19-0009; Rev 2; 8/95

EVALUATION KIT MANUAL

FOLLOWS DATA SHEET

±18-Bit ADC with Serial Interface

_______________General Description

The MAX132 is a CMOS, 18-bit plus sign, serial-output,

analog-to-digital converter (ADC). Multi-slope integration provides high-resolution conversions in less time

than standard integrating ADCs, allowing operation up

to 100 conversions per second. Low conversion noise

provides guaranteed operation with ±512mV full-scale

input range (2µV/LSB). A simple 4-wire serial interface

connects easily to all common microprocessors, and

twos-complement output coding simplifies bipolar measurements. Typical supply current is only 60µA and is

reduced to 1µA in sleep mode. Four serially programmed digital outputs can be used to control an

external multiplexer or programmable-gain amplifier.

The MAX132 comes in 24-pin narrow DIP and wide SO

packages, and is available in commercial and extended temperature grades.

High resolution, compact size, and low power make this

device ideal for data loggers, weigh scales, data-acquisition systems, and panel meters.

________________________Applications

Remote Data Acquisition

Battery-Powered Instruments

Industrial Process Control

Transducer-Signal Measurement

Pressure, Flow, Temperature, Voltage

Current, Resistance, Weight

____________________________Features

♦ Low Supply Current:

60µA (Normal Operation)

1µA (Sleep-Mode Operation)

♦ ±0.006% FSR Accuracy at 16 Conv/sec

♦ Low Noise: 15µV

RMS

♦ Serial I/O Interface with Programmed Output for

Mux and PGA

♦ Performs up to 100 Conv/sec

♦ ±2pA Input Current

♦ 50Hz/60Hz Rejection

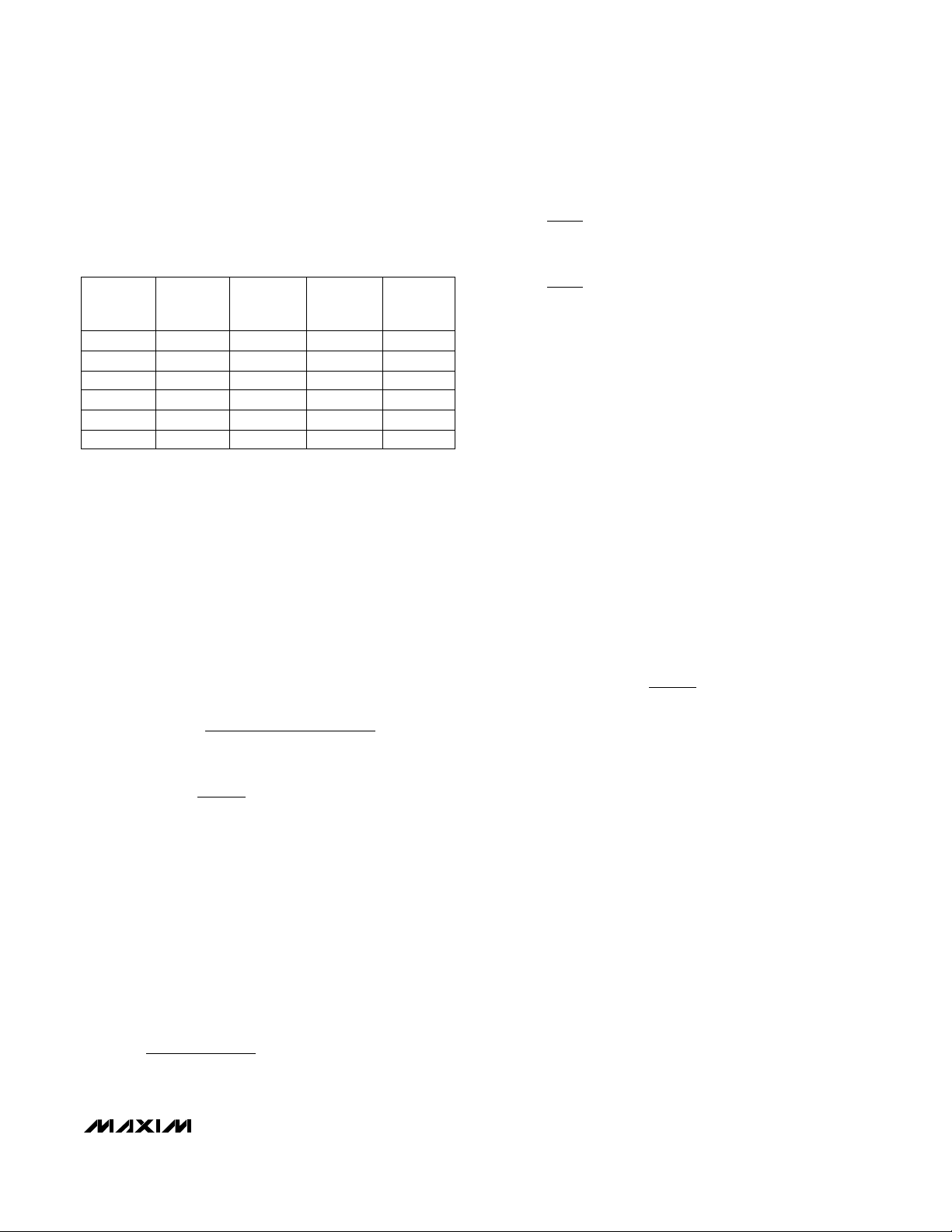

______________Ordering Information

PART

MAX132CNG

MAX132CWG

MAX132C/D 0°C to +70°C

MAX132ENG

MAX132EWG

MAX132MRG -55°C to +125°C

* Contact factory for dice specifications.

** Contact factory for availability and processing to MIL-STD-883.

TEMP. RANGE PIN-PACKAGE

0°C to +70°C

0°C to +70°C

-40°C to +85°C 24 Narrow Plastic DIP

-40°C to +85°C

24 Narrow Plastic DIP

24 Wide SO

Dice*

24 Wide SO

24 Narrow CERDIP**

MAX132

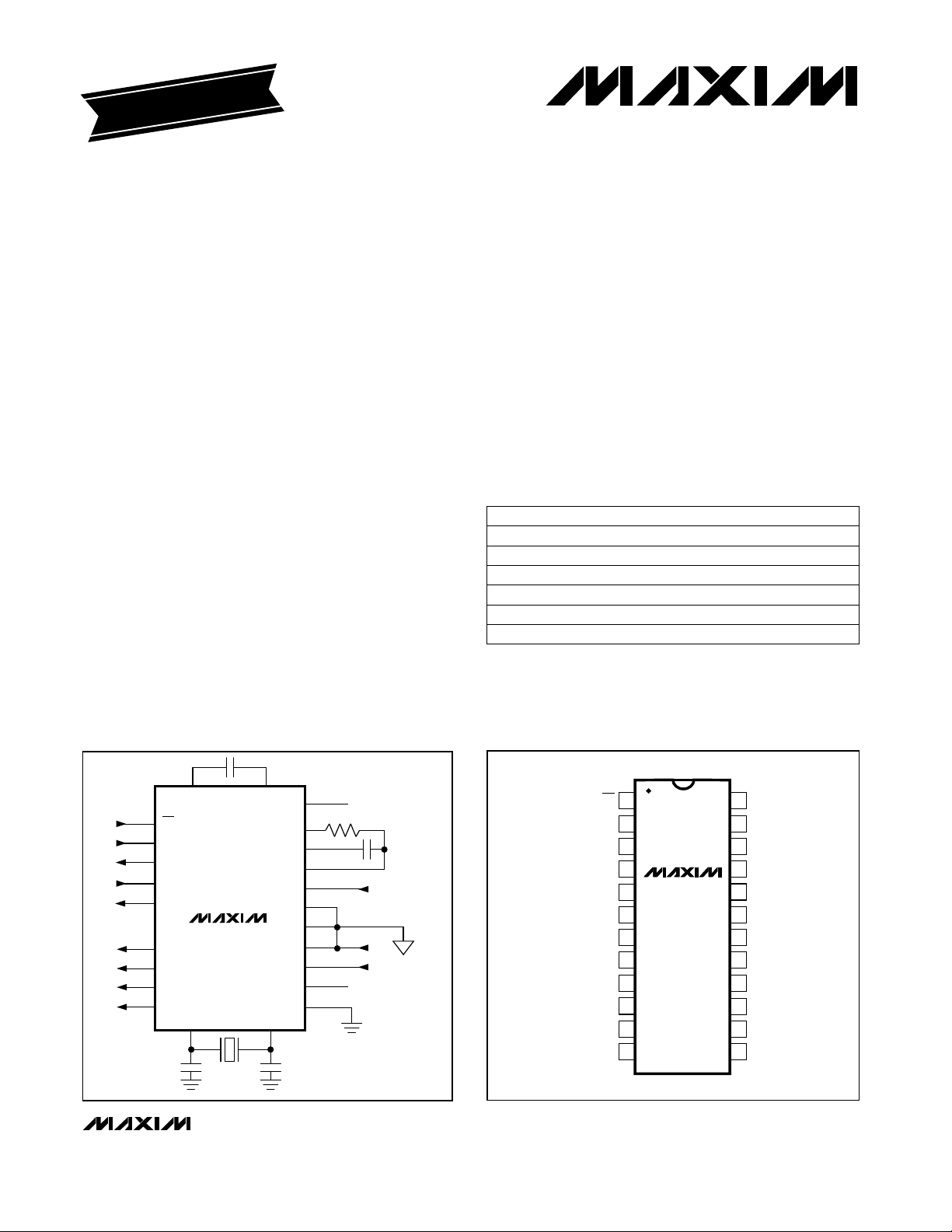

________________Functional Diagram

CREF- CREF+

CS

SCLK

EOC

DIN

DOUT

MAX132

P0

P1

P2

P3

________________________________________________________________

V+

BUF OUT

INT OUT

INT IN

REF+

REF-

AGND

IN LO

IN HI

V-

DGND

OSC2OSC1

+5V

602k

4.7nF

±512mV INPUT

-5V

__________________Pin Configuration

TOP VIEW

CS

1

DIN

2

DOUT

3

SCLK

4

OSC2

OSC1

P0

P1

P2

P3

EOC

DGND

MAX132

5

6

7

8

9

10

11

12

DIP/SO

Maxim Integrated Products

Call toll free 1-800-998-8800 for free samples or literature.

