FREQUENTIS

SAFETY GUIDELINES

00A46 E500.12

COPYRIGHT FREQUENTIS 2000

FREQUENTIS GmbH

Dieses Dokument ist elektronisch freigegeben.

This document is released electronically.

Spittelbreitengasse 34, A-1120 Vienna, DVR 0364797

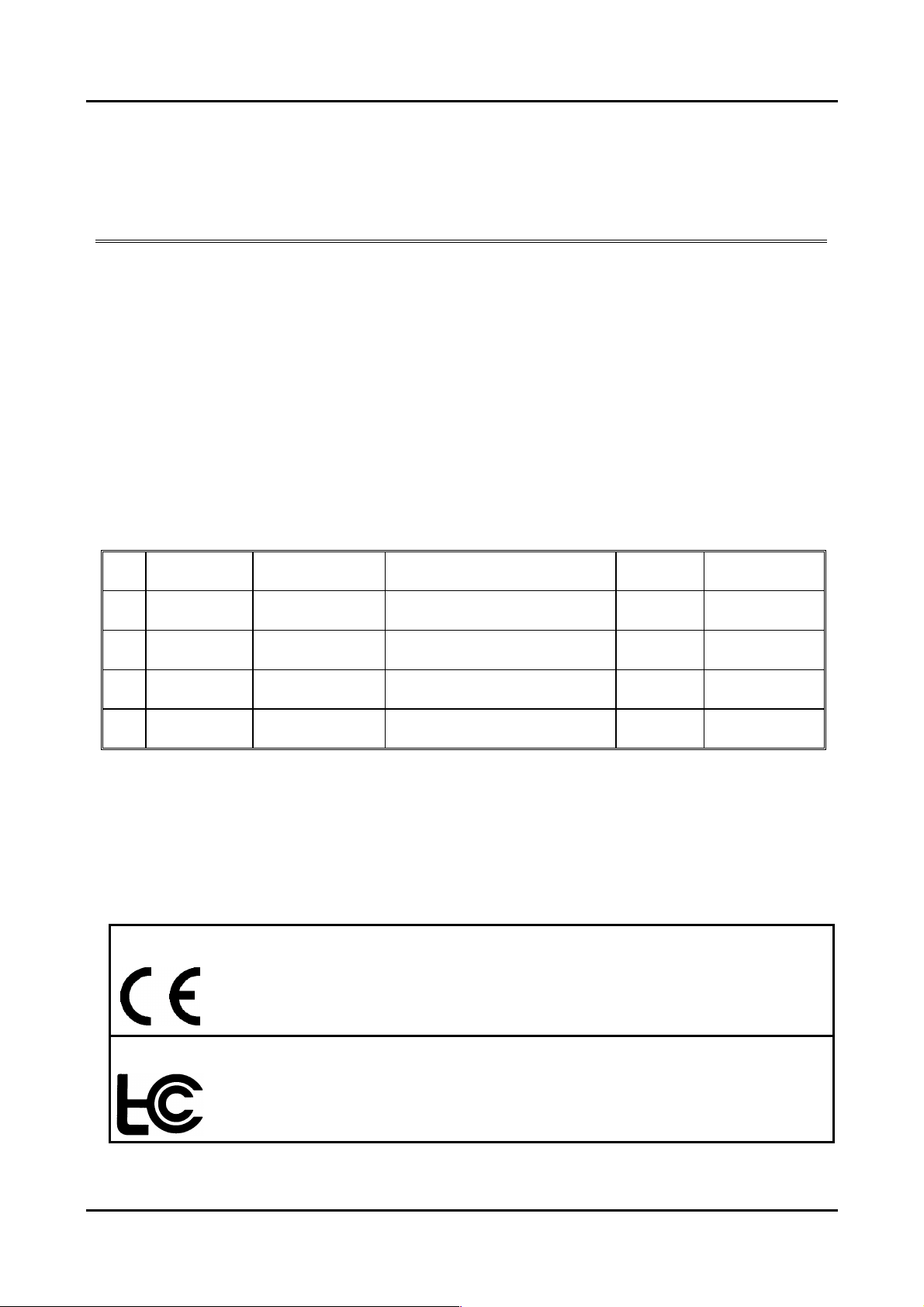

History Chart

Rev. Date Changed Page(s) Cause of Change Implemented

1.0 00-11-29 All sections New Document S. Meisel

1.1 01-07-20 All sections Wording & Corrections S. Meisel

1.2 04-02-01 D-1, 5, 6, 8, 9, 34, 35 UL- & EN-Requirements;

S. Meisel

VCS >> "system"

No. Action Name Signature Date Department

1 Prepared S. Meisel 04-07-12 TCI

2 Approved G. Herndl 04-07-16 SSG

3 Approved H. Schicht 04-07-13 TQC

4 Released F. Kalwitz 04-07-16 TCI

The information in this document is subject to change without notice.

All rights reserved. No part of the document may be reproduced or transmitted in any form or

by any means, electronic or mechanical, for any purpose, without the written permission of

FREQUENTIS GmbH.

Company or product names mentioned in this document may be trademarks or registered

trademarks of their respective companies.

Confirmed by the CE-label, the system complies with following EC-directives and EC-standards:

● 73/23/EC “Low Voltage”

● 89/336/EEC “Electromagnetic Compatibility”

● 99/5/EC “R&TTE” (Annex 2 Class I Equipment)

The system complies with Part 15 of the FCC Rules. Operation is subject to the following 2 conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

● EN 60950-1 (01)

● EN 55022 (98)

● EN 55024 (98)

D-1 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

Contents

1. Introduction .......................................................................... 4

1.1. Purpose.............................................................................................................4

1.2. Target Group.....................................................................................................4

1.3. Requirements Concerning Warranty.................................................................4

1.4. Description of the Warning Symbols .................................................................5

1.5. Definition of Terms and Synonyms ................................................................... 6

1.6. Major Warnings .................................................................................................6

2. Safety Instructions............................................................... 7

2.1. Safety-Critical Phases of Installation and Maintenance .................................... 7

2.2. Personal Safety.................................................................................................8

2.2.1. Fire Hazard .......................................................................................................8

2.2.2. Electric Shock ...................................................................................................8

2.2.2.1. Causes and Prevention of Electric Shock .........................................................9

2.2.2.2. Inspection to Prevent Electric Shock............................................................... 10

2.2.3. Injuries.............................................................................................................11

2.3. Handling Safety...............................................................................................11

2.4. Equipment Safety............................................................................................12

2.4.1. Mechanical Requirements...............................................................................12

2.4.2. Electrical Requirements ..................................................................................13

2.4.2.1. Safety Requirements....................................................................................... 13

2.4.2.2. Redundancy Requirements (if applicable) ...................................................... 14

2.4.2.3. Protective Earthing..........................................................................................15

3. Electrostatic Discharge (ESD) ..........................................16

3.1. Definition .........................................................................................................16

3.2. ESD-Protection of Sensitive Assembly Parts.................................................. 16

3.3. Handling of Devices Sensitive to Electrostatic Discharge...............................17

3.3.1. General Rules for Handling Electronic Assemblies.........................................17

3.4. ESD-protection at the Equipment Area ...........................................................17

3.5. ESD-Protected Workplace .............................................................................. 19

3.6. ESD-Protection during Shipping and Storage.................................................20

3.6.1. Packaging of Electronic Assemblies ...............................................................20

3.7. ESD-Regulations for Visitors........................................................................... 20

4. Overvoltage Caused by Electrical Transients / Lightning. 21

5. Electromagnetic Compatibility (EMC) .............................. 22

5.1. Generic Electromagnetic Compatibility Requirements.................................... 22

5.2. Specific Electromagnetic Compatibility Requirements.................................... 22

5.2.1. Electromagnetic Fields Emitted by Visual Display Units................................. 23

5.2.2. Check of Aerials and Receivers Adjacent to the Equipment...........................23

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC C-2

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

6. Equipment Labelling.......................................................... 24

6.1. Adhesive FREQUENTIS Equipment Labels ...................................................24

6.1.1. Labels Indicating Product Categories .............................................................25

6.1.2. Labels Indicating Standards............................................................................ 26

6.2. Cable Identification..........................................................................................27

6.2.1. Cable Identifier Tags....................................................................................... 27

6.2.2. Cable Types.................................................................................................... 27

