. Full brake use is only permitted until

the maximum maneuver speed. If you are faster

don’t apply the brake too fast or completely.

Engine

Manufacturer Hirth

Type 3503

Takeoff power 70 PS @ 6200 U-1

Constant power 65 PS @ 6000 U-1

Cylinder head

temperature

max. 110°C

Propeller HTC CCQW-3B-

166,5-CGt

Blade angle 24° bei 75%

(= 625mm radius)

WARNING

Don’t use the engine without propeller with

more than idle speed. Otherwise the engine

might be destroyed due too high rpm.

Fuel

The engine is operated with 2-stroke-mix 1:100.

The engine maker recommends unleaded 95

ROZ or more. For a short time AVGAS 100LL

or MOGAS can be used as well. Under very hot

conditions the use of AVGAS is better as the

risk of steam bubbles is less.

Fresh Breeze GmbH

14 Section 1 Technical Explanation

The 2-stroke-oil should be a high-quality

synthetic oil (at least API: TC res. Jaso FC or

ISO EGD).

As an alternative BlueMax-2stroke oil 1:100

may be used as well.

WARNING

Never use fuel without oil! Use fresh, clean

and water free fuel.

Engine Operation

Engine start procedure: Move the main switch to

the upper „on“ position. Now the fuel pump is

running.

Start the engine by pressing the red push button

or by using the pull starter on the right side of

the engine. If the engine is cold the injection

system can by activated (you can hear it for ca.

0.5 sec) with the gas pedal. Also if the engine is

cold the gas pedal should be pressed down a

little bit (but not that much that the injection

system is running again).

Shutdown: Just move the main switch to the

lower “off” position.

The 2-stroke engine needs no warm up – once if

it running full power may be applied at any time.

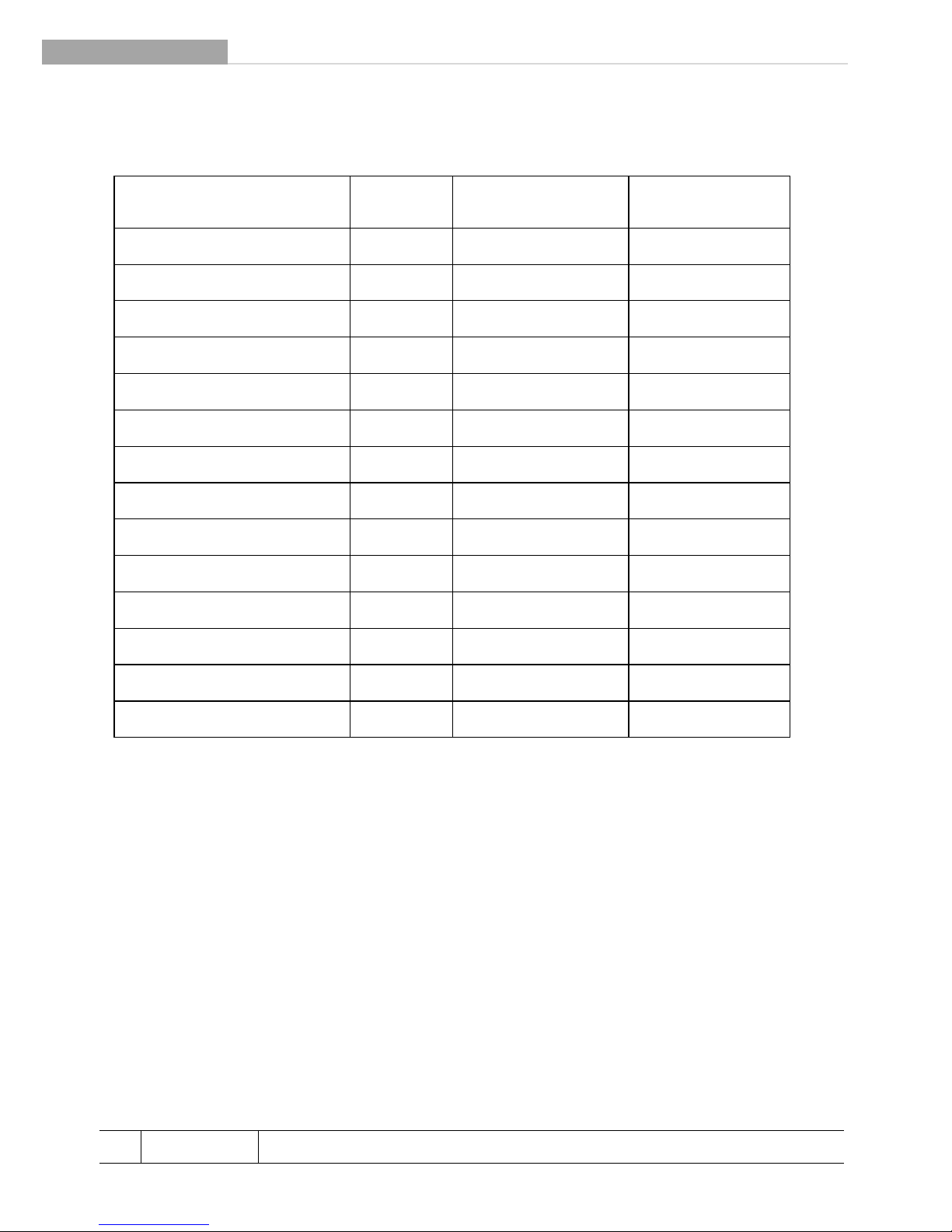

Engine instrumentation

The following figures must not be exceeded:

Value Range Max. Unit

Rev. per minute 0-9999 6200 Rpm

Water

temperature

40-120 110 °C

EGT (Exhaust

Gas Temp.)