24

23

22

21

20

19

18

17

16

15

14

13

V+

BUF OUT

INT OUT

INT IN

CREFCREF+

REF+

REFAGND

IN LO

IN HI

V-

1

±18-Bit ADC with Serial Interface

ABSOLUTE MAXIMUM RATINGS

Supply Voltage

V+ to DGND..............................................-0.3V < V+ < +6.0V

V- to DGND ................................................+0.3V < V- < -9.0V

V+ to V-............................................................................+15V

Analog Input Voltage (any input).....................................V+ to V-

Digital Input Voltage .....................(DGND - 0.3V) to (V+ + 0.3V)

Continuous Power Dissipation

MAX132

Narrow Plastic DIP (derate 8.70mW/°C above +70°C)....478mW

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

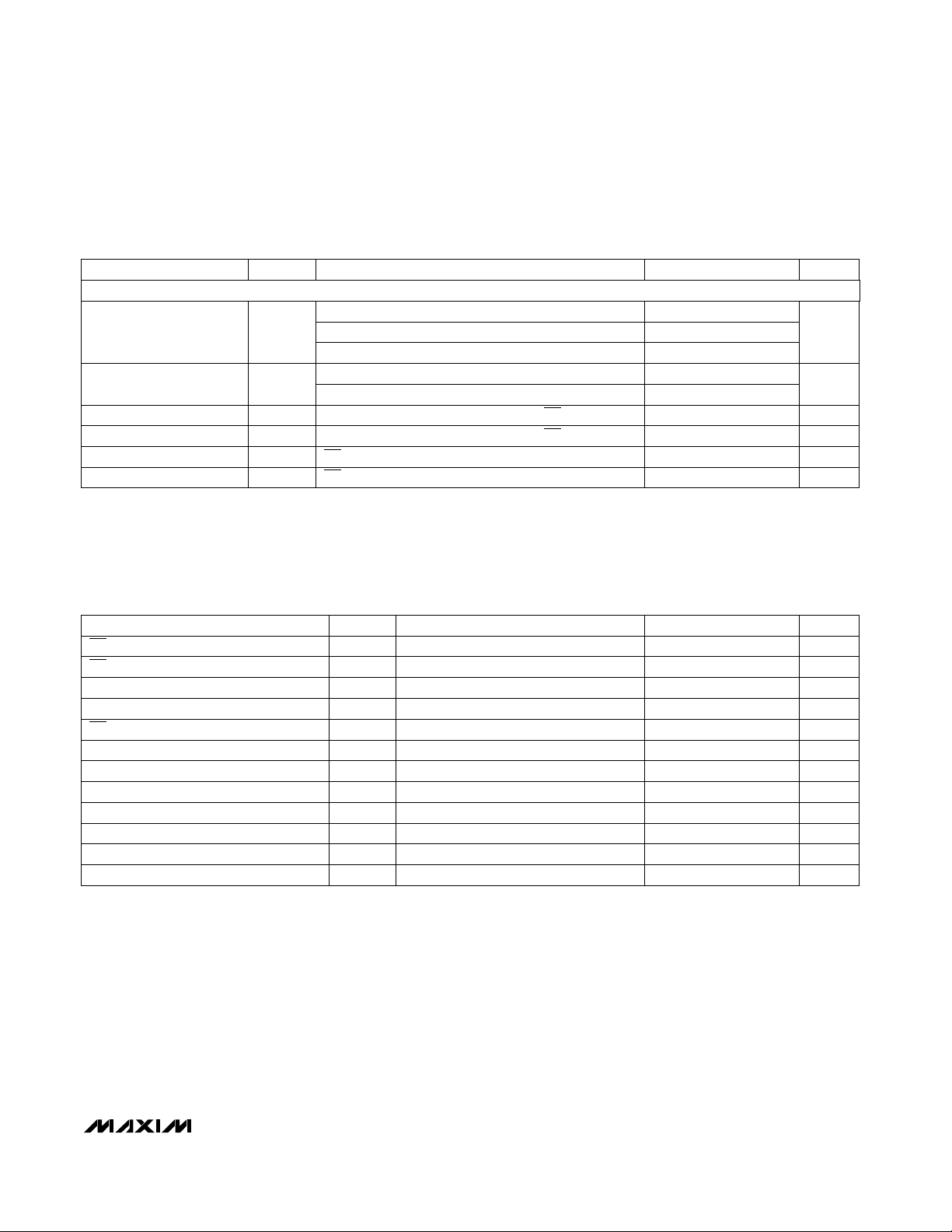

ELECTRICAL CHARACTERISTICS

(V+ = 5V, V- = -5V, DGND = AGND = IN LO = REF- = 0V, REF+ = 545mV, R

f

= 32,768Hz, 60Hz mode, TA= T

CLK

ACCURACY

Zero Error

Rollover Error

Conversion Time

Input Voltage Range

Leakage Current IN HI, IN LO

Common-Mode Rejection Ratio IN HI = IN LO

Common-Mode Range

Zero-Reading Drift

POWER REQUIREMENTS

Negative Supply Voltage

Positive Supply Rejection

Negative Supply Rejection

Negative Supply Current

Positive Sleep-Mode Current

Digital Ground Sleep-Mode

Current

to T

MIN

(Note 1)

VINHI = 0V % of FSR

(Notes 2, 3)

(Note 4)

f

= 32.768Hz

CLK

IN HI to IN LO, for specified accuracy

IN HI = IN LO V±3.0

(Note 3) ppm/°C±0.15 ±1.5

(Note 3) ppm/°C±5Scale Factor Temp. Coefficient

VINHI = 400mV, V- = -5.0V,

4.5V ≤ V+ ≤ 5.5V

VINHI = 400mV, V- = 5.0V,

-5.5V ≤ V- ≤ -4.5V

Digital input = 0V or V+

Digital input = 0V or V+

Digital input = 0V or V+

Digital input = 0V or V+

Digital input = 0V or V+ µA-1 -10Negative Sleep-Mode Current

Digital input = 0V or V+ µA0±2

, unless otherwise noted.)

MAX

CONDITIONS

Wide SO (derate 11.76mW/°C above +70°C)..............647mW

Narrow CERDIP (derate 12.50mW/°C above +70°C) ..688mW

Operating Temperature Ranges

MAX132C_ _ .......................................................0°C to +70°C

MAX132E_ _ ....................................................-40°C to +85°C

MAX132MRG.................................................-55°C to +125°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

TA= +25°C

TA= T

TA= +25°C

TA= +25°C

TA= T

TA= T

VCM= ±3.0V

TA= +25°C

TA= +25°C

TA= T

TA= +25°C

TA= T

MIN

MIN

MIN

MIN

MIN

to T

to T

to T

to T

to T

INT

MAX

MAX

MAX

MAX

MAX

= 602kΩ, C

= 0.0047µF, C

INT

±18Resolution

0 ±0.0076

±0.0168

0 ±0.010

±0.032

±2 ±10TA= +25°C

±12 ±250

±0.009 ±0.032VCM= ±500mV

±0.25 ±0.50

±0.003 ±0.0061

±0.003 ±0.0168

±0.003 ±0.0061

±0.003 ±0.0168

REF

% of FSR±0.0015 ±0.006Integral Nonlinearity

% of FSR

% of FSR

% of FSR±3.1Read-Zero 50Hz/60Hz Range

% of FSR

% of FSR

= 0.1µF,

UNITSMIN TYP MAXPARAMETER

Bits

ms63

mV±512

pA

µV15RMS Noise

V4.5 5.5Positive Supply Voltage

V-5.5 -4.5

µA60 125Positive Supply Current

µA-35 -65

µA-25 -60Digital Ground Supply Current

µA110

2 _______________________________________________________________________________________

±18-Bit ADC with Serial Interface

ELECTRICAL CHARACTERISTICS (continued)

(V+ = 5V, V- = -5V, DGND = AGND = IN LO = REF- = 0V, REF+ = 545mV, R

f

= 32,768Hz, 60Hz mode, TA= T

CLK

MIN

to T

, unless otherwise noted.)