6.2.2.1. Connector Plan ...............................................................................................28

6.2.2.2. Wiring List .......................................................................................................28

6.2.3. Labelling with Printed Sheathing..................................................................... 28

7. Handling of Equipment...................................................... 29

7.1. Required Tools................................................................................................29

8. Abbreviations ..................................................................... 30

9. Appendix............................................................................. 32

9.1. References to Standards ................................................................................32

9.2. Tables Concerning Safety Regulations...........................................................34

Illustrations

Fig. 3-1: Layout of Markings for Earth Bonding Points (Examples)............................... 18

Fig. 3-2: Earth Bonding Point at the Front of a Cabinet (Example) ...............................18

Fig. 3-3: Wrist Cable Connected to Grounding Point .................................................... 19

Fig. 6-1: ESD-Label and Structure of Serial Numbers ..................................................24

Fig. 6-2: Serial Number Label of a Board......................................................................25

Fig. 6-3: Example of the Two Cable Identifiers for One Cable ......................................27

Fig. 6-4: Complete Cable Designation ..........................................................................27

Fig. 6-5: Position of a Cable Identifier Tag.................................................................... 28

Fig. 6-6: Cable Sheath Printing .....................................................................................28

Fig. 7-1: ESD Field Service Kit......................................................................................29

Fig. 9-1: Structure of EN Standards (Example)............................................................. 32

Tables

Tab. 2-1: Causes and Prevention of Electric Shock .........................................................9

Tab. 6-1: Labels Indicating Product Categories .............................................................25

Tab. 6-2: Labels Indicating Standards............................................................................26

Tab. 9-1: Typical Static Charge Sources........................................................................34

Tab. 9-2: Typical Static Voltage Generation...................................................................34

Tab. 9-3: Maximum Resistance vs. Discharge Time for Static Safe Operations............ 34

Tab. 9-4: Minimum Sizes of Conductors in Power Supply Cords................................... 35

Tab. 9-5: Ranges of Conductor Cross-Sections.............................................................35

---------- END OF SECTION ----------

C-3 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

1. Introduction

Only trained personnel authorised by the customer and/or FREQUENTIS

may handle the system.

Always read this manual carefully before starting to install or service the

system.

For easy access, keep the Safety Guidelines at hand on site.

1.1. Purpose

These Safety Guidelines explain the precautions and basic information required

for correct handling of a system from the range of released products of

FREQUENTIS (e.g. VCS 3020 Series, VCX, DICORA). For details of the actual

configuration, please refer to the System Configuration document.

These Safety Guidelines are concerned with workplace and equipment safety not

including the reliability of the system.

1.2. Target Group

The Safety Guidelines contain precautions to be taken by the trained installation

and/or maintenance staff when servicing the system. They are intended for

everyone involved in preparing for the infrastructure, installing the system and/or

maintaining its components. Moreover, this manual is aimed at anyone who deals

physically with the system.

The staff is expected to be aware of obvious hazards. Furthermore, they have to

be appropriately trained for and experienced enough to recognise hazards in

their daily work, and to minimise risks to themselves and others.

The staff must be trained and observe, among others, appropriate ESD-practices

and procedures for handling the cabinets, boards and cabling. A FREQUENTIS

training course covering the technical part (basics and maintenance) of the

system is essential to achieve the correct handling of the system.

1.3. Requirements Concerning Warranty

Only trained personnel authorised by the customer and/or FREQUENTIS may

prepare the site, install, put into operation and maintain the system.

All warnings and instructions contained in the applicable documents supplied

must be observed. The meaning of the warning symbols used is described in

chapter 1.4. Major warnings e.g. concerning risks of injuries or damage to the

equipment are listed in chapter 1.6.

Violation or non-observance of the Safety Guidelines in this document cancels or

restricts the warranty provided by FREQUENTIS. In particular, FREQUENTIS

shall not be responsible for any resultant operational errors or any damages

caused to persons, properties or whatsoever.

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 4

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

If the customer wishes to make major changes to the system (i.e. any

system modification not described in the relevant revision of the System

Configuration document, Installation Manual or Maintenance Manual), for

instance, if the customer wants

● to move the system or parts of the core system to different locations,

● to extend, reduce or modify the system configuration,

● to connect third-party equipment to the system supply circuits,

● to change to power supplies not delivered by FREQUENTIS,

● to change the grounding concept,

FREQUENTIS must be informed in writing giving sufficient advance notice.

The customer then has to wait for written permission from FREQUENTIS

before carrying out such changes.

1)

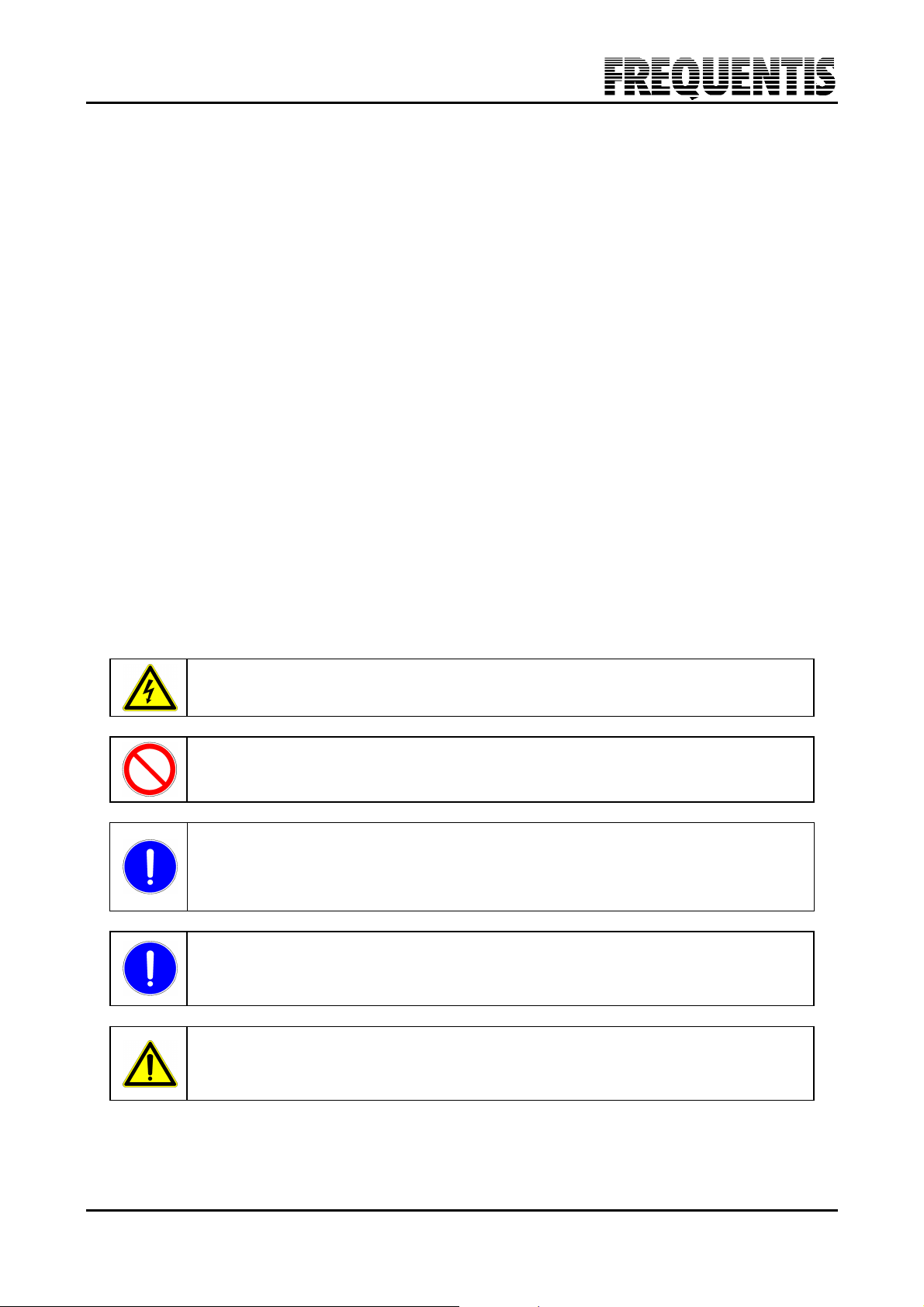

1.4. Description of the Warning Symbols

The Safety Guidelines and the other User Documentation contain warnings,

recommendations and safety precautions as defined in ISO 3864-1984 (E).