100-800

700 °C

Weight, center of gravity

The maximum legal take off weight of the

XCitor is 383 kg including pilots, fuel and

luggage. If any equipment is added afterwards

the payload must be reduced accordingly. The

pilot is responsible to maintain these limits.

Maximum take off weight 383 kg

The allowed range of the center of gravity (CG)

must not be exceeded.

If only one person is flying the XCitor the front

seat must be used. The pilot weight must be

more than 45 and less than 100 kg.

The rear seat may be loaded with minimum 0

and maximum 100 kg.

The CG must be located somewhere between 50

mm in front of the paraglider attachment and 50

mm aft this attachment point (refer to chapter

11, weight and balance).

This is important to keep the nod angle of the

trike in the correct range with a maximum of ±

10°, measured between ground and the upper

side of the engine mount.

Fresh Breeze GmbH

Standard procedures Section 2 15

02 Standard procedures

This chapter contains checklists and procedures

for standard use.

Set up and tear down for

transportation and flying

This is how to prepare the XCitor for flying, if it

was hauled to the airfield:

1. Remove the cable tree from the car and take

the XCitor of the trailer clutch

2. Remove tarpaulin and propeller protectors.

3. Remove the cable tree from the XCitor,

remove the light bar, stow both things

outside the trike.

4. Take the wing out of the trike, put it beside

it, take it out of its stuff bag.

5. Lay it as usually behind the trike, upside

down, trailing edge showing to the XCitor.

6. Check the way of all lines from the

attachment point at the trike to the wing. Put

the lines between prop cage and cable

binder. Pull the trike forward to straighten

and tighten the lines (never drive with speed

into the canopy).

7. Move the trim levers into a vertical position,

don’t start in an accelerated configuration.

Trim levers should therefore never be in

their rear position!

Tear down happens in the opposite order.

You are not allowed to trailer the trike faster

than 80 km/h. The towing vehicle must have a

minimum permissible drawbar load of 25 kg.

Road transportation is only permitted with

tarpaulin and propeller protectors.

Safety issues for ground

transportation

Prior to towing on public roads a safety check

has to be carried out. This check is similar to the

pre-flight check procedure.

In particular the main frame has to be checked

for cracks, especially in the area of the coupling

tube.

The rear axles must be checked as well, the

safety wire on the central wheel screw, the rear

rims, and the three wheel bolts on each side.

In case of a hard landing the rims could be

deformed slightly, causing the wheel bolts to

settle and to become loose.

The tire pressure must be between 2 and 2.5 bar

Daily inspection

We want to point out that nearly all technical

defects can be recognized early enough during a

conscientious and precise preflight-check.

Therefor we ask you to do the check in a correct

manner in your own interest.

Flight safety depends mainly on correct checks

and maintenance procedures.

1. Engine: Check for any leakage, loose

screws, cracks etc.

2. Propeller: Check correct sit, tight screws and

for damage.

3. Check oil and cooling agent level. The oil

level of the gear box must be in height of the

little gauge glas. Use gear oil SAE 80 GL 4

or GL5.

Cooling agent must be visible in the

transparent expansion bottle.

4. Check the gear box, the cooling system and

the fuel system for any leakage. Especially

check the tube connections.

5. Check the electrical connectors, the spark

plug socket, the gas cables and the bowden

cable distributor for a tight sit and

mechanical integrity.

Fresh Breeze GmbH

16 Section 2 Standard procedures

6. If your XCitor is equipped with an additional

gas pedal for teaching purpose. Make sure

that this gas pedal is not locked and at its

idle position.

Caution

The main switch must be shut off. A trained

person must be in the pilot seat.

Note

It is not possible to crank the engine via the

propeller as there is a centrifugal clutch in

between. If the motor shall be turned by hand

use the pull starter.

7. Check the paraglider: No dangled or

damaged lines.

No visible damages at the canopy, no tears

or stretched areas.

8. The attachment points of the wing should be

firmly clamped to the bent main tubes of the

XCitor frame.

9. Check the suspension system and the wheels

for any damage, especially the bungee cords

for abrasion and any cuts.

10. Check of the front brake

11. Check both trim levers: They must be

moveable with a given friction resistance (57 kg).

12. Pedals and bowden cables freely movable.

13. Does the gas pedal return to it’s idle

position, when unloaded? Therefore you

make check the gap between the idle setting

screw and the bowden cable segment under

the left side of the longitudinal engine

mount.

14. Check the seat board and the belts for

tightness, correct sit and damage

15. Tires: Check for damage and correct air

pressure (1,8-2,5 bar rear & front)

16. Main gear: Check rubber bearings, screws,

alu fittings for wear and tear

17. Lift off the front wheel, check if it can be

turned freely

Check prior to flight

Prior to any flight the responsible pilot has to

carry out a visual inspection.

The pilot learns the necessary knowledge during

his flight training and during a special briefing

for the XCitor, done by the dealer or flight

school who sells the trike.

Check especially the following points:

Engine

Propeller for correct sit, tight screws and

any damage

Manual engine cranking via pull starter,

check for free movement and unusual noise.

Muffler and exhaust system, connection

springs for tight sit.

Cooling agent must be visible in the

transparent expansion bottle.