MAX

CONDITIONS

DIGITAL SECTION

Output High

Output Low

Input High

Input Low

Input Current

Input Capacitance

DOUT, I

OH

DOUT, I

V

EOC, P0–P3, I

V

DOUT, I

OL

EOC, P0–P3, I

Referred to DGND, 4.5V ≤ V+ ≤ 5.5V, CS, DIN, SCLK

IH

Referred to DGND, 4.5V ≤ V+ ≤ 5.5V, CS, DIN, SCLK

IL

CS, DIN, SCLK, and DOUT when three-stated

IN

CS, DIN, SCLK, and DOUT when three-stated

IN

OUT

OUT

OUT

= -1mA

= -100µA

= -100µA

OUT

= 1.6mA

= 100µA

OUT

= 602kΩ, C

INT

= 0.0047µF, C

INT

3.5 4.3

4.0 4.5

4.0 4.7

0.1 0.4

0.1 0.4

INTERFACE TIMING

(Test Circuit of Figure 1, Figure 2, V+ = 5V, V- = -5V, DGND = AGND = 0V, TA= +25°C, unless otherwise noted.) (Note 3)

CONDITIONS

CS Lead Time

CS Lag Time

S

High Time

CLK

S

Low Time

CLK

CS High Pulse Width

DIN to SCLK Setup Time

DIN to SCLK Hold Time

DOUT Access Time from Three-State

Data Valid

DOUT Disable Time to Three-State

Delay to P0–P3 High

Delay to P0–P3 Low

1

2

3

4

5

6

7

8

9

10

11

12

See Figure 3

See Figure 4

REF

MAX132

= 0.1µF,

UNITSMIN TYP MAXSYMBOLPARAMETER

V

V

V2.4V

V0.8V

nA±10 ±500I

pF5C

UNITSMIN TYP MAXSYMBOLPARAMETER

ns500t

ns400t

ns400t

ns300t

µs1t

ns0t

ns200t

ns320t

ns60t

ns320t

ns230 350t

ns230 350t

Note 1: ±18-bit accuracy achieved by averaging multiple conversions.

Note 2: Maximum deviation from best straight-line fit.

Note 3: Guaranteed by design, not tested.

Note 4: Difference in reading for equal positive and negative inputs near full scale.

_______________________________________________________________________________________ 3

±18-Bit ADC with Serial Interface

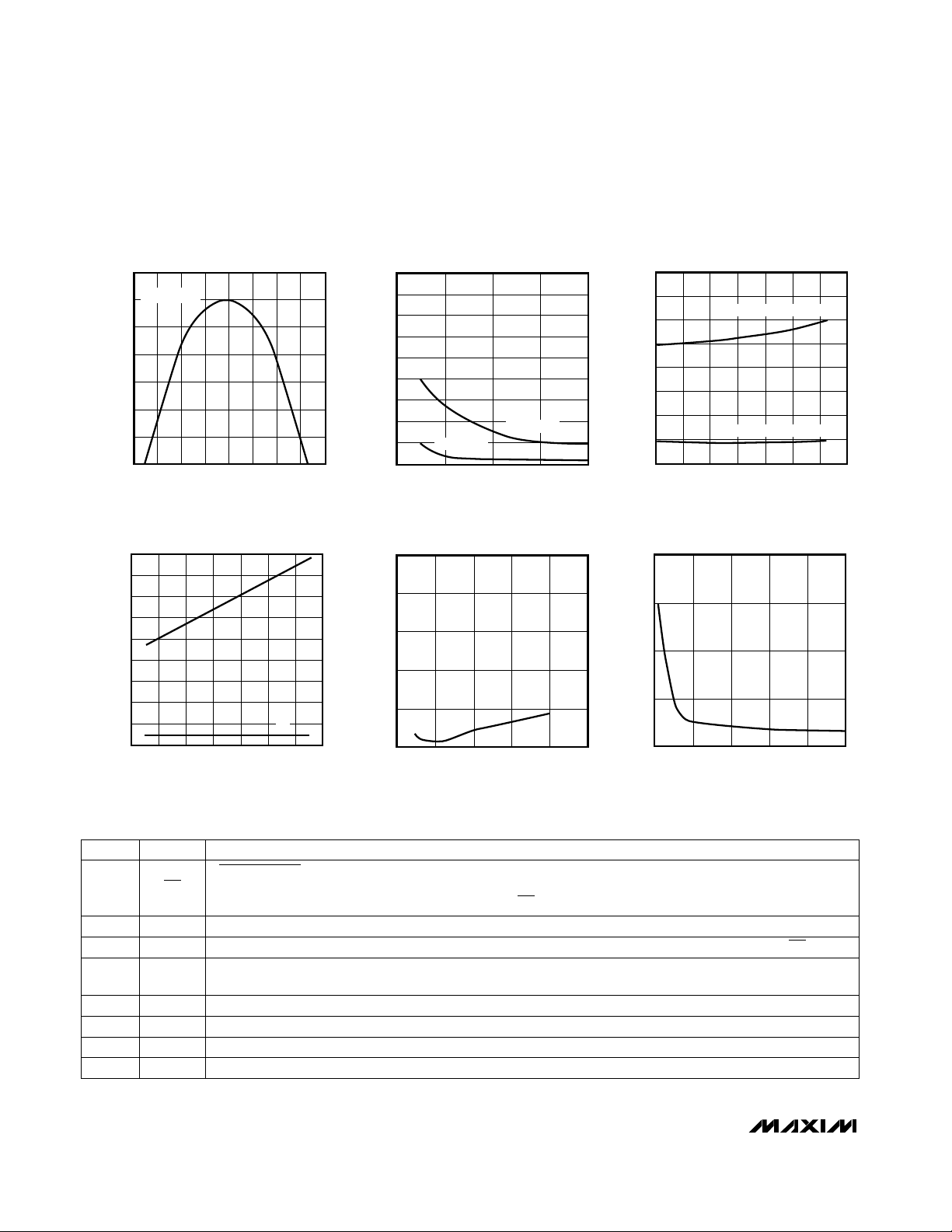

__________________________________________Typical Operating Characteristics

ERROR vs. COMMON-MODE

INPUT VOLTAGE (V

0.05

IN HI = IN LO

0

-0.05

MAX132

-0.10

-0.15

ERROR (% OF FSR)

-0.20

-0.25

-0.30

-3 -2 -1 0 1 2 3 4-4

COMMON-MODE VOLTAGE (V)

vs. CRYSTAL FREQUENCY

140

120

100

80

60

40

20

SUPPLY CURRENT (µA)

0

-20

-40

0 50 150

100 200 250 300 350

CRYSTAL FREQUENCY (kHz)

LO–AGND)

IN

SUPPLY CURRENT

50Hz/60Hz READ-ZERO OFFSET

vs. VREF

4.5

MAX132-01

4.0

3.5

3.0

2.5

2.0

1.5

1.0

READ-ZERO OFFSET (% OF FSR)

0.5

0

50Hz MODE

0 0.5 1.5

60Hz MODE

1.0 2.0

VREF (V)

MAX132-02

READ-ZERO OFFSET (% OF FSR)

FULL-SCALE ROLLOVER ERROR

vs. VREF

0.10

V+

V-

MAX132-04

0.08

0.06

0.04

0.02

ROLLOVER ERROR (% OF FSA)

0

0 0.5 1.0 1.5 2.52.0

VREF (V)

MAX132-05

)

RMS

NOISE (µV

50Hz/60Hz READ-ZERO OFFSET

vs. TEMPERATURE

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

-40 -20 20

60Hz MODE, VREF = 545mV

50Hz MODE, VREF = 655mV

0 40 60 80 100

TEMPERATURE (°C)

NOISE vs. NUMBER

OF SAMPLES AVERAGED

20

15

10

5

0

0102030 5040

NUMBER OF SAMPLES AVERAGED

MAX132-03

MAX132-06

______________________________________________________________Pin Description

PIN

CHIP SELECT Input has 3 functions: 1) When low, selects IC for communication; 2) on rising edge, loads

CS1

input shift register data into one of the command registers; 3) on falling edge, loads data from one of the

output registers into the output shift register. When CS is high, DOUT is high impedance.

Serial Data In, D7 first bit in. Data is clocked into the register on the rising edge of SCLK.DIN2

Serial Data Out, D7 first bit out. Data is clocked out at the falling edge of SCLK. High impedance when CSis high.DOUT3

SCLK4

Serial Clock Input. On SCLK’s rising edge, data is shifted into the internal shift register through DIN. On

SCLK’s falling edge, data is clocked out of DOUT.

Oscillator Output 2 is normally connected to a 32,768Hz crystal. Do not connect with external clock source.OSC25

Oscillator Input 1 is normally connected to a 32,768Hz crystal, or may be connected to an external clock.OSC16

User-programmable output bit 0—programmed through the serial port.P07

User-programmable output bit 1—programmed through the serial port.P18

4 _______________________________________________________________________________________

FUNCTIONNAME

±18-Bit ADC with Serial Interface

_________________________________________________Pin Description (continued)

PIN

User-programmable output bit 2—programmed through the serial port.P29

User-programmable output bit 3—programmed through the serial port.P310

End of Conversion Output goes high at end of conversion.EOC11

Digital Ground—power-supply returnDGND12

Negative Supply, nominally -5VV-13

Positive Analog InputIN HI14

Negative Analog InputIN LO15

Analog GroundAGND16

Negative Reference InputREF-17

Positive Reference InputREF+18

Positive Reference Capacitor connectionCREF+19

Negative Reference Capacitor connectionCREF-20

Integrator Input. Connect the integration capacitor between INT IN and INT OUT.INT IN21

Integrator Output. To minimize noise, this pin should drive the capacitor’s outside foil (negative end).INT OUT22