Disallowed - Interdict - Prohibition!

Risk of an electric shock.

Risk of serious injury or of severe damage to equipment.

Risk of severe damage to electrostatic sensitive devices.

Mandatory for operation.

This symbol emphasises extra information.

1)

Any change of the system configuration must be incorporated adequately in the accompanying

system- and user-documentation without delay agreed with FREQUENTIS.

5 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

1.5. Definition of Terms and Synonyms

Handling Dealing with or manipulating the system or its components in a

technical context.

Installation Initial set-up of the system hardware or parts of it, and operating

system configuration.

Maintenance Any action for keeping the system in working order (acc. to the

relevant maintenance level).

Service All actions taken to set-up or to keep the system in good operating

condition, including monitoring of the technical infrastructure,

maintenance and repair work.

Because of potential inconsistency in terminology, the following terms on the left

can be considered as synonyms for the terms on the right:

A/G-Communication ~ Radio Communication

G/G-Communication ~ Telephone Communication

Operator Position (OP) ~ Controller Working Position (CWP)

Project Specification ~ System Configuration Document

Documentation, DOC, (output) ~ Recording, REC, (output)

1.6. Major Warnings

The following warnings and precautions have to be observed strictly:

Some of the devices (e.g. power supplies and panels) operate at lethal

voltages.

Do not work on live system parts. De-energise all power supplies first then

follow the appropriate procedures.

The equipment is to be installed in Restricted Access Areas only

(dedicated equipment rooms, wall-mounting equipment cabinets, or the like)

in accordance with National Electric Code, ANSI/NFPA 70 (110-16 to 18). It is

suitable for mounting on concrete or other non-combustible surfaces only.

Only persons who are properly trained and capable of handling electronic

devices may service the system.

Observe the ESD- and EMC-regulations (refer to section 3 and 5).

Do not utilise non-released SW or HW additional to or instead of SW resp.

HW of the system configuration released by FREQUENTIS.

Do not apply wrong supply voltages.

---------- END OF SECTION ----------

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 6

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

2. Safety Instructions

Above all, basic prerequisites must be considered concerning safety instructions,

protection against electrostatic discharge, overvoltage caused by electrical

transients or lightning, electromagnetic compatibility, infrastructure planning, site

survey and area identification.

This section covers the safety-critical service phases: personal safety, fire

hazards, electrical shocks, injuries, handling safety and equipment safety.

2.1. Safety-Critical Phases of Installation and Maintenance

Only a fully trained technical crew may service the system as the crewmembers

may be exposed to potential hazards of various types while performing their

duties. These hazards must be eliminated or reduced to ensure that the staff is at

minimum risk.

All installation personnel shall be briefed on the potential hazards involved in

installing the system. Awareness of these hazards shall be promoted by the site

safety officer (person responsible for safety at the site), who shall be present

during all safety-critical phases of installation:

1) Unloading of equipment on site

2) Transport of equipment to final location

3) Installation of heavy system parts

4) Initial power application to fully-installed system

5) Changing of boards

The service life cycle consists of the following phases:

1) (Trans)shipment to site

2) Unloading on-site

3) Transport to final location

4) Erection and mechanical assembly at the final location

5) Cabling at the final location

6) Initial equipment power-up

7) Test and integration of fully powered system

8) Adding, changing or removing components

Each of these phases contains some or all of the hazards identified in the

following chapters. Detailed countermeasures are described for each type of

hazard.

The staff have to be aware of the typical hazards already identified and the action

required. The list is in no way conclusive and unforeseen hazards may occur at

any time. Each crewmember is responsible for identifying further hazards and

reporting them to the site safety officer.

7 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

2.2. Personal Safety

It is of utmost importance not to expose the personnel to unnecessary risks

during their work. Where essential activities involve a safety risk of any kind, the

site safety officer has to be informed. The site safety officer has to take measures

to provide adequate precautions against the hazard, such as fire extinguishers or

medical supervision. The following hazards are predictable:

● Fire hazard Chapter 2.2.1

● Electrical shock Chapter 2.2.2

● Injuries (e.g. tripping over cables or cuts from sharp objects) Chapter 2.2.3

2.2.1. Fire Hazard

Fire hazards can never be totally eliminated, but preventive measures should

ensure that any damage or injury is avoided.

● In particular, the correct type of fire extinguisher always has to be available in

the vicinity of current activities. The personnel shall be instructed by the

person responsible for site safety on the correct use of an extinguisher in an

emergency, the various types and their physical location.

● Burns and/or inhalation of fumes caused by fire must be reported immediately

for treatment by the medical staff.

● Smoking in the facility during the service period is not permitted.

To reduce the risk of fire, use only No. 26 AWG (>0.4 mm ∅) or larger wires

for telecommunication lines.

2.2.2. Electric Shock

Despite the care taken by skilled personnel at work, exposure to electric shock

due to unpredictable events can, however, never be excluded. Line driving and

ringing voltage are health hazards to the personnel. They therefore have to work

with special care during and after the initial power-up, particularly at the

backplanes of the core and interface racks.

Though the following safety precautions should prevent such potential hazards,

the power may be turned on inadvertently by third parties or electrical power may

already be available in other parts of the system.

● Each system component must be correctly connected to ground to minimise

personnel exposure to shock hazards. This must be completed before power of

any voltage is applied. The facility power engineer must ensure that all

grounding points are properly connected to the central bonding rail (the

building’s earth).

● Service activities after connection of the system to the main facility power shall

be co-ordinated by means of mobile communication between the

crewmembers and the facility power engineer, who is responsible for ensuring

that power application at a particular location does not affect other locations.

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 8

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

● Medical supervision should be provided, but first-aid counter-measurements

will provide the most effective treatment for electrical shock victims. Artificial

respiration is the prime recognised means of resuscitating an electrical shock

victim. All crewmembers must be trained in this method.

● A victim must be separated from live power contacts before resuscitation

measures are employed. If the source of power cannot be accessed or turned

off, a dry, insulated object, such as a broom, must be used to minimise the

risk that the person providing aid is not similarly exposed to the same hazard.

● Qualified medical attention must be sought in all cases of electrical shock

exposure to ensure that no symptoms remain. The site safety officer must be

immediately informed of an accident to notify the appropriate authorities.

● Provision must be made in the grounding system to protect the personnel

from live circuitry due to carelessness or equipment failure. A survey must be

performed of the available voltage sources that could be encountered at the

equipment area to provide adequate protection from electrical hazards.

The equipment may have more than one power supply cord! To avoid

electric shock, disconnect all power supplies before servicing the system.

2.2.2.1. Causes and Prevention of Electric Shock

Causes of Electric Shock Prevention

Contact with parts normally

at hazardous voltage.

Prevent access to parts at hazardous voltage

by fixed or locked covers, interlocks, etc.

Discharge capacitors at hazardous voltages.

Breakdown of insulation between

parts normally at hazardous

voltage and accessible conductive

parts.

● Connect the accessible conductive parts to

earth to limit the voltage to safe values and

the circuit breaker will disconnect the parts

having low impedance faults.

● Use double or reinforced insulation between

accessible conductive parts and parts which

are at hazardous voltages in normal use.

Breakdown of insulation between

parts at hazardous voltages,

applying it to accessible parts.

Segregate hazardous voltage circuits.

Separate by earthed metal screens or

reinforced insulation. Earth any circuits capable

of carrying fault currents.

Breakdown of insulation guarding

parts at hazardous voltage.

Insulation for parts at hazardous voltage accessible to the authorised representative must

have adequate mechanical/electrical strength

Leakage current from parts at

hazardous voltage to the casing.

Failure of PE-connection.

Limit leakage current to body to a safe value,

or provide high integrity protective earth

connection.

Tab. 2-1: Causes and Prevention of Electric Shock

9 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

2.2.2.2. Inspection to Prevent Electric Shock

Check, that

1) Protective devices comply with the site-specific requirements in accordance

with the (inter)national regulations.

• Protective earthing (PE) and equipotential bonding conductors meet the

required minimum cross-sections.

• PE- and neutral(N)-conductors are marked suitably and unmistakably.

