2008T Hemodialysis Machine

Operator’s Manual

Caution: Federal (US) law restricts this device to sale only by or on the order of a physician.

Note: The most recent version of this manual can be accessed at fmcna.com/frtmanuals.

490122 Rev U

2008T Hemodialysis Machine Operator’s Manual

© 2008 - 2019 Fresenius USA, Inc.—All Rights Reserved

This document contains proprietary information of Fresenius Medical Care Renal Therapies Group, LLC

and its affiliates (“Fresenius Medical Care”). The contents of this document may not be disclosed to

third parties, copied, or duplicated in any form, in whole or in part, without the prior written permission

of Fresenius Medical Care.

Fresenius Medical Care, the triangle logo, 2008, BlueStar, Clinical Data Exchange, Combiset, Twister,

NaturaLyte, GranuFlo, bibag, Crit-Line, CLiC, Optiflux, DIAFIX, and DIASAFE are trademarks of

Fresenius Medical Care Holdings, Inc., or its affiliated companies. Citrasate is a registered trademark of

Advanced Renal Technologies, Inc. in the United States and used under license from Advanced Renal

Technologies, Inc. All other trademarks are the property of their respective owners.

The 2008T hemodialysis machine is manufactured by:

Fresenius USA, Inc.

4040 Nelson Avenue

Concord, CA 94520

(800) 227-2572

Installation, maintenance, calibration and other technical information may be found in the 2008T

Technician’s Manual, P/N 490130.

Contact Fresenius Medical Care Technical Support for applicable Field Service Bulletins. The spare

parts manual for the model 2008T and other information may be found on our website at www.fmcna.com

Caution: Federal (US) law restricts this device to sale only by or on the order of a physician.

Caution: Frequency, duration, and parameters of treatment are to be determined by the prescribing

physician.

Note: Not all features are available in all regions.

Indications for Use:

2008T BlueStar Hemodialysis Machine: The 2008T BlueStar Hemodialysis Machine is indicated for

acute and chronic dialysis therapy in a healthcare facility.

Additional therapy options for patients receiving hemodialysis include: Isolated Ultrafiltration, Sustained

Low Efficiency Dialysis (SLED), and low volume hemodialysis (patients weighing ≥ 20kg and ≤ 40 kg).

This machine accommodates the use of both low flux and high flux dialyzers. The SLED therapy option is

not to be used for patients weighing ≤ 40 kg. The 2008T BlueStar Hemodialysis Machine is not to be used

for plasma replacement therapies, for patients weighing less than 20 kg, or for renal therapies using

substitution fluid.

bibag System (Optional): The bibag system is used with three stream proportioning hemodialysis systems

equipped with the bibag module such as the 2008T BlueStar Hemodialysis Machine and is intended for

use in bicarbonate hemodialysis for acute and chronic renal failure. The bibag is intended for

extracorporeal bicarbonate hemodialysis according to a physician’s prescription.

Crit-Line Clip Monitor (CLiC) (Optional): The Crit-Line Clip Monitor is used with the 2008T BlueStar

Hemodialysis Machine to non-invasively measure hematocrit, oxygen saturation and percent change in

blood volume. The CLiC device measures hematocrit, percent change in blood volume and oxygen

saturation in real time for application in the treatment of dialysis patients with the intended purpose of

providing a more effective treatment for both the dialysis patient and the clinician. Based on the data that

the monitor provides, the clinician/nurse, under physician direction, intervenes (i.e., increases or

decreases the rate at which fluid is removed from the blood) in order to remove the maximum amount of

fluid from the dialysis patient without the patient experiencing the common complications of dialysis

which include nausea, cramping and vomiting.

2 2008T Machine Operator’s Manual P/N 490122 Rev U

Indications for Use:

2008T Hemodialysis Machine: The 2008T Hemodialysis Machine is indicated for acute and chronic

dialysis therapy in a healthcare facility.

bibag System (Optional): The bibag system is used with three stream proportioning hemodialysis systems

equipped with the bibag module such as the 2008T Hemodialysis Machine and is intended for use in

bicarbonate hemodialysis for acute and chronic renal failure. The bibag is intended for extracorporeal

bicarbonate hemodialysis according to a physician’s prescription.

Crit-Line Clip Monitor (CLiC) (Optional): The Crit-Line Clip Monitor is used with the 2008T

Hemodialysis Machine to non-invasively measure hematocrit, oxygen saturation and percent change in

blood volume. The CLiC device measures hematocrit, percent change in blood volume and oxygen

saturation in real time for application in the treatment of dialysis patients with the intended purpose of

providing a more effective treatment for both the dialysis patient and the clinician. Based on the data that

the monitor provides, the clinician/nurse, under physician direction, intervenes (i.e., increases or

decreases the rate at which fluid is removed from the blood) in order to remove the maximum amount of

fluid from the dialysis patient without the patient experiencing the common complications of dialysis

which include nausea, cramping and vomiting.

2008T Machine Operator’s Manual P/N 490122 Rev U 3

Contents

About this manual… ........................................................................................................................ 9

Requirements ................................................................................................................................. 10

Related Reading ............................................................................................................................. 10

Conventions ................................................................................................................................... 11

About Hemodialysis…................................................................................................................... 14

General Warnings .......................................................................................................................... 16

Using a Central Venous Catheter ................................................................................................... 21

CHAPTER 1

Overview ................................................................................................................................................. 23

Function of the 2008T Hemodialysis Machine .............................................................................. 23

Organization of the 2008T Hemodialysis Machine ....................................................................... 23

The Control Panel .......................................................................................................................... 26

Control Panel Keypad .................................................................................................................... 27

The Back Panel .............................................................................................................................. 35

PatientCard Reader (Optional) ....................................................................................................... 37

Modules ......................................................................................................................................... 38

The Dialysate Path ......................................................................................................................... 44

IV Pole and Dialyzer Holder .......................................................................................................... 48

Moving the Machine ...................................................................................................................... 49

CHAPTER 2

Daily Preparation for Treatment ............................................................................................................. 51

Starting Point ................................................................................................................................. 51

Preparing the Dialysis Delivery System ........................................................................................ 52

Manual Machine Setup .................................................................................................................. 52

Auto Start Machine Setup .............................................................................................................. 56

Preparing the Extracorporeal Blood Circuit................................................................................... 59

Connecting the Extracorporeal Blood Circuit ................................................................................ 60

Priming the Blood Circuit .....................................

Testing the 2008T Hemodialysis Machine .................................................................................... 71

Recirculation and Final Set-Up Procedure ..................................................................................... 7 4

CHAPTER 3

Setting Treatment Parameters ................................................................................................................. 76

Recommended Order for Screen-by-Screen Entry ........................................................................ 77

New Treatment Key ....................................................................................................................... 78

4 2008T Machine Operator’s Manual P/N 490122 Rev U

......................................................................... 62

Entering a Treatment Parameter .................................................................................................... 79

Dialysate Screen Settings ............................................................................................................... 81

Home Screen Settings .................................................................................................................... 92

Ultrafiltration ................................................................................................................................. 97

Isolated Ultrafiltration .................................................................................................................. 100

Sodium Variation System ............................................................................................................ 102

Heparin Screen Settings ............................................................................................................... 106

Test & Options Screen Settings ................................................................................................... 111

Low Volume Dialysis .................................................................................................................. 114

Blood Pressure Screen Settings ................................................................................................... 115

Using the Default Parameters Screen ........................................................................................... 118

Using the PatientCard .................................................................................................................. 125

Starting Dialysis ........................................................................................................................... 134

CHAPTER 4

Monitoring the Treatment ..................................................................................................................... 136

Home Screen Monitoring ............................................................................................................. 137

Trends Screen Monitoring ........................................................................................................... 142

Kt/V & Access Flow Monitoring ................................................................................................. 145

Blood Temperature Monitor / Blood Volume Monitor Screen .................................................... 153

Crit-Line Screen ........................................................................................................................... 156

Blood Pressure Screen Monitoring .............................................................................................. 162

During Treatment ......................................................................................................................... 163

Blood Recirculation Procedure .................................................................................................... 165

Power Failure during Dialysis ..................................................................................................... 166

Completion of Dialysis ................................................................................................................ 169

Returning Blood to the Patient (Standard Method) ..................................................................... 170

Returning Blood to the Patient Using Assisted Reinfusion ......