Buffer-Amplifier Output drives the integrator resistor.BUF OUT23

Positive Supply, nominally +5VV+24

FUNCTIONNAME

MAX132

1

CS

4

SCLK

11

EOC

2

DIN

3

DOUT

7

P0

8

P1

9

P2

10

P3

32,768Hz

15pF

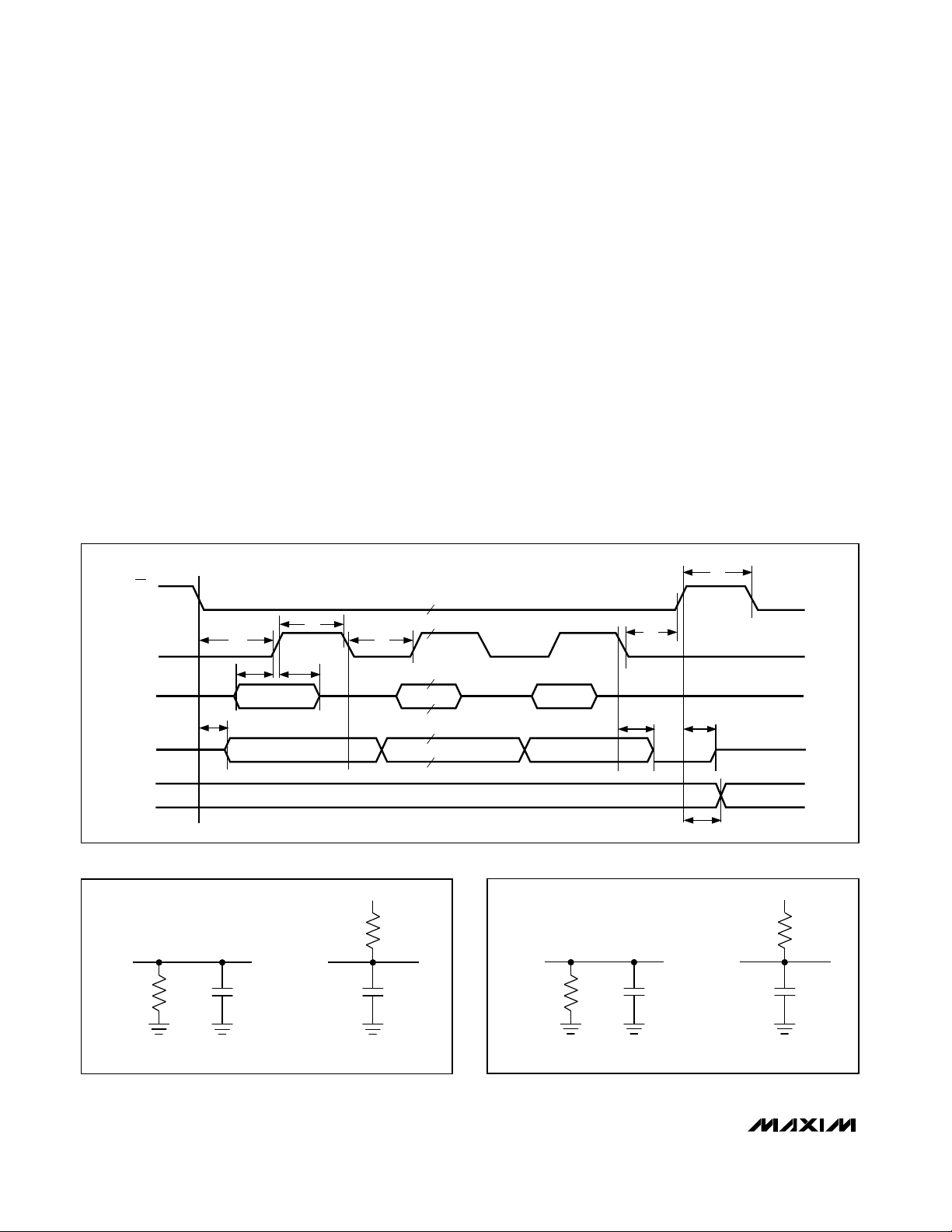

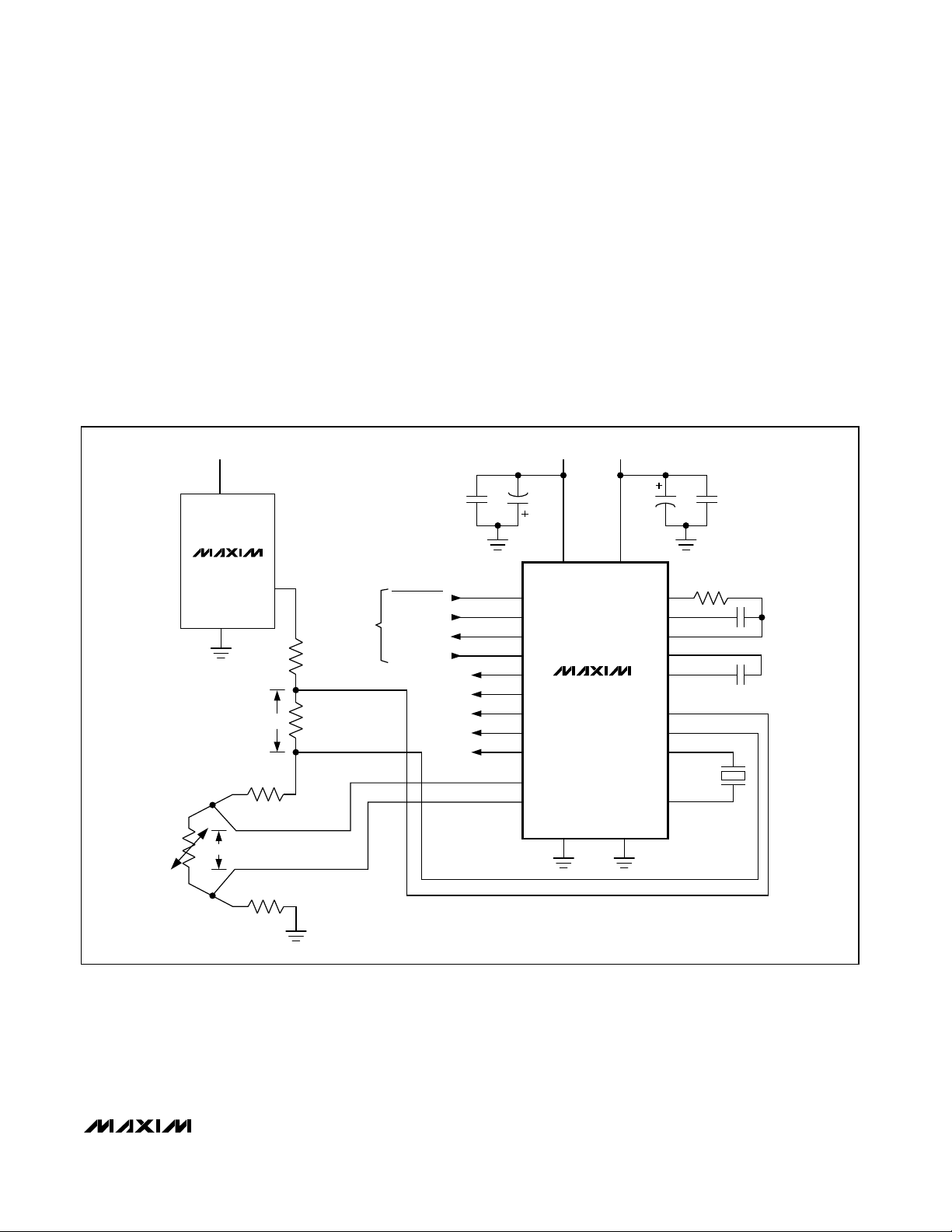

Figure 1. Test and Typical Application Circuit

REF+

REF-

IN LO

IN HI

15pF

+5V

24

V+

602k

23

22

4.7nF

21

18

17

16

15

14

13

V-

-5V

12

0.1µF

20

CREF- CREF+

MAX132

65

19

BUF OUT

INT OUT

INT IN

AGND

DGND

OSC2OSC1

120k

100k

40.2k

512mV INPUT

2.5V

MAX872

_______________________________________________________________________________________ 5

±18-Bit ADC with Serial Interface

____________Functional Description

The MAX132 integrates the input voltage for a fixed

period of time, then deintegrates a known reference

voltage and measures the time required to reach zero.

Good line rejection is achieved by setting the (input)

integration time equal to one 50Hz or 60Hz period. The

MAX132 has a 50Hz/60Hz mode selection bit that sets

MAX132

the integration time to 655/545 clock periods, respectively, so that 50Hz/60Hz rejection is obtained with a

32,768Hz crystal. The MAX132 is tested and guaranteed at a 16 conv/sec throughput rate. Figure 1 shows

the basic MAX132 application circuit, with component

values selected for 16 conv/sec .

For applications that don’t require 50Hz/60Hz rejection,

the MAX132 will operate up to 100 conv/sec at reduced

accuracy (typically 0.012% FSR nonlinearity, or ±13

bits). In these applications, the 50Hz mode is recommended because of its longer (655 count) integration

time. See

Increased Speed

CS

SCLK

t

1

section.

t

6

t

3

t

7

t

4

__________Analog Design Procedure

Input Voltage Range

and Input Protection

The recommended analog full-scale input range is

±512mV. Performance is tested and guaranteed at

±512mV full scale, corresponding to a 2µV/LSB resolution at 18 bits. Resolution is defined as follows:

Re / ( ) / ,solution Volts LSB V FS

[]

which corresponds to 2µV/LSB resolution at 18 bits.