• PE-conductors contain no switches, fuses or circuit breakers.

• Protective contacts of all plug-and-socket connections work efficiently.

• PE or neutral connection and disconnect points are identified.

2) Cross-sections of cords and cabling are appropriate to current consumption

at maximum load.

3) Connections are made in accordance with to the regulations.

4) Disconnect devices are implemented and suitably placed.

5) Inspection of the appliances shows no obvious lapse from safety provisions.

• All appliances meet the site specific environmental conditions and safety

requirements.

• All appliances are easily accessible for operation and maintenance.

• Warning labels for multiple supplies and/or multiple disconnection are

applied according to the respective appliances.

6) Personnel must be prevented from accessing

• bare parts normally operating at ELV or hazardous voltages and

• operational or basic insulation of such parts or wiring.

7) Generally, between an unearthed accessible conductive part and a primary

circuit double or reinforced insulation must be applied.

8) Conductive handles or their shafts, which are manually moved and earthed

only through a pivot or bearing must be separated from hazardous voltages

• by creepage distances and clearances of double or reinforced insulation,

• by supplementary insulation over accessible parts.

9) Insulation of internal wiring at hazardous voltages accessible to personnel

must not be

• subject to damage or stress,

• needed to be handled in normal operation routines,

• routed or fixed in such a way that unearthed metal parts are touchable.

10) Conductive parts of the equipment exposed to hazardous voltage in the event

of a single insulation fault must be reliably connected to a PE-terminal

resistant to significant corrosion.

11) Fire enclosures and fire prevention sheets are applied according to the

regulations.

12) Documentation for installation and maintenance is available at site.

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 10

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

2.2.3. Injuries

Whenever installation or maintenance work is performed, there is a risk of injury

due to mechanical parts. These injuries might be caused by moving parts, falling

items, tripping over cables, tools, sharp edges or working in confined spaces.

● Incautious or accidental movements can result in cuts, bruises and abrasions.

At all times crewmembers must be aware of their environment, the objects in

their vicinity and the presence or proximity of their team colleagues.

● When someone is working in a confined space, such as inside a controller

working position or under the raised false floor, a second person must be

present to supervise the inaccessible person, to check regularly his/her

physical condition and react quickly if there is any suspicion of injury.

● First-aid treatment of physical injuries shall be the prime defence against

further deterioration of the victim's condition. A first-aid box shall be made

available to the personnel on-site.

● Qualified medical attention must be sought in all cases of physical injury to

ensure that there is no risk of contamination or infection of a wound. To this

effect, the site safety officer shall be immediately informed of an accident and

he will notify the appropriate authorities.

2.3. Handling Safety

Moving parts of the equipment must not lead to injury under normal conditions. In

the case of parts accessible to personnel, constructive precautions have to

provide that -

● hazardous parts cannot be mounted with any enclosure part removed,

● enclosure parts are secured to the assembly requiring a tool for removal,

● interlocks protect against access to the potential hazard.

A suitable warning label protects from an obvious hazard caused by the moving

part. De-energising means have to carry warnings readily visible in a prominent

position where the risk of injury is highest.

In particular hard hats, heavy-duty leather gloves and steel-capped safety boots

shall be worn during all activities involving manhandling of corresponding

equipment. The phases of installation/maintenance intended for manhandling

activities are as described in chapter 2.1. No crewmember present in the zone of

operation shall be permitted to perform his/her tasks without taking these

precautionary measures:

● At all times during these phases, precautions shall be taken against human

strain. Sufficient manpower shall be secured when off-loading heavy

equipment, such as the racks, to ensure that no individual is overburdened.

● All individually transportable units must bear a label clearly indicating the

weight of that item, in order to enable the crew to identify the manhandling

resources necessary for that item. The crewmembers must always take

notice of the weight indications attached to the transport items.

● No person must lift equipment that is heavier than 20 kg. Several persons

may lift more than 20 kg, but their individual portion of the total load may not

exceed this weight.

11 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

● Lifting gear must be employed in all cases where the total load exceeds

50 kg. Where lifting gear is used, the immediate vicinity must be cleared of all

personnel except the authorised representative, to ensure that no hazards

exist due to incorrect loading.

● If the item is to be lifted by the eyebolts mounted on top of the racks, care

shall be taken to ensure that these are completely screwed in.

● Where pallets are used, the load shall be equally distributed over the

available pallet area to reduce the risk of accidental shifting. No personnel,

apart from the authorised representatives, are permitted to accompany the

equipment being transported, such as riding on a forklift truck, crane or hoist.

2.4. Equipment Safety

2.4.1. Mechanical Requirements

Mechanical equipment safety hazards can be caused by:

● Damage to the equipment during transport causing unexpected behaviour.

● Access to internal components using incorrect tools.

● Incorrect mechanical mating of connectors.

These safety hazards can be mitigated by applying the following rules:

● The equipment must be adequately secured during shipment/transport using

retaining lines and pallets if necessary. Smaller units must be packed to

prevent denting or perforation of the unit itself.

● All units must be inspected for obvious damage on arrival at the facility.

Those units with damaged packing shall be reported to the team leader, who

will initiate any insurance claims and further inspection of the damaged item.

At his discretion, the item may be released for installation or returned to the

company for replacement.

● Access to internal system components for adjustment purposes must always

be performed with the correct tools. For instance, a potentiometer may only

be accessed through perforated covers with an insulated screwdriver.

● Connectors can easily be damaged during mechanical mating activities. In

order to prevent this, both pin and socket (or both sides) connector halves

must be manually inspected for damage before attempting the mate.

● If a connector, its pins or sockets are damaged in any way, no attempt must

be made to connect the connector. This fact must be reported to the team

leader, who will initiate repair actions.

● If no damage is visible, both connector halves must be gently brought

together in such a way that the keying (if applicable) is lined-up. Mating is

achieved by constant pressure to the connector shell evenly over the mating

area until further movement is no longer possible and the connector can be

secured.

● If a connector is applied to the wrong connection point, serious damage may

occur to the equipment. For this reason, the cable label must match the

destination point. However, insert the connector to its destination shell with

care. If a mismatch is suspected, the mating operation must be stopped for

further technical investigation.

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 12

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

2.4.2. Electrical Requirements

The Installation Manual provides the required information to set-up the system

for safe and reliable operation, including the power supply concept and the

equipotential bonding and grounding concept.

2.4.2.1. Safety Requirements

Installation and construction of the power supply system must comply with the

international standards and national regulations.

Installation of the building’s power supply system must at least observe

the requirements in IEC 60364 or equivalent national regulations (for

instance, VDE 0100 in Germany, and ÖVE/ÖNORM E 8001 in Austria).

Subject to the specific national regulations, the equipment must still be connected

in accordance with (i.e. not contravening) IEC 60950, so that compliance with the

standard is maintained.

● If a plug on a power supply cord is used for disconnection, the according

socket with earthing contact must be located near the system and easily

accessible. The supply plug, if used as the disconnect device, must connect

the PE earlier than the supply connections and must break it later than the

supply connections. Device inlets must meet the following conditions,

compliant to IEC 60320:

● Hazardous voltages are not accessible during handling with connectors.

● Connectors can be inserted easily.

● Sockets are not used for mechanical securing.

● The PE-terminal for each appliance is connected to the PE-terminal inside

the equipment.

● Power supply cords shall not be exposed to sharp points or cutting edges.The

conductors have to be relieved from strain, including twisting. Compression

bushings must not be used as cord anchorage. If the flexible cord should

slip in its anchorage, causing the conductors to be strained, the protective

earthing conductor, if any, must be the last to take the strain.

● Cords must not be clamped by screws; knots must not be applied. When an

anchorage is made of conducting material, it must be supplementary

insulated from accessible metal parts. The insulation of the conductors must

be protected from abrasion.

● For equipment with a non-detachable power supply cord, which is intended to

be moved while in operation, cord guards of insulating material must be

applied at the power supply cord inlet opening, protecting against excessive

bending for at least five times the cross-section of the whole cable.

● Screws and nuts, which clamp external power supply conductors, must

comply with standards ISO 261 or 262 and the like, fixing not any other

component. Terminal strands must not be able to contact unearthed

conductive parts, even when these parts are separated by basic insulation

from other accessible conductors.