................................................... 171

CHAPTER 5

Disinfection and Maintenance .............................................................................................................. 178

Cleaning and Disinfection ............................................................................................................ 178

Cleaning the Exterior Surface ...................................................................................................... 182

Rinse Program .............................................................................................................................. 185

Acid Clean Program ..................................................................................................................... 186

Heat Disinfection Program .......................................................................................................... 187

Chemical/Rinse Program ............................................................................................................. 188

Chemical/Dwell Program ............................................................................................................. 190

Acid & Heat Disin (Disinfect) Program ...................................................................................... 191

Disinfect Log (Optional) .............................................................................................................. 194

2008T Machine Operator’s Manual P/N 490122 Rev U 5

CHAPTER 6

Alarms and Troubleshooting ................................................................................................................. 195

Operational Status ........................................................................................................................ 195

Troubleshooting ........................................................................................................................... 199

®

plus

Replacing the DIASAFE

Replacing the 9-Volt Battery ....................................................................................................... 274

APPENDIX A

Single Needle Dialysis (Optional) ........................................................................................................ 276

APPENDIX B

Sustained Low Efficiency Dialysis (SLED) (Optional) ........................................................................ 289

Preparation ................................................................................................................................... 289

Treatment Monitoring .................................................................................................................. 291

APPENDIX C

The CDX System (Optional) ................................................................................................................. 293

Machine Connections................................................................................................................... 295

Instructions for Clinic Information Systems Personnel ............................................................... 297

CDX PC Specifications for the Intel N3060 Processor ............................................................... 299

CDX PC Specifications for the Intel Atom D525 Processor ....................................................... 300

CDX PC Specifications for the Intel Atom N270 Processor ....................................................... 301

Filter ........................................................................................ 273

US

APPENDIX D

Concentrate Types ................................................................................................................................. 304

Estimated bibag disposable run times (minutes) .......................................................................... 307

APPENDIX E

Service Mode ........................................................................................................................................ 308

Treatment Options Screen ............................................................................................................ 309

Hardware Options Screen ............................................................................................................ 314

Default Settings Screen ................................................................................................................ 320

Auto Heat Disinfect (functional software version 2.69 or earlier) ............................................... 324

Enter Conc Screen: Selecting and Adding Concentrates ............................................................. 326

UF Profile Screen: Creating Custom UF Profiles ........................................................................ 331

Module Options Screen ................................................................................................................ 332

Scheduler Screen (functional software version 2.72 or later) ...................................................... 334

Auto Heat Disinfect (functional software version 2.72 or later) .................................................. 336

Auto Start (functional software version 2.72 or later) ................................................................. 338

CDX Auto On (functional software version 2.72 or later)........................................................... 340

PM Reminder ............................................................................................................................... 341

6 2008T Machine Operator’s Manual P/N 490122 Rev U

Diasafe Reminder ........................................................................................................................ 344

Testing the Dialysate.................................................................................................................... 347

Equipment Storage and Maintenance .......................................................................................... 349

Machine Specifications ................................................................................................................ 350

Essential Performance .................................................................................................................. 360

Manufacturer’s EMC Declaration ................................................................................................ 362

Product Improvement Policy ....................................................................................................... 366

Warranty ...................................................................................................................................... 366

Patents .......................................................................................................................................... 367

Glossary ................................................................................................................................................ 368

Index ..................................................................................................................................................... 374

2008T Machine Operator’s Manual P/N 490122 Rev U 7

This page intentionally blank

8 2008T Machine Operator’s Manual P/N 490122 Rev U

About this manual…

The purpose of the 2008T Hemodialysis Machine Operator’s Manual is to instruct qualified

patient-care staff in the function, operation, and maintenance of the 2008T hemodialysis

machine. It is not intended as a guide for performing hemodialysis, a medical treatment that

should only be performed under the supervision of a licensed physician.

This manual is organized to systematically guide a patient-care specialist through the set up,

operation, and clean up of the 2008T hemodialysis machine in daily use. The book begins

with an overview that introduces the operator to the major components and describes how

they are organized on the machine. Next, the operator is guided through a daily set-up

procedure. Once the machine has been prepared for daily use, a step-by-step guide to

preparing the machine for a patient-specific treatment is provided. The operator is then

provided a tour of the various treatment screen functions useful in monitoring the treatment,

followed by instruction in terminating treatment and post-treatment clean up. Also included

are sections on troubleshooting, maintenance, and treatment options.

The organization of the 2008T Hemodialysis Machine Operator’s Manual is as follows:

About this manual…

Preface

Identifies the intended audience, and describes how the manual is organized. It

addresses various issues regarding the performance of hemodialysis and product

liability, and provides information for contacting Fresenius USA, Inc.

Chapter 1—Overview

Introduces the operator to the 2008T hemodialysis machine, its features, their functions,

and how they are organized on the machine through pictures and descriptions.

Chapter 2—Daily Preparation for Treatment

Provides instructions on the recommended methods of preparing the 2008T

hemodialysis machine for daily, standard-dialysis operation.

Chapter 3—Setting Treatment Parameters

Describes how to enter treatment data, and guides the operator through the relevant,

treatment screens to enter patient-specific, treatment parameters in their recommended

order. The chapter also covers the procedure for beginning dialysis treatment.

Chapter 4—Monitoring and the Completion of Treatment

Guides the user through the screens used to monitor the dialysis treatment. It explains

the features of each screen and describes the information displayed. The screens that

provide a general overview of the treatment status are provided first, followed by the

screens providing more in-depth data that are narrower in scope. It concludes with a

description of the recommended, end-of-treatment procedure.

Chapter 5—Cleaning and Disinfection

Recommendations for scheduled cleaning and disinfection, as well as maintenance

procedures that should be performed by the operator are found here.

Chapter 6—Alarms and Troubleshooting

This chapter is indexed by alarm messages to provide the operator a quick-reference

guide for determining the cause and remedies for alarm situations.

2008T Machine Operator’s Manual P/N 490122 Rev U 9

About this manual…

Appendices

In addition, this manual includes several appendices covering optional hemodialysis

treatments, such as single-needle hemodialysis and Sustained Low Efficiency Dialysis

(SLED), and provides information on the setup, customizing, storage and specifications

of the 2008T hemodialysis machine.

Glossary

A glossary of terms is included

Index

An index to aid the operator in referencing information is included

Requirements

Operators of the 2008T hemodialysis machine must be trained to administer hemodialysis at

the direction of a physician. In addition, the operator should be:

Knowledgeable of hemodialysis methodology and relevant physiology.

Proficient in healthcare procedures regarding aseptic techniques.

Thoroughly familiar with the contents of this manual.

Fully trained and qualified to operate this machine, and able to distinguish between

normal and abnormal operation.