Consult the

Typical Operating Characteristics

vs. Number of Samples Averaged and other important

operating parameters. Note how accuracy depends on

common-mode input voltage (common mode is defined

here as |VINLO - AGND|). For optimum performance,

set the analog input full-scale between ±470mV and

= 262144

IN

t

5

t

2

for Noise

DIN

DOUT

P0–P3

t

8

MSB IN B6–B1 LSB IN

t

9

LSB OUTB6–B1MSB OUT

t

t11, t

10

12

Figure 2. Serial-Mode Timing

+5V

3k

DOUT DOUT

3k

DGND DGND

a. High-Z to VOH (t8) b. High-Z to VOL (t8)

C

L

C

L

Figure 3. Load Circuits for Access Time

6 _______________________________________________________________________________________

DOUT DOUT

3k

DGND DGND

a. VOH to High-Z (t10) b. VOL to High-Z (t10)

10pF

Figure 4. Load Circuits for Disable Time to Three-State

+5V

3k

10pF

±18-Bit ADC with Serial Interface

±660mV for 60Hz mode operation or between ±390mV

and ±550mV for 50Hz mode operation. The pseudodifferential input voltage is applied across pins 14 and

15 (IN HI, IN LO), and can range to within 2V of either

supply rail.

The inputs IN HI and IN LO lead directly to CMOS transistor gates, yielding extremely high input impedances

that are useful when converting signals from a high

input source impedance, such as a sensor. Input currents are only 2pA typical at +25°C. Figure 6 shows an

RC filter at the input to optimize noise performance.

Fault protection is accomplished by the 100kΩ series

resistance. Internal protection diodes, which clamp the

analog inputs from V+ to V-, allow the channel input

pins to swing from (V- - 0.3V) to (V+ + 0.3V) without

damage. However, if the analog input voltage at the

pins IN HI or IN LO exceed the supplies, limit the current into the device to less than 1mA, as excessive current will damage the device.

Reference Voltage Selection

The reference voltage sets the analog input voltage

range. For the nominal ±512mV full-scale input range, a

545mV reference voltage is used for the 60Hz mode

and a 655mV reference voltage is used in the 50Hz mode.

The reference voltage can be calculated as follows:

60

Hz Mode V

:

REF

( ) () )

=

262144

,

IN FS

()

545 512

counts V

or

50

Hz Mode V

:

REF

( ) () )

=

262144

,

IN FS

()

655 512

counts V

The recommended reference voltage range is 500mV

to 700mV. The MAX132 is tested with the nominal

545mV reference voltage in 60Hz mode. Use amplifiers

or attenuators (resistor dividers) to scale other full-scale

input signal ranges to the recommended ±512mV fullscale range.

References outside the recommended range may be

used with a degradation of linearity. A reference voltage from 200mV to 500mV will result in a lower signalto-noise ratio; a reference voltage from 700mV to 2V will

increase the rollover error.

The MAX872 2.50V reference, with its 10µA supply current, is ideally suited for the MAX132. Figure 7 shows

how 2.50V can be divided to obtain the desired reference voltage. The reference input accepts voltages

anywhere within the converter’s power-supply range;

however, for best performance, neither REF+ nor REFshould come within 2V of the supplies.

MAX132

C

DE-

DE+

REF

DE+

DE-

INT

REF+CREF+

DE DE

INT

IN HI

AGND

INT

IN LO

Figure 5. Analog Section Block Diagram

_______________________________________________________________________________________ 7

R

REF- CREF- INT IN INT OUT

REST

BUFFER

BUFFER

INT

C

INT

INTEGRATOR

8pF

64pF

MAX132

X8

COMPARATOR 1

Z1+ x 8

TO

DIGITAL

SECTION

COMPARATOR 2

±18-Bit ADC with Serial Interface

Differential Reference Inputs

and Rollover Error

The main source of rollover voltage error is due to

common-mode voltages. This error is caused by the

reference capacitor losing or gaining charge to stray

capacitance. A positive signal with a large commonmode voltage can cause the reference capacitor to

gain charge (increase voltage). In contrast, the refer-

MAX132

ence capacitor will lose charge (decrease voltage)

when deintegrating a negative input signal. Rollover

error is a direct result of the difference in reference to

positive or negative input voltages. With the recommended reference capacitor types, the worst-case

rollover error is 0.01% of full-scale. Connect REF- to

AGND to minimize rollover error. As outlined in the reference section, reference voltages below 500mV also

contribute to rollover errors.

+5V

24

V+

MAX132

V-

-5V

+545mV

18

REF+

13

±512mV

100k

0.1µF

14

IN HI

15

IN LO

16

AGND

17

REF-

Oscillator Circuit

The internal oscillator is typically driven by a crystal, as

shown in Figure 8, or by an external clock. If an external clock is used, connect the clock to OSC1 and leave

OSC2 floating. The duty-cycle can vary from 20% to

80%. The typical threshold voltage is approximately 2V.

For proper start-up, a full +5V CMOS-logic swing is

required.

The oscillator frequency sets the conversion rate. Use

32,768Hz for applications that require 50Hz or 60Hz

line rejection. This frequency yields 16 conv/sec. The

same clock frequency can be used to reject both line

frequencies because the MAX132 integrates for a different number of clock cycles in its 50Hz and 60Hz

modes. In each case, the MAX132 integrates for a single complete line cycle (20ms for the 50Hz mode,

16.67ms for the 60Hz mode). Refer to the

Speed

section for operation at higher conversion rates.

Increased

External Components

The MAX132 requires an integrator resistor (R

capacitor (C

), a reference capacitor (C

INT

crystal. All MAX132 tests are performed with a

32,768Hz crystal frequency. The crystal frequency, reference voltage, and integrator current determine the

values of R

INT

and C

INT

.

REF

) and

INT

), and a

Crystal

Figure 8 shows the internal oscillator drive circuitry used

with external crystals. The two external capacitors provide

DC bias at start-up. The 15pF capacitors shown are typical

values. The actual capacitance will vary, depending on the

crystal manufacturer’s recommendation and board layout.

Figure 6. MAX132 Input Circuit

+5V

1M

120k

REF+

1µF

REF-

Figure 7. Dividing MAX872 to Generate the MAX132’s

Reference Voltage

8 _______________________________________________________________________________________

100k

40.2k

MAX872

2.5V

150k

OSC1 OSC2

65

Figure 8. MAX132 Internal Oscillator Drive Circuitry

5pF5pF

15pF15pF

+5V

MAX132

±18-Bit ADC with Serial Interface

Table 1. Crystal Frequencies and

Integrator Capacitors for 50Hz to 60Hz

Operation

Crystal

Conv/sec

16

32

48

64

80

96

Note: Capacitor values are for a 3.0V integrator swing.

Manufactures of miniature quartz resonators include:

Freq.

(Hz)

32,768

65,536

98, 304

131,072

163,840

196,608

Epson of America

C-2 (through-hole), MC-306 (SMD)

Phone: (310) 787-6300; Fax: (310) 782-5320

The integrator resistor sets the maximum integrator output current for the integrate phase. A 602kΩ low-noise,

metal-film integrator resistor is recommended for use

with reference voltages between 545mV and 655mV.

Best linearity is achieved when the integration current

(I

) does not exceed 2.5µA. For other reference volt-

INT

ages, select R

INT

=

R

INT

and

=

I

INT

The oscillator frequency, integrator resistor, and integrator capacitor set the maximum integrator output voltage swing for full-scale reading. The integrator voltage

swing is about 3V and should not come within 2V of

either supply rail to avoid saturation. A 602kΩ integrator

resistor and a 4.7nF integrator capacitor are recommended with a clock frequency of 32,768Hz. If different

clock frequencies are used, select C

lowing equations:

C

INT

(pF)

4700

2700

1800

1200

1000

/60Hz

820

C

INT

(pF)

6800

3300

2000

1500

1200

1000

/50Hz

Resistor

(kΩ)

602

602

602

602

602

602

Integrator Resistor

as follows:

V

REF

25 05µµ

V

R

<<

. .

AI A

INT

REF

INT

Integrator Capacitor

using the fol-

INT

t

INT

545

, mod

=

f

for Hz e

OSC

60

or

t

INT

655

, mod

=

f

for Hz e

OSC

50

The integrator capacitor’s dielectric absorption directly

affects integral nonlinearity. High-quality metal-film

capacitors are recommended in the following order of

preference: polypropylene, polystyrene, polycarbonate, and polyester (Mylar). The polyester capacitor will

generate some integral nonlinearity.

To minimize noise, INT OUT should drive the outside

foil (negative end) of the capacitor. Manufacturers of

polypropylene capacitors include Sprague (715P),

Panasonic (ECQ-P), Roderstein (KP1835), Wima (FKP),

and CSF Thompson (PL/PS).

Reference Capacitor

The reference capacitor must be small enough to fully

charge from a discharged state on power-up in reasonable time, and large enough so the charge does not

droop excessively during a conversion. The reference

capacitor is normally 0.1µF for all oscillator frequencies.

For applications that require a physically smaller capacitor, the equation below will maintain C

.=0 0033

f

OSC

C

REF

proportionality:

REF

The reference capacitor must have low leakage, since

it stores the reference voltage while floating during the

deintegrate phase. Any leakage or charge loss during

this phase changes the scale factor and will cause an

error. Appropriate metal-film capacitors recommended

for their low-leakage characteristics1are (in this order):

polypropylene (up to +105°C, large size), teflon (suitable for use up to +125°C, large size), polystyrene,

polycarbonate, and polyester.

At temperatures above +85°C, capacitor leakage may

affect accuracy. In such cases, increasing the value of

C

up to 50% and more will help at the expense of

REF

longer start-up time at power-on. The start-up time is

proportional to C

tCFxxk

START UP REF−

and can be estimated by:

REF

= () µ 10 100 Ω

MAX132

Vt

() ()

IN FS INT

C

=<<135

INT

()

RV

() ( )

INT SWING

where V V V

, . ;

SWING

and

_______________________________________________________________________________________ 9

1

Pease, R.A., “Understanding Capacitor Soakage to Optimize

EDN

Analog Systems,”

, October 13, 1982, p.125.