13 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

● Where cord terminals are used for permanently connected equipment (non-

detachable power supply cords), the cord cross sections must fit the

respective clamps, otherwise, appropriate adapters must be applied (e.g. in

the case of increased WCS for long distances). Terminals must clamp with

sufficient contact pressure without damaging the conductor when tightened or

loosened, but so that the conductor cannot slip out, the terminal itself does

not work loose and the internal wiring is not subjected to stress (this aspect

has to be taken into account especially at the operator positions).

● Power supply cords consist of -

● a green/yellow PE-conductor electrically connected to the PE-terminal

inside the equipment and connected to the PE-contact of the plug, if

applicable, and

● conductors with minimum cross-sectional areas compliant to the standards

(see Tab. 9-4 and Tab. 9-5), corresponding to the maximum possible

current consumption (for examples refer to Tab. 9-5 in the Appendix).

Protective Devices

● Protective devices against excess current, short circuits and earth faults in

primary circuits, have to be included as integral parts of the equipment, or

part of the building installation.

● Where more than one phase conductor of a supply is used, any protective

device breaking the neutral conductor must break all phase conductors, too.

Devices for different conductors of the same supply shall be located together.

● For commercial (single-phase) equipment connected to standard supply

outlets, the building’s installation is regarded as providing protection in

accordance with the rating of the wall outlet.

● Fuses must be marked so that it is obvious to which circuit the fuse applies,

including its type, rated current, and voltage. Special fusing characteristics

must also be indicated.

In any case, AC or DC power supplies must be installed and maintained

according to the respective national regulations.

2.4.2.2. Redundancy Requirements (if applicable)

The system is designed for highest redundancy and availability. Therefore,

systems are typically installed with resilience against any single failure. This

redundancy concept is fully supported by the power supply concept.

The system provides the connections to two separate supply lines provided by

the site. If one power unit (or whole circuit) fails, alternate power units supply the

system without any malfunction or loss of performance during the downtime of

the failed supply.

Power distribution systems are usually structured radially and circuit breakers

have to be added at any point where the wire cross section is reduced.

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 14

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

The resulting series connection of overcurrent circuit breakers shall be

selective, which means that only the device next to the fault is triggered.

In addition, unwanted triggering of the main ground fault interrupters must

be avoided to ensure that other branches maintain energy flow.

General Rules

● Several branches with overcurrent circuit breakers connected to one ground

fault interrupter consider that a single defective unit can power down all

systems connected.

● Series connections of ground fault interrupters or overcurrent circuit breakers

operating on magnetic principles are not recommended because selectivity is

not ensured except under special conditions.

● Use slow blow fuses or special circuit protectors for heavy loads as the main

overcurrent protectors.

● Selectivity also depends on the characteristics of the (magnetic) circuit

breakers or the pre-arcing I²t of the fuses (Joule heat value), therefore always

follow the manufacturers instructions.

● Preferably, use combined ground fault/overcurrent circuit breakers.

Set up the power distribution system with utmost care regarding

availability. Especially, the redundant supplies A and B for the core

component cabinets must not both fail due to a single fault, i.e.

● they must not be disconnected simultaneously.

● no other equipment must be connected to the system's supplies

2.4.2.3. Protective Earthing

According to the safety standards, accessible conductive parts of the equipment,

that might assume a hazardous voltage in the case of a single insulation fault,

must be -

● reliably connected to a protective earthing terminal within the equipment, or

● at a fail-safe distance from these voltages by reinforced insulation.

The earthing conductors must be used on the power supply cords to protect the

personnel against electrical hazards from the cabinet equipment. Each power

supply must have its own grounding (protective earthing) in accordance with

EN 60950 or IEC 60950 (and the respective national regulations, if required). The

resistance of the earthing connection between the central earth connection point,

and each part required to be earthed must not exceed 0.1 Ω (without the

PE-resistance of the power supply cord).

Warning labels have to indicate to the personnel all the non-earthed parts

that have to be checked for hazardous voltages before being touched.

Vice versa, all parts of the system labelled with the earthing symbol must

remain permanently connected to the grounding system (together with

their subordinate components).

----------- END OF SECTION -----------

15 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

3. Electrostatic Discharge (ESD)

3.1. Definition

Electrostatic sensitive devices are components and assemblies, which can be

damaged, latently damaged or even destroyed by Electrostatic Discharge (ESD).

ESD is the fast discharge of electrical energy created by static sources. A device

sensitive to electrostatic discharge is affected by these high-energy surges,

dependent upon its construction and materials. In assembly areas, where,

unprotected electronic assemblies are attached to the electrostatic sensitive

components, future system failures may be caused by ignoring the basic

protective measures.

The damage due to ESD occurring during handling (e.g., see Tab. 9-2) or

processing can be the same as from electrically powered processes. Affected

components can fail to operate immediately or latently to operate or change in

value. The consequences of latent failure are the most serious, because the

product may fail after delivery although it passed the inspection.

Common materials such as plastic bags or containers are serious static

generators. Do not use these materials (e.g., see Tab. 9-1) in especially static

safe operating areas. Peeling an adhesive tape from a roll can generate 20 kV.

Even compressed air over insulating surfaces generates charges.

Static charges can be induced on nearby conductors (like human skin), and

discharged into other conductors (like boards). Electrostatic discharges are

normally too low to be felt (less than 3.5 kV), but still able to damage sensitive

components.

When working with boards, observe the following precautions for

handling devices sensitive to electrostatic discharge (ESDScomponents).

1) ESD sensitive devices are labelled with the symbol, shown left.

2) Special training is required for working with ESD sensitive devices.

3) Do not touch boards without taking ESD-precautions.

4) Transport and packaging must also provide full ESD-protection.

5) Improper handling cancels warranty and liability on the part of

FREQUENTIS.

3.2. ESD-Protection of Sensitive Assembly Parts

When built-in, each part of the system resists electrostatic discharge (no damage,

no malfunction, and no loss of performance). Sensitive spare parts (e.g. interface

or microprocessor boards) will be delivered in conducting packing material that

prevents damage caused by electrostatic discharge.

All electronic assemblies of systems from FREQUENTIS are tested in accordance

with EN 61000-4-2 with 4 kV contact discharge. Parts, which are touched by

personnel (e.g. touch panels) are additionally tested with 8 kV air discharge.

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 16

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

3.3. Handling of Devices Sensitive to Electrostatic Discharge

Before handling or processing electrostatic discharge sensitive (ESDS)

components, tools and equipment need to be tested carefully to ensure that they

do not generate damaging energy, including spike voltages. As required by most

ESD-specifications, periodic testing is recommended as a precaution because

equipment performance may degrade with use over time. The best ESD-damage

prevention is

● first to prevent, and

● then eliminate static charges if they do occur.

The amount of electrostatic energy generated depends on the characteristics of

the source, and many factors such as material, relative motion by contacting,

separation, or rubbing of the material, humidity etc...

3.3.1. General Rules for Handling Electronic Assemblies

1) Personnel must be trained in and follow the appropriate ESD-practices.

2) Minimise the handling of electronic components to prevent damage.

3) Keep workplaces clean. Avoid any food; do not smoke in the equipment area.

4) In general, handle electronic assemblies with clean hands or gloves (not

common plastics). Touch the board only at the edges and with full ESDprotection. Do not use hand creams or lotions containing silicone since they

can cause solderability problems and conformal coating adhesion problems.

When gloves are used, they need to be changed frequently.

5) Solderable surfaces are not to be handled with bare fingers. Lotions reduce

solderability, promote corrosion and dendritic growth. They can also cause

poor adhesion of subsequent coatings or encapsulates.

6) Never stack electronic assemblies because physical damage may occur. For

temporary storage, special racks need to be provided in assembly areas.

7) Do not take ESDS-components close to display screens.

8) Always assume the items are ESDS-components even if they are not

marked.

9) Never transport ESDS-components unless proper packaging is applied.

If there is any doubt about the sensitivity of an assembly, it must be

handled as a sensitive device until it is determined otherwise.

3.4. ESD-protection at the Equipment Area

ESDS-components must only be handled on condition that the floor conductivity

is sufficient (acc. to IEC 61340-4-1) when

1) a grounding strip is worn around the wrist

2) and/or ESD-shoes (which have to be checked before handling) are worn,

or when

3) the component/assembly is located on an ESD-protected workplace.