Related Reading

The following documents contain information related to the 2008T hemodialysis machine:

2008T Hemodialysis Machine bibag System Operator’s Instructions (P/N 508213)

2008T Hemodialysis Machine with CLiC User’s Guide (P/N 490206)

2008T Technicians Manual (P/N 490130)

2008T Calibration Procedures Manual (P/N 508032)

2008T Preventive Maintenance Procedures Manual (P/N 508033)

2008T Troubleshooting Guide (P/N 102297-01)

2008T Spare Parts Manual (P/N 490124)

2008T Installation Checklist (P/N 490129)

2008T Installation Checklist Instructions (P/N 508035)

2008T Field Service Bulletins may be obtained from the Fresenius Medical Care North

America (FMCNA) website: www.FMCNA.com or contact your clinic for more

information.

Comments are available concerning the expected increased recirculation of blood in the

extracorporeal circuit during single needle treatment when using the recommended

administration sets, dialyzers, catheters, and fistula needles.

The test procedures by which the effectiveness of disinfection has been verified are

available on request.

10 2008T Machine Operator’s Manual P/N 490122 Rev U

Conventions

Symbol Description

and

and

About this manual…

Warning! A warning is a statement that identifies conditions or actions

that could result in personal injury or loss of life. Warnings found in this

manual outside of this section are designated with the warning symbol.

Shock Hazard: A shock hazard warning refers to a risk of a possibly

severe electrical shock due to improper use or handling of the equipment.

Corrosive Substance Hazard: A corrosive substance hazard warning

refers to a risk of injury or machine damage due to improper use or

handling of the equipment.

Hot Surface, Fluid, or Vapors Hazard: A hot surface, fluid, or vapors

hazard warning refers to risk of burn injury due to improper use or

handling of the equipment.

Tip Hazard: A tip hazard warning refers to a risk of injury or machine

damage due to improper handling of the equipment.

No Pushing: A no pushing warning refers to a risk of injury or machine

damage due to leaning or pushing against the equipment.

Caution: A caution is a statement that identifies conditions or actions that

could result in damage to the machine.

Mandatory Action: A command describing required action to maintain

safety.

Consult Accompanying Documents: This symbol is located on the

2008T hemodialysis machine. It means, refer to the 2008T Operator's

Manual for additional information.

Note: Notes are advisory comments or recommendations regarding

practices or procedures.

Do not reuse

ON: This symbol, at the top of the switches on the back of your machine,

means the switch is in the ON position.

OFF: This symbol, at the bottom of the switches on the back of your

machine, means the switch is in the OFF position.

Degree of protection against electric shock: Type B

Degree of protection against electric shock: Type CF – Blood

Pressure Cuff only

2008T Machine Operator’s Manual P/N 490122 Rev U 11

About this manual…

Symbol Description

IPX1

MR Unsafe: An item which poses unacceptable risks to the patient,

medical staff or other persons within the MR (Magnetic Resonance)

environment.

Vertical drip-proof level of protection from liquid drips, leaks and spills

Protective ground terminal

Equipotentiality—this symbol may appear on older machines

RF transmitter: Intentional Radio Frequency (RF) transmissions for

wireless communications (see The CDX System, Appendix B)

12 2008T Machine Operator’s Manual P/N 490122 Rev U

About this manual…

Name Description

Button A button refers to specific fields located in the treatment screens that are

used to set treatment parameters or perform an action when selected.

Control Panel The control panel is located at the top third of the machine and contains

the display screen and panel keys used in controlling the treatment.

Display

Screen

Key A key is a pressure-sensitive, raised pad found on the control panel

Keyboard The keyboard is located below the display screen. It flips down for data

Screen The graphic image displayed inside the display screen. There are eight

Subscreen A smaller screen that can be opened from inside a particular main screen.

Touchpad A flip-down panel on the right side of the control panel that reacts to

Touchscreen Optional data input device that overlays the display screen. The

The area located at the top of the control console that displays the

treatment screens.

outside of the treatment screen that is used to enter a value, make a

selection, or initiate an action or process.

entry and can be closed again when not in use.

main screens all of which are accessible from any of the other screens.

Subscreens are not accessible from all main screens.

fingertip pressure. The touchpad controls an on-screen cursor (arrow).

touchscreen reacts to fingertip pressure.

2008T Machine Operator’s Manual P/N 490122 Rev U 13

About Hemodialysis…

About Hemodialysis…

Indications

Hemodialysis is prescribed by physicians for patients with acute or chronic renal failure,

when conservative therapy is judged inadequate. Dialysis therapy may be intermittent or

continuous.

Contraindications

There are no absolute contraindications to hemodialysis, but the passing of a patient’s blood

through an extracorporeal circuit may require anticoagulation to prevent blood clotting. In

addition, the parameters of dialysis should be optimized to avoid discomfort to the patient.

Many patients are taking medicinal therapy prescribed by their physicians. Due to the dialysis

treatment, some of the medication may be removed from the patient’s blood thereby lowering

the therapeutic level in the blood. In other cases, medications may not be excreted as quickly

as expected with patients with renal insufficiency and the level may be higher than expected.

Therefore, the prescribing physician should determine the appropriate dosage of the medicine

to obtain the desired medicinal response in the patient.

Some Side Effects of Hemodialysis

Dialysis therapy occasionally causes hypovolemia, hypervolemia, hypertension, hypotension

and related symptoms, headache, nausea, cramping or other muscular discomfort in some

patients. Hypothermia, hyperthermia, itching, anxiety, convulsions, seizure, and other

neurologic symptoms associated with dialysis dementia may also be manifested by the

patient. These symptoms are thought to occur if the patient’s blood volume or electrolyte

balance is not maintained within acceptable limits. Other, more serious, complications

arising from dialysis, such as hemorrhage, air embolism, or hemolysis, can cause serious

patient injury or death. The prescribing physician must understand that prescribing

insufficient bicarbonate may contribute to metabolic acidosis; excessive bicarbonate may

contribute to metabolic alkalosis. Both conditions are associated with poor patient outcomes,

including increased risk of mortality. Proper control of all elements of dialysis may prevent

or control these physiological reactions or complications.

Pyrogenic reactions may occur which can result in patient injury. Generally it is thought that

these may be controlled by maintaining the dialysate solution within the chemical and

bacteriologic limits (see Water Quality on page 351 of the “Machine Specifications” section

for more information). Failure to use these standards for water can also lead to accumulated

toxic effects. A regular program for disinfection and testing of the water treatment system,

piping, inlet lines, filters, concentrate feed containers or system, and the dialysate delivery

machine must be established and followed. This program will vary from facility to facility.

Infections or pyrogen reactions may also result from contamination of the extracorporeal

circuit or inadequate procedures used to reuse dialyzers.

14 2008T Machine Operator’s Manual P/N 490122 Rev U

About Hemodialysis…

Allergic reactions to chemical disinfectants may occur if insufficient procedures are used to

remove or maintain the residual disinfectant at acceptable levels. Chemical disinfectants are

used for dialyzer disinfection, machine disinfection, or for disinfection of water treatment and

distribution systems.

All blood connections must be made using aseptic technique.

All tubes and connections must be secured and closely monitored to prevent loss of blood or

entry of air into the extracorporeal circuit or errors in the ultrafiltration control system. The

patient may require blood transfusion or other medical intervention to prevent respiratory or

cardiac disorders if these occur.

The patient’s blood pressure and general physical status must be closely monitored during

dialysis in order to initiate appropriate remedial measures or therapy. Of particular

importance is the control of the patient’s serum potassium level to prevent cardiac

dysrhythmia and the patient’s blood clotting time to prevent clotting disorders.

These instructions are for the 2008T hemodialysis machine. The machine must only be

operated in accordance with these instructions. All operators of this machine must be

thoroughly trained and have read this entire manual and any applicable appendices before

using the machine. Improper care/use of this device may result in serious patient injury or

death.