Caution

When the motor is turned by hand for check

purpose the main switch must be switched off! A

trained person should be in the pilot seat of the

XCitor. If nobody else is available: Double

check very carefully the correct stop position

(lower position) of the main switch!

Put your left leg in front of the right rear wheel

so that the trike cannot start to roll when pulling

the starter rope!

Maintenance and care

Keep the XCitor and it’s wing clean and dry.

Don’t use any aggressive solvents.

Fresh Breeze GmbH

Standard procedures Section 2 17

Use grease or engine oil wherever metal slides

over metal (rear suspension struts).

Never use grease or oil between metal and

plastic (front struts): The plastic will swell!

Use there silicone based lubricants instead.

Never use grease or oil or something similar on

the upper bearing of the trim levers. The bearing

screw must be tightened so much that 5-7 kg

must be applied until the lever starts to move.

Periodical checks

Every 25 hours

Visible inspection of all screws

Play and the free movement of any

moveable parts like wheels, suspension

system, trim levers etc.

Lubrication of those parts:

Metal to Metal: grease or engine oil,

Metal to plastic: silicone spray

Friction force in the trim lever bearing: The

correct force to move the lever should be 57 kg at the handle.

Front brake

Gear oil level (glass gauge)

All bowden cables

All belts, belt buckles, guide rollers

Optical check of all weld seams for any

cracks

All rubber-metal-joints for cracks

Cooling agent level

Tension check of the water pump tension

Tightness check of the cooling system

(leakage, water loss)

Every 100 hours

Same as 25h-Check, plus:

Spark plug change (Denso W24FSR or

equal)

Gear oil change, gear oil according to SAE

80 API GL4 or 5

Every 2 years

Same as 100h-check, plus:

Cooling agent change, water with cooling

additive (protection against freezing and

corrosion)

Change of the water pump belt if there is

visible tear or damage

Replacement of all damaged or torn parts

The Hirth-2-stroke-engine requires no oil change

(beside the gear). Every 600 hours we

recommend a general overhaul at its maker

Hirth.

The ballistic recovery system requires a special

maintenance according to the additional manual.

Obligation of regular checks

In Germany this trike must be checked once a

year. This check must be carried out by a class 5

inspector. A list of certified inspectors can be

retrieved from the “DULV e.V.” (German

Ultralight Association).

The canopy is subject of this check as well. The

inspector may decide if the wing has to be

checked by its manufacturer or not (typically

every 2 years)

Standard procedures, checklists,

engine start

Whenever the engine is started somebody has to

be in the front seat, being able to operate the

cockpit.

Fresh Breeze GmbH

18 Section 2 Standard procedures

Fig. 2: 3D of XCitor cockpit

The picture below shows the position and the

purpose for the individual elements of the

cockpit.

The following tables describes the functions of

these elements:

On the panel

Name

Number Positions

Main Switch 1 ON OFF

Interkom 2

Refer to its separate manual

Water temperature

4

Between 80 and 105°C

Fresh Breeze GmbH

Standard procedures Section 2 19

Beside the panel

Engine start procedure

Main Switch ON. Charge light on.

Gas pedal Cold engine: kick pedal

50&down until fuel is

Name Positions Purpose

Gas pedal Up / down Giving gas with the right foot

Brake pedal Up / down Braking of the front wheel with the left foot

Trim lever Fore / aft Works like the brake line: In order to fly faster pull both levers

aft, for curve flying push inner lever fore

Cruise gas lever Fore / aft Used for gas setting during cruise. With the gas pedal only more

gas than set with the cruise gas can be applied, never less!

Control (brake)

lines

(not) pulled

down

Used to steer the canopy especially during take off, landing and

under turbulent conditions

Fresh Breeze GmbH

20 Section 2 Standard procedures

injected for ca. ½ sec. Can

be heard. Then don’t give

any gas at all.

Warm engine: Kick pedal

slightly down, ca. 10%.

Cruise gas lever During engine start this

lever MUST be at IDLE.

Propeller Danger zone free.

Brake pedal Kick down and hold.

Electric starter Press starter push button

until the engine starts gets

alive. If necessary give a

little bit gas.

Rolling on the ground

Get used to the XCitor’s ground behaviour by

roll tests on the ground. Do that in any case

before attempting to fly. Ground control is

achieved via the foot steerable front wheel. In

the air it is controlled via the canopy, either with

the trim levers or the brake lines. During take off

the XCitor steering and the X-Wing Evo steering

must be properly coordinated.

Take off and climb

Whenever it is possible take off directly against

the wind. The maximum permitted side wind

vector is 8 km/h.

Lay the X-Wing Evo behind the XCitor, upside

down, trailing edge towards the trike. Put the

lines into the holders (cable binders) beside the

cage. Check all lines for any tangles and knots

and being parallel.

Get into the XCitor, fasten seat belts, tighten

them.

Caution

The rear seat has 3 belt buckles! All 3 must be

closed prior to start! Not closing the buckles on

both sides will cause the front seat to move

forward when the front belt is loaded! So the

front belt cannot hold without the rear buckles

being closed!

Move the trim levers into a vertical position.

Check their bearing for being not to loose (the

friction force to move the handles – measured at

the handles) must be between 5-8 kg!).

Check wind direction and that the glider is

laying correctly behind the XCitor.

Take the brake lines into your hands.

Start the engine (see the corresponding chapter).

Open the foot brake.

Increase rpm until the glider can be pulled up

(depending on the wind: ca. 50% of the

maximum power)

Keep the rolling direction with your feet.