±18-Bit ADC with Serial Interface

___________________Digital Interface

Serial data at DIN is sent in 8-bit packets and is shifted

into the internal 8-bit shift register with each rising edge

of SCLK. The data is then latched into either command

input register 0 or command input register 1, as determined by the LSB of the data sent, and is latched on

the rising edge of CHIP SELECT (CS) Data is clocked

MAX132

out of the selected output register on each falling edge

of SCLK. D7(MSB) must be the first data bit to be shifted in and is the first bit to be shifted out.

Output data is shifted out at the same time command

data is shifted in. Command data must be clocked in

on the previous 8-bit read-write cycle to receive conversion data in the present cycle.

Since there is no internal power-on reset, initialize the

MAX132 immediately after power-up to insure correct

operation.

Table 2 defines each bit of five registers: the two command input registers, output register 0, output register

1, and the status output register.

Command Input Register 0

Register-Set Bits

Data bits D1 and D2 of command register 0 (RS1 and

RS0) determine the data to be read on the data bus.

These bits select which register outputs data to the bus.

Table 3 defines the bit values that determine which register is read on the next cycle (Figure 9).

REGISTER

INSTRUCTION

(DATA IN)

OUTPUT DATA

Figure 9. Instruction and Data Sequencing

CYCLE 1

START,

READ STATUS

CYCLE 2

READ HIGHER

BITS

OUTPUT STATUS

REGISTER

(EOC, POLARITY, B2–B0)

CYCLE 3

READ LOWER

BITS

REGISTER 1

( B11–B18)

CYCLE 4

START,

READ STATUS

REGISTER 0

( B3–B10)

Read-Zero Bit

The read-zero bit allows the ADC to calibrate on command for zero offset. The read-zero bit, when set to 1,

internally shorts the inputs; when a start-conversion

command is given, the zero error is converted. Subtract

the results from the standard external measurement

conversion when the read-zero conversion ends. If the

read-zero bit is set to 0, the converter measures the

voltage between IN Hl and IN LO once a start bit is

given. Take a new zero reading periodically and whenever the ambient temperature, the reference voltage, or

the common-mode input voltage are changed.

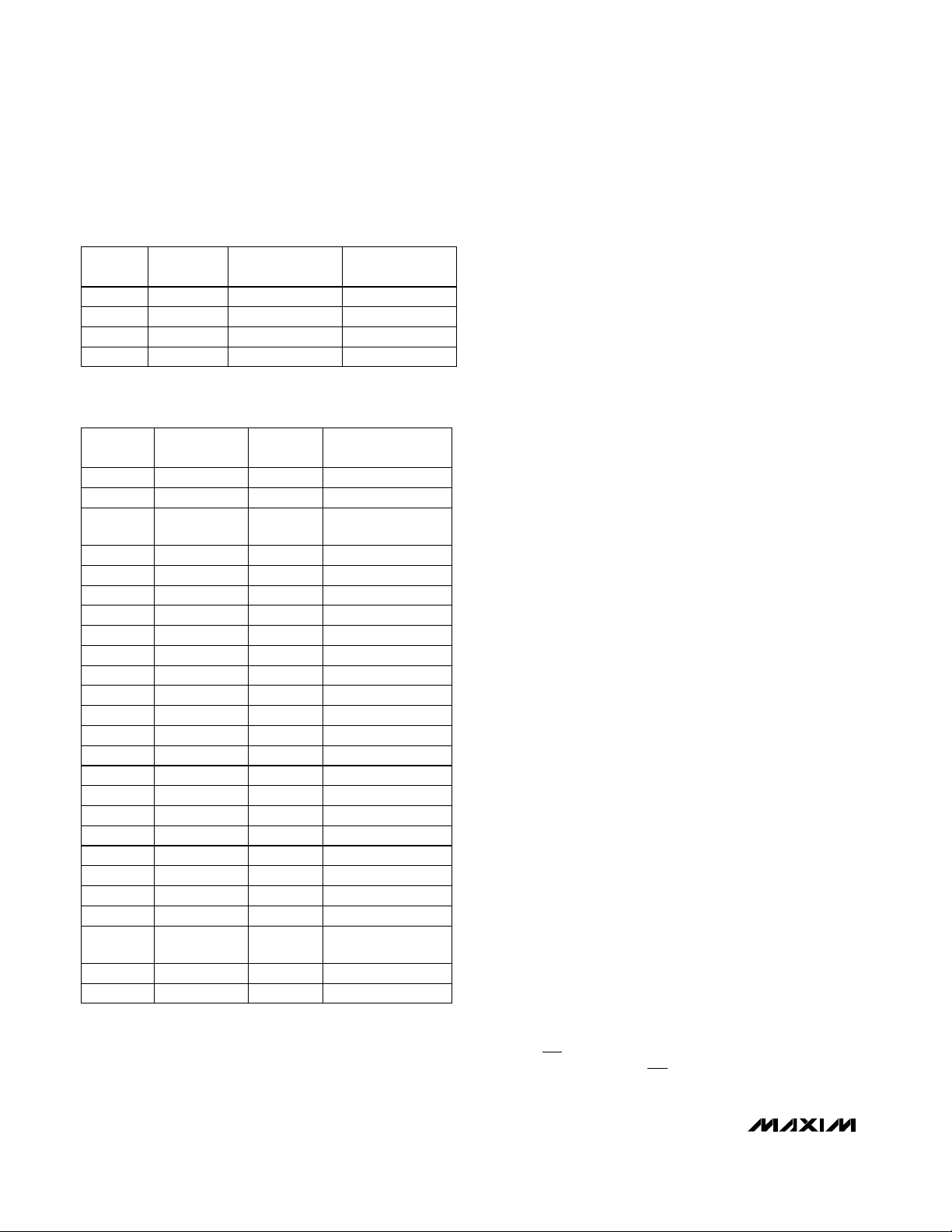

Table 3. Register Set-Bit Definitions

RS1

RS0

0

0

Selects Register 0; output for data bits B3–B10

0

1

Selects Register 1; output for data bits B11–B18

Selects Register 2; output status for data bits

1

0

B0–B2, polarity, sleep, integrating, EOC, and

collision bit

1 1 Invalid data

DEFINITIONS

Table 2. Register Map of Input and Output Data

REGISTER

Command Input

Register 0

Command Input

Register 1

Output Register 0

RS1 = 0, RS0 = 0

Output Register 1

RS1 = 0, RS0 = 1

Output Status

Register

RS1 = 1, RS0 = 0

*Note: Refer to Table 3.

10 ______________________________________________________________________________________

“1”

“0”

“1”

“0” No Collision Converting

D7 D6 D5 D4 D3 D2 D1 D0

Start

Convert

Returns to

0 at EOC

Set P3

Output

B10

B18

MSB

Collision

50Hz

60Hz

Set P2

Output

B9

B17

EOC

Sleep

Awake

Set P1

Output

B8

B16

Integrating

Input

Not

Integrating

DATA BIT

Read Zero

Read V

Set P0

Output

B7

B15

Sleep

Awake +Polarity

IN

Don’t Care

Don’t Care

Don’t Care

B14

-Polarity

B6

RS0*

Don’t Care

B5

B13

B2 B1

Don’t Care

RS1*

B4

B12

0

1

B3

B11

B0

LSB

±18-Bit ADC with Serial Interface

Averaging 2 or 3 read-zero measurements provides the

most accurate read-zero value. Perform a read-zero

sequence whenever a large change in the input voltage

is expected.

Sleep Bit

When the sleep bit is set to 1, (bit D5 in command input

register 0), the low-power sleep mode starts when EOC

returns high. In sleep mode, the supply current is typically 1µA and the oscillator shuts down. The interface

remains active and data can be read. When exiting

sleep mode, the analog circuitry needs time to stabilize

before the next conversion starts. Accomplish this by

writing a dummy instruction to emerge from sleep

mode, and wait at least one conversion cycle before

writing a start instruction.

50Hz/60Hz

With a 32,768Hz crystal, the 50Hz/60Hz bit sets the

integrate period equal to one line cycle for 50Hz/60Hz

environments. When D6 (in command input register 0)

is set to 0, the integrate count is an integer multiple of

60Hz (32,768Hz/60Hz = 546 counts). When D6 is set to

1, the integrate input count is an integer multiple of

50Hz (32,768Hz/50Hz = 655 counts). Achieve the

greatest AC rejection by adjusting the integration period for 50Hz or 60Hz.

Start Conversion Bit

The start conversion bit (D7) in command input register

0 initiates a conversion when set to 1. The MAX132

immediately starts a conversion, stops at conversion

end, and then waits for the next start-bit command. A

start instruction is needed to initiate each conversion.

To initiate a continuous data stream, write a separate

start command for each conversion in three ways:

1) Wait longer than a known conversion time and then

write another start command.

2) Poll either the EOC status register bit or the EOC

line to determine conversion end and start time for

the next conversion. EOC becomes 1 at conversion

end at count 0000 of the conversion counter (Figure

10).

3) Set the start bit to 1 before a conversion end. The

internal conversion counter is then checked for its

count. If the count is 0000 (EOC = 1), a new conversion starts and the conversion counter is set to

0001. The start bit resets to 0 after 5 clock cycles.

The MAX132 will not check the start bit again until

the conversion counter returns to a 0000 count. This

means a start command can be given any time after

0005 internal conversion count; the next conversion

starts when the counter returns to 0000.