Blood Pressure Module Contraindications

The 2008T blood pressure monitoring subsystem is not intended for neonatal use. The

following are generally accepted contraindications for using a timed automatic blood pressure

instrument utilizing the oscillometric principle:

Use of a heart lung machine

Peripheral circulation problems

Severe arrhythmia

Ectopic beats

Convulsions

Spasms

Tremors

Tachycardia

Use of incorrectly sized blood pressure cuffs may result in inaccurate blood pressure

readings.

This is a guideline only. Final determination of the suitability of any medical instrument for

use with any patient, including pregnant or pre-eclamptic patients, is the responsibility of the

treating physician.

2008T Machine Operator’s Manual P/N 490122 Rev U 15

General Warnings

General Warnings

This section contains general warnings statements regarding the use and maintenance of the

2008T hemodialysis machine. It is not a complete summary, and additional warning

statements specific to pertinent topics can be found within this manual.

Water

Warning! Connect water inlet according to the specifications for the machine. For further

information, see “Machine Specifications” on page 350. The correct ionic concentration and

bacterial quality can generally be achieved in the dialysate only with treated water that

meets water quality standards (see Water Quality and Dialysate Quality on page 351 of the

“Machine Specifications” section for more information). Be sure that all specifications are

satisfied. The water source must be monitored periodically to detect fluctuations in water

composition and quality that could have an adverse effect on the patient or dialysate delivery

machine. Particular attention must be taken for chemicals such as aluminum, chlorine, and

chloramine, as these chemicals can cause complications in dialysis patients.

Warning! Comply with all local regulations in respect of separation of devices in the water

supply in case of back siphonage; an air gap must be created between the machine’s drain

line and its drain.

Concentrates

Warning! The specific acid and bicarbonate concentrates, including the sodium,

bicarbonate, and electrolyte compositions, must be prescribed by a physician.

Warning! Many concentrate types are available for use in dialysate delivery machines.

Concentrates contain various amounts of dextrose, potassium, calcium, sodium, chloride,

magnesium, and other components. Most concentrates are designed as a two-part system of

acid and bicarbonate solutions which are mixed in the machine with water. Even within the

subgroup of bicarbonate type concentrates, there are at least four methods of compounding

the solutions. Each of these methods requires special calibrations or setups. Certain

methods are not supported. It is mandatory that the acid and bicarbonate types be matched

to each other. Be sure to use compatible solutions, labeling, and setups. These setups

include machine calibration, special adapters for certain concentrate types, correct setting of

concentrate option, and labeling. Failure to use the properly matched solutions and machine

calibrations may allow improper dialysate to be delivered to the patient, resulting in patient

injury or death. Verify composition, conductivity, and pH after converting to a different

type of concentrate.

Warning: Acid concentrate, bicarbonate concentrate, and water must be of the appropriate

quality to ensure safety and performance of the final dialysate are met (see Water Quality,

Dialysate Quality, and Concentrate Quality on page 351 of the “Machine Specifications”

section for more information).

Warning: The dissolved bibag bicarbonate concentrate must be used within 24 hours of

connecting to the dialysis machine. Do not refill the bibag container.

16 2008T Machine Operator’s Manual P/N 490122 Rev U

General Warnings

Warning! Connection to a central acid or bicarbonate feed system requires the installation

of certain mechanical parts. Contact Fresenius USA, Inc. for more information.

Warning! Bicarbonate and acid concentrates intended for other dialysate delivery machines

will deliver safe dialysate solution only if the machine is set up for them. The selection of

other dialysate concentrate types must be done by a qualified, authorized person. The

2008T hemodialysis machine can be set up for various concentrate types. Use Table 40 in

Appendix C to ensure that you have compatible concentrates and configurations.

Warning! Acid concentrate products are used as one component in mixing dialysate bath.

These acid products contain chemical compounds that, after mixing, yield acetate (and

citrate in certain products) in the dialysate. (Please refer to the acid concentrate product

labeling for specific acetate/citrate amounts.) After diffusion across the dialyzer membrane,

acetate (and citrate when present) is metabolized by the liver to serum bicarbonate and adds

to the serum bicarbonate that separately results from the diffusion of dialysate bicarbonate

across the dialyzer membrane. During dialysis, the dynamic of diffusion and concentration

gradients prevent serum bicarbonate concentration from exceeding the dialysate bicarbonate

concentration. The bicarbonate concentration of the dialysate is the “bicarbonate” setting on

the dialysis machine, and is the bicarbonate dose prescribed by the physician. On the 2008

series hemodialysis machines, the bicarbonate dose may be set in a range between 20 and 40

milliequivalents per liter, but may be set in different ranges in other machines.

When the dialysis session terminates, acetate (and citrate when present) that has not yet

metabolized may remain in the blood and will be converted to serum bicarbonate after

diffusion ceases, without possibility of diffusion out of the blood. The post dialysis

metabolism of acetate (and citrate when present) could thus briefly increase serum

bicarbonate concentration above the prescribed bicarbonate concentration of the dialysate.

Physicians should consider this possibility in prescribing bicarbonate dose.

Prescription of insufficient bicarbonate may contribute to metabolic acidosis; excessive

bicarbonate may contribute to metabolic alkalosis. Both conditions are associated with poor

patient outcomes, including increased mortality risk.

Warning! Incorrect composition will result if the acid concentrate nozzle is not connected

to the appropriate acid concentrate or the bicarbonate concentrate nozzle is not connected to

the appropriate bicarbonate solution. The acid and bicarbonate concentrates must match

those selected in the “Dialysate” screen. Patient injury or death may occur if incorrect

dialysate solution is used. Fresenius USA, Inc. recommends the operator use the concentrate

containers provided with the machine. These containers, being of different size and shape,

help to reduce the chances of mismatching the acid and bicarbonate concentrates.

Warning! Always verify the conductivity and approximate pH of the dialysate through

independent means before beginning treatment. Independent means could be by using an

external conductivity meter, pH meter, pH paper or by using the machine’s independent

conductivity test. Verify also when changing concentrates during treatment and when

switching from the bibag system to liquid bicarbonate*. The wrong conductivity or pH may

cause serious injury or death.

*Note: If alternative liquid bicarbonate concentrate sources are used (jugs or central delivery) the

end user must ensure the bicarbonate is of appropriate quality and is prepared per manufacturer’s

instructions.

2008T Machine Operator’s Manual P/N 490122 Rev U 17

General Warnings

Warning! The machine must be labeled to indicate the type of concentrate for which it is

configured. Check the composition (i.e., Na, Cl, K, Ca, Mg, HCO

solution after the machine is installed or after the machine is modified for different

concentrate types. Verify the conductivity and approximate pH of the dialysate solution

through independent means before initiating dialysis. Independent means could be by using

an external conductivity meter, pH meter, pH paper or by using the machine’s independent

conductivity test. Improper conductivity or pH could result in patient injury or death.

Machine

Warning! Failure to install, operate, and maintain this equipment according to the

manufacturer’s instructions may cause patient injury or death. If this equipment is modified,

appropriate inspection and testing must be conducted to ensure continued safe use of the

equipment. Substitution of a component different from that supplied may result in

measurement errors.

Warning! Use of this equipment adjacent to or stacked with other equipment should be

avoided because it could result in improper operation. If such use is necessary, this

equipment and the other equipment should be observed to verify that they are operating

normally.

) and pH of the dialysate

3

Warning! Use of accessories, transducers and cables other than those specified or provided

by the manufacturer of this equipment could result in increased electromagnetic emissions

or decreased electromagnetic immunity of this equipment and result in improper operation.

Warning! Proper functioning of the machine must be verified prior to initiating treatment.