As soon as the canopy comes up steer it active

with the brake lines and keep it centred behind

and above the XCitor. Prevent the X-Wing Evo

from shooting over by applying some brake.

Stabilize the glider above the trike. Keep on

rolling.

Check the position of the canopy. If necessary

steer the XCitor to the side and drive under the

canopy, if the wing is pulling too much to the

side.

If the glider is centred over the trike and

everything under control apply more gas (full, if

flying tandem). The XCitor will very soon take

off.

Flying solo control the power carefully and

reduce gas slightly after the take off:

Caution

The XCitor has much excessive power for solo

flights and may push you into a quite steep flight

position, which you may not be used to!

Fresh Breeze GmbH

Standard procedures Section 2 21

Cruise

Even during climb you may trim the XCitor to a

straight flight with the trim levers. Just push the

lever on the side you want to move to slightly

forward. Remember, the brake lavers act like a

brake line – pushing them forward makes the

XCitor move into that direction. Vice versa the

other lever may be pulled back.

Under normal flight conditions the brake lines

may be just set free so that the trim levers can be

operated easily.

The trike can be accelerated by pulling both trim

levers back at the same time. This is like

opening the brake lines.

If due to the torque of the propeller the trike flies

a curve just push he right lever fore until the

XCitor flies straight (the left side is loaded more

then the right, causing the right trike side

hanging down slightly more than the left:

therefore the trike wants to fly to the left side).

Cruise speed is between 45 and 75 km/h

depending on the rpm setting between 4200 and

5000 and on the trim setting and the total weight.

The most economical speed is roughly 65 km/h

depending on the load.

The maximum allowed speed (VNE) is 73 km/h

and must never be exceeded.

Under turbulent conditions the XCitor is not

allowed to fly faster than 65 km/h (manoeuvre

speed VA).

The fuel consumption is somewhere between

8l/h at low speeds (55 km/h) up to roughly 10l/h

at 70 km/h.

Landing

Any landing has to be made against the wind.

Reduce power and push both trim levers into a

slow position (vertical or a little bit slower).

Take both brake lines into the hands, but don’t

brake yet. Start to tighten the brake lines in 5-8

m height. Flare out, starting at 1-2m, with

continuously applying more brake. If you made

a perfect landing you should just apply full brake

if you touch the ground.

If you flared out being too high support the

descent with gas.

Being on the ground you may open the brake

lines again, wind them 1-2 times around your

hand, and brake again to make the glider falling

down behind the trike. If it is windy you may

repeat this procedure.

If the wind is quite strong apply the front brake

carefully, so that the glider can move with the

wind backwards and fall down.

Engine shut off

Gas pedal up to idle.

Main switch off.

Leave the trike only after the propeller has come

to a complete stop as it may run longer than the

engine due to the centrifugal clutch.

Checklist prior to start

Canopy laid out properly?

Lines straight and in parallel?

lines clipped into the cable binder at the

cage side?

Trim levers in a vertical position, and

clamped tight enough (5-7 kg)?

Cruise gas lever (and the teacher gas pedal,

if any) at idle position?

Enough fuel on board?

Seat belts fastened?

Helmet?

Prop free?

Wind not too strong and from ahead?

Brake lines close at hand?

Fresh Breeze GmbH

22 Section 2 Standard procedures

Flights under special conditions

Rain

Basically each conscientiously done flight

planning contains a weather check. So in

principle no flights under rainy conditions

should become necessary. Anyway, every pilot

may get into unforeseeable worse weather

conditions.

If the rain is only very light, the flight may be

continued for a certain time. But the wet canopy

will get heavier. Therefore flight speed will

increase, causing a higher stall speed as well.

With a wet wing fly carefully, avoid sudden

manoeuvres, and don’t be too slow when

landing.

If the rain gets stronger land! No flights in

strong rain!

Never stow a wet canopy away. It will

deteriorate. A wet canopy will also come up

during take off much slower and worse.

Wind

In general every take off and every landing has

to be made against the wind. Move always the

X-Wing Evo into the wind. If the XCitor has to

be rolled against the wind at an angle, the

leeward brake should be pulled slightly to keep

the wing on course.

If under strong wind conditions has to b landed

apply after touch down the front brake so that

the XCitor will not roll back. Prior to landing

you should wind up the brake lines around your

hands so that you have enough travel to make

the glider fall down behind the trike.

If the brake travel is not sufficient you may

release the brake and wind it up around your

hands one or two turns more. Repeat until the

glider is down.

It may help if the brake is slightly released so

that the XCitor rolls back with the wind in a

controlled manner.

In flight turbulences

Don’t fly under thermal conditions with

maximum speed. This will cause high wing

loads and also a small angle of attack. This will

cause the canopy to fold in easier, if suddenly

wind comes from above.

The best choice is a vertical position for the trim

lever.

Flights in snowy conditions

They are not permitted at all. In case ist starts to

snow during flight the flight must be cancelled.

Extreme temperatures

There are no „normal“ temperatures (between –

10 and +50° C) where limitations occur.

But you have to make sure that the cooling agent

is mixed accordingly to the manufacturers

instruction. At high temperatures keep watching

the water temperature carefully.

In addition the required power and the required

flight speed increases, so that the take off

distance gets longer than in winter. This is

similar to flights in high altitudes.

Special remarks

The XCitor has a unique trim system providing a

fully operational backup system for steering via

the brake lines.