MAX132

RESET 60Hz

0000

Figure 10. Conversion Timing (Negative Input Shown)

INT START

0001

ZERO INT

INT OUT

INTERNAL CONVERSION DATA LATCH

0111

INTEGRATE

50Hz mode

655

60Hz mode

______________________________________________________________________________________ 11

545

CHOP

659 667

DE-1 DE-2 DE-3 DE-4X8-1 X8-2 X8-3 ZERO INT

679

MAX

545

MAX

SOFT

OVERRANGE

AREA

(SEE TEXT)

47

RESET EVENTS

30

LATCH

16001346 1638 1783 1823 1970 2017 2047 0000

264

38 145

40 147

EOC

±18-Bit ADC with Serial Interface

Table 4. Overrange Values for

Resolution Used

Bits

Used

B18–B3

B18–B2

MAX132

B18–B1

B18–B0 ±18

Resolution

Bits

±15

±16

±17

Soft Overrange

Start Value

34,880

69,760

139,520

279,040 350,440

Hard Overrange

Maximum Value

43,805

87,610

175,220

Table 5. Output Values for 16-Bit

Resolution (Offset Corrected)

Input

+640mV

+576mV

+545mV

+512mV

+448mV

+384mV

+320mV

+256mV +4000 +16384

+192mV

+128mV

+64mV +1000 +4096

+15µV

0 +0000 0

-15µV

-64mV

-128mV

-192mV -D000 -12288

-256mV

-320mV

-384mV

-448mV -9000 -28672

-512mV

-545mV

-576mV

-640mV

* Soft Overrange Operation

Note: The MAX132 exhibits additional errors when operating

in the soft overrange area. Operation in this region is not

included in the specifications. The soft overrange values listed

in Table 5 do not include error correction.

Hexadecimal

Reading

+A000

+9000

+8840

+8000

+7000

+6000

+5000

+3000

+2000

+0001

-FFFF

-F000

-E000

-C000

-B000

-A000

-8000

-77C0

-7000

-6000

Decimal

Counts

+40960*

+36864*

+34880*

+32768 Positive Full Scale

+28672

+24576

+20480

+12288

+8192

+1

-1

-4096

-8192

-16384

-20480

-24576

-32768

-34880*

-36864*

-40960*

Comment

Positive Reference

Voltage

Negative Full Scale

Negative Reference

Voltage

Command Input Register 1

User-Programmable Output Bits P0 to P3

Command input register 1 always has data bit D0 = 1.

Data bits D4 to D7 of command register 1 control the

states of the user-programmable output pins P0 to P3,

respectively (Table 2). These four outputs can be used

to control an external multiplexer, programmable gain

amplifier, or other devices.

Output Registers

Output data is the sum of system offset (read zero) plus

the results of the external input voltage measurement.

Register 0

Register 0 contains the low-byte (bits B3–B10) conversion data. New data is available after EOC goes high.

Access register 0 by setting RS0 and RS1 to 0.

Register 1

Register 1 contains the high-byte (bits B11–B18) data.

Data is in a twos-complement format‚ where the polarity

bit is a 1 for negative polarity data. Access register 1

by setting control bits RS0 = 1 and RS1 = 0 when writing to the command input register.

Status Register

Bits B0–B2

The B0, B1, and B2 bits are located in the status register. At the end of each conversion these bits are updated and read back from the status register. For full

18-bit resolution, use bits B0–B2. Average multiple

results to increase accuracy. The polarity bit information is necessary to determine if the reading is not in

overrange (Tables 4 and 5).

Integrate Bit

The integrate (INT) bit is set to 1 at the beginning of the

integration phase and becomes 0 at the end. Poll INT

to determine the earliest time the input can be changed

without affecting the conversion.

End-of-Conversion Bit

The end-of-conversion (EOC) bit signals conversion status. If EOC is 1, the conversion is complete and the ADC

waits in zero-integrate mode at time = 0000 for the next

start instruction. A conversion cycle has 2048 counts.

EOC becomes 1 at count 0000 and 0 at count 0001.

Collision Bit

The collision bit warns the microprocessor (µP) that the

register’s data was changed during the read cycle. A

collision occurs if the internal result latches on the falling

edge of CS, causing the collision bit to be set to 1 on the

rising edge of the next CS. This occurs because these

two pulses are asynchronous. Once the status register is

12 ______________________________________________________________________________________

±18-Bit ADC with Serial Interface

read, the collision bit is automatically reset to 0. To determine collision status, read the status register collision bit

before and after reading output registers 0 and 1.

Collisions will not occur if a conversion’s read cycle is

completed before the next conversion begins.

Sequence Counter and Results Counter

A binary sequencing counter controls the conversion

phase’s sequencing (or timing). In integrate phase,

both start and stop occur at preset counts. The deintegration phases start at predetermined counts, but are

terminated when the comparator detects zero crossing

at the integrator output.

The results counter accumulates counts during all deintegrate phases. It is an up/down binary counter, with

the count direction determined by the deintegration

polarity. In the first deintegrate phase, the results

counter counts by 512. Since the second deintegrate

phase deintegrates a residual voltage multiplied by 8,

the results counter increments or decrements by 64

during this phase. It increments or decrements by 8

during the third deintegrate phase, and by 1 during the

fourth deintegrate phase. The results counter content

transfers to the results register at each conversion end.

Overrange Indication

B18 is not strictly an overrange bit. This 19th bit is necessary to exploit the converter’s full range, and to

ensure that a full 18-bit result can be achieved after a

zero reading has been deducted.

The actual overrange value is a function of the number

of bits of resolution used. Table 4 lists the overrange

values for different resolutions.

The MAX132 has two overrange levels (Figure 10 and

Table 4). The first level is a soft overrange that is set by

the user. Overrange is arbitrarily set at a value, preferably less than the 279,040 (including any zero offset)

raw counts soft limit. A nonlinearity step of about 64

counts occurs at raw count 279,040 and again at

330,240 counts.

The second level is a hard overrange with a maximum

value of 350,440 counts. Attempts to deintegrate values

greater than this will result in a value of ±350,440 counts.

____Multislope Conversion Phases

Multislope conversion allows 350,440 counts with a clock

frequency of only 32.768kHz. After zero-crossing, the

main comparator (with some delay) sends a signal to the

digital control section, which then terminates the deintegrate period by issuing commands to the analog switches. This action entails further delay because the

commands must be synchronous with the clock. As a

result, the delay between zero-crossing and switch actuation can exceed one clock cycle. A “residue” voltage

that represents unwanted extra counts in the conversion

result is left on the capacitor, while the integrator’s output

continues past the zero crossing.

Dual-slope converters ignore this residue voltage error.

However, the multislope MAX132 inverts, amplifies, and

deintegrates the residue, canceling the extra counts by

driving an up/down counter in the opposite direction.

This process of measuring and accounting for the residue

can be repeated for the successively smaller errors

remaining after each deintegration. (Deintegration is simply an integration of V

grator output ramps toward zero.) The MAX132, for

example, executes three cycles in which the residue is

inverted, multiplied by eight, and deintegrated (Figure 10).

, with polarity chosen so the inte-

REF

Integrate Phase

The MAX132 integrates the input signal by connecting

the integrator’s noninverting input to IN LO, and the

buffer input to IN Hl. The integration period is 545

counts for 60Hz mode and 655 counts for 50Hz

Deintegrate Phase

The integrator capacitor’s voltage polarity at the end of

integrate phase determines the polarity of the first deintegration phase. The first deintegration phase ends

when the comparator detects that the integration

capacitor has been discharged. The MAX132 then

goes into a rest phase, where both the buffer input and

the integrator’s noninverting input are connected to

AGND, integrating the system offset.

Near the end of the maximum allowable deintegration

period, the integrator capacitor voltage polarity is again

sampled, resulting in either a positive or negative deintegrate cycle.

Rest Phase

A rest phase follows each deintegrate phase. The rest

phase starts when the integrator crosses zero and ends

when the maximum count for that deintegration phase

has been reached.

First Times-Eight Phase

When the zero crossing is detected at the end of the

deintegrate phase, deintegration continues until the

next clock cycle. This causes the integrator to overshoot zero crossing slightly, leaving a small residual

voltage on the integration capacitor. The first timeseight (X8) phase inverts and multiplies this residual by

a factor of 8.

MAX132

______________________________________________________________________________________ 13

±18-Bit ADC with Serial Interface

Second Deintegrate Phase

The second deintegrate phase deintegrates residual

voltage on the integration capacitor that has been

through the X8 phase. Since the voltage across the

integration capacitor has been multiplied by 8, each

deintegration clock cycle corresponds to 1/8 of one

clock cycle during the first deintegration.

MAX132

Additional Times-Eight

and Deintegrate Phases

At the end of the second and third deintegration phases, the device performs a X8 multiplication of the residual voltage left on the integration capacitor. After each

of these X8 multiplications, a deintegration occurs,

resulting in a second, third, and fourth deintegration

phase. Each time the residual voltage on the integration

capacitor is multiplied by 8, the following deintegration

has 8 times finer resolution.

Zero-Integrate Phase

The zero-integrate phase zeros out the integrator to

prepare for the next integration (Figure 10). This phase

occurs at the beginning and end of each conversion. At

power-up, or in the hold mode prior to a conversion, the

MAX132 continues to zero integrate until a conversion

starts. When a conversion starts in 60Hz mode, another

111 clocks of zero integrate are completed before the

beginning of a conversion. In 50Hz mode, only one

additional zero integrate is performed before the conversion starts. An additional 20 clocks of zero integrate

occur at each conversion end.