Unidentified malfunctions or alarm failure could potentially expose a patient to a serious

health risk. Alarm limits for the arterial pressure monitor, venous pressure monitor, and

transmembrane pressure (TMP) monitor are automatically set and delayed for pressure

stabilization. Alarm limits for temperature and conductivity are calculated for the dialysate

composition and may be somewhat adjusted by the operator. These must be maintained

within safe physiological limits as specified by the prescribing physician.

Warning! Never perform maintenance when a patient is connected to the machine. If

possible, remove the machine from the treatment area when it is being serviced. Label the

machine to ensure it is not accidentally returned to clinical use before the service work is

completed. Disinfect the machine and test the dialysate for acceptable conductivity and pH

values before returning the machine to clinical use. Always test the machine when

maintenance is completed.

Warning! To avoid damaging the equipment or personal injury, internal adjustments to the

blood pressure module should only be made by a qualified technician.

Warning! The electrical source must be single phase, three-conductor type provided with a

hospital grade receptacle with protective earth and a ground fault interrupter at 120 volts, 60

Hz. The proper polarity and ground integrity must be initially checked and maintained.

Failure to do so may result in electrical shock or burn to the operator or patient. The

machine must be plugged directly into the electrical outlet; extension cords and power strips

are prohibited.

Warning! Shock hazard. Do not remove covers. Refer servicing to qualified personnel.

Replace fuses only with the same type and rating.

18 2008T Machine Operator’s Manual P/N 490122 Rev U

General Warnings

Warning! Do not install the 9-Volt battery backwards in the machine, as it will damage the

“No Power” alarm.

Warning! Do not use devices emitting strong electromagnetic radiation such as portable

phones, radio equipment (walkie-talkies, etc.), radio transmitters, and like equipment near

your machine. Improper operation may result.

Cellular phones and WiFi connected devices may be conditionally allowed. However, if any

interference is noted, such as false pressure readings that disappear when the external signal

is removed, it is recommended to move the cellular phone at least ten feet away from the

2008T hemodialysis machine when making or receiving phone calls. If a WiFi-connected

device (e.g. laptop computers, tablet devices, smartphones) is found to cause interference, it

is recommended to use that device at least four feet away from the 2008T hemodialysis

machine.

Portable RF (radio frequency) communications equipment (including peripherals such as

antenna cables and external antennas) should be used no closer than 30 cm (12 inches) to

any part of the hemodialysis machine, including cables specified by the manufacturer.

Otherwise, degradation of the performance of this equipment could result.

For exact separation distance recommendation, please refer to the Manufacturer’s EMC

Declaration statement on page 362.

Warning! While controls have been implemented throughout the development of the 2008T

to protect against cybersecurity threats, it is the responsibility of the customer to ensure

security controls such as WiFi encryption, firewalls, antivirus, access controls (including

physical controls), vulnerability management and other security controls are in place and

managed appropriately. Please consult your organization’s information security/risk

management group to ensure the proper controls are implemented to meet the company’s

policies and risk profile. Failure to properly implement protection could put prescription

data sent to the machine at risk.

Warning! Transducer protectors should be used between pressure ports and each pressure

monitor line of the extracorporeal system to prevent the internal transducer protectors from

getting wet. Wet transducer protectors must be replaced, as they will cause inaccurate

pressure readings. If the external transducer protector and the internal transducer protector

become contaminated with blood, the transducer protectors must be replaced and the

transducer, pressure ports, internal tubing and valve must be disinfected or replaced.

Warning! A new, sterile transducer protector should be placed on all the air connections

from the drip chambers to the machine pressure monitor ports. This will prevent

contamination of the machine and filters air that enters the chambers through the monitor

lines. If the transducer protector should get wet and air is not able to pass, replace the

transducer protector and clear the monitor line.

Warning! The machine is compatible with a number of venous lines. The Level Detector

module must be calibrated for the model venous line being used. In addition, verify that the

venous line clamp is capable of fully occluding the model of bloodline that your facility

uses. Improper functioning of the level detector may be caused by a clot of blood.

Warning! Possible Explosion Hazard if used in the presence of flammable anesthetics.

Warning! Check all bloodlines for leaks after the treatment has started. Keep access sites

uncovered and monitored. Improper bloodline connections or needle dislodgements can

result in excessive blood loss, serious injury, and death. Machine alarms may not occur in

every blood loss situation.

2008T Machine Operator’s Manual P/N 490122 Rev U 19

General Warnings

Warning! Air may enter into the extracorporeal circuit at connection points downstream of

the air detector, if pressures are negative. This can occur in cases such as single needle

applications or central venous catheter applications.

Warning! The dialysate path is a closed fluidics system. Discontinue use immediately if a

fluid leak is detected. Do not attempt to administer or continue dialysis treatment with a

machine which has a fluid leak, this could result in excessive fluid removal from the patient

leading to serious injury or death. System leaks may also pose a slip-and-fall hazard. Clean

up spills immediately.

Warning! Replace a leaking bibag disposable immediately. Spills can cause damage to

carpeting and other surfaces. To contain such spills, the machine should be on a spilltolerant surface. Spills can cause slips and falls; clean up spills immediately.

Warning! When using the bibag system, the acid and bicarbonate pressures must not exceed

10 psi when using a Central Delivery System. It may be necessary to use pressure

regulators in order to reach proper conductivity. When not using the bibag system, the

maximum supplied pressure is 2 psi.

Warning! High dose hydroxocobalamin (or any form of Vitamin B-12) causes discoloration

of the spent dialysate. This discoloration may cause a false blood leak alarm, stopping the

blood pump and preventing treatment unless the operator performs an override of the alarm.

The blood leak alarm can be reset and overridden for up to three minutes repeatedly by

following the blood leak alarm troubleshooting instructions in the operator’s manual in cases

where a blood leak test is negative for blood in the dialysate.

Discontinuation of the hemodialysis treatment could result in persistence or worsening of

acidosis, hyperkalemia, and volume overload which can lead to serious injury or death.

Caution: Only the bags manufactured by Fresenius Medical Care may be used in the bibag

connector.

Caution: System leaks may occur. Unattended operation of the machine (for example,

during disinfection at night) may result in flooding and can cause property damage. Clean

up spills immediately.

Caution: Be careful not to tip the machine when rolling over uneven surfaces. Push the

machine from the middle when moving it.

Caution: Do not squeeze the blood pressure cuff when deflating it. Squeezing the blood

pressure cuff may damage the machine's internal blood pressure module.

Note: The DIASAFE

®

plusUS filter is required when the bibag system is in use.

Note: A smoke detector should be properly installed in the room used for dialysis. Follow

the manufacturer’s instructions. The alarm should be tested according to the manufacturer’s

instructions. Replace the battery as specified.

Note: You must follow all environmental regulations regarding waste disposal and eventual

machine disposal. Contact your clinic for more information. Prior to the disposal of your

machine, any possible risk of infection from blood borne pathogens must also be eliminated

by appropriate disinfection.

20 2008T Machine Operator’s Manual P/N 490122 Rev U

General Warnings

Note: The temperature of the bloodline and the durometer of the tubing affect the ability of

the bloodline/blood pump system to prime during setup. Cold tubing may not prime as

readily as warm tubing.

Fresenius Medical Care manufactures bloodlines for use with the model 2008T

hemodialysis machine. The performance of bloodlines not manufactured by Fresenius

Medical Care cannot be guaranteed by Fresenius Medical Care and are therefore the

responsibility of the prescribing physician.