4) In addition, wearing a cotton coat it is recommendable.

17 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

EN 100015-1 specifies: The leakage resistance of respective parts must be in the

range between 1 MΩ and 35 MΩ, otherwise suitable action must be taken (e.g.

ESD-shoes, ESD-carpet).

For correct handling of ESDS-components, FREQUENTIS cabinets have a

dedicated grounding point (for the path-to-ground). These earth bonding points

are usually located at the front of the cabinet frame as shown in Fig. 3-2.

Fig. 3-1: Layout of Markings for Earth Bonding Points (Examples)

Fig. 3-2: Earth Bonding Point at the Front of a Cabinet (Example)

When removing boards from the system, first connect the wrist cable to the

grounding point as shown in Fig. 3-3. If no dedicated grounding point is available,

for instance, if a component is to be handled outside the cabinet(s), ESD-shoes

must be worn in all cases (proper floor conductivity must be provided).

Moving Electronic Assemblies

Handling assemblies with bare fingers contaminates the board/component and

causes soldering and coating problems. Fingerprints are hard to remove and will

often show up after exposure to humidity. Body oils and acids reduce

solderability, promote corrosion and dendritic growth, causing poor adhesion of

subsequent coatings or encapsulants. The best solution is to use gloves or other

protective handling devices to prevent such contamination.

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 18

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

Fig. 3-3: Wrist Cable Connected to Grounding Point

3.5. ESD-Protected Workplace

Soldering irons, solder extractors and testing instruments can emit sufficient

energy to destroy ESDS-components or seriously degrade them. An ESDprotected workplace is capable of preventing ESD-damage to ESDS-components

by providing –

● a line to earth for neutralising and draining off surges,

● static dissipative or antistatic working plates connected to a common ground,

● a wrist strap to drain off charges generated on the operator’s skin or clothing.

grounding

point

grounding

cable at wrist

Provisions in the grounding system commonly succeed (through resistance in line

with the ground path) in slowing down the charge decay time preventing sparks

or surges of energy from static charged sources. Values for maximum allowable

resistance and discharge times are given in Tab. 9-3).

Ensure personnel safety.

Consider an adequate decay or discharge time for ESD-potentials.

Keep any workplace free of static generating materials, especially untested

domestic appliances (see Tab. 9-1).

1) Periodically check ESD-protected workplaces to make sure they work.

2) Periodically check and maintain tools and equipment to avoid EOS/ESDhazards for assemblies or personnel caused by improper grounding methods

or oxide on grounding connectors.

In the case of DC-circuits, a floating neutral can have a potential of 80 to 100 V

instead of workbench or earth potential, and can damage ESDS-components or

even put someone's life at risk.

3) Therefore, use earth-fault protected electrical outlets at ESD-protected

workplaces.

19 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

3.6. ESD-Protection during Shipping and Storage

Devices, which are sensitive to electrostatic discharge (boards, sub-boards,

position electronics etc.) must be covered for transport or storage by conducting

protective sheathing (ESD-boxes).

When leaving devices on an ESD-protected workplace, they must be packed with

static shielding (e.g. shielded bags with ESD protection marking).

Exceptions from this regulation are products housed within closed conducting

cases, mechanical parts and cables.

1) Use enclosures with full ESD-protection when moving ESDS-components.

ESDS-components must always be protected from static sources when they are

not at ESD-protected workplaces. This protection can be conductive static

shielding boxes, bags or wraps. ESDS-components may only be pulled out of

their protective enclosures at ESD-protected workplaces.

3.6.1. Packaging of Electronic Assemblies

There are three different types of protective enclosure material:

● static shielding (or barrier packaging)

● antistatic materials

● static dissipative materials

Static shielding packaging prevents an electrostatic discharge from passing

through the package and into the assembly causing damage.

Antistatic packaging materials are used to provide inexpensive cushioning and

intermediate packaging for ESDS-components. Antistatic materials do not

generate charges when motion is applied. However, if an electrostatic discharge

occurs, it could pass through the packaging and into the component or assembly,

causing ESD-damage.

Static dissipative materials provide sufficient conductivity to dissipate applied

charges over the surface avoiding energy spots.

2) For transport or storage, any device sensitive to electrostatic discharge

(boards, sub-boards, position electronics etc.) must be covered by

conducting protective sheathing (ESD-boxes).

3) Parts leaving an ESD-protected workplace must be packed static

shielded. Complete the protection with static dissipative and antistatic

materials inside.

3.7. ESD-Regulations for Visitors

Visitors to ESD-protected areas shall be provided with cotton coats.

They have to be informed about the ESD-regulations and must follow all

the procedures mentioned above.

----------- END OF SECTION -----------

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 20

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

4. Overvoltage Caused by Electrical Transients / Lightning

International standards for voice communication systems were applied during the

development of FREQUENTIS systems. Third-party components (e.g. monitors)

have to meet the respective industrial standards. To protect the system against

malfunction and destruction caused by indirect stroke, a combination of both

voltage and current limiting devices is implemented. FREQUENTIS offers

operational reliability for the following environmental operating conditions. There

are always two steps in protection:

● Coarse protection: All telecommunication cables leaving the building have

to be supplied with arresters, usually gas-filled protectors, against transient

overvoltages. Rating and design must meet the local requirements, and must

be state-of-the-art.

Coarse protection is not included in the scope of the delivery and has to

be provided by the customer for each site. The overvoltage arresters have

to support a rated spark-over voltage of at least 150 V (up to 230 V).

● Fine protection: All FREQUENTIS system interfaces are equipped with both

voltage and current limiters connected on the load side of the coarse

protection, to minimise the residual energy of an indirect stroke, so that the

subsequent connected electronics are not damaged.

Using specially designed power supplies, the FREQUENTIS equipment is able to

resist surge pulses according to ITU-T recommendation K.21 (EN 61000-4-5).

Overvoltage protectors in interfaces correspond to ITU-T recommendation G.703.

Lightning protective measures have to be adjusted to the earthing concept

in compliance with national regulations.

----------- END OF SECTION -----------

21 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

5. Electromagnetic Compatibility (EMC)

Electromagnetic Compatibility (EMC) is the satisfactory working of an

apparatus, an installation or a system in an electromagnetic environment without

causing electromagnetic disturbances, which are unacceptable for other devices

in this environment.

Electromagnetic Immunity (EMI) from disturbance is the capability of

equipment to continue operating normally when an electromagnetic disturbance

occurs.

5.1. Generic Electromagnetic Compatibility Requirements

The FREQUENTIS system equipment is produced in accordance with the

regulations of the European community, i.e. the system do not generate an

environment that is dangerous to the personnel.

For EMC, the EC Directive 89/336 Electromagnetic Compatibility amended by

EEC Directive 92/31 and EEC-Directive 93/68, and

apply. All the equipment therefore meets the European standards EN 55022

(Radio disturbance characteristics measurement) as well as EN 55024 (Immunity

characteristics measurement).

Part 15 of the FCC Rules,

5.2. Specific Electromagnetic Compatibility Requirements

Compliance with EMC-limits no longer applies when –

● any door or enclosure part of an EMC-cabinet is opened,

● components not supplied by FREQUENTIS are installed in an EMC-cabinet

supplied by FREQUENTIS (e.g. supplementary installations to increase/filter

the airflow),

● racks and interfaces are not installed in an EMC-cabinet (e.g. non-protected

cabinet or stand-alone, i.e. non-FREQUENTIS cabinets).

Any modification of a FREQUENTIS-released system configuration

cancels EMC and EMI assured by FREQUENTIS.

Only cabinets supplied by FREQUENTIS may be used for the FREQUENTIS

core and interface equipment.

The cabinet doors must be closed to ensure EMC and EMI in the system.

When opening a cabinet or rack (e.g. for service purposes), first check the

operational state of adjacent equipment for potential risks due to

electromagnetic interferences.

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 22

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

5.2.1. Electromagnetic Fields Emitted by Visual Display Units

The only visual display unit (VDU), which might be equipped with a Cathode Ray

Tube (CRT) is/are the monitor(s) of the TMCS.

The TMCS-monitors are commercial off-the-shelf units, which meet the

requirements listed above (e.g. TCO 99) and the specific national standards.