__________Applications Information

Extended Delays Between Conversions

An extended delay between conversions can degrade

the subsequent conversion result due to capacitor

droop and internal offset/common-mode voltages. The

initial reading may be off by 4 to 6 counts in a ±15-bit

configuration. When the delay between conversions

exceeds 2 seconds (either because of a slower conversion rate or the use of sleep mode), it is recommended

that the first reading after this delay be discarded.

Increased Speed

The MAX132 is tested with a 32,768Hz clock frequency, which results in 16 conv/sec. Up to 96 conv/sec

may be achieved with higher clock frequencies and

some changes in component values, as shown in Table

1. Operation at higher conversion rates reduces accuracy, and care must be taken to get the best results.

Although either the 50Hz or 60Hz mode can be used,

complete rejection of 50Hz or 60Hz normal-mode noise

at conversion rates above 16 conv/sec is impossible.

Use the 50Hz mode when operating at more than 16

conv/sec, irrespective of the local line frequency. The

50Hz mode uses a slightly longer integration time than

the 60Hz mode, and generally gives lower-noise performance.

Table 1 lists the crystal frequencies and integrating

capacitor values for the 50Hz and 60Hz modes for various conversion rates, although the 50Hz mode is recommended for clock rates above 32,768Hz.

The raw data can be used where highest accuracy is

not required, and the least significant bits can be

ignored. At 96 conv/sec, the accuracy is 13 bits.

Improvements in accuracy can be gained by averaging

both the data and the zero readings, although data

averaging compromises the converter’s speed performance.

To maximize throughput, take zero readings only when

necessary, i.e., when the common-mode voltage

changes. It is not normally necessary to take a zero reading after every data reading‚ as an excessive number of

zero readings reduces the converter’s effective speed.

Noise Reduction

To minimize noise, each supply must be bypassed to

GND with a 0.1µF capacitor. A ground plane should

also be placed under the analog circuitry. Use the RC

network at the inputs as shown in Figure 6. Also refer to

the section “Noise Reduction Techniques” in the notes

for the MAX132 evaluation kit. To minimize the coupling

effects of stray capacitance, keep digital lines as far

from analog components and lines as possible. Also,

connect the integrator capacitor’s outside foil to the INT

OUT pin to minimize stray capacitive coupling. If possible, keep the digital interface inactive while the

MAX132 is converting.

Ratiometric Measurements

Figure 11 shows an application to measure temperature ratiometrically with an RTD sensor. The voltage

drops across the RTD sensor and the 250Ω reference

resistor are generated by the same current source. The

voltage of the sensor (VS) is fed directly into the differential inputs, and the voltage drop across the reference

resistor (VR) is brought into the differential reference

inputs. The relationship of these voltages is ratiometric

and unaffected by the actual current. The MAX132’s

output is proportional to VSdivided by VR, independent

14 ______________________________________________________________________________________

±18-Bit ADC with Serial Interface

of the overall accuracy of the current source. The current source delivers 2mA, resulting in about 500mV

across the 250Ω resistor—suitable to fit the MAX132’s

±512mV full-scale range. Note that the accuracy of the

reference resistor (0.1%) sets the circuit’s accuracy.

The power consumption of the RTD sensor is small

(0.5mW), minimizing errors caused by self-heating.

Interfacing to a µP Parallel Port

Figure 12 shows a high-level software subroutine for

reading output/status data and writing command data

+5V

0.1µF10µF

DATA IN

DATA OUT

CLOCK

RTD

PT100

IN

IC1

MAX872

GND

V

S

OUT

RW1

4.096V

V

R

INTERFACE

2k

250Ω

0.1%

SERIAL-

DATA

CHIP SELECT

to the MAX132. It provides an algorithm for serial communication when the µP port does not have a predefined serial interface protocol (i.e., SPI™ or Microwire™).

The routine sends command data (TxByte) to the

MAX132 while concurrently collecting the MAX132’s

output register data (selected by the previous write

cycle). Note that a write is required before each read to

change the next output register to be read, and that

the subroutine must be repeated three times to read

the output status register, Output Register 0, and

Output Register 1.

-5V +5V

0.1µF

600k

4.7nF

0.1µF

32,768Hz

13

V- V+

1

CS

2

DIN

3

DOUT

4

SCLK

11

EOC

7

PG0

8

PG1

9

PG2

10

PG3

14

IN HI

15

IN LO

DGND

12 16

IC2

MAX132

AGND

10µF

24

BUF OUT

INT OUT

INT IN

CREF+

CREF-

REF+ IN

REF- IN

OSC2

OSC1

23

22

21

19

20

18

17

5

6

MAX132

RW2

Figure 11. Ratiometric Configuration Using the Differential Reference Inputs

SPI is a trademark of Motorola, Inc. Microwire is a trademark of National Semiconductor Corp.

______________________________________________________________________________________ 15

RW1, RW2 WIRE RESISTANCE

±18-Bit ADC with Serial Interface

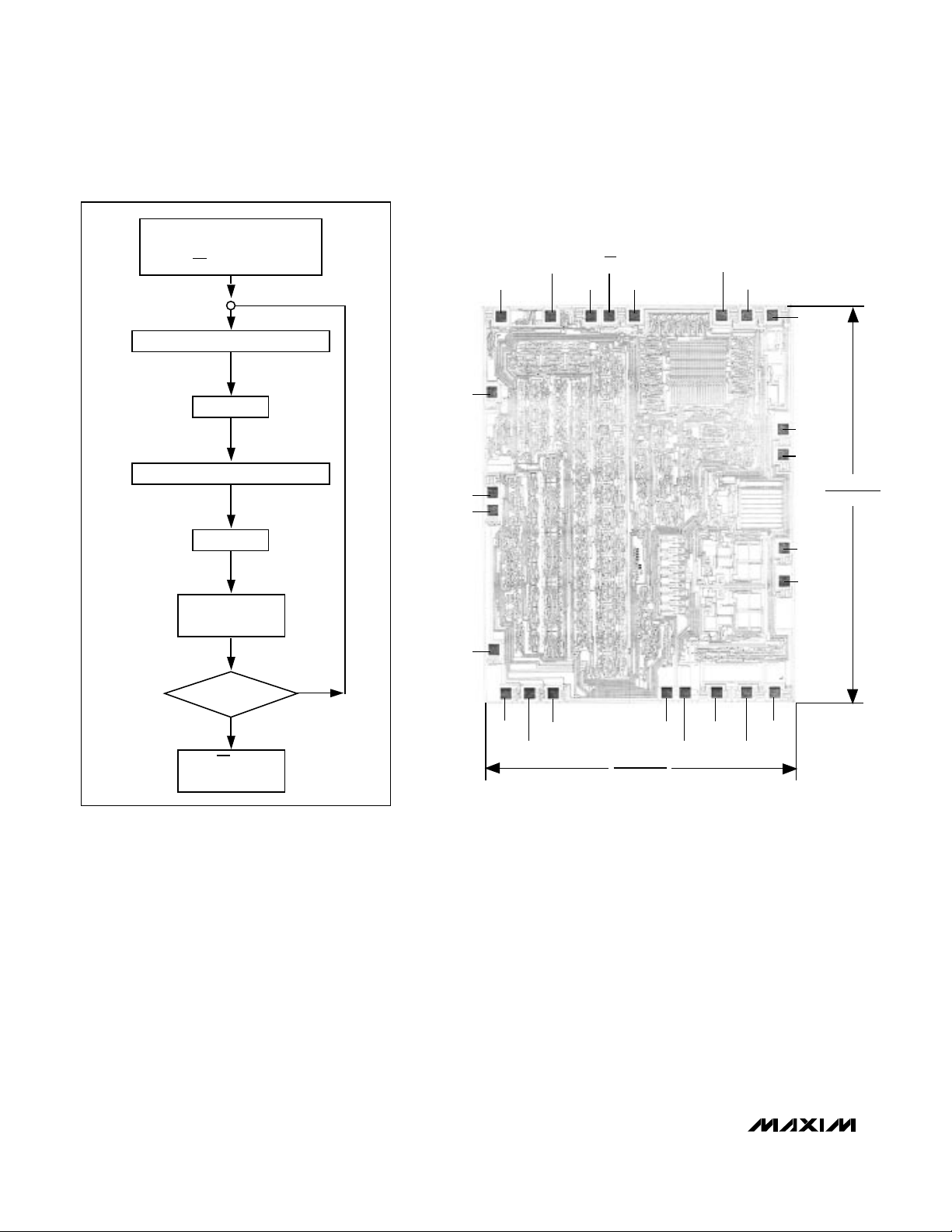

___________________Chip Topography

WAIT UNTIL EOC PIN IS HIGH

CLEAR SCLK

CLEAR CS

SCLK

DOUT

DINCSV+

BUF OUT

INT OUT

MAX132

WRITE DIN132 FROM TxByte’s MSB

READ DOUT132 INTO RxByte’s LSB

SET SCLK

CLEAR SCLK

SHIFT RxByte LEFT

SHIFT TxByte LEFT

REPEAT 8 TIMES

SET CS

RETURN RxByte

OSC2

OSC1

PG0

PG1

PG2

PG3

EOC

DGND

0.144"

(3.66mm)

IN HI

V- IN LO

INT IN

CREF-

CREF+

0.186"

(4.72mm)

REF+

REF-

AGND

Figure 12. MAX132 Read/Write Algorithm

16 ______________________________________________________________________________________

TRANSISTOR COUNT: 2799

SUBSTRATE CONNECTED TO V+

Loading...

Loading...