Note: The following materials come into contact with purified water, dialysate, or dialysate

concentrate:

Dyflor (PVDF)

Ethylene-propylene terpolymer (EPDM)

Foraflon (PVDF)

Glass

Lupolen (PE)

Makrolon (PC)

Noryl (PPE & PS)

Polyethersulfone (PES)

Polyphenylene oxide (PPO)

Polyphenylene oxide 20% glass fiber (PPOGF20)

Polyphenylsulfone (PPSU)

Polypropylene (PP)

Polypropylene 20% glass fiber (PP-GF20)

Radel 10 & 20% glass fiber (PES)

Stainless steel (types 300 & 316)

Silicone (Si)

Teflon (PTFE)

Thermocomp (PES)

Titanium – TiAl 4 V6

Ultem (PEI)

Ultradur+ (PBT)

Victrex (PEEK)

Vinyl chloride polymer (PVC)

Using a Central Venous Catheter

Shock Hazard: Ensure that no conductive electrical devices connected to or near the patient,

including water and concentrate central delivery systems connected to the machine, have

leakage currents above the maximum CF applied parts limit of 10 μA AC/DC and 50 μA

AC/DC in a single fault condition. Failure to follow these precautions may result in serious

injury or death.

2008T Machine Operator’s Manual P/N 490122 Rev U 21

General Warnings

Maintenance

Assembly, installation, adjustment, or repair is to be performed only by persons authorized by

the facility medical director or by Fresenius USA, Inc.

Questions?

For further information regarding the operation, repair, parts, or maintenance of the 2008T

hemodialysis machine, please contact:

Fresenius USA, Inc. (800) 227-2572

Attention: Service Department

4040 Nelson Avenue

Concord, CA 94520

www.FMCNA.com

Additionally, updates to this operator’s manual are available for download here:

www.fmcna.com/product-support-documentation/

22 2008T Machine Operator’s Manual P/N 490122 Rev U

Chapter 1

Overview

The 2008T hemodialysis machine is designed to perform hemodialysis in hospitals and

dialysis clinics. It can be used for patients suffering chronic or acute renal failure.

Function of the 2008T Hemodialysis Machine

The 2008T hemodialysis machine is designed to provide hemodialysis treatment by

controlling and monitoring both the dialysate and extracorporeal blood circuits.

In the extracorporeal blood circuit, the blood is continuously circulated from the patient

through a dialyzer, where toxins are filtered out through a semi-permeable membrane, before

being returned to the patient. During this process, the extracorporeal blood circuit is

monitored for venous and arterial blood pressures, and for the presence of air and blood. The

2008T hemodialysis machine can also administer heparin evenly throughout the treatment.

In the dialysate circuit, the dialysate concentrates are mixed with purified water, heated,

degassed, and delivered to the dialyzer. Balancing chambers ensure that the incoming flow

of the dialysate is volumetrically equal to the outgoing flow in order to control ultrafiltration

from the patient.

Organization of the 2008T Hemodialysis Machine

The 2008T hemodialysis machine is designed for functional efficiency. The back of the

machine houses the utility connections such as water source, drain, and electrical

connections. By mounting them to the back, the water lines and power cord remain out of the

way during treatment.

The front of the machine contains all of the controls the operator needs access to during

hemodialysis. It can be broken down into three main sections. The top section contains the

control panel and houses the computer that runs the treatment program. The middle section

contains the modules used for the safe transmission of the blood to and from the dialyzer.

Dialysate is the primary concern of the bottom section of the 2008T hemodialysis machine.

Here the concentrates used to make up the dialysate are mixed and pumped to the dialyzer.

The following pages contain front and rear views of the 2008T hemodialysis machine and a

brief description of the machine’s features. You should familiarize yourself with the location

and purpose of these features.

2008T Machine Operator’s Manual P/N 490122 Rev U 23

Chapter 1—Overview

Figure 1 – 2008T Hemodialysis Machine—Front View

24 2008T Machine Operator’s Manual P/N 490122 Rev U

Chapter 1—Overview

Figure 2 – 2008T Hemodialysis Machine—Rear View

2008T Machine Operator’s Manual P/N 490122 Rev U 25

Chapter 1—Overview

The Control Panel

The control panel (see Figure 3) is located at the top, front of the 2008T hemodialysis

machine and contains keys that allow the user to control the operation of the 2008T

hemodialysis machine. Located at the top of the control panel is a display screen that can

show a variety of treatment screens which the operator uses to set treatment parameters and

monitor the treatment.

The treatment display screen provides a means of setting the treatment parameters and

monitoring the treatment and patient status during dialysis. The operator can access

treatment screens, select the Tx Clock, and set treatment parameters by selecting specific,

identified sites (buttons) on the screen by using the touchpad cursor or by touching them

directly with the touchscreen. Changes to settings and parameters selected on the screen must

then be confirmed by pressing the CONFIRM key on the control panel.

Touchscreen

Keypad

Touchpad

Keyboard

Figure 3 – The Components of the Control Panel

26 2008T Machine Operator’s Manual P/N 490122 Rev U

Control Panel Keypad

Figure 4 – Control Panel Keypad

Chapter 1—Overview

The Control Panel Keypad contains seven keys associated with starting or stopping the basic

power and alarm aspects of any dialysis treatment. The table below lists each key and its

function.

Caution: Use a finger to press the keys and the touchscreen. Use of objects to press the

keys or touchscreen may result in damage or premature failure.

Note: Pressing any control panel key (except for the Power key) while displaying CDX or

in Low Power Mode will switch the machine back to full power Dialysis Mode. See page

293 for more information on CDX and page 334 for information about Low Power Mode.

Table 1 – Control Panel Keypad Keys

Press … To …

Turn the machine on. Hold for one second to turn the power off and, if blood

is sensed, the machine will power down with an audible alarm.

If the CDX Auto On feature is running for the day, pressing the Power key

will only cause the machine to power down for two minutes, after which it

will restart. See page 340 for more information about the CDX Auto On

feature.

Silence an alarm for two minutes or until another alarm occurs. The red

light above the key is on if an alarm is muted.

Functional software version 2.72 or later: A muted alarm is also indicated in

the Dialogue Box, see page 30 for more information.

Note: The following alarms are muted for an extra four minutes

(for a total of six minutes) when using a bibag disposable for the

bicarbonate source: Conductivity Low, Conductivity High, bibag:

Cond Low, Bicarb Cond 2 Low, Bicarb Cond 2 High, Low

Temperature, and High Temperature.

2008T Machine Operator’s Manual P/N 490122 Rev U 27

Chapter 1—Overview

Press … To …

(New Treatment) Erase the current treatment information and move the

summary information to the previous record in the “Trends” screen.

Press the CONFIRM key on the touchpad or Enter on the keyboard to

complete the action. To cancel, press the Escape key on the touchpad or the

Esc key on the keyboard.

If the Service Mode ‘Default Rx Screen’ option is set to ‘Yes’ and no

PatientCard is used, pressing and confirming the New Tx key will instead

display the “Default Parameters” screen. See page 118 for more information.

Reset the machine after an alarm.

Press and hold for two seconds to spread the alarm window by 300 mmHg for

arterial and venous pressures and fully open the transmembrane (TMP)

pressure window for 30 seconds. The light above the Reset key will not be on.

During a blood leak alarm, press and hold for three seconds to override the

alarm and keep the blood pump running for three minutes. The light above the

Reset key will be on during an override.

Note: The Reset key is only used to reset alarms; it does not reset

or cancel changes to a parameter.

Start an unscheduled, manual blood pressure measurement when the cuff is

deflated, or instantly deflate the inflated blood pressure cuff.

Warning! Too frequent measurements can cause injury to the

patient due to blood flow interference.

Note: Certain versions of the blood pressure module require a 30

second delay between blood pressure measurements.

Note: Pressing the Stat/Deflate key while displaying CDX will only

exit CDX. The operator must then press the Stat/Deflate key again

in order to take a blood pressure measurement.