Only for take off and landing the brake lines

should be used as they provide more feedback

and a quicker response.

Due to the clockwise running propeller the

XCitor will bank slightly to the left and therefore

fly a wide left curve.

Fresh Breeze GmbH

Standard procedures Section 2 23

Pushing the trim lever on the right side into a

more fore position than the one on the left side

will counteract that.

But even narrow curves are possible just with

the trim system. Due to the propeller torque

curves to the left side will be narrower than

curves to the side (as long as you fly with engine

power).

Caution

Don’t steer with the brake to the same side as

you do already with the trim system! Both inputs

will be added causing steep curves with bank

angles outside the limit of 60°. They can be

controlled and finished – that was proven in

flight tests – but this may be difficult for

inexperienced pilots.

Also high G loads will occur during such narrow

curves. If you try to push just the (outer) trim

lever forward this may be very difficult due to

the high wing loads. In this case use the brake

lines to stop the curve. Then – if still desired –

the trim levers can be moved as usual.

Note

Make sure that during the start check the correct

friction force of the trim levers was checked (5-8

kg!). If the move significantly easier they may

be pulled back during high G manoeuvres into

the fast position. When flying in a narrow curve

anyway (via the brake line) this may cause an

unexpected narrowing of the curve radius,

increasing speed at the same time.

This curve must be finished with the brake line

as it may require much force to move the trim

lever forward again.

Note

Avoid to fly curves with the trim system in

addition to the brake lines into the same

direction.

If one trim lever moves back due to too light

movement and high G loads counteract the

resulting curve with the brake line.

Fresh Breeze GmbH

24 Section 3 Emergency procedures

03 Emergency procedures

As already mentioned in chapter ‘Certification’,

engines for ultralight airplanes don’t have to be

certified accordingly to aeronautical standards

due to cost reasons.

Therefore you have to be aware that such an

engine may quit at any time. Please keep that

always in mind!

Caution

Fly only having always a plan in mind where to

land in case of a forced landing. Train flying and

landing with the engine shut off. Get familiar

with the glide ratio of your XCitor.

Only if you do so you will never get into a

situation which will surprise and overextend

you.

Engine failure

If the engine of your XCitor quits suddenly and

unexpected we recommend the following

procedures:

During take off roll,

not airborne yet:

Keep direction, and

brake the XCitor

At take off, in the air: Straight landing

Being higher than 80

m:

If necessary make a

flat curve to land the

XCitor against the

wind.

In flight, being

higher than 100m:

Search for a suitable

landing field, watch

wind direction and

speed. Try to land

against the wind or up

the hill.

Over trees or high

grass etc.:

Land as if the surface

of the plants would be

the runway. Land as

slow as possible.

Rough running

engine, power loss

May indicate an iced

carburettor.

Watch rpm, emergency

landing

Note

Fresh Breeze could never notice any case of

carburettor icing even at typical icing conditions

(0 - 4°C, high humidity) due to the injection

system. But this is no warranty at all!

Engine start during flight

Engine start during flight can be easily done.

Switch the main switch on and press the starter

button. Everything else as described in chapter

‘Engine operation’.

Smoke or fire on board

In case of smoke or fire on board we recommend

the following procedures:

Fire at the engine on

the ground:

Leave the trike as soon

as possible.

Fire at the engine

during take off:

Emergency landing,

leave the trike as soon

as possible.

Fire at the engine

during flight:

Emergency landing,

leave the trike as soon

as possible.

Fresh Breeze GmbH

Emergency procedures Section 3 25

Flying with the engine shut off

The speed of the best glide ratio is somewhere

between 55 and 65 km/h depending on the wing

load.

The glide ratio without running engine is

roughly 1:4, at idle speed 1:5.

The best glide ratio is achieved if the trim levers

are in a slow position (vertical or even more

forward).

Forced landings

There are emergency landings in case of e.g. an

engine failure and safety landings in case of e.g.

an upcoming thunderstorm.

Landings without running engine are easier if

the trim system is set to “slow” (vertical or more

forward).

In case of a tire failure (pressure loss) try to

touch down as slow as possible, using the front

wheel for direction control.

Flaring as usual, in case it may be helpful to

wind the brake lines around your hand to

increase the travel of the brake line.

Loss of directional control

As the XCitor can be controlled either via the

conventional brake lines or the newly developed

trim system it is very unlikely that both systems

will fail completely.

If the ability to steer is reduced try to make flat

and wide curves.

If the brake lines fail flare out using the trim

system, supported with some gas.

Fresh Breeze GmbH

26 Section 4 Safety

X-Wing Evo

This chapter is about the X-Wing Evo, the wing

of the XCitor trike. Pilots should have at least a

basic knowledge about paragliding from their

flight school courses. Therefore the manual only

focus on the specialties of the canopy and its

suspension system.

The X-Wing Evo was designed as a part of the

XCitor system together with the newly designed

trim system, all components were carefully

adjusted for maximum performance and safety.

Therefore the glider can only be flown on the

XCitor and the XCitor is not allowed to be used

with any other wing as long as Fresh Breeze

does not provide any other information.

If there are any questions left which are not

covered by this manual please contact your local

dealer.

04 Safety

Safety notices

Safety notices are issued when defects arise

during use of a paraglider which could possibly

also affect other gliders of the same model. The

notices contain instructions on how the affected

gliders can be inspected for possible faults and

the steps required to rectify them.

Fresh Breeze publishes on its website any

technical safety notices and airworthiness

instructions which are issued in respect of Fresh

Breeze products. We will also send you safety

notices directly by email if you have registered

your product.