The other VDUs are equipped with non-CRT devices (flat screen displays, e.g.

colour active matrix LCD-modules incorporating amorphous silicon TFT [Thin

Film Transistor], TFD [Thin Film Diodes] or passive LCD [Liquid Crystal Display],

all with backlights and resistive touch surface). These VDUs do not therefore emit

substantial electromagnetic fields.

5.2.2. Check of Aerials and Receivers Adjacent to the Equipment

Type and characteristics of aerials / receivers adjacent to the system, their

sensitivity and the applied frequencies have to be identified. Check the potential

risks due to disturbance of these third-party appliances.

To avoid potential interference problems do not install receiving or

emitting aerials and highly sensitive receivers within a certain distance of

the system's equipment, in particular closer than 50 m to the position

electronics and interface cabling.

---------- END OF SECTION ----------

23 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

6. Equipment Labelling

r

r

r

r

Equipment labelling of the delivered system is essential for identifying the system

state.

The hardware can be traced back down to component level by means of serial

numbers while the software/firmware can be traced back down to module level by

means of the label and version number.

If any equipment labels get damaged during operation, the customer is

responsible for replacing them with intact ones in the same positions.

To comply with the relevant standards (specific colours, materials or font

sizes), use original labels in all cases.

Safety instructions and the respective equipment marking must be durable and

legible, and in the customary language. Marking in English is acceptable for

equipment accessible to maintenance only. Labels must not be placed on

removable parts so that the marking is not ambiguous when the part is removed.

Generally, the equipment must be marked with the power rating for selecting the

correct voltage, frequency and current-carrying capacity. If the device can be

operated at several voltage ranges, the switch conditions must be described.

Labels not visible from outside the equipment must be directly visible when a

door or enclosure is opened, attached to the equipment to clearly indicate the

location of the marking. Devices not to be connected directly to the main supply

need not be marked with their rated current.

6.1. Adhesive FREQUENTIS Equipment Labels

Quality control labels are applied to the specific FREQUENTIS-components.

Checked samples are signed manually.

Serial Numbers

HW-Numbe

Product:

Finished: 30Semi-finished: 40-

The ESD-sensitivity symbol is used to indicate that an

electrical or electronic device or assembly is susceptible to

damage from an ESD-event. Each ESDS-component

(board, PCB, module,…) is marked with this label.

Fig. 6-1: ESD-Label and Structure of Serial Numbers

2

The ESD-symbol may also be integrated in the marking of the earth bonding points (see Fig. 3-1).

YYNNNVV - sssss

Counte

Serial numbe

Variant

Year+Counte

2

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 24

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

The serial numbers of racks and boards are labelled on the components in plain

text and as a barcode (code 128) (see Fig. 6-2). The serial numbers of power

supplies are printed on the rear of the components.

Fig. 6-2: Serial Number Label of a Board

6.1.1. Labels Indicating Product Categories

Label Component / Description of Labelling

Sub-boards: The drawing number of the PCB-layout is used

for identifying of small PCBs (no label).

PIP 02. 00 30-960600

REV:02 QC Test

198

Minimum identification if an appropriate label fits on the subboard: Serial number, revision and bar code (128 Bit).

For larger sub-prints, the product name and the

FREQUENTIS Logo are usually added.

FREQUENTIS

Module

Rack

Cabinets

Firmware

Cables

Produktnummer: 1998002130

Bezeichnung: POS 3025

FREQUENTIS

SPM20.21

Rev.:01

30-9204503-006

FREQUENTIS

30-9515502-006

BGT DATA 02

Rev.:00

If there is no specific definition in the System Configuration on

customer request, the board’s identification system is applied.

Name, version, checksum on EPROM and/or EPLD

1.007

CAB1/21/X29

CAB1/18/X103

108-K-15 (1)

Label with type and length of cable. In the case of outsourcing

included in the order (see chapter 6.2).

40-9705101-889

4CPPC 02.00

Test

QC

QC

TEST REV.: 02 QC

00

Boards: Label with serial number

Boards and modules:

Label with product number

For both, serial and product numbers, the last two

digits of the product number identifying the product

revision, have to be filled into the first box after

“Rev.”.

If the revision is increased (e.g. change of

software/firmware), the new revision number is

entered in the next box.

Tab. 6-1: Labels Indicating Product Categories

25 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

6.1.2. Labels Indicating Standards

Label (Example)

PE (Protective Earth)

Earth connection point

HIGH LEAKAGE CURRENT

Earthing is essential

before connecting supply

230 V ~ 50 Hz

Maximum Load 500 W

Plugs & Switches

OFF

Stand-by

ON

Push/push

Description

Main earth connection point of the FREQUENTIS-cabinets.

This symbol is reserved for the protective earth only.

Earth terminal of each C-Box and each PowerPanel. All other sub-

ordinate FREQUENTIS earth connection points remain unmarked.

The power rating marking as well as the

disconnection warning must be applied

near the connecting supply terminal.

Leakage Current exceeding 3.5 mA must carry a warning label like

this (acc. to IEC 60364-7-707).

Power supply outlet sockets accessible to the operator must be

marked with the maximum connectable load.

IEC 60417, 5007…10-a require adjacent marking of switches clearly

indicating their function, using the following symbols:

O and | may be used as OFF and ON markings on any primary

power switches, including isolating switches. If figures are used to

indicate different status, OFF is indicated by 0 (zero).

'+' and '–' are used to indicate in/decreasing adjustment values.

The symbol for separate collection of electric and electronical

devices marks components, which require special disposal

according to Directive 2002/96/EC.

CE-Labelling

(LVD-, EMC- and R&TTECompliance)

For all systems delivered in Europe, the CE-conformity must be

marked by the CE-label representing the DOC issued by

FREQUENTIS. The label is applied nearby the connecting supply

terminal on the resp. cabinet.

System approval numbers (outside EC) specific to national standards

PSTN-Label

(if applicable)

are placed on the cabinet(s) or on one of the racks. If only parts of the

system are approved, relevant interface approval numbers are placed

on each board, if applicable.

FCC-Label (USA): The equipment complies with Part 68 of the FCC

(US Federal Communications Commission) rules. A label is located

on the rear of the unit containing the FCC registration number and/or

the Ringer Equivalence Number (REN)

3

. For instance, the following

information is provided to the local telephone company on request:

Loopstart Leased line DSU

FIC 02LS2 (BCB) FIC Metallic (ERIF) FIC 04DU5-64 (NI64)

JT RJ11C SOC 7.0Y SOC 6.0N

REN 1.1B AC, 0.3 DC JT RJ48S JT RJ48S

Tab. 6-2: Labels Indicating Standards

3)

The REN determines the quantity of devices, which may be connected to the telephone line. Excessive RENs on the telephone line

may result in the devices not ringing in response to an incoming call. In most, but not all areas, the sum of RENs should not exceed five

(5.0). To be certain of the number of devices that may be connected to a line, as determined by the total RENs, contact the local PSTN.

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 26

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

6.2. Cable Identification

6.2.1. Cable Identifier Tags

All cables (except earthing wires, peripheral TMCS-cables and those to

footswitches) are labelled at both ends close to the connectors with identifier tags

containing the following information:

st

line Particular project specific cable number (column 10 in the Cabling List)

1

nd

2

line Destination of cable at connector 1 (columns FROM in the Cabling List)

(Cabinet Number / Cabinet Level / Connector name on target component)

rd

3

line Origin of cable at connector 2 (columns TO in the List of Cables)

th

4

line Type of cable with the length in the unit [dm = 10 cm]. The connector

number as used in the System Configuration is given in parentheses.

1.007 1.007

CAB1/21/X291 CAB1/18/X103

CAB1/18/X103 CAB1/21/X291

108-K-15 (1) 108-K-15 (2)

Fig. 6-3: Example of the Two Cable Identifiers for One Cable

Ensure that the correct cable end is attached to the corresponding

connector. Wrong connection can lead to a fault or damage of the

connected equipment.

6.2.2. Cable Types

Cables of the same physical configuration are identified by a unique term:

● Number each cable type different in the used components (parts list),

● Type reflects the safety category:

K Cable with standard PVC-Insulation

S Special cable (e.g. variant of a standard cable for special use)

LSF Low inflammable, halide-free insulation (Low Smoke and Fume)

HLF Halide-free insulation

● Length is the length of the particular cable in [dm].