Turn the ultrafiltration pump on or off. During ultrafiltration, the green light is

illuminated. This light will flash when ultrafiltration is interrupted.

Note: When the UF pump is turned off, there is no “minimum”

ultrafiltration occurring.

Prime the extracorporeal blood circuit. Pressing Prime will keep the blood

pump running when air is sensed in the venous blood chamber and an air

detector alarm is present (as is the case during initial set up when the blood

circuit tubing is empty). The pump will run for:

Two minutes, or

Until an adequate fluid level is detected by the ultrasonic sensors in the level

detector module, or

Until the volume set in Service Mode is reached.

28 2008T Machine Operator’s Manual P/N 490122 Rev U

Treatment Display Section

Chapter 1—Overview

Status Light

Status Box

Touchscreen

Screen-Buttons

Figure 5 – Control Panel – Treatment Display Section

Dialogue Box

The Treatment Display section is used to display information and access and set all treatment

parameters.

At the top of the Treatment Display Section is the Status Light. The Status Light indicates

the machine’s status with an illuminated dome. Its color matches the Status Box (see Figure

5). The lights (red, green, or yellow) are used to display status information. This allows

clinic personnel to monitor the status of each 2008T hemodialysis machine from a distance

during treatment. There are several selections for the meaning of the lights described in the

‘Beacon’ option on page 315. When the Status Light flashes green with the display screen

off, the machine is in Low Power Mode. To turn the display back on, simply touch the

touchscreen, keyboard, or touchpad. For more information about Low Power Mode, see page

334.

The Status Box appears at the top left corner of every treatment screen. During normal

operation it displays the operational mode of the machine—Dialysis or SLED. During alarm

situations, it displays an informational message. It may also prompt the operator for a

specific action in situations when the treatment parameters are being set.

2008T Machine Operator’s Manual P/N 490122 Rev U 29

Chapter 1—Overview

To the right of the Status Box, is the Dialogue Box. During normal treatment, the Dialogue

Box displays the current time, the time of the last blood pressure reading and the patient’s

blood pressure and pulse rate at that time. Starting in functional software version 2.72, the

Dialogue Box also displays the Bell button (see Figure 6). Selecting the Bell button displays

a pop-up window allowing the operator to adjust the alarm volume (plus) or ▬ (minus)

buttons. If an alarm is muted, the Bell button displays a red X over it.

The Dialogue Box also displays advisory messages when an action is required by the operator

(for example, to correct a treatment parameter that is outside the range of allowable limits) or

when more information about a situation is available. For a listing of advisory messages, see

the “Troubleshooting” section on page 199.

Dialogue Box

Adjusting

Alarm Volume

Alarm Volume

Locked at

‘Medium’

Alarm Volume

Adjusted by

External Knob

Alarm Muted

Bell button Current Time Pulse

Time of last BP reading Blood Pressure

Dialogue Box

Advisory

Message

Figure 6 – Dialogue Box Features (functional software version 2.72 with BlueStarTM

Premium)

The treatment display screen, or touchscreen, contains the area for viewing and entering the

various treatment settings. Adjustments to treatment parameters and options are made using

buttons. For a description of the various types of buttons and their states, see Figure 7 on the

next page.

30 2008T Machine Operator’s Manual P/N 490122 Rev U

Chapter 1—Overview

ScreenButtons

ParameterButtons

ActionButtons

MovementButtons

ToggleButtons

Normal

Light blue or

light yellow with

black text

Selected

Dark blue,

dark yellow, or

gray X in toggle

—must confirm

or escape

Unavailable

Gray

Running

Green

Out of Range

Red

Figure 7 – Button Types and States

Screen-buttons along the bottom edge of the display screen are common to all treatment

screens in the Dialysis and SLED programs. See Table 2 below for a description of these

screen-buttons. Specific information regarding each treatment screen can be found in

Chapter 3, “Setting Treatment Parameters” and Chapter 4, “Monitoring the Treatment.”

Table 2 – Common Screen-Buttons

Select … To …

View current treatment data including treatment time remaining, UF

data, arterial, venous, and transmembrane pressures, and dialysate

data.

2008T Machine Operator’s Manual P/N 490122 Rev U 31

Chapter 1—Overview

Select … To …

View charts that provide graphic views of treatment effectiveness

(Kt/V), sodium variation system (SVS) and ultrafiltration (UF) profiles,

and patient’s blood pressure over time.

Displays the summary data of the patient’s treatment progress.

View and select acid/bicarbonate concentrate type, bicarbonate,

sodium, electrolyte concentrations, and conductivity settings.

View Pressure test, Alarm test, and Diasafe test options and results.

View treatment options for low volume and single needle patients, high

flux dialyzers, enter a patient ID number, and access Auto Prime,

Assisted Reinfusion, and dialysate sampling features.

View options for administering heparin gradually over the course of the

treatment and/or as a bolus injection. This button turns green during

treatment when the heparin pump is running (functional software

version 2.34 or later).

View estimate of treatment effectiveness based on the actual dialyzer

clearance.

View the Access Flow messages and data

View arterial and venous blood temperature data with machines

equipped with the optional Blood Temperature Module. For more

information, see Blood Temperature Monitor Operating Instructions

Or

(P/N 470164).

View the relative blood volume data and trends with machines

equipped with the optional Blood Volume Module. For more

information, see Blood Volume Monitor Operating Instructions (P/N

490041).

When the Crit-Line in a Clip (CLiC) device is used during the

treatment, the “Crit-Line” screen replaces the “BTM BVM” screen. The

“Crit-Line” screen can be configured (in Service Mode) to show either

blood volume or hematocrit. Additionally, the “Crit-Line” screen can

alternately display blood pressure or oxygen saturation graphs during

the treatment. Most of the commonly viewed data from other screens

are also grouped on the “Crit-Line” screen for convenient monitoring.

For more information, see the 2008T Hemodialysis Machine with CLiC

User’s Guide (P/N 490206).

View all pulse and blood pressure test results taken during treatment.

Blood pressure alarm limits and inflation pressure and frequency of

blood pressure tests are set in this screen.

32 2008T Machine Operator’s Manual P/N 490122 Rev U

Chapter 1—Overview

Fold-Down Keyboard

Figure 8 – Control Panel – Fold-Down Keyboard

The keyboard is located directly below the display screen. It folds down for entering

treatment parameter values or making selections inside the treatment screens and folds up

again to prevent accidental changes. Folding up the keyboard also provides an unobstructed

view of the blood pump and arterial and venous drip chambers.

Table 3 – Keyboard Keys

Press … To …

Enter numerical values when setting parameters for such treatment options as

ultrafiltration rate, times, goal, and volumes.

Scroll up or down a list of parameter choices or to increase (up arrow) or

decrease (down arrow) parameter values. To speed up the rate at which the

value changes, press and hold the key down.

Note: (CDX only) holding down the Shift key while pressing an arrow key will

shift to the secondary function printed on the key.

Save a treatment parameter entry or confirm an action initiated on the display

screen. The Enter key is a backup, safety feature designed to prevent

accidental changes to the intended treatment parameters.

Note: The Enter key functions the same as the CONFIRM key on the touchpad

Void the current entry and return to previously entered parameter value before

CONFIRM is pressed. If the on-screen cursor disappears, press the Esc key to

show it again.

Note: The Esc key functions the same as the Escape key on the touchpad.

CDX only: Pressing the blue CDX key will switch between displaying Dialysis or

SLED and the optional Clinical Data Exchange (CDX) system. For more

information, see page 293.