WARNING

The paraglider owner is responsible for

carrying out the action required by the

safety notice.

Safety notices are issued by the certification

agencies and also published on the relevant

websites. You should therefore visit on a regular

basis the safety pages of the certification

agencies and keep up-to-date with new safety

notices which cover any products relating to

paragliding (refer to Appendix for addresses).

Services such as RSS are also

available which allow internet users

to follow various websites and

changes to them without having to

access them individually. This

allows much more information to be followed

than was previously the case.

Disclaimer, exclusion of liability

and operating limits

Use of the paraglider is at the pilot’s own risk!

The manufacturer cannot be held liable for any

personal injury or material damage which arises

in connection with Fresh Breeze GmbH or

which occurs in connection with the XCitor and

its components like the X-Wing Evo. The

certification and warranty shall be rendered

invalid if there are changes of any kind (incl.

paraglider design or changes to the brake lines

beyond the permissible tolerance levels) or

incorrect repairs to the glider, or if any

inspections are missed (annual and 2-yearly

check).

Pilots are responsible for their own safety and

must ensure that the airworthiness of the glider

is checked prior to every flight. The pilot should

launch only if the paraglider is airworthy. In

addition, when flying outside of Germany, pilots

must observe the relevant regulations in each

country.

The glider may only be used if the pilot has a

licence which is valid for the area or is flying

under the supervision of an approved flying

instructor. There shall be no liability on the part

of third parties, in particular the manufacturer

and the dealer.

Fresh Breeze GmbH

Safety Section 4 27

In terms of the warranty and guarantee

conditions, the paraglider may not be flown if

any of the following situations exists:

the inspection period has expired, or the

inspection has been carried out by the pilot

him/herself or by an unauthorised inspector

the take-off weight is not within the

permissible weight range

the glider is flown in rain or drizzle, cloud,

fog and / or snow

the canopy is wet

there are turbulent weather conditions or

wind speeds on launch higher than 20km/h

air temperature below -10°C and above 50°C

the glider is used for aerobatics/extreme

flying or flight manoeuvres at an angle

greater than 60°

the pilot has insufficient experience or

training

the pilot has incorrect or inadequate

equipment (reserve, protection, helmet etc.)

the glider is used for winch-launching

there have been modifications to the canopy,

lines or risers which have not been approved

the glider is opened in free fall - this is not a

parachute

For your safety

Prudence and risk-awareness are basic

requirements for the safe practice of paragliders,

for the very reason that it is so easy to learn and

practically anyone can do so. Carelessness and

overestimating one’s own abilities can quickly

lead to critical situations. A reliable assessment

of conditions for flying is particularly important.

Paragliders are not designed to be flown in

turbulent weather. Most serious accidents with

paragliders are caused by pilots misjudging the

weather for flying.

In Germany, paragliders are subject to the

guidelines for air sports equipment and must not

under any circumstances be flown without a

valid certification. Any attempt to fly without

proper training is highly dangerous. Independent

experimentation is strictly prohibited. This

Manual does not replace the need to attend

training at a paragliding school.

A specialist must test-fly and inspect the

paraglider before your first flight. The test-flight

must be recorded on the paraglider information

label.

When you fly for the first time, fly under the

supervision of a flight instructor and in a well

known area. For this flight and for all other

flights, you must wear an approved helmet,

gloves, firm shoes and suitable clothing. Only

fly if the wind direction, wind speed and current

and forecasted weather conditions guarantee a

safe flight.

The Manual must be passed on to any new

owner if the XCitor or X-Wing Evo is sold. It is

part of the certification and belongs with the

model.

Observe the other specific safety advice in the

various sections of this Manual.

Flying with a wet canopy or when it is raining or

snowing is prohibited; it may cause the glider to

stall.

Do not under any circumstances alter the

construction of your paraglider. If you do so, any

claims under the warranty will not be accepted

and the certification will lapse.

WARNING

The safety advices and instructions

contained in this Manual must be followed

in all circumstances. Failure to do so shall

render invalid the certification and/or result

in loss of insurance cover, and could lead to

serious injuries or even death.

Fresh Breeze GmbH

28 Section 4 Safety

Types of use

The paraglider may only be used for the purpose

for which it is designed. Any use other than as

intended is not permitted. Do not under any

circumstances use the paraglider as a parachute.

Winch launch

The X-Wing Evo does not have certification for

winch launch. Do not under any circumstances

tow the X-Wing Evo with a car, motorboat, a

winch or any similar device.

Aerobatics

Aerobatics are prohibited in Germany. The

XCitor is not designed for any aerobatics

including banking angles of more then 60°.

WARNING

Any type of acrobatic manoeuvre at all on

the XCitor is contrary to law and illegal.

The pilot would be putting his/her life at

risk. Acrobatics involves a risk of

unpredictable flight attitudes, which could

lead to damage to material and structural

failure.

Fresh Breeze GmbH

Features Section 5 29

05 X-Wing Evo features

Describtion

The X-Wing Evo is a paraglider which was

especially designed to fit the XCitor trike.

Together with the newly designed suspension

system it was tested and certified within the

limits as described in the technical data section

by the Air Turquoise SA (official test laboratory

of Switzerland) and DGAC.

The X-Wing Evo is either controlled as usual

using brake lines or by a newly developed trim

system, which can be used as well to

compensate the propeller-induced torque.