The Connector Plan, Wiring List and Parts List form part of the standard

FREQUENTIS Hardware Documentation, which is available on request. All

information necessary for proper connection of the pre-assembled cabling

supplied is covered by the System Configuration Document.

}

Number

Fig. 6-4: Complete Cable Designation

connector plan or wiring list is numbered consecutively.

}

Type

Length (dm)

K

}

x

xxxx1- -

The identifier tags must be applied so that they can be read easily as shown in

Fig. 6-5 (reading direction towards the viewer, app. four cm from the connector).

27 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

6.2.2.1. Connector Plan

The pinning of a 9-pin Min-D socket to a quadruple paired cable is shown as an

example (A and B are not exchangeable):

6.2.2.2. Wiring List

1002

CAB3/4/X17

CAB3/7/X361

1-K-15 (1)

1-K-015

Rev. 2.0

08/00 - Test O. K.

3 cm

Fig. 6-5: Position of a Cable Identifier Tag

The Wiring List, part of the FREQUENTIS Hardware Documentation, describes

the circuit interconnection wiring for all connectors on the respective cable

according to the Connector Plan, including the wire cross sections in mm2.

No. Cross Section From Pin To Pin Comment

1 twisted pair 0.14 ST1 1, 6 ST2 1, 6

Additional cable layer plans can be provided for cables that split up into several

connectors at one side.

6.2.3. Labelling with Printed Sheathing

This non-abrasive labelling is applied along the cable coating. It is acid- and

grease-proof, and includes all information mentioned above.

FREQUENTIS VOICE COMMUNICATION SYSTEM

Fig. 6-6: Cable Sheath Printing

1−K−015

08/00 Rev 2.0 Test O.K.

----------- END OF SECTION -----------

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 28

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

7. Handling of Equipment

Boards of the same type can be replaced only if they have the same jumper

settings (see Maintenance Manual) and the same firmware (see System

Configuration document).

When working with boards, remember the following precautions for

handling components sensitive to electrostatic discharge:

1) ESD sensitive devices are labelled with the symbol shown left.

2) Special training is required for working with ESD sensitive devices.

3) Do not touch boards without taking ESD-precautions.

4) Transport and packaging must also provide full ESD-protection.

5) Improper handling cancels warranty and liability on the part of

FREQUENTIS.

For detailed information, please refer to Section 3

7.1. Required Tools

Check the availability of the required tools (no special tools or test equipment are

required to set up the system, except for safety and test purposes):

Standard Tools (all tools insulated complying with ESD-requirements)

Operational Maintenance Screwdrivers of several sizes

Philips screwdrivers of several sizes

Wrenches of several sizes

Intermediate Maintenance Various (diagonal cutting) pliers

Soldering iron

Solder extraction tool

Soldering tin

ESD Field Service Kit (recommended)

1 ESD-blanket with

1 spiral-shaped cable and

1 wrist strap with cable clip

1 connecting cable to

the protective contact of a

2-pole and earth-socket outlet

1 connecting cable with crocodile clip

Fig. 7-1: ESD Field Service Kit

----------- END OF SECTION -----------

29 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

Author: S. Meisel No: 00A46 E500.12 COPYRIGHT FREQUENTIS 2000

8. Abbreviations

AC Alternating Current

acc. according

approx. approximately

AWG American Wire Gauge

BCB Battery Central Type B; analog 2-wire interface connecting to telephone line

CAB Cabinet

CE Conformité Européene; European conformity

CRT Cathode Ray Tube

CSA Canadian Standardization Association

CWP Controller Working Position

D/A Digital to Analog

DC Direct Current; Data Coupler

DICORA Dispatcher Communication Railway

DOC Output for recording (summarised context for the use of recording outputs);

Declaration of Conformity

DSU Data/Digital Service/Signalling Unit

e.g. exempli gratia; for instance

EBP Earth Bonding Point

EC European Community

EEC European Economic Community

ELV Extra Low Voltage

EMC Electromagnetic Compatibility

EMI Electromagnetic Immunity; Electromagnetic Interference

EN European Norm

EOS Electrical Overstress

EPLD Electrically (EPROM based) Programmable Logic Device

EPROM Erasable Programmable Read Only Memory

ERIF Extended Radio Interface (analog 4-wire interface)

ESD Electrostatic Discharge; Electrostatic Damage

ESDS Electrostatic Discharge Sensitive (components)

FCC Federal Communications Commission (US)

FIC Facility Interface Code

FRQ FREQUENTIS

G/G Ground to Ground communication

HLF Halide-Free Insulation

HW Hardware

IEC International Electrotechnical Commission

SAFETY GUIDELINES FREQUENTIS File: SGL REV.1.2.DOC 30

COPYRIGHT FREQUENTIS 2000 Author: S. Meisel No: 00A46 E500.12

IF Interface

ISDN Integrated Services Digital Network

ISO International Standardisation Organisation

ITU-T International Telecommunications Union - Telecommunications Sector

JT Jack Type

LAN Local Area Network

LCD Liquid Crystal Display

LED Light Emitting Diode

LSF Low Smoke and Fume (low inflammable, halide-free insulation)

LVD Low Voltage Directive

NI64 Network Interface, 64 kBit/s

NFPA National Fire Protection Association

ÖNORM Österreichische Norm; Austrian standard

OP Operator Position

ÖVE Österr. Verband für Elektrotechnik; Austrian electrical engineering association

PCB Printed Circuit Board

PE Protective Earth

PS Power Supply

PSTN Public Switched Telephone Network

R&TTE Radio and Telecommunications Terminal Equipment

REC Recording (output)

REN Ringer Equivalent Number (US)

resp. respectively

Rev. Revision

SI Système International; international system for measurement units

SOC Service Ordering Code

STxx Stecker xx; Connector XX

SW Software

TCO Tjänstemännens Central Org. (Swedish Confederation of Professional Employees)

TFD Thin Film Diodes

TFT Thin Film Transistors

TMCS Technical Monitoring and Control System

VCS Voice Communication System

VCX Voice Communication Exchange

VDE Verband Deutscher Elektrotechniker; German Association of Electrotechnicians

VDU Visual Display Unit

WCS Wire Cross Section

----------- END OF SECTION -----------

31 File: SGL REV.1.2.DOC FREQUENTIS SAFETY GUIDELINES

No: 00A46 E500.12 Author: S. Meisel COPYRIGHT FREQUENTIS 2000

9. Appendix

The contents of this section are for information only.

9.1. References to Standards

EMC Directive 89/336/EC

Emission Immunity

Domestic/Office Industry Domestic/Office Industry

Generic

Test

Emission

Emission

Harmonics EN61000-3-2 EN61000-4-4 EN61000-4-4 Burst

Flicker EN61000-3-3 EN61000-4-5 EN61000-4-5 Surge

EN61000-6-3 EN61000-6-4 EN61000-6-1 EN61000-6-2

Differentiation by measured

quantity of test disturbance

IEC/CISPR14/1 =

EN55014-1

IEC/CISPR22 Cl.B

EN55022

=

IEC/CISPR 11 =

EN 55011

EN61000-4-2 EN61000-4-2 ESD

EN61000-4-3 EN61000-4-3

EN61000-4-6 EN61000-4-6 Injected HF-Currents

EN61000-4-8 EN61000-4-8 Magnetic LF-Fields

EN61000-4-11 EN61000-4-11 Voltage Variations

EN 55024

Radiated HF-Fields

incl.”900MHz”

Fig. 9-1: Structure of EN Standards (Example)

Connection between the respective International (IEC), European (EN) and

German (VDE) regulations (if applicable):

IEC 1000-4-x = EN 61000-4-x = VDE 0847-x

Directive 73/23/EEC on the harmonisation of the laws of Member States

relating to electrical equipment designed for use within

certain voltage limits. 19 February 1973

amended by Directive 93/68/EEC of 22 July 1993

Directive 89/336/EEC on the approximation of the laws of the Member States

relating to electromagnetic compatibility. 3 May 1989

amended by Directive 92/31/EEC 26 April 1992

and by Directive 93/68/EEC 22 July 1993

Directive 99/5/EC on Radio equipment and telecommunications terminal

equipment (R&TTE) and the mutual recognition of their

conformity. 9 March 1999

ANSI/NFPA 70 National Electric Code, 110-16 to 18; 1999