CDX only: The blue Fn (Function) Lock key selects the secondary function of

keys with blue function numbers (F1-F12) at the top of the keyboard. Press the

Fn Lock key and then press a function key to select that function. The Fn Lock

light in the upper left corner of the keyboard indicates the lock status: when the

light is on, the function lock is on. Press the Fn Lock key again to turn off the

function lock.

Note: Older versions of the keyboard instead feature a Fn key which must be

held down to select the secondary functions of the blue function number keys.

2008T Machine Operator’s Manual P/N 490122 Rev U 33

Chapter 1—Overview

Fold-Down Touchpad

Figure 9 – Control Panel – Touchpad

The touchpad is located directly below the Control Panel Keypad. It folds down to reveal a

touchpad which is used to move the on-screen cursor arrow. It also features two keys:

Table 4 – Touchpad Keys

Press … To …

Select a field highlighted by the on-screen cursor arrow.

Save a treatment parameter entry or confirm an action initiated on the

display screen. The CONFIRM key is a backup, safety feature designed

to prevent accidental changes to the intended treatment parameters.

Note: The CONFIRM key functions the same as the Enter key on the

keyboard.

Void the current entry and return to previously entered parameter value

before CONFIRM is pressed.

Note: The Escape key functions the same as the Esc key on the

keyboard.

Tap the touchpad to select a field highlighted by the on-screen cursor

Touchpad

arrow

Tap the touchpad again to confirm a change.

Note: The on-screen cursor arrow will disappear if not moved for five seconds. Move the

cursor using the touchpad for it to reappear.

It also disappears when a value is entered but not yet confirmed. To display the cursor

again, press the Escape key to cancel the change or press the CONFIRM key to confirm the

change.

34 2008T Machine Operator’s Manual P/N 490122 Rev U

The Back Panel

Chapter 1—Overview

CDX

Speaker

USB Port 2 RS 232 Port

Hour Meter Ethernet Port

Figure 10 – Back Panel (with obsolete external hour meter and volume knob)

9-V Battery

Compartment

Dialysis Mode Alarm

Volume Control Knob

Heater On/Off

Switch

Mains Power Supply

On/Off Switch

Dialysis Mode

Speaker

The back panel of the 2008T hemodialysis machine is located on the back of the machine at

the top of the cabinet. It contains additional controls like audible volume, switches and

various connections.

Table 5 – Back Panel Features

Feature Function

CDX Speaker

USB Port 2

Sound from the CDX PC (optional) will be produced by this speaker only

when the machine is displaying CDX (see page 293 for more

information). It is muted when displaying Dialysis/SLED treatment

screens.

Expansion for CDX PC (optional). Only self-powered USB devices may be

connected when the 2008T hemodialysis machine is used with a patient.

Warning! Do not connect devices requiring an external AC

power connection to the machine's USB ports (for example:

printers, card readers, or USB hard drives that plug into a wall

outlet). Only freestanding (self-powered) devices such as

USB flash drives are permitted. Inserting a powered USB

device into your machine's USB ports may adversely affect the

machine's electrical safety and patient isolation.

2008T Machine Operator’s Manual P/N 490122 Rev U 35

Chapter 1—Overview

Feature Function

RS 232 Port

Volume

Control

(Dialysis

Mode Only)

Dialysis Mode

Speaker

Hour Meter

Electrically isolated RS 232 serial interface connector; hard wired, used

for display terminal connection.

Used to adjust the volume (sound pressure level) of the dialysis machine

audible alarms. Does not affect the volume from the separate CDX

speaker.

For functional software version 2.72 or later, this external volume control

knob may be disabled or absent. In this case, the alarm volume is

controlled using buttons on the touchscreen. For more information, see

page 30.

The Dialysis Mode speaker makes two different sounds: a Low Alarm

sound, and a High Alarm sound. The two sounds are distinct; the first

one is used for lower priority alarms, and the second for more important

alarms.

This displays the number of hours the machine has run over its lifetime.

See the “2008T Preventive Maintenance Procedures Manual” (P/N

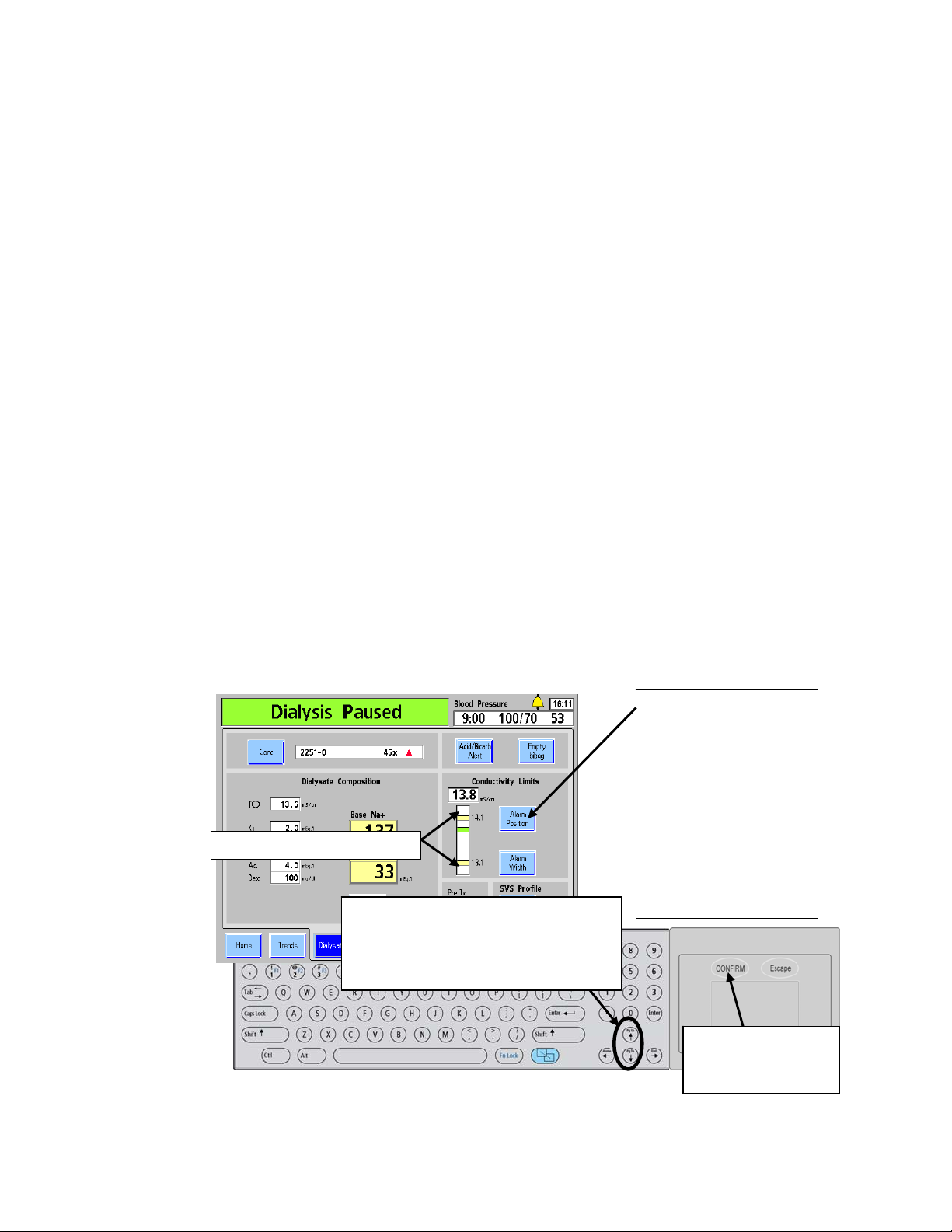

508033) for information on scheduled maintenance.