Shifting the connection point between trike and

paraglider fore and aft the complete system can

be adjusted in a wide range according to

different load and equipment states.

Suspension system

⇒

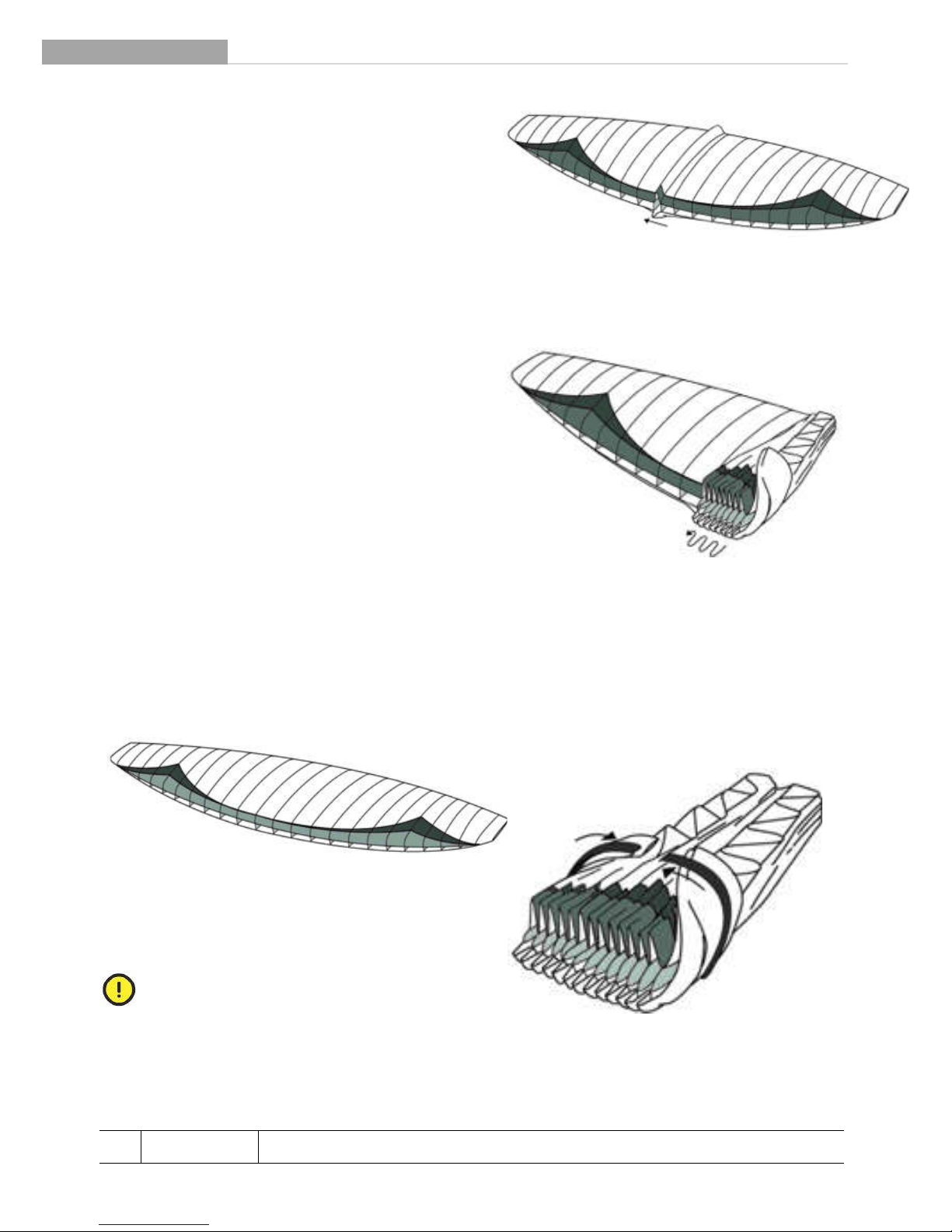

Possible canopy collapses in turbulent air

will become more dynamic as the wing load is

increased. Decreasing the canopy’s angle of

attack by opening the trimmers (fast flight) will

intensify this effect.

Due to this reason the X-Wing Evo is not

allowed to be steered simultaneously by the

brake lines and the trim system into the same

direction if the trim levers are set to a fast flight

position (which more aft than vertical).

This would be possible if e.g. the trim levers are

set to a narrow curve, and then additional brake

input is applied to make the curve even

narrower.

If the brake lines are just for steering the trim

levers should only be used to compensate the

engine torque and for general speed settings, not

for an additional steering.

In general the inputs of the trim system and of

the brake lines will be added to each other.

Note

It is crucial to ensure that changes to the brakes

do not cause them to be activated when you

don't want them to be. The paraglider should

first be pulled up and brought under control

whenever the brake line was modified.

The trim system is helpful to set the trim speed

(cruise speed) and do counteract the engine

torque. During take off and landing the trim

levers should be in a slow (=vertical) position.

The paraglider is connected with the suspension

bows using four 6mm-carabiners. The

suspension bows have four holes close to their

upper edge where these carabiners go through.

The first (most forward) carabiner takes the Alines, the last one (most aft) the D-lines etc. The

left bow is connected with the left side of the

canopy, the right bow with its right side.

Both bows are connected with a rotatable joint

which keeps them also in the correct distance to

each other. For easier transportation this joint

can be taken apart, it is just stuck together.

The lower end of the suspension bows is

connected with a 3-ton-belt (30 mm polyester

belt) to a bigger carabiner which is the main

joint between wing and trike. This carabiner is

used to separate the wing from the XCitor if

necessary. Check that it is correctly closed prior

to each flight (as all the other carabiners).

The XCitor has another polyester belt loop

around its top tube (roll over tube) which goes

into this carabiner as well. This loop cannot

move forward or aft as it is tied to an aluminium

clamp around the main tube with a 5mmPolyester rope.

Moving this clamp fore or aft changes the flying

angle of the XCitor and is used to adjust it to

different weight and equipment states.

The connection rod between both suspension

bows lays on top of the XCitor prior to start, one

can say, on it’s roof.

Fresh Breeze GmbH

30 Section 5 Features

Technical data

Description

Units 28 24

Flat Area m² 33,80 29,92

Flat Wingspan m 13,0 12,6

Flat Chord m 3,1 2,8

Flat AR 5,0 5,3

Projected Area m² 27,95 24,74

Projected Span m 10,1 9,8

Projected Height m 3,1 2,9

Projected AR 3,7 3,9

Nr Cells 53 53

Bridle Count 230 230

Bridle Length m 548 513

Bridle Height m 6,9 6,7

Min. take-off weight kg 200 200

Max. take-off weight kg 383 306

Fresh Breeze GmbH

Setting up and test flying Section 6 31

06 Setting up the X-Wing

Evo and test-flying

Before the first flight

WARNING

A specialist must test-fly and inspect the

paraglider before your first flight. The testflight must be recorded on the paraglider

information label.

During production, the X-Wing Evo goes

through several quality control checks before

finally undergoing an exact type certification

test. Conformity with the reference specimen is

checked and certified before the glider is

delivered to the customer. Extreme care is taken

in the manufacture of all patterns, lines and riser

lengths. They show a high level of precision and

should not be altered under any circumstances.

WARNING

Any changes or improper repairs to this

paraglider shall render invalid the

certification and warranty.

Adjusting the main brake lines

The X-Wing Evo is delivered ex factory with a

brake adjustment marked which complies with

the test sample and which should not be altered.

This adjustment will allow you to steer and land

the paraglider almost without delay.

The main brake lines must be checked by an

expert before the test flight.

Factory setting

Correctly adjusted brake lines have nearly no

idle displacement. This means that the brake

lines must not be pulled very much down before

the trailing edge of the canopy starts to move

downwards and the glider starts to react. The

manufacturer has pre-set the brakes in this way,

which means you are able to steer and land the

glider with nearly no delay. Note that the brake

cascades already cause drag by their

aerodynamic resistance.

Modern gliders such as the X-Wing Evo have

less tolerance with regard to adjustment of the

brake lines. It is therefore normally not

necessary to alter the length.

If you do nevertheless adjust the brakes, under

no circumstances should you go above or below

the tolerance levels.

Incorrect adjustment

If the brake lines are too long, the paraglider

reacts slowly and is difficult to land. The brake

lines can be adjusted during flight by wrapping

them around your hands which will improve the

flight characteristics. Adjust the brake lines to

the correct length after you have landed.

Changes to the braking distance should always

be made in small increments of no more than 2

to 3cm and must be tested before the next take

off. The left and right brakes must be adjusted

symmetrically.

If the brakes are shortened, care must be taken

that the paraglider is not slowed down in trim

and accelerated flight because of the brake lines

being too short. Safety issues may arise and

performance and launch behaviour may

deteriorate if the brake lines are shortened too

much.

WARNING

If the brake lines are too short, the

following risks could arise:

Fresh Breeze GmbH

32 Section 6 Setting up and test flying

there could be an early or unexpected

stall

the paraglider does not launch well

and there is a risk of deep stall

the paraglider exhibits dangerous

behaviour in extreme flying

the trailing edge of the paraglider is

braked in accelerated flight which, in

an extreme case, could cause a

frontal collapse

Recommendation

We recommend the ‘wrap’ technique prior to a

landing as well. Doing so the potential brake

travel can be increased. This makes it easier

especially under windy conditions to make the

glider come down straight behind the trike.

Don’t fly too slow and don’t wrap the brake

more than 1x around the hand as long as you are

in the air so that no stall might occur during the

flight.

Brake knots

The overhand knot and bowline knot shown

below are the most suitable for connecting the

brake line to the brake handle.

Fig. 3: Overhand knot

Fig. 4: Bowline knot

WARNING

Loose, unsuitable or incorrectly tied brake

line knots can cause the main brake line to

loosen and then lead to loss of control of

the glider.

Ensure that only overhand or bowline knots

are used and that they are tied correctly.

First flight

Carry out your first flights only during stable

weather, and in a familiar area.

Fresh Breeze GmbH

Setting up and test flying Section 6 33

You should steer gently and carefully to begin

with so that you can become accustomed to the

reactions of the glider without stress.

WARNING

Do not overestimate your own abilities. Do

not allow the paraglider category or the

behaviour of other pilots to make you

careless.

Fresh Breeze GmbH

34 Section 7 Flying

07 Flying the X-Wing Evo

Pre-flight check and laying out the

paraglider

Before launching, always check the following:

Any tears in the glider or other damage?

Any knots or tangles in the lines?

Brake lines clear and attached firmly to the

handle?

Brake lines adjusted to the correct length?

Is the handle connected to the magnetic

holder strapped around the “roll over tube”

close to the trim levers?

All carabiners fastened securely to the lines

and to the suspension bows?

Is the canopy dry?

Risers and seams in good condition?